Patents

Literature

98results about How to "Improve calcination efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of tungsten powder used for high-density alloy

ActiveCN109261980ALarge specific surface areaAvoid high temperature and violent volatilizationHigh densityAmmonium paratungstate

The invention belongs to the technical field of powder metallurgy, and specifically relates to a preparation method of tungsten powder used for high-density alloy. The method specifically includes thefollowing steps that high-specific-surface-area tungsten oxide preparation, boat loading, reduction, cooling and sieving. The high-specific-surface-area tungsten oxide is prepared through ammonium paratungstate, hydrogen serves as a reducing agent, the high-specific-surface-area tungsten oxide can be reduced tungsten powder at high temperature more than 800 DEG C, the reduced tungsten powder is cooled in multi-stage mode, and finally, the tungsten powder is subjected to ultrasonic sieving to obtain near-spherical tungsten powder, wherein grain growth is complete, the tungsten powder is full,the activity is low, the dispersion property is good and the tungsten powder has particle morphology.

Owner:ZIGONG CEMENTED CARBIDE CORP

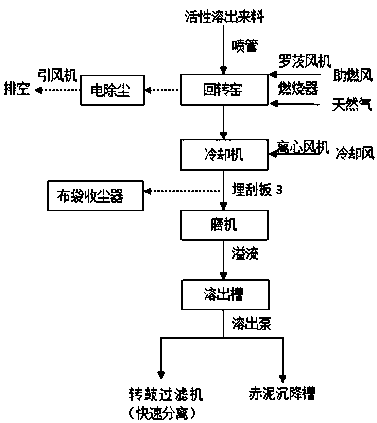

Method for treating inert aluminum ash in aluminum ash treatment technology

InactiveCN108640137AWon't pile upSafe and efficient handlingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFlue gasSlurry

The invention discloses a method for treating inert aluminum ash in an aluminum ash treatment technology. A mixture of aluminum ash and raw slurry is fired through a rotary kiln, is cooled through a cooling machine and is finally subjected to clinker leaching in a ball grinding mill in sequence. A device provided by the invention can be used for safely and efficiently treating the inert aluminum ash in the aluminum ash; lime milk is prepared and reacts with F<-> to generate CaF2, so that harmful elements and harms caused by the fact that the F<-> enter flue gas are eliminated; meanwhile, organic matters accumulated by a Bayer process can be treated. The rotary kiln is arranged and materials with different grain diameters can be uniformly mixed; the calcination efficiency and effect are improved.

Owner:YUNNAN WENSHAN ALUMINUM

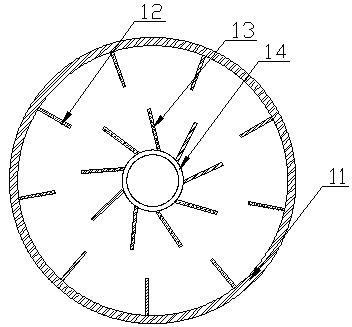

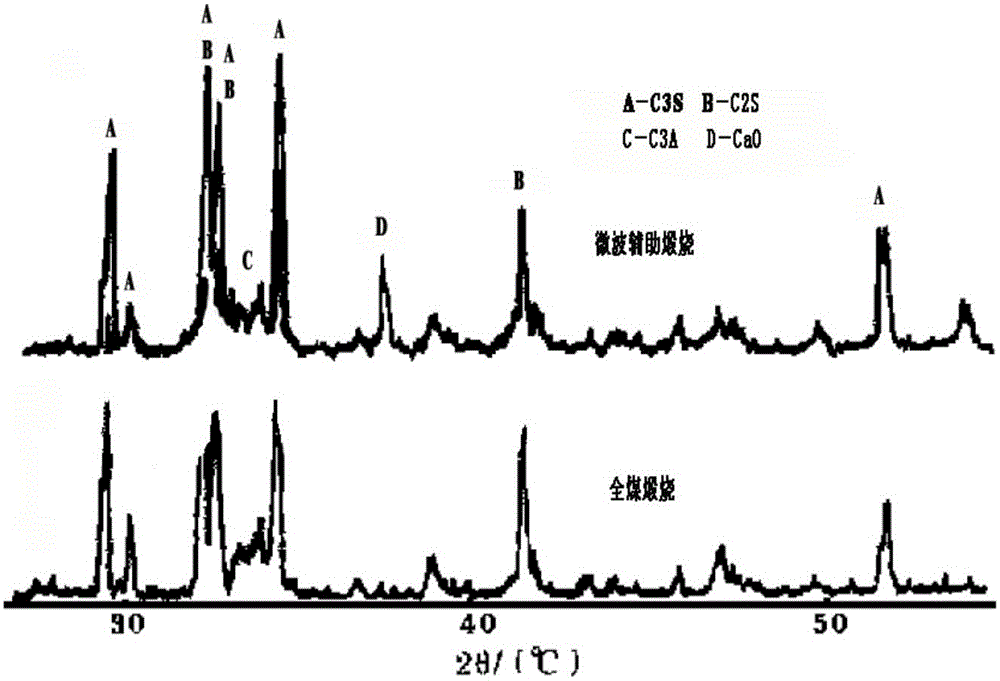

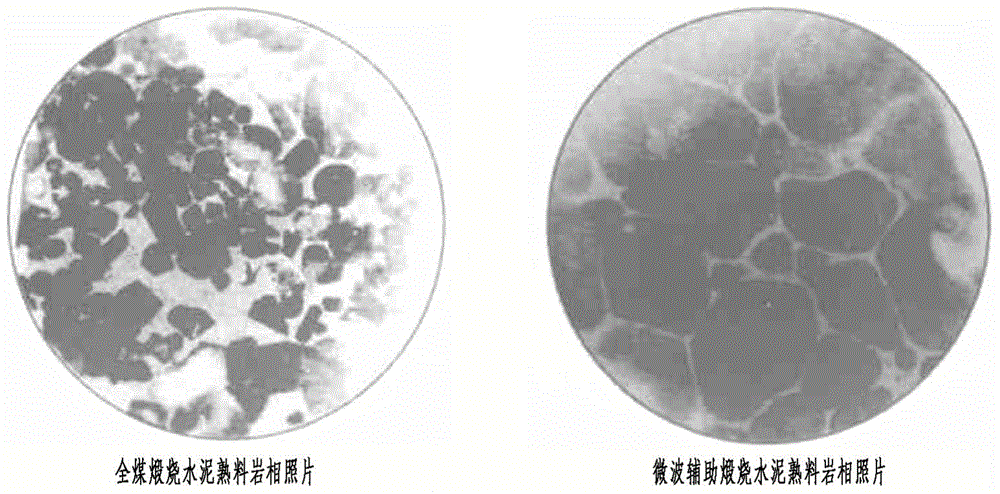

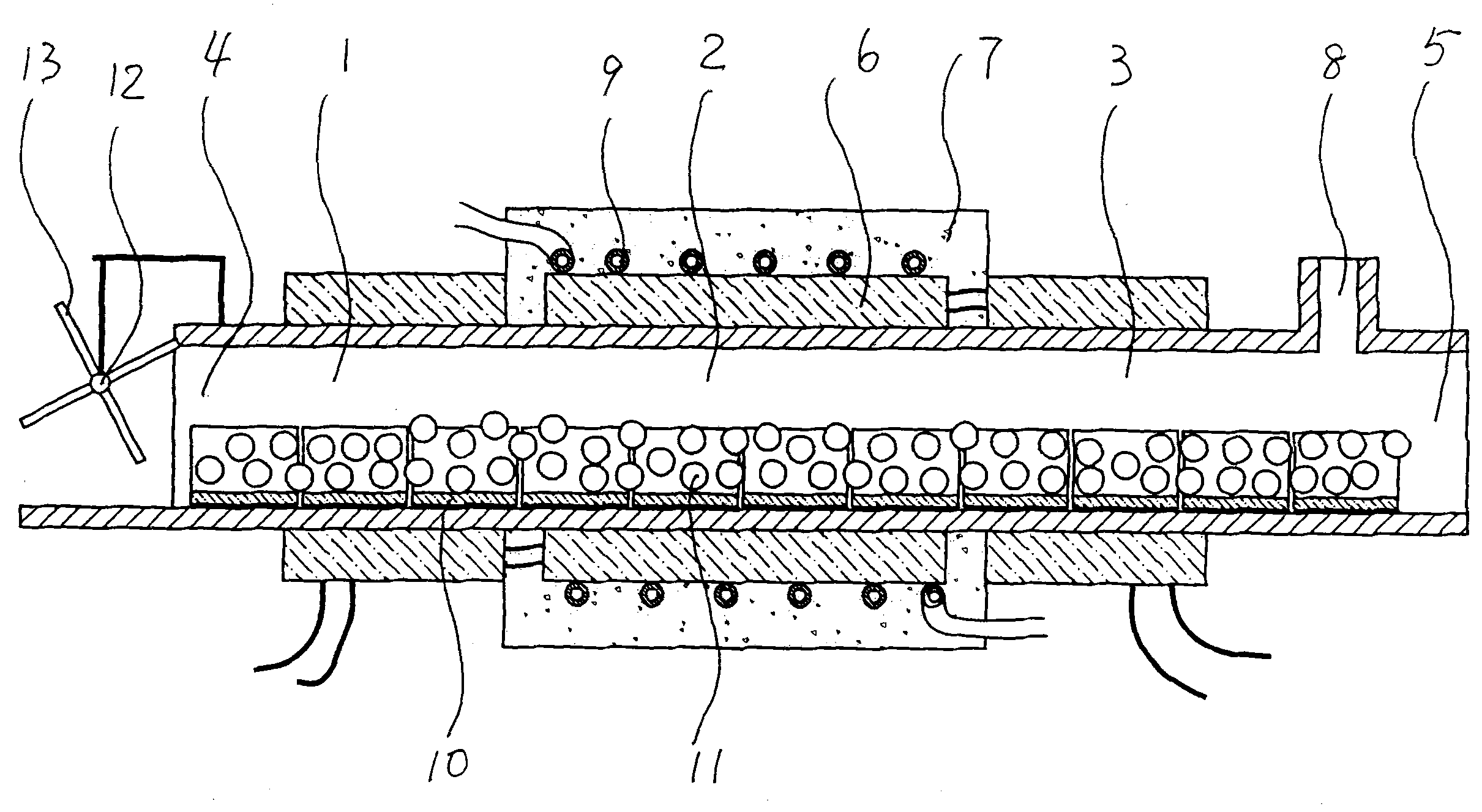

Microwave kiln for assisting in cement clinker calcination and microwave calcination method thereof

ActiveCN104457217AUniform radiationAdjustable speedRotary drum furnacesWaste heat treatmentThermodynamicsProcess engineering

The invention discloses a microwave kiln for assisting in cement clinker calcination. The microwave kiln for assisting in cement clinker calcination comprises a kiln body and further comprises a rotary kiln cover, a driving mechanism, a fixed kiln cover, a distributing device, a microwave generator and a waveguide tube, wherein a draught fan is installed on the bottom of the kiln body, and the rotary kiln cover is installed on the kiln mouth of the kiln body. According to the microwave kiln for assisting in cement clinker calcination, microwave field radiation is even; the rotary kiln cover is arranged, the waveguide tube and the microwave generator are installed on the rotary kiln cover and rotate along with the rotary kiln cover, and a microwave field which is large in coverage area and even in microwave radiation is formed gradually in the kiln body by microwaves emitted by the microwave generator during rotation; in addition, an annular power supply slide wire and the driving mechanism are arranged, the rotating speed of the rotary kiln cover can be adjusted through the driving mechanism, and thus the microwave field can be adjusted.

Owner:张雪华

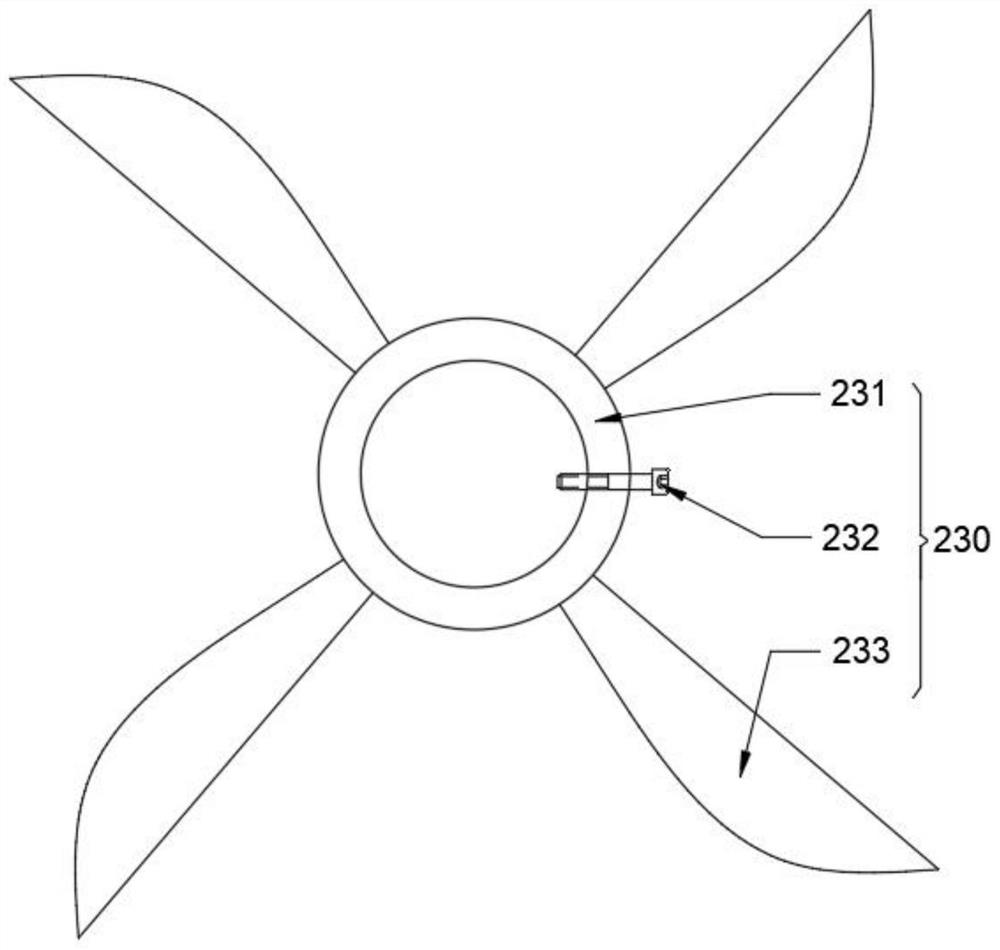

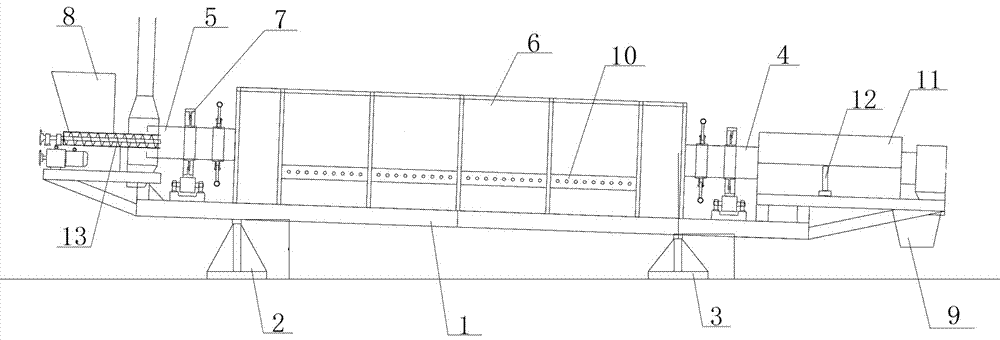

Continuous production device for calcining and whitening black talc and production process thereof

ActiveCN103803567AImprove insulation effectGood coolingAlkaline-earth metal silicatesEnergy inputBrickCooling effect

The invention discloses a continuous production device for calcining and whitening black talc and a production process thereof. The continuous production device comprises a coarse particle suspension preheater, a white talc rotary kiln and a grate type cooling machine with a heat preservation kettle, which are sequentially connected; the production process comprises the following steps: A. superfine-grinding black talc; B. preheating by a preheater at the kiln tail; C. calcining in the rotary kiln; and D. preserving heat by the heat preservation kettle and cooling. The design of the coarse particle suspension preheater is adopted and the tail gas waste heat of the white talc rotary kiln is fully utilized, so that the energy consumption is reduced; the calcining efficiency is improved due to a pickaxe-shaped spiral pushing device of the rotary kiln and spirally-arranged heat-resisting bricks with ribs, and the grate type cooling machine with the heat preservation kettle can achieve excellent heat-preservation and cooling effects; and the continuous production device can achieve large-scale continuously-mechanical production for calcining white talc and adopts center-control automatic operation, so as to greatly improve the labor productivity and achieve stable quality and environment-friendly production, thereby having good economic and environment-protection benefits.

Owner:SICHUAN CALCINER TECH

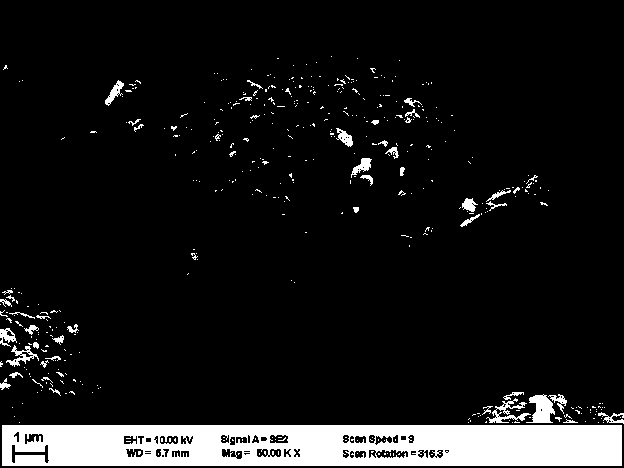

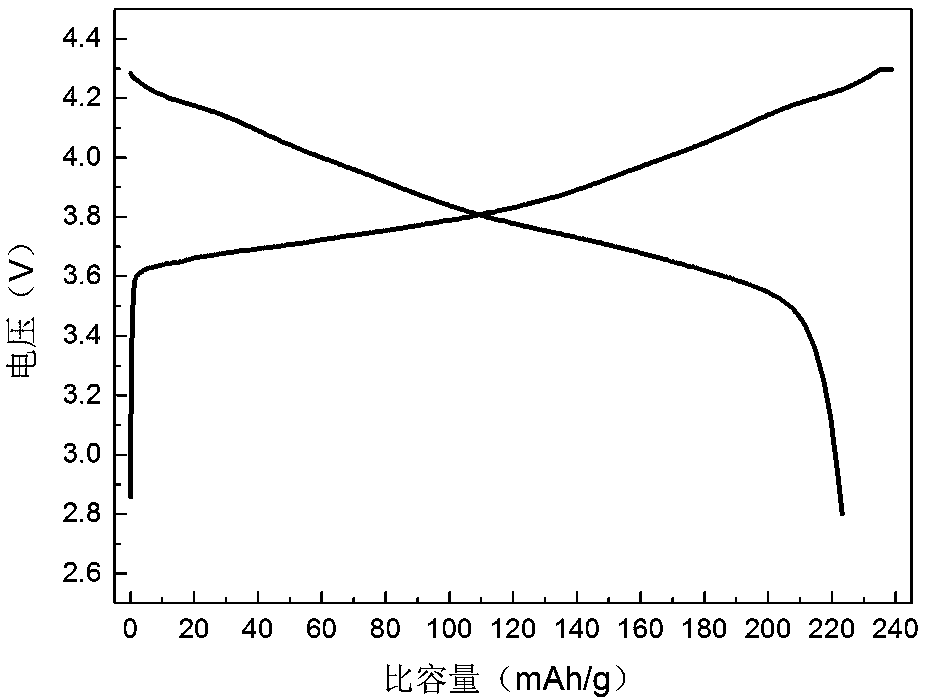

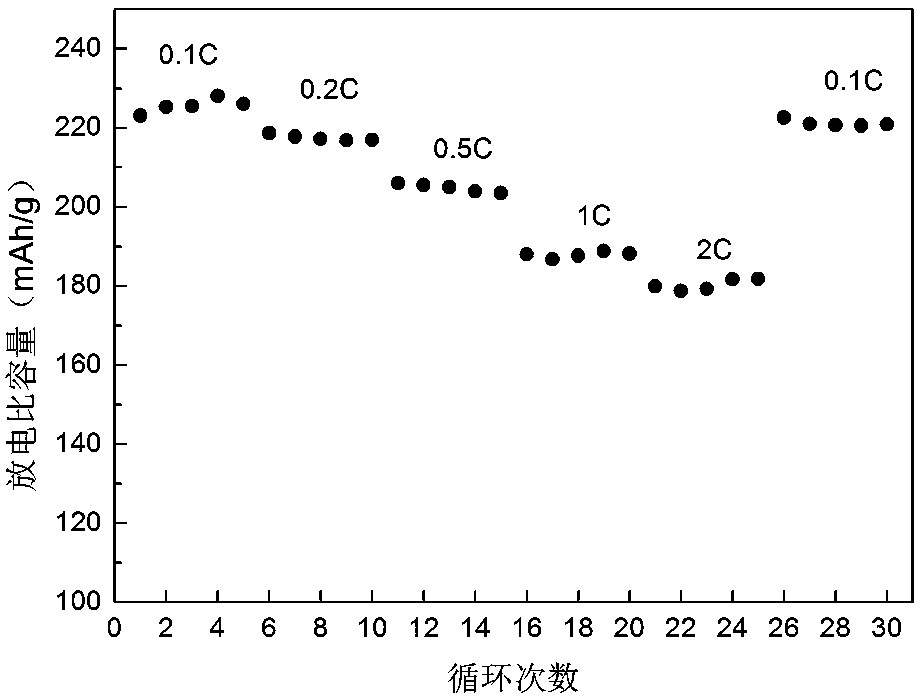

Method for preparing proportion-adjustable nickel-rich positive electrode material of lithium ion battery

InactiveCN108199038AThe stoichiometry is simpler than the processHigh tap densityCell electrodesSecondary cellsOxygenLithium-ion battery

The invention belongs to the technical field of lithium ion battery material preparation, and particularly relates to a method for preparing a proportion-adjustable nickel-rich positive electrode material of a lithium ion battery. According to the scheme of the invention, a chemical formula of the positive electrode material is xLiNi1 / 3Co1 / 3Mn1 / 3O2.yLiNiO2.zAl2O3, wherein x is greater than or equal to 0.2 and less than or equal to 0.5, y is greater than or equal to 0.5 and less than or equal to 0.8, z is greater than or equal to 0 and less than or equal to 0.1, and the sum of x and y is equalto 1. The preparation steps are as follows: controlling the feed speed ratio according to the value of x:y, implementing multi-layered stacking on LiNi1 / 3Co1 / 3Mn1 / 3O2 and LiNiO2 by alternate precipitation, synthesizing a nickel-rich positive electrode material precursor with multiple composite structures, and then performing mixed calcination with an aluminum salt gel to achieve that the outer layer is coated with Al2O3, and finally adopting an ozone-oxygen mixed atmosphere calcination mode to further shorten the calcination time of the material and improve the calcination efficiency. The nickel-rich positive electrode material prepared by the method has high tap density and excellent electrochemical performance.

