Patents

Literature

94results about How to "Quick Stir to Mix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

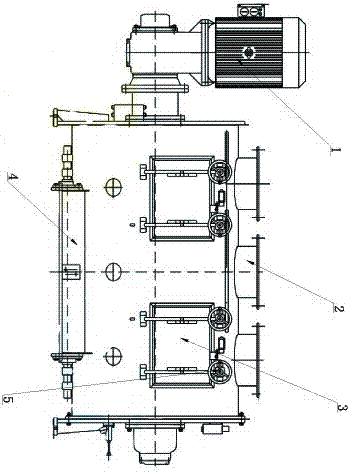

Acid liquor mixing equipment

PendingCN111151186AImprove mixing efficiencyImprove stirring efficiencyTransportation and packagingFluid removalProcess engineeringStatic mixer

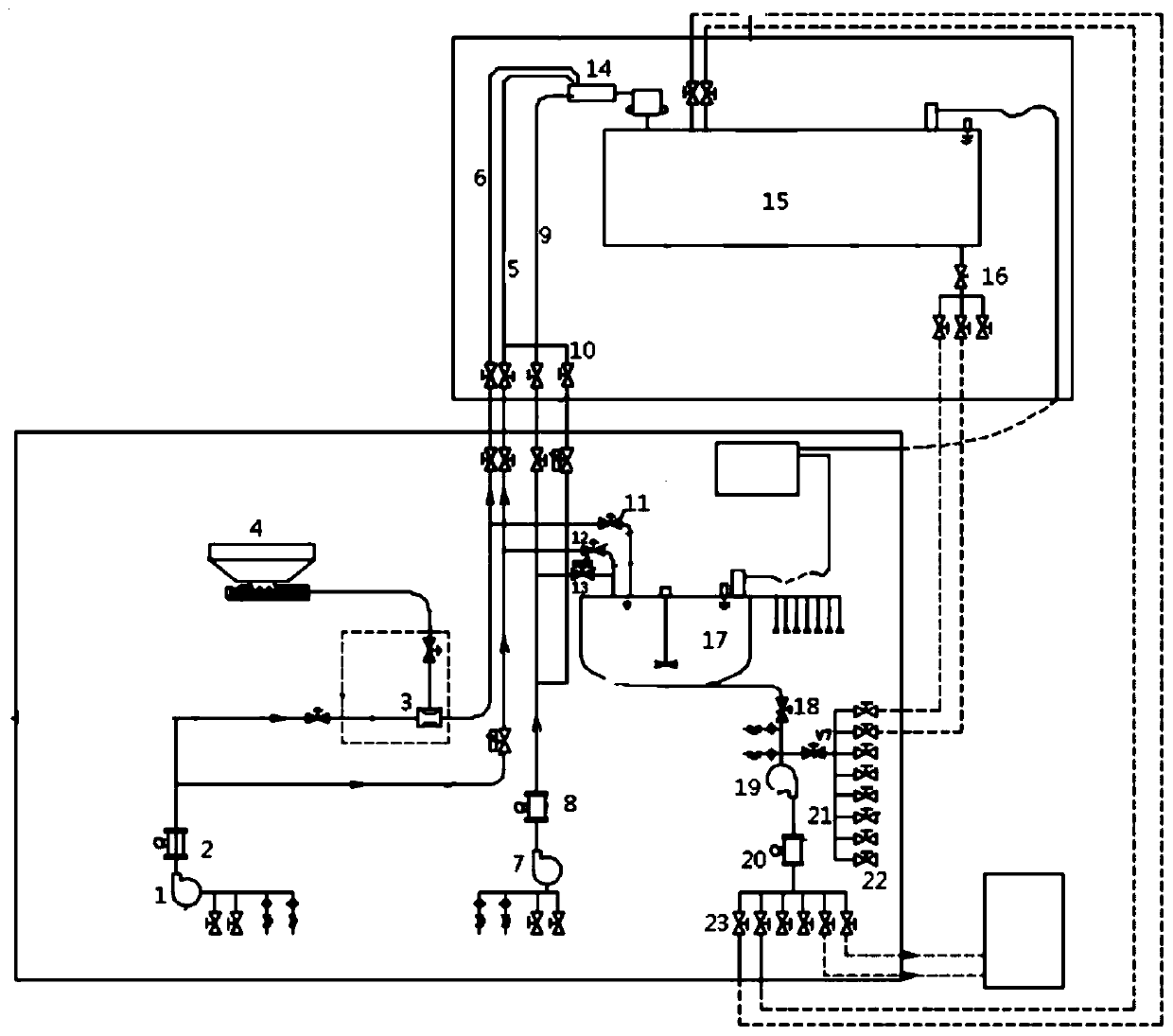

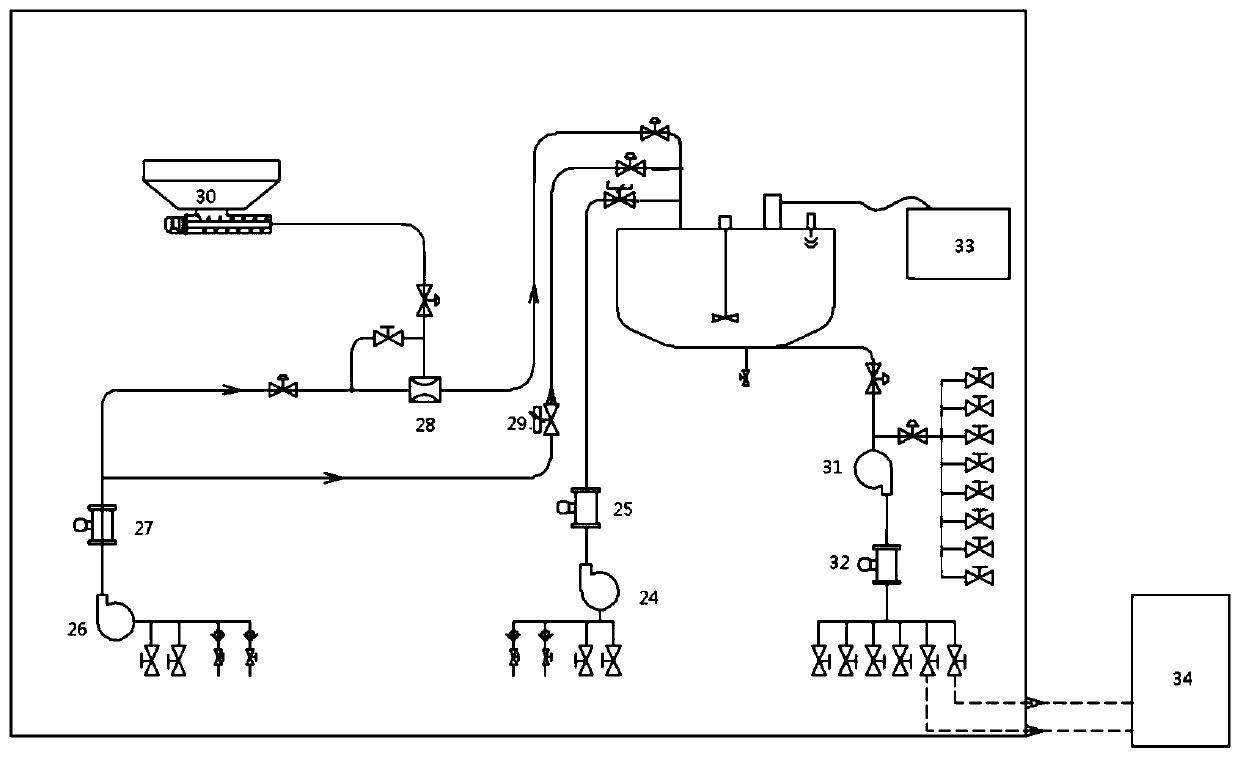

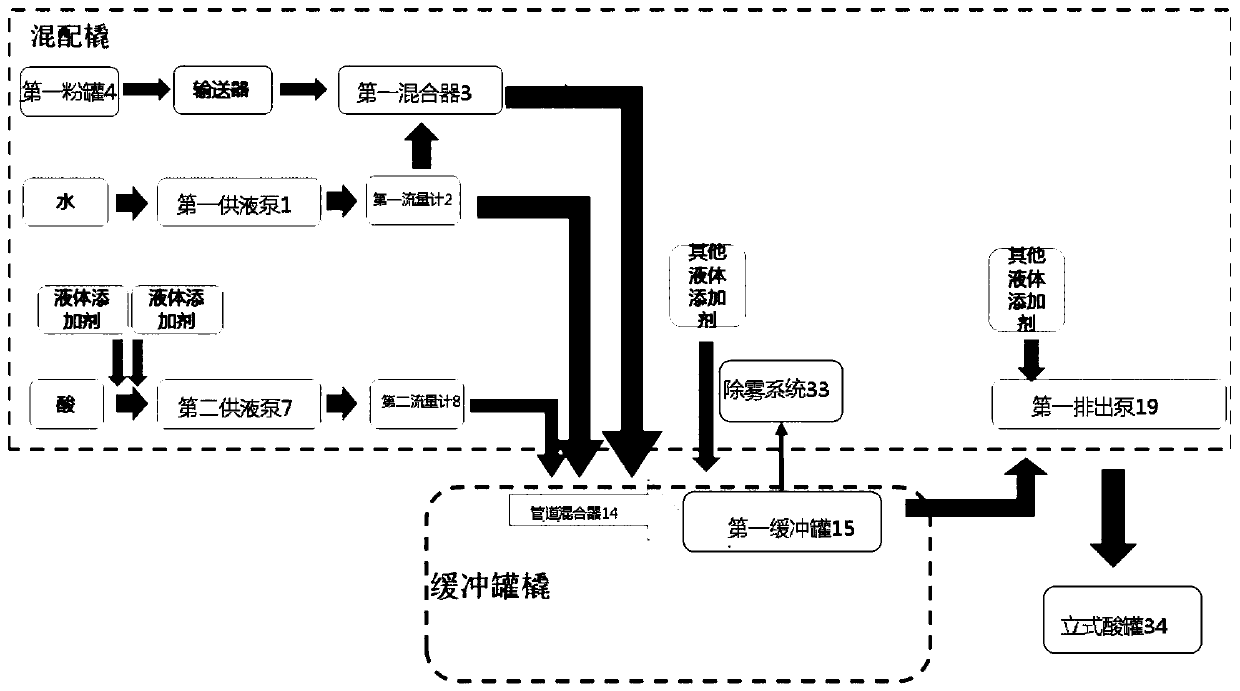

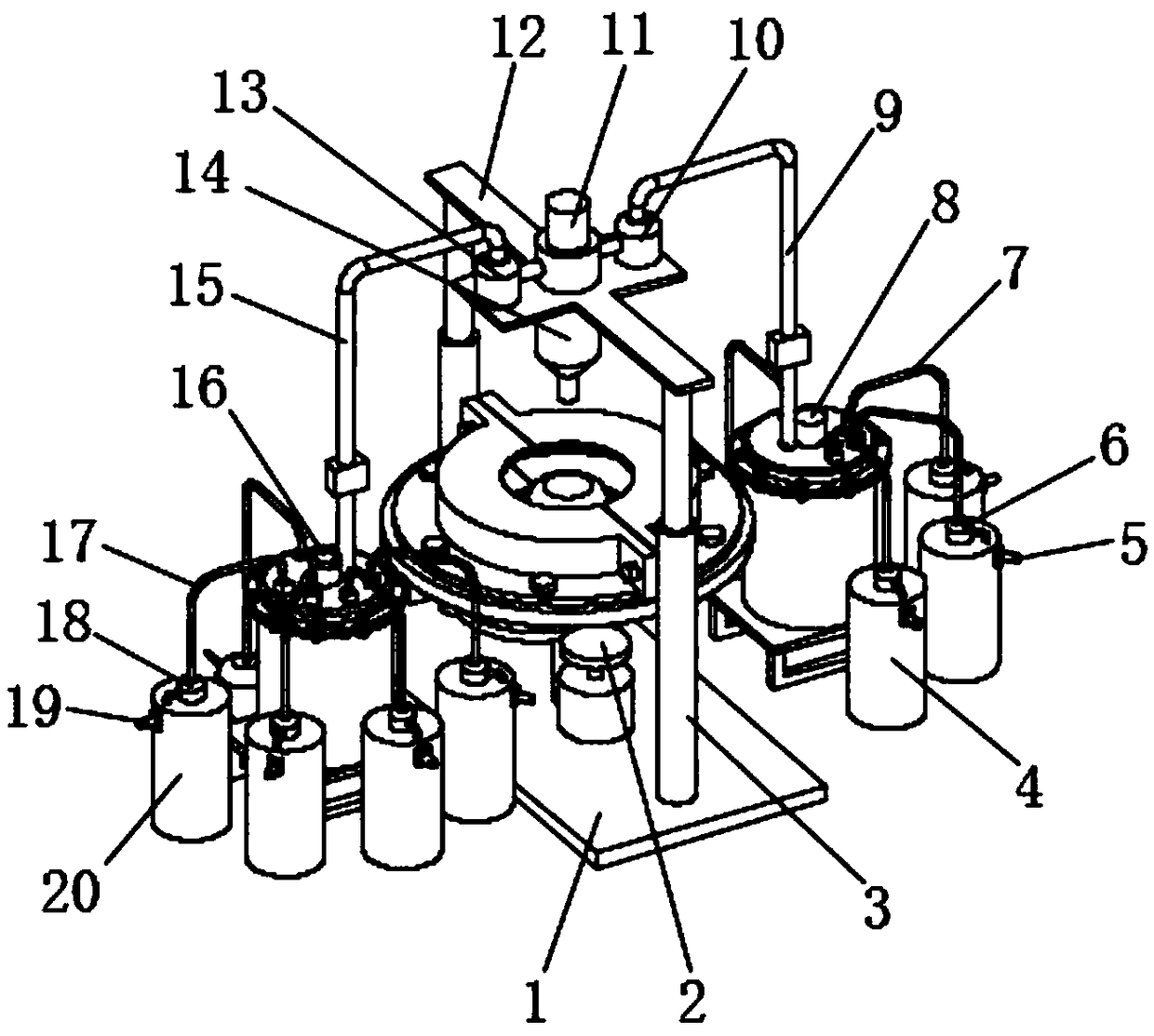

Acid liquor mixing equipment comprises a buffer system, a pipeline mixing pipe system and an output system. The pipeline mixing pipe system is communicated with the buffer system and is used for mixing materials in a pipe and spraying the mixed material to the buffer system. The buffer system is connected with the output system and is used for outputting the stirred mixed material in real time through the output system. Materials are mixed in the pipe through a spraying system, the efficiency of the mixing and stirring process can be improved through one or more of a spraying mixer, a three-way mixer, a static mixer, a rotational flow mixer and the like, rapid stirring and mixing can be achieved, and prepared acid liquor is output in real time through the output system connected with a stirring system. Through the connection of the pipeline mixing pipe system, the stirring system and the output system, the two processes of acid liquor preparation and acid liquor output can be continuously carried out, and the production efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

