Patents

Literature

205 results about "Metal adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The adsorption of metals typically starts at pH around 2 and the maximum adsorption percentage is achieved at pH > 6 depending on the identity of the metal. For Cu 2+, the adsorption was 82% at pH 6.1 for Sphagnum sp. whereas the highest percentage of adsorption was reached for P. purum (92%) at pH 5.2.

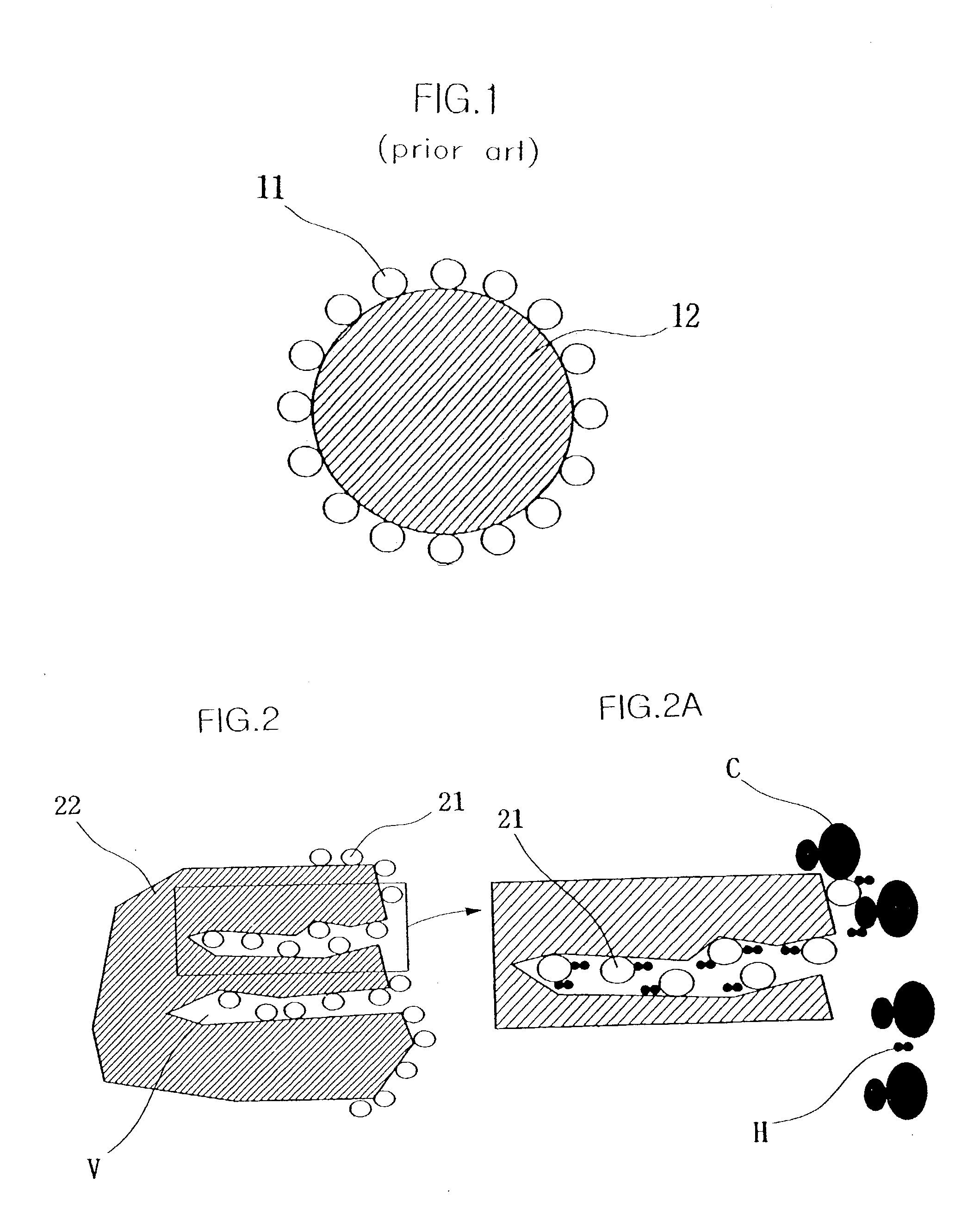

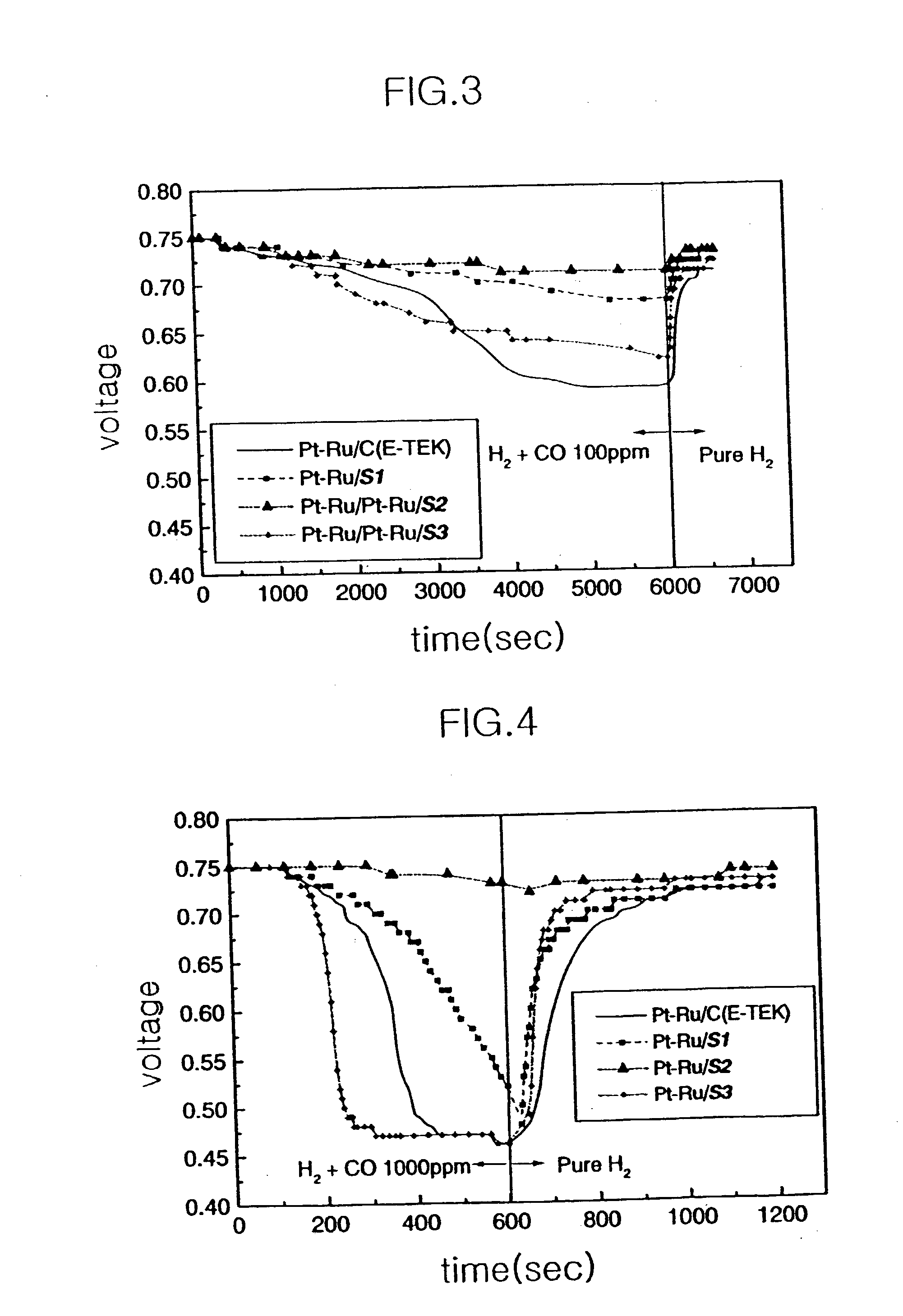

Electrocatalyst for fuel cells using support body resistant to carbon monoxide poisoning

InactiveUS20040248730A1Cell electrodesMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

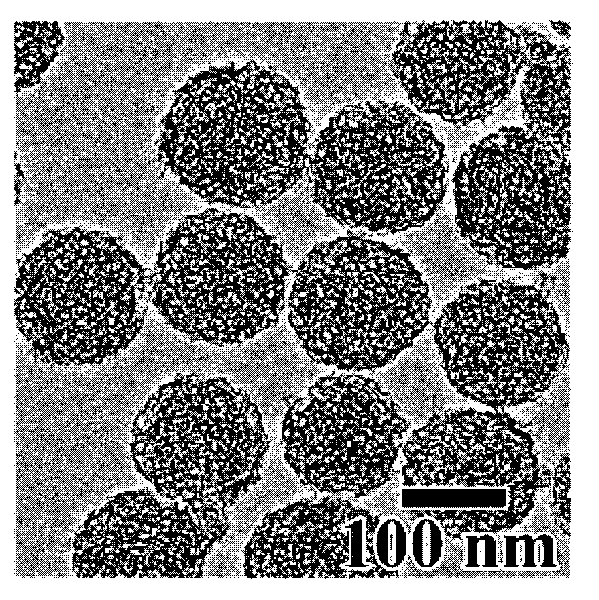

Disclosed is an electrocatalyst for fuel cells, in which a porous carbon material including pores having a diameter smaller than a kinetic diameter of carbon monoxide is used as a support body and contact probability between an activated metal and carbon monoxide is decreased, thereby preventing fuel cell performance from being degraded by carbon monoxide. The electrocatalyst is obtained by adsorbing 10-80 parts by weight of an activated metal to 20-90 parts by weight of a porous support body, characterized in that the porous support body has a total surface area of 200-2,500 m<2> / g including an outer surface thereof and an inner surface of pores thereof, and has a plurality of pores penetrating into an interior of the support body with an average diameter of 2-15 nm and a total volume of 0.4-2.0 m<3> / g, and the activated metal is alloyed with 20-95 at % of platinum and 5-80 at % of one metal selected from among Ru, Sn, Os, Rh, Ir, Pd, V, Cr, Co, Ni, Fe and Mn. As for such an electrocatalyst, carbon monoxide does not fundamentally come in contact with the activated metal adsorbed to the inner surface of the pores of the support body, thereby minimizing degradation of fuel cell performance, thus overcoming fuel-feeding problems.

Owner:KOREA INST OF ENERGY RES

Particulate or particle-bound chelating agents

The invention generally relates to compositions and methods for chemically mechanically polishing a substrate, including a polishing accelerator, which is normally one or more oxidizers, an abrasive material, and chelating particles and / or metal-absorbent clay material. In addition, the invention can also involve methods of forming chelator particles and methods of separating metal-containing ions from polishing and / or etching solutions after polishing and / or etching.

Owner:VERSUM MATERIALS US LLC

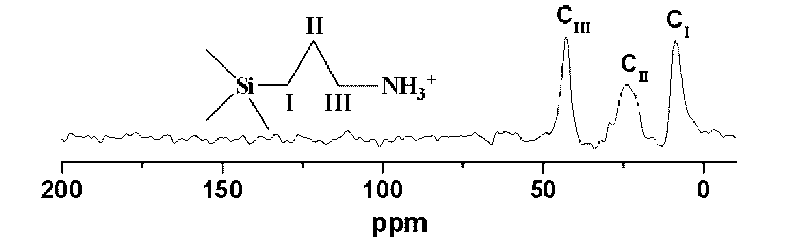

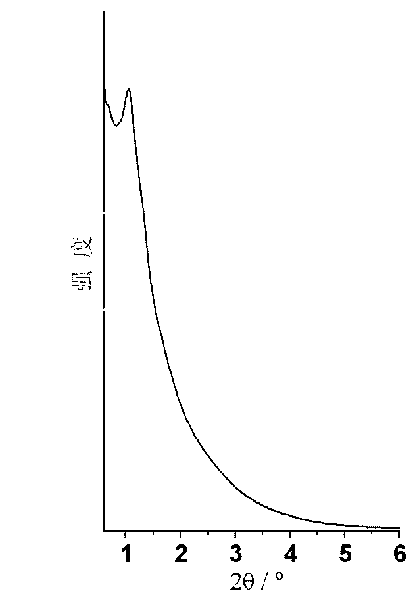

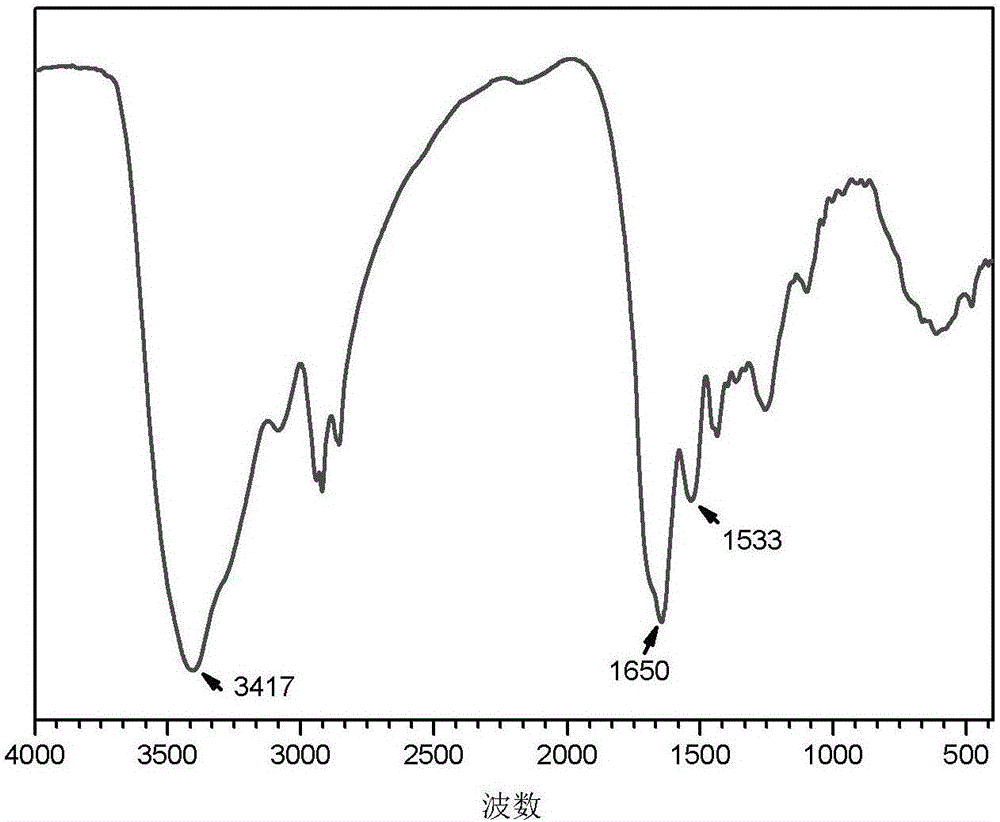

Method for preparing amino group or quaternary ammonium salt functional silicon dioxide mesoporous spherical material

The invention relates to a method for preparing an amino group or quaternary ammonium salt functional silicon dioxide mesoporous spherical material in the technical field of metal adsorption. The silicon dioxide mesoporous spherical material is obtained by the following steps of: dissolving an anion surface active agent and a non-ionic surface active agent into deionized water; then adding ethanol into the deionized water, heating and stirring; sequentially adding siloxane and organic siloxane into the deionized water to prepare a silicon dioxide mixed solution; heating, standing and reacting the silicon dioxide mixed solution to obtain a silicon dioxide sediment; carrying out centrifugal drying on the obtained silicon dioxide sediment and removing the surface active agents by extraction processing. The steps are simple; by leading a co-structure-directing agent into a reaction system, the amido part of the co-structure-directing agent and the anion surface active agent are combined respectively by acid-base neutralization function and double-decomposition reaction, and the siloxane part and an inorganic source carry out copolycondensation to form a silicon wall, thereby the functional mesoporous silicon material containing an amino group or quaternary ammonium salt is synthesized.

Owner:SHANGHAI JIAO TONG UNIV

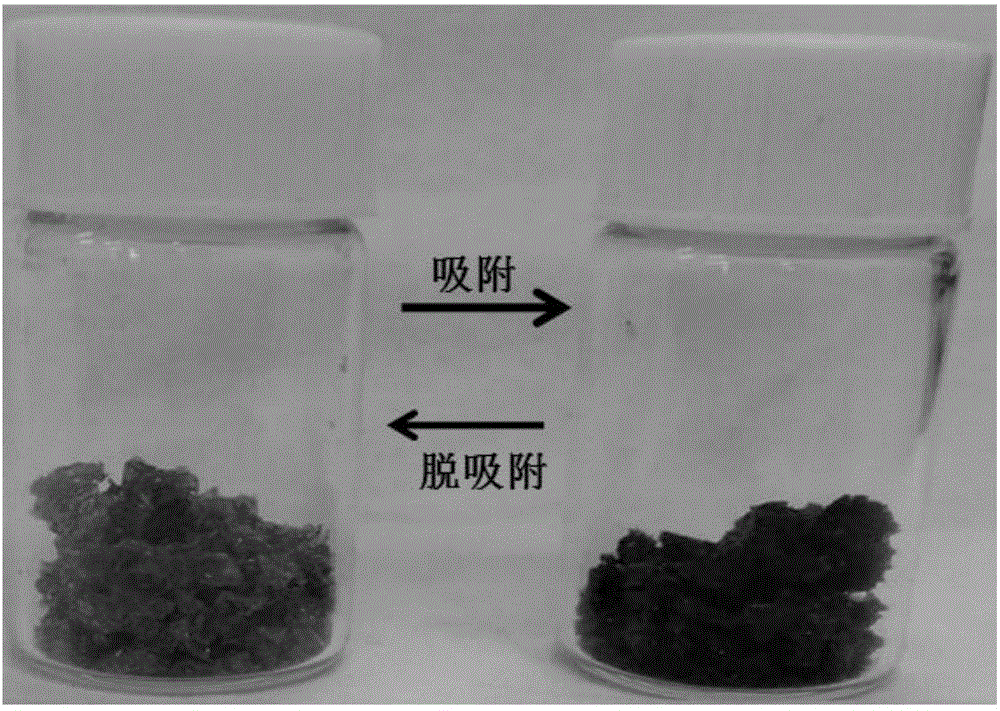

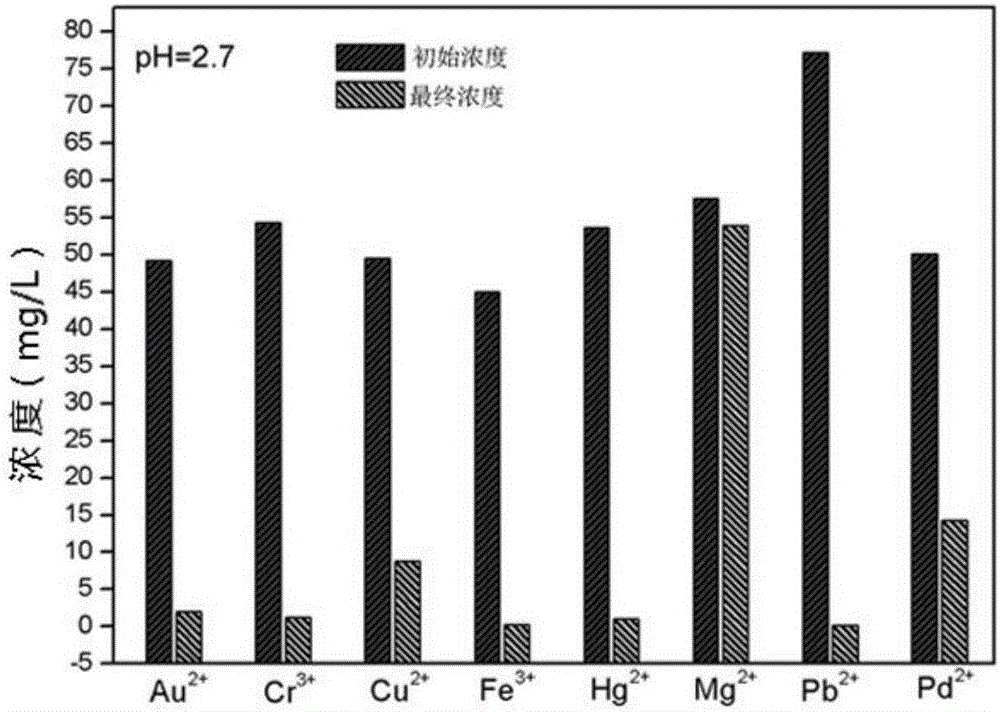

Cross-link polyamino acid type metal adsorbent, method for preparing same and method for adsorbing metal

ActiveCN106832265ANon-toxicNo pollution in the processOther chemical processesWater contaminantsCross-linkPetroleum product

The invention provides a cross-link polyamino acid type metal adsorbent, a method for preparing the same and a method for adsorbing metal, and belongs to the field of technologies for adsorbing metal. The cross-link polyamino acid type metal adsorbent structurally comprises one or two types of linear (I) and branching (II) constitutional units and cross-linking agents with the functionality higher than or equal to 2. The constitutional units and the cross-linking agents are coupled with one another to obtain the cross-link polyamino acid type metal adsorbent. The corresponding method is used for adsorbing the metal by the aid of the cross-link polyamino acid type metal adsorbent. The cross-link polyamino acid type metal adsorbent and the methods have the advantages that cross-link polyamino acid contains a type or a plurality of types of massive amino, hydroxyl, carboxyl, sulfhydryl, guanidyl, acylamino, phenolic hydroxyl and imidazole groups, and accordingly the metal can be adsorbed by cross-link polyamino acid; amino acid is a renewable resource, accordingly, dependence on petroleum products can be prevented, and the cross-link polyamino acid type metal adsorbent is non-toxic and is free of pollution and good in environmental friendliness.

