Embedded type mold protection system and method based on ZigBee network

A protection system and embedded technology, applied in the field of injection molding machine molds, can solve problems such as mold safety, achieve good portability, easy scalability, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

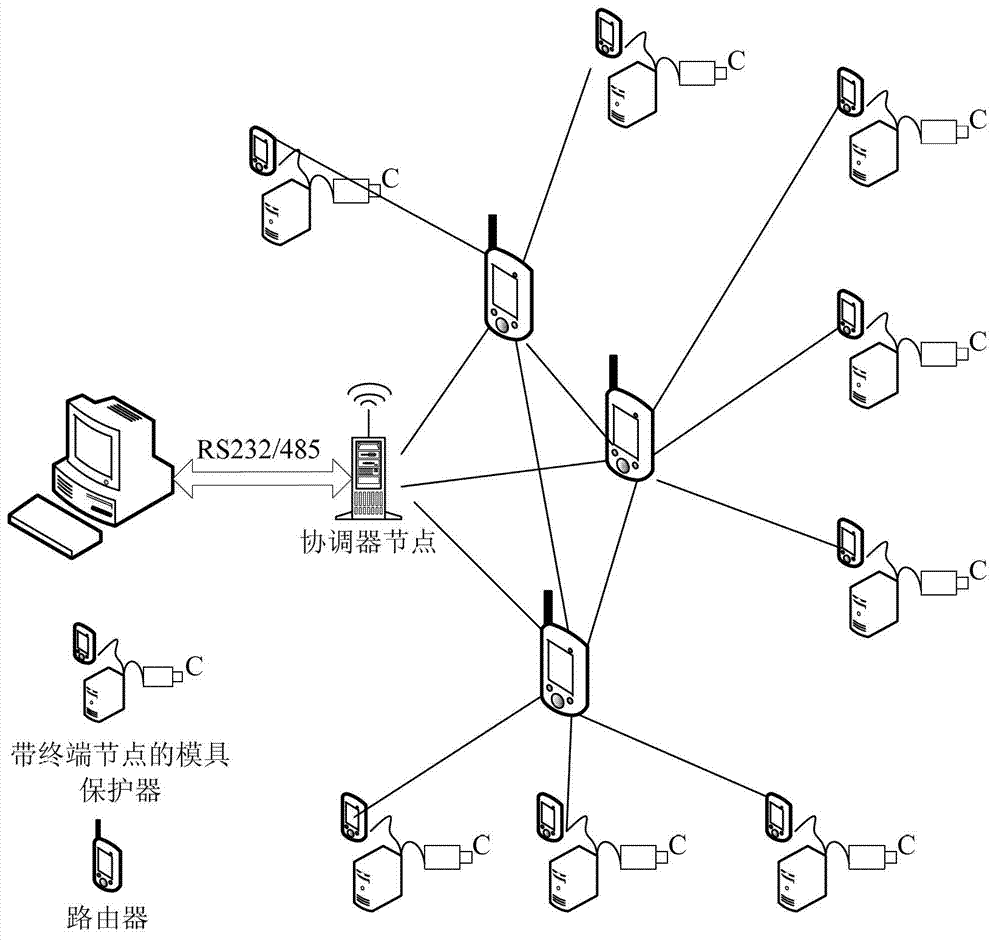

[0044] refer to Figure 1~Figure 5 , an embedded mold protection system based on ZigBee network, the whole system consists of multiple sets of mold protectors (terminal nodes), multiple routing nodes, a coordinator node and a PC, such as figure 1 shown.

[0045] One disadvantage of conventional mold protectors is that after abnormality is detected, an alarm is issued only through a buzzer and a display unit. In this case, when a worker needs to monitor multiple devices, constant patrolling is necessary. Considering the existence of this situation, the present invention designs a single mold protector as a wireless sensor node with data wireless transmission and reception capabilities, builds a ZigBee wireless network with the mold protector as the terminal node in the workshop, and realizes remote monitoring of the mold state .