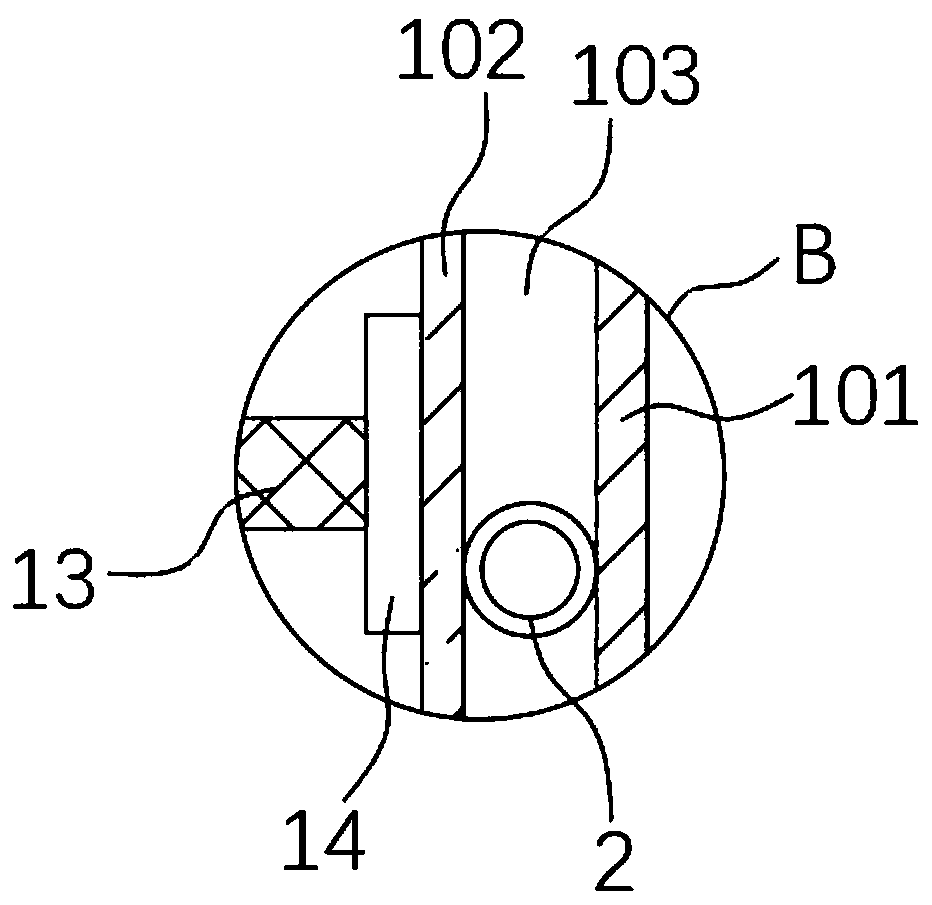

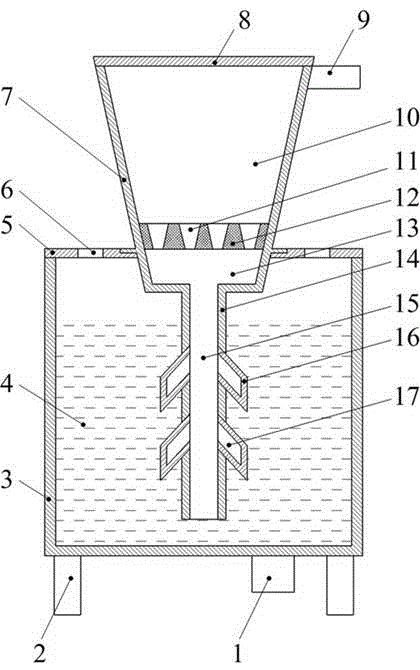

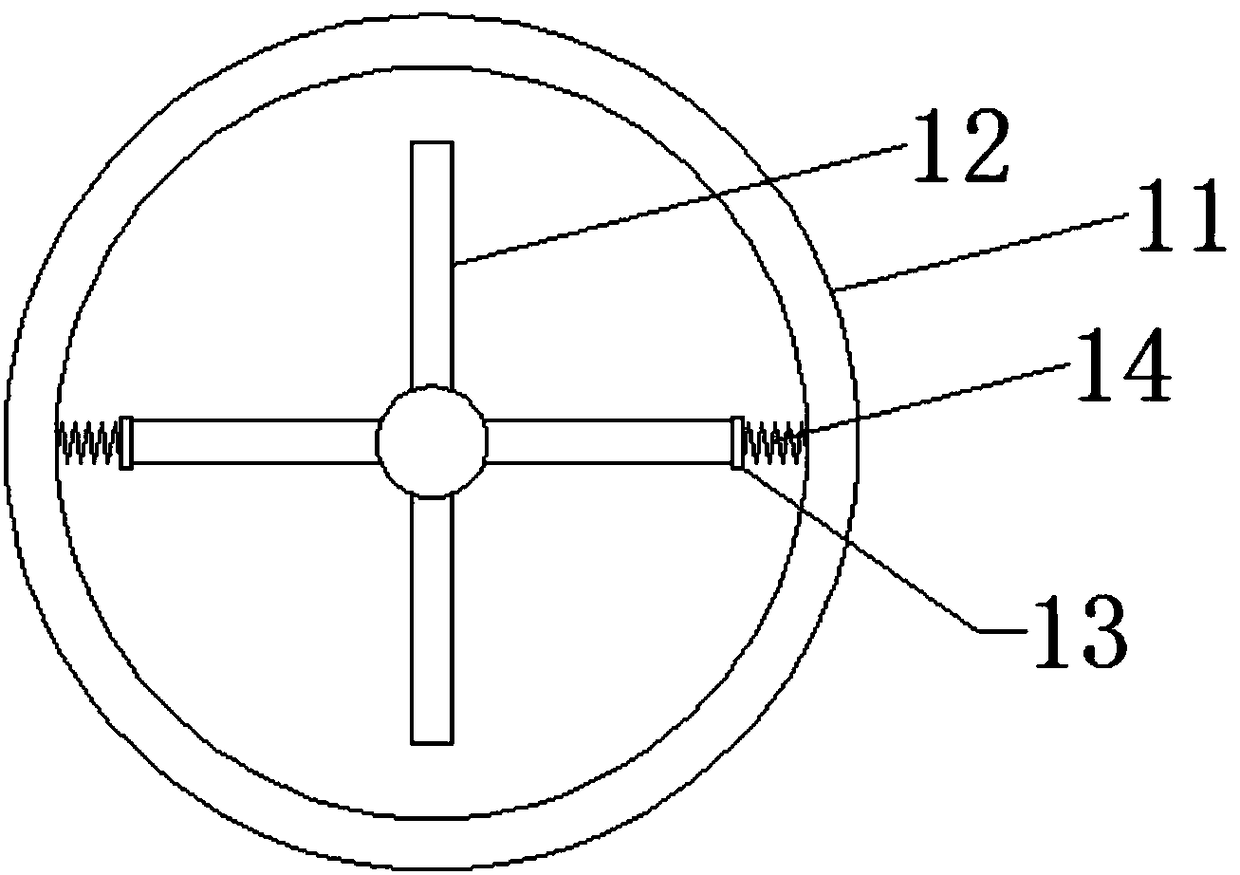

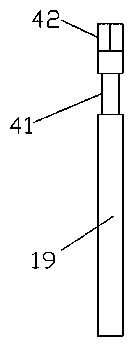

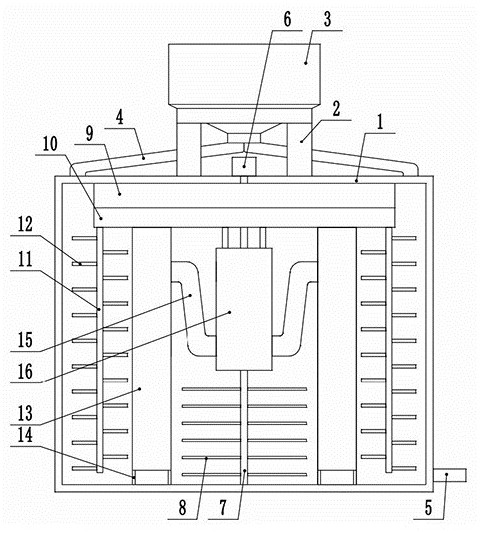

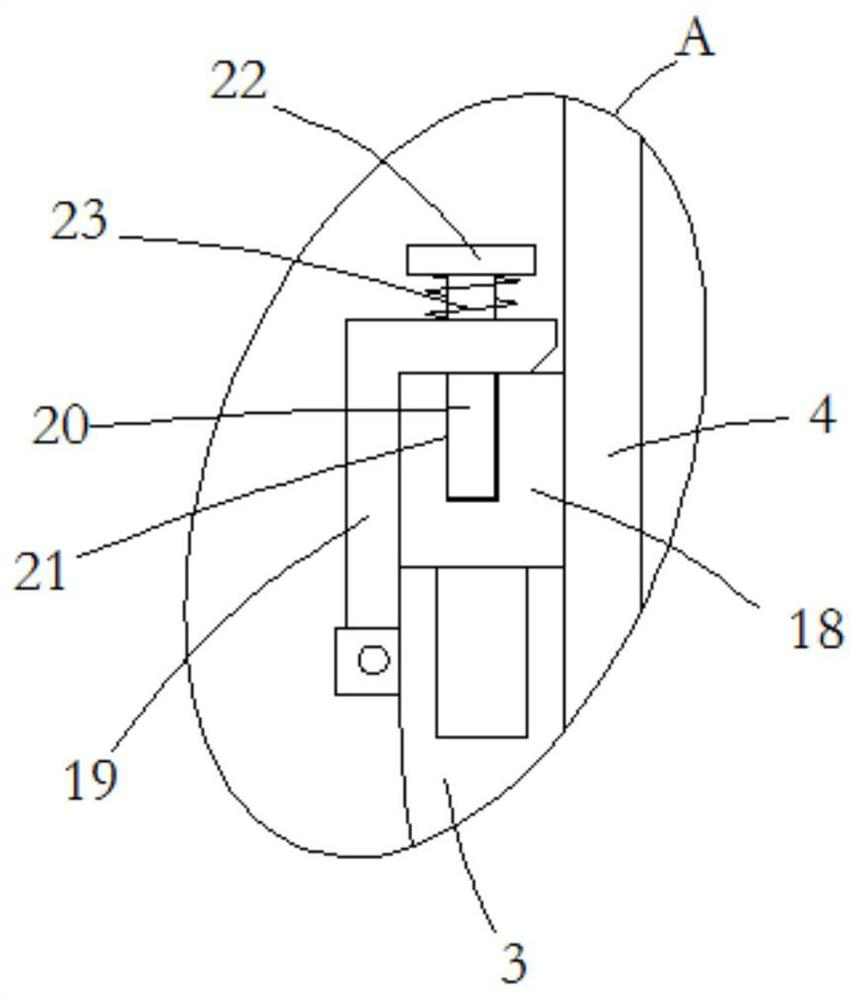

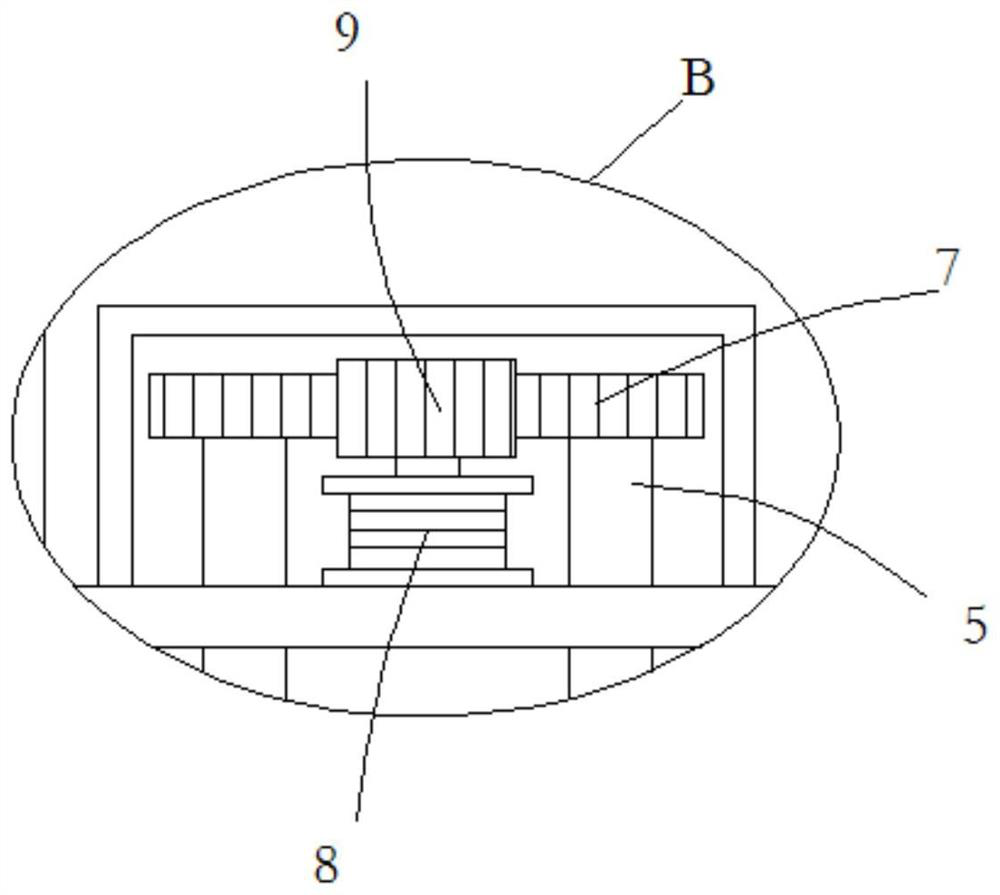

Petroleum mechanical device suitable for heavy oil exploitation

InactiveCN110327821ASolve the problem of thermal inefficiencyIncrease widthShaking/oscillating/vibrating mixersTransportation and packagingElectromagnetic heatingPetroleum

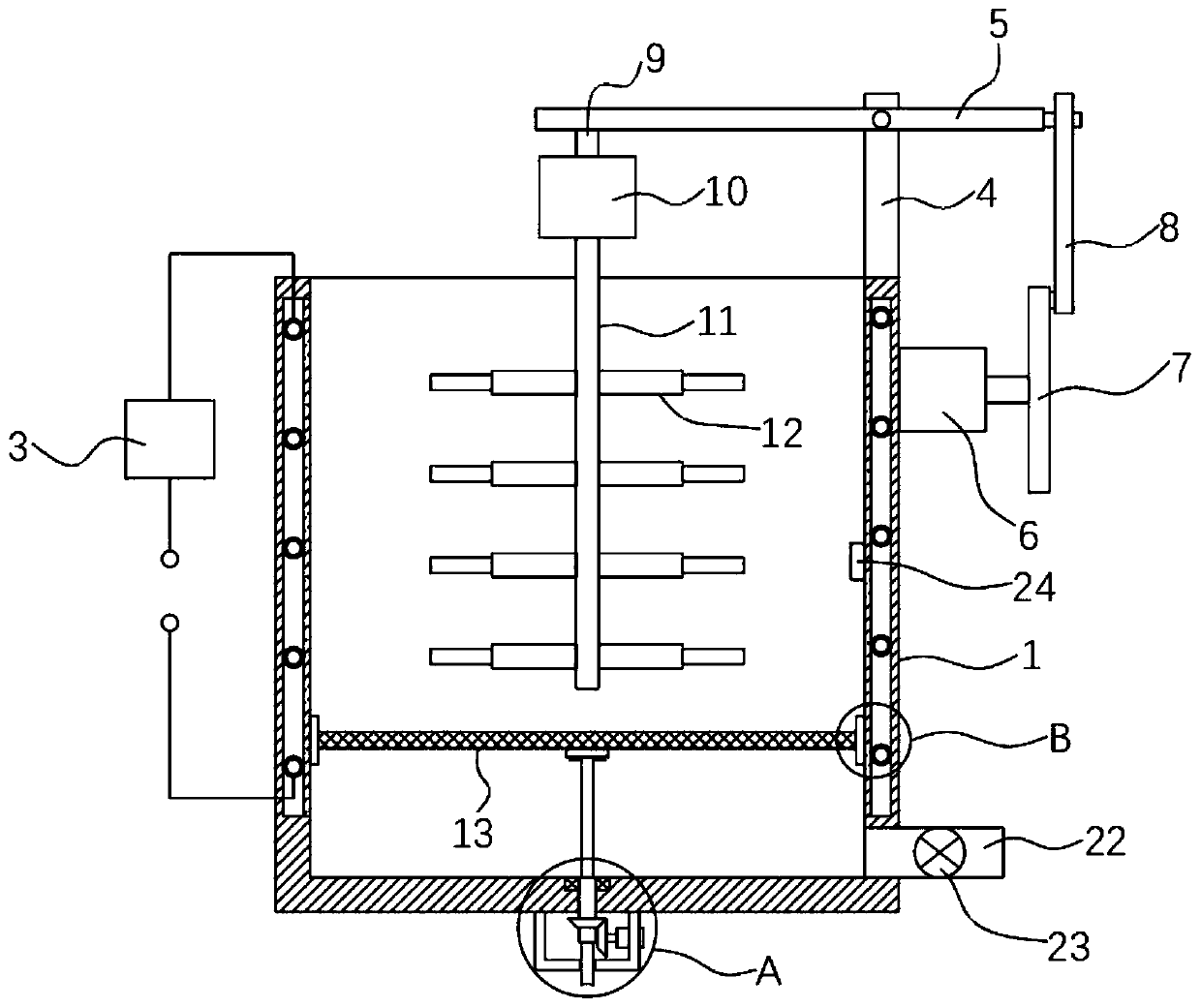

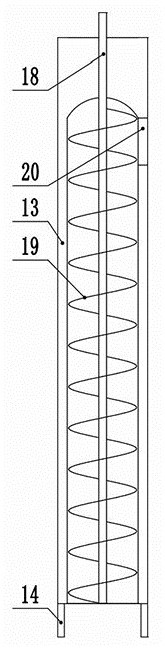

The invention discloses a petroleum mechanical device suitable for heavy oil exploitation, the petroleum mechanical device comprises a tank body, wherein the tank body comprises a metal frame and an outer frame which are arranged inside and outside and are hermetically and fixedly connected with each other. A built-in cavity is formed between the metal frame and the outer frame; an electromagneticinduction coil which is arranged in a spring shape is arranged in the built-in cavity; one end of the electromagnetic induction coil is connected with an electromagnetic heating controller. The electromagnetic heating controller is connected with a mains power supply; and the other end of the electromagnetic induction coil is connected with the mains power supply. The upper end of the tank body is fixedly connected with a support rod, the upper end of the support rod is rotatably connected with a cross rod, the left end of the cross rod is fixedly connected with a motor rod, and the lower endof the motor rod is fixedly connected with a stirring motor. According to the invention, a mixed liquid of heavy oil and water can be quickly stirred and mixed, the heating efficiency is improved through an electromagnetic heating mode, and the problem of blockage caused by impurities flowing out through a liquid outlet pipe is avoided.

