Patents

Literature

231results about How to "Short calcination time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing synthetic rutile

InactiveCN101244841AAvoid pollutionReduce manufacturing costTitanium dioxideIlmenitePollution prevention

The invention relates to a production method of artificial rutile, belonging the technical field of chemical engineering, which provides a method of producing high-taste artificial rutiles made of raw ilmenite containing Mg with high Ca contents and has good production continuousness, low energy consumption and less pollution. The production method provided by the invention comprises the following steps: a. ilmenite concentrate is oxidized and roasted at 800-1100 DEG C, and then reduced and roasted at 600-900 DEG C; b. the reduced and roasted ilmenite concentrate is leached by hydrochloric acid with 18-24 percent concentration under normal pressure; c. cleaned and filtered; d. the filter cake is collected and calcined. The production method can used for producing artificial rutile, and has the advantages of low production cost, environmental pollution prevention, low production energy consumption, and easy capacity for continuous production, thereby enjoying wide application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

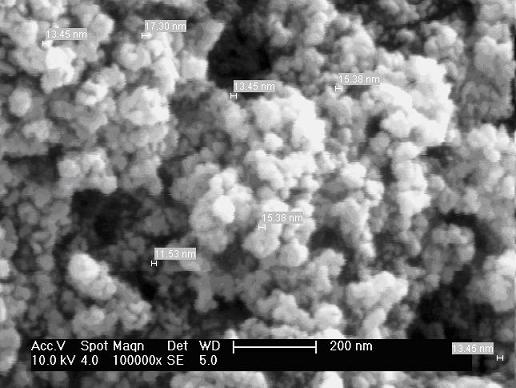

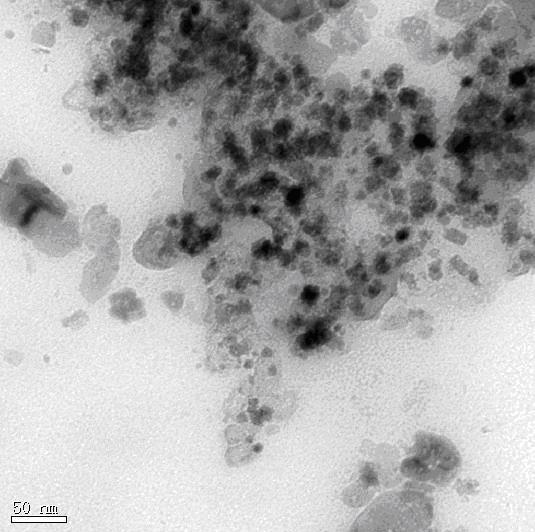

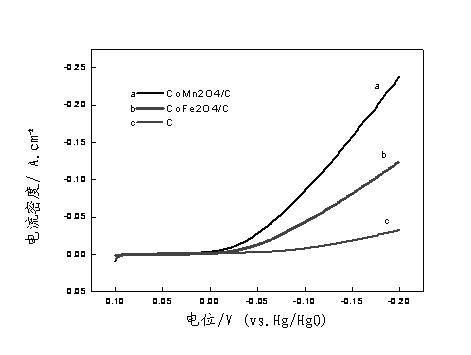

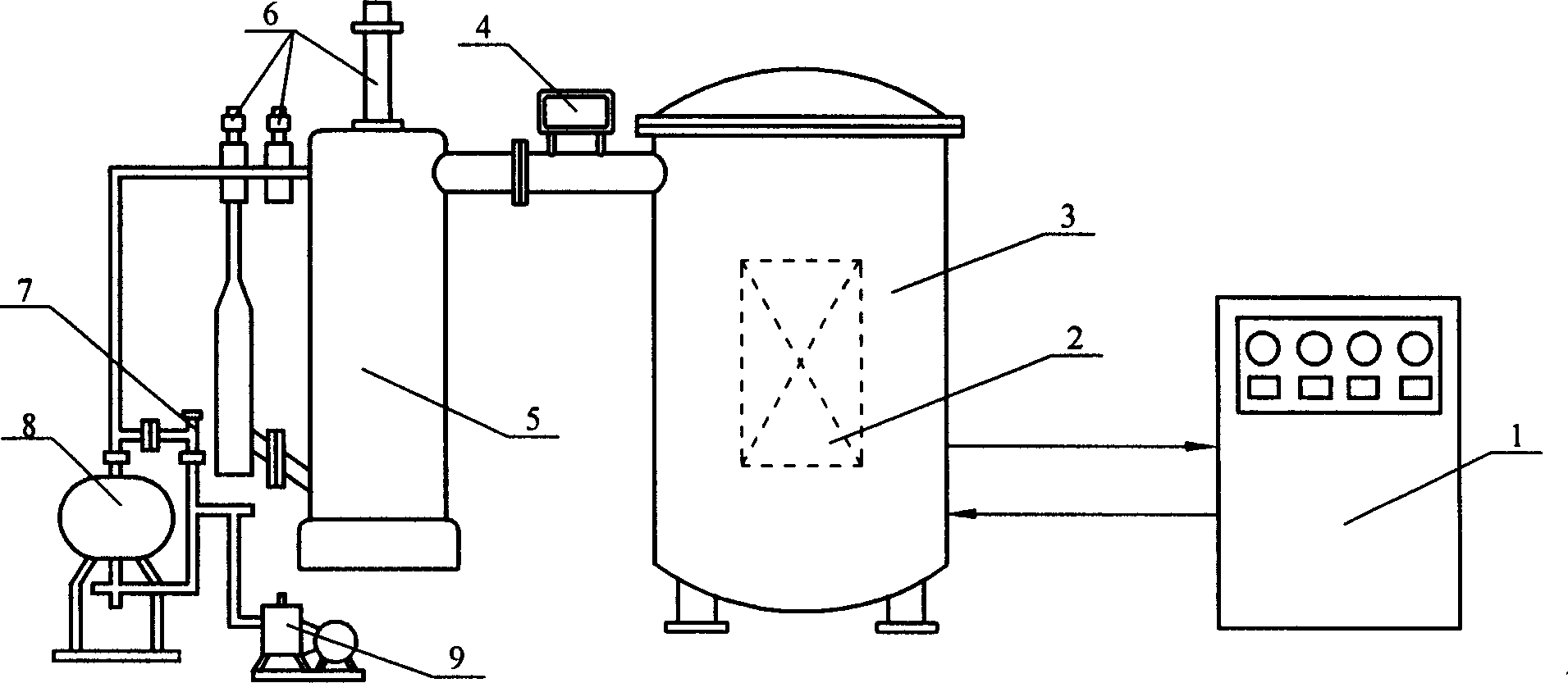

Transition metal composite oxide catalytic material and microwave preparation method thereof

InactiveCN101908628AAvoid uneven heating inside and outsideAvoid uneven heatingCell electrodesCatalyst activation/preparationHigh current densityComposite oxide

The invention discloses a transition metal composite oxide catalytic material and a microwave preparation method thereof, can output larger working voltage under higher current density, and has simple preparation method, easily controlled preparation process and rich raw material resources. The preparation method comprises the following steps: taking the nitrates of two transition metals according to the stoichiometric ratio of two metal elements, adding distilled water to prepare a solution, adding carbon black, stirring for reaction, and centrifuging to obtain the precipitate; washing the precipitate; drying at 50-80 DEG C and pulverizing to obtain a precursor, wherein the mass ratio of the transition metal composite oxide to the carbon black is 6:4, the A transition metal is one of Co, Mn, Fe and Ni, and the B transition metal is one of Co, Mn and Fe; and calcining the precursor by microwave to obtain the transition metal composite oxide catalytic material. The microwave calcining method of the invention has simple process and high efficiency, and the prepared spinel has a nano crystal form, small particle size and even distribution.

Owner:TIANJIN JIUJU ENERGY TECH DEV

Method and device of obtaining active lime by vacuum calcining limestone

A process for preparing high-activity lime by vacuum calcining of lime stone includes such steps as crushing lime stone, loading in tank, heating in electric vacuum furnace at 750-900 deg.C under 100-1000 Pa, and quick cooling. Its activity is 380-450 ml.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

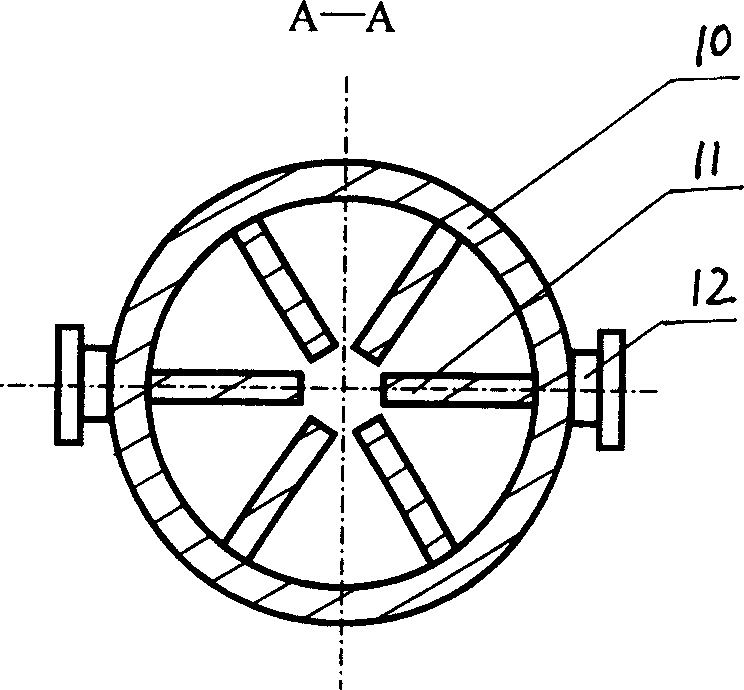

Sludge coal ash high-strength ceramsite and preparation method thereof

ActiveCN104261802AIn line with the principles of sustainable developmentRaise the ratioCeramic materials productionClaywaresSludgeExpanded clay aggregate

The invention discloses sludge coal ash high-strength ceramsite and a preparation method thereof. By using sludge and coal ash as main raw materials, the ceramsite is prepared by mixing, prilling and calcining by synergic match with an additive. The ceramsite is prepared from the following raw materials in parts by weight: 40-70 parts of sludge, 30-55 parts of coal ash, 0.5-1.5 parts of calcium sulphoaluminate, 0.5-1 part of phthalate, 1-3 parts of water glass and 0.5-1 part of a deodorant, wherein the water content of sludge is controlled within 35-50wt%. The sludge coal ash high-strength ceramsite is prepared by the following steps: mixing the materials; prilling; drying; calcining; and cooling. The ceramsite disclosed by the invention is economical, environment-friendly, efficient and energy-saving and scientific and reasonable in match of components of raw materials, and the prepared sludge coal ash high-strength ceramsite has the advantages of high cylinder compressive strength and high absorption.

Owner:CHONGQING HAOPAN ENERGY SAVING TECH

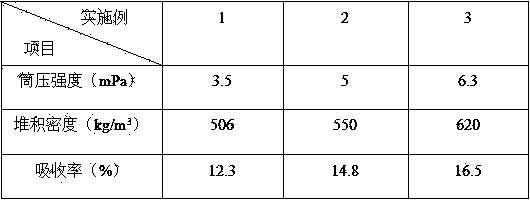

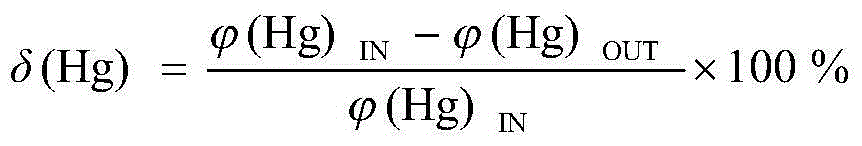

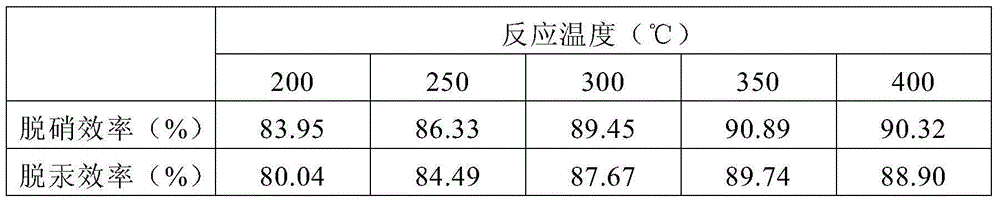

Regeneration method for inactivated TiV-based honeycomb denitration catalyst having combined denitration and demercuration modification function

ActiveCN104888806AImprove denitrification activityImprove mercury oxidation abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryStrong acids

The invention discloses a regeneration method for an inactivated TiV-based honeycomb denitration catalyst having the combined denitration and demercuration modification function. Firstly, the physical and chemical properties of an SCR denitration catalyst are detected, and the inactivated reasons of the catalyst are analyzed. Secondly, the regenerable catalyst is subjected to ultrasonic cleaning in deionized water, a strong alkaline solution or a strong acid solution, so that deposited ashes and pernicious elements in the catalyst can be removed. Thirdly, the cleaned catalyst is immersed in a combined denitration and demercuration regeneration solution, until the activity of the catalyst is stable. Finally, the activated catalyst is transferred to a microwave oven to be dried and calcined through the microwave heating process. The catalyst, obtained through the above method, successively has the combined oxidation and demercuration capacity, while the denitration activity of the catalyst is recovered at the same time. At a temperature smaller than 350 DEG C, the denitration efficiency of the catalyst is up to be equal to or over 90%, and the demercuration efficiency of the catalyst is up to be equal to or over 90%. Meanwhile, the condition that the cost is increased due to the demercuration process after the flue gas denitrification process can be avoided. Therefore, the method is economical and environmentally-friendly, thus being suitable for industrial promotion.

Owner:HUANENG CLEAN ENERGY RES INST

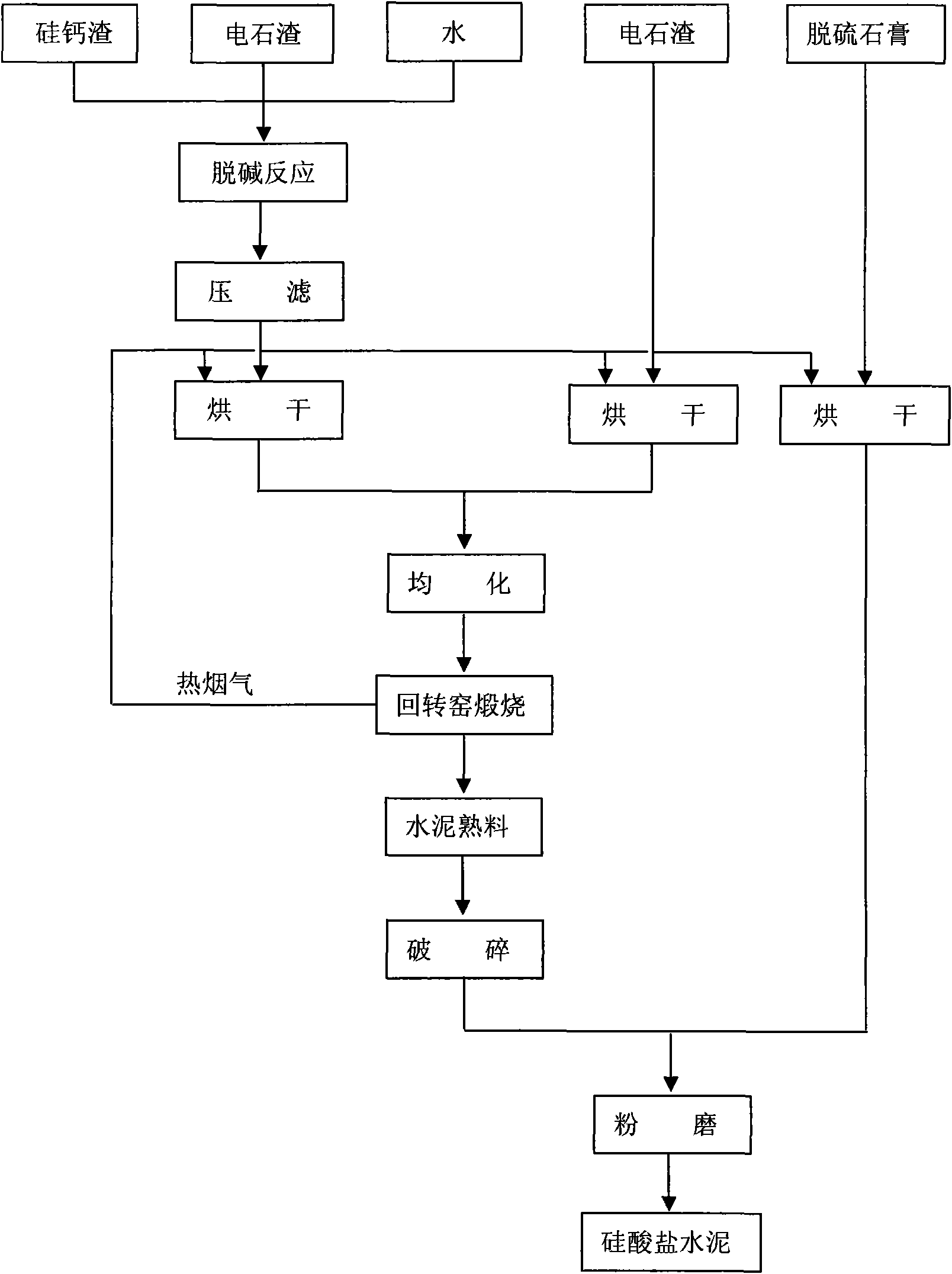

Method for producing silicate cement by using silico-calcium dregs and carbide dregs

InactiveCN101591150AReduce contentMeet the requirements of alkali contentCement productionCalcinationMaterials science

The invention provides a method for producing silicate cement by using silico-calcium dregs and carbide dregs, relating to the technical field of building materials. The method has the following steps: 1. adding carbide dregs and water into silico-calcium dregs followed by dealkalization and carrying out pressure filtering and drying on the dealkalized silico-calcium dregs if the alkali content in the silico-calcium dregs is high, or directly drying the silico-calcium dregs if the alkali content in the silico-calcium dregs is low; and drying the carbide dregs and desulfurated plaster respectively; 2. dosing and homogenizing the dealkalized silico-calcium dregs and carbide dregs after drying; 3. sending the homogenized crude materials into a rotary kiln for high temperature calcinations and obtaining the cement clinker after cooling; and 4. smashing the cement clinker and sending the smashed cement clinker and the dried desulfurated plaster into a cement grinding mill for grinding to prepare the silicate cement. Compared with the prior art, the method of the invention is simple in process, low in investment, low in production cost, low in energy consumption, and stable in the prepared silicate cement performance.

