Patents

Literature

4596results about How to "Improve stirring efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid liquor mixing equipment

PendingCN111151186AImprove mixing efficiencyImprove stirring efficiencyTransportation and packagingFluid removalProcess engineeringStatic mixer

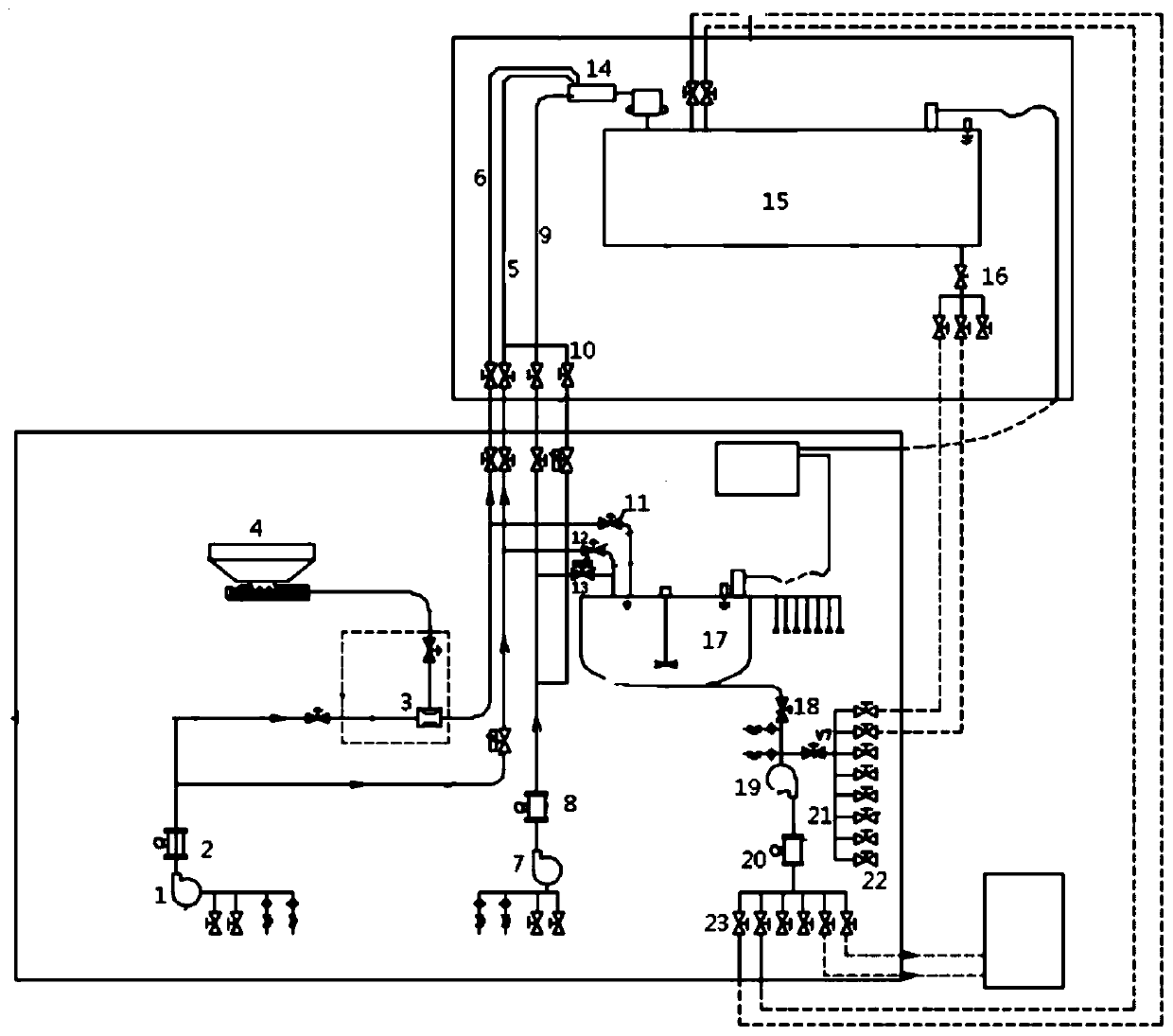

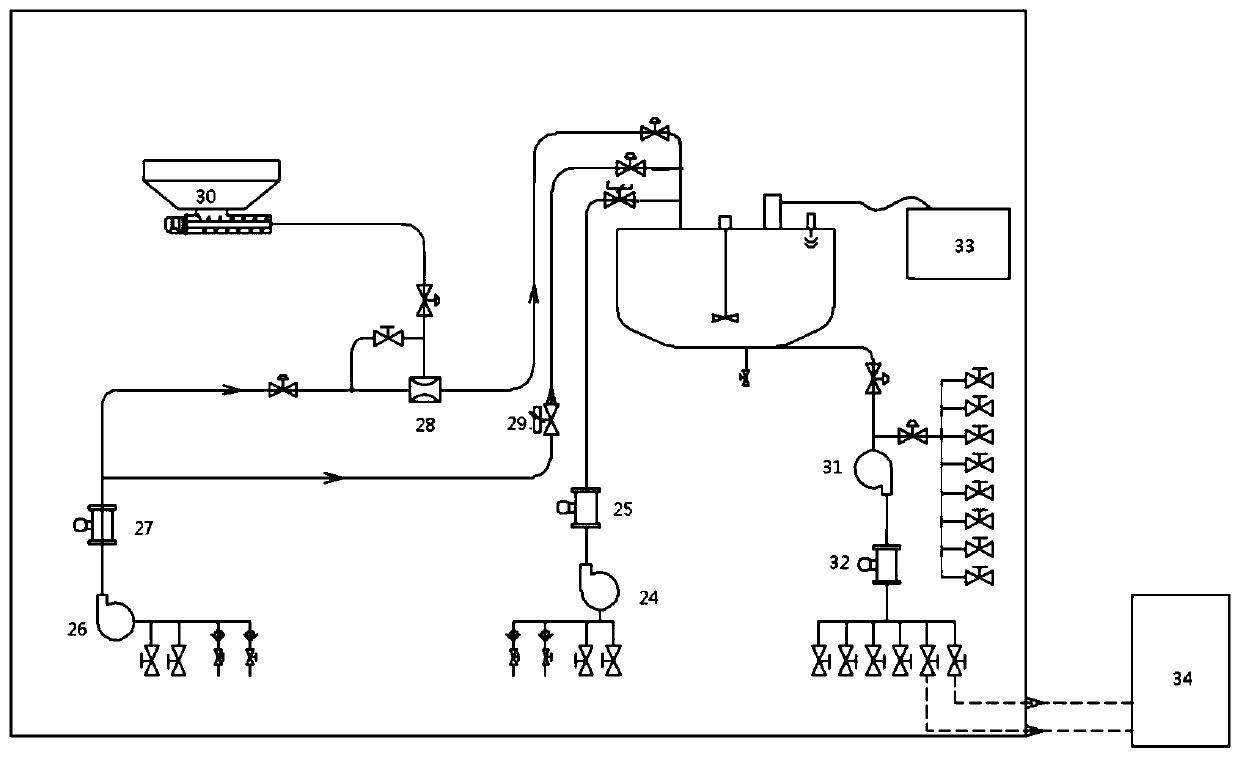

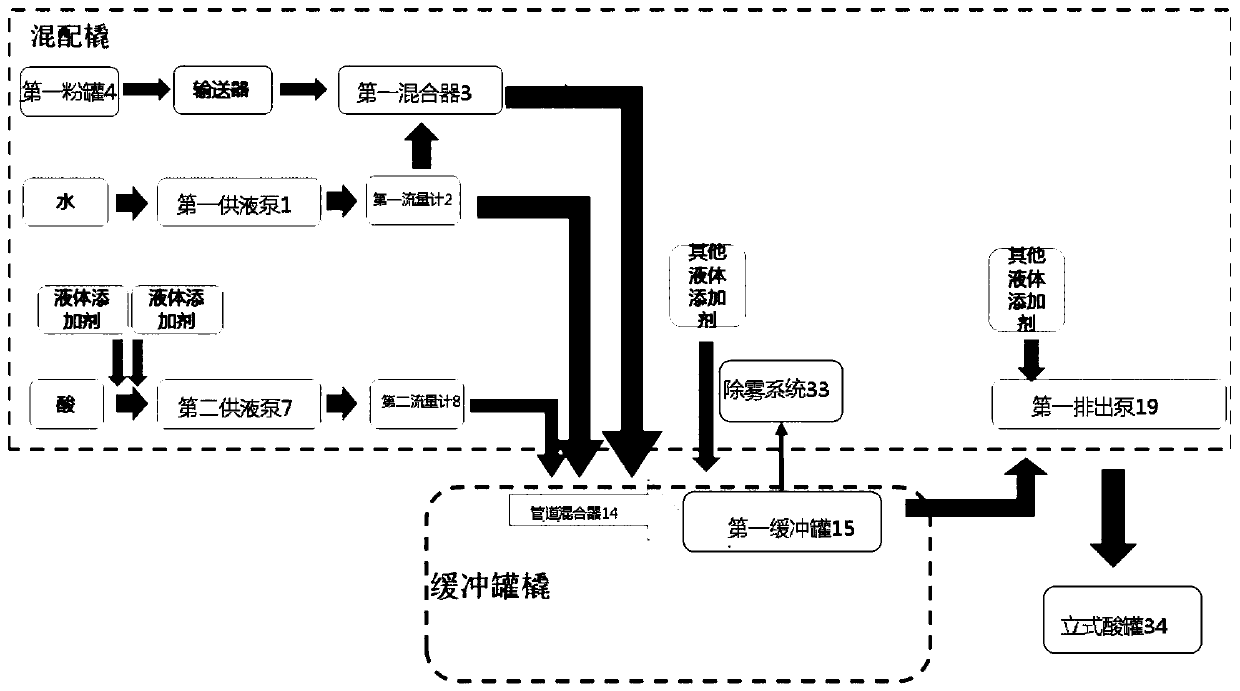

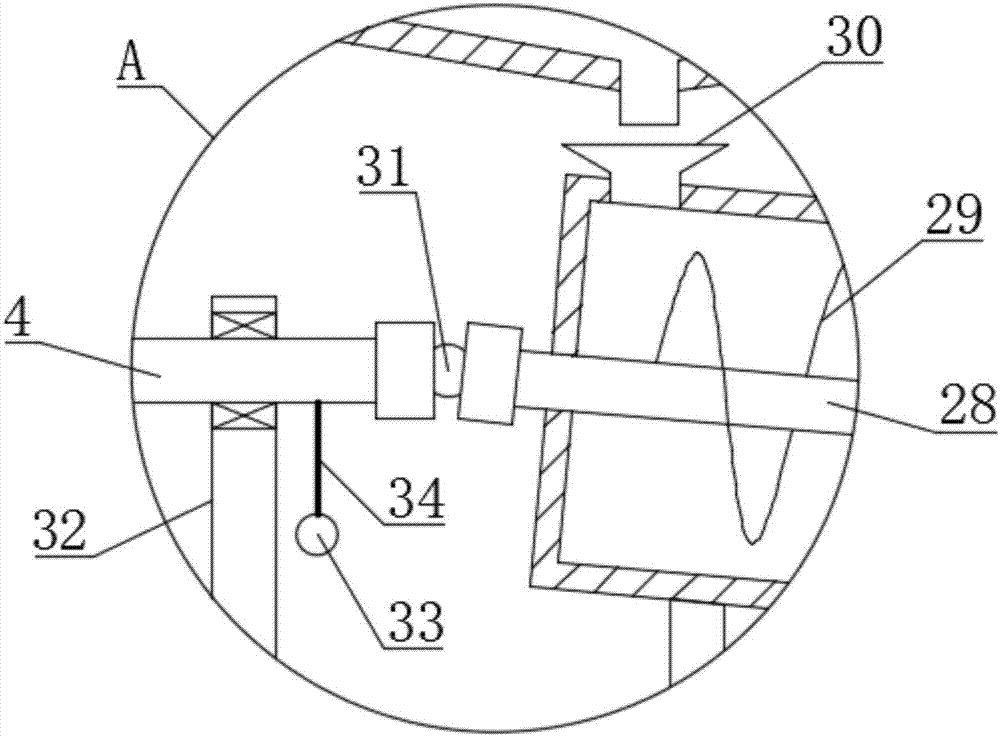

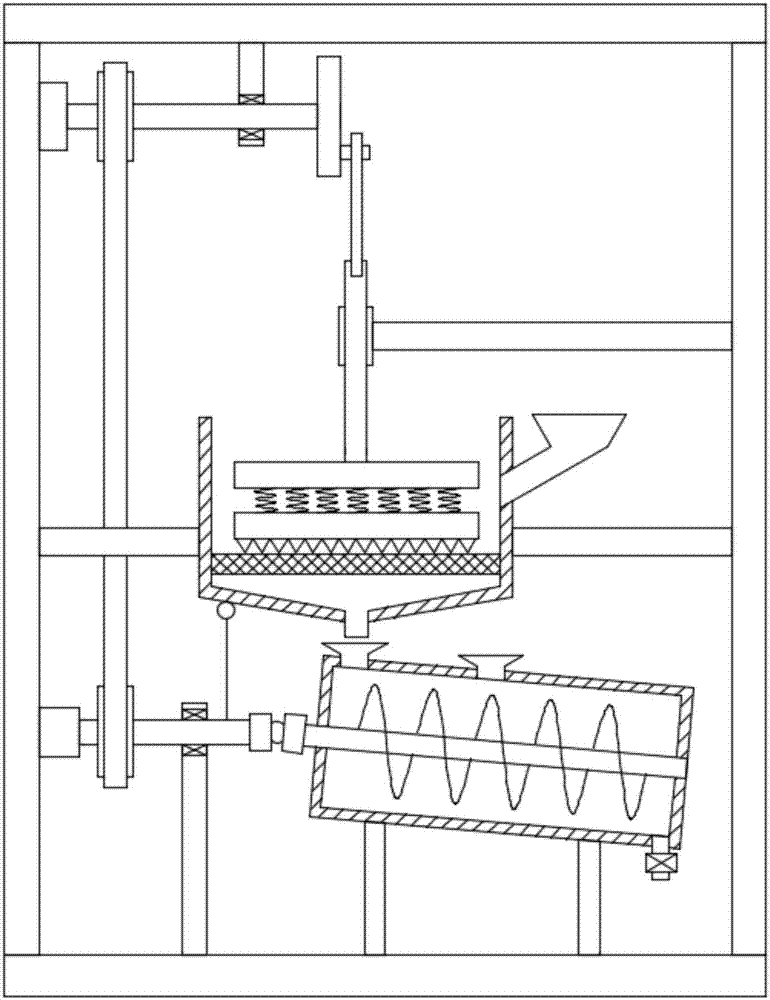

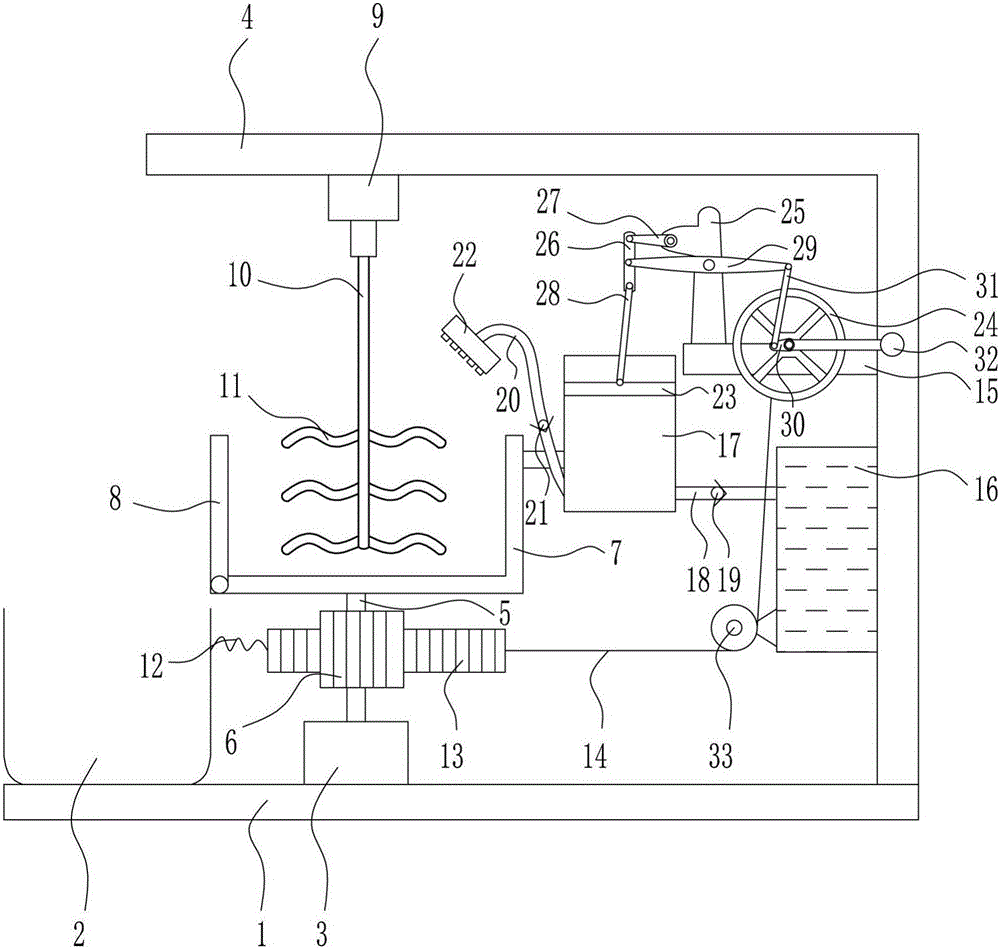

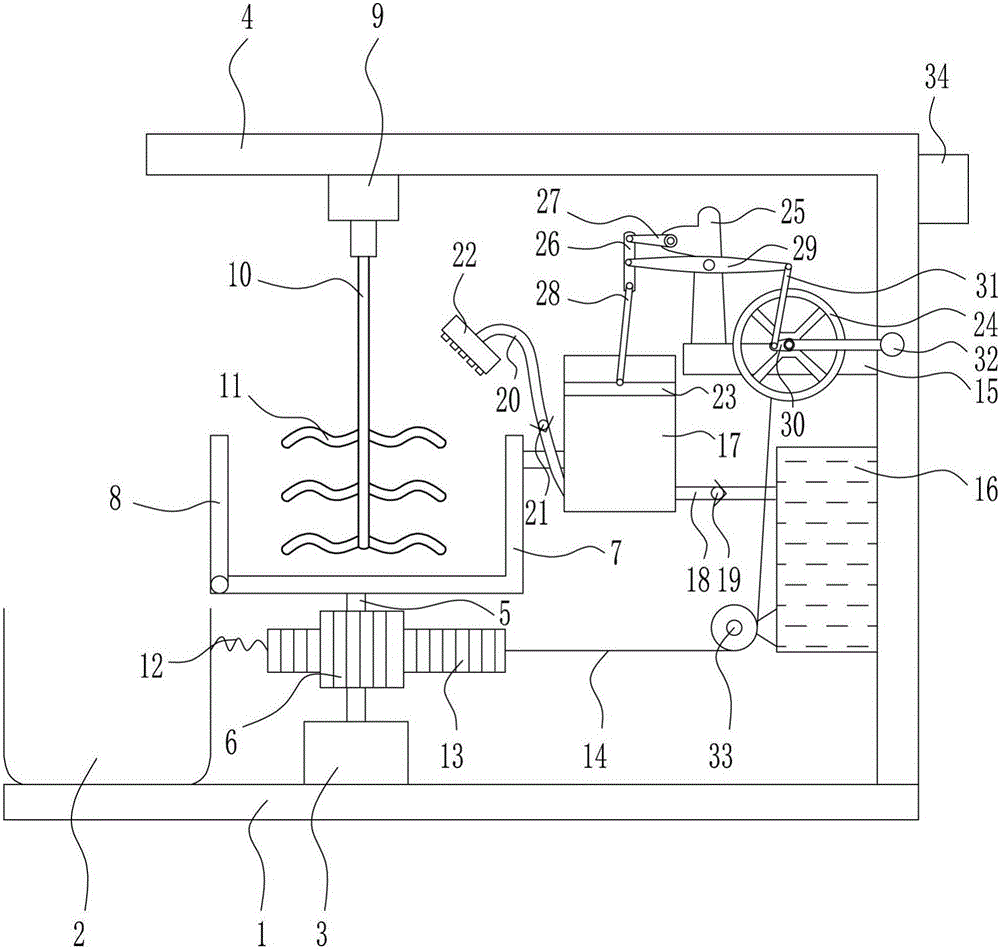

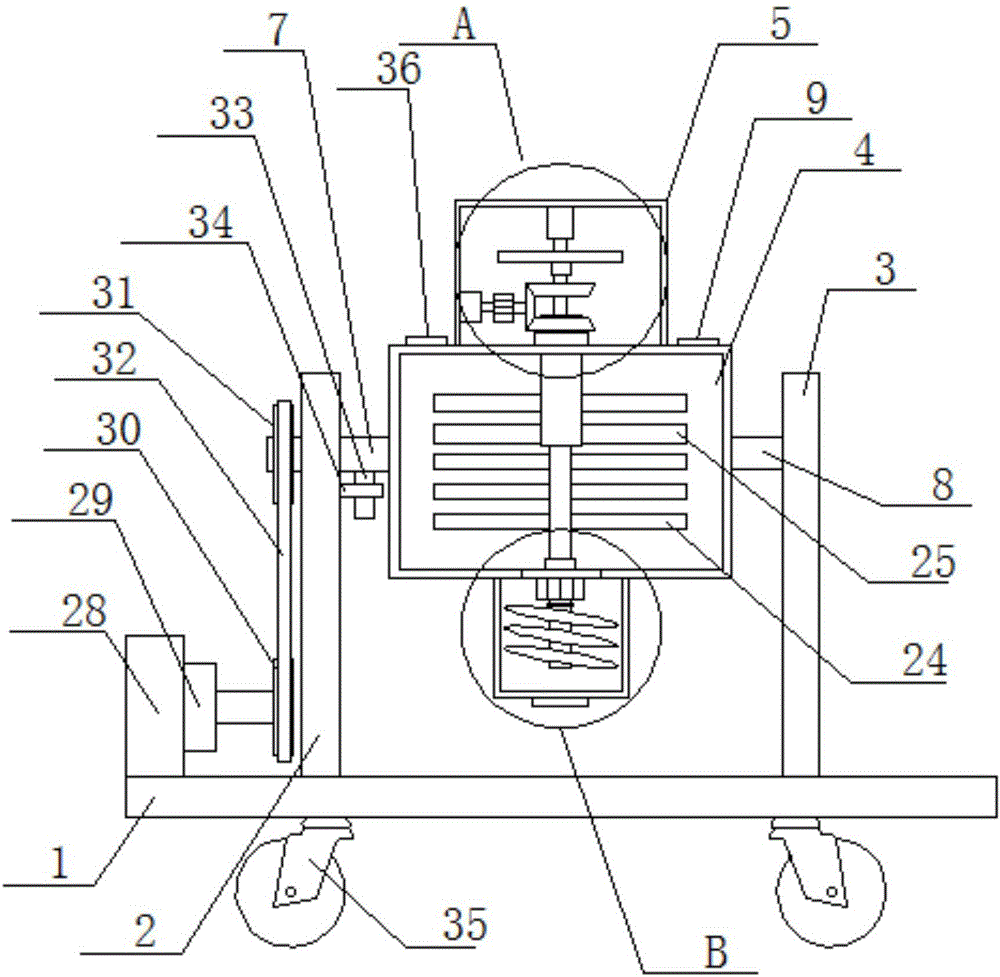

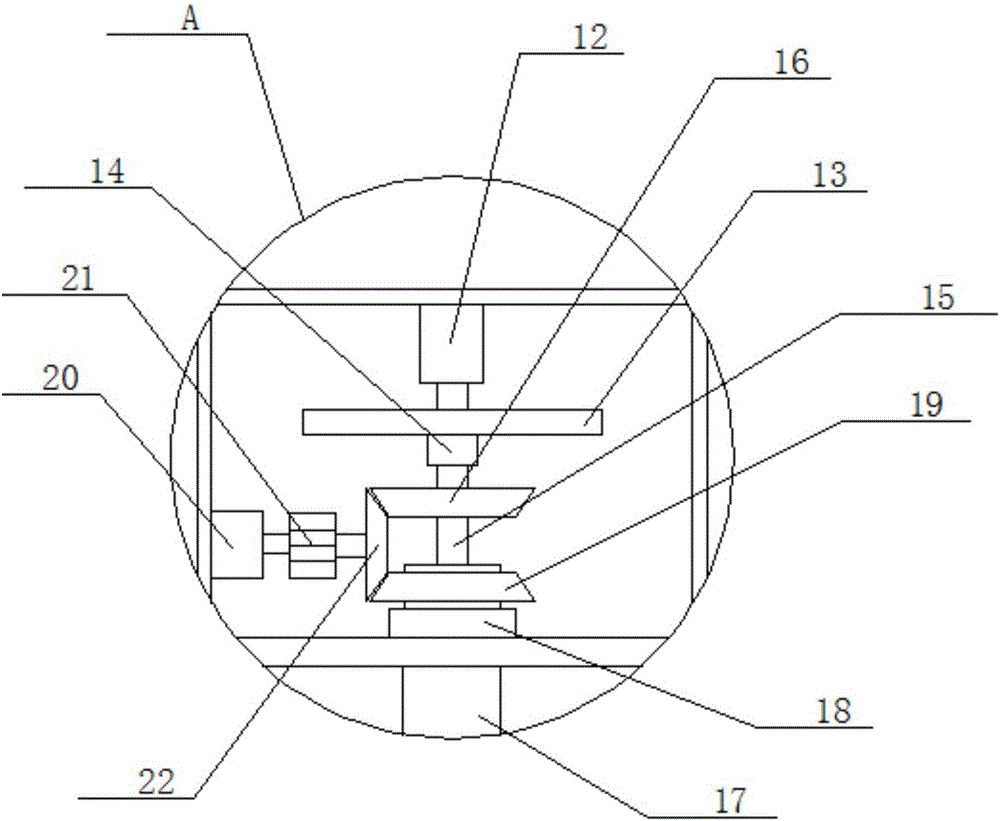

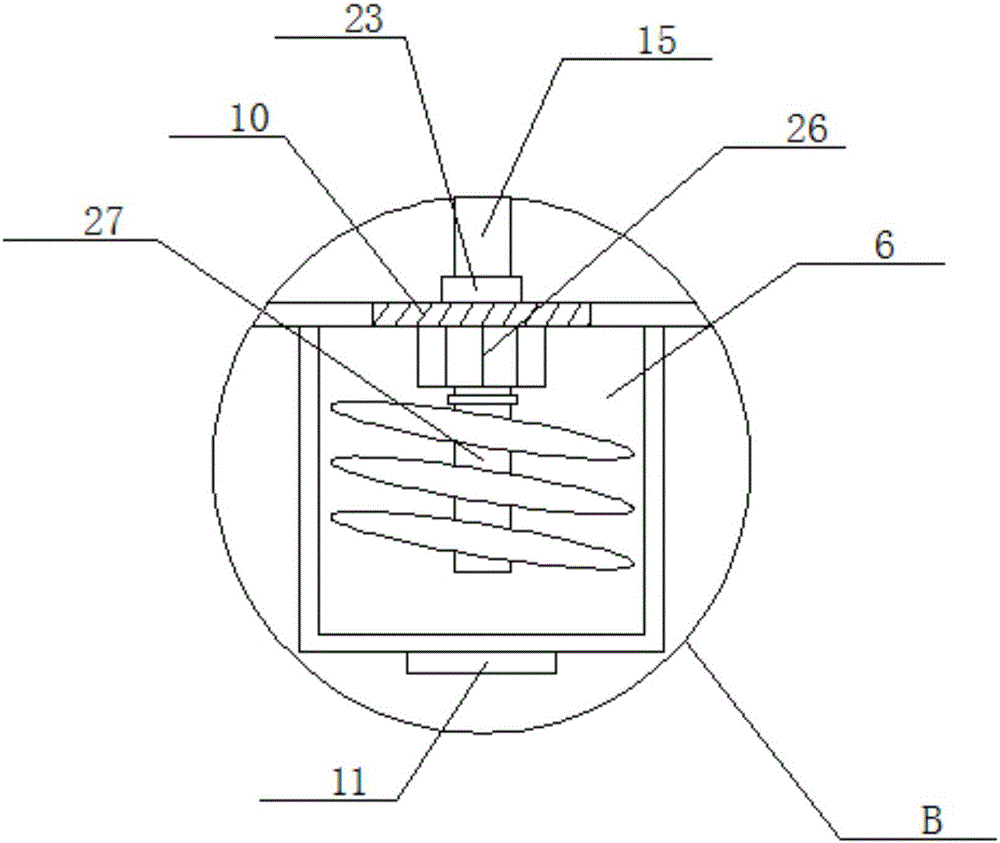

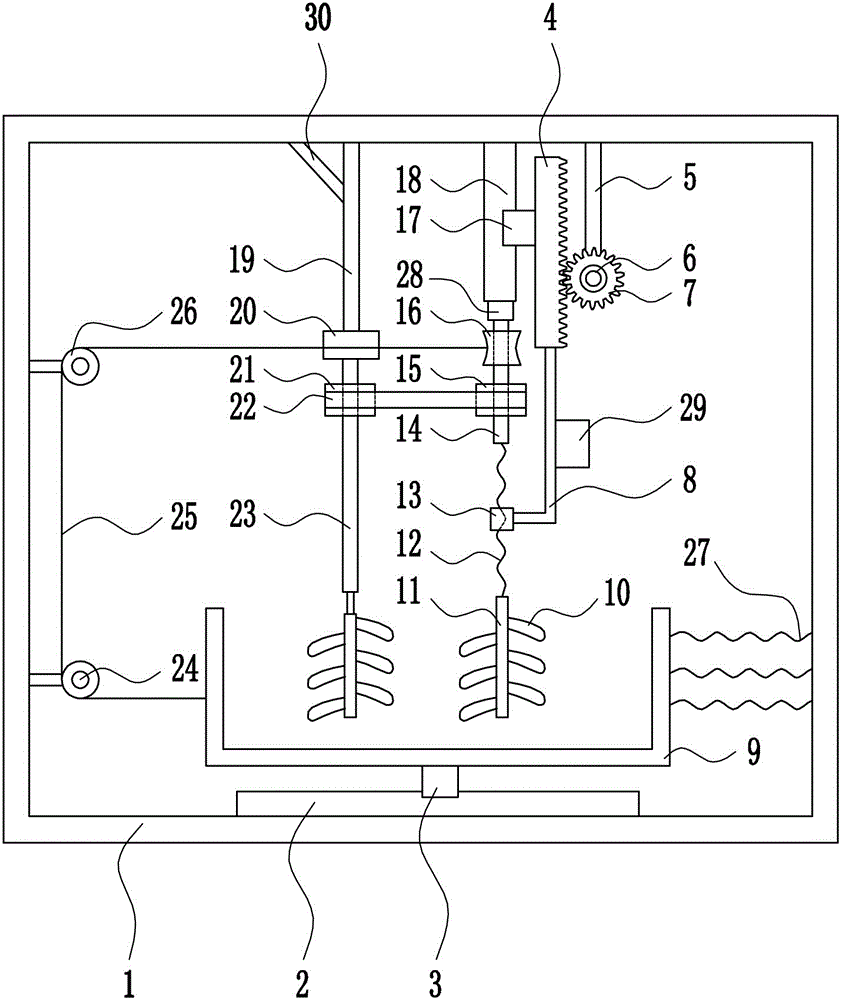

Acid liquor mixing equipment comprises a buffer system, a pipeline mixing pipe system and an output system. The pipeline mixing pipe system is communicated with the buffer system and is used for mixing materials in a pipe and spraying the mixed material to the buffer system. The buffer system is connected with the output system and is used for outputting the stirred mixed material in real time through the output system. Materials are mixed in the pipe through a spraying system, the efficiency of the mixing and stirring process can be improved through one or more of a spraying mixer, a three-way mixer, a static mixer, a rotational flow mixer and the like, rapid stirring and mixing can be achieved, and prepared acid liquor is output in real time through the output system connected with a stirring system. Through the connection of the pipeline mixing pipe system, the stirring system and the output system, the two processes of acid liquor preparation and acid liquor output can be continuously carried out, and the production efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