Owner:徐州亚泰电机有限公司

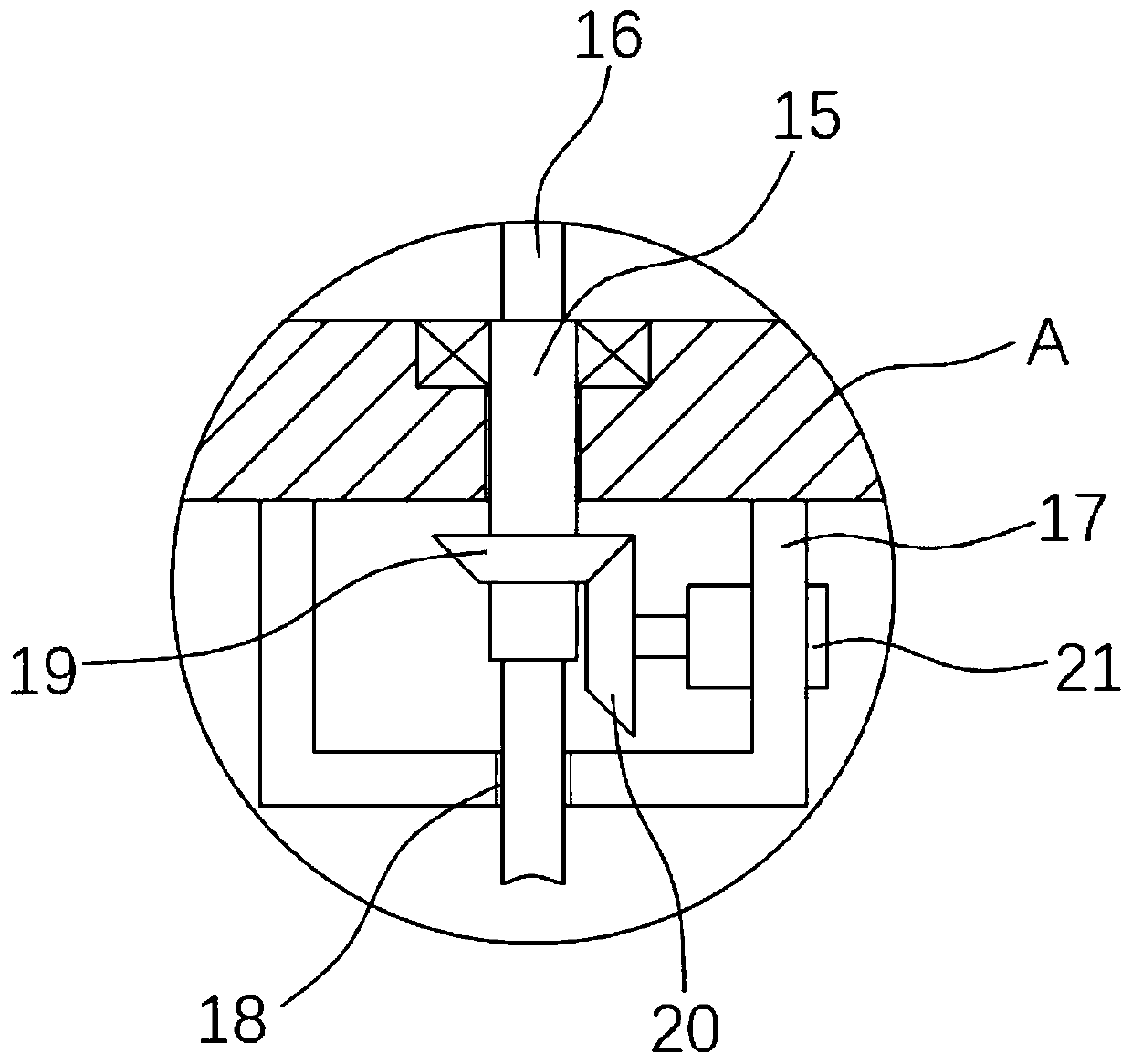

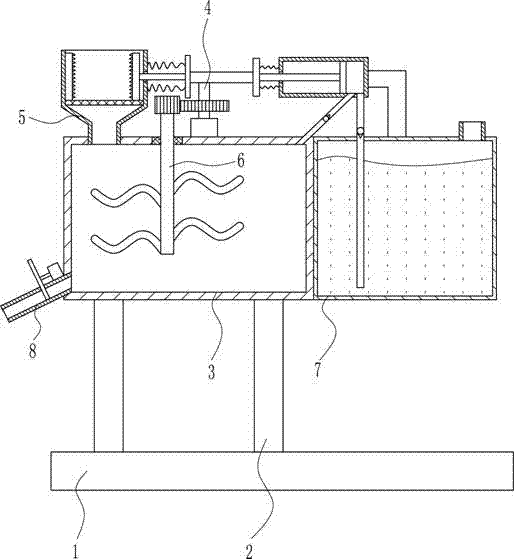

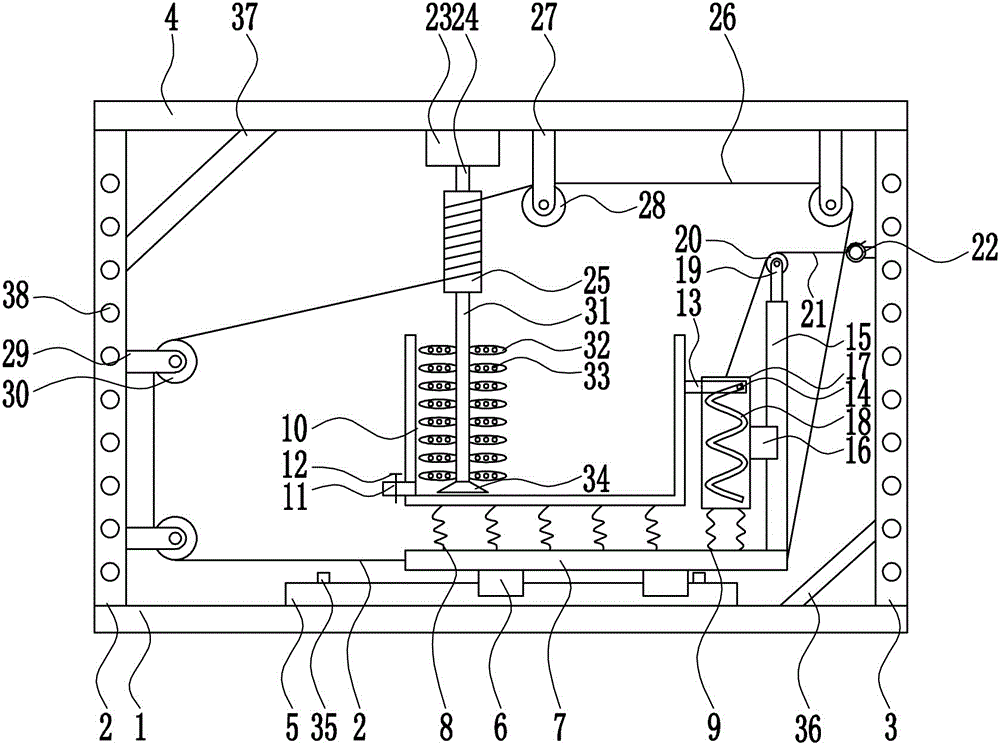

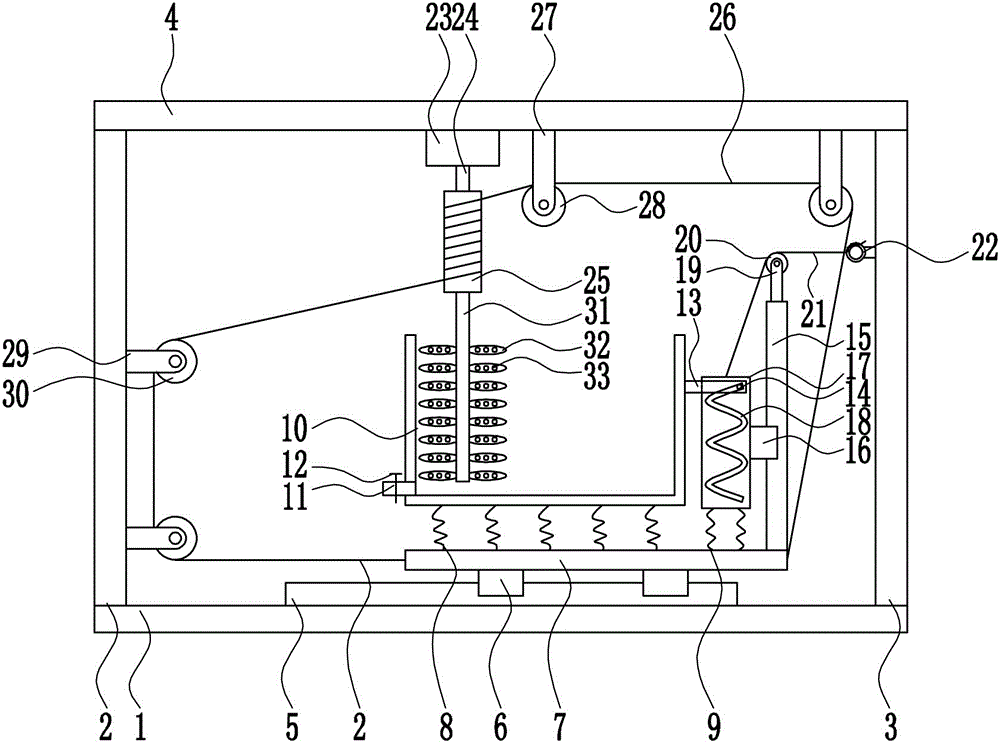

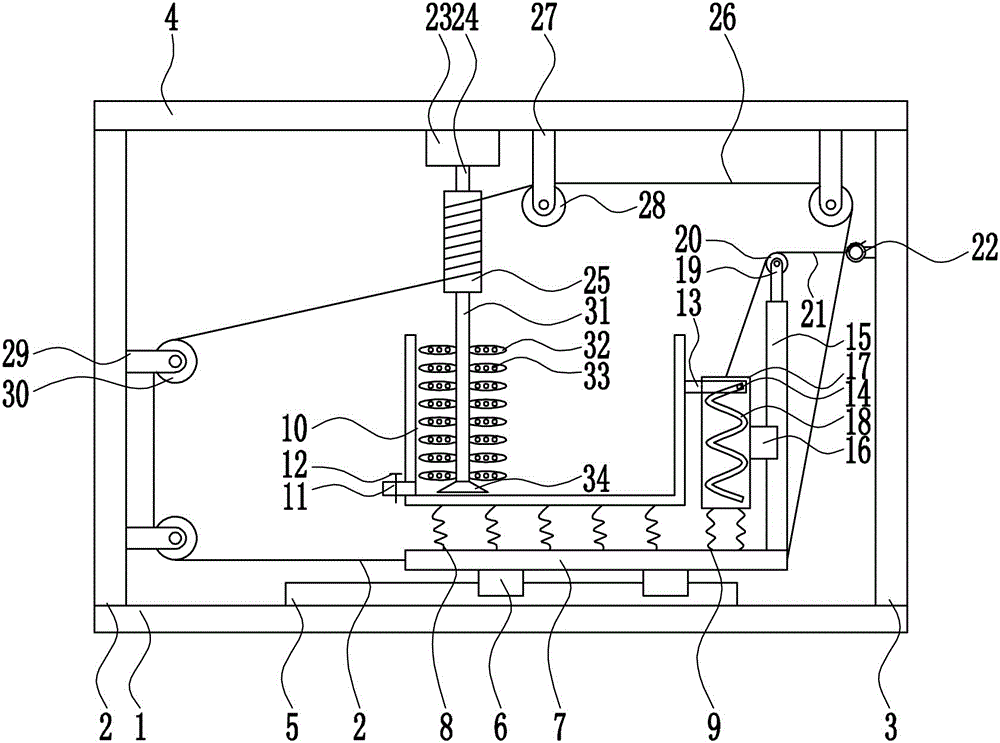

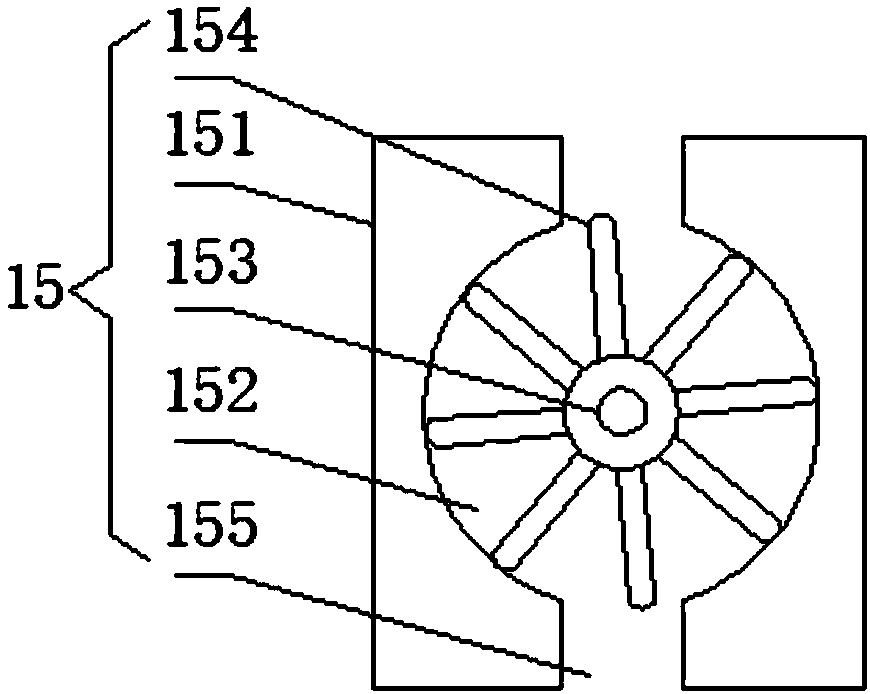

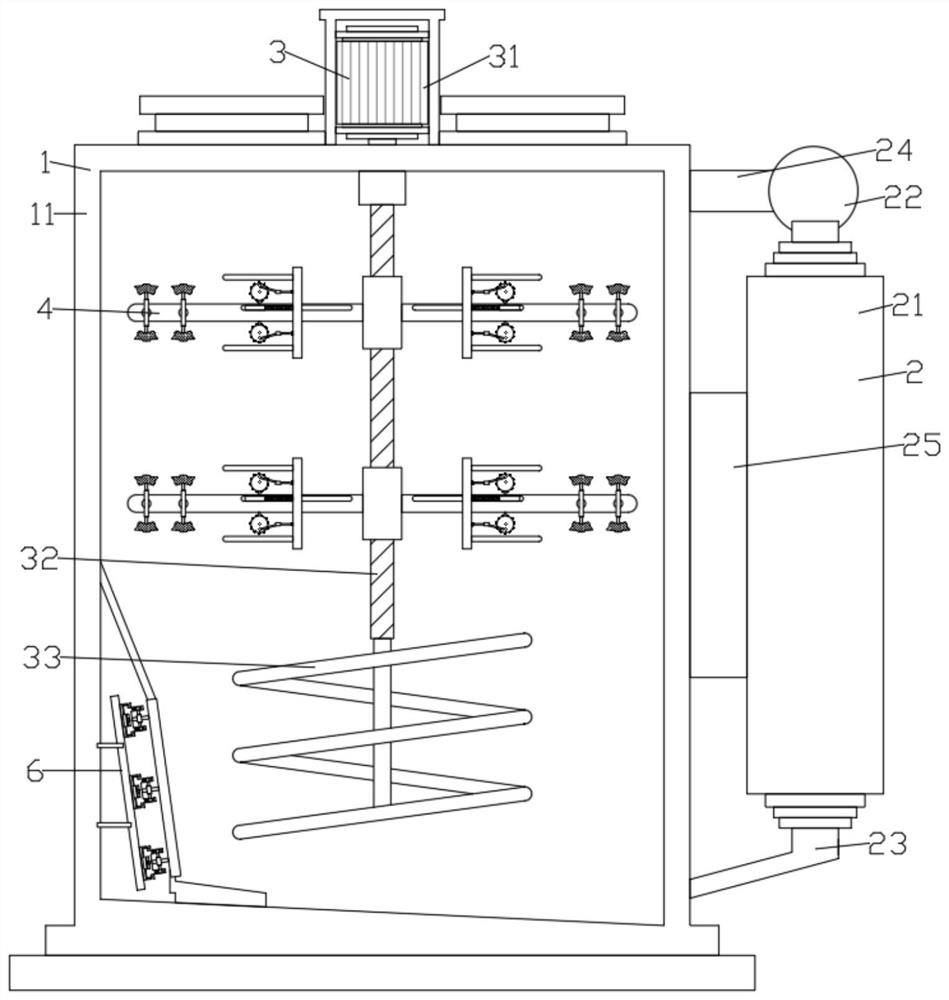

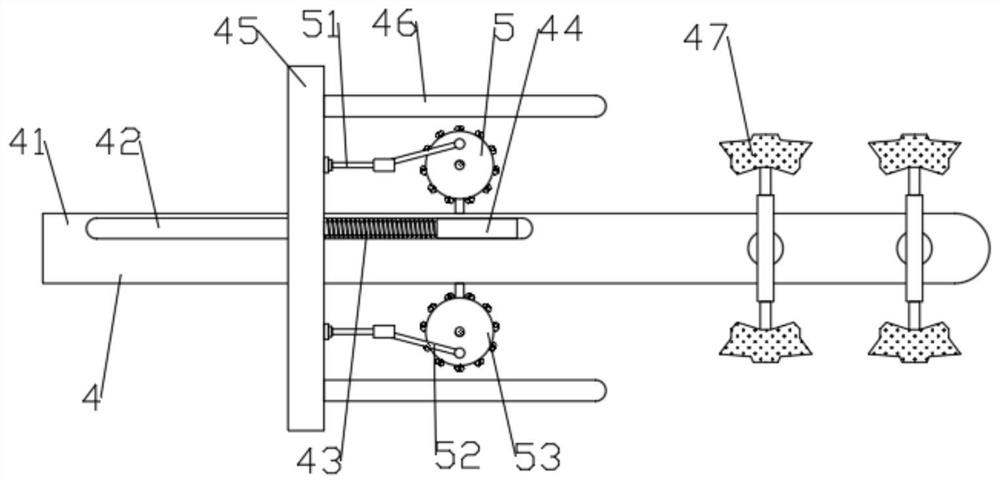

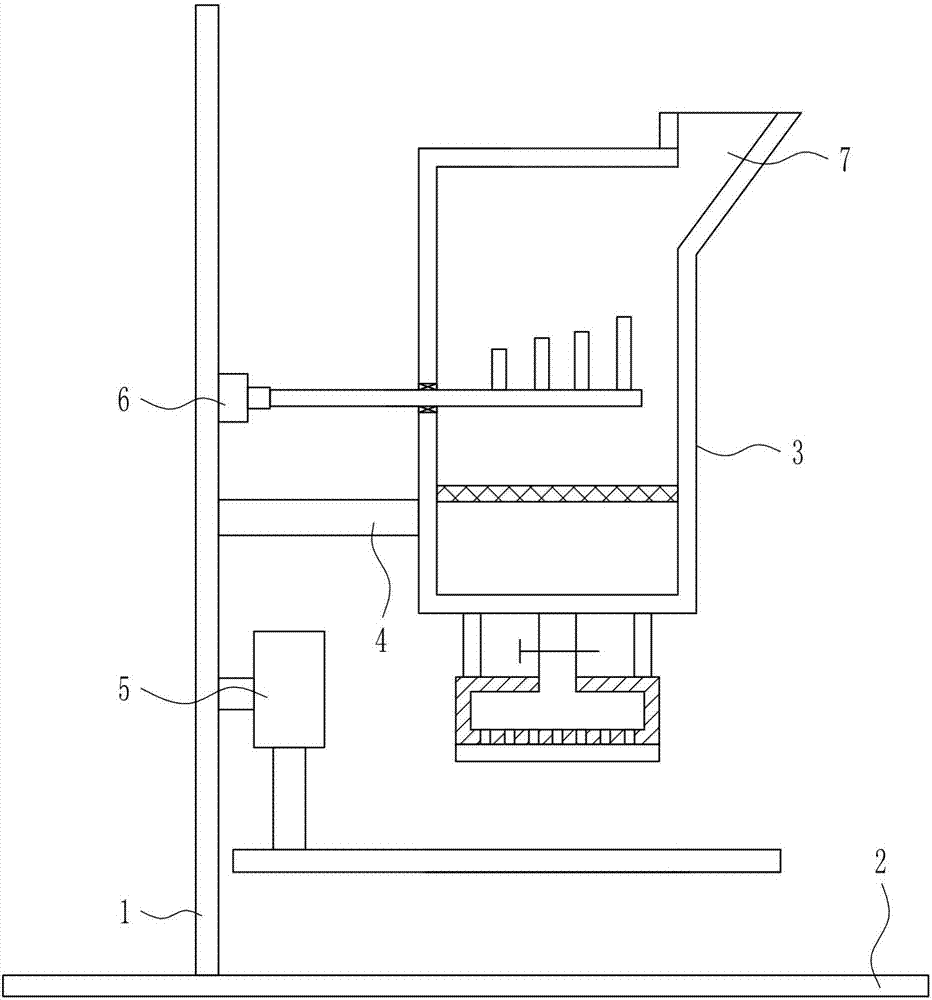

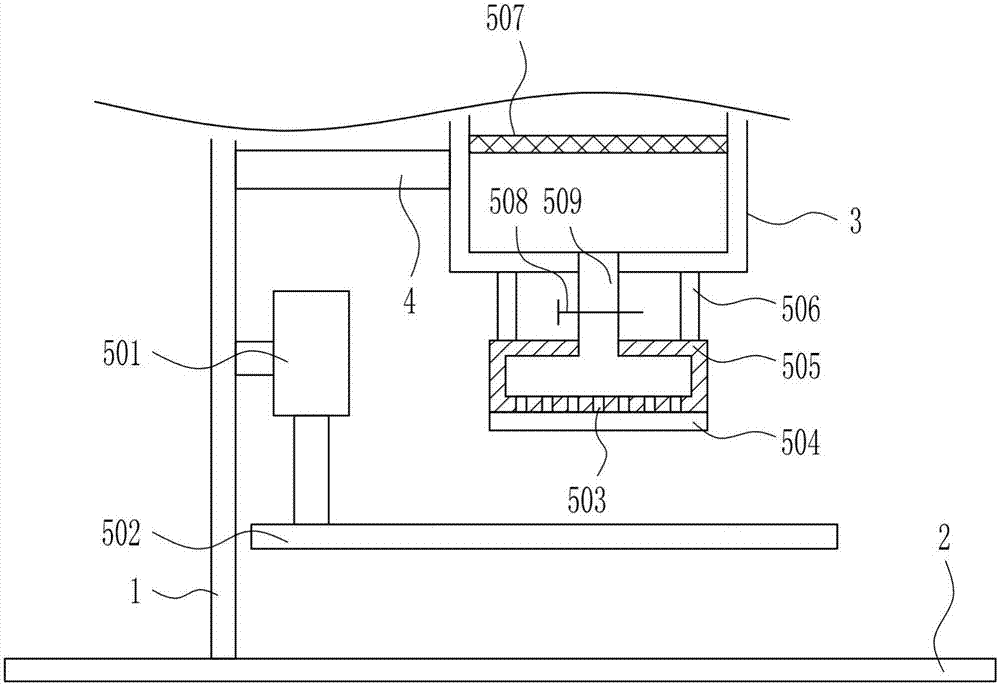

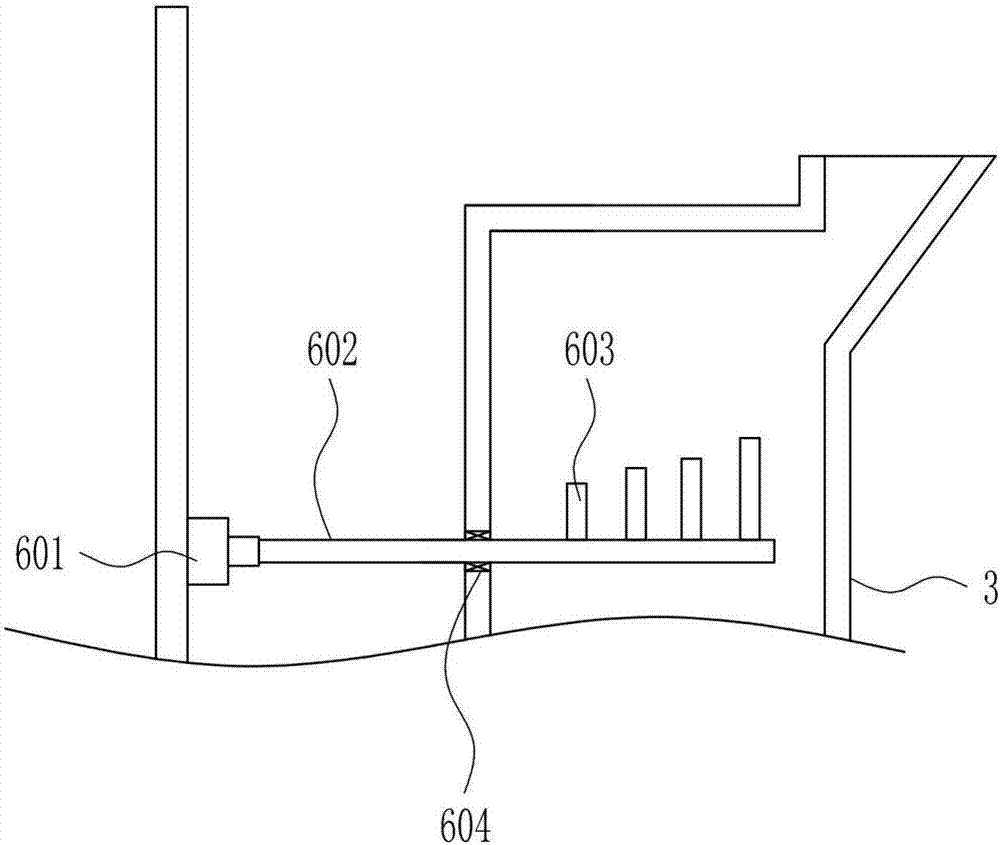

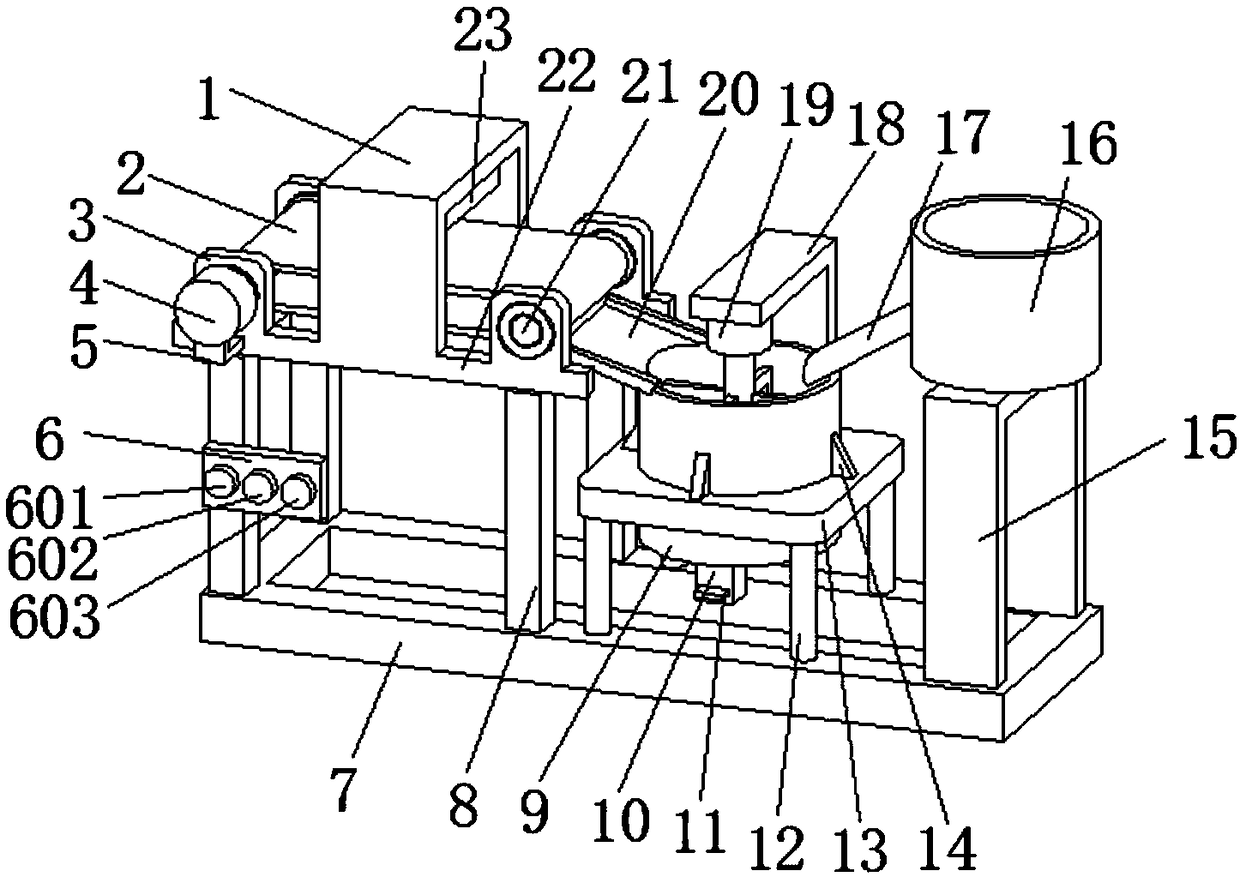

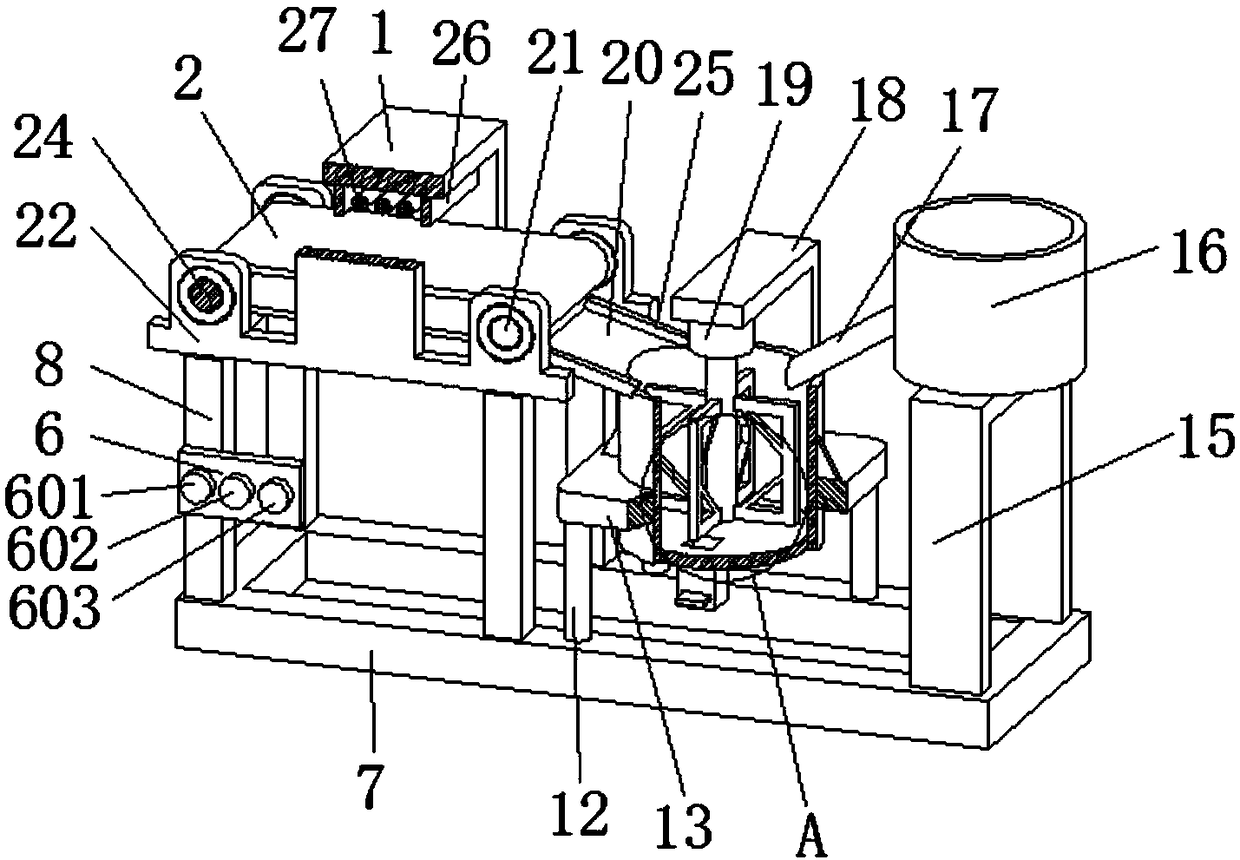

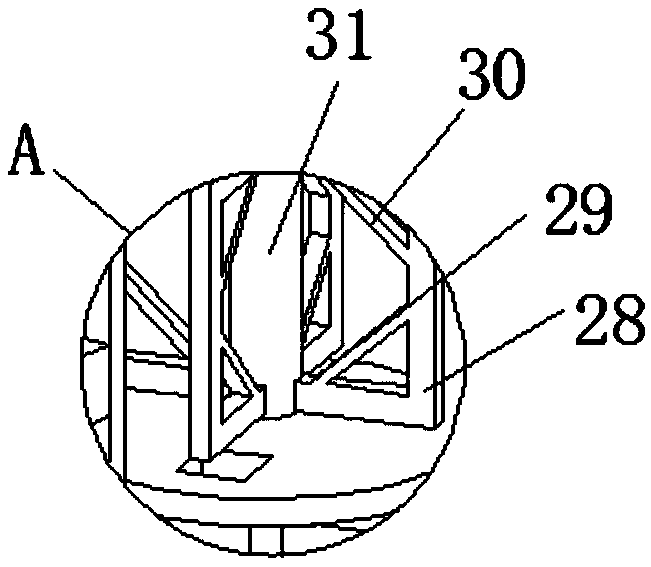

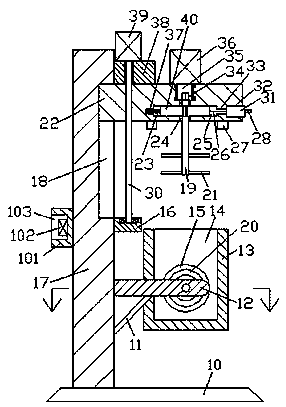

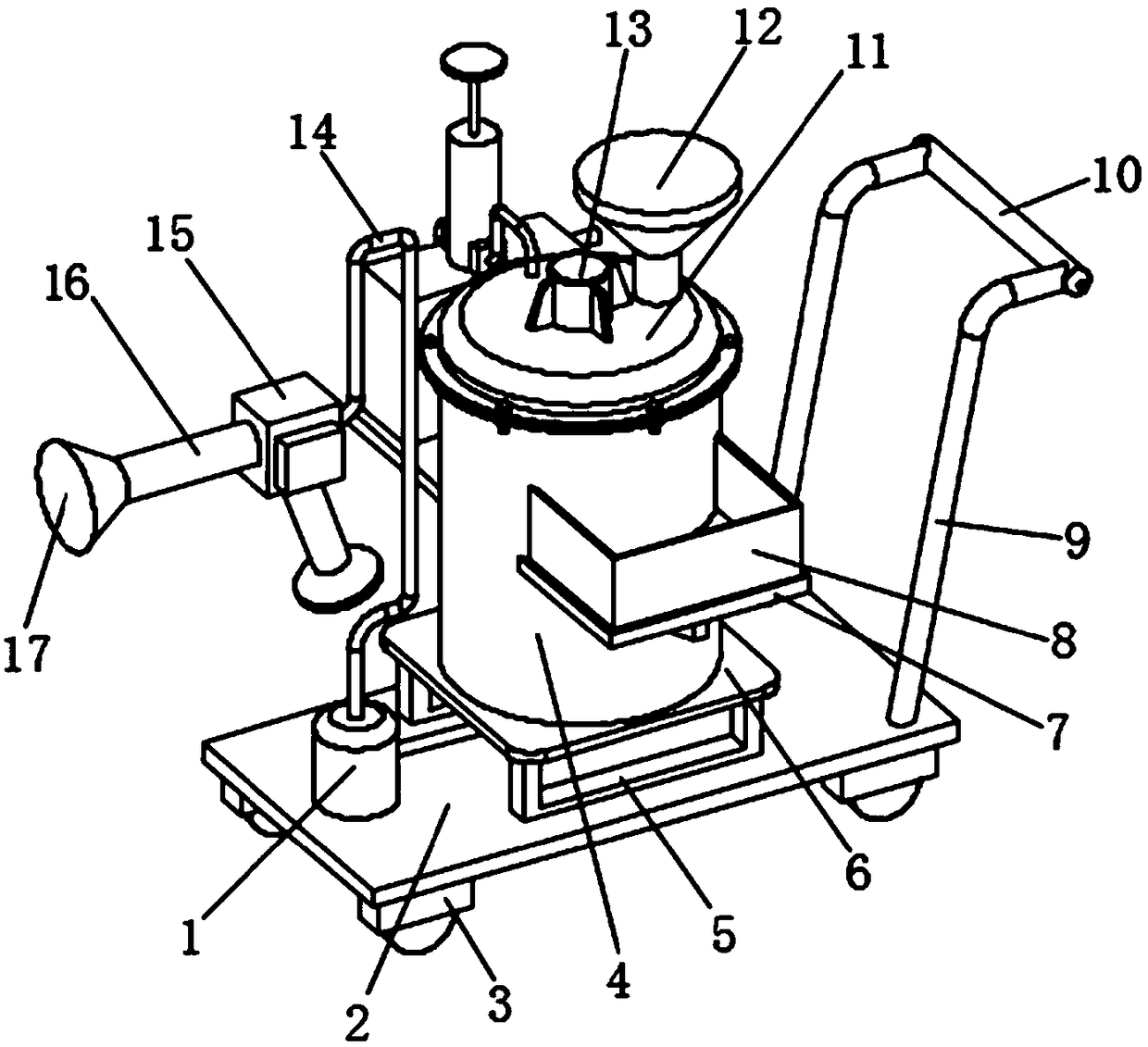

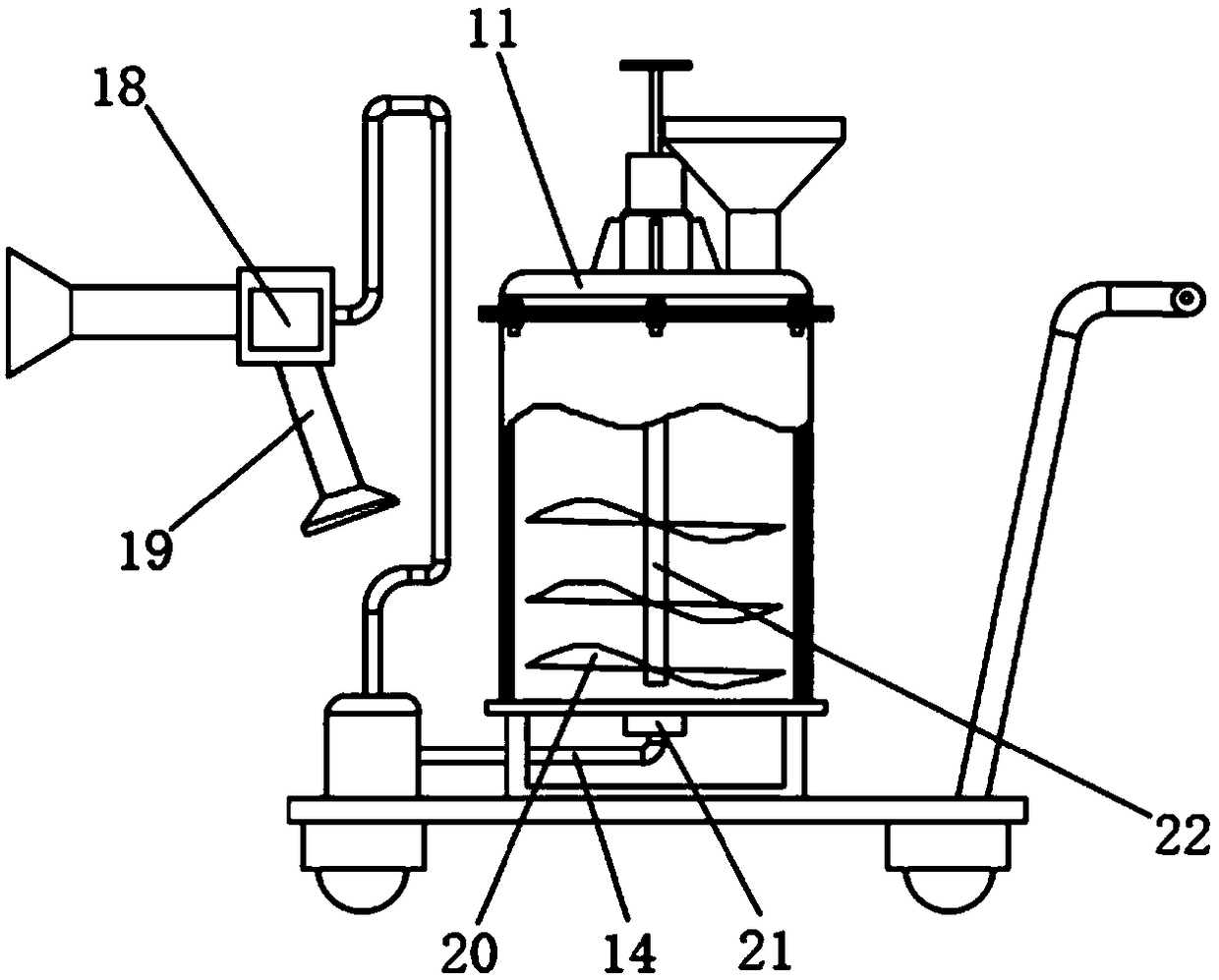

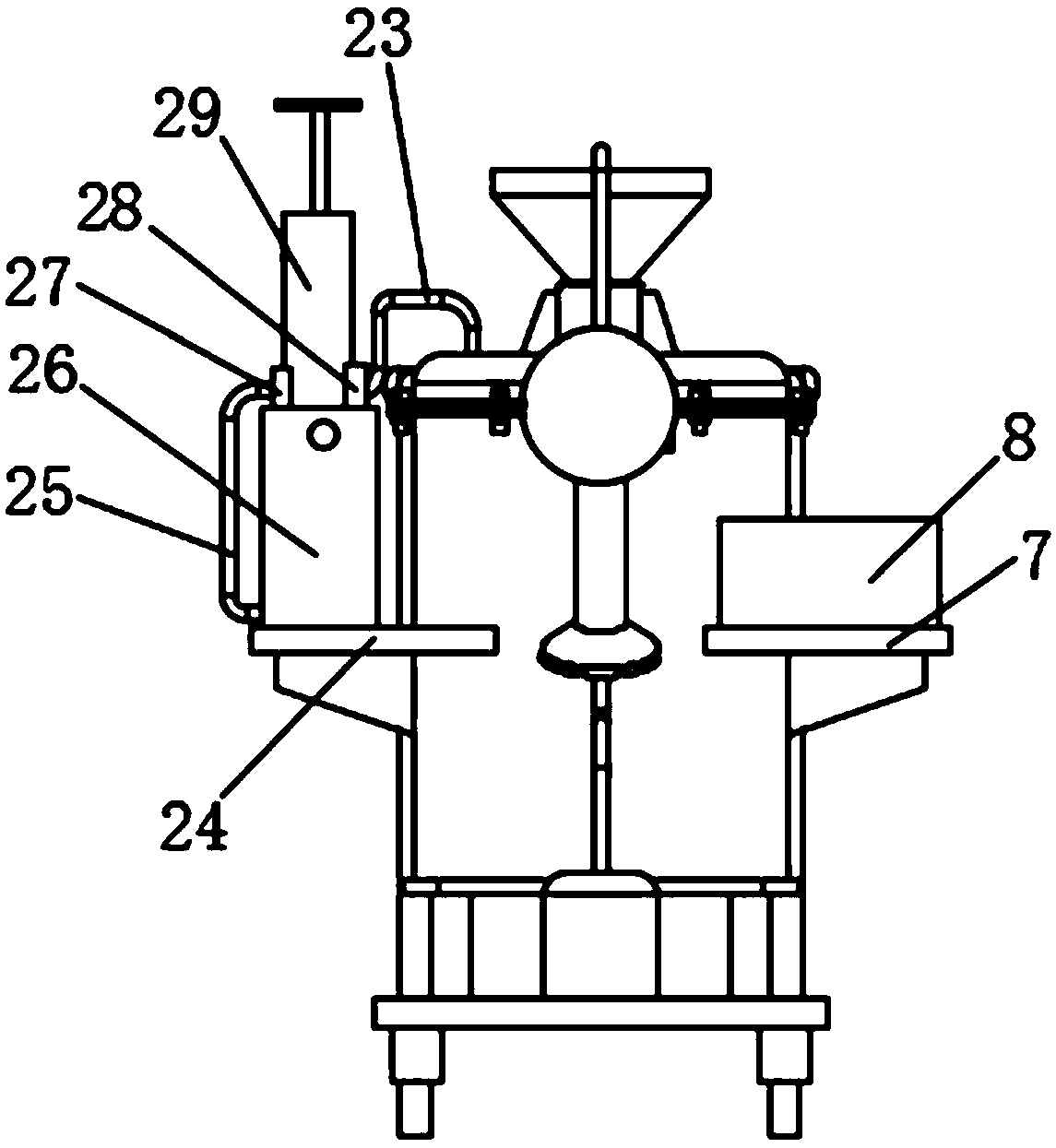

Quick agent adding device for sewage treatment tank

InactiveCN107185432AImprove stirring efficiencySave energyRotary stirring mixersTransportation and packagingSewage treatmentMixing tank

The invention relates to an adding device, in particular to a quick agent adding device for a sewage treatment tank. Technically, the invention aims to provide the quick agent adding device for a sewage treatment tank with the characteristics of high mixing efficiency and fast agent adding speed. In order to solve the technical problems, the invention provides a mining transportation device with sorting functions. The device comprises a base plate, brackets, a mixing tank, a driving mechanism, a dosing mechanism, a stirring mechanism, a water adding mechanism, a discharge mechanism and an otter board, the mixing tank is fixedly connected to the base plate through two brackets, the water adding mechanism is fixedly connected a side of the mixing tank, and