Owner:TONGFANG ENVIRONMENT

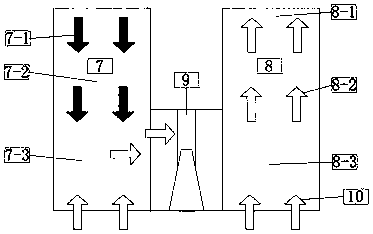

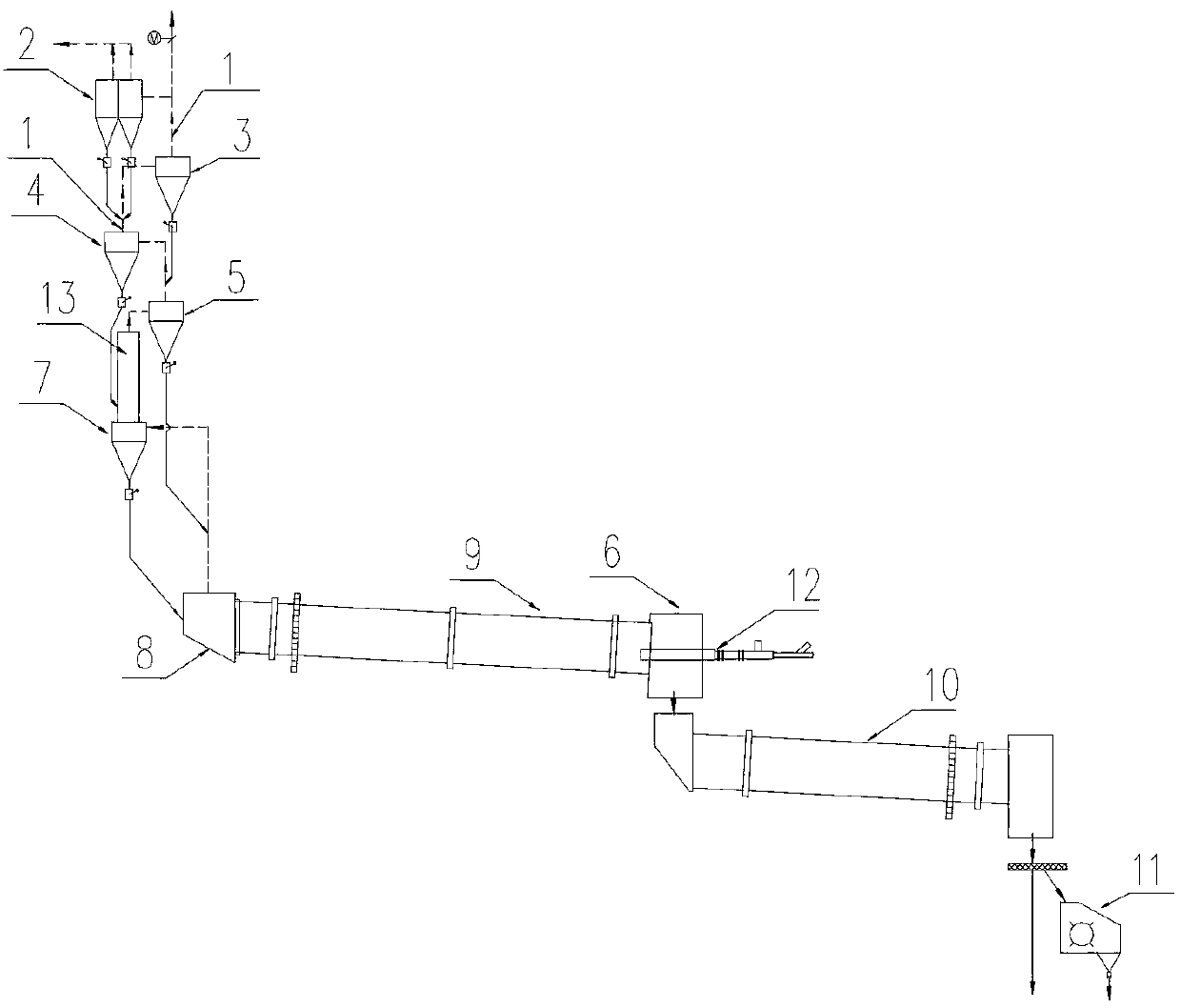

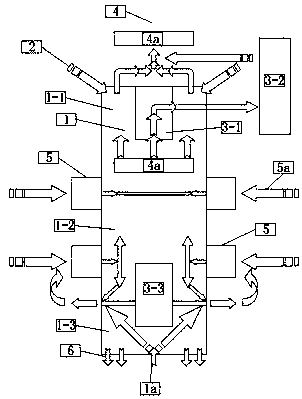

Lime kiln device adopting circulating hot air

The invention relates to a lime kiln device adopting circulating hot air and a production method for industrial lime. According to the lime kiln device adopting the circulating hot air and the production method for the industrial lime, in the preparation process of the lime, limestone is calcined by using the circulating hot air, the calcined waste circulating hot air is used for preheating limestone ore, and the preheated waste circulating hot air is cooled, is subjected to dust removal, then is conveyed to a regenerative heating furnace set, is heated to a set calcining temperature and thenis sent back to a lime kiln system for calcining. The lime kiln device adopting the circulating hot air and the production method for the industrial lime have the advantages that the limestone is calcined by using the circulating hot air, so that the quality of the lime can be remarkably improved, the yield of the lime can be increased, the productivity can be improved, and high-purity CO2 can beconveniently recycled; and the lime kiln system adopts the regenerative heating furnace set for heating, a lime kiln is not provided with a burner system, regenerative heating furnaces can utilizes low-heating-value blast furnace gas as fuel, and therefore the structure of a kiln body can be conveniently simplified, and the operation cost of the lime kiln can be lowered.

Owner:王长春 +3

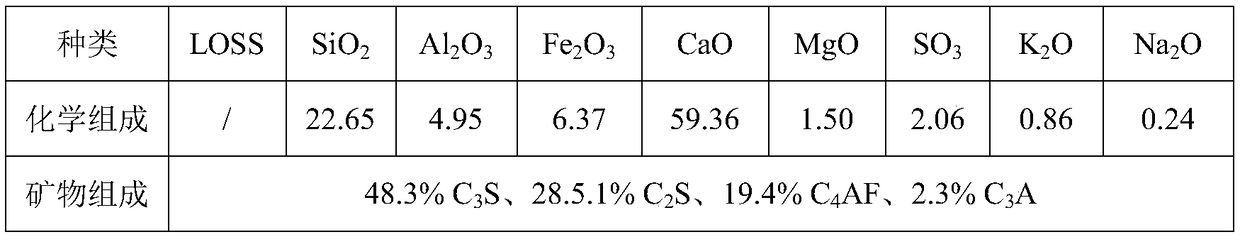

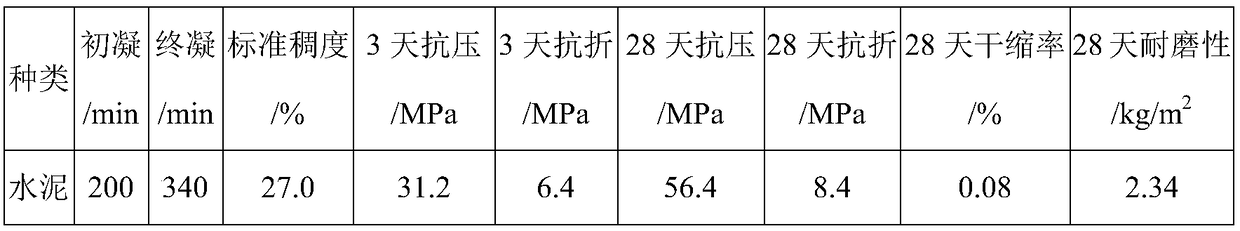

Road delayed-coagulation cement and preparation method thereof

InactiveCN108726904AReduce consumptionReduce calcination temperature and liquid phase viscosityCement productionResource utilizationEconomic benefits

The invention relates to road delayed-coagulation cement and a preparation method thereof. The road delayed-coagulation cement comprises special cement clinker, limestone waste, modified steel slag powder and phosphorus gypsum. According to the road delayed-coagulation cement, a cement raw material is prepared from carbon-containing shale, the phosphorus gypsum serves as mineralizing agents of clinker calcination, steel slag powder is prepared in a crushing, iron removing and grinding manner, the steel slag powder and the limestone waste serve as cement admixtures, and the phosphorus gypsum serves as a cement delayed coagulant. By the aid of the technical scheme, the prepared road delayed-coagulation cement has the advantages that coagulation time is suitable, early strength is high, laterstrength is rapidly increased, breaking strength is high, abrasion resistance is good, dry shrinkage performance is low and the like. Efficient resource utilization of solid waste such as the carbon-containing shale, the limestone waste, steel slag and the phosphorus gypsum is achieved, and the road delayed-coagulation cement has important economic benefits and social benefits.

Owner:GEZHOUBA SONGZI CEMENT

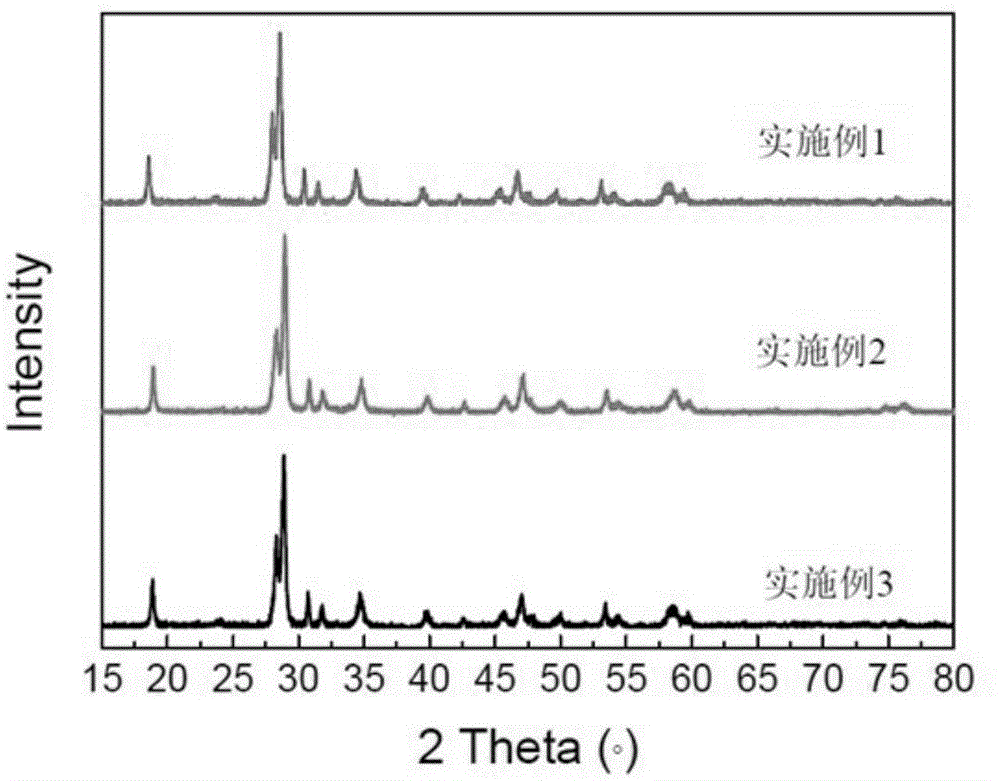

Method for preparing magnesium potassium titanate by directly utilizing magnesium oxide

ActiveCN102230223ALow costReduce corrosion lossPolycrystalline material growthFrom solid stateMicrowaveTitanium

The invention discloses a method for preparing magnesium potassium titanate by directly utilizing magnesium oxide, belonging to the technical field of inorganic material preparation. The method is mainly characterized in that: magnesium oxide, titaniferous compound and potassium titanate are directly taken as raw materials, the raw materials are mixed to be uniform, the mixture is calcined for 30 minutes to 24 hours at high temperature of 900-1300 DEG C, magnesium potassium carbonate (K2MgTi4O10, namely K2O. MgO. 4TiO2) can be prepared by one-step synthesis, and the obtained magnesium potassium carbonate after calcination is smashed, thus the finished product is obtained. Magnesium oxide is utilized as a reaction raw material, material cost is reduced, no fluxing agent is used in the preparation process, and no alkali magnesium raw material is used, thus rapid equipment corrosion loss in the high temperature alkali environment is reduced in the preparation process of the magnesium potassium titanate, the method is more applicable to mass production, and the process is simplified; meanwhile, calcination under microwave catalysis is utilized to speed up synthetic reaction of the magnesium potassium titanate, thus the production efficiency is improved.