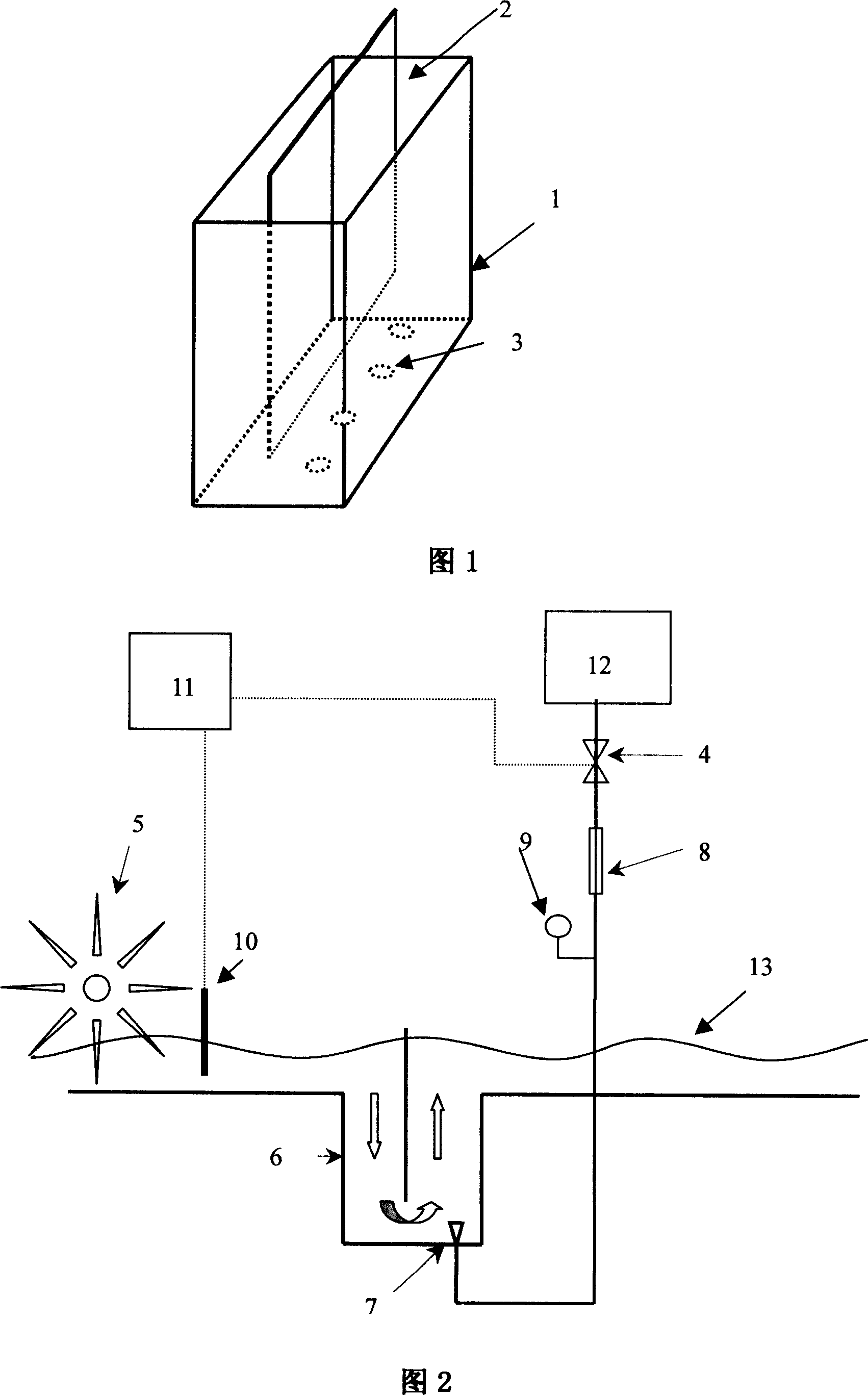

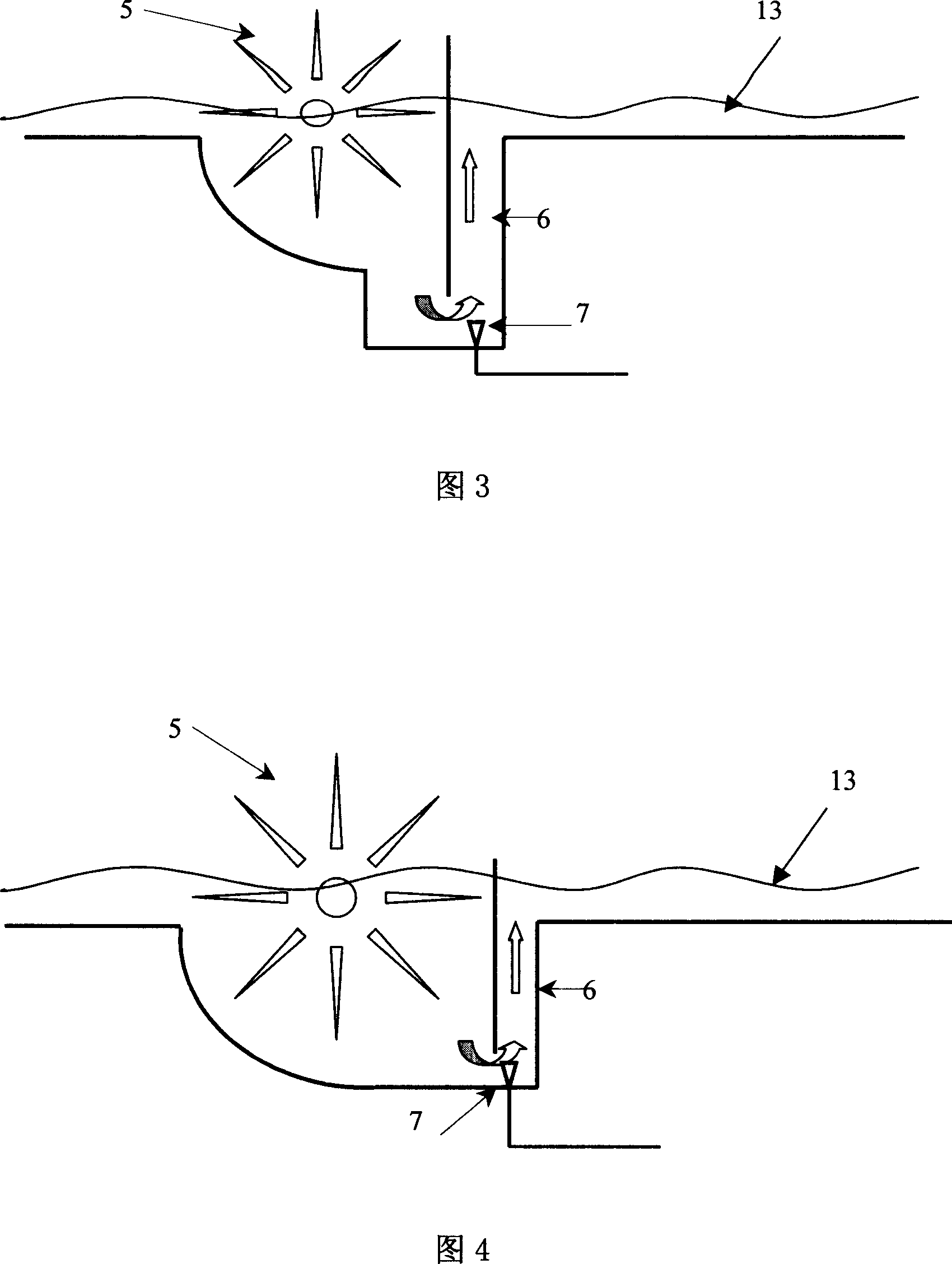

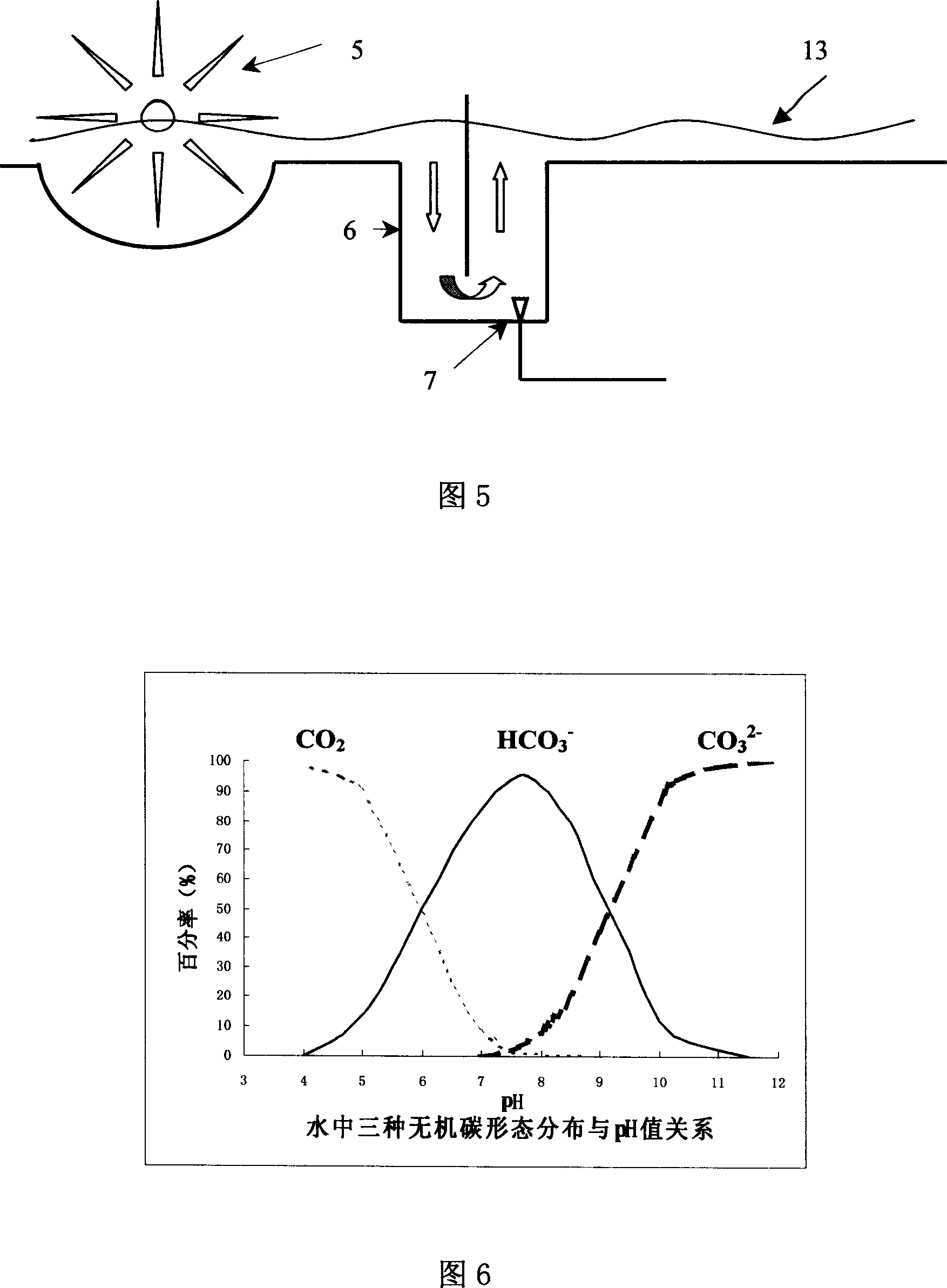

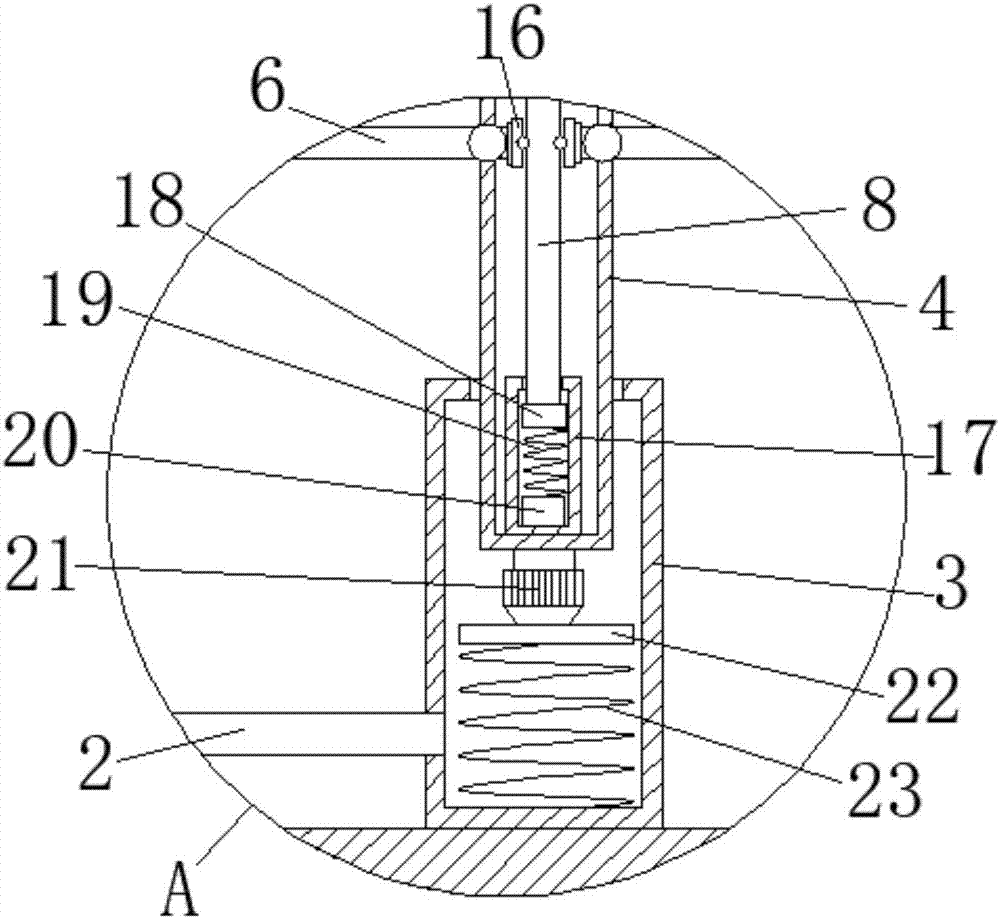

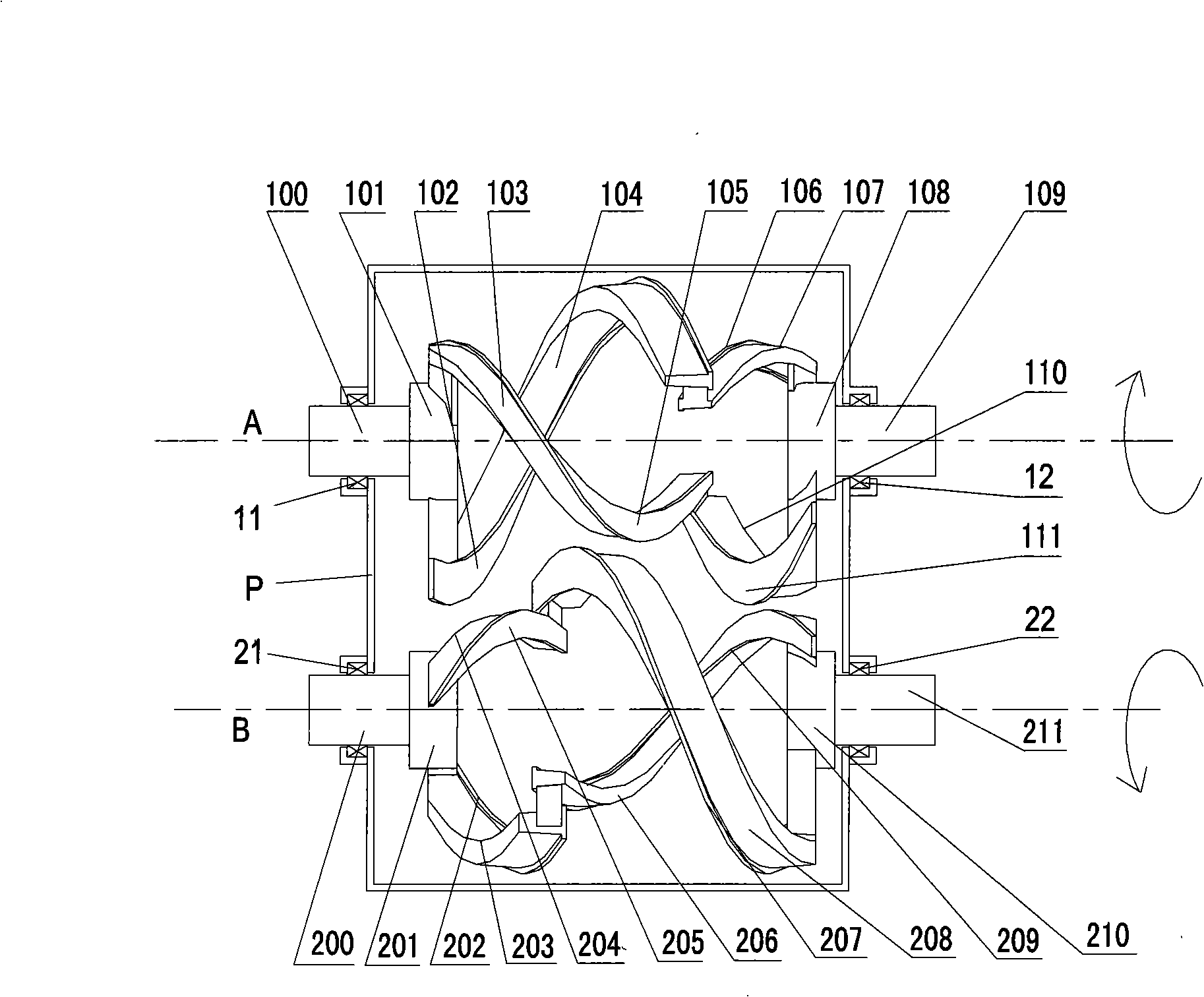

Carbon compensator for large-scale culturing micro-algae, its utilization and use

InactiveCN1982432AIncrease profitReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsVapor liquidContact time

A carbon supplementing apparatus for supplying carbon dioxide efficiently in micro-algae culturing tank, its usage and use are disclosed. A vertical baffle plate is installed above in the container with 10-50 cm gap, gas distributor is arrange at bottom of tank, the apparatus is built-in the bottom of tank, whose upper edge is aligned with the tank bottom, baffler plate is above culturing level of tank so as to pass culturing fluid to the apparatus with agitator driven. It has longer vapor-liquid contact time, more vapor-liquid contact area and higher carbon dioxide efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