Owner:HARBIN INST OF TECH AT WEIHAI +1

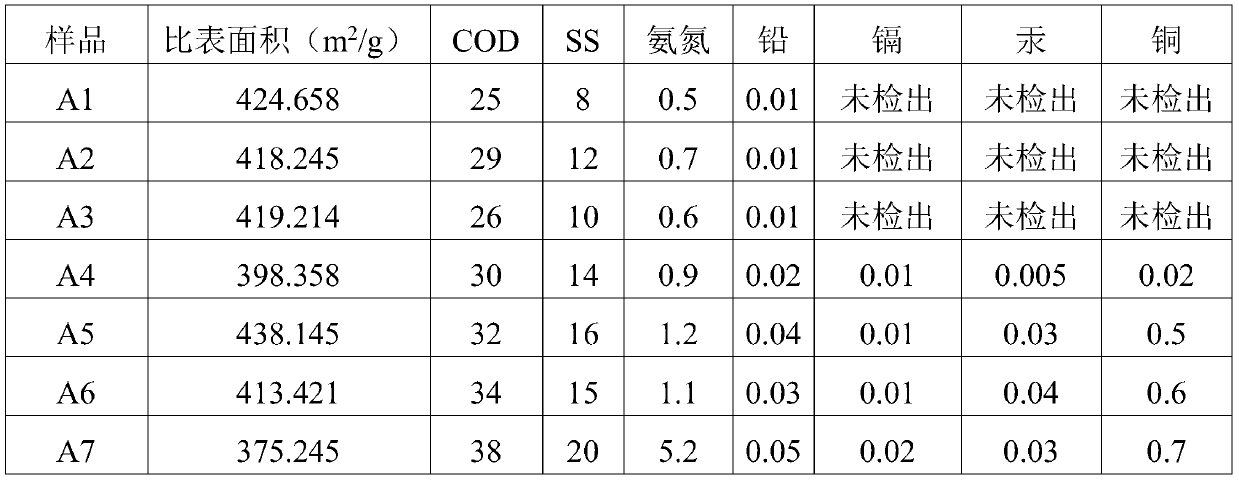

Composite bone charcoal powder as well as preparation method and application thereof

ActiveCN110152607AImprove efficiencyGood adsorption effectOther chemical processesWater contaminantsBiomassNitrogen gas

The invention belongs to the technical field of production of bone charcoal powder and particularly relates to composite bone charcoal powder as well as a preparation method and application thereof. The preparation method of the composite bone charcoal powder comprises the following steps: (1) collecting collected bones and removing impurities; crushing the collected bones, and then blending witha biomass material and fly ash and treating to obtain mixed powder; then conveying the mixed powder into a bone charcoal furnace and carrying out primary calcining; (2) taking out the mixed powder subjected to the primary calcining; adding an alkaline solution; after carrying out standing treatment, filtering and washing with water; then carrying out drying treatment on the mixed powder; (3) carrying out secondary calcining; putting the mixed powder into the bone charcoal furnace and carrying out calcining treatment under the protection of nitrogen gas; (4) taking out a carbonized material formed by calcining; and carrying out immersion, activation, acid washing, pH (Potential of Hydrogen) value regulation and drying on the carbonized material to obtain the composite bone charcoal powder.According to the preparation method provided by the invention, the biomass material and the fly ash are blended in a primary calcining treatment process, so that the calcining treatment difficulty ofthe collected bones is reduced, and the uniformity of the specific surface area is improved after the collected bones are calcined into the bone charcoal powder.

Owner:安徽省淮河制胶有限公司

Gypsum powder preparation process and system

InactiveCN110423026AAvoid Repeated FragmentationReduce crushing energy consumptionGrain treatmentsEngineeringCrusher

The invention discloses a gypsum powder preparation process and system. The system comprises a conveying device, a jaw crusher, a hammer crusher, a feeding device, a rotary kiln calcining pot and a centrifugal pulverizer which are arranged in sequence, wherein the conveying device comprises a primary conveyer belt, a secondary conveyer belt and a third conveyer belt; discharge baffle plates are correspondingly mounted on the primary conveyer belt, the second conveyer belt and the third conveyer belt; a primary collecting plate which communicates with the jaw crusher, a secondary collecting plate which communicates with the hammer crusher and a third collecting plate which communicates with the feeding device are additionally arranged on a rack; a waste heat channel is formed between the feeding device and the rotary kiln calcining pot; and the centrifugal pulverizer is connected with a storage tank. As ores are graded in a conveying process, energy consumption for continuously crushingthe ores can be reduced, and the ore crushing efficiency can be improved; and in addition, due to adoption of the waste heat channel and a novel centrifugal pulverizing component, the product qualitycan be further improved, and the energy consumption cost for production can be lowered.

Owner:康定龙源穗城石膏有限责任公司

Novel method for reducing nitrogen oxide emission through preheating calcination

PendingCN112500003AEmission Reduction MethodsSave energyGas treatmentDispersed particle filtrationAir preheaterFresh air

The invention discloses a novel method for reducing nitrogen oxide emission through preheating calcination. The method comprises the following steps of: (1) air supply: preheating fresh air through anair preheater and then feeding the preheated fresh air into a calcination chamber; (2) drying: before calcining, drying a raw material and pulverized coal through high-temperature airflow to reduce the water content of the raw material and the pulverized coal; (3) preheating: preheating the dried raw material and pulverized coal by secondary air, mixing tail gas and air to reduce the air oxygen content of the secondary air, and generating a certain amount of combustible gas with reducibility such as CO to reduce NOx generated through pyrolysis; (4) calcining: calcining the preheated raw material and pulverized coal at high temperature; and (5) cooling: forming clinker from the calcined raw material and pulverized coal, cooling the clinker, and entering the next process. The problems of high consumption of ammonia water and high denitration cost in flue gas denitration treatment corresponding to clinker production are solved.

Owner:兰溪诸葛南方水泥有限公司

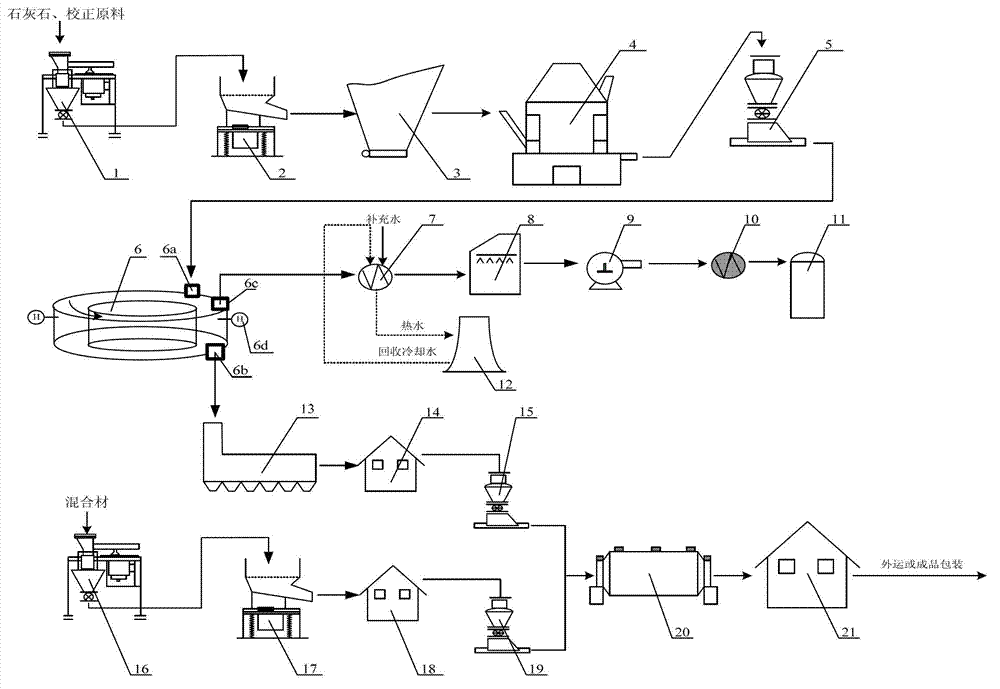

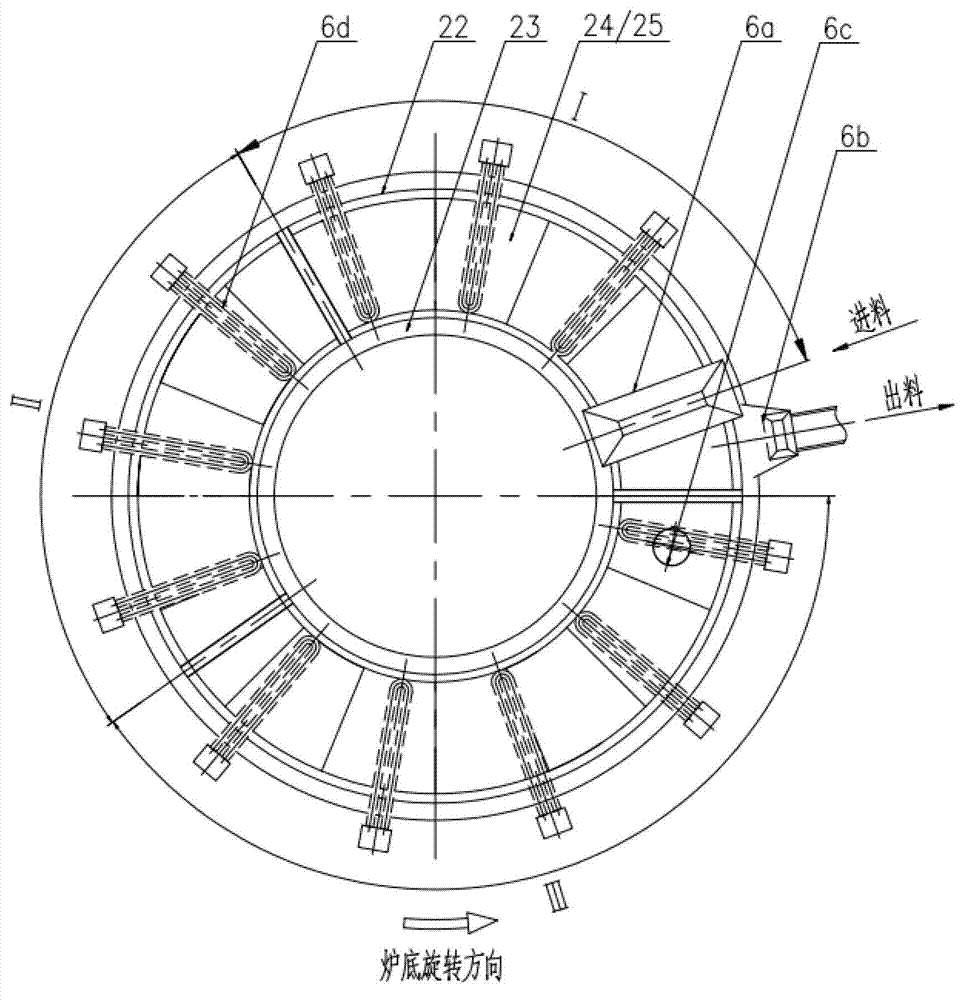

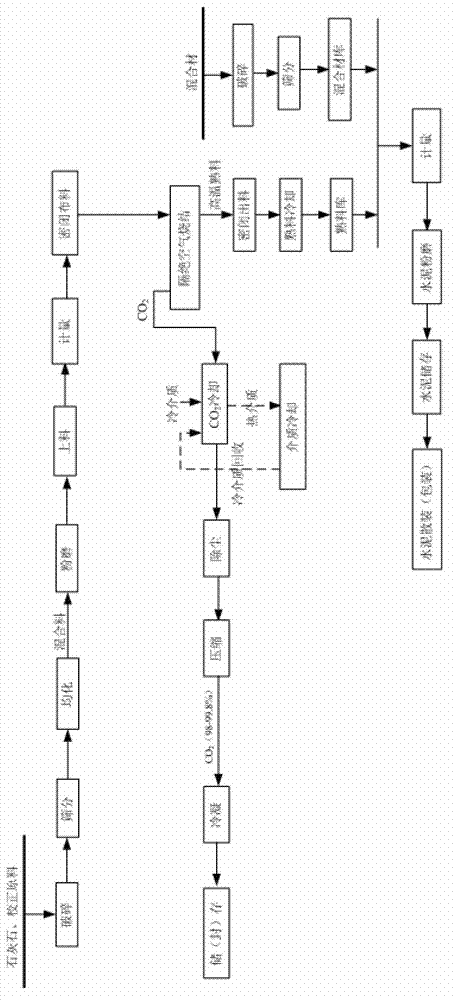

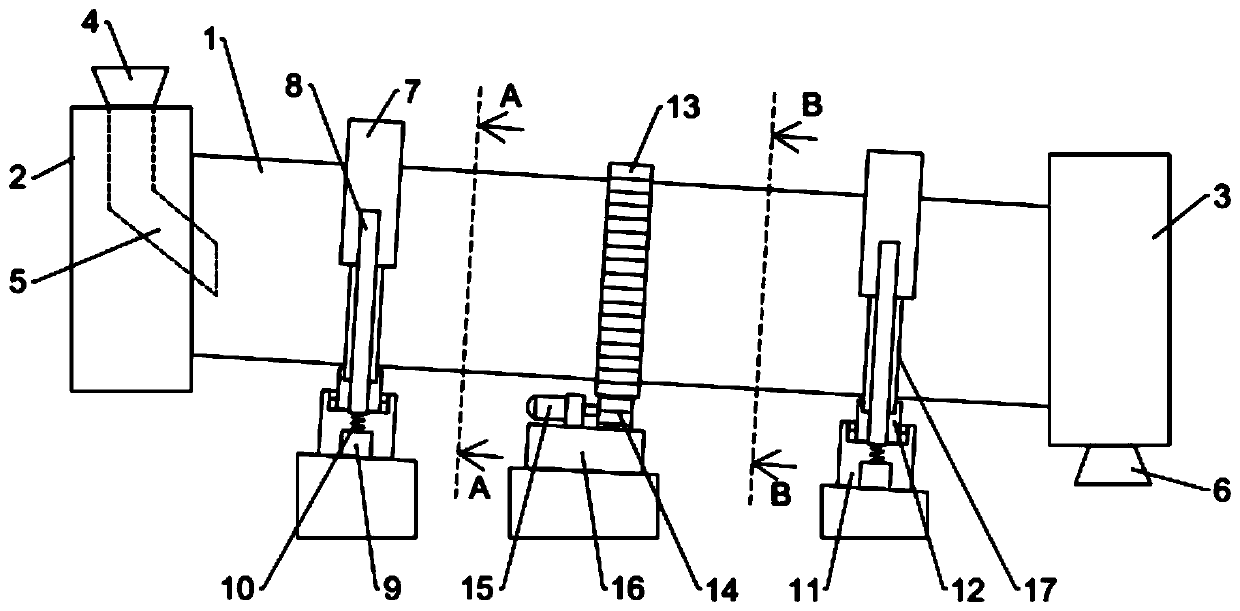

Method and equipment for producing cement and gathering CO2 by utilizing closed ring-shaped calcination furnace

InactiveCN103043930AFor subsequent useEasy to handleFurnace typesClinker productionMixed materialsCement grinding

The invention discloses a method and equipment for producing cement and gathering CO2 by utilizing a closed ring-shaped calcination furnace. The equipment comprises a raw material crusher, a material screening machine, a material homogenizing cabin, a material flour mill, a material metering device and a closed ring-shaped calcination furnace which are connected with one another sequentially, wherein the closed ring-shaped calcination furnace is connected with a CO2 gathering mechanism and a grate cooler respectively; the grate cooler is connected with a clinker storage warehouse and a clinker metering device respectively; the clinker metering device and a blending material preparing mechanism are connected with a cement grinding mill respectively; and the cement grinding mill is connected with a cement storage warehouse. The method comprises the following steps: raw material preprocessing, raw material preparing, clinker calcinating, discharging, carbon gathering, mixed material preparing and cement manufacturing process. The equipment provided by the invention has a compact structure, low investment intensity and a low operation cost, and is easy to maintain. The technological conditions for realizing the production of cement and the gathering of CO2 are mature, and the procedures are simple, so that CO2 generated in the cement producing process can be gathered effectively.

Owner:XIAN UNIV OF SCI & TECH

Refining method of active metallurgical lime

InactiveCN108191268AHigh activityImprove qualityGas purification with selectively adsorptive solidsGas contaminants removalGranularityCalcination

The invention provides a refining method of active metallurgical lime and relates to the field of production and preparation of lime. The method specifically comprises pretreatment, preheating treatment, calcination treatment and cooling treatment. According to the refining method of the active metallurgical lime, by controlling CaO content and granularity of raw materials, calcination temperatureof a reaction process and fuel, activity of the active lime is improved, sulfur content is reduced, and quality of the active lime is improved.

Owner:广西华洋矿源材料有限公司

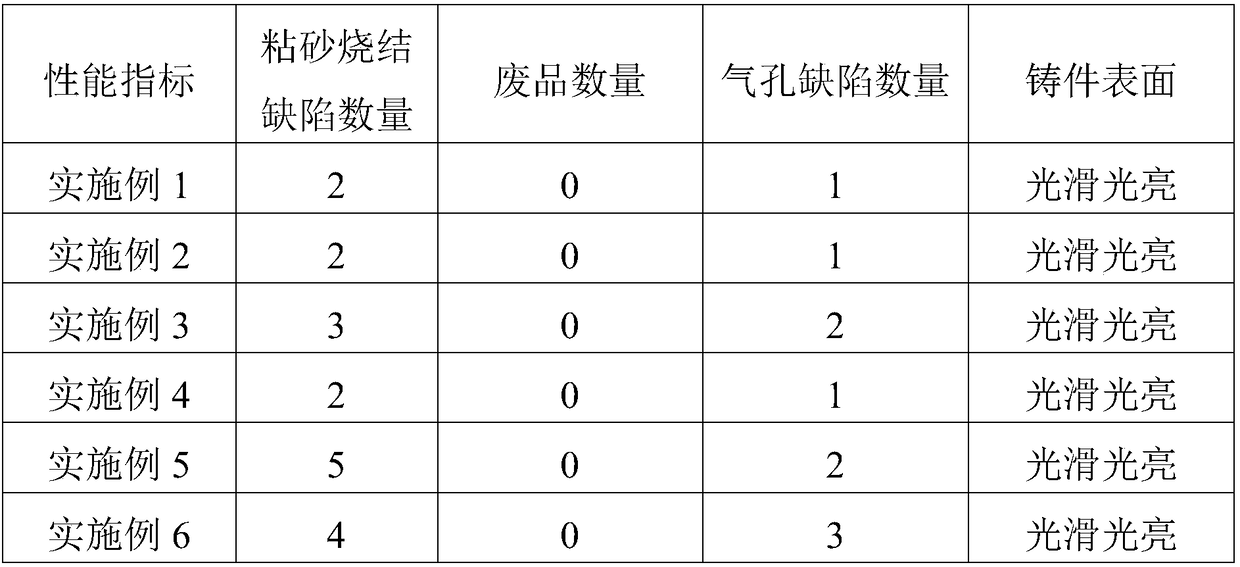

Anti-cracking casting coating based on attapulgite

InactiveCN108543909AImprove suspension performanceStrong bonding abilityFoundry mouldsFoundry coresSodium silicateSodium carboxymethylcellulose

The invention belongs to the technical field of casting, and particularly relates to an anti-cracking casting coating based on attapulgite. The prepared raw materials of the coating comprise aggregates, magnesium oxide, sodium silicate, carboxymethyl cellulose sodium, silica sol and modified attapulgite; the preparation method of modified attapulgite comprises the following steps of grinding and refining the attapulgite, adding the composite coupling agent, stirring, heating to 70 DEG C and preserving heat for 2-3 hours, adding a dispersing agent, continuously stirring and heating to 80 DEG C,and discharging the materials and drying the materials to obtain the modified attapulgite. The aggregate is taken as a carrier, the magnesium oxide, the sodium silicate and the carboxymethyl cellulose sodium are mixed, the suspension performance of components in the coating can be improved by the magnesium oxide, and meanwhile, the magnesium oxide is excellent refractory materials; and the sodiumsilicate has excellent binding capacity, and meanwhile, the effect of increasing the stability is achieved in the coating; and the added modified attapulgite is used as a reinforcing agent, so that the mechanical strength of the coating is remarkably improved.

