Patents

Literature

486results about How to "Unique craft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

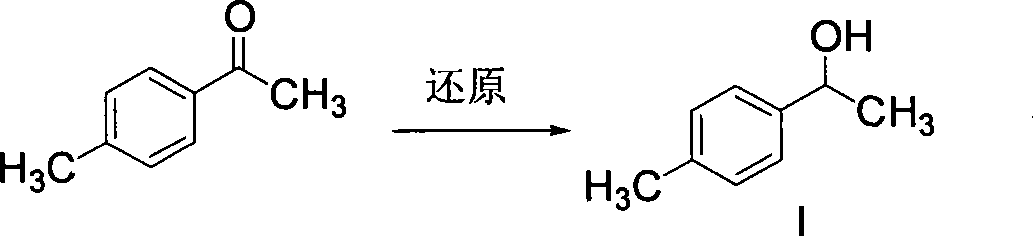

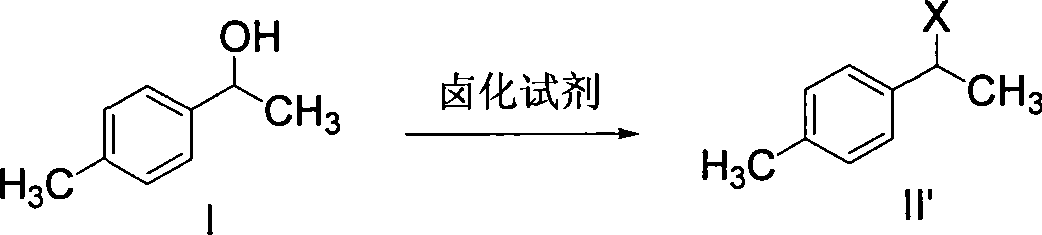

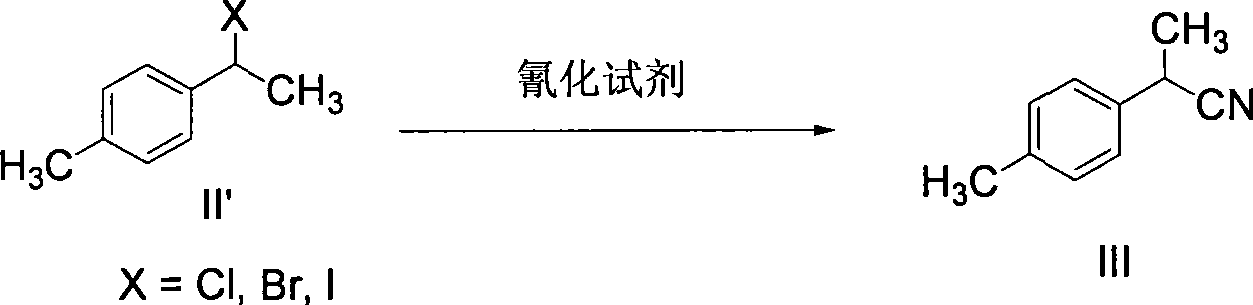

Method for synthesizing loxoprofen sodium

ActiveCN101412670ARaw materials are easy to getUnique craftOrganic compound preparationCarboxylic compound preparationSolventHydrolysis

The invention discloses a synthetic method for loxoprofen sodium, which is prepared by taking methyl acetophenone as an initial raw material through reduction, acylation or halogen substituent, cyanation, hydrolysis, bromination, condensation, decarboxylation and salifying. The method has the advantages of easily obtained raw material, unique technology, simple and stable operation, and high productive rate in each step of reaction; and all solvents used in the synthesis process can be recycled, so the production cost is reduced greatly. Tests show that the obtained product has reliable quality and stable performance, and can be further used for making preparation of non-steroidal anti-inflammatory drugs such as the loxoprofen sodium.

Owner:ZHEJIANG APELOA JIAYUAN PHARMA +1

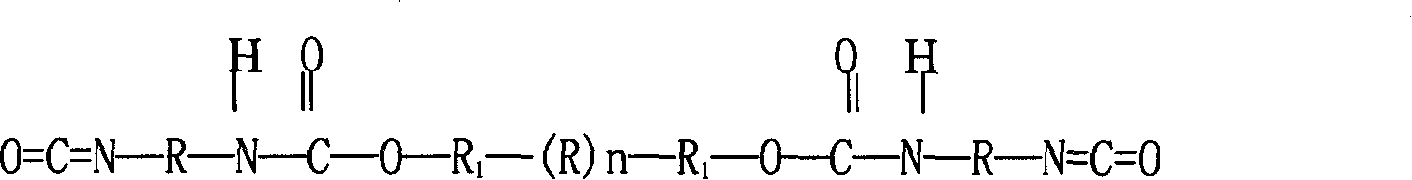

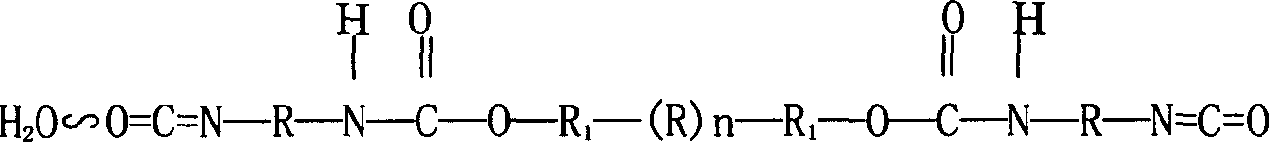

Polysiloxane-polyether copolymer modified aqueous polyurethane preparation method

InactiveCN1884335AImprove heat resistanceImprove low temperature resistanceLiquid surface applicatorsFibre treatmentCarbamateSolvent

The invention relates to a method for preparing aqueous polyurethane. It comprises following steps: employing polyisocyanates bridging agent, proceeding copolymerization with excess aqueous polyether, liquid ploydimethyl oxosilane ternary block and getting ployoxosilane-polyether polymer, introducing polyurethane and organic silicon when generating carbamate with carbamate to main chain, adding chain propagation agent for chain propagation reaction and getting preploymer containing hydrophilic group; adding mixture of polyhydroxy compound and dissolvent into reaction system for second chain propagation reaction; neutralizing by adding neutralization agent, adding water for emulsification, adding polyamine for chain propagation; distilling to remove dissolvent after reaction and getting aqueous polyurethane modified with aqueous polyurethane-polyether polymer. The product possesses characteristics of polyurethane and polysiloxane, the storage stability, mechanics property and comprehensive performance is increased and it mainly is used as pigmentum and aqueous industrial coating material.

Owner:山东圣光化工集团有限公司

High performance aerated concrete and production method thereof

InactiveCN101328041AImprove performanceLow shrinkageSolid waste managementCeramicwareUltimate tensile strengthFly ash

The invention discloses a high performance aerated concrete and a method for preparing the same. The product comprises fly ash and / or quartz tailing powder, lime, cement, desulfurization gypsum and aluminum powder pastes. The preparation method comprises steps of mixing and stirring, moulding and curing. The technology of the invention is unique and easy to operate. The fly ash and quartz tailing are made full use of, which changes waste into valuables. The prepared aerated concrete has advantages of good property, low shrinkage of 0.6-07, high intension and reduces the formation of the wall crack.

Owner:南通建工集团股份有限公司

Method for preparing gingko protein peptide

ActiveCN103609831AIncrease contentHigh extraction rateProtein composition from vegetable seedsVegetable proteins working-upFood additiveSide effect

The invention relates to a method for deeply processing gingko, and particularly discloses a method for preparing gingko protein peptide. The method mainly comprises the following steps: (1), processing raw materials; (2), preparing gingko powder; (3), preparing gingko protein powder; (4), carrying out primary enzymolysis; and (5), carrying out secondary enzymolysis to obtain gingko glycopeptides, amino acid balance peptide and gingko polypeptide products. The utilization of gingko resources is expanded, and new resources are provided for developing products with special functions. The method is special and simple in process, and low in production cost; the gingko protein peptide is safe without toxic and side effects; the novel preparation process of the gingko polypeptide product is developed, a new utilization field of the gingko is opened up. The gingko polypeptide prepared by adopting the method provided by the invention can be used as raw material for developing health care foods, food additives and medicine raw materials and excipients.

Owner:徐州绿之野生物食品有限公司

Process for producing soybean protein peptide using soybean as raw material

InactiveCN1500881AIncrease methionine contentNutrition scienceFermentationGlycopeptideTherapeutic effect

The present invention is the technological process of preparing soybean protein peptide with soybean as material. The technological process includes dissolving soybean protein, the first enzymolysis, centrifugal separation to obtain supernatant and precipitate; separating and enzymolyzing the supernatant and the precipitate, with soybean glycopeptide being obtained via enzymolyzing the supernatant; centrifugally separating the precipitate enzymolyzing product to obtain supernatant and precipitate for the second time; separately drying the the supernatant and the precipitate to obtain amino acid balanced peptide and soybean polypeptide separately. The technological process is unique and low in cost, and the products have nourishing and auxiliary treatment effects and no toxic side effect and may be used widely in medicine and health food.