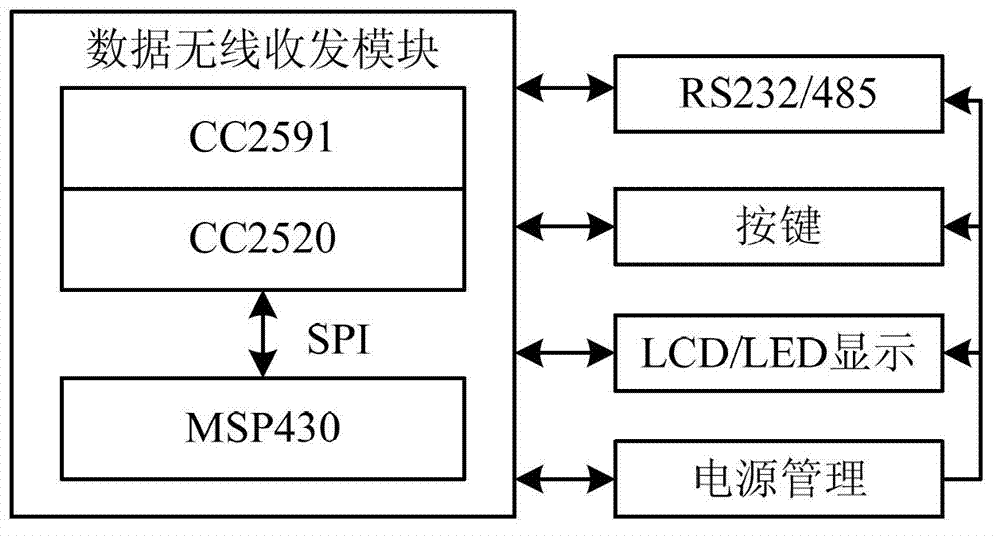

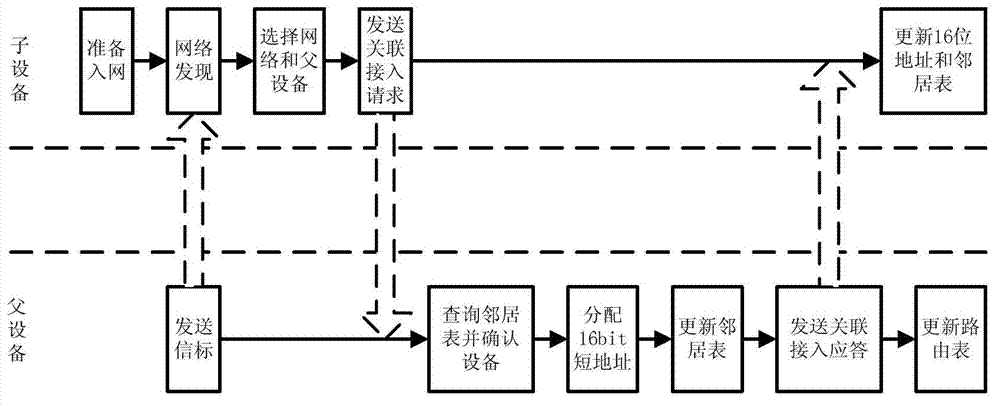

[0046] Firstly, further explain the wireless sensor network based on ZigBee technology. The network contains a terminal node, multiple routers an...

Embodiment 2

[0062] A single mold protector is implemented as Figure 5 As shown, the specific steps are as follows:

[0063] Step 1: After injection molding, the main control board waits for the mold opening signal. When the injection molding machine opens the movable mold to the maximum position, the signal is sent to the main control board through the I / O signal adapter board. At this time, the main control board waits After a set delay time (to ensure that a clear image can be taken), the infrared camera is controlled to capture the cavity image at this time. It should be emphasized that the reason why the infrared light source and infrared camera are used is that the images captured by ordinary cameras are easily affected by light changes and cause false detection by the system, while the infrared camera only accepts images of specific bands. This effect.

[0064] Step 2: Due to the vibration of the industrial site and the inaccurate return of the moving model, it is easy to cause p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com