Patents

Literature

253results about "Magnesium silicates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

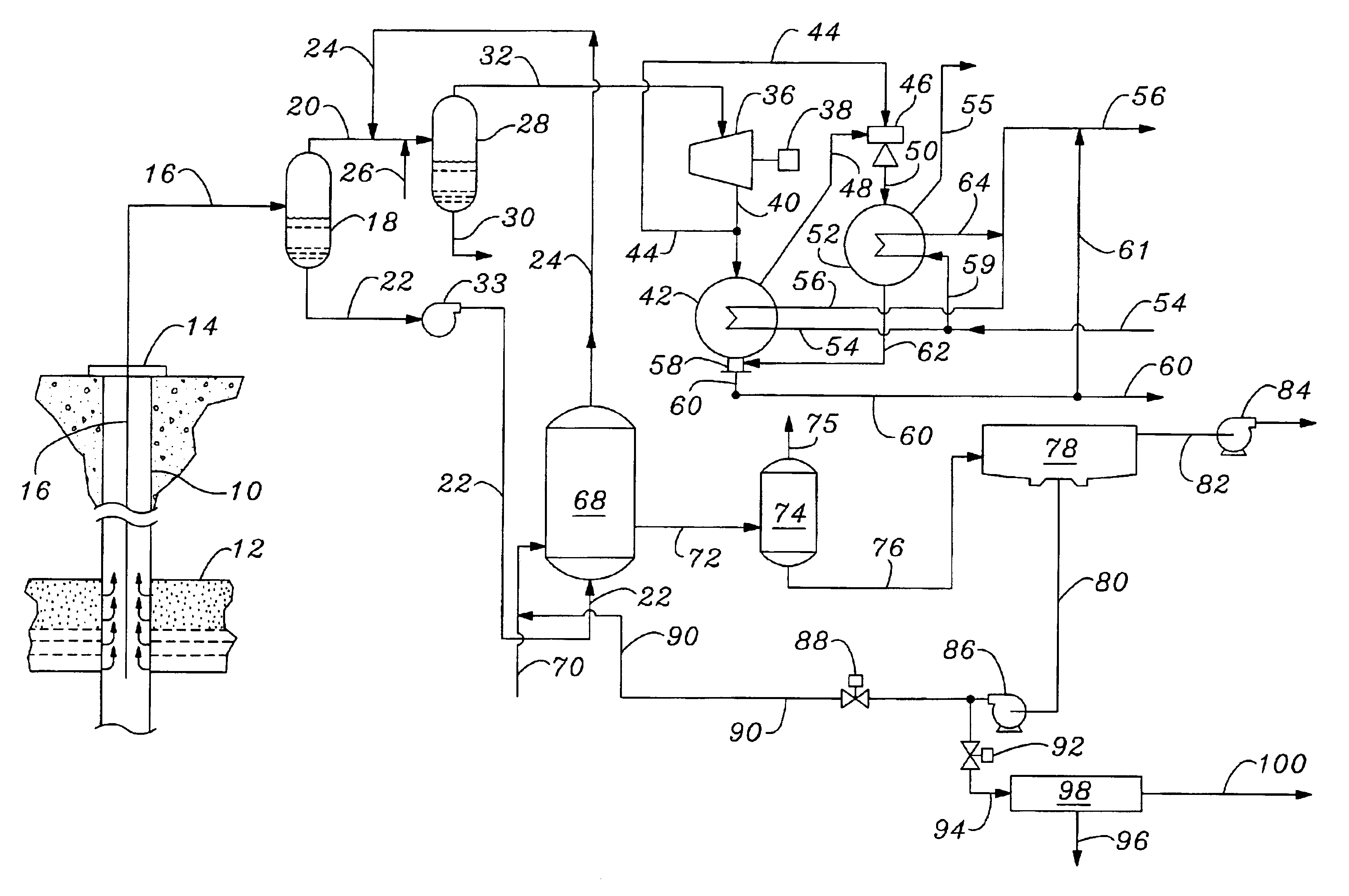

Method for synthesizing crystalline magnesium silicates from geothermal brine

Crystalline magnesium silicates are synthesized from silica-containing brines, preferably spent geothermal brines, by mixing the brine with a magnesium-containing compound, adjusting the pH of the resultant mixture between 8.0 and 14, and crystallizing the magnesium silicate from the mixture at a temperature between 50° C. and 200° C. Kerolite is preferably synthesized from brine by adjusting the pH in a range between 9.5 and 10.5 and heating the mixture to between 100° C. and 170° C. to precipitate the crystalline kerolite. The brine remaining after the crystallization step is depleted in silica and can be further processed without significant problems caused by silica scaling.

Owner:UNION OIL OF CALIFORNIA

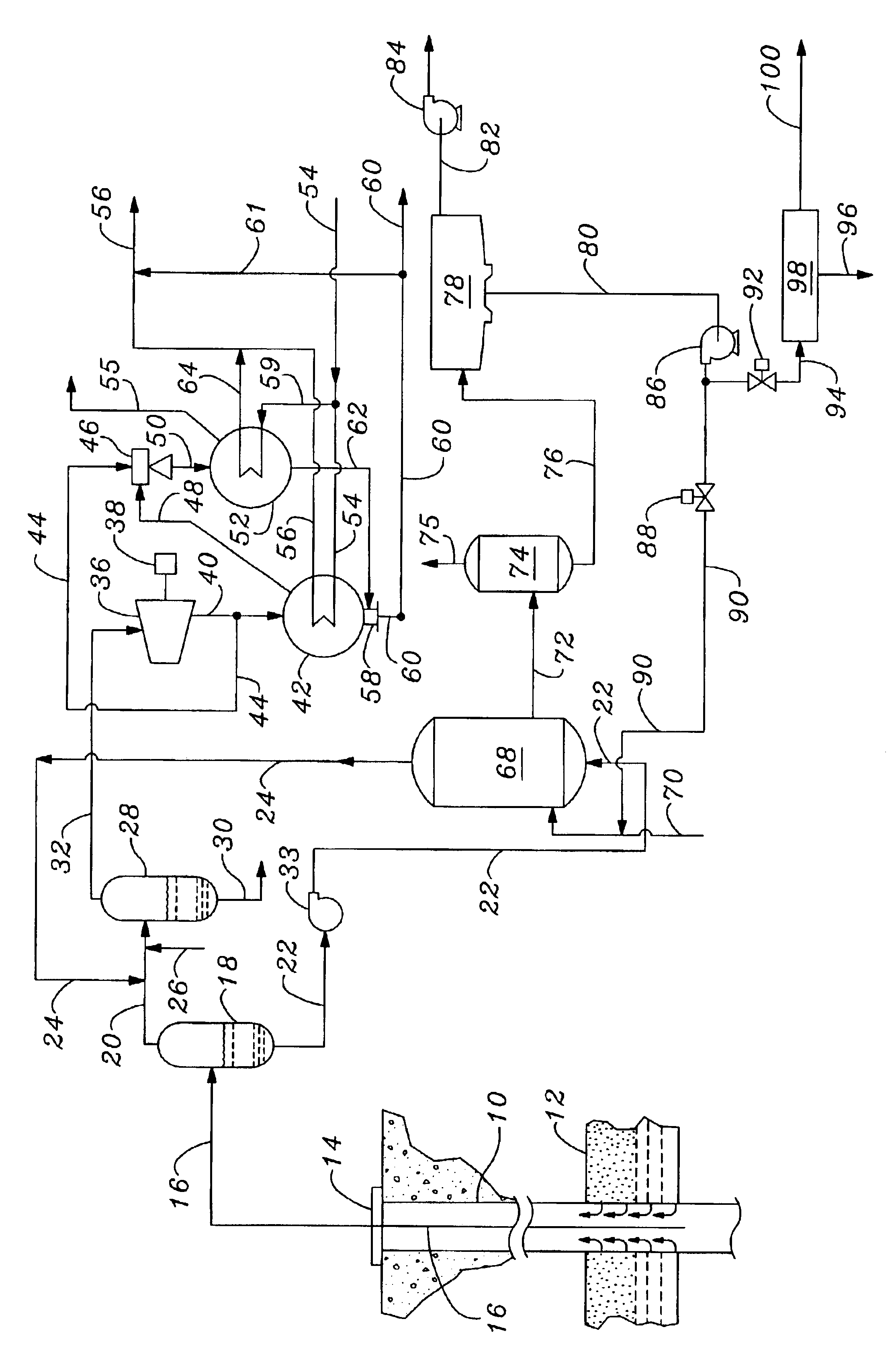

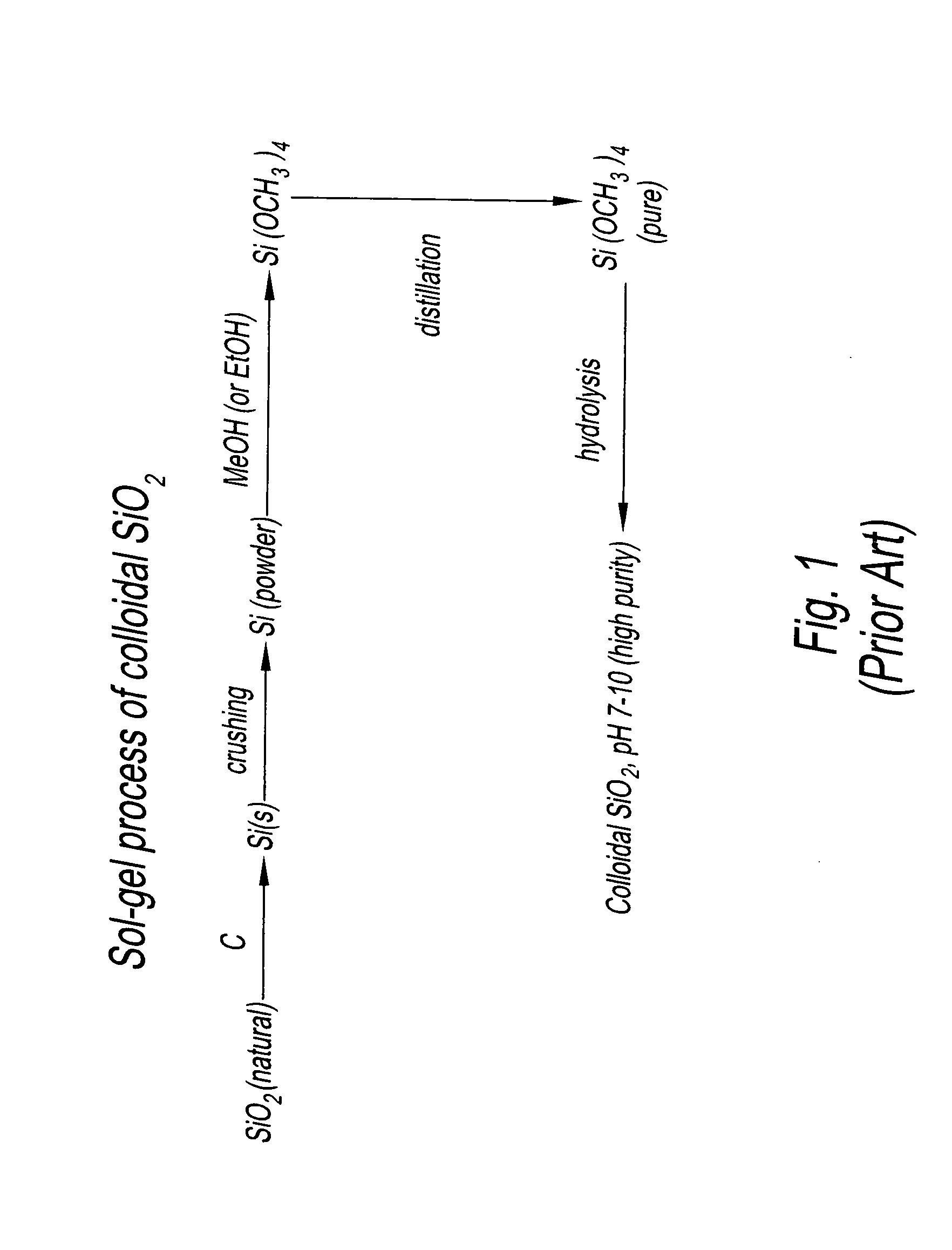

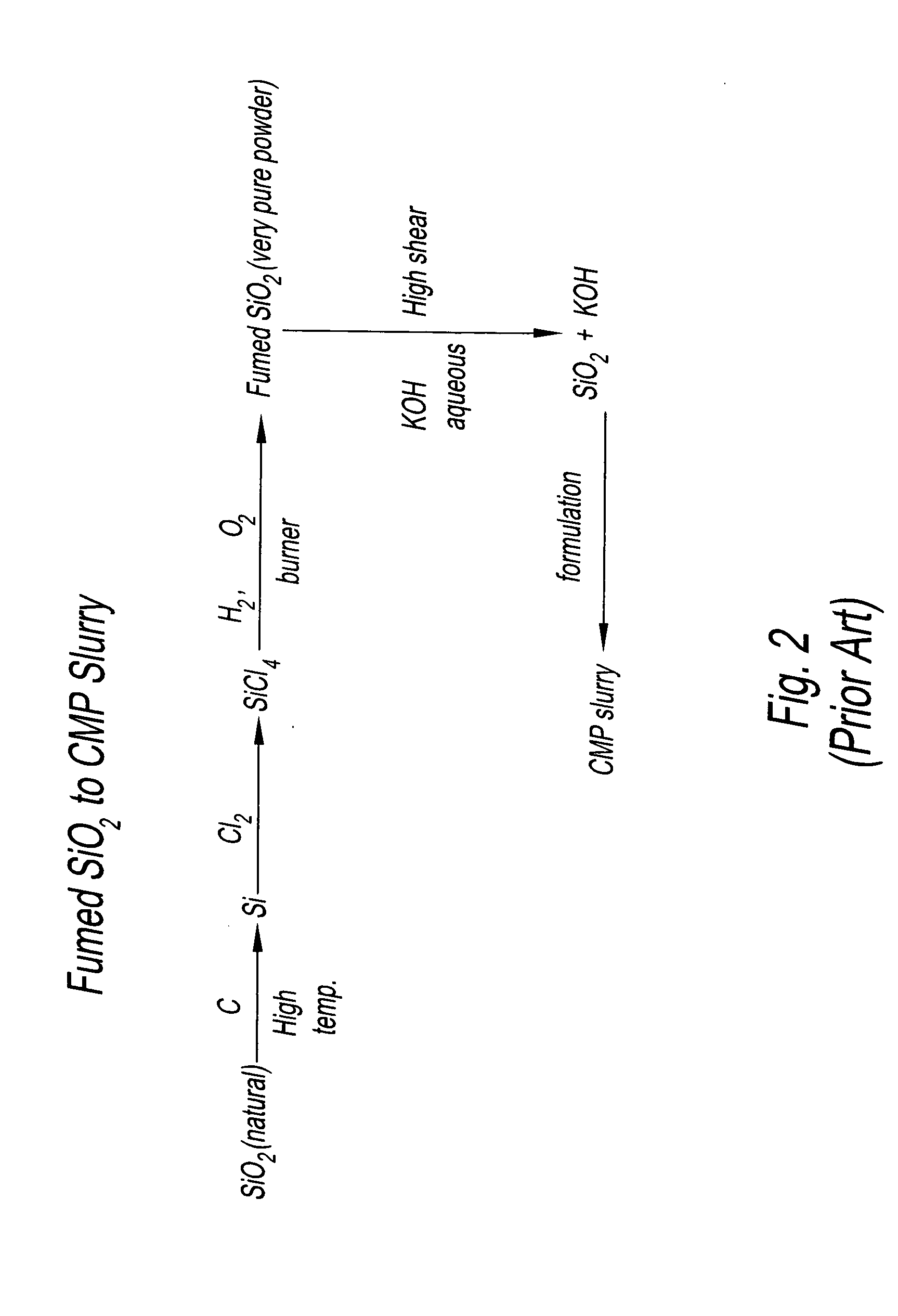

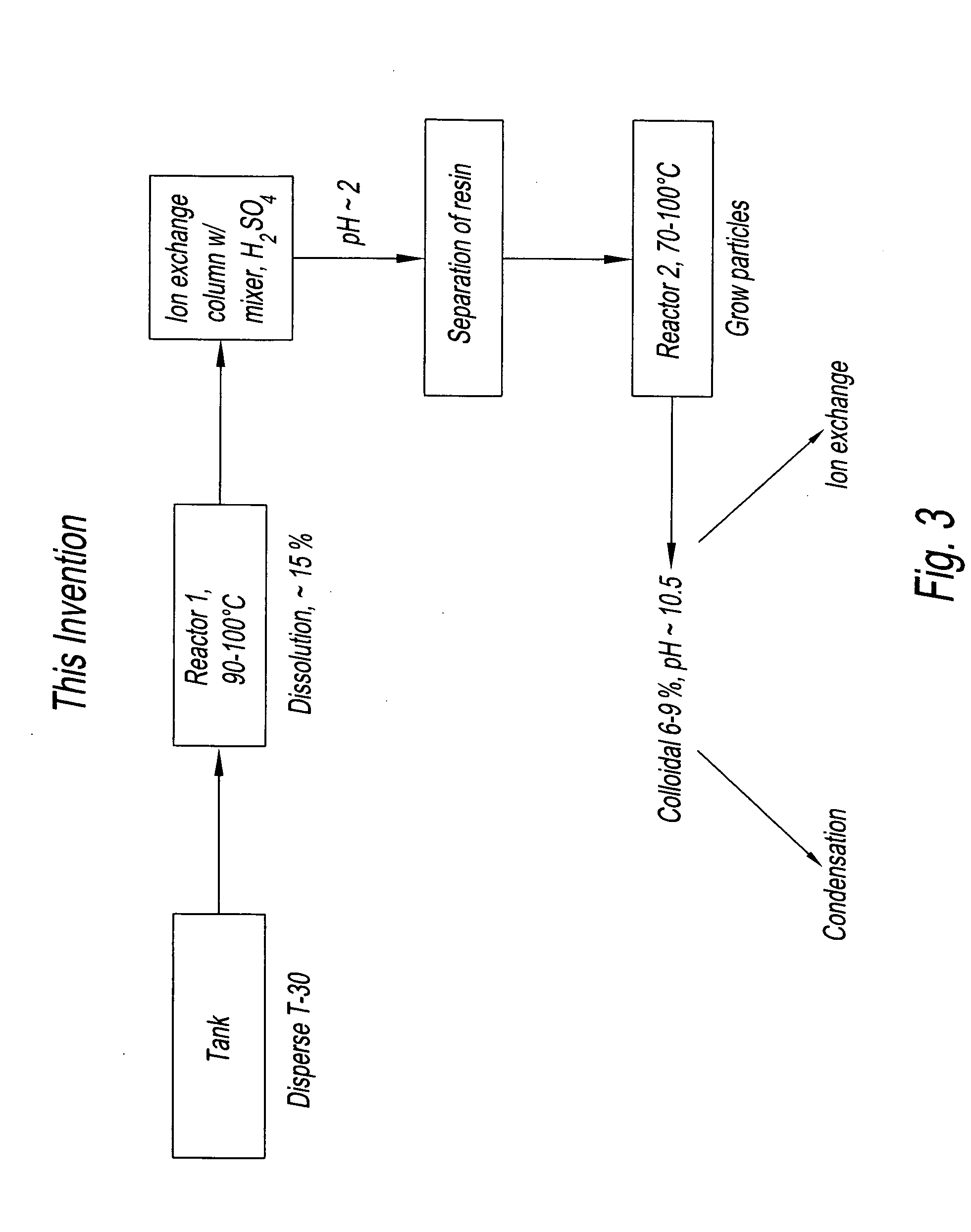

Fumed silica to colloidal silica conversion process

InactiveUS20060283095A1Low to moderate costHigh rateMagnesium silicatesPigmenting treatmentColloidal silicaSilicic acid

A method of manufacturing a colloidal silica dispersion, by dissolving a fumed silica in an aqueous solvent having an alkali metal hydroxide to produce an alkaline silicate solution; removing the alkali metal via ion exchange to produce a silicic acid solution; adjusting the temperature, concentration and pH of the silicic acid solution to values sufficient to initiate nucleation and particle growth at elevated temperatures; and cooling the silicic acid solution at a rate sufficient to produce the colloidal silica dispersion. The colloidal silica particles in the colloidal silica dispersion have a mean particle size about 2 nm to about 100 nm. Also provided is a method of chemical mechanical polishing a surface of a substrate by contacting the substrate and a composition having a plurality of colloidal silica particles according to the present invention and a medium for suspending the particles. The contacting is carried out at a temperature and for a period of time sufficient to planarize the substrate.

Owner:PLANAR SOLUTIONS

Anticorrosive pigment composition and coating compositions containing the same

A nontoxic anticorrosive pigment composition free from toxic heavy metals comprises a condensed phosphoric acid aluminum salt, typically aluminum dihydrogen tripolyphosphate, and magnesium silicate, typically magnesium hexasilicate. The anticorrosive pigment composition enhances the thermal resistance of paint films when formulated in a coating composition containing a chlorine-containing vinyl polymer such as vinyl chloride-vinylidene chloride copolymer emulsion paints.

Owner:TAYCA CORP

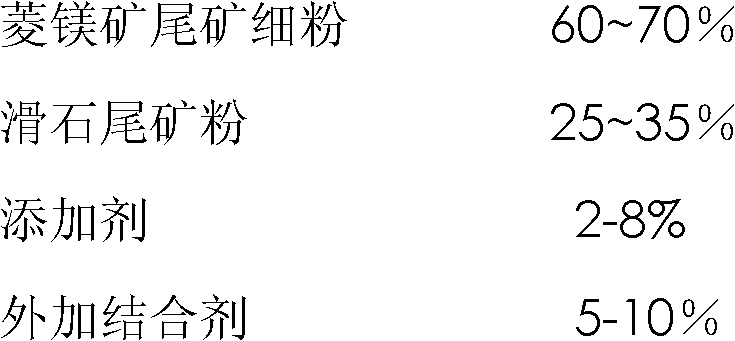

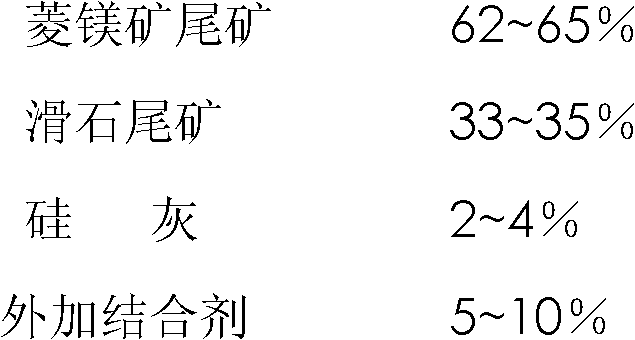

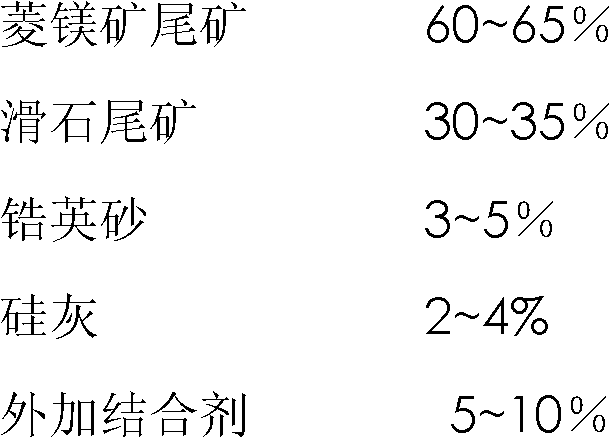

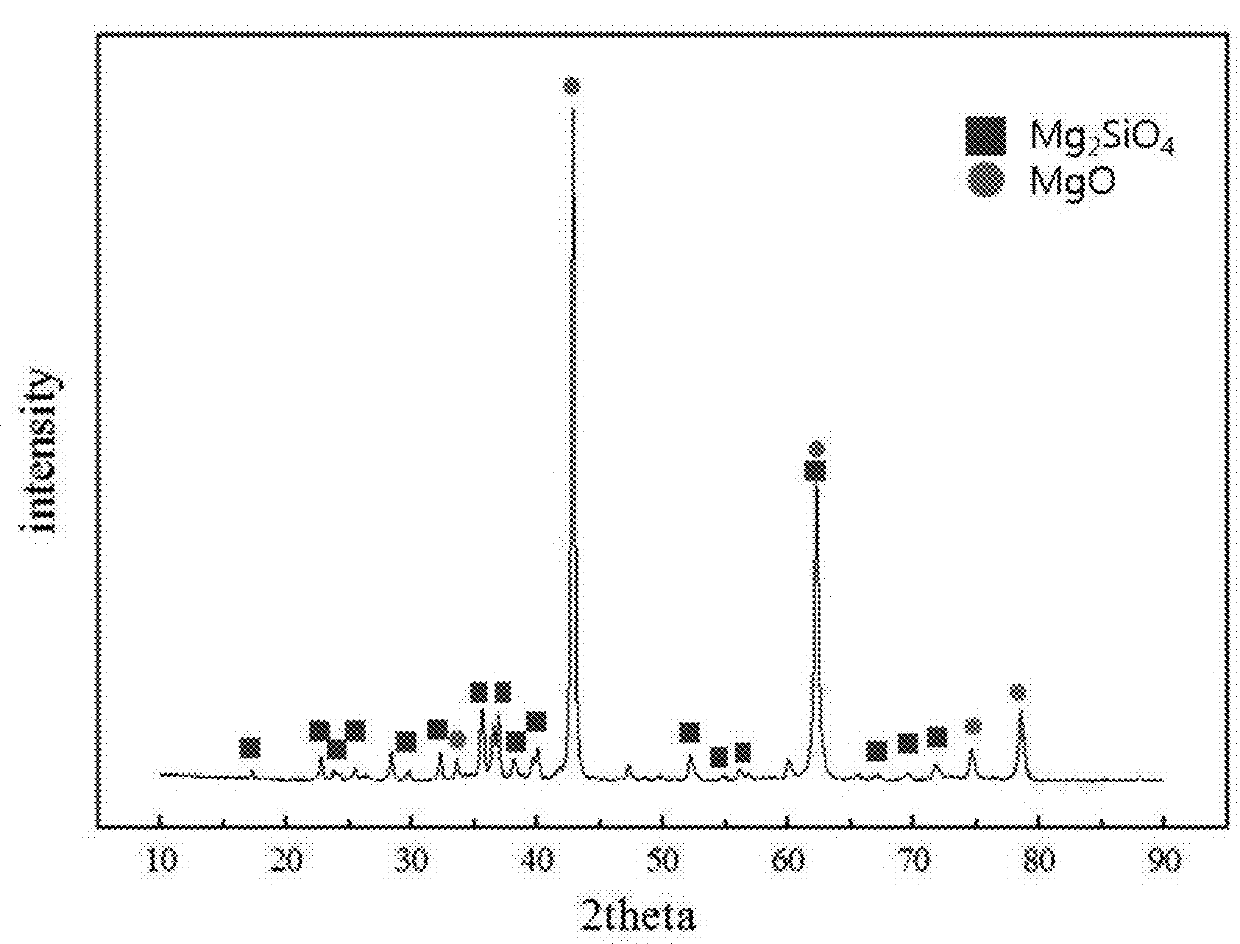

Method for synthesizing high-purity forsterite with magnesite tailings and talc tailings

The invention discloses a method for synthesizing high-purity forsterite by using magnesite tailings and talc tailings, which effectively utilizes tailings resources and can be used to produce high-density refractory materials used under high-temperature conditions above 1600°C. The present invention uses magnesite tailings and talc tailings as the main raw materials, adds additives and binders, and manufactures high-purity forsterite refractory raw materials through batching, mixing, molding, drying, high-temperature synthesis and crushing. The weight percent content of each component is as follows: 60-70% of fine magnesite tailings powder; 25-35% of talc tailings powder; 2-8% of additives; 5-10% of external binder. Using magnesite tailings and talc tailings to synthesize high-purity forsterite refractory raw materials, the use temperature is high (above 1600 ℃), the bulk density is high (greater than 2.55g / cm3), and the combined content of olivine and periclase is greater than 97%. The utility model has wide application field, comprehensive utilization of waste, and low production cost.