Owner:陆晓民

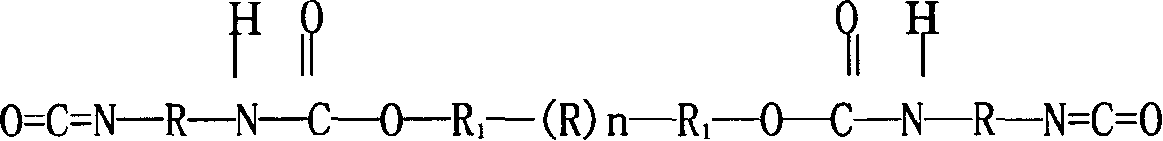

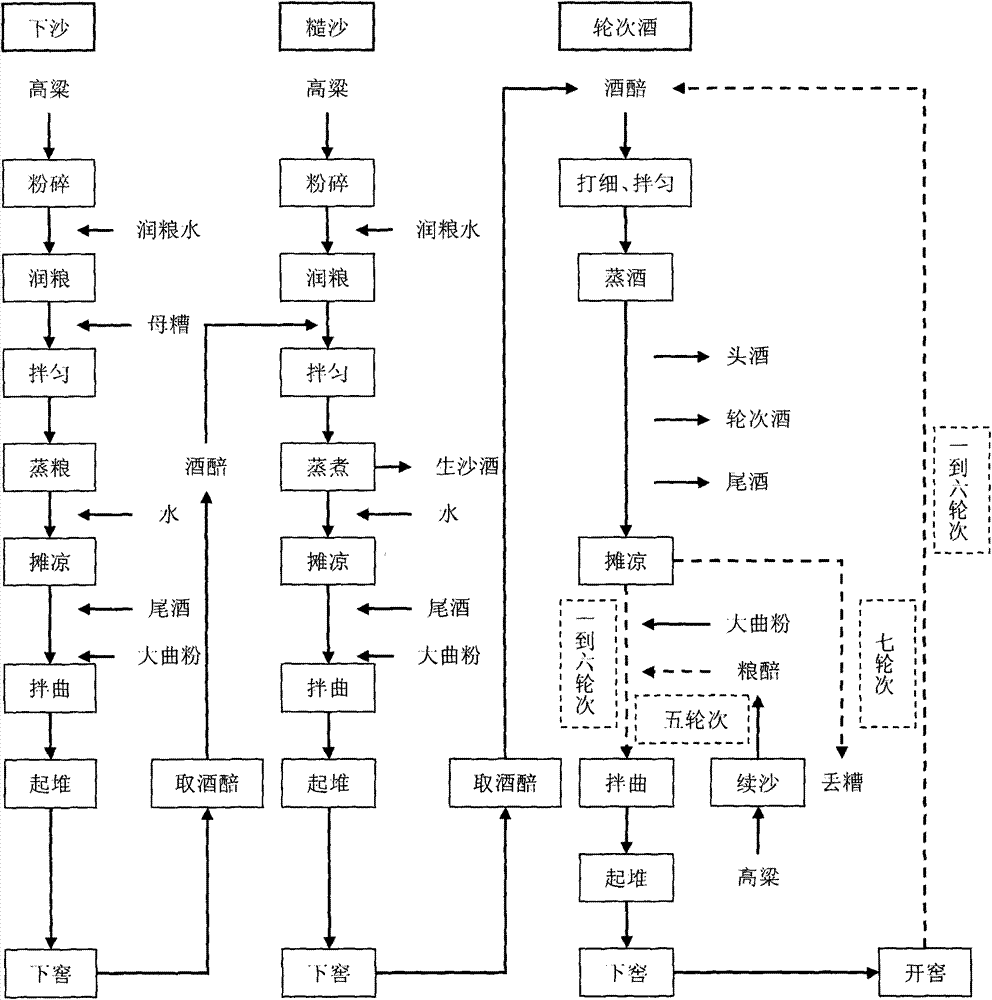

Mild thick-flavor white spirit and production method thereof

The invention belongs to the technical field of wine brewing and particularly relates to mild thick-flavor white spirit and a production method thereof. A brewing technique of the mild thick-flavor white spirit comprises the following steps: feeding raw materials for the first time; roughly treating the raw materials; feeding the raw materials for the second time; treating the raw materials; fermenting grains after the first to six wine taking in turn, and taking wine; double times of feeding, one time of raw material treatment, nine times of fermentation, ten times of stewing and seven times of wine taking are performed during one production period. The brewing technique is characterized in that in comparison with traditional thick-flavor white spirit, the mild thick-flavor white spirit disclosed by the invention is characterized in that the crushing rate of fed broomcorn, the amount of used yeast for preparing hard liquor, the amount of used grain wetting water and the stacking fermentation temperature are regulated; no pit bottom liquor is generated during production; the yield and the labor productivity are increased; the grain consumption and the energy consumption are reduced; the sour and bitter tastes of first and second produced wine, and the burned food taste of six and seven produced wine are reduced; the wine is mild, mellow, elegant and smooth in style, remarkable in thick flavor, and lasting in tail taste, and the fragrance can be retained in an empty cup for a long time.

Owner:贵州茅台酒厂(集团)保健酒业有限公司

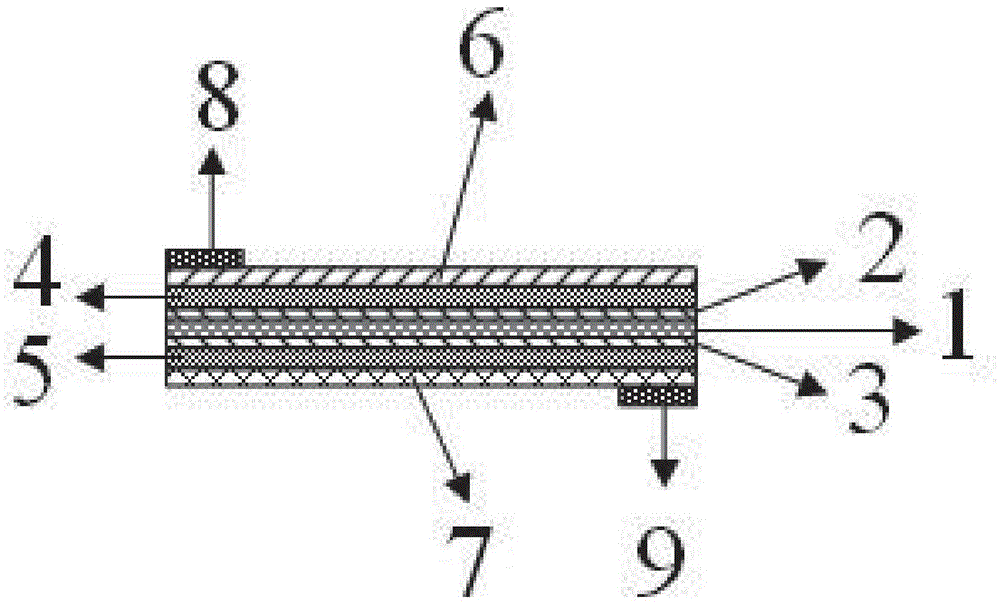

Flexible lithium ion battery and preparation method thereof

InactiveCN104485478AImprove efficiencyImprove cycle lifeFinal product manufactureElectrolyte accumulators manufactureComposite filmElectrical battery

The invention discloses a flexible lithium ion battery. The flexible lithium ion battery is composed of a case packaging and an electrical core packaged in the case packaging; the electrical core comprises a cathode and an anode, an upper extraction electrode arranged on the cathode, and a lower extraction electrode arranged on the anode; the electrical core also comprises a polymer electrolyte fire-retardant composite layer arranged at the middle part of the electrical core; the polymer electrolyte fire-retardant composite layer is a composite thin film composed of a polymer electrolyte layer arranged in the middle, and solid fire retardant layers arranged on the upper surface and the lower surface respectively. The invention also discloses a preparation method of the flexible lithium ion battery. The solid fire retardant-containing flexible lithium ion battery is high in efficiency, long in cycle life, and large in energy density, and is capable of satisfying electric energy demands of flexible electronic devices. The solid fire retardant is capable of improving safety performance of the flexible lithium ion battery effectively. The preparation method is unique, is convenient for processing and batch production, and is high in practical value.

Owner:东莞市鸿德电池有限公司

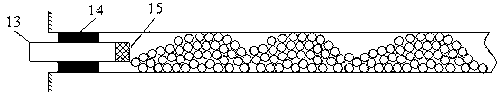

Method for preventing drilling collapse of downhole coal bed

ActiveCN103195471AStrong maneuverabilityUnique craftGas removalDrilling machines and methodsCoalDrill hole

The invention discloses a method for preventing drilling collapse of a downhole coal bed and belongs to a method for preventing drilling collapse. During constructing a gas extraction hole of the coal bed, a drill bit retreats a certain distance after arriving a finished hole position, porous materials in a porous material conveying device are conveyed to a reserved filling section of the front end of the drill bit through an inner hole of a drill rod by the aid of the compressed air. Then the porous materials are conveyed once when the drill bit retreats a certain distance each time until the drill bit retreats to a preset sealed hole position. Porous materials reserved in holes can support hole walls to prevent collapse, and meanwhile, gaps between the holes and the porous materials provide good passages for gas suction and flowing, gas of the coal bed can be guaranteed to leak from the drilled holes to some extent even if the drilled holes collapse. The method for preventing drilling collapse of the downhole coal bed has the advantages that system and process are unique, drilling gas extraction is high in flow and concentration, the method has widely practicality and is particularly applicable to drilling of the coal bed with firmness coefficient f smaller than 0.5.