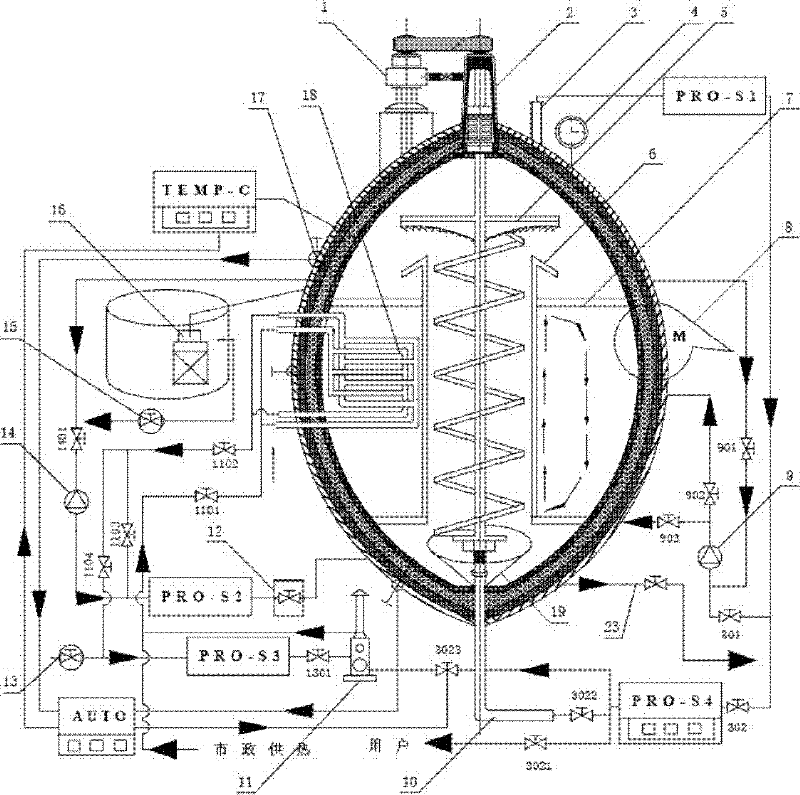

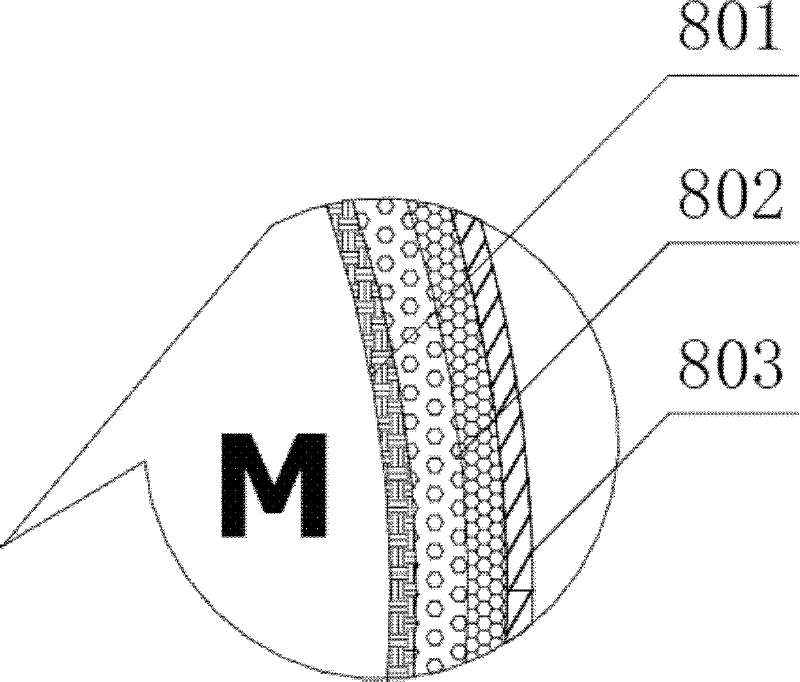

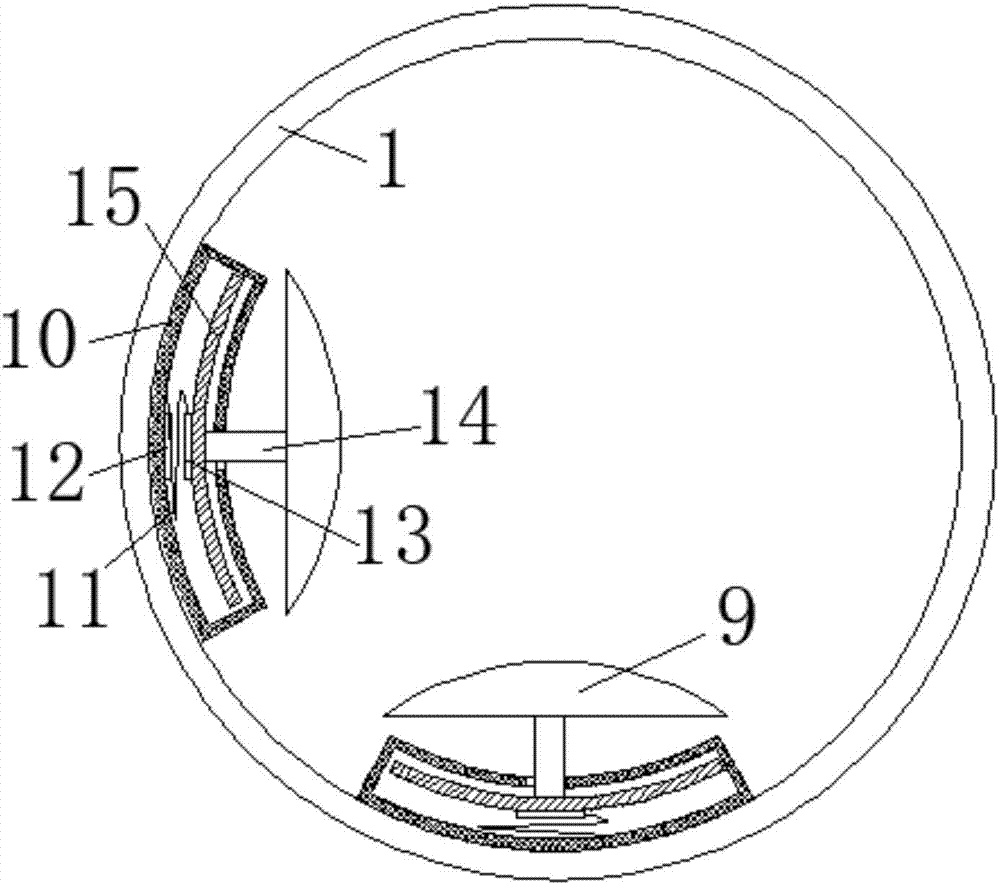

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

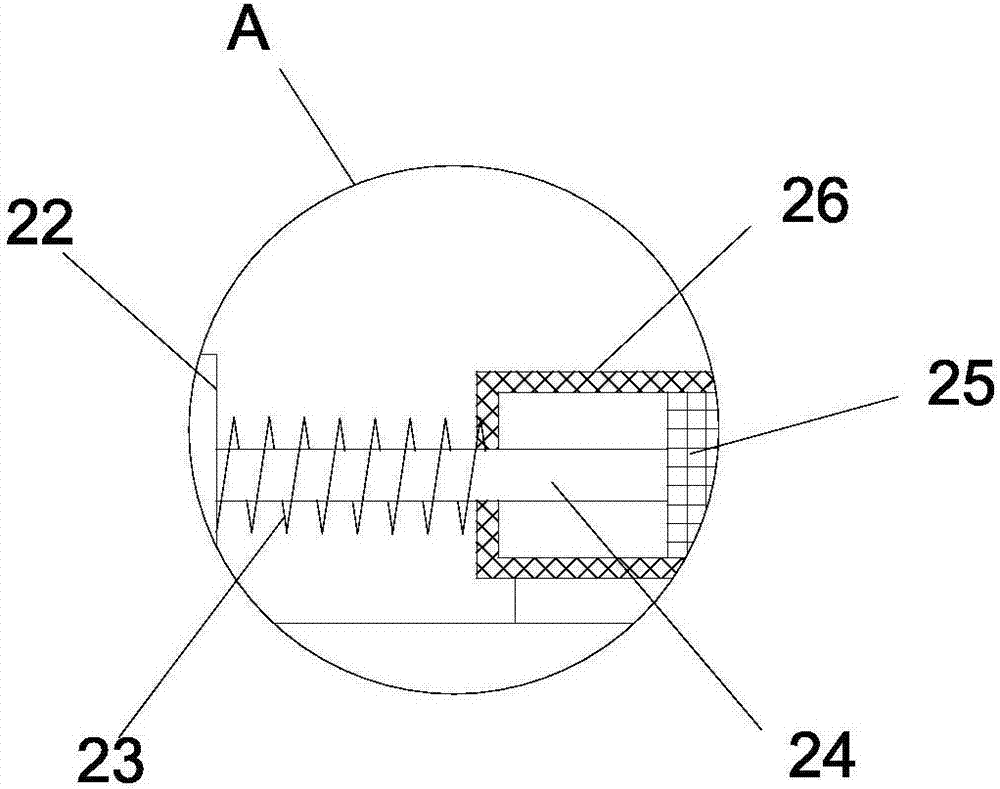

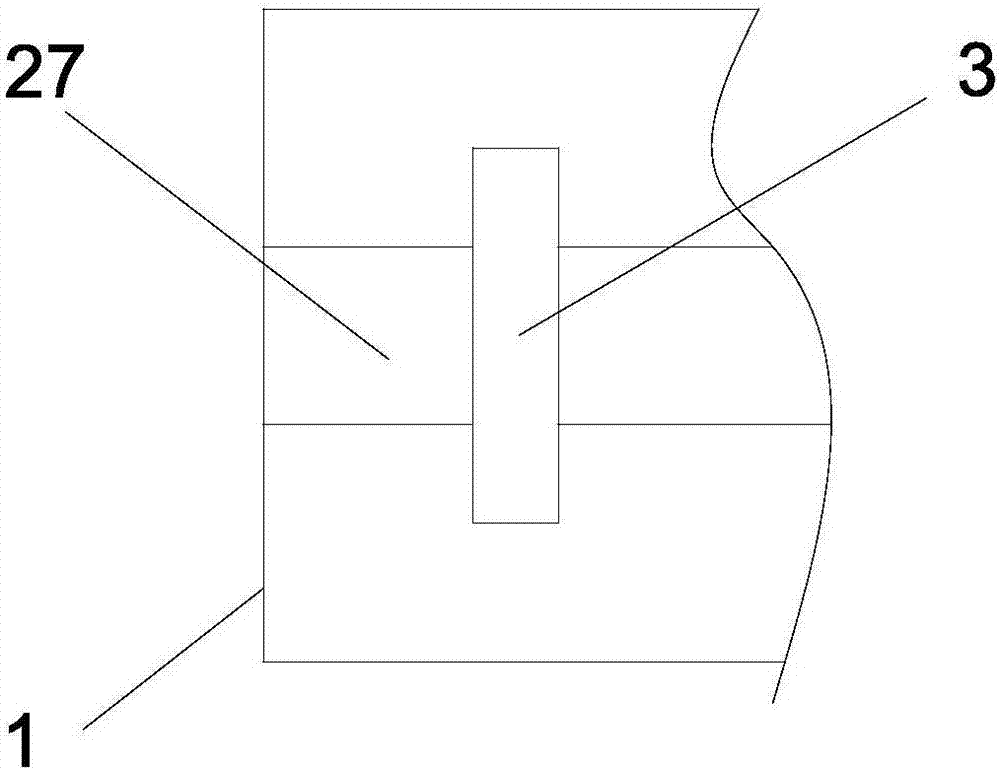

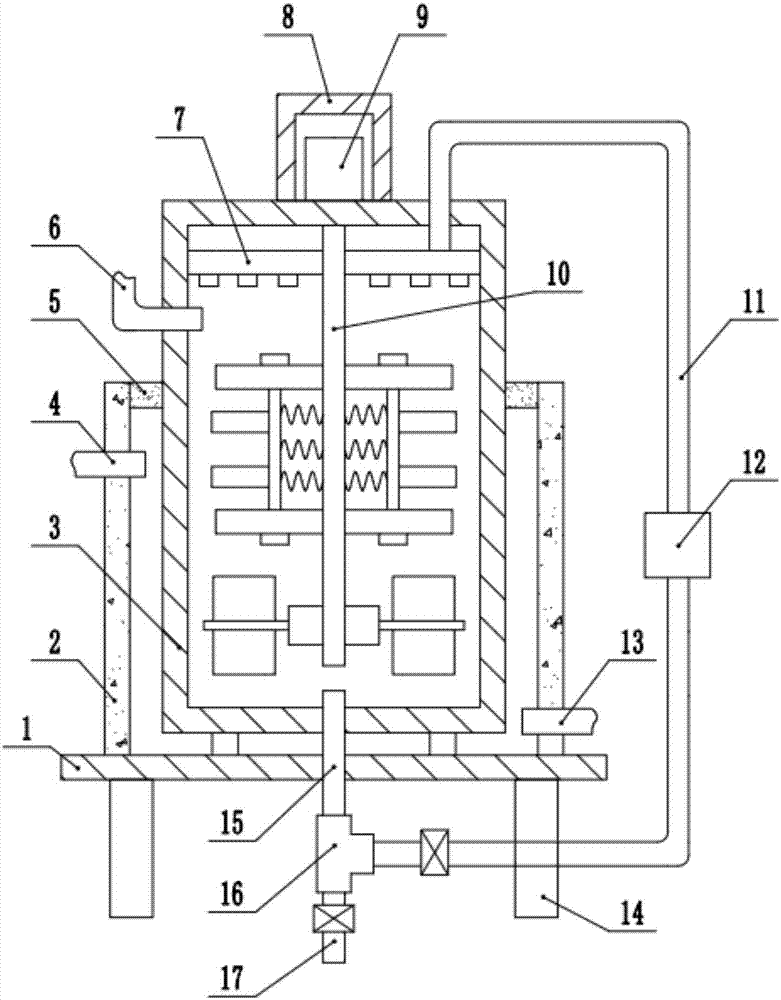

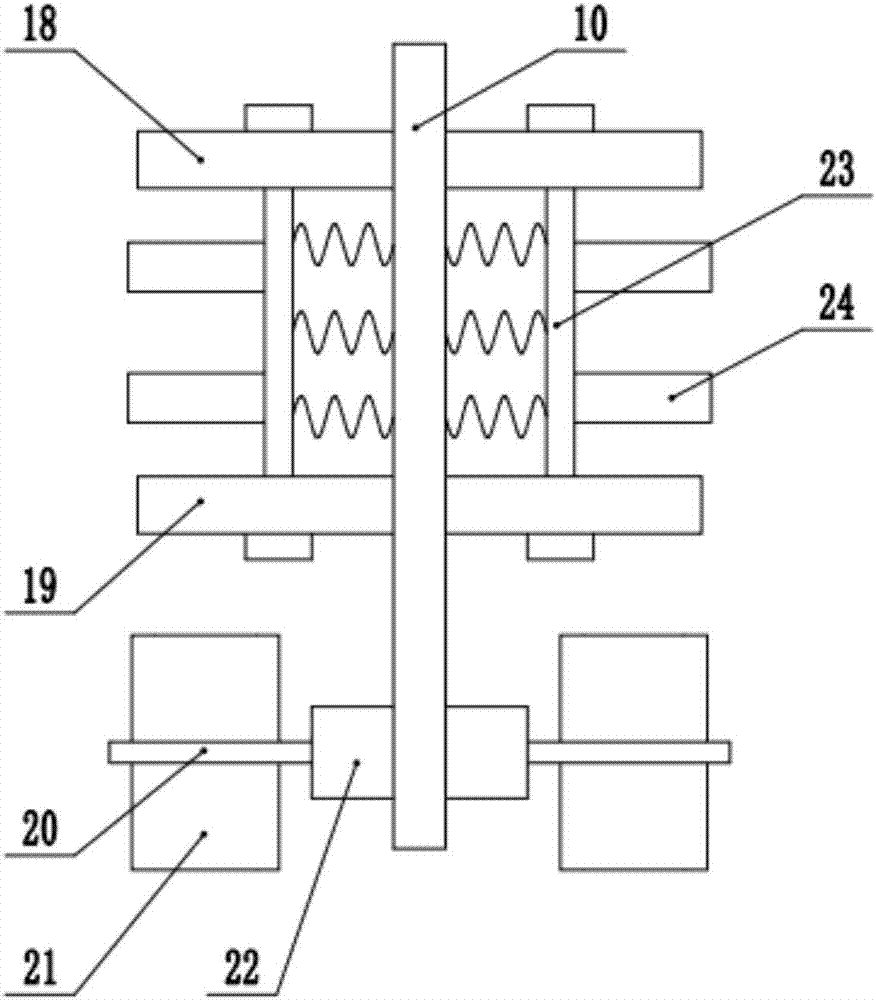

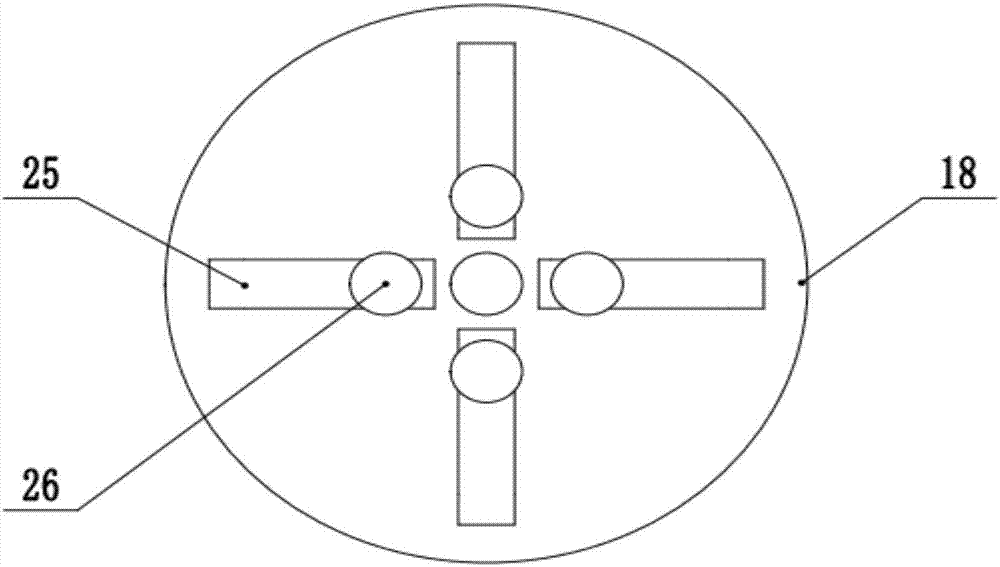

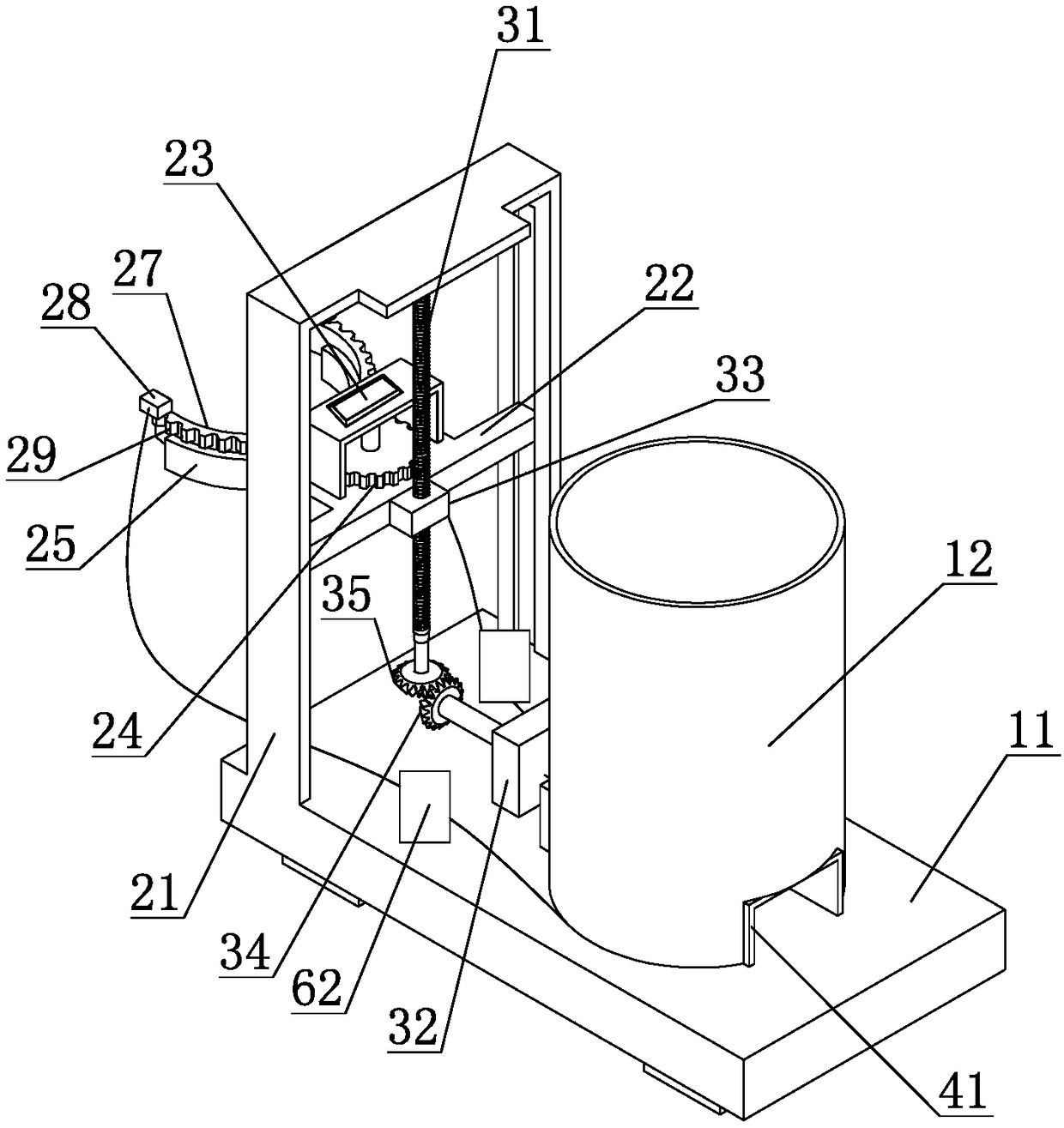

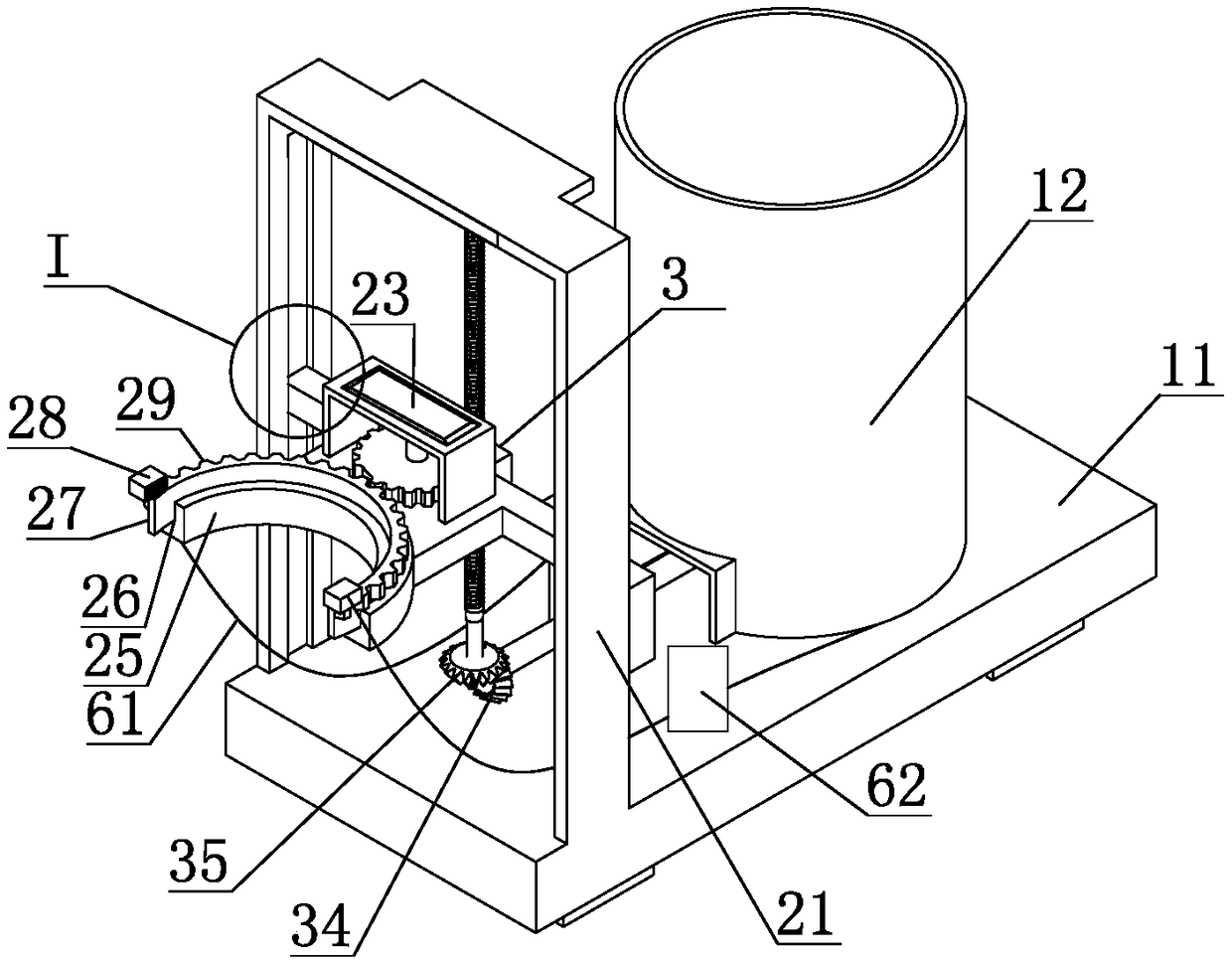

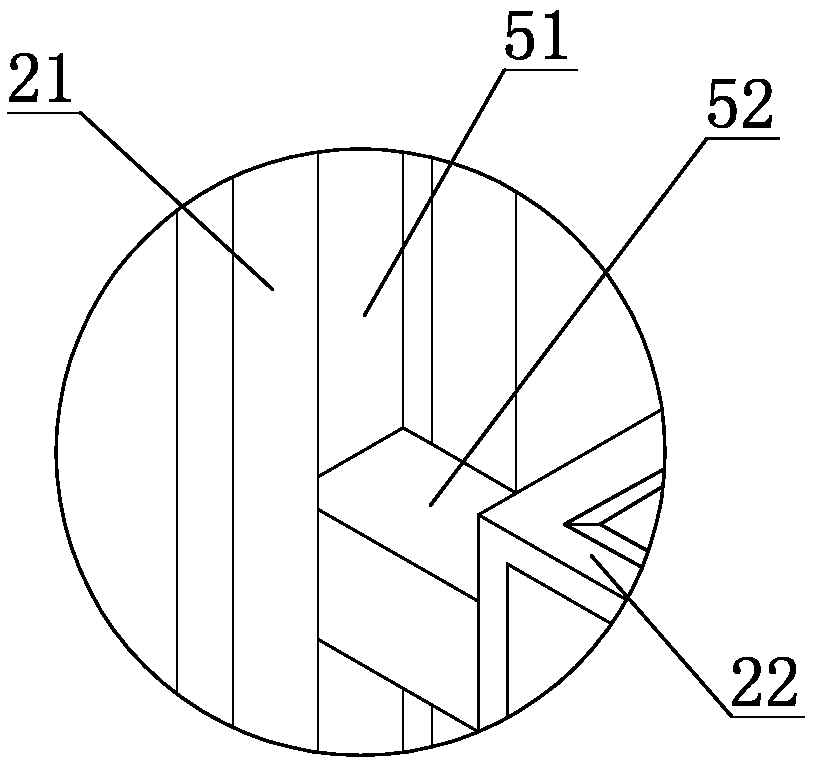

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

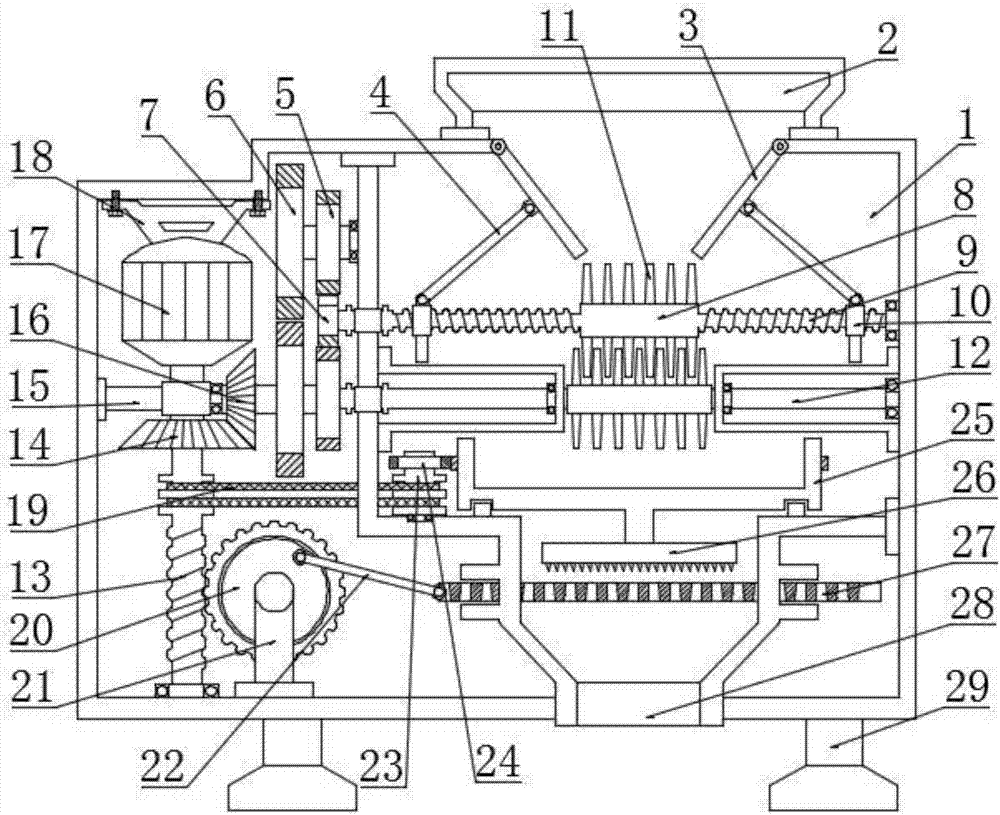

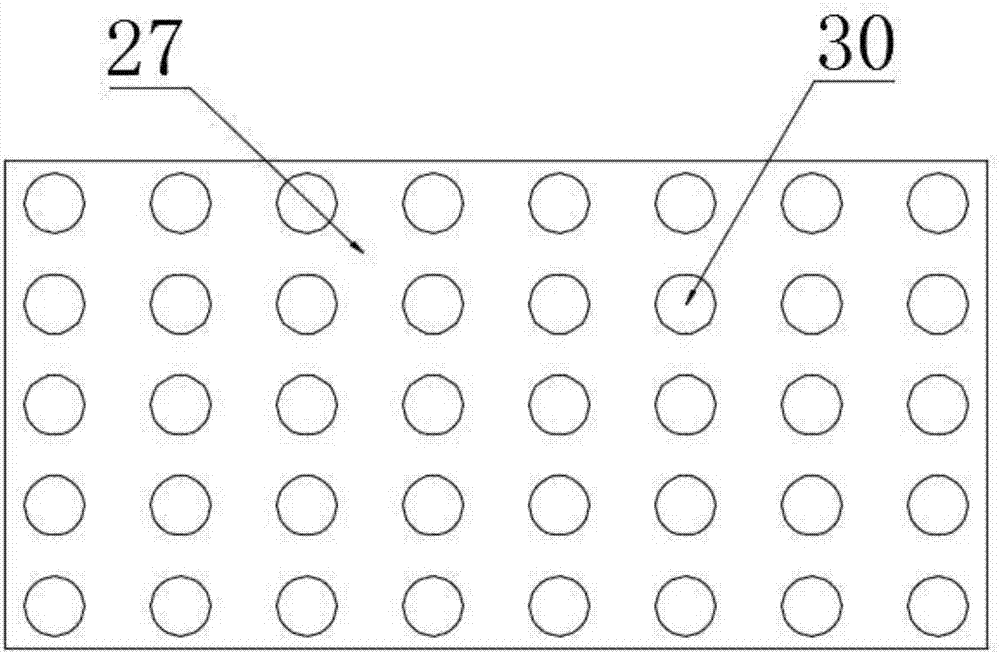

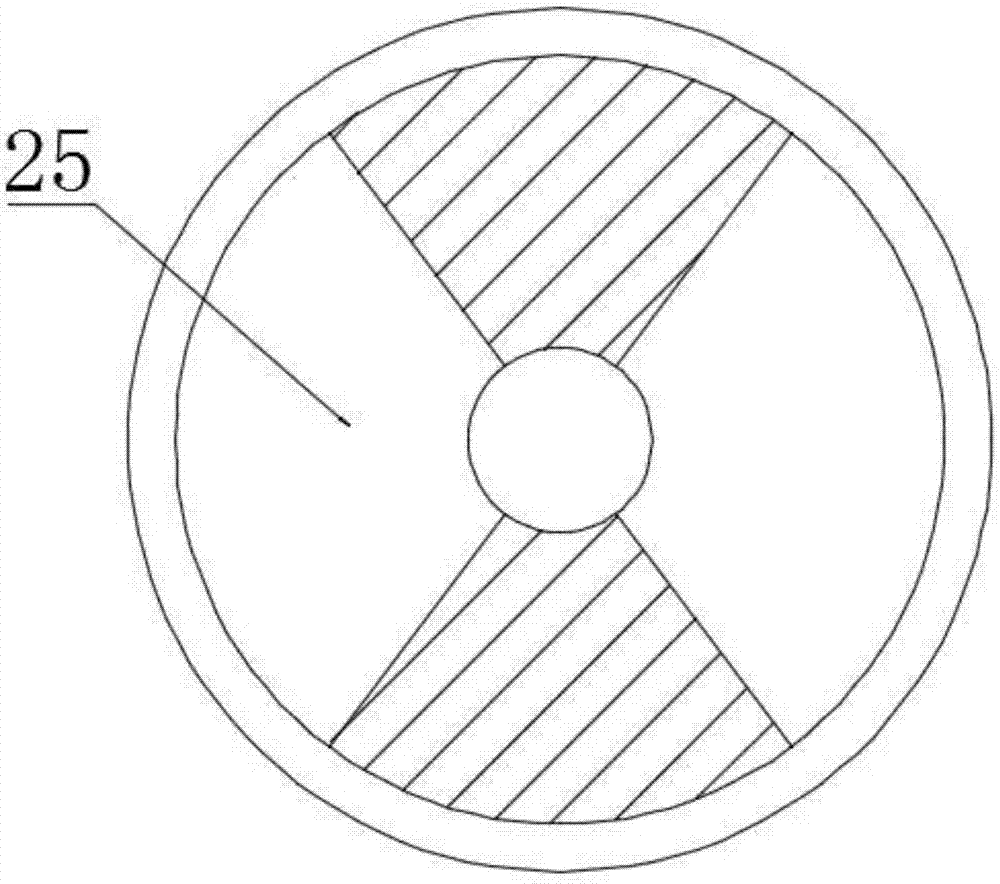

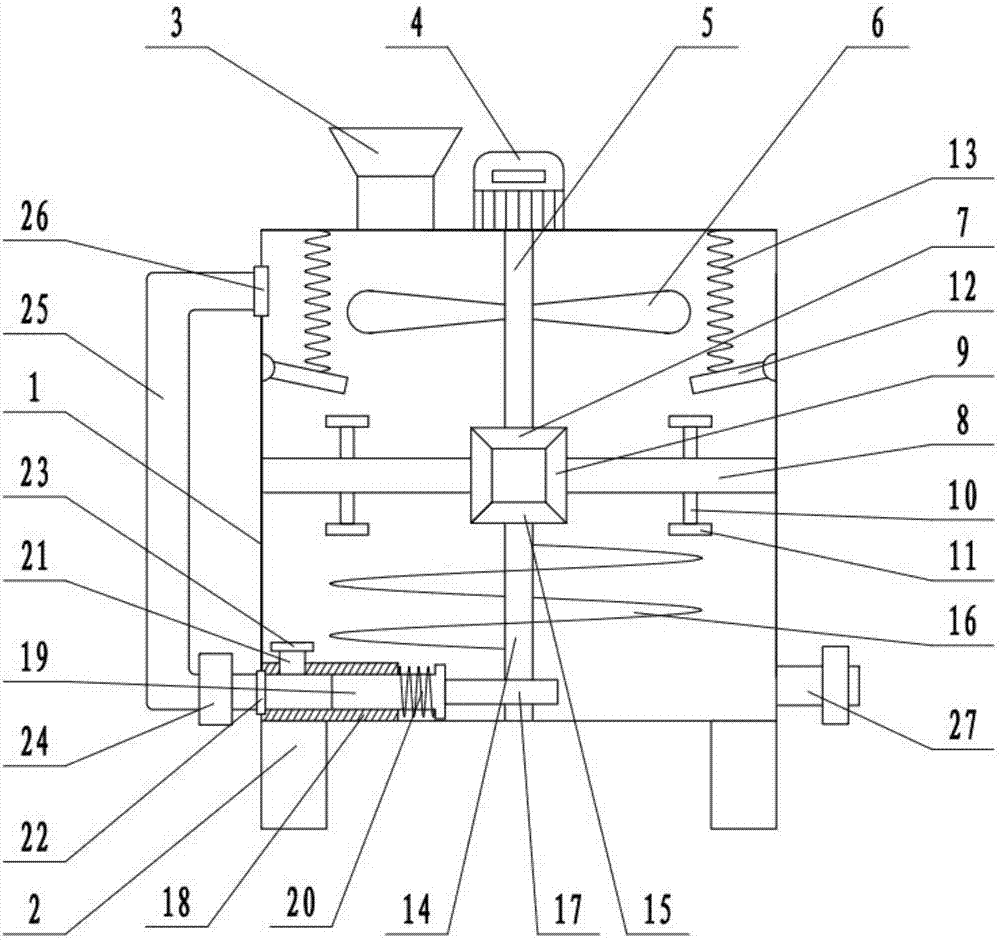

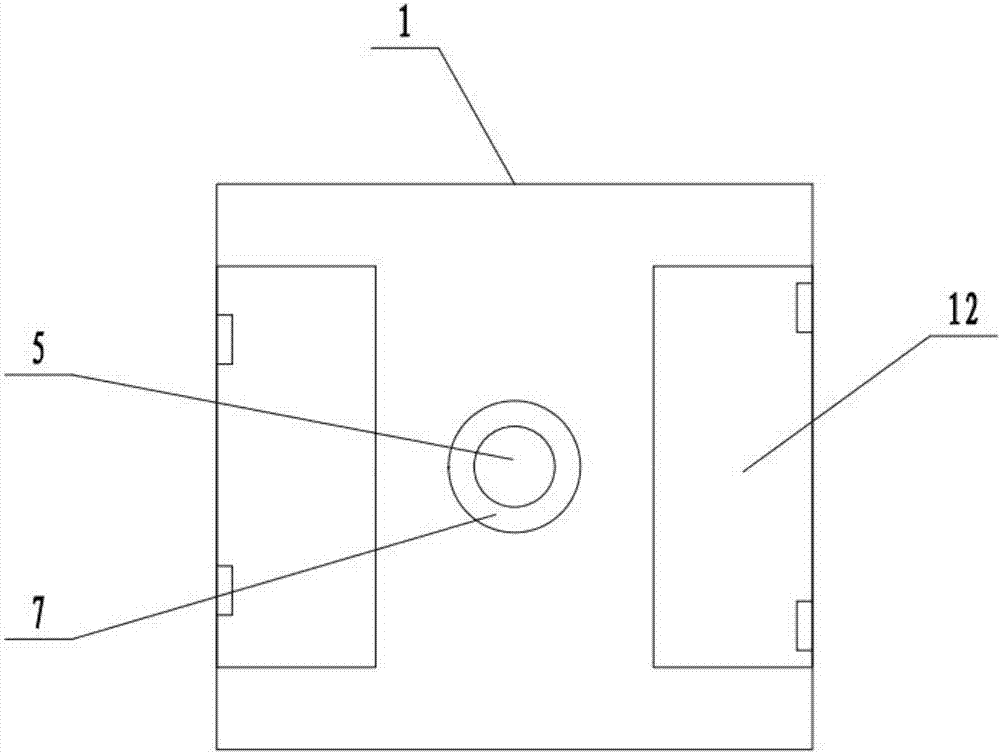

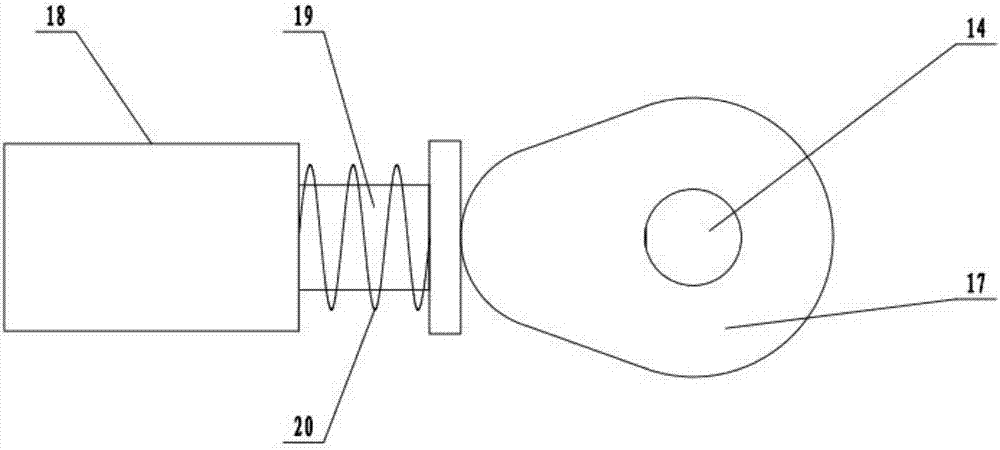

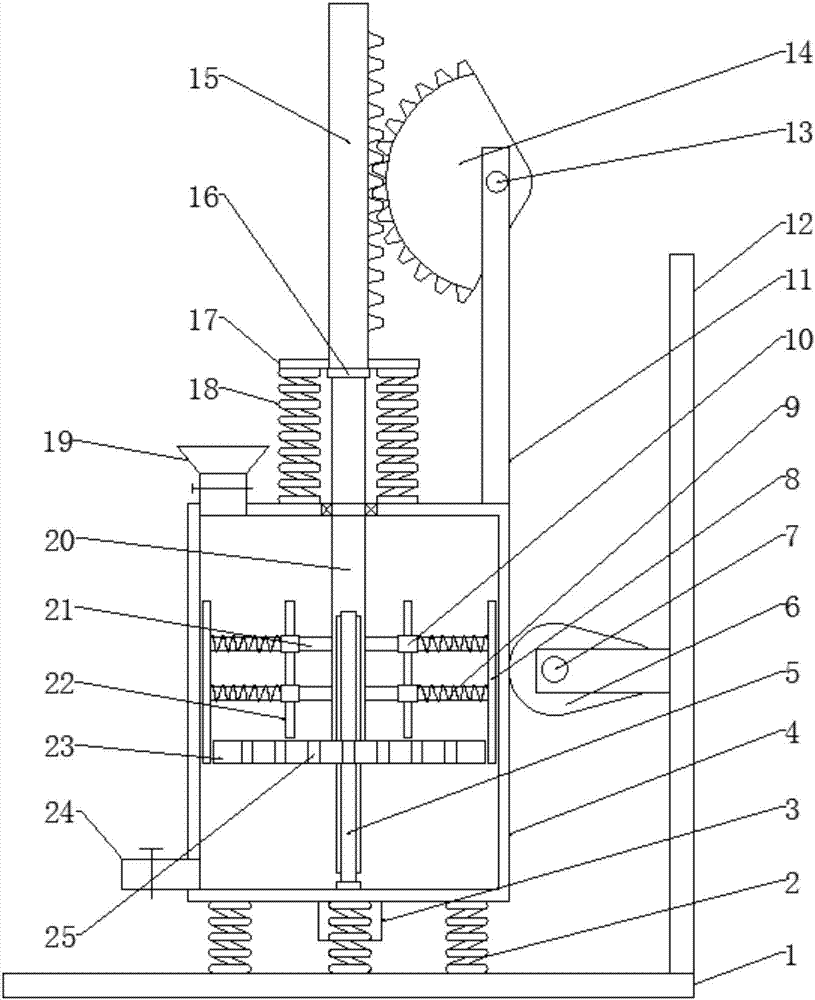

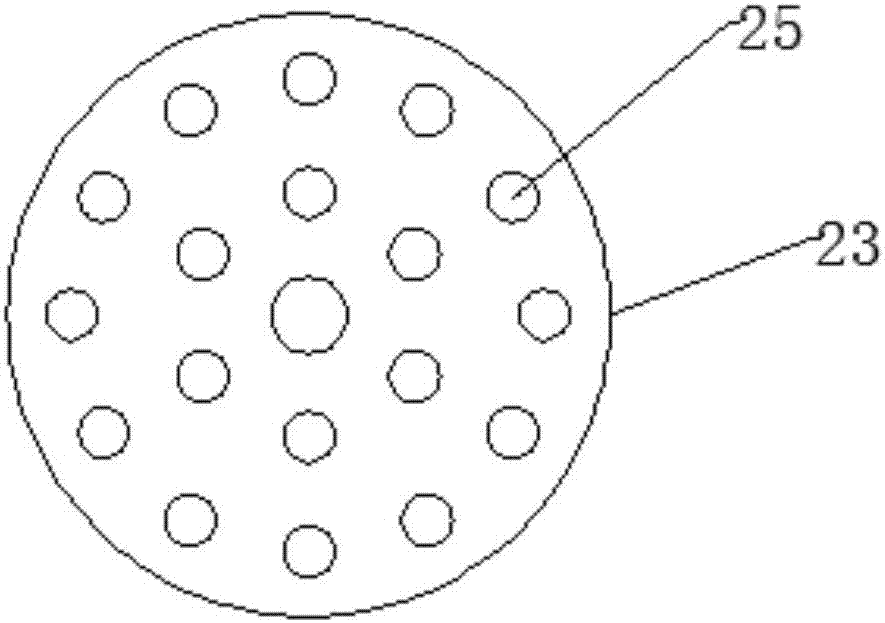

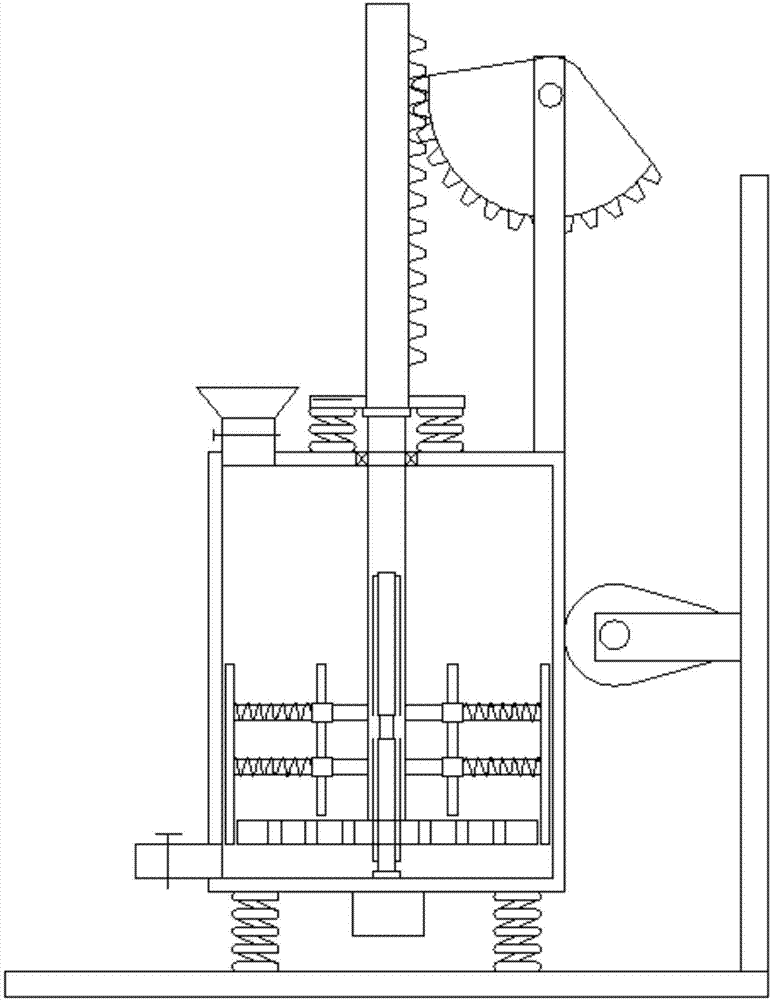

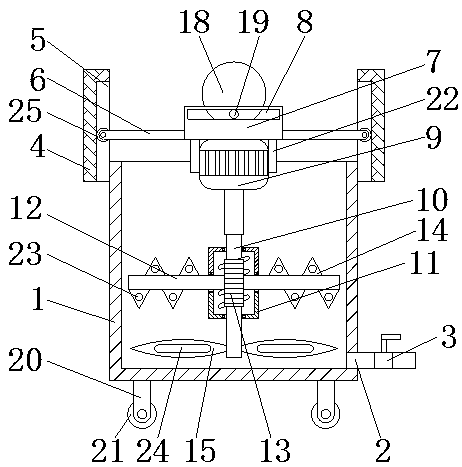

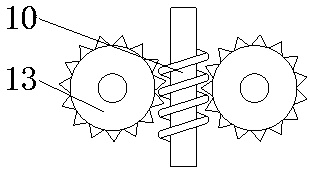

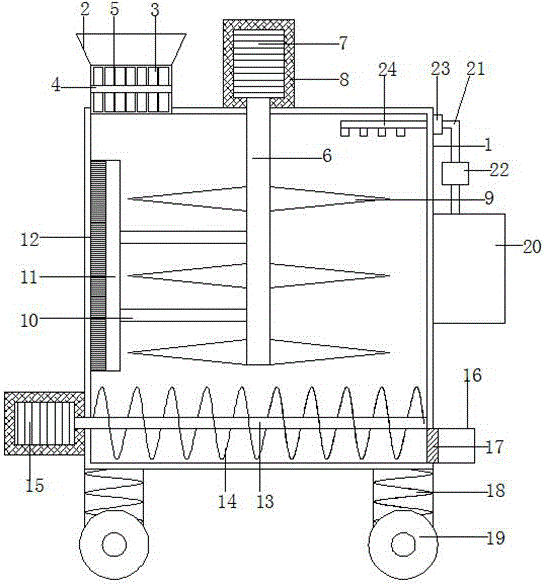

Efficient agricultural fertilizer stirring and crushing device

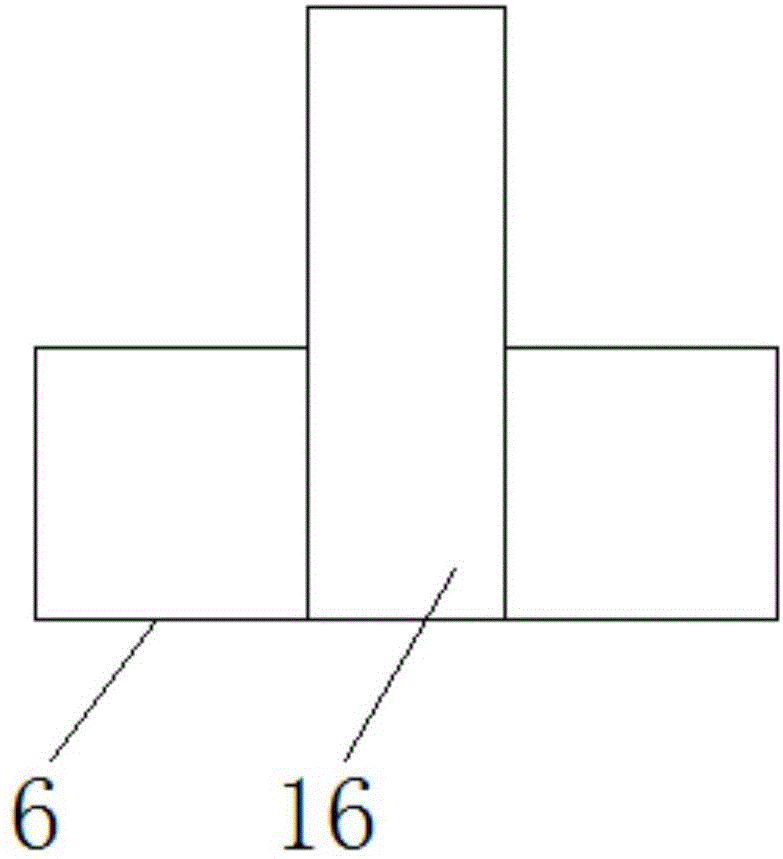

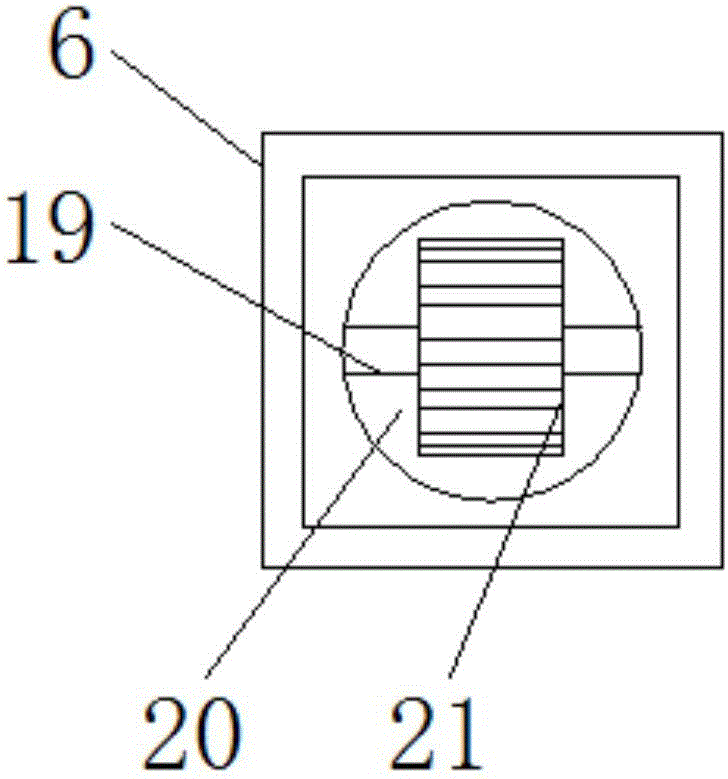

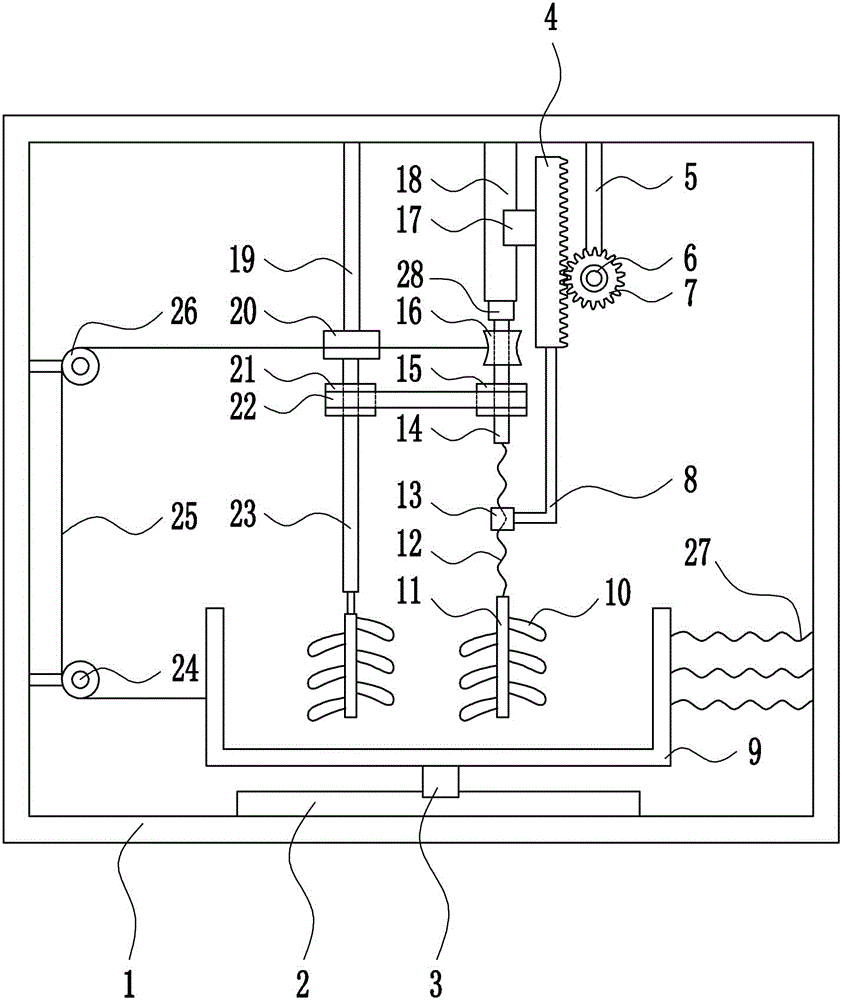

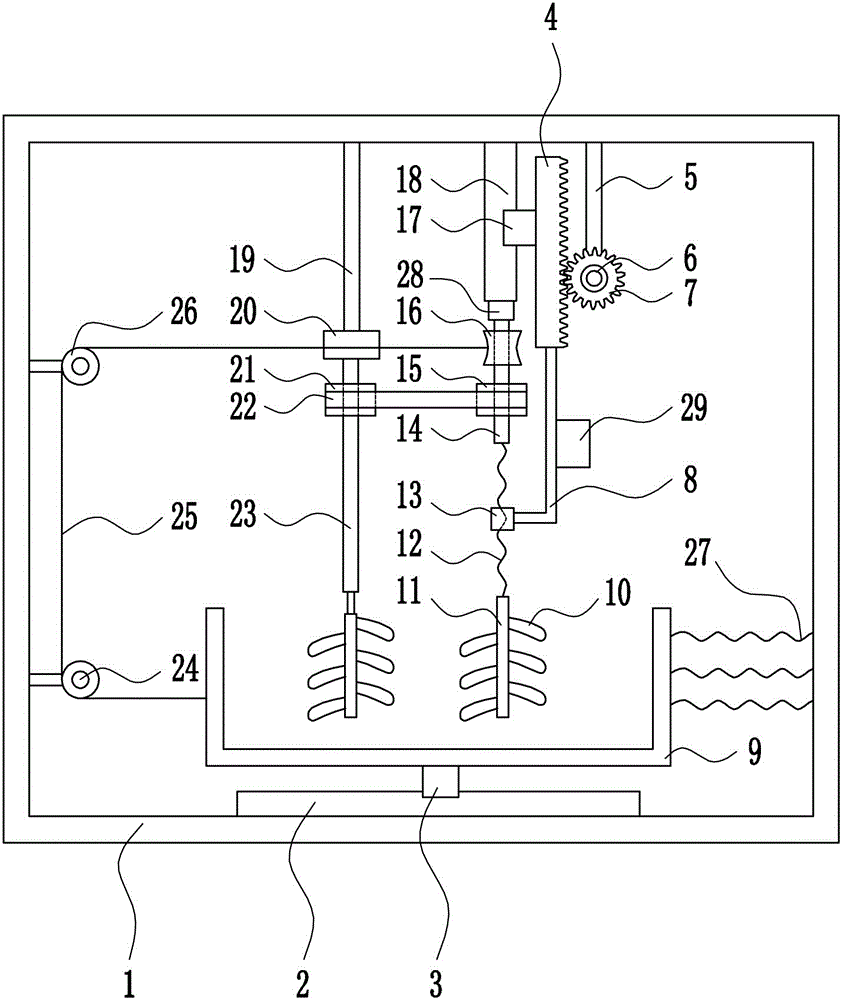

InactiveCN107486295AImprove crushing efficiencyImprove stirring efficiencyTransportation and packagingMixer accessoriesDrive shaftGear wheel

The invention discloses an efficient agricultural fertilizer stirring and crushing device. A feeding inlet is fixedly connected to the upper end of a device body, movable partition plates are arranged at the lower end of the feeding inlet and hinged to the device body, the middle of the lower portion of each movable partition plate is hinged to the upper end of a supporting rod, the lower end of each supporting rod is hinged to a threaded sliding block, a two-way threaded rod is connected to the threaded sliding blocks in a threaded and sleeved manner, and the left end of the threaded sliding block is fixedly connected with a semicircular gear; and the upper end and the lower end of each semicircular gear are each intermittently meshed with a pinion, the pinions at the upper ends are rotationally connected with the device body, the pinions at the lower ends are fixedly connected with a driven shaft, the left end of each pinion is fixedly connected with a big gear wheel, and the left end of the driven shaft is fixedly connected with a second bevel gear. According to the efficient agricultural fertilizer stirring and crushing device, a bevel gear set is used for driving the semicircular gears to rotate positively or negatively, and then the two-way threaded rod is driven to rotate positively or negatively along with the semicircular gears; and the two-way threaded rod drives the threaded sliding blocks to move left and right to control intermittent feeding of the movable partition plates at the same time of driving a stirring roller to achieve stirring crushing. The device is simple and practical in structure, and the crushing and stirring efficiency of fertilizers are greatly improved.

Owner:田楷

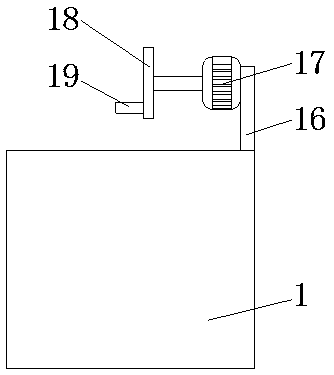

Self-circulating type coating stirring device for architectures

InactiveCN107308834AStir wellImprove stirring efficiencyShaking/oscillating/vibrating mixersFlow mixersHelical bladeInner loop

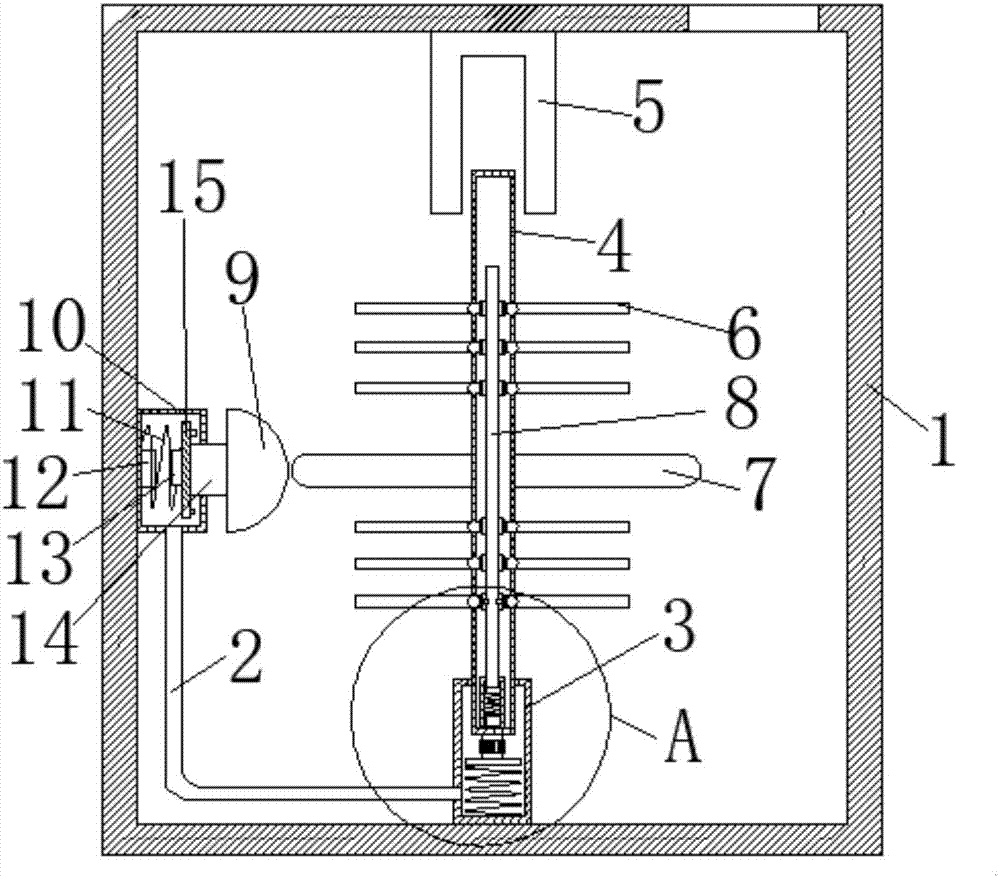