Owner:UNIV OF SCI & TECH LIAONING +1

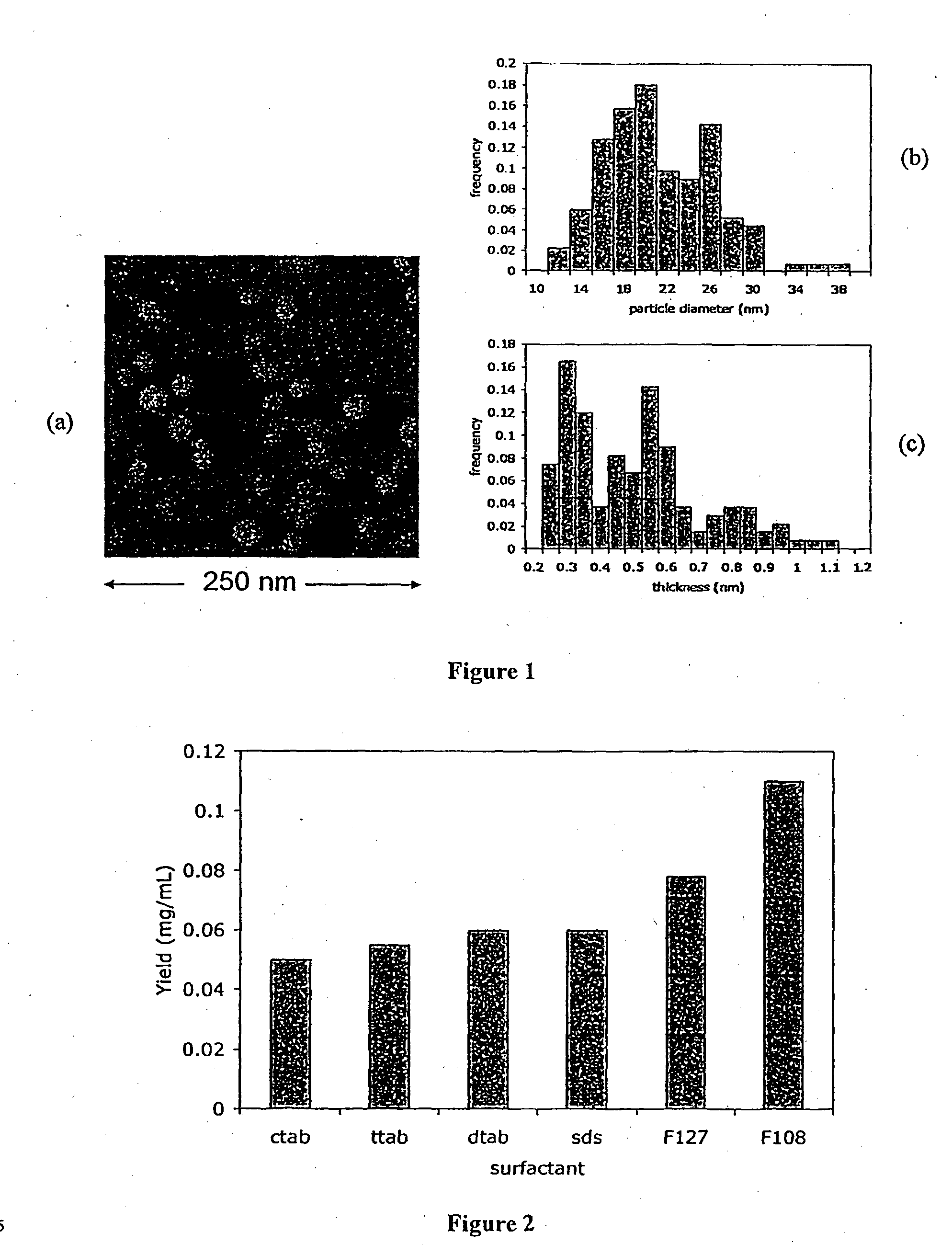

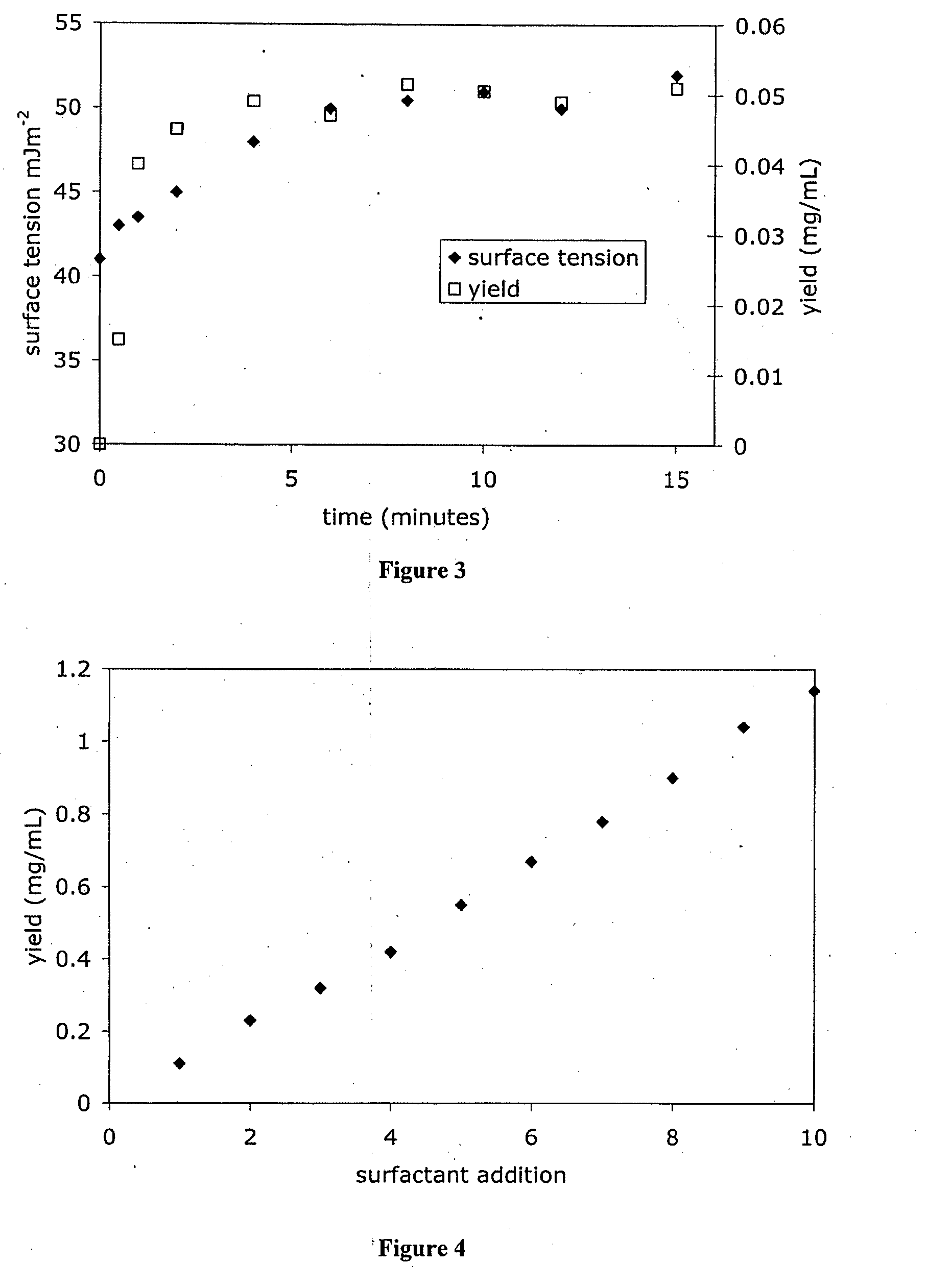

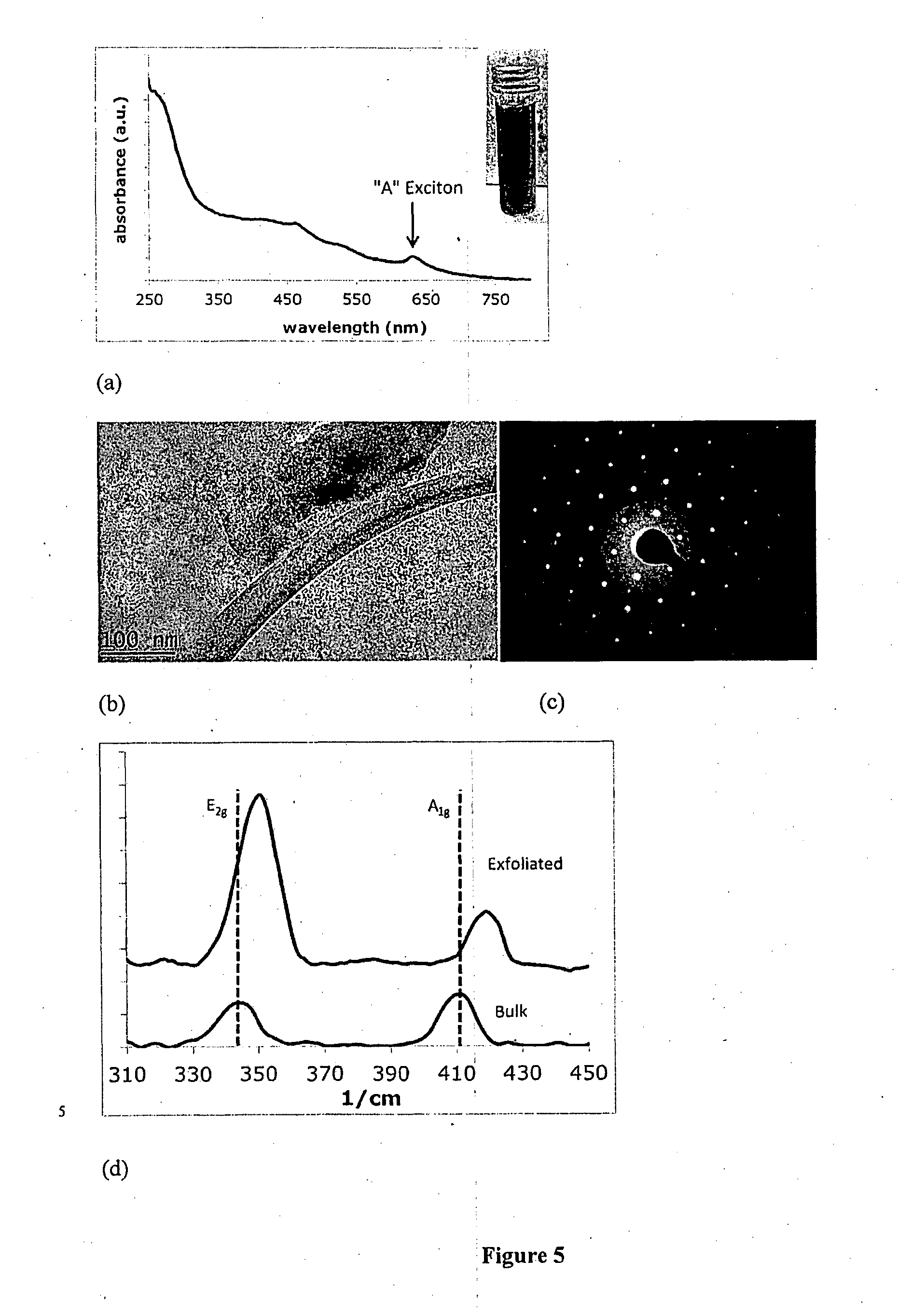

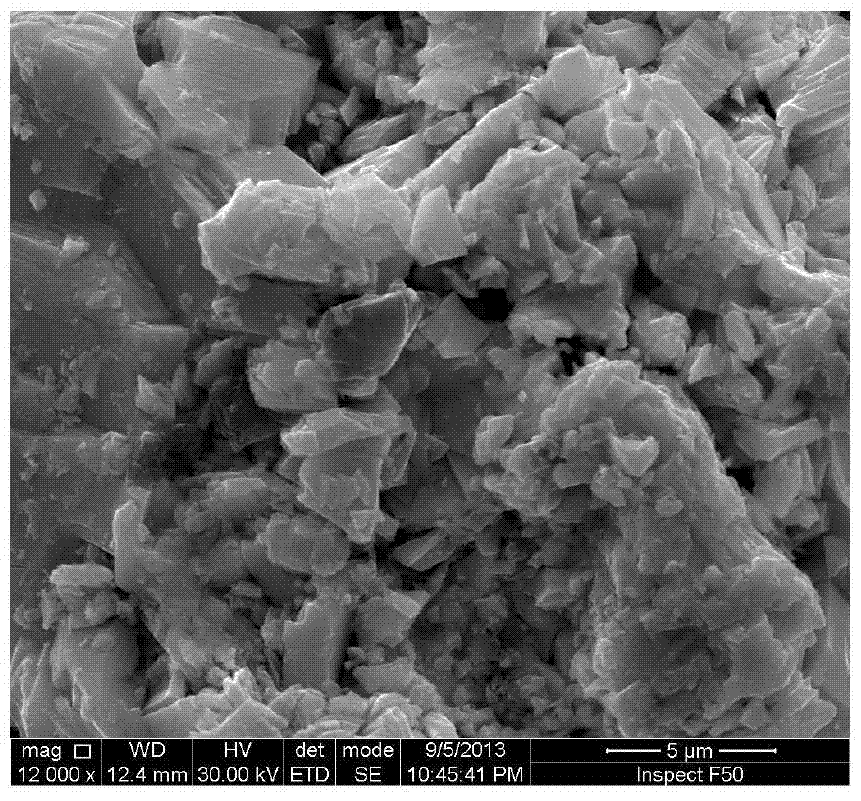

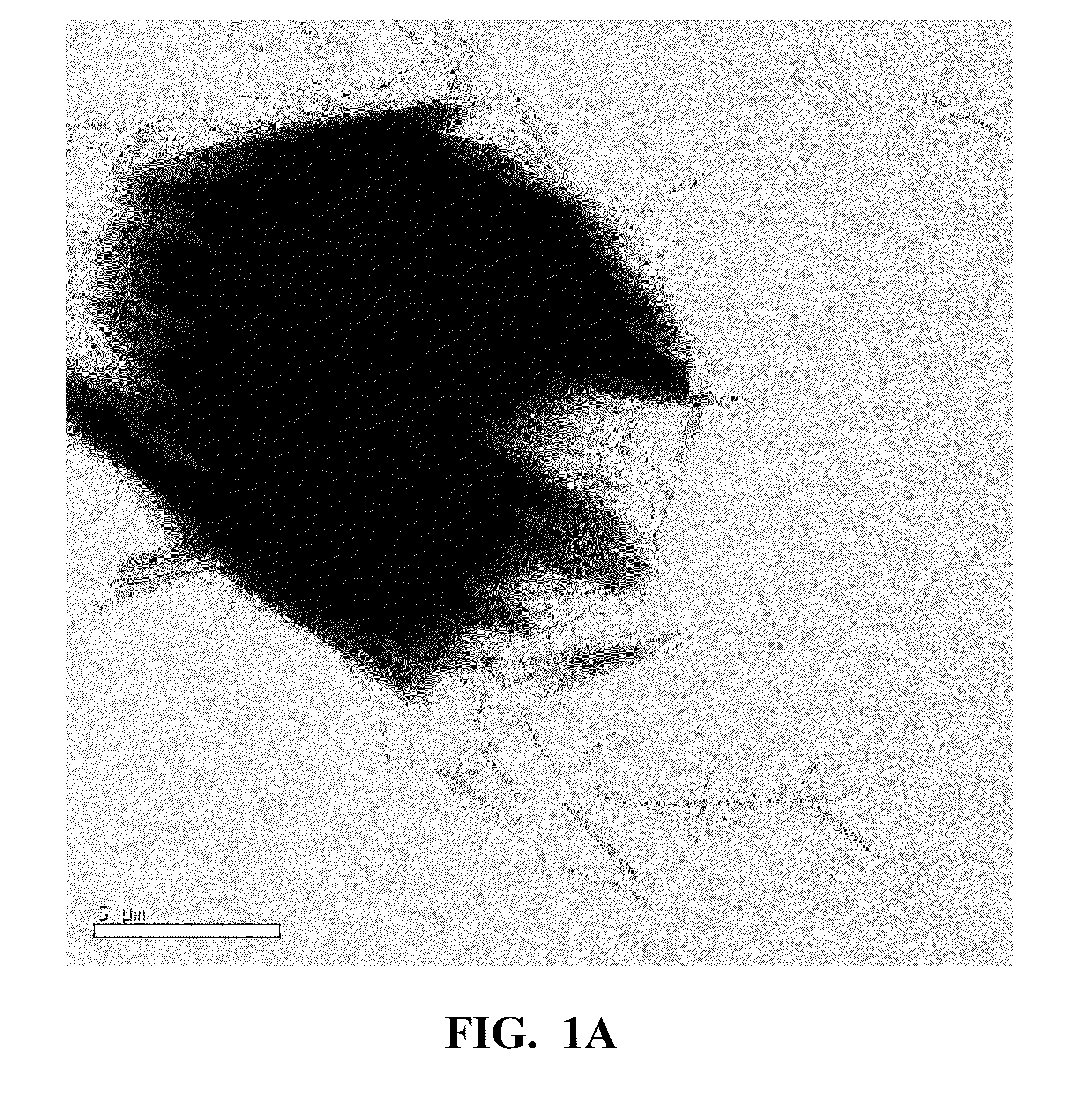

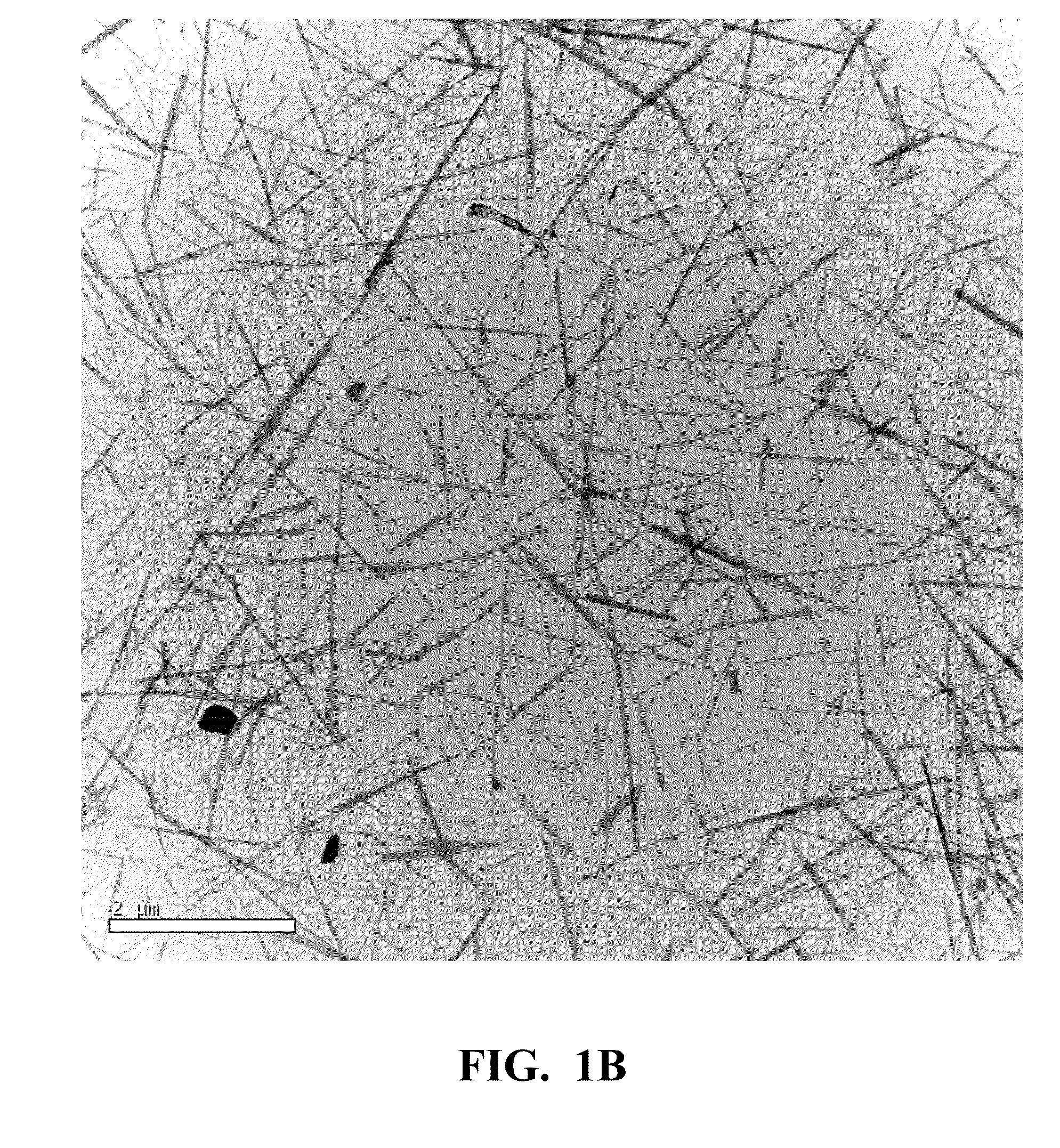

Exfoliating Laminar Material by Ultrasonication in Surfactant

Disclosed herein is a method for exfoliating a laminar material to form an exfoliated material, in which the laminar material is ultrasonicated in a solution of a surfactant for sufficient time to form the exfoliated material. At all times during the ultrasonication the concentration of the surfactant in the solution is maintained sufficient to form a complete monolayer on the surfaces of the laminar material and the exfoliated material in the solution, or sufficient to sterically stabilise the laminar and exfoliated materials against aggregation.

Owner:FLEX G PTY LTD

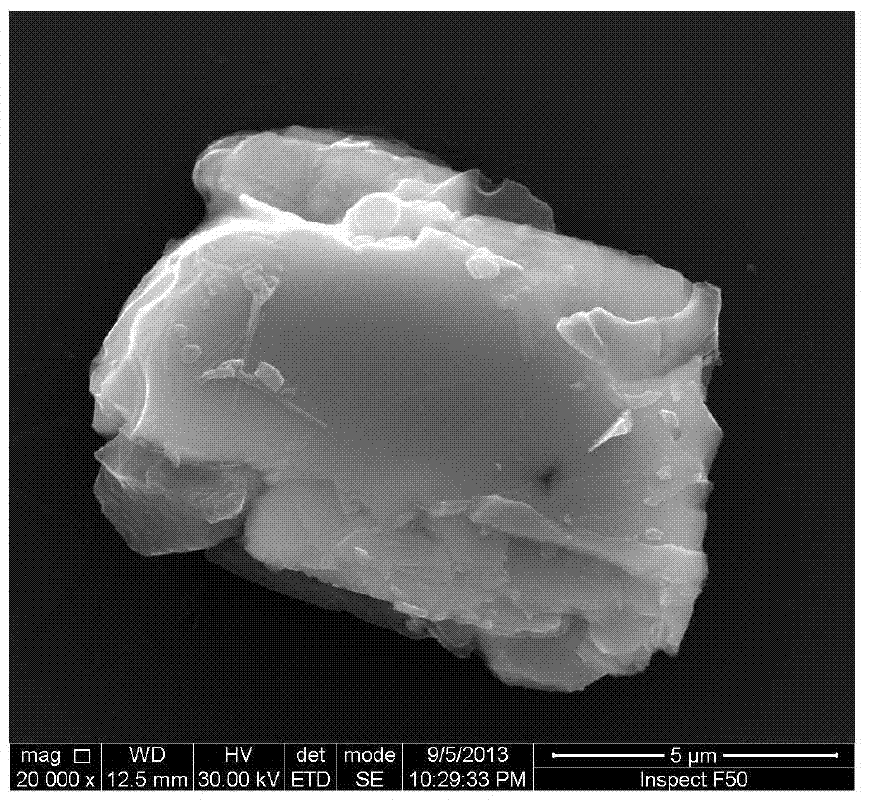

Preparation method of micro-nano hydroxyl magnesium silicate

InactiveCN104261417AHigh purityHigh activityMagnesium silicatesMaterial nanotechnologyMicro nanoSodium hydroxide

The invention provides a preparation method of micro-nano hydroxyl magnesium silicate. The method is capable of producing high-quality micro-nano hydroxyl magnesium silicate powder products in large scale. The method comprises the following steps: preparing sodium hydroxide into a 0.001-2mol / L solution; mixing nanometer magnesia and nanosilicon dioxide in a container according to a mole ratio of 1 to (0.5-2), adding the prepared sodium hydroxide solution into the container, transferring the solution to a reaction kettle, and reacting for 24-96 hours under the condition at the temperature of 170-300 DEG C; filtering the reacted mixture solution by pure water and drying the filter cake after filtering under the condition at the temperature of 50-100 DEG C to obtain the micro-nano hydroxyl magnesium silicate powder. According to the method, by virtue of precursor nanometer magnesia and nanosilicon dioxide, the micro-nano hydroxyl magnesium silicate is synthesized by a high-temperature hydrothermal method under the condition of a strong base; the thickness of hydroxyl magnesium silicate powder pieces is between 60 nanometers and 20 microns.

Owner:UNIV OF SCI & TECH LIAONING

Process for sequestration of carbon dioxide by mineral carbonation

InactiveUS7722850B2Improve cooling effectMagnesium silicatesCalcium/strontium/barium carbonatesSyngasSilicon dioxide

The invention provides a process for sequestration of carbon dioxide by mineral carbonation comprising the following steps:(a) converting a magnesium or calcium sheet silicate hydroxide into a magnesium or calcium ortho- or chain silicate by bringing the silicate hydroxide in direct or indirect heat-exchange contact with hot synthesis gas to obtain the silicate, silica, water and cooled synthesis gas;(b) contacting the silicate obtained in step (a) with carbon dioxide to convert the silicate into magnesium or calcium carbonate and silica.