Owner:长春鑫螯科技有限公司

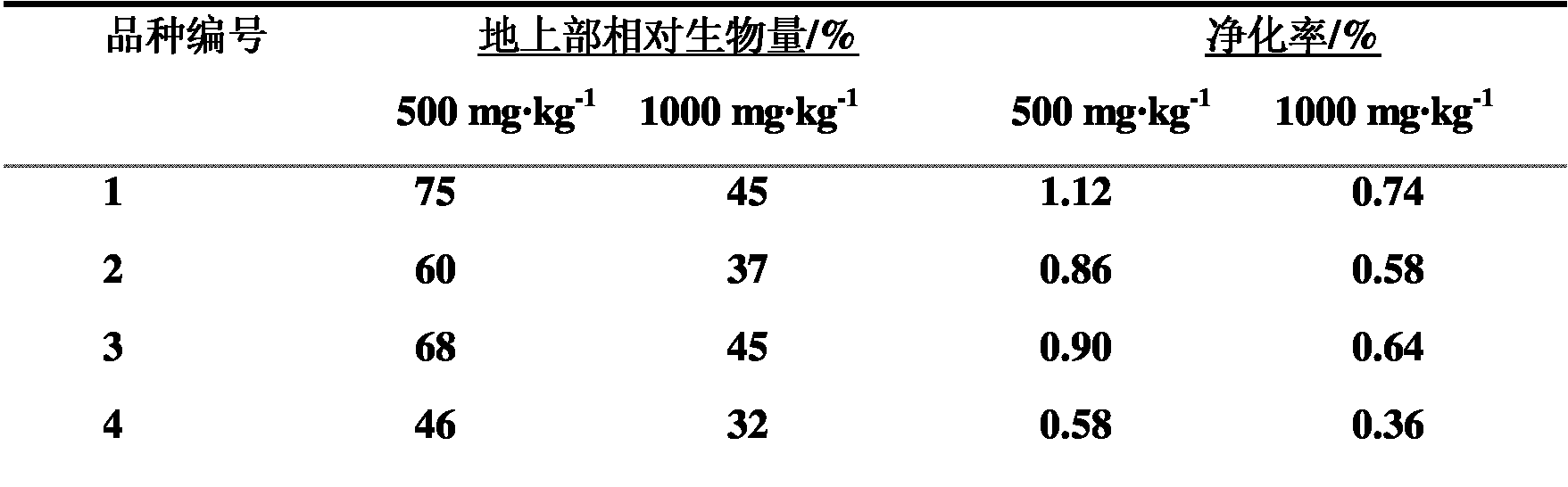

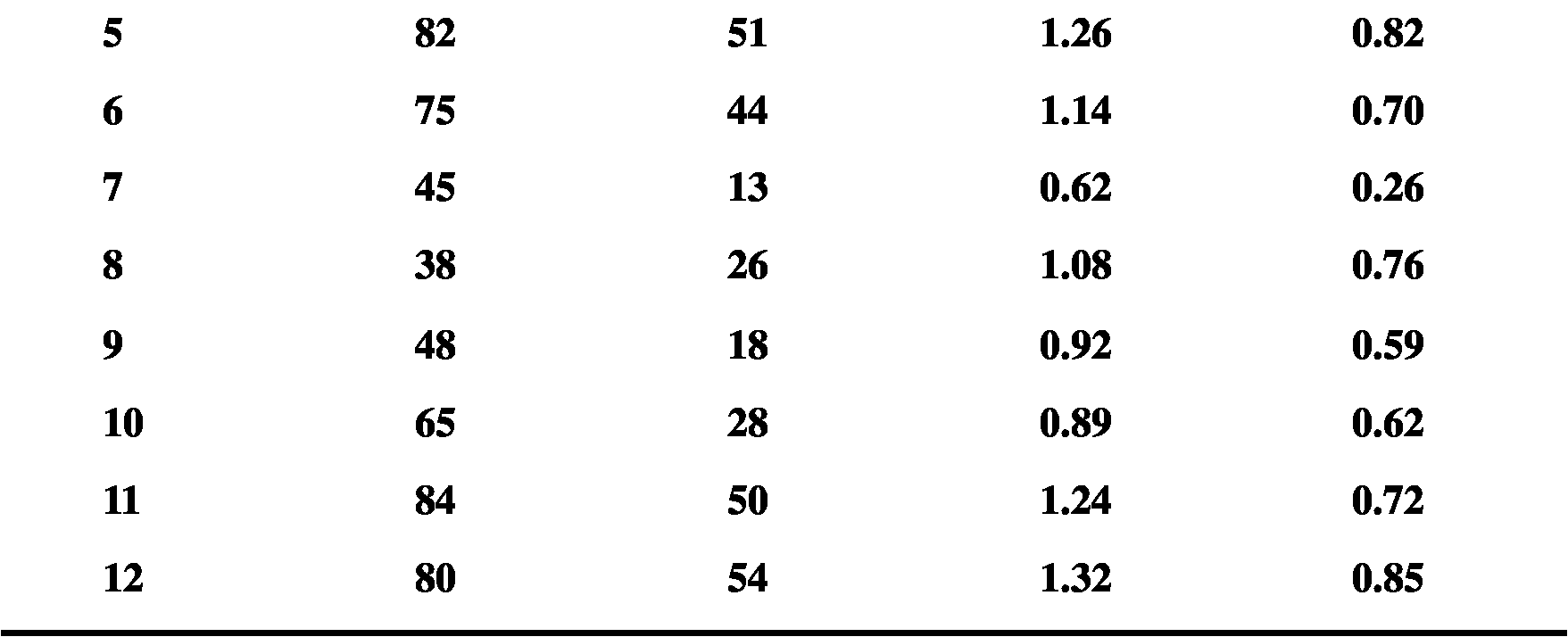

Construction method of trichoderma-rape combined adsorption of heavy metal cadmium and zinc in farmland soil

InactiveCN102277302AOvercome the shortcomings of small planting area and low efficiency of adsorption of heavy metalsPromote growthBiocideFungiSnow moldDisease

A construction method for antagonistic Trichoderma-Brassica napus joint adsorption of heavy metals cadmium and zinc in farmland soil in the field of metal adsorption technology, by inoculating bacterial agents prepared by adsorbing heavy genus antagonistic Trichoderma strains to bacteria containing Cd or Zn and Sclerotinia sclerotiorum The soil of the wheat grain culture is further used to cultivate Brassica napus and obtain the Trichoderma-rape symbiont with high efficient adsorption of heavy metals. The invention realizes the dual purposes of bioremediation of heavy metal pollution in farmland soil and treatment of soil-borne diseases, has good repair effect, low cost, is easy to manage and operate, and does not produce secondary pollution, so it has high universal use value in the field.

Owner:SHANGHAI JIAO TONG UNIV

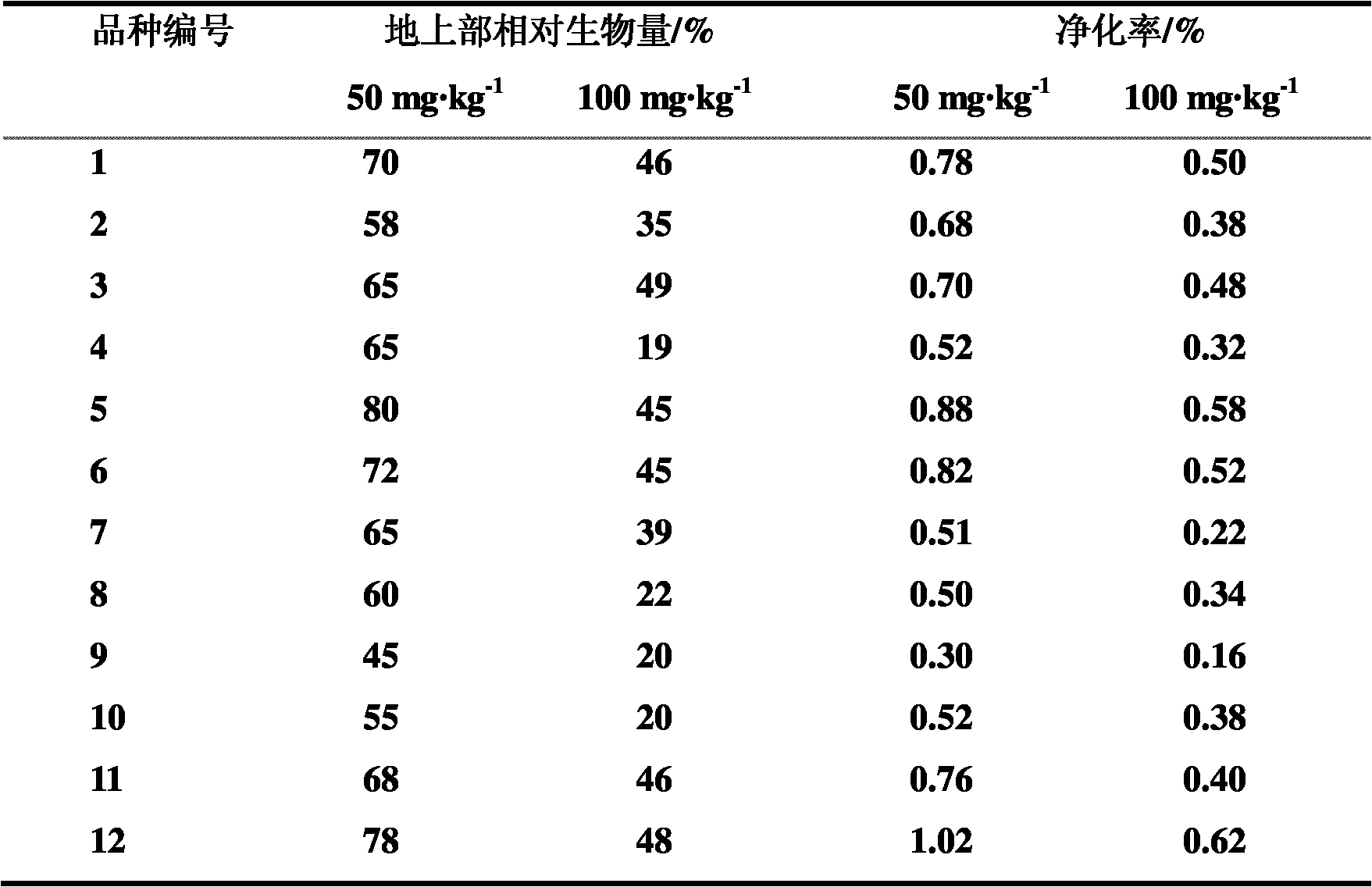

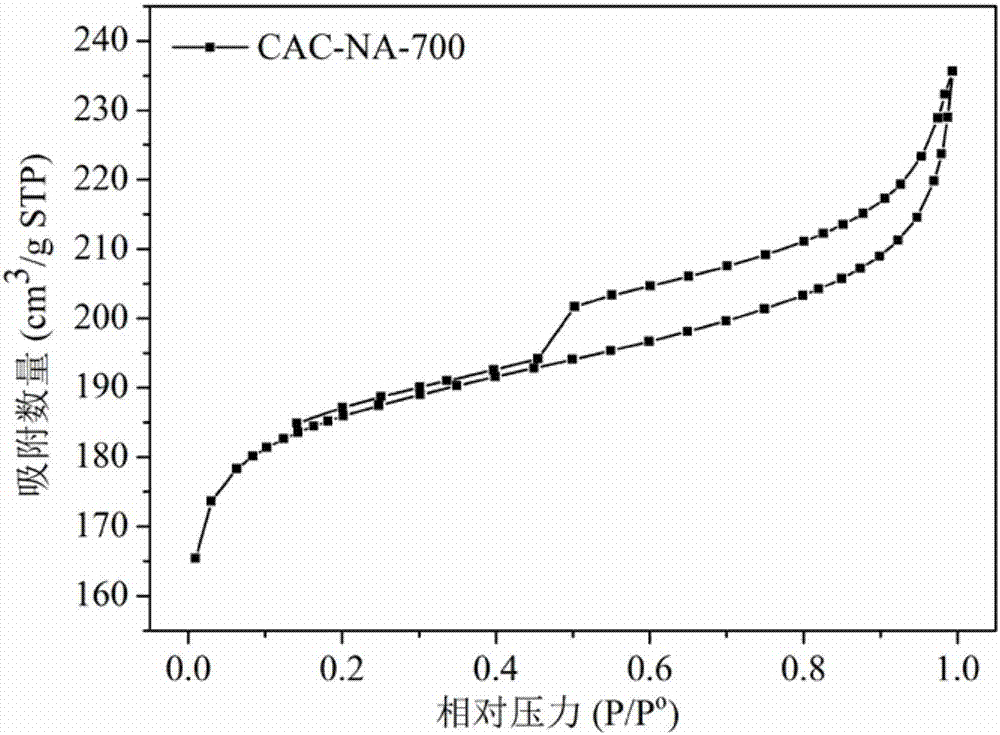

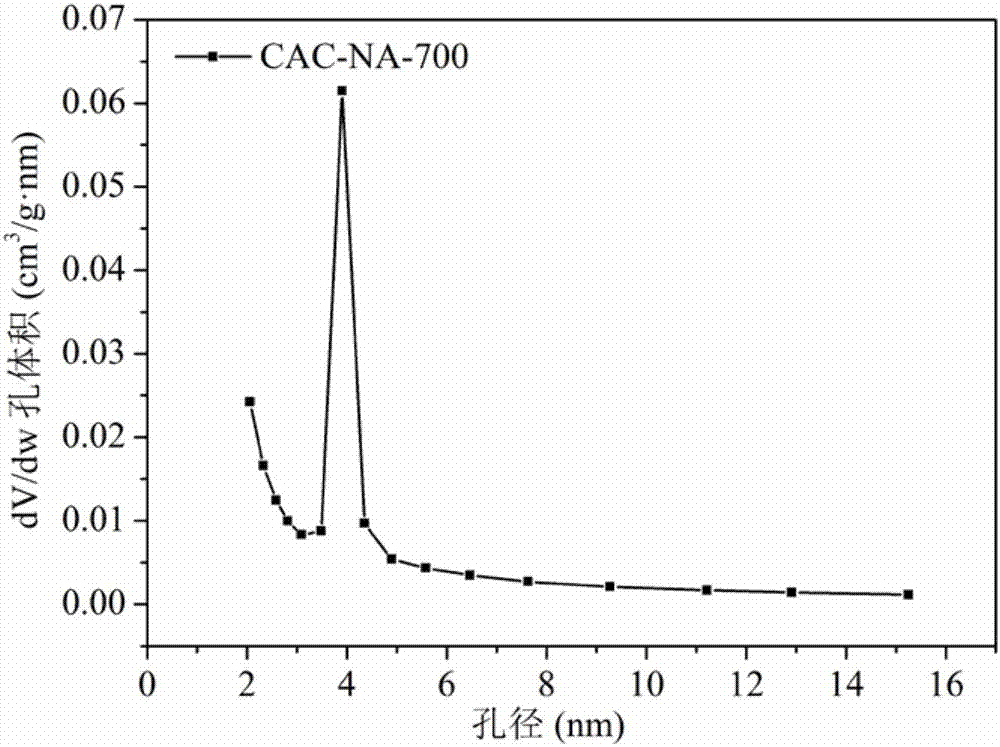

Cellulose modified activated carbon heavy metal adsorption material, and preparation method and application thereof

InactiveCN107159152ANo pollution in the processWide variety of sourcesIon-exchange process apparatusOther chemical processesCelluloseSorbent

The invention belongs to the technical field of biomass resource reuse and new environmental functional materials, and especially relates to a cellulose modified activated carbon heavy metal adsorption material (CAC-NA), a preparation method thereof, and an application thereof in the fields of environmental treatment and restoration, especially the restoration of heavy metal pollution, such as the heavy metal adsorption field. The preparation method comprises the following steps: (1) heating cellulose in nitrogen atmosphere to carbonize the cellulose in order obtain cellulose charcoal; (2) mixing the cellulose carbon with a strong alkali and water, drying the obtained mixture to obtain cellulose activated carbon-alkali, and heating the cellulose activated carbon-alkali to obtain cellulose activated carbon; and (3) mixing the cellulose activated carbon with concentrated nitric acid, carrying out a heating and stirring reaction, and filtering, washing and drying the obtained reaction product to obtain the cellulose modified activated carbon heavy metal adsorption material. The cellulose modified activated carbon heavy metal adsorption material has the characteristics of high adsorption rate, high adsorption capacity and high removal rate, the heavy metal cadmium adsorption capacity of the material reaches 368 mg / g, and the material is a heavy metal adsorbent having excellent performances.

