Electroplating device and electroplating method thereof

An electroplating device and electroplating treatment technology, applied in the direction of electrolytic coating, etc., can solve the problems of unstable plating adhesion and continuity, short effective length of busbar, and influence on electroplating quality, so as to improve electroplating efficiency and quality, complete pickling, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

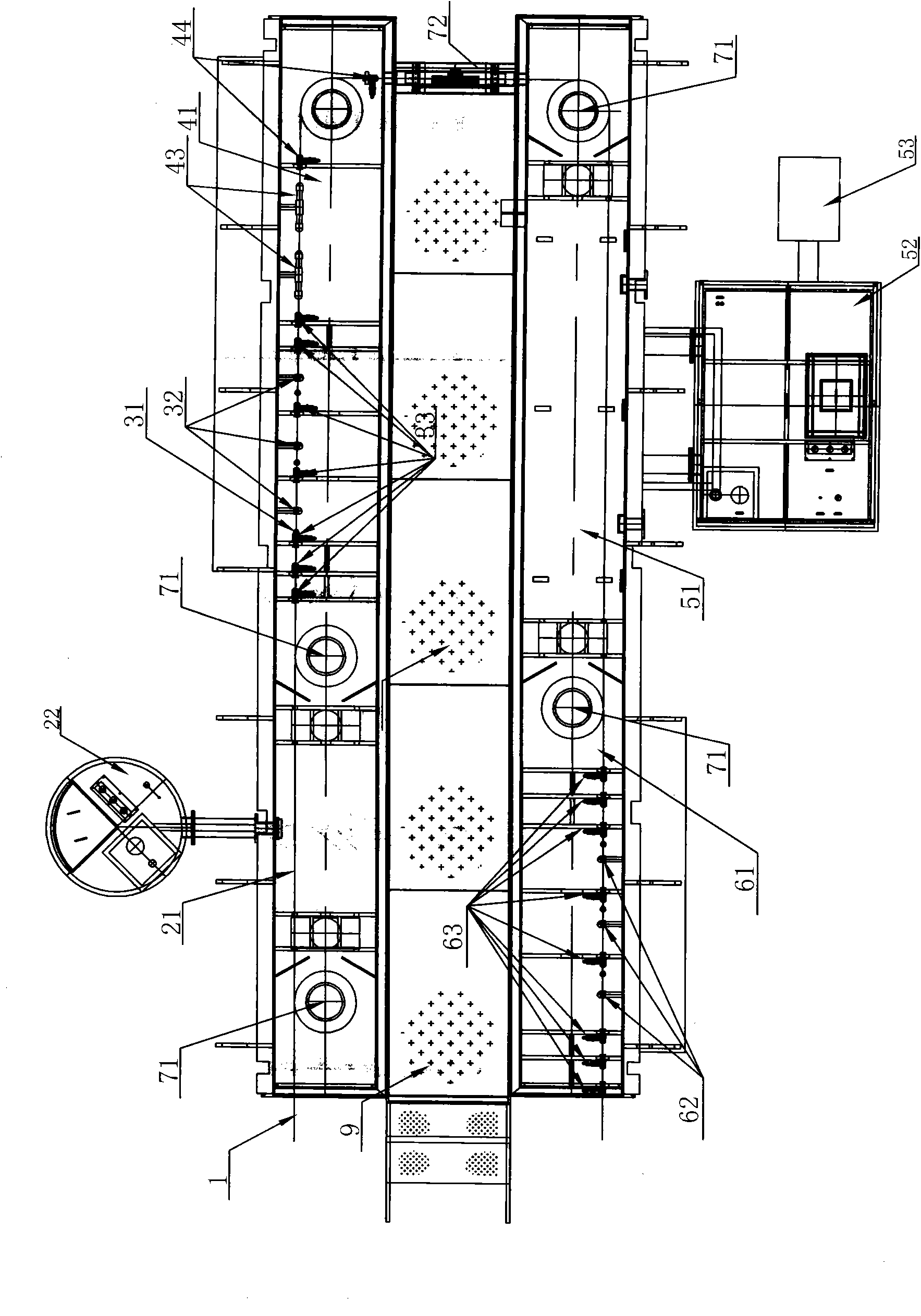

[0031] see figure 1 , figure 2 , image 3 , as described in the legend therein, an electroplating device for electroplating a busbar 1, including a degreasing system for removing oil stains on the surface of the busbar 1, and a first water washing and air-drying system for removing residues on the surface of the busbar 1 , a pickling system for removing oxides on the surface of the busbar 1, an electroplating system for electroplating the busbar 1, a second water washing and air-drying system for removing residues on the surface of the busbar 1, the degreasing system, the pickling system and the electroplating system are all equipped with multi-groove rollers 7 for conductively storing the busbar 1 .

