Method for preparing proportion-adjustable nickel-rich positive electrode material of lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of incomplete co-precipitation, poor electrolyte matching and compatibility, and high surface pH, and achieves simple process, electric The effect of excellent chemical properties and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

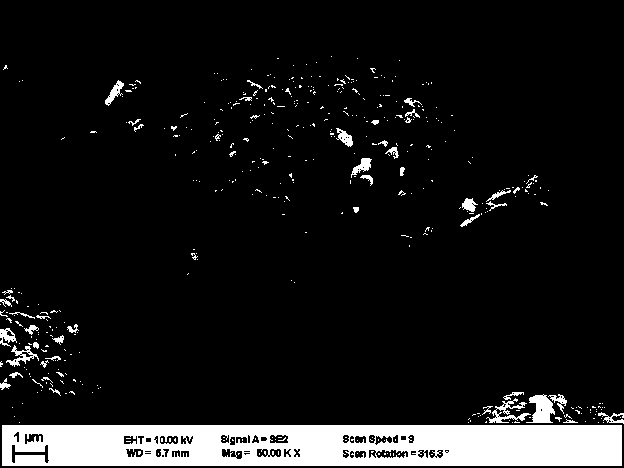

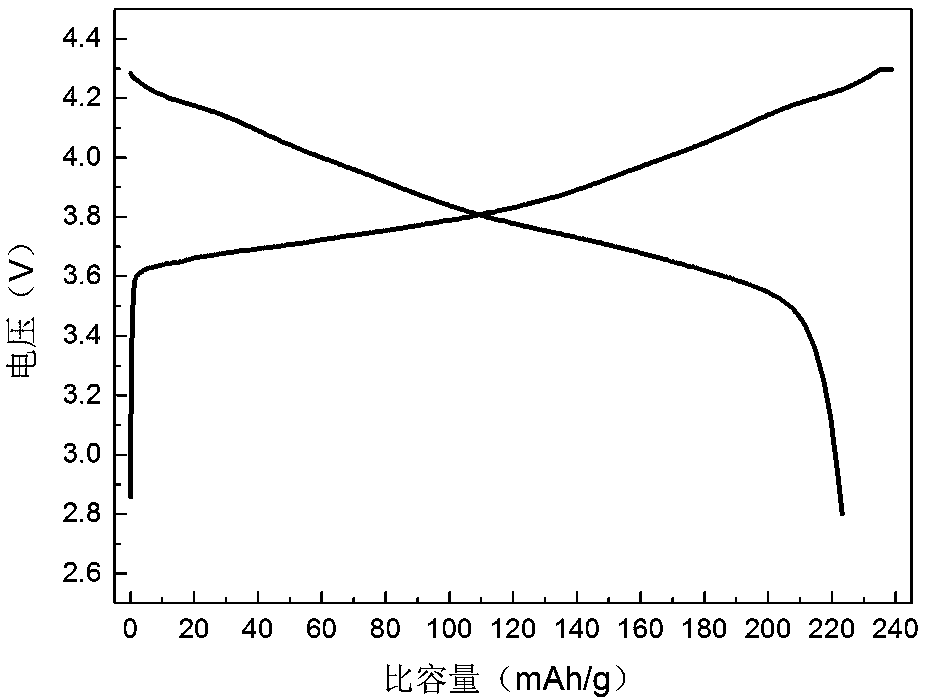

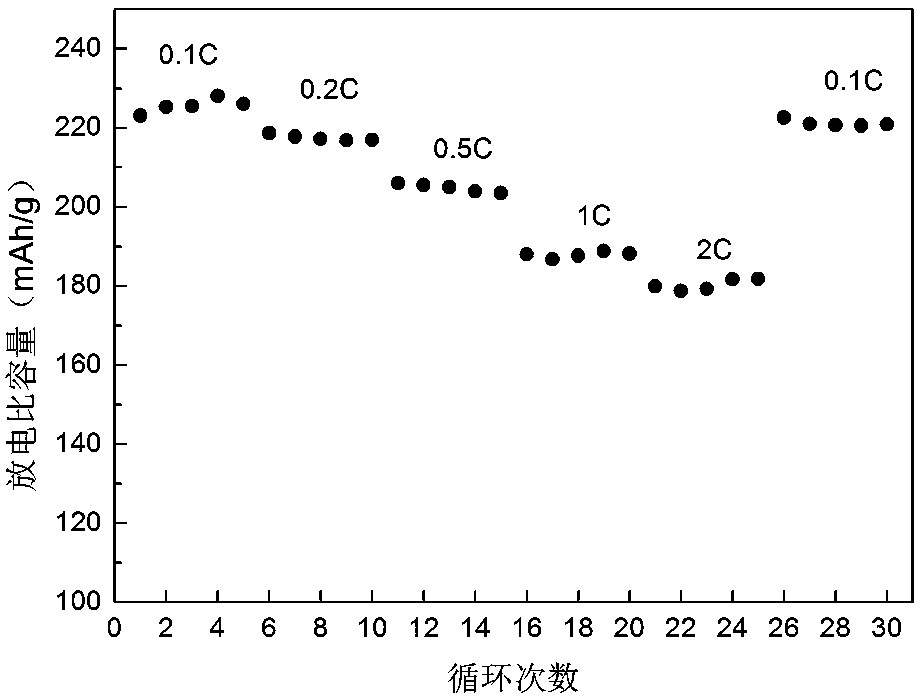

[0025] What this example prepares is nickel-rich cathode material 0.3LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 0.7 LiNiO 2 0.025Al 2 o 3 .

[0026] In this example x=0.3, y=0.7, z=0.025, x:y=3:7.

[0027] Prepare 2mol / L NiSO according to stoichiometric ratio 1:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O metal salt solution A600mL, prepare 2mol / L NiSO 4 ·6H 2O solution B1400mL, prepare 4mol / L NaOH and 1.6mol / L ammonia water mixed solution C2200mL; put 200mL deionized water in the reaction kettle, heat the water bath to the water temperature of 55°C, keep stirring, the stirring speed is 800rpm, and nitrogen gas For protection, first add the above-mentioned C solution to the kettle dropwise to pH=11.60, then drop the above-mentioned two solutions of A and C into the reaction kettle at the same time, the feed rate of the A solution is 0.9mL / min, adjust the feed rate of the C solution so that The pH in the kettle was maintained at 11.60±0.02 (monitored with a pH meter); after 1...

Embodiment 2

[0031] What this example prepares is nickel-rich cathode material 0.4LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 0.6LiNiO 2 0.03Al 2 o 3 .

[0032] In this example x=0.4, y=0.6, z=0.03, x:y=2:3.