Owner:ANHUI SOLID FOUNDRY CO LTD

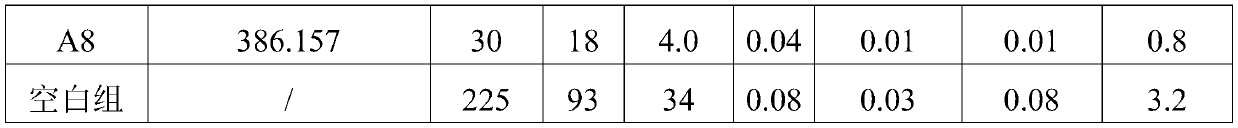

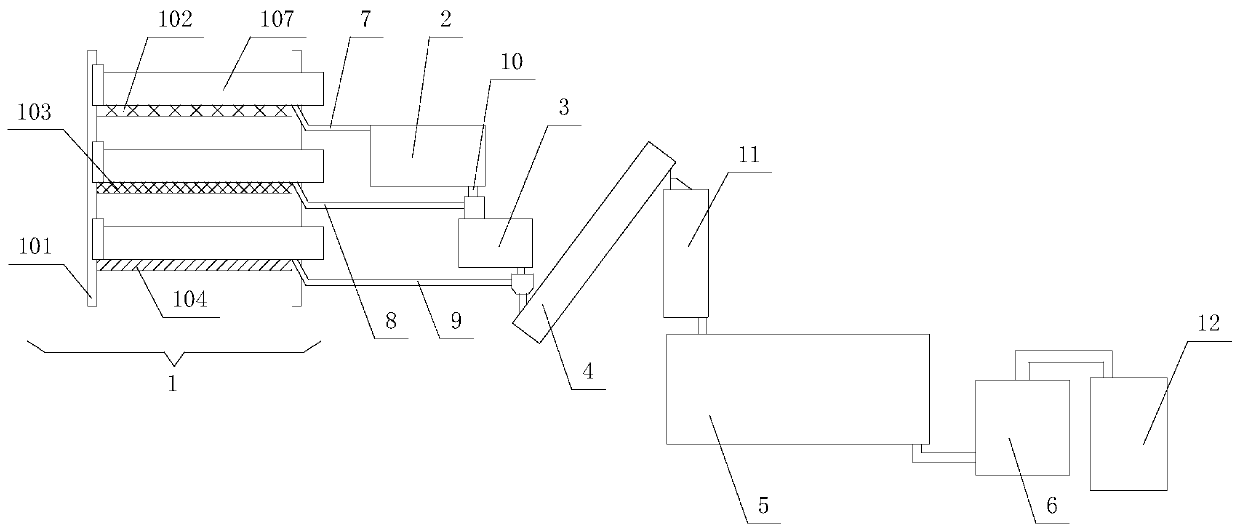

Method for extracting metal cobalt and tungsten from scrap hard alloy and special calcining device

The invention discloses a method for extracting metal cobalt and tungsten from a scrap hard alloy and a special calcining device, belonging to the technical field of recovery of the scrap hard alloy. The method comprises the following steps of: placing the scrap hard alloy into a hydrogen environment inside a tubular calcining furnace, and calcining at the temperature of 1700-1750 DEG C; then separating powder through crashing and ball-milling; and then extracting the metal cobalt and the metal tungsten by using a chemical method. In an extraction process of the metal cobalt and the metal tungsten, the scrap hard alloy is firstly calcined so that it is extremely easy to obtain the powder through the ball-milling, and the efficiency of extracting the metal cobalt, the metal tungsten and other metal elements by utilizing the scrap hard alloy is greatly enhanced.

Owner:河北六隆硬质合金股份有限公司

Calcination method of titanium gypsum

The invention discloses a calcination method of titanium gypsum. The method comprises the following steps: feeding titanium gypsum containing free water into a material charging bin, drying and crushing the titanium gypsum at 50 to 60 DEG C, then feeding the titanium gypsum into a furnace bin at 180 to 220 DEG C for high-temperature calcination, crushing, grinding and screening the titanium gypsum, and finally discharging the titanium gypsum from the furnace. The method effectively solves the problem of running away of dust namely titanium gypsum powder pollution in the traditional gypsum calcination, solves the problem of time and labor consuming in the traditional process through a one-step method, and is higher in efficiency. The whole process is accomplished in a closed mode and the problems are solved at one step. According to the method, heating is performed through a boiling furnace, fuel is sufficiently utilized, and the method is energy-saving and environment-friendly.

Owner:ANHUI BAOLIYUAN BUILDING MATERIAL TECH DEV

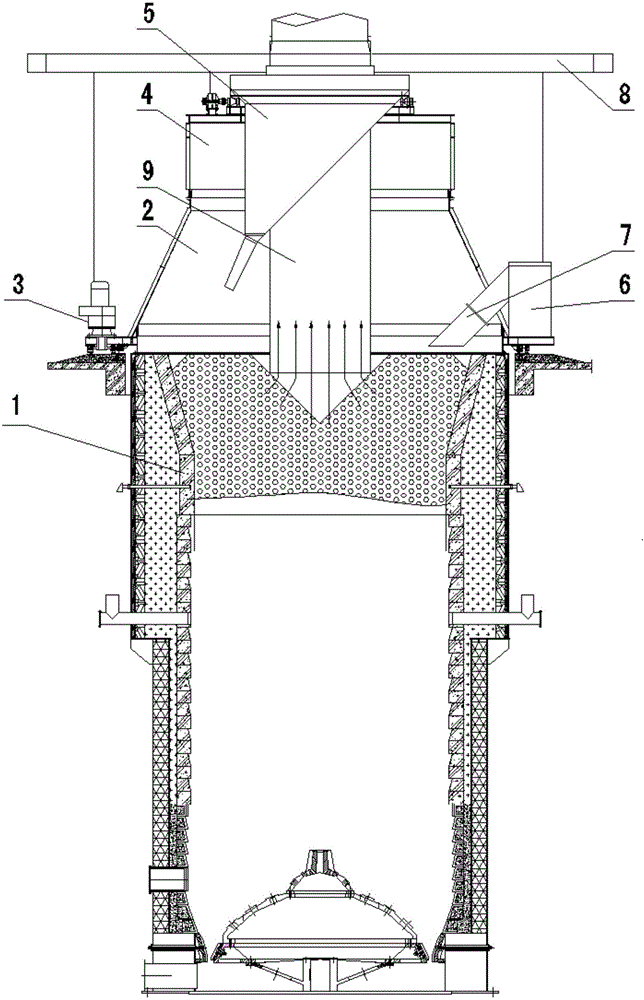

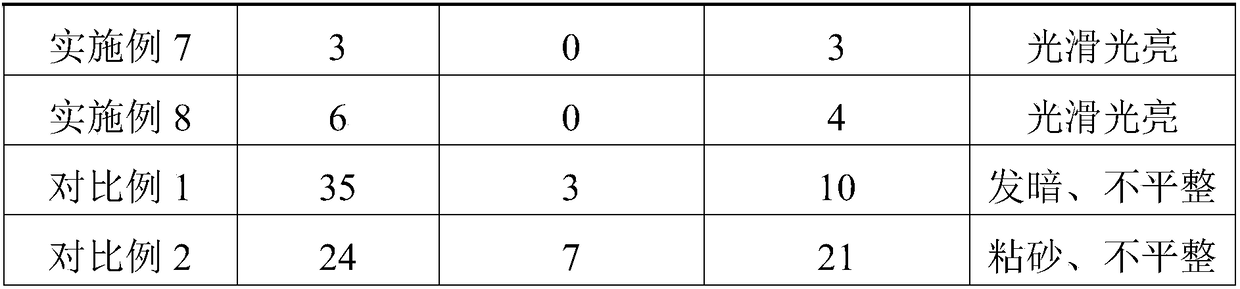

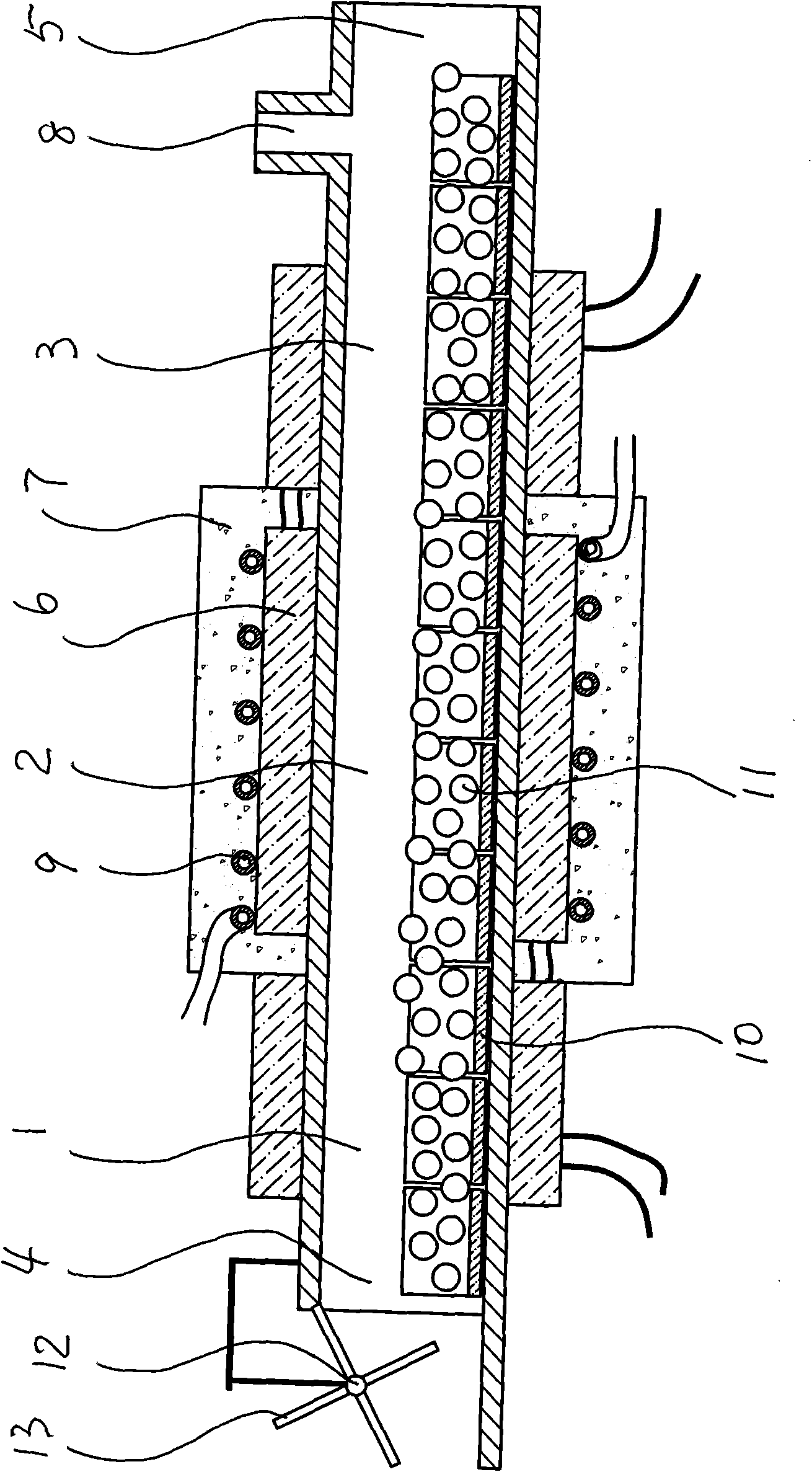

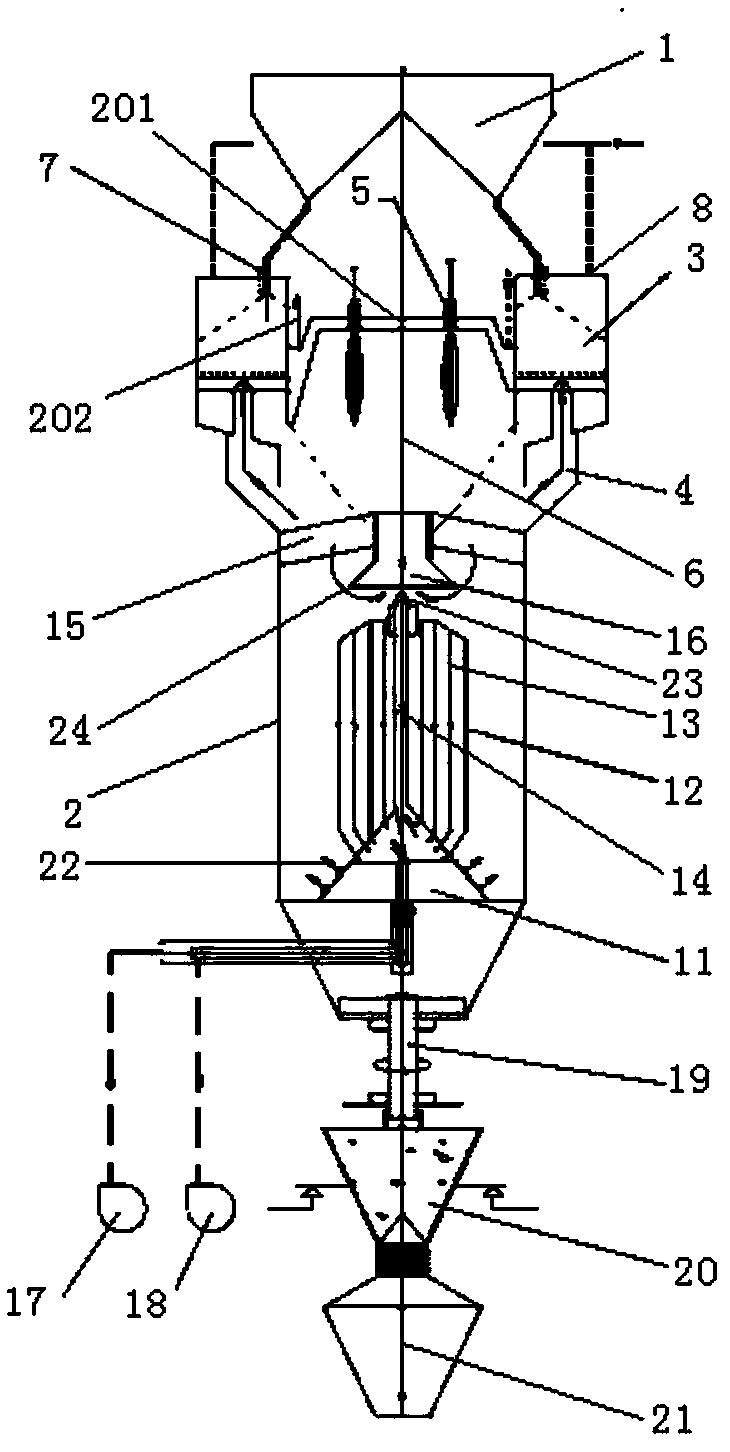

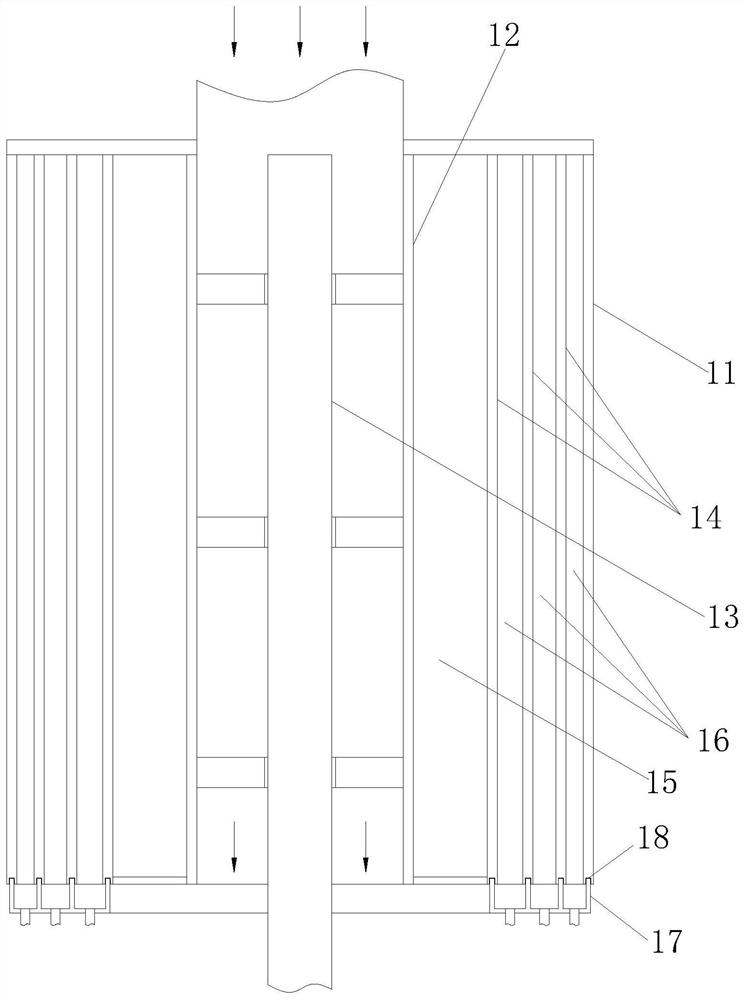

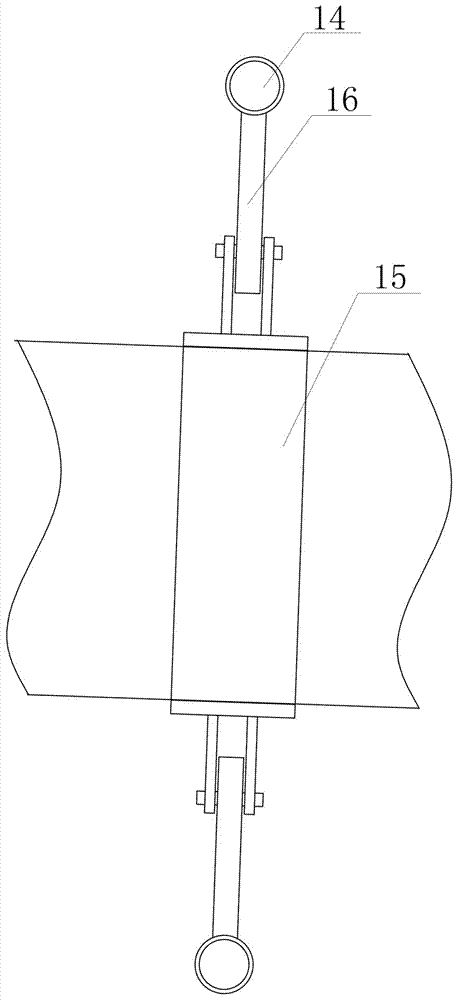

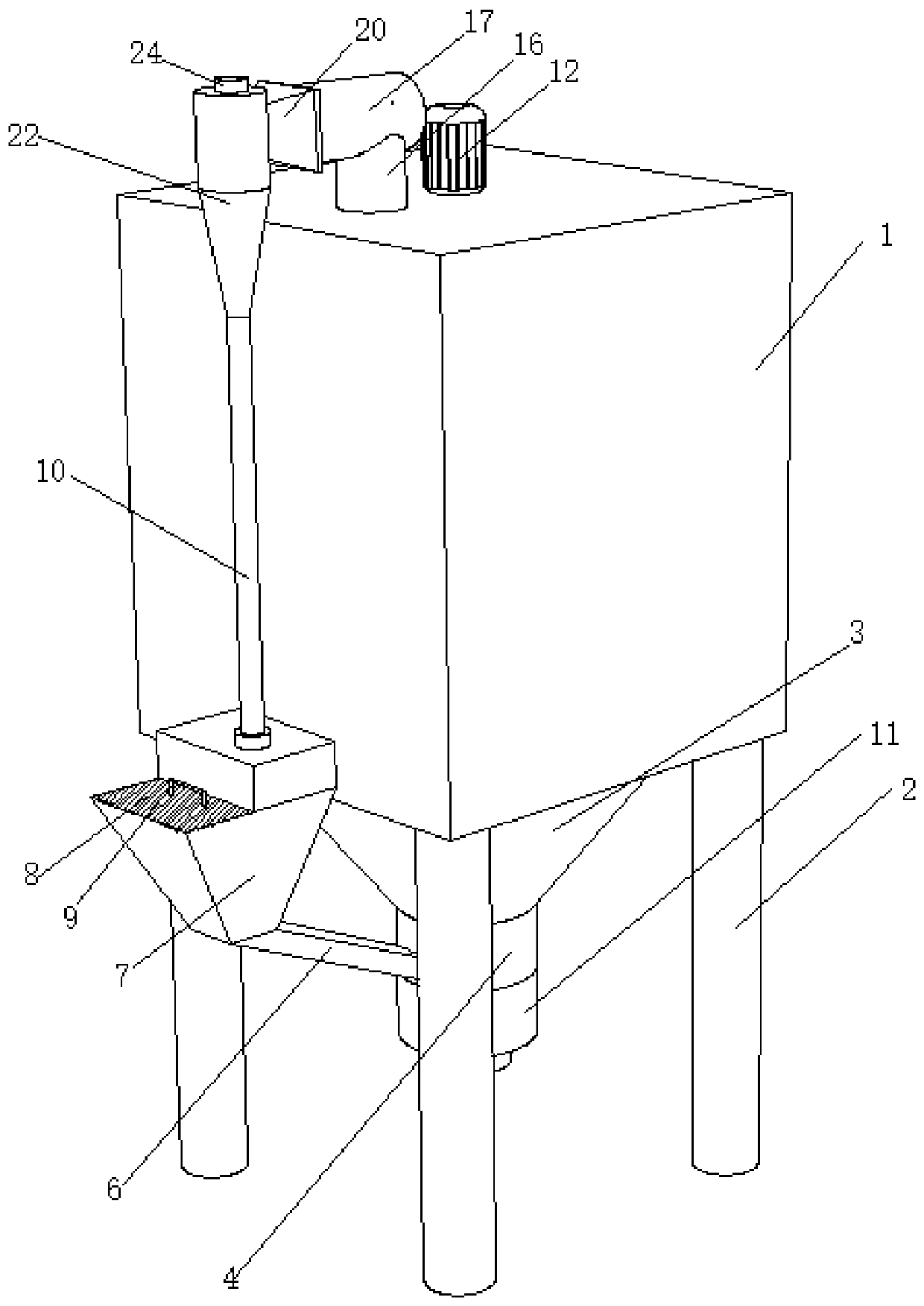

Internal circulation type fine lime shaft kiln and calcination method thereof

ActiveCN109160749AThe decarburization reaction is completeFully automatedCombustion chamberMineral Sources

The invention discloses an internal circulation type fine lime shaft kiln and a calcination method thereof. The lime shaft kiln comprises a feed bin (1), a height adjustable feed pipe (7), a shaft kiln body (2), an annular preheating chamber (3), a multi-burner combustion chamber (6), an ejector (16), a hollow cross beam (15), a built-in heat exchanger (12), a bottom wind seat (11), a cooling airblower (17), a driving air blower (18), an ash extractor (19), a metering bin (20) and a storage bin (21). The selection of the internal circulation type fine lime shaft kiln with a push rod or without the push rod is determined according to the contents of water and impurities in a limestone raw material. Aiming at the defects of the prior common lime shaft kiln that the finely grained limestonecannot be calcined or well calcined, the invention is applicable to the calcination of the limestone with small size of 5-15 mm and medium size of 15-30 mm, thereby enlarging the utilization range ofsolid wastes and saving mineral resources.

