Patents

Literature

102results about How to "Reduced physical fitness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

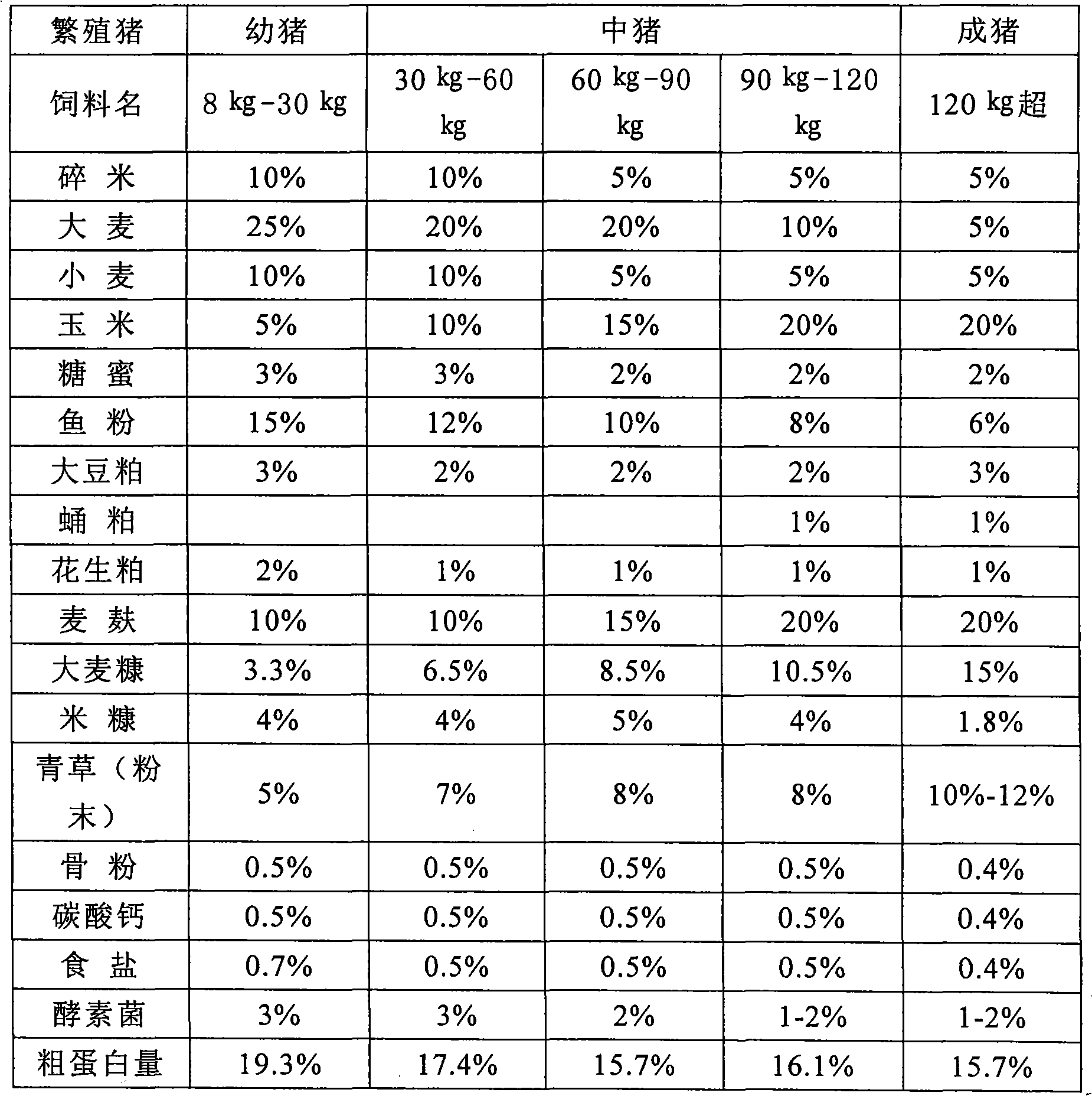

Ferment biological complete feed

InactiveCN102008008AIncrease Utilization and Conversion RatesPromote growth and developmentFood processingAnimal feeding stuffBARLEY BRANNutritional composition

The invention discloses a ferment biological complete feed which relates to the technical field of complete feeds. A formula of the ferment biological complete feed comprises the following components in percentage by weight: 5-10 percent of broken rice, 5-25 percent of barley, 5-10 percent of wheat, 5-25 percent of corn, 2-3 percent of molasses, 6-16 percent of fish meal, 2-3 percent of bean pulp, 1-2 percent of peanut meal, 10-20 percent of wheat bran, 3.3-15 percent of barley bran, 1.8-5 percent of rice bran, 5-12 percent of green grass powder, 0.4-0.5 percent of bone meal, 0.4-0.5 percent of calcium carbonate, 0.4-0.7 percent of salt and 1-3 percent of ferment bacterium. The total crude protein amount of the feed is 15.7-20 percent. The complete feed can remarkably improve the conversion ratio and the utilization ratio of the feed or additives, ensure that nutrition components in the feed or the additives can be really and completely absorbed and utilized, simultaneously improve the living organism balance, enhance the disease resistance capacity of livestock, eliminate the drug residue and guarantee the body health of people and organic food sources.

Owner:徐维康

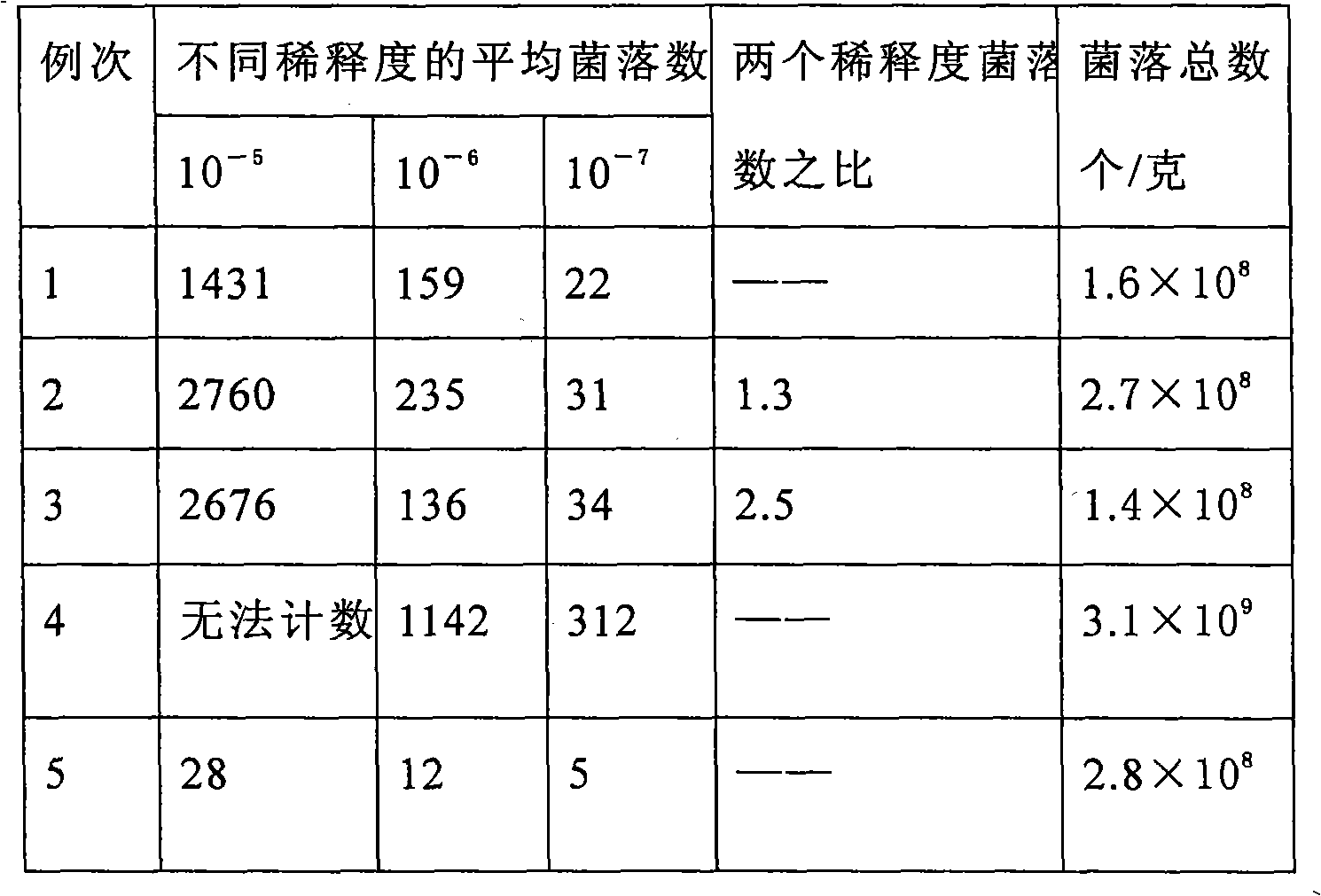

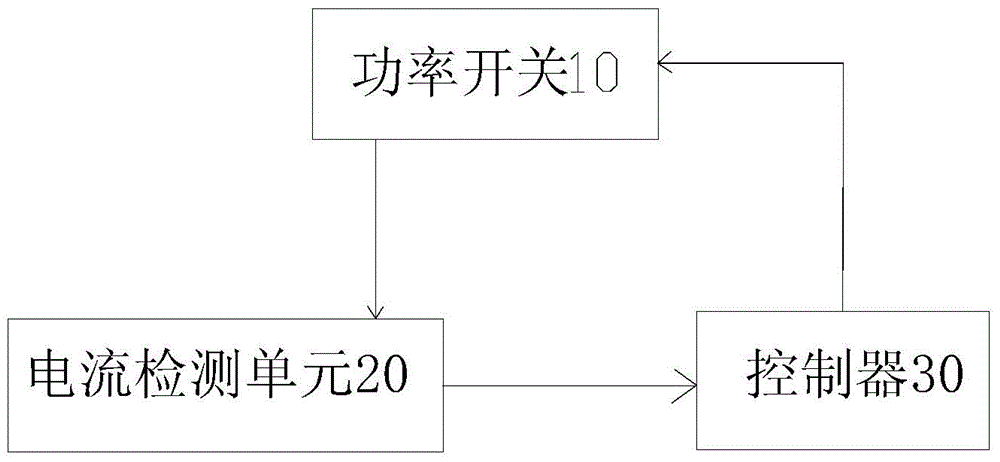

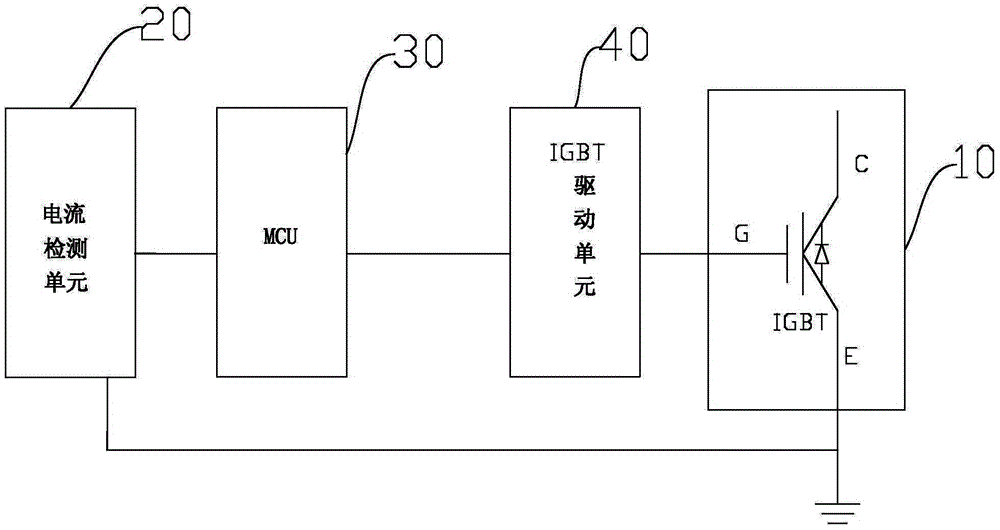

Electromagnetic heating device and control method thereof

ActiveCN104902600AEMI suppressionReduce electromagnetic interferenceInduction heating controlLower limitControl signal

The invention discloses a control method of an electromagnetic heating device. The control method comprises the following steps: detecting a working current of a power switch of the electromagnetic heating device; and adjusting pulse width of a control signal for controlling the power switch to be turned on and turned off according to the working current so as to enable the working current to change between a preset target lower-limit current and a preset target upper-limit current. The control method of the electromagnetic heating device can change working frequency of the electromagnetic heating device by adjusting the pulse width of the control signal, thereby suppressing electromagnetic interference generated by the electromagnetic heating device during working, reducing the electromagnetic interference, reducing influence of the electromagnetic interference on the health of human body and normal working of other electric appliances, and fully meeting living needs of people. The invention also discloses the electromagnetic heating device.

Owner:MIDEA GRP CO LTD +1

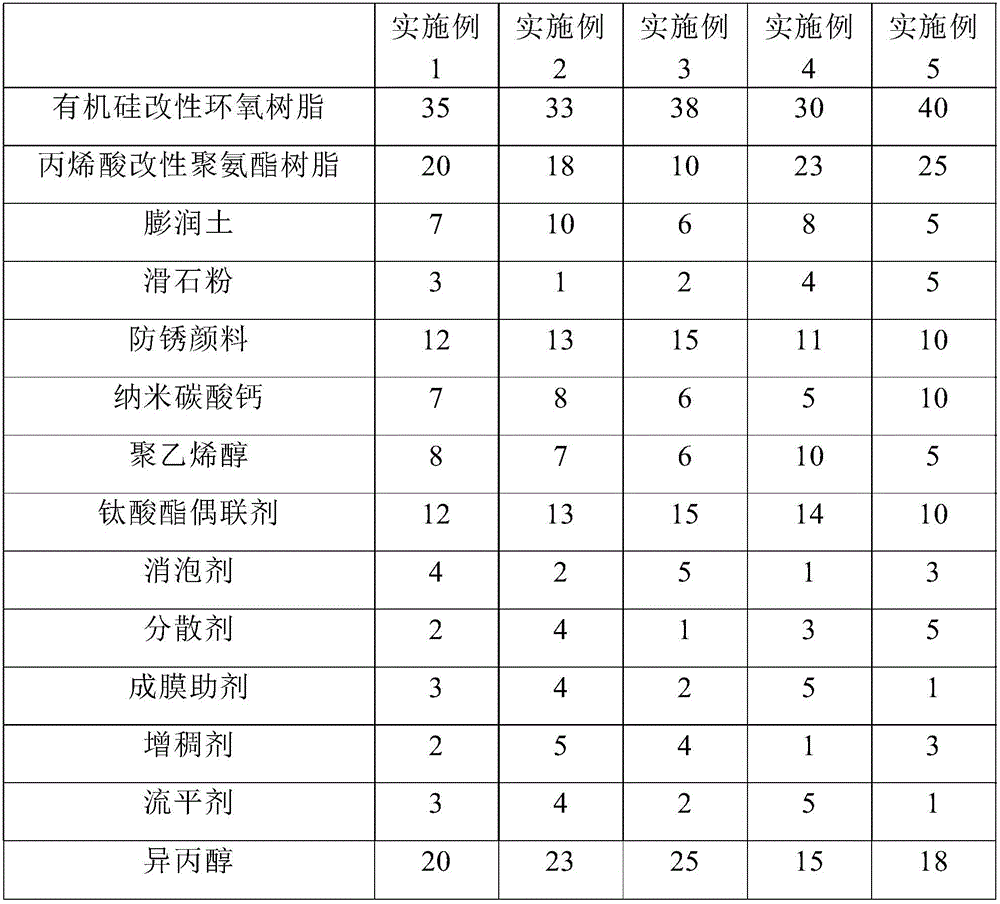

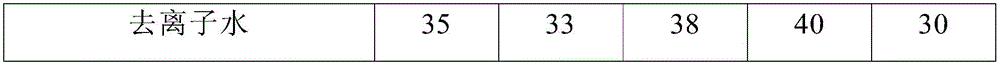

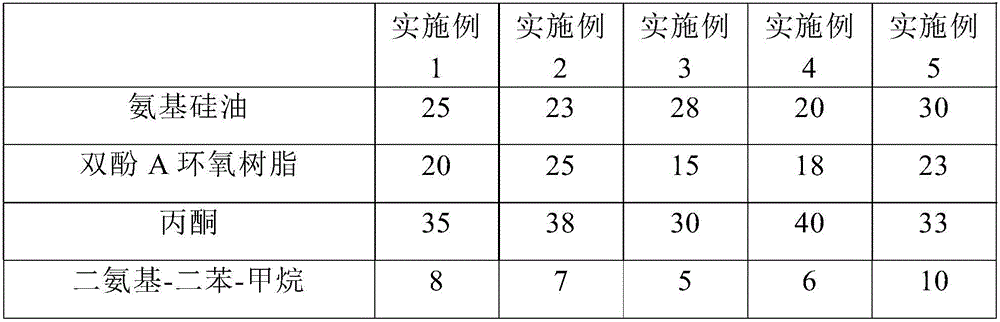

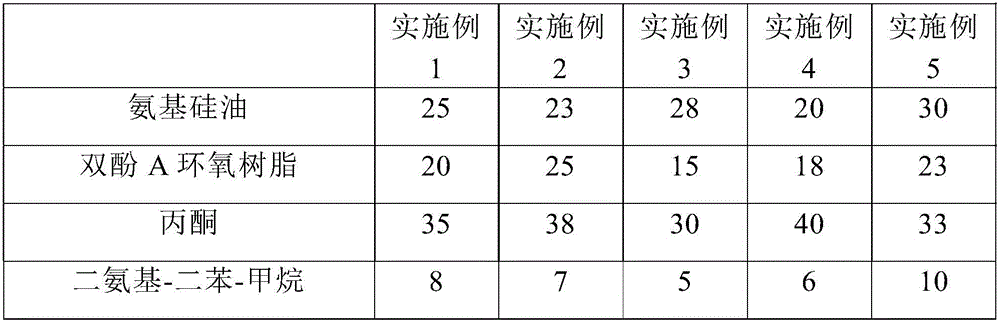

Environmentally friendly abrasion-resistant anticorrosive coating and preparation method thereof

InactiveCN106118360AHigh glossImprove antistatic performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolyvinyl alcohol

The invention provides an environmentally friendly abrasion-resistant anticorrosive coating and a preparation method thereof. The environmentally friendly abrasion-resistant anticorrosive coating is prepared from, organic silicone modified epoxy resin, acrylic acid modified polyurethane resin, bentonite, talcum powder, antirust paint, nano calcium carbonate, polyvinyl alcohol, a titanate coupling agent, a defoaming agent, a dispersing agent, a coalescing agent, a thickening agent, a flatting agent, isopropyl alcohol and deionized water. The organic silicone modified epoxy resin and the acrylic acid modified polyurethane resin are matched, the modified epoxy resin and the polyurethane resin make the coating have good glossiness, good antistatic capability, better mechanical properties and ageing resistance and abrasion resistance properties, the added antirust paint can effectively improve the anticorrosive capability of the coating, also has price and environmental protection advantages, has strong adhesion, good ductility, high temperature resistant and long service life, roll-coating replaces spray-coating during coating, a production environment is effectively improved, and the coating is conducive to the body health of workers.

Owner:TAICANG JINXIN PAINT

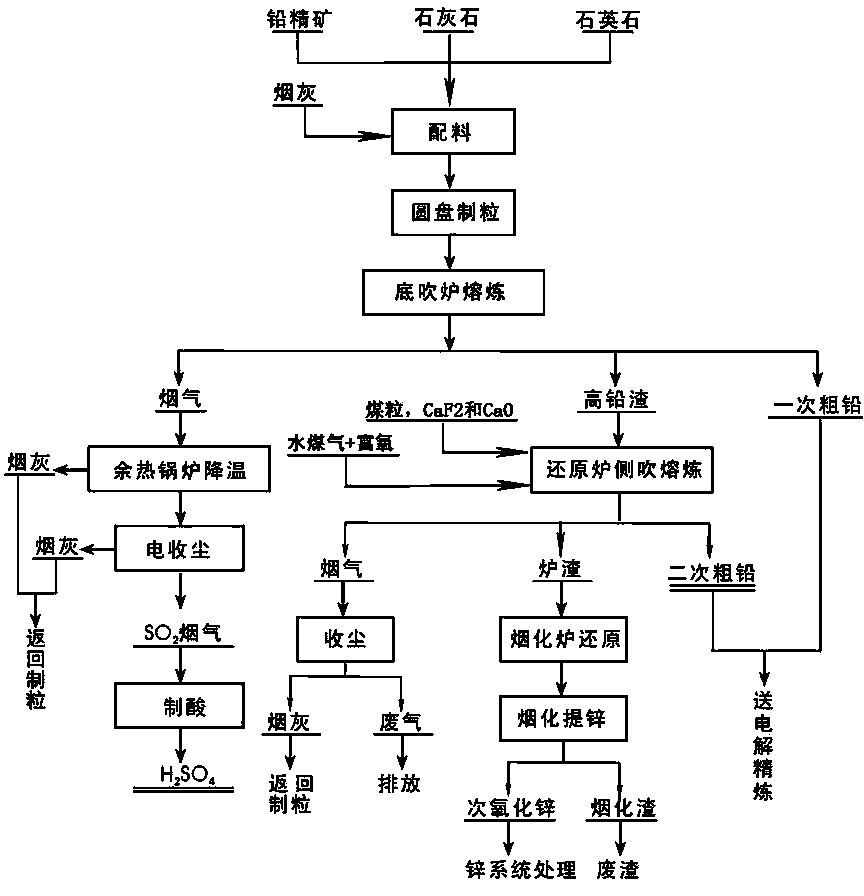

Liquid-state high-lead slag side-blowing water-gas reduction process

ActiveCN103361491AEasy to separateSignificant synergistic effectProcess efficiency improvementLiquid stateSlag

The invention relates to a liquid-state high-lead slag side-blowing water-gas reduction process, and belongs to the technical field of metallurgy. The process mainly comprises the steps of: directly injecting liquid-state high-lead slag melt subjected to oxidization smelting by a bottom blowing furnace into a reduction furnace, and directly reducing liquid-state high-lead slag into secondary lead bullion through side blowing in the reduction furnace by adopting combination of water gas and oxygen-enriched air. The reduction process is simple in technology, low in production cost and good in reduction controllability, and helps to realize low-pollution low-carbon-economy industrialized production.