Owner:SOUTH CHINA UNIV OF TECH

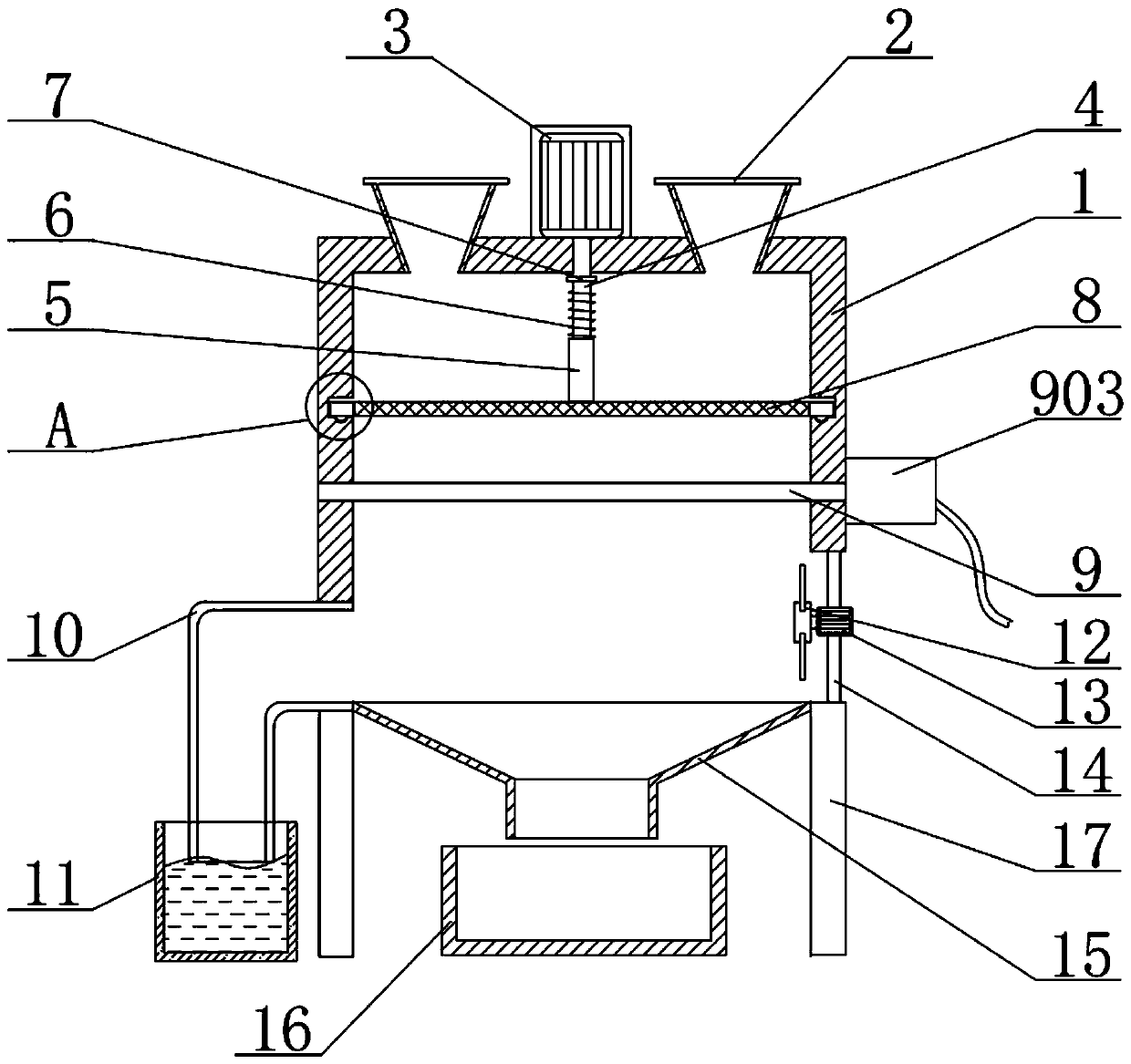

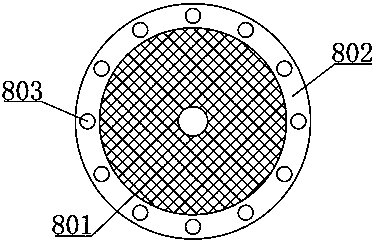

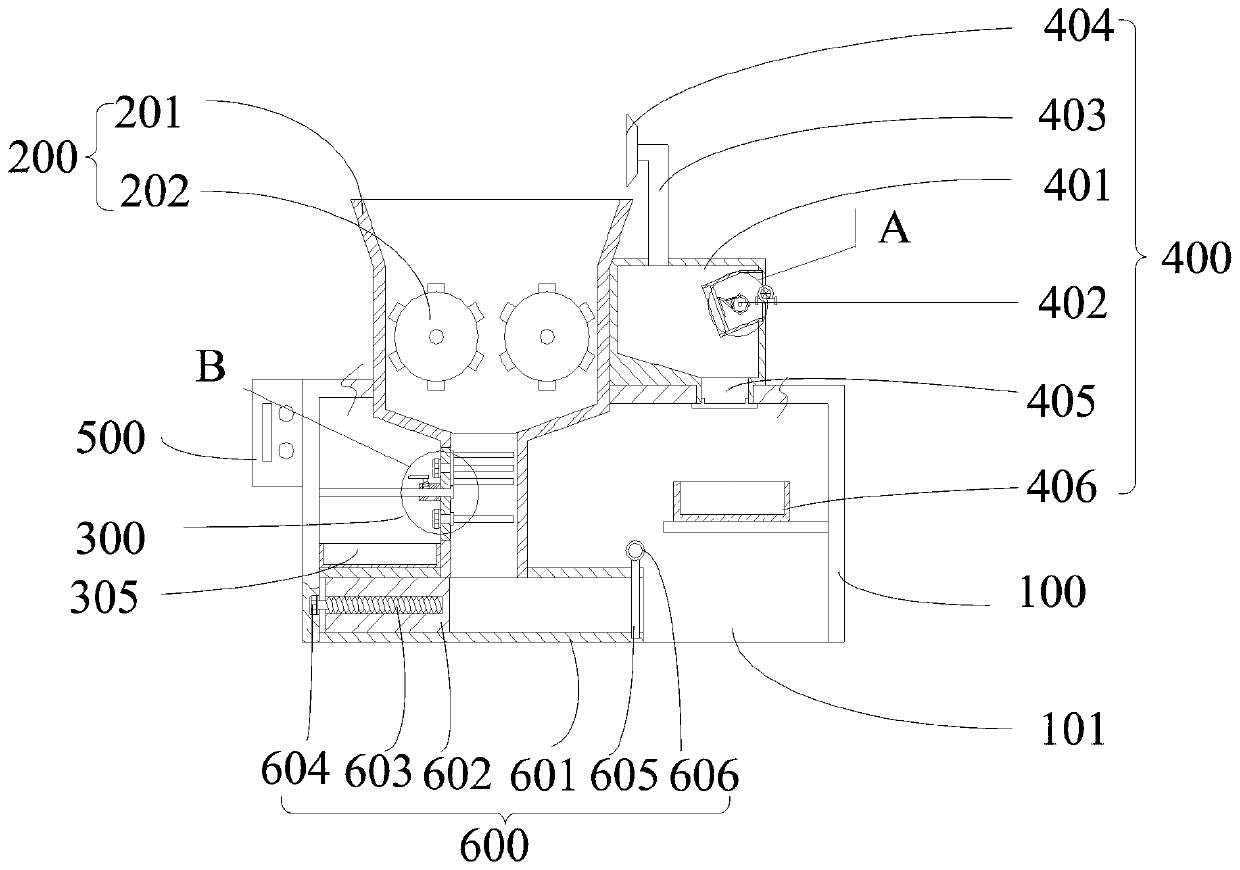

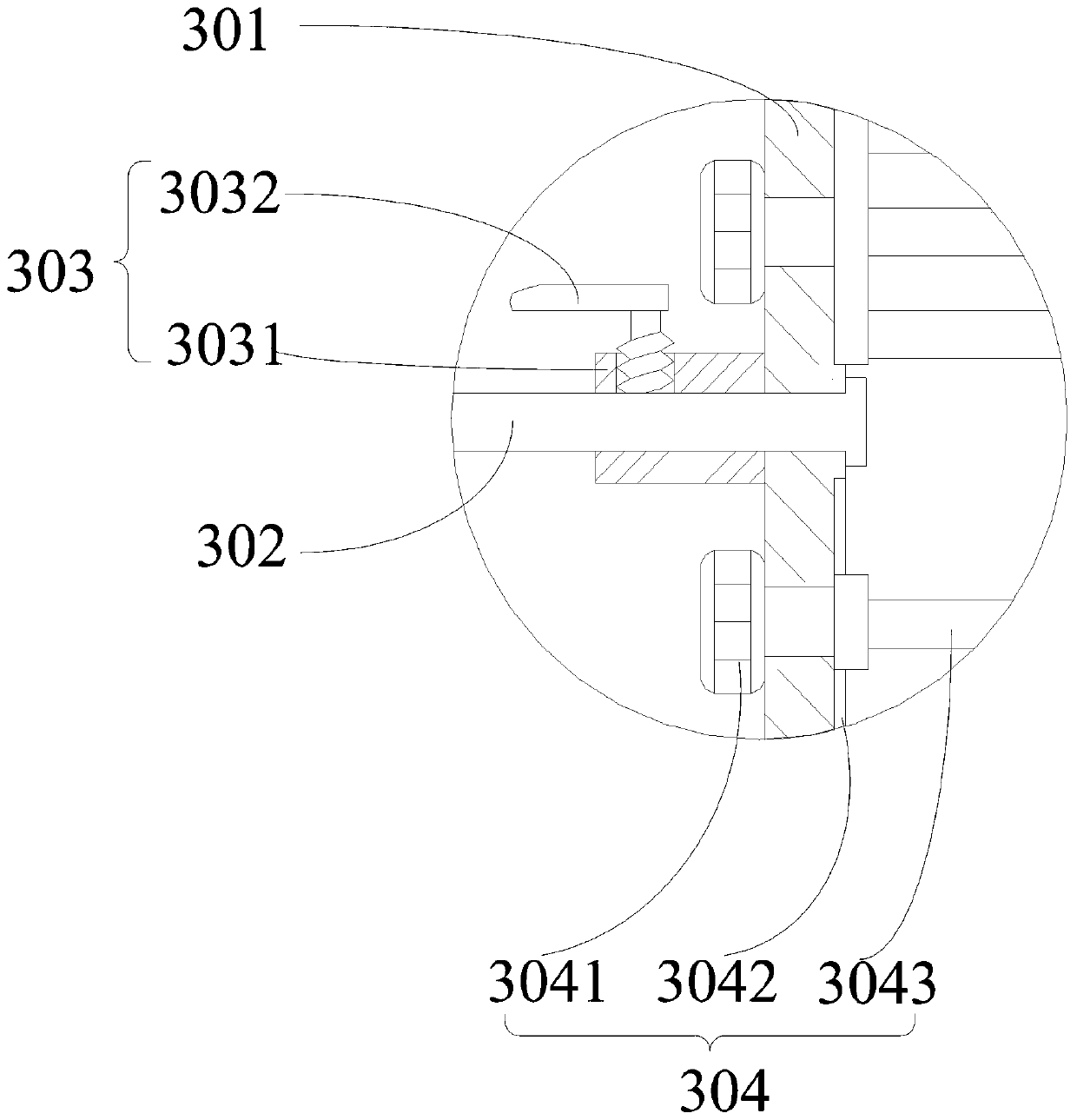

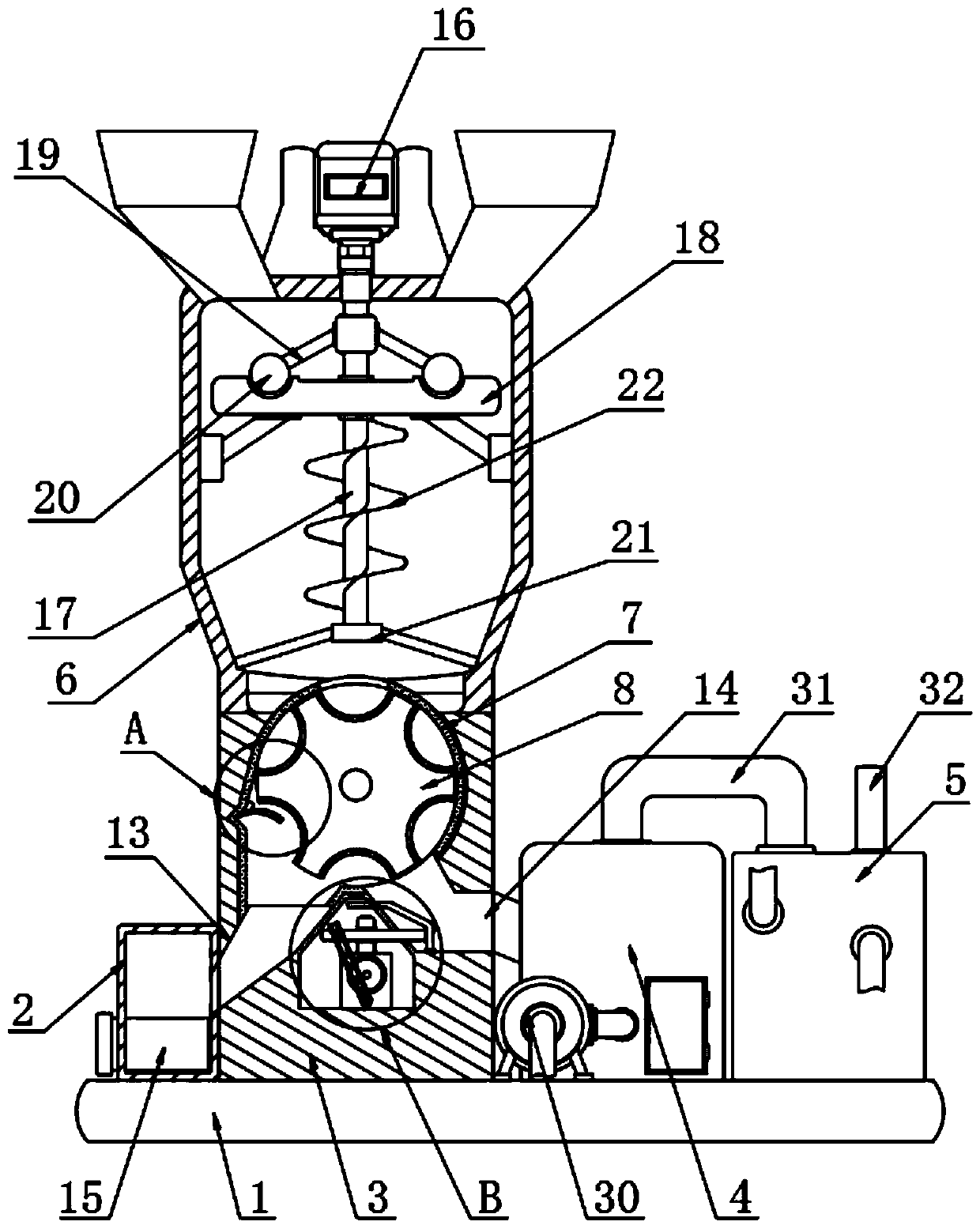

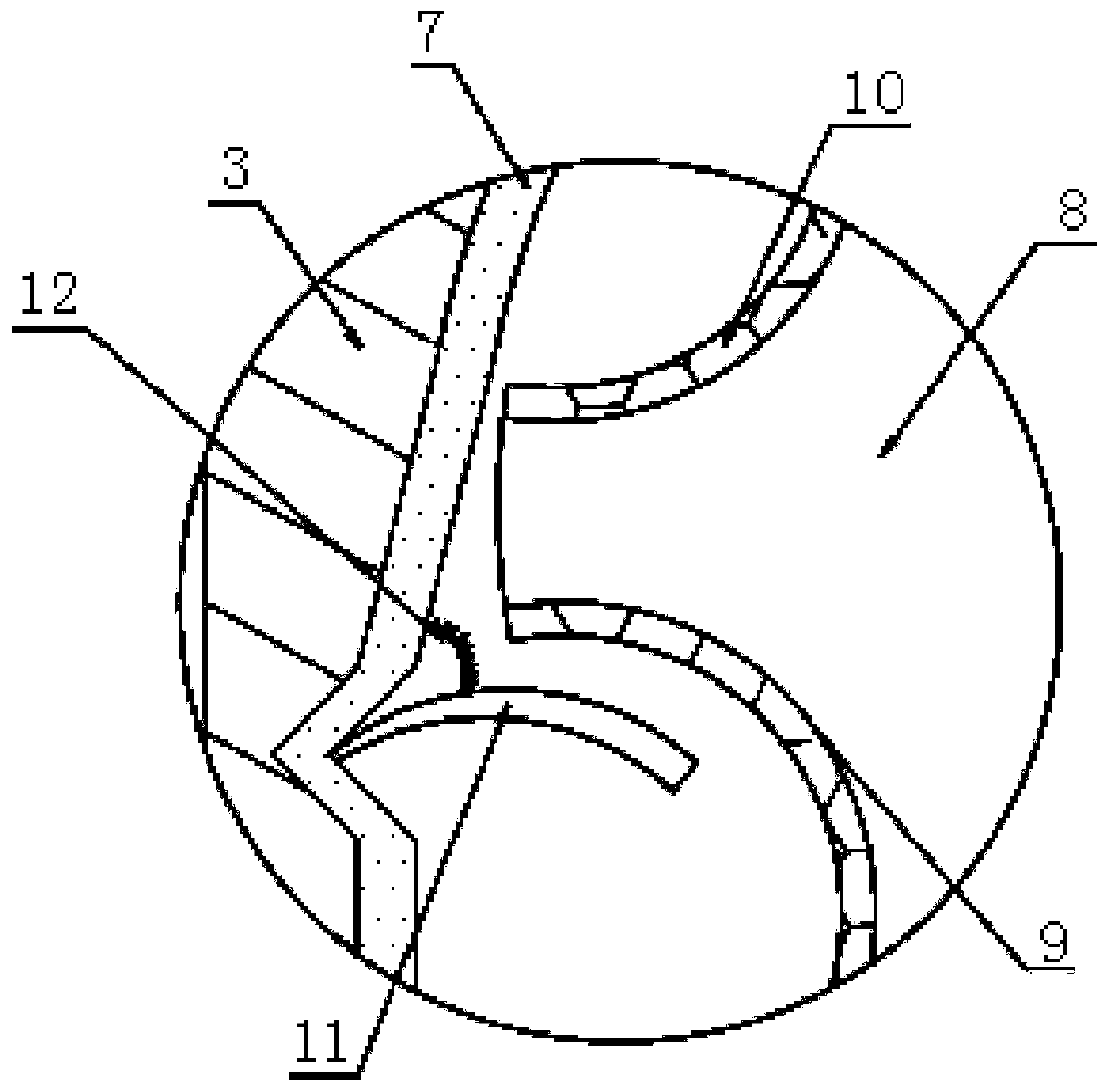

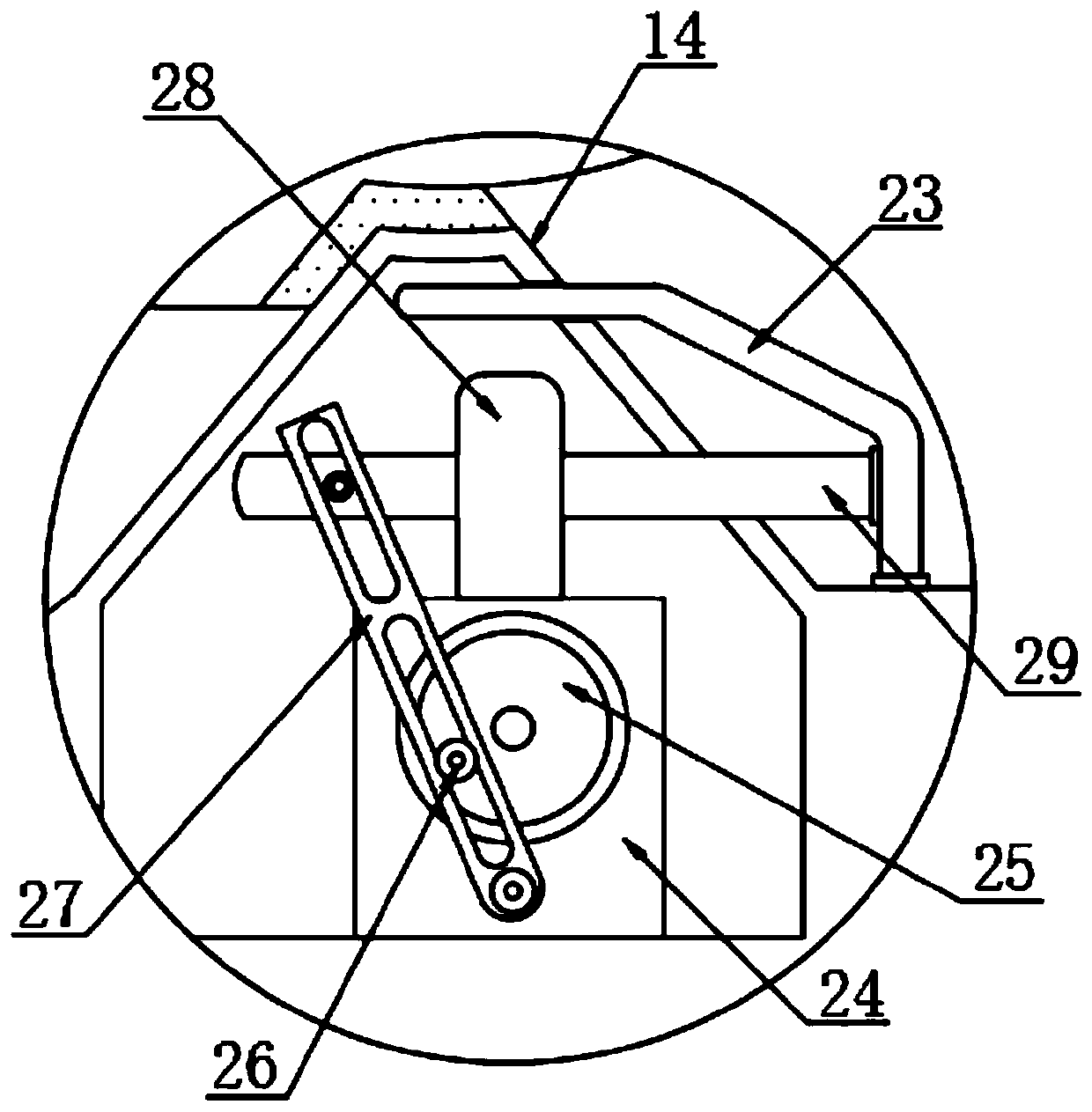

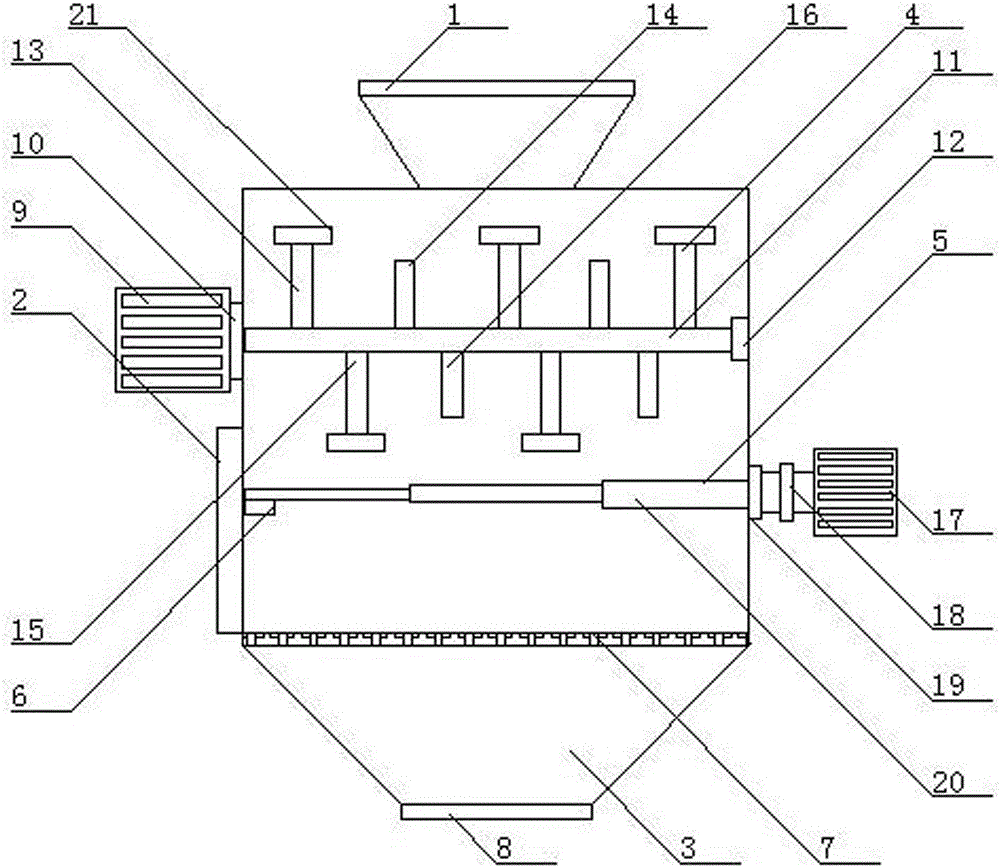

Processing, screening and impurity removing device of feeds

InactiveCN107752104AEffective Rotary Vibration ScreeningImprove cleanlinessSievingGas current separationMetal adsorptionAgricultural engineering

The invention relates to the technical field of feed impurity removal, in particular to a feed processing, screening and impurity removal device, which includes a box body and a vibrating screen. The inside of the box body is provided with a vibrating screen and a metal adsorption device arranged up and down, and the inside of the box body The wall is provided with a groove, the first motor is fixed at the center of the top of the box, and the end of the main shaft of the first motor runs through the top of the box and is fixedly connected with a sleeve rod, and the top of the sleeve rod is fixedly connected with a baffle, and the sleeve A spring is provided on the outside of the rod, and a sleeve is slidably connected to the bottom end of the sleeve rod, and a slider is fixedly connected to the periphery of the sleeve rod, and a chute is provided on the inside of the sleeve, and the slider is slidably connected to the chute. The bottom end of the sleeve is fixedly connected to the vibrating screen, the right side wall of the box is fixedly provided with a fan, the left side wall of the box is fixedly connected with a removal pipe, and a waste liquid pool is provided below the outlet of the removal pipe. It can automatically remove various impurities mixed in the feed, has a high degree of automation, is environmentally friendly, and is worthy of popularization.

Owner:邛崃驰阳农牧科技有限公司

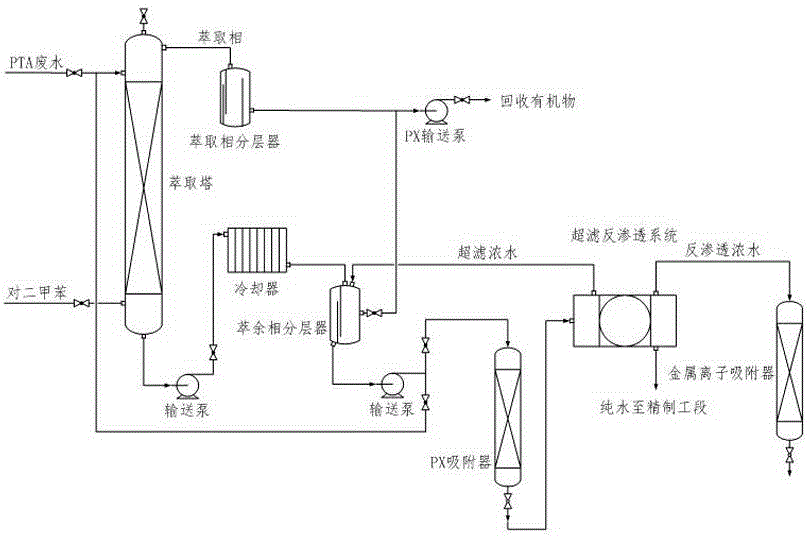

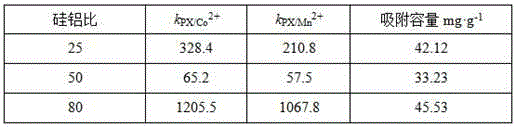

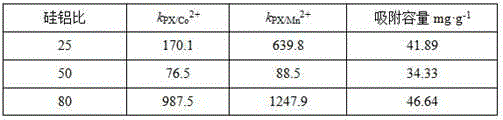

Process for treatment of PTA refining wastewater through high-selectivity adsorbent

InactiveCN104876354AAvoid erosionExtended service lifeOther chemical processesWater contaminantsSorbentUltrafiltration

The invention discloses a process for treatment of PTA refining wastewater through a high-selectivity adsorbent. The process comprises the following steps: extracting, selectively adsorbing p-xylene through the high-selectivity adsorbent, carrying out ultrafiltration and reverse osmosis and carrying out metal adsorption. The high-selectivity adsorbent is prepared through the following specific steps: uniformly mixing a silicon source, an aluminium source, a template agent and water according to a ratio, stirring for dissolving, transferring the mixture to a stainless steel crystallization kettle with a polytetrafluoroethylene liner, heating for crystallization, filtering, washing, drying and roasting so as to obtain an initial molecular sieve with good degree of crystallinity; deeply processing the initial molecular sieve, and forming to prepare into a strip-shaped high-selectivity molecular sieve. According to the process provided by the invention, the high-selectivity adsorbent is adopted to adsorb p-xylene in wastewater, the adsorption selectivity coefficient of p-xylene to cobalt ions can reach 7890 maximally, the adsorption selectivity coefficient of p-xylene to manganese ions can reach 9578 maximally and the adsorption capacity of p-xylene can reach 40 mg / g or above, so that erosion of p-xylene to a reverse osmosis membrance can be effectively avoided.

Owner:FUZHOU UNIV

Waste collecting device for constructional engineering

PendingCN111330960AReduced physical fitnessReduce environmental problemsDispersed particle filtrationTransportation and packagingMetal adsorptionWorking environment

The invention relates to a waste collecting device for constructional engineering. The waste collecting device comprises a fixed seat with a first mounting hole and a second mounting hole at the top and a scrap outlet at the bottom; a crushing mechanism is mounted at the first mounting hole, and a waste channel of the crushing mechanism extends to the scrap outlet; a metal adsorption mechanism isdetachably connected to the waste channel and used for adsorbing metal substances in chippings; a dust collection mechanism is mounted at the second mounting hole, the top of the dust collection mechanism corresponds to an inlet of the crushing mechanism, and the bottom of the dust collection mechanism corresponds to the scrap outlet; and a control box electrically connected with the crushing mechanism, the metal adsorption mechanism and the dust collection mechanism is fixed on the fixed seat. The dust collection mechanism is arranged at the inlet of the crushing device, a large amount of dust is sucked away, and adverse effects of the dust on health of workers and the working environment are reduced; and the metal adsorption mechanism is detachably connected to the waste channel, metal substances in the chippings are separated, and later machining treatment of wood chippings is guaranteed.

Owner:河北宏龙环保科技有限公司

MOFs method used for deep removing of dibenzothiophene sulfides in automobile diesel oil

ActiveCN105642232AImprove desulfurization efficiencyLarge adsorption capacityOther chemical processesCopper organic compoundsMetal adsorptionSorbent