Owner:SHELL OIL CO

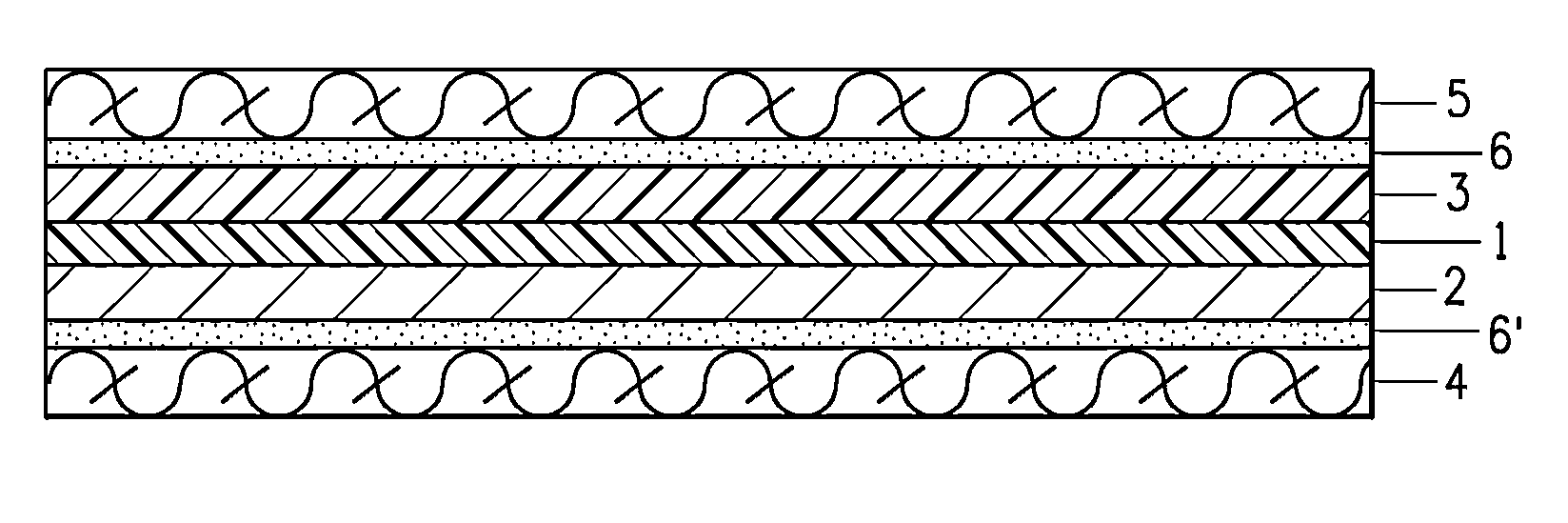

Chitosan films with reduced shrinkage and laminates made therefrom

InactiveUS20130052116A1Reduce Shrinkage ProblemsMagnesium silicatesProtective equipmentPhosphateMontmorillonite

Inclusion of a needle structured clay or the plate structured clay sodium montmorillonite in a chitosan film was found to reduce shrinkage of the film. The needle structured clay is purified and processed into a substantially dispersed form by subjecting an aqueous slurry of the clay with water-soluble phosphate dispersant to a high pressure, high shear mixing process or to sonication. Laminates fabricated from chitosan film including dispersed clay can be used in make a variety of finished articles that can be used to provide protection from hazardous chemical and biological agents.

Owner:EI DU PONT DE NEMOURS & CO

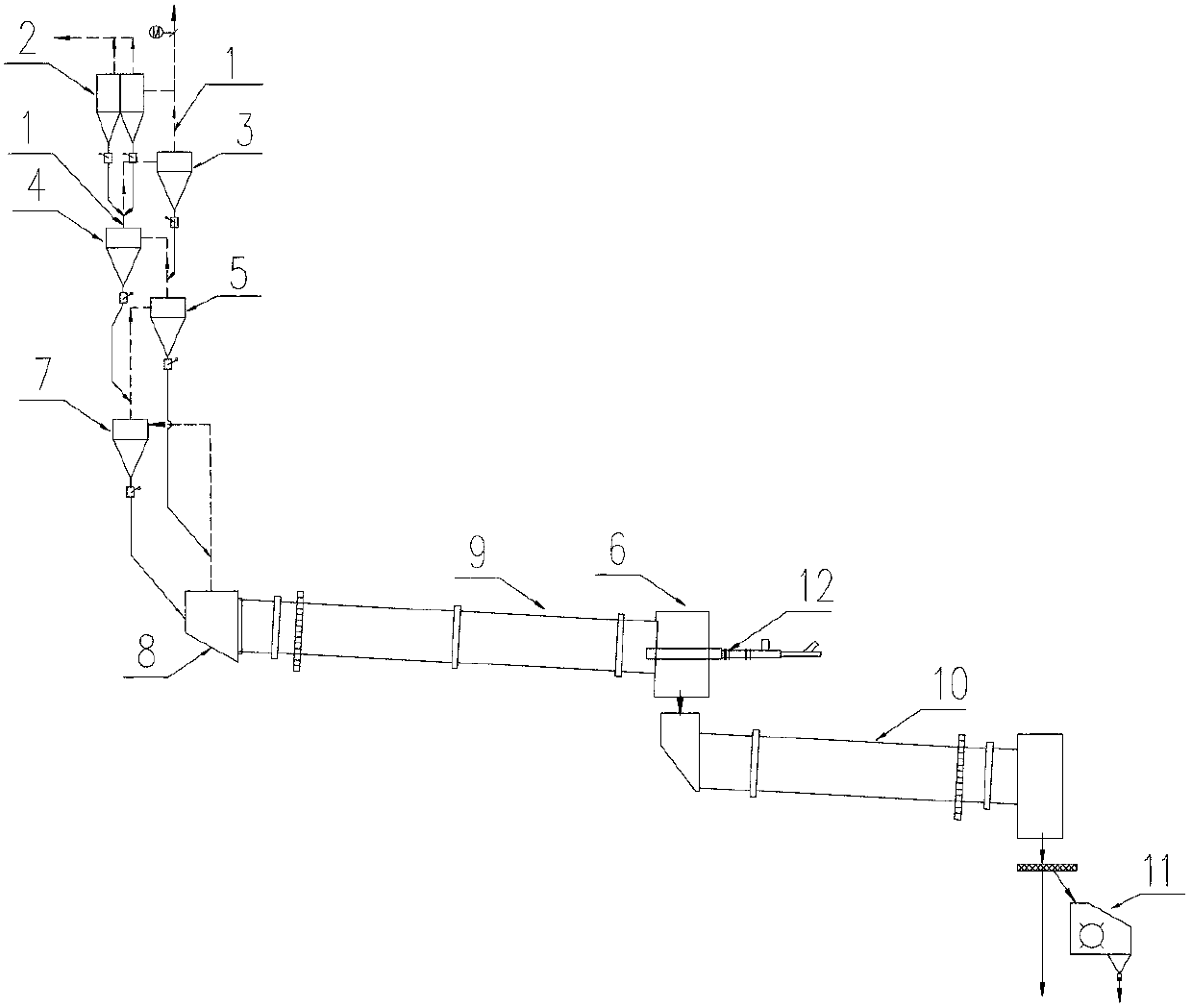

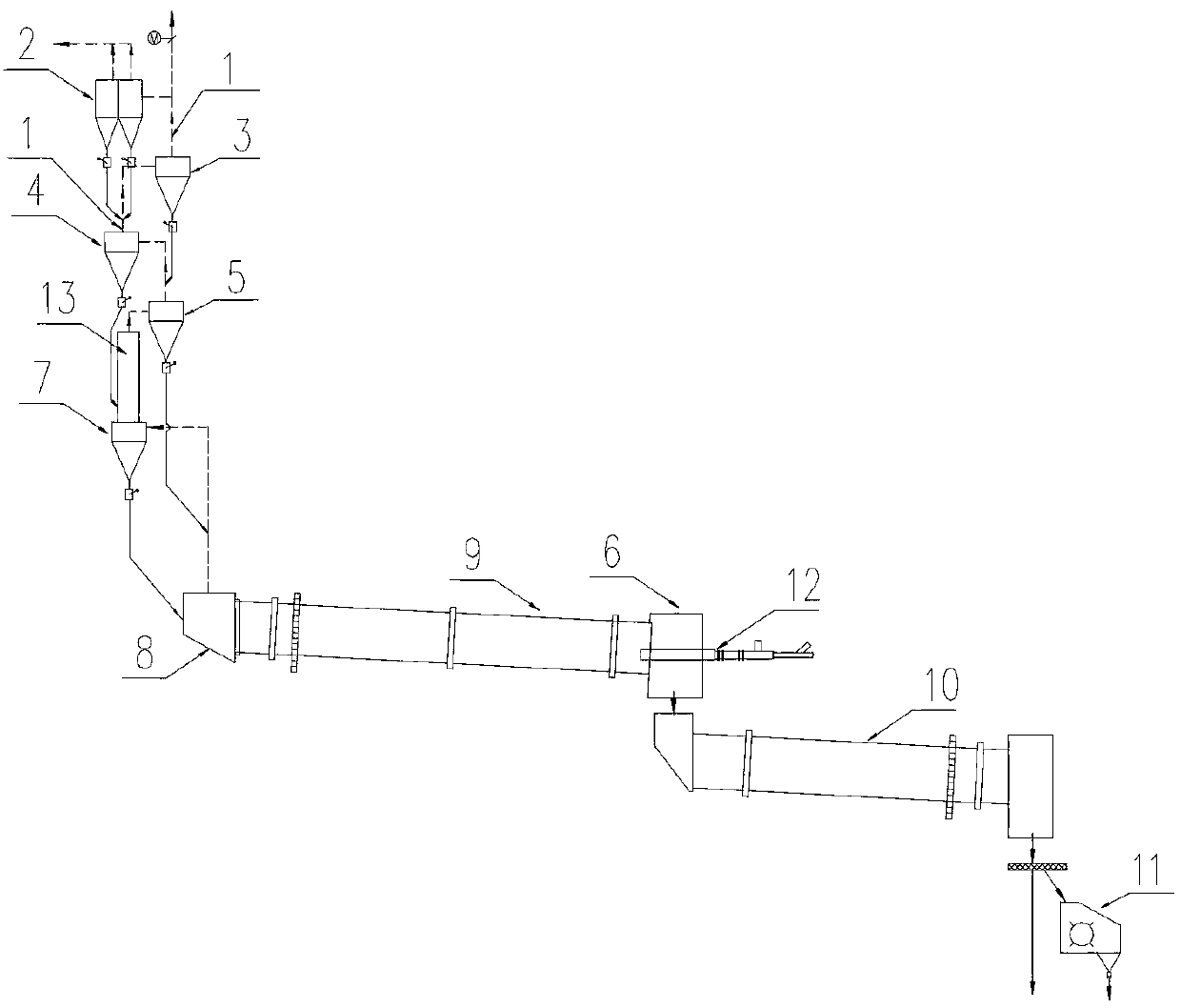

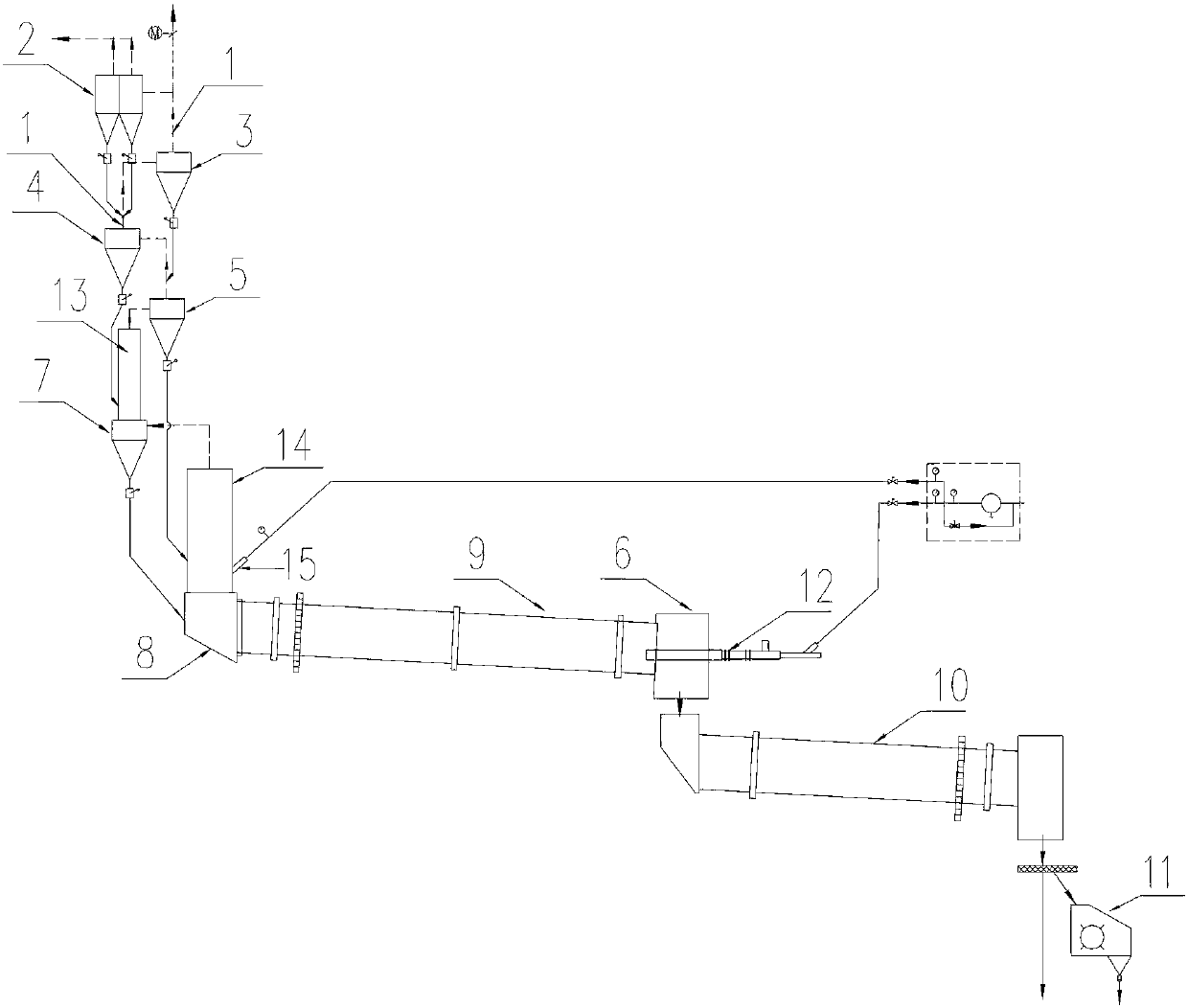

Process and device for whitening calcined black talc

InactiveCN103342371AShort calcination timeIncrease production capacityMagnesium silicatesCombustionWhitening Agents

The invention discloses a process for whitening calcined black talc. Black talc ore is taken as a raw material and is sequentially subjected to mineral separation, crushing, grinding, calcining in a rotary kiln and cooling by a cooling machine, and then granular and blocky calcined black talc products with whiteness of more than or equal to 90 are obtained, wherein the temperature of a burning zone in the calcining procedure in the rotary kiln is 800-1400 DEG C, and the standing time of the raw material in the kiln is 30-90 min. The invention also discloses a device adopting the method. According to the process and the device, a preheater system is adopted for preheating, and a rotary kin calcining process is adopted, so that the calcining time is greatly shortened, and the production capacity is remarkably improved; combustion and heat release of organic matters in black talc are fully considered; the production cost is lowered due to no addition of a whitening agent; dry-method grinding is adopted, and the process is advanced; compared with a process that the black talc is calcined by an annular kiln, the process disclosed by the invention has the advantages that emitted waste gas can be treated to reach the national environmental requirement, the automation degree is high, and parameters are measureable and controllable.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

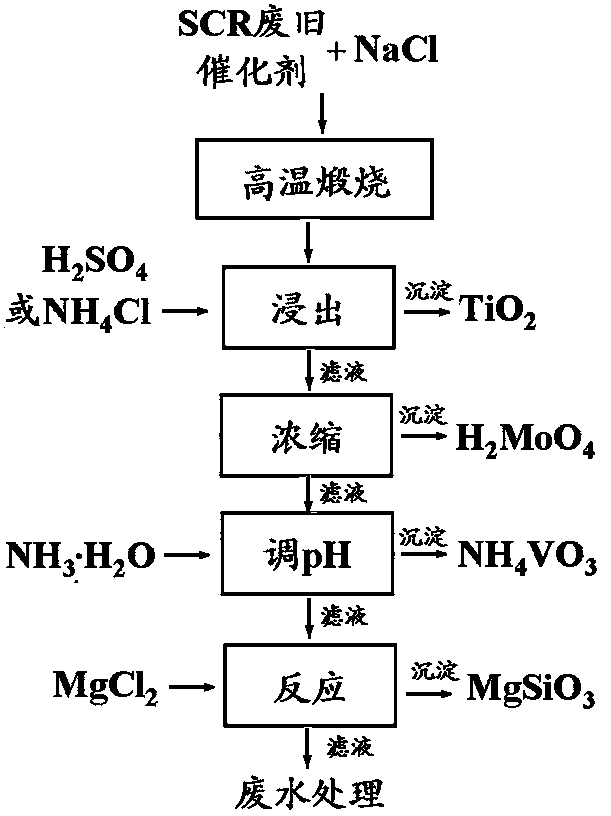

Method for recovering Ti, V, Mo and Si in SCR (selective catalytic reduction) waste catalyst by combination of activation calcination and acid leaching

ActiveCN104178636APromote generationImprove processing efficiencyMagnesium silicatesProcess efficiency improvementSal ammoniacWater recovery

The invention discloses a method for recovering Ti, V, Mo and Si in a SCR (selective catalytic reduction) waste catalyst by combination of activation calcination and acid leaching. The method comprises the following steps: (1) performing pretreatment on the SCR waste catalyst; (2) performing high-temperature calcination for activation; (3) performing acid leaching to obtain white TiO2 powder; (4) performing evaporation and concentration on a leaching solution to obtain a white precipitate, namely H2MoO4; (5) adding NH3.H2O into the leaching solution to regulate pH to 8.0-9.0 to obtain a NH4VO3 precipitate; (6) adding ammonia water into the leaching solution to regulate the pH to 8.0-9.0, further adding MgCl2 to obtain MgSiO3 and enabling filtrate to enter a waste water recovery system. By the process disclosed by the invention, H2MoO4, NH4VO3, TiO2 and MgSiO3 are obtained by recovery. The method disclosed by the invention has the advantages of no discharge of harmful secondary pollutants, simple process, low recovery cost, very high economic and social benefits and feasibility of implementation.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

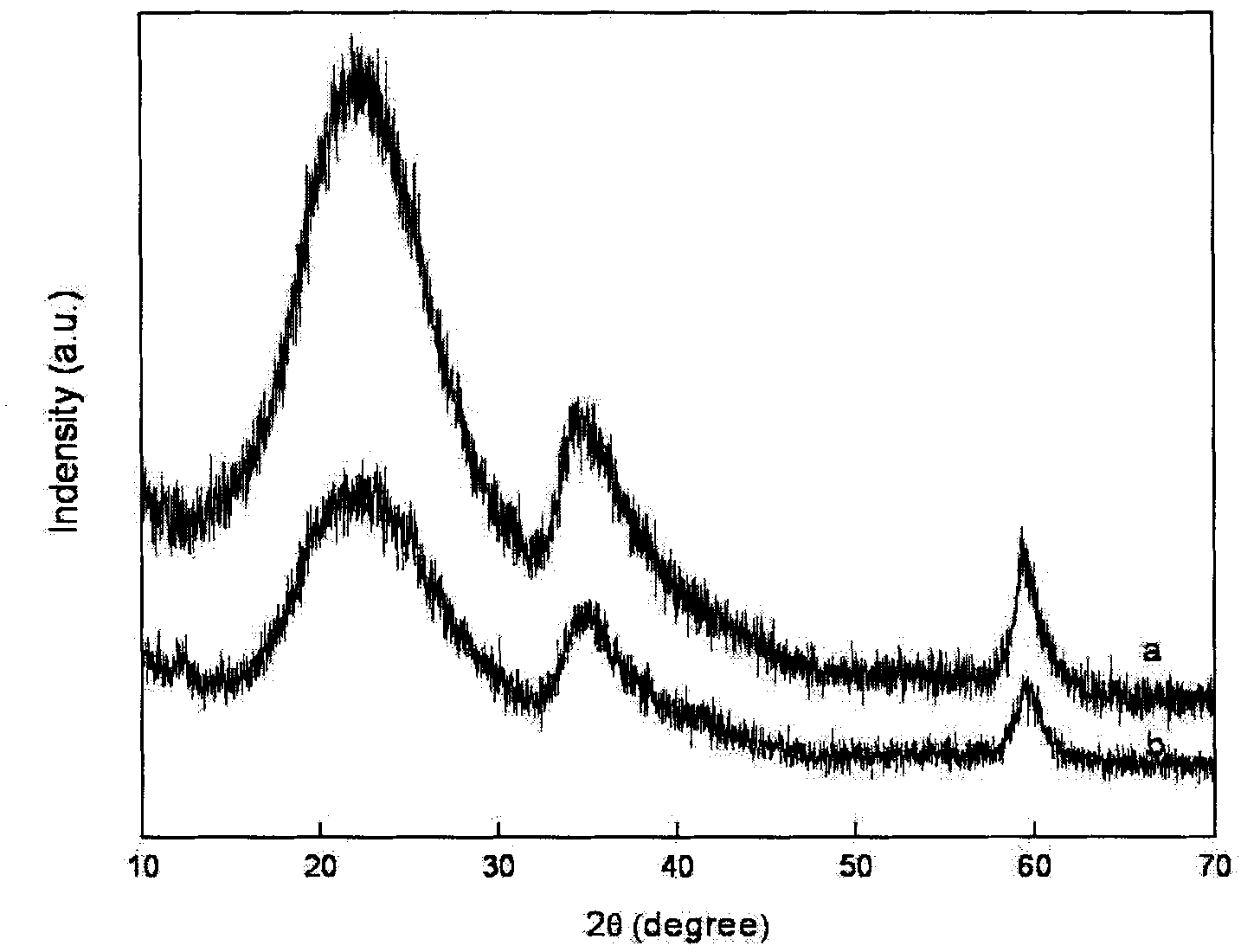

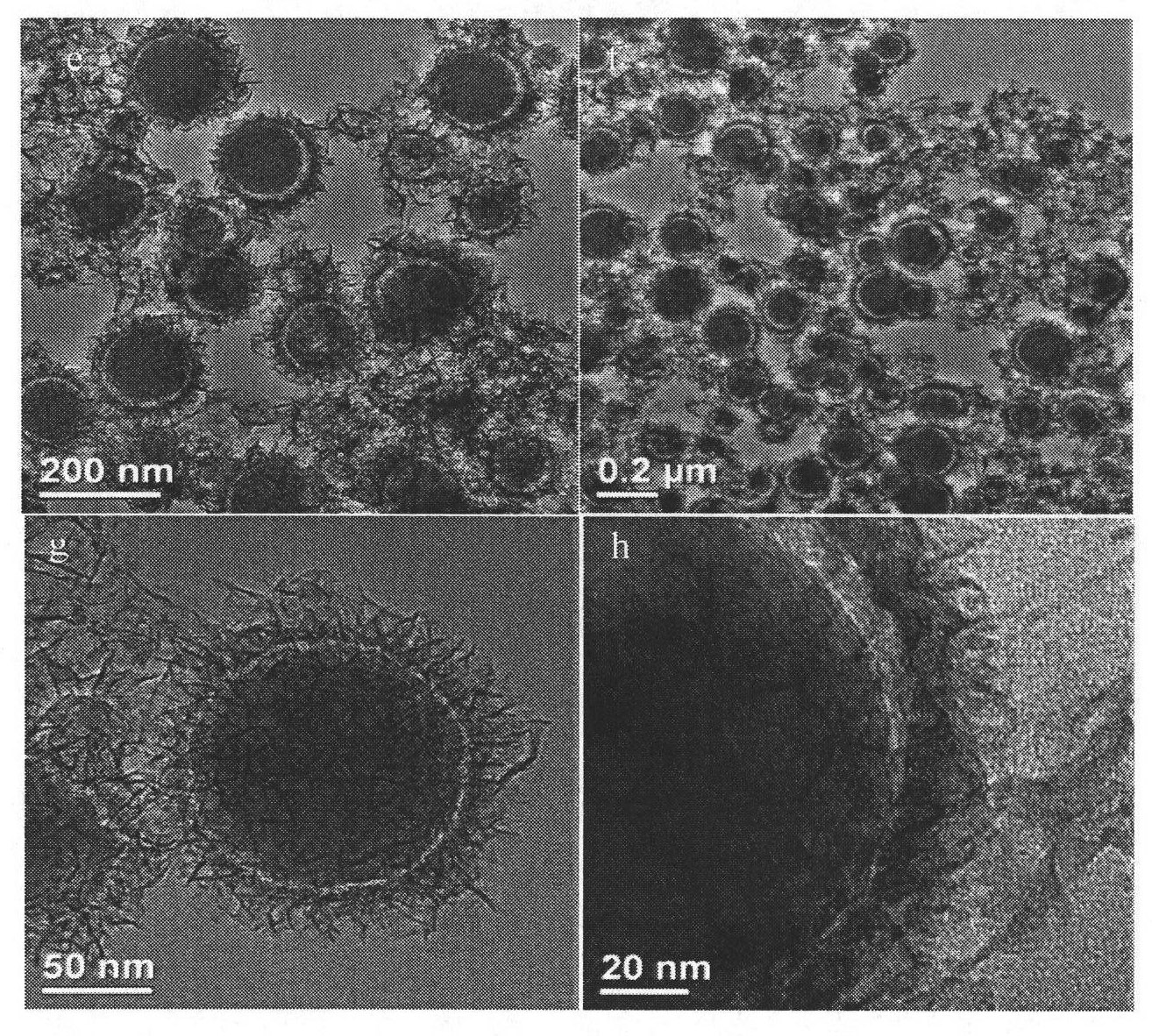

Preparation method of silicate nano hollow structure material

InactiveCN101920970ALarger than surfaceLarge ion exchangeMagnesium silicatesNanostructure manufactureNitratePolyethylene glycol

The invention relates to a preparation method of a silicate nano hollow structure material, which comprises the following steps: (1) orderly adding 0.2 mol / L nitrate solution and 0.2 mol / L sodium silicate solution into mixed liquor of ethanol and polyethylene glycol to form a mixed solution, wherein the mixed solution respectively comprises 20-30 parts of ethanol, 2-3 parts of polyethylene glycol, 1 part of nitrate solution and 1-2 parts of sodium silicate solution in parts by volume; (2) adding NaOH solution into the mixed solution obtained in step (1), wherein the volume ratio of NaOH solution to nitrate solution is 1:0.03-0.2; and after conducting magnetic stirring, transferring the mixed solution to a hydrothermal kettle, reacting under the hydrothermal condition of 100-200 DEG C, filtering and drying to obtain the silicate nano hollow structure material. The obtained silicate hollow material can be used for heavy metal ion absorption, and can also be used in the fields of catalysis, medicines, environmental pollution treatment and the like.