Owner:HUNAN HUAXIN RAREANDPRECIOUS METALS TECH CO LTD

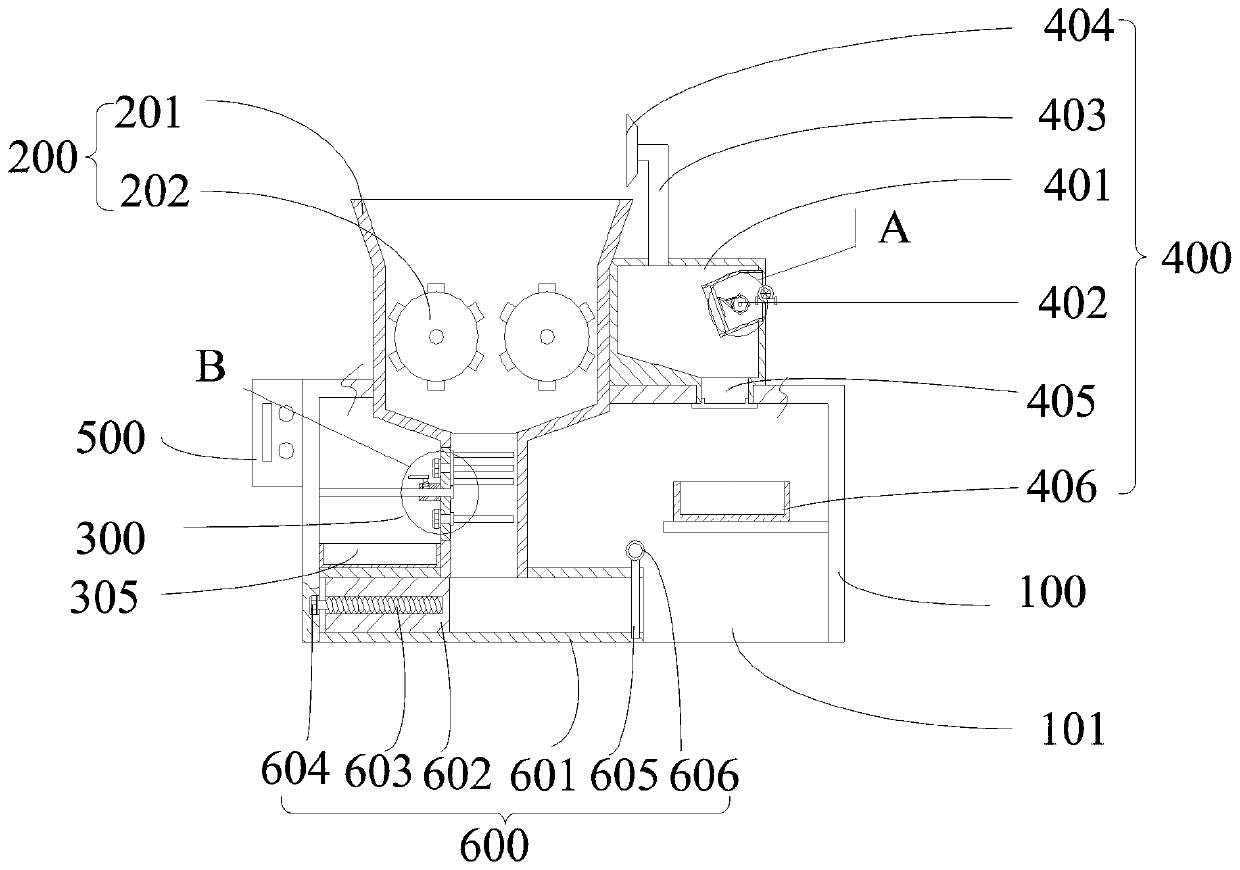

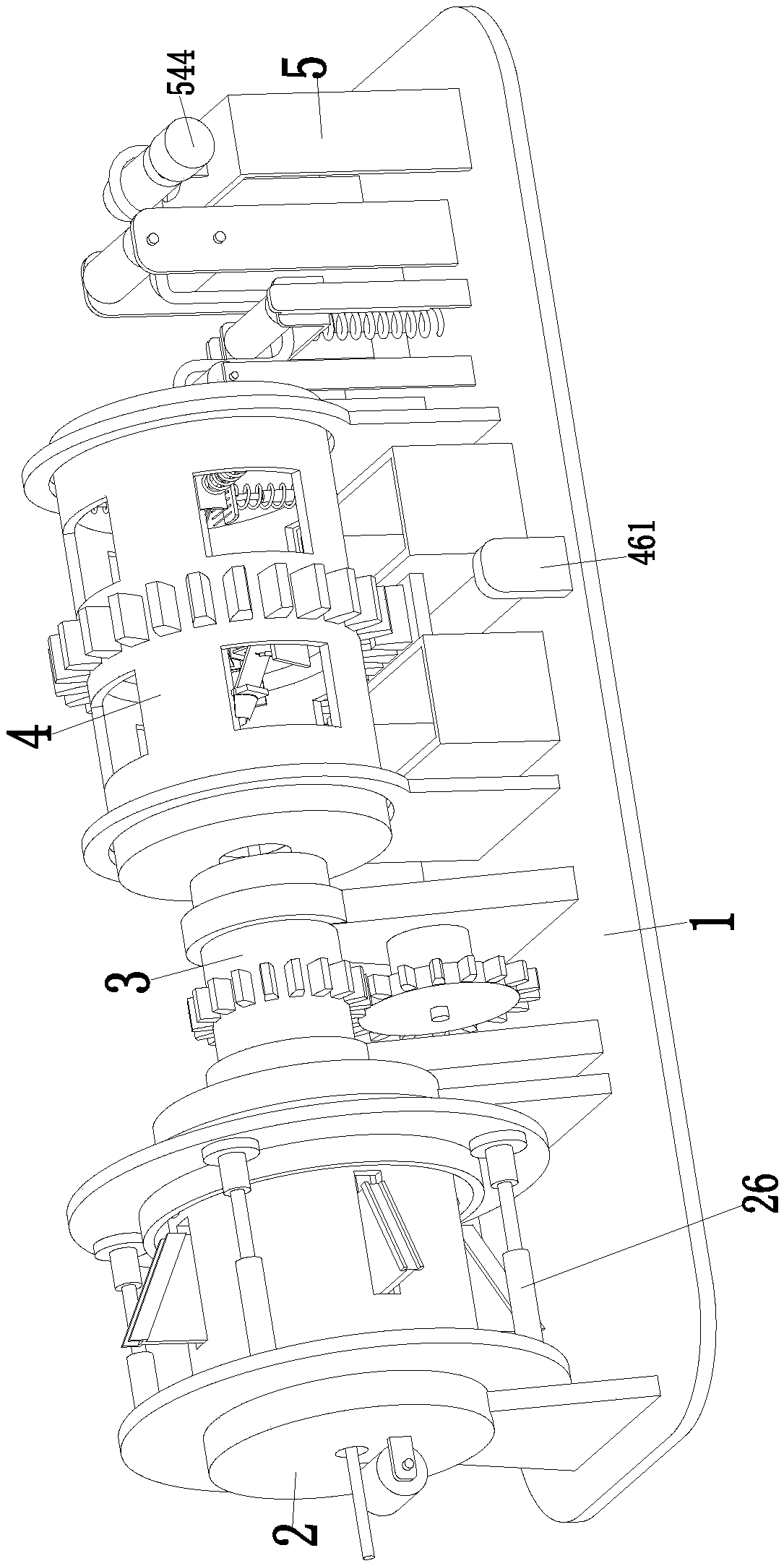

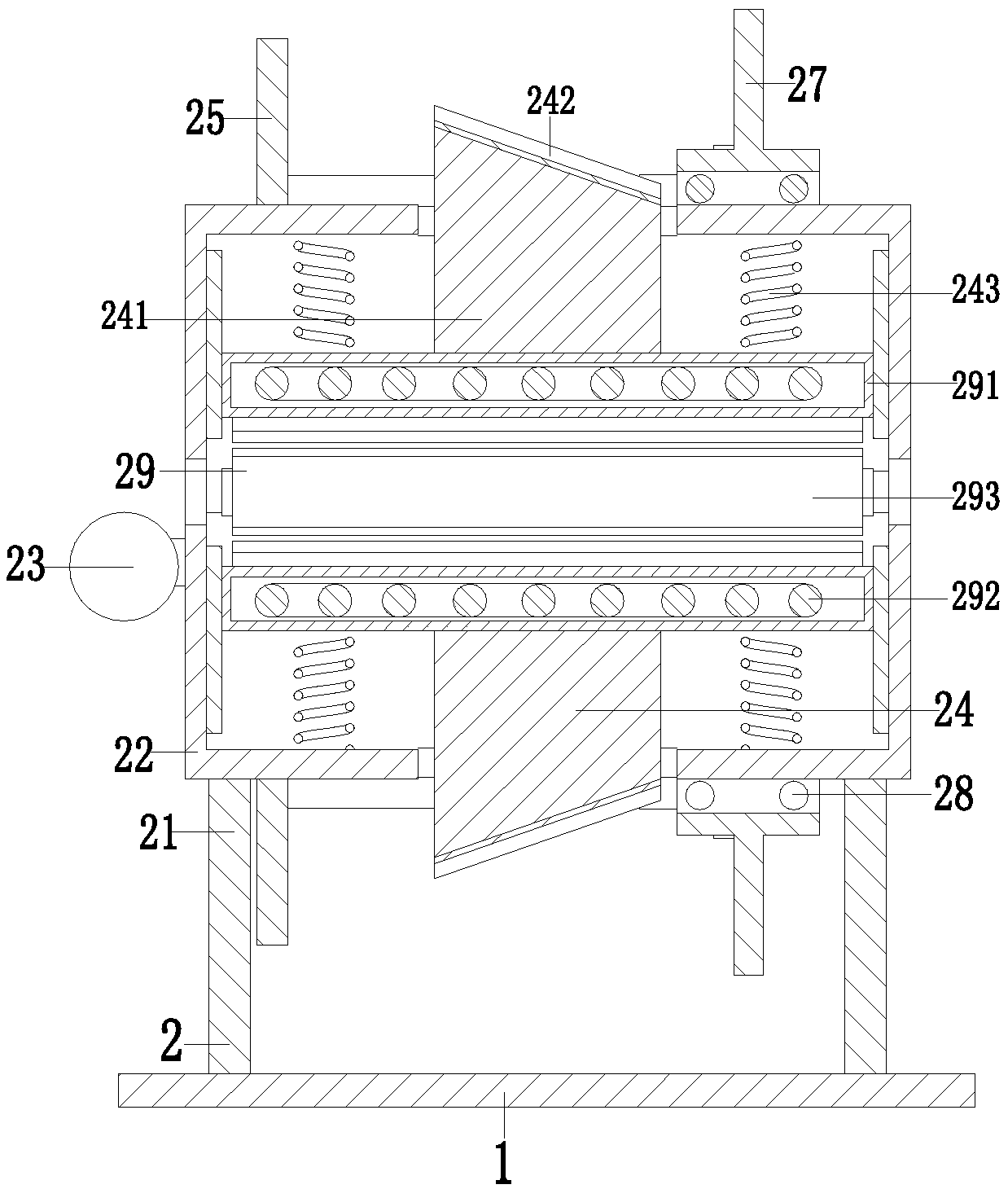

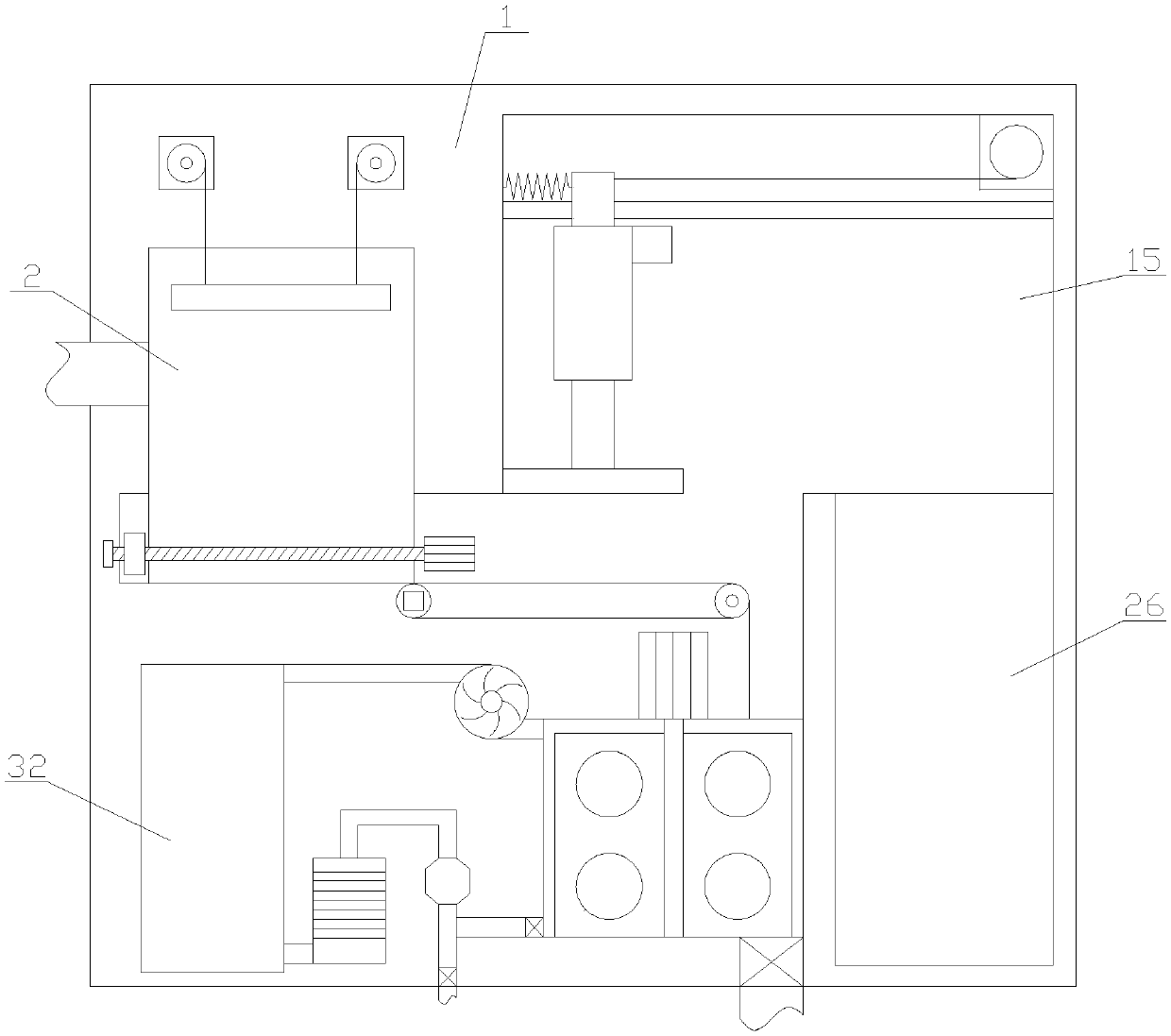

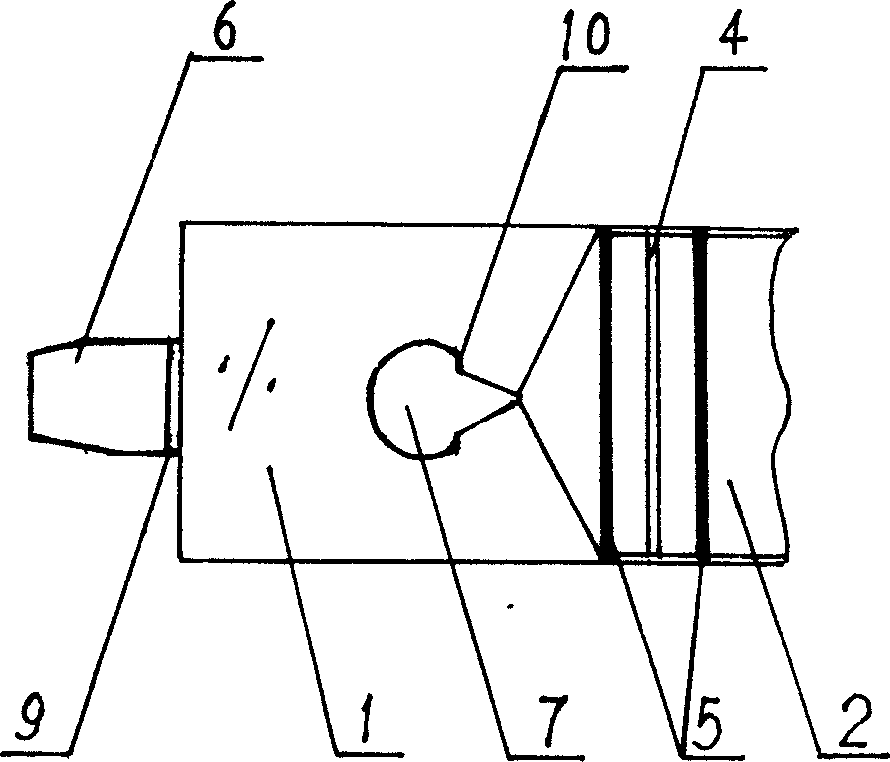

Waste collecting device for constructional engineering

PendingCN111330960AReduced physical fitnessReduce environmental problemsDispersed particle filtrationTransportation and packagingMetal adsorptionWorking environment

The invention relates to a waste collecting device for constructional engineering. The waste collecting device comprises a fixed seat with a first mounting hole and a second mounting hole at the top and a scrap outlet at the bottom; a crushing mechanism is mounted at the first mounting hole, and a waste channel of the crushing mechanism extends to the scrap outlet; a metal adsorption mechanism isdetachably connected to the waste channel and used for adsorbing metal substances in chippings; a dust collection mechanism is mounted at the second mounting hole, the top of the dust collection mechanism corresponds to an inlet of the crushing mechanism, and the bottom of the dust collection mechanism corresponds to the scrap outlet; and a control box electrically connected with the crushing mechanism, the metal adsorption mechanism and the dust collection mechanism is fixed on the fixed seat. The dust collection mechanism is arranged at the inlet of the crushing device, a large amount of dust is sucked away, and adverse effects of the dust on health of workers and the working environment are reduced; and the metal adsorption mechanism is detachably connected to the waste channel, metal substances in the chippings are separated, and later machining treatment of wood chippings is guaranteed.