The invention discloses a MOFs method used for deep removing of dibenzothiophene sulfides in automobile diesel oil, and belongs to the field of application of novel porous adsorption materials in chemical engineering. The MOFs method comprises following steps: an organic ligand and a metal salt are dissolved in deionized water, a solvent is added, and a metal plate is coated with a prepared reaction liquid until the thickness of an obtained coating layer ranges from 0.1 to 2mm; the metal plate is delivered into an adsorption column, reaction is carried out for 8 to 24h at 30 to 220 DEG C; diesel oil is added via a bottom end, and a modified doublemetal organic framework synthesized in the metal adsorption column is used for absorption removal of sulfides. The MOFs method possesses relatively large adsorption capacity and excellent selectivity; reaction can be carried out at normal temperature under normal pressure; energy consumption is reduced; and adsorbent desulphurization efficiency is increased.

Owner:SINOPEC YANGZI PETROCHEM +1

Method for regulating heavy metal adsorption in single system using carbon nanomaterial

InactiveCN105880268AFast adsorptionImprove adsorption capacityOther chemical processesWater contaminantsMetal adsorptionRoom temperature

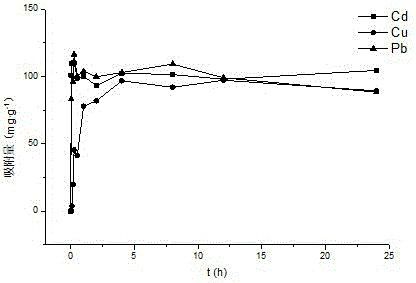

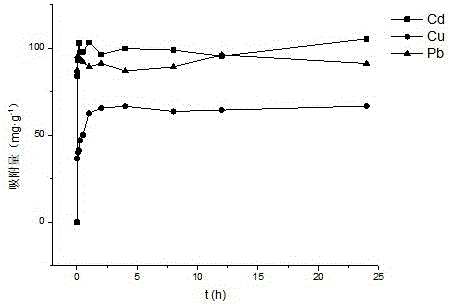

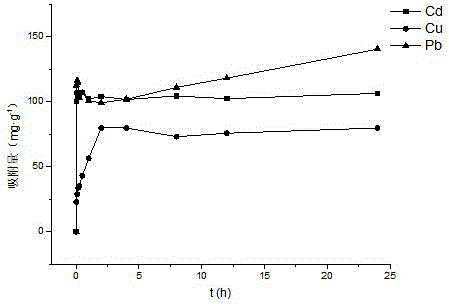

The invention discloses a method for regulating the adsorption of heavy metals in a single system by using carbon nanomaterials. It is to weigh 50 mg of carbon nanomaterials into a 150 ml Erlenmeyer flask, add 100 ml, 100 mg·L ‑1 Cu 2+ , Pb 2+ 、Cd 2 Single ion solution, adjust the pH to 6, shake at room temperature for 1 min, 3 min, 5 min, 10 min, 15 min, 30 min, 1 h, 2 h, 4 h, 8 h, 24 h, and filter the solution quickly , The residual concentration of metal ions in the filtrate was determined by atomic absorption spectrophotometry. The invention further discloses the application of the method for regulating the adsorption of heavy metals in a single system by carbon nanomaterials in improving the adsorption speed of heavy metals. Among them, the adsorption affinity is strong for carbon nanotubes and Cd, strong for graphene oxide and Cu, and strong for graphene and Pb.

Owner:TIANJIN NORMAL UNIVERSITY

Biological heavy metal adsorbing and flocculating agent and preparation method thereof

InactiveCN102764632AImprove adsorption capacityWon't breakOther chemical processesWater contaminantsMetal adsorptionSewage

The invention provides a biological heavy metal adsorbing and flocculating agent and a preparation method thereof. The adsorbing and flocculating agent consists of the following components in parts by mass: 1 to 2 parts of chitosan, 2 to 3 parts of citric acid, 0.5 to 1 part of ethanol, 1.5 to 3 parts of sophorolipid, and 80 to 150 parts of water. The biological heavy metal adsorbing and flocculating agent has a remarkable chelating effect on heavy metal substances, and can efficiently adsorb and flocculate the heavy metal substances in sewage in sewage treatment, so that the heavy metal substances are thoroughly separated from the heavy metal substances, the treated water does not damage the soil environment in farmland irrigation and does not destroy water in rivers, lakes and the like in direct discharge, production and pollution of harmful algae can be lightened, and the soil environment and the water environment are effectively protected.

Owner:HAO YUAN TE CONTROL

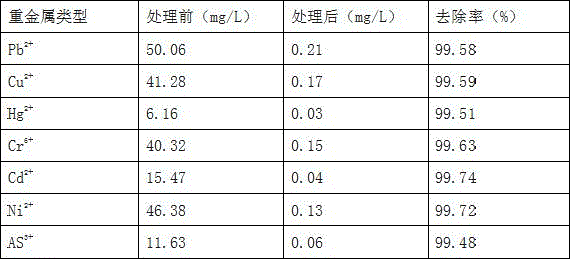

Treatment method for heavy-metal-containing wastewater

The invention relates to a treatment method for heavy-metal-containing wastewater. The treatment method comprises the following steps: 1) adding a heavy metal adsorbent into the heavy-metal-containing wastewater, and fully stirring or shaking for 2-5 hours; carrying out centrifugal separation on the heavy metal adsorbent, or standing, so that supernatant is obtained after the heavy metal adsorbent is precipitated; 2) adding a complexing agent into the supernatant obtained in the step 1), and fully stirring or shaking for 1-3 hours; adding a reducing agent, and fully stirring or shaking for 1-3 hours; regulating the pH value to be 8-12 with an alkaline solution, heating to 60-80 DEG C, fully reacting for 2-3 hours, and carrying out solid-liquid separation; 3) enabling the liquid obtained in the step 2) to pass through activated CD-180 macroporous adsorption resin, enabling effluent liquid to pass through D61 macroporous cation exchange resin, and collecting effluent liquid; and 4) enabling the effluent liquid obtained in the step 3) to pass through a reverse osmosis cellulose acetate membrane at the pressure of 0.5-2MPa, so that the heavy-metal-containing wastewater is treated. The treatment method has the advantages that the content of target heavy metals in wastewater can be obviously reduced, and removal rates reach more than 90% respectively; and meanwhile, the technology is simple, and the operation is convenient, so that the method has good application prospects.

Owner:JINING UNIV

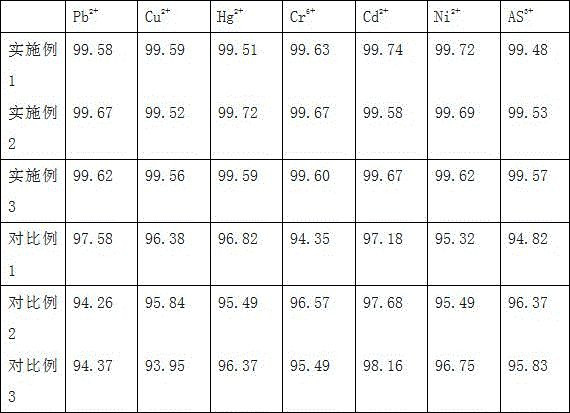

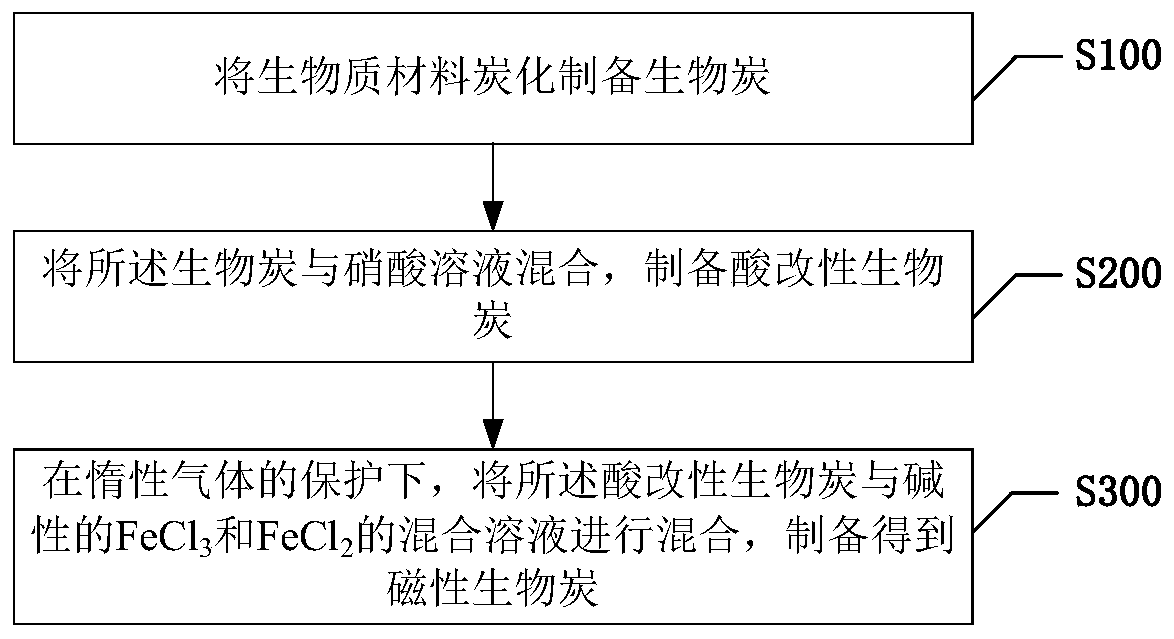

Magnetic biochar and preparation method thereof

InactiveCN111054308APromote regenerationEasy to recycleOther chemical processesAlkali metal oxides/hydroxidesMetal adsorptionSewage

The invention discloses magnetic biochar and a preparation method thereof. The preparation method comprises the steps: carbonizing a biomass material to prepare biochar, then mixing the biochar with anitric acid solution to prepare acid-modified biochar, and mixing the acid-modified biochar with an alkaline mixed solution of FeCl3 and FeCl2 under the protection of inert gas to prepare the magnetic biochar. According to the method, the biochar is modified by nitric acid, so that the metal adsorption performance of the biochar is improved; meanwhile, Fe3O4 is modified on the surface of the acid-modified biochar to obtain the magnetic biochar; and after sewage is treated, the magnetic biochar is easily separated from water, so that regeneration and cyclic utilization of the magnetic biocharare facilitated.

