Anti-cracking casting coating based on attapulgite

A technology of attapulgite and foundry coating, applied in foundry molding equipment, coating, mold and other directions, can solve the problems of unsafe, flammable and explosive alcohol, not environmental protection, etc., achieve excellent bonding ability and improve suspension performance , the effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

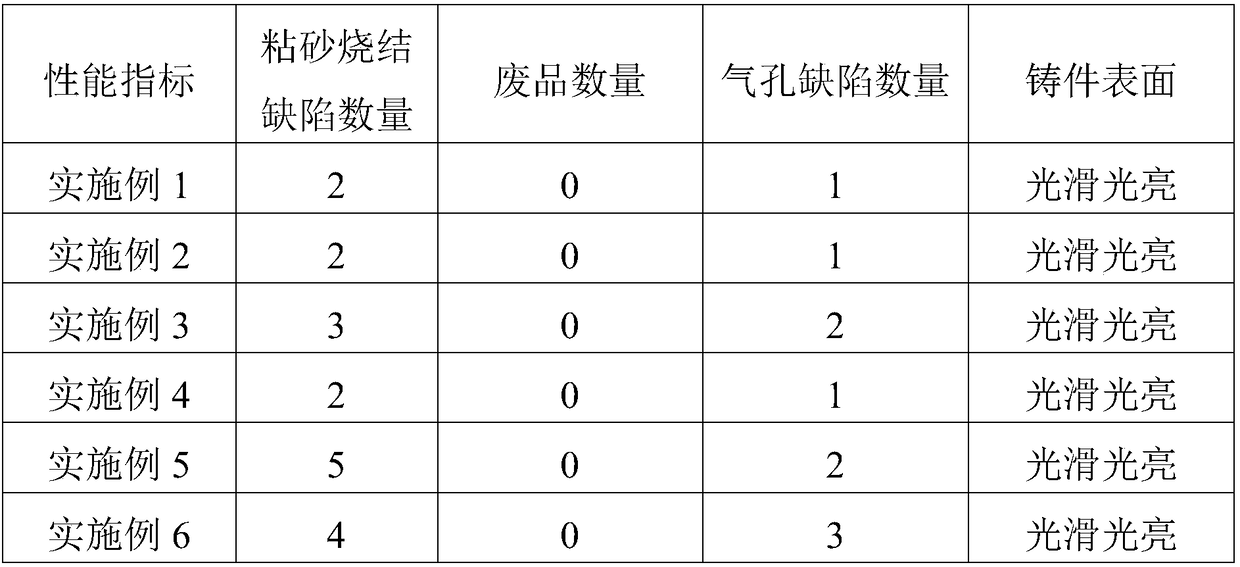

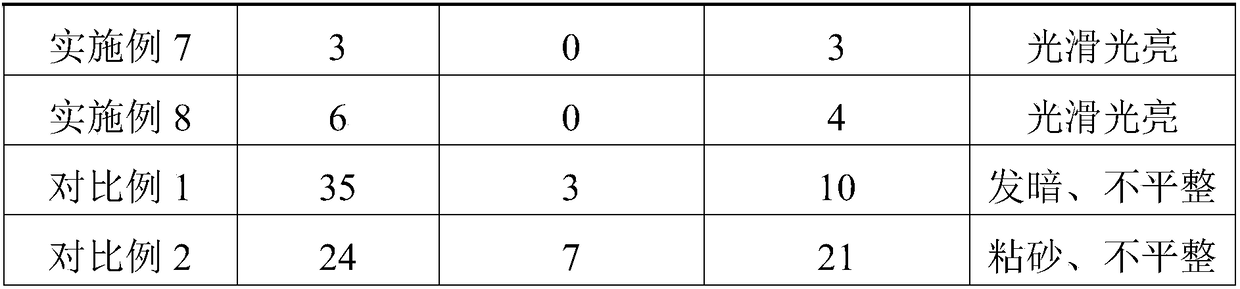

Examples

preparation example Construction

[0021] The preparation method of the modified attapulgite is as follows: grind and refine the attapulgite and add a composite coupling agent, then stir, heat up to 70°C and keep it warm for 2-3 hours, then add a dispersant, continue to stir and heat up to 80°C °C, the material was discharged and dried to obtain modified attapulgite.

[0022] The foundry dust of the present invention mainly comes from two aspects, one is the flue gas dust discharged during the cupola smelting process, which includes metallurgical dust, carbon dust and dust; the other is from the sand treatment system , Casting shakeout and iron sand dust in the process of casting cleaning; Due to the limitations of many factors, the efficient use of foundry dust has always been a common problem in the foundry field. If it is not handled properly, it will easily lead to environmental pollution and waste of resources. The present invention uses it as the raw material for the preparation of the paint, utilizes the...

Embodiment 1

[0033] A crack-resistant casting coating based on attapulgite, the preparation raw materials of the coating include: 38kg of mullite powder, 18kg of casting dust, 8kg of magnesium oxide, 5kg of sodium silicate, 4kg of sodium hydroxymethylcellulose, 12kg of silica sol, Modified attapulgite 14kg;

[0034] The preparation method of this foundry coating is:

[0035] Add mullite powder, foundry dust, magnesium oxide, sodium silicate, sodium hydroxymethyl cellulose and modified attapulgite into a high-speed mixer and mix evenly, then unload and transfer to the mixer, add silica sol, and ultrasonically Disperse for 25 minutes, then spread the mixture into sheets, and under the protection of an inert gas, calcinate at a high temperature of 880°C for 8 minutes, and finally grind the calcined residue and pass through a 50-mesh sieve to obtain the casting coating.

Embodiment 2

[0037] The composition of the anti-crack casting coating in this example and Example 1 is basically the same, and the preparation method is the same. The difference is that in the preparation raw materials of the coating, mullite powder is replaced by cordierite powder, and the rest remain unchanged.

[0038] Specifically, the raw materials for the preparation of the paint include: 38kg of cordierite powder, 18kg of foundry dust, 8kg of magnesium oxide, 5kg of sodium silicate, 4kg of sodium hydroxymethylcellulose, 12kg of silica sol, and 14kg of modified attapulgite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com