Owner:CHINA UNIV OF MINING & TECH

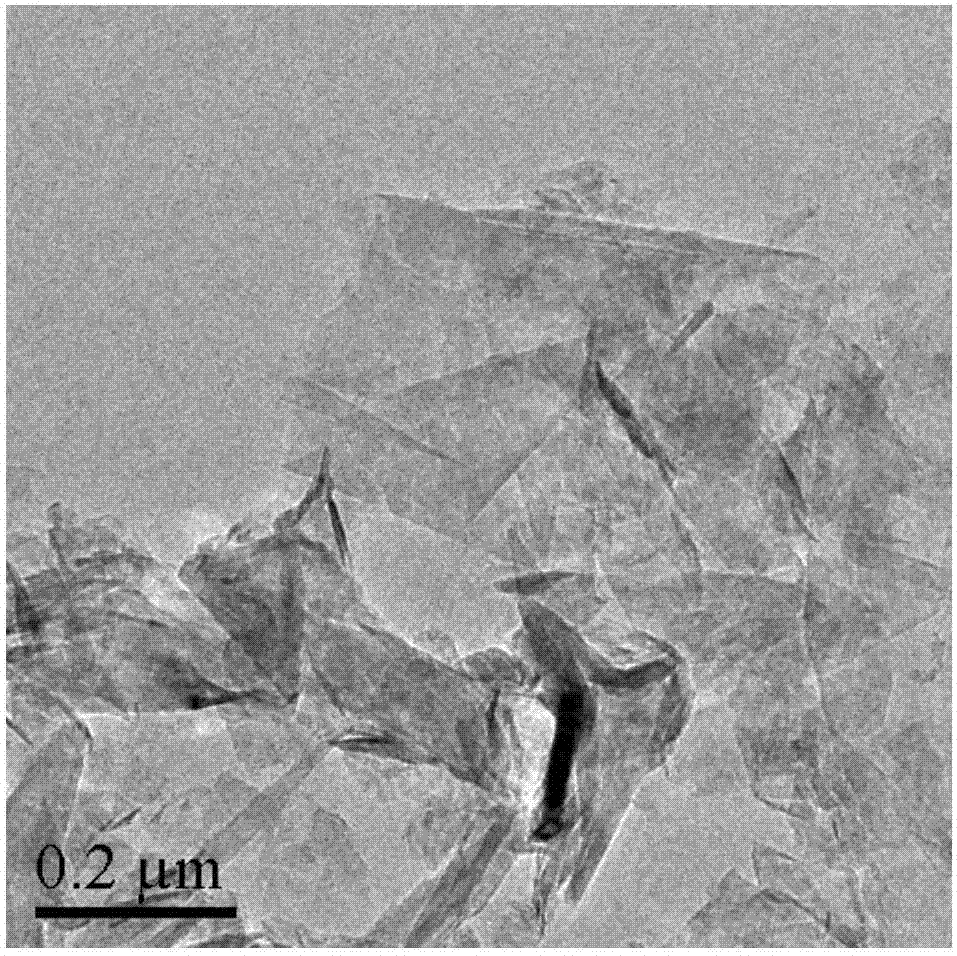

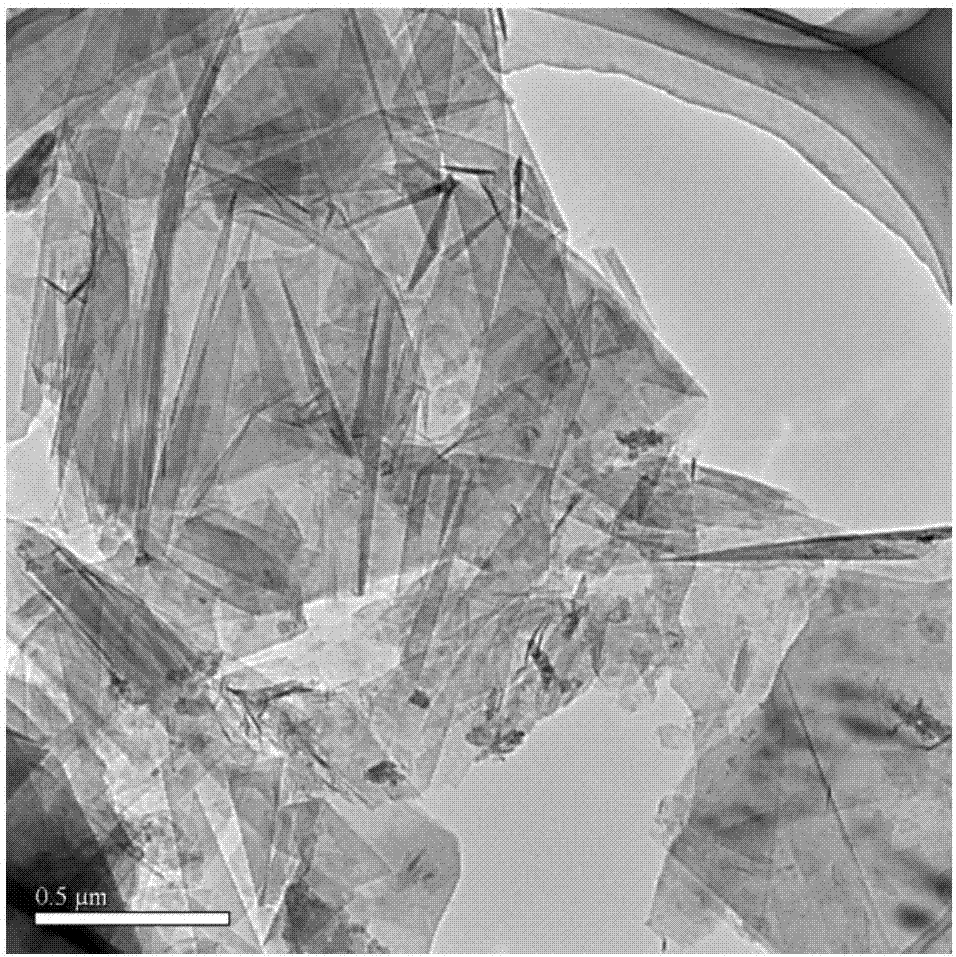

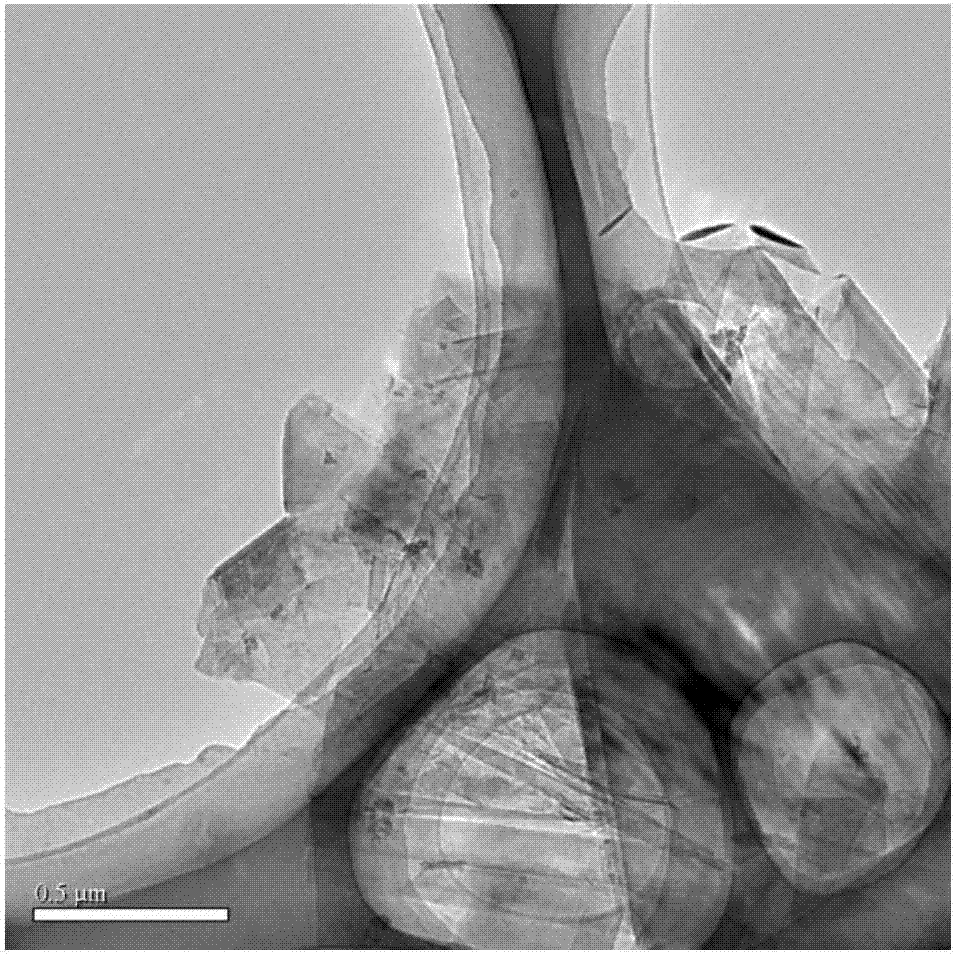

Method for preparing functionalized graphene by synchronous ultrasonic chemical and mechanical chemical method

InactiveCN107792848AIncrease concentrationUnique craftGrapheneBulk chemical productionDispersion stabilityChemical reaction

The invention discloses a method for preparing functionalized graphene by a synchronous ultrasonic chemical and mechanical chemical method. The method comprises the steps of adding a graphite raw material and a functionalized reagent into ultrasonic ball milling equipment, and carrying out ultrasonic ball milling for 1-72h at a rotating speed of 100-500rpm under an ultrasonic environment to obtainfunctionalized graphene containing functional groups. According to the method, graphite is stripped by synchronous ultrasonic ball milling to obtain graphene, and by virtue of ultrasonic chemical andmechano-chemical actions, the functionalized reagent and the graphene rapidly react chemically, and functionalized modification of the graphene is realized at the same time, so that the stripping efficiency and dispersion stability of the graphene are effectively improved, the structure and the performance of the graphene material are regulated and controlled, and the application field of the graphene material is expanded.

Owner:广东烯谷碳源新材料有限公司 +1

Method for producing environment-friendly particle board through continuous hot pressing of total eucalypt wood leftover material

ActiveCN106363714ASolve insufficient resourcesSave raw materialsLaminationLamination apparatusNational standardParticle board

The invention discloses a method for producing an environment-friendly particle board through continuous hot pressing of a total eucalypt wood leftover material. The method comprises the procedures like chipping, flaking, drying, two-time screening (veneer removing and grit removing), sorting and polishing, mixing glue, hot press molding, aftertreatment, sanding and board selecting. According to the method, the eucalypt wood leftover material is fully utilized, and the wood waste is reduced; the produced particle board reaches the national standard and meets the GB / T4897-2015 requirement in Particle Board and the GB18570-2001 requirement in Indoor Decorating and Refurbishing Materials Limit of Formaldehyde Emission of Wood-based Panels and Finishing Products; melamine impregnated paper can be pasted on the surface of a produced panel; and the particle board is manufactured into high-end desk panels, wardrobe and cabinet panels, partitions, wood floors, ceilings, and other panels.

Owner:广西华晟木业有限公司

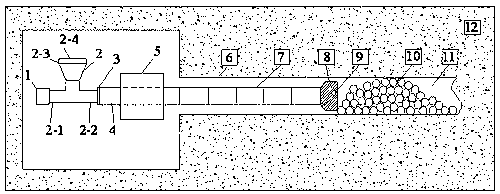

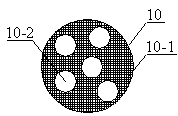

Multiple step type drilling and protecting integrated system and process for soft coal seam

ActiveCN102747953AEffective supportLarge diameterDrill bitsDirectional drillingWhole bodyAir compressor

The invention discloses a multiple step type drilling and protecting integrated system and a process for a soft coal seam. The system mainly comprises an air compressor, a high-pressure rubber hose, a hole protecting drilling machine, a rack, a hole protecting drilling rod, a guider and a simple drill. The process comprises the steps of firstly drilling a hole by using a common drilling rod and a common drill and pulling the common drilling rod and the common drill out of the hole after the hole is formed; then performing second drilling of the formed drill hole by using the hole protecting drilling rod and the simple drill in a matching mode, and simultaneously performing wind-power auxiliary slagging, when an end hole point is drilled, the hole protecting drilling rod is not withdrawn, the whole body is left inside the hole, and hole wall supporting and gas extraction functions are achieved; and finally pulling out and recycling the hole protecting drilling rod through the hole protecting driller after the gas extraction is completed. According to the system and the process, the process is unique, a hole protecting pipe can transmit high-pressure air and can extract gas, the coal dust discharging performance is strong, the hole protecting pipe moves forwards along the drill hole easily, the hole protecting pipe diameter is large, the hole protecting length is long, the problems that the soft coal seam is small in hole protecting pipe diameter and short in feeding distance are solved, and the system and the process are particularly suitable for soft high gas coal seams with a value of a sturdiness coefficient f, which ranges between 0.3 and 0.8.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of sweet soybean paste

The invention discloses a preparation method of sweet soybean paste, which comprises the following steps: (1) mixing and stirring raw materials and water to obtain a mixture 1; (2) steaming the mixture 1, and cooling the mixture 1 to room temperature; (3) inoculating a yeast starter to obtain a mixture 2; (4) performing low-temperature fermentation of the mixture 2 at 38-45 DEG C to obtain a mixture 3; (5) performing high-temperature fermentation of the mixture 3 at 45-52 DEG C to obtain a mixture 4; and (6) cooling the mixture 4 to 34-38 DEG C, and performing post fermentation to obtain the sweet soybean paste. The raw materials contain standard wheat flour, soybean powder and bran; and after the mixture 4 is cooled to 34-38 DEG C, the mixture 4 is mixed with Saccharomyces cerevisiae and / or lactobacilli, and then post fermentation is performed.