the discharge mechanism is fixedly connected below a mixing tank end far from the water adding mechanism. According to the invention, through cooperation of the driving mechanism, the dosing mechanism, the stirring mechanism and the water adding mechanism, drugs can be stirred and mixed rapidly, and through the discharge mechanism, the agent can reach a better effect.

Owner:段建英

Raw material uniformmixing device for photosensitive paint production

PendingCN106311050AStir wellImprove work efficiencyShaking/oscillating/vibrating mixersTransportation and packagingMixing effectPetroleum engineering

The invention belongs to the technical field of photosensitive paint production, and in particular relates to a raw material uniform mixing device for photosensitive paint production. The invention solves the technical problem of providing a raw material uniform mixing device with good mixing effect, high operational efficiency and simple structure for photosensitive paint production. Aiming at solving the technical problem, the invention provides the raw materialuniformmixing device for photosensitive paint production, comprising a bottom plate, a left rack, a right rack, a top plate, a first slide rail, a first slide block, a shifting plate, a first spring, a second spring, a stirring frame, a discharge pipe, a valve and the like, wherein the left rack is welded at the top left end of the bottom plate, the right rack is welded at the top right end of the bottom plate, and the top plate is welded at the top ends of the left rack and right rack. Theraw materialuniform mixing device provided by the invention achieves the effects of good mixing effect, high operational efficiency and simple structure.