Owner:北京无界实验科技有限公司

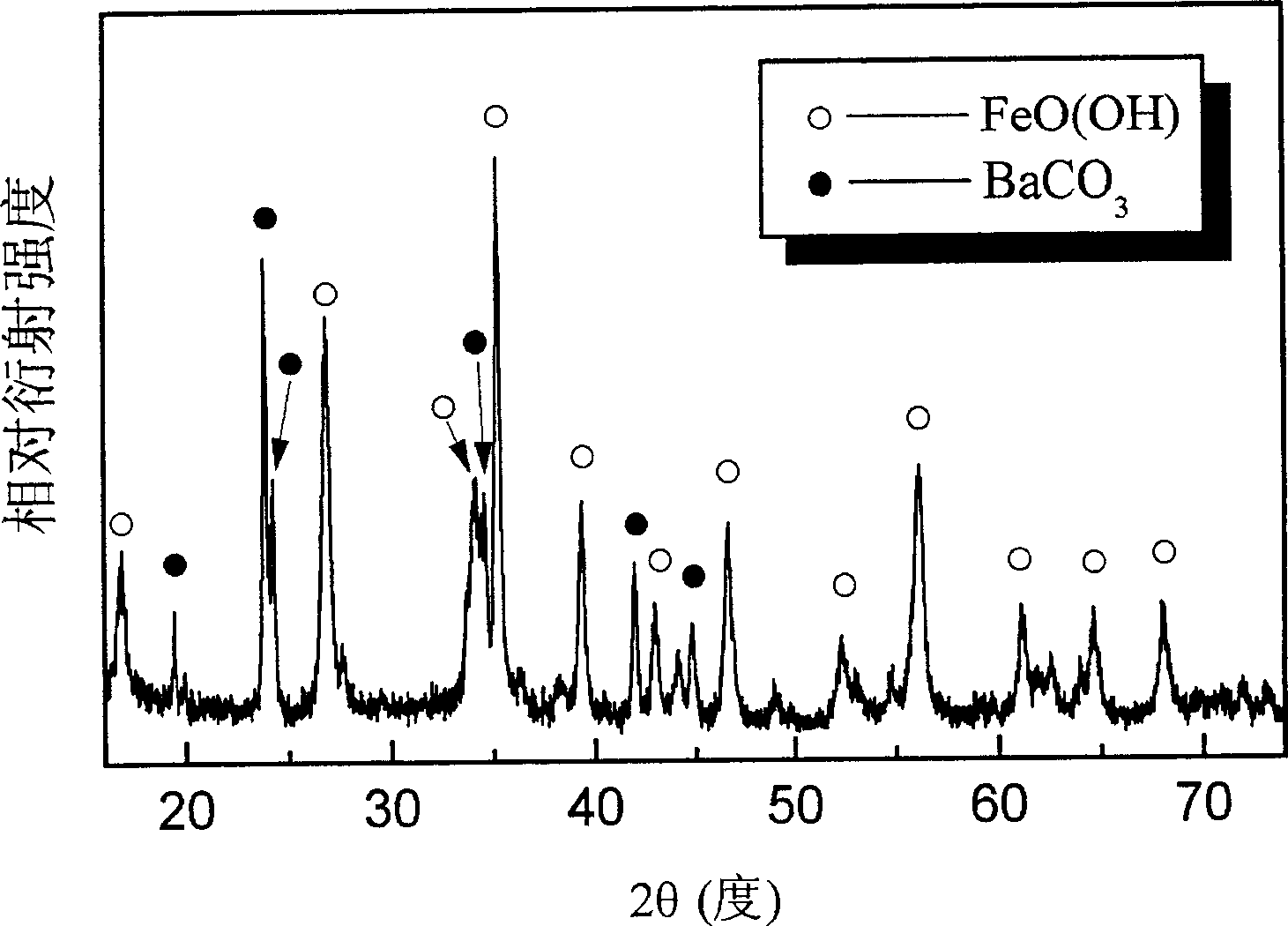

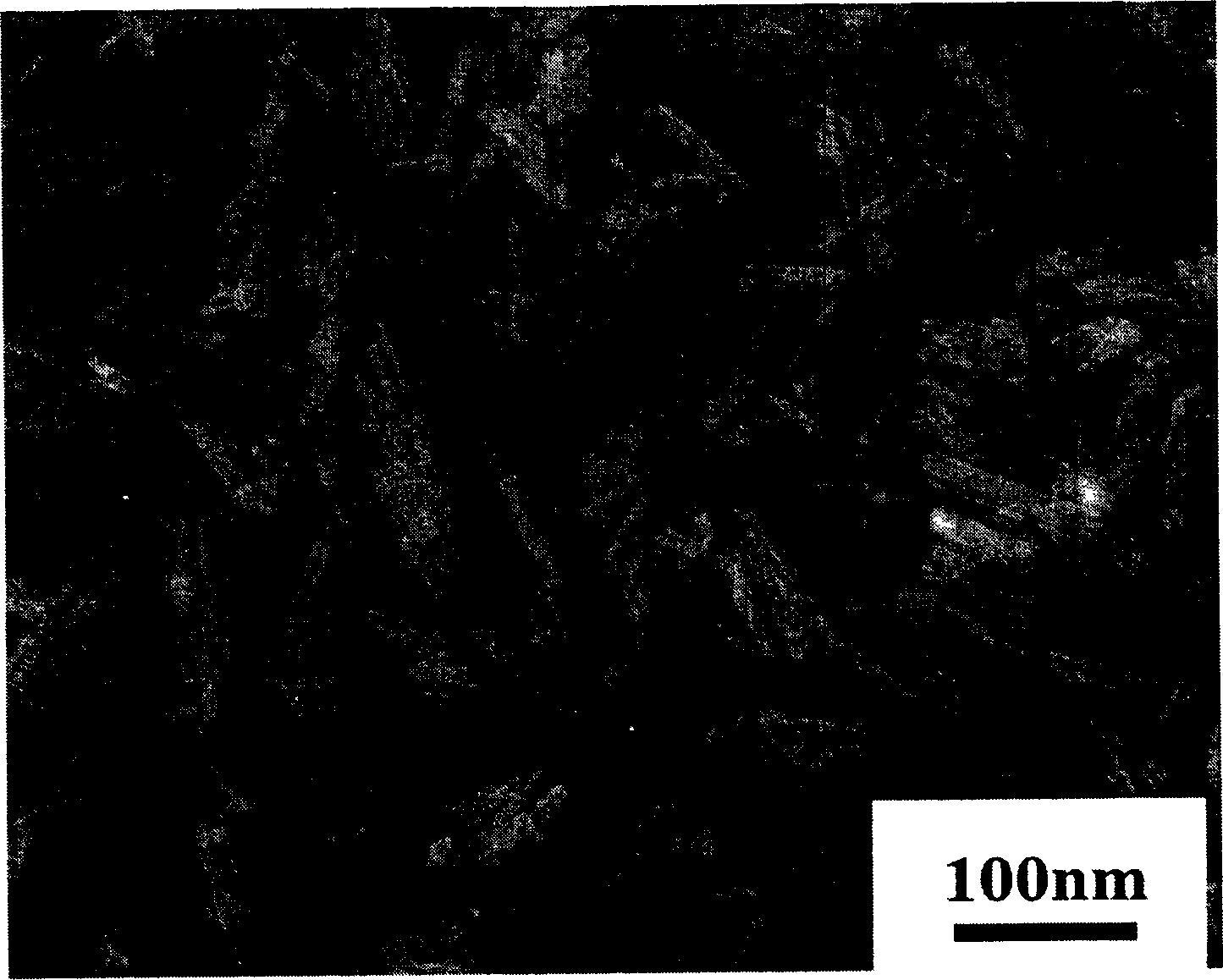

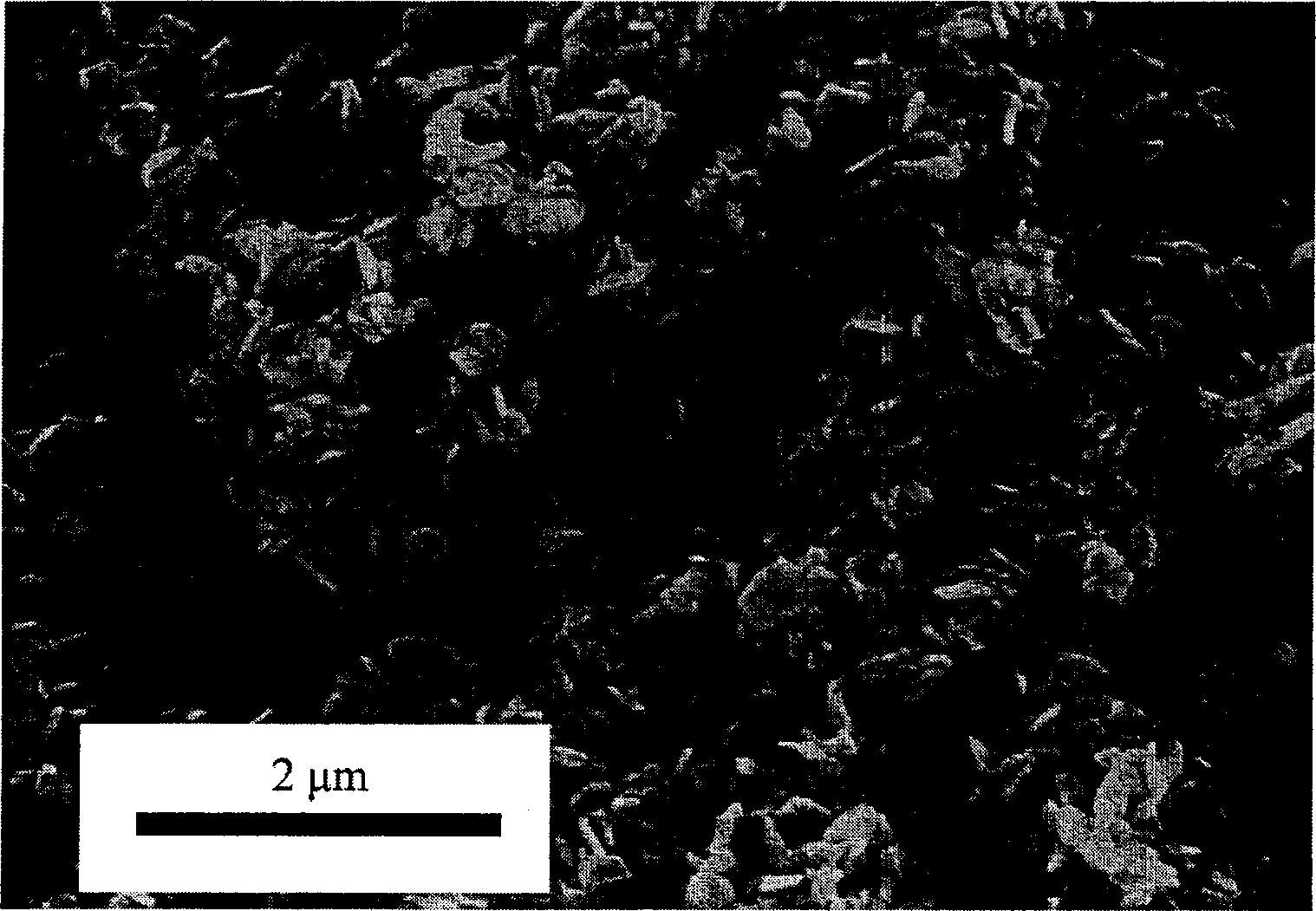

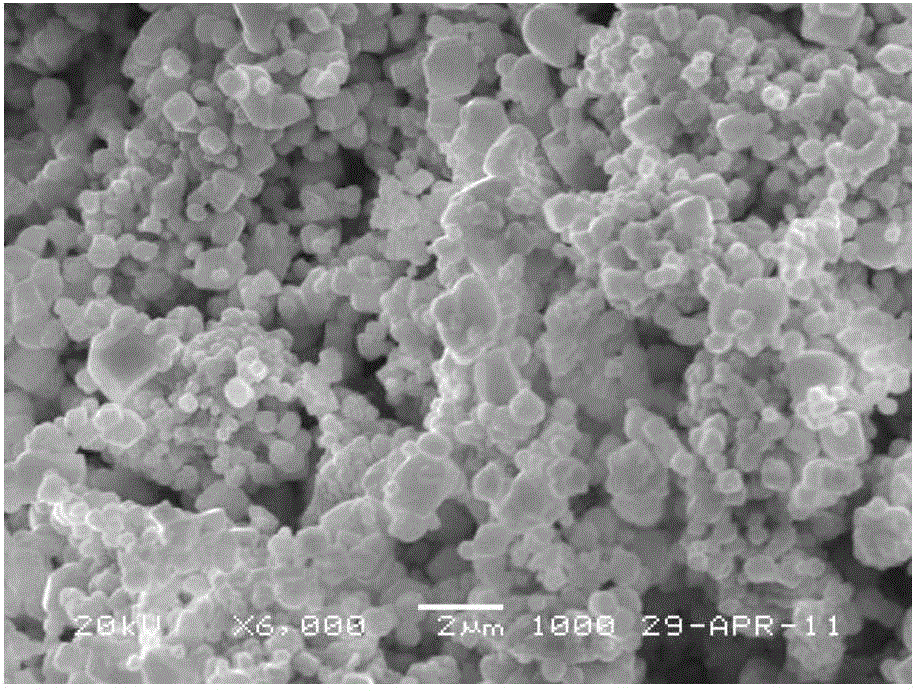

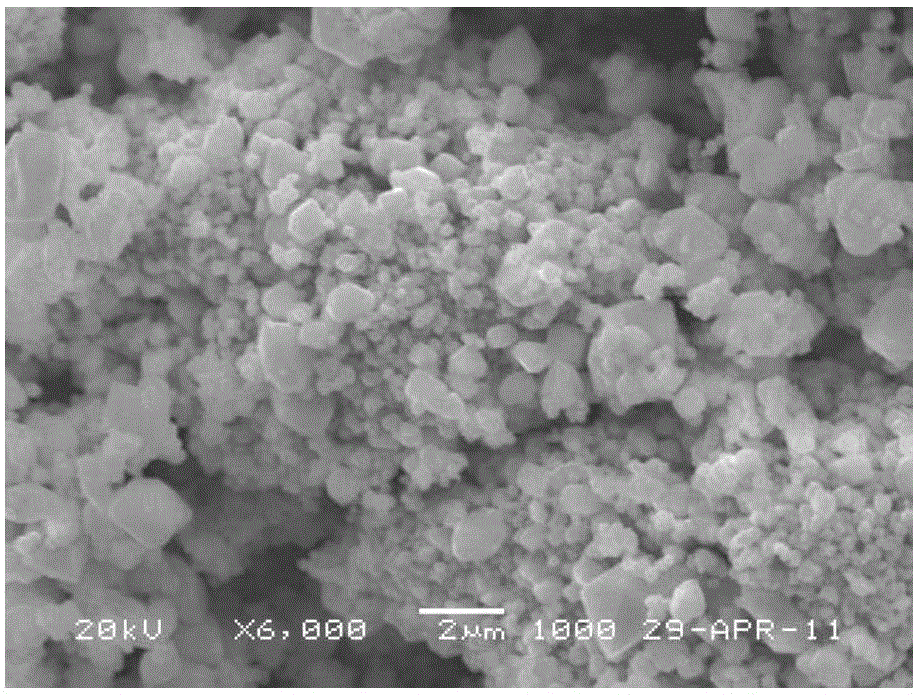

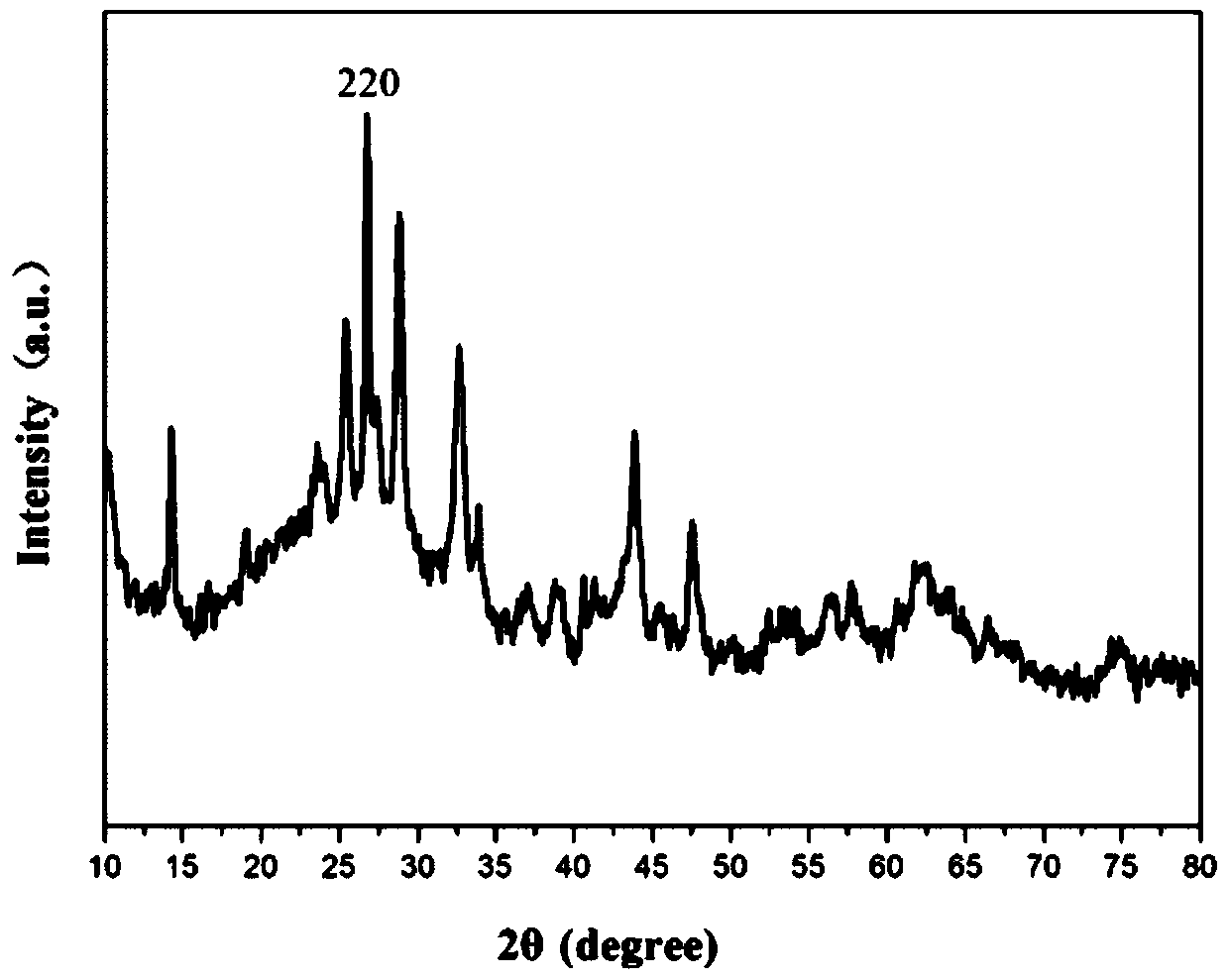

Hexagonal sheet-like barium ferrite magnetic nanometer powder preparation method

InactiveCN1880272ACalcination temperature is lowShort calcination timeHigh volume manufacturingHigh density

A preparing method of hexagonal piece barium ferrite nanometer magnetic powder includes: the predecessor body composed with the mixture of powdered BaCO3 and FeO(OH) powder the fineness of which belongs to nanometer is burnt for hexagonal piece barium ferrite nanometer magnetic powder. The optimal fineness of powered BaCO3 is nanometer and optimal nanometer FeO(OH) powder is the spindly FeO(OH) powder. The invention is suitable for application of perpendicular magnetic recording medium of high density and microwave absorber. The invention has the outstanding advantages as follows: well energy conservation effect for low calcinations heat and short calcinations time; high purity and good crystal model; simple process, low level demand for production facility, that is suitable for mass production in industry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