Owner:上海东锦食品集团有限公司 +1

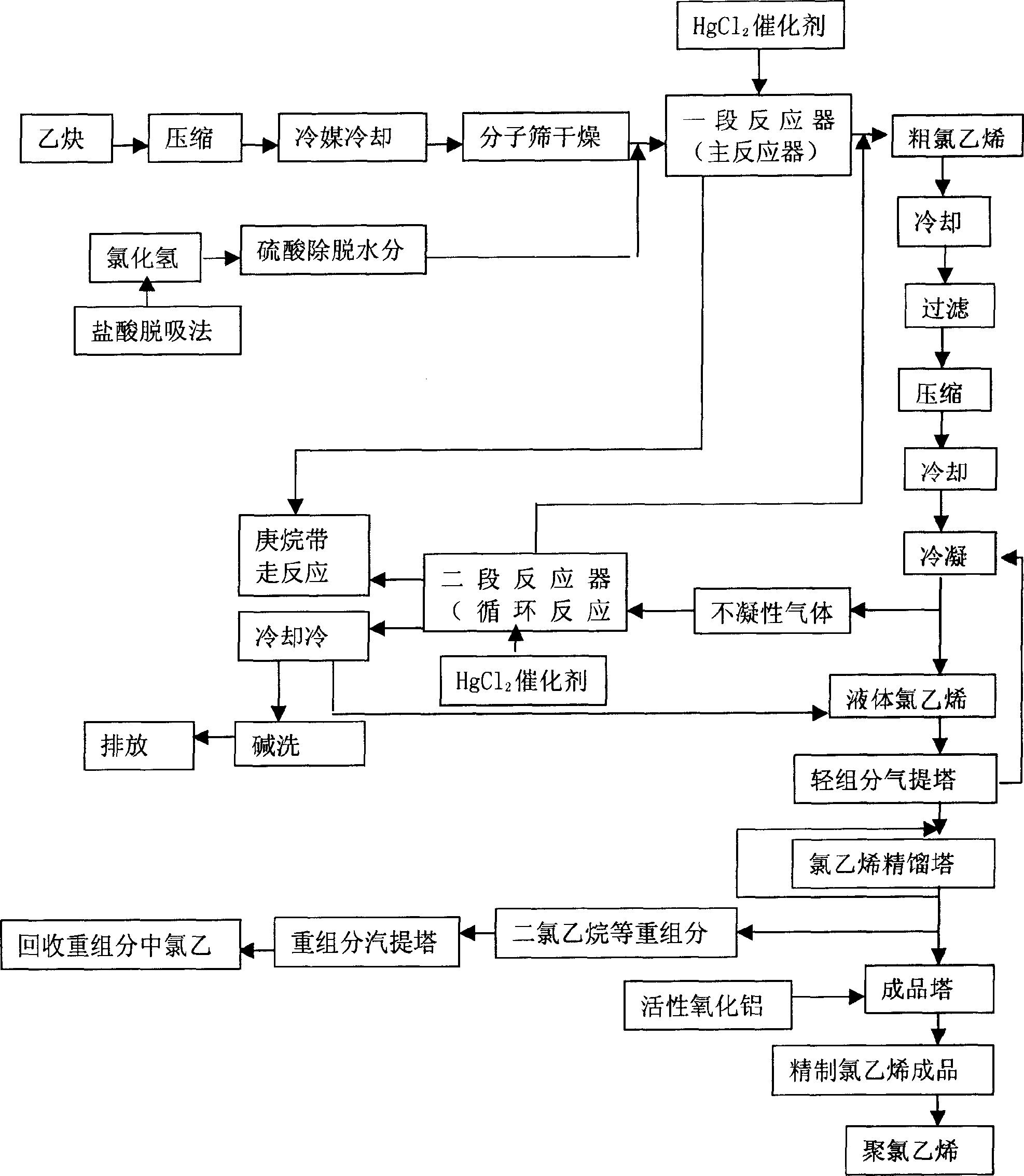

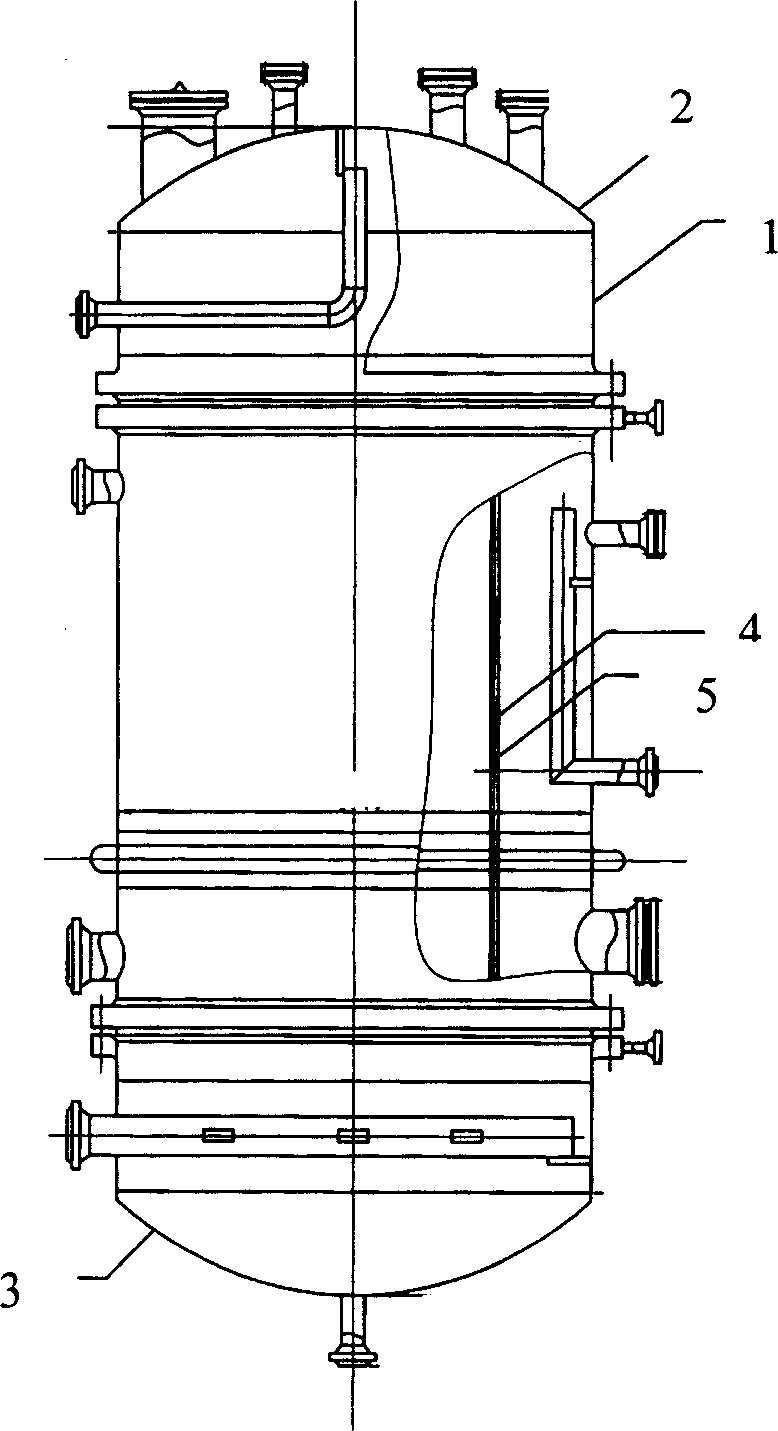

Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

InactiveCN1884241ASmooth responseAvoid corrosionPreparation by halogen halide additionSewage treatmentUltimate tensile strength

The invention discloses a new method of chloroethylene through acetylene method and specific equipment, which comprises the following steps: disposing raw material gas strictly; reacting two-segment compensation; recycling heptane; cooling; radiating; providing specific catalyst and reactor to synthesize chloroethylene; disposing effluent with mercury to obtain high-purity chloroethylene monomer.

Owner:刘大军

Medicine composition, preparing method and use for preparing gynacecopathia medicine

A Chinese medicine in the form of tablet, capsule, powder, particles, oral liquid, or injection for treating gynopathy is prepared from 10 Chinese-medicinal materials including ginseng, cnidium fruit, astragalus root, mother wort, etc through unique process. Its advantages are quickly taking its effect, high cure rate and short course of treatment.

Owner:HARBIN OT PHARMA

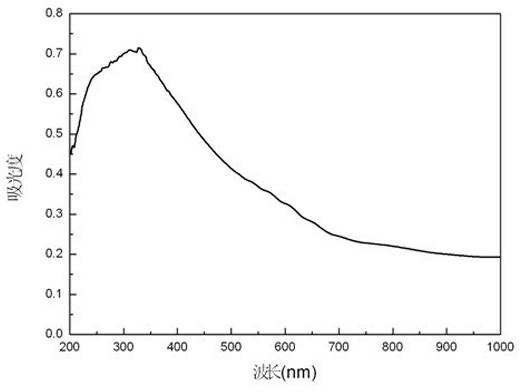

Method of producing graphene by stripping graphite via time-space-synchronous ultrasonic treatment and ball-milling process

The invention discloses a method of producing graphene by stripping graphite via time-space-synchronous ultrasonic treatment and a ball-milling process. The method includes the steps of: adding a graphite raw material and a stripping reagent into an ultrasonic ball milling device and performing ball milling for 2-96 h under an ultrasonic environment; and separating, washing and drying the mixtureto obtain graphene powder. Through the time-space-synchronous ultrasonic treatment and the ball-milling process, the graphite is stripped; due to the synergistic effect of the two methods, interlayerin-situ expansion of the graphite is formed and meanwhile a strong shear force is applied to the graphite during ball milling. The method is high in efficiency and yield and is suitable for large-scale production of graphene.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

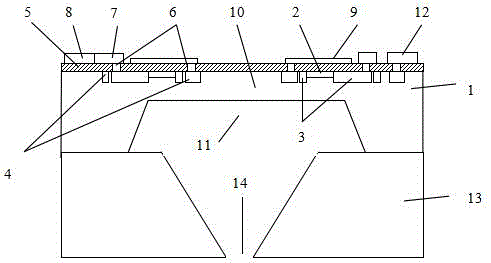

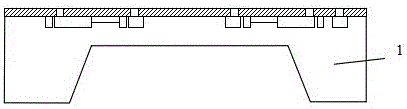

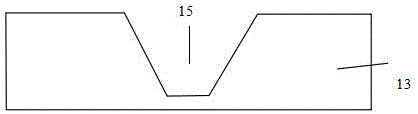

Manufacturing method of high-precision pressure sensor based on silicon-silicon bonding

ActiveCN106153221AEnsure finishing control accuracyReduce distortionForce measurement using piezo-resistive materialsBonding processOptoelectronics

The invention discloses a manufacturing method of a high-precision pressure sensor based on silicon-silicon bonding. The high-precision pressure sensor comprises a sensitive silicon wafer layer and a substrate silicon wafer layer and is characterized in that the substrate silicon wafer layer is connected to the back of the sensitive silicon wafer layer, and the sensitive silicon wafer layer and the substrate silicon wafer layer use silicon-silicon bonding process to form a pressure sealing cavity; the substrate silicon wafer layer and the sensitive silicon wafer layer are made of homogenous monocrystalline silicon materials, and the substrate silicon wafer layer is provided with a pressure guide through hole in the center. The manufacturing method has the advantages that the substrate silicon wafer layer and the sensitive silicon wafer layer are made by using the monocrystalline silicon materials as the substrates, the substrate silicon wafer layer and the sensitive silicon wafer layer are connected in an airtight manner through the silicon-silicon bonding process, the pressure sealing cavity of a silicon-silicon homogenous material structure is formed, various influences, caused by the pressure sealing cavity of the silicon-glass heterogeneous material structure of a conventional pressure sensor, on the performance of the sensor due to the feature difference of two different materials are avoided, static pressure errors are reduced effectively, temperature excursion of the sensor is lowered, and the comprehensive precision of the sensor is increased.

