Method of producing graphene by stripping graphite via time-space-synchronous ultrasonic treatment and ball-milling process

A technology of exfoliating graphite and ball milling, which is applied in the direction of graphene and nano-carbon, can solve the problems of low yield of graphene, low production efficiency, and low yield, and achieve the effects of controllable cost, mild conditions and unique process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

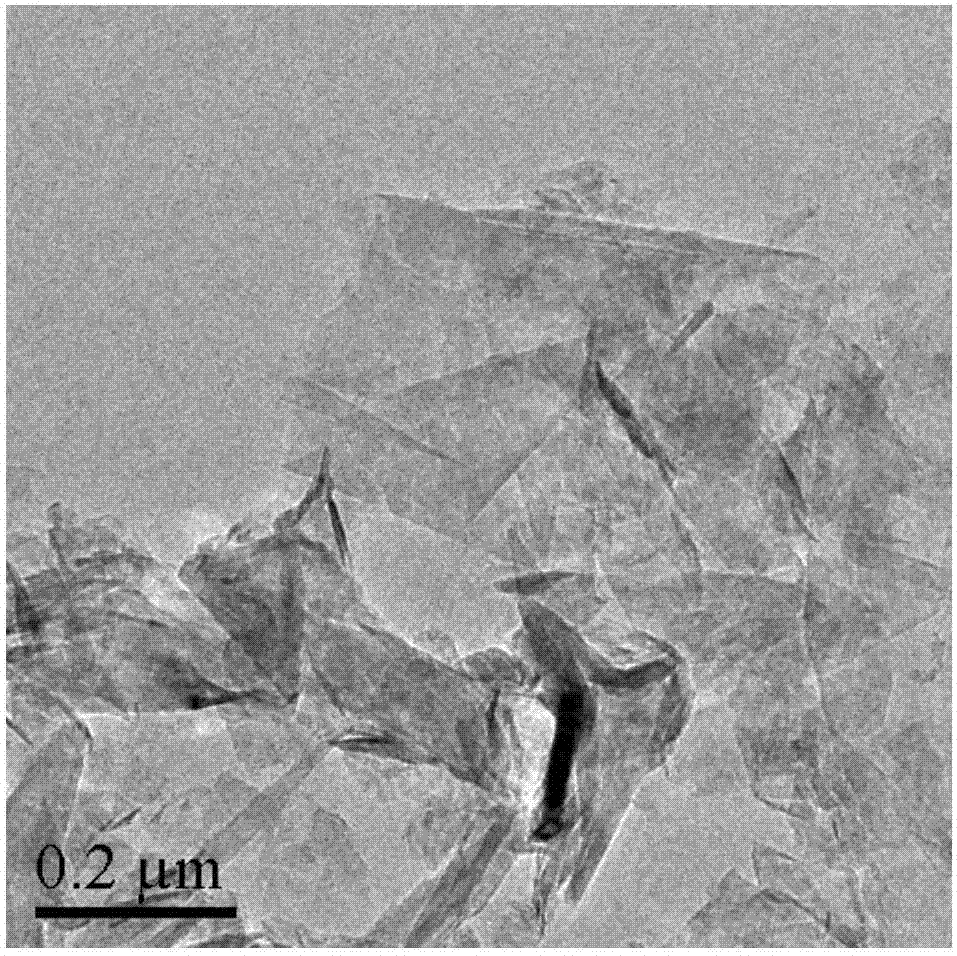

Image

Examples

Embodiment 1

[0026] 5g of graphite and 50mL of N-methylpyrrolidone were put into an ultrasonic ball mill, the ultrasonic power was controlled at 1.5kW, and the milling speed was 500rpm. After ultrasonic milling for 2 hours, the product was separated, washed, and dried to obtain graphene powder.