Owner:FOSHAN UNIVERSITY

Industrial solid waste treatment device

InactiveCN111207399AQuick crushEasy to separateIncinerator apparatusMetal adsorptionProcess engineering

The invention discloses an industrial solid waste treatment device, and relates to the technical field of solid waste treatment. The device comprises a fixed base, wherein a metal collection box, a separation box, a combustion box and a purification box are respectively and fixedly connected to the top of the fixed base from left to right; a grinding box is fixedly connected to the top of the separation box; a separation cover is fixedly connected to an inner cavity of the separation box; and the top of the separation cover penetrates through the separation box and the grinding box and extendsto an inner cavity of the grinding box. According to the industrial solid waste treatment device, waste materials fall into discharging grooves and are driven by a rotating cylinder to be conveyed clockwise and downwards; metal substances are adsorbed by metal adsorption blocks, and then the waste materials are conveyed into the combustion box along a second separation pipeline; and the metal substances fall into the metal collection box along a first communication pipeline and can be rapidly separated from the waste materials through the centralized treatment by a centralized drawer, so thatsolid waste is recycled at the maximum speed limit, and the utilization rate of resources is increased.

Owner:叶广丽

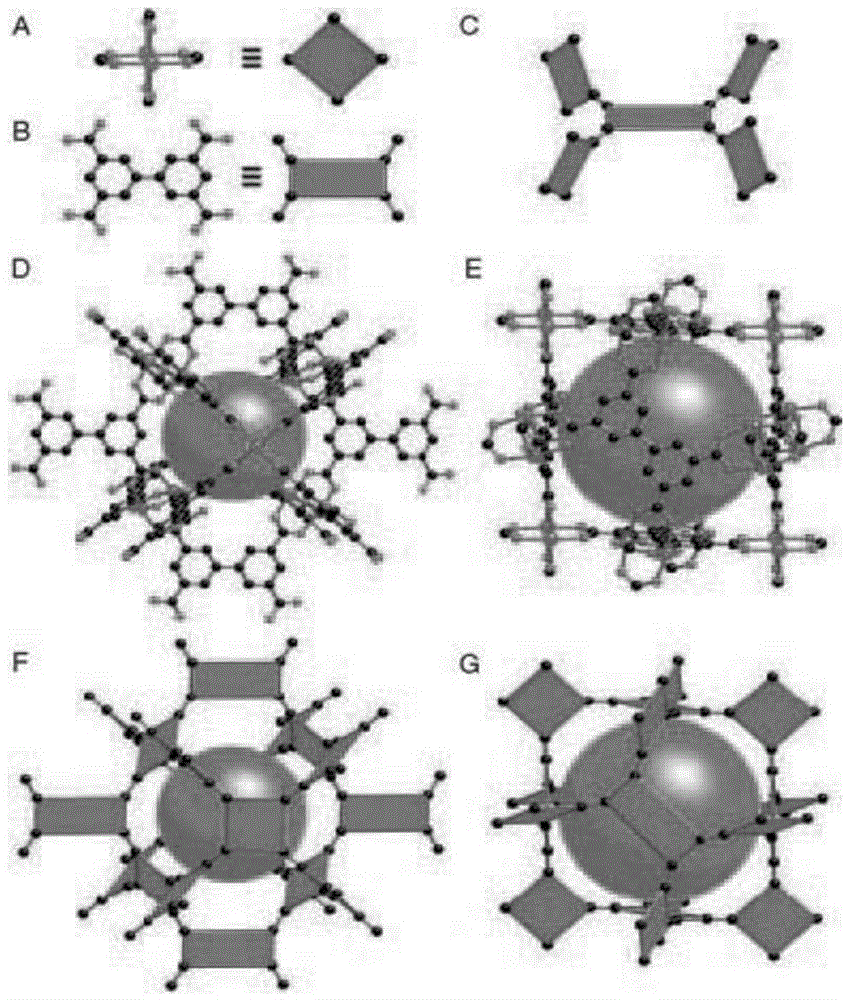

MOFs dual-metal adsorption material (Fe, Co)-BTC and preparation method thereof

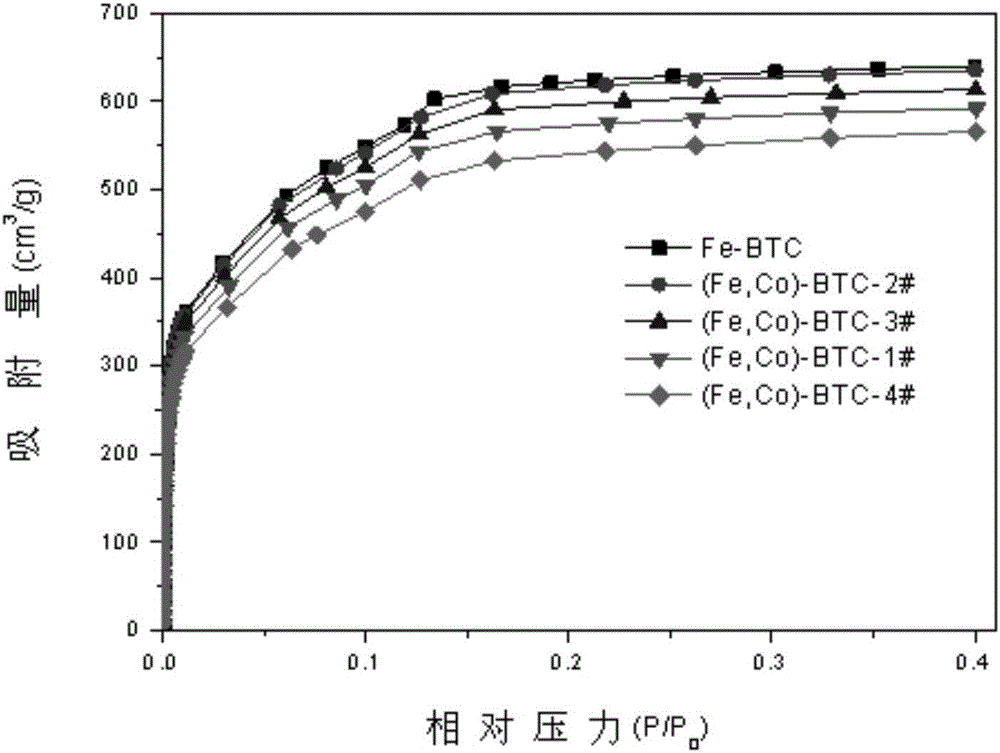

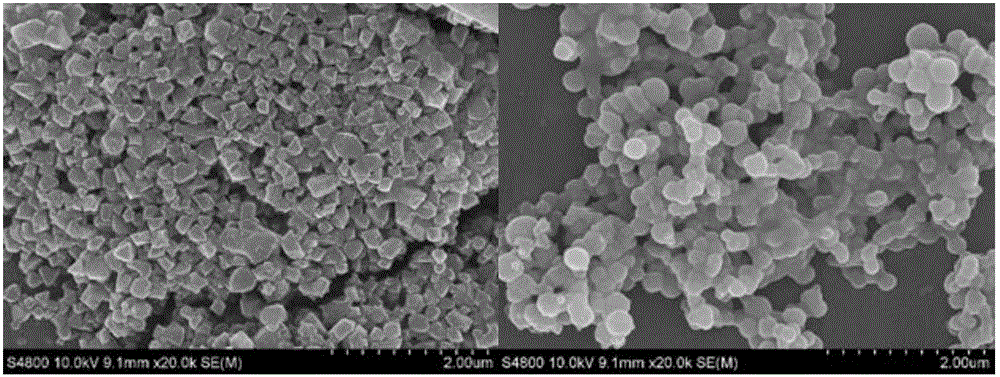

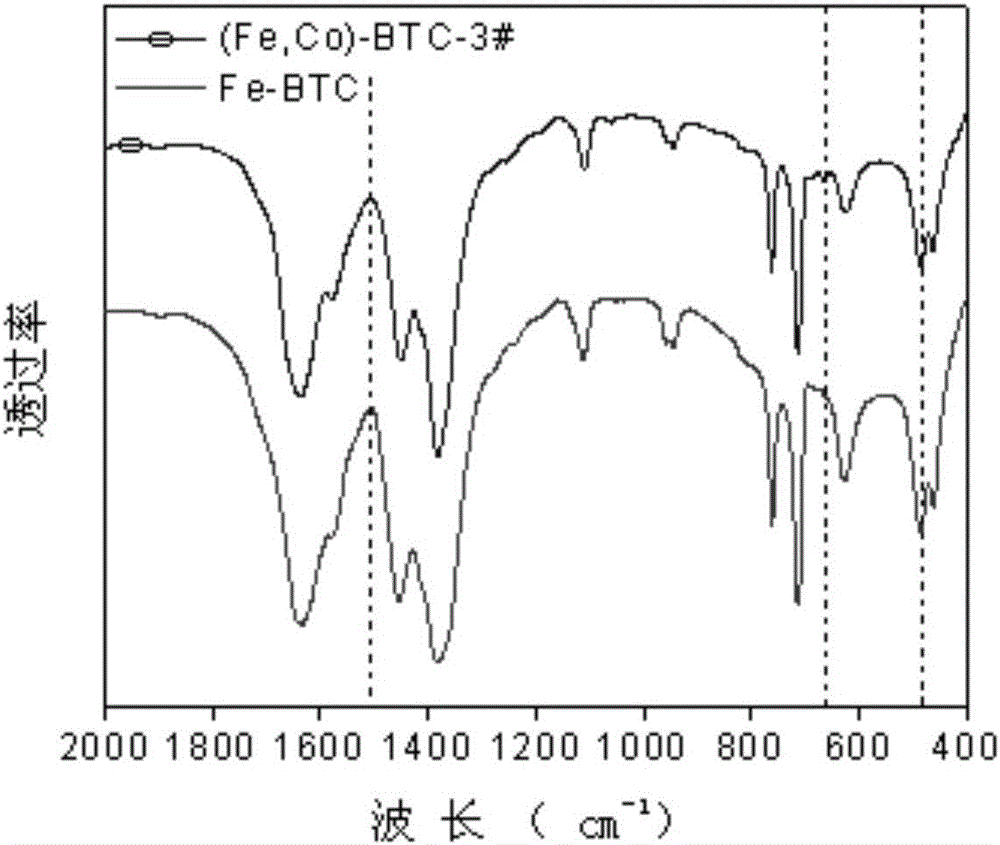

InactiveCN106076242AIncrease forceHigh adsorption capacityGas treatmentOther chemical processesNitrateIron powder

The invention belongs to the technical field of adsorption materials, and discloses a MOFs dual-metal adsorption material (Fe, Co)-BTC and a preparation method thereof. The preparation method comprises the following steps: mixing reduced iron powder, cobalt nitrate hexahydrate, mesitylenecarboxylic acid and water, uniformly stirring and mixing so as to obtain a ternary water mixed solution, adding a salpeter solution and a sodium fluoride solution, uniformly mixing so as to obtain reaction mother liquor, heating the reaction mother liquor to 150-180 DEG C, performing synthesis reaction for 8-16 hours, separating and purifying the reaction product, and performing vacuum activation, thereby obtaining the MOFs dual-metal adsorption material (Fe, Co)-BTC. Compared with a conventional Fe-BTC adsorbent, the MOFs dual-metal adsorption material (Fe, Co)-BTC disclosed by the invention enhances the action on CO2, and can remarkably increase the adsorption content of CO2.

Owner:SOUTH CHINA UNIV OF TECH

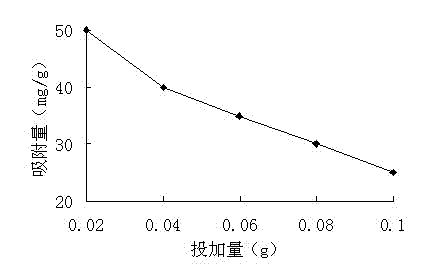

Preparation method of adsorbent and application of adsorbent to heavy metal adsorption

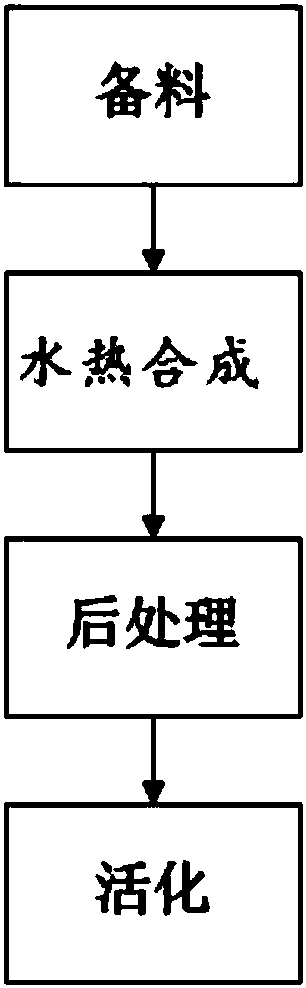

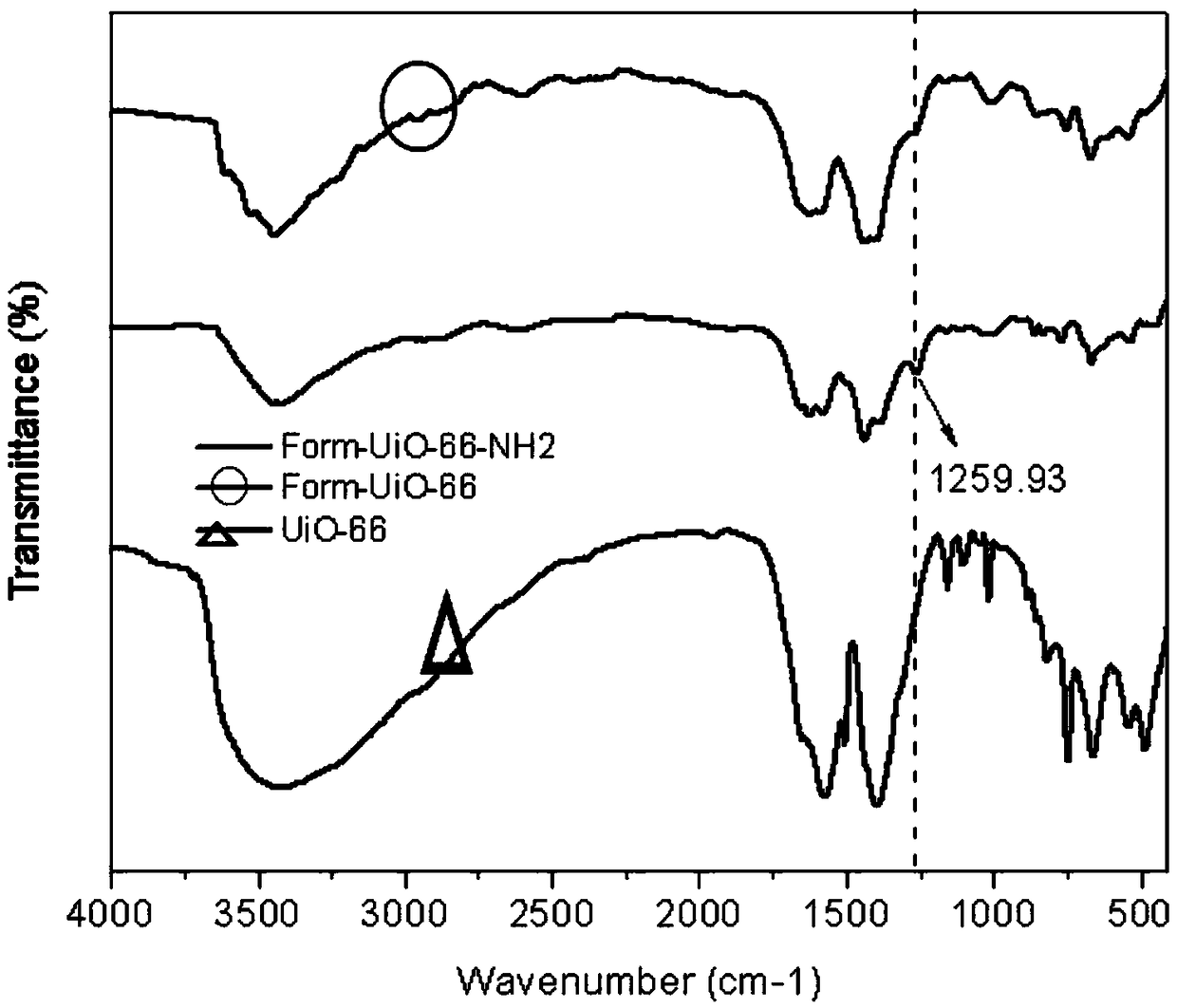

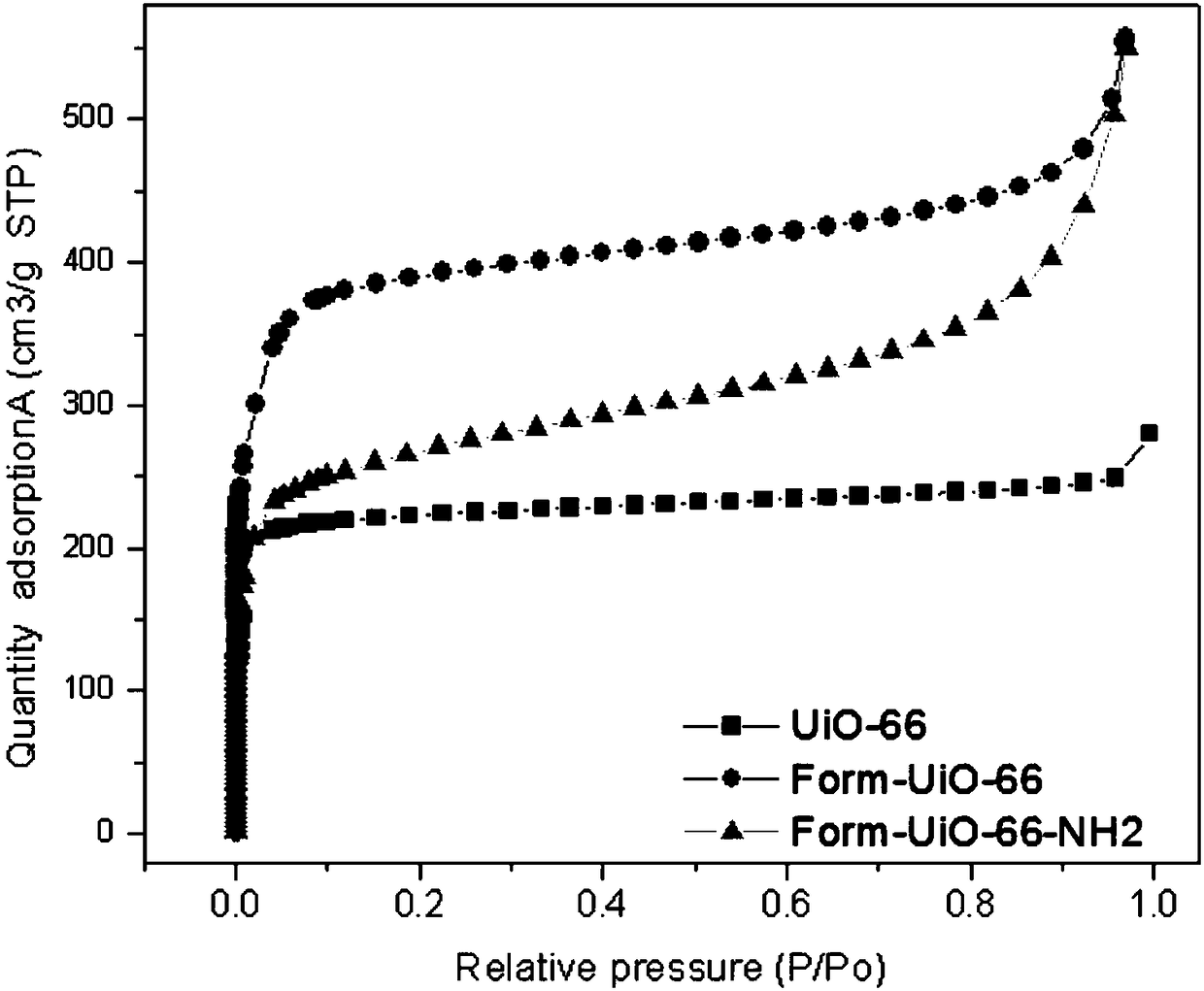

InactiveCN108295825ASolve the technical defect of poor adsorption capacityLarge specific surface areaOther chemical processesWater contaminantsMetal adsorptionSorbent

The invention belongs to the field of heavy metal pollution control, and particularly relates to a preparation method of an adsorbent and application of the adsorbent to heavy metal adsorption. The invention provides the preparation method of the adsorbent. The preparation method comprises the follows: preparing materials, performing hydrothermal synthesis, post-treatment and activation. The invention further provides application of the absorbent prepared with the preparation method to adsorption of heavy metals in water. Experimental determination shows that a product prepared with the preparation method has an enlarged specific surface area and significantly enhanced adsorption capacity; meanwhile, the product still has good hydrothermal stability and chemical stability. With the preparation method of the absorbent, provided by the invention, the technical defect that in the prior art, a metal organic framework-based adsorbent has poor adsorption capacity is overcome.