Owner:余松涛

Rapid drying and calcination method for honeycomb denitration catalyst

InactiveCN110433873AImprove drying efficiencyImprove calcination efficiencyDrying solid materials without heatCatalyst activation/preparationTunnel kilnMicrowave

The invention discloses a rapid drying and calcination method for a honeycomb denitration catalyst. The method comprises the following steps: step 1, packaging a catalyst wet blank after extrusion molding by using a carton, putting the packaged catalyst onto an open plastic plate, and placing the plastic plate onto a drying trolley; step 2, after the drying trolley is filled, pushing the drying trolley into a microwave drying device in the form of a tunnel kiln, and allowing the drying trolley to automatically run to an outlet of the microwave drying device according to a set speed to completedrying operation; and step 3, after the packaging carton is removed, immediately putting the catalyst onto a calcining trolley, pushing the calcining trolley into a microwave calcining device in theform of a tunnel kiln, and allowing the trolley to automatically run to an outlet of the calcining device according to a set speed to complete calcining operation. By adopting the above technical solution provided by the invention, the activity of the catalyst can be ensured, and the production time can be shortened.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

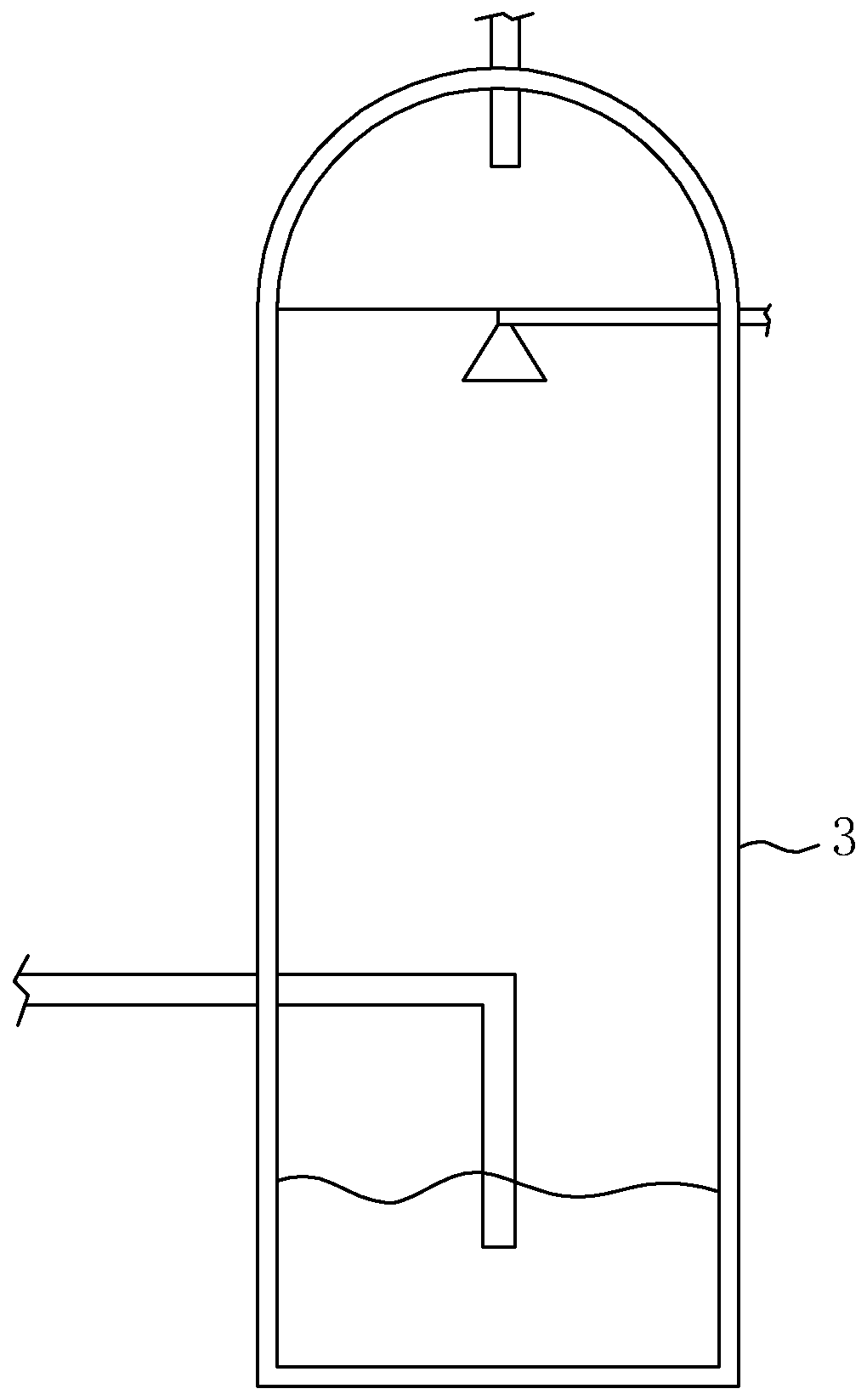

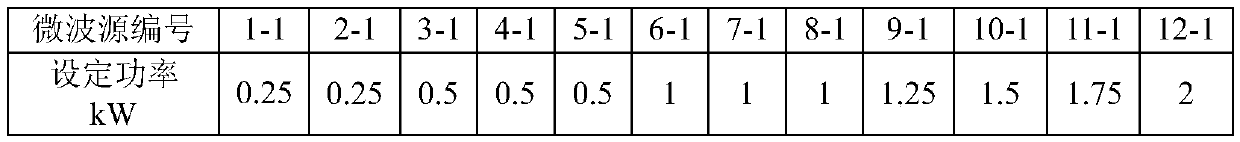

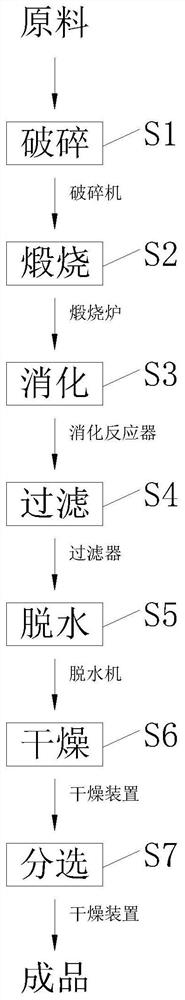

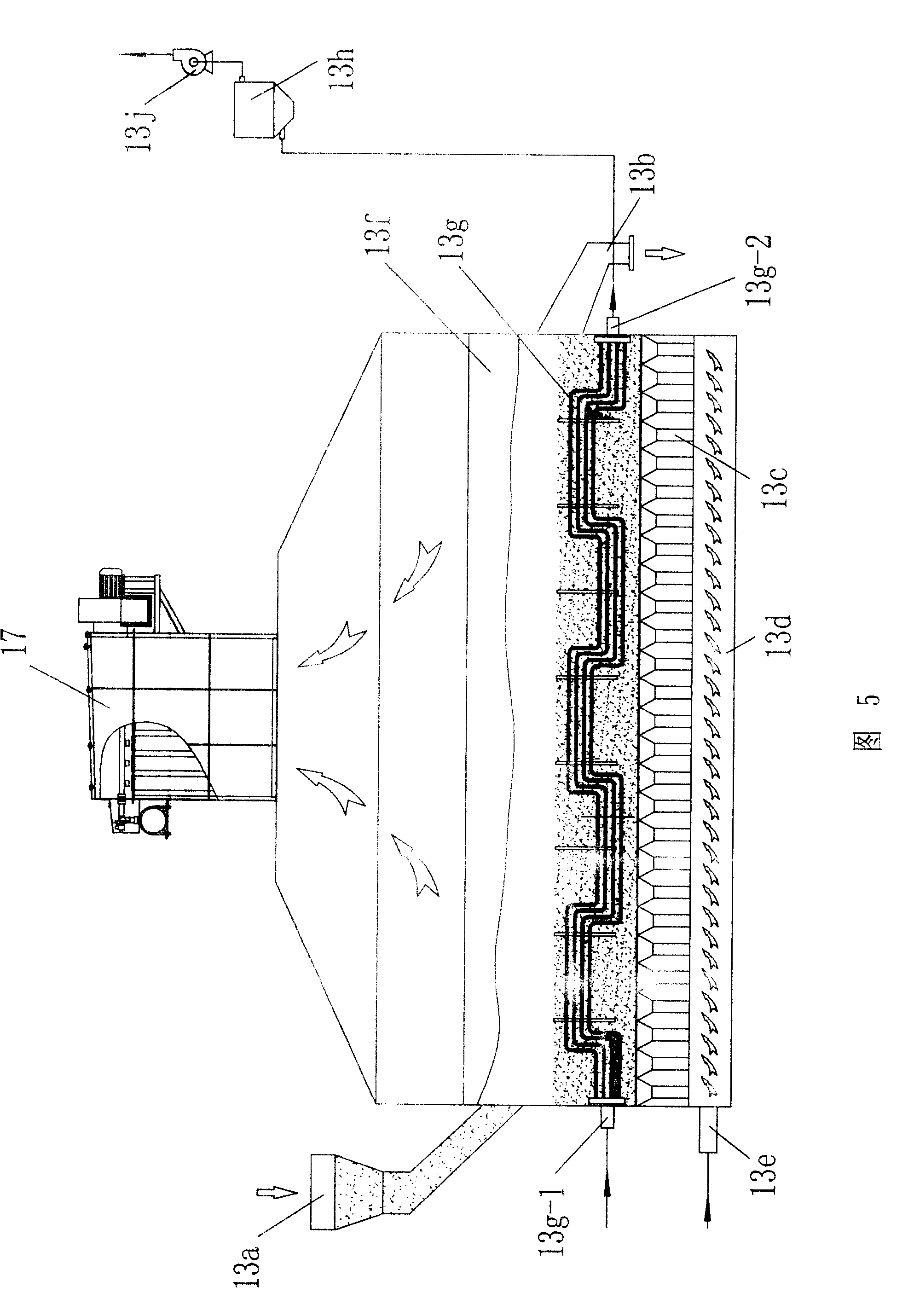

Calcium hydroxide production process and calcium hydroxide production line

InactiveCN112125538AImprove calcination efficiencyHigh yieldSievingScreeningExhaust fumesCalcium hydroxide

The invention provides a calcium hydroxide production process, which comprises the steps of S1, crushing, S2, calcining, S3, digesting, S4, filtering, S5, dehydrating, S6, drying and S7, sorting, wherein a calcining furnace in the S2 adopts a gas calcining kiln, the S6 and the S7 are completed by adopting a drying device, the drying device comprises an outer cylinder and an inner cylinder, a rotating shaft for driving the inner cylinder to rotate is arranged in the inner cylinder, a plurality of middle cylinders are arranged between the outer cylinder and the inner cylinder, sieve pores are formed in the middle cylinders, and the outer cylinder and the inner cylinder are sequentially divided into a filter residue layer and a plurality of sorting layers from inside to outside; a cylinder bottom capable of being opened and closed is arranged at the bottom of the filter residue layer, a material collecting groove is formed in the bottom of the sorting layer, and the material collecting groove, the outer cylinder and the middle cylinders are arranged at intervals; and waste gas generated by the gas calcining kiln preheats crushed materials in the S and then is led to the inner cylinder.

Owner:XUANCHENG YANGLIUQING CHEM CO LTD

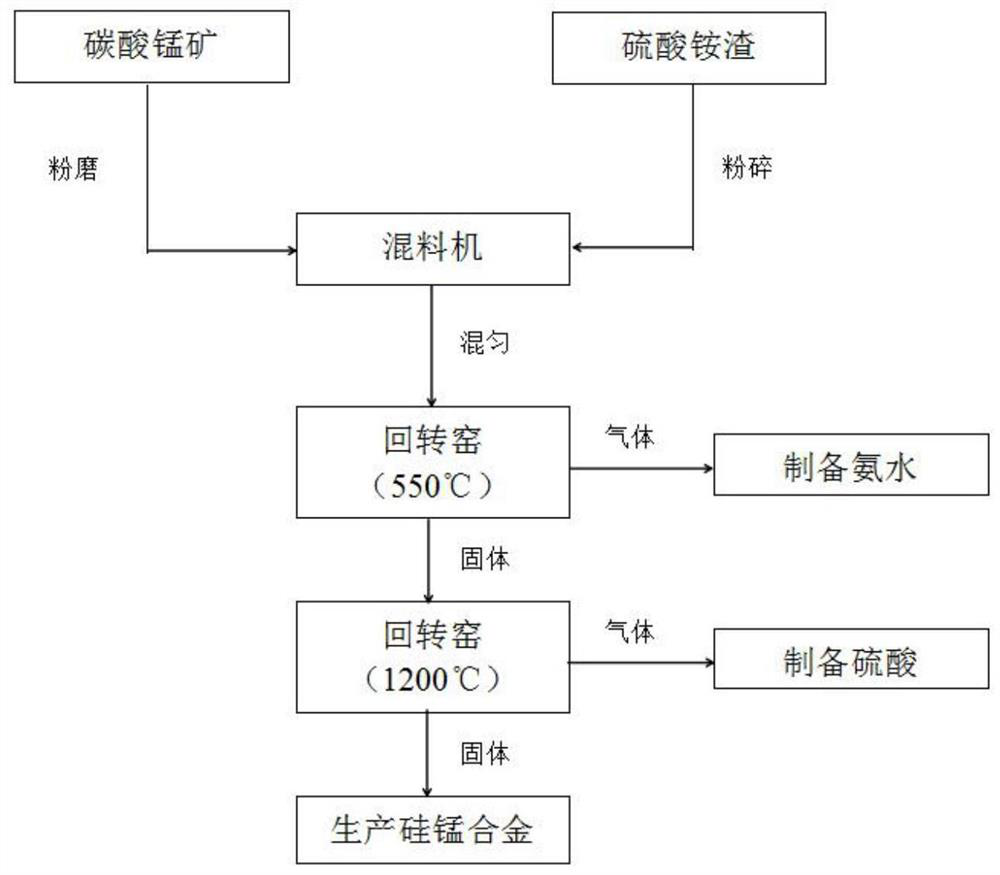

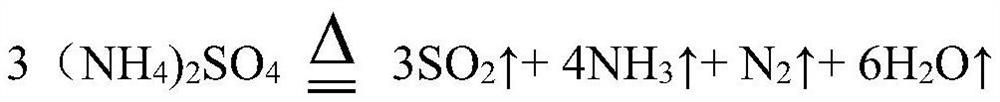

Two-stage calcining treatment method for electrolytic manganese ammonium sulfate slag

PendingCN111825106AImprove calcination efficiencyImprove resource utilizationSulfur compoundsProcess efficiency improvementChemical industryManganese sulphate

The invention belongs to the technical field of chemical industry treatment, and relates to a two-stage calcination treatment method for electrolytic manganese ammonium sulfate slag. The method comprises the following steps: 1, carrying out first-stage calcination sulfur fixation and deamination: mixing ammonium sulfate slag with manganese ore powder, feeding the mixture into a rotary kiln at 550DEG C, and carrying out a reaction to generate a semi-finished product mainly containing manganese sulfate and magnesium sulfate and a mixed gas mainly containing ammonia gas and SO2; and 2, carryingout two-stage calcination desulfurization to prepare sulfuric acid: sending the semi-finished product into a rotary kiln with a temperature of 1200 DEG C, carrying out a reaction to generate solid slag mainly comprising magnesium oxide and magnesium dioxide, and SO2 gas, and preparing the SO2 gas into sulfuric acid. According to the method, dry calcination is adopted, and a two-stage calcination mode is adopted, so that the calcination efficiency is high, the generated gas, solid and the like can be recycled, the resource utilization rate is high, and the economic benefit is good.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

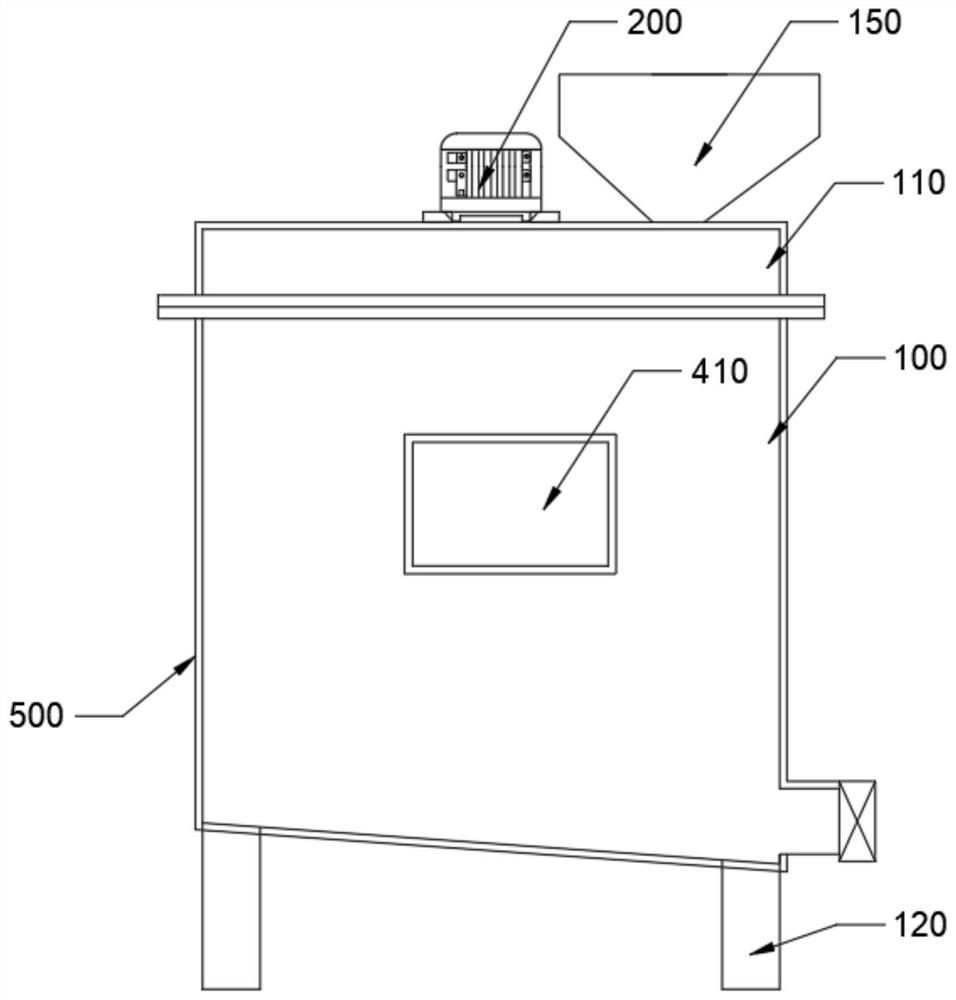

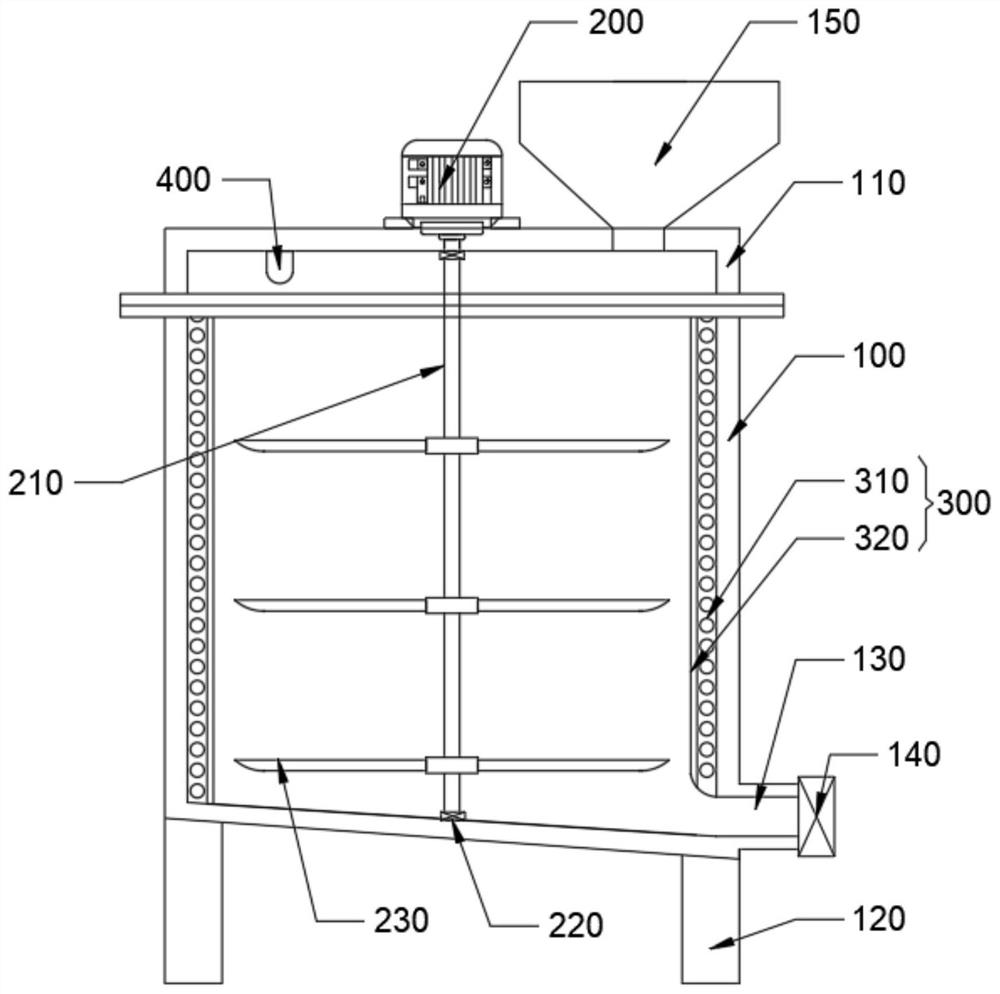

Desulfurized gypsum calcining device

The invention belongs to the technical field of industrial solid waste calcining devices, and particularly relates to a desulfurized gypsum calcining device which comprises a shell, a motor, a calcining device and a temperature sensor, wherein the top of the shell is fixedly provided with an upper cover through bolts, and the bottom of the side wall of the shell is fixedly provided with a discharge port; a control valve is in threaded connection with the end of the discharging port, a feeding hopper is installed on one side of the top of the upper cover in a penetrating mode, the top of the upper cover is connected with the motor in a penetrating mode, a rotating rod is fixedly installed at the bottom of the motor through a coupler, and bearings are clamped to the upper end and the lower end of the rotating rod. A stirring assemblies are evenly and fixedly installed in the middle of the rotating rod, the calcining device is fixedly installed on the inner side wall of the shell, the calcining device comprises a heating wire and a heat conduction plate, and the heating wire is located on the inner wall of the heat conduction plate. The device achieves uniform stirring of gypsum, thecalcining quality is guaranteed, and the calcining efficiency is improved. In addition, a comprehensive effet of saving resource is achieved.