Owner:TSINGHUA UNIV

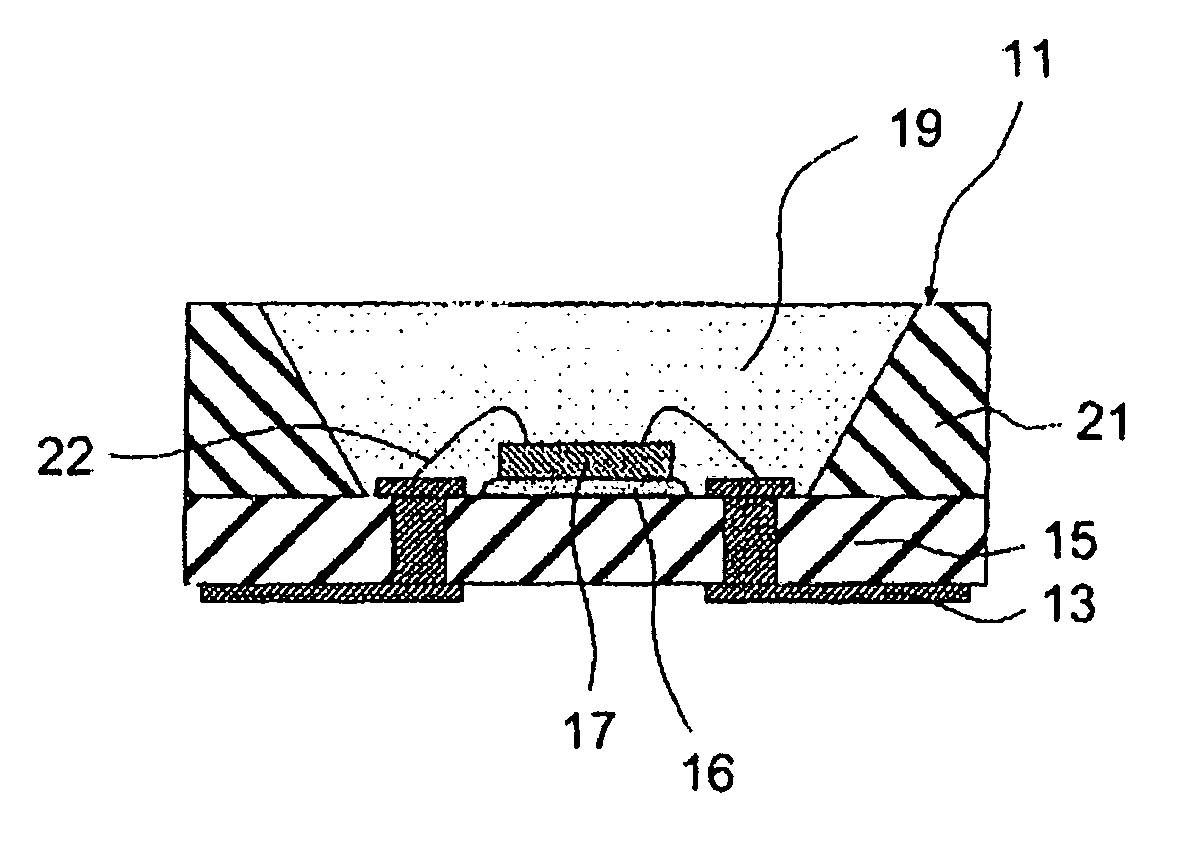

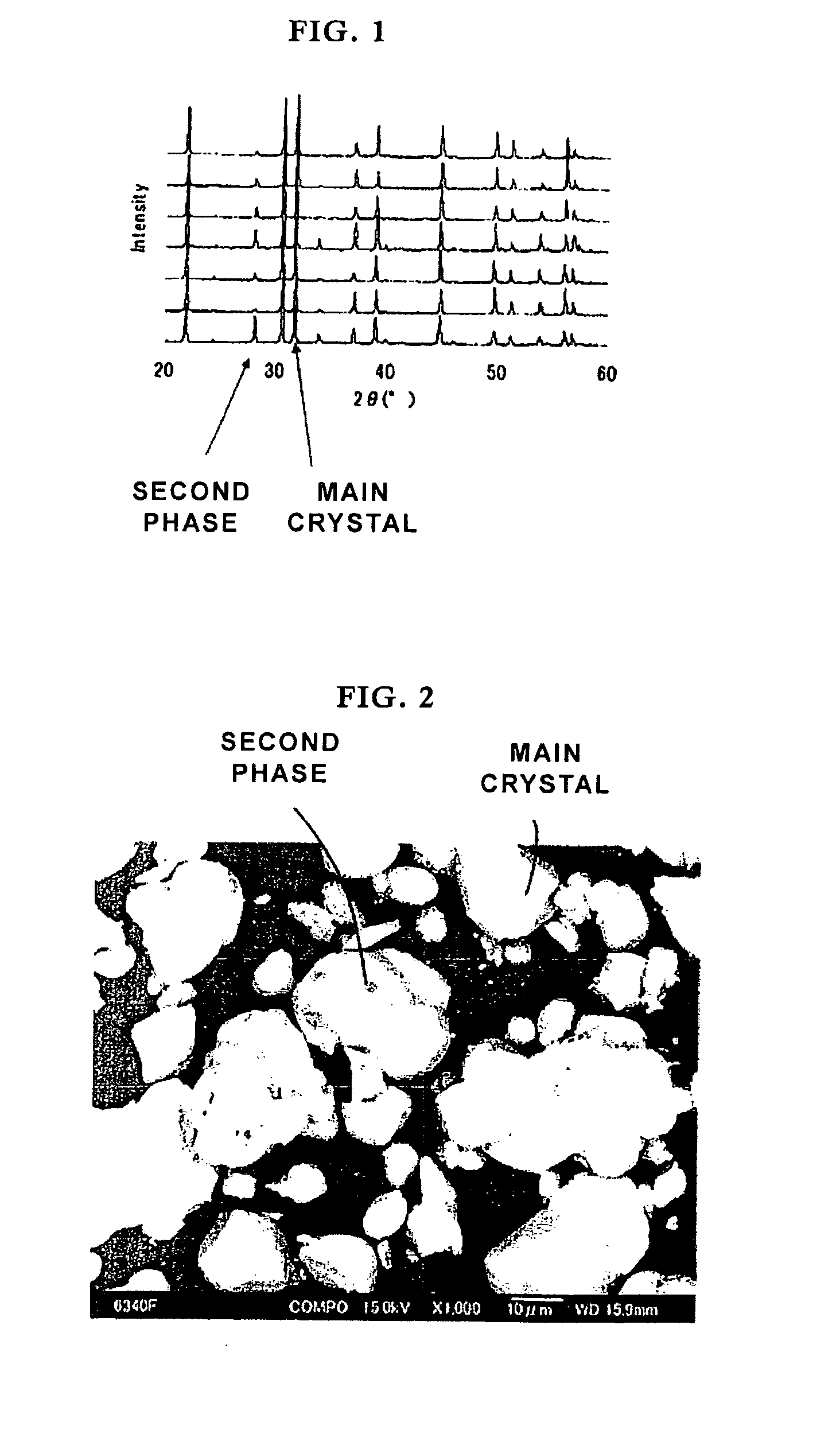

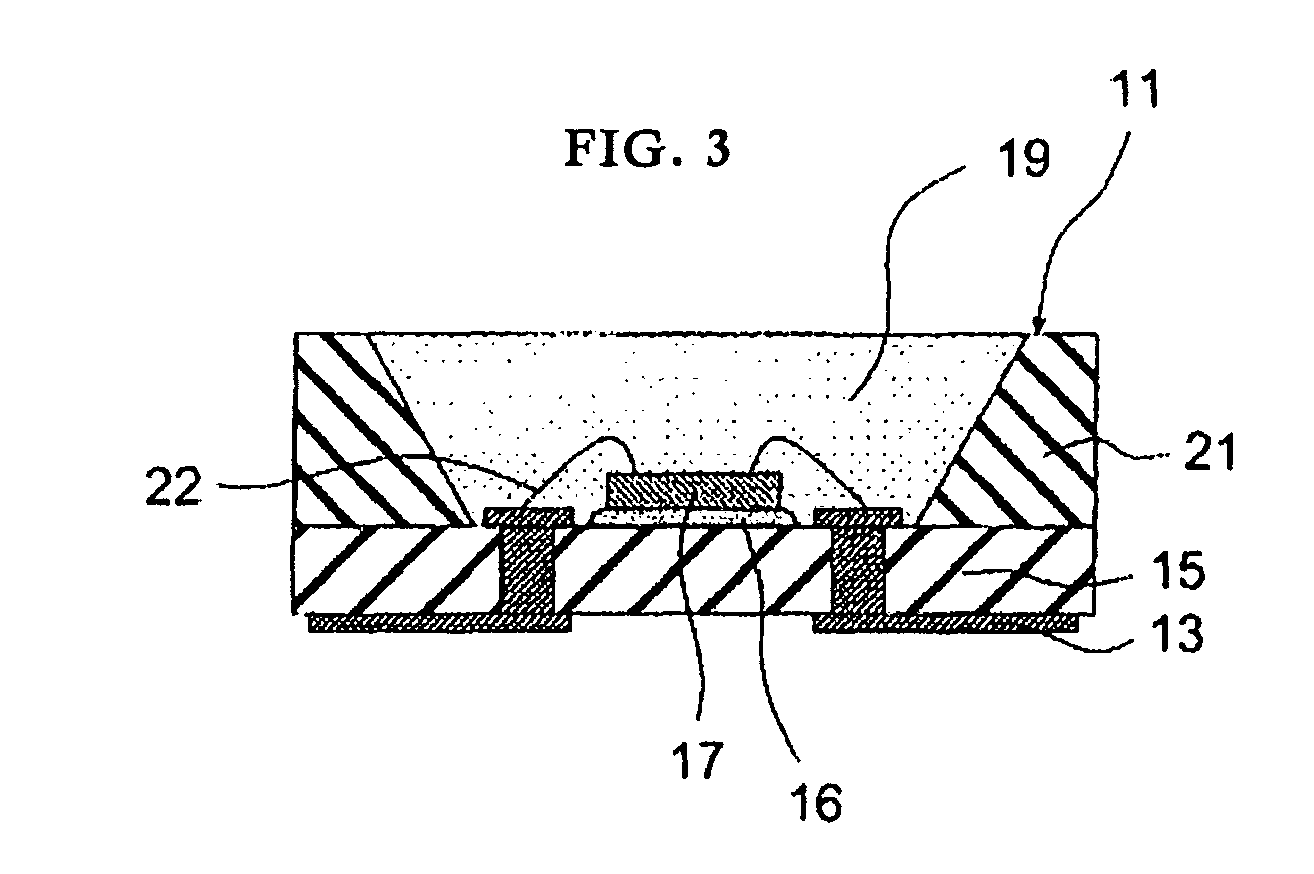

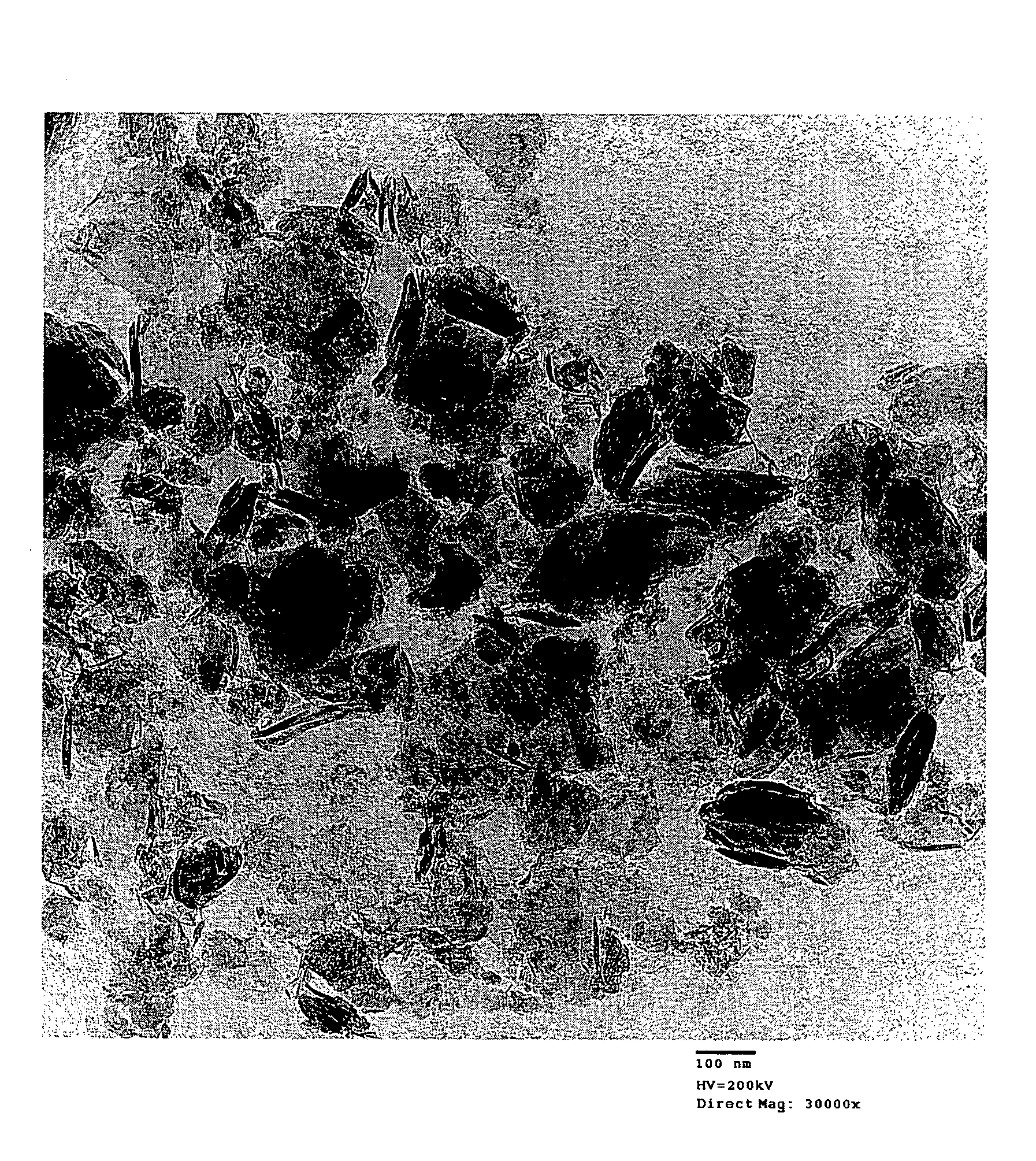

Phosphor, process for producing the same, wavelength converter and illumination device

InactiveUS20100214763A1Increase red quantum efficiencySuppress generationMagnesium silicatesAlkaline-earth metal silicatesFluorescenceX-ray

A fluorescent substance contains M1 (M1 is: barium; barium and strontium; or barium and calcium), europium, magnesium, manganese, and silicon as essential components. The amount of the europium is 0.14 mol or smaller per mol of the silicon, and the amount of the manganese is 0.07 mol or smaller per mol of the silicon. The main crystals are a solid solution of europium and manganese in M13MgSi2O8. When X-ray diffraction intensities for the M13MgSi2O8 crystals, M12MgSi2O7 crystals, M12SiO4 crystals, and M1MgSiO4 crystals are expressed by A, B, C, and D, respectively, then B / (A+B+C+D) is 0.1 or less, C / (A+B+C+D) is 0.1 or less, and D / (A+B+C+D) is 0.26 or less.