Owner:河北宏龙环保科技有限公司

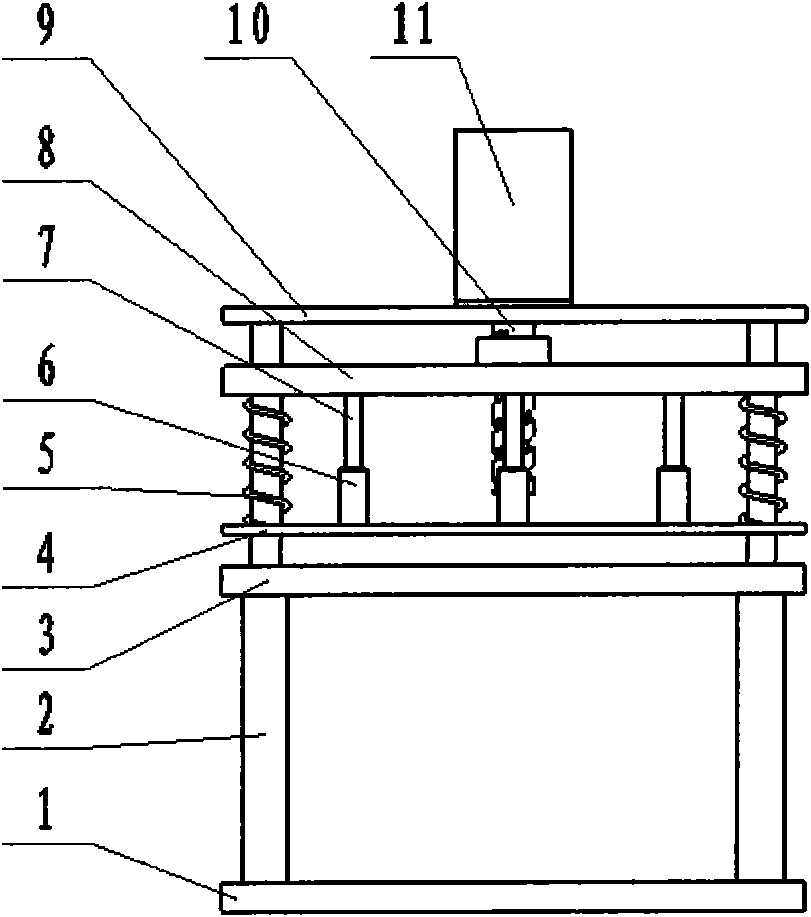

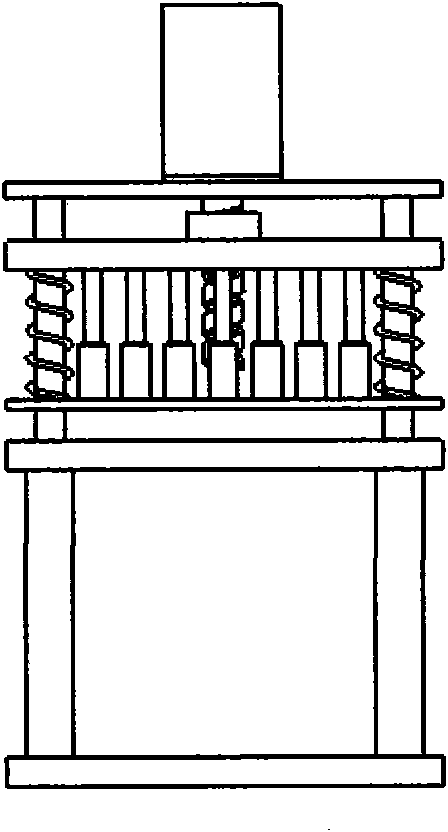

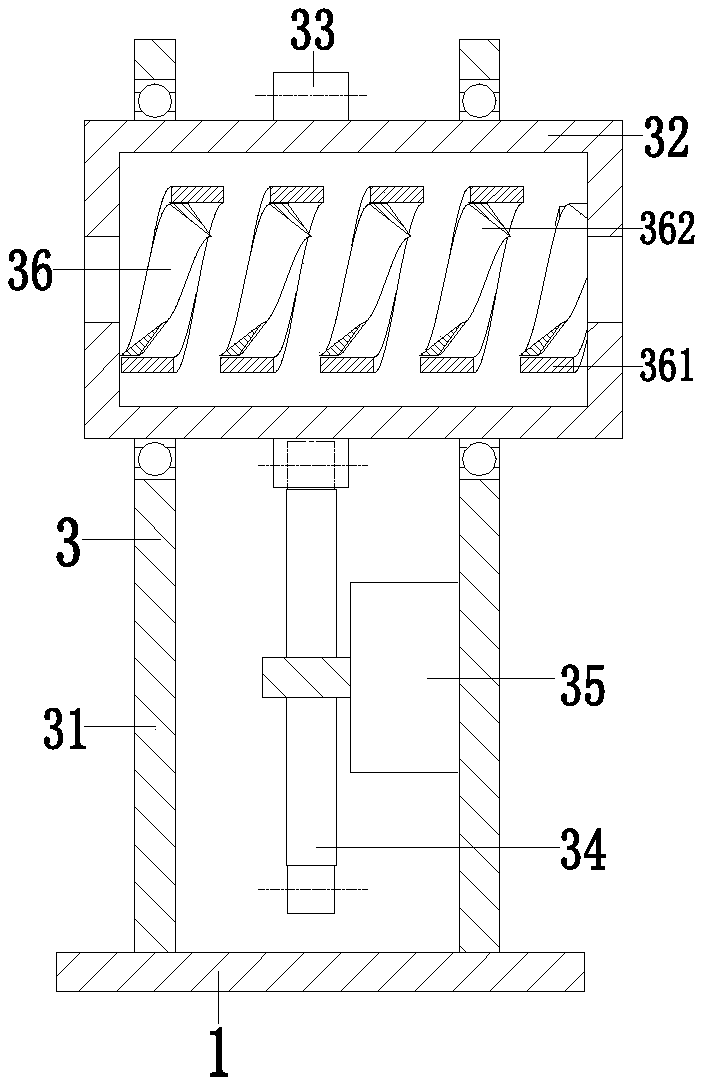

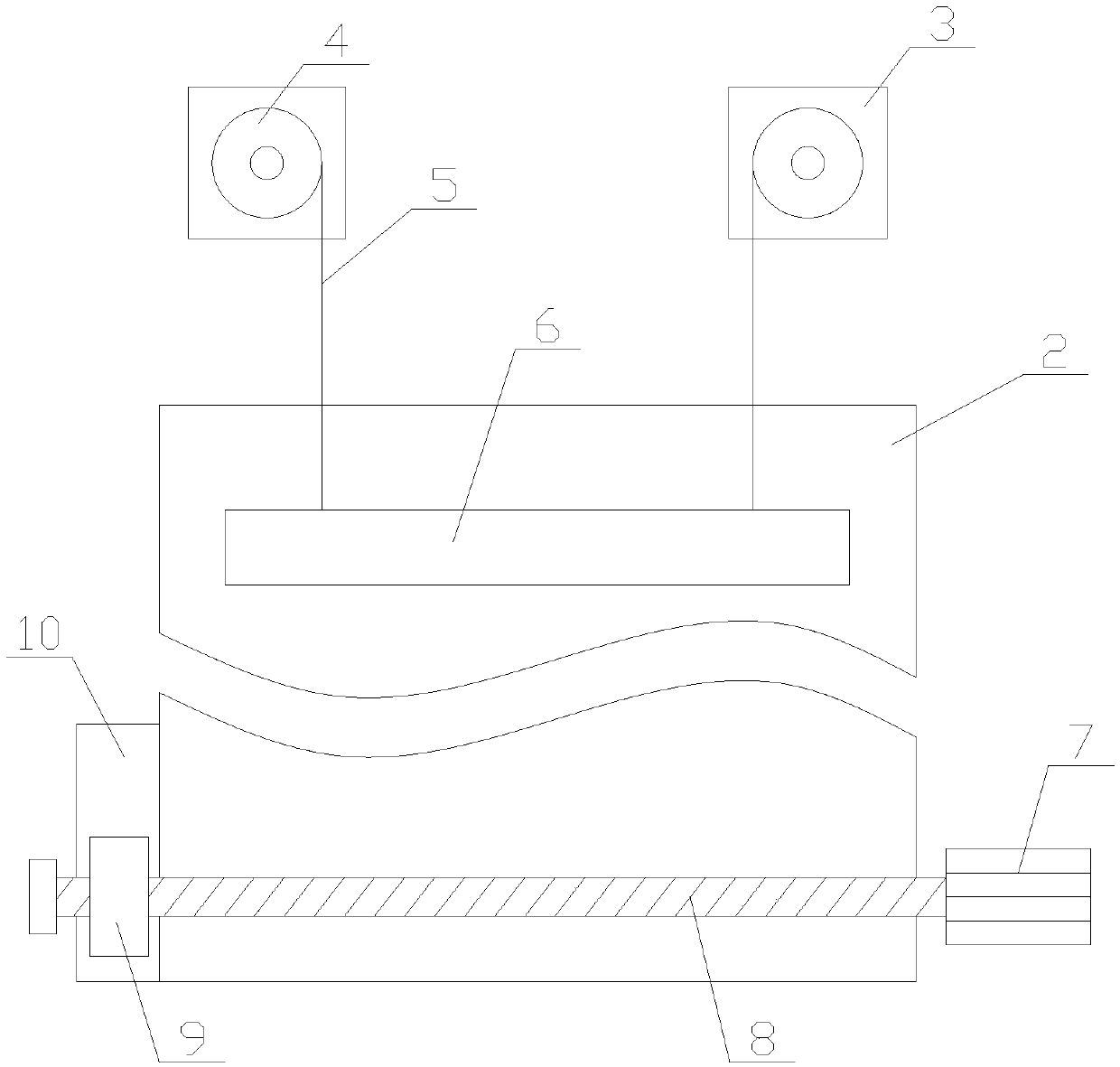

Cloth blanking equipment

InactiveCN101555662AProtect your healthReduced physical fitnessPreparing sample for investigationSevering textilesWorking environmentEngineering

The invention relates to cloth blanking equipment which comprises a machine frame and a clamping mechanism that is used for clamping cloth and includes a lower clamping plate, an upper clamping plate and a puller spring, wherein the lower clamping plate is fixedly arranged on the machine frame, the upper clamping plate is arranged over the lower clamping plate, and the upper clamping plate is arranged on the machine frame and can slide up and down; a cutting board is arranged over the upper clamping plate, the cutting board is arranged on the machine frame and can slide up and down, both ends of the puller spring are respectively fixed on the cutting board and the upper clamping plate; a knife group is arranged below the cutting board, the upper clamping plate is provided with a cutting hole, a charging hole is arranged on the lower clamping plate, the cutting hole and the charging hole are respectively arranged under each knife of the knife group, the cutting board is connected with a drive mechanism used for controlling the cutting board to lift up and down, and the drive mechanism is arranged on the machine frame. The cloth blanking equipment effectively prevents polluting the work environment and improves the reliability of the test results.

Owner:ZHEJIANG UNIV OF TECH

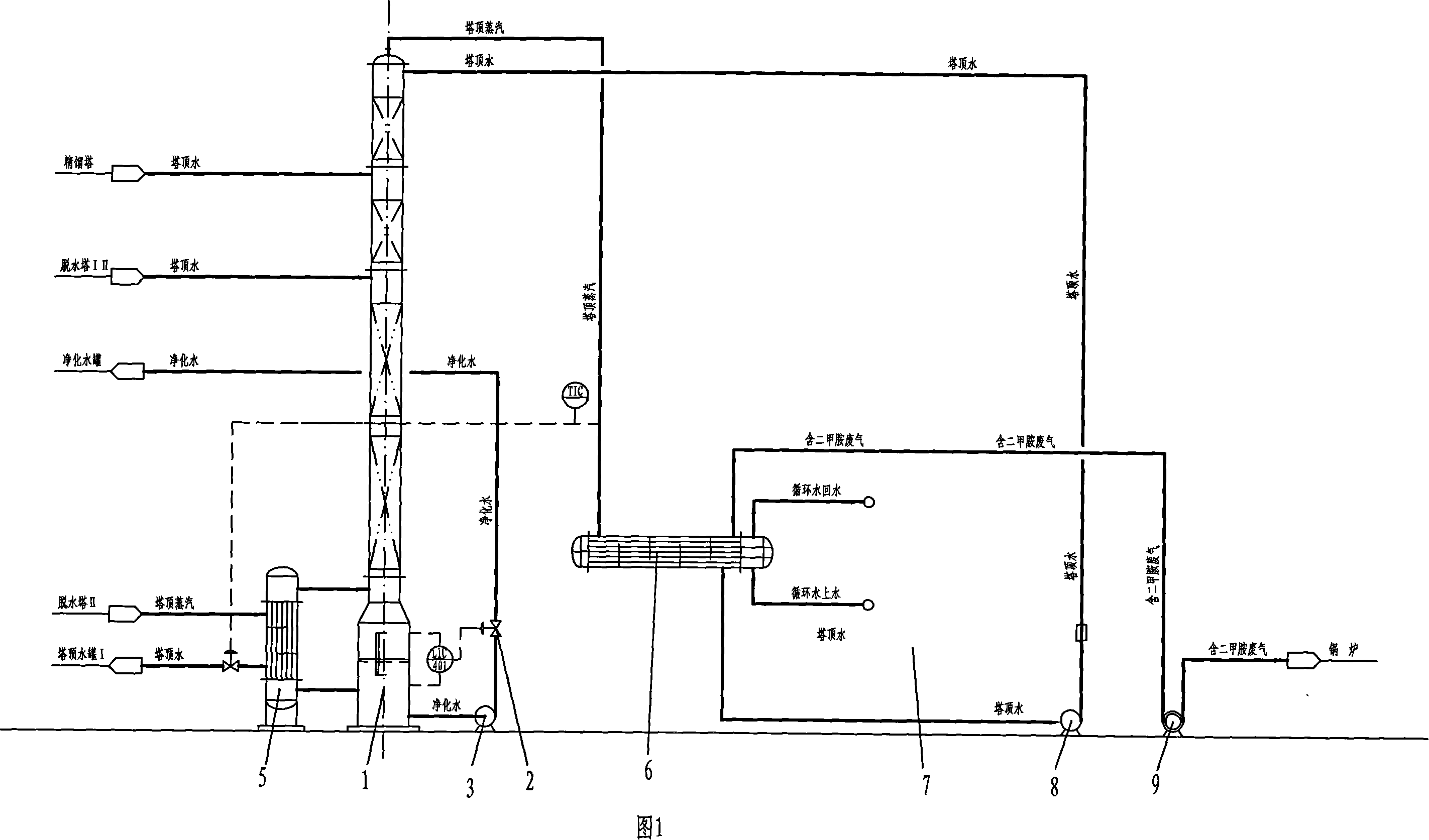

Method for treating waste gas from dimethylamine recovery by synthetic leather dimethyl formamide

InactiveCN101139302AReduce pollutionReduce spendingChemical industryCarboxylic acid amide separation/purificationDistillationVacuum pump

The present invention is a treatment method of synthesizing the leather dimethyl formamide and recycling the dimethylamine emission. The method comprises the preheating, de-amine and drainage to form the top water de-amine technology of the DMF recycling tower; the concentration of the top water dimethylamine of the dehydration tower I and the dehydration tower II in the recycling of the three towers is relatively low and the top water dimethylamine is sent into the middle section of the de-amine tower; the concentration of the top water dimethylamine of the distillation column is relatively high and the top water dimethylamine is sent into the upper section of the de-amine tower for filtering downward; the dimethylamine in the water on the tower top is taken away by the lifting steam in the de-amine tower; the purified water after the removal of the dimethylamine is collected in the tower kettle and then enters the storage tank for the recycling in the wet production; the inside of the de-amine tower consists of four sections of high-efficient wire packing; the pressure of the vacuum work is 16 KPa; the temperature on the tower top is 50 DEG C; the tower reactor is 55 DEG C; the tower reactor of the de-amine tower is heated with the vapor on the top of the dehydration tower II and the distillation column, or is directly heated with the left steam of the boiler; the dimethylamine exhaust is pumped out by the vacuum pump; the concentration of the dimethylamine is 20 percent to 30 percent; and the dimethylamine exhaust is sent to the boiler for burning; the energy-saving and exhaust-discharging effects are good. Compared with the device of the same category, the required heat and cooling water are greatly lowered; the economic benefit and social benefit are obvious.

Owner:YANTAI DONGJIE ENVIRONMENTAL PROTECTION MACHINERYENG +1

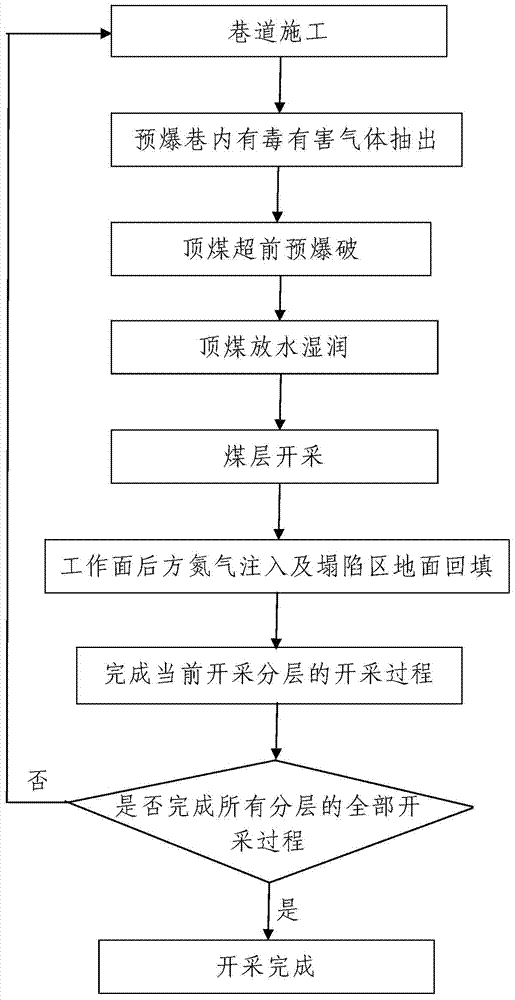

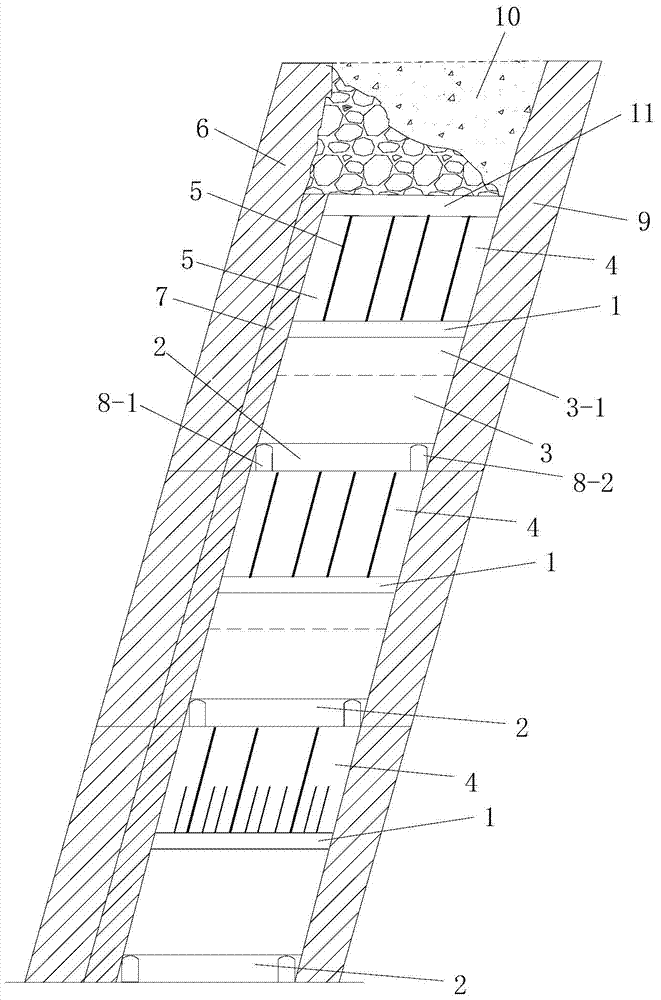

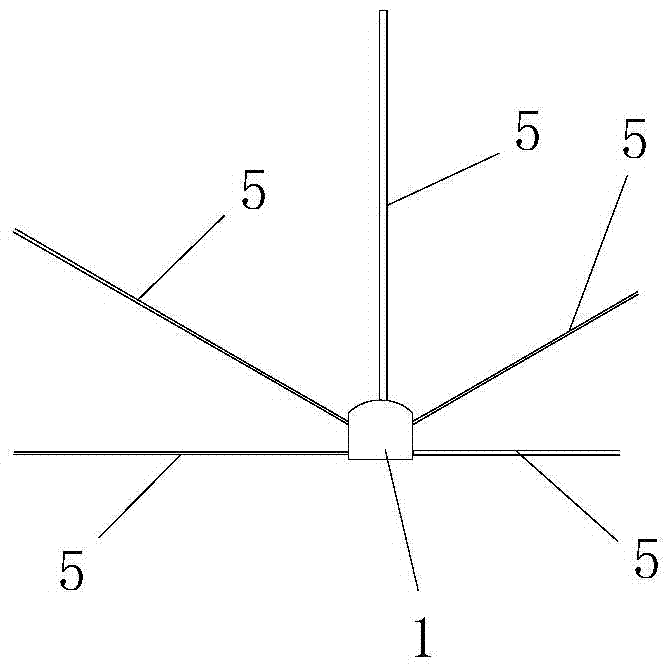

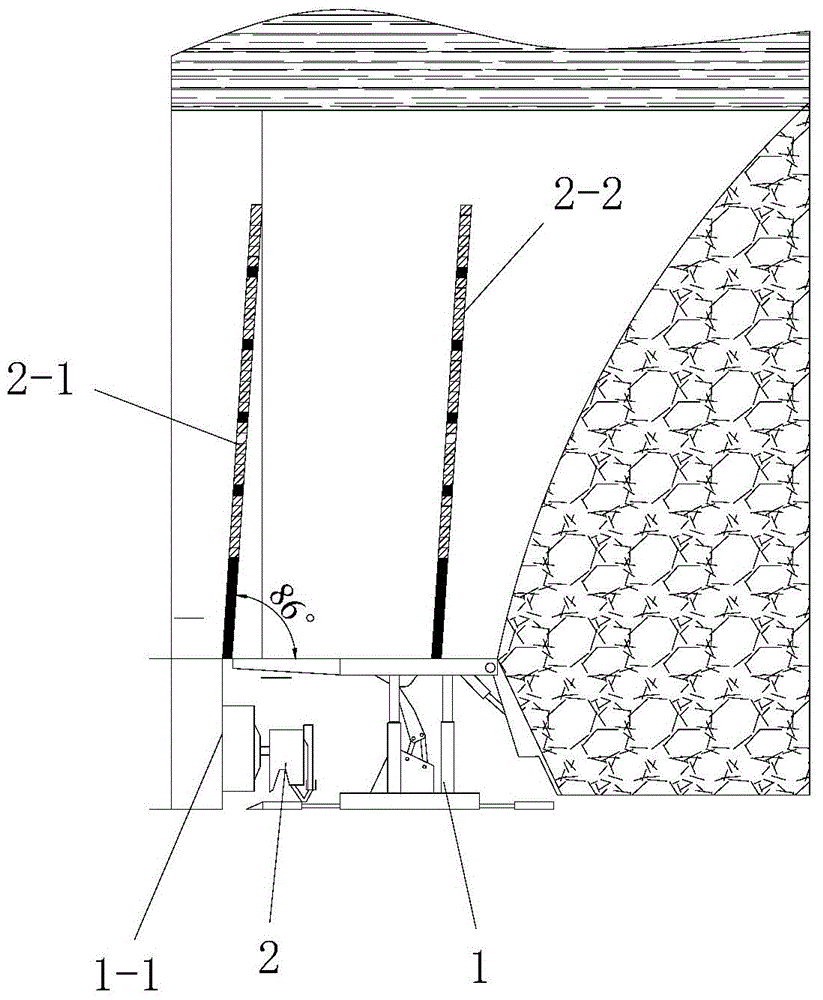

Three-dimensional roof controlling method for fully mechanized caving of steeply inclined and extremely thick coal seam

InactiveCN104847351AThe method steps are simpleReasonable designUnderground miningBlastingMining engineeringCombined use

The invention discloses a three-dimensional roof controlling method for fully mechanized caving of a steeply inclined and extremely thick coal seam. The steeply inclined and extremely thick coal seam is mined in multiple sections from back to front along the trend of the coal same, each of the mining sections is cut into multiple sub-layers from top to bottom, and the uppermost sub-layer is a top sub-layer; when any mining section is mined, the multiple sub-layers of the mining section are respectively minted from top to bottom, and the process comprises the following steps: I, mining the top sub-layer: comprising the steps of tunnel construction, extraction of toxic and harmful gas in a pre-denotation roadway, advanced pre-blasting of top coal, drainage to wet the top coal, coal mining and nitrogen injection behind a working face and ground backfill of a subsidence area; II, mining the next sub-layer; and III, repeating the step II once or multiple times till the mining processes of all sub-layers of the mining section are completed. The method disclosed by the invention is simple in step, reasonable in design, convenient to implement and good in using effect, and various protective measures are combined in use, so that the potential safety hazards such as roof caving, gob fire and the like can be effectively eliminated.