The invention discloses a self-circulating type coating stirring device for architectures. The self-circulating type coating stirring device comprises a tank body, support legs, a feeding opening, stirring blades, a helical blade and a discharging opening, wherein a motor is fixedly connected to an upper surface of the tank body; an upper rotating shaft penetrates through a top part of the tank body and deepens into the tank body; side rotating shafts are respectively arranged at a left side and a right side of the upper rotating shaft; a lower rotating shaft is arranged on a lower part of the upper rotating shaft; the helical blade is fixedly connected to the lower rotating shaft; a cam is arranged at a tail end of the lower rotating shaft in a sleeving manner; a sleeve is fixedly connected to a bottom part of the tank body; a piston cylinder is arranged inside the sleeve; a right end of the piston cylinder is pressed against the cam; a circulating pipeline is mounted on a side wall of the tank body; the coatings are poured into the tank body, an upper layer of coatings are stirred by utilizing the stirring blades, and a permanent magnet rotates continuously; when the permanent magnet is relatively close to a movable plate, the movable plate is attracted to rotate downwards, and when the permanent magnet is away from the movable plate, the movable plate rotates upwards under an effect of a first spring so as to stir the coatings; the coatings are circulated in the tank body, so that a stirring effect is further improved.

Owner:HUIAN WEIKE ELECTRONICS TECH CO LTD

Concrete mortar stirring and mixing device for building construction

InactiveCN107053480AImprove the mixing effectImprove stirring efficiencyCement mixing apparatusLiquid ingredients supply apparatusHelical bladeArchitectural engineering

A concrete mortar mixing device for building construction, including a main body, a mixing bucket is arranged inside the main body, a limit spring is arranged between the mixing bucket and the main body, a number of auxiliary mixing blades and a number of auxiliary mixing blades and a number of Auxiliary cutting blade, the spur rack slides through the body, the left end of the spur rack is fixed with a limit plate, the limit plate is located outside the body, a first return spring is arranged between the limit plate and the body, and a piston is fixedly installed on the body The water-drawing sleeve, the left end of the piston rod is vertically fixed with a piston top plate, the cam is in contact with the right side of the transmission plate, and the cam is in contact with the left side of the piston top plate; the spiral blade arranged at the bottom of the stirring shaft in the present invention will move the bottom of the mixing tank The concrete mortar is turned upwards to make the mixing more complete. Driven by the wire rope, the mixing bucket vibrates up and down, making the concrete mortar shake up and down in the mixing bucket, which promotes the mixing effect of the concrete mortar.

Owner:长沙鼎成新材料科技有限公司

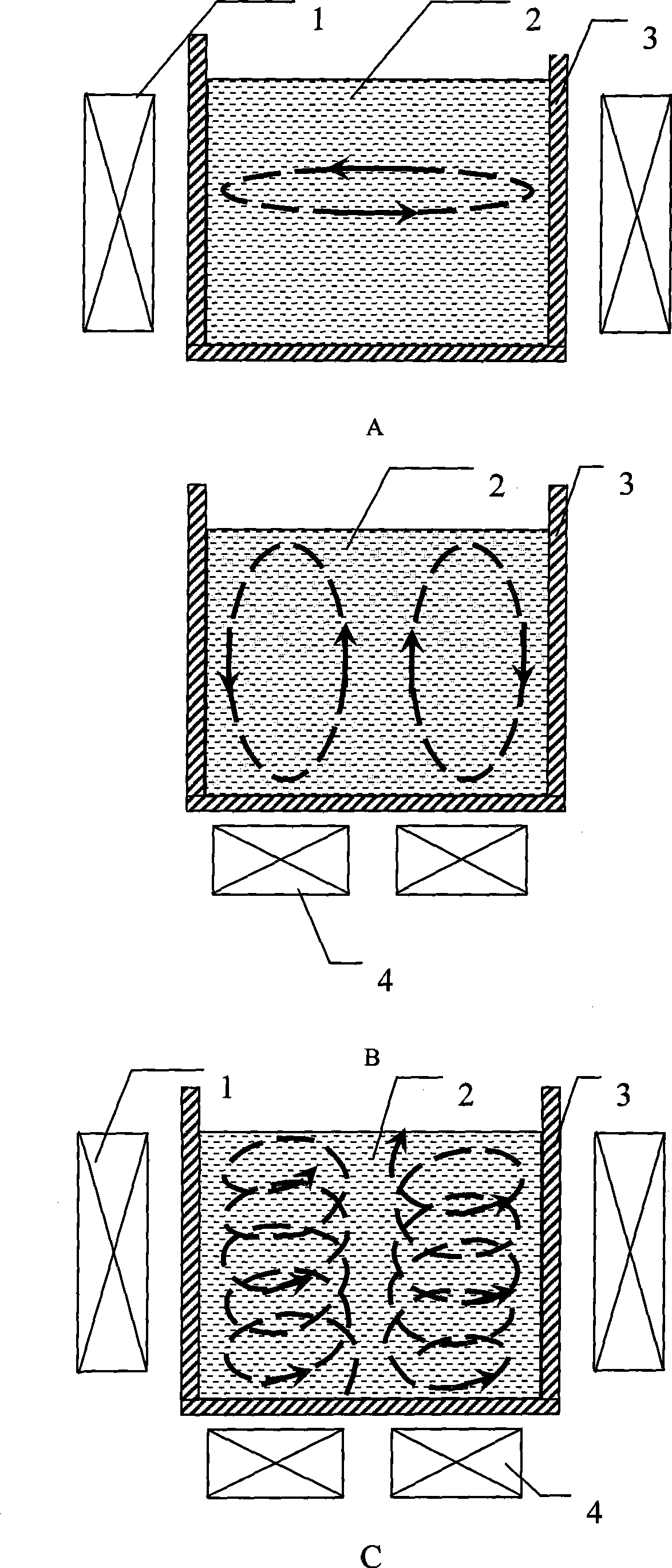

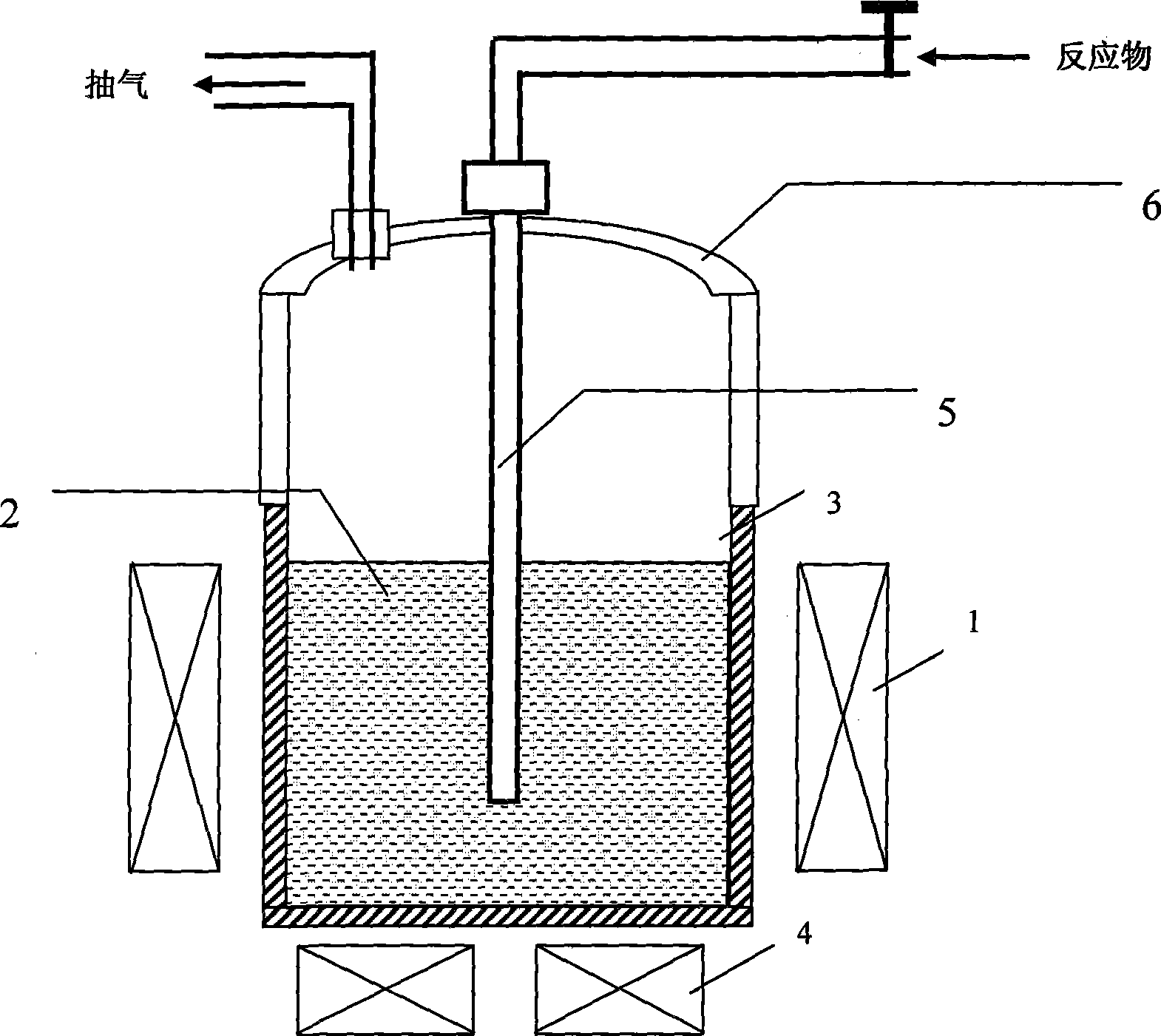

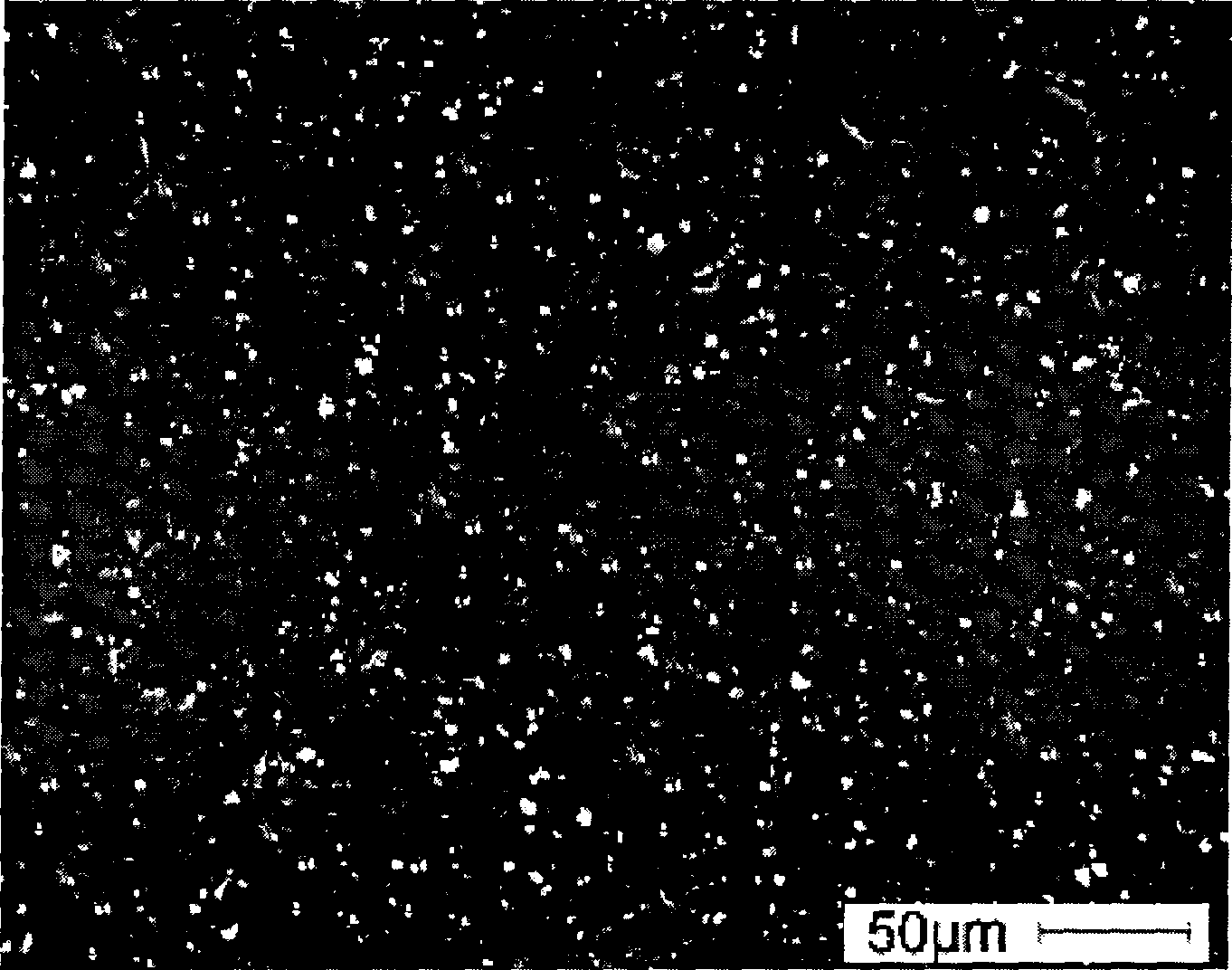

Metal matrix composition home-position synthesizing method in combined electric magnetic field

The invention provides a method for continuously producing particle reinforced metal matrix composites in an industrial scale, which adopts the synthesis of metal matrix composites in a combination magnetic field. The method is characterized in that: the combination of a rotating magnetic field and a travelling wave magnetic field is adopted to synthesize a preparation particle reinforced metal matrix composite fused mass in the in-situ synthesis process of composites. The low frequency rotating magnetic field is placed at the outer side of a composite material molten pool, and the center of a coil of the magnetic field and the center of the fused mass are at the same height; and the travelling wave magnetic field is exerted at the bottom part of the composite material molten pool, and the coil center of the travelling wave magnetic field and the center of the composite material molten pool are at the same position. The composite material particle reinforced phases prepared by the method are distributed evenly and thinned, interior tissues are compact and have no structural defects such as loosening and hole shrinkage, the degree of finish of external surfaces of casting blanks is high, defects are eliminated, and the friction resistance and the abrasion resistance of the composites are obviously improved.