Owner:KYOCERA CORP

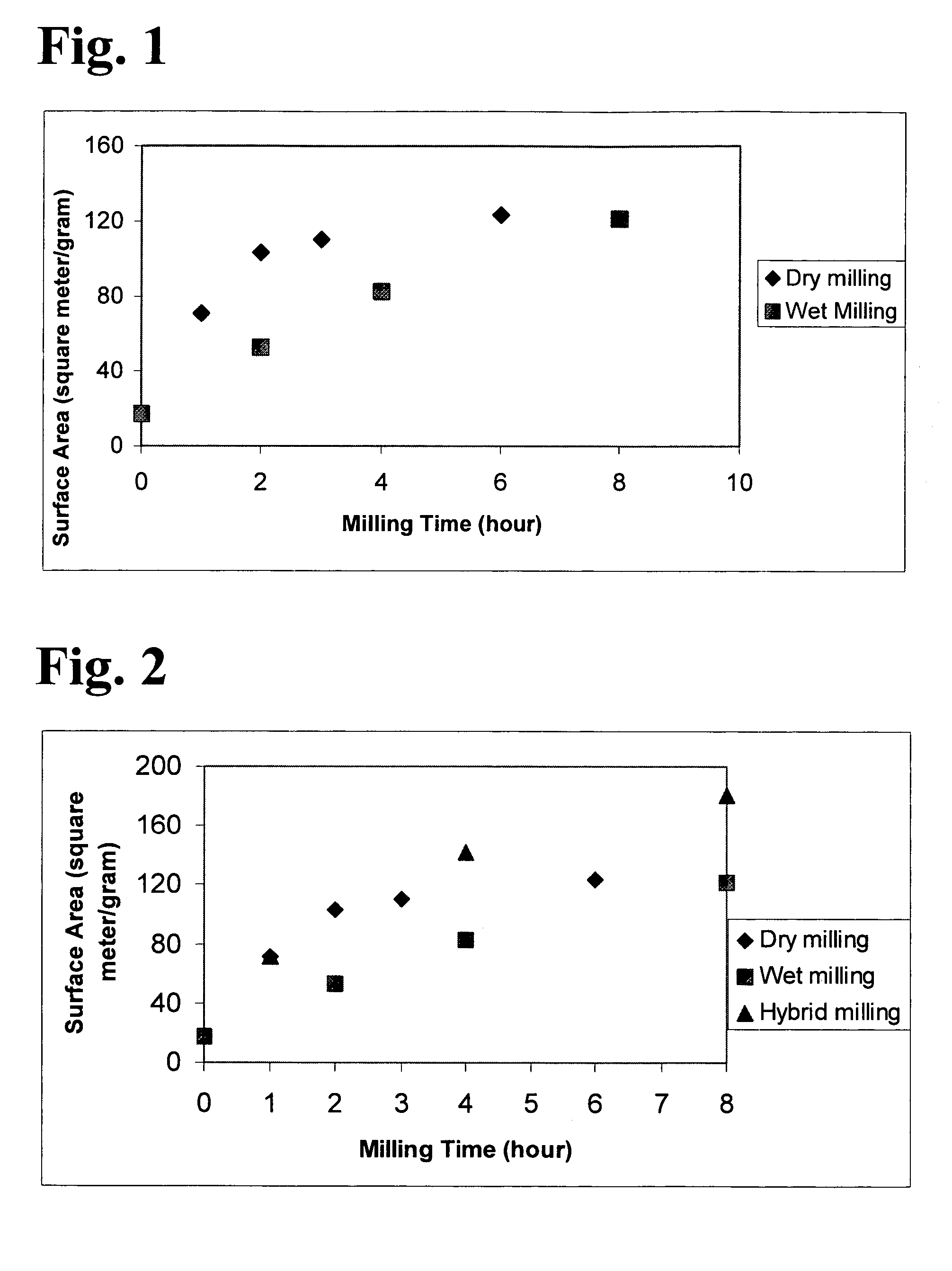

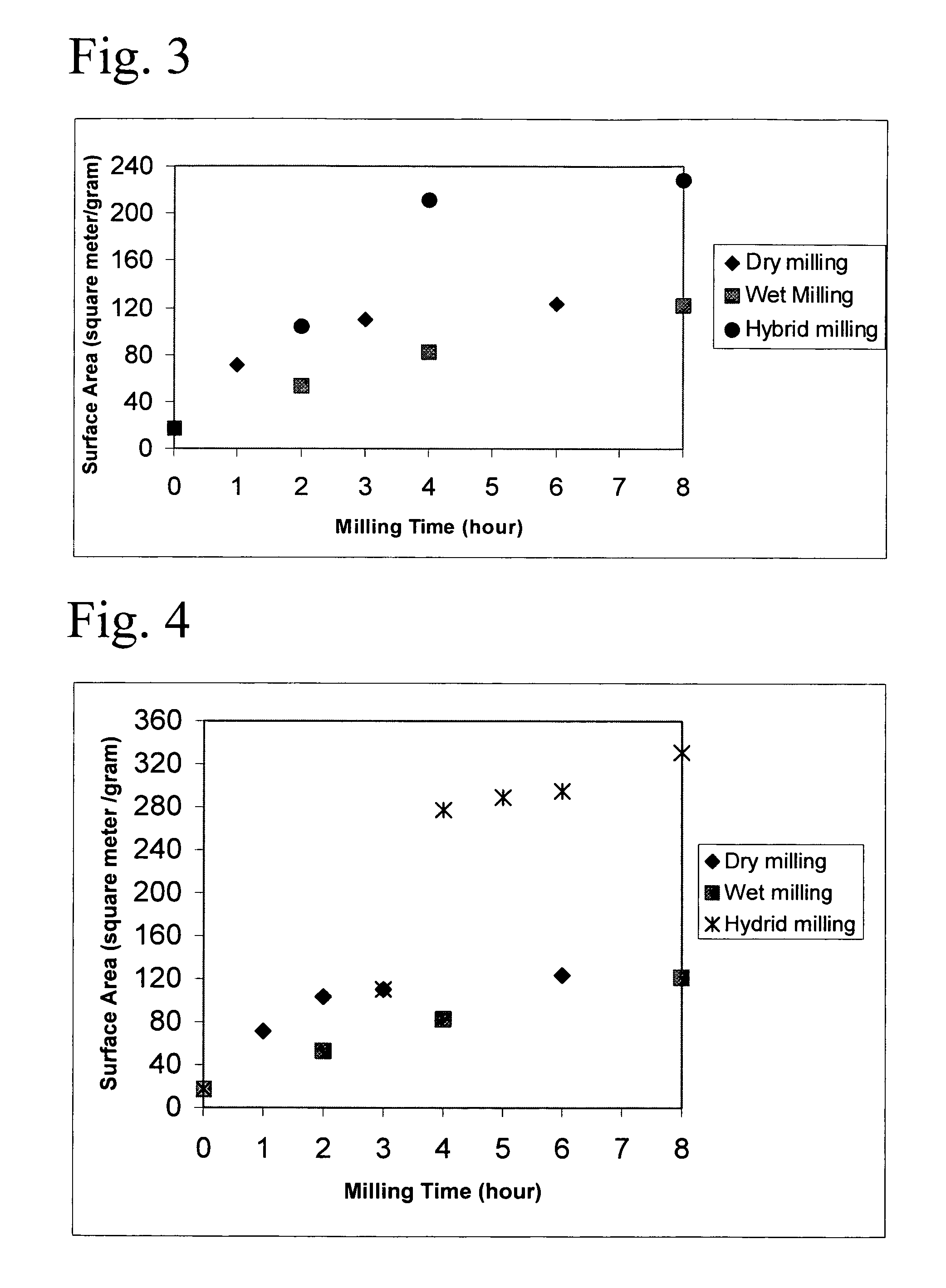

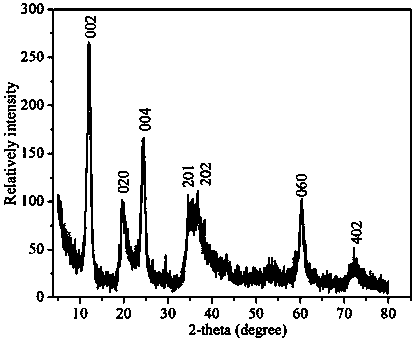

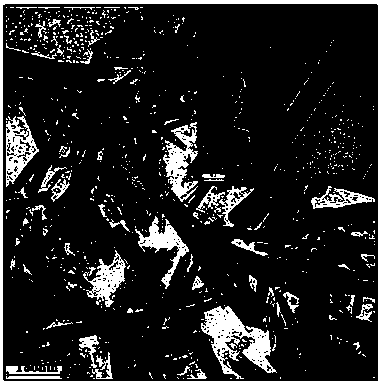

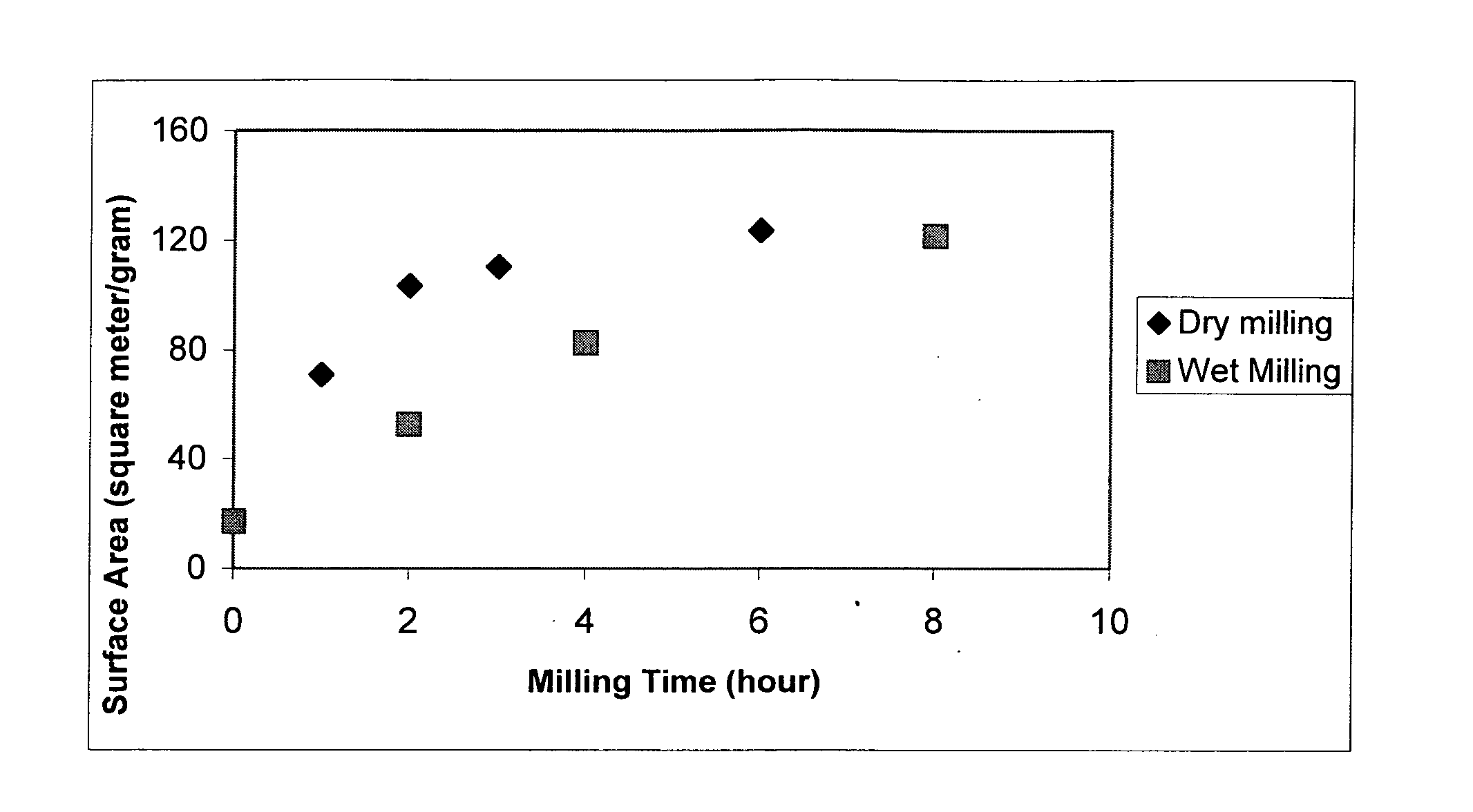

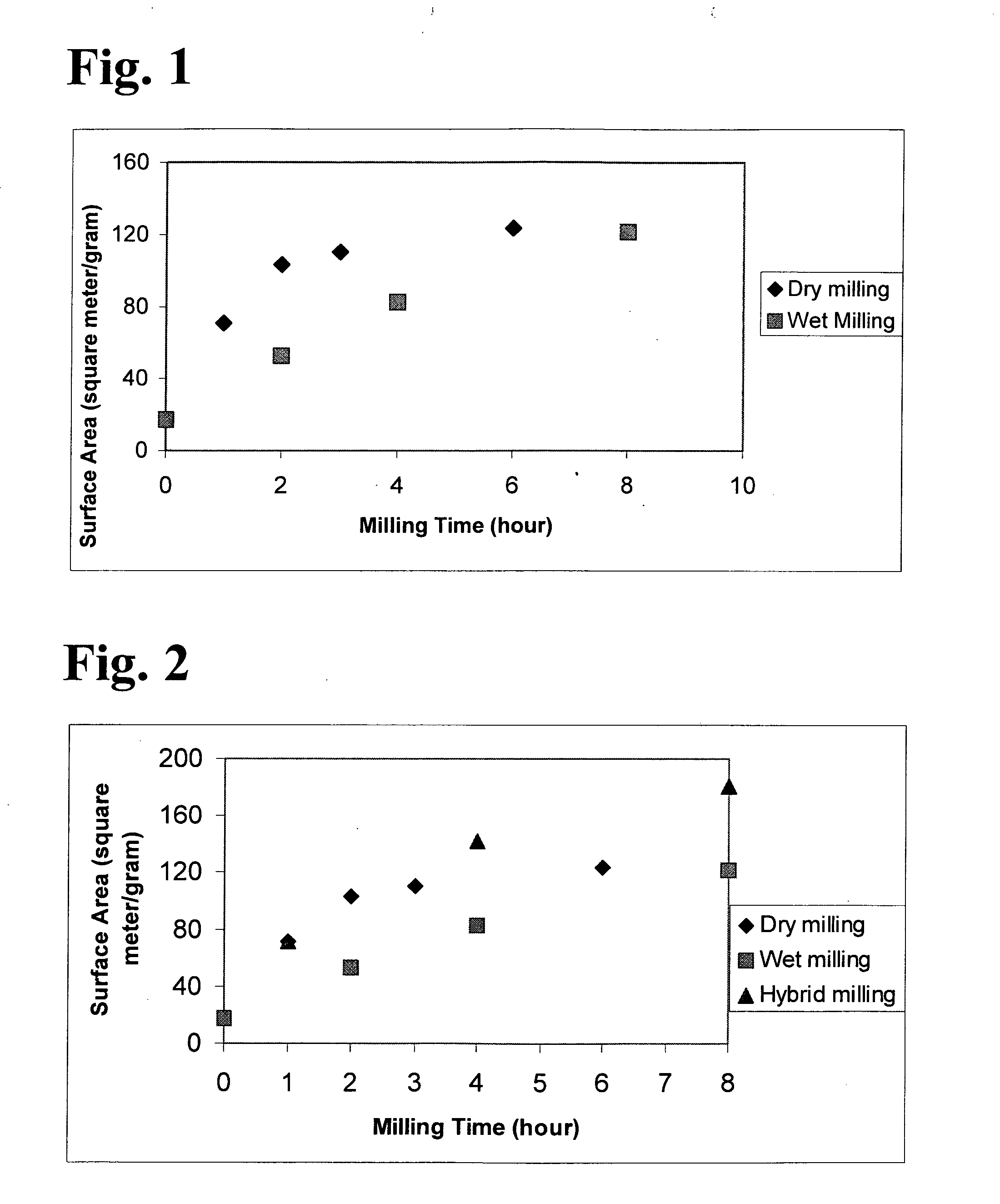

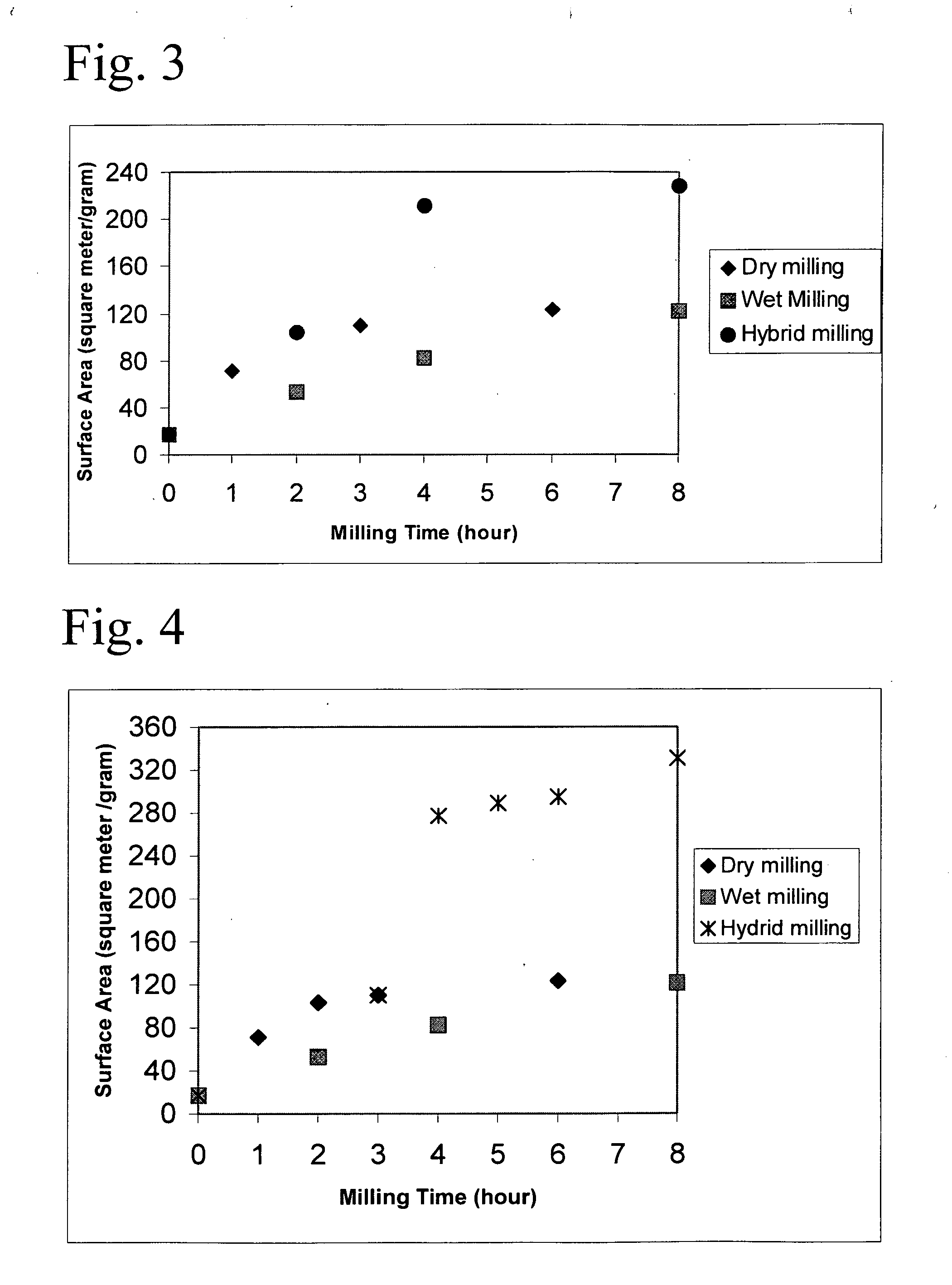

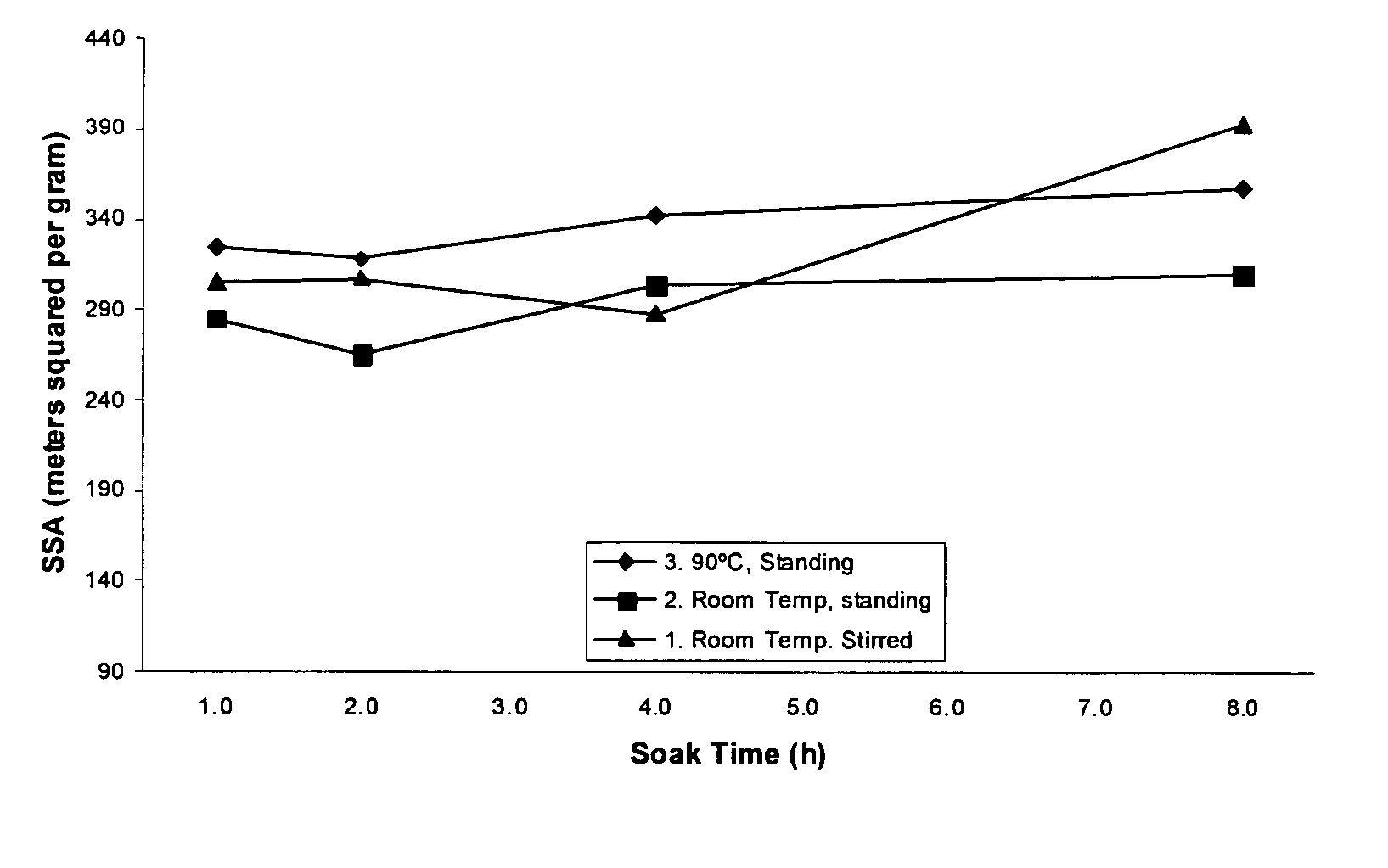

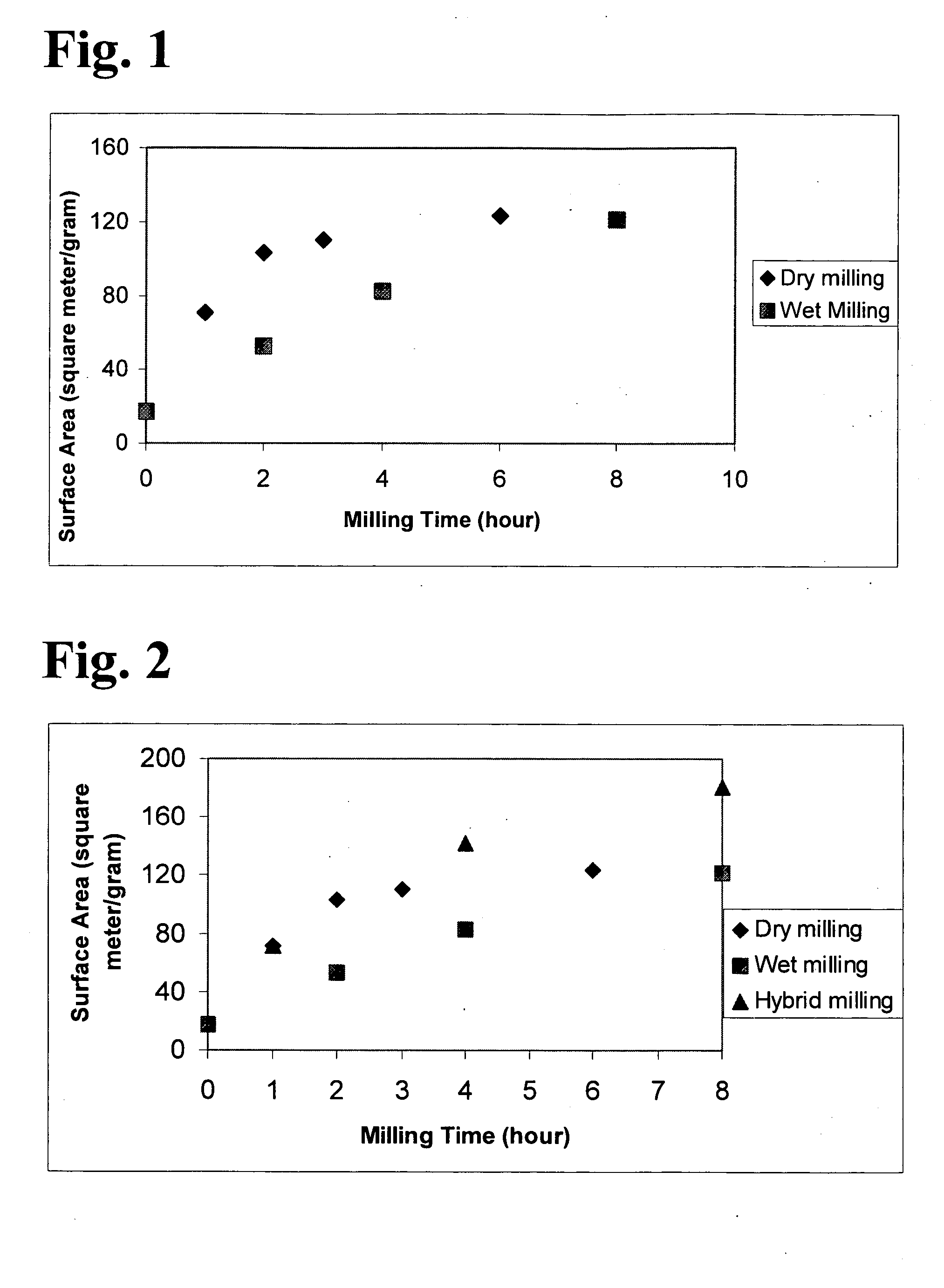

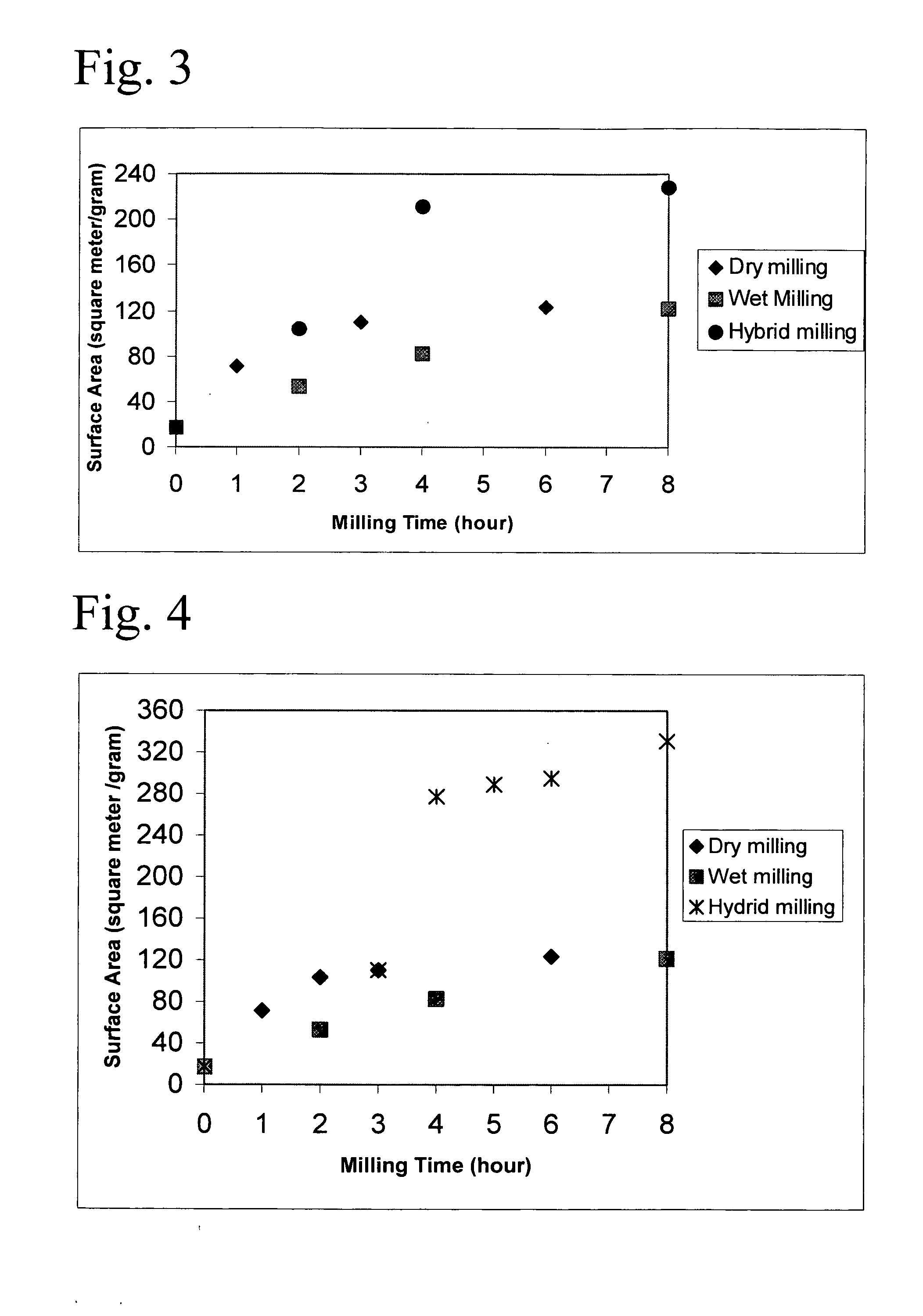

Nano-talc powders of high specific surface area obtained by hybrid milling

The invention provides high surface area talc compositions by a novel hybrid milling method or soaking method. The hybrid milling method comprises dry milling talc powder followed by mixing with water and wet milling to provide a nano-talc slurry with high surface area, also of the invention. The soaking method comprises dry milling talc powder followed by mixing with water and soaking the powder for a period of time to provide high surface area nano-talc slurry, also of the invention. The slurry may be dewatered and dried to provide dry nano-talc powder. The nano-talc powder provided by the invention is a novel hydrophilic talc composition also of the invention.

Owner:NANOMAT

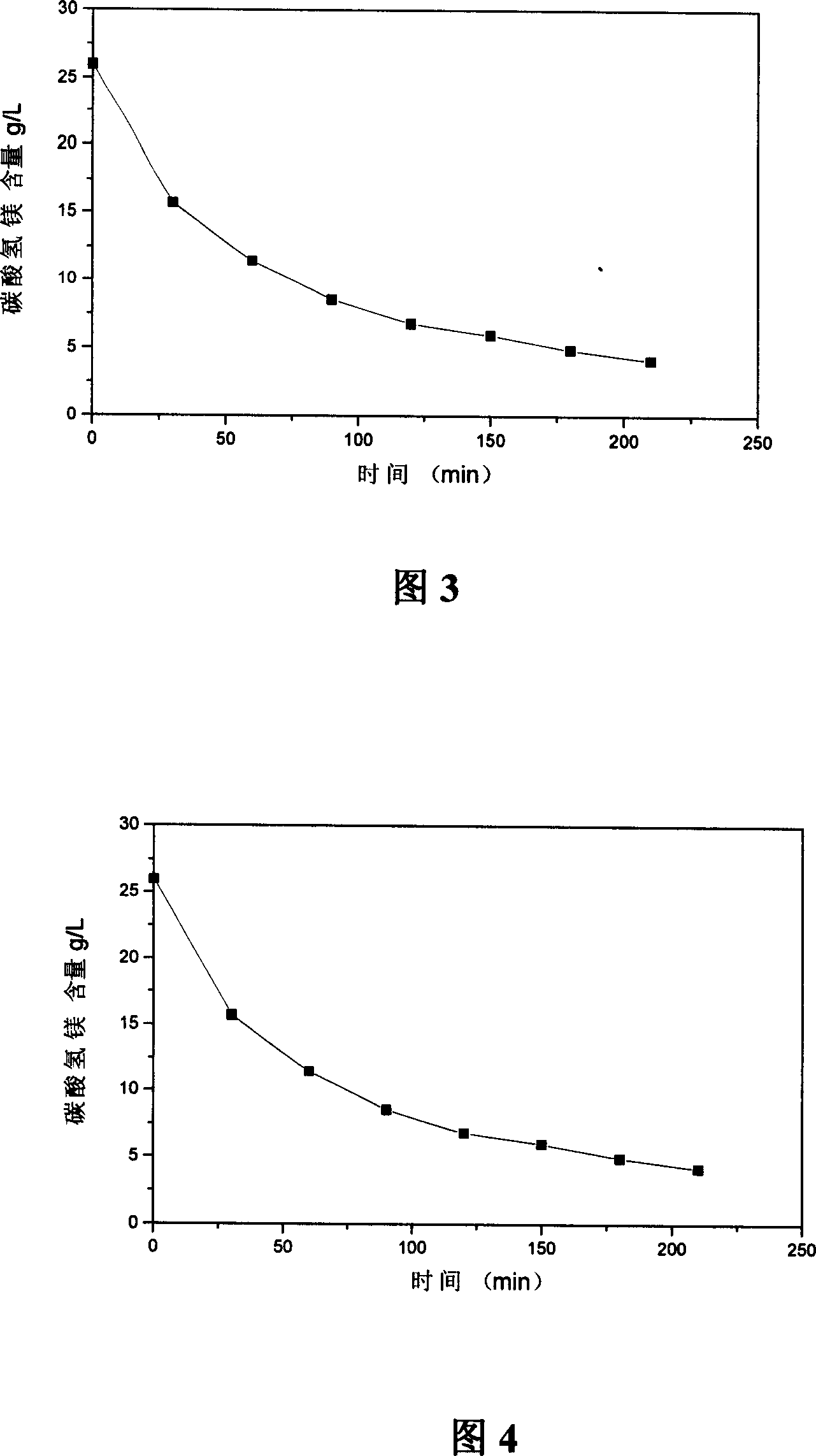

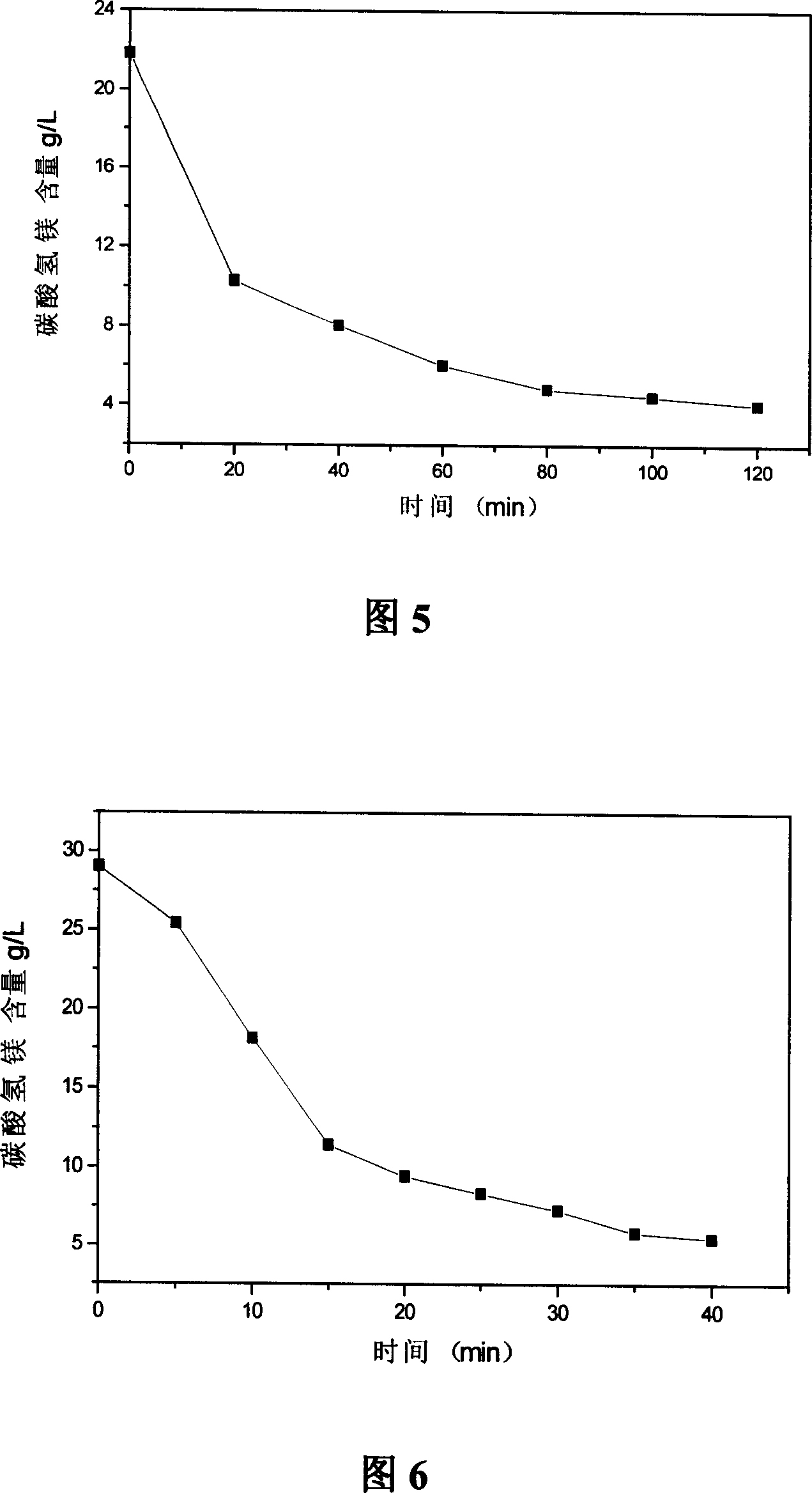

Method for preparing alkaline type magnesium carbonate by low temperature pyrogenation of Mg(HCO3)2 water and coproducing magnesium silicate

InactiveCN1970451AHigh yieldLow pyrolysis temperatureMagnesium silicatesMagnesium carbonatesMagnesium bicarbonateSodium silicate

The invention discloses a recycling method of magnesium in the heavy magnesium water solution, which comprises the following steps: aerating air in the heat decomposing reactor bottom under indoor temperature; reducing partial pressure of carbon dioxide through extracting into vacuum; transmitting 80-90% magnesium bicarbonate in the heavy magnesium solution into the sediment of basic magnesium carbonate sediment; filtering; drying to obtain the basic magnesium carbonate; adding sodium silicate in the filtrate; reacting residual 10-20% magnesium bicarbonate and sodium silicate to obtain magnesium silicate; recycling magnesium in the heavy magnesium solution completely.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hydrothermal synthesis production method of magnesium lithium silicate

InactiveCN101195488ANo pollution in the processMagnesium silicatesAlkali metal silicatesLithiumHydrothermal synthesis

The invention provides a process for producing lithium-magnesium silicate with cheap MgCl2 (MgO) and sodium silicate (potassium, potassium sodium). The process is employed to prepare a mixed solution which is prepared according to the ion ratio of MgCl2 (MgO), sodium silicate (potassium, potassium sodium) and LiCl (Li2CO3), the ion ratio is Li-1: Mg+2: Si+4=0.3: 2.7: 4, the pH value of the mixed solution is adjusted to 11-14 by aqueous alkali, and mixed solution is produced by reacting for 6-20 hours in a high-pressure reactor at the temperature of 130 DEG C to 250 DEG C, and lithium-magnesium silicate products are obtained after the mixed solution is washed, dried and ground. The molecular formula of the produced lithium-magnesium silicate is A0.3+SLi0.3+xMg2.7xSi4O10 (OH) 2, wherein A is potassium type sodium ion, 0<=S<=0.4, 0<=x<=0.2. The process is simple, the production cycle is short, and the cost is low. The invention is applicable to industrial production, and is non-toxic, nuisanceless, and non-polluted.