Owner:XIAN UNIV OF SCI & TECH

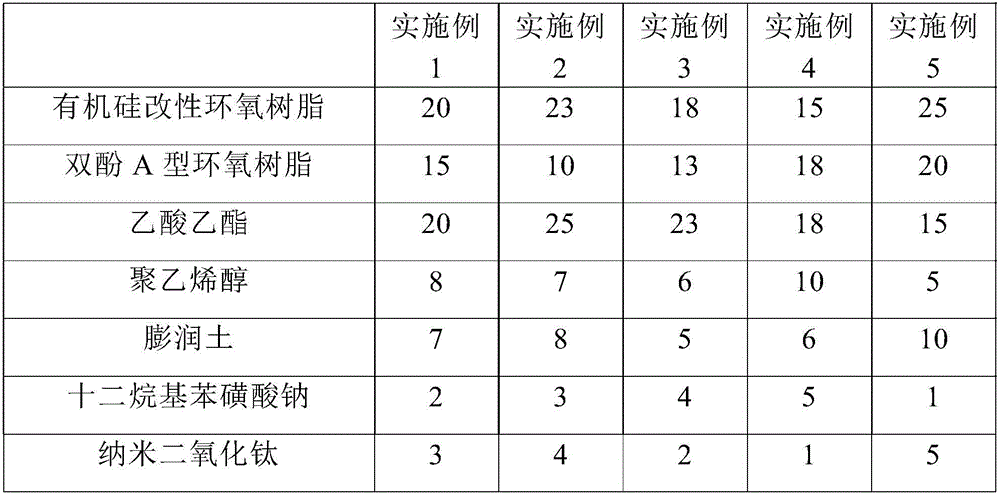

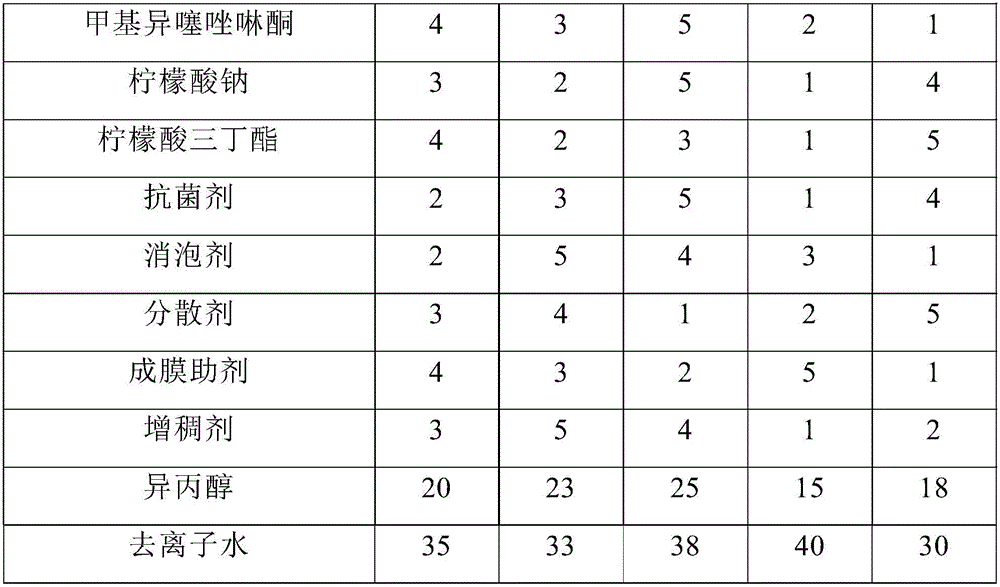

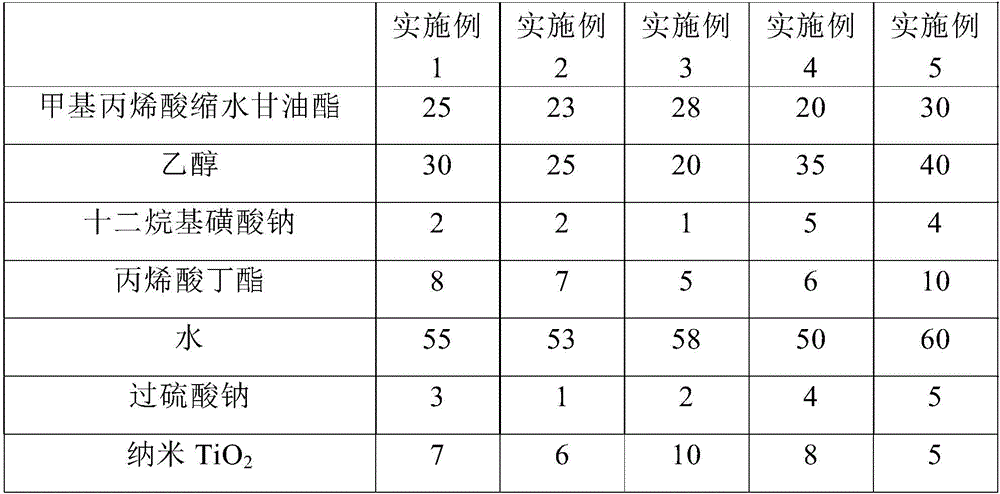

Environment-friendly waterproof antibacterial coating and preparation method thereof

InactiveCN106085118AHigh glossImprove antistatic performanceAntifouling/underwater paintsPaints with biocidesPolyvinyl alcoholTemperature resistance

The invention provides an environment-friendly waterproof antibacterial coating and a preparation method thereof. The coating is prepared from the components of organosilicon-modified epoxy resin, bisphenol-A epoxy resin, ethyl acetate, polyvinyl alcohol, bentonite, sodium dodecyl benzene sulfonate, nanometer titania, methylisothiazolinone, sodium citrate, tributyl citrate, antibacterial agent, deforming agent, dispersing agent, coalescing agent, thickening agent, isopropyl alcohol and deionized water. In the coating, the organosilicon-modified epoxy resin is matched with the bisphenol-A epoxy resin, so that the coating has high glossiness, high anti-static electricity capacity, high mechanical property, high aging resistance and high chemical corrosion resistance; the methylisothiazolinone and the antibacterial agent are added, so that the antibacterial capability of the coating can be improved effectively; moreover, the environment-friendly waterproof antibacterial coating has the advantages of low cost, environmental friendliness, high adhesive force, high extensibility, high temperature resistance and long service life; a roller coating way is adopted instead of spraying during coating, so that the production environment is improved effectively, and the physical health of workers is facilitated.

Owner:TAICANG JINXIN PAINT

Recycling processing intelligent robot for waste and old aluminum coil of cable

InactiveCN107705938AIncrease temperatureRapid physical changeBasic electric elementsElectronic waste recyclingEngineeringUltimate tensile strength

The invention relates to a recycling processing intelligent robot for a waste and old aluminum coil of a cable, and the robot comprises a bottom plate, wherein the upper end of the bottom plate is sequentially provided with a heating device, a rubbing and kneading skin-cutting device, a separation device and a coiling device. The robot can solve problems that an aluminum coil needs to be heated inthe in the conventional manual processing process of the surface insulator of the waste and old aluminum coil, the surface insulator of the aluminum coil needs to be peeled off manually, the manual rubbing and kneading operations of the surface insulator of the aluminum coil are complex, the pungent smell emitted by the heated aluminum coil insulator affects the health of a worker, the manual peeling of the insulator on the aluminum is not completed, and the manual processing of the surface insulator of the aluminum coil is large in labor intensity, is large in time waste and is low in work efficiency. The device can achieve the high-efficiency recycling of the surface insulator of the waste and old aluminum coil.

Owner:盛珊瑜

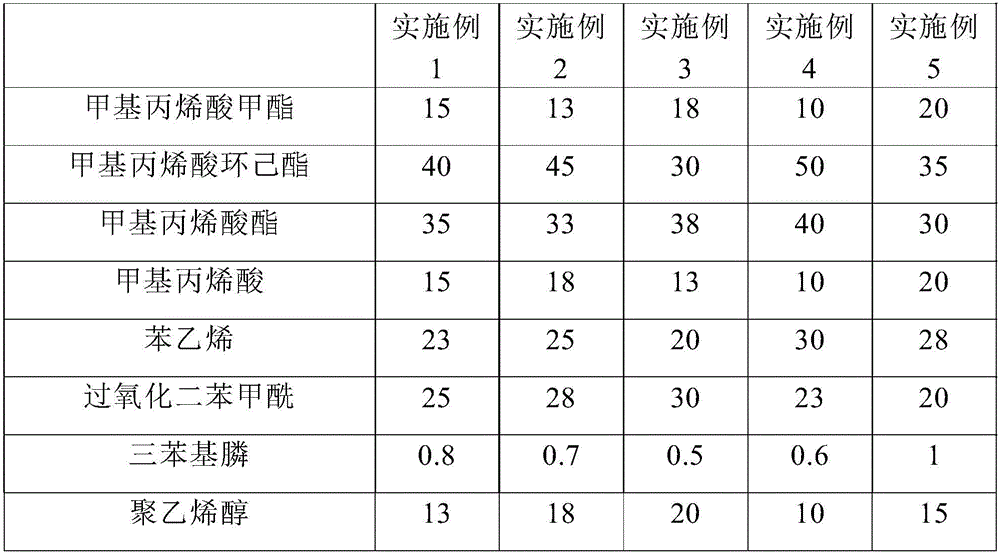

Environment-friendly wear resistant and high-weather resistant polyurethane enamel and preparation method thereof

InactiveCN106010189AHigh hardnessGood for healthFireproof paintsMagnetic paintsEnvironmental resistanceWater based

The present invention provides an environment-friendly, wear-resistant and highly weather-resistant polyurethane enamel and a preparation method thereof. The enamel includes the following components: Component A: water-based hydroxyacrylic resin, water-based polyurethane emulsion, hydroxymethyl cellulose, titanate coupling agent , Stabilizer, leveling agent, wetting and dispersing agent, emulsifier, pigment and filler, deionized water; component B: water-based hexamethylene diisocyanate trimer. The enamel is composed of two components, with water-based hydroxyacrylic resin, water-based polyurethane emulsion and hydroxymethyl cellulose as the main components of A component, and water-based hexamethylene diisocyanate trimer as B component, which can Effectively improve the hardness of enamel paint film, the composition design is reasonable, dilute with deionized water as solvent, instead of organic solvent, friendly to the environment, improve wear resistance, strong adhesion, good ductility, high temperature resistance, long service life, When coating, roller coating is used instead of spray coating, which can effectively improve the production environment and benefit the health of workers.

Owner:TAICANG JINXIN PAINT

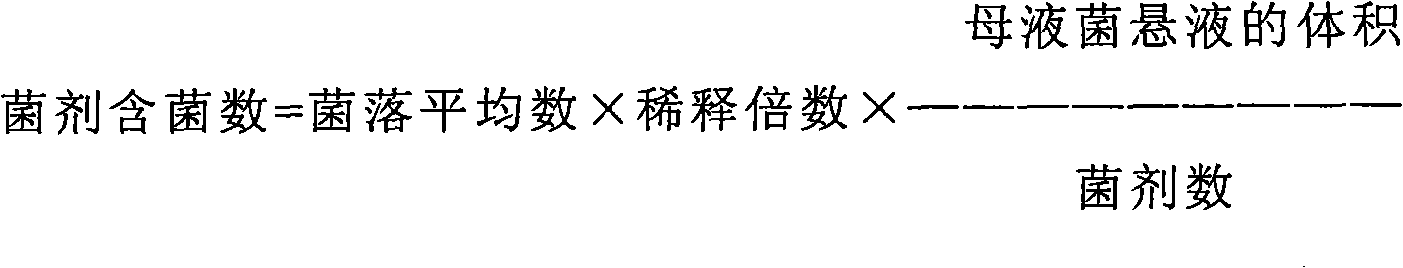

Ferment feed synergist and preparation method thereof

InactiveCN102008009AImprove conversion rateIncrease profitFood processingClimate change adaptationDiseaseAnimal science

The invention discloses a ferment feed synergist and a preparation method thereof, relating to the technical field of feed synergists. The synergist is prepared from the following components in percentage by weight: 50 percent of water and 50 percent by weight of synergistic raw materials, wherein the synergistic raw materials comprise the following components in percentage by weight: 30 percent of rice bran, 30 percent of wheat bran, 20 percent of straw powder, 3 percent of brown sugar, 9 percent of bacterial enzymes, 7 percent of bone or shell powder and 1 percent of trace elements. The synergist can fed together with traditional feed or additive to remarkably improve the conversion rate and the utilization rate of the feed or the additive and enables the nutrient contents in the feed or additive to be truly and fully absorbed and utilized. Meanwhile, the invention can improve the balance of animal bodies, enhance the disease resistance of livestock and poultry, eliminate drug residues, ensure people's health, promote the development of the eco-organic food, eliminate bacteria breeding and create a healthy biological food chain.

Owner:徐维康

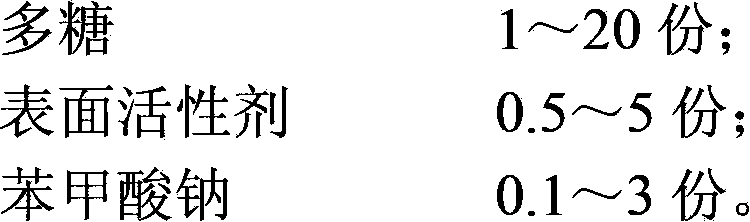

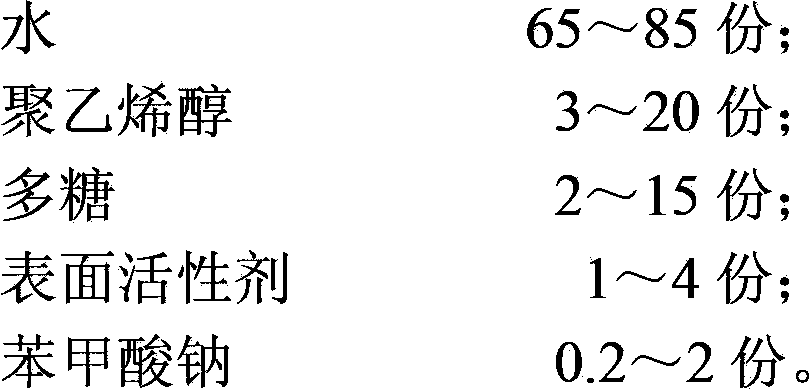

Dust inhibition agent for inhibiting dust suspension, and preparation method thereof

InactiveCN103484062AInhibition suspensionEffectively fixedOther chemical processesPhysical well beingPolyvinyl alcohol

The present invention relates to a dust inhibition agent for inhibiting dust suspension. The dust inhibition agent comprises, by weight, 50-90 parts of water, 2-30 parts of polyvinyl alcohol, 1-20 parts of polysaccharide, 0.5-5 parts of a surfactant, and 0.1-3 parts of sodium benzoate, wherein the dust inhibition agent has characteristics of no toxicity, no harm, biodegradability and no secondary pollution. During a use process, the diluted dust inhibition agent is sprayed on sand soil heap, ash heap, road surface and the like, provides effects of wetting, adhesion, condensation, moisture absorption, dust resistance, etching resistance and erosion resistance through capturing, absorbing and aggregating dust micro-particles, and forms a layer of an adhesive film with a network structure on the surface so as to effectively fix dust and form a protection film on the surface of the material, such that the dust is fixed, dust re-suspension is inhibited, material loss can be effectively reduced, dust pollution is reduced, the environment is protected, and health of workers and the surrounding population are protected.

Owner:MCC TIANGONG GROUP

Environment-friendly, acid-proof and high-temperature-resistant exterior wall coating material and preparation method thereof

InactiveCN106047063AHigh glossImprove antistatic performanceFireproof paintsAnti-corrosive paintsThermal insulationSolvent

The invention provides an environment-friendly, acid-proof and high-temperature-resistant exterior wall coating material and a preparation method thereof. The coating material comprises the following components: organic silicon-modified epoxy resin, bisphenol-A epoxy resin, a thermal insulation filler, nano-silica, an anti-rusting pigment, carboxymethyl cellulose, acetone, nano-calcium carbonate, butyl acetate, a cosolvent, deionized water, dibutyl phthalate, a pH regulator, a dispersing agent, a film forming agent and a thickening agent. The bisphenol-A epoxy resin is matched with the organic silicon-modified epoxy resin, so that the coating material has good lustrousness and static electricity resistance and relatively good mechanical property, ageing resistance and chemical corrosion resistance; by adding the thermal insulation filler and the anti-rusting pigment, the high temperature resistance, the corrosion resistance and the acid resistance of the coating materials are effectively improved; furthermore, the coating material has the superiorities in price and environmental protection, is strong in adhesive force, good in ductility and long in service life and can resist high temperature; and a spray painting manner is replaced with a roller painting manner during the painting, so that the production environment is effectively improved, and the body health of workers is improved.

Owner:TAICANG JINXIN PAINT

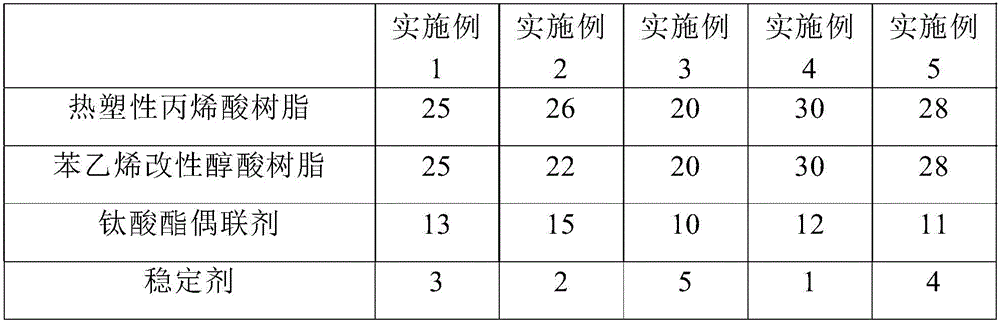

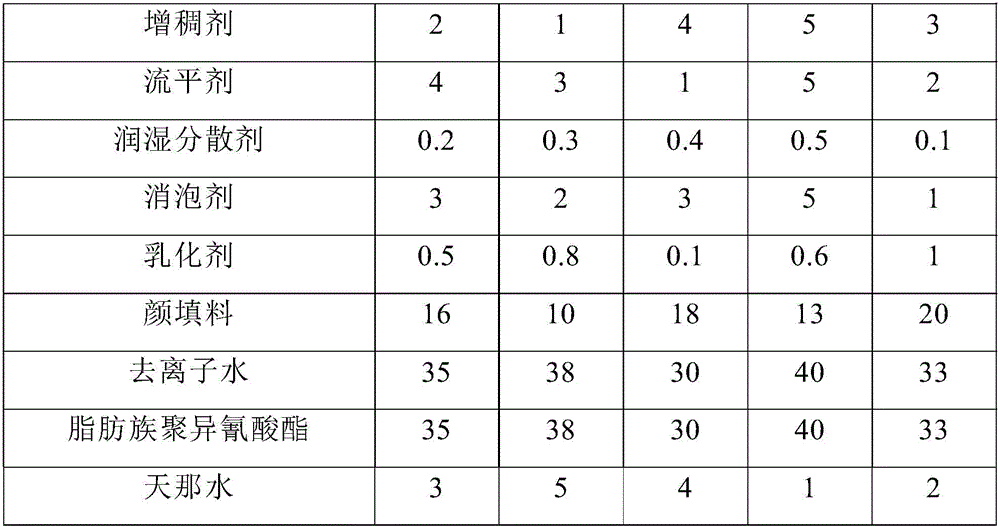

Environment-friendly wear-proof two-component plastic cement paint and preparation method thereof

InactiveCN106047139AHigh hardnessReasonable designFireproof paintsPolyurea/polyurethane coatingsSolventHardness

The invention provides environment-friendly wear-proof two-component plastic cement paint and a preparation method thereof. The plastic cement paint comprises the component A and a component B, wherein the component A comprises styrene modified alkyd resin, thermoplastic acrylic resin, a titanate coupling agent, a stabilizer, a thickening agent, a flatting agent, a wetting dispersant, a defoaming agent, an emulsifying agent, pigment fillers and deionized water; and the component B comprises aliphatic polyisocyanate and banana oil. The plastic cement paint comprises two components, the styrene modified alkyd resin and the thermoplastic acrylic resin are taken as the main components of the component A and are matched with aliphatic polyisocyanate serving as the component B, so that the paint film hardness of the plastic cement paint can be effectively improved; the constituent design is reasonable, and deionized water is utilized as a solvent to replace organic solvents for dilution, so that the plastic cement paint is environmentally friendly, strong in adhesive force, good in ductility and long in service life and can resist high temperature, and the wear resistance is improved; and a spray painting manner is replaced with a roller painting manner during the painting, so that the production environment is effectively improved, and the body health of workers is improved.

