Metal defect detection method of laser-electromagnetic ultrasonic nondestructive testing system

An electromagnetic ultrasonic and non-destructive testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as large amplitude, and achieve the effects of simple equipment, good repeatability and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The specific implementation method of metal material surface defect detection is as follows:

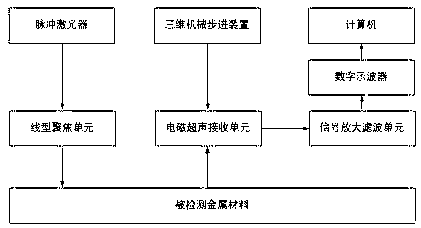

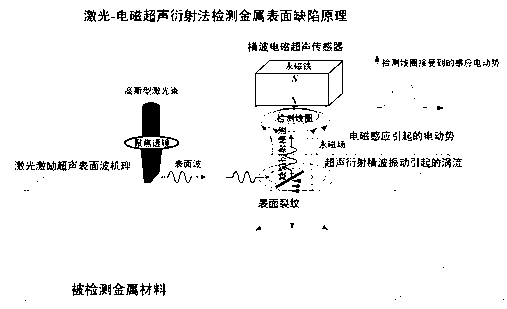

[0030] figure 1 It is a schematic diagram of a laser-electromagnetic ultrasonic nondestructive testing system. First, the pulsed laser, three-dimensional mechanical stepping device, transverse wave electromagnetic ultrasonic sensor, signal amplification and filtering unit, digital oscilloscope and computer are electrically connected in sequence, and the electromagnetic ultrasonic receiving unit is fixed on the three-dimensional mechanical stepping device. Calibrate the positions of the pulsed laser and the linear focusing unit so that they are placed concentrically. Adjust the position of the cylindrical lens in the linear focusing unit so that the distance between the 45-gauge steel and the cylindrical lens is 200 mm.

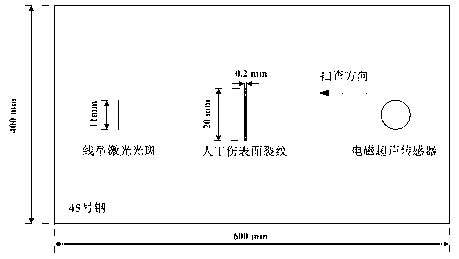

[0031] figure 2 A schematic diagram of artificially damaged surface cracks in No. 45 steel is given. The size of No. 45 steel is 400 mm×600 ...

Embodiment 2

[0034] Embodiment 2: The specific implementation method of detecting internal defects of metal materials is as follows:

[0035] Figure 5 A schematic diagram of the artificial damage holes inside the No. 45 steel is given. The size of the No. 45 steel is 900 mm × 200 mm × 300 mm. The hole-type artificial damage is processed inside 60 mm from the upper surface of the No. 45 steel by the drilling and milling machining center. , whose dimensions are 7 mm×30 mm, 5 mm×30 mm and 3 mm×30 mm in turn, and the detection results of 3 mm×30 mm holes are given in the examples. The output energy of the calibrated pulse laser is 150 m J / pulse, and the position of the cylindrical lens in the linear focusing unit is adjusted so that the two are placed concentrically, and the surface of the 45th steel to be detected is located in the cylindrical lens of the linear focusing unit. focal length. Turn on the working power of the transverse wave electromagnetic ultrasonic sensor and the three-dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Snr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com