Method for preventing drilling collapse of downhole coal bed

A coal seam and drill pipe technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve problems such as collapse and collapse of high-gas soft coal seams, achieve large gas drainage flow, and reduce the possibility of hole collapse , the effect of wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

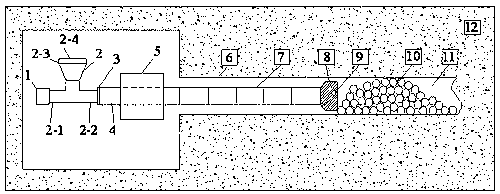

[0023] Embodiment 1: the method for preventing borehole from collapsing, the steps are as follows:

[0024] a. Use the drilling device to construct gas drainage drilling holes in the underground coal wall, and stop drilling when the drill bit reaches the final hole position. Generally, the drilling depth is 80-100m, and the length of each drill pipe is 0.8-1.0m;

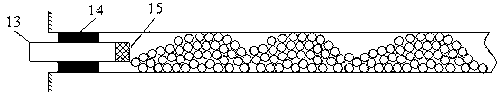

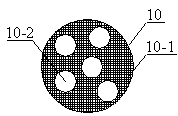

[0025] b. Withdraw 3~4 drill pipes, connect the compressed air to the porous material conveying device, and convey the porous material in the porous material conveying device to the inner hole of the drill pipe, so that the porous material enters through the inner hole of the drill pipe The reserved drilling space in front of the drill bit will stop the air supply until it is filled with more than 2 / 3 of its volume capacity;

[0026] d. Repeat step b until there are only 10 to 20 drill pipes left in the hole, stop conveying the porous material, and withdraw all the remaining drill pipes in the hole;

[0027] e. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com