Reductively biodegradable type honeycomb polyurethane support, and preparation method and application thereof

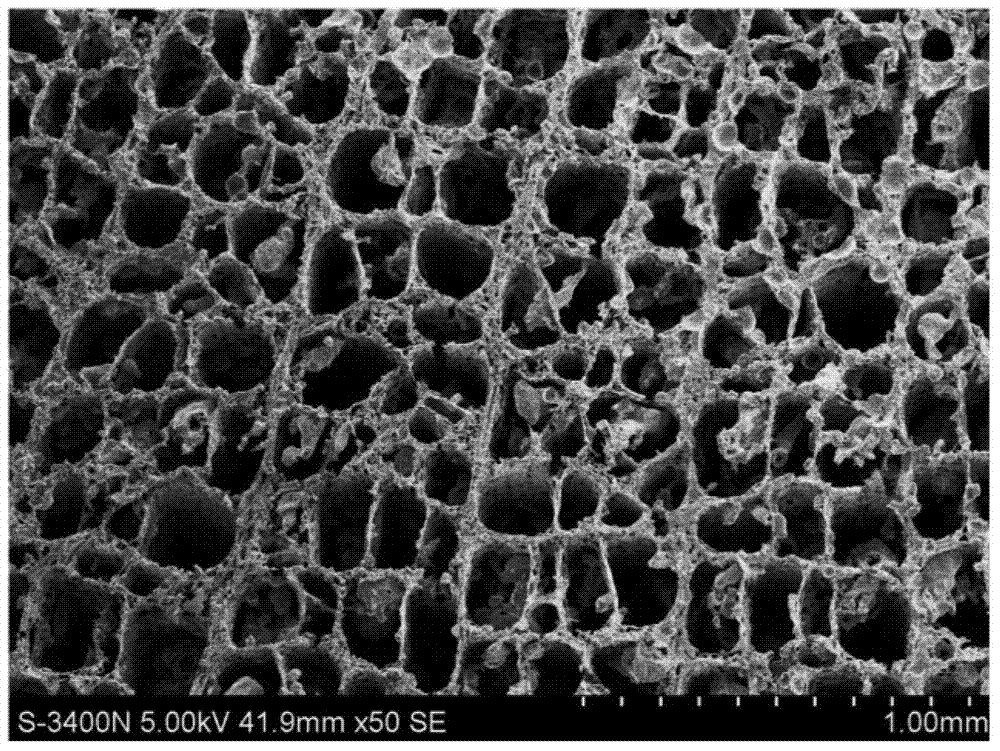

A technology of polyester polyurethane and polyurethane, which is applied in the field of bioreductive and degradable cellular polyurethane scaffolds and its preparation, can solve the problems of small pore diameter, complicated process, and low porosity, and achieve uniform pore size distribution and controllable performance The effect of strong resistance and good biomechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of bioreducible degradable honeycomb polyurethane support comprises the following steps:

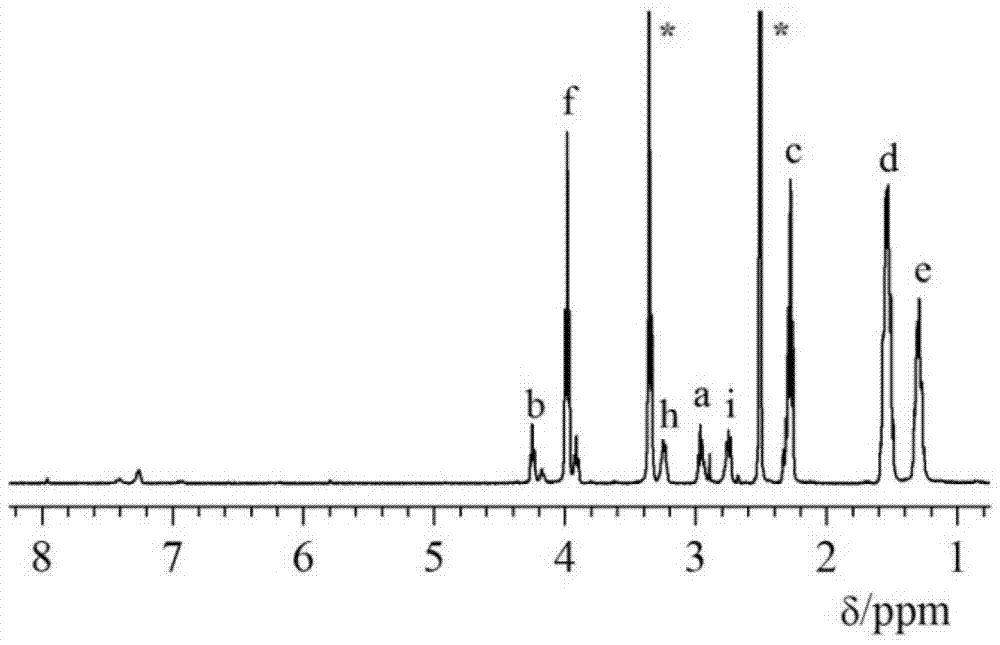

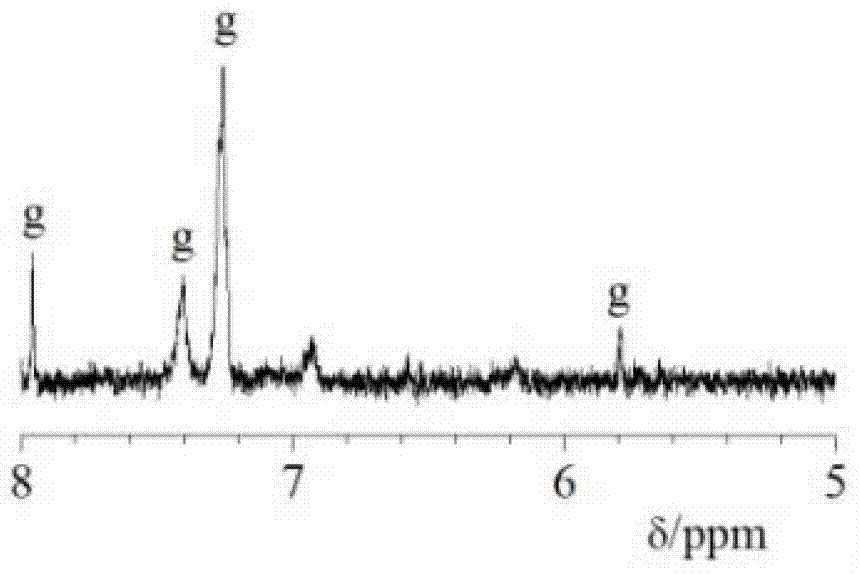

[0047] 1) Synthesis of double-terminated hydroxyl polycaprolactone containing disulfide bonds:

[0048] Add anhydrous initiator 2,2′-dithiodiethanol and monomer caprolactone in a molar ratio of 1:12, and then add the catalyst stannous isooctanoate with a monomer caprolactone molar weight of 5‰ , reacting at 125°C for 30 hours under the protection of argon, purifying the product obtained by the reaction by dissolving in dichloromethane / precipitating with ether, and then drying in vacuum to obtain a disulfide bond-containing double-terminal hydroxyl polycaprolactone;

[0049] 2) Synthesis of polyester polyurethane containing disulfide bonds:

[0050] Put 2,2′-dithiodiethyl isocyanate and the disulfide bond-containing double-terminal hydroxyl polycaprolactone obtained in step 1) at a molar ratio of 1.02:1 in a reaction vessel as reactants, and then add Water ...

Embodiment 2

[0060] The preparation method of bioreducible degradable honeycomb polyurethane support comprises the following steps:

[0061] 1) Synthesis of double-terminated hydroxyl polycaprolactone containing disulfide bonds:

[0062] Add anhydrous initiator 2,2′-dithiodiethanol and monomer caprolactone in a molar ratio of 1:6 into the reaction vessel, and then add catalyst stannous isooctanoate with 1% molar amount of monomer caprolactone , reacting at 110°C for 48 hours under the protection of argon, purifying the product obtained by the reaction by dissolving in dichloromethane / precipitating with ether, and then drying in vacuum to obtain a disulfide bond-containing double-terminal hydroxyl polycaprolactone;

[0063] 2) Synthesis of polyester polyurethane containing disulfide bonds:

[0064] Put 2,2′-dithiodiethyl isocyanate and the disulfide-bond-containing double-terminal polycaprolactone obtained in step 1) in a molar ratio of 1.05:1 in a reaction vessel as reactants, and then ad...

Embodiment 3

[0070] The preparation method of bioreducible degradable honeycomb polyurethane support comprises the following steps:

[0071] 1) Synthesis of double-terminated hydroxyl polycaprolactone containing disulfide bonds:

[0072] Add anhydrous initiator 2,2′-dithiodiethanol and monomer caprolactone in a molar ratio of 1:18, and then add catalyst stannous isooctanoate with a monomer caprolactone molar weight of 5‰ , reacting at 120°C for 40 hours under the protection of argon, purifying the product obtained by the reaction by dissolving in dichloromethane / precipitating with ether, and then drying in vacuum to obtain a disulfide bond-containing double-terminal hydroxyl polycaprolactone;

[0073] 2) Synthesis of polyester polyurethane containing disulfide bonds:

[0074] Put dithiodimethylisocyanate and disulfide bond-containing double-terminated polycaprolactone obtained in step 1) in a reaction vessel at a molar ratio of 1.04:1 as reactants, and then add anhydrous toluene to form mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com