Owner:安陆鲸鱼嘴电子科技有限公司

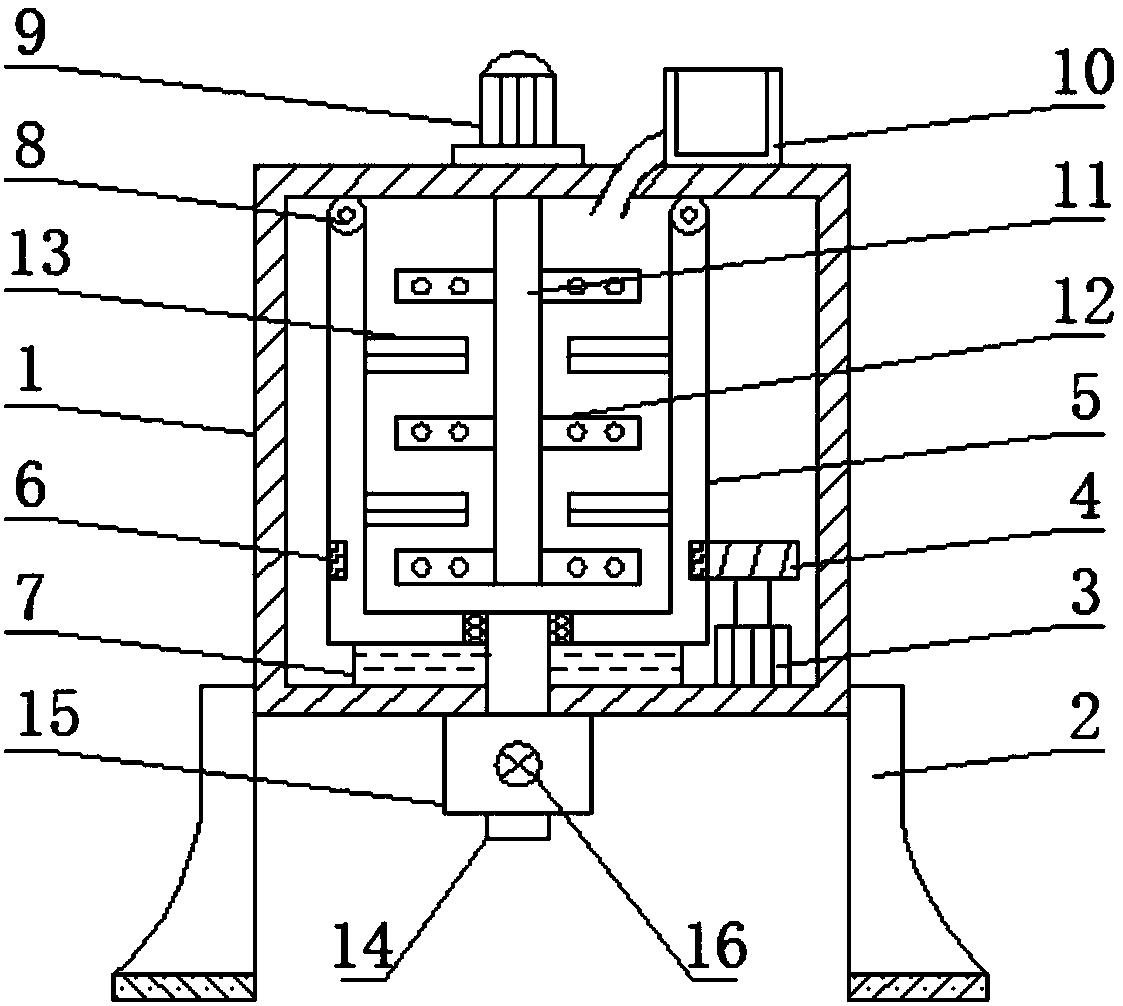

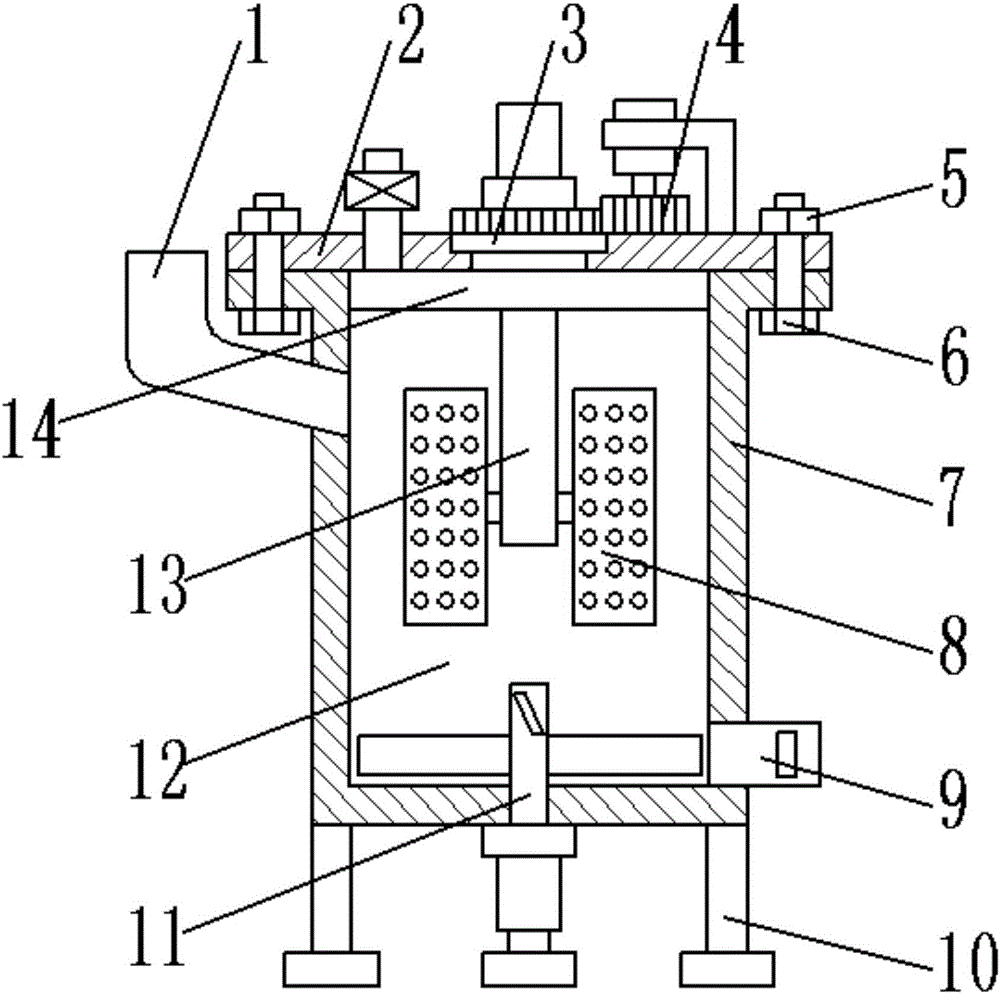

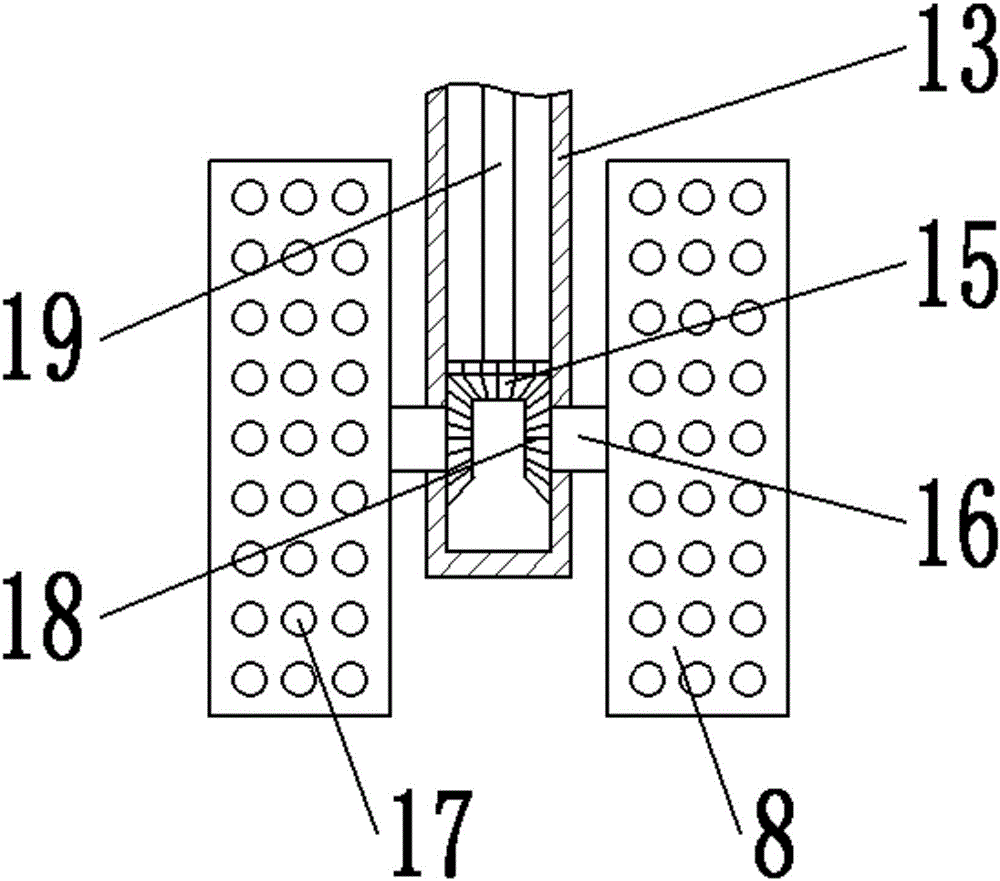

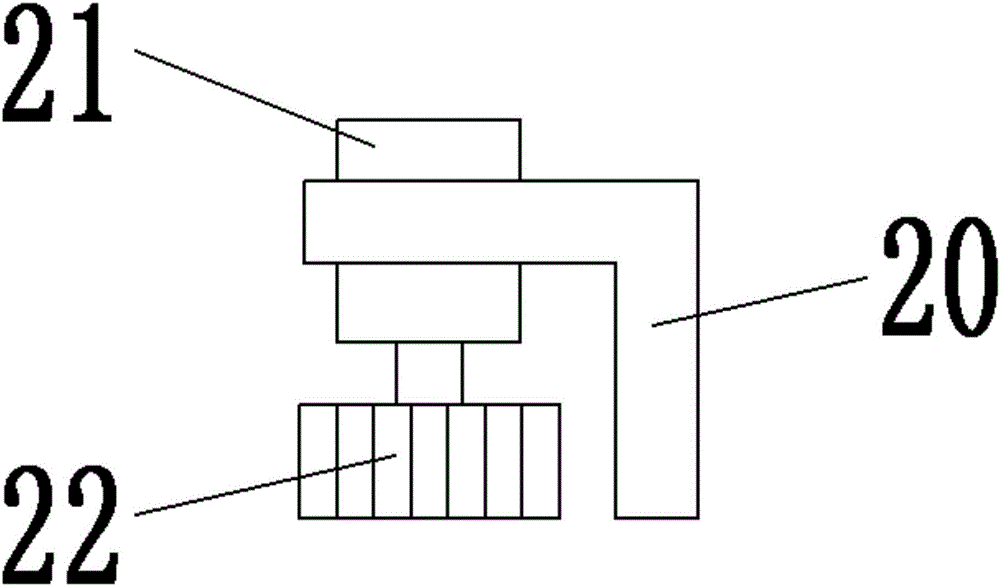

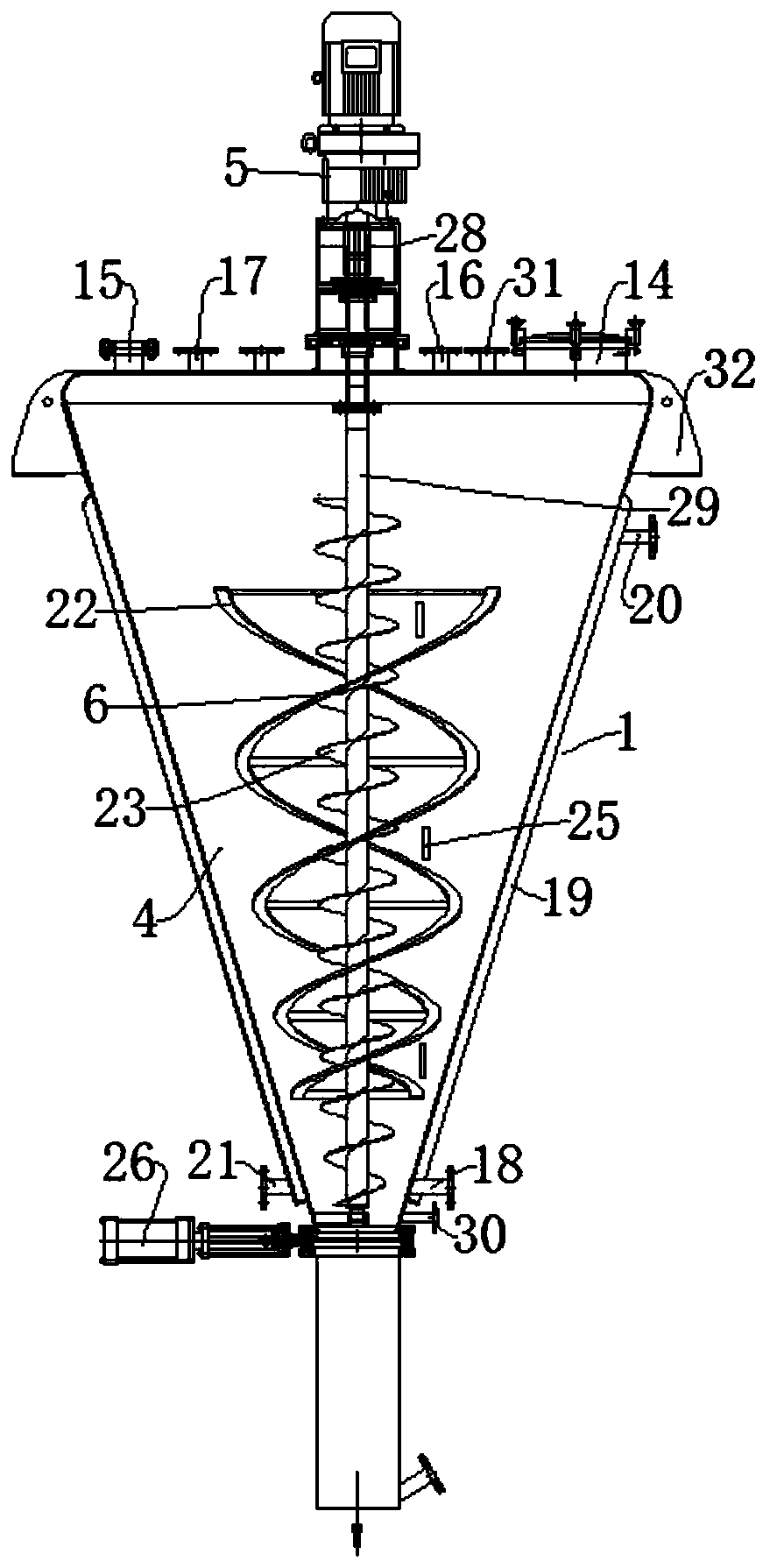

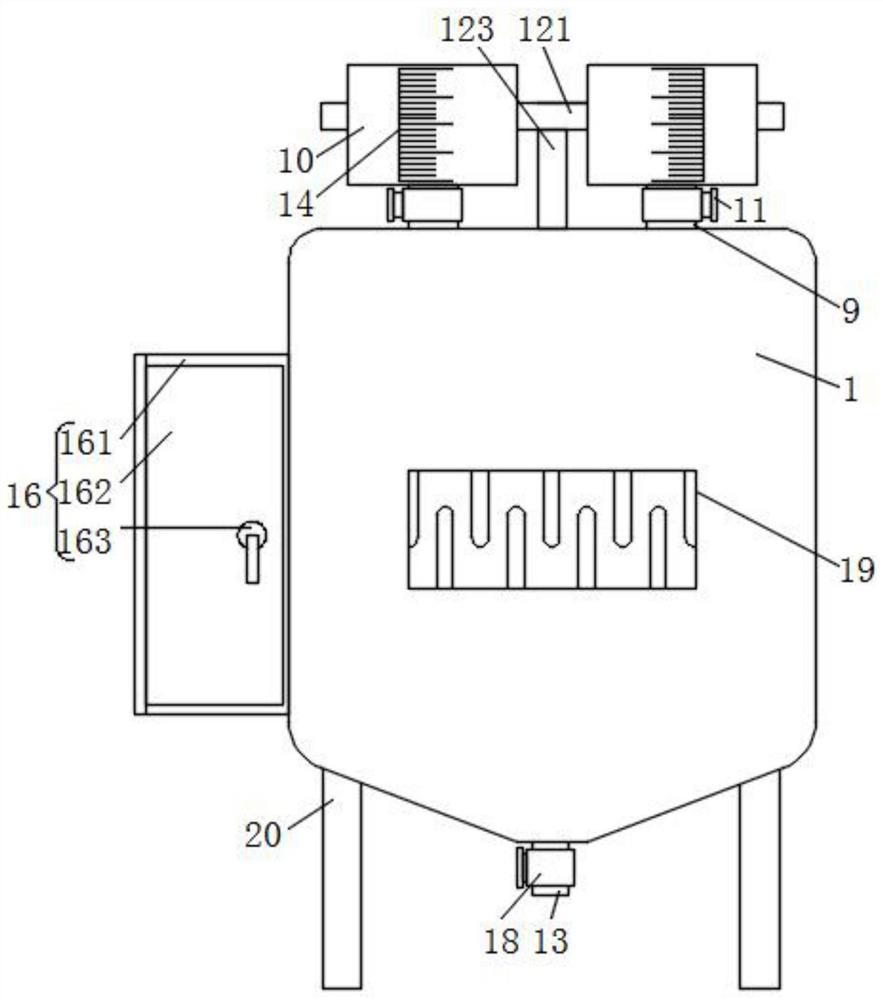

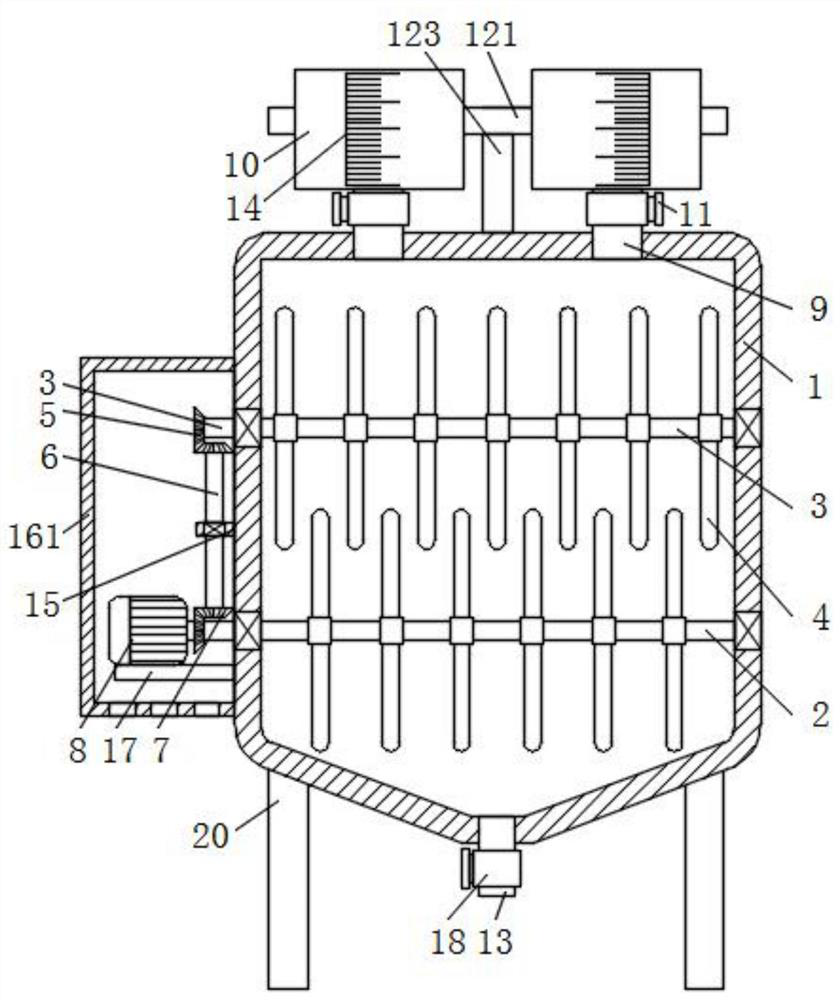

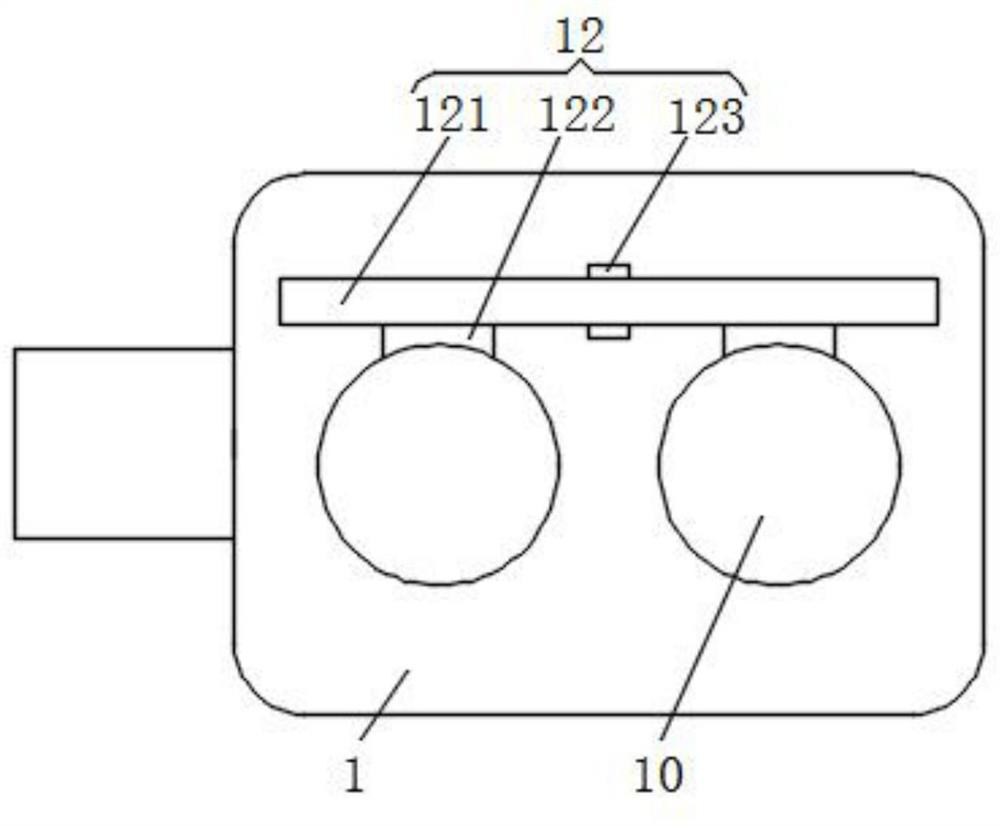

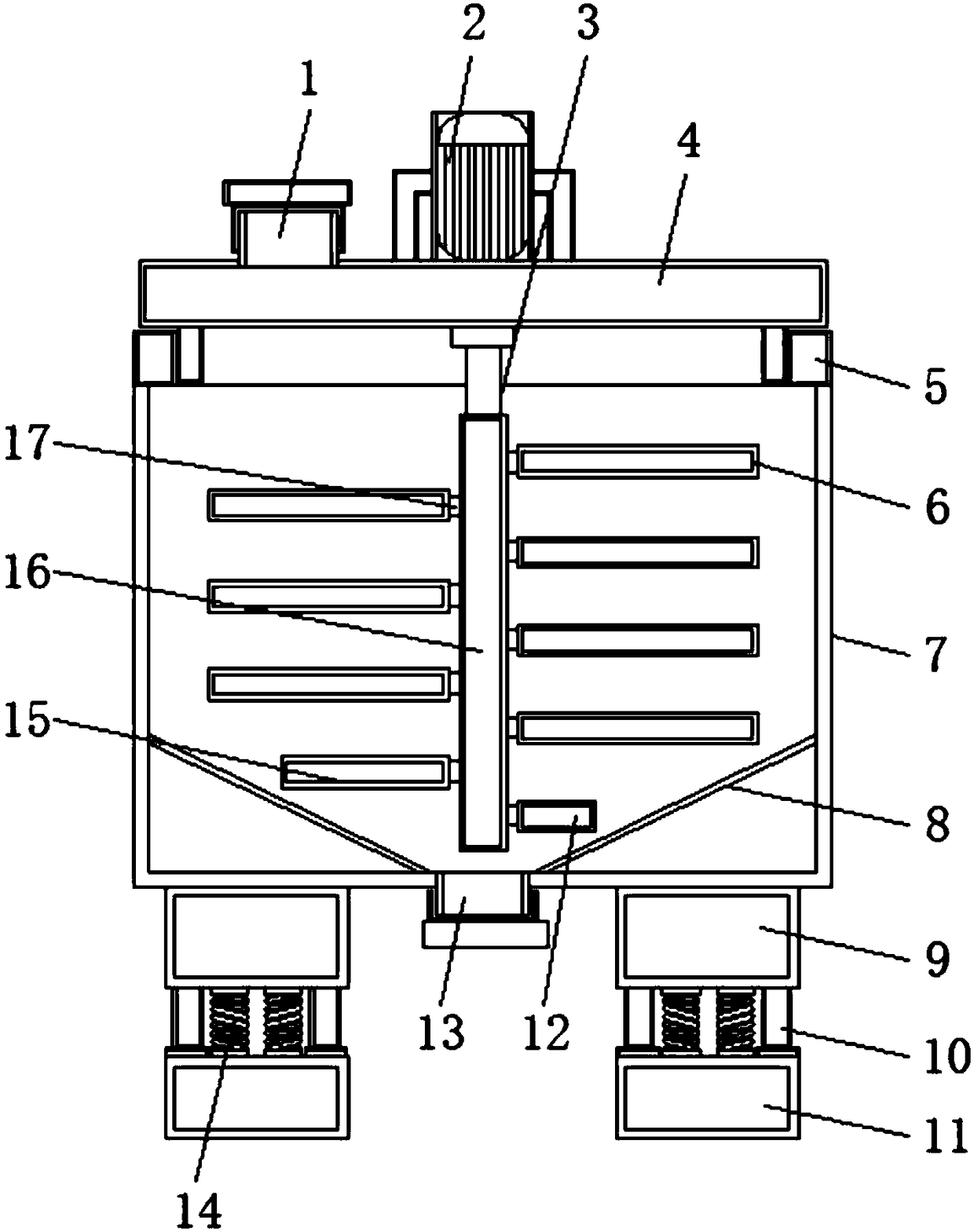

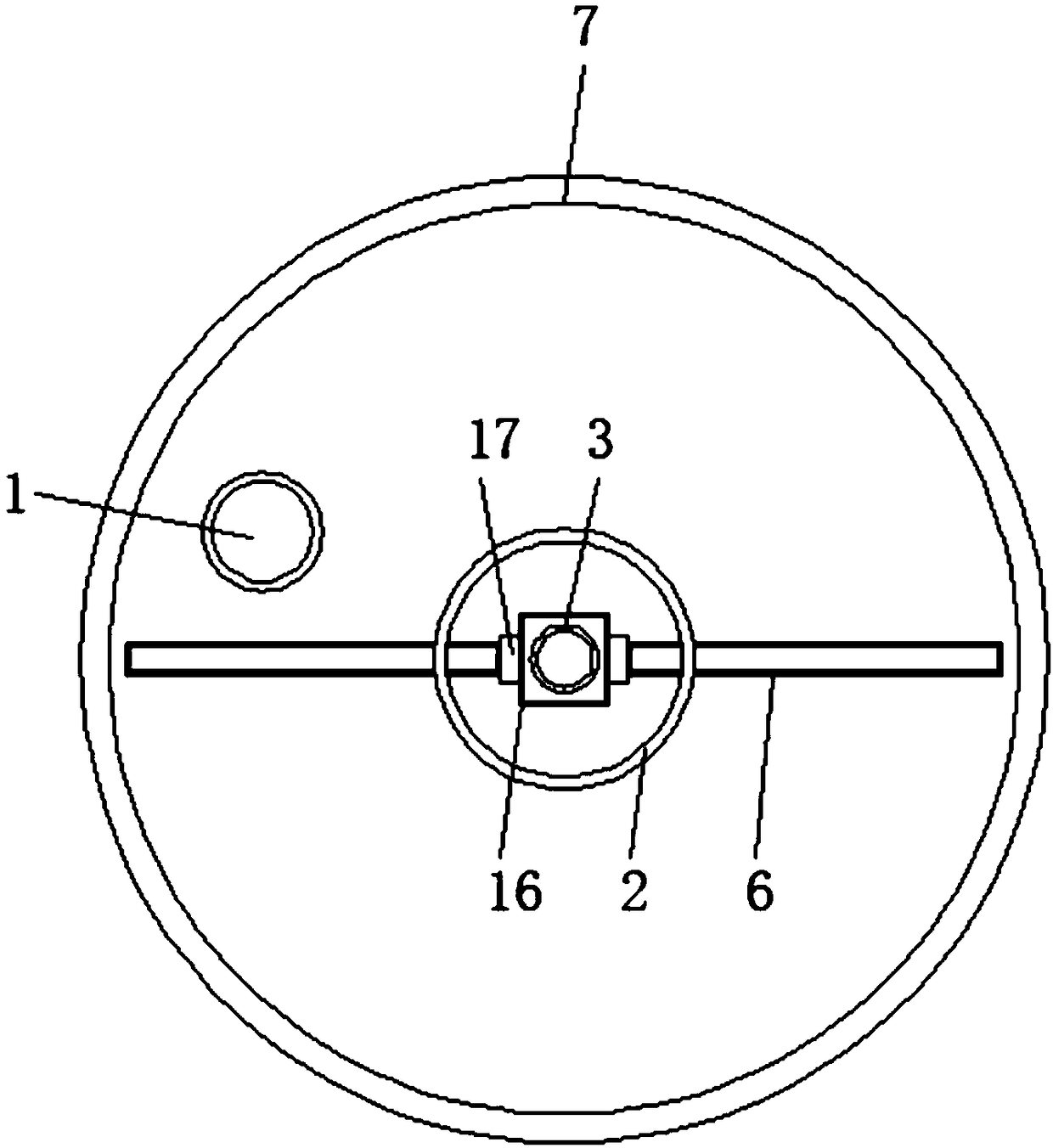

Bidirectional agitating tower-type multilayer liquid washing agitating kettle

InactiveCN108273428AEasy to stir and mixQuick Stir to MixRotating receptacle mixersTransportation and packagingMotor driveHeater Rod

The invention discloses a bidirectional agitating tower-type multilayer liquid washing agitating kettle in the technical field of daily chemical product production equipment. The kettle comprises a housing, wherein a first motor is mounted on the right side of the bottom of an inner cavity of the housing; an outer wall on the left side of a gear is connected with a kettle body; a second motor anda feed hopper are mounted on the left side and the right side of the top of the housing respectively; heating rods are uniformly arranged on an inner wall of the kettle body; the bottom of a dischargepipe extends to the outer side of the bottom of the housing; and a quantitative discharge device is mounted at the bottom of the discharge pipe. The kettle is simple to operate; rotation directions of the first motor and the second motor are opposite; the kettle facilitates quickly agitating and mixing a liquid washing product in the kettle body; the heating rods are mounted in the kettle body; the control of the temperature of the liquid washing product in the kettle body is facilitated; a discharge motor drives separating plates on a rotating shaft to rotate; the liquid washing product canfurther pass through the discharge pipe; quantitative outflow of agitated and qualified raw materials in the kettle body at regular time is achieved; the discharge is controlled conveniently accordingto the quantity required by a user; and the raw material waste is avoided.

Owner:扬州市钰翔轻工机械设备厂

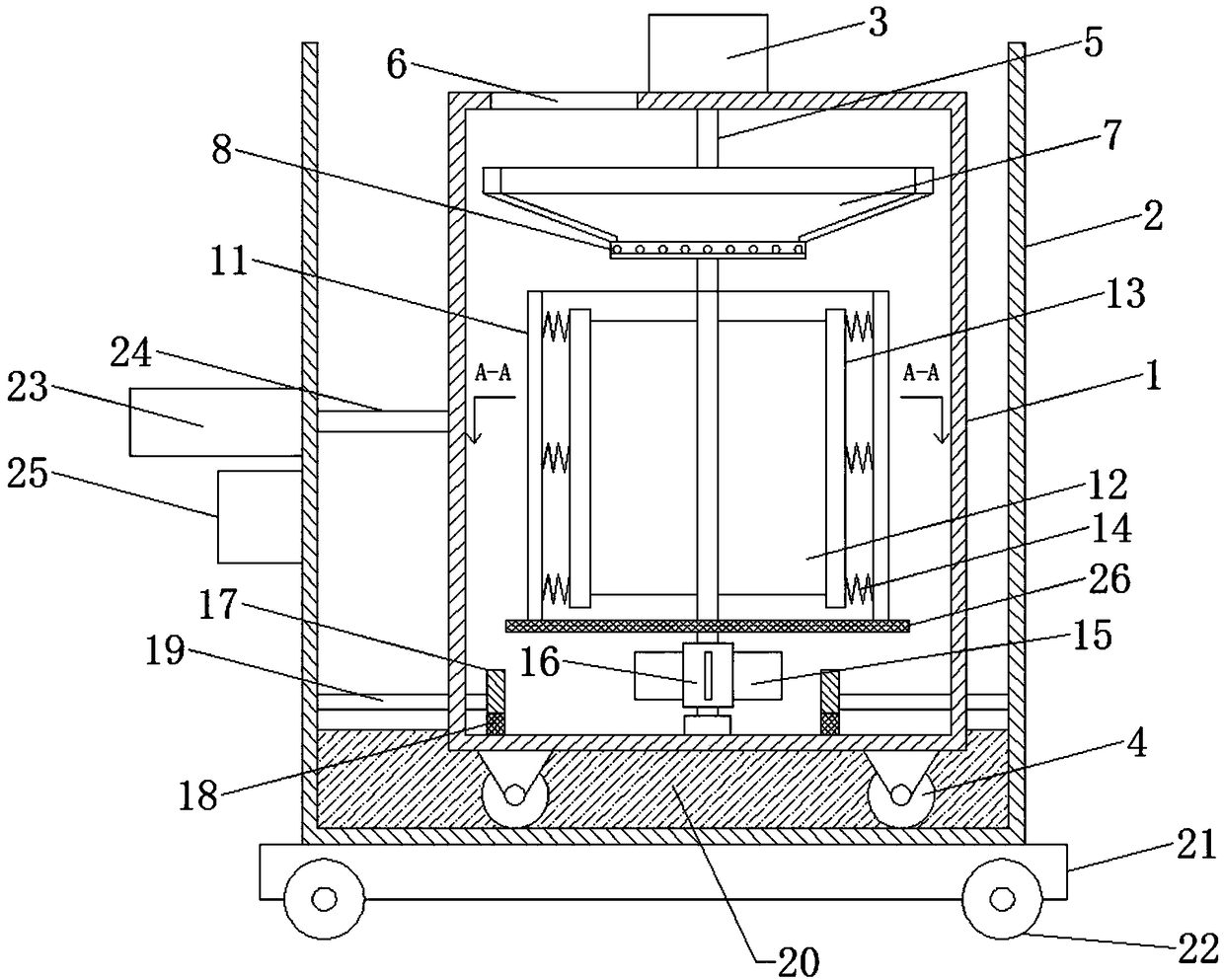

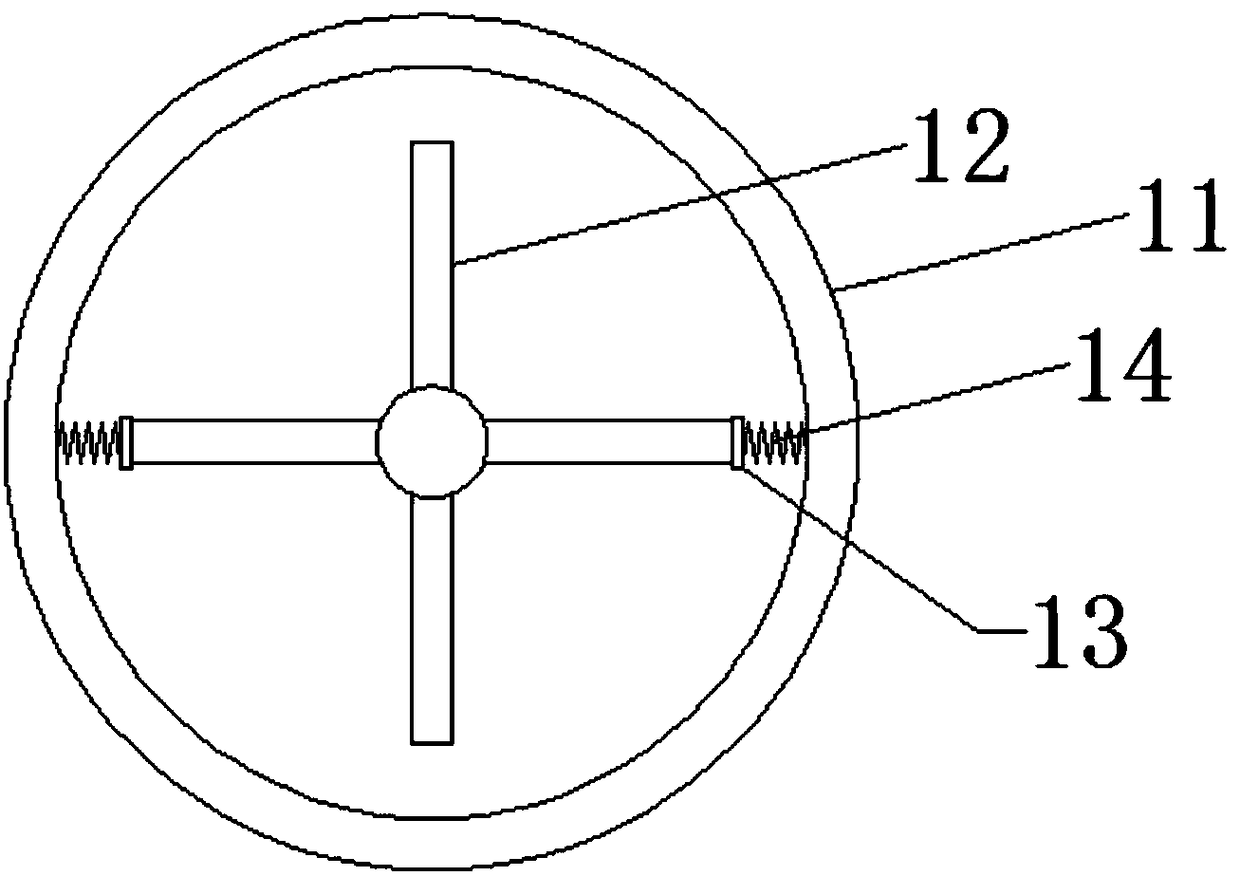

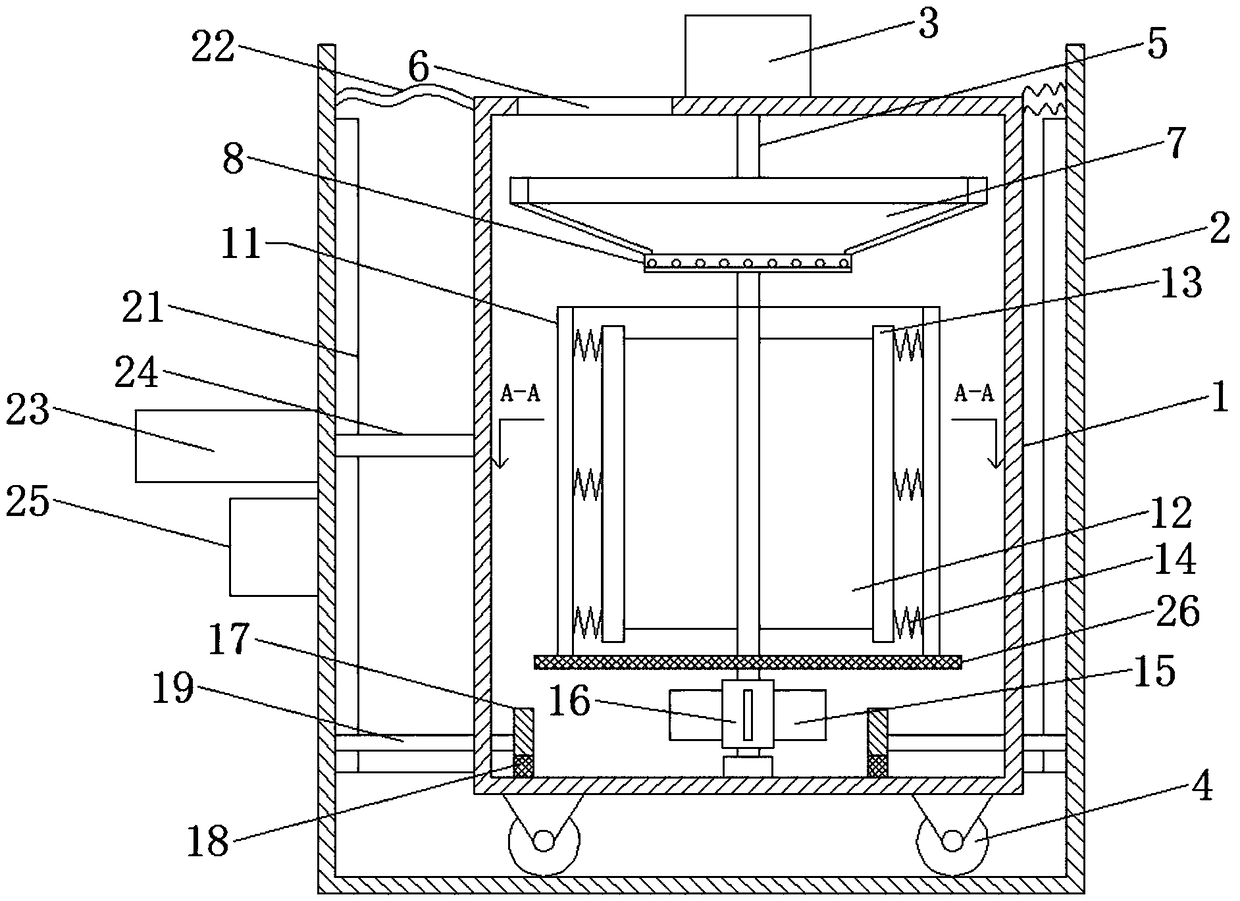

Movable material mixing equipment for building

InactiveCN108556139AAvoid Stirring Dead AngleLarge swingMixing operation control apparatusPretreatment controlPneumatic cylinderDrive shaft

The invention discloses movable material mixing equipment for building. The movable material mixing equipment comprises a cylinder body, a shell, a motor and a feeding opening. Multiple moving wheelsare fixedly installed on the bottom of the cylinder body. A horizontal connecting rod is fixedly connected to a piston rod of a pneumatic cylinder. The connecting rod extends into the tail end in theshell and is fixedly connected with the cylinder body. A horizontal material guide hopper is coaxially fixed to a transmission shaft. A horizontal dispersing disc is fixed to the lower end of the material guide hopper. A supporting screen plate is provided with a screen cylinder which is arranged on the outer side of a main stirring blade in a sleeving manner. A plurality of connecting springs arefixedly connected to the left side and the right side of the inner wall of the screen cylinder. According to the equipment, by means of the arranged material guide plate and the rotating dispersing disc, materials entering the equipment are spread in the cylinder body uniformly, the materials make contact with materials in the cylinder body uniformly, and the materials are stirred and mixed conveniently and fast. The cylinder body moving left and right enables the materials in the cylinder body to waggle left and right, the materials in the cylinder body can move conveniently in the horizontal direction, and the stirring dead angle is avoided.