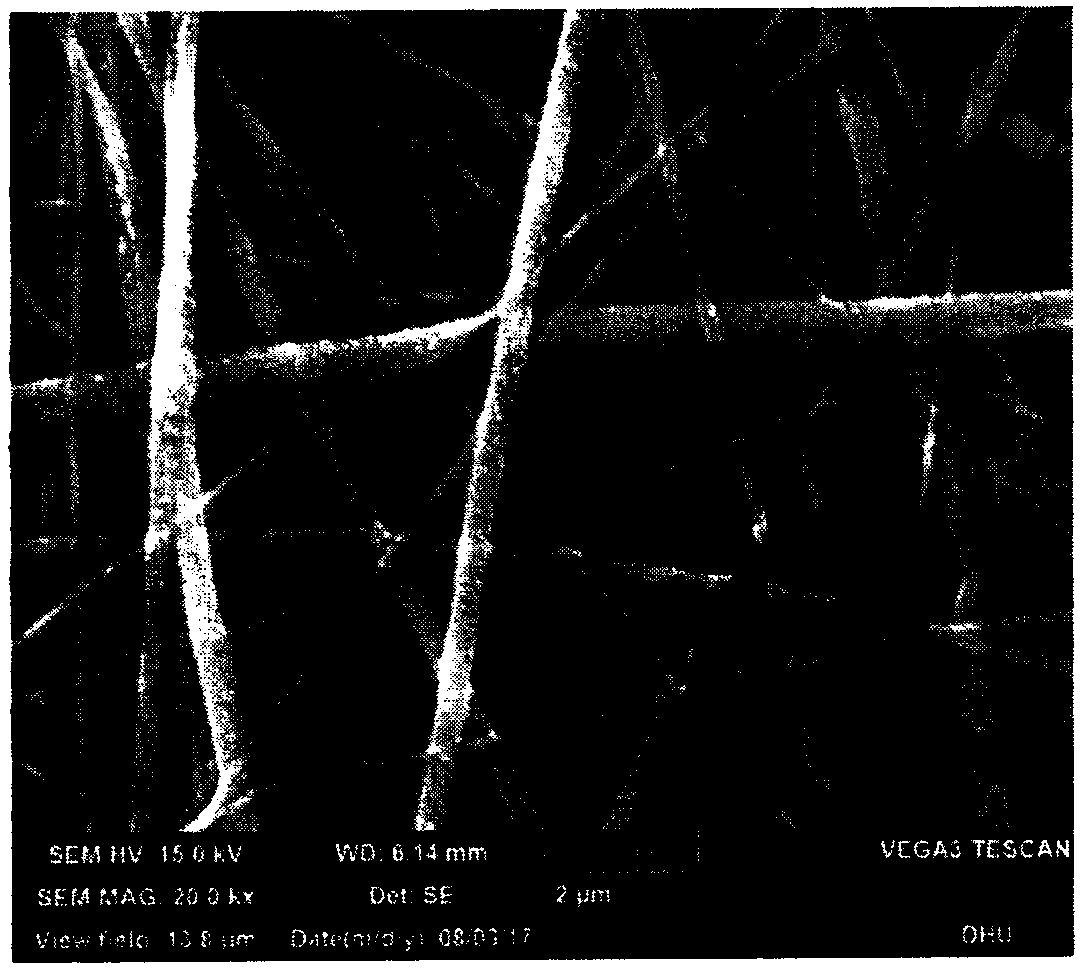

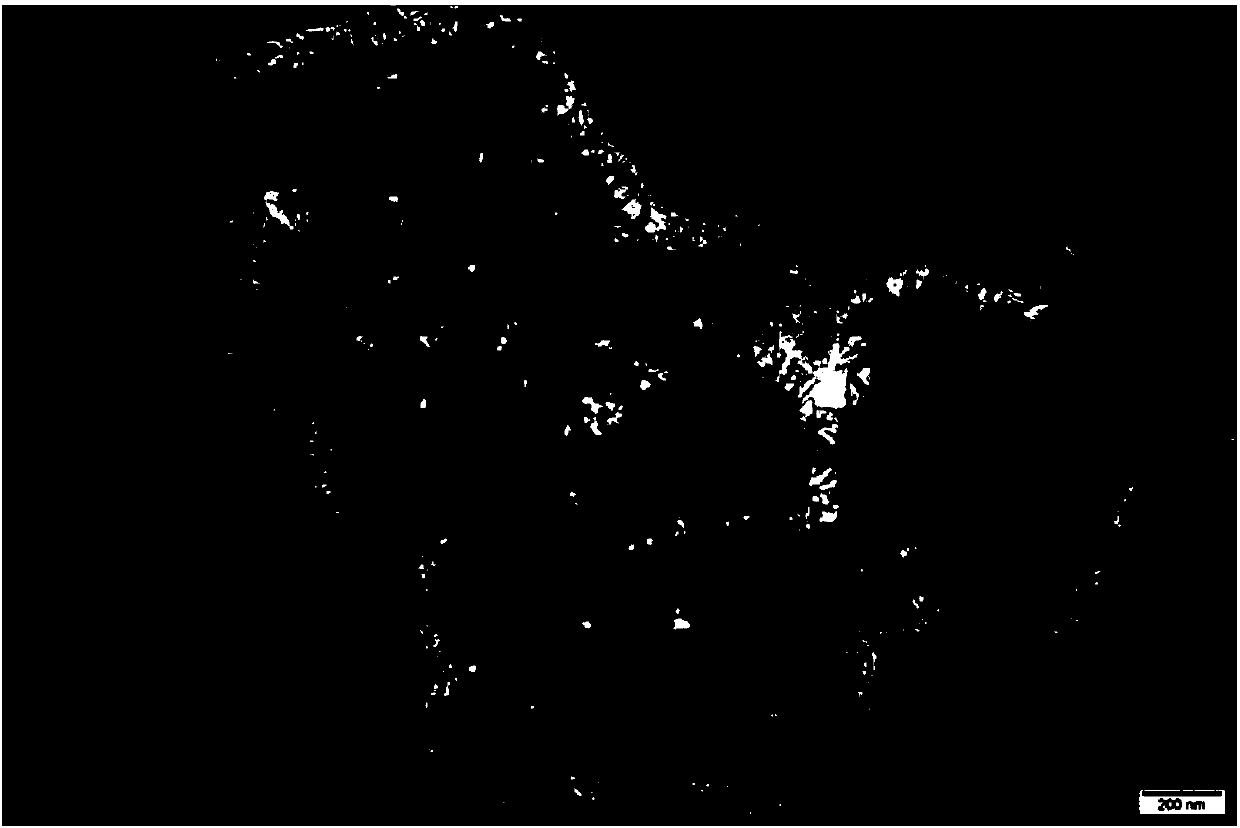

Manufacturing method of flexible titanium dioxide/carbon composite porous nanofiber membrane material

PendingCN109112728ACalcination temperature is lowShort calcination timeElectro-spinningNon-woven fabricsCarbon compositesFiber

The invention provides the manufacturing method of a flexible titanium dioxide / carbon composite porous nanofiber membrane material. The method comprises the following steps of step1, dissolving a titanium source and a high molecular polymer in an organic solvent to obtain a precursor solution; step2, carrying out electrostatic spinning on the obtained precursor solution under electrostatic high pressure to obtain a precursor nanofiber membrane on a receiving device; and step3, calcining The precursor nanofiber membrane under the protection of an inert gas atmosphere to obtain the flexible titanium dioxide / carbon composite porous nanofiber membrane material. In the invention, an electrostatic spinning technology is simple, there are many spinning raw materials, a calcining temperature for manufacturing the flexible composite porous nanofiber is low, calcining time is short, manufacturing cost is greatly reduced and production efficiency is increased, and a large scale production potential is possessed.

Owner:DONGHUA UNIV

Meta titanate treatment method

The invention relates to a meta titanate treatment method, comprising the following steps of: pulping metatitanic acid; adding an alkaline compound into the metatitanic acid pulp until the pH value is above 3; filtering and washing; adding dissoluble aluminum salt, dissoluble phosphate, dissoluble potassium-containing compounds and zinc-containing compounds into a filter cake and mixing uniformly; and calcining and crushing to obtain titanium dioxide. Compared with the prior art, the meta titanate treatment method provided by the invention has the advantages that the energy consumption is reduced; the production efficiency is improved; and the mellowness of the titanium dioxide is improved.

Owner:LOMON BILLIONS GRP CO LTD

Preparation method of molybdenum bismuth vanadate yellow pigment

InactiveCN103601244ASimple production processEasy to operateMolybdeum compoundsBismuth vanadateCalcination

The invention discloses a preparation method of molybdenum bismuth vanadate yellow pigment. The method includes: taking Bi2O3, V2O5 and MoO3 as raw materials, adopting an alkali metal nitrate as a molten salt medium, conducting ball milling to obtain a powder precursor, and then preparing the molybdenum bismuth vanadate yellow pigment by a molten salt technique. The method provided by the invention utilizes the liquid environment provided by the molten salt medium to effectively lower the calcination temperature for product synthesis and shorten the time of heat preservation, thus helping to reduce energy consumption, and also avoiding the problem of great acid and alkali consumption in a liquid phase precipitation-calcination method. Therefore, the method is conducive to production cost reduction. The raw materials involved in the method are easily available, the product has good quality and uniform particle size distribution, the preparation process is simple and is easy to realize industrialization.

Owner:HUNAN UNIV OF SCI & TECH

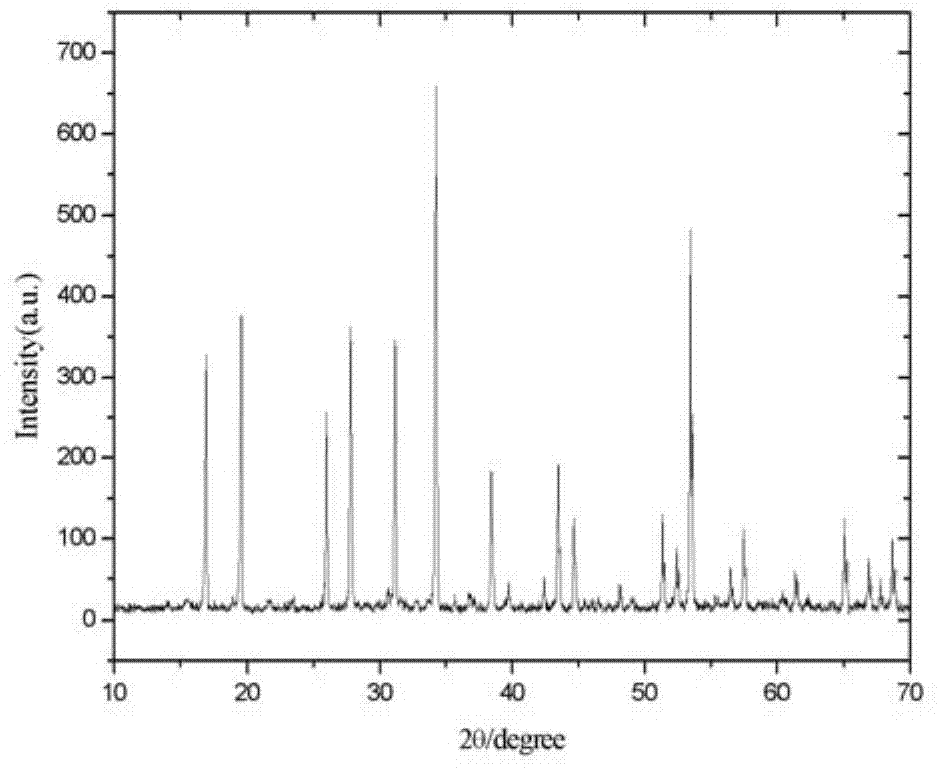

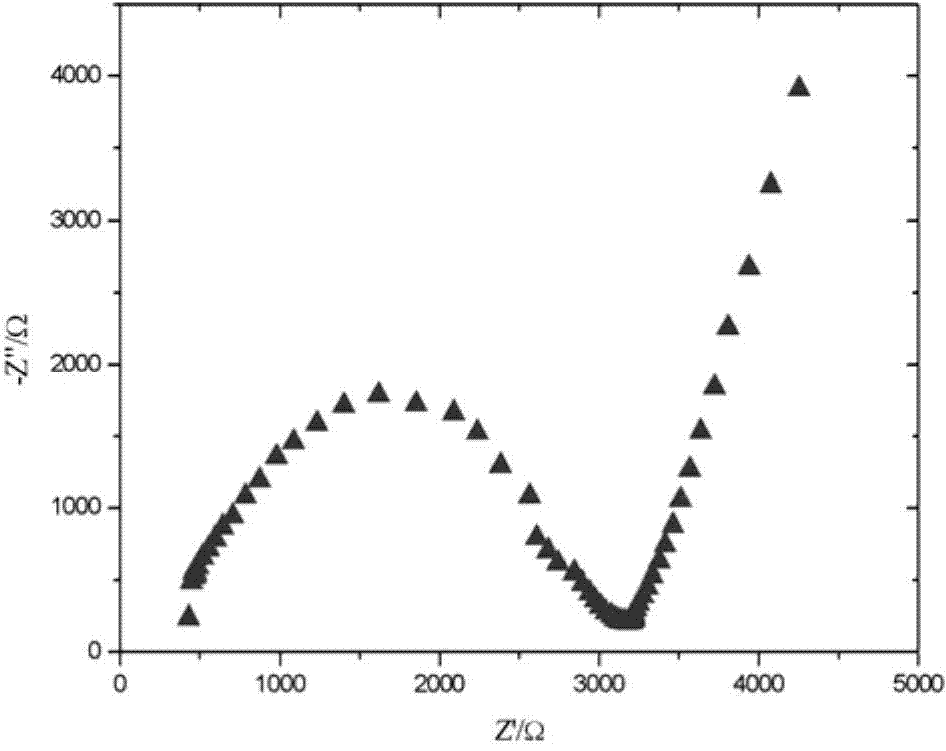

Garnet-structure lithium lanthanum tantalate-based solid electrolyte material and preparation method thereof

InactiveCN103594726AWill not cause churnImprove electrochemical performanceFinal product manufactureElectrolyte accumulators manufactureLanthanumElectrochemistry

The invention discloses a garnet-structure lithium lanthanum tantalate-based solid electrolyte material and a preparation method thereof. The lithium lanthanum tantalate-based solid electrolyte material is a compound of Li5La3Ta2O12 doped at the lanthanum site and / or tantalum site; and the preparation method comprises the following steps: dissolving tantalum pentoxide in a H2C2O4 solution; adding lithium salt and lanthanum slat and the salt of a lanthanum site-doped compound and / or the salt of a tantalum site-doped compound, and mixing to obtain a solution; adding EDTA into the obtained mixed solution for reaction until transparent and clear sol appears; adding a water-soluble high-molecular polymer and continuously reacting until gel appears; drying the obtained gel and calcining; performing mould pressing of the calcined particles to obtain a blank; and further calcining the blank to obtain the solid electrolyte material. The preparation method is mild in conditions, simple in process and simple to operate, and can realize industrial production; the prepared solid electrolyte material has good electrochemical stability and relatively high electrical conductivity, and can be used for preparing an all-solid-state lithium ion battery.

Owner:CENT SOUTH UNIV

Method for preparing inorganic mineral polymers through lead and zinc mine tailings

InactiveCN104003632AGood heat insulation at high temperatureIncreased durabilityCement productionMining engineeringMetakaolin

The invention discloses a method for preparing inorganic mineral polymers through lead and zinc mine tailings. The method includes the steps that activating treatment is carried out on the lead and zinc mine tailings through the wet-process alkalize calcination, alkali-activator is added for inorganic polymerization reaction after metakaolin and sand are added and stirred, the inorganic mineral polymers of a net structure are formed, and a foaming agent and a foam stabilizer can be added into the obtained inorganic mineral polymers to be further prepared into foamed inorganic mineral polymers. The obtained finished inorganic mineral polymers are good in durability, have good high temperature heat insulating property, will not release poisonous substances even when exposed in flame, and can be used for backfill and sealing after a mine is mined, building materials and other aspects. Not only can the stacking problem of the lead and zinc mine tailings be effectively solved and environmental pollution be reduced, but also a new path is developed for developing and utilizing waste lead and zinc mine tailings in China, a new exploration direction is provided for relevant research on recycling of tailings, and the method has a great significance to energy conservation, emission reduction, environmental protection, waste utilization and creation of the environment-friendly society.

Owner:FUZHOU UNIV

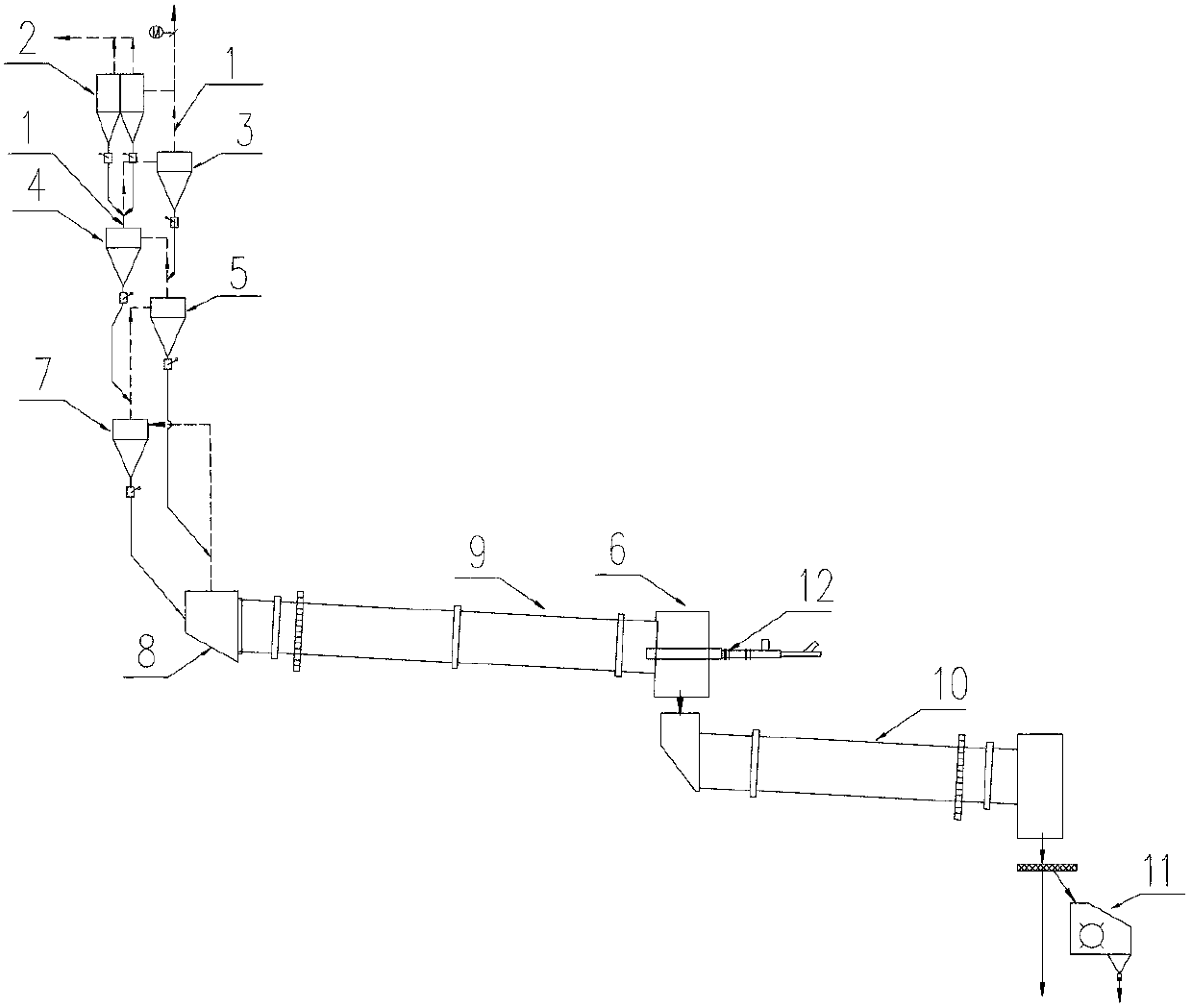

Process and device for whitening calcined black talc

InactiveCN103342371AShort calcination timeIncrease production capacityMagnesium silicatesCombustionWhitening Agents