Owner:SHENYANG ACAD OF INSTR SCI

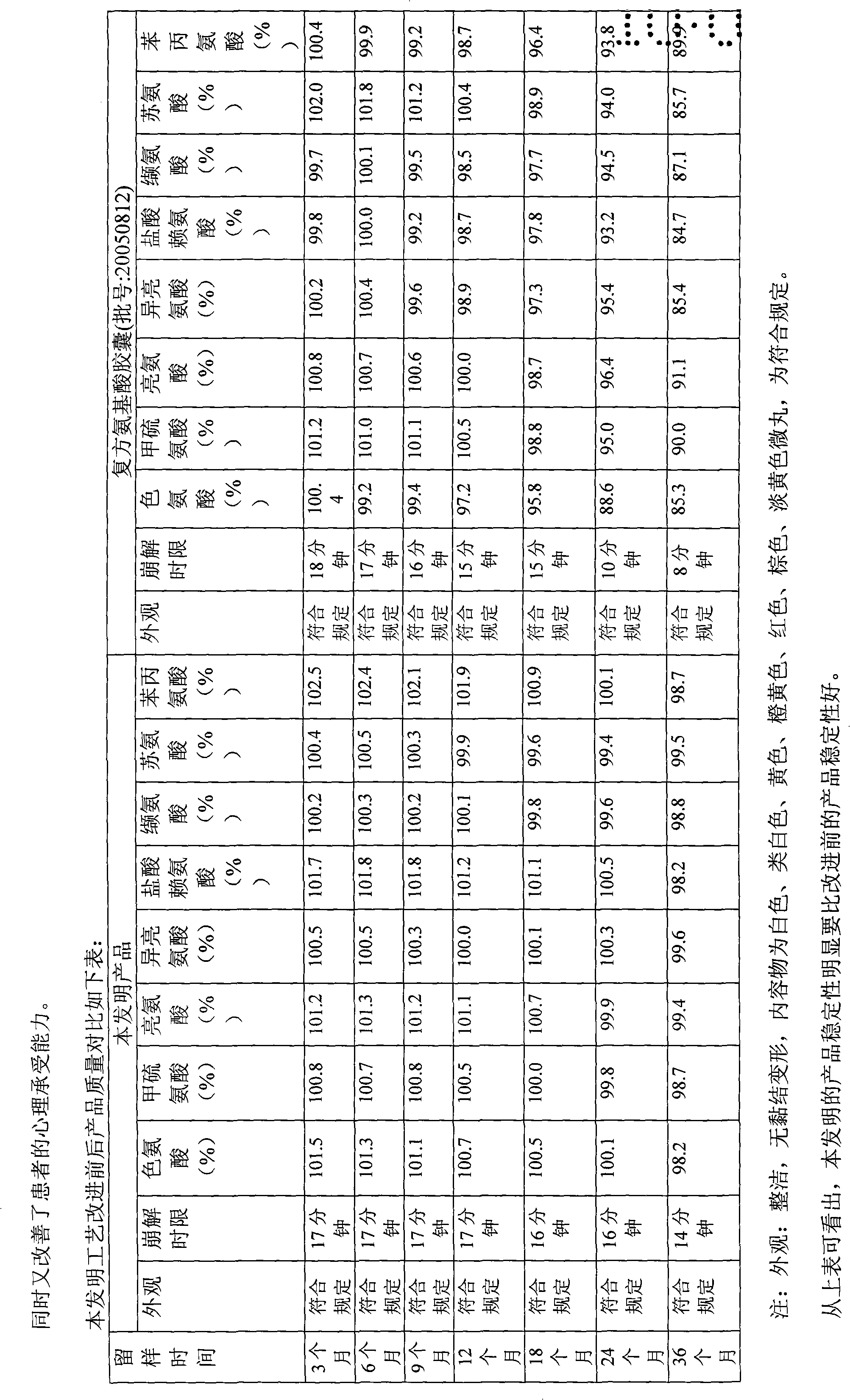

8-amino acid/11-vitamin containing micro granule capsule and preparation method thereof

ActiveCN101773512AImprove bioavailabilityUnique craftPeptide/protein ingredientsHydroxy compound active ingredientsDiseaseLiver and kidney

The invention discloses an 8-amino acid / 11-vitamin containing micro granule capsule and a preparation method thereof, wherein the micro granule capsule contains 7 ball micro granules consisting of the following raw materials in part by weight: 2.66-9.9 parts of thiamine mononitrate micro granule, 16.35-20.5 parts of vitamin micro granule a, 35.0-44.1 parts of amino acid micro granule a, 11.4-14.4 parts of vitamin micro granule b, 6.65-10.5 parts of amino acid micro granule b, 12.73-16.0 parts of vitamin C micro granule and 5.7-9.36 parts of vitamin AD micro bead. The method has the advantages of scientific and reasonable proportion, good stability of products, no toxicity and side effect and excellent biological effect, and can be used for the preparation of medicines treating chronic liver and kidney diseases and of food alleviating and eliminating physical fatigue caused by sports training.

Owner:SHENZHEN WANHE PHARMA

Method for casting ultralong, large-sized machine tool casting parts

ActiveCN101439398AIncrease stiffnessPrevents wall displacementFoundry mouldsFoundry coresMachine toolCasting

The invention relates to a method for casting a machine tool casting, in particular to a method for casting an overlong large machine tool casting. The invention is characterized in that the method comprises the steps as follows: preparing a pit, manufacturing a casting model, molding, making a core, pressing a box, pouring, shaking out sand normally and blasting ball. The invention provides the method for casting the overlong large machine tool casting. The technical method is unique, combines EPS with a wood pattern main frame mold and uses a casting technology of molding in the pit, and the invention can reduce the expense for producing tool equipment and solve the casting difficulty that the overlong large casting has the size problems such as being deformed easily during the production.

Owner:KOCEL EQUIP

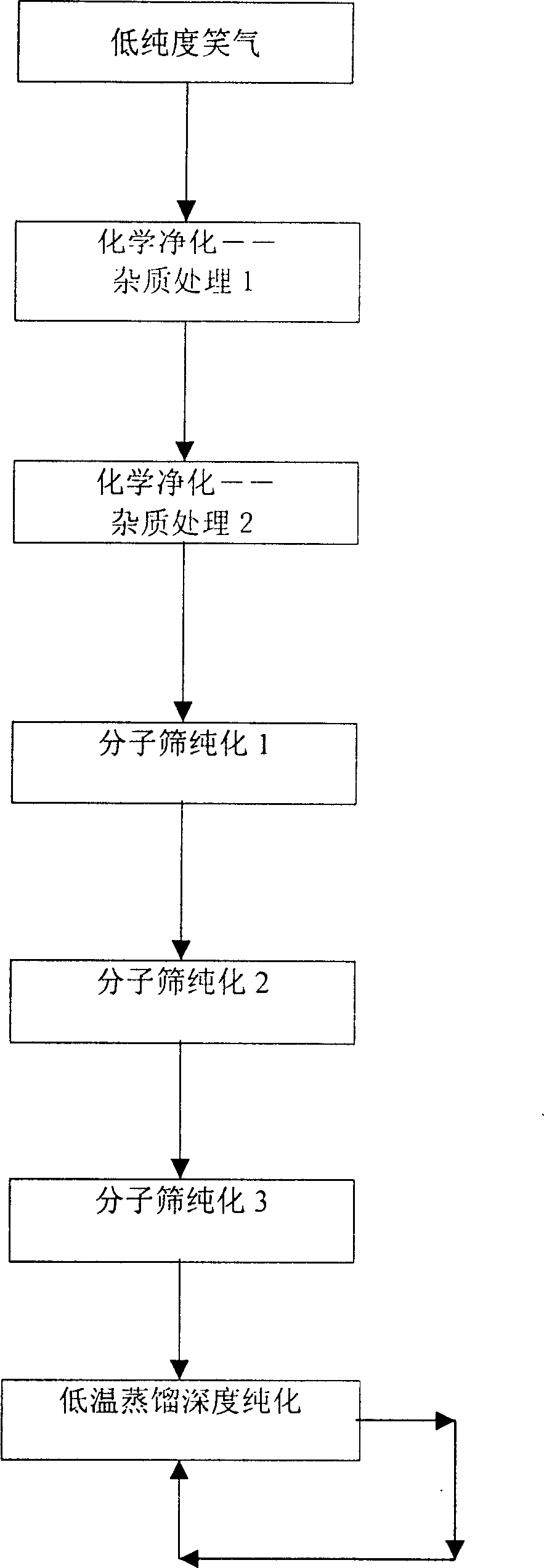

Electronic-grade dental gas purification process

The invention relates to a refinement process for electronic grade laughing gas. Its flow process is as follows: laughing gas of low purityí·chemical purificationí·molecular sieve purification, heatingí·low temperature distillation for deeper purificationí·electronic grade laughing gas. The invention applies molecular sieve and low temperature distillation to remove impurity in laughing gas and produces raw laughing gas with wet-type heating method, so its safety coefficient is improved a lot, possesses the characteristic of unique craft, convenient operability and full localization of manufactures. Furthermore, it has the quality of advanced world level, replacing import goods and exporting abroad.

Owner:GUANGZHOU SENYIN GAS

Method for making green plum fruit wine

InactiveCN101942373AInnovativeUnique craftAlcoholic beverage preparationMicroorganism based processesYeastFruit wine

The invention discloses a method for making green plum fruit wine. Green plum fruits are used as a raw material. The method for making the green plum fruit wine comprises preparation of a culture medium, pulp blending, amplified culture of active dry yeast, main fermentation, post fermentation, blending, inspection and storage. The method has the advantages of innovativeness of the fermentation process, unique process, low cost, full space utilization and capability of improving the utilization rate and comprehensive economic value of the green plum resource; and the brewed green plum fruit wine has high total flavone content (141.48mg / L), high wine yield (260.1 percent) and high alcoholic strength (10.2 percent).

Owner:ANHUI AGRICULTURAL UNIVERSITY

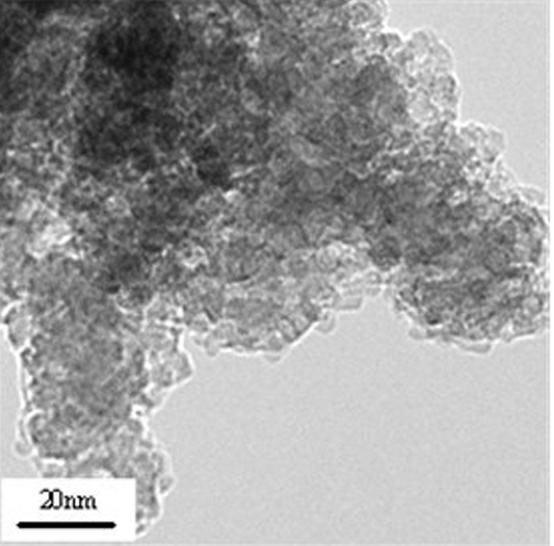

Method for preparing indium vanadate nano particles

InactiveCN102602997AUnique craftCrystallize fastNanotechnologyVanadium compoundsNanoparticlePotassium hydroxide

The invention relates to a method for preparing indium vanadate nano particles, The method comprises the steps of: dissolving indium nitrate, ammonium metavanadate and hexadecyl trimethyl ammonium bromide in water, mixing according to the mol ratio of indium to vanadium of 1: (1 to 2), then adding the hexadecyl trimethyl ammonium bromide according to a mol ratio of indium to vanadium to hexadecyl trimethyl ammonium bromide of 1: (1 to 2): (0.02 to 0.05), stirring for 10 to 12h, regulating a pH value to 8 by utilizing potassium hydroxide, and filtering, washing and drying generated precipitate to obtain solid powder; and mixing the solid powder with 10mol / L of potassium hydroxide solution according to a mass ratio of 1: (25 to 50), then putting into a reactor to have hydro-thermal treatment for 8 to 24h at the temperature of 150 to 180 DEG C to obtain an indium vanadate precursor, and drying the indium vanadate precursor and then placing into a muffle furnace to be baked for 1 to 2h at the temperature of 450 to 550 DEG C and then naturally cooling to obtain the indium vanadate nano particles. The method has the advantages of simpleness in operation, relatively low synthesized temperature, controllable appearance shape and high photocatalytic activity of the indium vanadate nano particles; and the application field of an indium vanadate nano material can be further widened.