Owner:JIANGSU UNIV

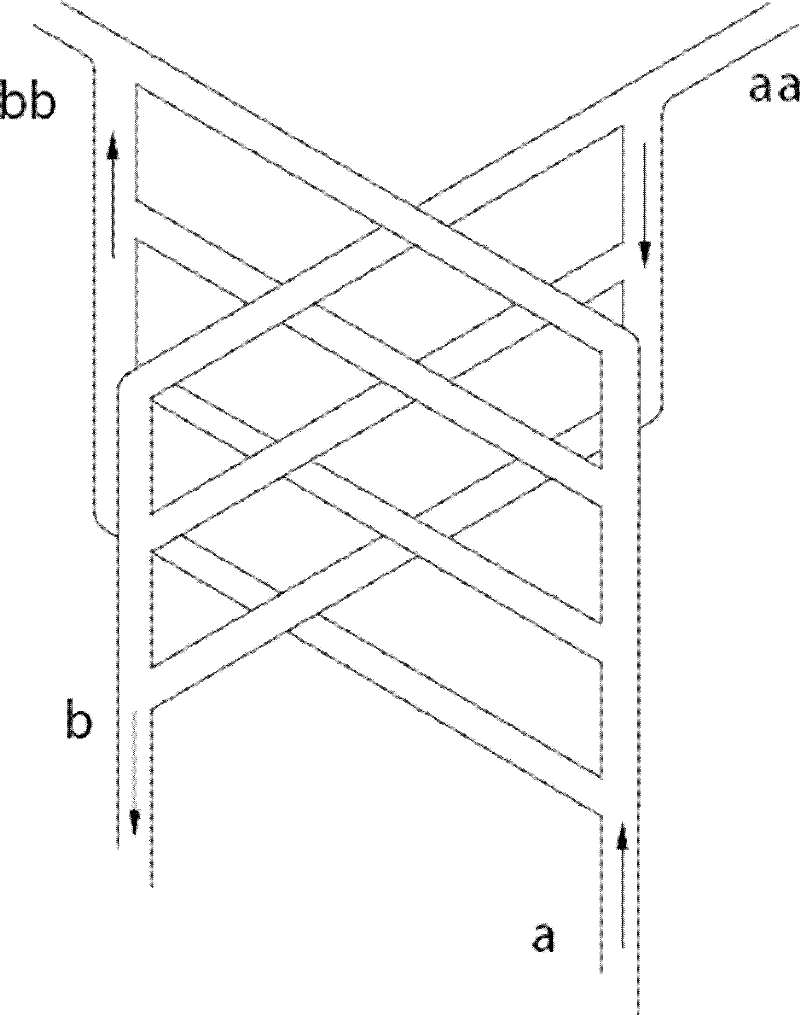

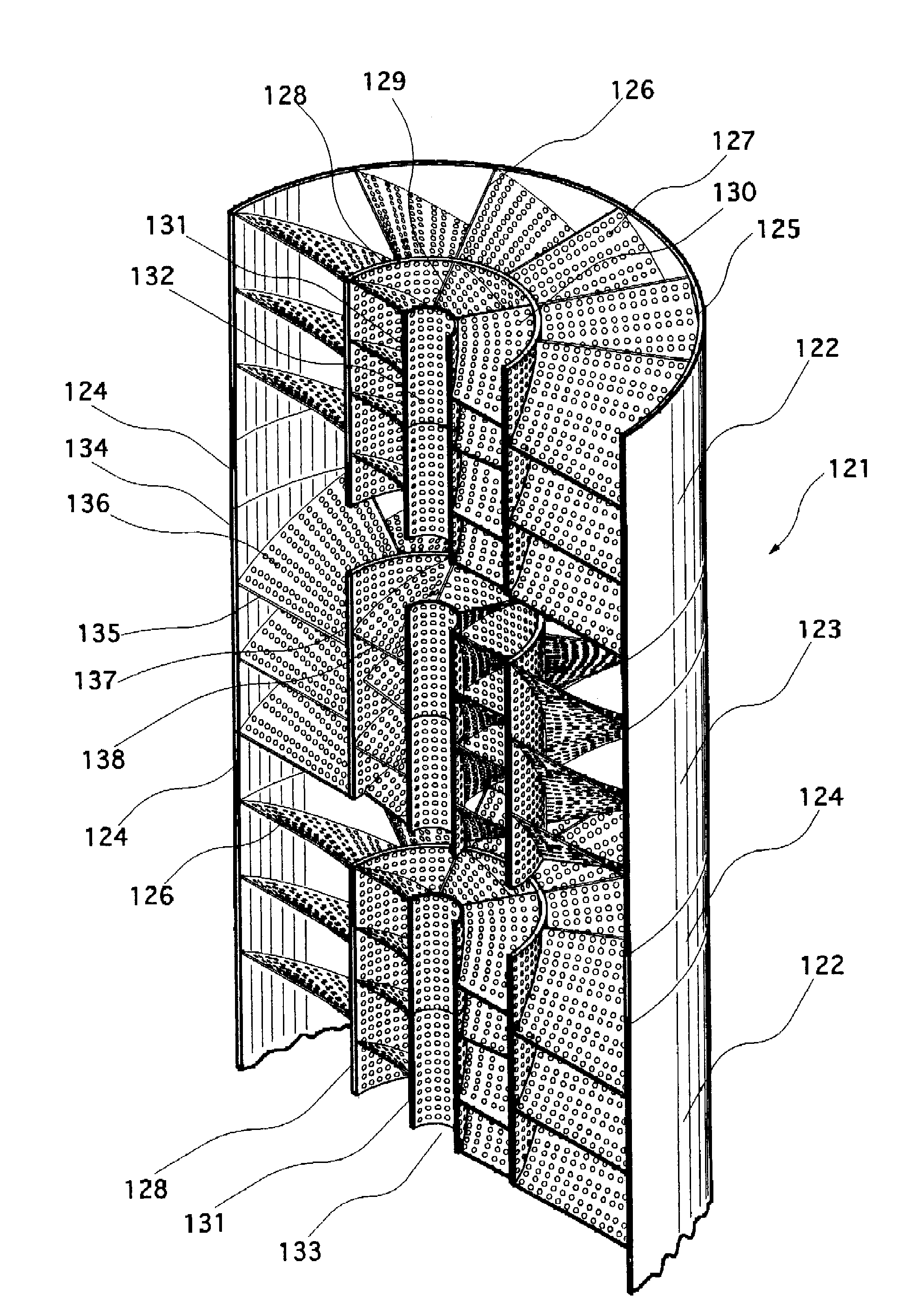

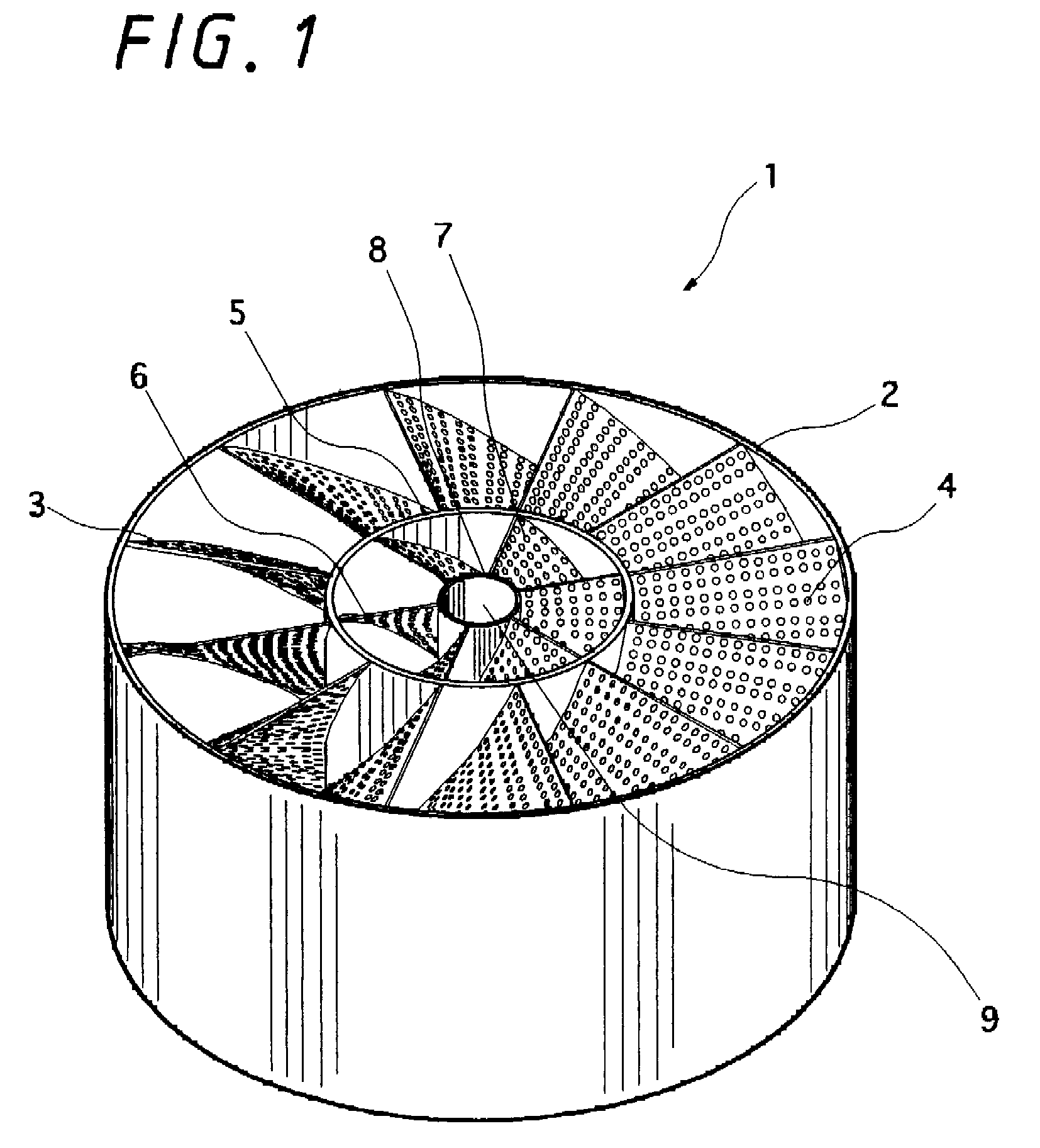

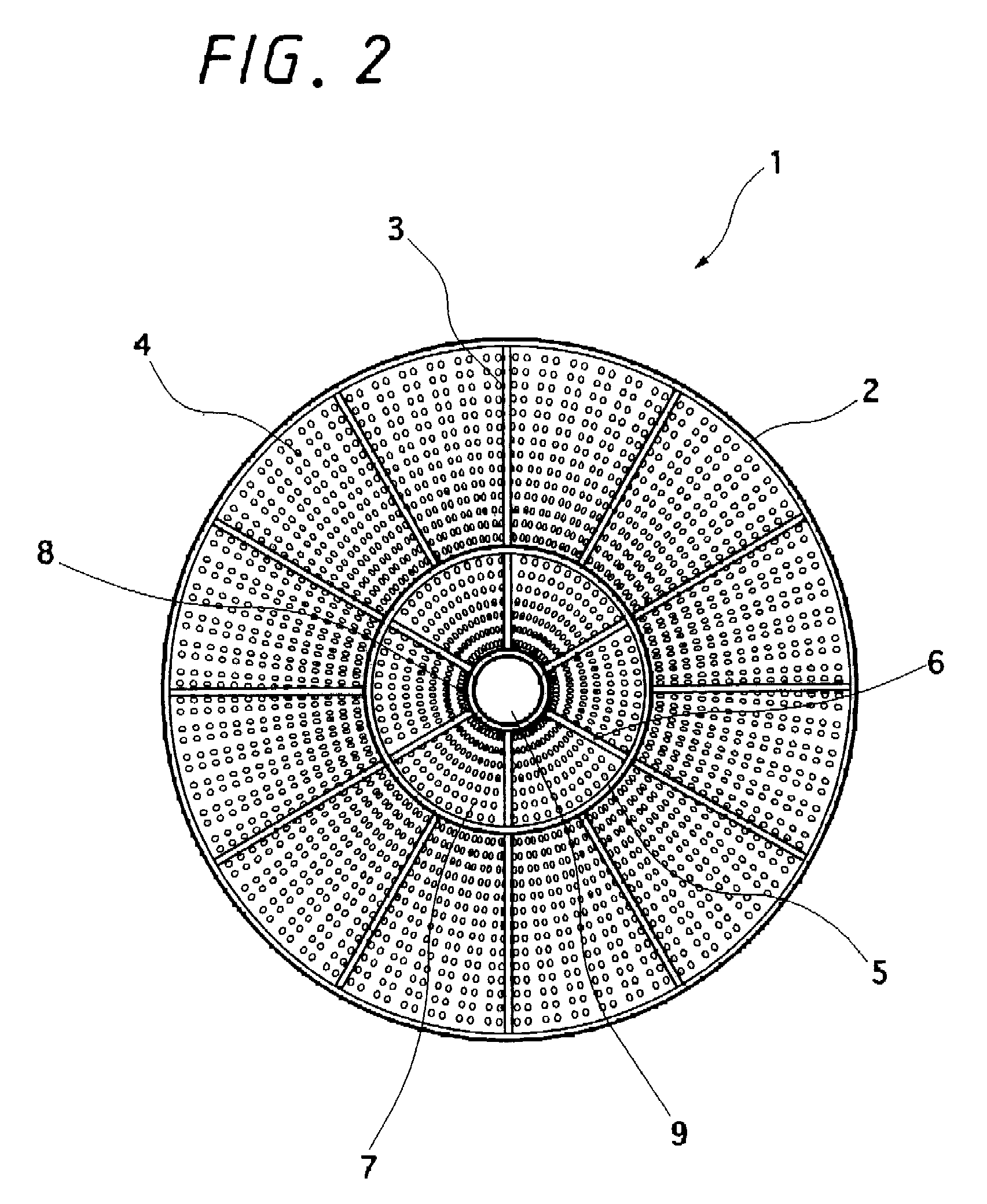

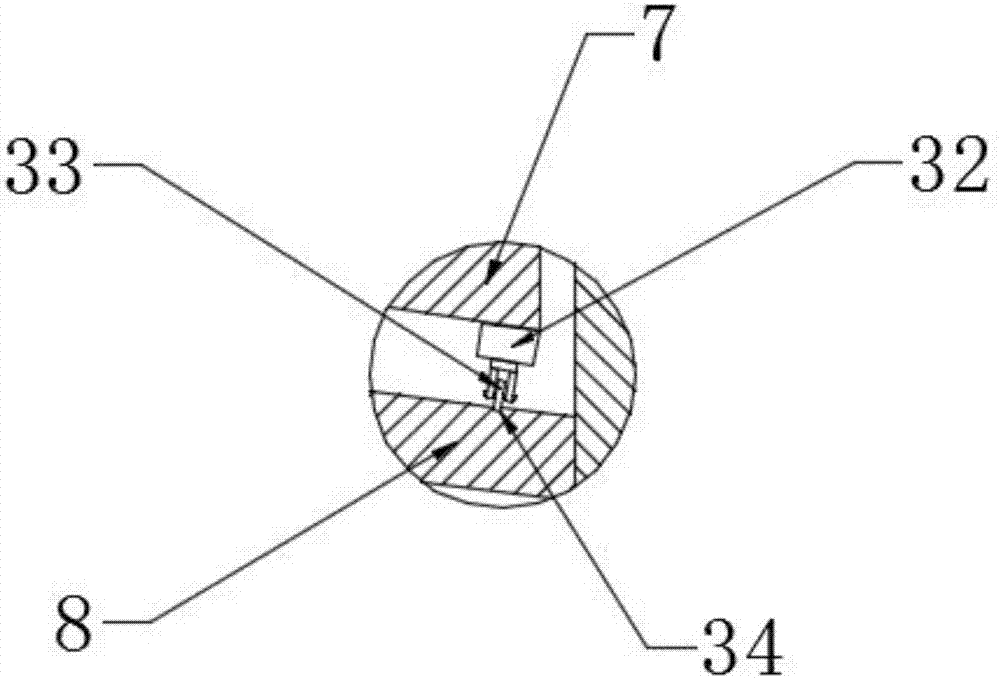

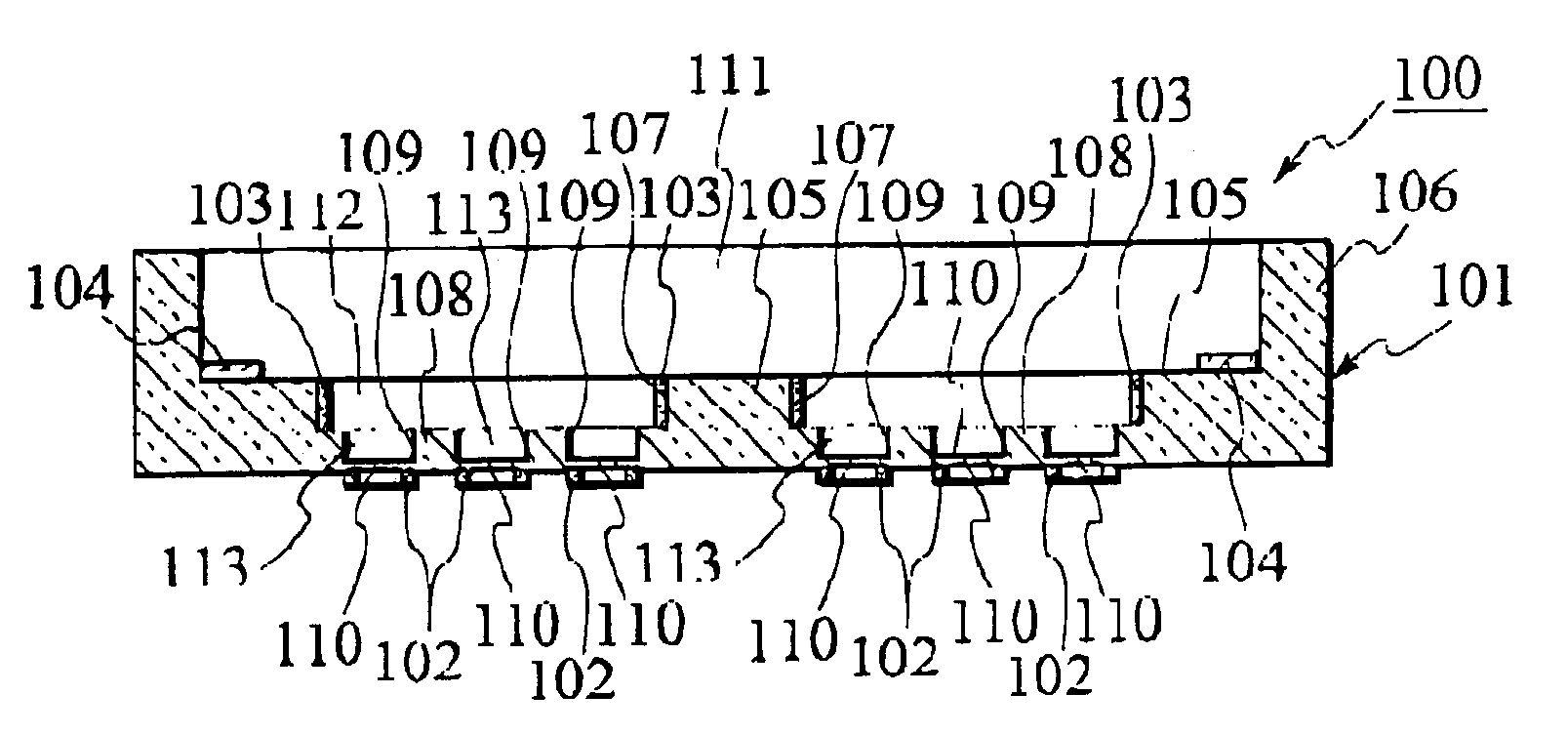

Mixing element and static fluid mixer using same

ActiveUS7510172B2Low pressure lossImprove efficiencyFlow mixersTransportation and packagingEngineeringHelix

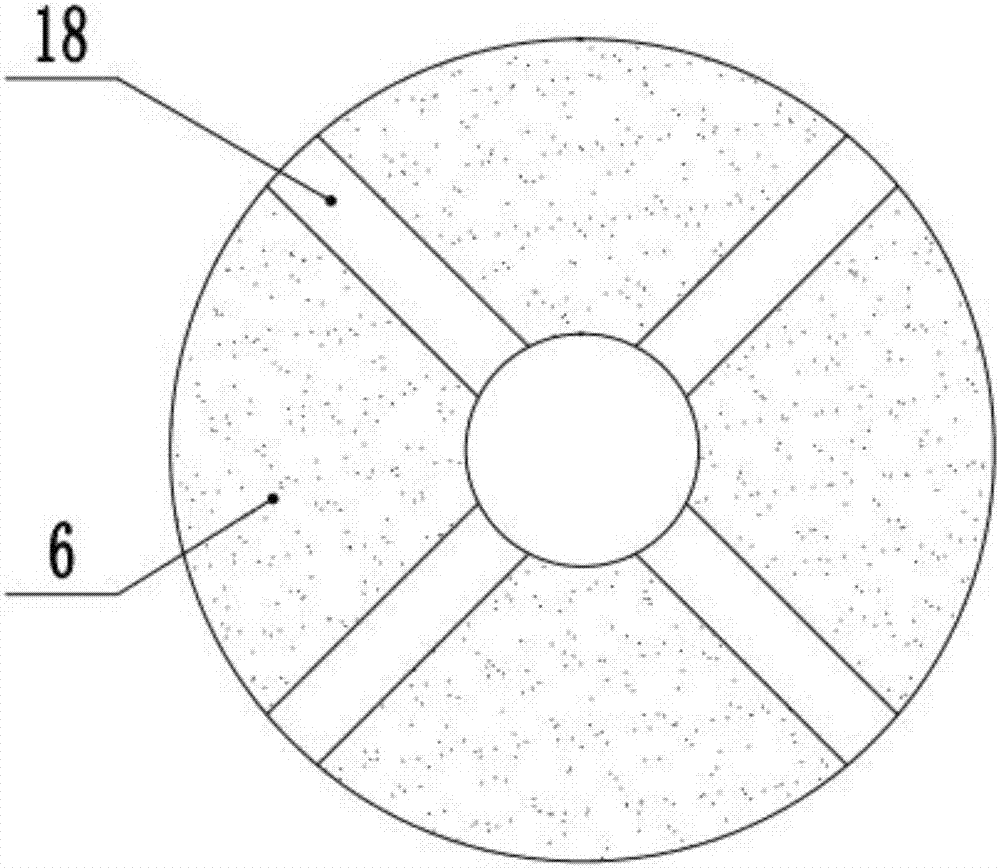

A mixing element, which is produced at low cost, has high mixture agitation effectiveness, and is easily made large, and a static fluid mixer using the mixing element are provided. Further, a gas-liquid treatment apparatus with high treatment ability is provided. A mixing element 1 includes: a cylindrical passage tube 2 trough which fluid flows; a plurality of spiral rightward rotation type first blades 3 formed of a perforated object, which are provided in the passage tube 2; a first inner cylindrical tube 5 shaped like a cylinder and disposed inside the blades 3; a plurality of spiral rightward rotation type blades 6 provided in the inner cylindrical tube 5; and an opening 9 formed in the axial center portion of the blades 6. A static fluid mixer is formed by using at least one mixing, element 1 mentioned above.

Owner:ANEMOS CO LTD

Device for uniformly stirring and mixing coating for buildings

PendingCN107469709AWell mixedAvoid wastingShaking/oscillating/vibrating mixersTransportation and packagingEngineeringCam

The invention discloses a device for uniformly stirring and mixing a coating for buildings. The device comprises a base plate, a stirring barrel, a first spring, a hollow shaft, a rack, a limiting block, a second spring, a fan-shaped gear, a first motor, an extruding plate, a stirring rod, a variable frequency motor, a spline shaft, a lateral plate, a second motor and a cam. The variable frequency motor, the spline shaft, the hollow shaft, the stirring rod, a scraper, a slide sleeve, a stirring support rod and a third spring are arranged on the device disclosed by the invention; the stirring support rod is driven to move left and right by the slide sleeve under the cooperation effect of the parts, so that the stirring efficiency is increased and the coating is more uniformly mixed; the first motor, the fan-shaped gear, the rack and the extruding plate are arranged on the device; the stirring rod is driven to move up and down under the cooperation effect of the parts so as to further increase the stirring efficiency, and meanwhile, the coating in the stirring barrel is continuously circulated in the up-and-down motion process of the extruding plate, so that the stirring and uniform mixing efficiency is further increased and the mixing is more uniform; and the second motor, the cam and the first spring are arranged on the device, so that the stirring barrel is continuously shaken and the coating is more fully and uniformly mixed.