Owner:GUANGDONG UNIV OF TECH

Method of preparing hexavalent chromium biological adsorption material by taking lotus seedpod as material

ActiveCN105289526ALarge specific surface areaImprove adsorption capacityOther chemical processesWater contaminantsMetal adsorptionMagnetic carbon

The invention discloses a method of preparing a hexavalent chromium biological adsorption material by taking lotus seedpod as a raw material. The lotus seedpod is dried at room temperature and then is prepared into carbon xerogel by using a hydrothermal process; under an acidic condition, the carbon xerogel is oxidated; under an acidic condition, the oxidated carbon xerogel is reduced by using nanometer iron powder, and magnetic carbon xerogel is prepared; the magnetic carbon xerogel is immersed into liquid nitrogen, and a sample is freeze-dried to be prepared into a heavy-metal adsorption material. The method is applied to heavy-metal hexavalent chromium adsorption in water.

Owner:HUNAN UNIV OF SCI & TECH

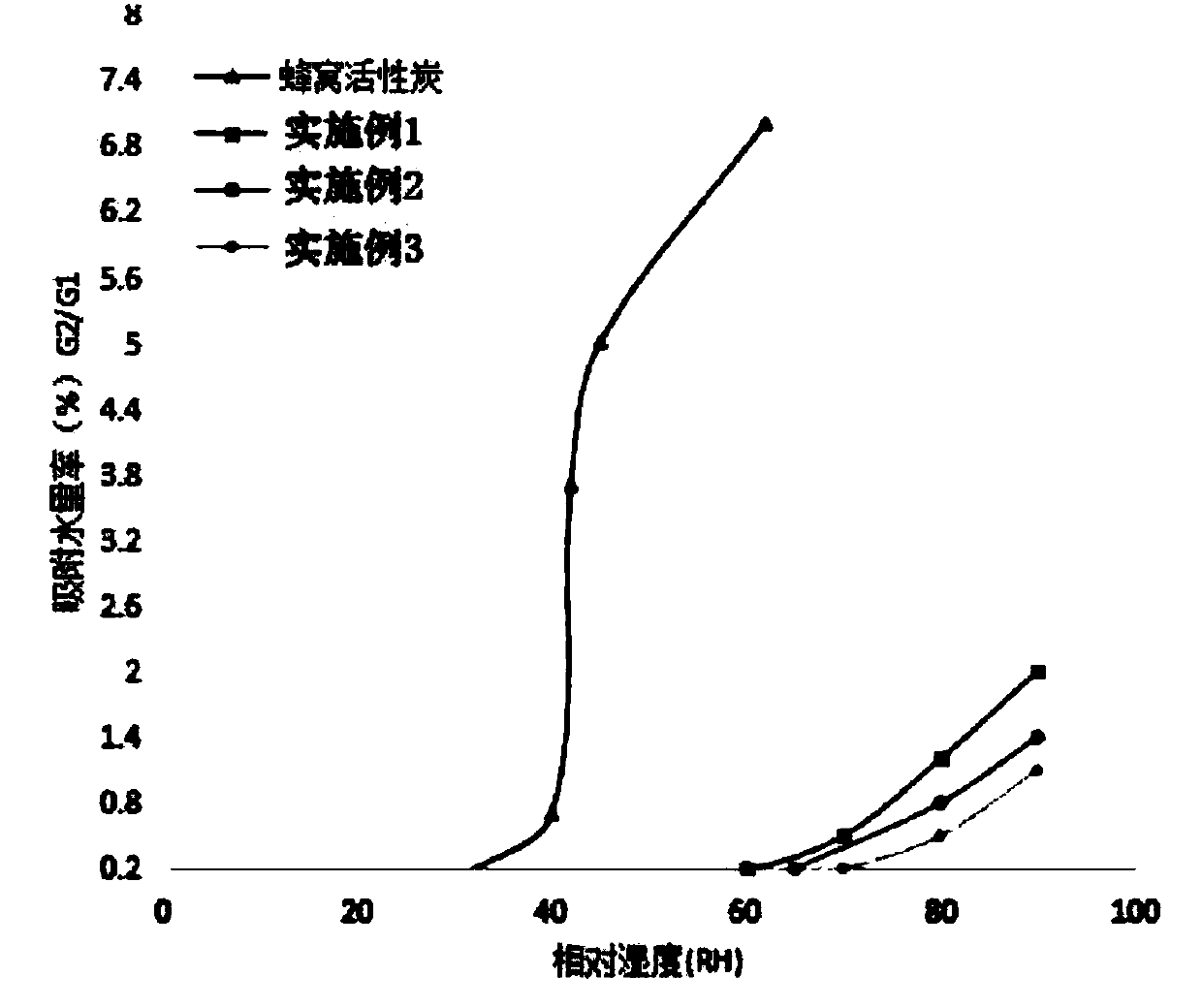

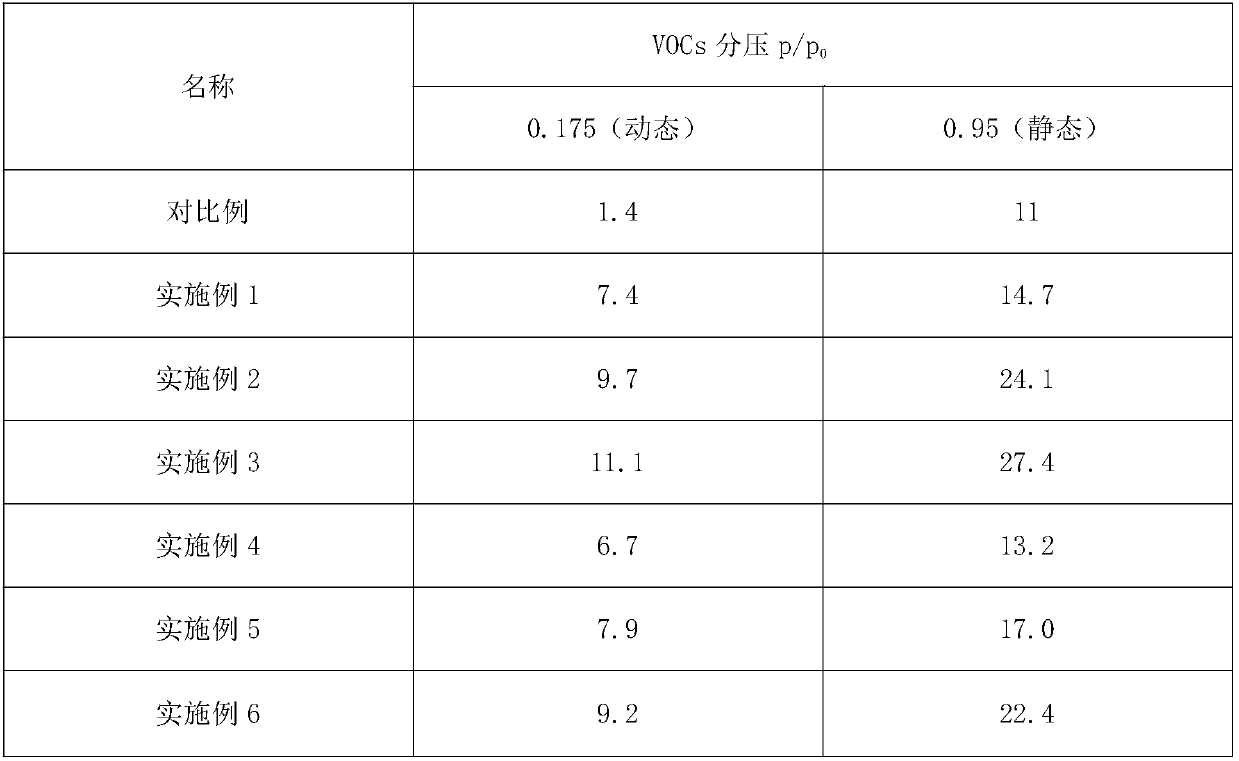

Hydrophobic honeycomb-shaped zeolite material as well as preparation method and application thereof

ActiveCN107583604AImprove hydrophobicityHas a pore size gradient distributionOther chemical processesDispersed particle separationTO-18High humidity

The invention belongs to the technical field of environment protection of inorganic non-metal adsorption materials and in particular relates to a hydrophobic honeycomb-shaped zeolite material as wellas a preparation method and application thereof. The material is prepared from ZSM-5 type zeolite and Y-type zeolite, wherein the ZSM-5 type zeolite and the Y-type zeolite account for 80 percent to 84percent of the hydrophobic honeycomb-shaped zeolite material and a transformed crystal accounts for 12 percent to 18 percent of the hydrophobic honeycomb-shaped zeolite material; the mass ratio of the ZSM-5 type zeolite to the Y-type zeolite ranges from (2 to 3) to (3 to 2); the diameter range of micro-pores of the hydrophobic honeycomb-shaped zeolite material is 0.5nm to 2.0nm. According to thehydrophobic honeycomb-shaped zeolite material provided by the invention, a ZSM-5 type molecular sieve material and a Y-type molecular sieve material are selected and mixed, so that the range of a porediameter (0.5nm to 2.0nm) of the honeycomb zeolite material is expanded; basic requirements of adsorbing waste gas with different molecular sizes (0.4nm to 1.4nm) in large-air-quantity and low-concentration VOCs (Volatile Organic Compounds) are met. The hydrophobic property and the specific surface area of the honeycomb zeolite material are improved through steps of crystal transformation, waterdraining, acid washing and the like, and the hydrophobic honeycomb-shaped zeolite material is applied to the large-air-quantity and low-concentration VOCs in an RH 80 percent high-humidity air environment.

Owner:景德镇佳奕新材料有限公司

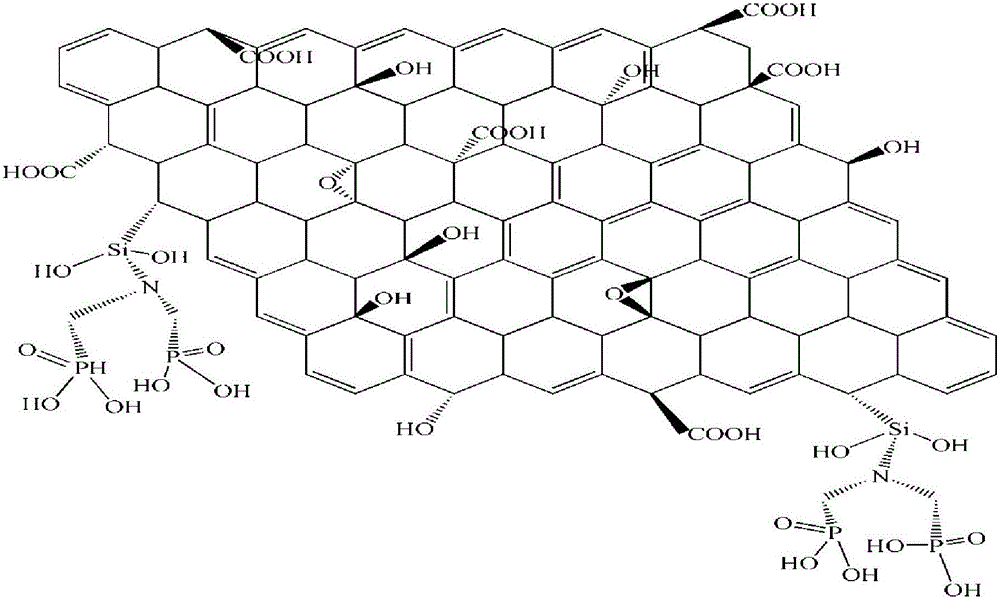

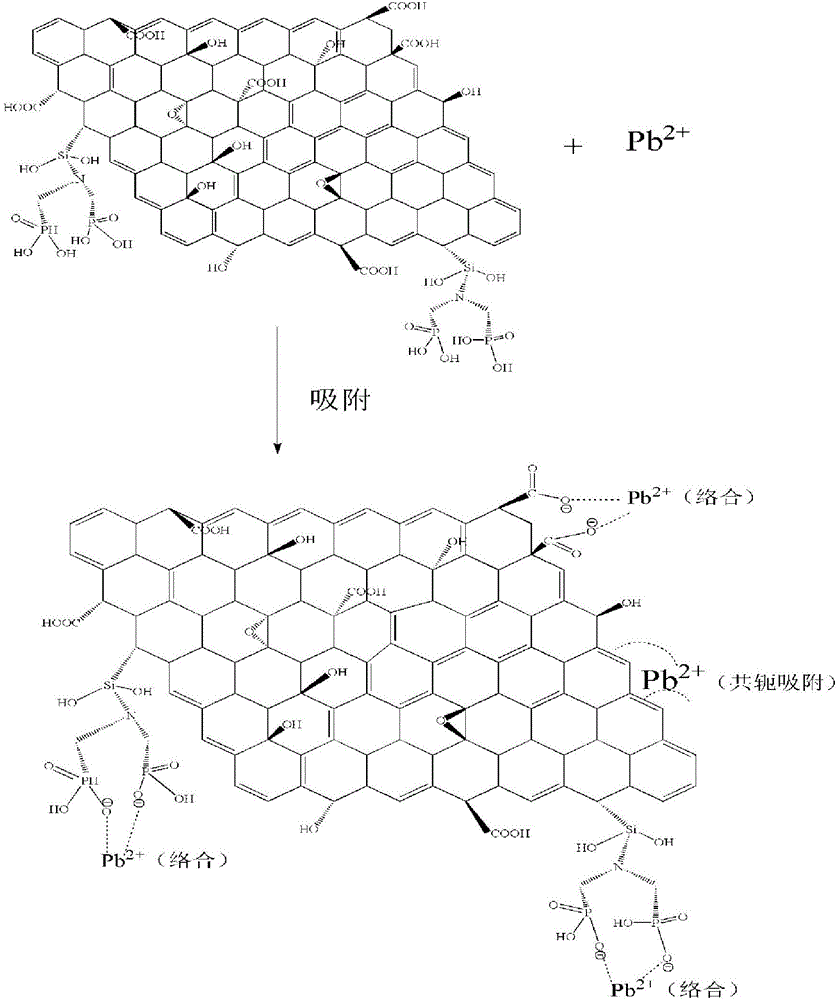

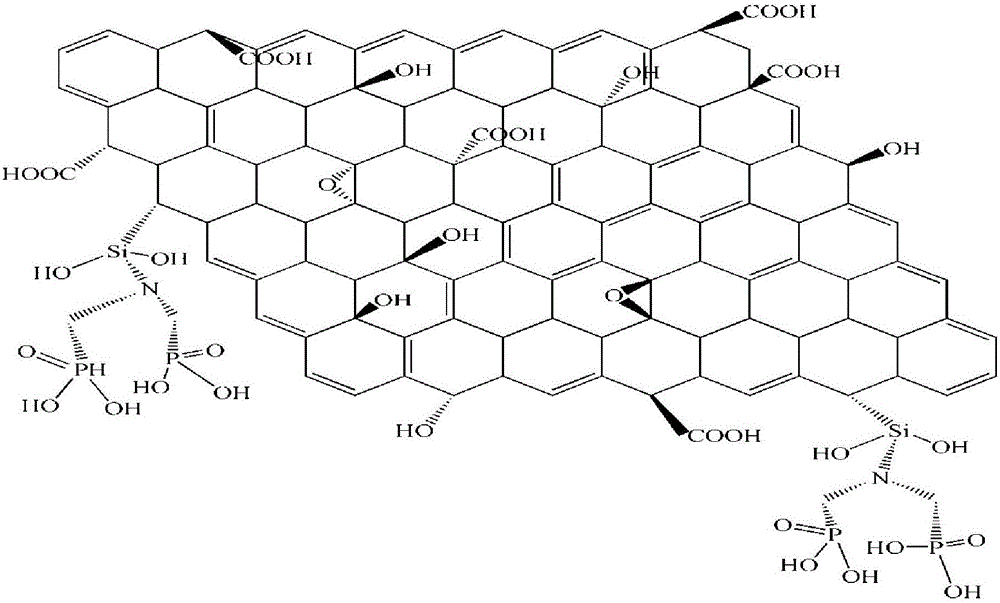

Chemical modified graphene oxide ionic type sewage treatment agent and preparation method thereof

InactiveCN106167285AOvercoming the problem of poor selectivityOther chemical processesGroup 5/15 element organic compoundsMetal adsorptionCompound (substance)

The invention relates to a chemically modified graphene oxide ionic sewage treatment agent, which is characterized in that the modified graphene oxide is formed by connecting graphene oxide and organic phosphate through chemical bonds formed by organosiloxane; The adsorption of graphene oxide to high-valent metals, the complexation of organic phosphate and carboxylate to metal ions, and its application to heavy metal ion sewage treatment, a chemically modified graphene oxide ion-type sewage treatment agent of the present invention , for Pb 2+ 、Cr 6+ The adsorption capacity of heavy metal ions such as ions is far greater than that of graphene oxide; the invention also provides a preparation method of chemically modified graphene oxide ion adsorption sewage treatment agent. The graphene oxide ionic sewage treatment agent prepared by the invention has strong selectivity for heavy metal ion adsorption and excellent effect, and can be used for industrial sewage treatment containing heavy metal ions.

Owner:UNION FOSHAN CHEM +1

Porous heavy metal ion adsorbent based on biochar and preparation method of porous heavy metal ion adsorbent

ActiveCN107952422ARaw materials are cheap and easy to getSimple preparation processOther chemical processesWater contaminantsSorbentInorganic compound

The invention discloses a porous heavy metal ion adsorbent based on biochar and a preparation method of the porous heavy metal ion adsorbent. The porous material comprises active components and a support, wherein the active components comprise biochar and hydroxyapatite; the support adopts kaolin as a structure promoter. The main preparation process of the adsorbent comprises steps of slurry preparation, slurry foaming, gelation, slurry injection into a mold, blank demolding and blank drying. The method has the following characteristics: the porous adsorbent is prepared from the biochar as anactive component and an inorganic compound as the support, waste is recycled, heavy metals can be removed, the adsorbent has the characteristic of being easy to recycle, and cyclic utilization of theadsorbent is realized. By means of the rich porous structure, mass transfer resistance is reduced, adsorption capacity and adsorption efficiency for the heavy metals are increased, and the adsorbent has good application prospect and environmental effect.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

Method for deeply removing heavy metals in water by using resin-based copper phosphate nanoflower coating

ActiveCN107096513AAchieve organic-inorganic compatibilityAchieve Chelation RemovalOther chemical processesWater contaminantsHigh concentrationPhosphate

The invention discloses a method for deeply removing heavy metals in water by using a resin-based copper phosphate nanoflower coating. A polydopamine (PDA) adhesive coating is formed on the surface of an ion exchange resin, so that bovine serum albumin (BSA) can be stably guided on the surface of the resin to form a cphosphate nanoflower coating, and the resin-based copper phosphate nanoflower coating is obtained; the resin-based copper phosphate nanoflower coating is put in a glass adsorption column, the temperature of polluted water is controlled to be 5 to 55 DEG C, the pH is controlled in the range of 3 to 7, the polluted water flows through a fixed bedpost adsorption device filled with an adsorption material at a flow rate of 10 to 50 BV / h, and the effluent water can reach safety control standard; when calcium ions, magnesium ions, sodium ions and potassium ions with high concentrations exist in water, the material still has higher metal adsorption and removal effects. The method can realize chelation removal for target heavy metals, deep purification for heavy metal ions is further promoted, and the benefit to environmental protection is obvious.

