Method for preparing magnetic metal adsorption materials from spherical bacterial celluloses

A technology for bacterial cellulose and adsorption materials, which is applied in microorganism-based methods, biochemical equipment and methods, alkali metal compounds, etc., can solve the problems of high cost and poor performance of metal adsorption materials, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

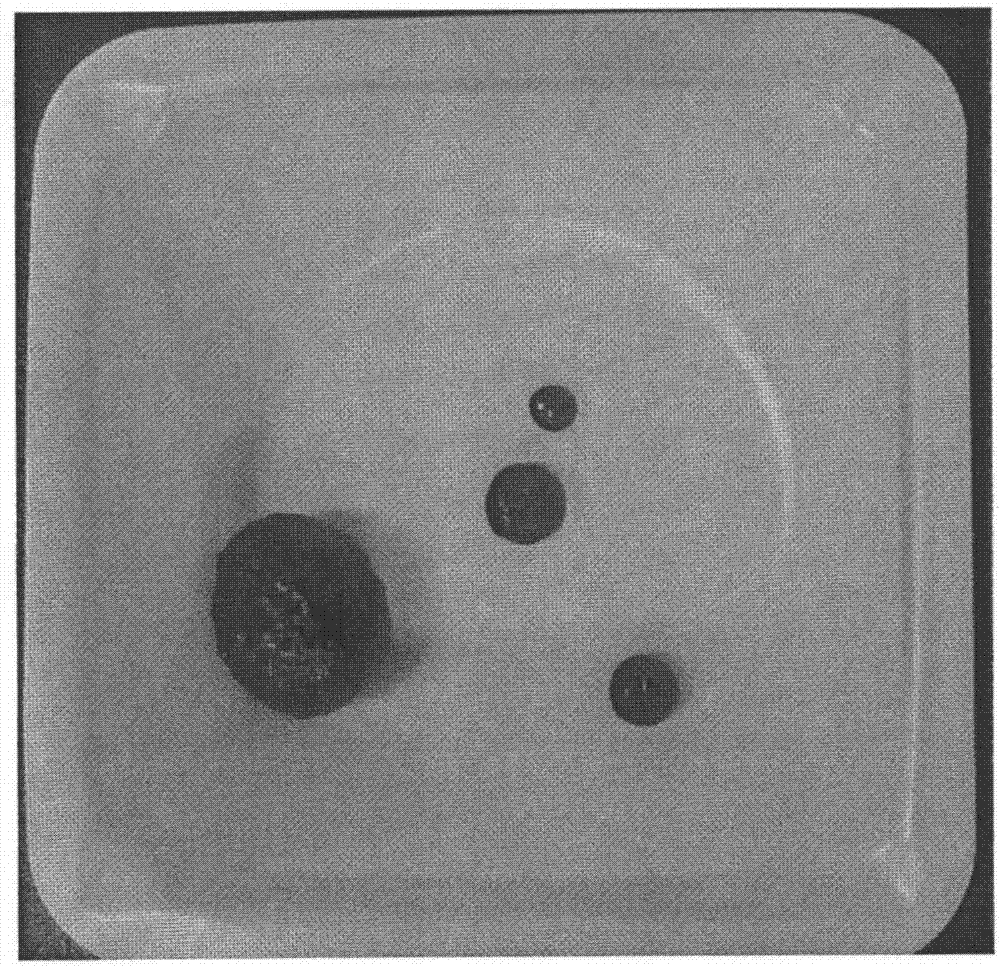

[0031] A method for preparing magnetic metal adsorption material with bacterial cellulose balls, the specific steps are:

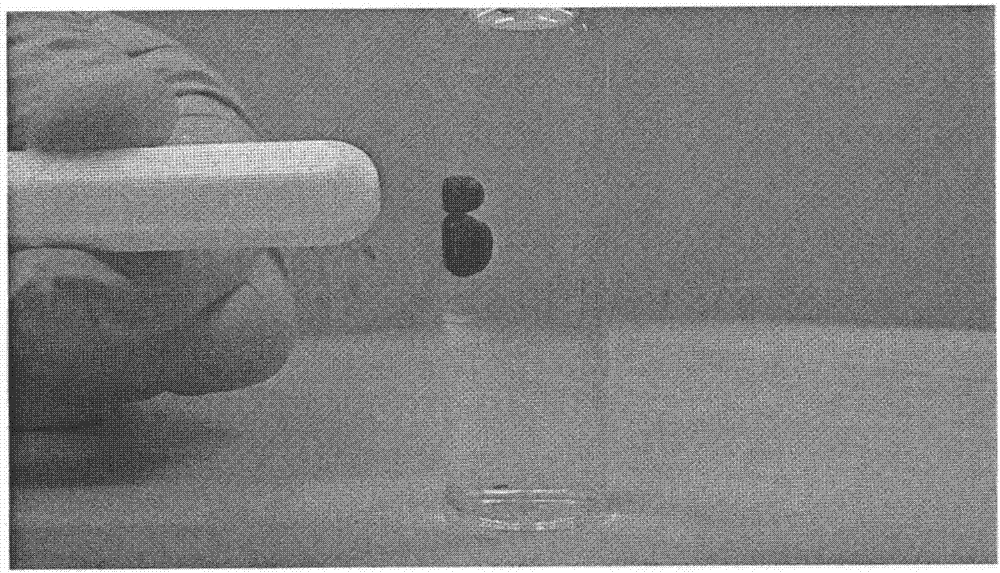

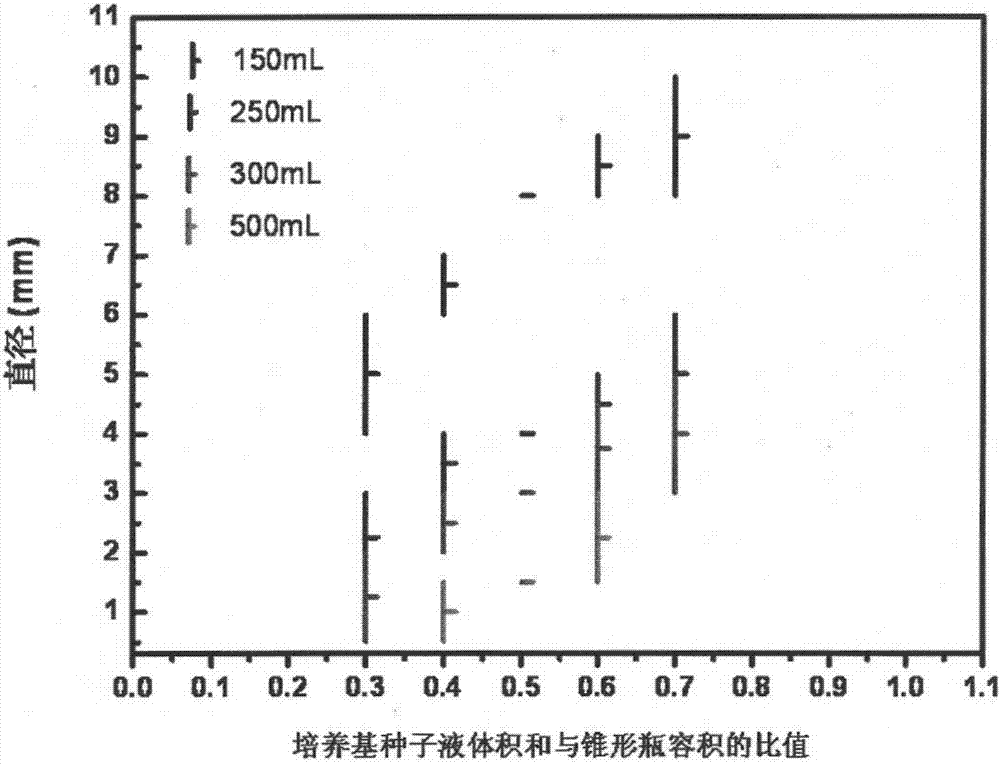

[0032] (1) Under sterile conditions, inoculate Acetobacter xylinum in 30 mL of liquid medium (composition: fructose 50 g / L, peptone 5 g / L, yeast extract 5 g / L, sodium monohydrogen phosphate 2.6 g / L, without Water citric acid 1.15g / L, the rest is water), in 32 ℃ incubator static culture 48h, obtain seed liquid. Add 25mL of seed liquid and 100mL of liquid medium into a 250mL Erlenmeyer flask, and incubate for 120h in a shaker with a rotation speed of 150rpm and a temperature of 32°C to obtain bacterial cellulose balls. Immerse the prepared bacterial cellulose balls in 0.1mol / L sodium hydroxide solution, wash at 80°C for 2 hours, remove residual bacteria and culture medium, and then wash with deionized water until the pH value is neutral;

[0033] (2) After immersing 100g bacterial cellulose balls into 50mL of a solution containing 2.36mg TEMPO and 23.6mg Na...

Embodiment 2

[0037] A method for preparing magnetic metal adsorption material with bacterial cellulose balls, the specific steps are:

[0038] (1) Under sterile conditions, inoculate Acetobacter xylinum in 30 mL of liquid medium (composition: fructose 50 g / L, peptone 5 g / L, yeast extract 5 g / L, sodium monohydrogen phosphate 2.6 g / L, without Water citric acid 1.15g / L, the rest is water), in 32 ℃ incubator static culture 48h, obtain seed liquid. Add 25mL of seed solution and 50mL of liquid medium into a 150mL Erlenmeyer flask, and incubate for 120h in a shaker with a rotation speed of 200rpm and a temperature of 32°C to obtain bacterial cellulose balls. Immerse the prepared bacterial cellulose balls in a sodium hydroxide solution with a concentration of 0.1mol / L, wash at 80°C for 2 hours, remove residual bacteria and culture medium, and then wash with deionized water until the pH value is neutral;

[0039](2) After immersing 100g bacterial cellulose balls into 50mL of a solution containing ...

Embodiment 3

[0043] A method for preparing magnetic metal adsorption material with bacterial cellulose balls, the specific steps are:

[0044] (1) Under sterile conditions, inoculate Acetobacter xylinum in 30 mL of liquid medium (composition: fructose 50 g / L, peptone 5 g / L, yeast extract 5 g / L, sodium monohydrogen phosphate 2.6 g / L, without Water citric acid 1.15g / L, the rest is water), in 32 ℃ incubator static culture 48h, obtain seed liquid. Add 25mL of seed liquid and 100mL of liquid medium into a 250mL Erlenmeyer flask, and incubate for 120h in a shaker with a rotation speed of 150rpm and a temperature of 32°C to obtain bacterial cellulose balls. Immerse the prepared bacterial cellulose balls in a sodium hydroxide solution with a concentration of 0.1mol / L, wash at 80°C for 2 hours, remove residual bacteria and culture medium, and then wash with deionized water until the pH value is neutral;

[0045] (2) After immersing 100g bacterial cellulose balls into 50mL of a solution containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com