Owner:TAICANG JINXIN PAINT

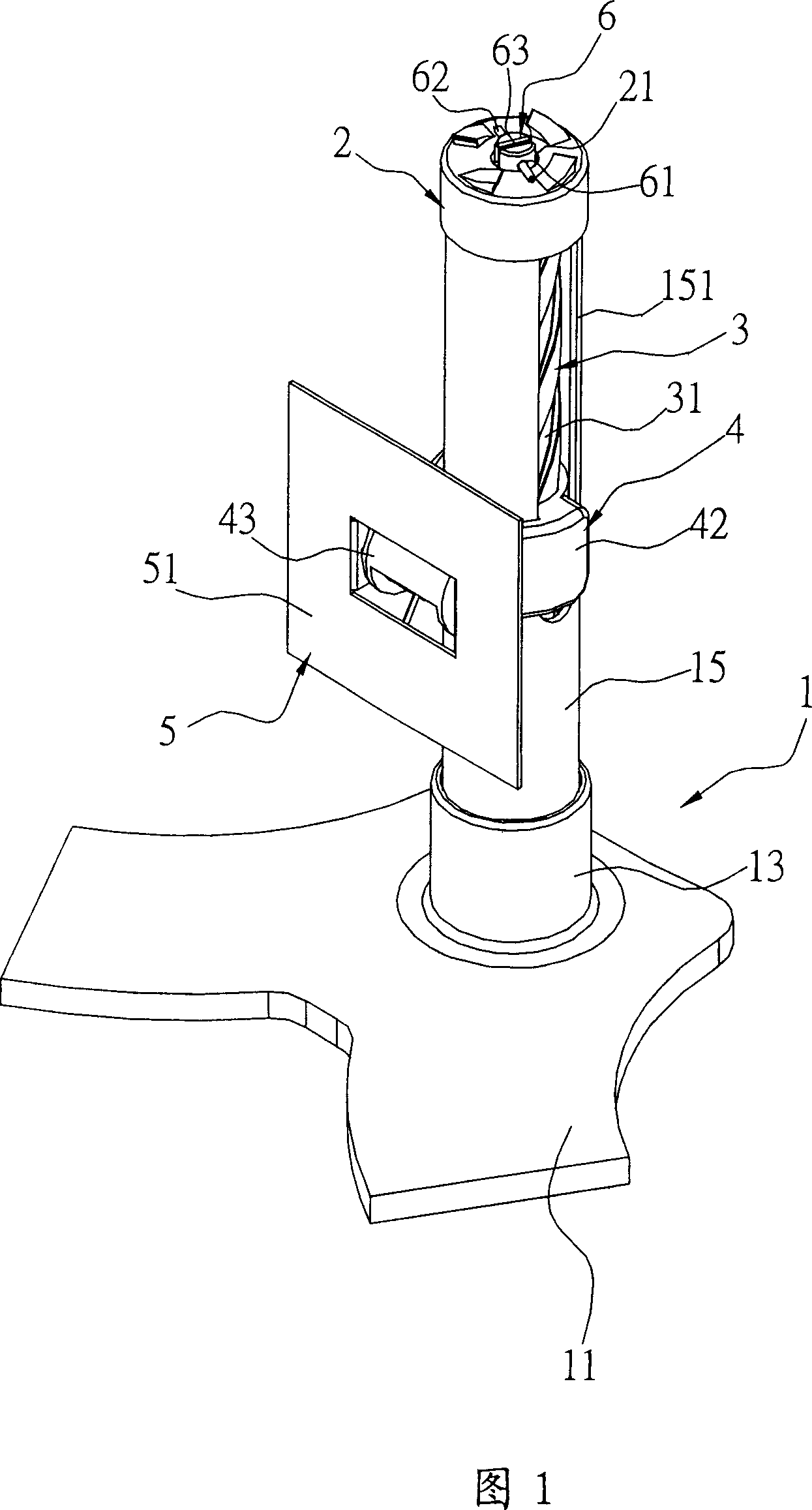

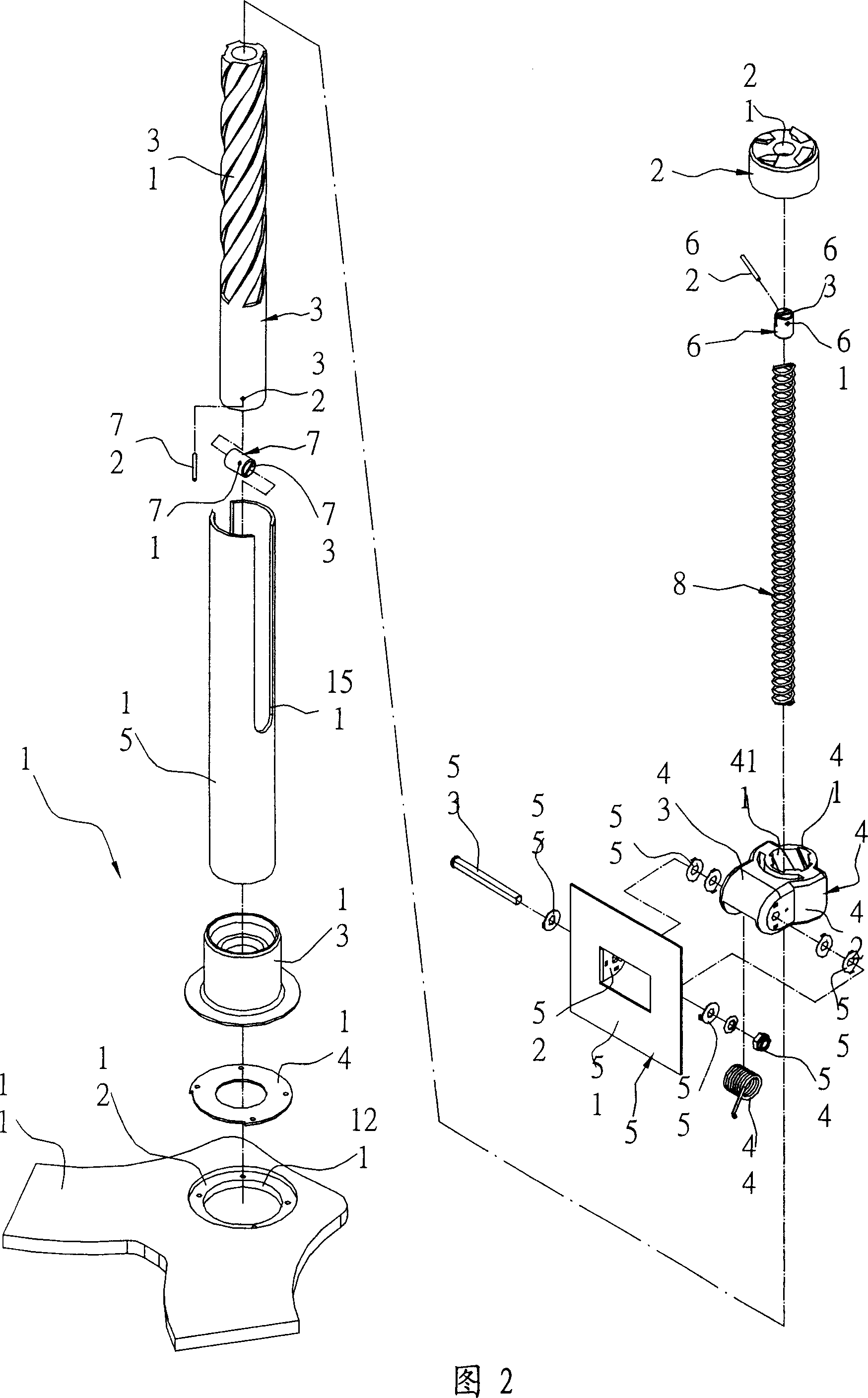

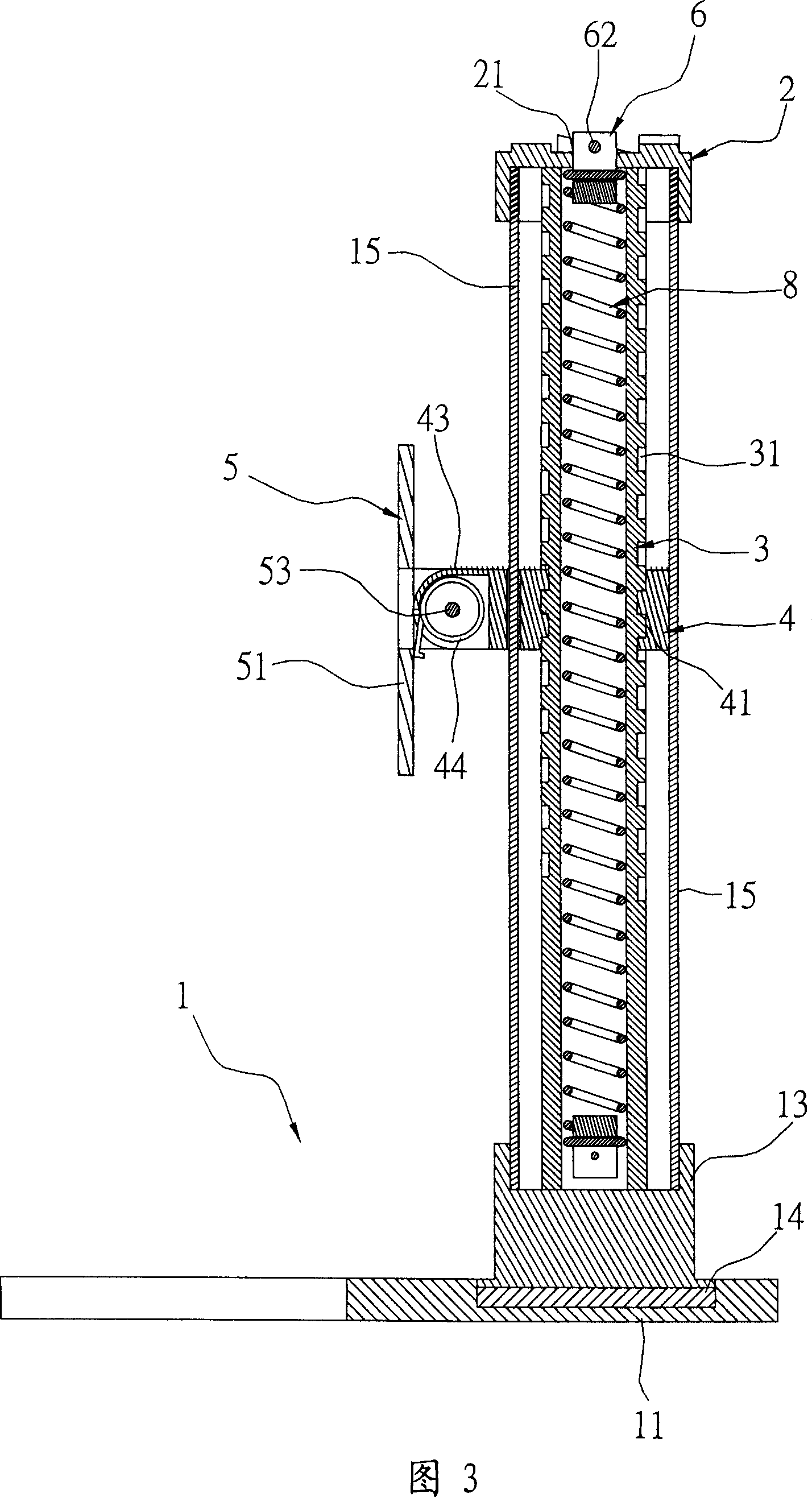

Height adjustable structure

InactiveCN101116578AMeet the needs of operability and convenienceHealth CareAdjustable chairsVariable height tablesEngineeringMechanical engineering

Owner:邱柏森 +1

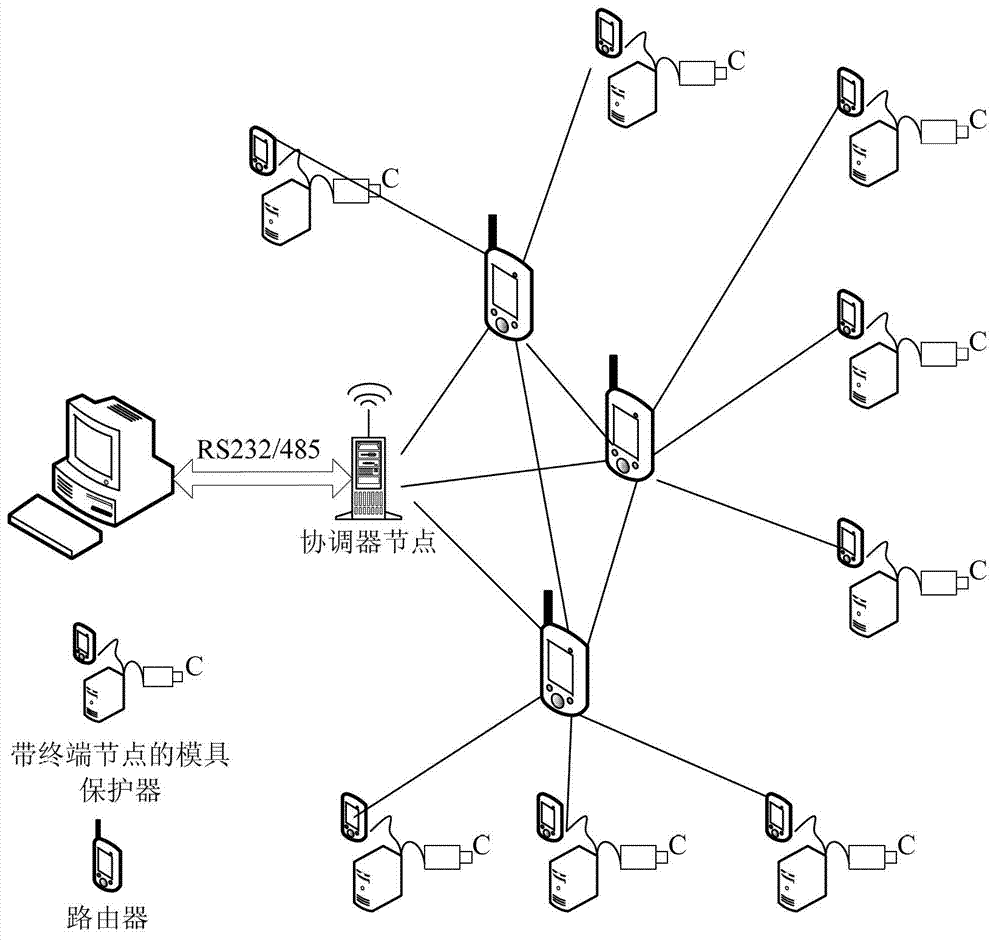

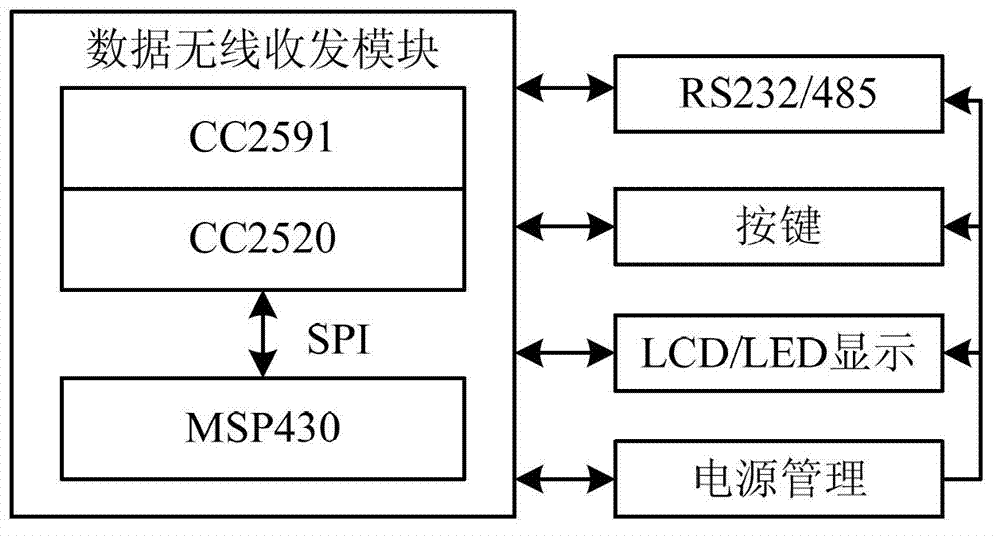

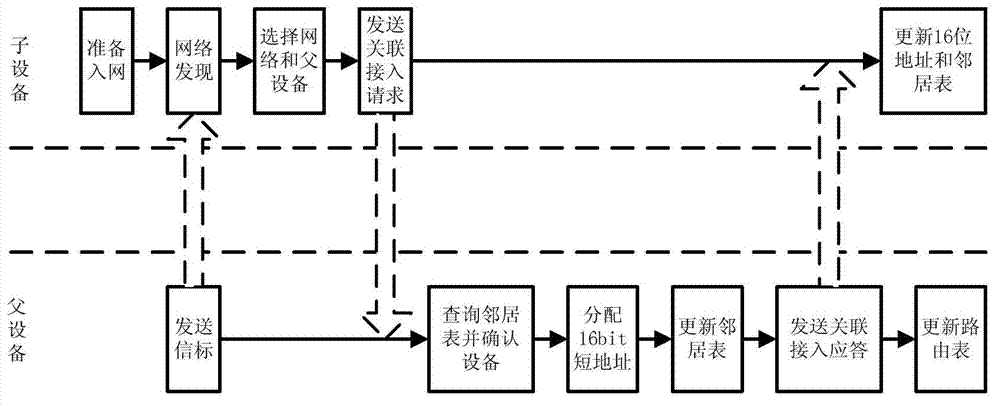

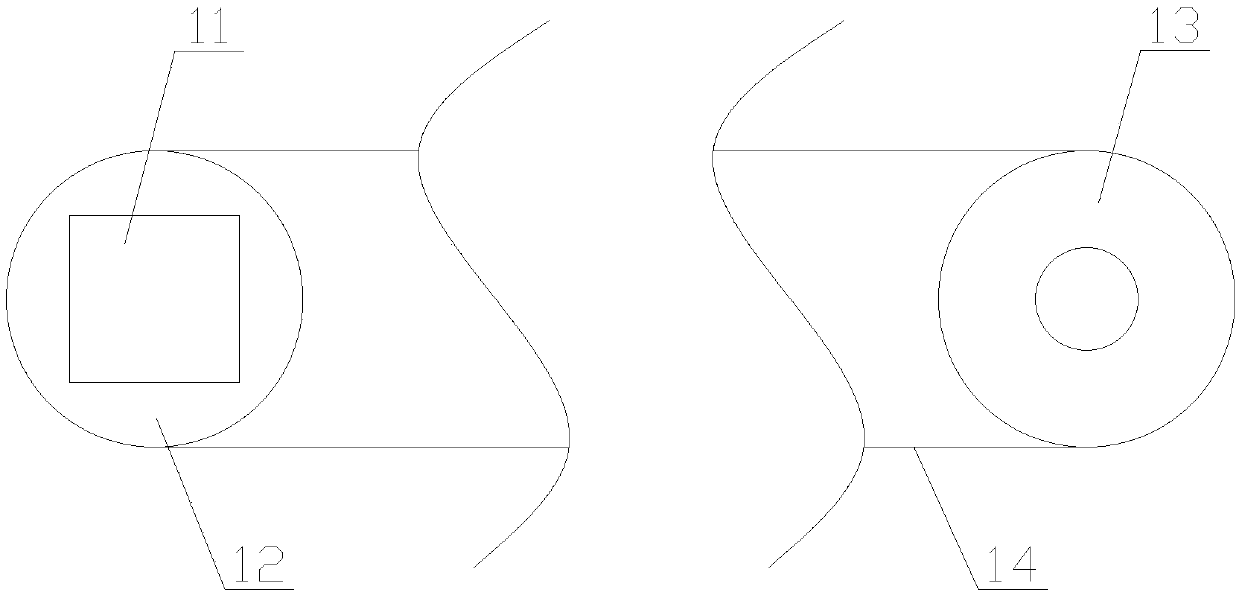

Embedded type mold protection system and method based on ZigBee network

The invention relates to an embedded type mold protection system based on a ZigBee network. The system comprises a coordinator, a router node, an embedded type mold protector with a wireless transceiver function, and a host computer. The coordinator is in charge of the establishment and maintenance of the ZigBee network, the addition of child nodes, data collection, and communication between the network and the host computer. The router node is in charge of data routing, and is used for ensuring correct data exchange between a main node and the embedded type mold protector with the wireless transceiver function. The embedded type mold protector with the wireless transceiver function is used for monitoring the safety of the mold, and is used for providing mold information. The host computer is used for displaying the real-time status of each terminal node in the system. The invention also provides an embedded type mold protection method based on the ZigBee network. The invention provides a remote monitoring scheme of the safety of an injection molding machine. With the scheme provided by the invention, mold safety and product quality of the injection molding machine can be ensured.