Owner:YANSHAN UNIV

Modification method for improving bacteria heavy metal adsorption capacity, adsorbent and application thereof

InactiveCN102965312AEasy to handleEasy to operateBacteriaWater contaminantsCross-linkEnvironmental resistance

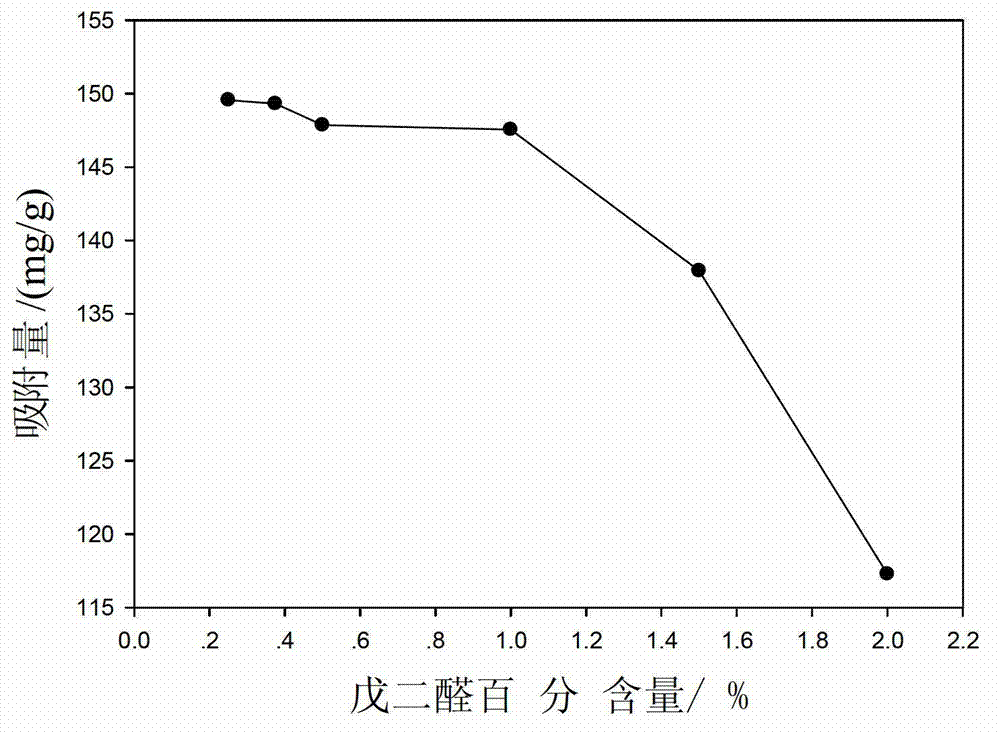

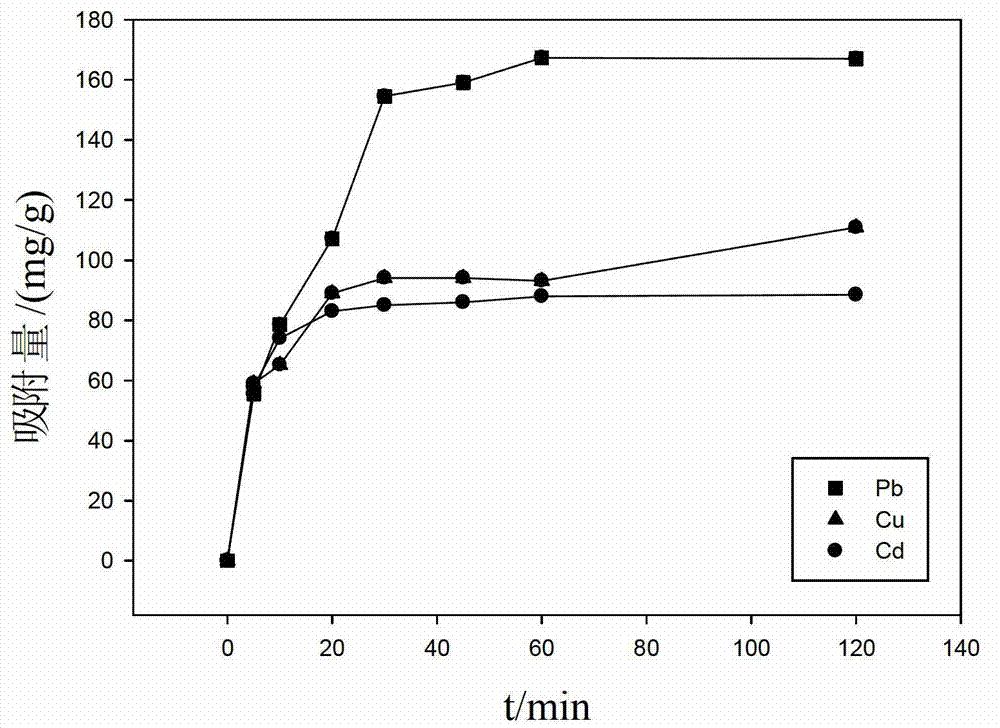

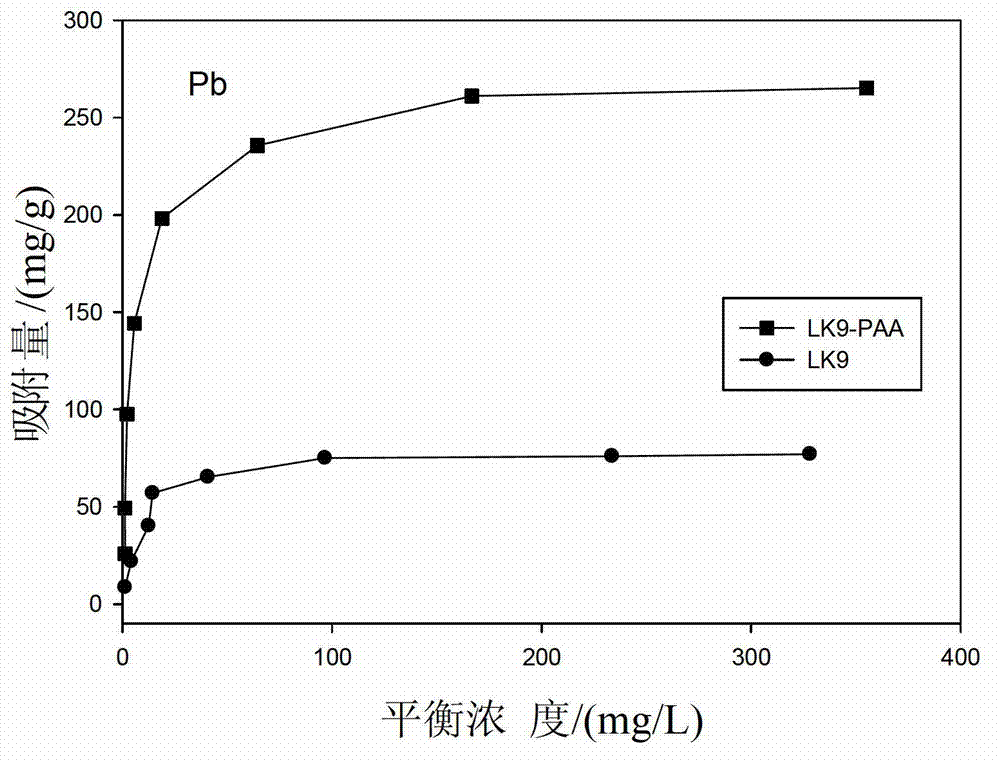

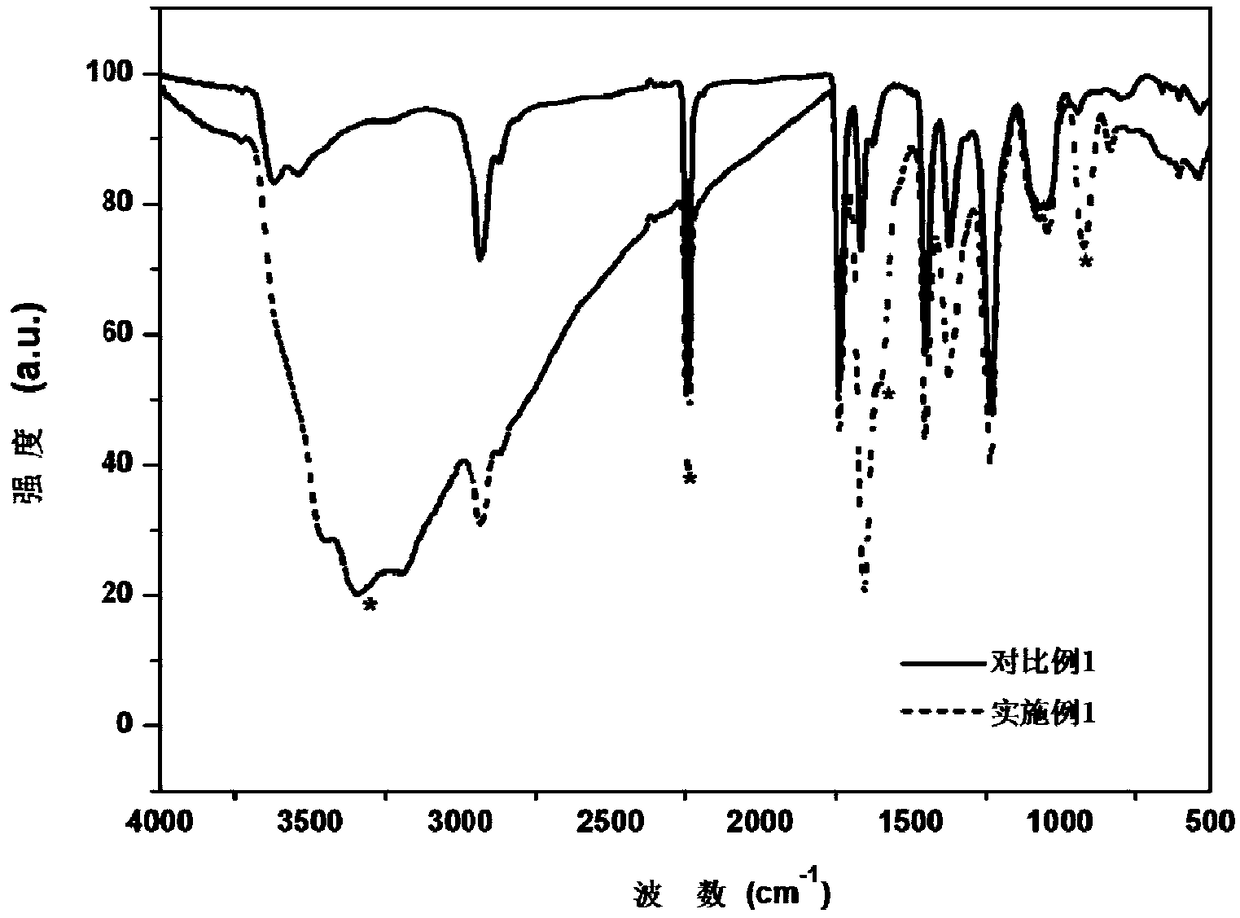

The invention provides a modification method for improving bacteria heavy metal adsorption capacity, an adsorbent and the application of the method. The method takes glutaraldehyde as a cross-linking agent, and comprises the step of: connecting poly allyamine hydrochloride (PAA / HCl) to the surface of plant endophyte Pseudom onas sp. LK9 thallus so as to cause the surface of the thallus to have a great deal of amino groups and further improve the adsorption effect of the thallus for heavy metals. The maximum adsorbing capacities of the obtained adsorbent for the heavy metals Pb<2+>, Cd<2+> and Cu<2+> are respectively 269.9mg / g, 145.0mg / g and 148.0mg / g; and compared with an LK9 adsorbent which is not modified, the adsorbing capacities are respectively increased by 192.98mg / g, 121.85mg / g and 128.35mg / g. The invention has the characteristics of being simple in method, simple and convenient to operate, remarkable and rapid in adsorption effect, environment-friendly and the like, thus having great application potential in the aspect of heavy metal pollution water treatment.

Owner:HUNAN UNIV

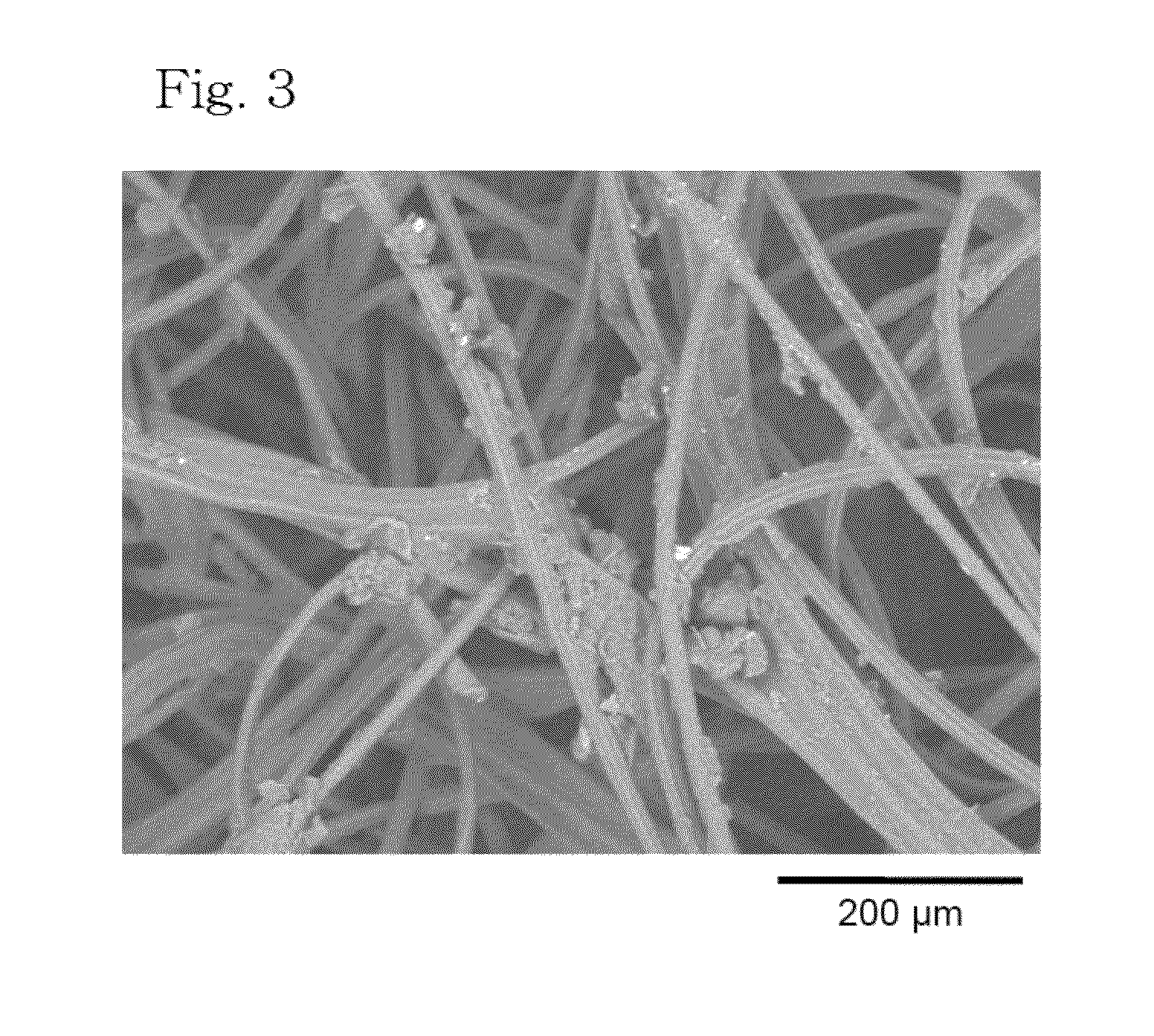

Amidoximized polyacrylonitrile fiber and preparation method and applications thereof

ActiveCN108893797AEasy to operateSave manufacturing costOther chemical processesWater contaminantsMetal adsorptionElectrospinning

The invention provides a preparation method of an amidoximized polyacrylonitrile fiber. The preparation method includes the following steps: preparing a polyacrylonitrile solution and a first organicsubstance solution, wherein the first organic substance includes an organic substance having a hydroxyl group and an amino group; evenly mixing the polyacrylonitrile solution and the first organic substance solution to prepare a spinning solution, wherein the mass concentration of polyacrylonitrile in the spinning solution is 8%-15%; carrying out electrostatic spinning on the spinning solution at40 DEG C to 60 DEG C to obtain the amidoximized polyacrylonitrile fiber; or carrying out electrostatic spinning on the spinning solution at a temperature greater than or equal to 20 DEG C and less than 40 DEG C, and then carrying out vacuum drying at 60 DEG C to 80 DEG C to obtain the amidoximized polyacrylonitrile fiber. The preparation method provided by the invention is simple in operation. Theamidoximized polyacrylonitrile fiber is prepared by controlling the temperature of the electrostatic spinning, and the prepared amidoximized polyacrylonitrile fiber has excellent metal adsorption properties and reusability.

Owner:SHENZHEN UNIV

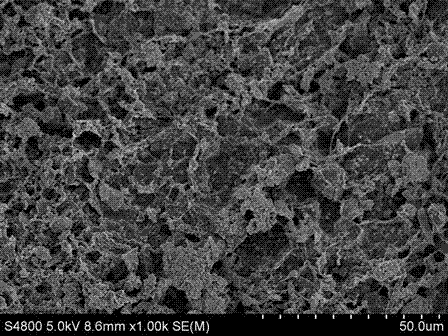

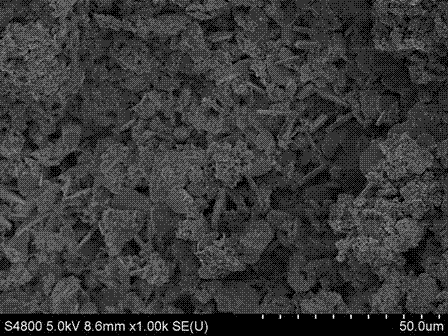

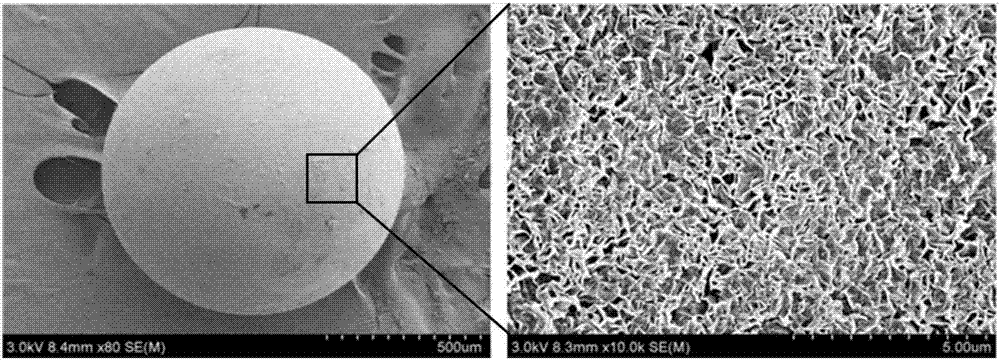

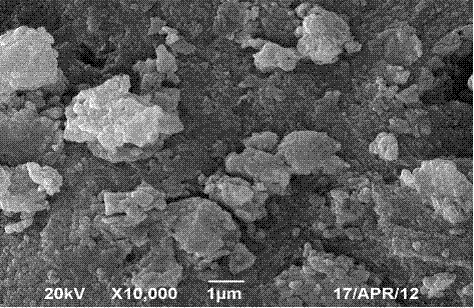

Method for preparing magnetic metal adsorption materials from spherical bacterial celluloses

InactiveCN106984280AImprove metal adsorption performanceHigh metal adsorption performanceOther chemical processesMicroorganism based processesMetal adsorptionNanoparticle

The invention discloses a method for preparing magnetic metal adsorption materials from spherical bacterial celluloses. The method is characterized by including fermenting the spherical bacterial celluloses; selectively oxidizing the spherical bacterial celluloses by the aid of TEMPO (2, 2, 6, 6-tetramethyl-1-piperidinyloxy) oxidizing systems to obtain oxidized spherical bacterial celluloses; immersing the oxidized spherical bacterial celluloses in mixed solution with Fe2+ and Fe3+ and allowing the oxidized spherical bacterial celluloses to sufficiently absorb iron ions; washing the oxidized spherical bacterial celluloses with the adsorbed iron ions by the aid of deionized water and immersing the oxidized spherical bacterial celluloses in sodium hydroxide solution to obtain wet-state magnetic oxidized spherical bacterial celluloses. The method has the advantages oxidation modification is carried out on bacterial celluloses to improve the metal adsorption performance, then the metal adsorption materials can be prepared by the aid of processes for synthesizing magnetic nano-particles on the surfaces of nano-celluloses, and the reusable magnetic spherical bacterial celluloses with high metal adsorption performance can be prepared under the condition of low cost.