Owner:YANGZHOU POLYTECHNIC INST

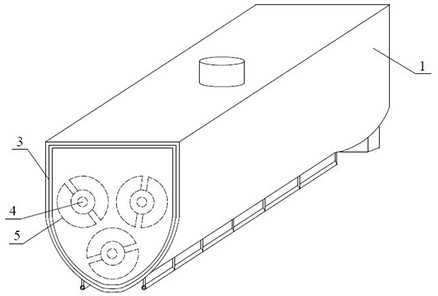

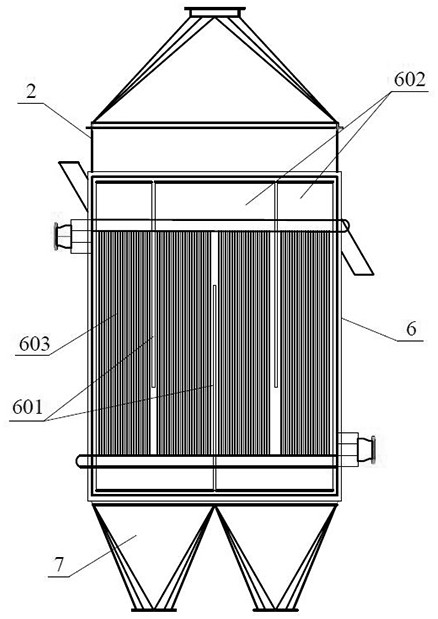

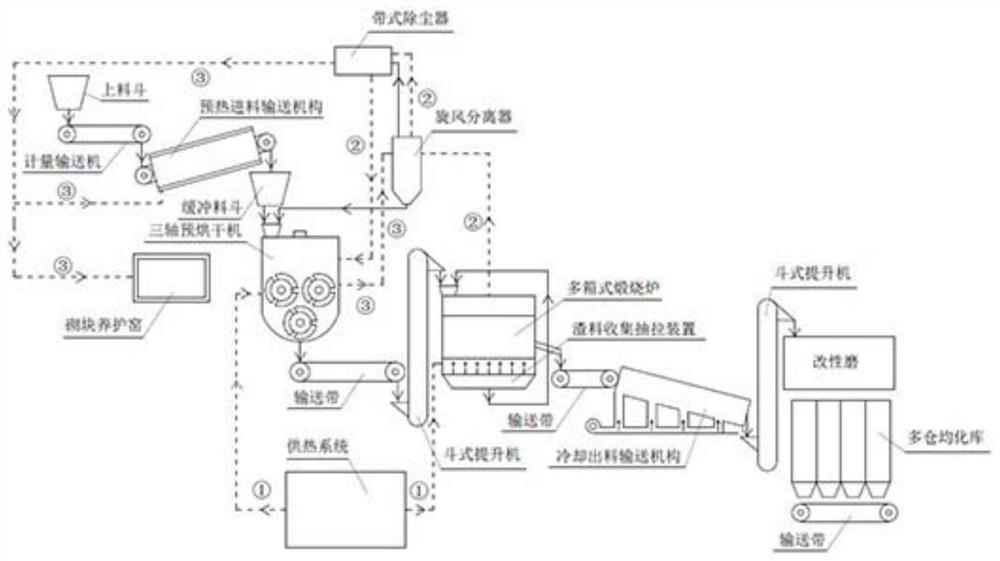

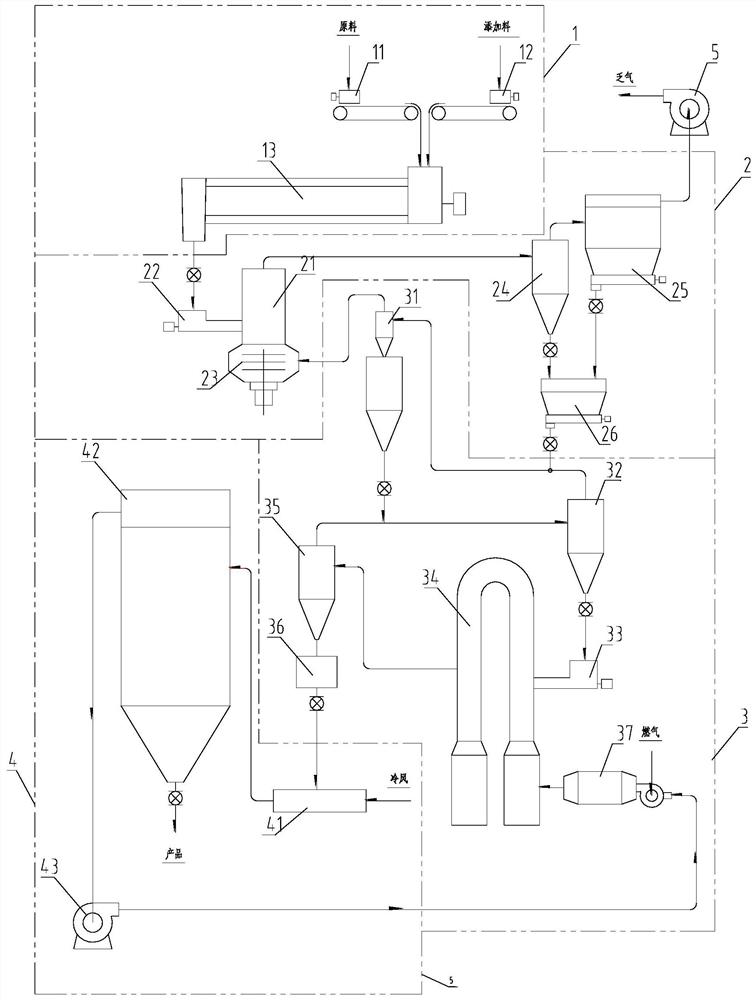

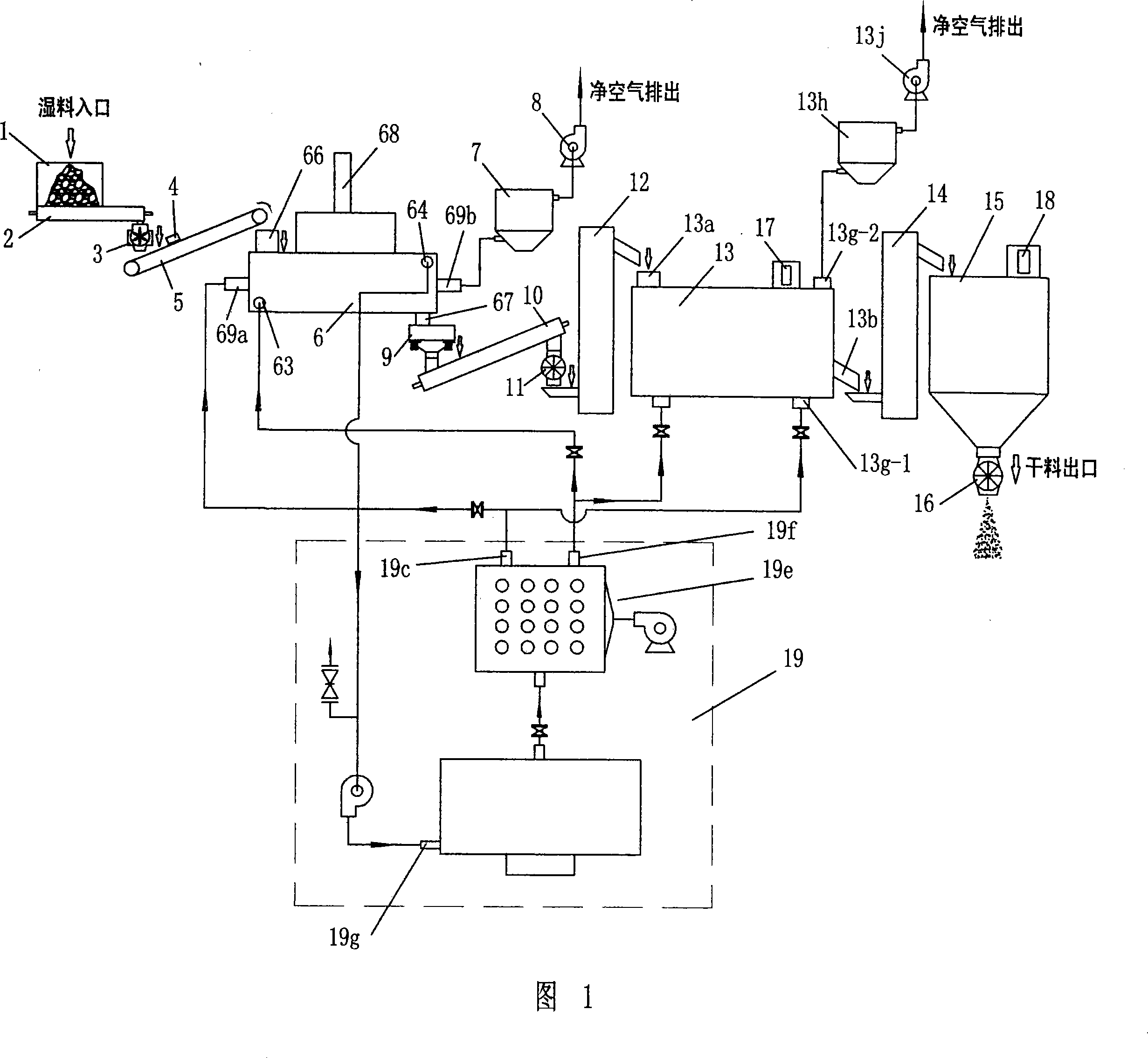

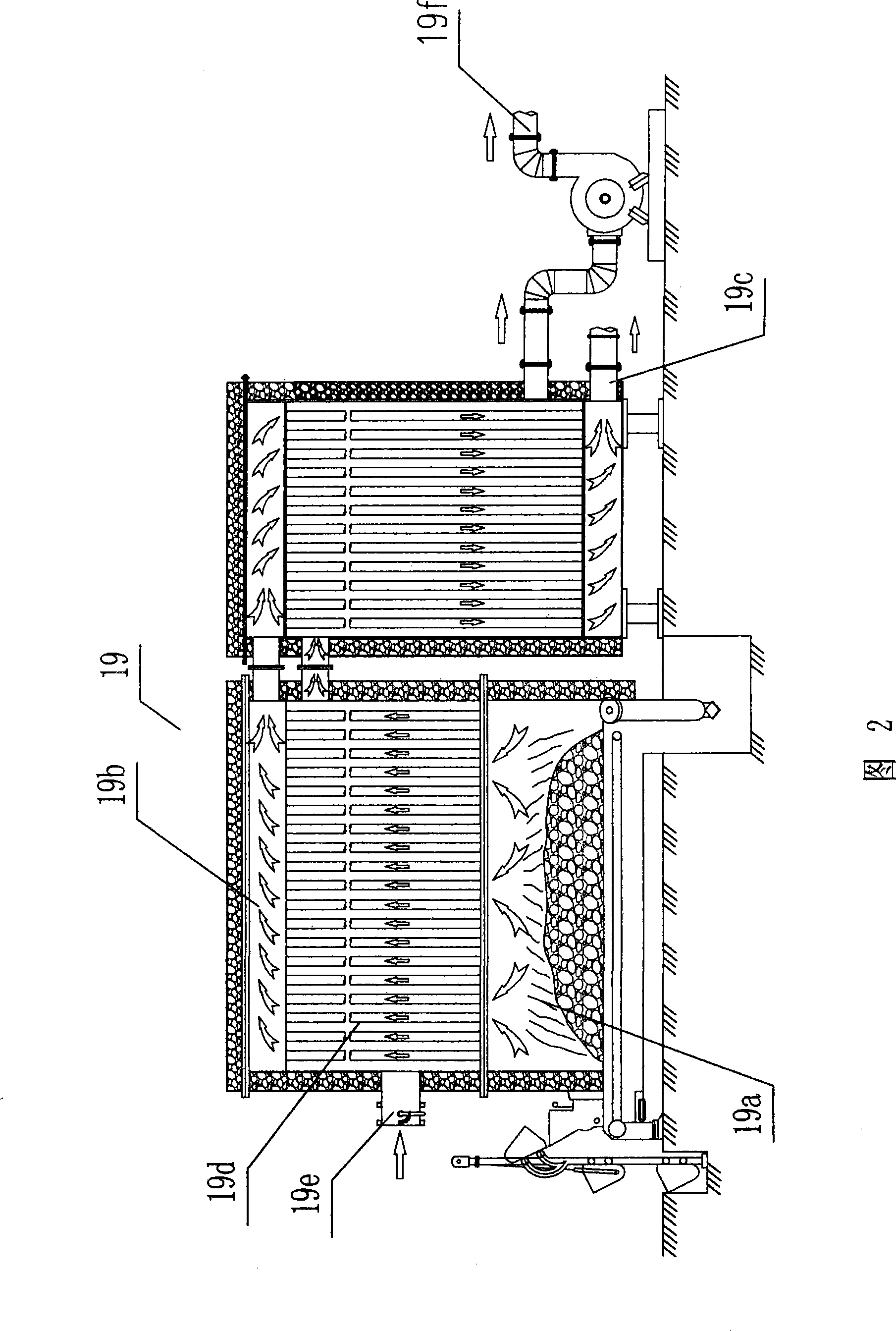

Energy-saving treatment system for preparing gypsum cementing material from industrial byproduct gypsum

The invention discloses an energy-saving treatment system for preparing a gypsum cementing material from industrial by-product gypsum, wherein the energy-saving treatment system comprises a raw material system, a drying and calcining system, a heat supply system, a modification system, a purification system, an energy-saving conveying system and a waste heat utilization system; the raw material system is used for providing the industrial byproduct gypsum and conveying the industrial byproduct gypsum to a treatment production line; the drying and calcining system comprises a three-shaft pre-drying machine and a multi-box type calcining furnace, wherein the three-shaft pre-drying machine is used for secondary utilization of heat; the heat supply system is used for providing a heat source for the multi-box type calcining furnace and the three-shaft pre-drying machine and conveying waste heat in the multi-box type calcining furnace to the three-shaft pre-drying machine; the modification system comprises a modification mill and a multi-bin homogenization silo; the purification system is used for recycling dust and moisture in the drying and calcining processes; the energy-saving conveying system comprises a preheating feeding conveying mechanism and a cooling discharging conveying mechanism; and the waste heat utilization system comprises a building block curing kiln for utilizing waste heat of the three-axis pre-drying machine. According to the energy-saving treatment system, raw materials can be uniformly heated, a building gypsum product prepared through calcination is single in phase structure and stable in quality, meanwhile, heat is fully utilized, the waste heat utilization efficiency is high, and cost is saved.

Owner:河南鼎隆新材料科技有限公司

A steel bag rotation furnace

ActiveCN105271159BReduce generationUniform heating in all directionsPhosphorus compoundsEngineeringHeating furnace

A ladle rotary furnace, which includes a support body, the front section of the support body and the bottom of the rear section are respectively provided with a spiral seat and a twisted seat, the support body is provided with a furnace body, and the furnace body includes a front feeding port end and a heating furnace in the middle As well as the rear discharge port end, there are driving mechanisms at the bottom of the feed port end and the discharge port end, a storage bin is provided at the upper part of the feed port end, a cooling mechanism is provided at the discharge port end, and a cooling mechanism is provided at the discharge port end. A discharge mechanism is provided at the bottom of the end of the material port, and a heating mechanism is provided inside the heating furnace.