Owner:成增勋

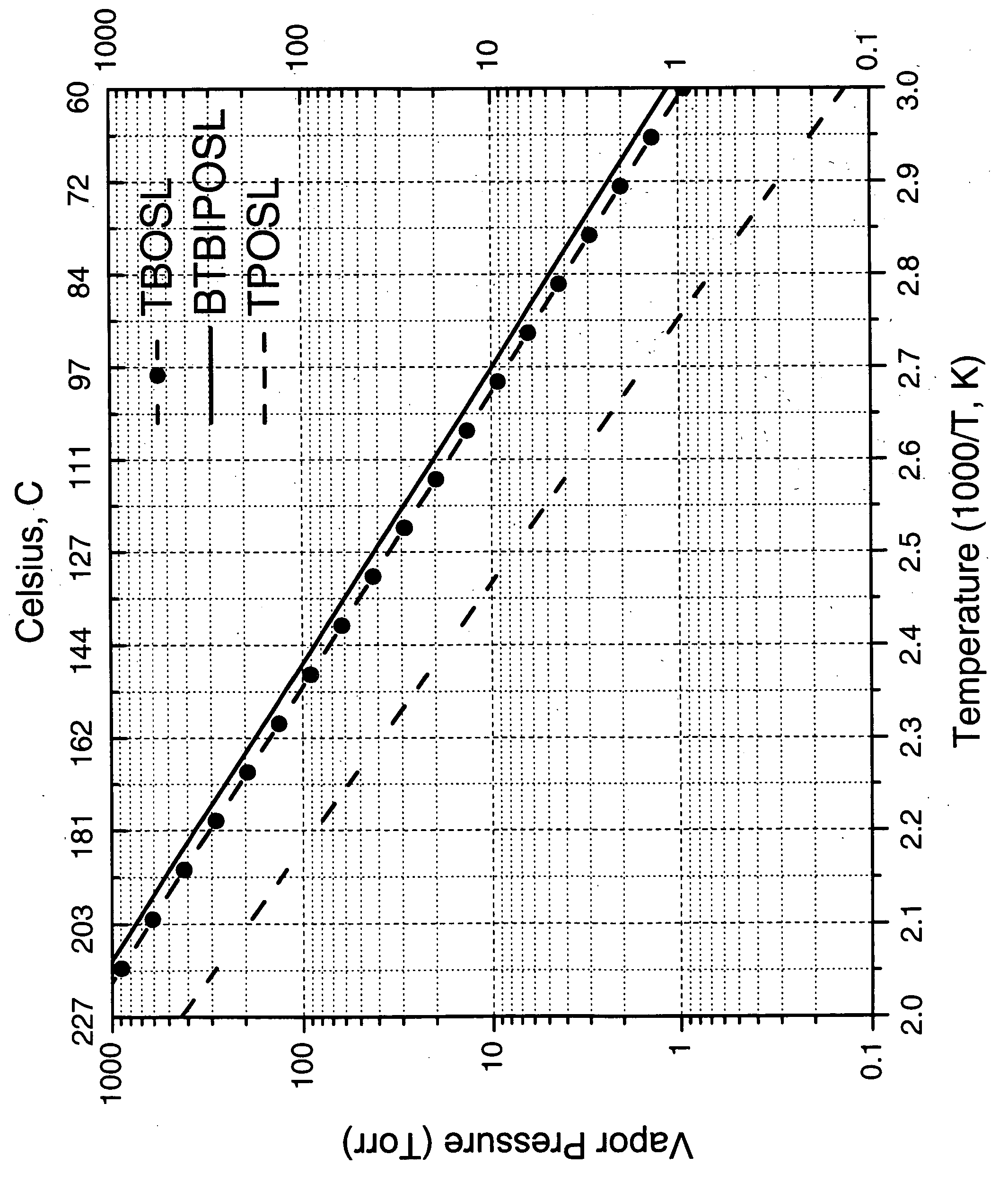

Precursors for silica or metal silicate films

A composition selected from the group consisting of bis(tert-butoxy)(isopropoxy)silanol, bis(isopropoxy)(tert-butoxy)silanol, bis(tert-pentoxy)(isopropoxy)silanol, bis(isopropoxy)(tert-pentoxy)silanol, bis(tert-pentoxy)(tert-butoxy)silanol, bis(tert-butoxy)(tert-pentoxy)silanol and mixtures thereof; its use to form a metal or metalloid silicate layer on a substrate and the synthesis of the mixed alkoxysilanols.

Owner:VERSUM MATERIALS US LLC

Alkaline aluminum extraction and dealkalized red mud obtaining method and dealkalized red mud obtained and application of dealkalized red mud

ActiveCN104649304ALess quantityIncrease added valueMagnesium silicatesAluminium oxides/hydroxidesRed mudAluminium hydroxide

The invention discloses an alkaline aluminum extraction and dealkalized red mud obtaining method, which comprises the following steps: (1) raw materials including an aluminiferous raw material, a sodium oxide precursor, a magnesium oxide precursor and an optional calcium oxide precursor are prepared according to a raw material formula; (2) the raw materials are roasted at 800-1300 DEG C to obtain a sintered clinker; (3) the sintered clinker undergoes dissolution and solid-liquid separation to obtain red mud and a digested liquor; (4) the digested liquor undergoes desilicication and carbonating disintergration so as to obtain aluminium hydroxide; and (5) the red mud is dealkalized to obtain the dealkalized red mud containing magnesium silicate, wherein the raw material formula satisfies that molar ratio of the components oxides ([MgO]+[CaO]) / ([SiO2]+[TiO2]) is 0.9-1.1. The invention also discloses dealkalized red mud obtained by the above method and an application of the dealkalized red mud. By the method provided by the invention, high standard dissolution rate of aluminium oxide can be maintained, and added value of aluminum extraction is high.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

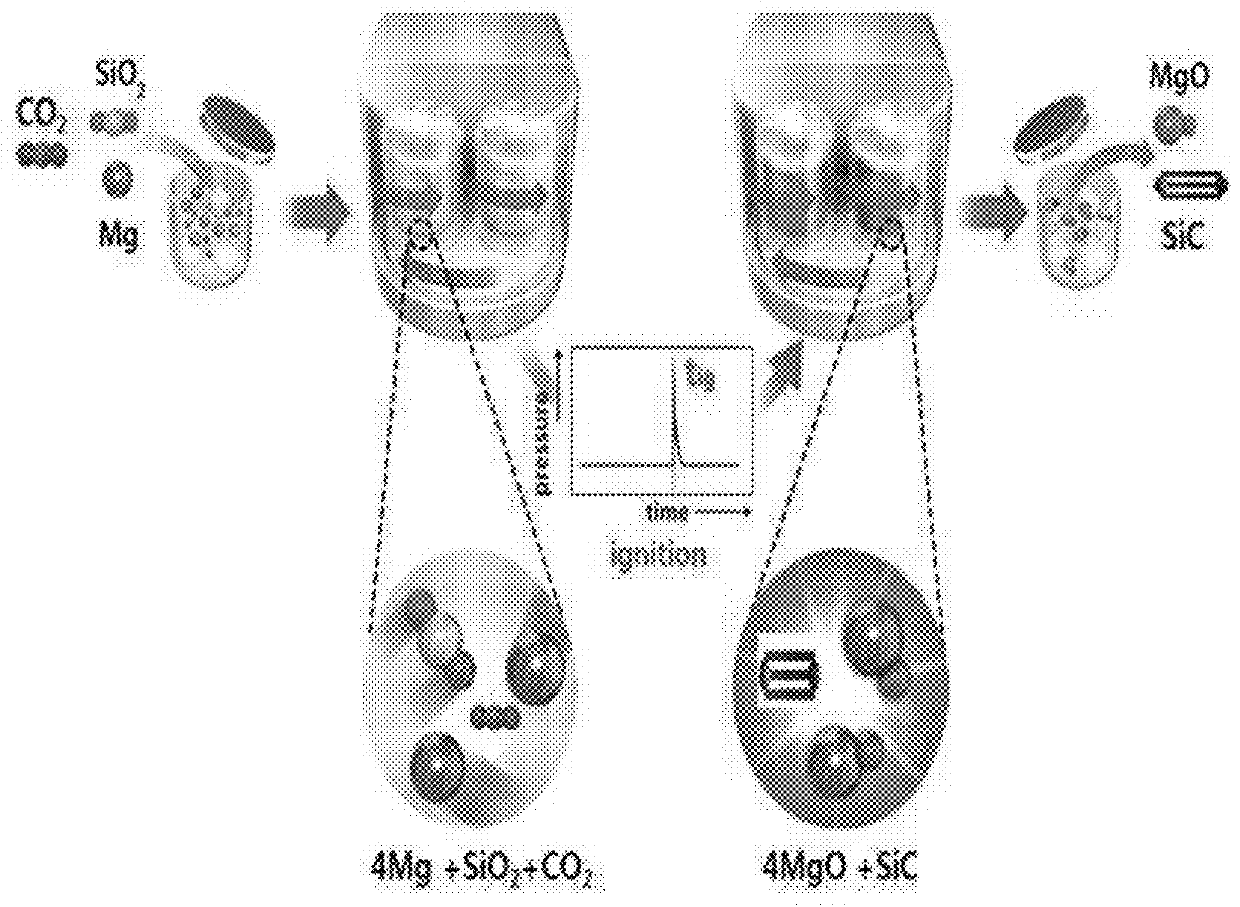

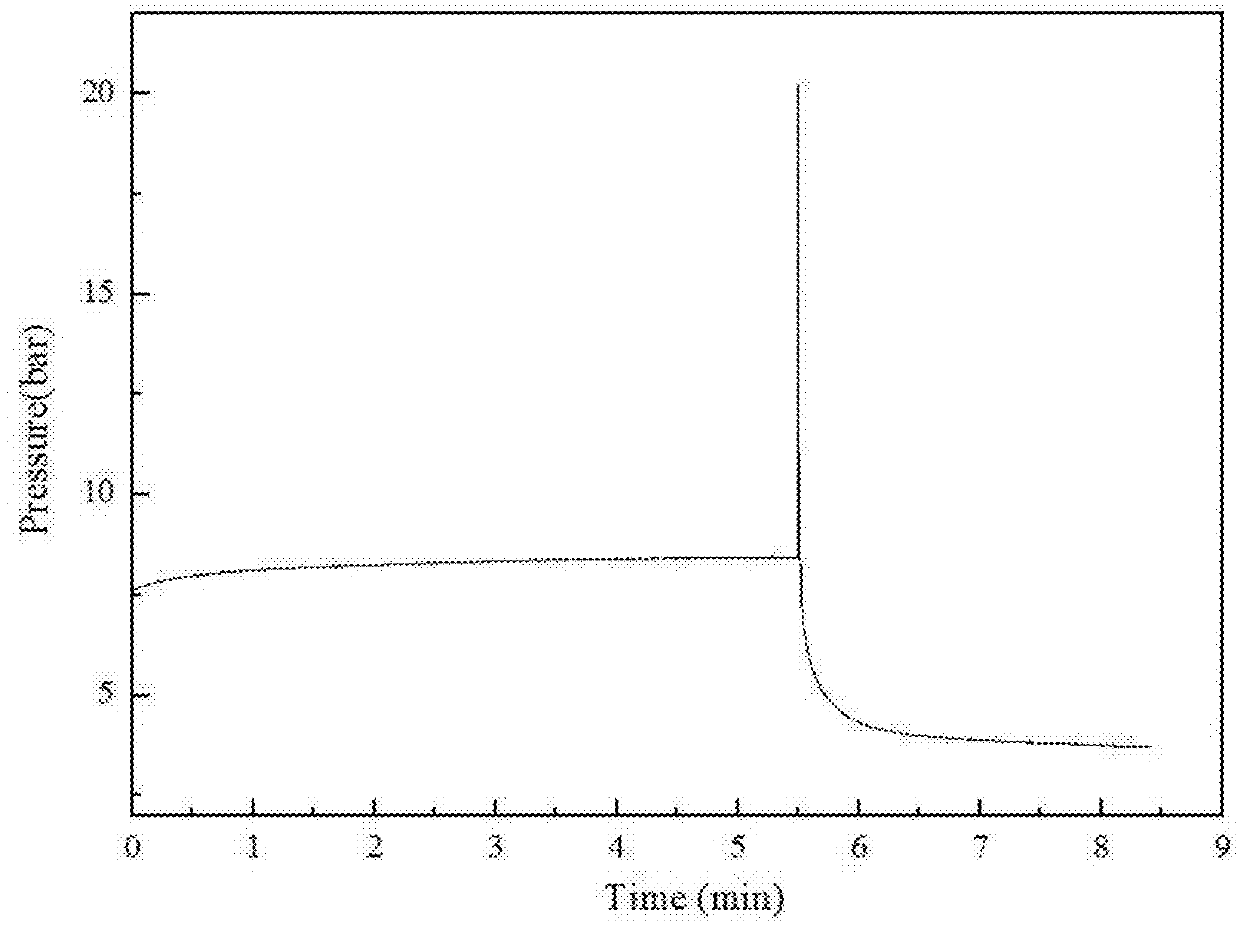

Manufacturing method of silicon carbide and silicon carbide manufactured using the same

ActiveUS20180179071A1High yieldCarbon dioxide is effectively reducedMagnesium silicatesMetal silicidesSiliconReducing agent

A method of preparing silicon carbide according to the present invention includes reacting a silicon-containing compound with carbon dioxide, wherein a reducing agent is optionally used.

Owner:KOREA INST OF ENERGY RES

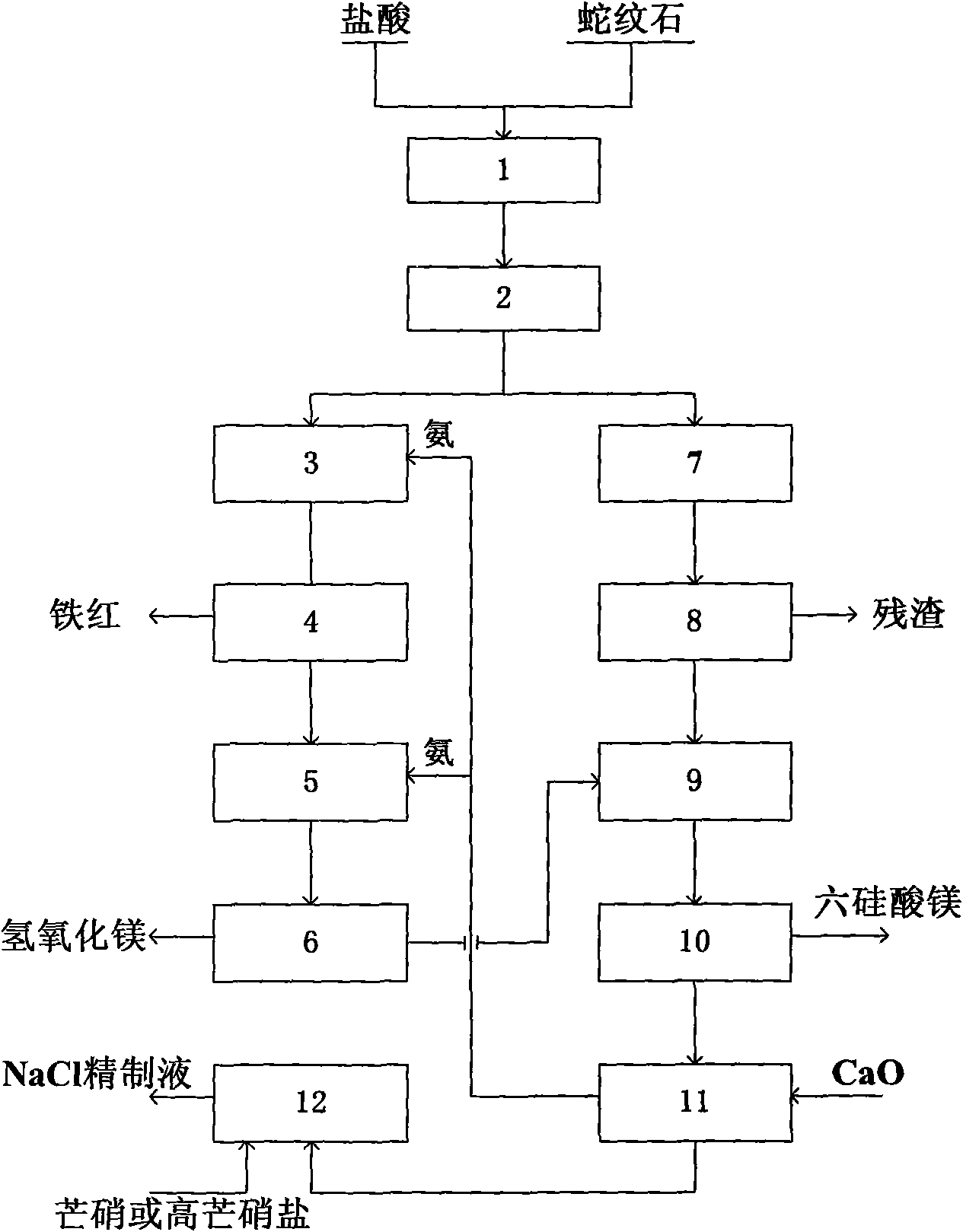

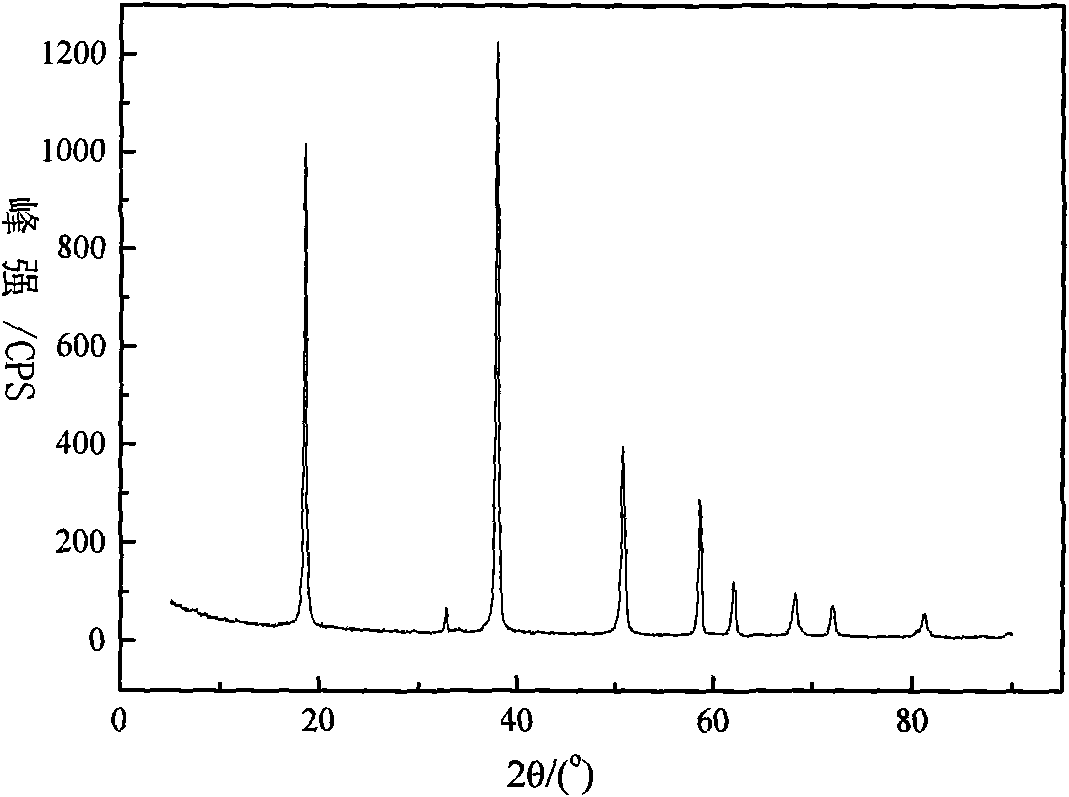

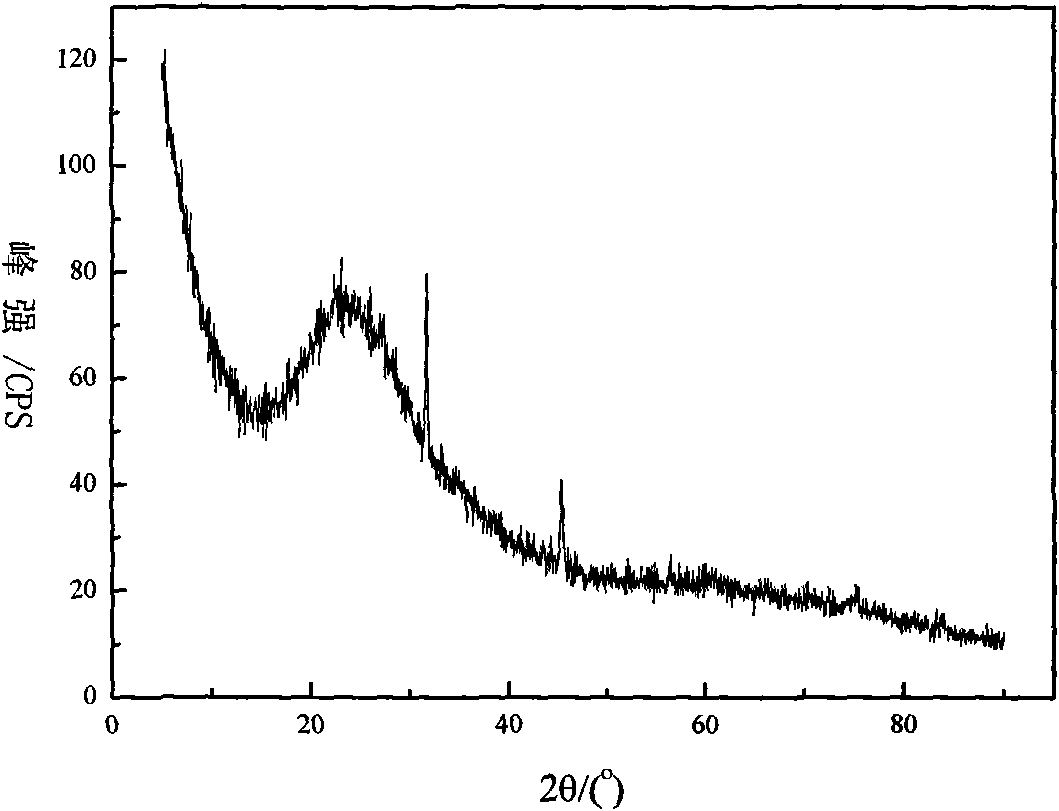

Method for preparing highly pure magnesium hydroxide and magnesium hexa-silicate by using olivine tailing mine

InactiveCN101607721AGuaranteed cycleReduce manufacturing costMagnesium silicatesSolid waste disposalSlurryOlivine

The invention discloses a method for preparing highly pure magnesium hydroxide and magnesium hexa-silicate by using olivine tailing mine, which comprises the following steps: step one. olivine tailing mine and muriatic acid are blended, leached and reacts; step two. pickle liquor leached by acid is added into an enamel reactor and oxidized by adding oxidant hydrogen peroxide; step three. the component of a solid product after reaction is a ferric oxide which is washed and dried after solid-liquid separation to be iron oxide red; step four. filtrate after solid-liquid separation is continously added with ammonia water; step five. sizing agent containing magnesium hydroxide stays in reactant, aged, washed, dried and ground to obtain highly pure magnesium hydroxide; step six. solid leached by muriatic acid reacts with caustic soda to produce serous fluid containing sodium silicate; and step seven. reaction product which reacts with caustic soda solution is filtered and washed to obtain magnesium hexa-silicate. The method causes magnesium oxide to be fully recycled. The method ensures complete circulation of ammonia, increases yield of magnesium oxide in mineral, reduces the cost of magnesium hydroxide, and simultaneously ensures the purity of the magnesium hydroxide which reaches more than 99%.