Owner:ZHENGZHOU UNIV

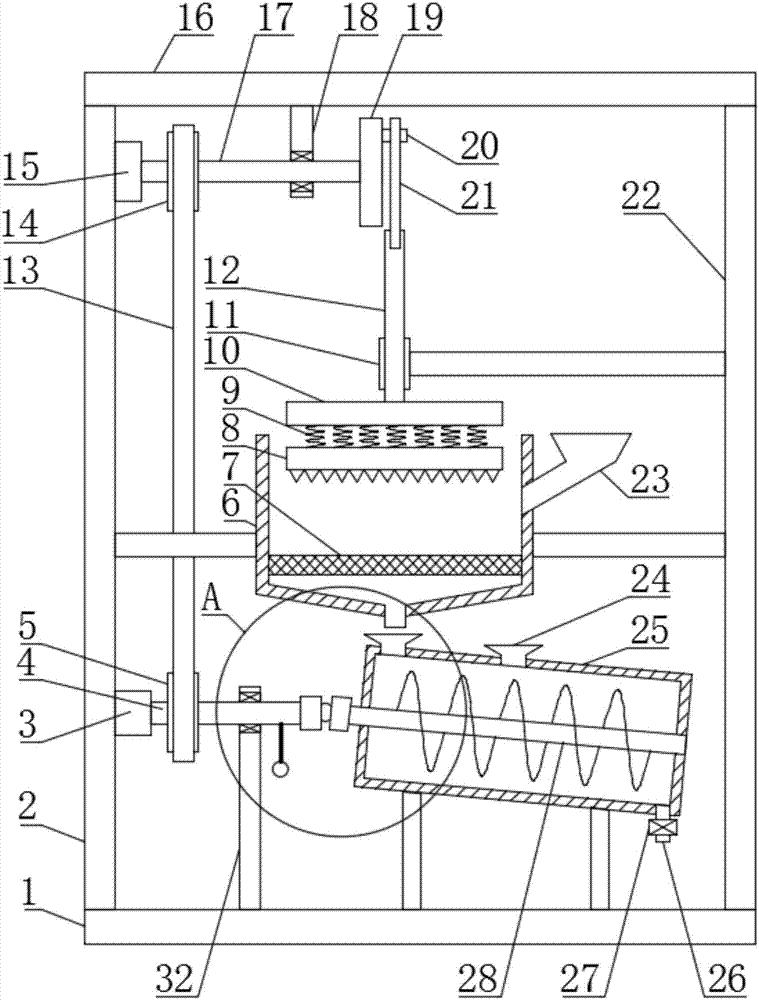

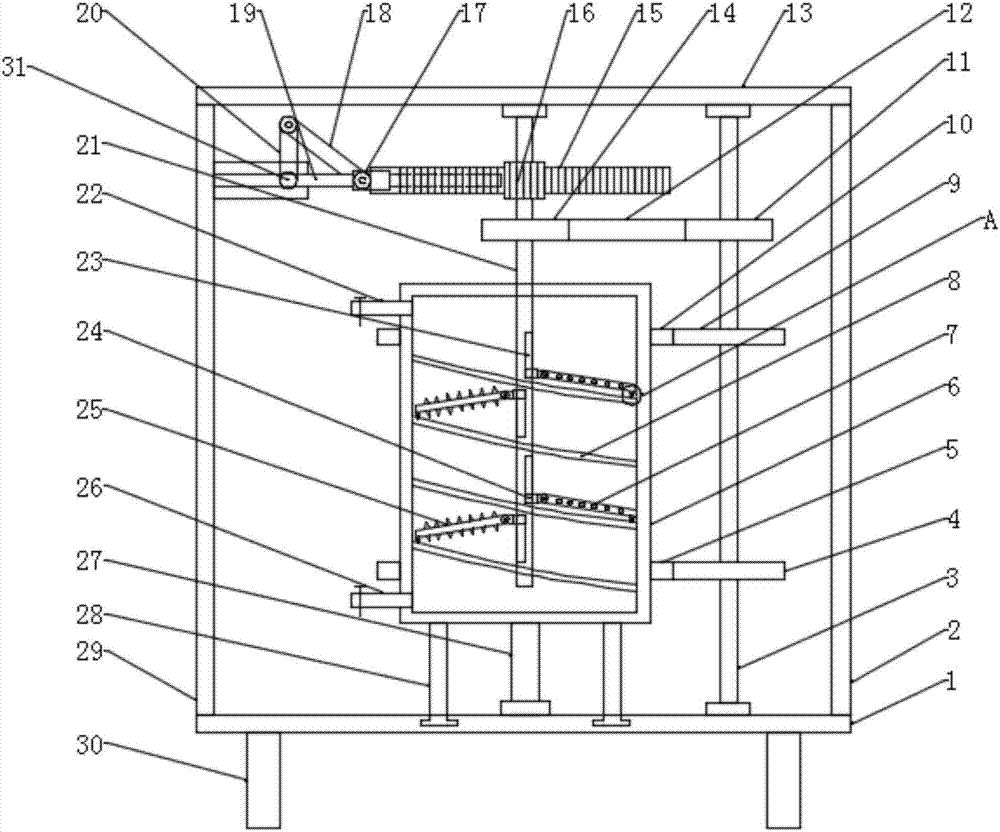

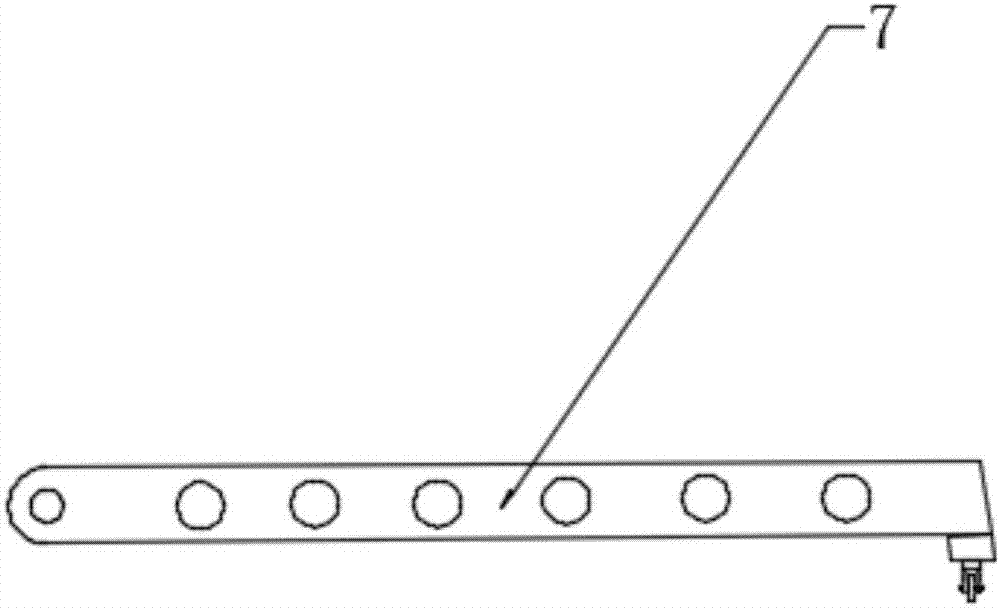

Stone-crushing concrete preparation device for buildings

InactiveCN107415049APlay a buffer roleAvoid cloggingMixing operation control apparatusPretreatment controlStone particleSpiral blade

The invention discloses a stone-crushing concrete preparation device for buildings. The stone-crushing concrete preparation device comprises a base, wherein a left supporting plate and a right supporting plate are correspondingly arranged on the left side and the right side of the base; a crushing box is fixedly arranged between the left supporting plate and the right supporting plate through a support; an extruding plate is fixedly arranged at the inner bottom of the crushing box; a marble is connected to a first rotating shaft through a snapline and positioned below the crushing box; an agitator is obliquely arranged on the base through a support, and a receiving hopper is arranged on the left side of the top of the agitator; a third rotating shaft is rotationally connected to the interior of the agitator; a spiral blade is mounted on the third rotating shaft; and the left end of the third rotating shaft penetrates the left side wall of the agitator and is connected with the right end of the first rotating shaft through a universal coupler. According to the stone-crushing concrete preparation device, the bottom of the crushing box is knocked by the marble, so that adhesion blockage is prevented; and screened stone particles directly enter the agitator to prepare concrete without manual control, so that the processing efficiency is effectively improved.

Owner:李小强

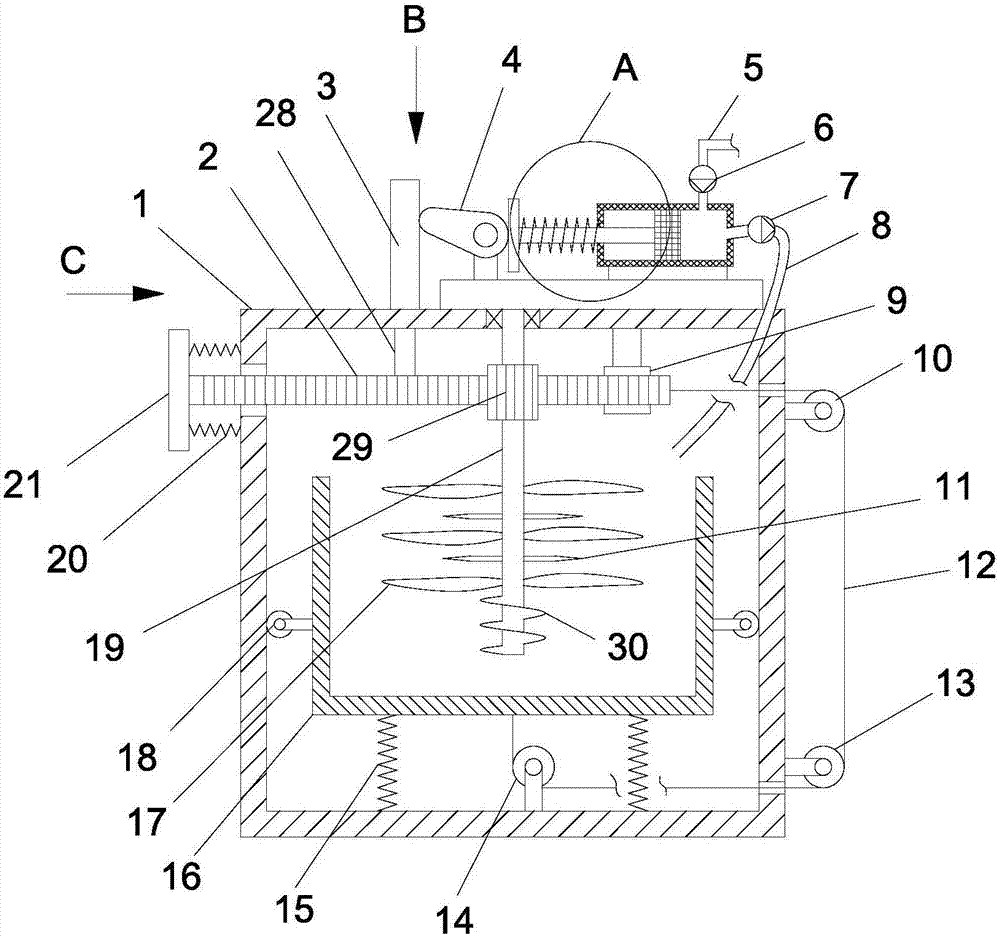

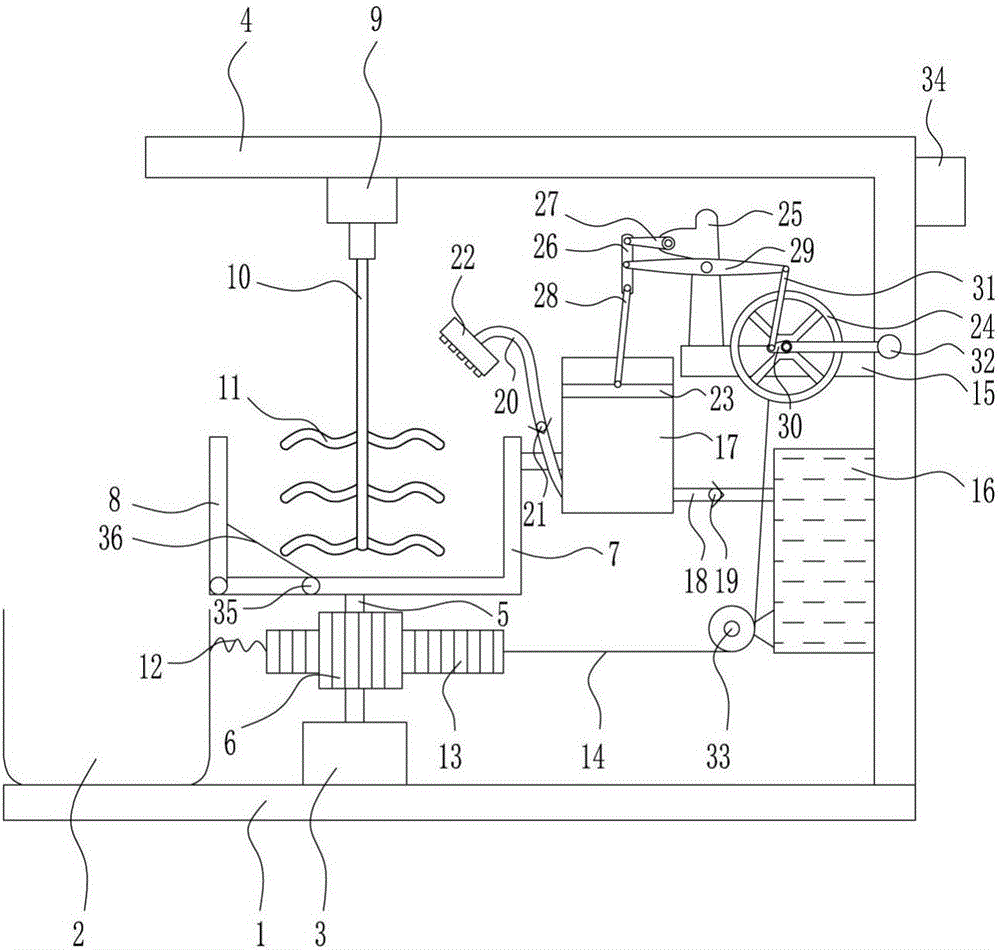

Arm exercise type feed stirring device for animal husbandry

InactiveCN106108081AReasonable mixing timeImprove stirring efficiencyRotating receptacle mixersFeeding-stuffArm exerciseEngineering

The invention relates to an animal husbandry feed stirring device, in particular to an arm exercise type feed stirring device for animal husbandry. The arm exercise type feed stirring device for animal husbandry is diverse in function, reasonable in feed stirring time and high in stirring efficiency. In order to achieve the technical aim, the arm exercise type feed stirring device for animal husbandry comprises a bottom plate, a collecting frame, a bearing seat, a support shaped like an Arabic number '7', a rotary shaft, a gear, a stirring tank, a rotary plate, a motor, a rotary rod, stirring rods, a spring, a compression cylinder, a water inflow pipe, a first one-way valve, a water outflow pipe, a sprayer, a piston, a roller, a supporting frame, a movable rod, a first connecting rod, a swing rod, a cam, a handle, a pulley and the like. The mode that the handle is shaken by hand in a forward and backward alternate mode is adopted, the roller rotates in a forward and backward alternate mode while the handle is shaken in the forward and backward alternate mode, then the piston is driven to pump water, and the pumped water is sprayed into the stirring tank through the sprayer.

Owner:杨国锋

Efficient paint stirring equipment for building decoration

InactiveCN107115813AReduce resistanceAvoid breakingRotating receptacle mixersTransportation and packagingVertical deflectionGear wheel

The invention discloses efficient paint stirring equipment for building decoration. The equipment comprises a bottom plate, a first connecting rod, a second connecting rod, a sliding sleeve, a rack, a first gear, a first rotating shaft, a stirring tube, a chute, a slide block, a first stirring rod, a second stirring rod, a universal rolling wheel, a spiral rail, a first belt wheel, a second belt wheel, a third rotating shaft, a second gear and a third gear. The efficient paint stirring equipment for building decoration is provided with the first connecting rod, the second connecting rod, the sliding sleeve, the rack and the first gear; through the matching of the components, the first stirring rod and the second stirring rod are driven to do positive and reverse rotation, so that the stirring efficiency is improved; the chute, the slide block, the universal rolling wheel and the spiral rail are installed; through the matching of the components, the first stirring rod and the second stirring rod realize the vertical deflection during the rotation; the stirring efficiency is improved; the first belt wheel, the belt, the second belt wheel, the third rotating shaft, the second gear and the third gear are installed, so that the rotating directions of the stirring tube and the first rotating shaft are opposite; and the stirring efficiency is improved.

Owner:王佳宝

Concrete stirrer with high stirring efficiency

ActiveCN106584675AIncrease designHigh feasibilityDischarging apparatusCement mixing apparatusDrive motorEngineering

The invention relates to a concrete stirrer with high stirring efficiency. The concrete stirrer comprises a base, a first supporting plate, a second supporting plate, a main body, a control room, a discharge box, a control mechanism, a discharge mechanism and a turnover mechanism, wherein the control mechanism comprises a lifting air cylinder, a fixed plate, a first bearing, a first rotary shaft, a first bevel gear, a sleeve, a second bearing, a second bevel gear, a telescopic air cylinder, a drive motor, a third bevel gear and a third bearing; the discharge mechanism comprises a rotary motor and a screw; and the turnover mechanism comprises a turnover motor, a speed reducer, a first belt wheel, a second belt wheel and a transmission belt. The concrete stirrer adopts dual stirring modes which are simultaneous and reverse, and discharge adopts a screw squeezing type discharge method, so that discharge stability is improved; and moreover, during discharge, concrete is stirred again through a screw in a reversible mode, and the concrete stirrer further can regulate the position of a discharge hole; and the base of the concrete stirrer is equipped with universal wheels, so that travelling is convenient.

Owner:ANHUI JARLO CONSTR MACHINERY

Omni-directional efficient concrete mixer

InactiveCN107511928ASimple structureStir more comprehensivelyCement mixing apparatusEngineeringOmni directional

The invention discloses an all-round high-efficiency concrete mixer, which comprises a box body. The top wall of the box body is provided with a feeding port, and the inner bottom wall of the box body is fixedly connected with a first cylinder. The high-efficiency concrete mixing device has a simple structure. , when the second stirring blade is separated from the extruding block, the installation rod moves downward under the action of the third spring, so that the first stirring blade and the second stirring blade vibrate up and down while rotating, improving the stirring efficiency, and, in When the second stirring blade squeezes the extruded block, the first copper sheet and the second copper sheet will contact, thereby energizing the electromagnet, and through the rotation of the second stirring blade, the electromagnet is periodically energized and de-energized, so that The plunger moves up and down under the action of the second spring, thereby causing the first mixing blade to swing, so that the concrete mixer can mix concrete more comprehensively and fully.

Owner:徐秋裂

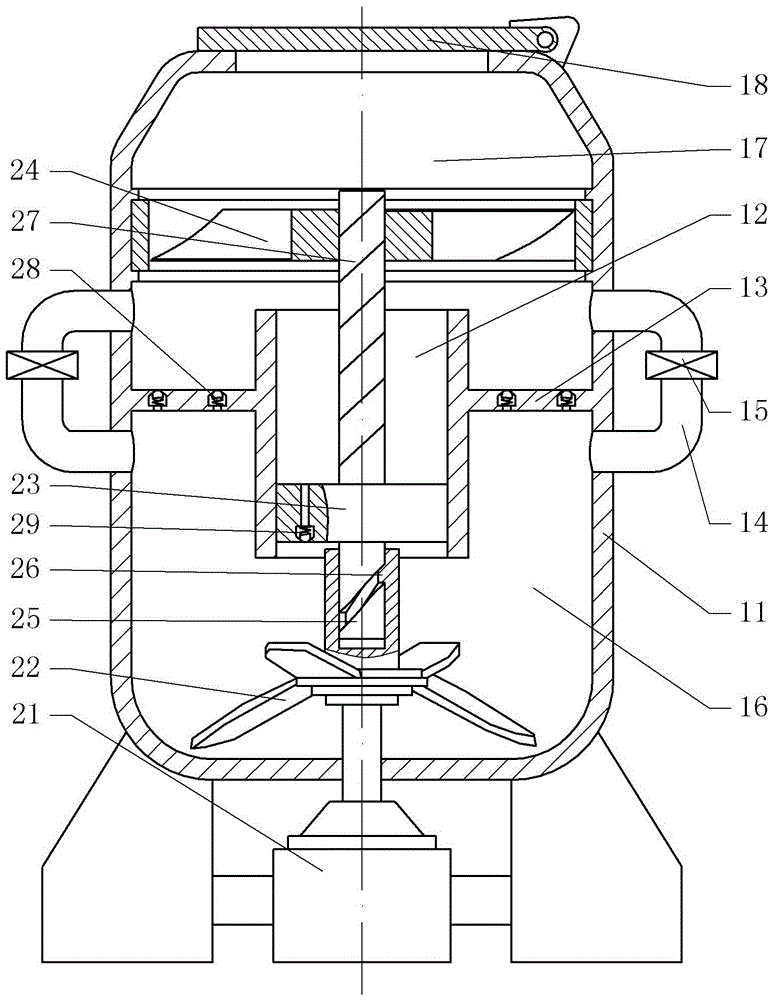

Fertilizer slurry stirring and emulsifying device

InactiveCN106731923AImprove stirring efficiencyGood emulsificationFlow mixersTransportation and packagingFertilizerPiston

The invention discloses a fertilizer slurry stirring and emulsifying device and relates to fertilizer production equipment. The fertilizer slurry stirring and emulsifying device comprises a seat body, an emulsifying barrel and a stirring device, wherein the emulsifying barrel is fixed to the seat body, the emulsifying barrel comprises an outer barrel body and an inner barrel body, a partition plate is arranged in the middle of the outer barrel body, the inner barrel body is arranged in the outer barrel body and is fixed with the outer barrel body through the partition plate, a sealing cover is arranged at the top of the outer barrel body, and a discharging valve is arranged at the lower end of the outer barrel body; the stirring device comprises a driving motor, a stirring blade and a piston, the driving motor is arranged on the seat body, the stirring blade is arranged at the lower portion of the outer barrel body, the stirring blade is further in rotary connection with the outer barrel body, and the stirring blade is connected with the driving motor; the piston is in slide connection in the inner barrel body, a cylindrical cam is arranged at the lower end of the piston, and a linkage block matched with the cylindrical cam is arranged on a rotation shaft of the stirring blade; a first one-way valve is arranged on the partition plate, a second one-way valve is arranged on the piston, and an opening direction of the first one-way valve is opposite to an opening direction of the second one-way valve. The fertilizer slurry stirring and emulsifying device has a good stirring effect and can quickly emulsify slurry.

Owner:徐州致诚会计服务有限公司

Stirring equipment for production of potassium chlorate

PendingCN107670535AStir wellImprove stirring efficiencyRotary stirring mixersTransportation and packagingReciprocating motionEngineering

The invention discloses stirring equipment for production of potassium chlorate. The stirring equipment for production of potassium chlorate comprises a box, wherein the bottom of the right side of the box communicates with a discharging tube; a valve is arranged on the surface of the discharging tube; tops of two sides of the box are fixedly connected with supporting plates separately; chutes areformed in opposite sides of the supporting plates; a cavity of each chute is slidably connected with a sliding rod; the end, which is away from the cavity of the corresponding chute, of each slidingrod extends to the outside of the corresponding chute and is fixedly connected with a movable plate; an elongated hole is formed in the top of the front surface of each movable plate; and the bottom of each movable plate is fixedly connected with a first motor. By cooperation of the movable plates, the elongated holes, a second motor, a rotating plate and a guiding rod, the movable plates can vertically move in a reciprocating manner, and drive worms, cross rods, stirring teeth and stirring blades to move vertically, materials in the cavity of the box can be fully stirred, the material stirring efficiency is improved, and the material reaction speed is increased.

Owner:LEIYANG JINYUE SCI & TECH DEV

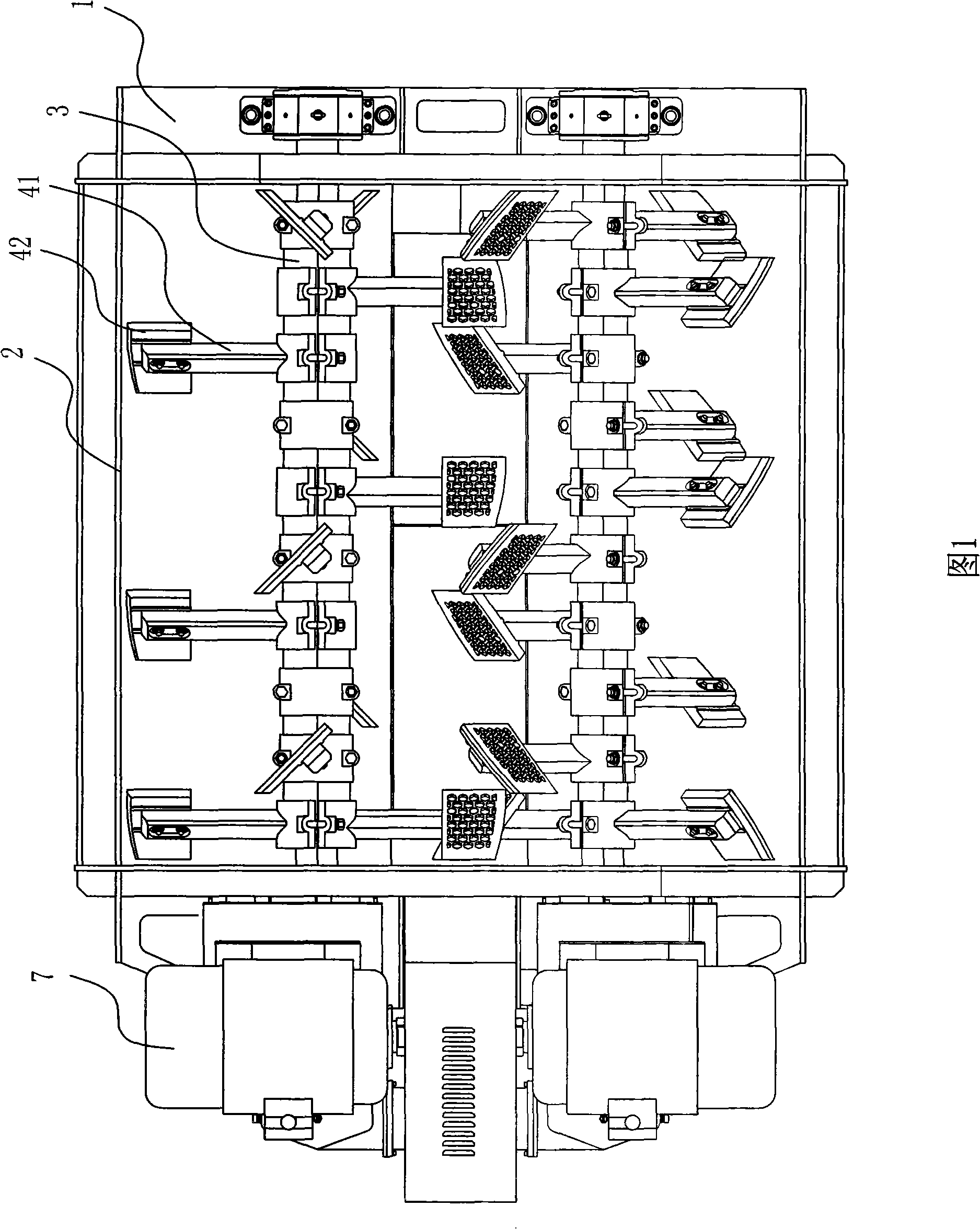

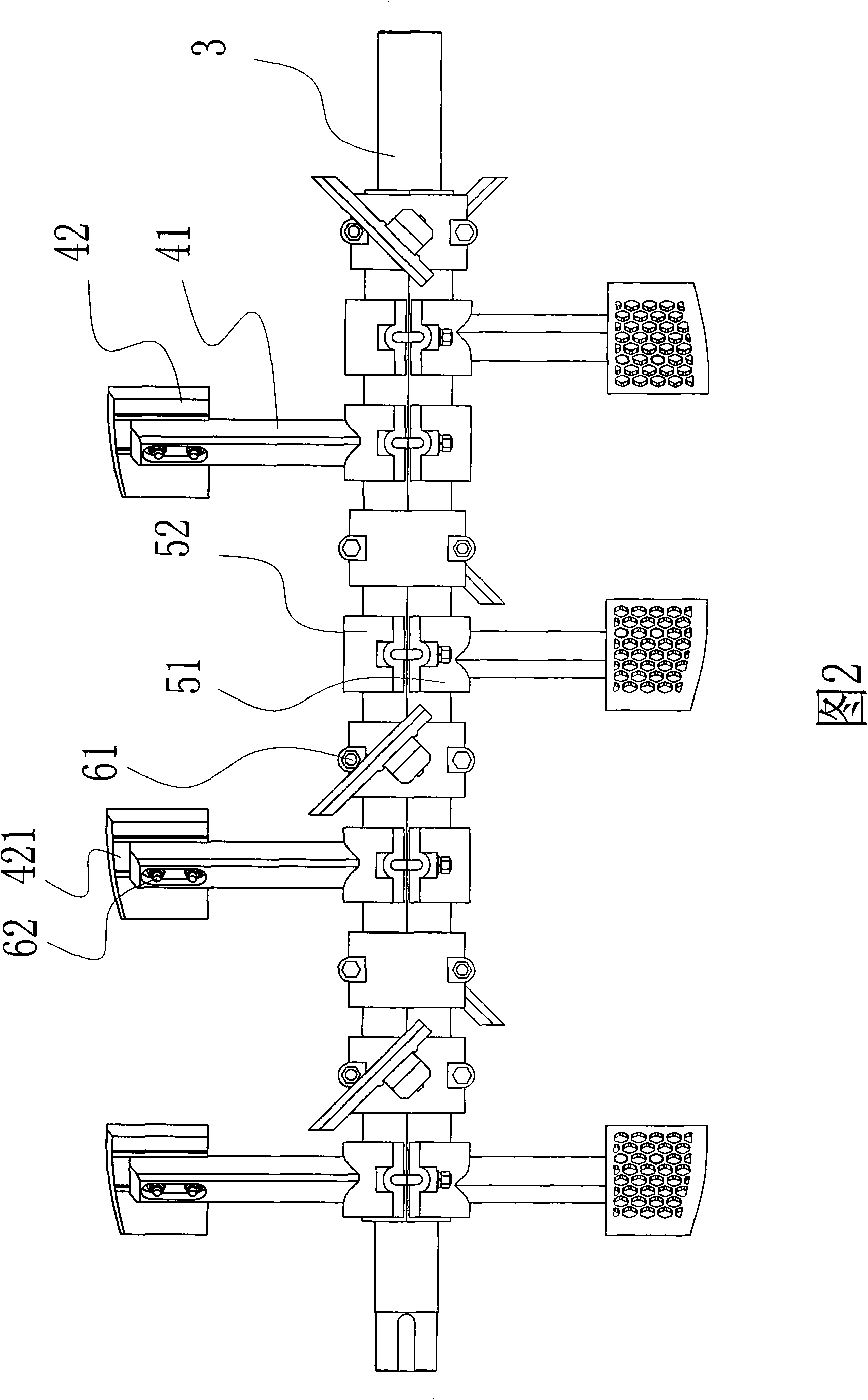

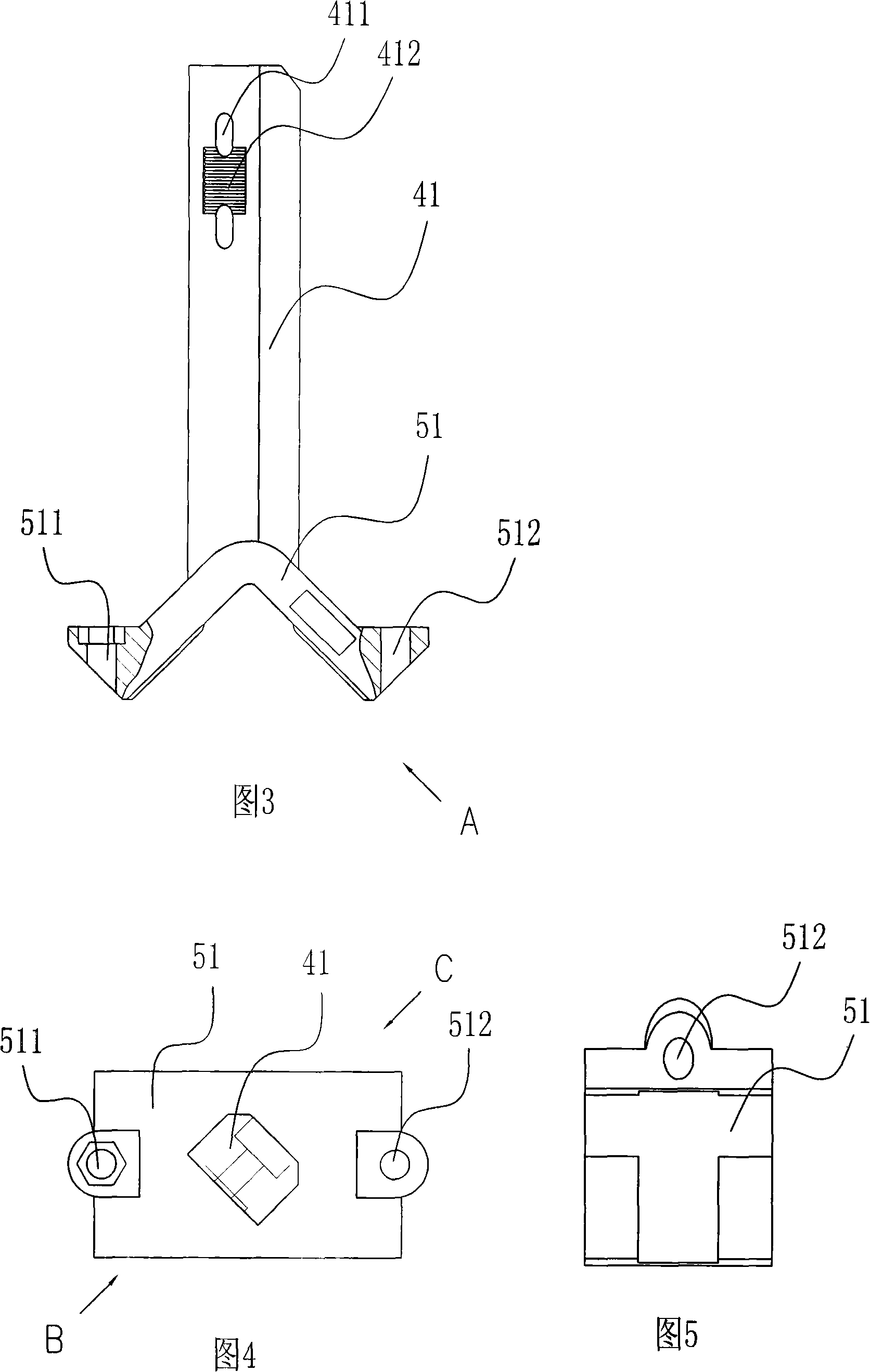

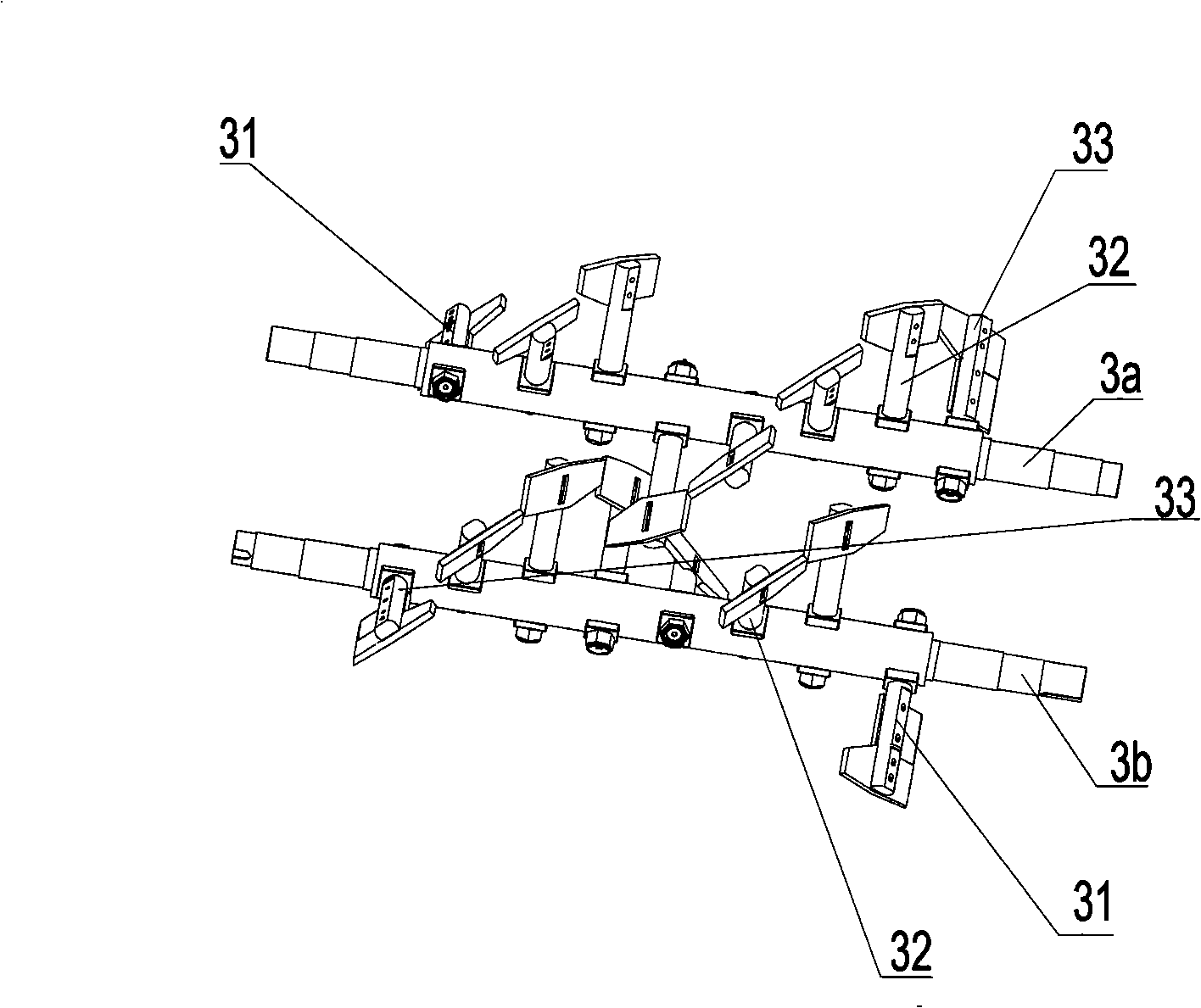

Forced action mixer with adjustable stirring unit

InactiveCN101323149AGood mixing effectImprove stirring efficiencyCement mixing apparatusFastenerBituminous concrete