The invention discloses a process for whitening calcined black talc. Black talc ore is taken as a raw material and is sequentially subjected to mineral separation, crushing, grinding, calcining in a rotary kiln and cooling by a cooling machine, and then granular and blocky calcined black talc products with whiteness of more than or equal to 90 are obtained, wherein the temperature of a burning zone in the calcining procedure in the rotary kiln is 800-1400 DEG C, and the standing time of the raw material in the kiln is 30-90 min. The invention also discloses a device adopting the method. According to the process and the device, a preheater system is adopted for preheating, and a rotary kin calcining process is adopted, so that the calcining time is greatly shortened, and the production capacity is remarkably improved; combustion and heat release of organic matters in black talc are fully considered; the production cost is lowered due to no addition of a whitening agent; dry-method grinding is adopted, and the process is advanced; compared with a process that the black talc is calcined by an annular kiln, the process disclosed by the invention has the advantages that emitted waste gas can be treated to reach the national environmental requirement, the automation degree is high, and parameters are measureable and controllable.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

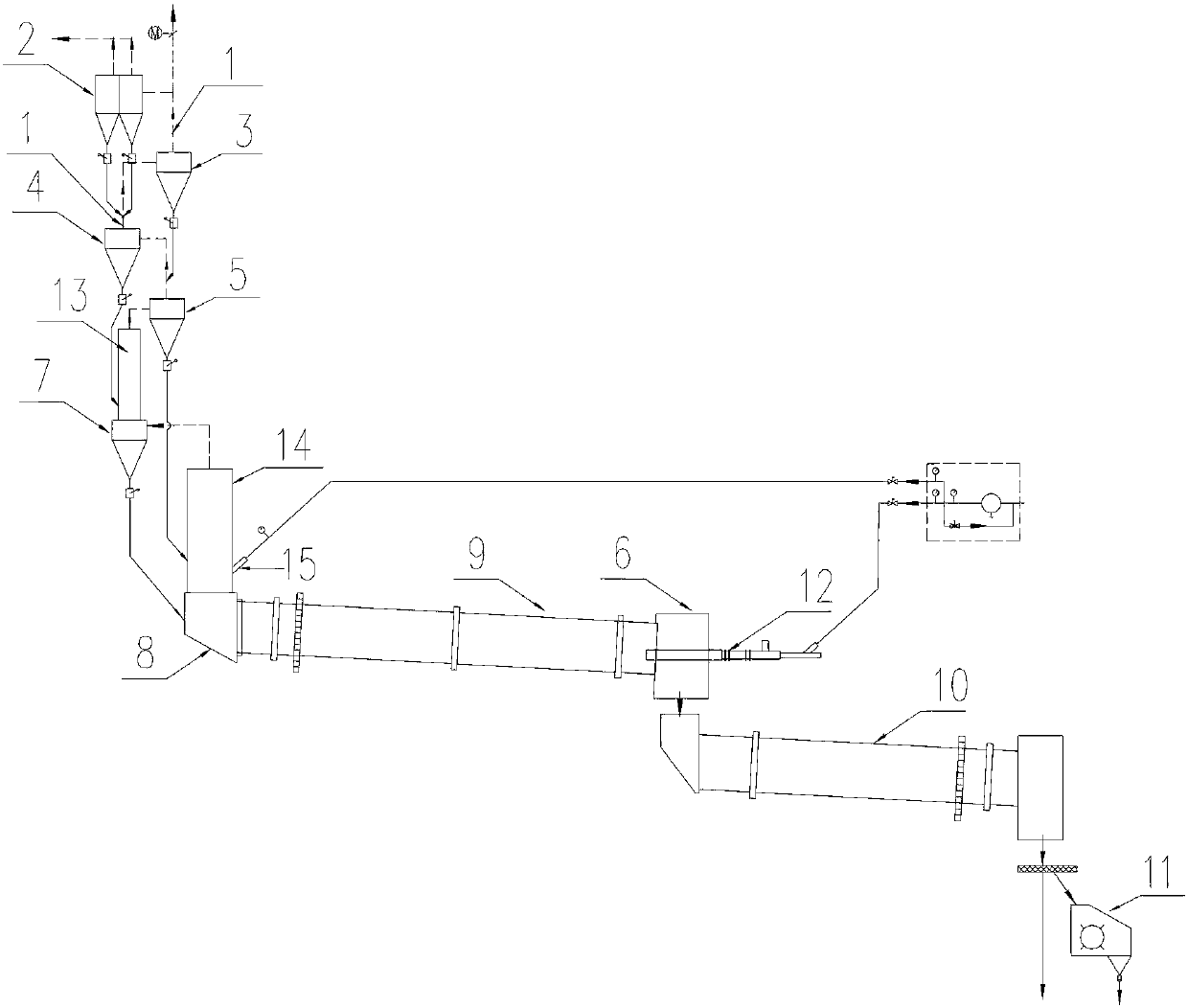

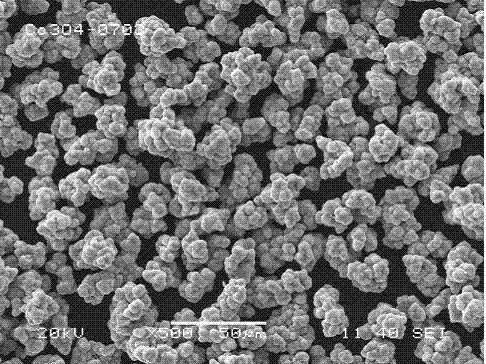

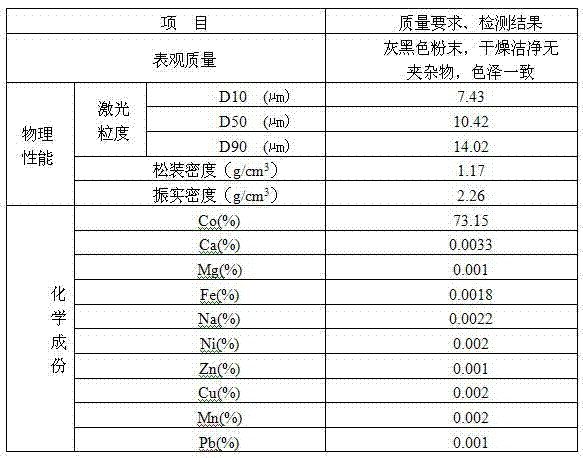

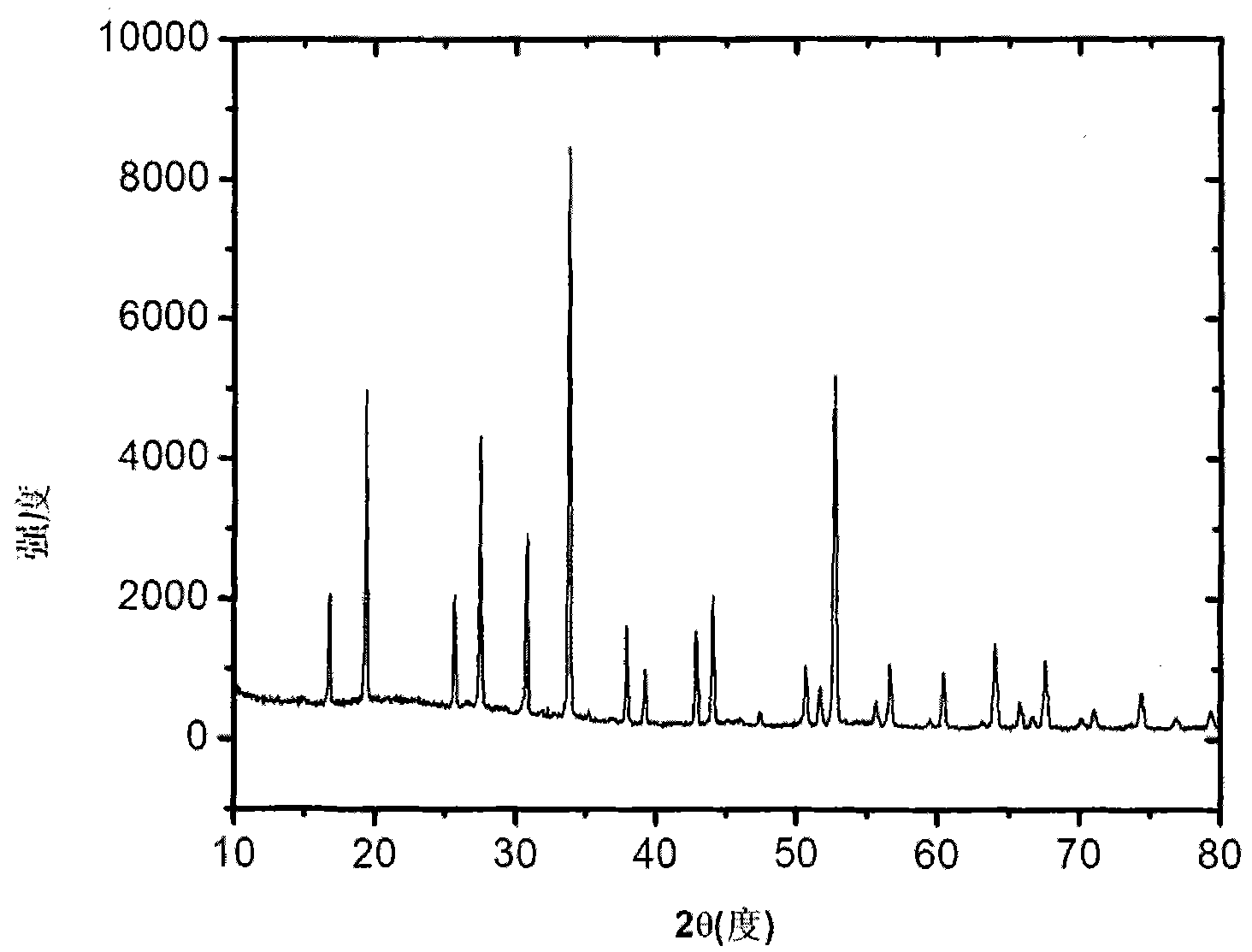

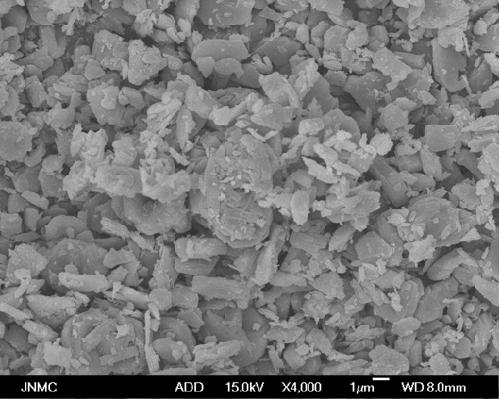

Preparation process of cobaltosic oxide for continuous production of batteries

ActiveCN102820468AGood lookingFine granularityCell electrodesCobalt compoundsAfter treatmentLithium carbonate

A preparation process of cobaltosic oxide for continuous production of batteries is a process for preparing the cobaltosic oxide by using a cobalt contained material to continuously synthesize cobalt carbonate and continuously roasting and resolving in an oxidizing atmosphere. Continuous production of the cobaltosic oxide can be completed through several steps of preparation of cobalt solution, preparation of precipitator, lithium carbonate synthesizing, ageing, filtering and washing, burning and after treatment. The preparation process continuously synthesizes the cobalt carbonate, and continuously roasts and resolves the cobaltosic oxide, is apt to control technical indexes in a production procedure, can achieve automatic production, is favorable for reduction of labor intensity, improves efficiency of labor and lowers cost. Produced products are high in purity, excellent in physical performance indexes and good in stability and consistency.

Owner:GANZHOU TENGYUAN COBALT INDAL

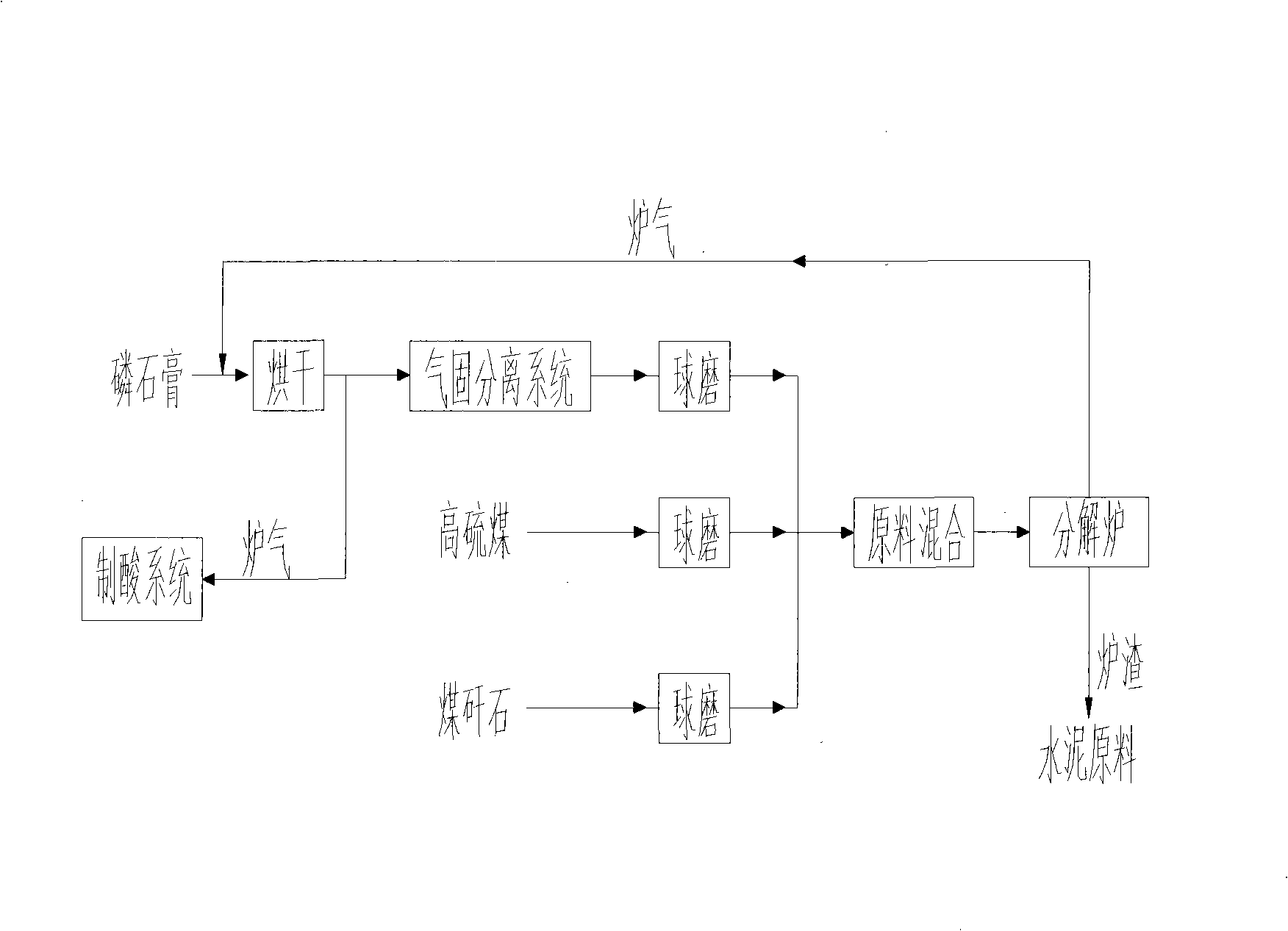

Method for reductively decomposion of ardealite by composite reducer

InactiveCN101323436ALow reaction temperatureShort calcination timeChemical industrySulfur compoundsChemistryDecomposition

The invention relates to a method for adopting a compound reducing agent to reduce and decompose phosphogypsum; the method comprises the following steps of: using high-sulphur coal and coal gangue to prepare the compound reducing agent; utilizing tail gas to dry the phosphogypsum and the compound reducing agent which are ground and mixed evenly and then transferred into a reducing and decomposing furnace; carrying out reduction and decomposition till the reaction is completed. The invention makes full use of sulphur in the high-sulphur coal and the coal gangue to produce stable SO2 with high concentration and provides qualified feed gas for acid-making technique; calcium sulfate is reduced and decomposed to obtain calcium oxide slag which is taken as raw material for producing cement. The method of the invention reduces the reaction temperature and energy consumption, lowers the production cost, is beneficial to reducing energy consumption, reduces the production cost further without causing secondary pollution, thus providing a new path for the comprehensive utilization of the coal gangue and the phosphogypsum and realizing energy-saving and emission reduction. The invention also develops potential sulfur resources and can bring good economic benefit, thus forming an industry chain of circular economy for wet-process phosphoric acid enterprises.

Owner:KUNMING UNIV OF SCI & TECH

High temperature calcination method of electrolytic aluminum cathode scrap residue

The invention discloses a high temperature calcination method of electrolytic aluminum cathode scrap residue. The method is characterized by comprising the following steps of: crushing and ball milling the electrolytic aluminum cathode scrap residue; separating powdered carbon through floatation; then removing iron-containing impurities from the powdered carbon through magnetic separation; and calcining the powdered carbon by a calcining furnace to remove fluoride salt and sulfur from the powdered carbon, thus obtaining high-purity powdered carbon. According to the invention, through direct high temperature calcination of the powdered carbon recovered from the electrolytic aluminum cathode scrap residue, the processes of asphalt blending, tar kneading and profiling are reduced, so that the method is simpler; and compared with calcined carbon blocks, the powdered carbon grains are small and quick in temperature rise, and can rapidly reach a high temperature over 1700 DEG C in the calcining furnace, so that sulfur and fluoride salt are gasified and released. Therefore, the calcination time is greatly reduced, and the calcination can be finished in 10-20 minutes, thus saving a large amount of heating time and electric energy. The calcined powdered carbon has the advantages of low volatile component, low sulfur, high purity and more balanced quality, and can be used as a high-quality carbon raw material.