[0033] Prepare 2mol / L NiSO according to stoichiometric ratio 1:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O metal salt solution A800mL, prepare 2mol / L NiSO 4 ·6H 2 O solution B1200mL, prepare 4mol / L NaOH and 0.6mol / L ammonia water mixed solution C2200mL; put 300mL deionized water in the reaction kettle, heat the water bath to the water temperature of 50°C, keep stirring, the stirring speed is 700rpm, and nitrogen gas For protection, first add the above-mentioned C solution to the kettle dropwise to pH=11.40, then drop the above-mentioned two solutions of A and C into the reaction kettle at the same time, the feed rate of the A solution is 1.2mL / min, adjust the feed rate of the C solution so that The pH in the kettle was kept at 11.40±0.05 (monitored with a pH meter); after 0.5h, sol...

Embodiment 3

[0035] What this example prepares is nickel-rich cathode material 0.25LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 0.75LiNiO 2 .

[0036] In this example x=0.25, y=0.75, z=0, x:y=1:3.

[0037] Prepare 2mol / L NiSO according to stoichiometric ratio 1:1:1 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O metal salt solution A800mL, prepare 2mol / L NiSO 4 ·6H 2 O solution B2400mL, prepare 4mol / L NaOH and 0.6mol / L ammonia water mixed solution C3500mL; put 250mL deionized water in the reaction kettle, heat the water bath to the water temperature of 55 ° C, keep stirring, stirring speed 500rpm, nitrogen gas For protection, first add the above-mentioned C solution to the kettle dropwise to pH=11.80, then drop the above-mentioned two solutions of A and C into the reaction kettle at the same time, the feed rate of the A solution is 1.0mL / min, adjust the feed rate of the C solution so that The pH in the kettle was kept at 11.80±0.03 (monitored with a pH meter); after 2 hours, the A solution was stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com