Owner:YICHANG HONGCHANG ELECTRONICS

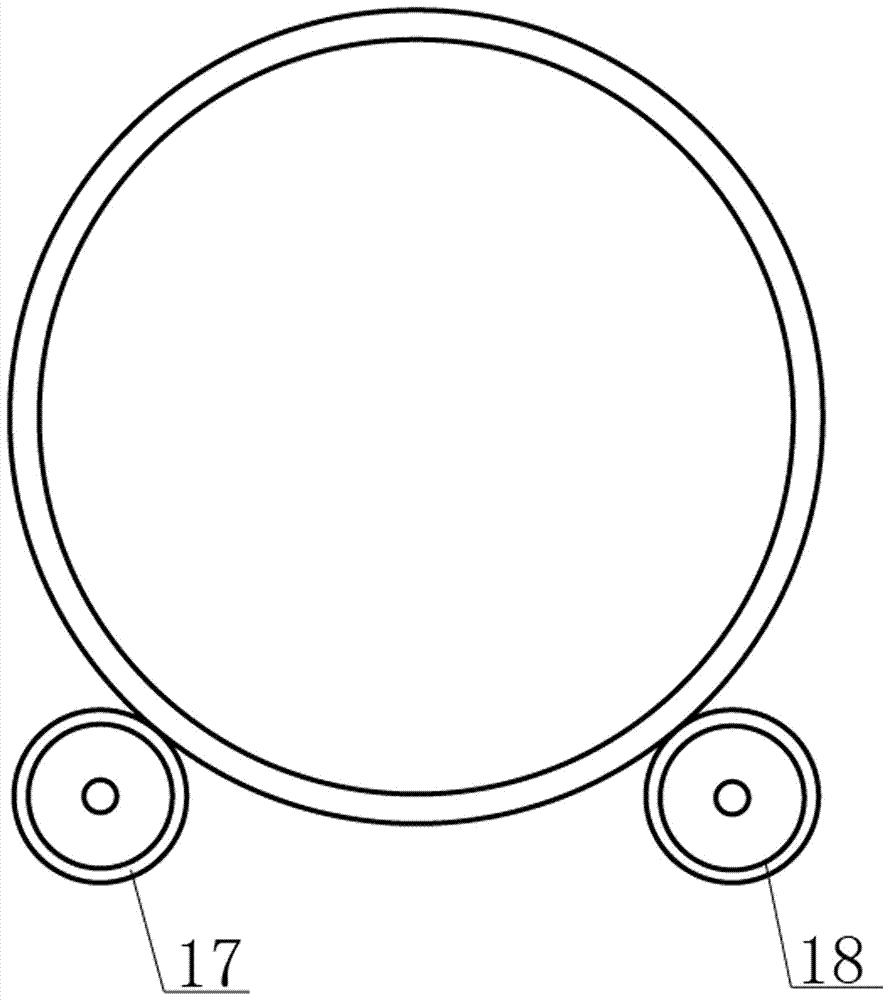

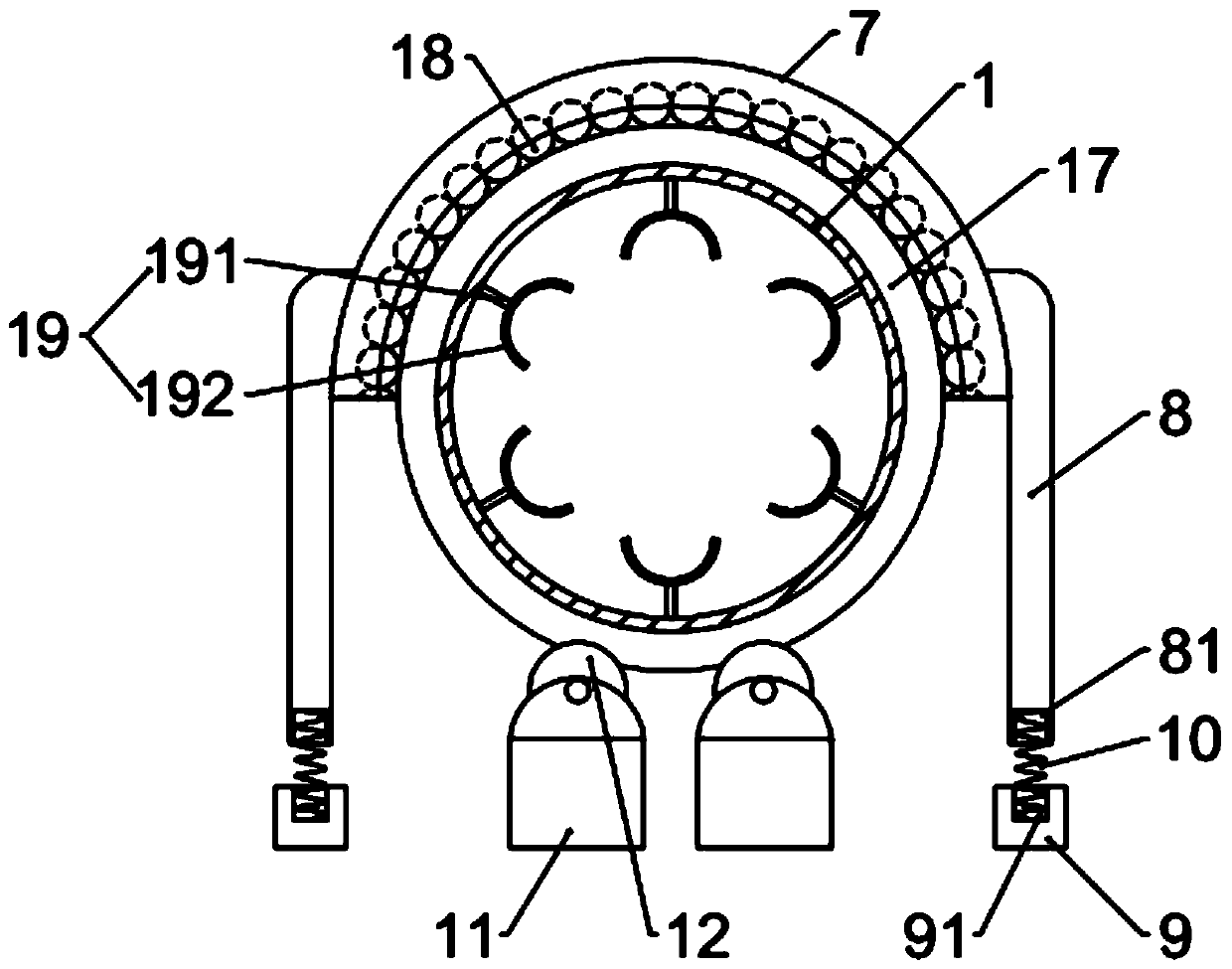

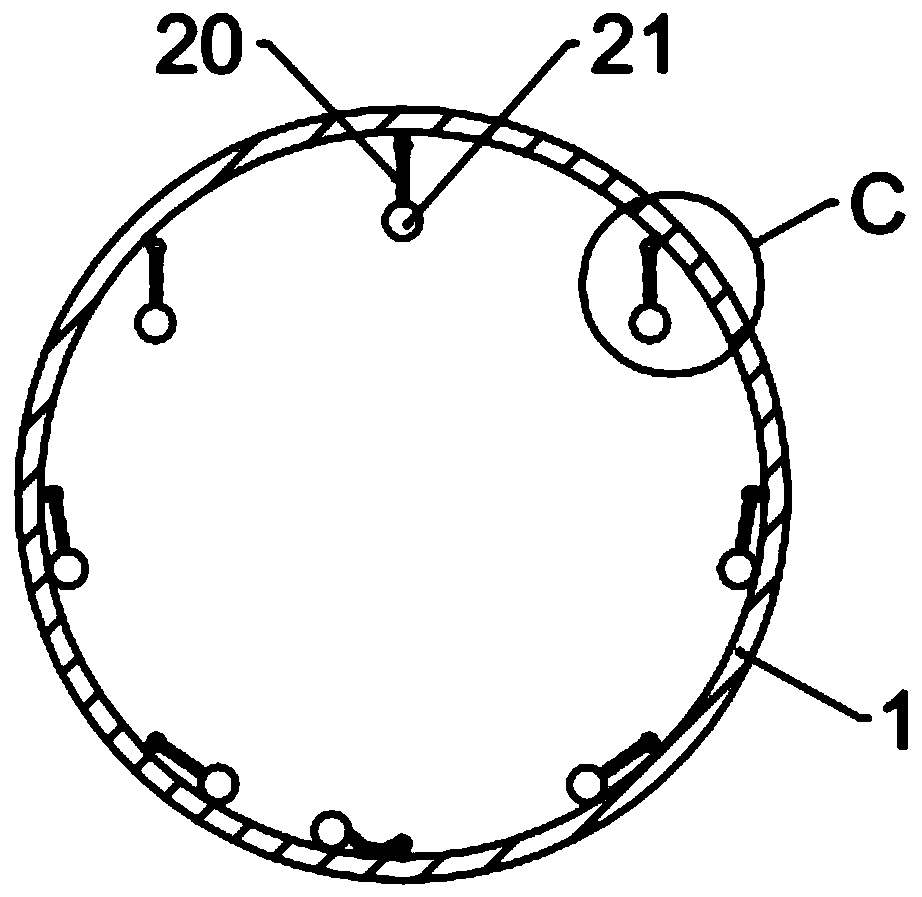

Rotary kiln for producing petroleum coke

PendingCN109827425AReduce shakingReduce the impactRotary drum furnacesPetroleum cokeMechanical engineering

The invention provides a rotary kiln for producing petroleum coke. The rotary kiln comprises a barrel body. Multiple wheel belts are arranged outside the barrel body in a sleeving manner and fixedly connected. A limiting housing is arranged on the upper half of each wheel belt in a housing manner. Each limiting housing is internally provided with multiple rolling wheels which are sequentially arranged into a semicircle. The rolling wheels are in rolling connection with the upper halves of the wheel belts. Support pillars are fixedly connected to the outer wall of each limiting housing, whereinthe support pillars are symmetrically arranged at the two sides of the barrel body. A shock absorption spring is connected to the bottom of each support pillar. A base is connected to the bottom of each shock absorption spring. A mixing mechanism and a beating mechanism are alternately arranged inside the barrel body in the axial direction. The mixing mechanism is composed of multiple mixing components which are uniformly distributed in the circumferential direction. Each mixing component comprises a support plate and a mixing plate, wherein each support plate is fixedly connected with the inner wall of the barrel body, and each mixing plate is fixedly connected with the corresponding support plate. The beating mechanism comprises multiple chains and beating balls, wherein the chains areuniformly distributed in the circumferential direction, and the beating balls are fixedly connected with the chains. According to the rotary kiln, when the barrel body rotates, the shaking degree is low; the service life is long; calcination raw materials are not likely to adhere to the inner wall of the barrel body; the energy consumption is lowered; and the production efficiency is high.

Owner:镇江东亚碳素焦化有限公司

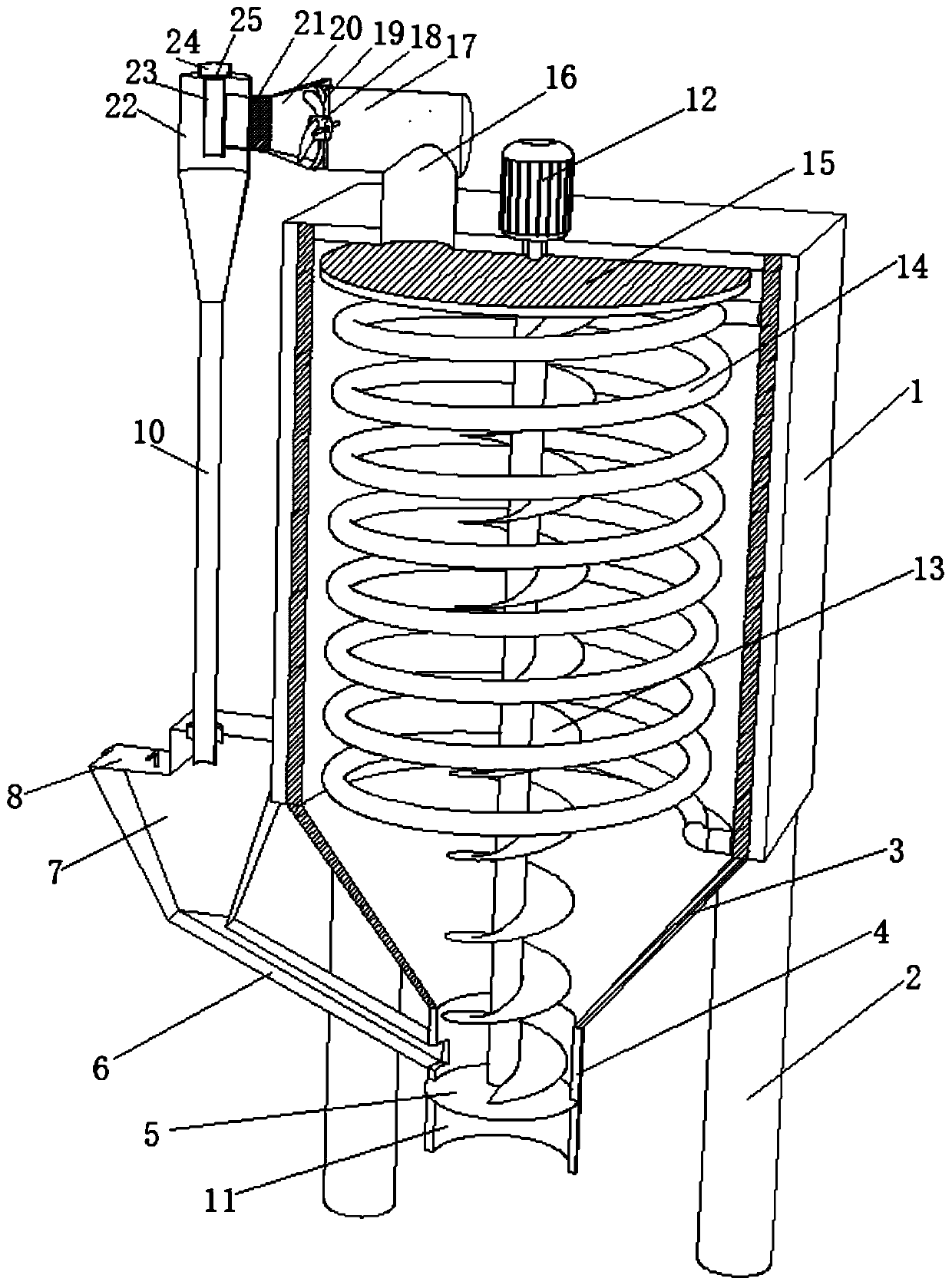

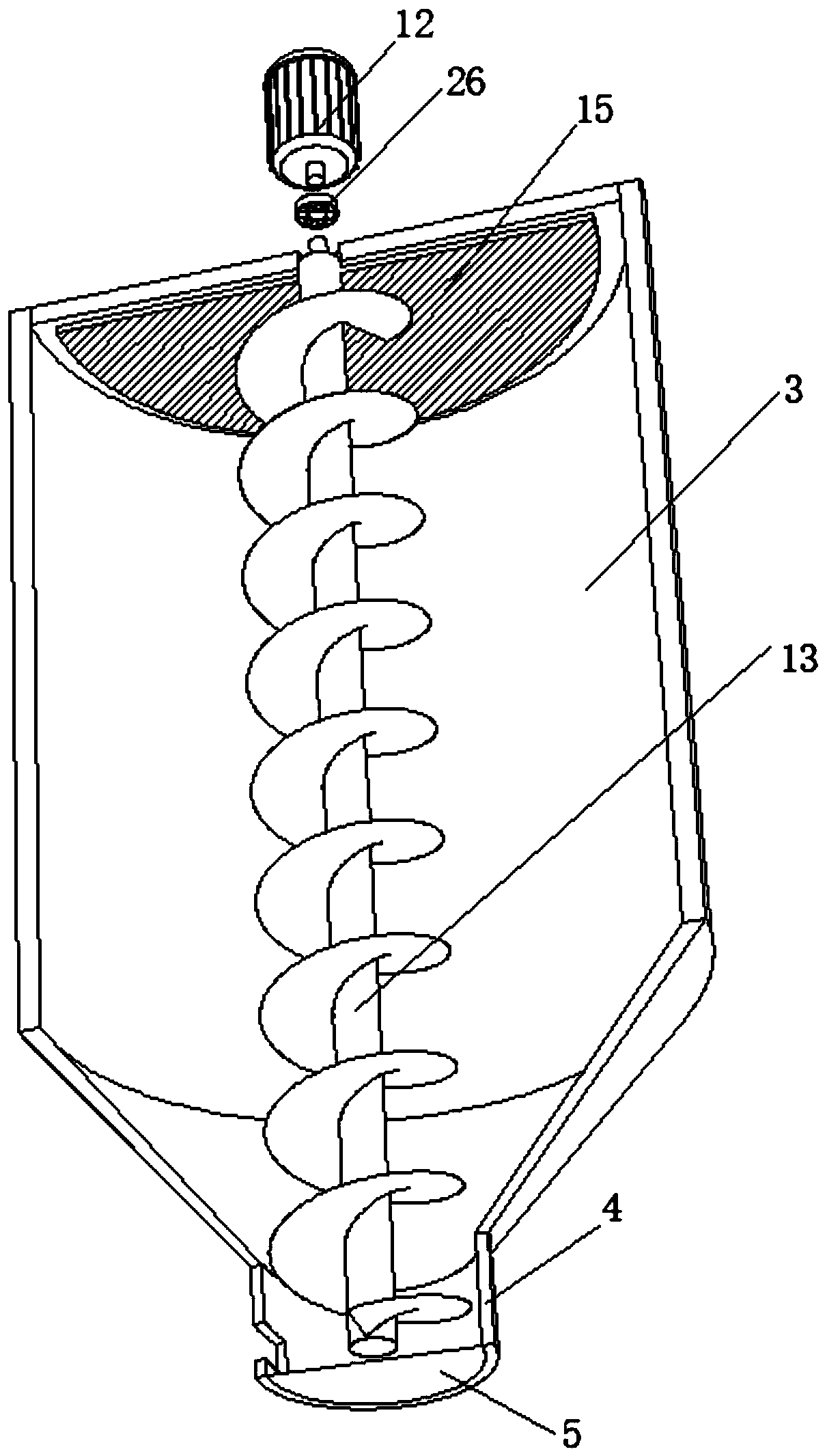

Calcination device in alkali preparation process

InactiveCN110806098ACalcined thoroughlyGuaranteed purityVertical furnacesCarbonate preparationThermodynamicsHelical blade

The invention relates to the technical field of chemical alkali preparation, and discloses a calcination device in an alkali preparation process. The device comprises a heat insulation box, a supportcolumn is fixedly installed at the bottom of the heat insulation box, a calcining box is fixedly installed in the heat insulation box, a feeding cylinder is fixedly installed at the bottom of the calcining box, a baffle is movably installed at the bottom of the feeding cylinder, and a discharging port is fixedly installed at the bottom of the feeding cylinder. According to the calcination device in the alkali preparation process, a spiral blade is installed in the calcining box, a material blocking plate is installed at the top of the spiral blade, the spiral blade can transport raw materialsat the bottom of a calcinator to the top of the calcinator under the driving of a driving motor, a spring-shaped heating pipe heated and calcine the materials in the falling process, and the materialsare transported to the upper part of the calcinator by the spiral blade again after the materials fall to the bottom of the calcinator, and the action is repeated, so that compared with an existing alkali-preparation calcination device, the raw materials can be more thoroughly calcined, and the purity of the soda ash product is guaranteed.