Owner:海宁市黄湾镇资产经营有限公司

Energy-saving garbage treatment equipment

InactiveCN111215167AImprove crushing effectImprove screening accuracyGrain treatmentsDust controlArchitectural engineering

The invention relates to energy-saving garbage treatment equipment. The energy-saving garbage treatment equipment comprises a base, the base is internally provided with a crushing mechanism, a transport mechanism, a screening box, a storage box and a dust removal mechanism, wherein the screening mechanism is arranged in the screening box, the crushing mechanism comprises a crushing box, a fixed plate, a pushing unit and two lifting units, the screening mechanism comprises a fourth motor, a turning wheel, a power fixed rope, a moving block, a spring, a telescopic unit and an electromagnet, andthe dust removal mechanism comprises a fifth motor, a dust prevention box, a driving valve, a water box, a water pump, a filter element, a return pipe, a purification chamber and a plurality of blades. According to the energy-saving garbage treatment equipment, the building garbage treatment equipment can separate the steel bars from the building garbage through cooperation of the crushing mechanism and the screening mechanism, the recycling rate of the building waste is increased, moreover, the building waste treatment equipment can remove dust generated in the building waste treatment process through the dust removal mechanism, air pollution caused by dust is prevented, and body health of workers is guaranteed.

Owner:扬州舒洁家政服务有限公司

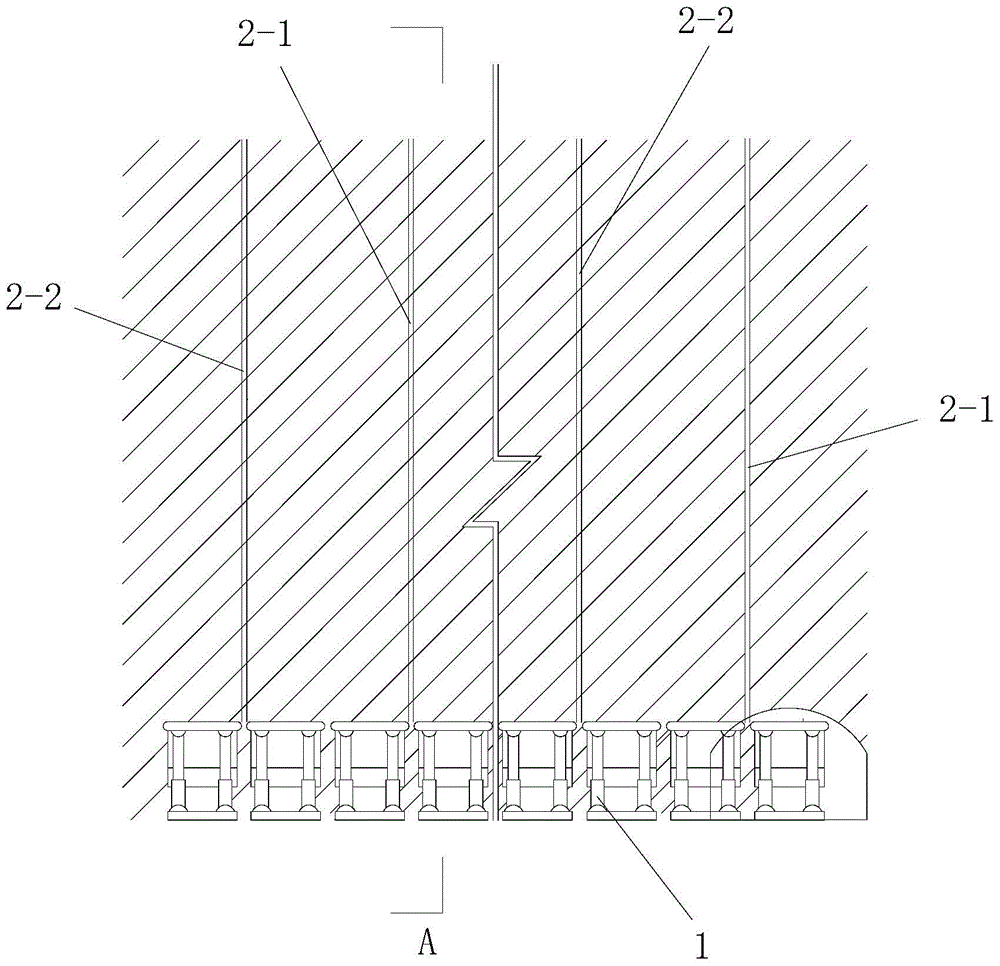

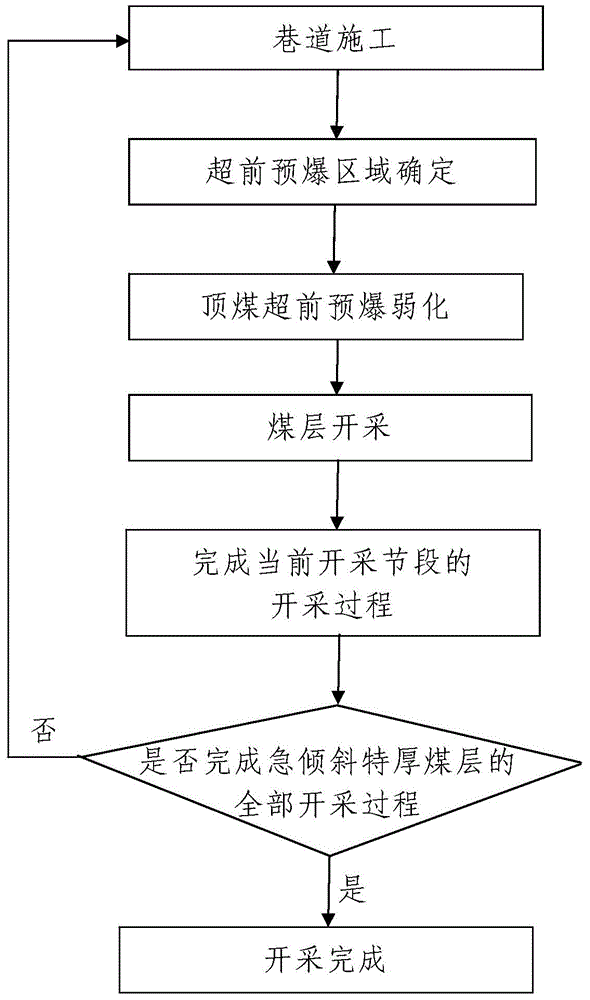

Steep-dip ultra-thick coalbed mining technique based on top-coal advancing pre-detonation weakening

InactiveCN104879128AThe process steps are simpleReasonable designUnderground miningSurface miningDetonationCoal

The invention discloses a steep-dip ultra-thick coalbed mining technique based on top-coal advancing pre-detonation weakening. The steep-dip ultra-thick coalbed mining technique includes exploiting steep-dip ultra-thick coalbed from back to front along coalbed bearing in several exploiting periods. In one of the exploiting period, the steps include firstly, constructing a roadway; secondly, weakening top-coal advancing pre-detonation, to be specifically, 201, determining a coalbed to be detonated; 202, drilling blast holes from an intake airflow road by a drilling machine; 203, charging and sealing the blast holes; 204, detonating for the first time; 205, detonating for the second time; thirdly, exploiting the coalbed; fourthly starting the next exploiting period; repeating the fourth step for many times until the steep-dip ultra-thick coalbed is completely exploited. The steep-dip ultra-thick coalbed mining technique is simple in steps, reasonable in design, high in exploitation efficiency and working-face recovery ratio, and good in using effect, and the problem that an existing mining technique is complicated, low in working-face recovery ratio and low in exploitation efficiency and causes many potential safety hazards is solved.

Owner:XIAN UNIV OF SCI & TECH

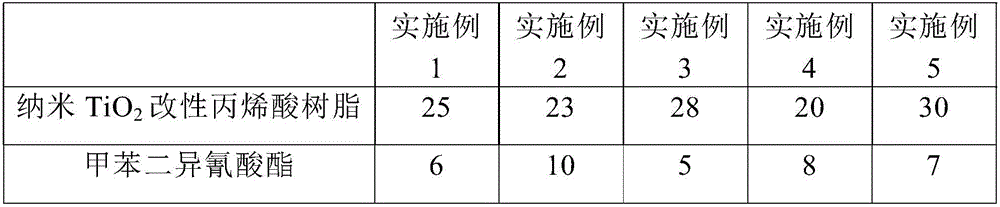

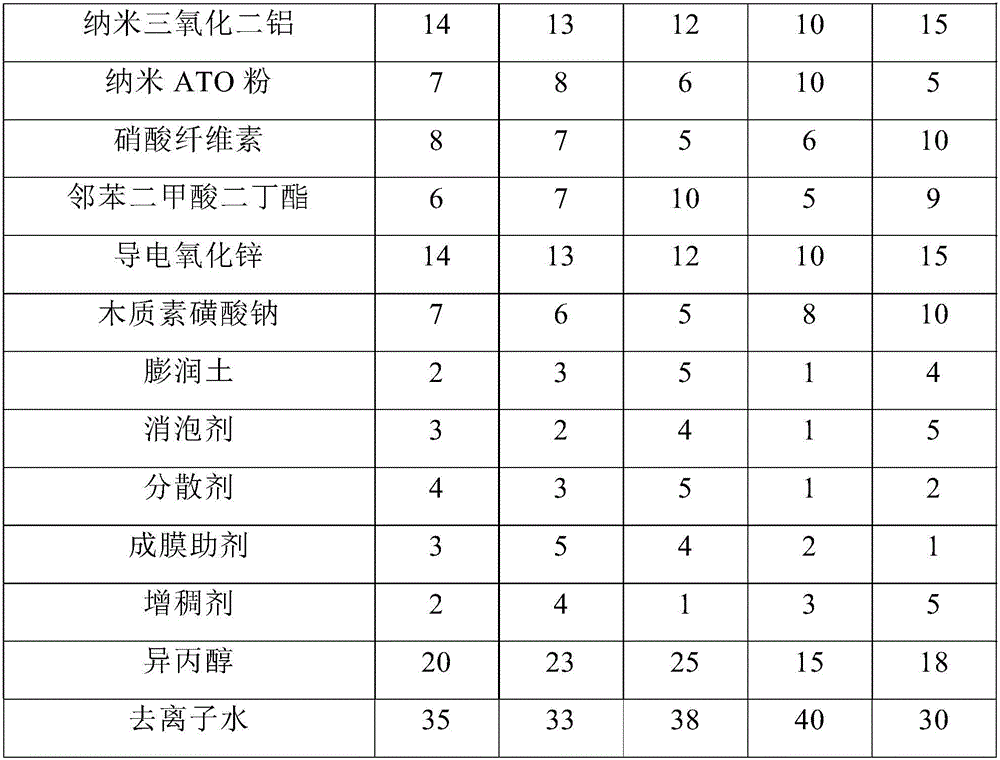

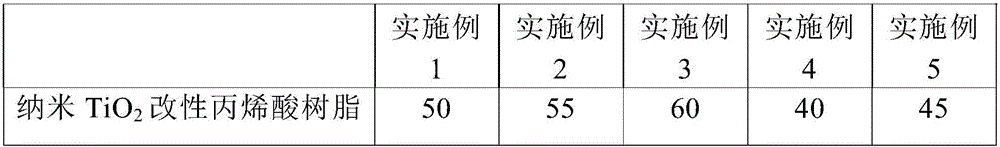

Environment-friendly anti-static building coating and preparation method thereof

InactiveCN106085078AHigh glossImprove antistatic performanceAnti-corrosive paintsRadiation-absorbing paintsCelluloseSodium Bentonite

The invention provides an environment-friendly anti-static building coating and a preparation method thereof. The coating is prepared from nano-TiO2-modified acrylic resin, toluene diisocynate, nano-aluminium oxide, nano-ATO powder, cellulose nitrate, dibutyl phthalate, conductive zinc oxide, sodium lignin sulfonate, bentonite, a defoaming agent, a dispersing agent, a film forming aid, a thickening agent, isopropanol and deionized water. According to the coating, by adopting the nano-TiO2-modified acrylic resin to cooperate with cellulose nitrate, the good glossiness, anti-static capacity, mechanical property, aging resistance and chemical corrosion resistance are achieved; by adding the nano-ATO powder and conductive zinc oxide, the anti-static capacity of the coating can be effectively improved; in addition, the coating also has cost and environmental friendliness advantages, is high in adhesive force, good in ductility, resistant to high temperature and long in service life, is applied in a rolling mode instead of a spraying mode during application, effectively improves a production environment and is beneficial for physical health of workers.

Owner:TAICANG JINXIN PAINT

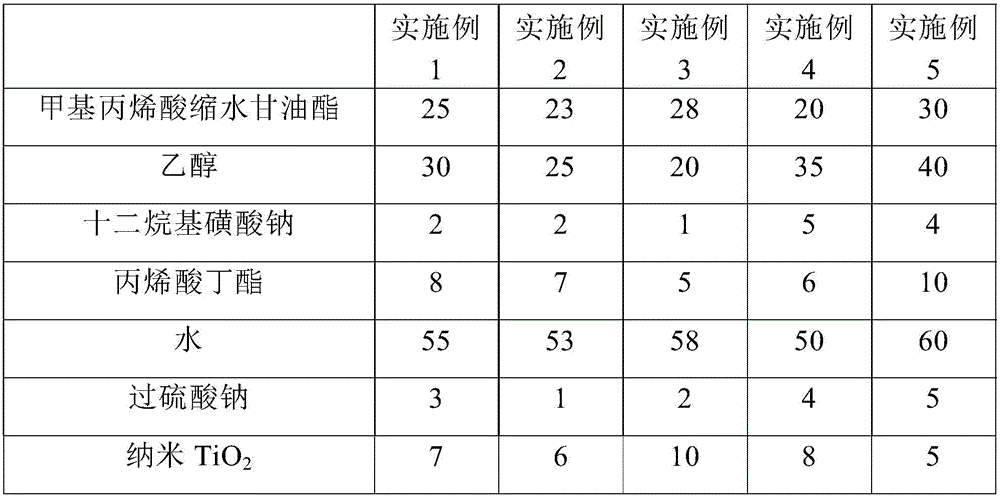

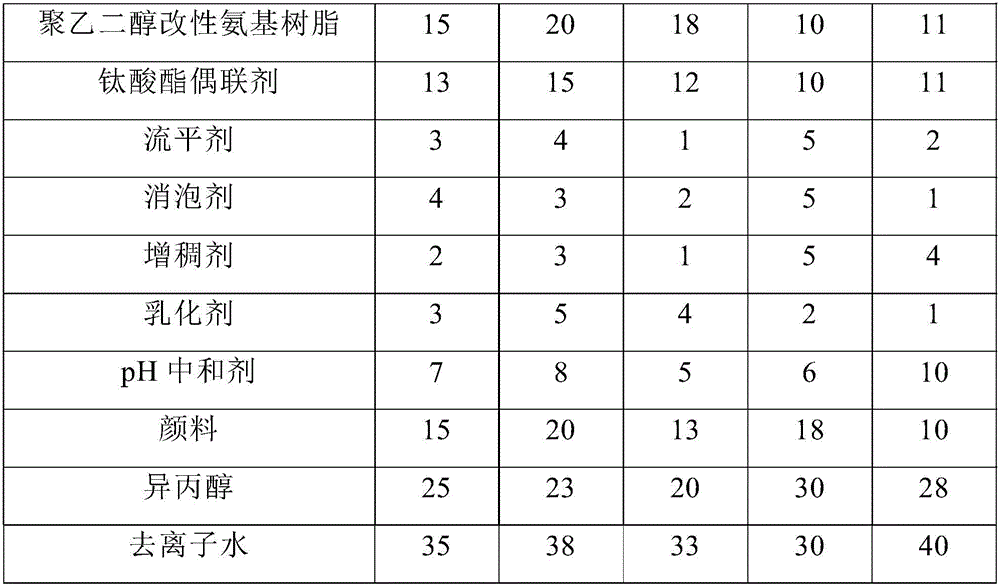

Environment-friendly high-hardness acrylic acid amino baking varnish and preparation method thereof

InactiveCN106047013AHigh hardnessImprove adhesionAnti-corrosive paintsEnvironmental resistanceAcrylic resin

The invention provides environment-friendly high-hardness acrylic acid amino baking varnish and a preparation method thereof. The environment-friendly high-hardness acrylic acid amino baking varnish comprises the following components: nano TiO2 modified acrylic resin, polyethylene glycol modified amino resin, a titanate coupling agent, a leveling agent, a defoaming agent, a thickening agent, an emulsifier, a pH neutralizing agent, pigment, isopropanol and deionized water. The baking varnish takes the special nano TiO2 modified acrylic resin, the polyethylene glycol modified amino resin and the titanate coupling agent as main components; due to the modified acrylic resin and amino resin, the hardness of a baking varnish membrane can be effectively improved, the adhesion property can be improved, and the corrosion resistance can be improved; the constituting components are reasonably designed, the deionized water is taken as a solvent for dilution, and an organic solvent is replaced, so that the baking varnish is environment-friendly, is good in wear resistance, good in adhesion property, good in ductility, good in high temperature resistance and long in service life; and the baking varnish can be applied in a spraying manner instead of roller painting, is capable of effectively improving the production environment, and is beneficial to body health of operators.

Owner:TAICANG JINXIN PAINT

Disposable self-destructing sterilized syringes

InactiveCN1644223ATo achieve the purpose of one-time useAvoid reuseInfusion syringesIntravenous devicesSilica gelSelf-destruct

An expendable self-destroy aseptic injector is composed of an external graduated sleeve tube and a tubular or cross bar-type push rod. It features that the front end of said push rod has a movable push plug matched with the liquid outlet of external sleeve tube, its front segment has one or more slots for embedding one or more sealing rings made of silica gel or PVC in them, and its back end has a concave surface for matching with finger end.

Owner:陈志法

Method for extracting superoxide dismutase from animal blood

InactiveCN103436500ALow costSimple and efficient operationOxidoreductasesUltrafiltrationPrecipitation

The invention discloses a method for extracting superoxide dismutase from animal blood. The method comprises the following steps: A. blood separation; B. hemolytic cell breaking; C. heat denaturation; D. filter pressing; E. ultrafiltration and concentration; F. precipitation for removing hybrid protein. Such organic solvents as chloroform, ethanol and acetone, and the like, are completely eliminated, and a rough product SOD with high activity is simply and conveniently separated out through a heat denaturation and metal salt precipitation method according to the structure characteristics and physicochemical properties of SOD molecules, which is a revolutionary improvement of SOD production. Since no inorganic solvent is used, the method is low in cost and is more suitable for industrial production. Hemoglobin is removed by thermal denaturation in the invention, so that hemolysis can be realized at normal temperature, the operation is simpler and more convenient and the energy consumption is reduced.