Owner:DONGHUA UNIV

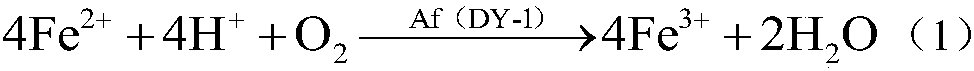

Strain of Acidithiobacillus ferrooxidans and its application in environmental treatment

ActiveCN108018250AStrong metal resistanceChange in surface activityBacteriaWater contaminantsMicroorganismMetal adsorption

The invention discloses a strain of Acidithiobacillus ferrooxidans and its application in environmental treatment. The Acidithiobacillus ferrooxidans is Acidithiobacillus ferrooxidans DY-1 and has a preservation number of CCTCC NO: M2017806. Through good biological oxidation, bio-acidic effect, strong metal tolerance and metal adsorption capacity, the Acidithiobacillus ferrooxidans DY-1 can produce significant effects in decoloration and deodorization of black and odor water and ecological restoration of sediments and does not damage the existing water system. The Acidithiobacillus ferrooxidans DY-1 can be used as a vanguard for the treatment on severely polluted water and lay a good water quality and ecological micro-environment foundation for water quality improvement and water ecological balance of the later treatment methods using other microorganisms and aquatic plants.

Owner:武汉新禹智水环保科技有限公司

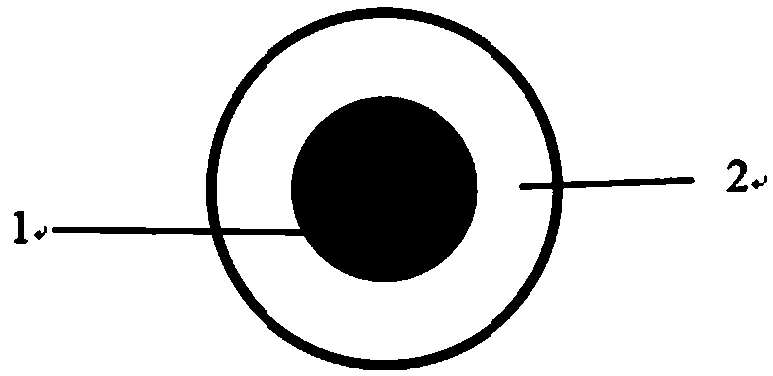

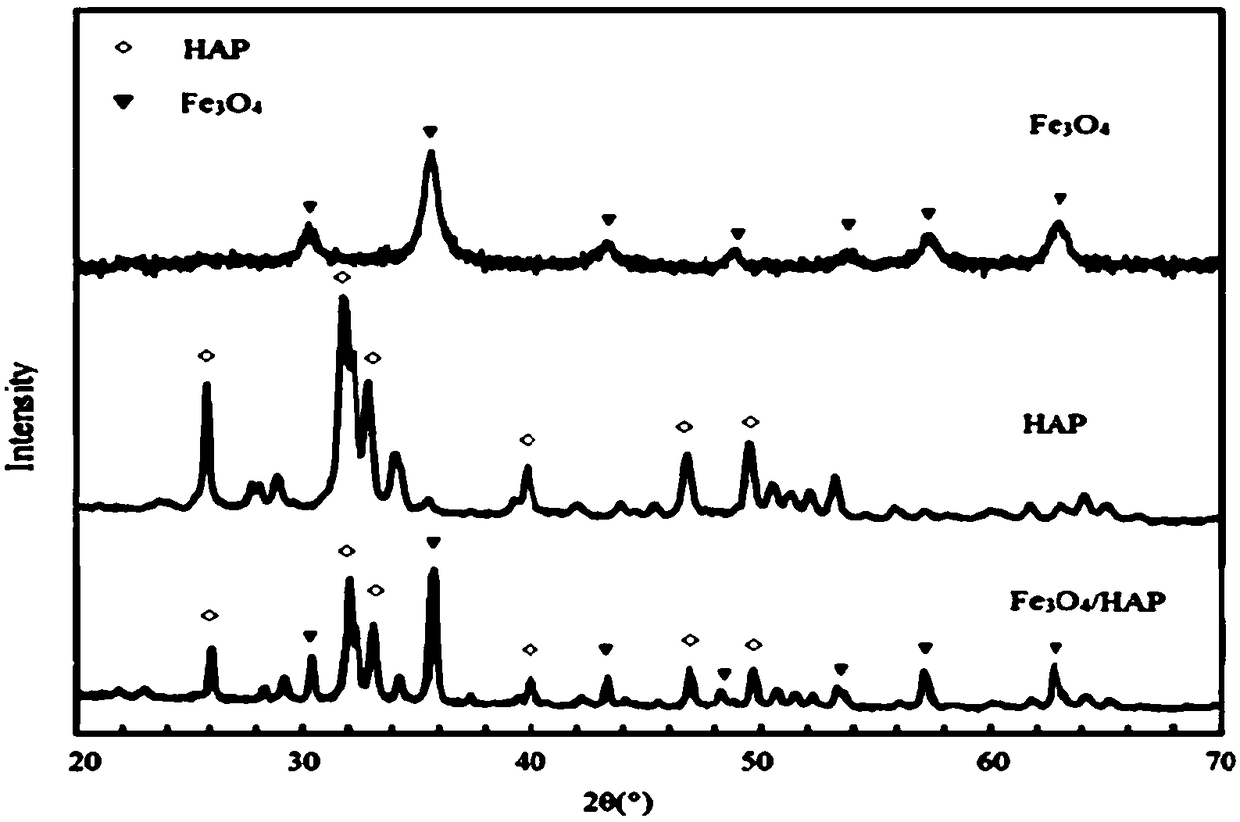

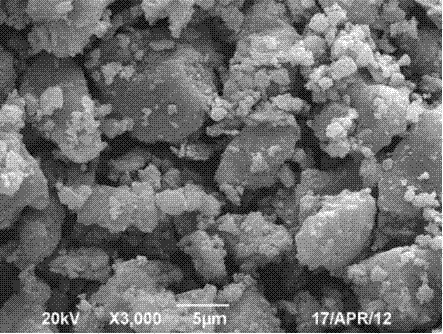

Strong-magnetic hydroxyapatite heavy metal adsorption material and preparation method thereof

InactiveCN109200989AImprove adsorption capacityUniform and firm coatingOther chemical processesWater contaminantsOrganic solventMetal adsorption

The invention belongs to the field of environmental control, and relates to a strong-magnetic hydroxyapatite heavy metal adsorption material and a preparation method thereof. The method adopts the technology of one-pot method and two-stage: in the first stage, under stirring of aeration, ferrite is added dropwise to react with alkali to generate a ferroferric oxide magnetic material; and in the second stage, hydroxyapatite is loaded on the surface of the ferroferric oxide magnetic material to generate the magnetic hydroxyapatite. The preparation technology is simple and easy to control, does not use any organic solvents, is environmentally friendly, low in manufacturing cost, and is suitable for large-scale production and application. The prepared magnetic hydroxyapatite has the characteristics of being high in magnetism, evenly and firmly coating, and good in dispersibility, and can be applied to treatment of heavy metal polluted wastewater, soil, solid waste and the like.

Owner:HUATIAN ENG & TECH CORP MCC

Preparation method of diatomite heavy-metal adsorption material

InactiveCN102886241AEfficient removalUnique craftOther chemical processesWater/sewage treatment by sorptionMetal adsorptionSorbent

The invention provides a preparation method of a diatomite heavy-metal adsorption material. The method comprises the following steps of: loading an aluminum-magnesium hydroxyl metal oxide on the surface of diatomite by utilizing a co-precipitation method; and washing and drying to obtain the diatomite heavy-metal adsorption material. The preparation method disclosed by the invention has a unique process and is convenient to operate; the large-scale industrial production is easily realized and the dispersion performance of the aluminum-magnesium hydroxyl metal oxide in a water solution is easily improved, the contact between an adsorbent and each metal ion in the water solution is enhanced and the adsorption efficiency is improved; and the preparation method facilitates the bonding between the surface of the diatomite and the aluminum-magnesium hydroxyl metal oxide to form a chemical bond, so as to improve the loading stability. The invention can further expand the application of the diatomite in a water quality purification field and provides a novel concept for removing heavy-metal ions in water body.

Owner:CHANGSHA UNIVERSITY

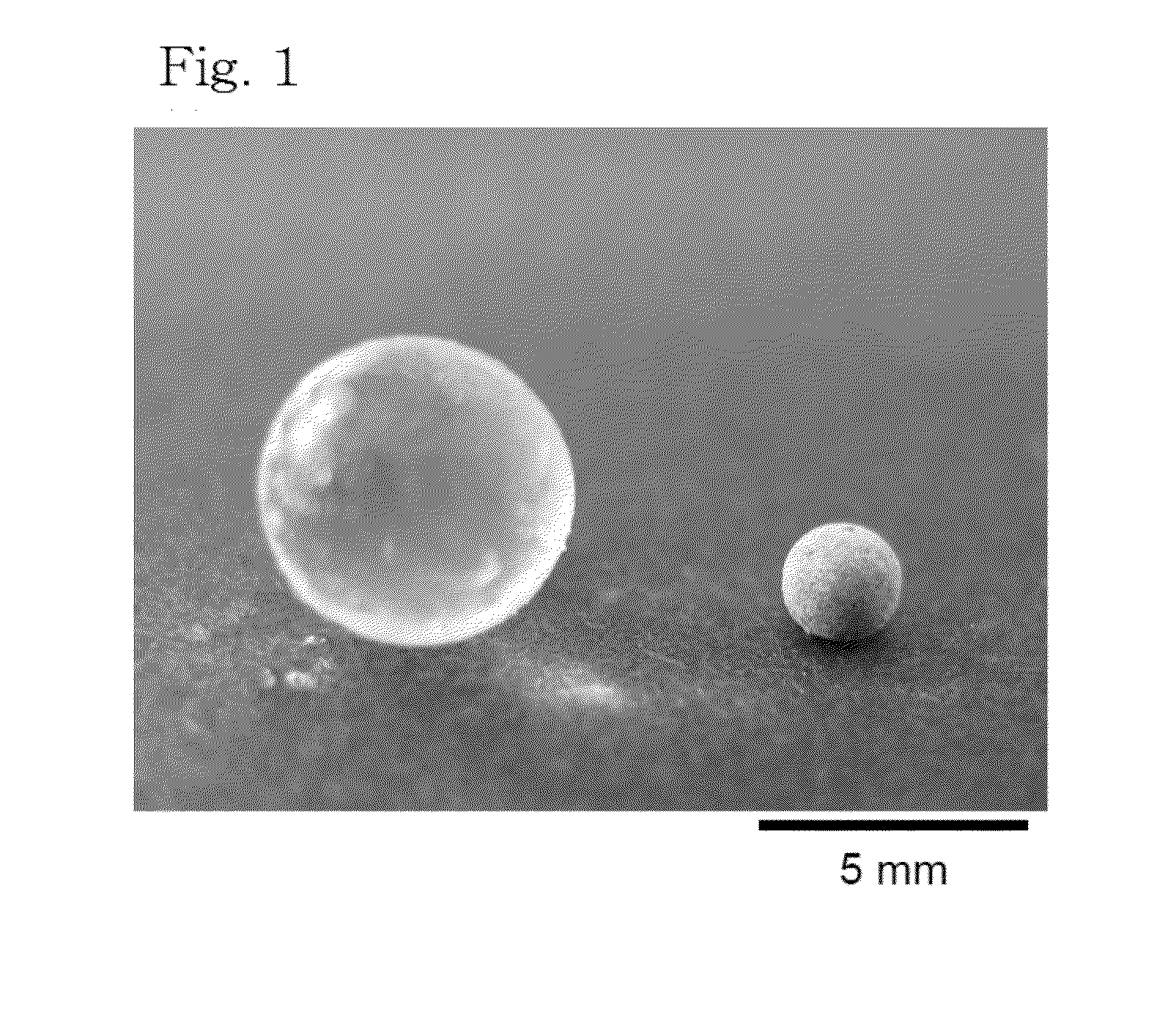

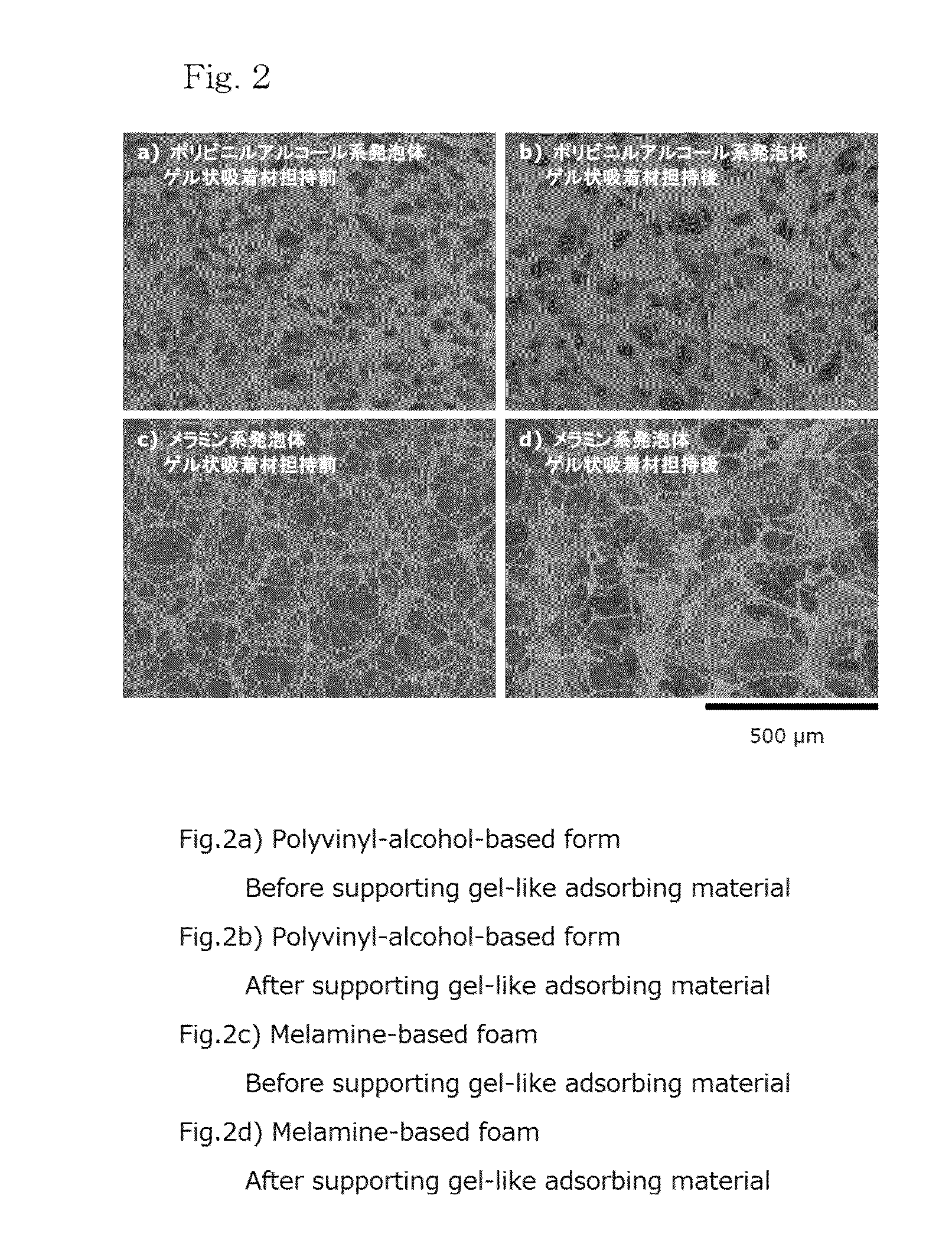

Metal-adsorbing gel and adsorbent supporting metal-adsorbing gel

InactiveUS20150069292A1High metal adsorption capacityLower the volumeOther chemical processesOrganic anion exchangersIndustrial waste waterMetal adsorption

ProblemThe present invention provides, in a metal-adsorbing material used for the removal and recovery of a wide range of heavy metals in treated solutions such as industrial waste water, service water, and environmental water, a gel-like metal-adsorbing material having a large amount of metal adsorption and capable of meeting various demands; and also provide a metal adsorbent having a gel-like metal-adsorbing material supported on a porous carrier.Means for ResolutionA metal-adsorbing polymer selected from polyethyleneimine and polyallylamine is crosslinked with a polyglycidyl ether, whereby a gel-like metal-adsorbing material having a large amount of metal adsorption and capable of meeting various demands is produced. Further, a hydrophilic porous carrier is impregnated with a metal-adsorbing polymer, followed by crosslinking with a polyglycidyl ether, whereby a metal adsorbent having a gel-like metal-adsorbing material supported on the porous carrier, which has a large amount of metal adsorption and can meet various demands, is produced.

Owner:NIPPON FILCON

Magnetic separating device for rice processing

InactiveCN106513167AQuality assuranceImprove adsorption capacityMagnetic separationGrain millingMetal adsorptionMagnetic separator

The invention discloses a magnetic separating device for rice processing. The magnetic separating device comprises a machine body; a feeding funnel is arranged in the middle of the top end of the machine body; a clearing door is arranged at the lower end at the left side of the machine body; a tapered discharge hopper is arranged at the bottom end of the machine body; a stirring magnetic separator is arranged at the upper end inside the machine body; a telescopic baffle plate mechanism is arranged at the middle lower end inside the machine body; a fixed blocking part is arranged at the middle lower end at the left side inside the machine body; and a metal adsorption net is arranged at the lower end inside the machine body. The magnetic separating device for rice processing solves the problems that magnetic separating equipment in the prior art is generally not good in magnetic separating effect, is low in working efficiency and is inconvenient to use; a stirring magnetic-separating design is adopted to carry out magnetic separating processing while stirring; and the metal adsorption net is arranged, so that dual adsorption effects are achieved, rice can be quickly and comprehensively subjected to magnetic separating processing, the magnetic separating effect is better, and magnetic separating efficiency is extremely high.

Owner:HARBIN MIMI RICE IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com