Owner:衡阳凯美科化工有限公司

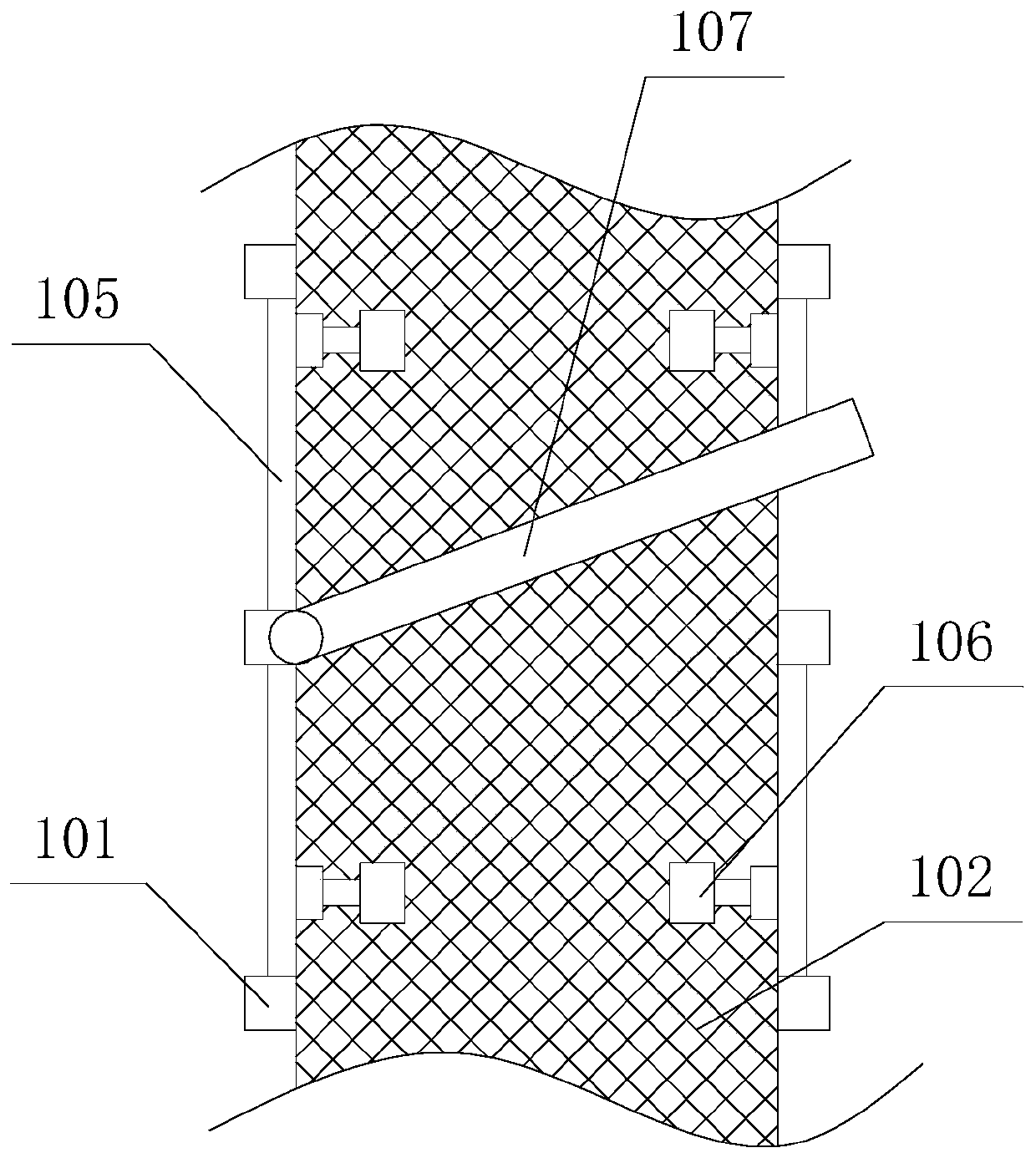

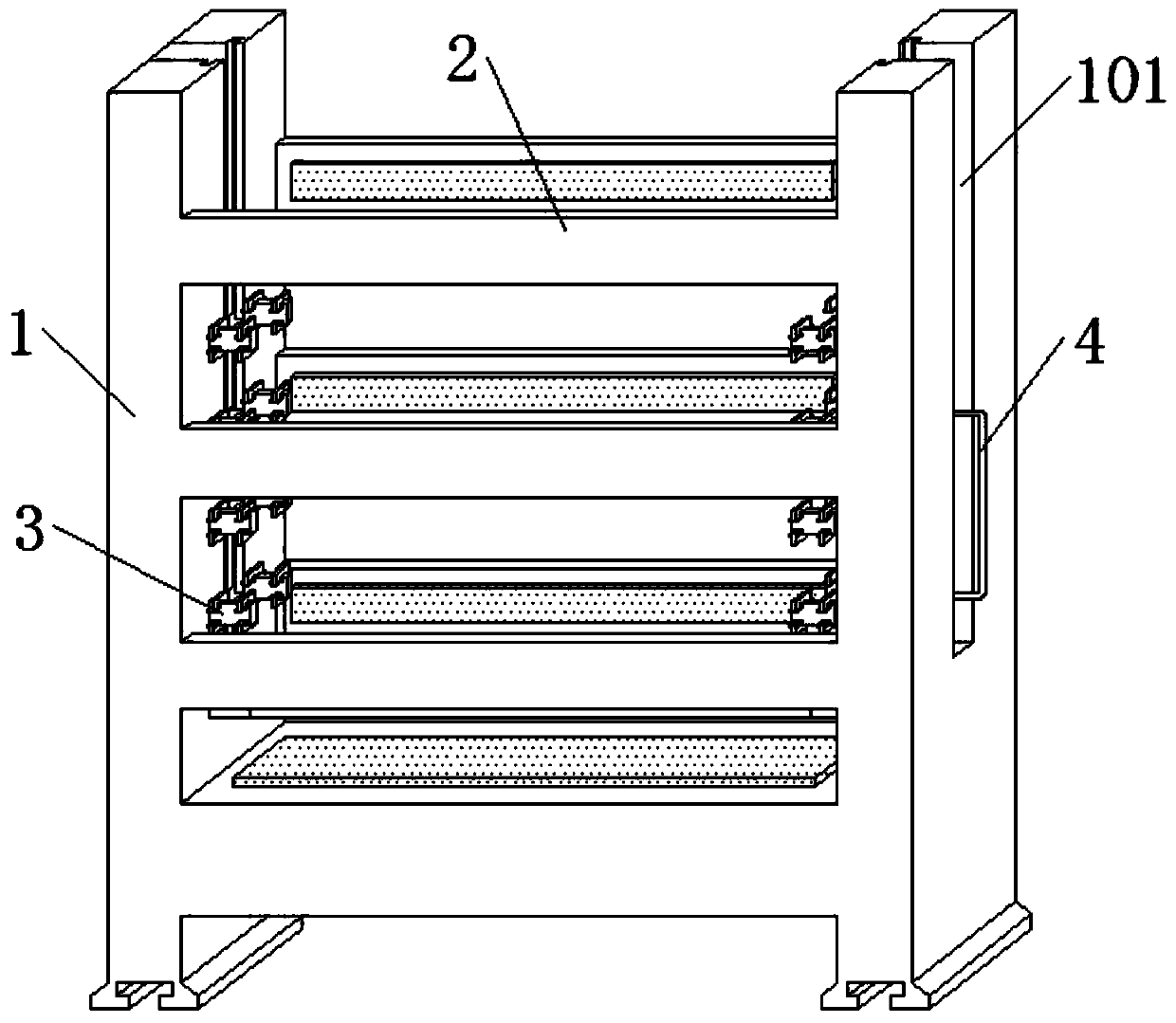

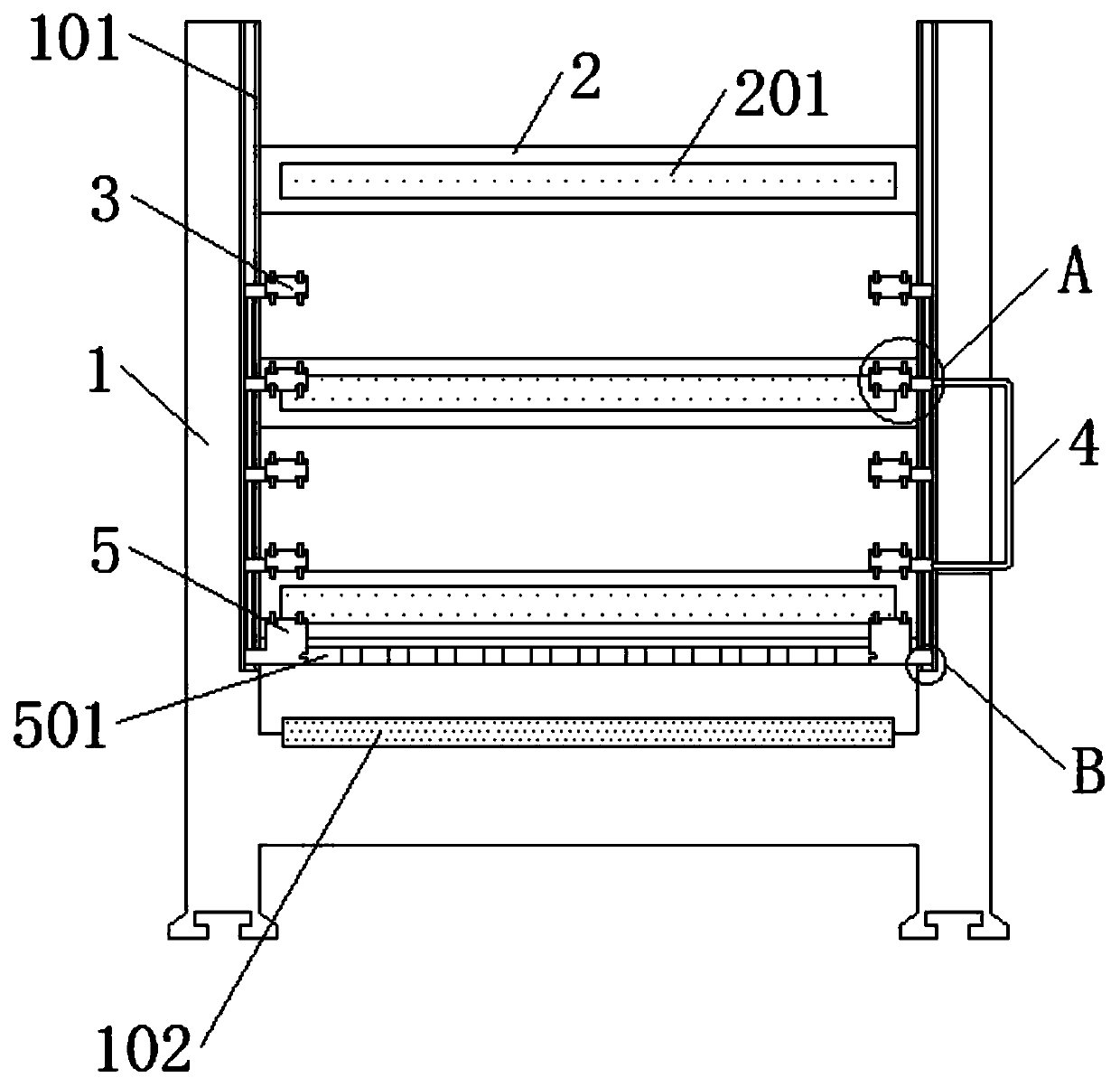

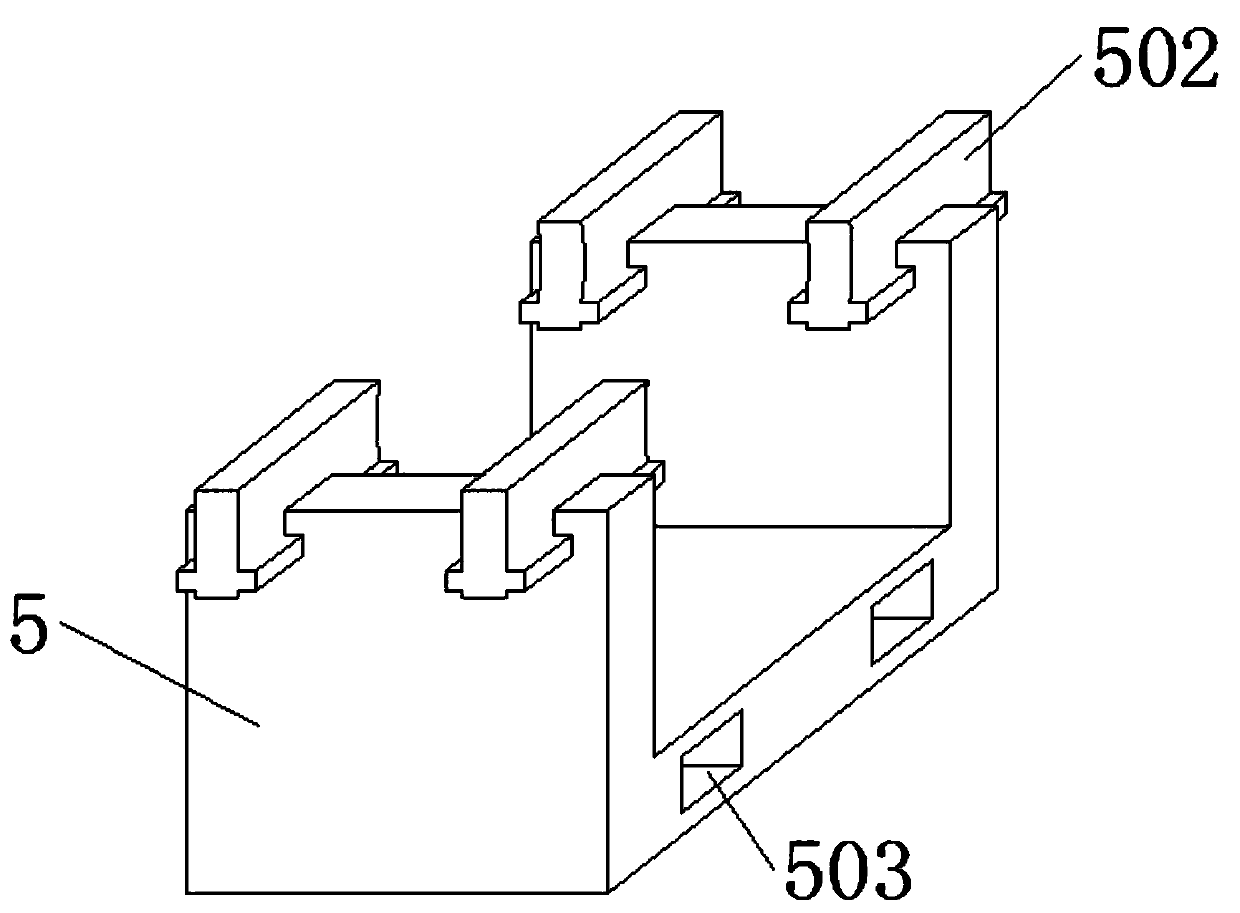

Multi-point limiting type engine ceramic blade calcining supporting frame

The invention provides a multi-point limiting type engine ceramic blade calcining supporting frame. The multi-point limiting type engine ceramic blade calcining supporting frame comprises a main frame, sliding grooves, transverse plates, limiting blocks, a sliding pull rod and a bottom supporting block; the transverse plates are arranged at the front end and the rear end of the main frame; the left end and the right end of the main frame are movably connected with the limiting blocks through the sliding grooves; the outer sides of the limiting blocks are fixedly connected with the sliding pullrod; and the bottom supporting blocks are arranged at the bottom ends of the limiting blocks. The whole multi-point limiting type engine ceramic blade calcining supporting frame is stable in structure and convenient use and operate, and has good fixing and supporting effects, and the calcining efficiency is improved.

Owner:安徽盈锐优材科技有限公司

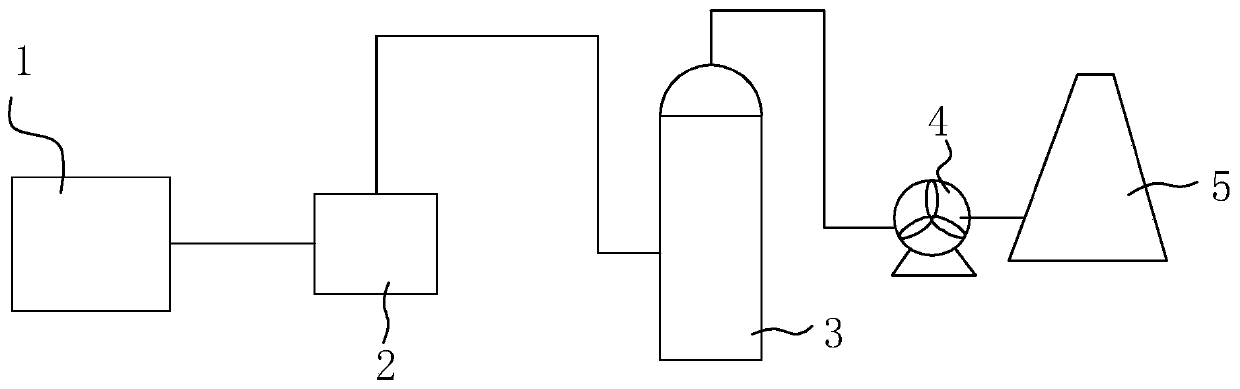

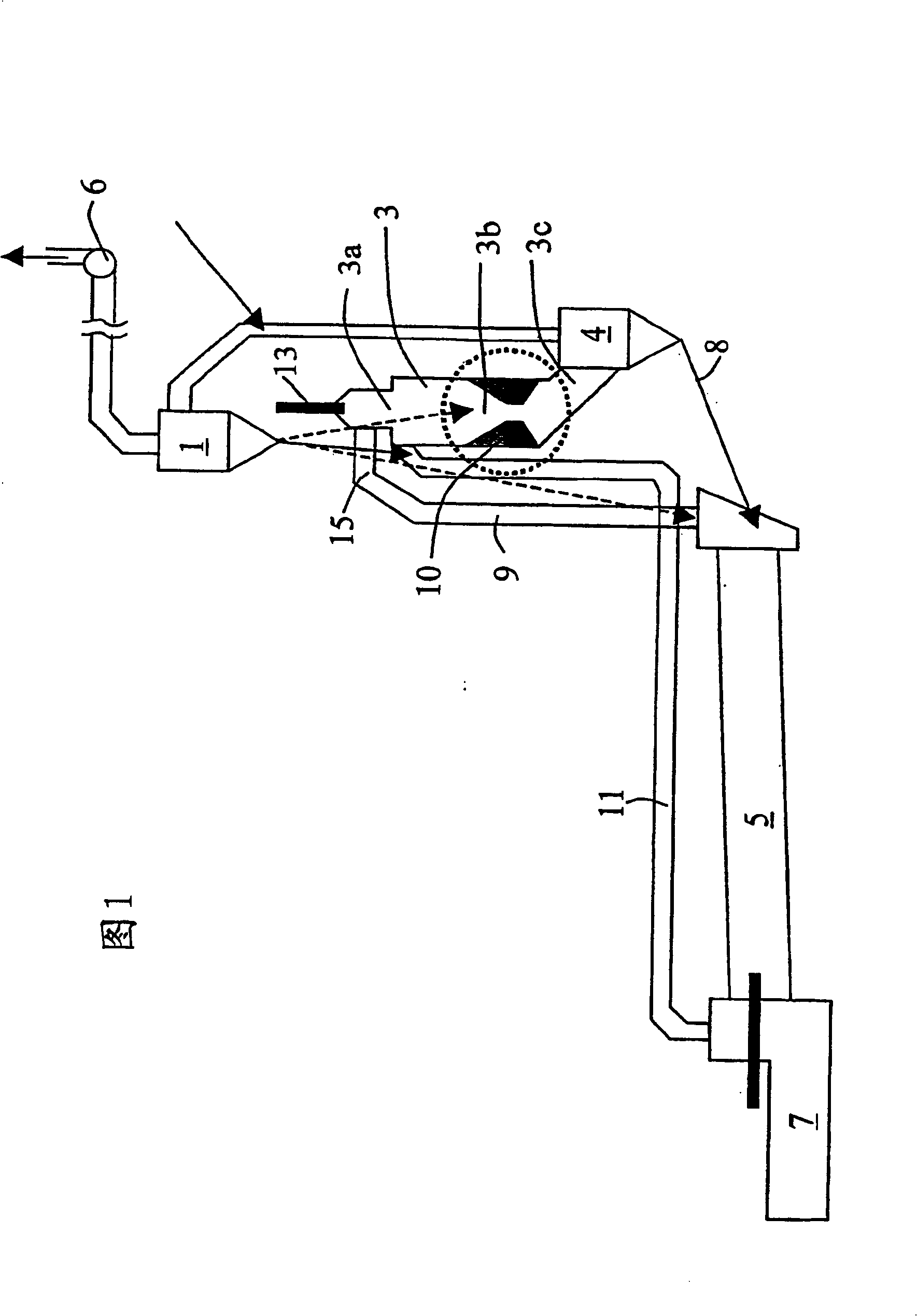

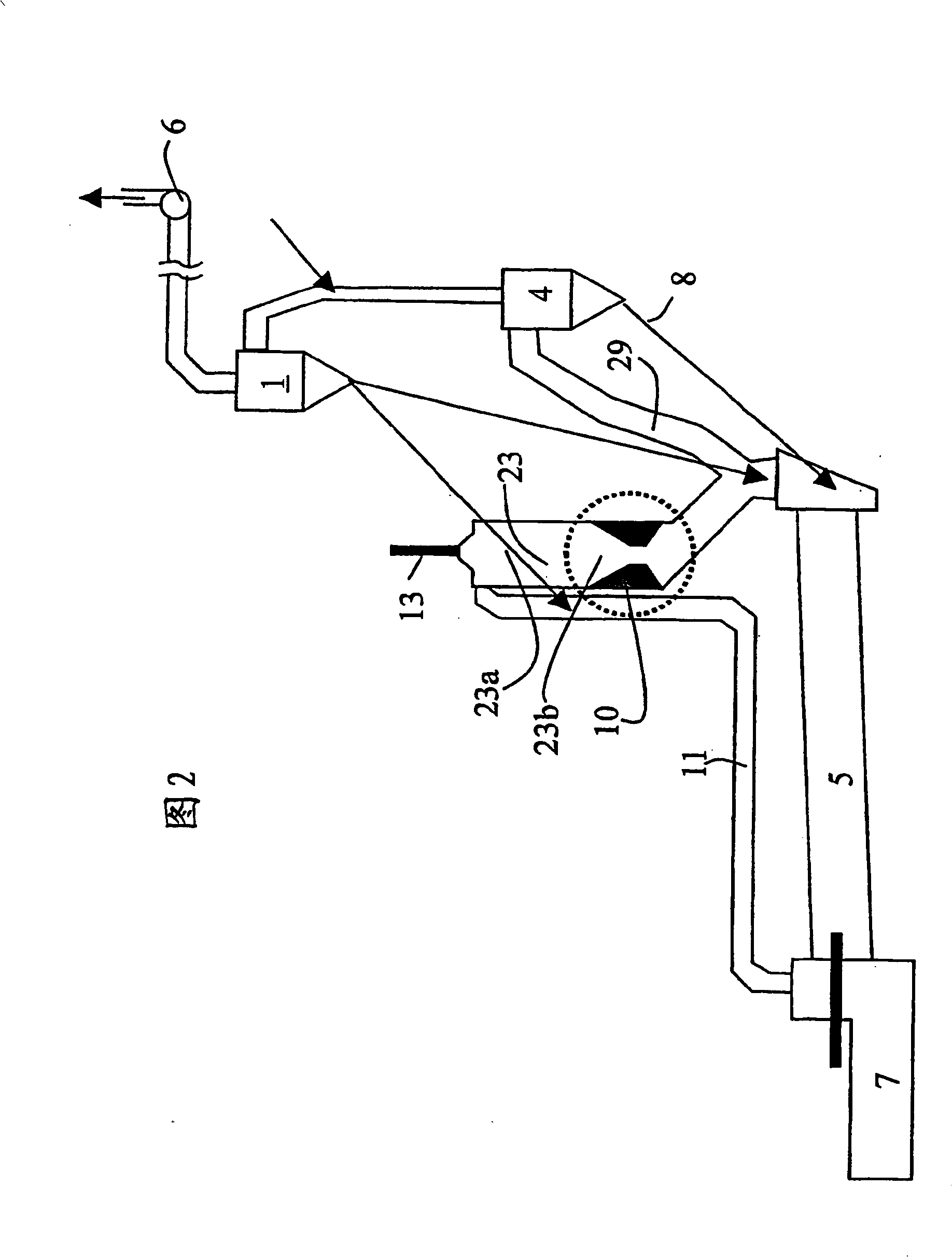

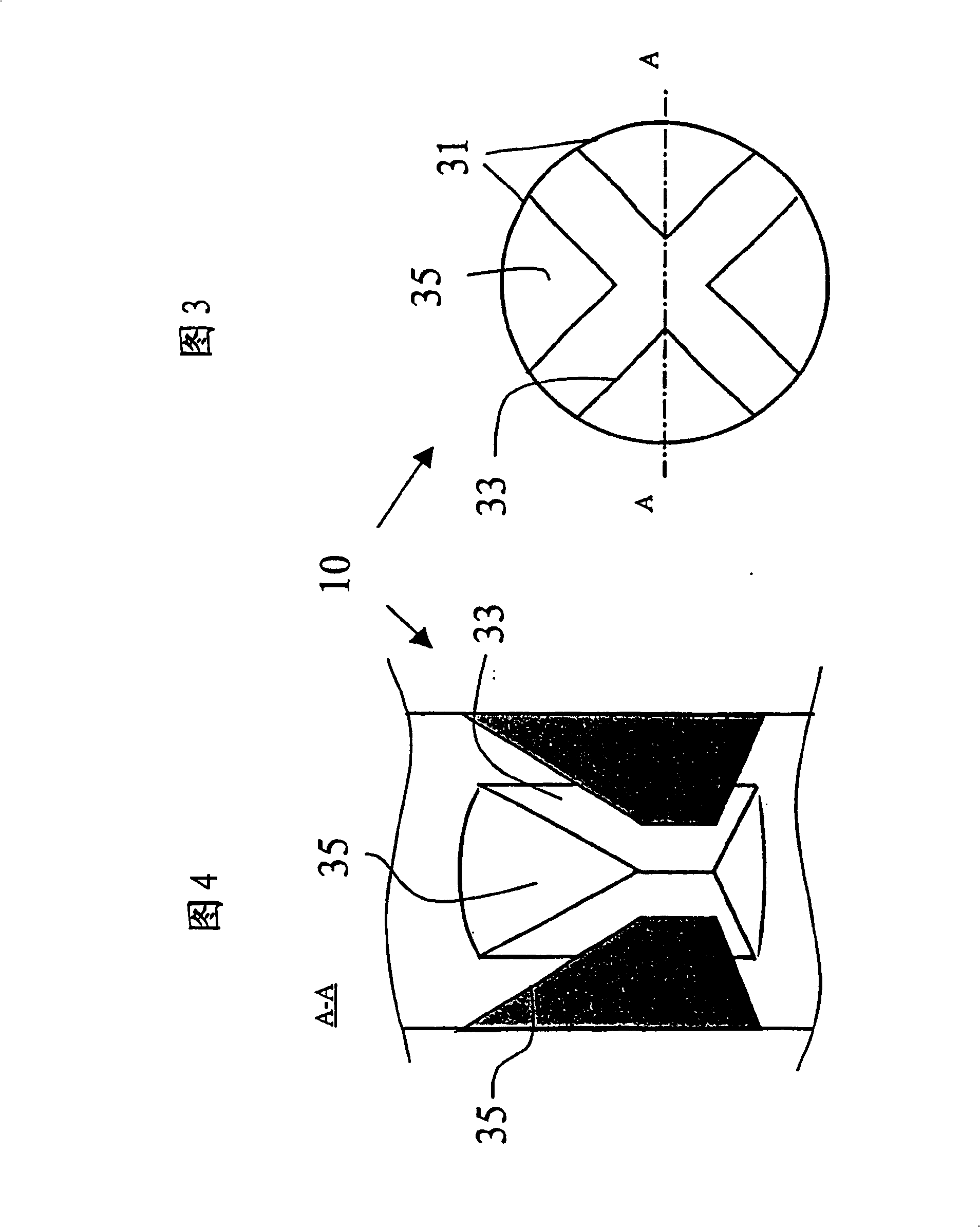

Method and plant for manufacturing cement clinker

InactiveCN100432607CImprove calcination efficiencyEfficient mixingRotary drum furnacesCharge supportsThermodynamicsProcess engineering

A method and plant for manufacturing cement clinker are disclosed, in which cement raw meal is calcined in a calciner (3, 23). The calciner (3, 23) comprises an upper zone (3a, 23a) and a lower zone (3b, 23b), where fuel, combustion gas and raw meal are introduced into the upper zone of the calciner and directed downward through the calciner. The combustion gas and raw meal are introduced tangentially into the calciner and subject to rotation follow a spiral-shaped flow path, and, under the action of gravity, the raw meal is primarily directed down along the wall of the calciner. The rotation of the combustion gas in at least the lower zone of the calciner is subjected to braking and approximately simultaneously or subsequently at least some of the combustion gas and at least some of the raw meal in the lower zone of the calciner is directed in the direction towards the centre-line of the calciner.