A compulsory mixer provided with an adjustable mixing unit comprises a horizontal mixing cylinder body, a mixing shaft which can act as support rotationally along the axial direction and a plurality of mixing units which are spaced along the axial direction and arrayed in a screwed manner with deviating from the mixing shaft at different angles in sequence in the circumferential direction. The mixing unit comprises a mixing arm and a mixing blade. A mounting hole extending in the direction of length is arranged on the mixing arm. The mixing arm is connected with the mixing shaft by a dismountable sleeve. The mixing blade is flexibly fixed on the mixing arm by a fastening component that goes through the mounting hole. And a tooth part arranged between the mixing blade and the contact face of the mixing arm is used for locating the mixing blade and the contact face of the mixing arm. The intervals, installation angles and number of the mixing units can be adjusted according to the requirement for mixing. In addition, the mixing unit can be moved in the direction of the length of the mixing arm and the installation position of the mixing blade also can be adjusted, thus meeting the diversified demands placed on mixing asphalt concrete to achieve the best effect of mixing and highest mixing efficiency.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

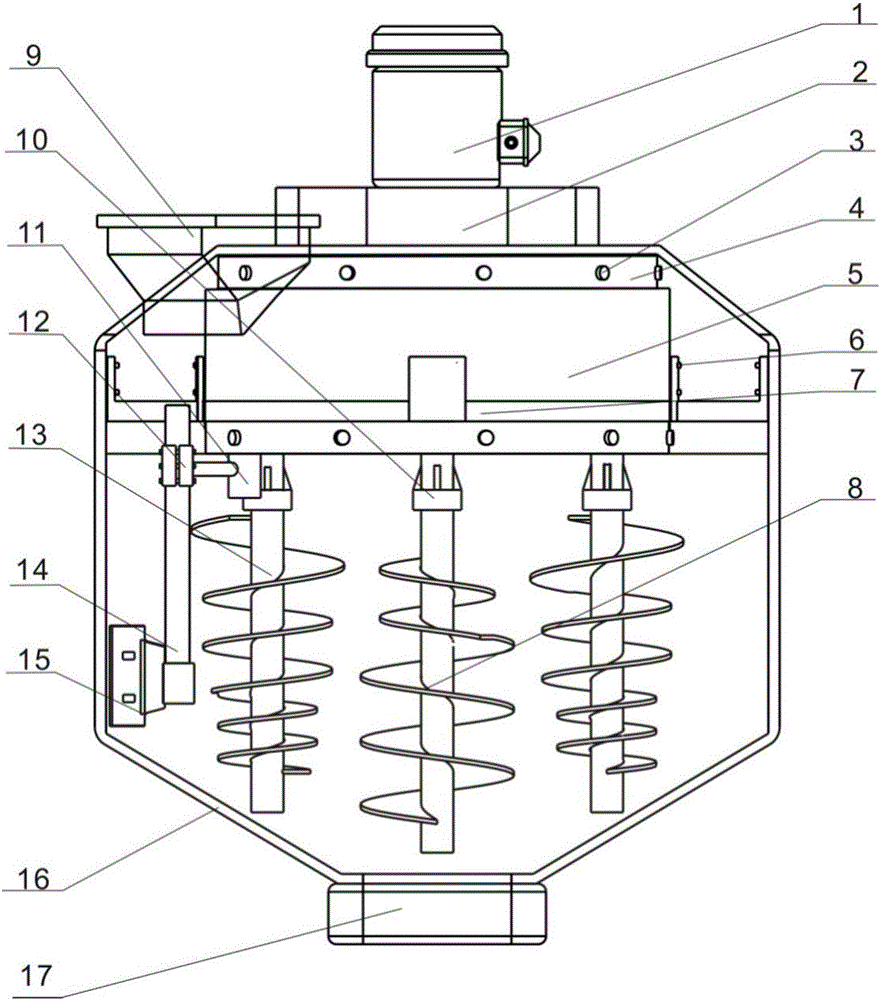

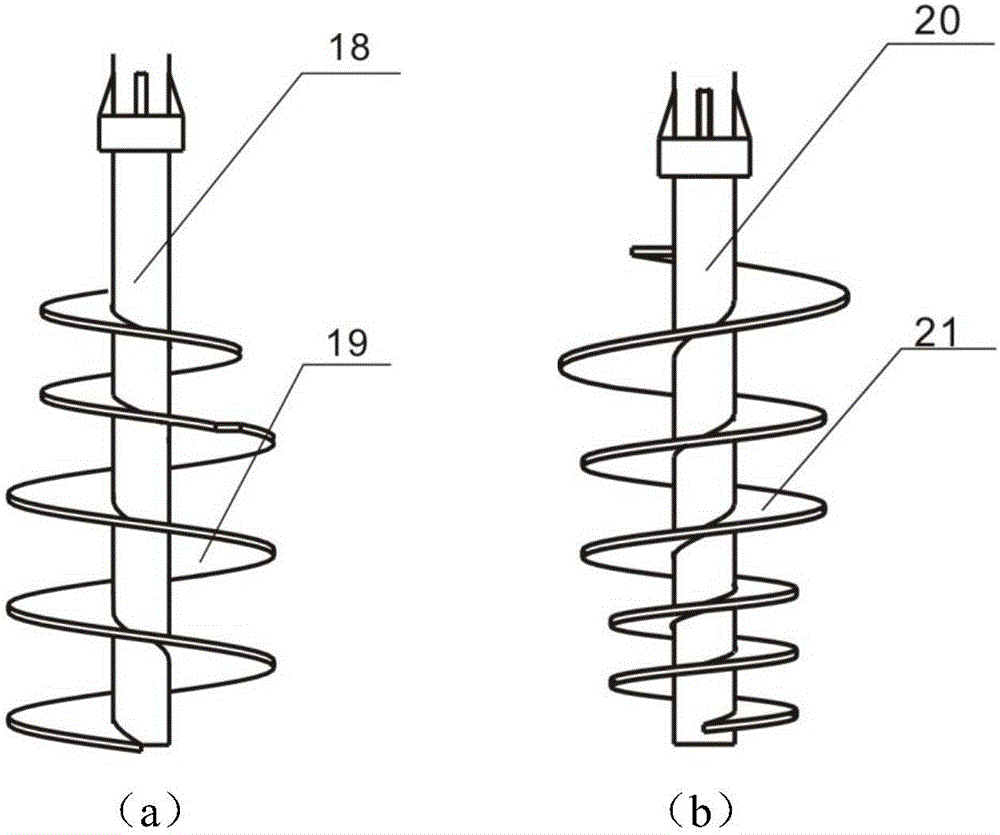

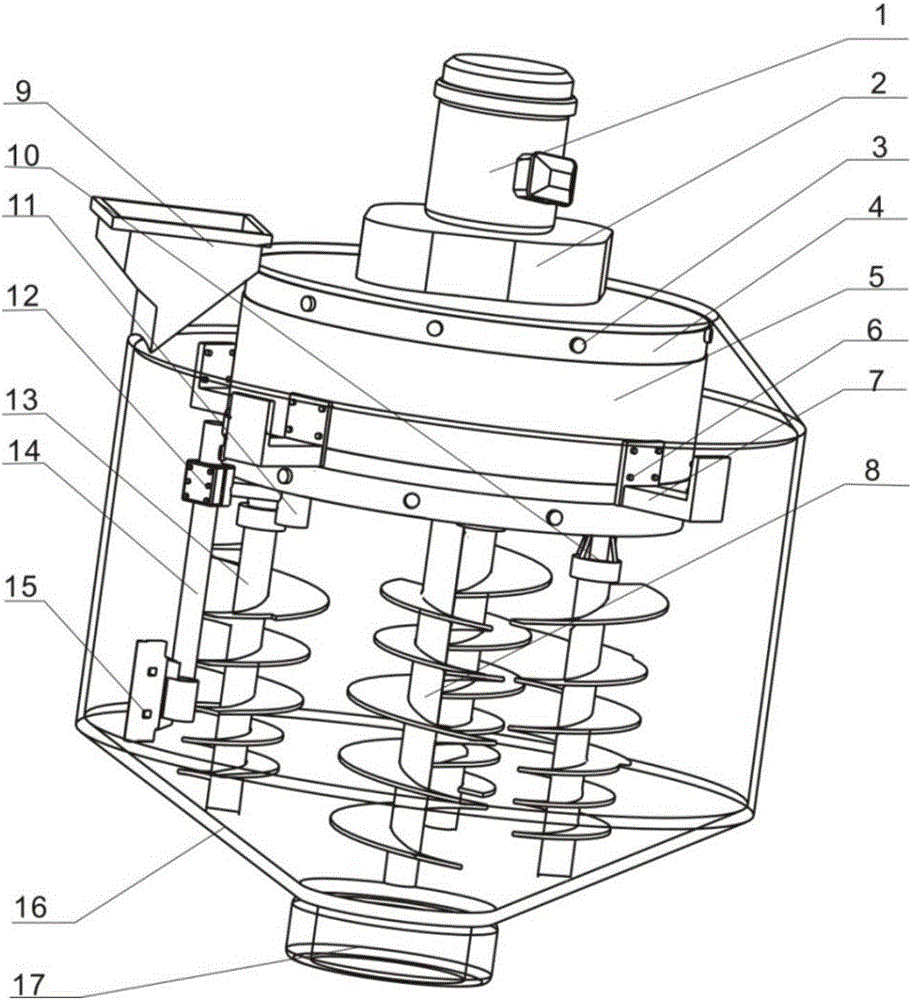

Variable-diameter variable-pitch spiral vertical planetary mixer

InactiveCN106738338AReduce use costImprove stirring efficiencyCement mixing apparatusVertical mixingEngineering

The invention discloses a variable-diameter variable-pitch spiral vertical planetary mixer. The mixer comprises a central screw rod doing fixed-axis rotation, a plurality of planetary screw rods doing planetary motion, a movable scraping plate doing fixed-axis rotation, a planetary gear device and a driving device, wherein a central blade is arranged on the central screw rod, planetary blades are arranged on the planetary screw rods, and the center blade and the planetary blades are variable-diameter and variable-pitch spirals. The mixer is a vertical mixing device which integrates the principles of spiral conveying, planetary motion, gravity and the like, and under the action of the central screw rod, the planetary screw rods, the self-weight and the movable scraping plate, a mixture forms large motion cycles from bottom to top and then from top to bottom while the mixture in the material field also forms a plurality of small motion cycles. According to the mixer, inefficient mixing zones can be effectively reduced, and the mixing efficiency and quality can be improved. Thus, the mixer is suitable for occasions mixing materials such as concrete.

Owner:CHANGAN UNIV

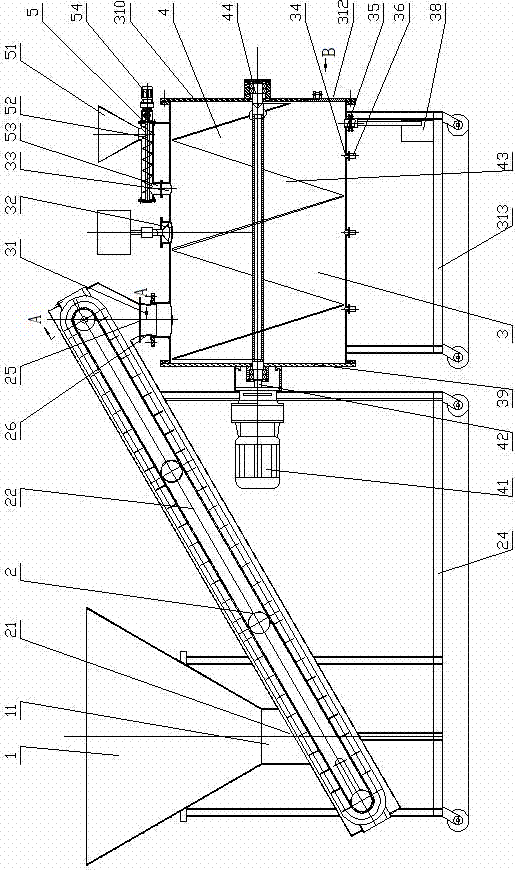

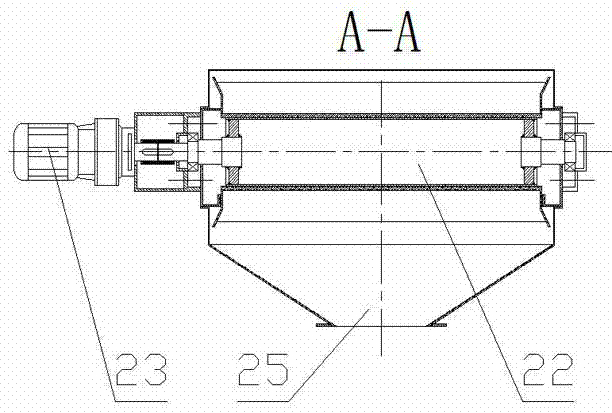

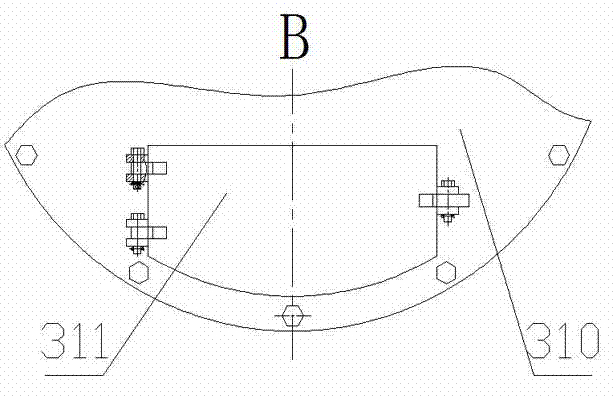

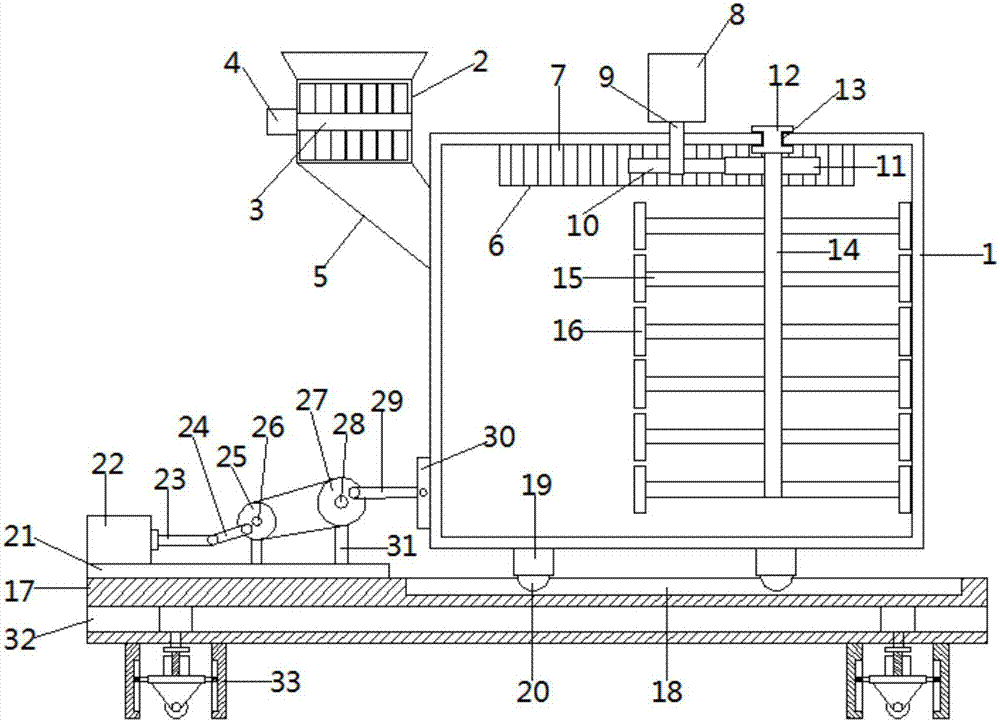

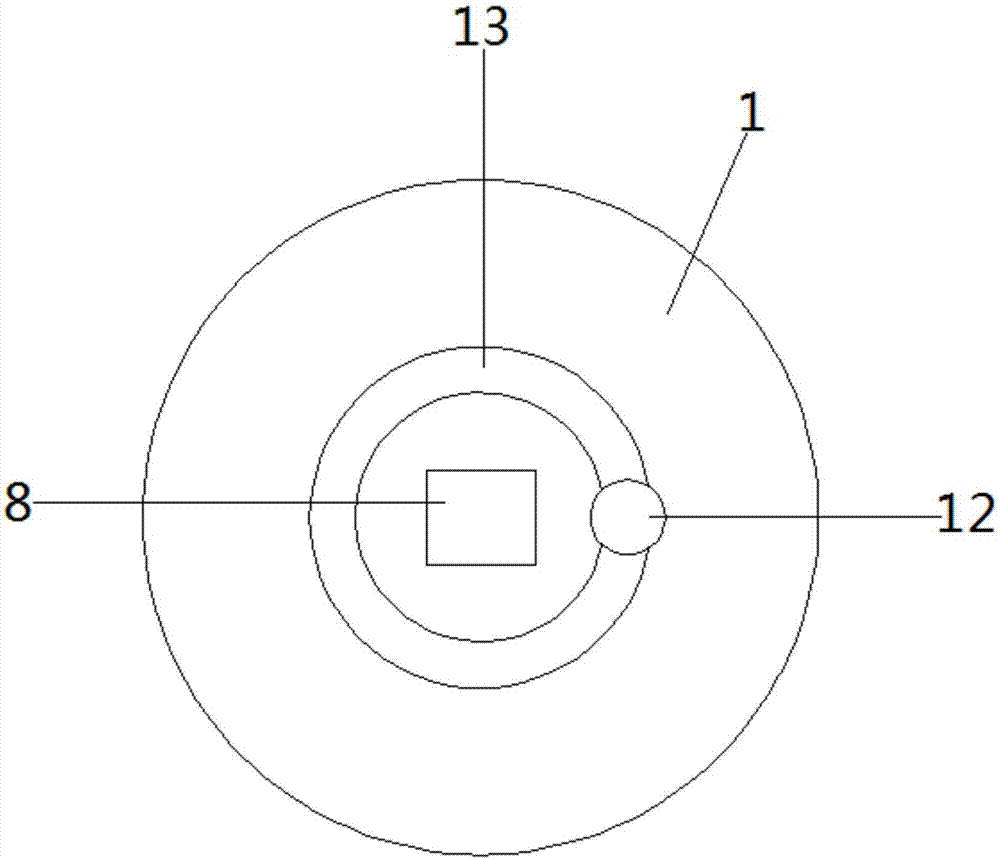

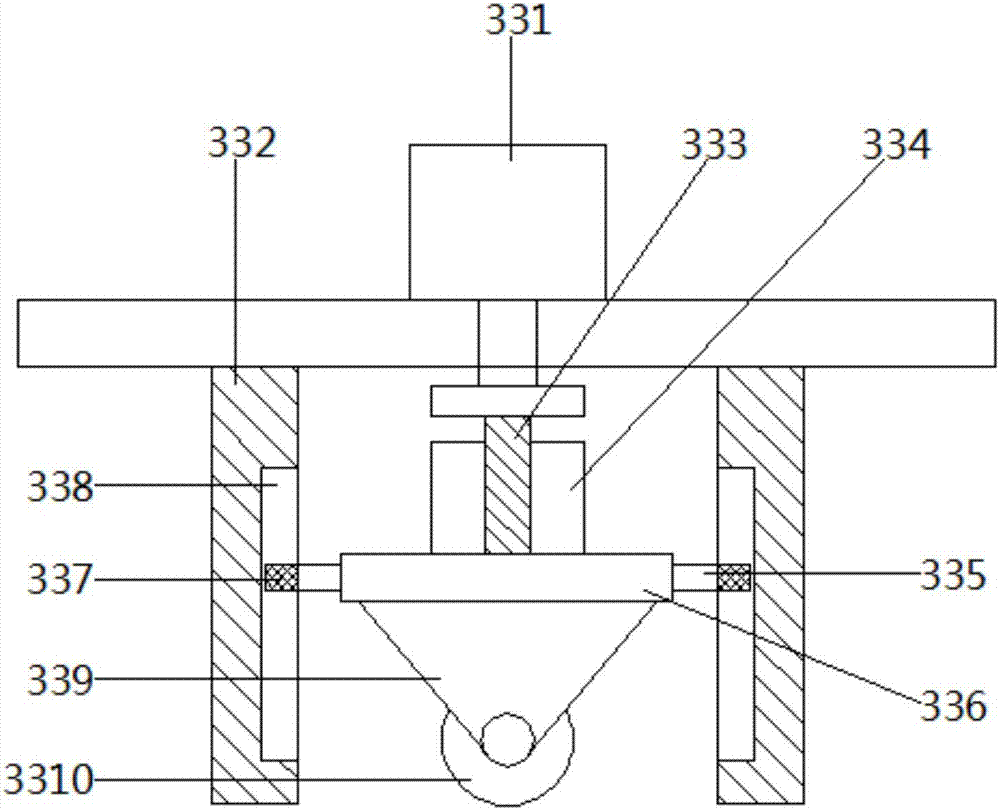

Horizontal reciprocated type agitating equipment of straw powder dust wastes

InactiveCN103172422AHigh degree of automationImprove stirring efficiencyBio-organic fraction processingRotary stirring mixersResource utilizationAgricultural engineering

The invention discloses horizontal reciprocated type agitating equipment of straw powder dust wastes, which is suitable for batching agitation and fermentation agitation in resource utilization production of gardening straw powder dust base materials and belongs to the technical field of agricultural machinery. The horizontal reciprocated type agitating equipment comprises a storage bin, a belt feeding machine, an agitating working cabin, a spiral agitating device, an auxiliary feeding machine and a humidifier. According to the horizontal reciprocated type agitating equipment disclosed by the invention, the straw powder dust wastes in the storage bin are mainly and quantitatively added to the agitating working cabin through controlling the conveying speed and time of the belt feeding machine and weighing the agitating working cabin; the auxiliary feeding machine is used for controlling the rotary speed and a rotary angle of a spiral shaft to quantitatively add the materials into the agitating working cabin in an auxiliary manner; the humidifier controls a metering pump at fixed time and increases the humidity of the materials; a motor is controlled by controlling the agitation to forwardly and backwardly drive the horizontal spiral agitating device to carry out reciprocated type agitating work; and the horizontal spiral agitating device is controlled to rotate forward so that the materials which are subjected to agitation treatment in the agitating working cabin are quantitatively discharged. The horizontal reciprocated type agitating equipment disclosed by the invention is high in agitation efficiency, low in power consumption and integrated in agitation and material discharging.

Owner:JIANGSU UNIV

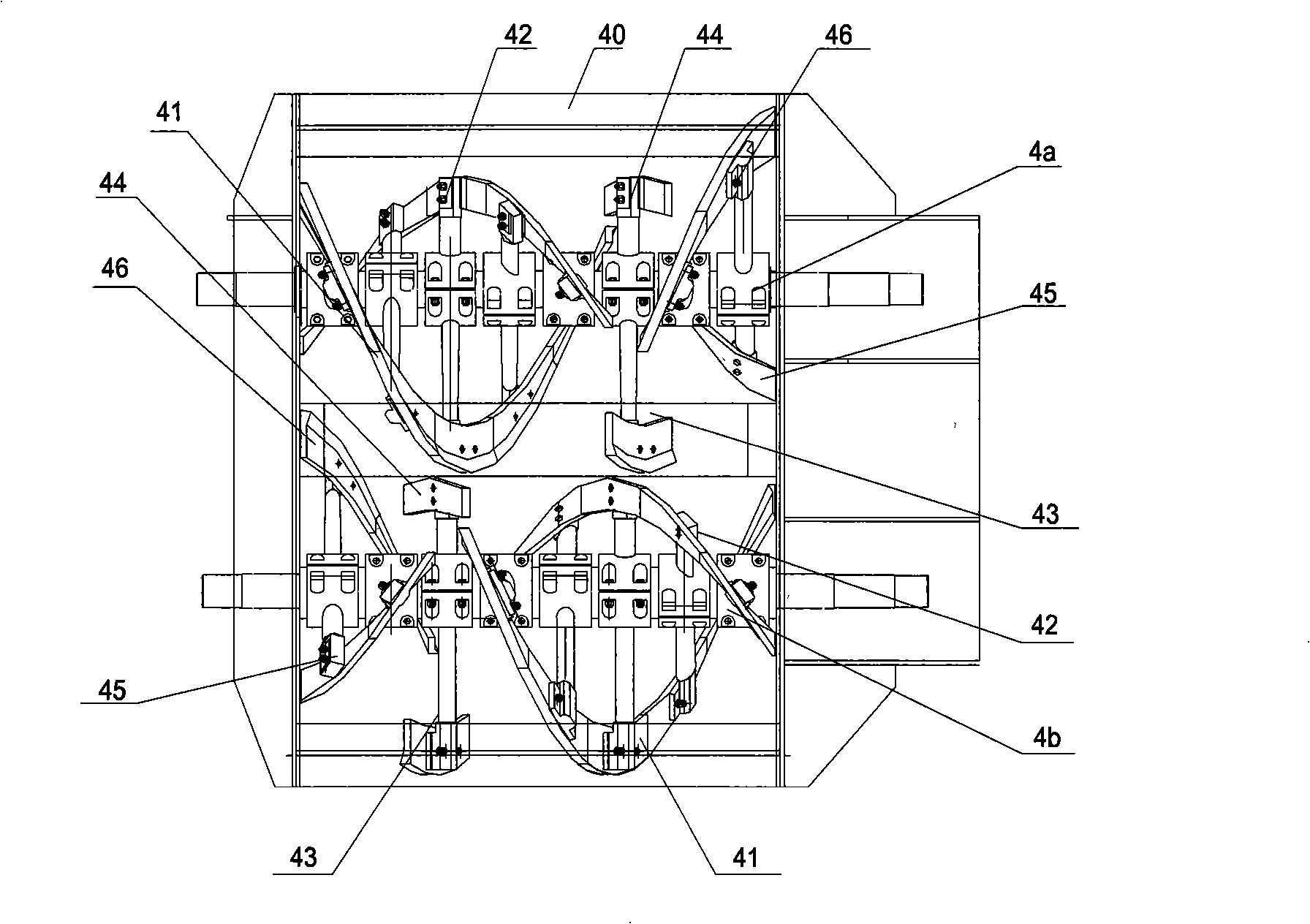

Double-helix shaft double-helical ribbon concrete batch plant

InactiveCN101347961ANot easy to hold the shaft and agglomerateSpeed up the flowCement mixing apparatusFistHorizontal axis

The invention relates to a double spiral axis double spiral ribbon concrete mixing plant, which relates to a mixer for clay or cement and other materials which turns around the horizontal or basically horizontal axis. The concrete mixing plant is provided with a machine body, a first agitation system and a second agitation system. The fist agitation system is provided with a left spindle head, a right spindle head and four spiral axes which are connected with the left and right spindle heads. The second agitation system is provided with the left spindle head, the right spindle and the four spiral axes which are connected with the left and right spindle heads. The direction of the spiral of an internal return unit shaft is opposite to that of the spiral of an internal feeding unit shaft; and the direction of the spiral of an external feeding unit shaft is opposite to that of the spiral of the external return unit shaft. The left and right spindle heads of the first agitation system and the second agitation system are connected with a bearing bracket arranged on the machine body. The speed at which the spindle axes move relative to materials is larger;, so the materials are subject to smaller resistance when being mixed in the mixer, the cement is difficult to curdle around the axes, and the materials flow smoothly in the mixer, thus ensuring that the mixer has .lower energy consumption and higher mixing efficiency, reducing cleaning time and increasing the service efficiency of the mixer.

Owner:蔡达棋

High-efficiency agitation device for chemical production

InactiveCN106378029AQuality assuranceQuality improvementTransportation and packagingRotary stirring mixersHelical bladeIron removal

The invention discloses a high-efficiency agitation device for chemical production. The high-efficiency agitation device comprises an agitation barrel, wherein the left end of the upper side of the agitation barrel is provided with a material feeding hopper; the lower side of the material feeding hopper is connected with an iron removal cavity; an iron removal rotating shaft is horizontally arranged in the center of the interior of the iron removal cavity; the outer wall of the iron removal rotating shaft is provided with permanent magnet sheets in a longitudinal symmetry manner. By using a high-efficiency pre-crushed chemical material agitator, the iron removal can be carried out on a raw material of a chemical material; in an agitation process, the scraping and the washing can be carried out on the chemical material, which is adhered to an inner wall, by a scraping and washing hairbrush; the waste which is caused as the chemical material is adhered to the inner wall is avoided; the material discharge can be carried out when a helical blade positively rotates; the agitation and the mixing can be carried out on the chemical material at a bottom when the helical blade negatively rotates; the agitation effect and efficiency are improved; the automatic and quantitative water addition can be realized; the quality of the material is guaranteed; the effective shock absorption can be realized by a spring pillar; further, the movement is more convenient and quicker; the practicability and the convenience are high.