Owner:CHANGSHA UNIVERSITY

Artificial texture stone and production method thereof

The invention provides an artificial texture stone and a production method of the artificial texture stone. The method comprises the following steps of: preparing main color slurry and auxiliary color slurry; pouring the main color slurry and the auxiliary color slurry onto a material guide rail, and forming a pre-mixed colorful slurry body with different colors and different textures through helical push; making the pre-mixed colorful slurry body naturally flow into a die to form naturally flowing color textures; and forming. According to a formula and the production method for the artificial texture stone which is scientific in component proportion and rational in process, the process is unique, and the cost is low; the produced product is outstanding in surface texture, and the textures are vivid; and the decoration effect of the product is enhanced.

Owner:SHANGHAI APE STONE

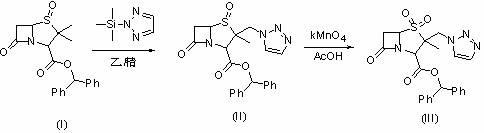

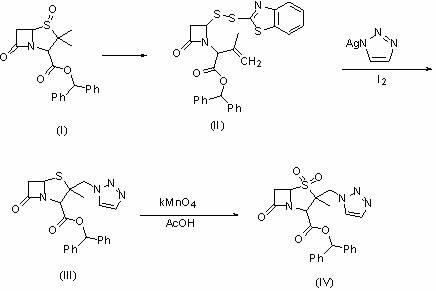

Method for preparing 2 beta-methyl penicillanate benzhydryl dioxide

ActiveCN102304139AIncreased nucleophilic reactivityReduce pollutionOrganic chemistryAcetic acidCupric bromide

The invention provides a method for preparing a 2 beta-methyl penicillanate benzhydryl dioxide, which is to prepare the 2 beta-methyl penicillanate benzhydryl dioxide by four-step reactions. In the method, hydrobromic acid and sodium nitrite or cupric bromide serving as a brominating agent and other methods are adopted, especially bromide is generated by using adsorption of anionic resin, and water is a side product, so that the method is safe and environmentally friendly; the resin can be used repeatedly; the reaction molar yield can be remarkably improved, reaching over 75 percent; and dichloromethane, water, little glacial acetic acid, particularly as well as a catalytic amount of concentrated sulfuric acid are used to replace massive glacial acetic acid serving as a solvent, so that massive glacial acetic acid is removed. The method has unique process, stable product quality, mild process condition and easy control, the traditional azidation reaction and ethynylation reaction are eliminated, the production cost is reduced, the environmental pollution is greatly reduced, and no special equipment is required. The method is suitable for industrial generation in scale.

Owner:JIANGXI FUSHINE PHARMA CO LTD

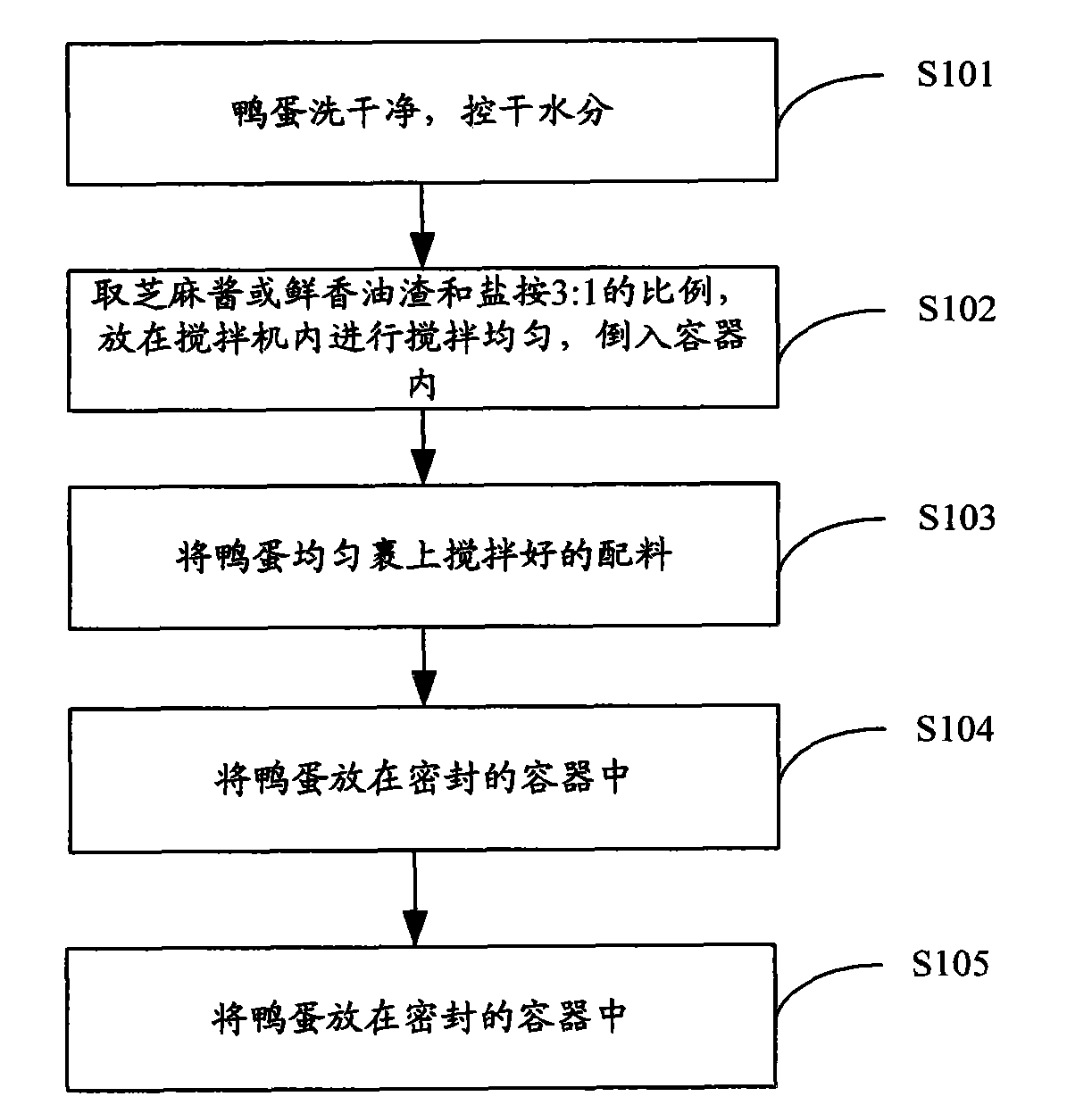

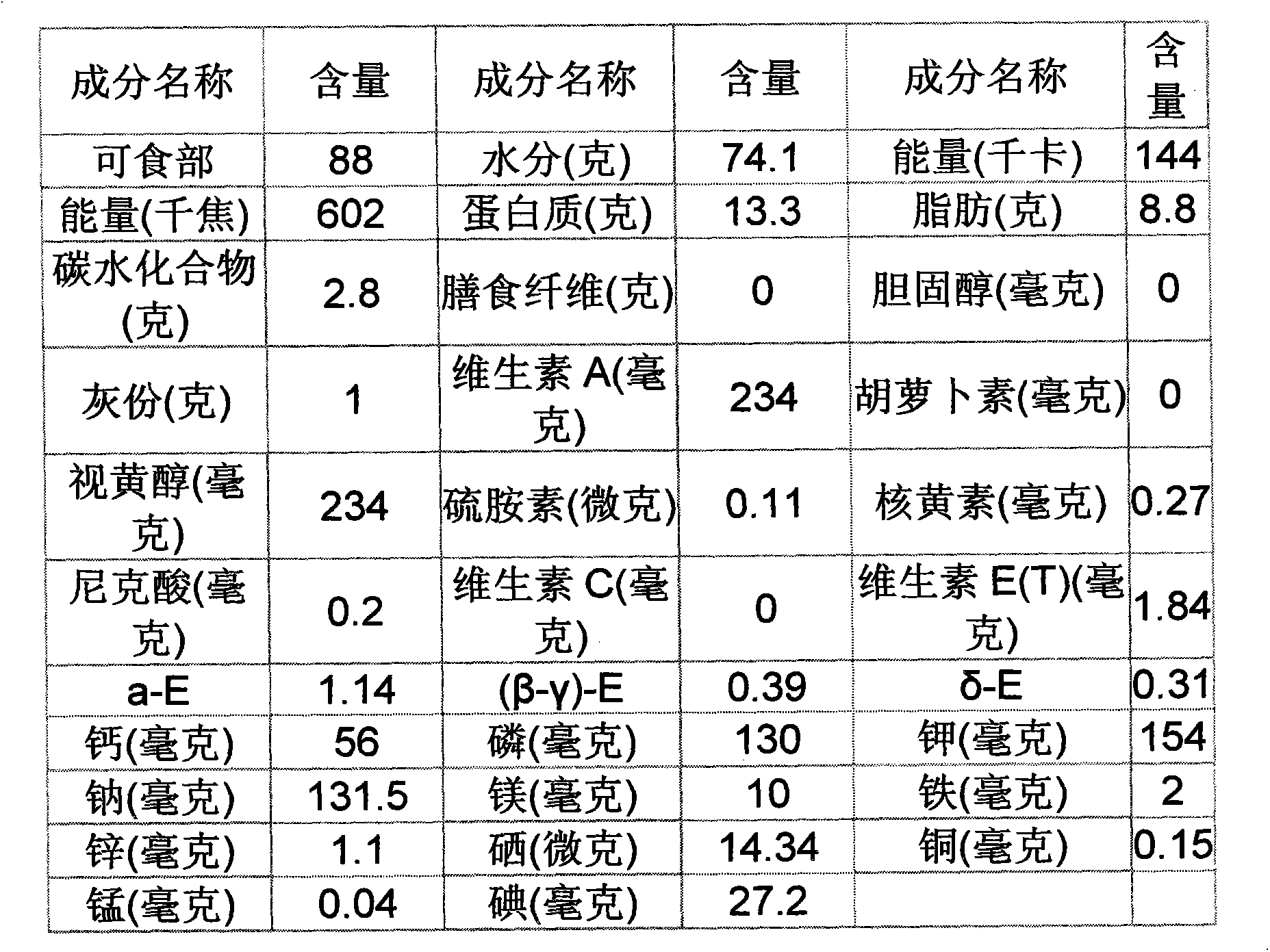

Salting method for sesame paste flavored salted duck eggs

The invention discloses a salting method for sesame paste flavored salted duck eggs. The salting method comprises the following steps of: cleaning duck eggs and drying the cleaned duck eggs; uniformly mixing sesame paste or fresh sesame oil residues with salt in the ratio of 3:1 in a mixer, and pouring the mixed ingredients into a container; evenly coating the mixed ingredients on the duck eggs; putting the duck eggs into a sealed container; and storing the container at a shady, cool and ventilate place without light for 30-40 days at 15-20 DEG C. The sesame paste flavored salted duck eggs produced by the method have soft and oily yolks and pale yellow egg whites, have the flavor of sesame paste, can be eaten after being washed and cooked for 10min, and are preferably cooked by a pressure cooker. The sesame paste flavored salted duck eggs can be stored for six months at a shady, cool and dry place, have delicate and pale yellow in egg whites, soft and bright yolks and the flavor of sesame paste, and are special in technology, thick in mouth feel, rich in nutrition, green, pollution-free and convenient to eat.