Owner:宜昌弘林华镁矿业投资有限公司

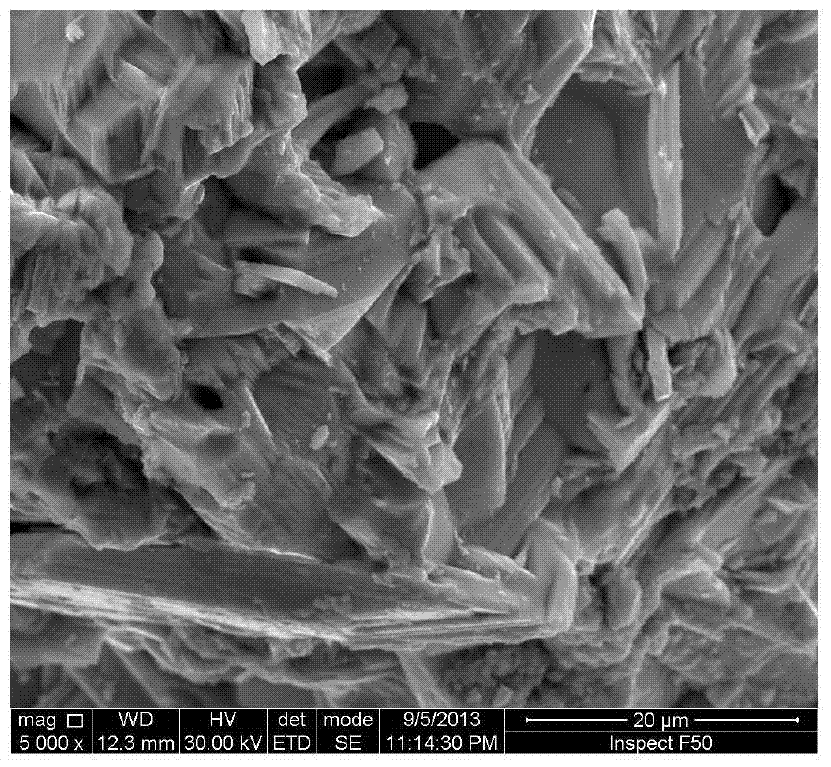

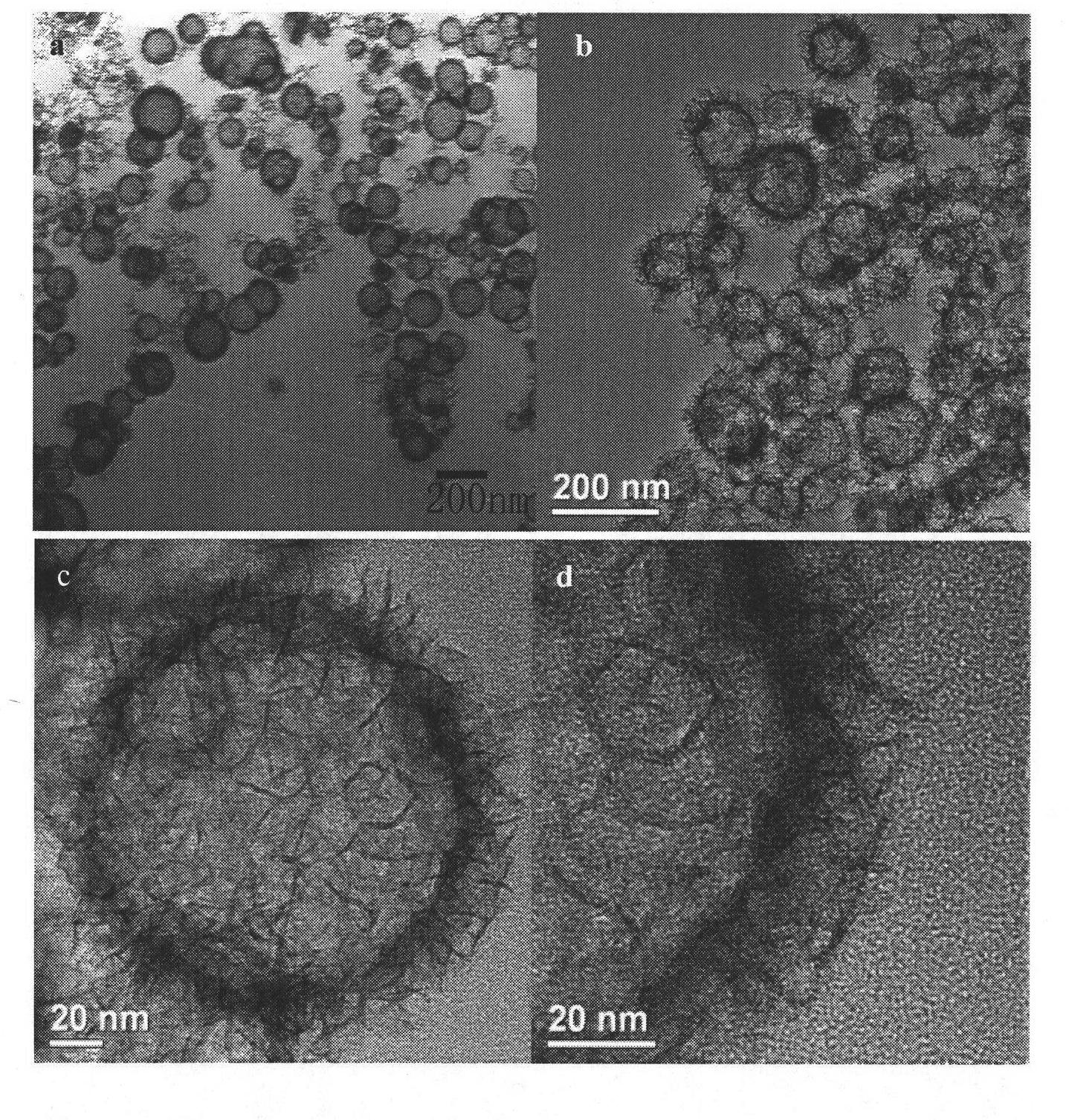

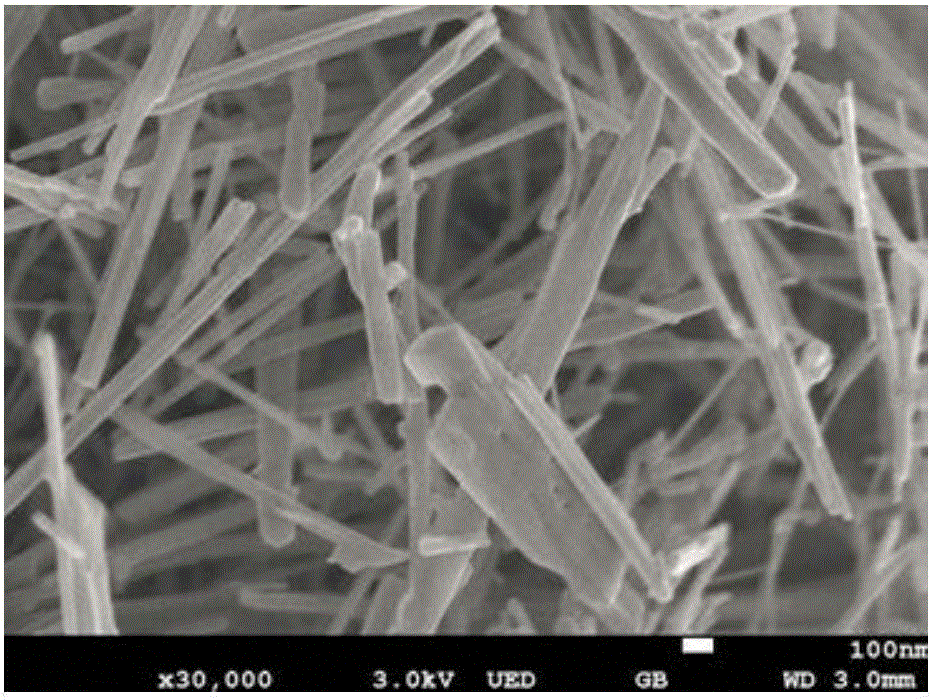

Method for preparing magnetic chrysotile nanotube

ActiveCN103466647AGood chemical stabilityStrong magnetismMagnesium silicatesMaterial nanotechnologyIron saltsAdditive ingredient

The invention discloses a method for preparing a magnetic chrysotile nanotube. The method comprises the following steps: adding amorphous silica, a magnesium compound, a bivalent iron salt and water into a reaction kettle under the protection of nitrogen, and uniformly mixing the ingredients to obtain a mixed solution, wherein the mass concentration of the amorphous silica in the mixed solution is 2-25%, the mass concentration of the magnesium compound is 1-20%, and the mass concentration of the bivalent iron salt is 0.2-15%; adding a sodium hydroxide solution into the mixed solution to regulate the pH value to 10-13.5, and then, transferring the solution into a high-pressure reaction kettle, reacting for 12-72 h at 180-240 DEG C under a sealed condition, filtering, washing and drying the product after the reaction to obtain the magnetic chrysotile nanotube. The magnetic chrysotile nanotube prepared by the method has strong magnetism, and the specific magnetism of the magnetic chrysotile nanotube is 12.78 A.M2.kg<-1>.

Owner:HEFEI UNIV OF TECH

Organic solvent dispersed nano-talc slurry

InactiveUS20060086837A1Calcium/strontium/barium carbonatesMagnesium silicatesThermoplasticPolymer science

The invention provides high surface area talc compositions by a novel hybrid milling method or soaking method. The hybrid milling method comprises dry milling talc powder followed by mixing with water and wet milling to provide a nano-talc slurry with high surface area, also of the invention. The soaking method comprises dry milling talc powder followed by mixing with water and soaking to provide high surface area nano-talc slurry. The slurry may be dewatered and dried to provide dry nano-talc powder. The nano-talc powder provided by the invention is a novel hydrophilic talc composition. Further embodiments of the invention include organic solvent dispersed nano-talc slurries and methods for providing the same. These slurries can be used to provide polymer nano-talc composites in the form of coatings, sealing and gasketing materials, foams, extruded thermoplastic and thermoset sheets and films, thermoplastic pellets, thermoplastic and thermoset molded polymer composite articles. Another embodiment is a polyurethane nano-talc composite article derived from the organic solvent dispersed slurries.

Owner:NANOMAT

Methods of providing nano-talc powders

The invention provides high surface area talc compositions by a novel hybrid milling method or soaking method. The hybrid milling method comprises dry milling talc powder followed by mixing with water and wet milling to provide a nano-talc slurry with high surface area, also of the invention. The soaking method comprises dry milling talc powder followed by mixing with water and soaking the powder for a period of time to provide high surface area nano-talc slurry, also of the invention. The slurry may be dewatered and dried to provide dry nano-talc powder. The nano-talc powder provided by the invention is a novel hydrophilic talc composition also of the invention.

Owner:NANOMAT

Magnesium silicate fiber blanket and production method thereof

ActiveCN101706030AWith insulationWith sound-absorbing functionMagnesium silicatesThermal insulationFiberThermal insulation

The invention relates to a magnesium silicate fiber blanket belonging to the technical field of fire-proof heat preservation and insulation materials. The magnesium silicate fiber blanket is characterized by comprising the following materials with oxides in percentage by weight: 40%-85% of SiO2, 3%-40% of MgO, 2%-30% of CaO, and the balance of one or the any combination of B2O3, Al2O3, Fe2O3, Na2O and K2O, wherein the total amount of the SiO2, the MgO and the CaO is more than or equal to 85%. The magnesium silicate fiber blanket is processed through the procedures of material melt, centrifugal thread throwing or blowing fiber forming, cotton collection, pinprick, heat treatment, cutting, and the like. The magnesium silicate fiber blanket has functions of non-inflammation, heat insulation, sound absorption and fire prevention and is a fire-resistant heat-preserving heat-insulating fire-proof material which is widely suitable for various heat engineering equipment and pipelines.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

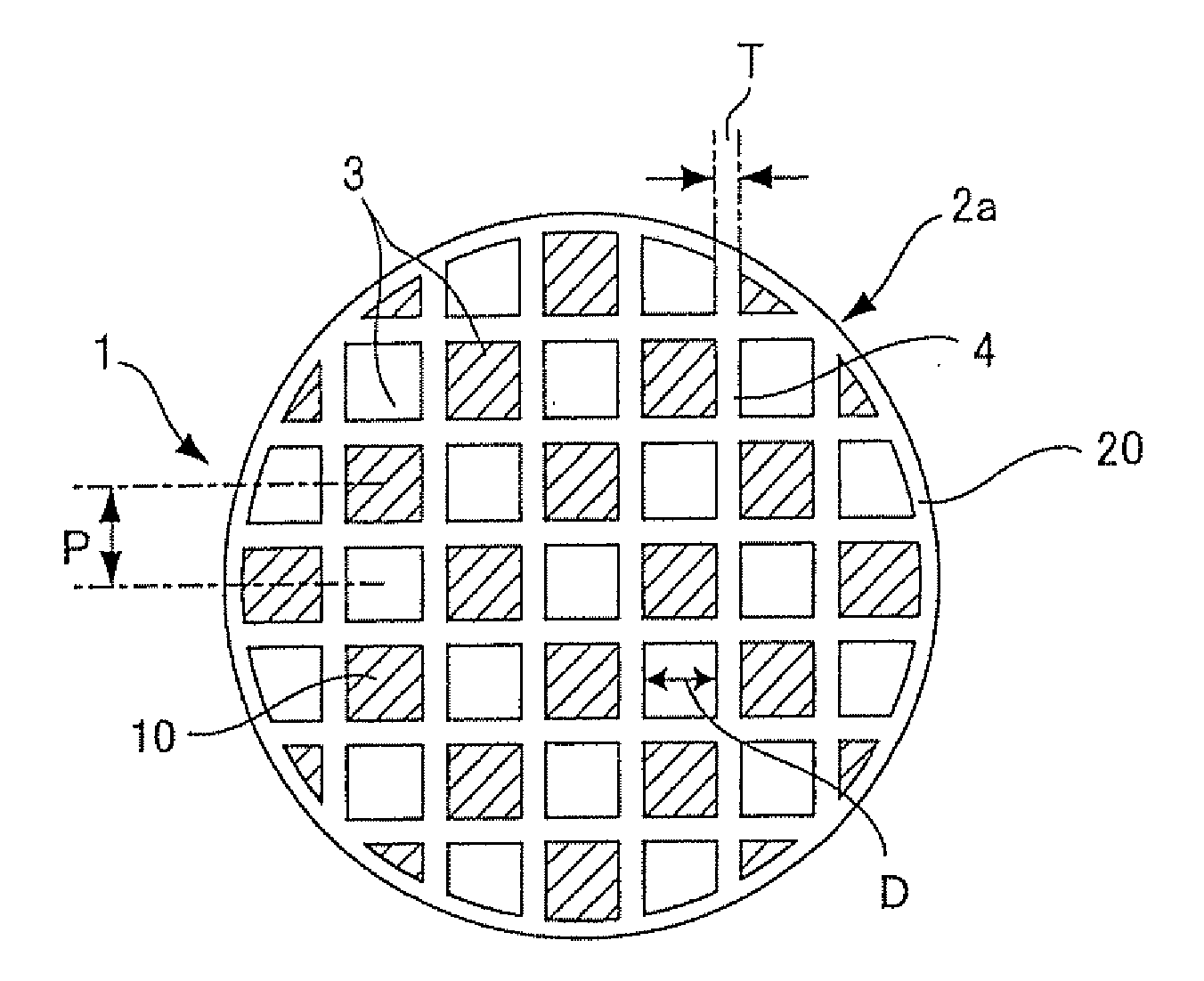

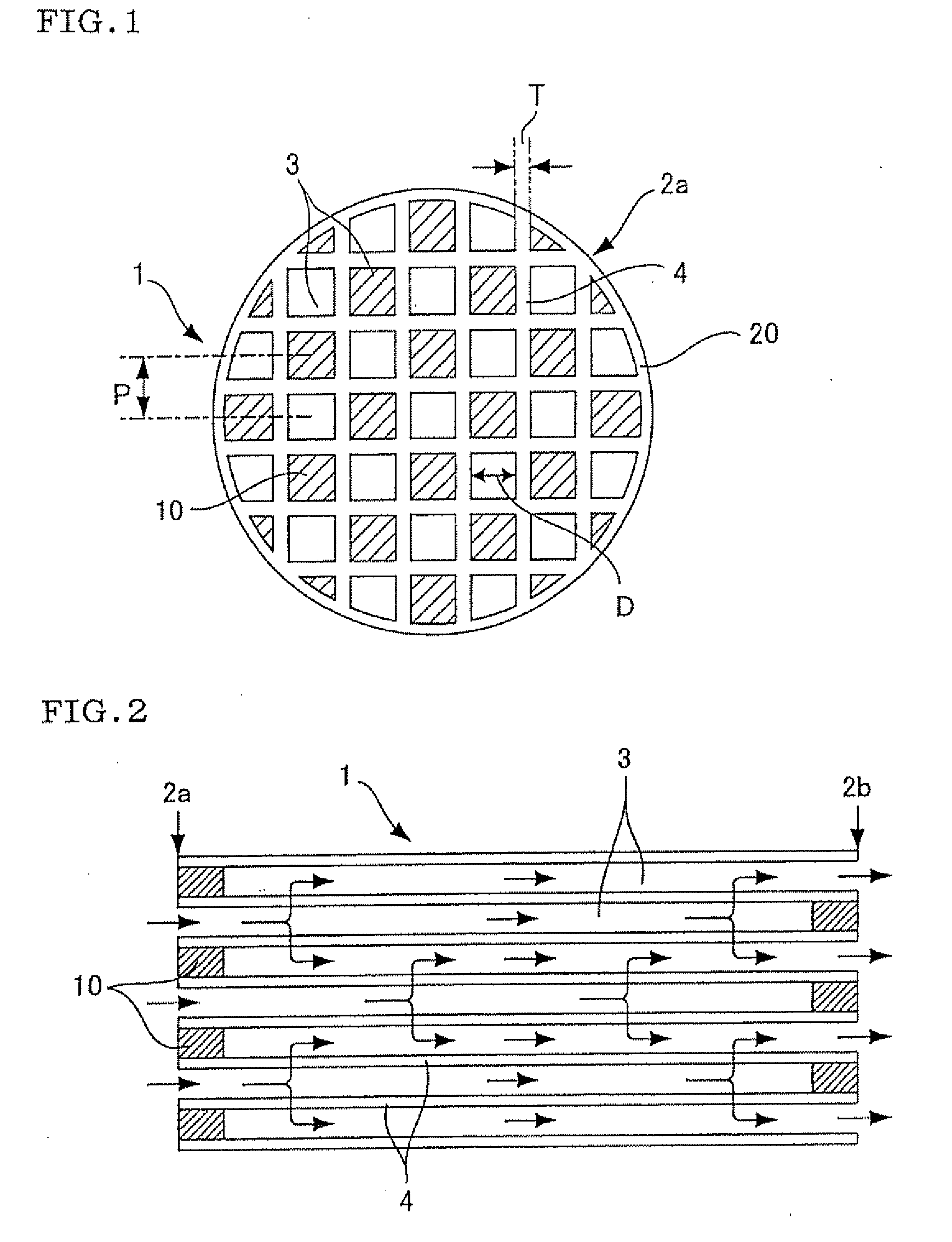

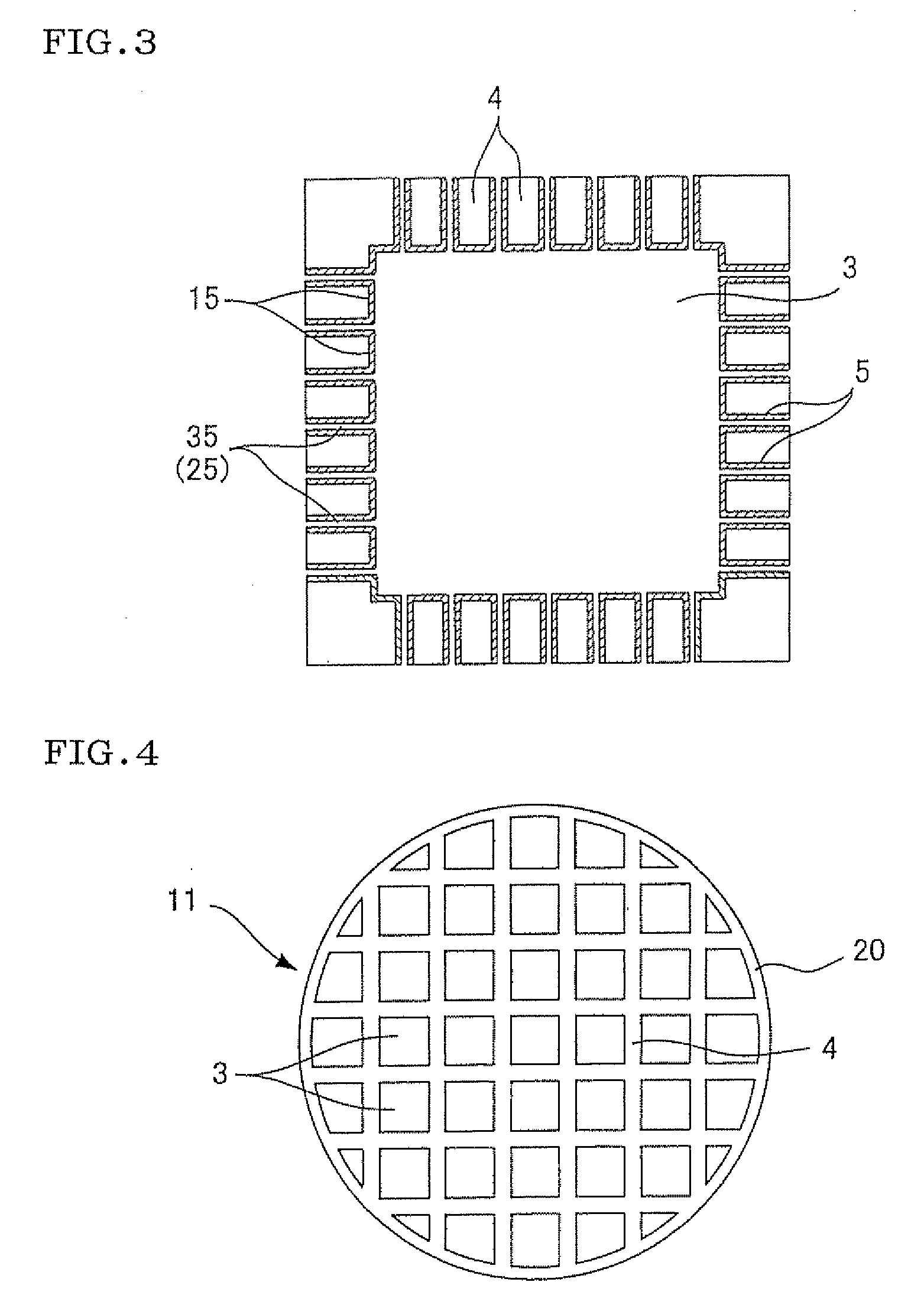

Ceramic structure and process for producing the same

ActiveUS20090005240A1Thermal stressInhibit thermal stressMagnesium silicatesInternal combustion piston enginesPore distributionMetallurgy

There is disclosed a ceramic structure which comprises a material having a controlled pore distribution and including cordierite as the main crystal phase. In the pore distribution, the volume of pores having pore diameters smaller than 20 μm accounts for 15% or less of the total pore volume, and the volume of pores having pore diameters of 20 to 100 μm accounts for 70% or more of the total pore volume. This ceramic structure is suitable for realizing a ceramic catalyst body which has excellent purification efficiency, is reduced in pressure loss, and is mountable even in a limited space.

Owner:NGK INSULATORS LTD

Method for preparing superfine calcinated talc powder

InactiveCN1803609ACalcination process is simpleFeeding and discharging are convenientMagnesium silicatesInorganic pigment treatmentUltra fineTalc

Owner:刘兴良

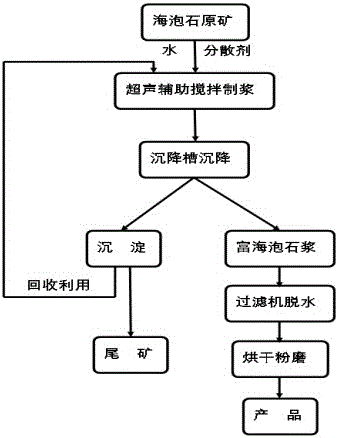

Method for purifying low-grade sepiolite

The invention discloses a method for purifying low-grade sepiolite. The method comprises the following steps: adding water and a dispersing agent into raw ore of sepiolite, and pulping under coactions of mechanical stirring, ultrasonic assistance and dispersion of the dispersing agent; obtaining sepiolite-enriched ore pulp through gravity settling; dehydrating, drying and grinding by using a vacuum filter, thereby obtaining a product. The method mainly aims to rapidly purify a sepiolite product under coactions of ultrasonic assistance and dispersion of the dispersing agent on the basis of a settling method. The method is simple in process, relatively short in preparation flow and preparation cycle, no other aids are needed except a small amount of the dispersing agent, ore pulp pollution is avoided, and later fine processing or secondary purification can be facilitated.