Owner:浙江迈康生物工程有限公司

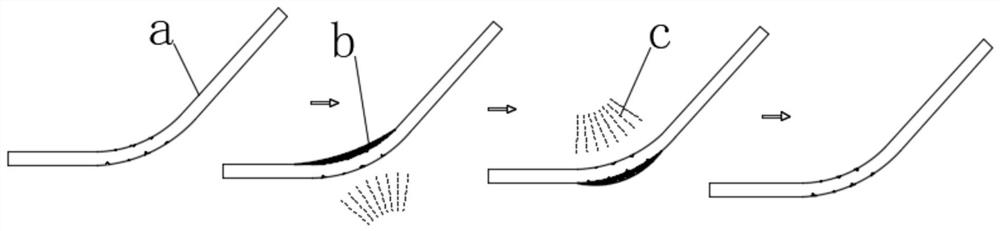

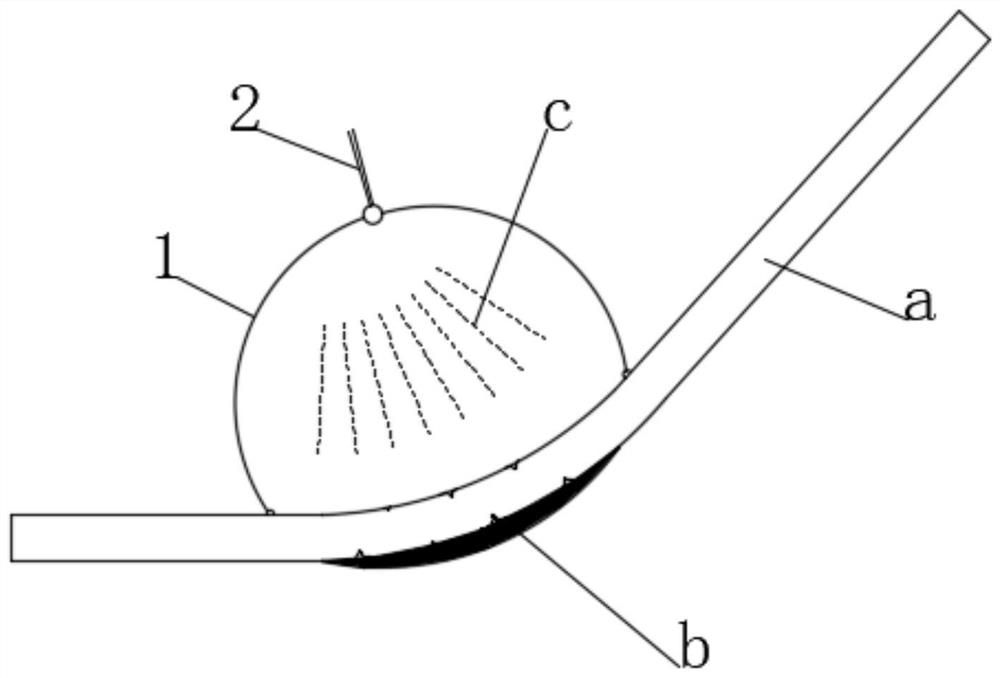

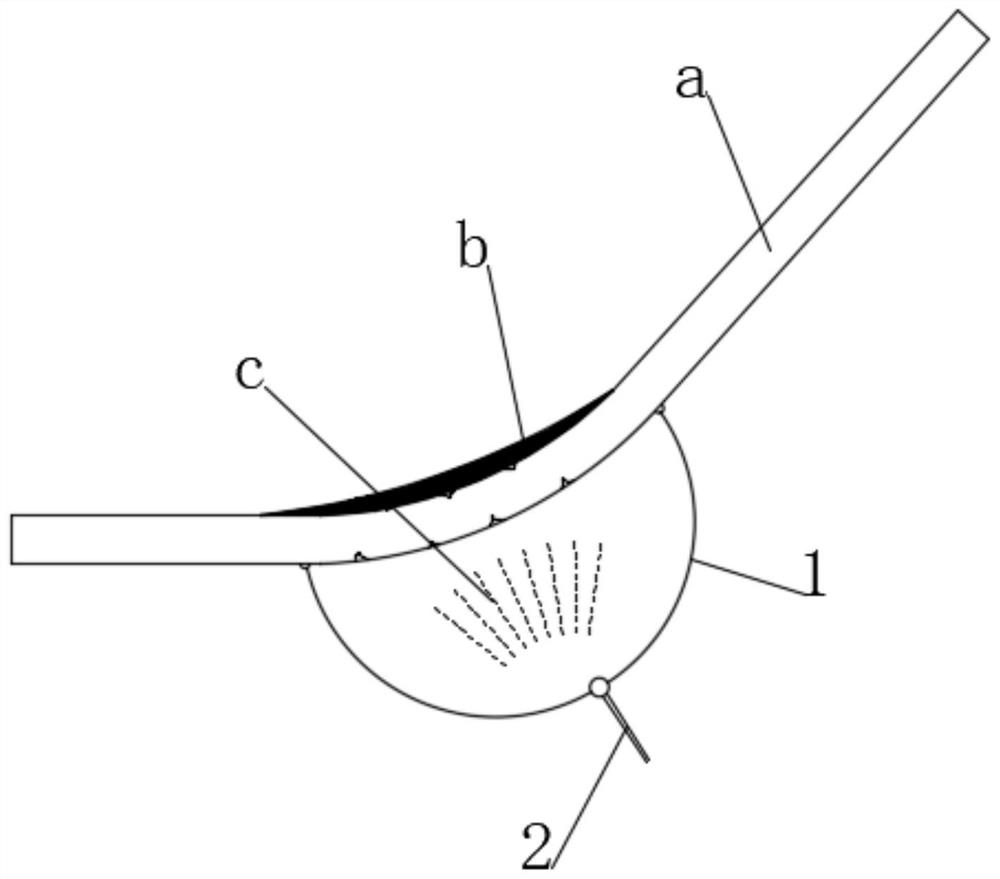

Self-seam-filling repairing method for bent position of metal plate

ActiveCN112077528AEfficient recyclingReduce wasteIncreasing energy efficiencyStructural engineeringMetal powder

The invention discloses a self-seam-filling repairing method for the bent position of a metal plate, and belongs to the field of metal plate bending. According to the self-seam-filling repairing method for the bent position of the metal plate, seam-filling metal powder is sprayed on the inner wall and the outer wall of the bent position of the metal plate in batches, the seam-filling metal powdercan be effectively guided to permeate into a micro-crack in cooperation with a soft magnetic strip, then fixed-point micro-melting is carried out on the bent position, and the effect of repairing thecrack under the condition that the position of the crack does not need to be determined can be achieved. Compared with the prior art, the repairing efficiency of the crack is remarkably improved, meanwhile, under the action of a dispersion inner convergence suction cover, on one hand, the sprayed seam-filling metal powder can be effectively isolated from the external space, meanwhile, after spraying, static extending fluff extends outwards and is erected, the seam-filling metal powder can be attracted and assisted to get close to a semi-shaped suction strip and be adsorbed, the diffused seam-filling metal powder is recycled, and the waste of the seam-filling metal powder is reduced; and on the other hand, workers are effectively protected against inhaling the seam-filling metal powder, andthen the influence of the seam-filling metal powder on the health of the workers is effectively reduced.

Owner:杭州浩顺钣金有限公司

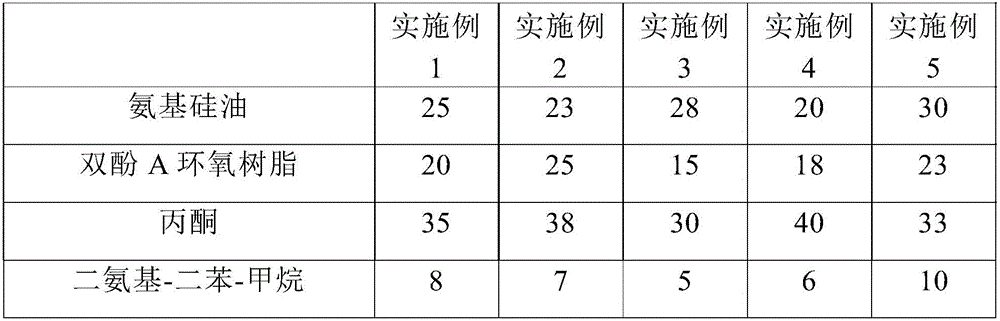

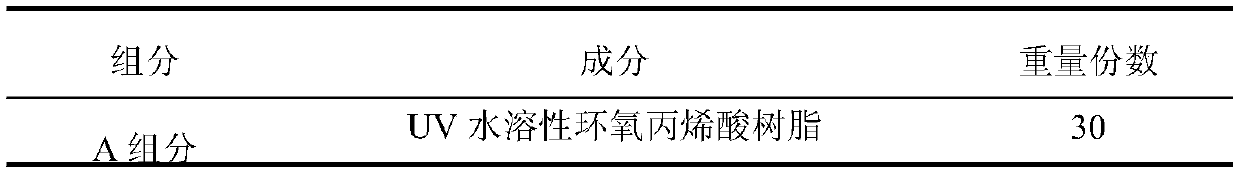

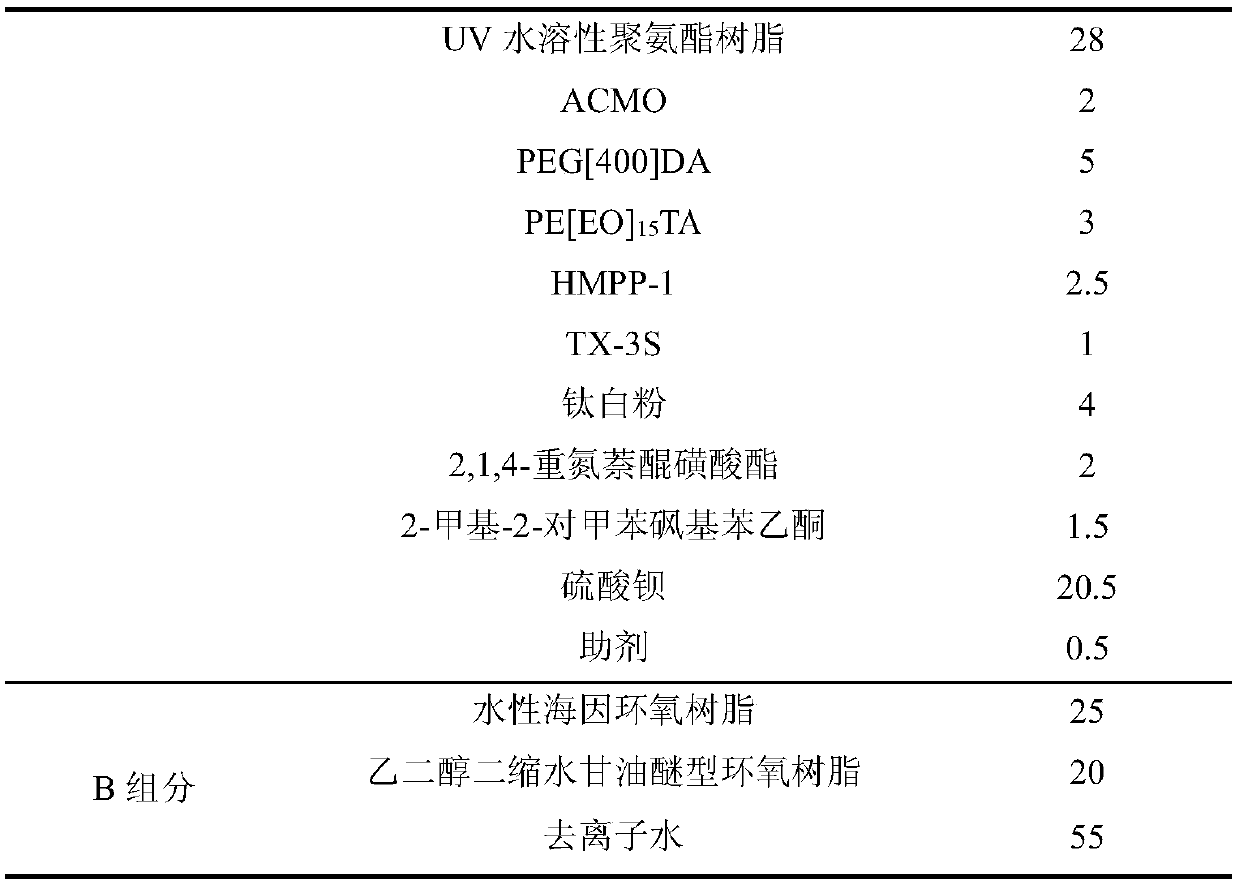

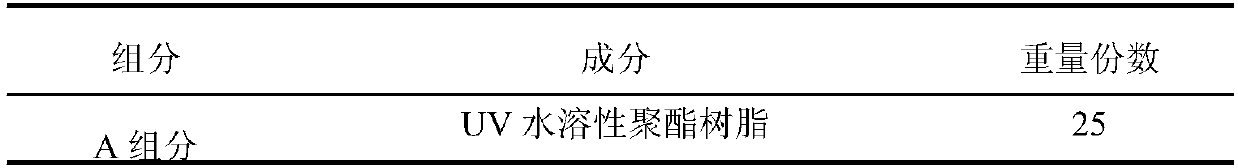

Photosensitive printing ink for 3D glass, preparation method thereof and preparation method of photosensitive coating

The invention discloses photosensitive printing ink for 3D glass, a preparation method thereof and a preparation method of a photosensitive coating. The photosensitive printing ink comprises, by weight, a component A and a component B, the component A comprises 50-65 parts of UV water-soluble resin, 3-15 parts of hydrophilic UV monomer, 1-6 parts of waterborne photoinitiator, 1-5 parts of photo-acid generator, 2-5 parts of pigment, 15-25 parts of filler and 0.01-1.0 part of aid, the component B comprises 35-55 parts of waterborne epoxy resin and 45-65 parts of water, a weight ratio of the component A to the component B is 8-15:1, and the UV waterborne resin comprises organic amine group. Adopted solvents are all water solutions, a diluent is a water solution, a developing agent is a watersolution, no other chemical substances are added, and almost no VOC is emitted in the process of drying, so that the photosensitive printing ink belongs to environment-friendly products and is suitable for modern mass production.

Owner:松井新材料研究院(广东)有限公司

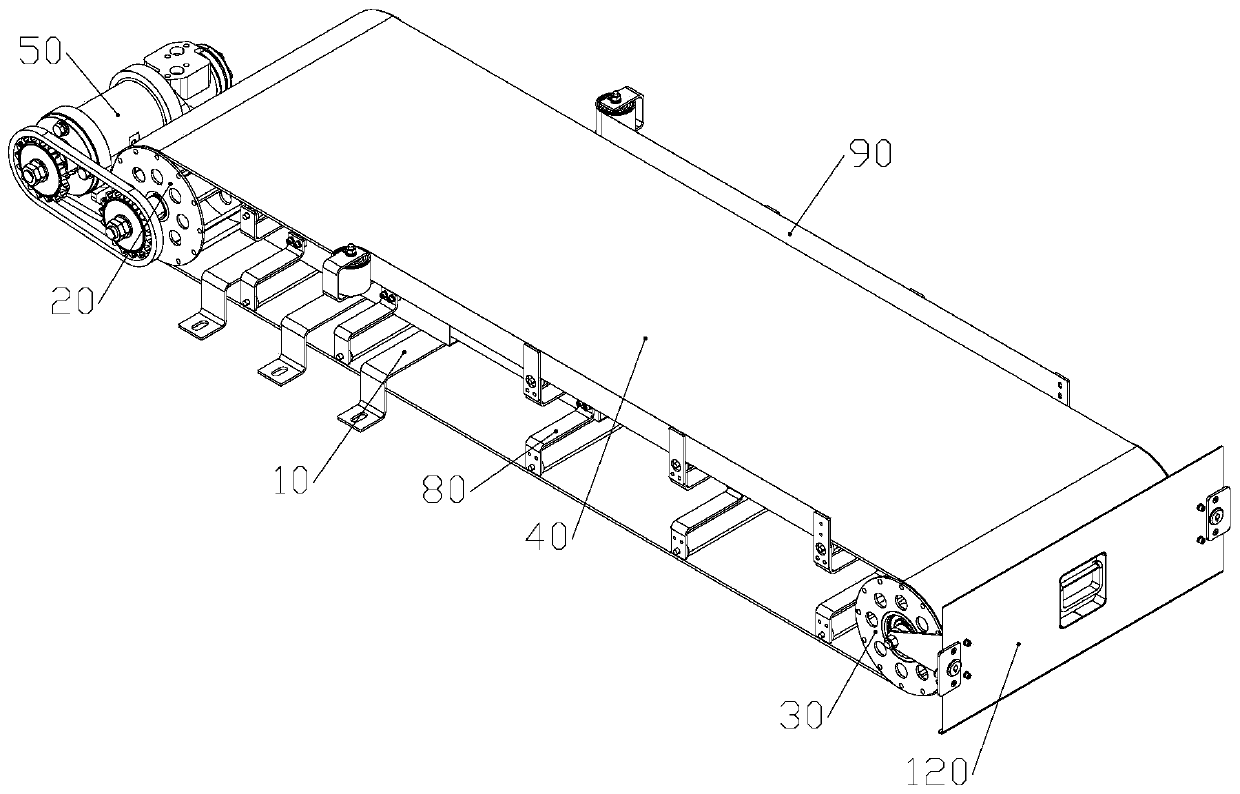

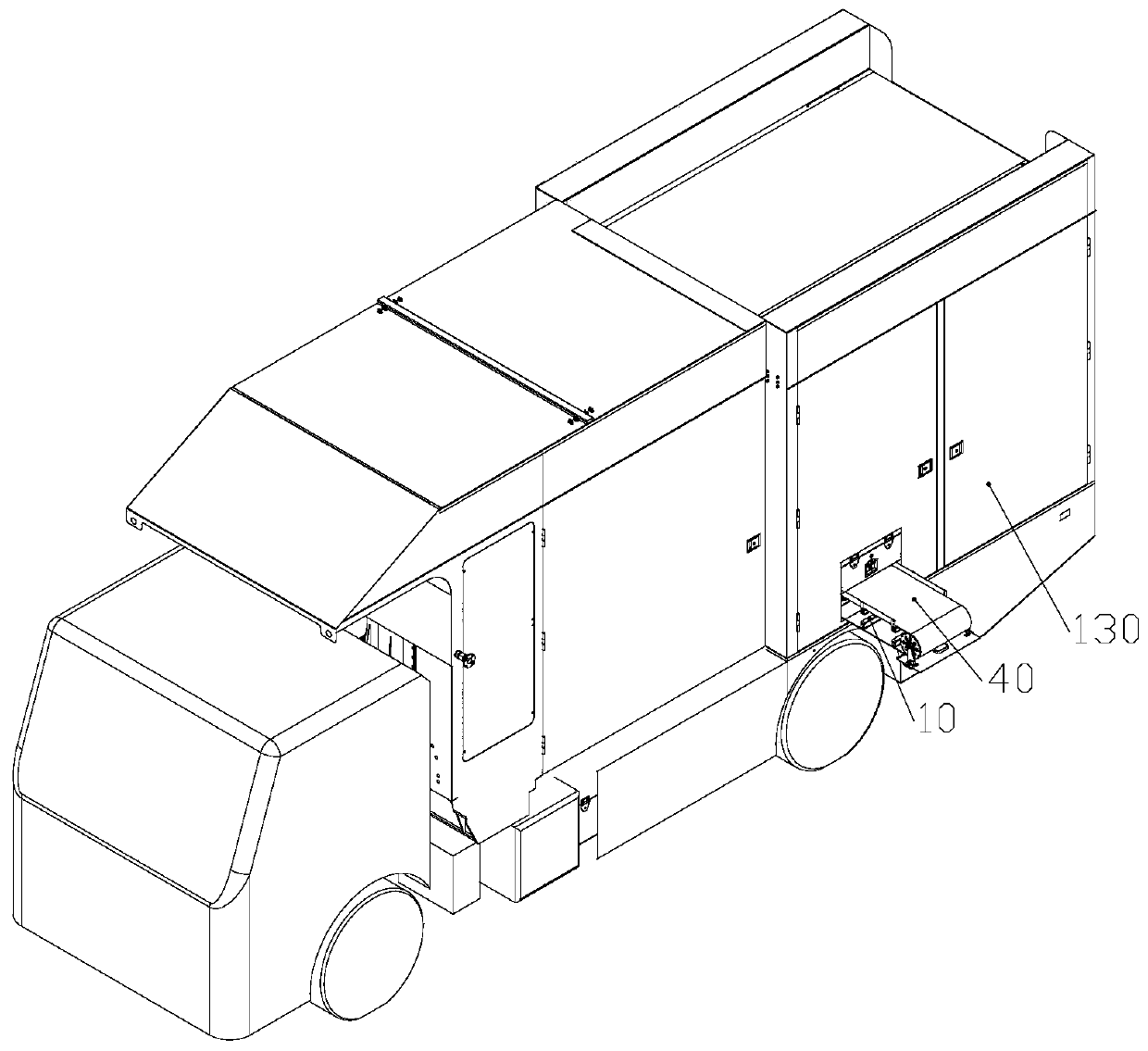

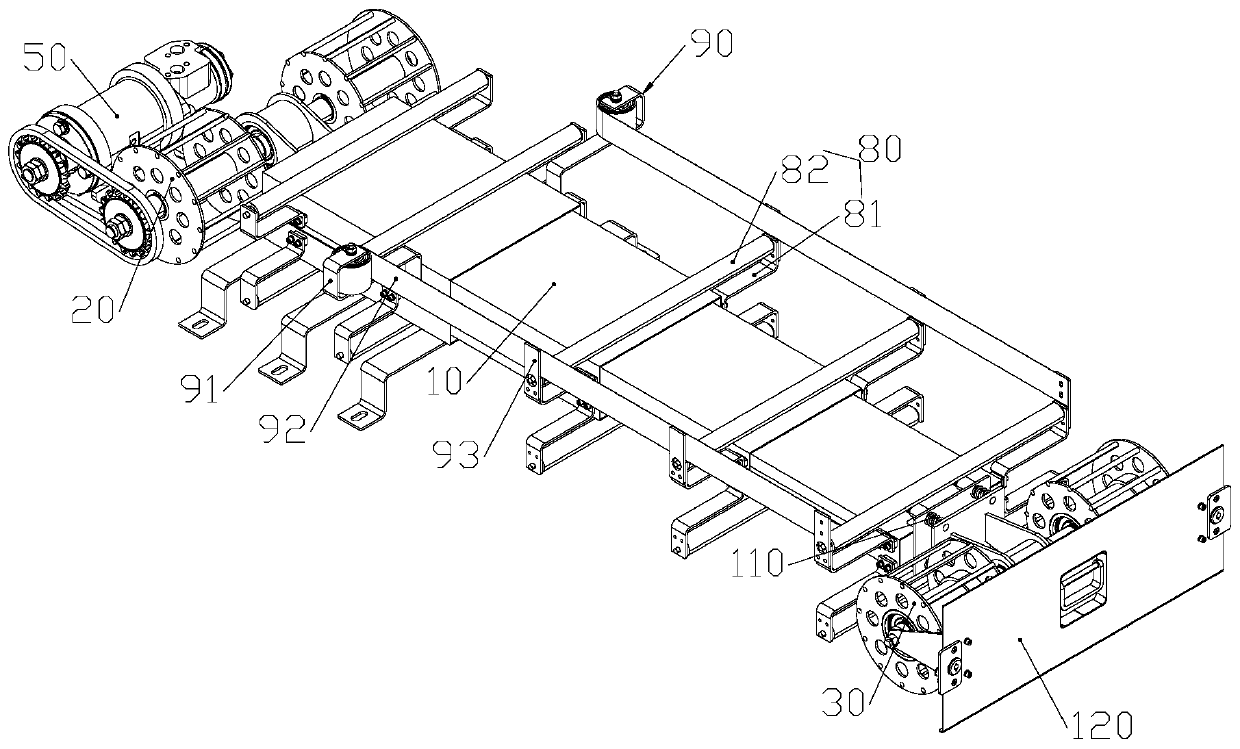

Vehicle-mounted docking and conveying device

PendingCN110921364AReduce work intensityReduced physical fitnessConveyorsRollersIn vehicleCantilever

The invention discloses a vehicle-mounted docking and conveying device. The device comprises a multi-stage telescopic frame which is telescopically arranged in the material conveying direction, wherein the mounting end of the multi-stage telescopic frame is connected in a compartment of a vehicle-mounted device, and the cantilever end of the multi-stage telescopic frame is used for extending out of the compartment and then extending into the docking device. The mounting end of the multi-stage telescopic frame is connected with a driving roller assembly which is rotationally arranged, the cantilever end of the multi-stage telescopic frame is connected with a driven roller assembly which is rotationally arranged, a conveying belt used for conveying materials is wound around the driving roller assembly and the driven roller assembly, and the multi-stage telescopic frame is arranged in an annular ring enclosed by a conveying belt. The driving roller assembly is connected with a driving assembly, the driving assembly is used for driving the driving roller assembly to rotate after the multi-stage telescopic frame extends in place and tensioning the conveying belt, and then the conveyingbelt moves under the driving of the driving roller assembly to convey the material.