Owner:南安泰达农业科技有限公司

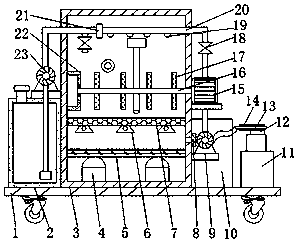

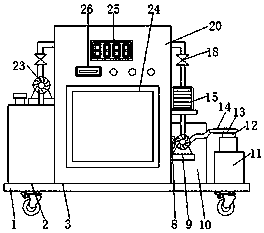

Urinary surgery flushing device

PendingCN108578811AAccurate measurementAvoid water shortageCannulasEnemata/irrigatorsUrologic surgeryMedicine

The invention belongs to the technical field of medical treatment equipment and especially relates to a urinary surgery flushing device. Aiming at the problems that a water temperature cannot be controlled and flexibility is not good, the urinary surgery flushing device is characterized by comprising a bottom plate, wherein a box body is welded to the top of the bottom plate, a water tank is welded to the top of the bottom plate, a second water pump is welded to the top of the water tank, a second water inlet pipe is welded to an inner wall of a water inlet of the second water pump, one end far from the second water pump of the second water inlet pipe is communicated with the water tank, and a second water outlet pipe is welded to an inner wall of a water outlet of the second water pump. The urinary surgery flushing device disclosed by the invention can heat liquid according to different requirements, so that use comfortableness of the device is improved; a transmission rod and a stirring blade are driven to rotate, so that quick stirring and mixing are achieved, time is saved, and the work efficiency of the device is improved; the liquid can be sterilized, so that safety of the device is improved; the height of a spray pipe can be adjusted according to different requirements, so that flexibility of the device is improved.

Owner:范玉录

Chemical material stirring and mixing equipment with high stirring force

InactiveCN106693764AEfficient mixingReduce stirring resistanceRotary stirring mixersTransportation and packagingEngineeringSolid material

The invention provides chemical material stirring and mixing equipment with high stirring force. The chemical material stirring and mixing equipment comprises a tank body and an upper lid; the inside of the tank body is provided with a stirring cavity; the upper surface of the upper lid is provided with a driving device and a transmission device, and the lower surface of the upper lid is provided with a liquid entering device; the transmission device is arranged in a turntable mounting groove; the transmission device is composed of a first motor and a first straight gear; the transmission device is composed of a turntable, a second straight gear, a second gear and a sleeve; the liquid entering device is composed of a spraying dish and a liquid entering pipe; the bottom of the stirring cavity is provided with a stirring device; the stirring device is composed of a third motor, a stirring shaft and a stirring plate. According to the chemical material stirring and mixing equipment with the high stirring force, the driving device and the transmission device drive a stirring piece to conduct the rotation in the horizontal direction and the rotation in the vertical direction, which is beneficial to conducting efficient stirring on materials in the tank body; the spraying area and the spraying speed of liquid materials are increased through the liquid entering device, which brings convenience to sufficient contact with solid materials, and is beneficial to fast stirring and mixing among the materials.

Owner:郑州吉音动漫科技有限公司

Aluminum alloy material and manufacturing method thereof

The invention relates to an aluminum alloy material and a manufacturing method thereof. The main component of the aluminum alloy material is aluminum. The aluminum alloy material further comprises tin, cadmium, zinc, copper, silicon, manganese, chromium, nickel and titanium. The manufacturing method comprises the following steps of (1) preheating the tin, the cadmium, the zinc, the copper, the silicon, the manganese, the chromium, the nickel and the titanium respectively, and stirring the components respectively until all the components are completely fused; (2) quickly heating all the fused components until the temperature rises up to 1,857 DEG C, and simultaneously mixing and uniformly stirring the components; (3) pouring a mixed solution of all the fused components obtained in the step (2), and performing natural cooling after pouring is completed. The aluminum alloy material can meet requirements on the material performances, particularly the performances of machining forming, surface quality, heat treatment and the like, of high-strength aluminum alloys in the field of industry; the manufacturing method is simple and is convenient to implement and popularize.

Owner:WUXI LEHUA AUTOMATION TECH

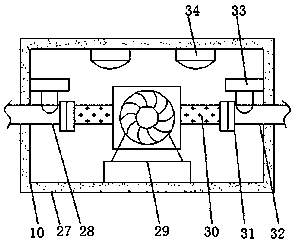

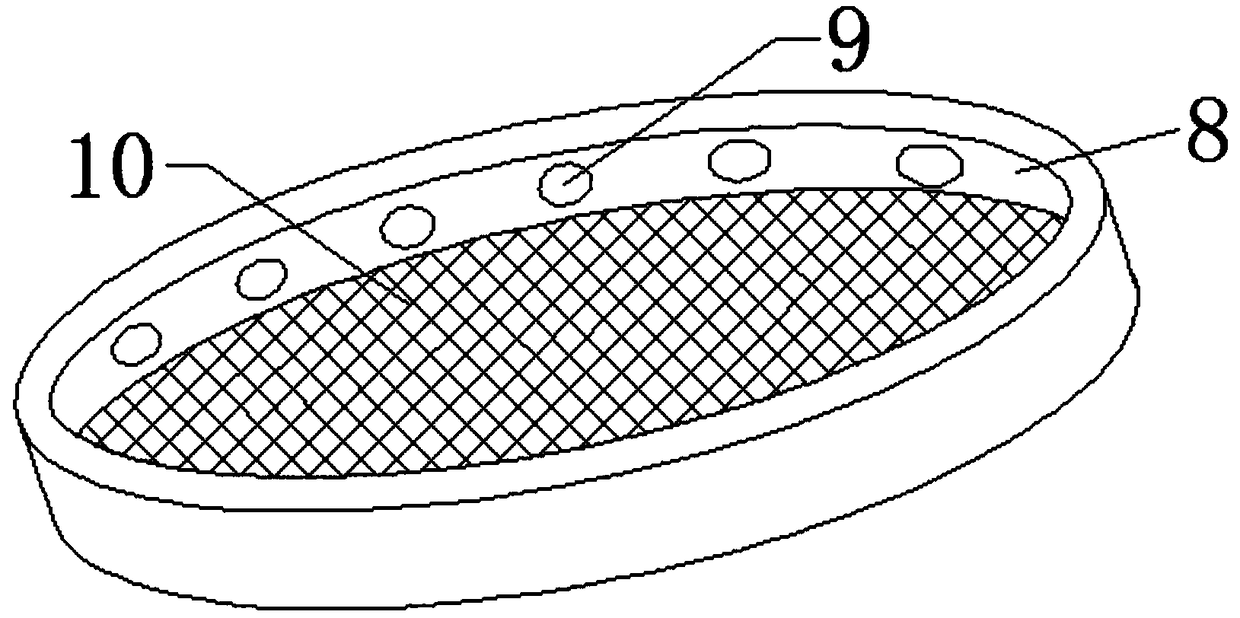

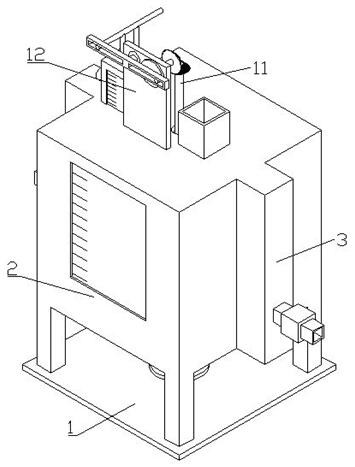

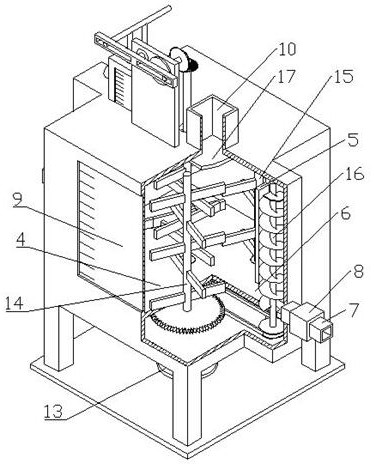

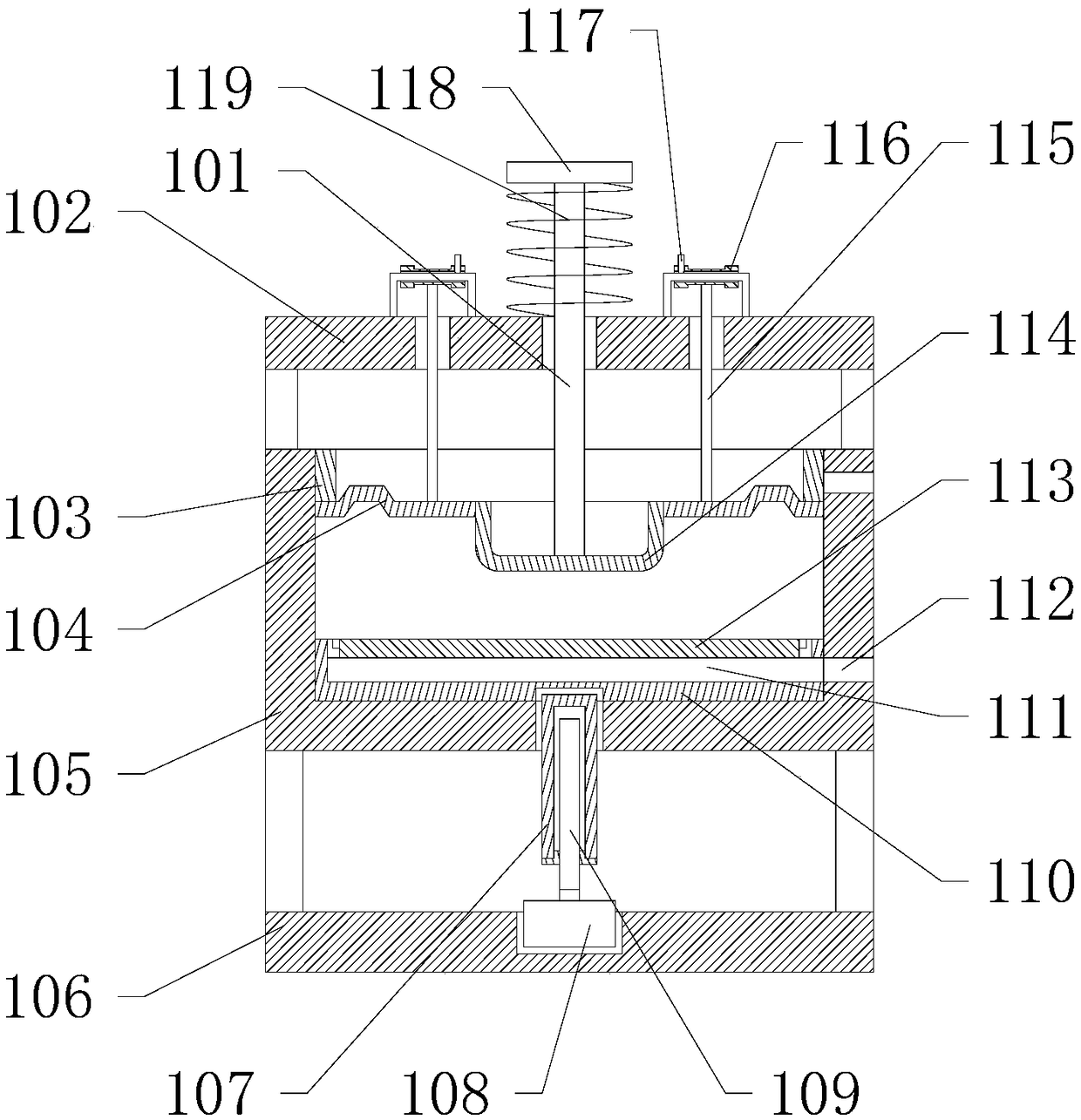

Edible mushroom vacuum stirring sterilization cooling and inoculation integral machine

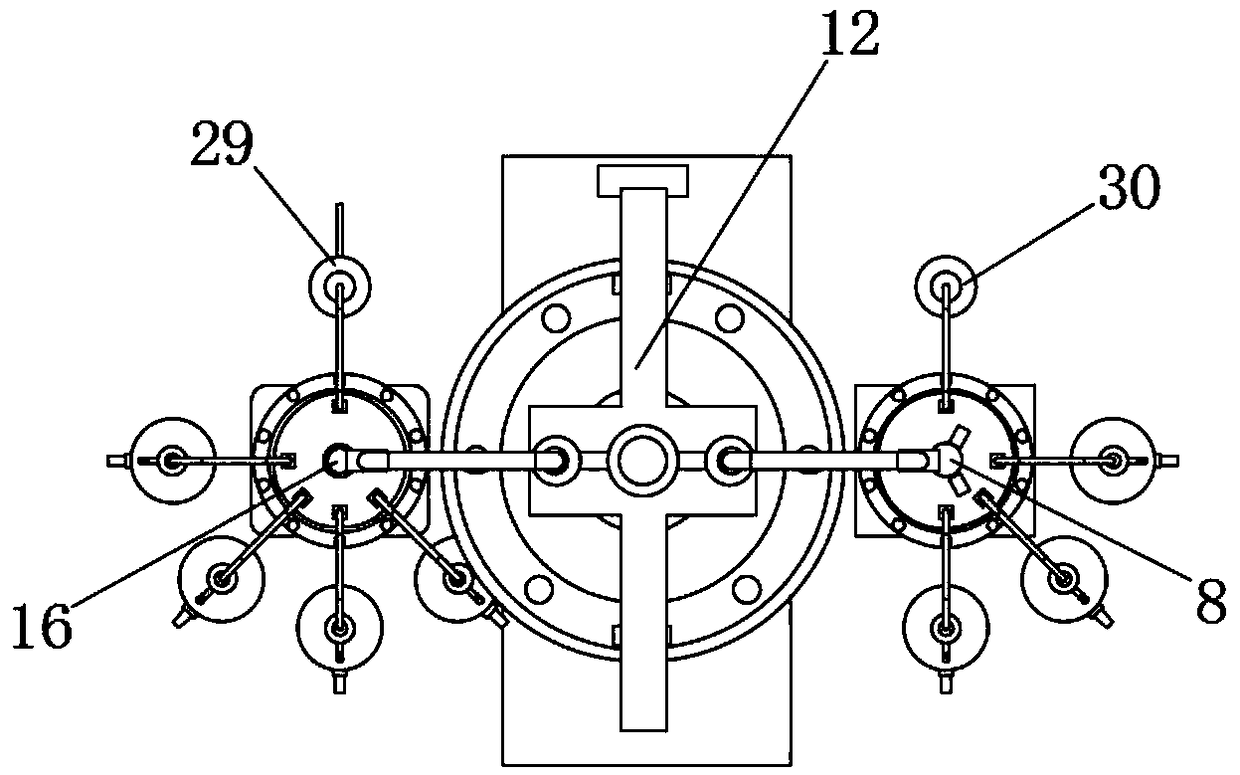

PendingCN111226696AQuick Stir to MixHeating up fastDispersed particle filtrationTransportation and packagingAir filterEngineering

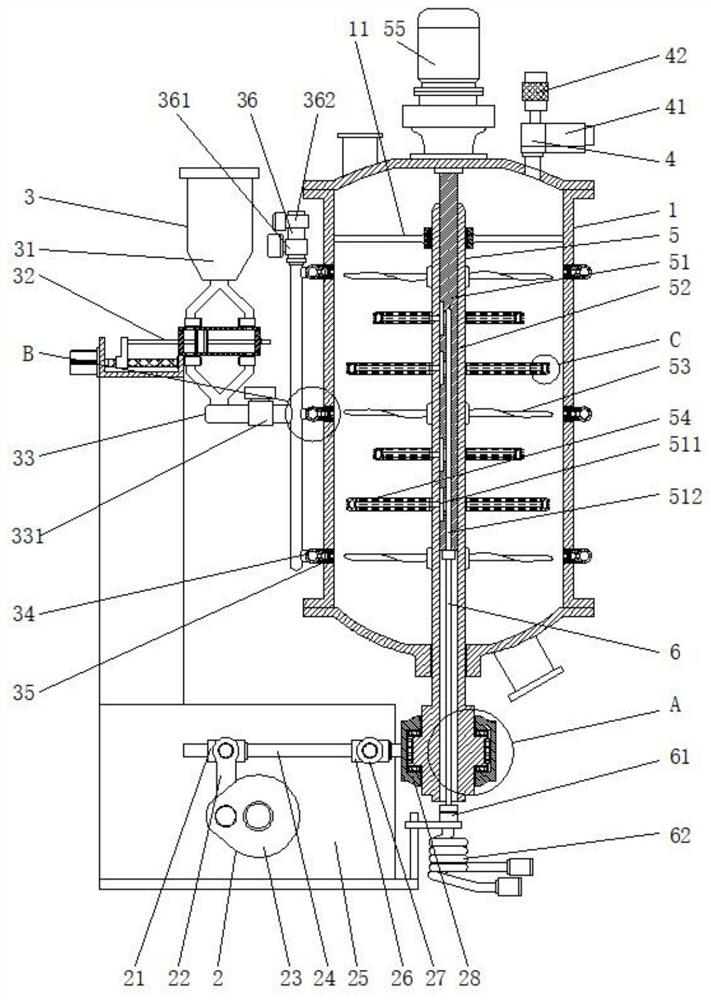

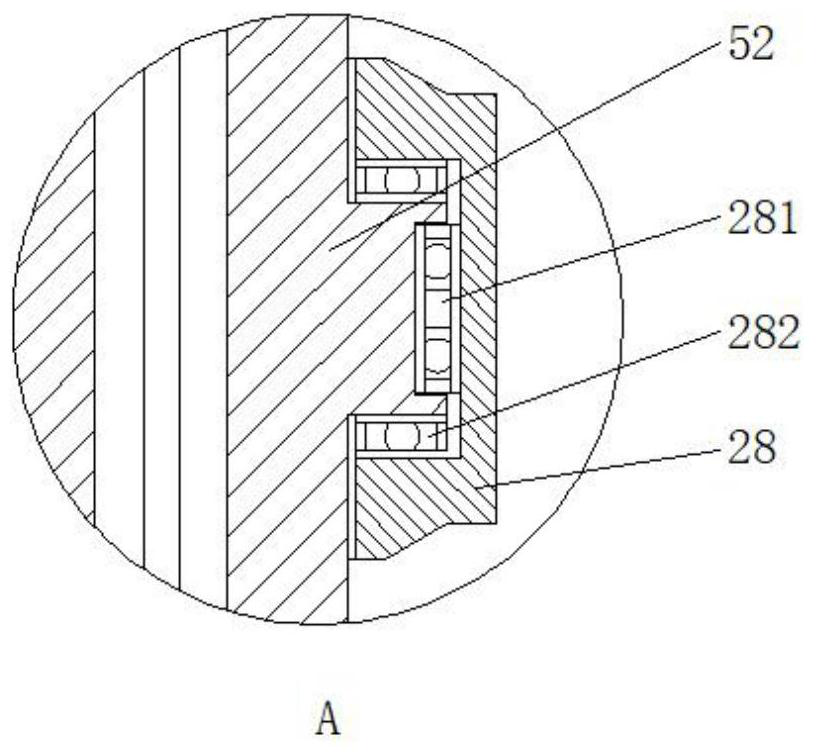

The invention discloses an edible mushroom vacuum stirring sterilization cooling and inoculation integral machine. The machine comprises a vacuum stirring sterilization cooling and inoculation device,a connecting tube, a bracket and a solid mushroom seed feeding machine, wherein the vacuum stirring sterilization cooling and inoculation device is arranged on the bracket; the connecting tube is arranged below the vacuum stirring sterilization cooling and inoculation device and is connected with an external packaging machine; the solid mushroom seed feeding machine is arranged above the vacuum stirring sterilization cooling and inoculation device; and the vacuum stirring sterilization cooling and inoculation device comprises a cabin, a driving motor set, a turnover stirring part, a vacuum pump, a cold water machine, an air compressor, an air filter I, an air filter II, a sterile filter and a steamer. The invention relates to the technical field of edible mushroom base processing, and inparticular provides the edible mushroom vacuum stirring sterilization cooling and inoculation integral machine which integrates stirring, sterilization, cooling and inoculation of edible mushroom rawmaterials and is efficient and energy-saving.