[0032] The multi-groove roller 7 rotates along the horizontal plane around its axis.

[0033] A tension device 8 for pre-tensioning the busbar 1 is also provided between the multi-groove rollers 7 .

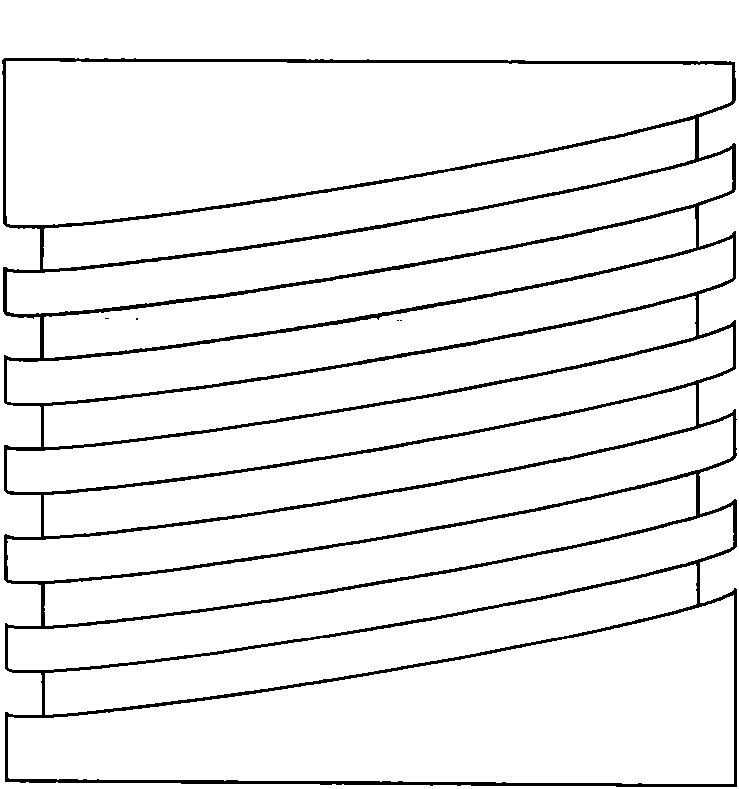

[0034] Preferably, the multi-grooved roller 7 is a spiral grooved roller....

Embodiment 2

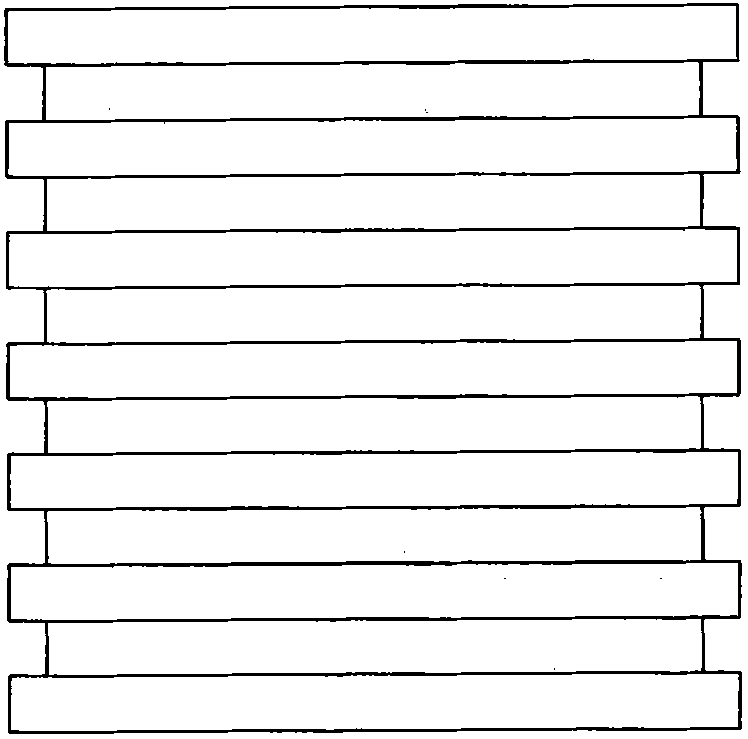

[0059] The rest are the same as in the first embodiment, the difference is that the multi-grooved roller is a circumferential grooved roller

Embodiment 3

[0061]The rest is the same as that of Example 1, except that the pickling solution is a 10%-15% hydrochloric acid solution, and an appropriate amount of water or hydrochloric acid can be added according to the concentration of the pickling solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com