Owner:周俊和 +1

Lithium lanthanum bismuthate-based solid electrolyte material and preparation method thereof

InactiveCN102044700AIncreased overall conductivity at room temperatureReduce the temperatureFinal product manufactureElectrolyte accumulators manufactureWater soluble polymersWater soluble

The present invention discloses Lithium lanthanum bismuthate-based solid electrolyte material and preparation method thereof. The chemical formula of the material of Lithium lanthanum bismuthate-based solid electrolyte after the doping of lanthanum and the doping of lithium are conducted is La(3-x)AxLi(5+delta)Bi(2-y)ByO12. In the formula, A is the lanthanum position dopant, X is a value from 0 to 1.25, B is the bismuth position dopant, and Y is a value from 0 to 1.25. The preparation method of the material is as follows: according to the formula, weighing nitrates or carbonates or chlorides or acetates or alkoxides or oxides soluble in acids of lithium, lanthanum, bismuth, the lanthanum-position dopant and / or the bismuth-position dopant, preparing a solution by using the above chemicals,adding a lanthanum salt solution, a bismuth solution, a solution of lanthanum-position dopant and / or a solution of bismuth-position dopant dropwisely, adding citric acid and nitric acid successively to obtain a sol, adding a water-soluble polymer into the sol to form a gel, drying the gel, performing heat treatment to obtain nanocrystal powder, moulding the powder into a green body, and calciningto obtain the Lithium lanthanum bismuthate-based solid electrolyte material. The prepared material can be used as a solid electrolyte material and can be applied to all-solid-lithium ion battery.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

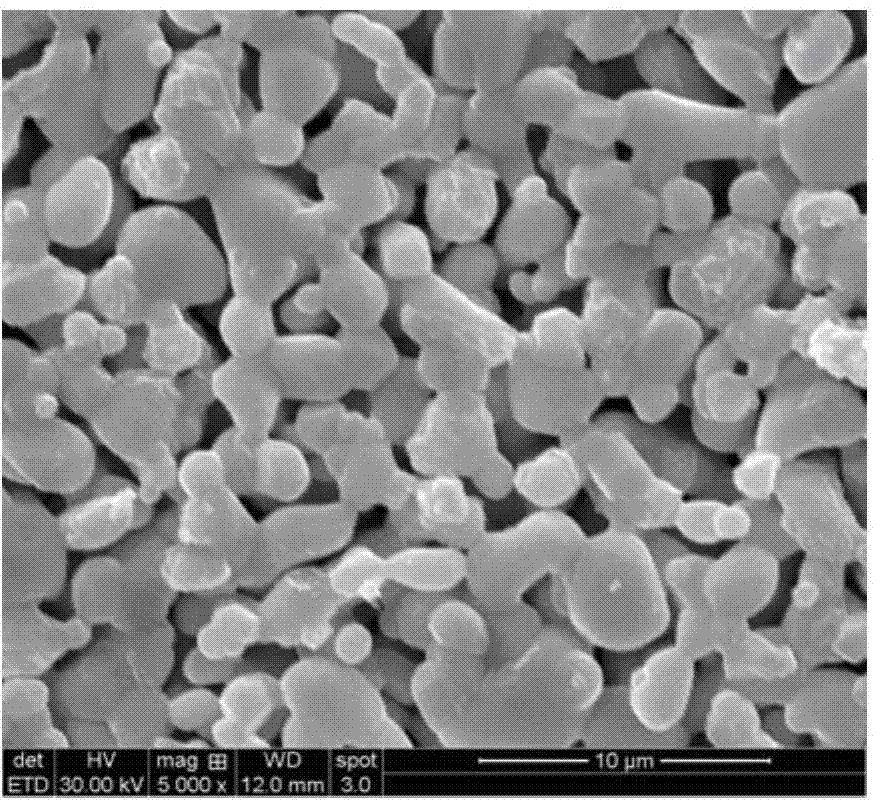

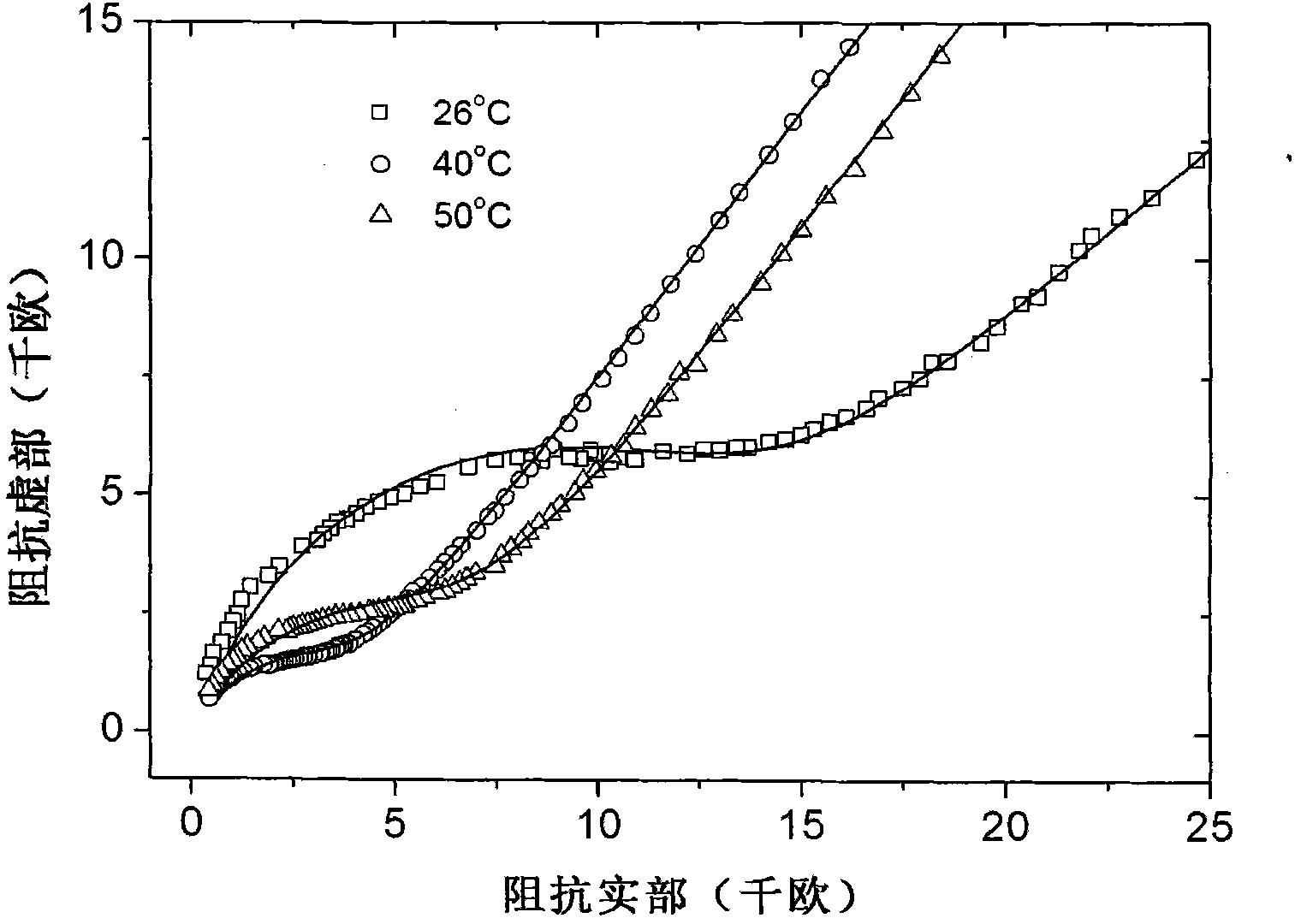

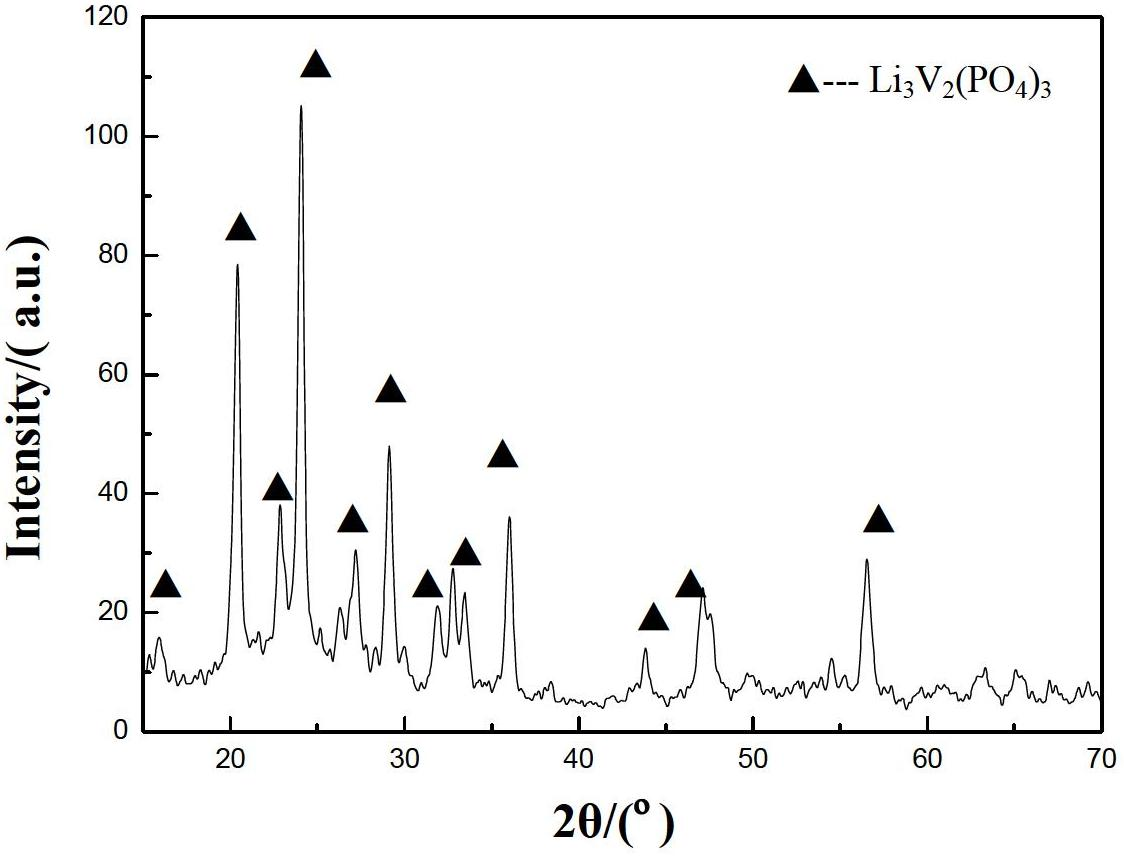

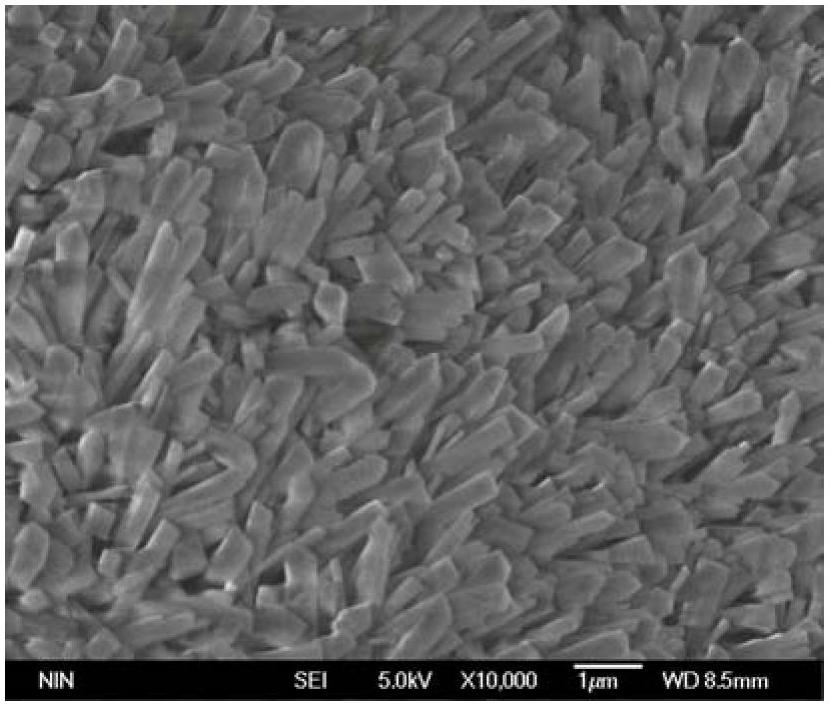

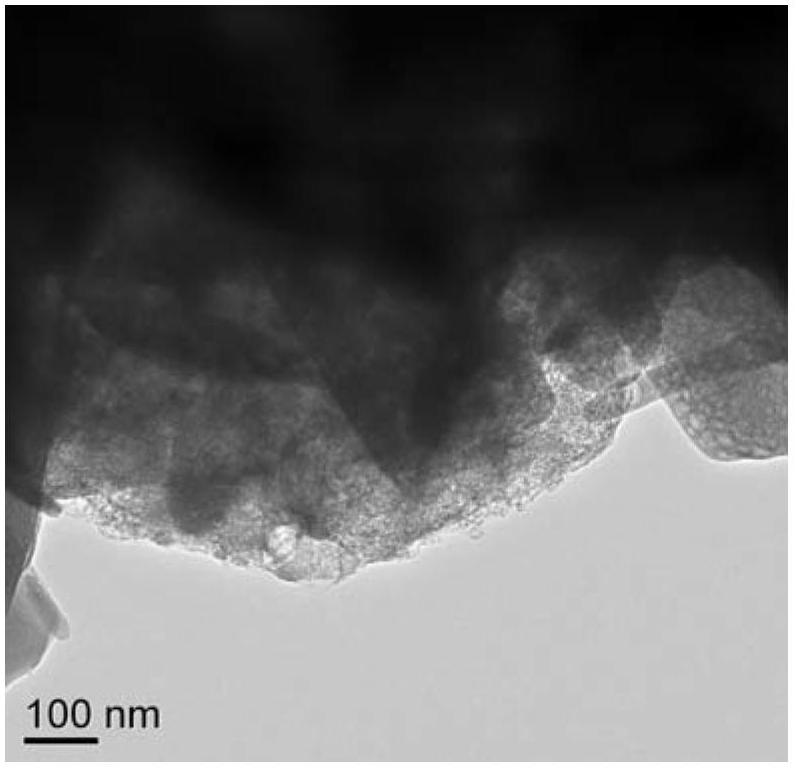

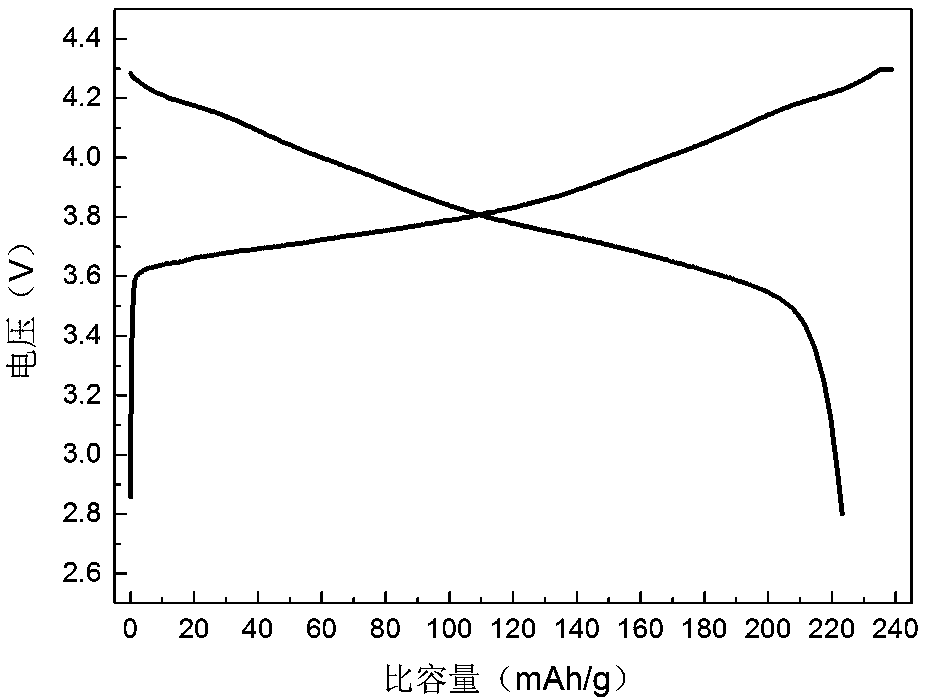

Preparation method of lithium ion battery cathode material carbon-coated columnar lithium vanadium phosphate

InactiveCN102664263AShorten the formation timeHigh purityCell electrodesPhosphorus compoundsLithium-ion batteryAqueous solution

The invention provides a method for preparing a lithium ion battery cathode material carbon-coated columnar lithium vanadium phosphate, which comprises the following steps: preparing a NH4VO3 water solution of which the concentration is 0.06-0.10 mol / L, sequentially adding LiOH.H2O, citric acid and H3PO4 into the solution, and evenly mixing to form a precursor solution, wherein the LiOH.H2O-NH4VO3 -H3PO4-citric acid mol ratio is 3:2:3:2; putting the precursor solution into a hydrothermal kettle to react at 160 DEG C for 1-2 hours, so as to obtain a blue gel after the reaction finishes, drying the gel, and grinding the dried gel to obtain powder; and calcining the dry gel powder in an N2 furnace to obtain the carbon-coated columnar lithium vanadium phosphate composite material. By combining the hydrothermal method and the calcining technique, the technique provided by the invention is simpler and more efficient as compared with the traditional sol-gel method, and has the advantages of lower calcining temperature and shorter calcining time as compared with the traditional solid-phase method. Besides, the powder has the advantages of high purity and uniform dimension, and the crystal appearance appears columnar.

