Strong-magnetic hydroxyapatite heavy metal adsorption material and preparation method thereof

A technology of hydroxyapatite and adsorption materials, applied in the field of environmental governance, can solve the problems of reduced heavy metal adsorption capacity, limited industrialization and application, complex preparation process, etc., and achieves the advantages of recycling and reuse, easy control, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

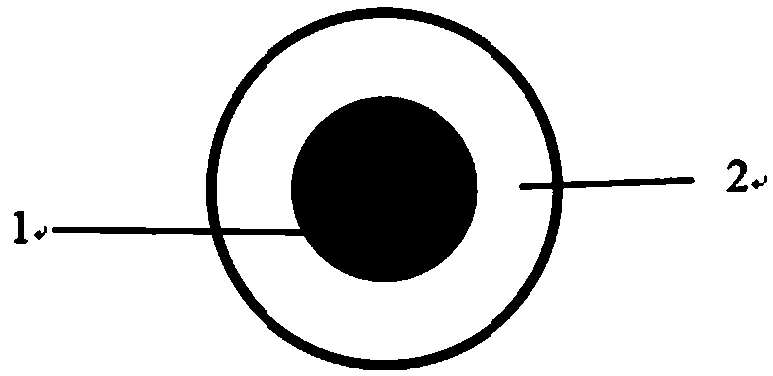

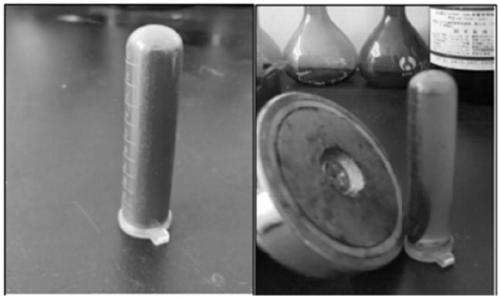

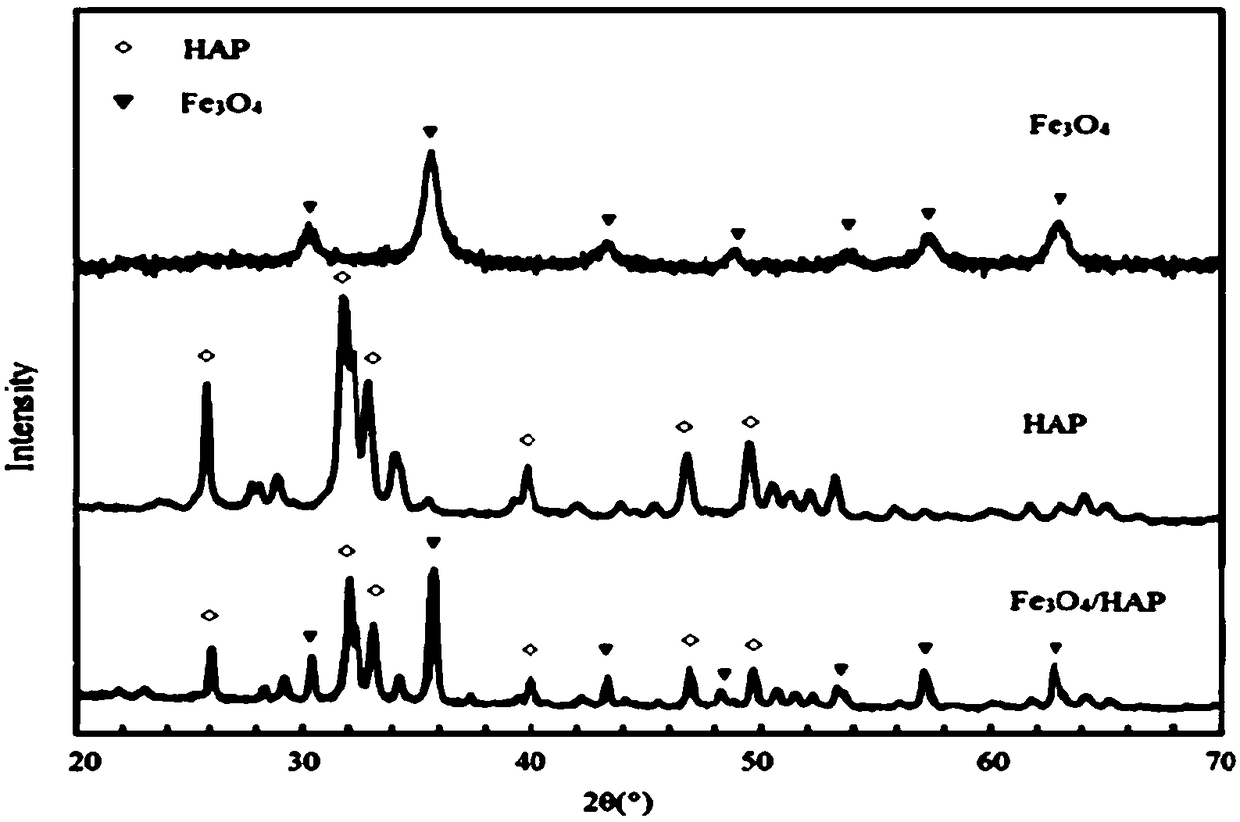

Method used

Image

Examples

Embodiment 1

[0081] (1) preparation of ferric oxide

[0082] Step 1: Prepare 100ml of 2M sodium hydroxide solution and 100ml of 1M ferrous sulfate solution;

[0083] Step 2: Put 200ml of water into a 500ml beaker, aerate and stir at an aeration rate of 1L / min, and heat to 60°C;

[0084] Step 3: Add sodium hydroxide and ferrous sulfate solution dropwise to the beaker of step 2 at the same time to maintain pH10;

[0085] Step 4: After the ferrous sulfate solution has been added dropwise, react with constant temperature aeration for 2 hours to obtain ferric oxide emulsion;

[0086] (2) Preparation of Magnetic Hydroxyapatite

[0087] Step 5: Prepare 50ml of calcium chloride solution with a concentration of 1.67M and 50ml of a 1M disodium hydrogen phosphate solution;

[0088] Step 6: heat the above iron ferric oxide emulsion to 60°C under stirring;

[0089] Step 7: Add calcium chloride solution and disodium hydrogen phosphate solution dropwise at the same time, and maintain pH 10 with lye; ...

Embodiment 2

[0094] In the same method as in Example 1, step 1 uses a ferrous chloride solution with a concentration of 1M to replace the ferrous sulfate solution with a concentration of 1M, and the remaining methods are the same as in Example 1 to obtain material 2.

Embodiment 3

[0096] In the same method as in Example 1, in step 7, a 1.67M calcium nitrate solution was used instead of a 1.67M calcium chloride solution, and the remaining methods were the same as in Example 1 to obtain material 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com