Owner:F L SMIDTH & CO AS

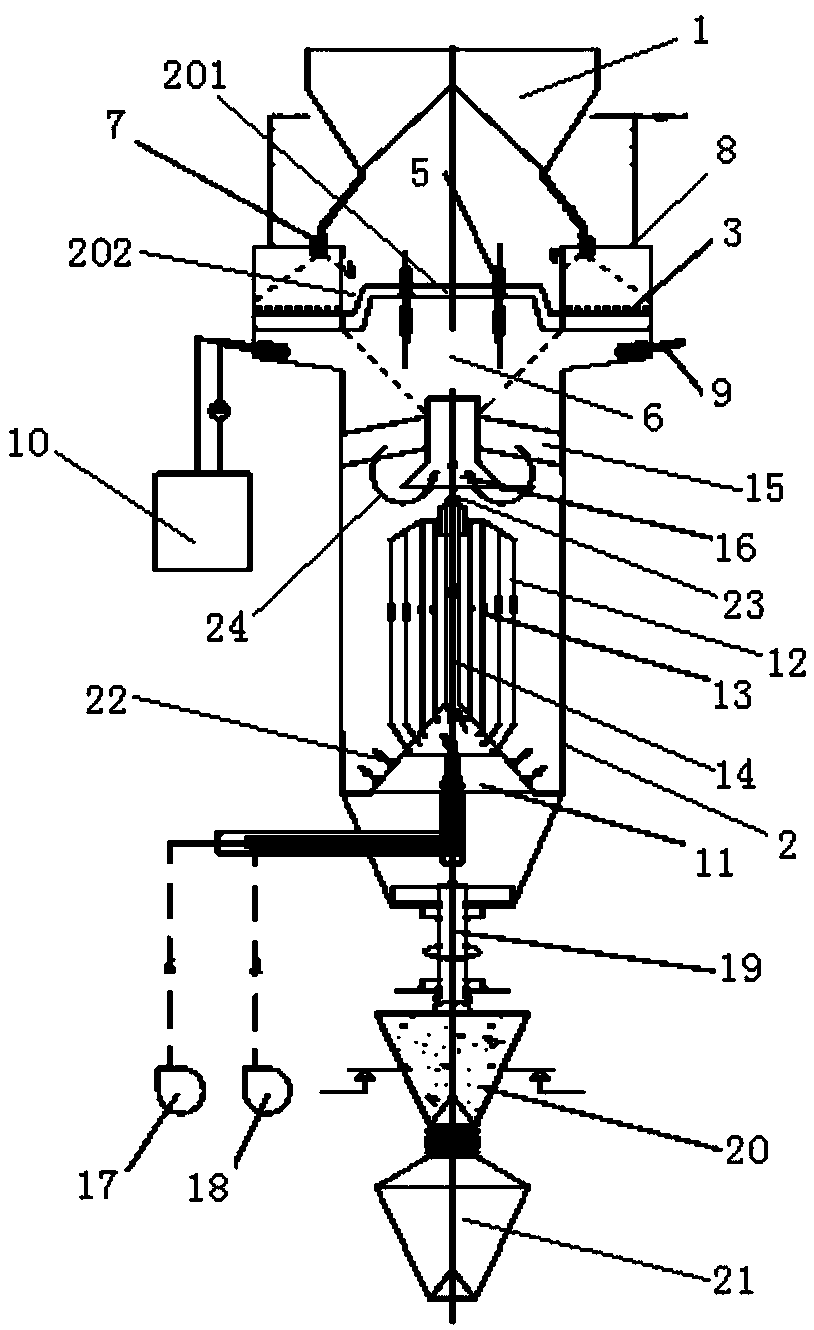

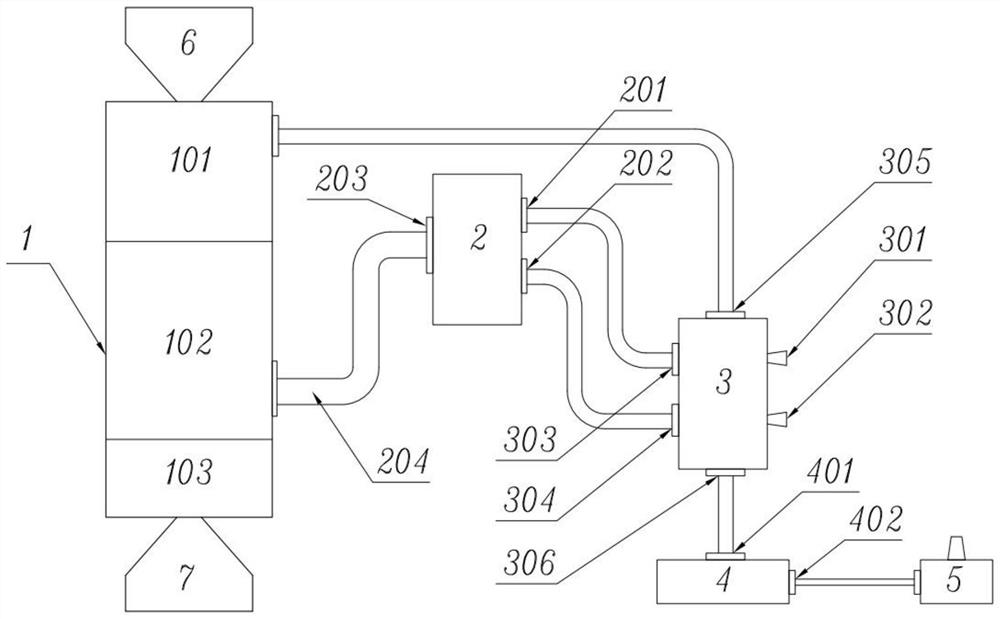

Device and method for producing self-excited II type anhydrous gypsum by utilizing industrial byproduct gypsum

The invention discloses a device and method for producing self-excited II type anhydrous gypsum by utilizing industrial byproduct gypsum. The process device comprises a two-stage dynamic cyclone calcining system, a rotary flash evaporation drying system, an industrial byproduct gypsum pretreatment system, a II type anhydrous gypsum cooling system, a system high-pressure induced draft fan, a pipeline system and the like. The process method comprises the step of continuously and sequentially performing operations according to the type and property of an industrial by-product gypsum material; performing raw material selective dehydration, performing pretreatment, performing drying dehydration, performing two-stage dynamic calcination and performing II type anhydrous gypsum product cooling process treatment. A process device system is totally closed, negative pressure state operation is achieved, echelon utilization of system heat is achieved, and energy conservation and consumption reduction are achieved. A high-quality II-type anhydrous gypsum product which is excellent in mechanical property and capable of realizing self-excitation subsequently can be prepared from the industrial by-product gypsum, so that the resource utilization of the industrial by-product gypsum is expanded, and the method and the production device can realize large-scale industrial production.

Owner:辽宁东大粉体工程技术有限公司 +1

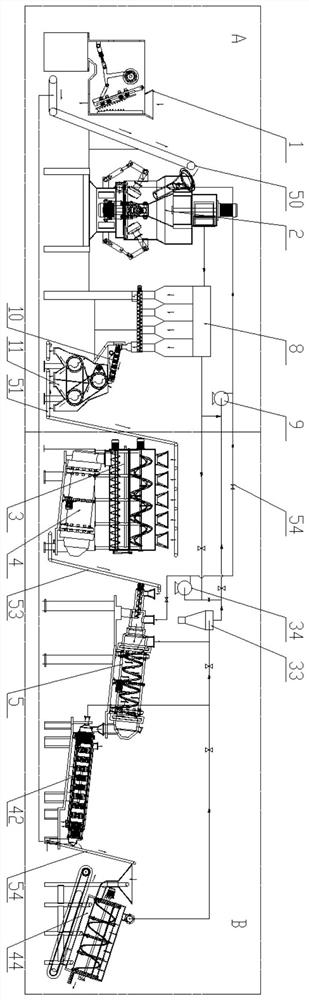

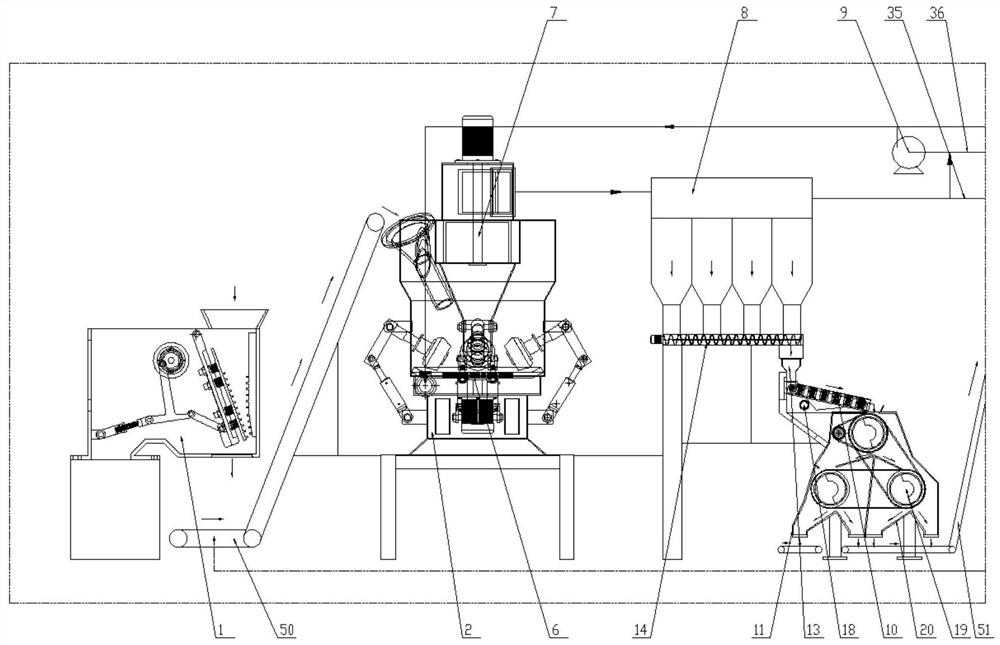

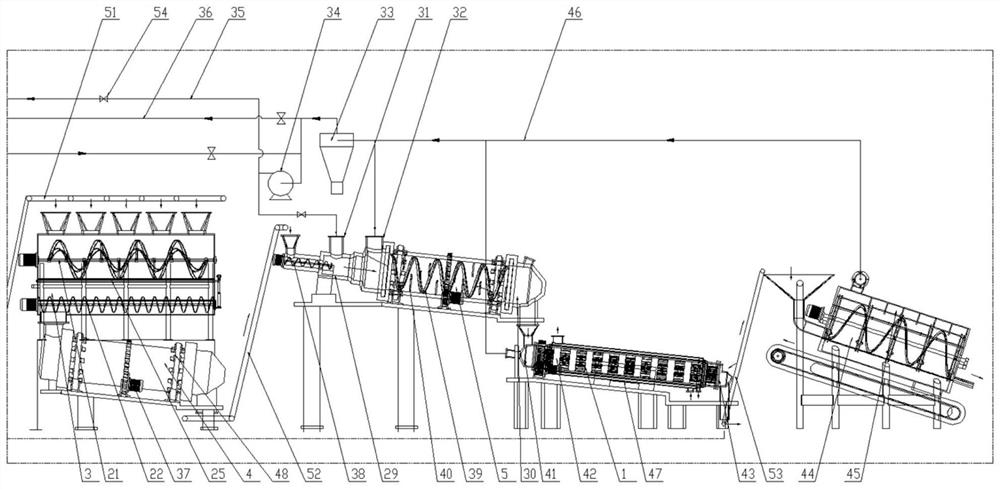

Automatic sand powder production line for metallurgical casting

ActiveCN112496256AIncrease the feeding spaceLower feeding heightMould handling/dressing devicesEngineeringAgitator

The invention relates to an automatic sand powder production line for metallurgical casting. The production line comprises a crushing machine, a grinding machine, a batching machine, a granulator anda calcining rotary furnace which are sequentially arranged, a cage-shaped rotor in the grinding machine is connected with an electrostatic dust collector, the electrostatic dust collector is connectedwith a first fan, a magnetic separation impurity removal device is arranged at the bottom of a material distribution device at the bottom of the electrostatic dust collector, a horizontal stirrer anda first screw conveyor are arranged in the batching machine, a cyclone dust collector and a second fan are arranged between an air inlet pipe and a smoke outlet pipe of a first feeding shell of the calcining rotary furnace, and a screening device is arranged on one side of a second discharging shell of an air cooling rotary cylinder. The whole production line achieves automatic production, the number of machining and transferring devices is reduced, the device cost and occupied space are remarkably reduced, the treatment amount is increased, quality control and production of smelting and casting sand powder with different water content, different magnetic impurities, different particle sizes and different raw materials are achieved, the machining treatment efficiency and effect are improved, continuous production is facilitated, and one set of equipment can meet various smelting and casting sand powder production requirements.

Owner:上海冶铸材料科技有限公司

Gypsum calcining system

The invention discloses a system for calcinating plaster and a calcinating method thereof. The system includes a crusher for crushing the plaster material, a plaster drying device for drying the crushed plaster material, an oscillating sieve for sieving the dried plaster material, a calcinatory of a fluid bed for calcinating the sieved plaster material, a storage tower for storing the calcinated plaster as well as a hot air boiler for providing a thermal source for the plaster drying device and the calcinatory of the fluid bed. By adopting the device which first dries and then calcinates in the invention greatly promotes the efficiency and improves the quality of calcinating; besides, by adopting the single storage tower to carry out cooling, the efficiency of the whole system is greatly improved; the crushing and sieving of the plaster material guarantees that the calcinatory of the fluid bed sufficiently calcinates the plaster material, thus facilitating the production quality.

Owner:潍坊天洁环保科技有限公司

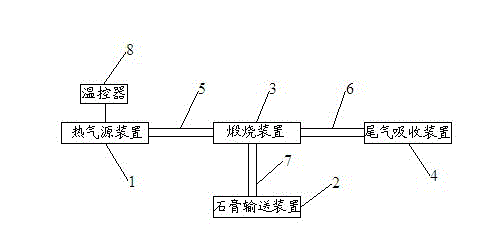

Desulfurized gypsum calcination apparatus

The invention discloses a desulfurized gypsum calcination apparatus which comprises a hot gas source device, a gypsum conveying device, a calcination device and a tail gas absorption device, wherein the hot gas source device is connected with the inlet end of the calcination device through a first pipeline; the outlet end of the calcination device is connected with the tail gas absorption device through a second pipeline; the bottom of the calcination device is connected with a third pipeline; the inlet end of the third pipeline is connected with the gypsum conveying device; and the outlet end of the third pipeline is connected with the calcination device. By using the above manner, the desulfurized gypsum calcination apparatus has a simple structure, can ensure sufficient gypsum supply to the inside of the calcination device, ensures the continuity of the calcination process, ensures the full integrality of the calcination process and improves the calcination efficiency.

Owner:CHANGZHOU VOCATIONAL INST OF ENG +1

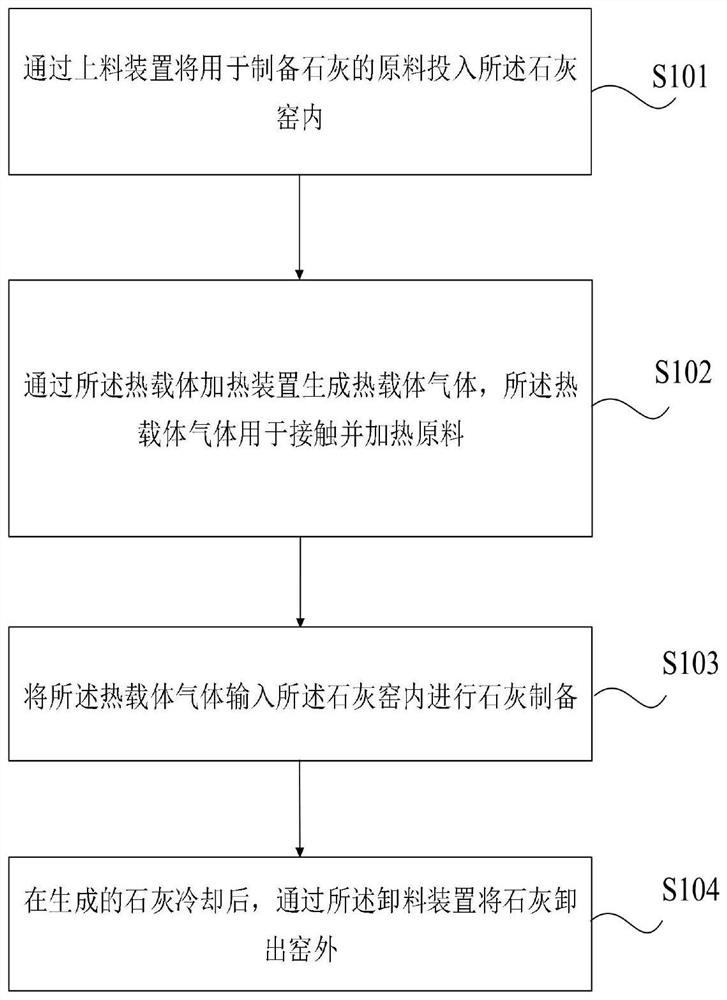

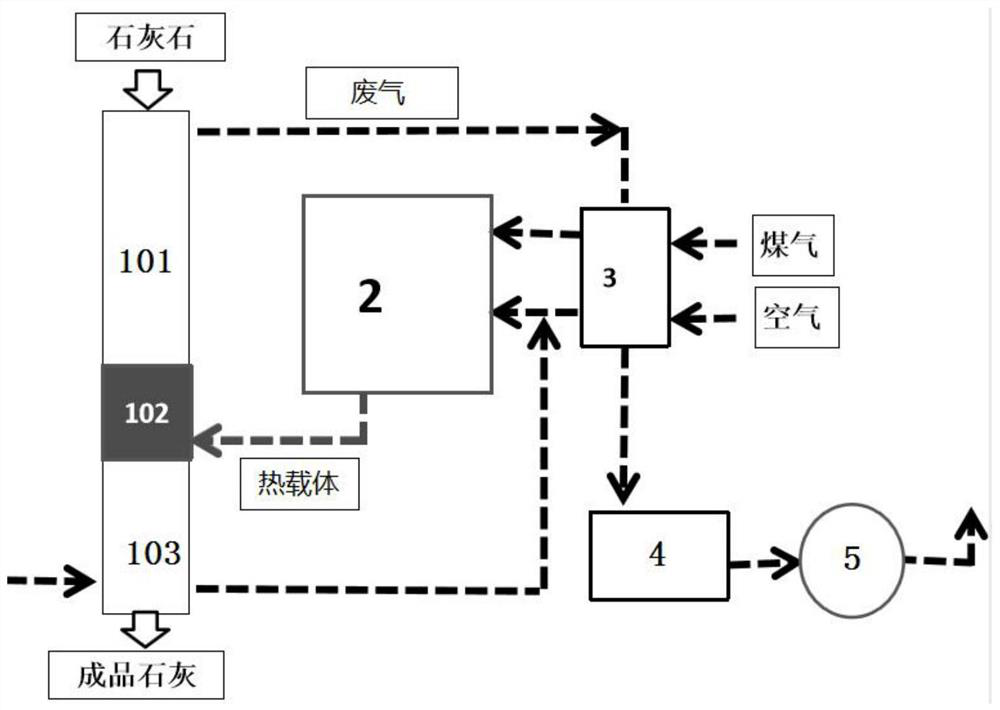

Lime kiln and lime preparation method

The embodiment of the invention provides a lime kiln and a lime preparation method. The lime kiln comprises a lime kiln body and one or more heat carrier heating devices arranged outside the kiln body; the heat carrier heating device comprises a fuel gas input port, an air input port and a heat carrier output port; the kiln body is connected with the heat carrier output port through a heat carrier conveying pipeline; and a high-temperature-resistant lining is laid on the inner wall of the heat carrier conveying pipeline. When the device is used for preparing lime, no combustion flame exists in the kiln, but the heat carrier heating device is used for providing hot flue gas for the lime kiln so as to heat raw materials in the kiln, so that the temperature and the pressure of heat carrier gas can be accurately controlled, the temperature and the pressure in the lime kiln are stable, and the calcining efficiency is improved.

Owner:明光瑞尔竞达科技股份有限公司

Ceramic processing technology

InactiveCN112645701AImprove function and effectImprove compactnessSilicon compoundsWollastoniteCalcination

The invention discloses a ceramic processing technology which comprises the following steps: 1, modifying bentonite: adding bentonite into a surfactant, stirring at a low speed of 50-100r / min for 10-20min, washing with water, drying, and grinding to 50-100 meshes; in ceramic processing, spodumene is used as a base material, bentonite is treated in a surface agent, then blasting treatment is carried out, wollastonite in the surface agent is inserted into the bentonite in a penetrating mode, meanwhile, the effect of wollastonite on bentonite can be improved through shell powder, and therefore in the hot-pressing calcination process, the spodumene is jointly improved through bentonite and wollastonite.

Owner:XUCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com