Owner:廖文赟

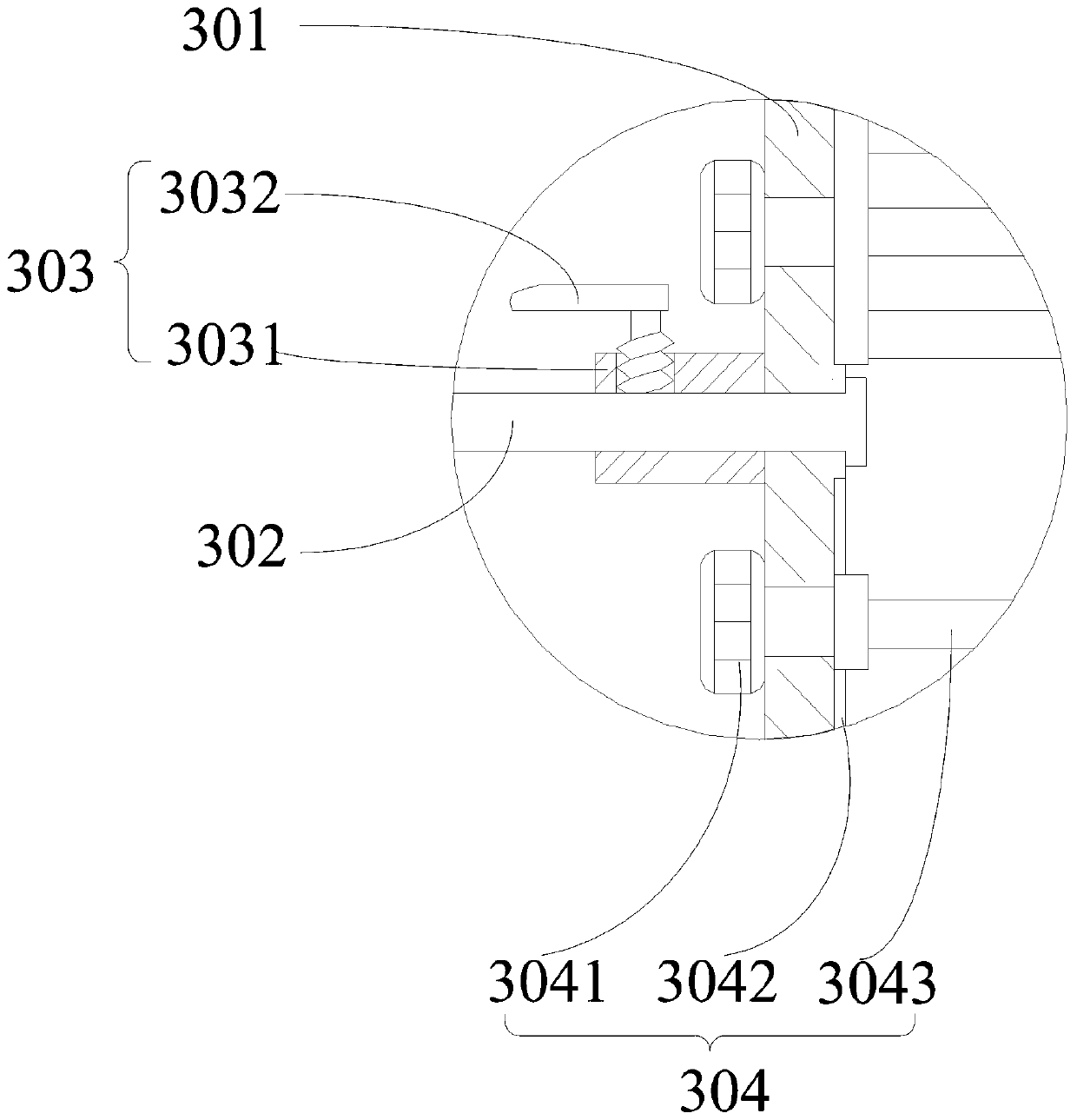

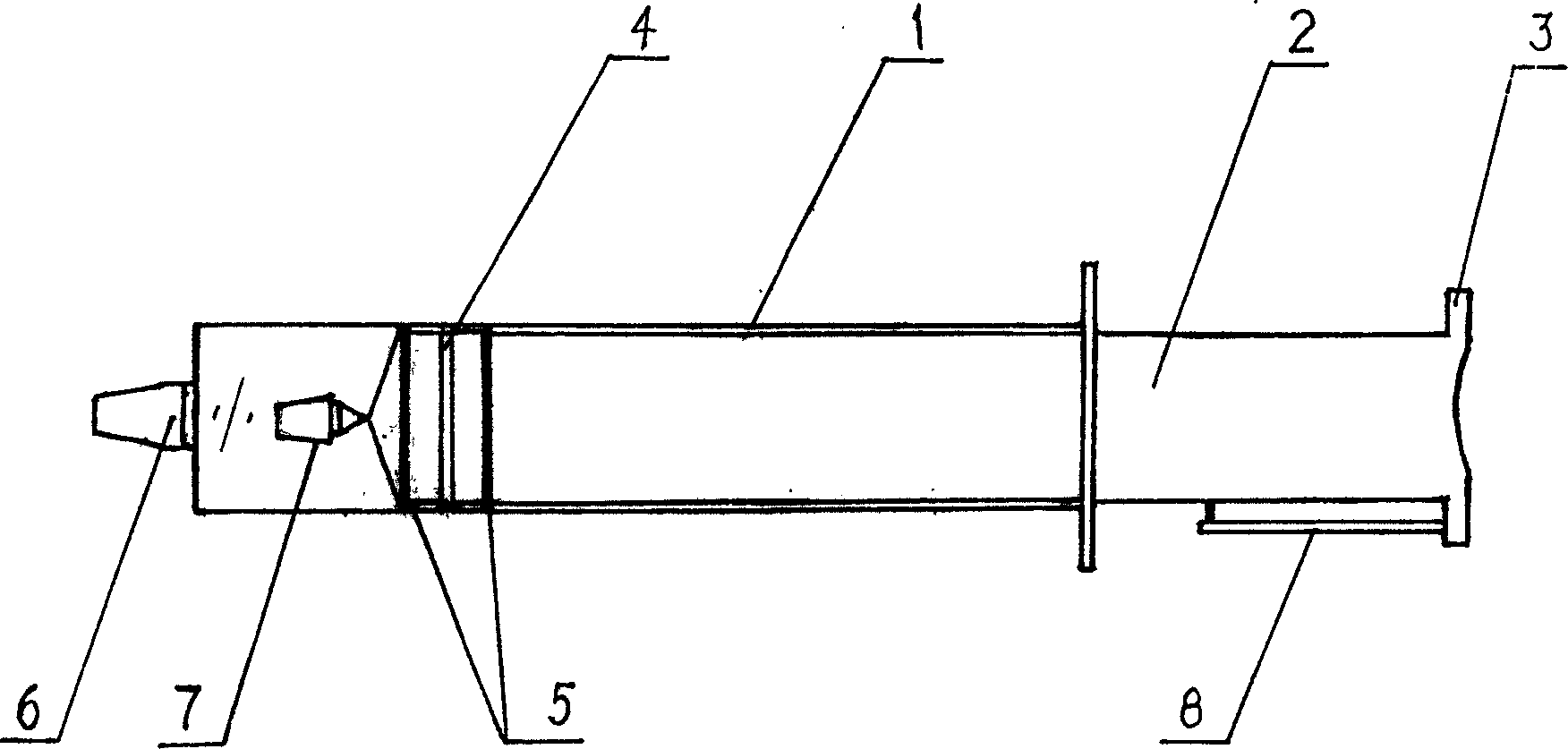

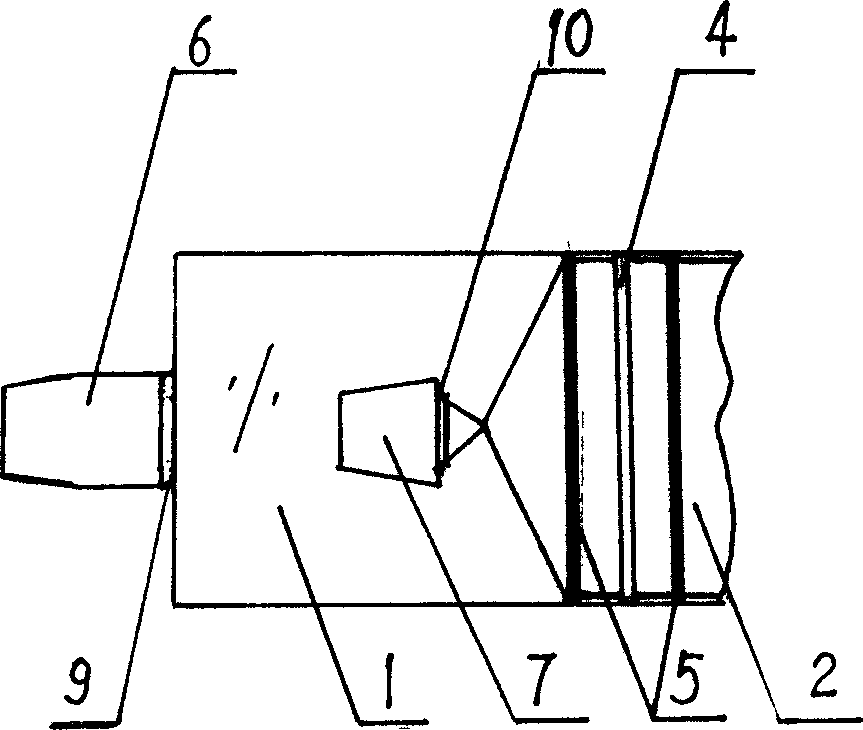

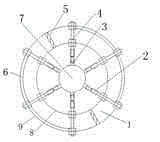

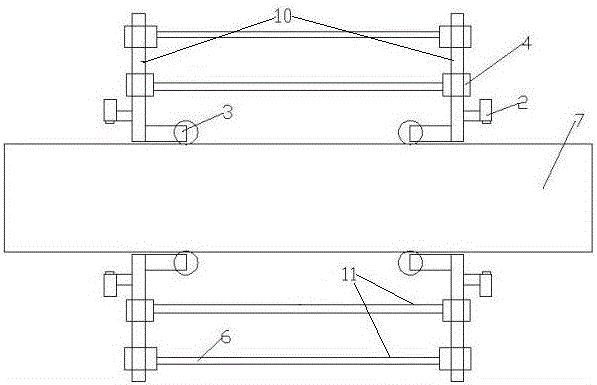

Paint spraying device for pipeline

InactiveCN105855109AReduce manufacturing costReduced physical fitnessSpraying apparatusSpray nozzleSupport plane

The invention discloses a paint spraying device for a pipeline. The paint spraying device comprises a machine frame (1). The machine frame (1) comprises two supporting frames (10) parallel in the front-back direction. The two supporting frames (10) are connected through connecting rods (11). Six spray nozzles (2), six wheels (3) and six adjusting mechanisms (4) are installed in the plane of the supporting frames (10). The supporting frames (10) are fixed to the pipeline (7) through locking devices (5). By the adoption of the structure, paint spraying of pipelines with different pipe diameters can be achieved, the labor intensity is relieved, the paint spraying loss is reduced, a traditional manual paint spraying technique is replaced, the physical harm to a worker is reduced, paint is sprayed more uniformly, and the working efficiency is reduced.

Owner:QUZHOU COLLEGE OF TECH +1

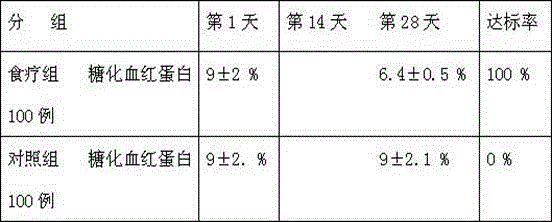

Biscuit for early preventing and controlling type 2 diabetics and preparation method thereof

PendingCN106212614ANo toxicityFull of nutritionDough treatmentBakery productsPolygonum fagopyrumBitter gourd

The invention relates to functional food and a preparation method thereof, in particular to biscuit for early preventing and controlling type 2 diabetics and a preparation method thereof. The biscuit for early preventing and controlling type 2 diabetics comprises the following raw materials according to weight ratio: 18 to 30g of tartary buckwheat, 30 to 50g of cowpea, 15 to 20g of black bean, 15 to 20g of baked black sesame, 80g of wheat embryo, 9 to 15g of rhizoma polygonati, 6 to 9g of folium mori, 15 to 30g of Chinese yam, 15 to 25g of bitter gourd, 6 to 15g of radix puerariae, 6 to 12g of radix polygonati officinalis, and a proper amount of water. The biscuit has the advantages that the pure natural and common food formula is adopted, the toxicity is avoided, the rich nutrients are contained, the safety in eating is realized, and the interference is effective; the biscuit is the blood glucose-reducing functional food.

Owner:史华民

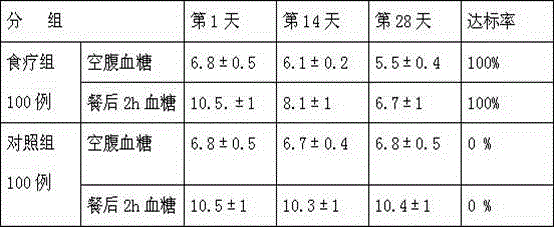

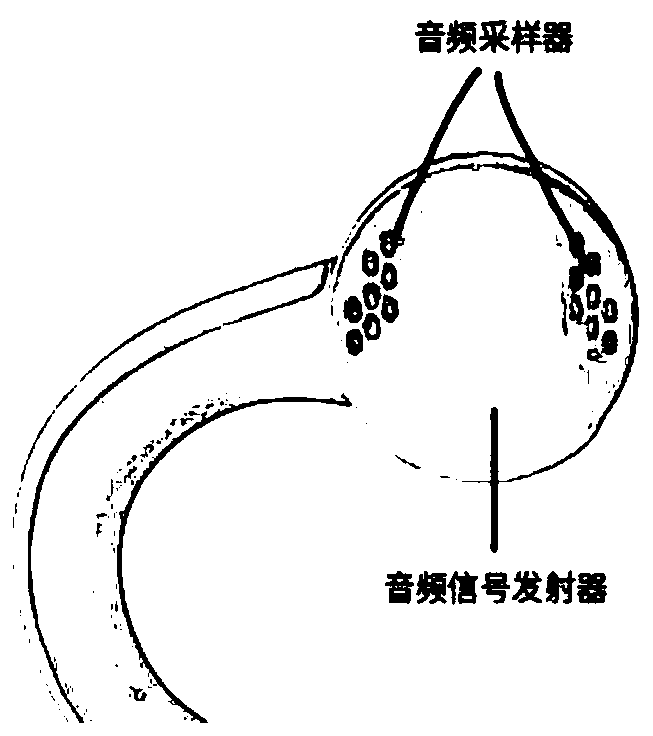

Electronic snore-ceasing equipment

ActiveCN110742720AEasy to judgePlay a filtering roleSnoring preventionDiagnostic recording/measuringAudio power amplifierNoise

The invention discloses electronic snore-ceasing equipment. The electronic snore-ceasing equipment comprises a voice frequency sampler, a voice frequency signal gain amplifier, a central controller, avoice frequency signal transmitter and an adaptive regulator, wherein the voice frequency sampler is used for collecting voice signals and converting the collected voice signals into electric signals, the voice frequency signal gain amplifier is used for amplifying the electric signals, the central controller comprises a voice frequency identification module and a white noise generation module, the voice frequency identification module is used for identifying the amplified electric signals to determine a first snore, the white noise generation module is used for determining white noise according to the first snore, the voice frequency signal transmitter is used for converting white noise signals into vibration signals and sending the vibration signals, and the adaptive regulator is used for regulating the white noise according to voice signals collected again after the vibration signals are sent. The snoring frequency of patients is reduced, the sleep quality is improved significantly, the apnea phenomenon is reduced, and suspense contraction force is enhanced.

Owner:音置声学技术(上海)工作室

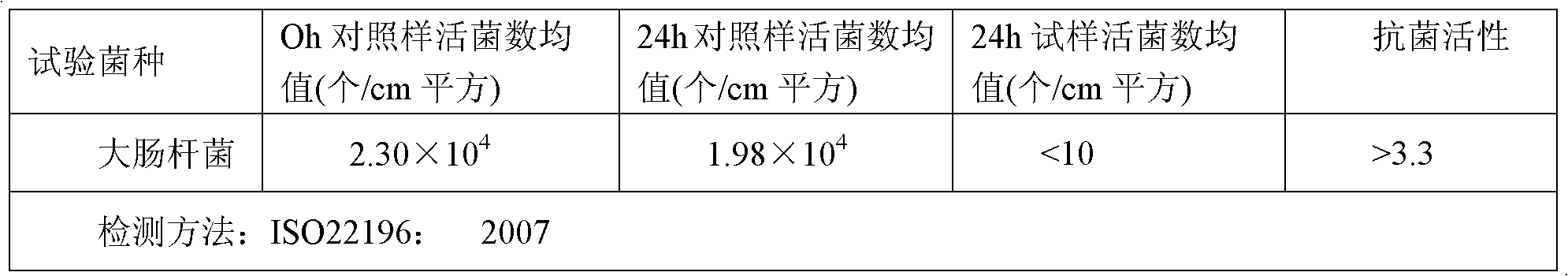

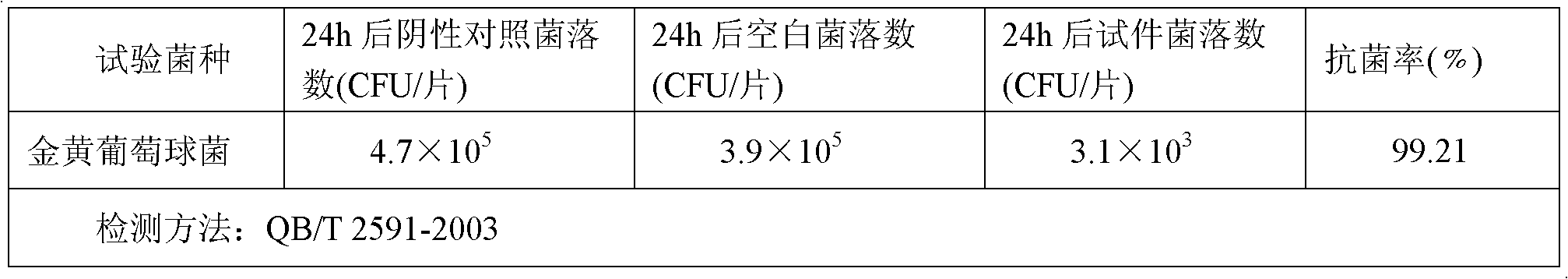

Method for preparing plastic antibacterial elastic paint spectacle frame

InactiveCN102591033AImprove antibacterial propertiesReduced physical fitnessAntifouling/underwater paintsFramesEnvironmental resistanceTitanium dioxide

The invention discloses a method for preparing a plastic antibacterial elastic paint spectacle frame and aims to provide the economic and environmental-friendly method for preparing the plastic antibacterial elastic paint spectacle frame. The key points of the method are that the method comprises the following steps of: 1, preparing a mixed solvent, i.e. mixing propylene glycol methyl ether acetate with butyl ester to obtain the mixed solvent; 2, blending paint, i.e. adding nano titanium dioxide and nano silver into the mixed solvent obtained in the step 1, adding polyether polyurethane and acuring agent after uniformly stirring, and uniformly stirring again to obtain the paint; 3, spraying, i.e. after spraying the paint blended in the step 2 on a plastic spectacle frame, placing the plastic spectacle frame in the air to naturally air-dry the plastic spectacle frame; and 4, lighting, i.e. after the paint is cured on the spectacle frame, placing the spectacle frame under an ultraviolet lamp to irradiate the spectacle frame. The invention belongs to the technical field of preparation of the spectacle frame.

Owner:周盛琪 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com