Owner:唐湘梅

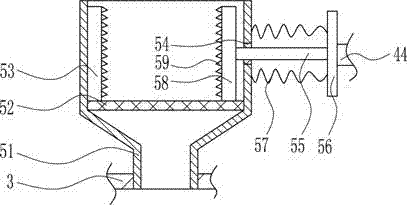

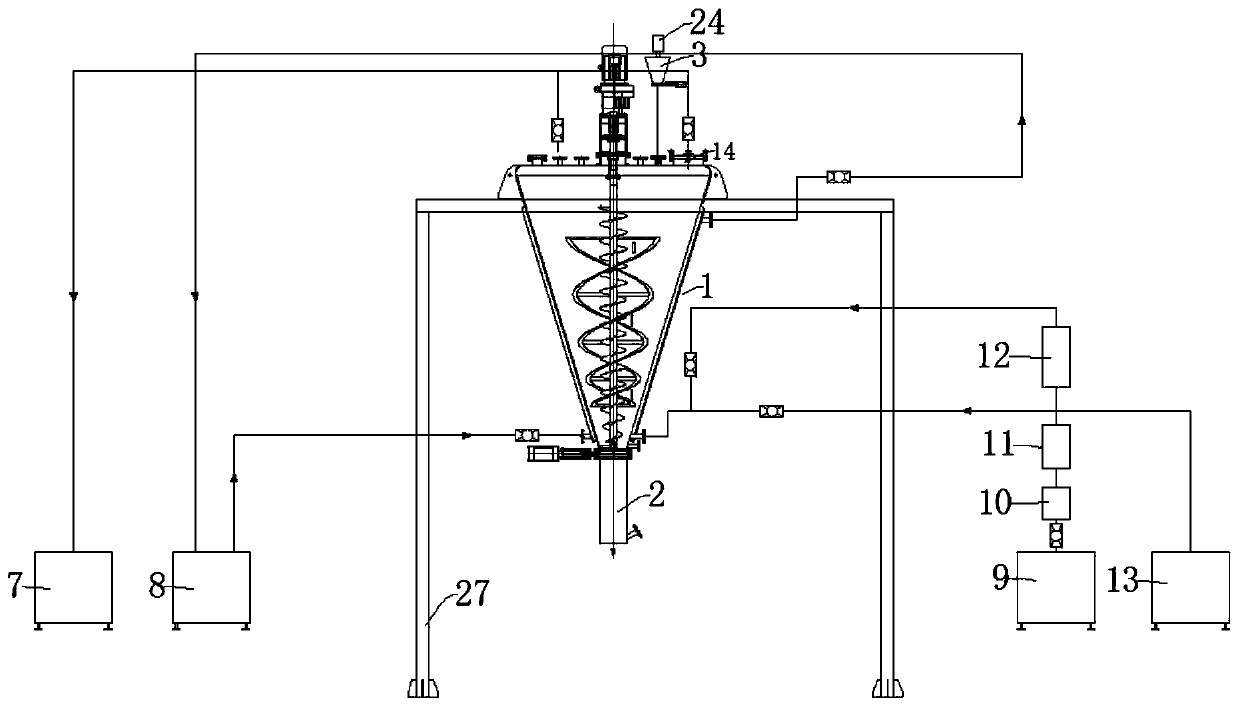

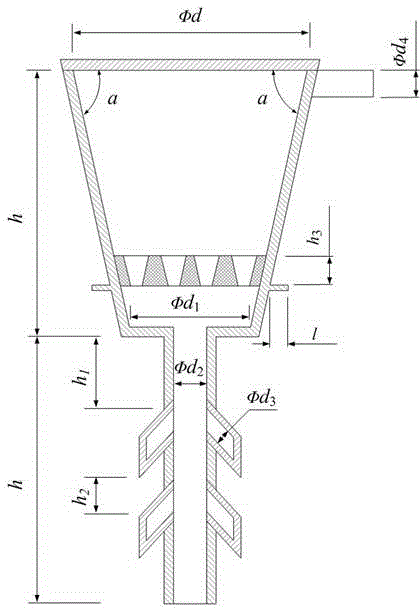

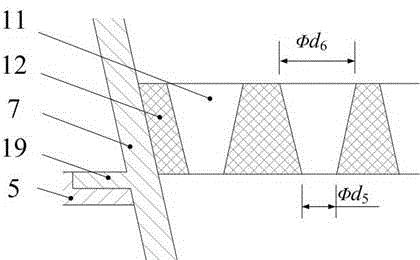

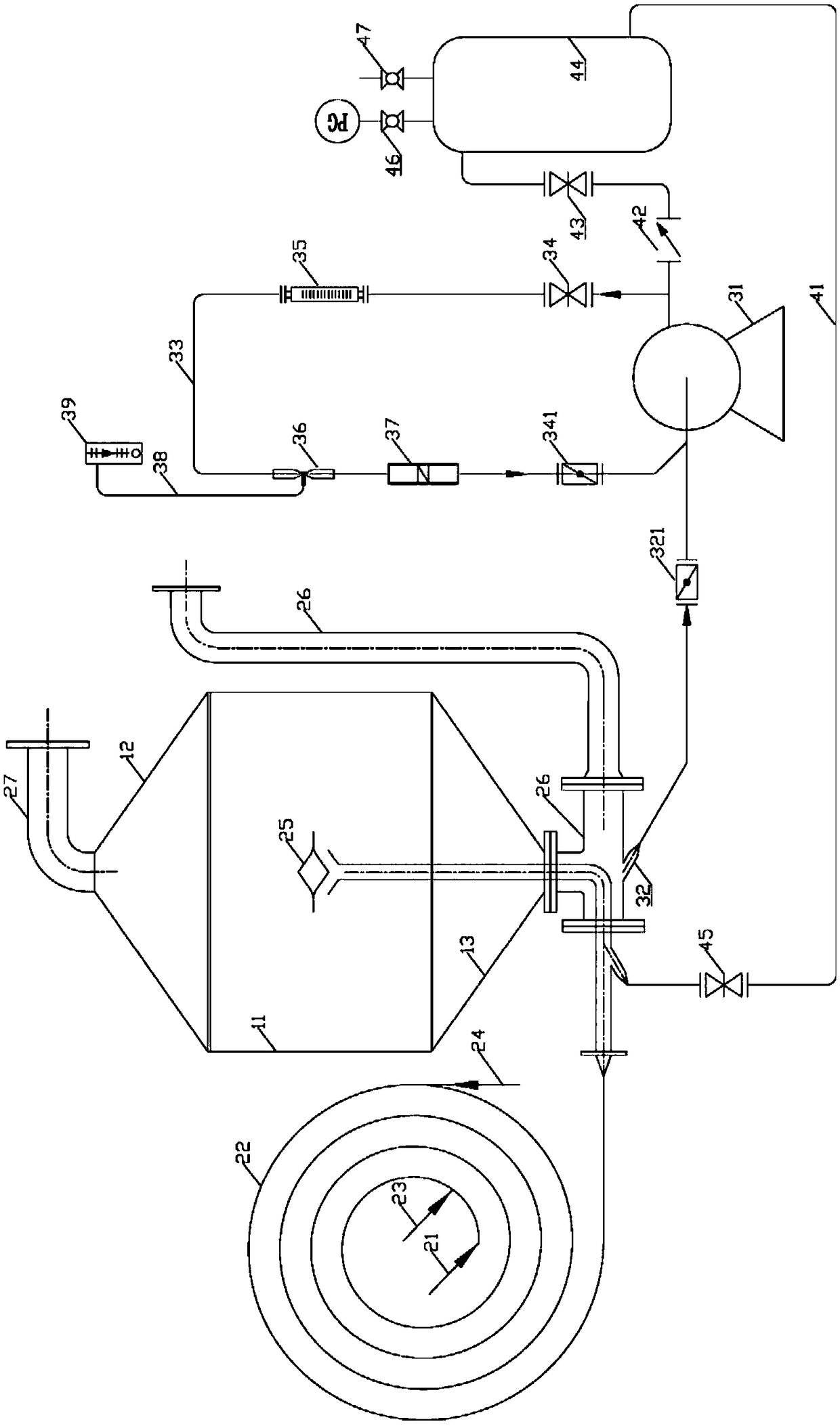

Material-fluid separation pulping equipment using airflow eddy kinetic energy

The invention discloses material-fluid separation pulping equipment using airflow eddy kinetic energy. The material-fluid separation pulping equipment mainly comprises an airflow eddy crushing device and a pulp generation device. The material-fluid separation pulping equipment is characterized in that the material-liquid separation includes that using airflow eddy kinetic energy to crush the material and mixing with liquid water to generate size. The material-fluid separation pulping equipment realizes the minimum energy-loss gas circulation through a gas inlet pipeline tangential to the edge of the outer side of the upper end of a conical material cylinder, realizes acceleration rotational flow and increases the airflow eddy crushing force through the conical material cylinder, realizes the crushed material sieving through a crushed material filtering device and realizes to quickly mix and stir to generate uniform pulp through a main crushed material conveying pipe, a branch crushed material conveying pipe and a liquid barrel.

Owner:UNIV OF JINAN

Proportioning device for liquid soap processing

PendingCN112007580ASolve the problem of low ratio accuracyReduce laborTransportation and packagingRotary stirring mixersHand sanitizerProcess engineering

The invention relates to the technical field of liquid soap processing and discloses a proportioning device for liquid soap processing. The proportioning device comprises a shell, wherein a first stirring rod and a second stirring rod are arranged in and rotatably connected with of the shell through sealed bearings respectively; stirring blades fixedly sleeve the surface of the first stirring rodand the surface of the second stirring rod; and the other end of the first stirring rod and the other end of the second stirring rod penetrate through and extend out of the shell. The proportioning device of the invention overcomes the problems that an existing proportioning device for liquid soap processing is low in proportioning accuracy and low in stirring and mixing efficiency; raw materialscan be directly proportioned without tools by checking scale marks while the raw materials are added, so the labor amount of workers is reduced, and proportioning accuracy is improved; and meanwhile,the second stirring rod is driven by a transmission rod to conduct cross stirring at the same time, so the raw materials can be stirred and mixed faster, and production efficiency is improved.

Owner:广东浩宇清洁环保设备有限公司

Uniformly-heated raw material mixing device for chemical industry

InactiveCN108525632AEasy to moveLarge swingShaking/oscillating/vibrating mixersRotary stirring mixersChemical industryEngineering

The invention discloses a uniformly-heated raw material mixing device for the chemical industry. The uniformly-heated raw material mixing device comprises a barrel, a shell, a motor and a material inlet, wherein a plurality of moving wheels are fixedly installed on the bottom of the barrel, a heating cavity is arranged between the barrel and the shell, the inner wall of the shell is provided witha heating layer, and a sealing cover is arranged between the top of the barrel and the shell in a sealing manner; a piston rod of an air cylinder is fixedly connected with a horizontal connecting rod,and the tail end, entering the shell, of the connecting rod is fixedly connected with the barrel; a horizontal scattering disc is fixed on the lower end of a guiding hopper; and a supporting screen is provided with a mesh tube sleeving the outer side of a main stirring blade, and the left side and the right side of the inner wall of the mesh tube are respectively fixedly connected with a plurality of connecting springs. By arranging a guiding plate and the rotary scattering disc, a raw material is uniformly scattered in the barrel, so that the raw material can be rapidly stirred and mixed; and the heating layer can provide the appropriate temperature for the reaction, so that the mixing reaction of the chemical raw material is ensured to be performed normally.

Owner:南安泰达农业科技有限公司

Drying device for titanium dioxide production

PendingCN113834286AQuick Stir to MixImprove drying efficiencyDrying gas arrangementsDrying machines with non-progressive movementsMetallurgyDioxide titanium

The invention is suitable for the technical field of chemical engineering, provides a drying device for titanium dioxide production, is used for titanium dioxide processing, and solves the problem that titanium dioxide is easy to accumulate at an outlet pipe due to the fact that the stirring range of a rotating blade in an existing device cannot be adjusted. The drying device comprises a circulating drying main body which comprises a drying cavity and a circulating part, a titanium dioxide mixing mechanism and a mixing mechanism driving assembly; the titanium dioxide mixing mechanism is arranged in the drying cavity and is used for mixing and stirring titanium dioxide and crushing the titanium dioxide; and the mixing mechanism driving assembly is connected with the titanium dioxide mixing mechanism and is used for driving the titanium dioxide mixing mechanism. According to the embodiment of the invention, the titanium dioxide mixing mechanism is arranged, when the titanium dioxide mixing mechanism works, titanium dioxide can be rapidly stirred and mixed, meanwhile, dynamic balance of flowing of titanium dioxide in the device is broken, caked titanium dioxide can be crushed, the contact area between the titanium dioxide and the caked titanium dioxide is increased, and the drying efficiency of the titanium dioxide is improved.

Owner:HUNAN CHUANGDA YUTU CHEM CO LTD

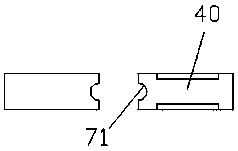

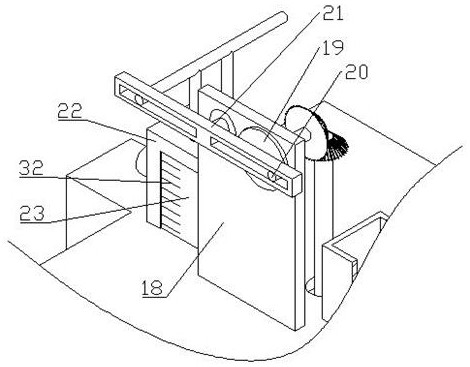

Dyeing fat liquoring equipment for leather dyeing machining

ActiveCN106957931AEfficient and convenient dippingFatliquoring is efficient and convenientLeather impregnationEngineeringHigh fat

The invention relates to dyeing fat liquoring equipment, in particular to dyeing fat liquoring equipment for leather dyeing machining and aims at achieving the technical purpose of providing the dyeing fat liquoring equipment for leather dyeing machining, wherein the dyeing fat liquoring equipment for leather dyeing machining is high in fat liquoring efficiency. To achieve the above technical purpose, the dyeing fat liquoring equipment for leather dyeing machining is provided and comprises a left support and the like. The left support is arranged on the left side of the top of a bottom plate. The right side of the left support is sequentially provided with a stirring device, a support rod and a fat dipping device from top to bottom. A treatment box is arranged at the right end of the support rod, an inlet is formed in the right side of the top of the treatment box, and the treatment box is connected with the stirring device. The dyeing fat liquoring equipment achieves the effect of high fat liquoring efficiency, the dyeing fat liquoring equipment is utilized for leather fat liquoring, the stirring device is mainly utilized for stirring fat liquoring mixing liquid, and then the fat liquoring device is utilized for fat dipping.

Owner:江西泽晞新材料有限公司

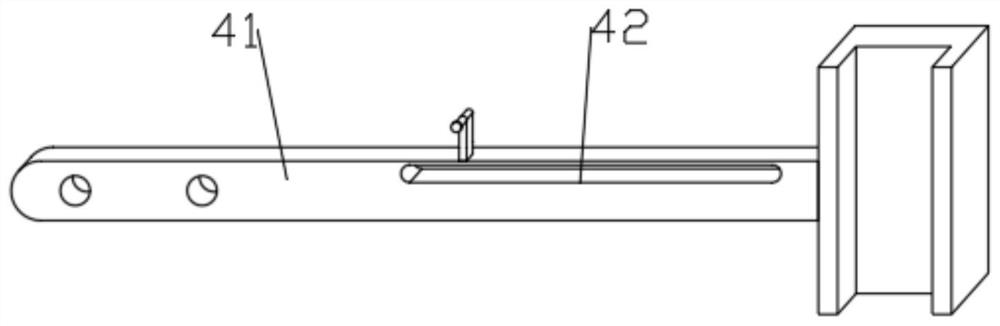

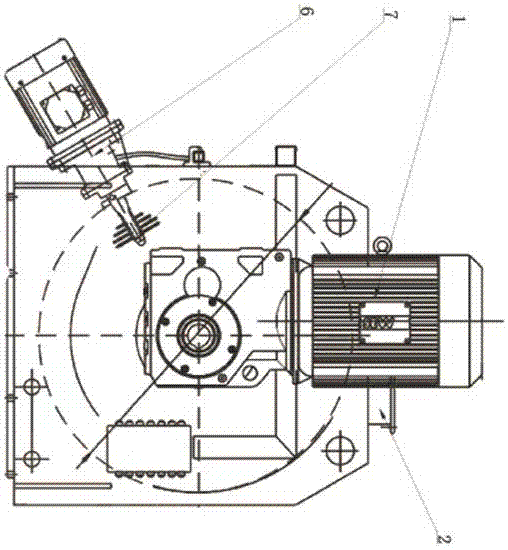

Device for preparing fertilizers by residual sludge and agricultural and forestry waste

InactiveCN109293412AQuick Stir to MixSimple structureTransportation and packagingRotary stirring mixersSludgeEngineering

The invention discloses a device for preparing fertilizers by residual sludge and agricultural and forestry waste. The device comprises a supporting seat, four first supporting rods are equidistantlyarranged on the left side of the upper surface of the supporting seat, a control panel is arranged in the middle of the front side surface of one first supporting rod, a first switch, a second switchand a third switch are arranged on the side surface of the control panel, a mounting frame is arranged at the upper ends of the four first supporting rods, bearing blocks are arranged at four cornersof the upper surface of the mounting frame, inner rings of the two bearing blocks on the left side of the upper surface of the mounting frame are in sleeve connection with driving rollers, inner ringsof the two bearing blocks on the right side of the upper surface of the mounting frame are in sleeve connection with driven rollers, and the outer surfaces of the driving rollers and the driven rollers are in sleeve connection with conveying belts. According to the device for preparing the fertilizers by the residual sludge and the agricultural and forestry waste, the residual sludge can be heated and dried, the agricultural and forestry waste and the dried residual sludge are rapidly mixed, stirred and prepared into the fertilizers, and the fertilizers can be continuously produced and processed.

Owner:方鑫悦

Agent stabilizing device for water treatment

InactiveCN109126519AAdjustable stirring positionImprove production efficiencyRotary stirring mixersTransportation and packagingEngineeringWater treatment

The invention discloses an agent stabilizing device for water treatment. The agent stabilizing device comprises a bottom frame, a support is mounted on the bottom frame, a first sliding cavity is formed in the right end face of the support, a lifting frame is mounted in the first sliding cavity in a sliding fit manner and extends out of the right end face of the support, a lower fixing block and an upper fixing block are fixedly arranged on the right end face of the support and on the upper side and the lower side of the first sliding cavity, a spiral shaft is mounted in the lifting frame in athreaded fit manner, the tail end of the bottom of the spiral shaft is rotatably connected with the lower fixing block, the tail end of the top of the spiral shaft is in clearance fit with the upperfixing block, a first motor is mounted at the tail end of the top of the spiral shaft in a power matched manner and fixedly arranged on the top end face of the upper fixing block, a mounting hole is formed in the bottom end face of the lifting frame, and a first steering shaft is mounted in the top wall of the mounting hole in a running fit manner.

Owner:广州利萨智能化科技有限公司

Mixing and stirring device for food processing

InactiveCN112108044AWell mixedQuick Stir to MixRotary stirring mixersTransportation and packagingProcess engineeringIndustrial engineering

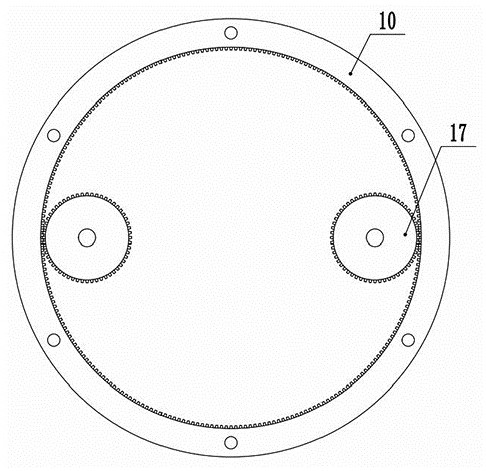

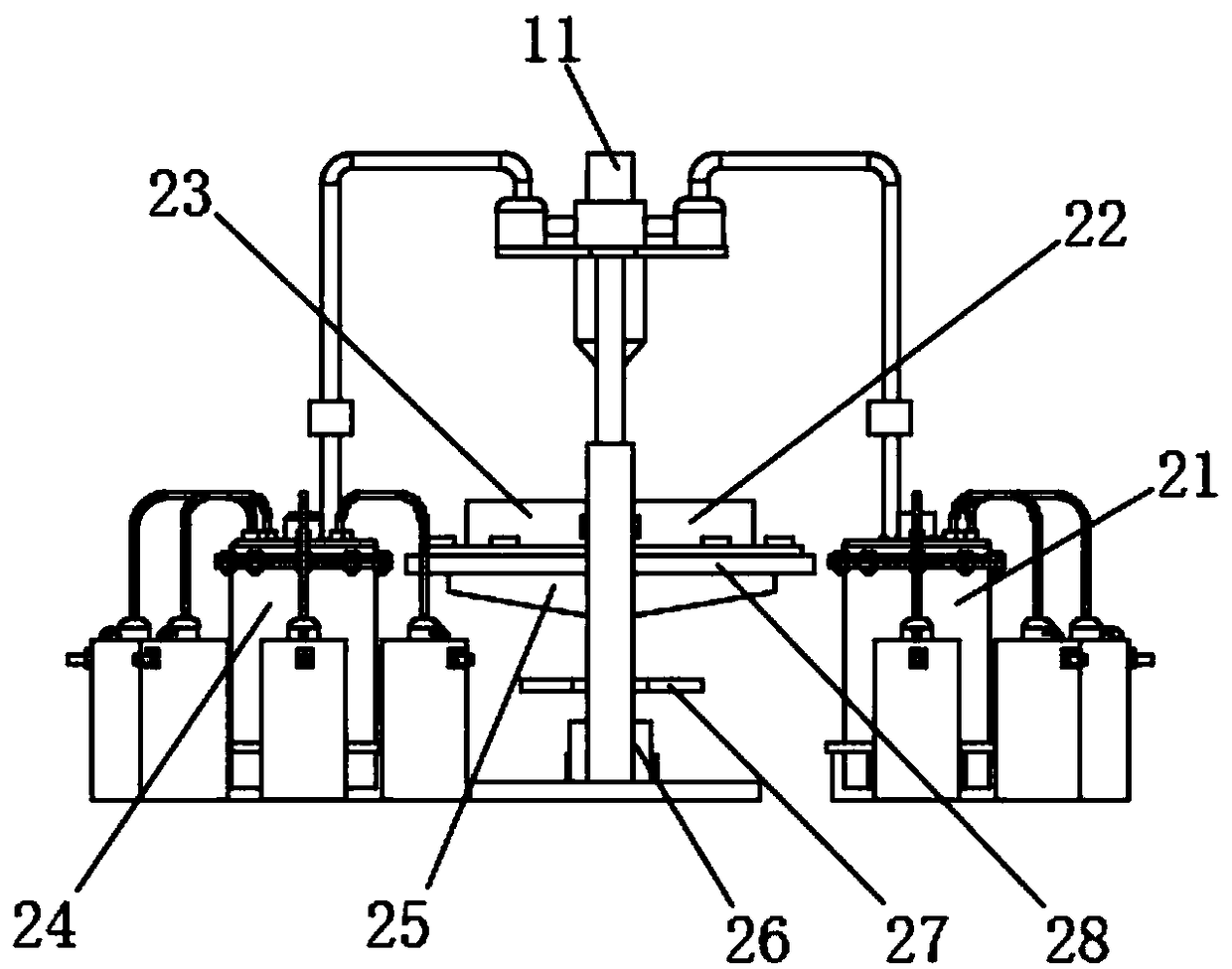

The invention discloses a mixing and stirring device for food processing. The mixing and stirring device comprises a base, a main stirring barrel, auxiliary stirring barrels, a partition plate, an upper circulating opening, a lower circulating opening, a discharging pipe, an electromagnetic on-off valve, a visual window, a discharging barrel, a stirring part and a water injection part, wherein thevertical main stirring barrel is fixed on the top end of the base; and the vertical auxiliary stirring barrels are fixed at the left end and the right end of the main stirring barrel respectively. According to the invention, a main stirring paddle, auxiliary stirring paddles and a spiral conveying paddle can be simultaneously driven to perform stirring in multiple directions through transmissionof gears and a belt, so raw materials can be mixed more uniformly; intermittent feeding can be performed while mixing and stirring are being performed, so a small amount of the raw materials fed eachtime can be rapidly stirred and mixed, stirring time is saved, and stirring efficiency is improved; a discharging amount can be controlled to a certain extent without high-precision elements, and therefore,e input cost is saved.