Owner:XIANGTAN UNIV

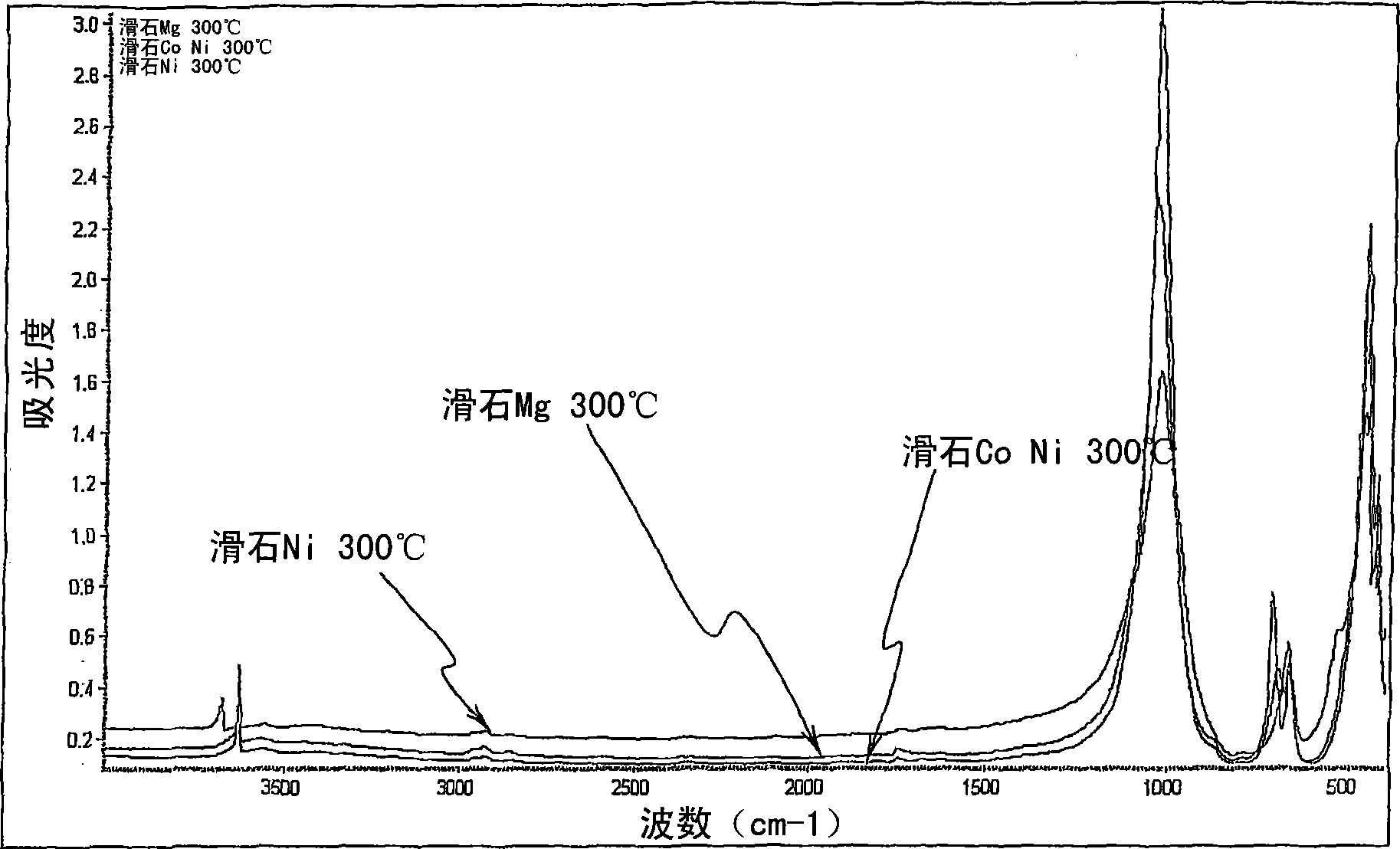

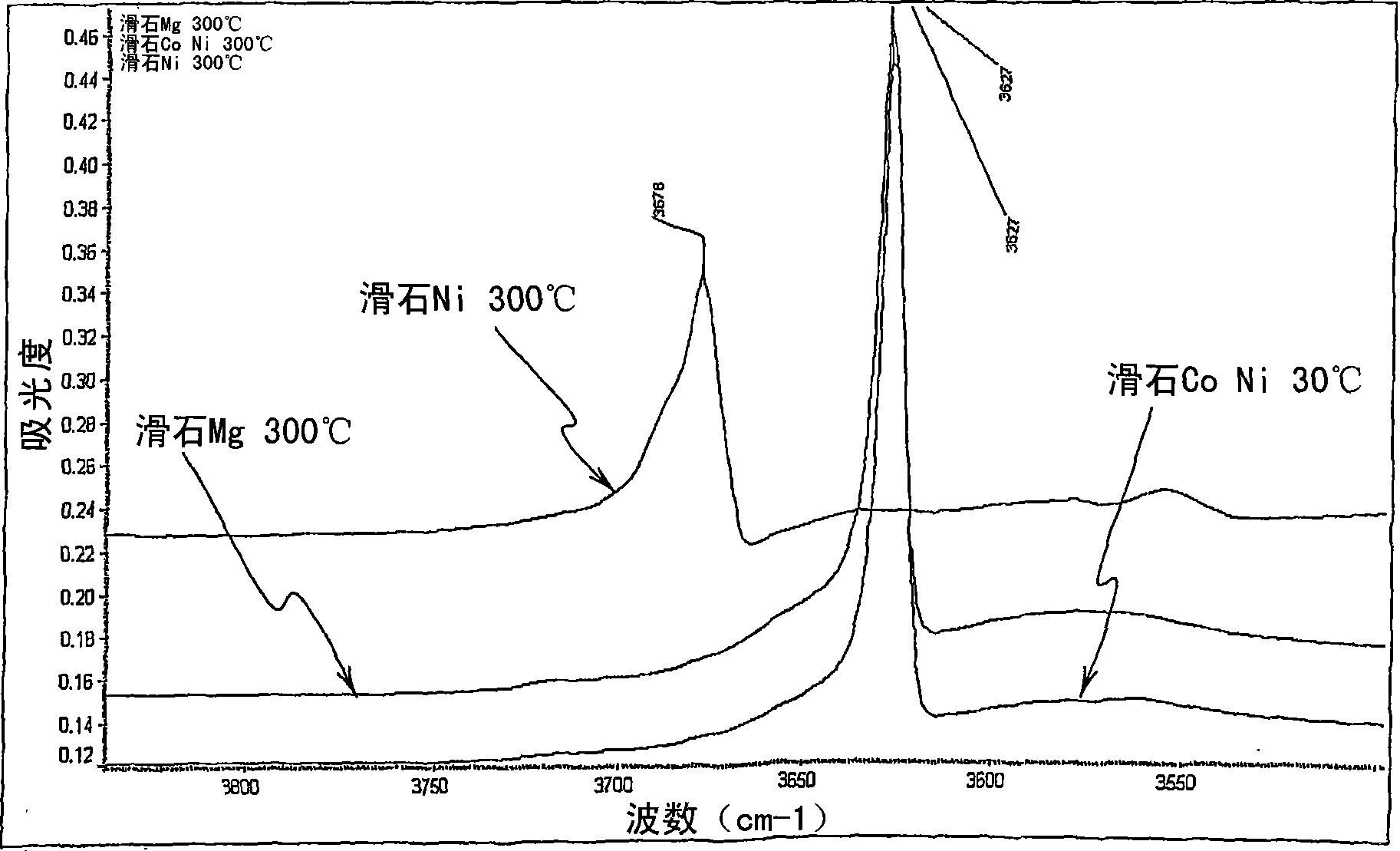

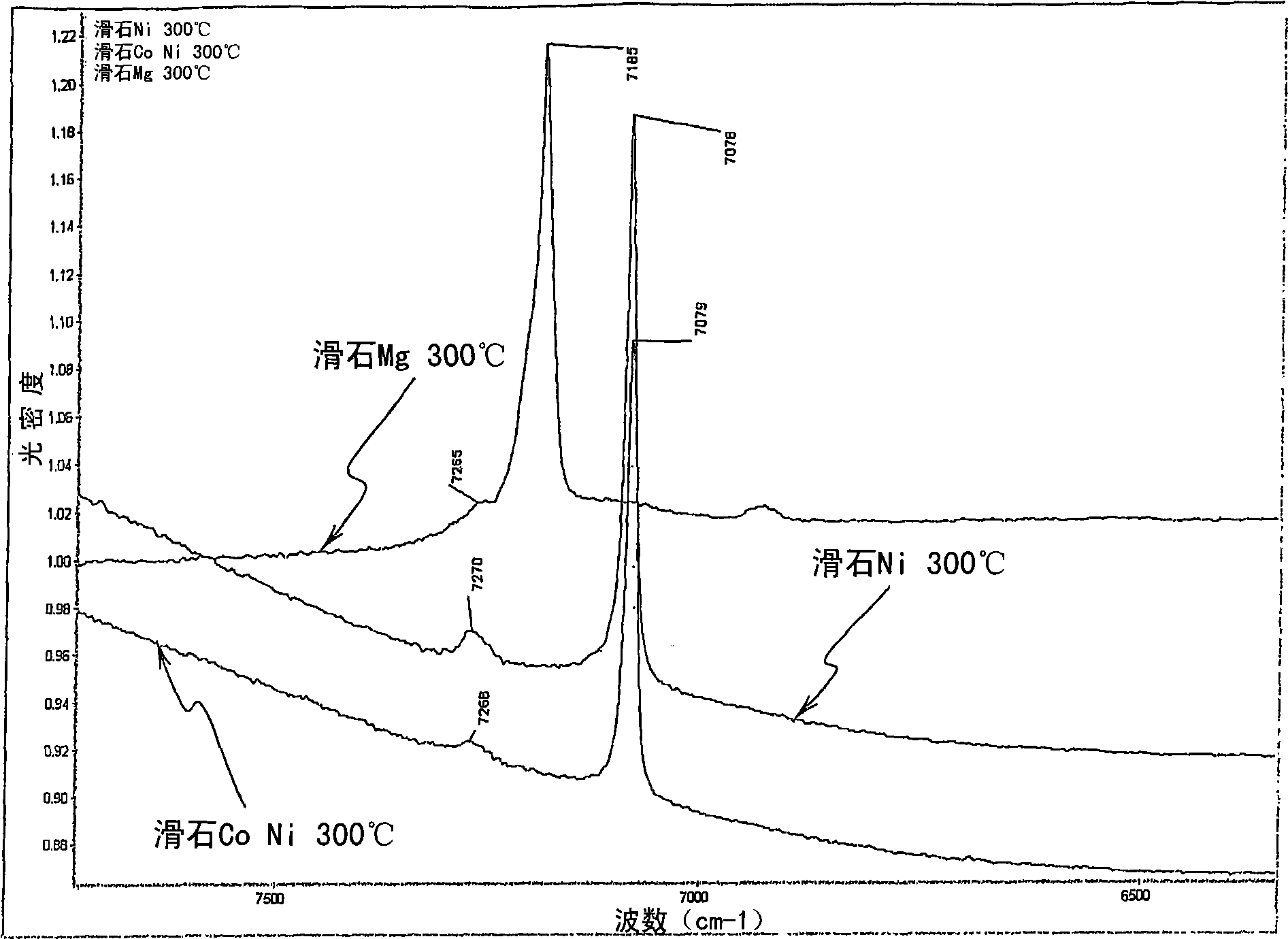

Method for preparing talcose compositions comprising synthetic mineral particles containing silicon, germanium and metal

ActiveCN101489933AAccurately determineAccurate predictionMagnesium silicatesPigmenting treatmentDivalent metalLiquid state

The invention relates to a method for preparing a composition, that is a talcose composition, comprising synthetic mineral particles which contain silicon, germanium and metal, have a crystalline and lamellar structure, and are of formula (SixGe1-x)4 M3O10(OH)2, wherein M is at least one divalent metal and is of formula Mgy(1)Coy(2)Zny(3)Cuy(4)Mny(5) Fey(6)Niy(7)Cry(8), and x is a real number of the interval [0; 1]. According to said method, a gel containing silicon, germanium and metal, of formula - (SixGe1-x)4M3O11, n'H2O -, in the liquid state, is subjected to a hydrothermal treatment over a defined period of time and at a temperature of between 300 DEG C and 600 DEG C, said time and temperature being selected according to the desired particle size and structural stability for the mineral particules containing silicon, germanium and metal, to be prepared.

Owner:LUZENAC EURO +1

High-strength white olivine light material and method of producing the same

InactiveCN101492298AWide variety of sourcesReduce manufacturing costMagnesium silicatesHigh intensityOlivine

The invention relates to a high-strength forsterite lightweight material and a preparation method thereof. The invention adopts a technical proposal that carbonate powder accounting for 20 to 70 percent of the total weight and talc raw-ore powder accounting for 30 to 80 percent of the total weight are mixed and then added with a bonding agent accounting for 3 to 10 percent of the weight of a mixture of the carbonate powder and the talc raw-ore powder, and the mixture of the three materials is stirred for 5 to 25 minutes, pressed, molded, dried for 12 to 36 hours at a temperature of between 60 and 110 DEG C or naturally dried indoors for 24 to 48 hours, sintered in air for 2 to 6 hours at a temperature of between 800 and 1,400 DEG C, naturally cooled, soaked in water for 24 to 48 hours and finally dried for 12 to 36 hours at a temperature of between 60 and 110 DEG C or naturally dried indoors for 24 to 48 hours, so that the high-strength forsterite lightweight material can be obtained. The preparation method has the characteristics of extensive raw material sources, low production cost and easiness for industrial production. The material prepared by the method has the advantages of excellent performances, compressive strength of between 10 and 40 MPa, volume density of between 0.6 and 1.5 g / cm, long life span, service temperature at 1,200 DEG C and benefit to energy conservation and consumption reduction.

Owner:WUHAN UNIV OF SCI & TECH

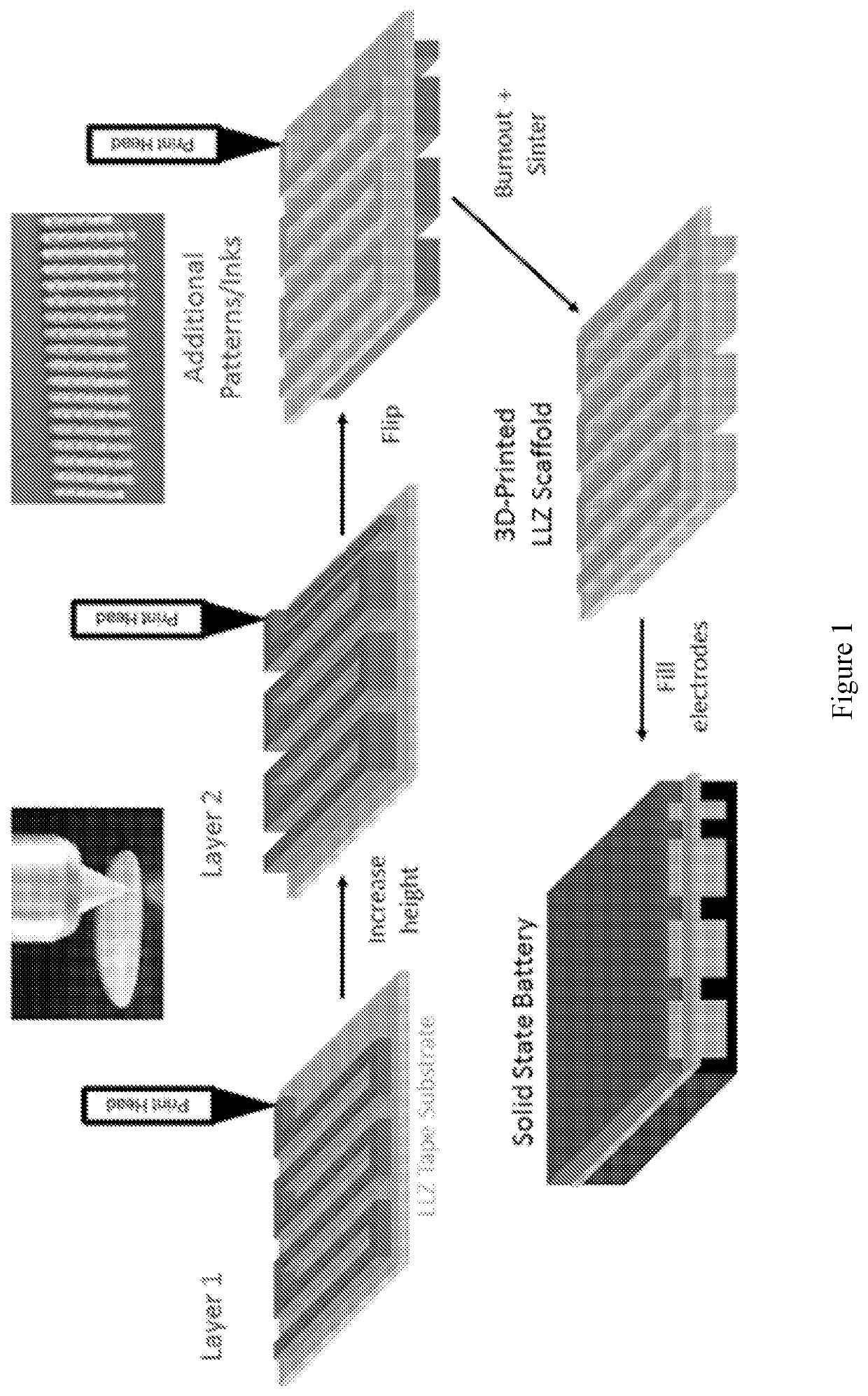

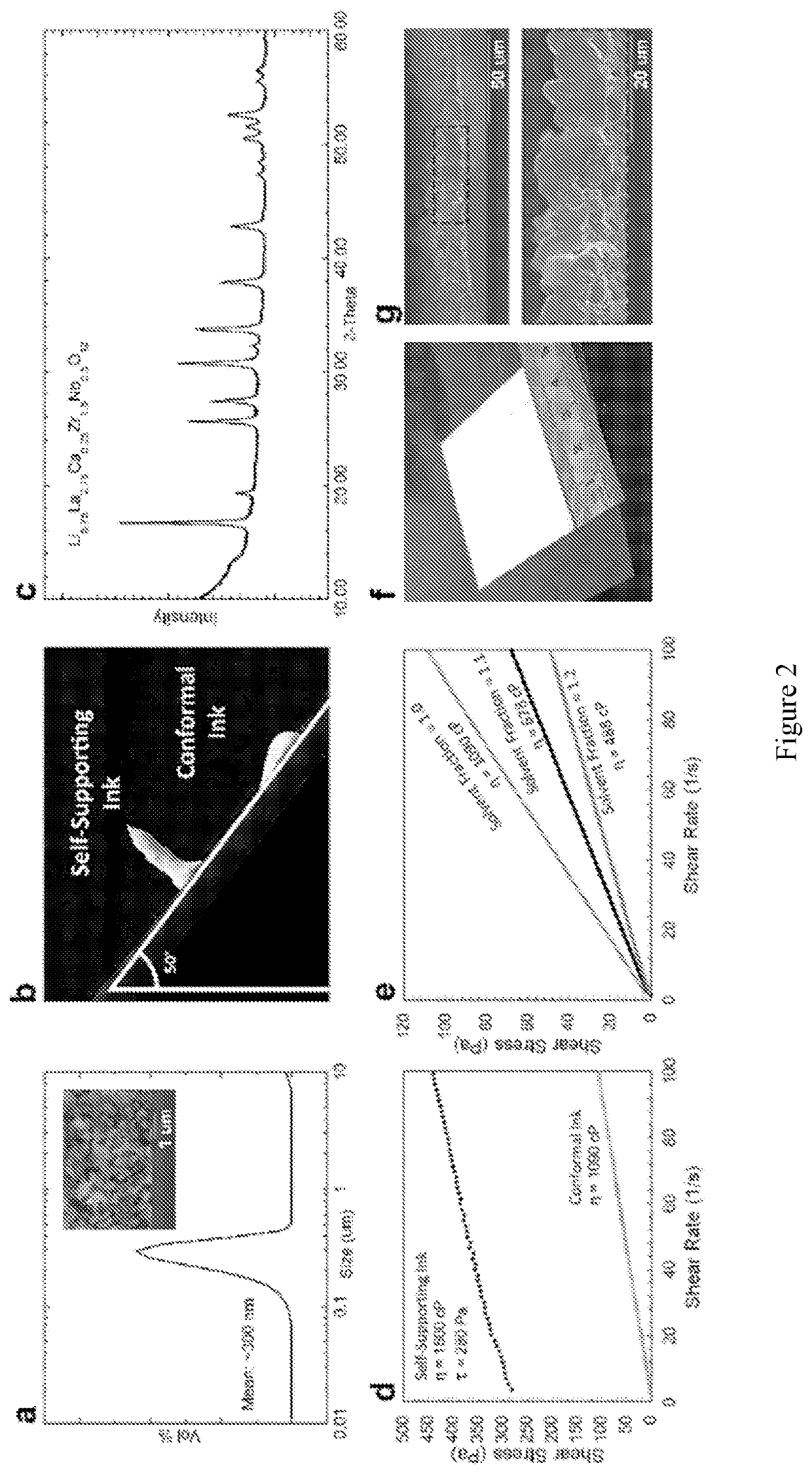

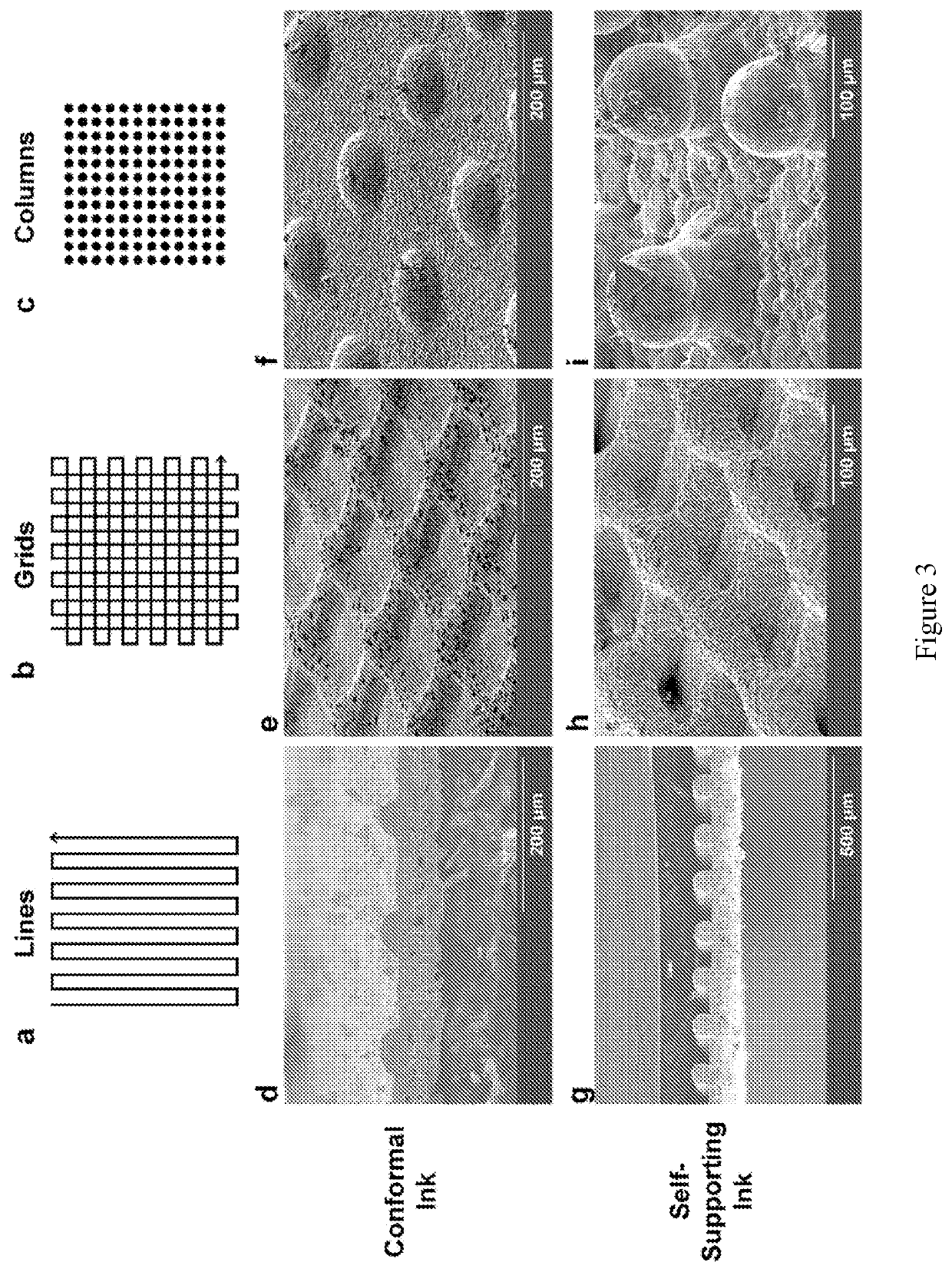

Ordered porous solid electrolyte structures, electrochemical devices with same, methods of making same

Provided are solid-state electrolyte structures. The solid-state electrolyte structures are ion-conducting materials. The solid-state electrolyte structures may be formed by 3-D printing using 3-D printable compositions. 3-D printable compositions may include ion-conducting materials and at least one dispersant, a binder, a plasticizer, or a solvent or any combination of one or more dispersant, binder, plasticizer, or solvent. The solid-state electrolyte structures can be used in electrochemical devices.

Owner:UNIV OF MARYLAND

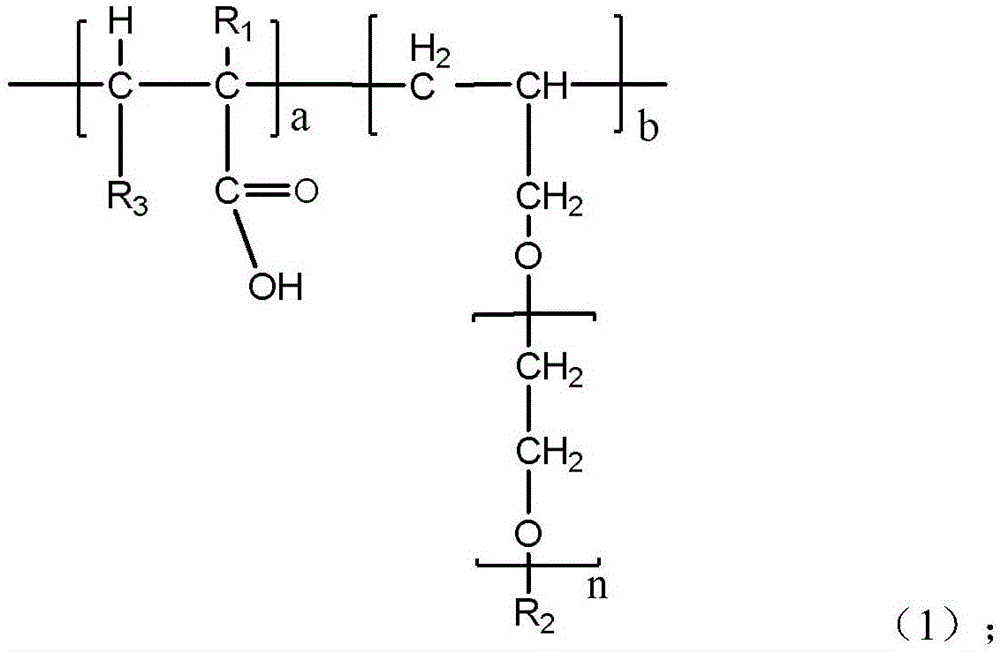

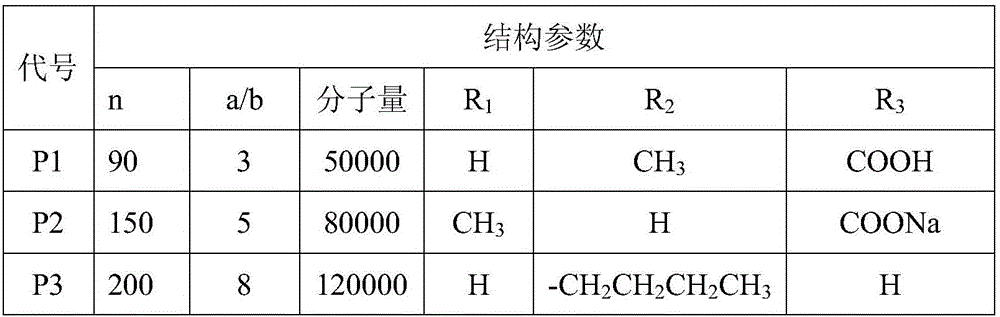

Fibrous nano silicate concrete admixture and preparation method thereof

ActiveCN106277901AImprove early strengthImprove toughnessMagnesium silicatesAlkaline-earth metal silicatesCalcium silicateMagnesium salt

The invention discloses a fibrous nano silicate concrete admixture. The fibrous nano silicate concrete admixture is a compound prepared by magnesium silicate and calcium silicate in a high molecular polymer dispersing agent water solution, wherein the magnesium silicate is prepared by soluble magnesium salt and soluble silicate according to the mole ratio of 1: 1.2 to 1: 1.6, the calcium silicate is prepared from soluble calcium salt and soluble silicate according to the mole ratio of 1: 1 to 1: 1.5, the soluble calcium salt is magnesium nitrate, the soluble calcium salt is calcium nitrate, the soluble silicate is sodium silicate, a high molecular polymer dispersing agent is shown by a formula shown in the description. The fibrous nano silicate concrete admixture can remarkably improve the early strength of concrete. In addition, the concrete toughness has an obvious improving effect, early hydration of cement can be accelerated, and improvement of bending resistance and tension resistance capability of a cement-based material is promoted.

Owner:JIANGSU SOBUTE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com