Owner:泰安马拉磨油脂调料有限公司

Method for synthesizing high molecular retanning dyeing auxiliary agents through enzyme catalysis

InactiveCN101870990AImprove permeabilityImprove absorption rateTanning treatmentDyeing processSodium bicarbonateDye absorption

The invention relates to a method for synthesizing high molecular retanning dyeing auxiliary agents through enzyme catalysis, which comprises the following steps: dissolving p-aminobenzene sulfonic acid and 2, 3-dihydroxy naphthalene-6-sodium sulfonate into de-ionized water, using a sodium bicarbonate solution for regulating the pH value of the system, and finally, obtaining the retanning dyeing auxiliary agents through co-polymerization reaction carried out under the horse radish peroxidase (HRP) catalysis. The invention uses HRP as catalysts of the polymerization reaction, and the HRP has the advantages of high efficiency, high selectivity and environment protection when being used for catalyzing the polymerization. The invention has the advantages that phenols or arylamines can carry out polymerization in ortho positions or para positions of hydroxide groups and amino groups for forming a polymer with directly connected C-C structures and large pi conjugated systems, the formaldehyde pollution in the traditional synthesized retanning agents is avoided, and at the same time, the products with the conjugated systems contain a large number of auxochromic groups such as -NH2, -OH and -SO3H and the like. Retanning leather is full and soft, and the dye absorption rate is higher than 99 percent, and in addition, the retanning dyeing auxiliary agents have obvious dyeing aid effect.

Owner:SHAANXI UNIV OF SCI & TECH

Surface graphene-coated high-capacity spherical hard carbon negative electrode material

ActiveCN107026262AWide variety of sourcesConvenient sourceCell electrodesGrapheneReduction treatmentMicrosphere

The invention relates to the technical field of a lithium ion battery, specifically to a surface graphene-coated high-capacity spherical hard carbon negative electrode material. The negative electrode material is characterized by comprising the following processing steps of (1) preparing a hard carbon precursor; (2) preparing polymer microspheres; (3) preparing spherical hard carbon; (4) preparing a graphite oxide coating body; and (5) performing carbonization and thermal reduction treatment. Compared with the prior art, the spherical hard carbon in the inner core has the advantages of unique appearance and good pore diameter distribution, uniform particle granularity distribution, high stacking density and the like; and the spherical hard carbon surface coating graphene forms the conductive network of the core-shell structure, so that ion and electron transmission can be facilitated, thereby improving the electrical conductivity of the negative electrode material.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Needle bush fiber paper yarn and preparation method for same and application

ActiveCN106222828APromote degradationImprove protectionNatural cellulose pulp/paperWater-repelling agents additionYarnFiber

The invention relates to a needle bush fiber yarn and a preparation method for the same and application. The paper yarn is mainly made of main material and auxiliary material according to weighty by parts. The main material comprises 100 parts of needle bush slurry; the auxiliary material is formed by 0.04 to 0.06 parts of softener, 0.06 to 0.08 parts of water-repellent agent and microscale of dyeing agent. The paper yarn preparation step is formed by first, preparing slurry, in which needle bush is pulped with water, second, adding auxiliary material and evenly stirring, third, making paper, in which making paper slurry into thin weaving paper with weight of 11 to 22g, fourth, slitting the paper into paper strips with 2 to 4mm width, and fifth spinning, in which twisting the elongated paper strip into 21 to 32 paper yarns. The paper yarn can be applied to paper-made socks, underwears, knitting shirts, paper towel, paper shoes and paper caps and great ventilation and water absorption can be achieved; sweat can be absorbed and bacteria can be resisted and odor can be eliminated; and the needle bush fiber paper yarn can be recovered, thereby causing no pollution to the environment.