Owner:陕西精泰计量检测校准有限责任公司

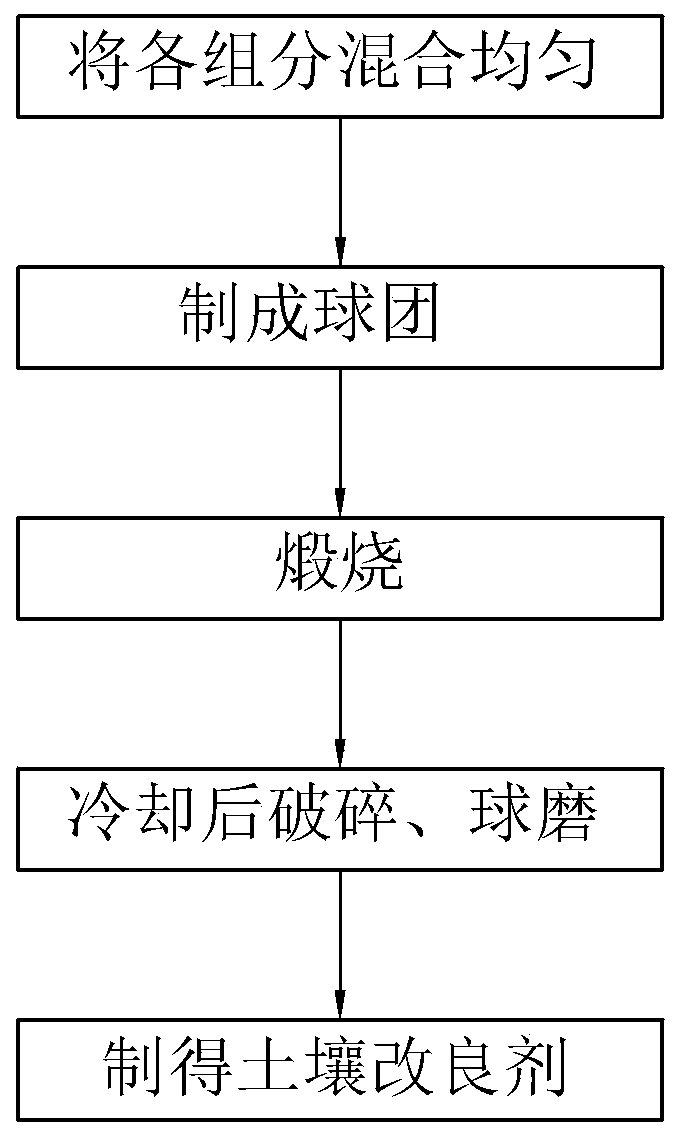

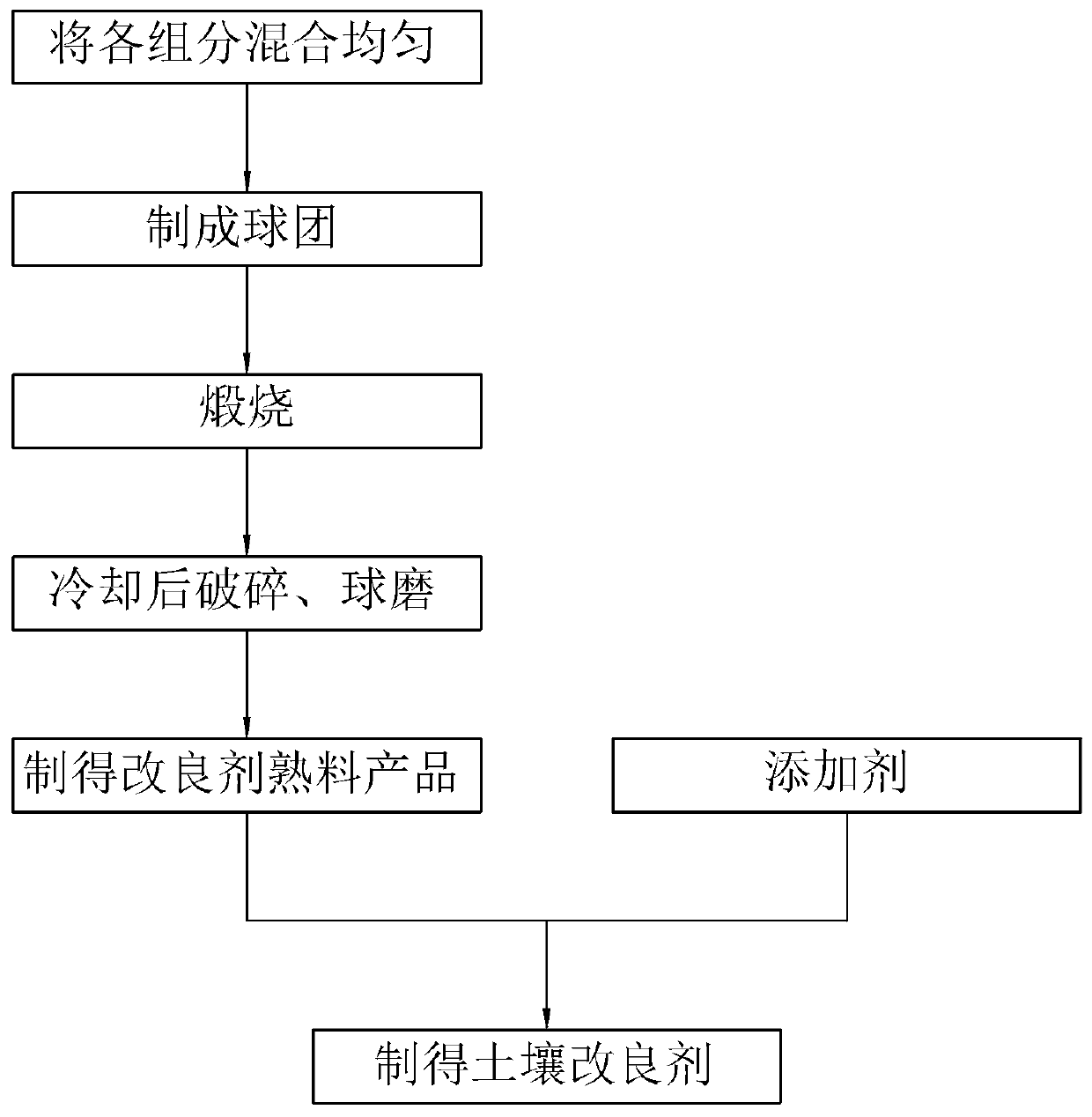

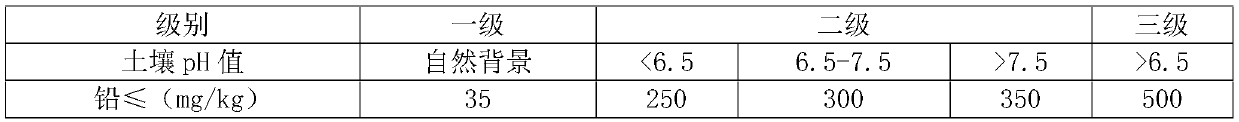

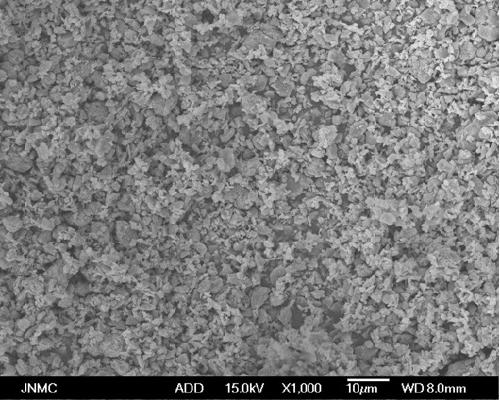

Soil conditioner as well as preparation method and use method thereof

ActiveCN110079332AWide variety of sourcesReduce typesCalcareous fertilisersAgriculture tools and machinesDickiteAlunite

The invention relates to the technical field of soil remediation, in particular to a soil conditioner as well as a preparation method and use method thereof. The soil conditioner comprises the following components in percentage by weight: 40-60% of copper tailings, 20-40% of fluorite tailings or limestone, 6-20% of talc, serpentine or dolomite, and 2-5% of a pellet curing agent, wherein the totalweight is 100%; and the copper tailings include quartz, alunite and dickite. The preparation method comprises the following steps: step 1, weighing the components and mixing the components uniformly;sep 2, preparing the mixture obtained in the step 1 into pellets; step 3, calcining the pellets at a temperature of at least 1000 DEG C for at least 1.5 hours; and step 4, cooling activated pellets and performing ball milling to obtain the soil conditioner. The soil container contains non-ferrous metal and non-metallic ores, various major, medium and trace elements necessary for the growth of crops, fruit trees and seedlings, and basically no additional major, medium and trace elements need to be added.

Owner:SHENZHEN MPD HITECH CO LTD

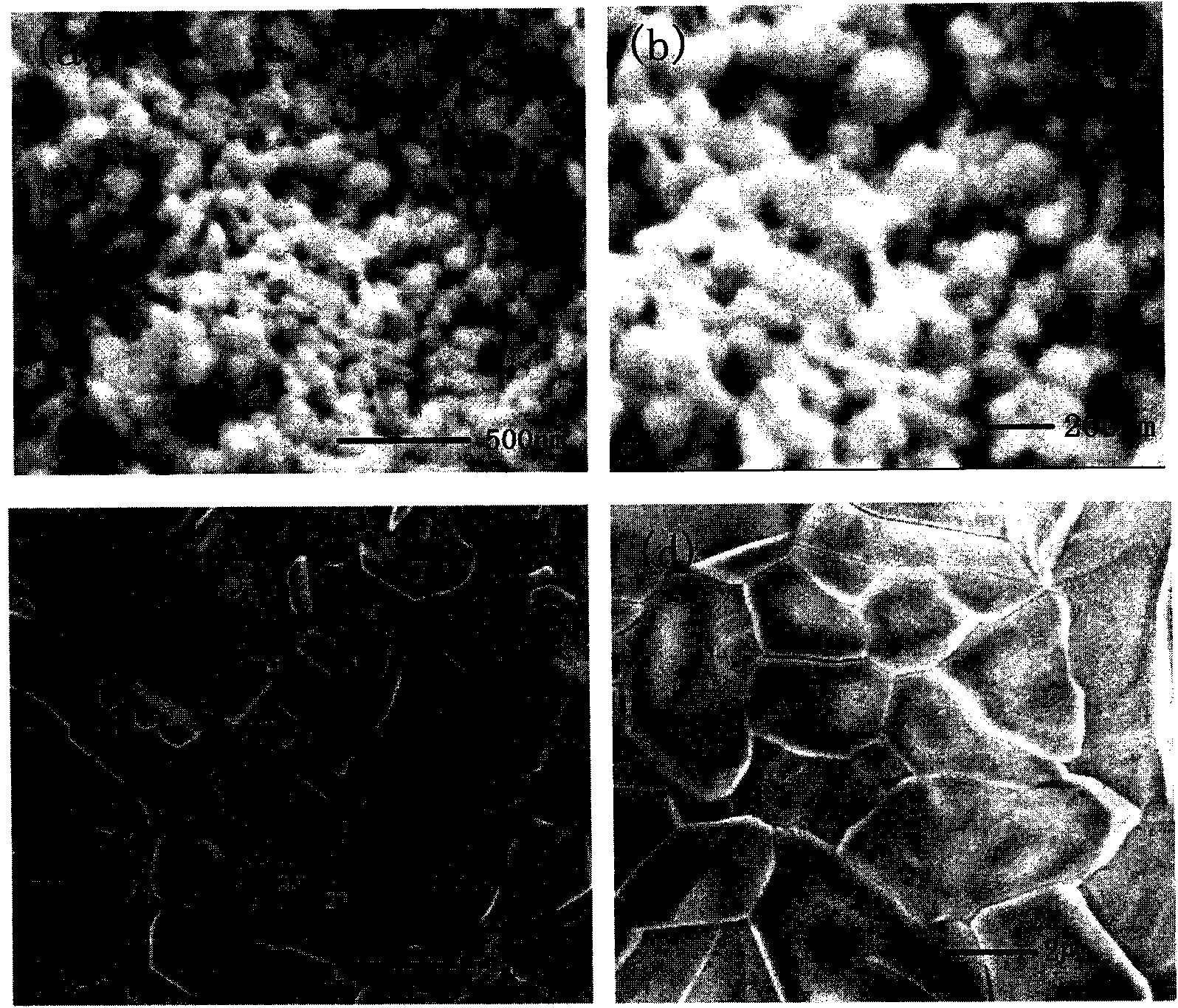

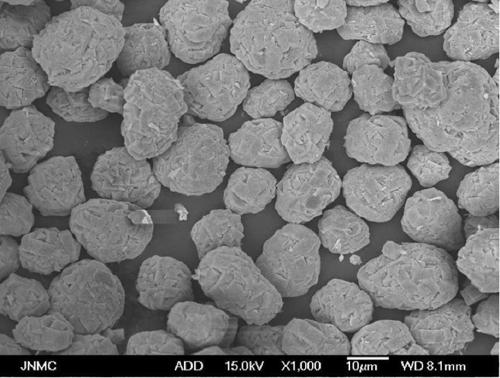

Method for preparing large-granularity cobaltosic oxide

ActiveCN108946824AImprove direct yieldReduce manufacturing costCobalt oxides/hydroxidesLithium-ion batterySeed crystal

The invention belongs to the field of anode materials of lithium ion batteries, and provides a method for preparing large-granularity cobaltosic oxide. The method adopts a cobalt solution with certainconcentration as a cobalt source, a sodium hydroxide solution as a precipitator, an ammonia solution as a complexing agent and a hydrazine hydrate solution as a reducing agent, and comprises the following steps: adding a certain amount of cobalt hydroxide flashing dry dust collecting material and the hydrazine hydrate solution into a reaction kettle when synthesis is started; transforming the dust collecting material into a cobalt hydroxide precursor seed crystal under intense stirring, and synthesizing a cobaltosic oxide precursor product with the granularity of 16-18mu m by a wet method through a certain process condition; adding a certain amount of conductive carbon black into the reaction kettle after synthesis is completed, aging for a period, washing and drying the mixture, and calcining under a certain condition to obtain the large-granularity cobaltosic oxide product. By utilizing the process, the spherical or sphere-like cobaltosic oxide product having a laser granularity of16-18mu m, tap density of more than 2.0g / cm<3> and specific surface area of 1.0-3.0m<2> / g can be prepared.