Owner:GUANGXI UNIV

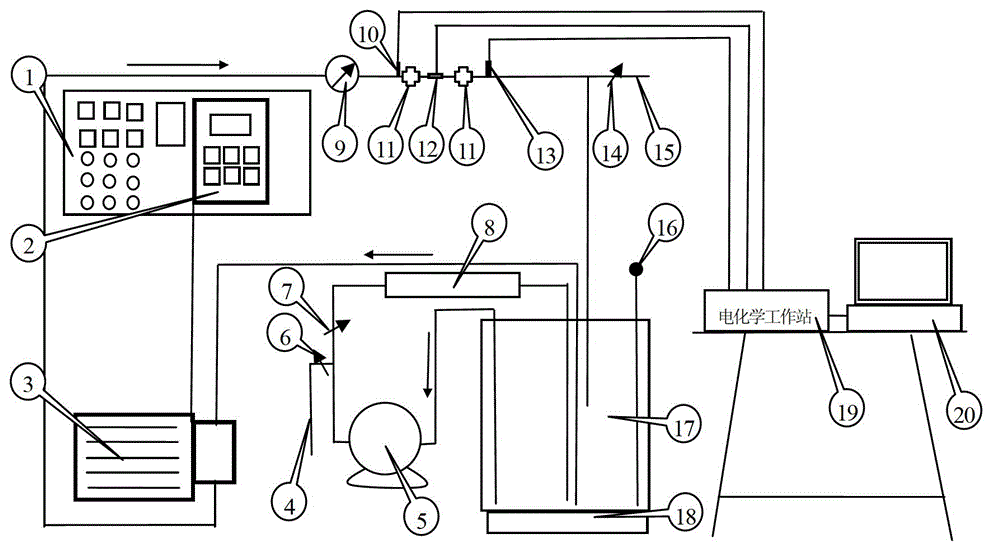

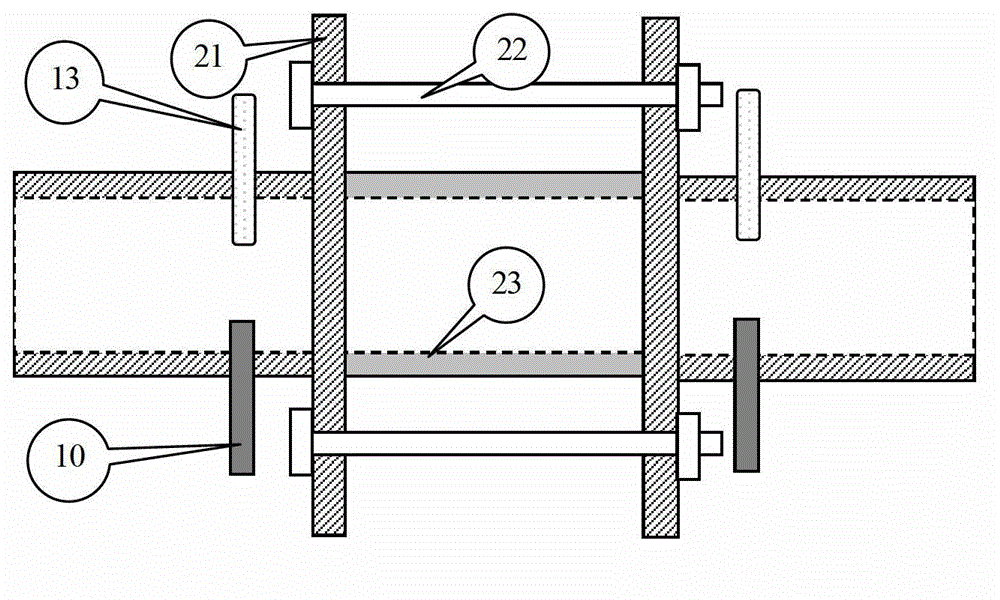

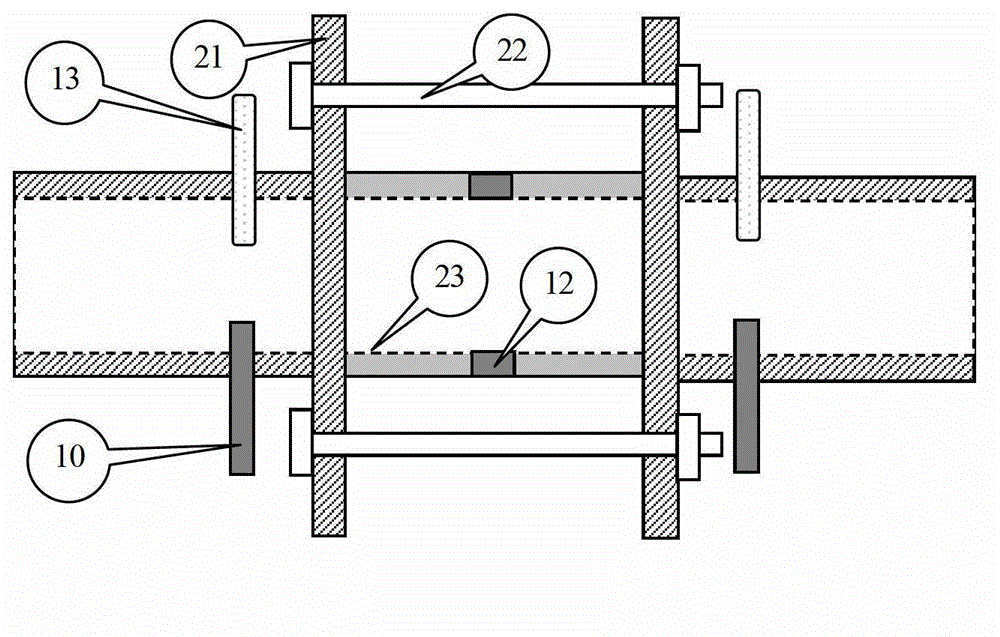

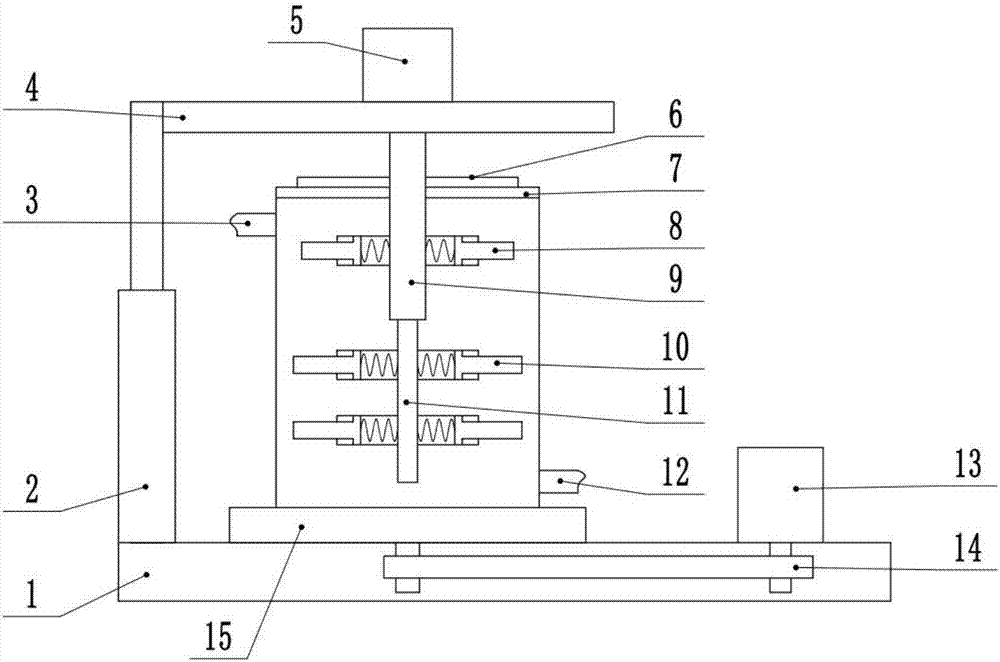

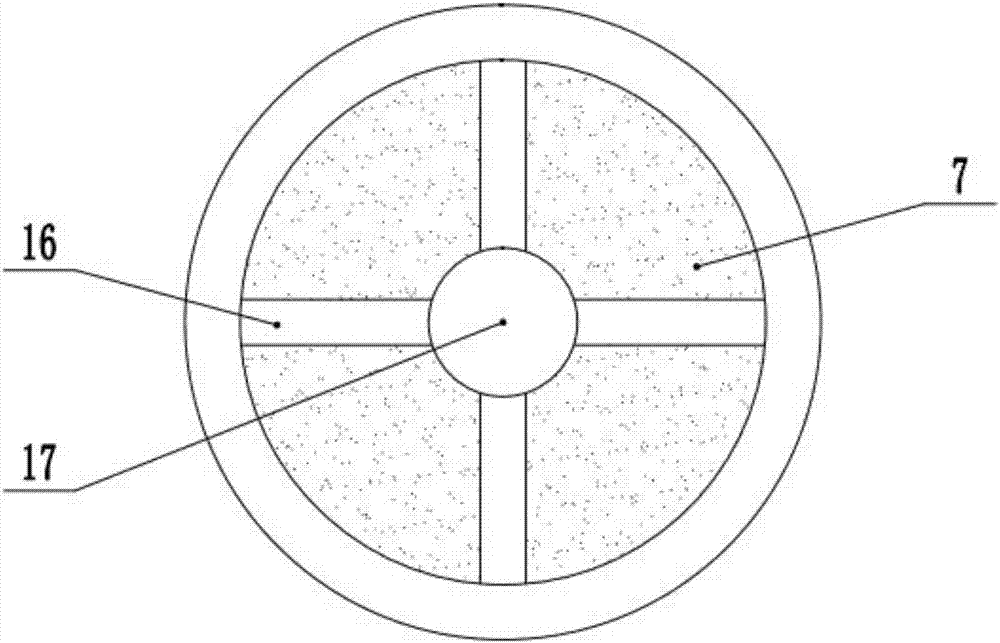

Pipe flow type inner wall erosion corrosion test device

InactiveCN103335939AImprove stirring efficiencyImproved media uniformityWeather/light/corrosion resistanceAuxiliary electrodeTangential force

The invention relates to the field of erosion corrosion tests, and particularly relates to a pipe flow type inner wall erosion corrosion test device which can be used for simulating the tangential force structure flow pattern on the pipeline surface at different flow speeds in pipe flow in an inner wall erosion corrosion test and used for realizing weight loss measurement of a material, real-time measurement of electrochemical parameters and the like. The pipe flow type inner wall erosion corrosion test device is composed of a power pump, a frequency converter, an electromagnetic flowmeter, a special clamp, a stirring pump, a cooler, a heater, a thermocouple, a slurry tank and the like; and the key lies in that tubular samples with different diameters can be adopted and are connected with a pipeline system by the special clamp, and the tubular samples are used as working electrodes which cooperate with reference and auxiliary electrode experimental tubular samples to realize real-time measurement of the electrochemical parameters. The device provided by the invention can be used as a small test device for simulating the inner wall erosion corrosion of a pipeline, and is used for evaluating the erosion corrosion resistance of a real pipe, and solves the problem of high construction cost of a traditional pipe flow type erosion corrosion test device.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Building-paint stirring device convenient for cleaning of stirring shaft

InactiveCN107126889AEasy to cleanEasy to use for a long timeRotating receptacle mixersTransportation and packagingCouplingEngineering

The invention discloses a building-paint stirring device convenient for cleaning of a stirring shaft. The building-paint stirring device comprises a base, a stirring motor, a fixing cover and rotary seat; the rotary seat is rotatably installed on the base, and a stirring barrel is fixedly installed on the rotary seat; a telescopic support is fixedly installed on the left side of the base, a top plate is fixedly installed at the telescopic end of the telescopic support, the stirring motor is fixedly installed on the upper side of the top plate, and the output end of the stirring motor is fixedly connected with the stirring shaft through a coupler; the stirring shaft is of a telescopic structure and is composed of a main telescopic rod and an auxiliary telescopic rod; a first stirring blade and a second stirring blade are respectively and symmetrically arranged on a main stirring rod and an auxiliary stirring rod. The building-paint stirring device is simple in structure; after stirring is competed, the stirring shaft can be taken out from the stirring barrel and cleaned conveniently, and long-term use of the stirring device is facilitated; paint stirring efficiency is improved through arrangement of the telescopic stirring blades and the rotatable stirring barrel.

Owner:宋衡星

High-efficiency paint stirring and mixing device capable of automatically turning

InactiveCN107020031AStir wellAvoid condensationFlow mixersRotary stirring mixersCircular discEngineering

The invention discloses a high-efficiency paint stirring and mixing device capable of automatically turning. The device comprises a base, a heating seat, a stirring barrel, a stirring motor and a stirring shaft, wherein the heating seat is fixedly arranged on the base; the stirring barrel is fixedly mounted inside the heating seat; the output end of the stirring motor is fixedly connected with a stirring shaft; an upper disc and a lower disc are arranged on the stirring shaft; a plurality of stirring blades are arranged on the outer side of the vertical stirring shaft; two turning motors are symmetrically arranged at the bottom of the stirring shaft; the output ends of the turning motors are fixedly connected with the vertical stirring shaft; a turning plate is arranged on the vertical stirring shaft. The heating seat is arranged on the outer side of the stirring barrel, so that paint is heated in the stirring process and is prevented from being condensed into pieces; the turning plate is arranged at the bottom of the stirring shaft, so that the paint is prevented from being stacked at the bottom of the stirring barrel; therefore, the paint is uniformly stirred, and the stirring efficiency is improved.

Owner:六安市智奇工业设计有限公司

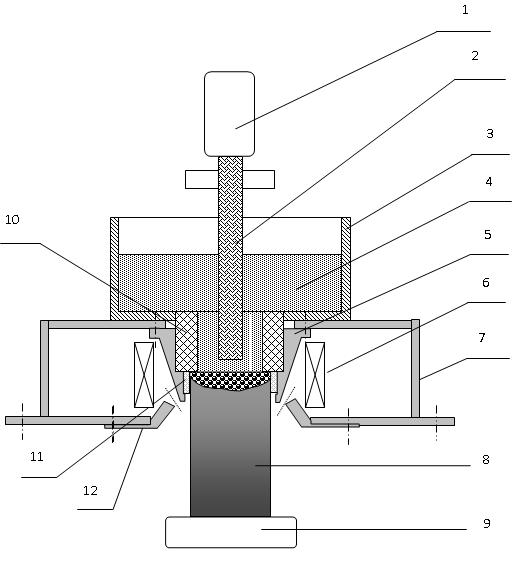

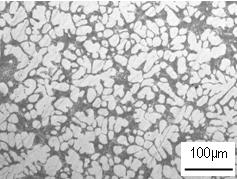

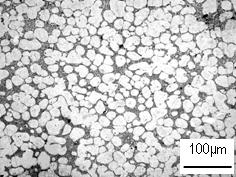

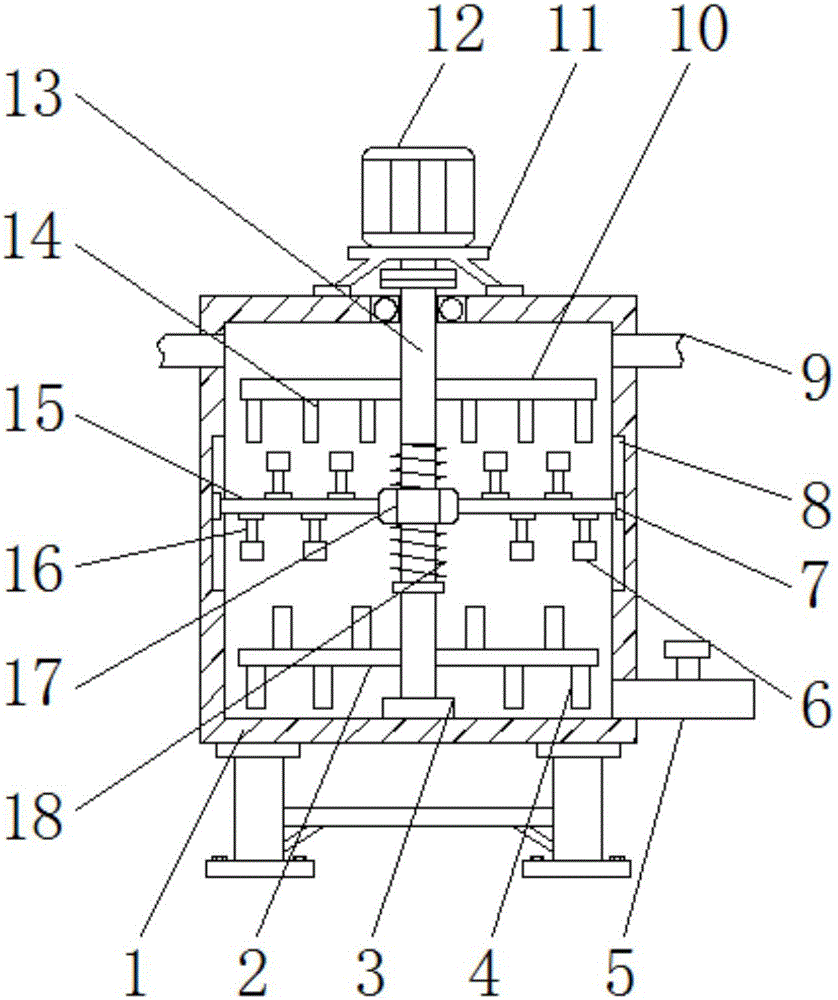

Continuous casting method for producing aluminium alloy semisolid casting ingot

The invention belongs to the technical field of metal semisolid processing and relates to a continuous casting method for producing an aluminium alloy semisolid casting ingot. The continuous casting method is characterized by comprising the following steps: firstly, a flow splitting disc, a flow guiding pipe and a stirring rod of a mechanical stirrer positioned at the central part of the flow guiding pipe are preheated at the temperature of 50-80 DEG C; then overheat aluminium liquid with qualified smelting is casted into the flow splitting disc continuously at the temperature of 100-200 DEG C higher than the temperature of a liquid phase line; when the level of the aluminium liquid in the flow splitting disc reaches the range from 50 to150mm, a dummy ingot base starts to act, the continuous casting process is started, and the level of aluminium liquid in the flow splitting disc needs to be maintained in the range from 50 to 150mm; and finally, while the process of continuous casting is started, simultaneously an electromagnetic stirrer positioned at the outer part of the flow guiding pipe and the mechanical stirrer positioned at the central part of the flow guiding pipe are started and aluminium liquid flowing through the flow guiding pipe is stirred. The continuous casting method has the advantages that the aluminium alloy semisolid casting ingot can be produced in a low-cost and large-batch manner, and the continuous casting method is especially suitable for batch production of large-diameter aluminium alloy semisolid casting ingots.

Owner:TIANJIN FLEMINGS ALUMINUM

High-efficiency-stirring mixing device for chemical engineering

InactiveCN107433157AImprove stirring efficiencyEasy to useTransportation and packagingRotary stirring mixersBlend timeScrew thread

The invention discloses a high-efficiency-stirring mixing device for chemical engineering. The device comprises a box body, the tops at two sides of a box body inner cavity both communicate with a liquid inlet pipe, the bottom at the right side of the box body inner cavity communicates with a liquid outlet pipe, and the centers at the two sides of the box body inner cavity are separately provided with a sliding groove. According to the invention, stirring boxes, a forward / reverse rotation electrical machine, a stirring shaft, a connection rod, fixing rods, a thread sleeve, screw threads, fixing shafts, through holes and vane wheels are arranged in the device and are used in a cooperating manner, and a plurality of chemical mixed solutions can be stirred up and down, thus stirring efficiency of the mixing device for the chemical engineering is higher, problems that when a conventional mixing device for the chemical engineering is used, the conventional mixing device for the chemical engineering can just stir a plurality of the chemical mixed solutions left and right, and cannot stir a plurality of the chemical mixed solutions up and down and left and right at the same time, so that a condition that the uniform-mixing time of a plurality of the chemical mixed solutions is relatively long, and stirring efficiency of the conventional mixing device for the chemical engineering is relatively low are solved.

Owner:张家港保税区贤德国际贸易有限公司

High-efficiency cement mixing device for construction sites

InactiveCN106142348ASave human effortLow costCement mixing apparatusLiquid ingredients supply apparatusLeft wallMaterials science

The invention relates to a mixing device, and particularly relates to a high-efficiency cement mixing device for construction sites. The technical problem to be solved is to provide the high-efficiency cement mixing device for construction sites with the high mixing efficiency. In order to solve the technical problem, the high-efficiency cement mixing device for construction sites comprises a tank, a first sliding rail, a first sliding block, a gear rack, a second connecting rod, a rotating motor, a gear, a supporting rod, a placing groove, blades, mixing rods, a lead screw and the like, wherein the first sliding block is arranged on the first sliding rail; the placing groove is formed in the top of the first sliding block; a spring is arranged on the right wall of the placing groove; the right end of the spring is connected to the inner right wall of the tank; and a second fixed pulley and a first fixed pulley are arranged on the inner left wall of the tank. The high-efficiency cement mixing device achieves the effect of high-efficiency cement mixing.

Owner:陈雯娣

Lime slurry smearing device for trees

PendingCN109395943AAchieving Circumferential CoverageRealize smearing workSpraying apparatusPlant protectionEngineeringSlurry

The invention discloses a lime slurry smearing device for trees, and relates to the technical field of tree maintenance. The lime slurry smearing device for trees includes a base, wherein a lime slurry containing bucket is arranged on the base; a support frame is arranged at the front portion of the base; a support plate is slidably connected with the support frame; a first motor is arranged on the support plate; the output end of the first motor is provided with a gear; the front end of the support plate is provided with a curved plate; the curved plate is provided with a curved sliding rail;the inside of the curved sliding rail is slidably connected with a curved slider; the ends of the curved slider are provided with two spaying heads; the spray heads are connected with the lime slurrycontaining bucket; a rack is arranged on the upper portion of the outer wall of the curved slider; and the rack meshes with the gear. The lime slurry smearing device for trees has the beneficial effect that the lime slurry can be quickly smeared on the trees without dead angle.

Owner:韩东峻

Concrete mixing device for quickly mixing concrete conveniently

InactiveCN107322804AImprove stirring efficiencyStir wellCement mixing apparatusSold ingredients supply apparatusEngineeringAir bubble

The invention discloses a concrete mixing device which is convenient for rapid mixing. Motor, the bottom end of the feeding hopper is connected with the feeding port opened on the body through the feeding pipe, the material on the upper side inside the body can be discharged from the discharge port, and a second motor is arranged on the upper side of the body, the second motor The output shaft passes through the upper surface of the machine body and is fixedly connected with the first gear. The invention is a concrete mixing device convenient for rapid mixing, which can pre-crumble the materials, and the stirring shaft revolves around the body axis while rotating. It can fully mix the internal materials, and scrape off the materials adhered to the inner wall of the machine. During the mixing process, it can drive the machine body to shake left and right, further improving the mixing efficiency, and can effectively avoid the generation of air bubbles. In addition, it can be conveniently It can be fixed and moved with high convenience.

Owner:徐柳华

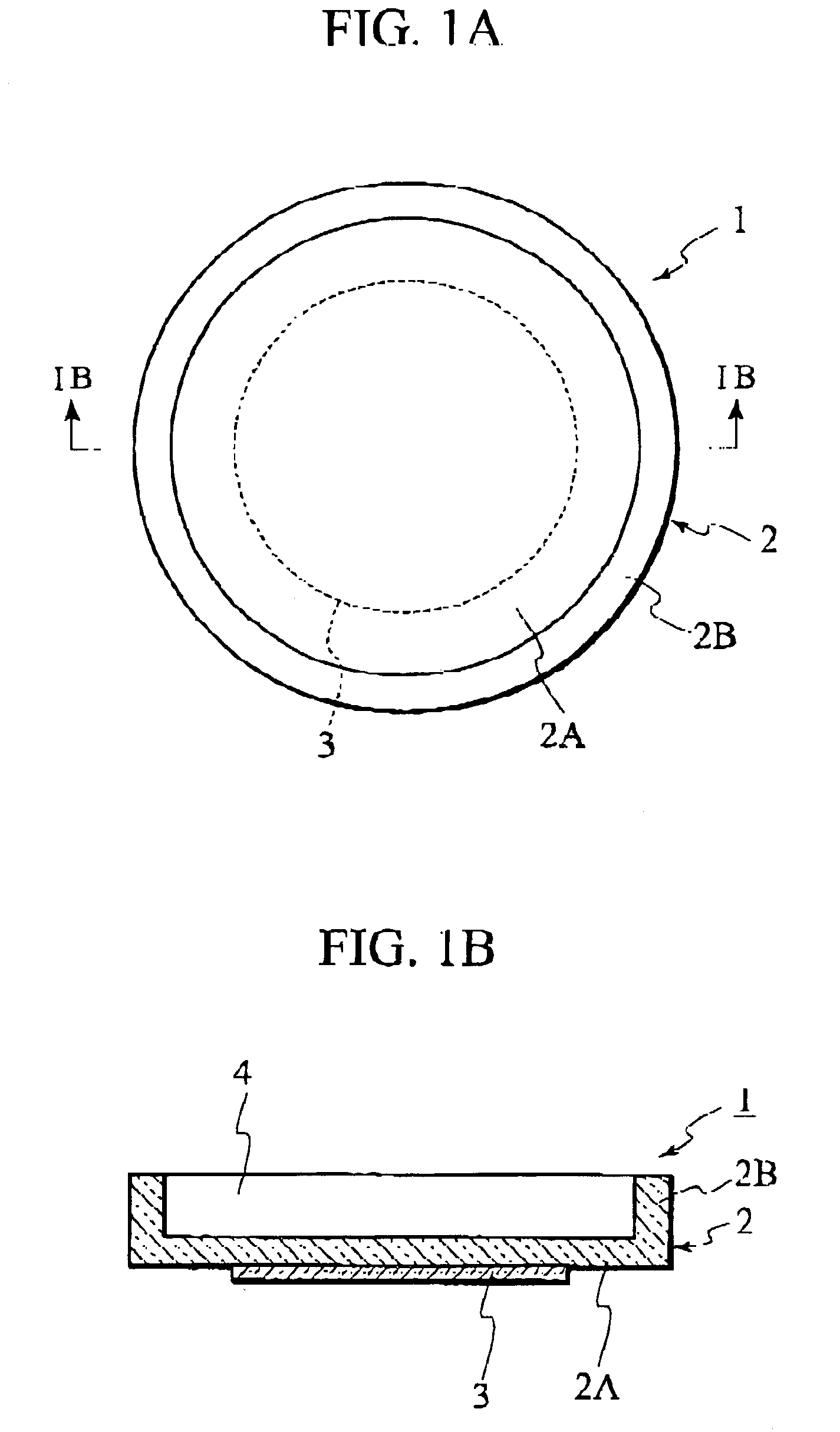

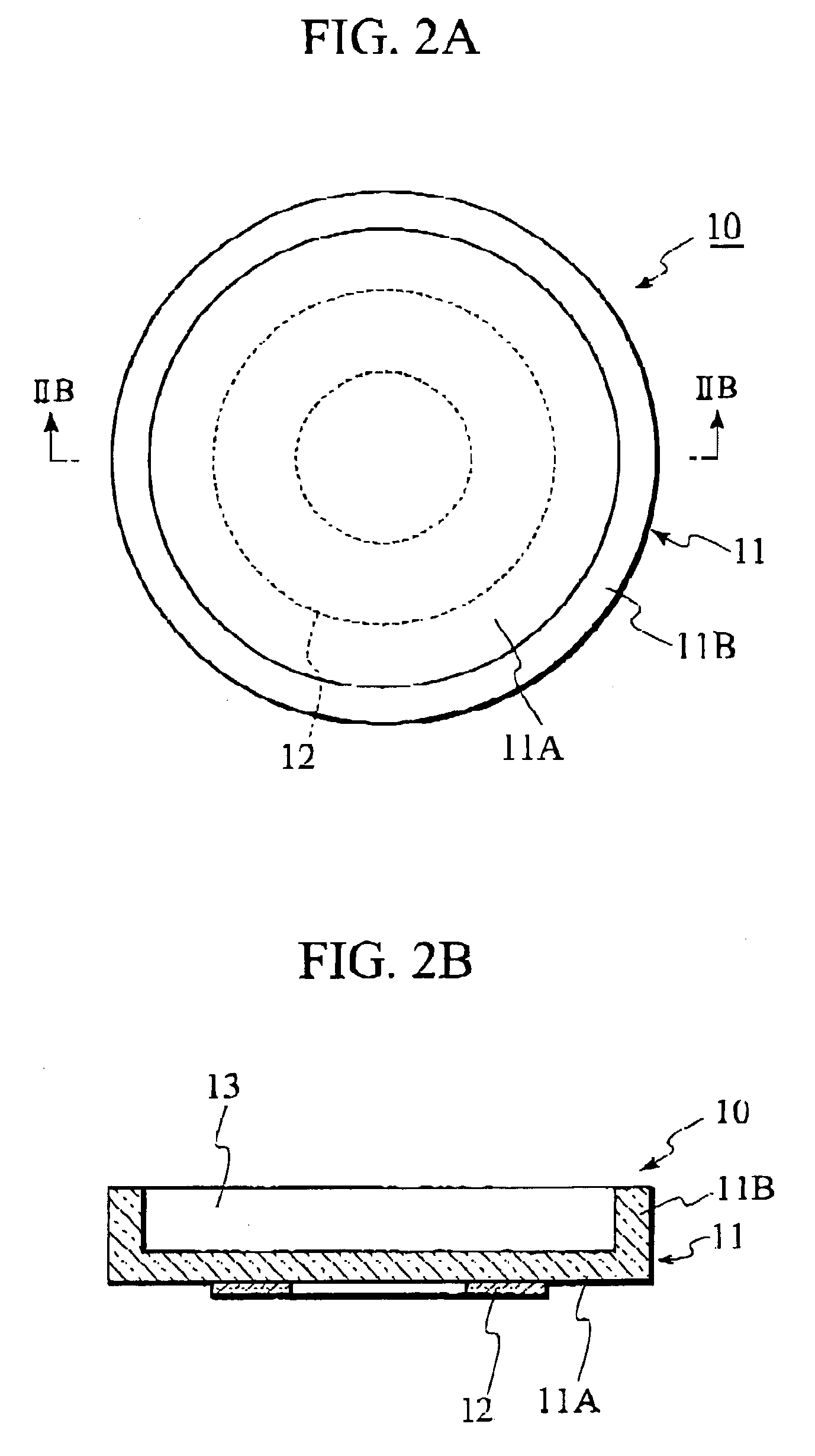

Reaction cell and operation method thereof

InactiveUS7341697B2Easy to controlSmall sizeBioreactor/fermenter combinationsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricityEngineering

A reaction cell is provided with a vessel-like cell main body and a circular piezoelectric / electrostrictive oscillator fixed to an outside of a bottom surface of the cell main body. The cell main body includes a circular bottom plate portion and a circumferential wall portion which rises from a circumferential edge of the bottom plate portion so as to thereby surround the bottom plate portion. The bottom plate portion and the circumferential wall portion are integrally formed from ceramics. A solution accommodation space is formed above the bottom plate portion and is partially enclosed by the circumferential wall portion. The piezoelectric / electrostrictive oscillator is concentrically adhered to the outside of the bottom surface of the cell main body.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com