Owner:太仓兴鑫纸业有限公司

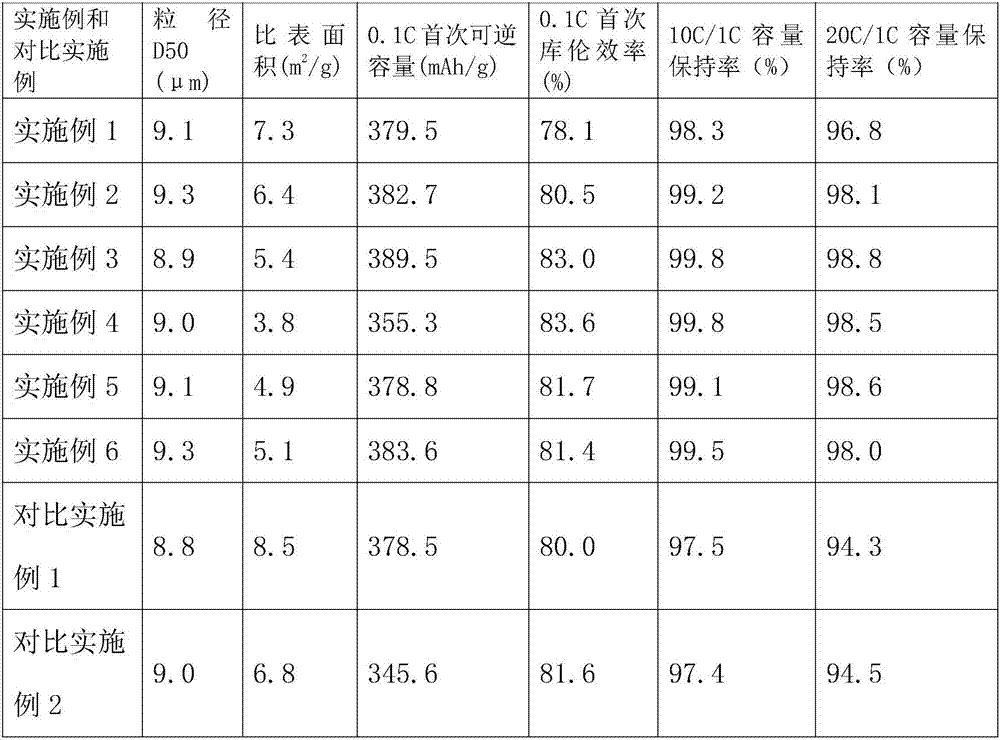

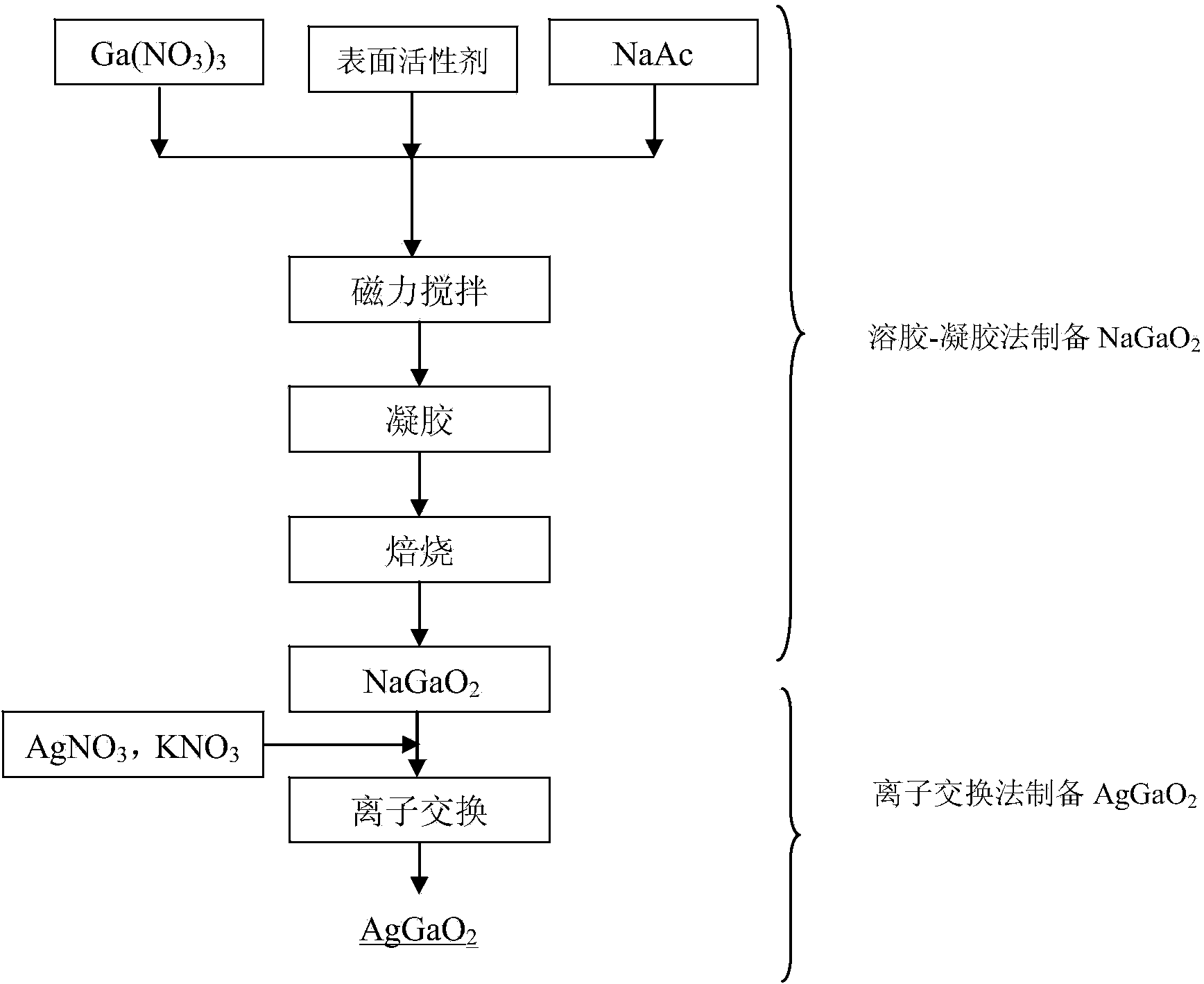

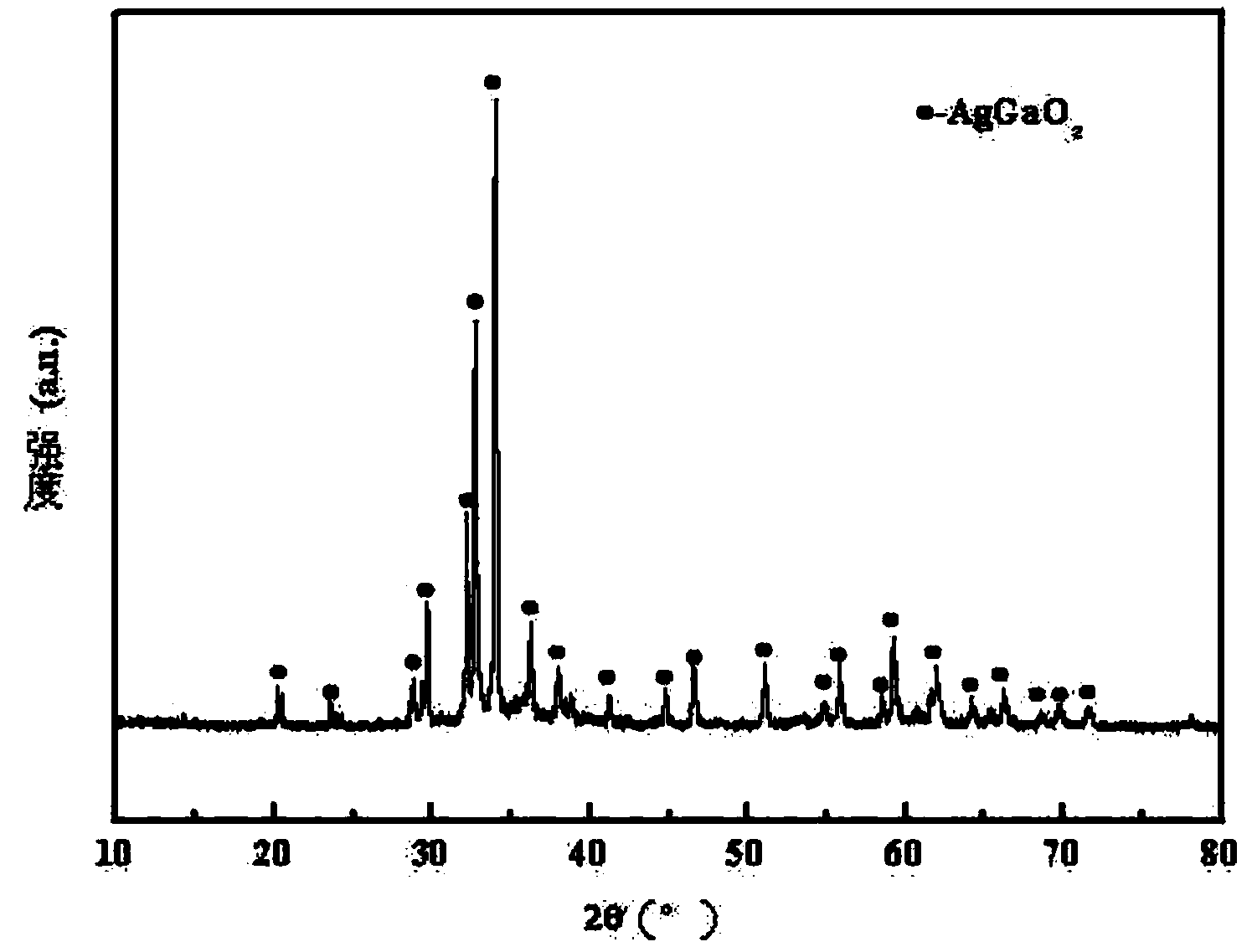

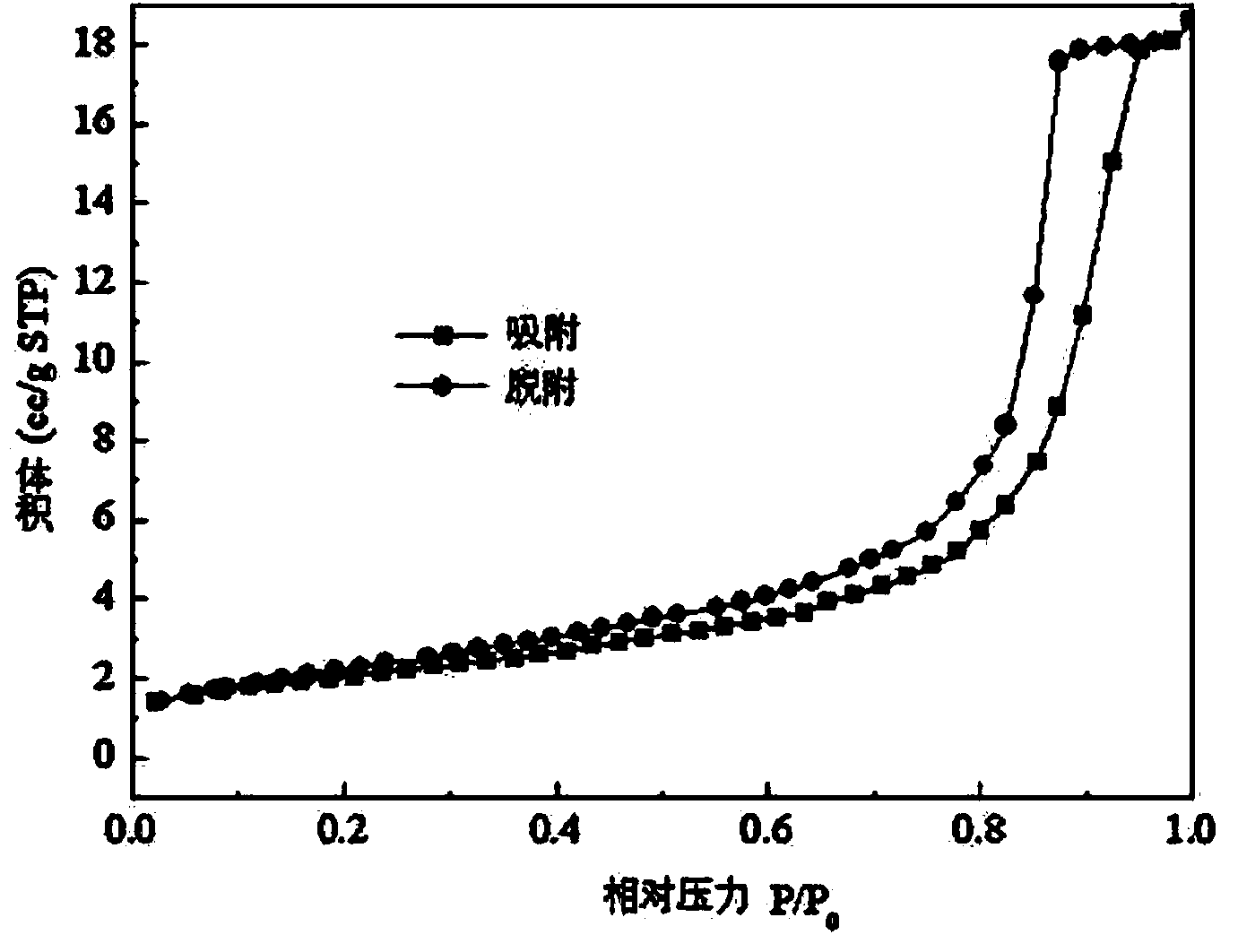

Method for preparing mesoporous AgGaO2 photocatalytic material

InactiveCN103447033AHigh activityFacilitate chemical reactionsGallium/indium/thallium compoundsMetal/metal-oxides/metal-hydroxide catalystsIon exchangeMetal

The invention relates to a method for preparing a mesoporous AgGaO2 photocatalytic material. The mesoporous AgGaO2 photocatalytic material is prepared through two steps. Firstly, mesoporous AgGaO2 is prepared by the utilization of the sol-gel method, and then, the prepared AgGaO2 is used as a raw material to be synthesized to form AgGaO2 through the ion exchange method. The method has the advantages of being unique in technology and convenient to operate. The prepared mesoporous AgGaO2 is large in specific surface area, adjustable and controllable in pore structure and high in photocatalysis activity, and has broad application prospects in the fields such as indoor air purification. The method for preparing the mesoporous AgGaO2 photocatalytic material can provide a new idea for optimization design and large-scale preparation of other novel polybasic metallic oxide photocatalytic materials containing silver.

Owner:CHANGSHA UNIVERSITY

Compound amino acid capsule including eight amino acids and eleven vitamins

ActiveCN103142633AImprove bioavailabilityUnique craftHydroxy compound active ingredientsPeptide/protein ingredientsThiamineVitamin C

The invention relates to a compound amino acid capsule (8-11) and a preparation method thereof, specifically to a capsule including pellets of eight amino acids and eleven vitamins and a preparation method thereof. The capsule comprises 7 spherical pellets which are composed of the following raw materials by weight: 2.66 to 9.9 parts of a thiamine mononitrate pellet, 16.35 to 20.5 parts of a vitamin pellet a, 35.0 to 44.1 parts of an amino acid pellet a, 11.4 to 14.4 parts of a vitamin pellet b, 6.65 to 10.5 parts of an amino acid pellet b, 12. 73 to 16.0 parts of a vitamin C pellet and 5.7 to 9.36 parts of a vitamin AD bead. The capsule provided by the invention has the advantages of a scientific and reasonable ratio, good stability, no toxic and side effects, high security and good biological effects and can be applied in preparation of medicines used for treating chronic liver and kidney diseases and of foodstuffs used for alleviating and eliminating physical fatigue caused by exercise training. The capsule provided by the invention has characteristics superior to those of the prior art.

Owner:SHENZHEN WANHE PHARMA

Preparation method of water-base spraying coating for large-size iron casting

ActiveCN103878303AImprove rheologyImprove spraying effectFoundry mouldsFoundry coresWater basedSpray coating

The invention relates to a production method of a fireproof coating for a sand mould casting and particularly relates to a preparation method of a water-base spraying coating for a large-size iron casting, which is used for a large-size thick-wall iron casting and is suitable for a spraying coating process. The method comprises the following steps: adding water into a high-speed dispersion kettle; starting electric agitation; slowly adding hydroxypropyl methyl cellulose; after adding the material, continuing to agitate; adding sodium pentachlorophenate, an organic silicon de-foaming agent and an activating agent into the dispersion kettle; starting the electric agitation and slowly adding attapulgite into the dispersion kettle while keeping high-speed agitation; after adding the material, dispersing; sequentially adding PVA (Polyvinyl Acetate), ethyl silicate and aluminum sulfate into the dispersion kettle; after adding the material, dispersing; sequentially adding bauxite and sillimanite into the dispersion kettle under an agitating state; after adding the material, finishing dispersion; discharging and packaging. The production method provided by the invention is unique in raw materials and process, high in environmental protection coefficient, excellent in coating rheological property and good in spraying performance; the coating is easy to sinter and is particularly suitable for the large-size iron casting.

Owner:共享新材料(山东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com