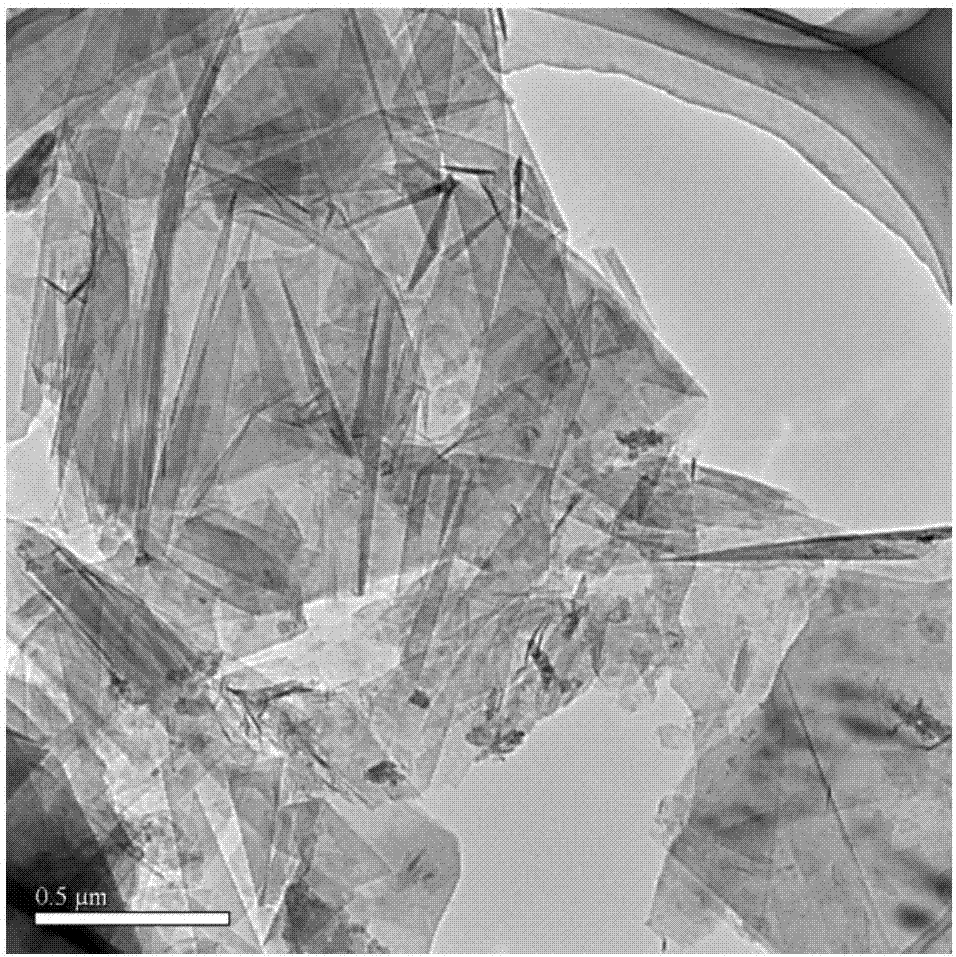

Embodiment 2

[0028] 5g of graphite and 150mL of N,N-dimethylformamide were put into an ultrasonic ball mill, the ultrasonic power was controlled at 5kW, and the milling speed was 500rpm. After ultrasonic milling for 1h, the product was separated, washed, and dried to obtain graphene powder.

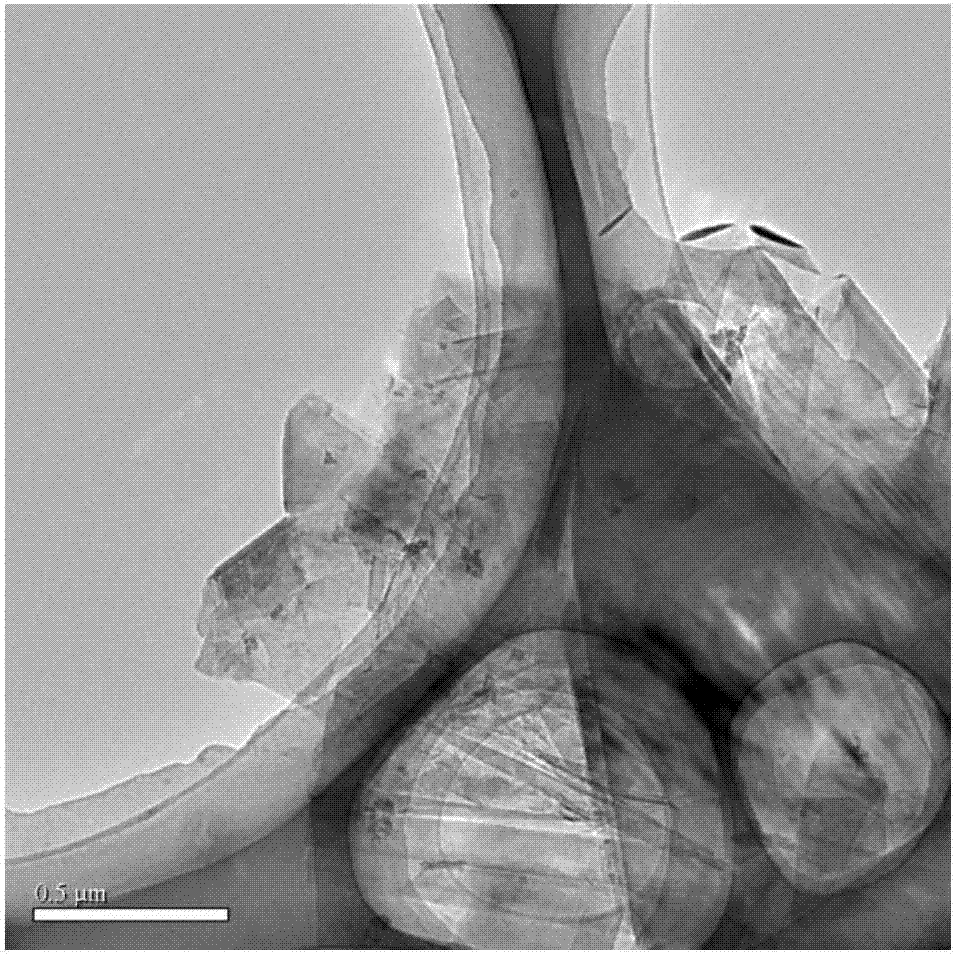

Embodiment 3

[0030] Put 5g of graphite and 50mL of 1-butyl-3-methylimidazolium hexafluorophosphate into an ultrasonic ball mill. The ultrasonic power is controlled at 2.5kW, and the milling speed is 500rpm. After ultrasonic ball milling for 3 hours, the product is separated, washed and dried to obtain graphite ene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com