Owner:南通金通储能动力新材料有限公司

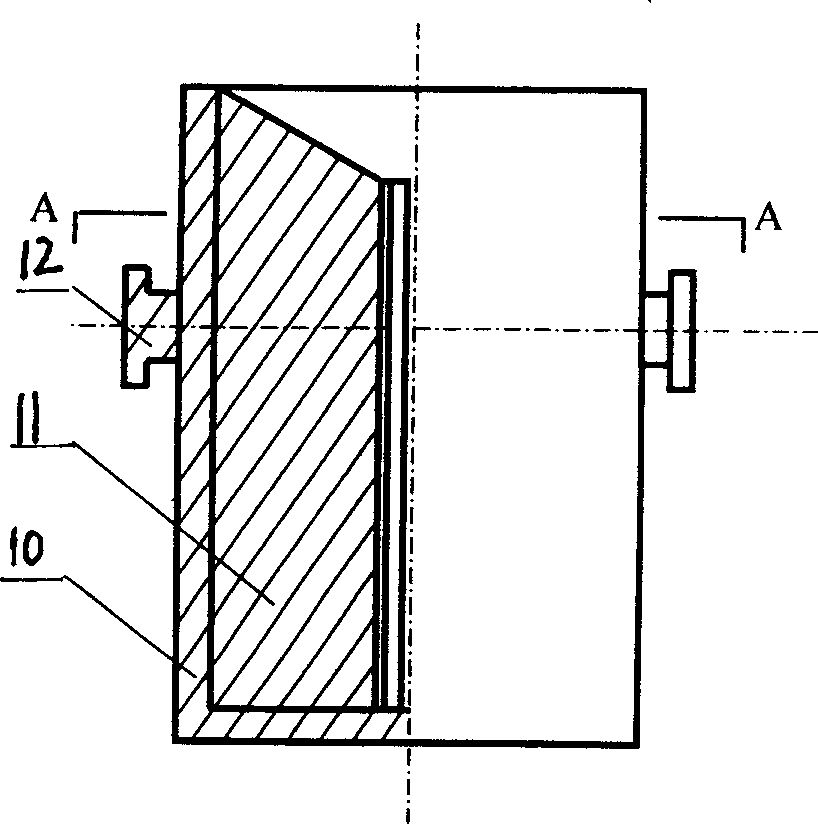

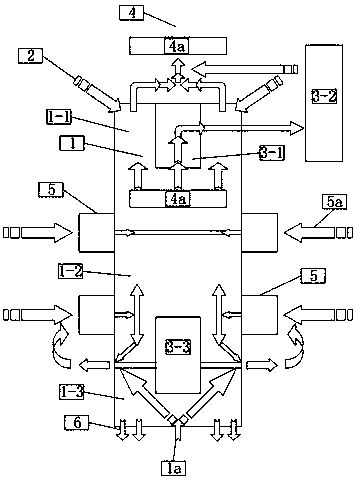

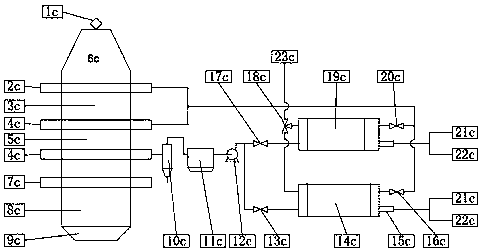

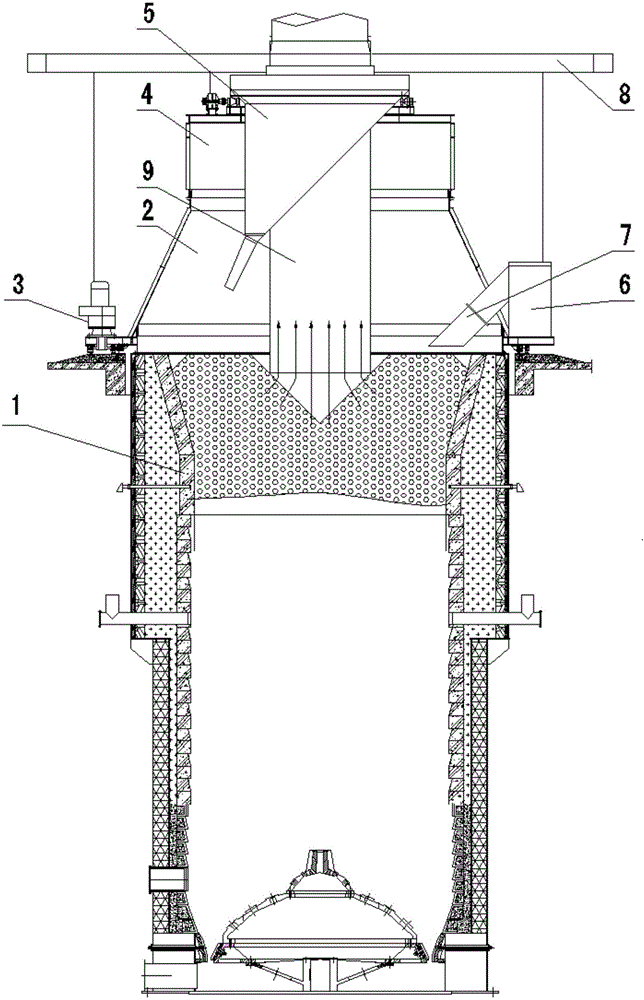

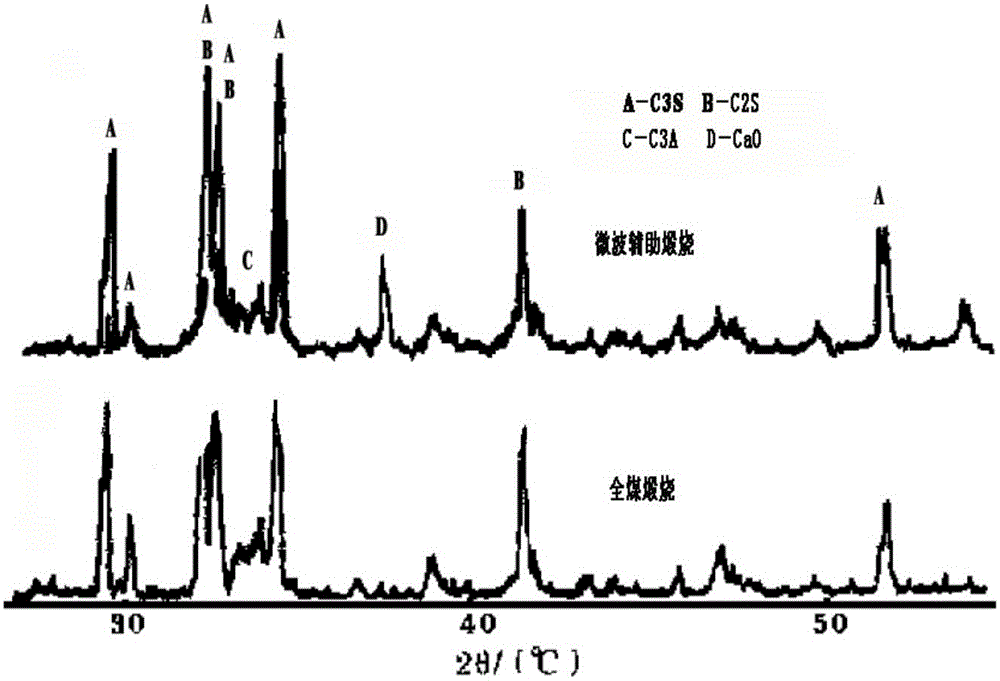

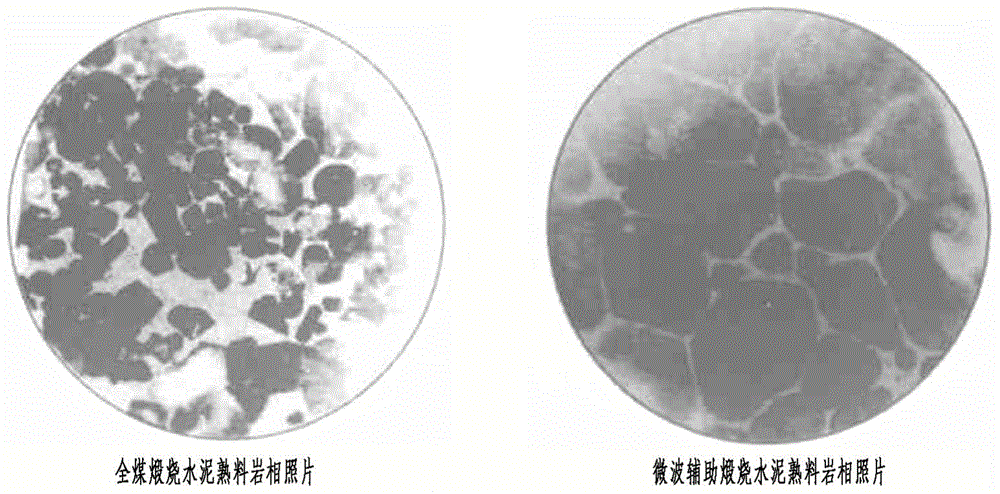

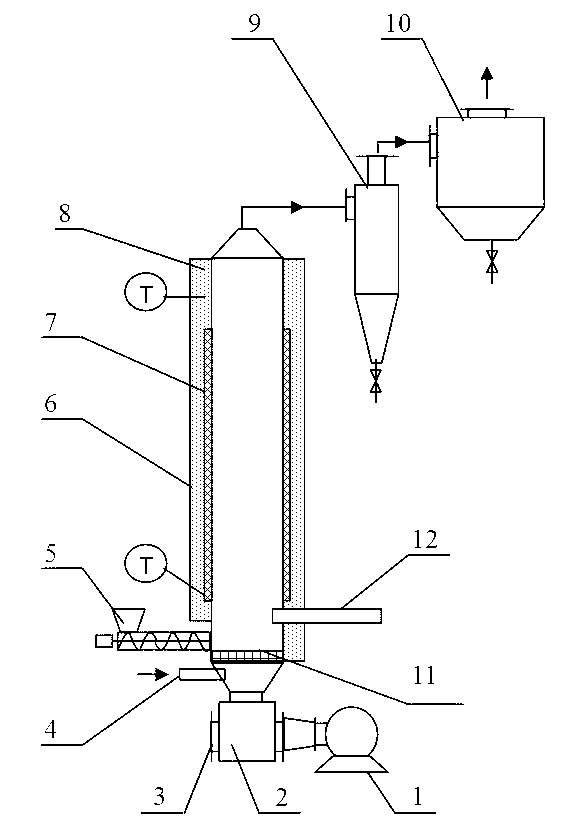

Microwave kiln for assisting in cement clinker calcination and microwave calcination method thereof

ActiveCN104457217AUniform radiationAdjustable speedRotary drum furnacesWaste heat treatmentThermodynamicsProcess engineering

The invention discloses a microwave kiln for assisting in cement clinker calcination. The microwave kiln for assisting in cement clinker calcination comprises a kiln body and further comprises a rotary kiln cover, a driving mechanism, a fixed kiln cover, a distributing device, a microwave generator and a waveguide tube, wherein a draught fan is installed on the bottom of the kiln body, and the rotary kiln cover is installed on the kiln mouth of the kiln body. According to the microwave kiln for assisting in cement clinker calcination, microwave field radiation is even; the rotary kiln cover is arranged, the waveguide tube and the microwave generator are installed on the rotary kiln cover and rotate along with the rotary kiln cover, and a microwave field which is large in coverage area and even in microwave radiation is formed gradually in the kiln body by microwaves emitted by the microwave generator during rotation; in addition, an annular power supply slide wire and the driving mechanism are arranged, the rotating speed of the rotary kiln cover can be adjusted through the driving mechanism, and thus the microwave field can be adjusted.

Owner:张雪华

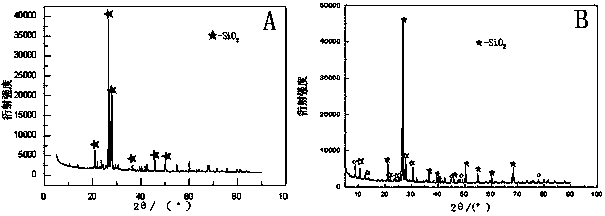

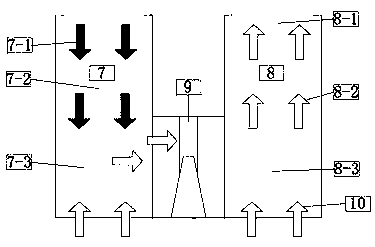

Method for desorbing residual carbon in siliceous dust by means of oxygen-enriched calcination and device therefor

InactiveCN102849751AIncrease oxidation rateAvoid meltingHeat treatmentsSilicaPhysical chemistryResidual carbon

The invention belongs to the technical field of the removal of residual carbon in siliceous dust, and particularly relates to a method for desorbing residual carbon in siliceous dust by means of oxygen-enriched calcination and a device for desorbing the residual carbon in the siliceous dust by means of oxygen-enriched calcination. The removing method provided by the invention comprises the step of calcining the siliceous dust which contains the impurities and is under the fluidized state for 1-2minitues under the temperature of 600-800DEG C and the condition of oxygen enrichment, wherein the condition of oxygen enrichment means that the oxygen mole fraction in the gas is 30-34% in the process of calcining. The removing device provided by the invention comprises a fluidized bed calcining tower, a burning mechanism, a temperature measurement mechanism, a blasting mechanism, a material transporting mechanism, an oxygen supply mechanism and a product collecting mechanism. The invention adopts a fluidized bed calcining technology under the state of oxygen enrichment, and the oxidation speed of the residual carbon in the siliceous dust can be effectively accelerated in the process of calcining under the state of oxygen enrichment, so that the calcining time can be shortened; and the calcining can be carried out under the state of fluidization, so that the fusion and the bonding coalescence among silica particulates in the siliceous dust can be effectively avoided, and the diameters of the fine particulates can be guaranteed to be invariable.

Owner:ANHUI UNIV OF SCI & TECH

Hollow nickel molybdate nanoflower assembled by nanosheets and preparing method of hollow nickel molybdate nanoflower assembly

ActiveCN107651713AObvious hollow structureIncrease contact areaMaterial nanotechnologyNickel compoundsMolybdateAmmonium hydroxide

The invention discloses a hollow nickel molybdate nanoflower assembled by nanosheets and a preparing method of the hollow nickel molybdate nanoflower assembly. The preparing method comprises the stepsof using Ni(NO3)2.6H2O and (NH4)6Mo7O24 as raw materials, adopting ammonium hydroxide as a solution PH modifier and a catalyst, using microemulsion formed by CTAB, cyclohexane, ethyl alcohol and water as a template, and preparing the hollow nickel molybdate nanoflower material through a hydrothermal reaction and calcination treatment. The hollow nickel molybdate nanoflower assembled by the nanosheets is of an obvious hollow structure, compared with a pure spherical structure, the specific surface area can be increased through the hollow structure, so that the contact area of an electrolyte and the hollow nickel molybdate nanoflower assembled by the nanosheets is increased; electrochemical properties are improved; framework base materials are not needed, the mass is low, and raw materialsare saved.

Owner:QILU UNIV OF TECH

Lime kiln device with application of hot-air

The invention relates to a lime kiln device with hot-air calcination and a method for producing lime by the utilization of the lime kiln device. When preparing lime, hot air generated from a combustion apparatus outside a kiln is used for calcination of limestone; waste hot air used after the calcination is used for preheating of the limestone mineral aggregate; the waste hot air used after preheating is discharged out of the kiln body, and then undergoes dedusting and finally used for preheating of coal gas and oxidizing air. Through the use of hot air for calcination of limestone, lime quality can be remarkably improved, lime yield is raised, and productivity is enhanced. The lime kiln proposed by the invention is not provided with a burner system, and the hot air for high temperature calcination is from a combustion furnace device outside the kiln. Blast-furnace gas can be used as a fuel for the combustion furnace device, and hot flue gas generated by the combustion device can be used as the hot air. Thereby, the kiln structure is simplified, and operating cost of the lime kiln is reduced.

Owner:王长春 +2

Production process of active lime

The invention discloses a production process of active lime. The process comprises the following steps of (1) screening and pretreatment of limestone, (2) mixing, (3) preheating, (4) calcining, (5) cooling and (6) post-treatment. Firstly, an additive used in the production process reduces underfiring and overburning of the lime, increases the decomposition speed of CaCO3, shortens the calcining time, correspondingly reduces the energy consumption and is beneficial to industrial popularization. Furthermore, carbon is also added, decompression operation is adopted after preheating and before cooling separately, correspondingly the elements sulfur and carbon which remain in lime raw materials can be volatilized out more thoroughly, and the recombination of the elements with calcium oxide is avoided, so that the purity of the active lime is improved, and the activity degree of quicklime is further improved.

Owner:新兴永和河北能源科技股份有限公司

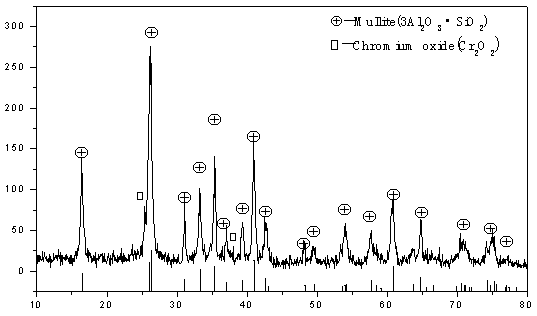

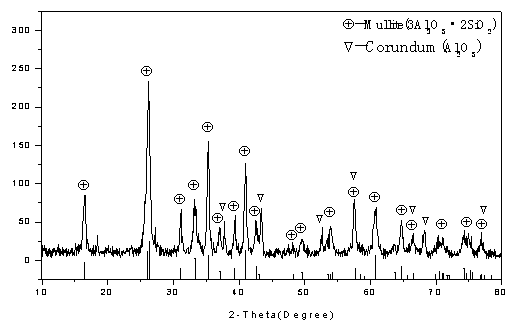

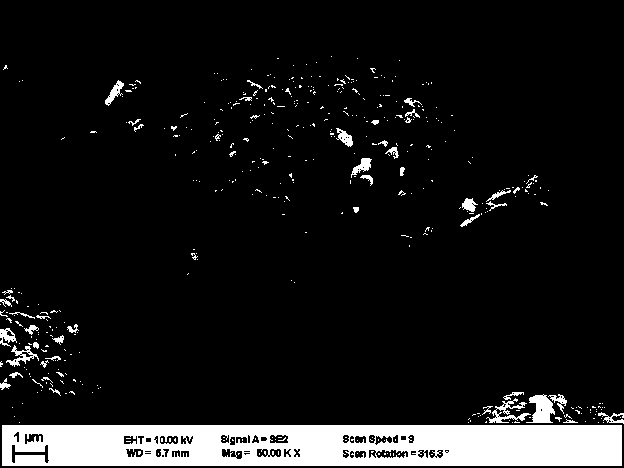

Mullite nano-whisker prepared by using pyrite tailing as raw material and preparation method of mullite nano-whisker

InactiveCN104313695AUniform diameterUniform length distributionPolycrystalline material growthFrom solid statePyriteIron removal

The invention discloses a method for preparing a mullite nano-whisker by using pyrite tailing as a raw material, and belongs to the field of nano-whisker preparation and mineral resource recycling. The method comprises the following steps: preparing the raw material, pickling for removing iron, calcinating for removing C, S and organic matters, preparing a precursor, and performing calcination and acid soaking for removing a glass phase. According to the invention, the prepared nanoscale mullite whisker has good quality, has excellent properties of both the mullite whisker and the nano-whisker, and has a high additional value and a remarkable economic benefit; in addition, the adopted raw material pyrite tailing is waste mineral materials after mineral dressing, so that the products are low in cost of raw materials, and the secondary recycling of pyrite resources is achieved; meanwhile, compared with other preparation methods, the preparation process of the invention requires lower calcination temperature and shorter calcination time, so that reduction of energy consumption is facilitated, thereby reducing production cost and resource consumption, and increasing economic benefits.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for preparing proportion-adjustable nickel-rich positive electrode material of lithium ion battery

InactiveCN108199038AThe stoichiometry is simpler than the processHigh tap densityCell electrodesSecondary cellsOxygenLithium-ion battery

The invention belongs to the technical field of lithium ion battery material preparation, and particularly relates to a method for preparing a proportion-adjustable nickel-rich positive electrode material of a lithium ion battery. According to the scheme of the invention, a chemical formula of the positive electrode material is xLiNi1 / 3Co1 / 3Mn1 / 3O2.yLiNiO2.zAl2O3, wherein x is greater than or equal to 0.2 and less than or equal to 0.5, y is greater than or equal to 0.5 and less than or equal to 0.8, z is greater than or equal to 0 and less than or equal to 0.1, and the sum of x and y is equalto 1. The preparation steps are as follows: controlling the feed speed ratio according to the value of x:y, implementing multi-layered stacking on LiNi1 / 3Co1 / 3Mn1 / 3O2 and LiNiO2 by alternate precipitation, synthesizing a nickel-rich positive electrode material precursor with multiple composite structures, and then performing mixed calcination with an aluminum salt gel to achieve that the outer layer is coated with Al2O3, and finally adopting an ozone-oxygen mixed atmosphere calcination mode to further shorten the calcination time of the material and improve the calcination efficiency. The nickel-rich positive electrode material prepared by the method has high tap density and excellent electrochemical performance.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com