Owner:岳玺石

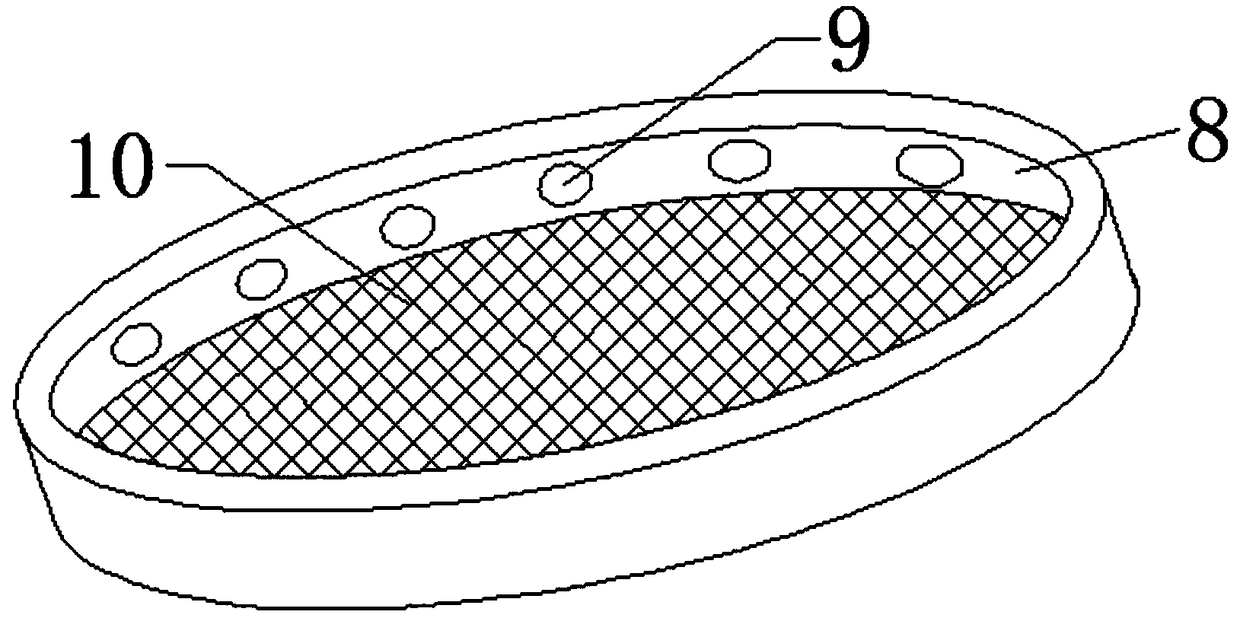

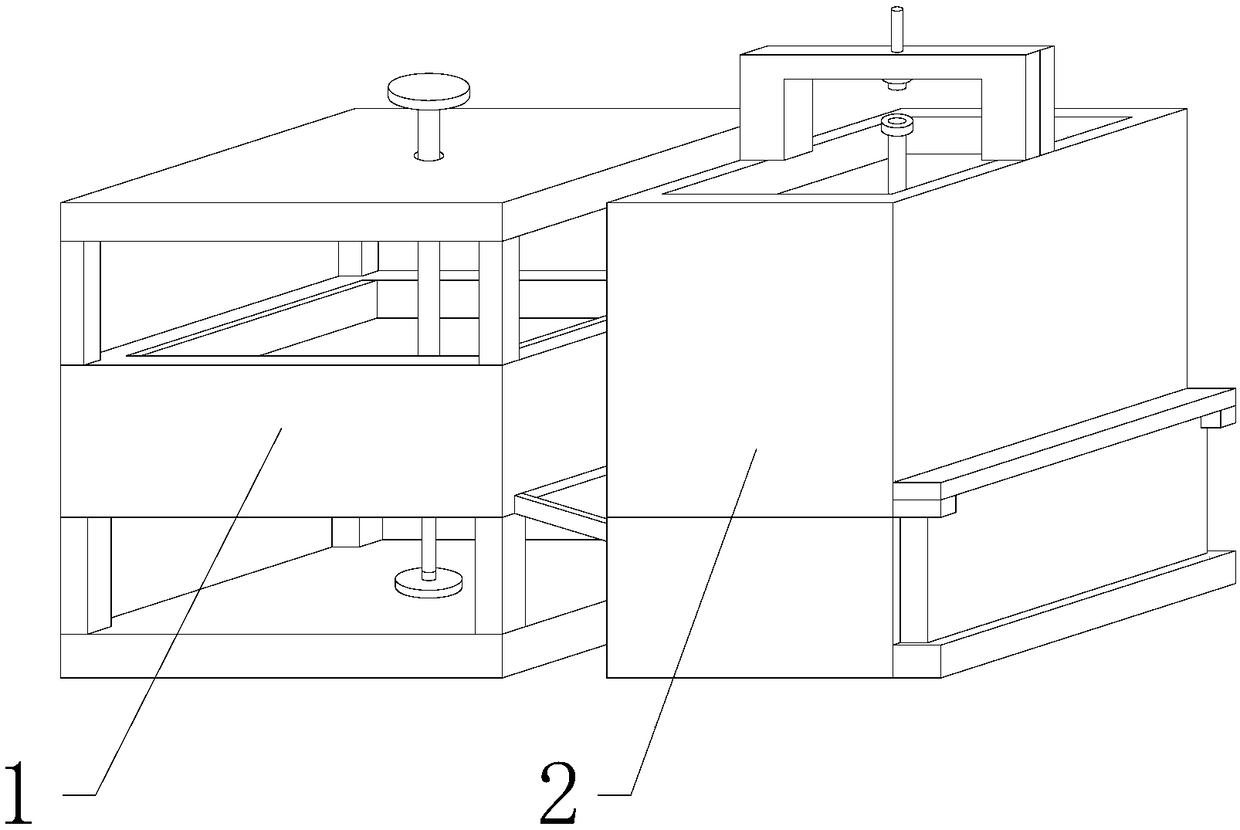

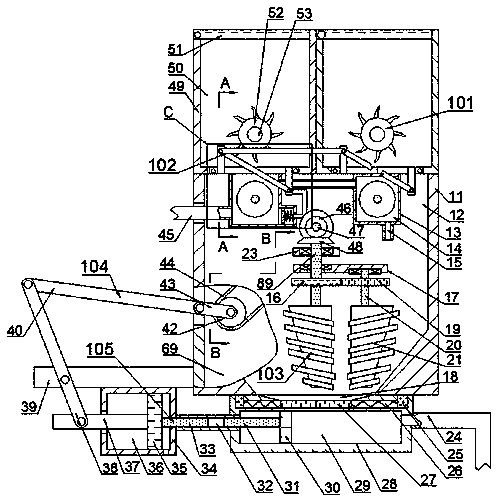

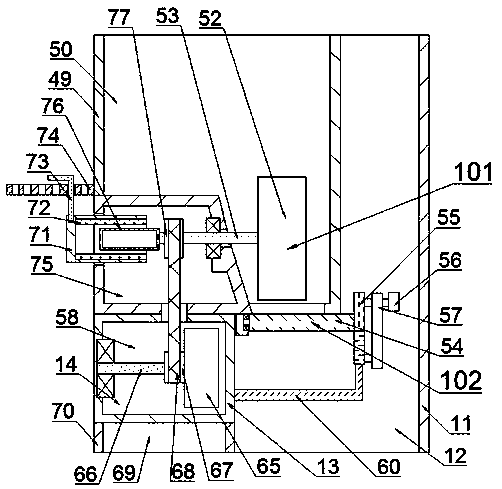

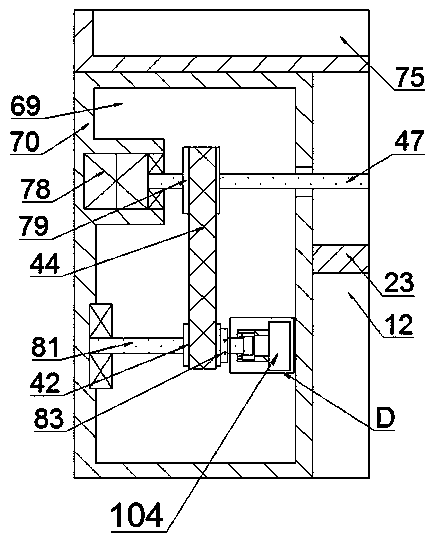

Paper pulp molding and pad printing apparatus

PendingCN108978358AHigh precisionGood molding and anti-counterfeiting effectNon-fibrous pulp additionPulp material addition processesPressure die castingMechanical engineering

The invention provides a paper pulp molding and pad printing apparatus. The paper pulp molding and pad printing apparatus comprises a molding mechanism and a conveying mechanism. The molding mechanismis arranged on the left side of the conveying mechanism. The molding mechanism comprises a fixing rod, an upper cover, a baffle board, an outer corrugated board, a lower mold seat, a base board, a top pipe, a motor, a first screw rod, a push board, a water storage chamber, a water discharge tank, a first filter board, an upper press mold, a draw rope, a winding wheel, a threaded rod, a pressure board and a spring. The conveying mechanism comprises a limiting rod, a support frame, a mixing box, a conveying inclined tube, an inclined board, a support box body, a second filter board, a sealing board, a stirring shaft, mixing blades, a hollow tube, a first round gear, a second round gear, a second screw rod and a floating board. Compared with the prior art, the paper pulp molding and pad printing apparatus has the following beneficial effects: a rapid water squeezing function is achieved; precision of mold casting is increased; molding and anti-counterfeiting effects are good; a functionof rapidly mixing and stirring is fulfilled; and high control precision of transmission capacity is acquired.

Owner:永发(江苏)模塑包装科技有限公司

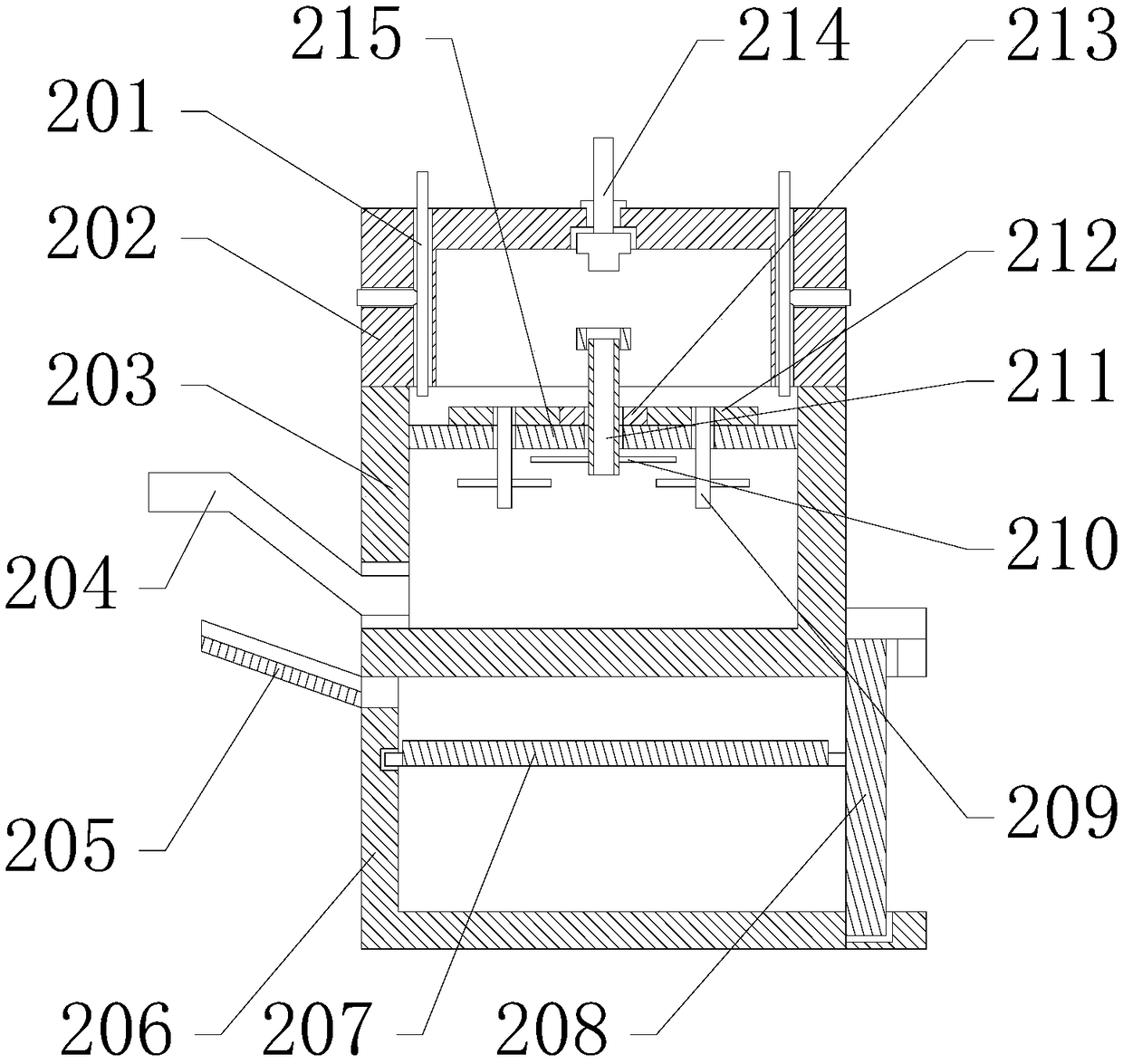

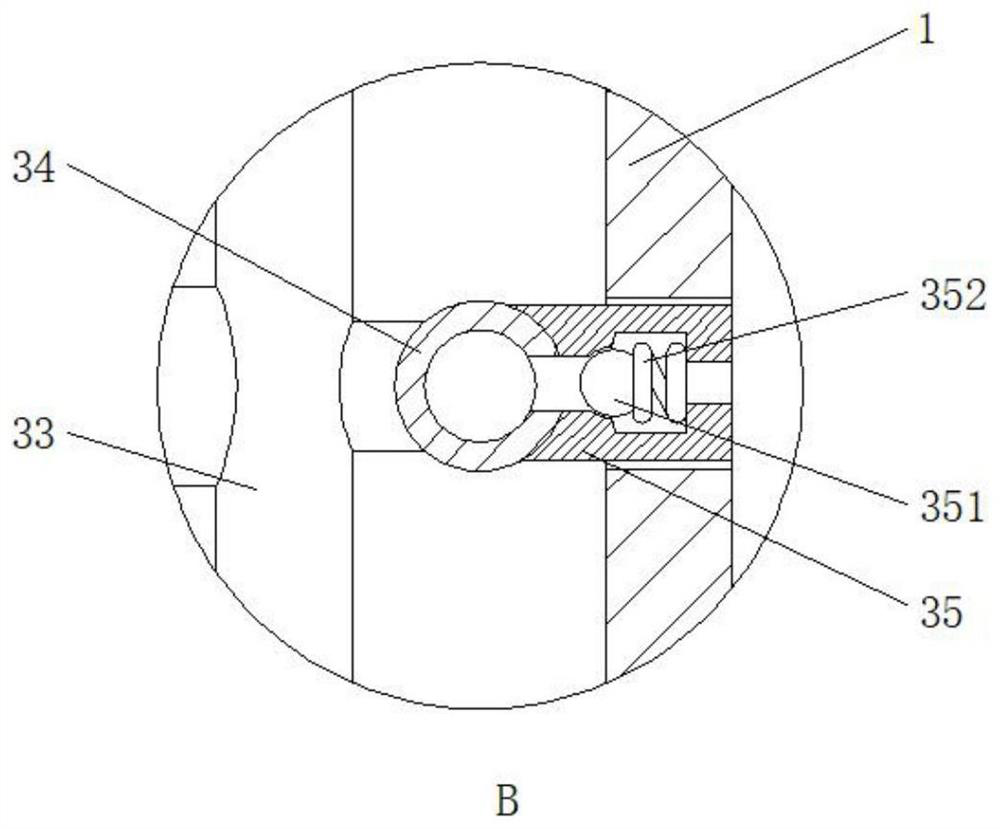

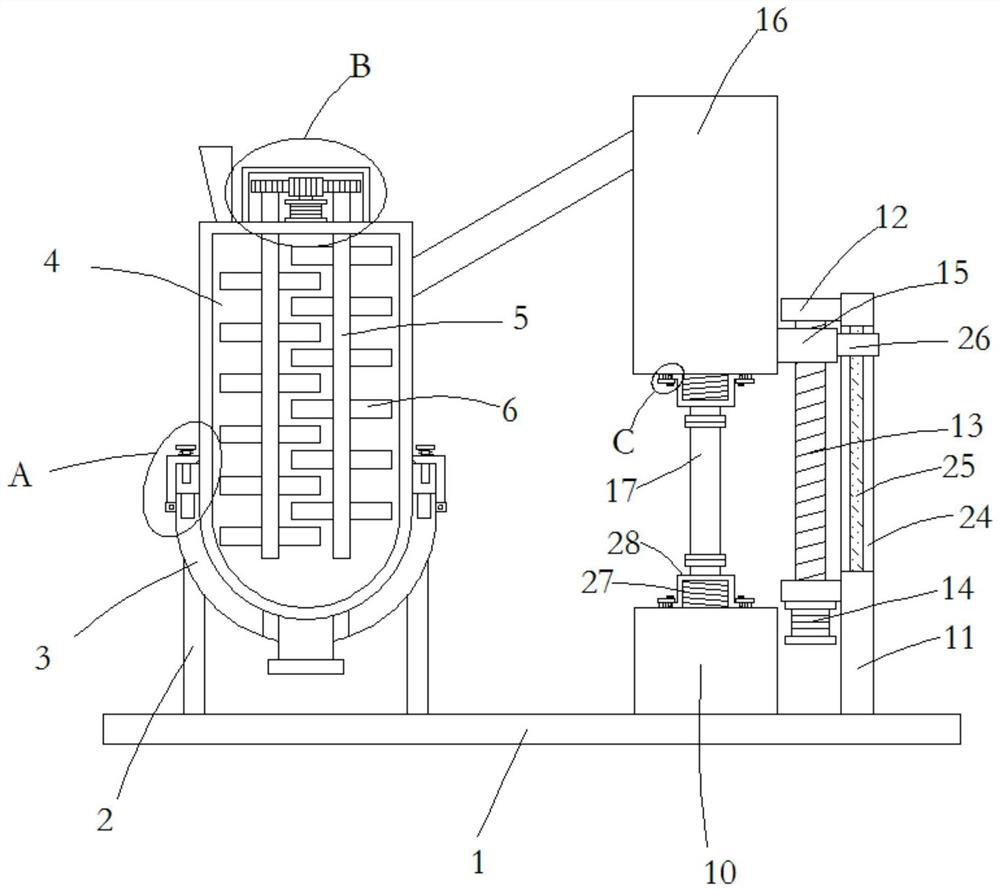

Grouting equipment for constructing impervious curtain of dam

ActiveCN110295601AAvoid Dust ProblemsAvoid difficult drivingFoundation engineeringRaw materialArchitectural engineering

The invention discloses grouting equipment for constructing an impervious curtain of a dam. The grouting equipment comprises a mixing box, wherein a mixing cavity opened downward is formed in the mixing box, a quantifying device is arranged in the mixing cavity, an opening device located on the front side of the quantifying device and controlled by the quantifying device is arranged in the mixingcavity, a mixing device located on the lower side of the quantifying device for stirring concrete is arranged in the mixing cavity, a power device located on the left side of the mixing device and located out of the end surface of the left side of the mixing cavity partially is arranged in the mixing cavity, and a pressurizing device is arranged on the end surface of the lower side of the mixing cavity. A quantative inputting device can set different inputting proportions by adjusting the resistance of a damper and is easy to fit different operating demands. A twin-screw stirring device can stir and mix raw materials quickly, and then concrete is poured into a construction station by a pressure conveying device, so that concrete is stirred and poured automatically in a construction site.

Owner:XINJIANG GUOTONG PIPELINE CO LTD

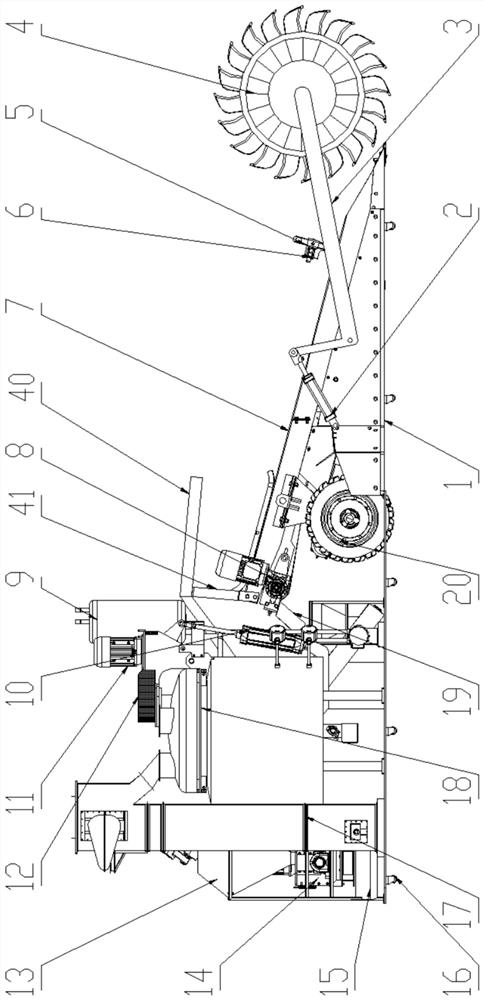

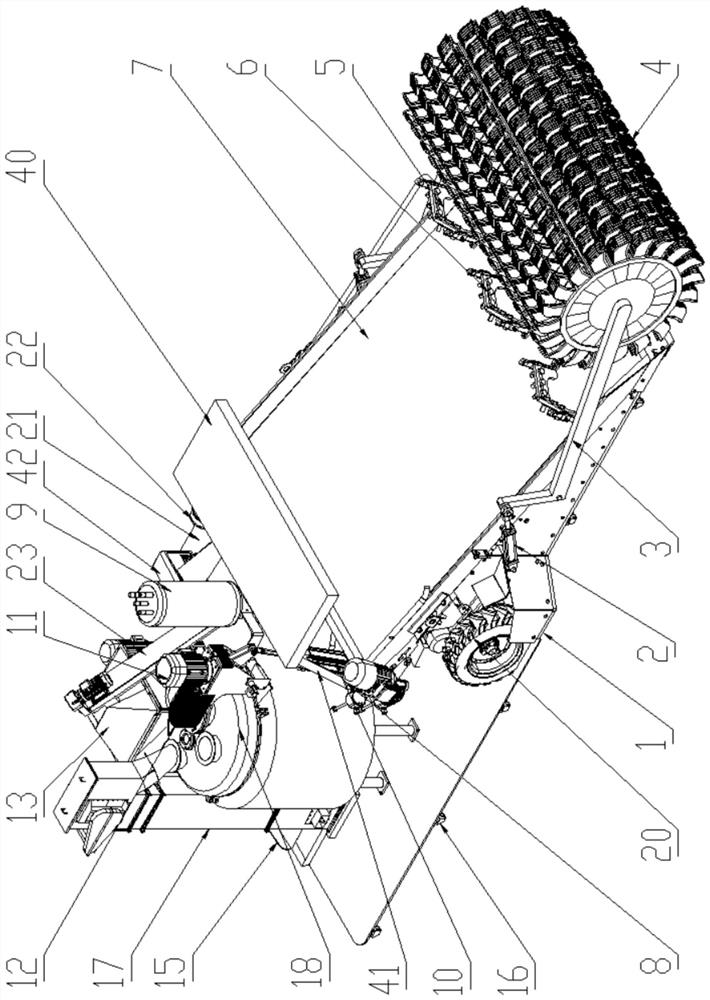

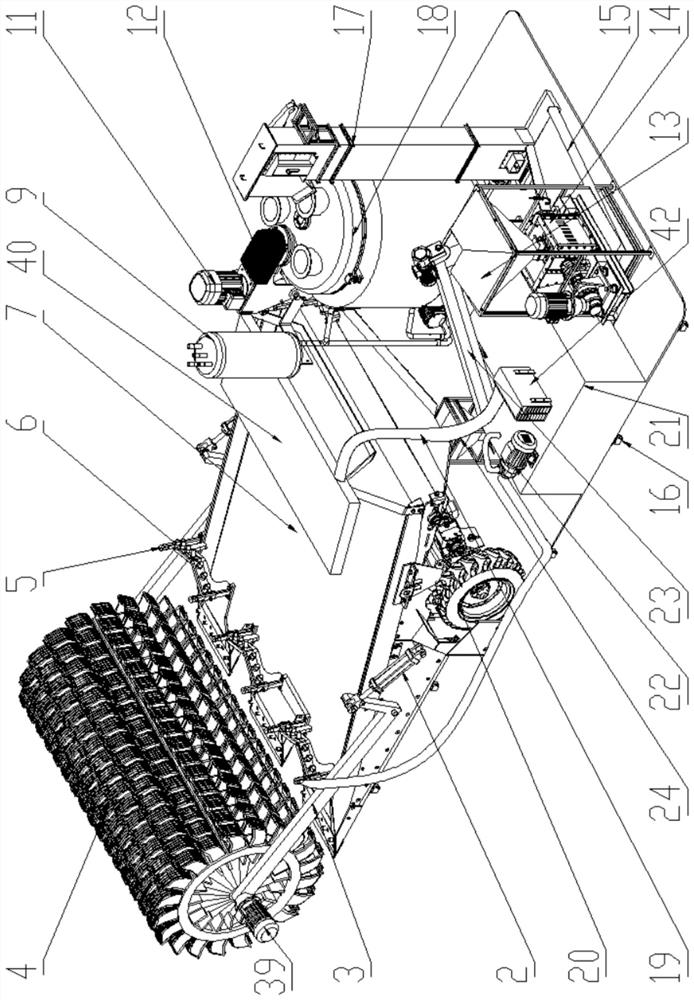

Asphalt mixing preparation device and preparation method using waste pavement asphalt

PendingCN113718615AImprove efficiencyExtended service lifeRoads maintainenceCleaning using liquidsAsphaltWater tanks

The invention provides an asphalt mixing preparation device and preparation method using waste pavement asphalt, belongs to the technical field of asphalt production, and is used for solving the problem that existing equipment cannot be used for producing and preparing asphalt on site while recycling the waste pavement asphalt. The device comprises a chassis plate, a lifting weighing mechanism and a walking conveying mechanism are sequentially arranged at the upper end of the chassis plate, a fine crushing mechanism and a material guide plate are arranged at the lower end of the lifting weighing mechanism, an adjusting milling mechanism is arranged on the walking conveying mechanism, and a fine material elevator, a stirring and mixing mechanism and a water tank are further arranged at the upper end of the chassis plate; a drying mechanism is arranged between the water tank and the walking conveying mechanism, the water inlet end of the spraying water pump is connected to the interior of the water tank, and the water inlet end of the spraying water pump is connected to a spraying pipe frame; and the device is high in automation degree, planing and milling are carried out while walking is carried out, the efficiency is high, waste pavement asphalt materials are quantitatively output, the matching proportion is met, and pavement asphalt is rapidly produced and prepared on site by recycling the waste pavement asphalt.

Owner:六安万方沥青施工有限公司

Omnibearing multifunctional mixing apparatus

InactiveCN107376696ARapid secondary mixingSecondary mixing is sufficientRotary stirring mixersTransportation and packagingEngineeringHybrid device

The invention relates to an omnibearing multifunctional mixing apparatus in the field of mixing equipment. The access doors are arranged at two sides of a mixing apparatus body, a latch is arranged below the access door, a locking device is arranged between the upper side of the access door and the mixing apparatus body, a stroke switch is arranged on the access door through cooperation, a feed inlet is arranged over the mixing apparatus body, a discharging door body is arranged below the mixing apparatus body, support bearings are respectively arranged at two sides of the mixing apparatus body, a rotor is arranged between the support bearings, a drive unit is arranged at the support bearing at any side of the mixing apparatus body through cooperation, and the drive unit is arranged by cooperating with the rotor; an auxiliary mixing device is arranged between the intermediate and the lower side of the mixing apparatus body, the auxiliary mixing device is transversely arranged at intervals, the bracing frames are arranged below the mixing apparatus body, the bracing frames are arranged at the two sides of the mixing apparatus body, the multifunctional mixing apparatus cooperates with the auxiliary mixing device with slant arrangement through the transversely arranged rotor, the materials can be rapidly mixed and stirred, and the production efficiency is increased.

Owner:任洁

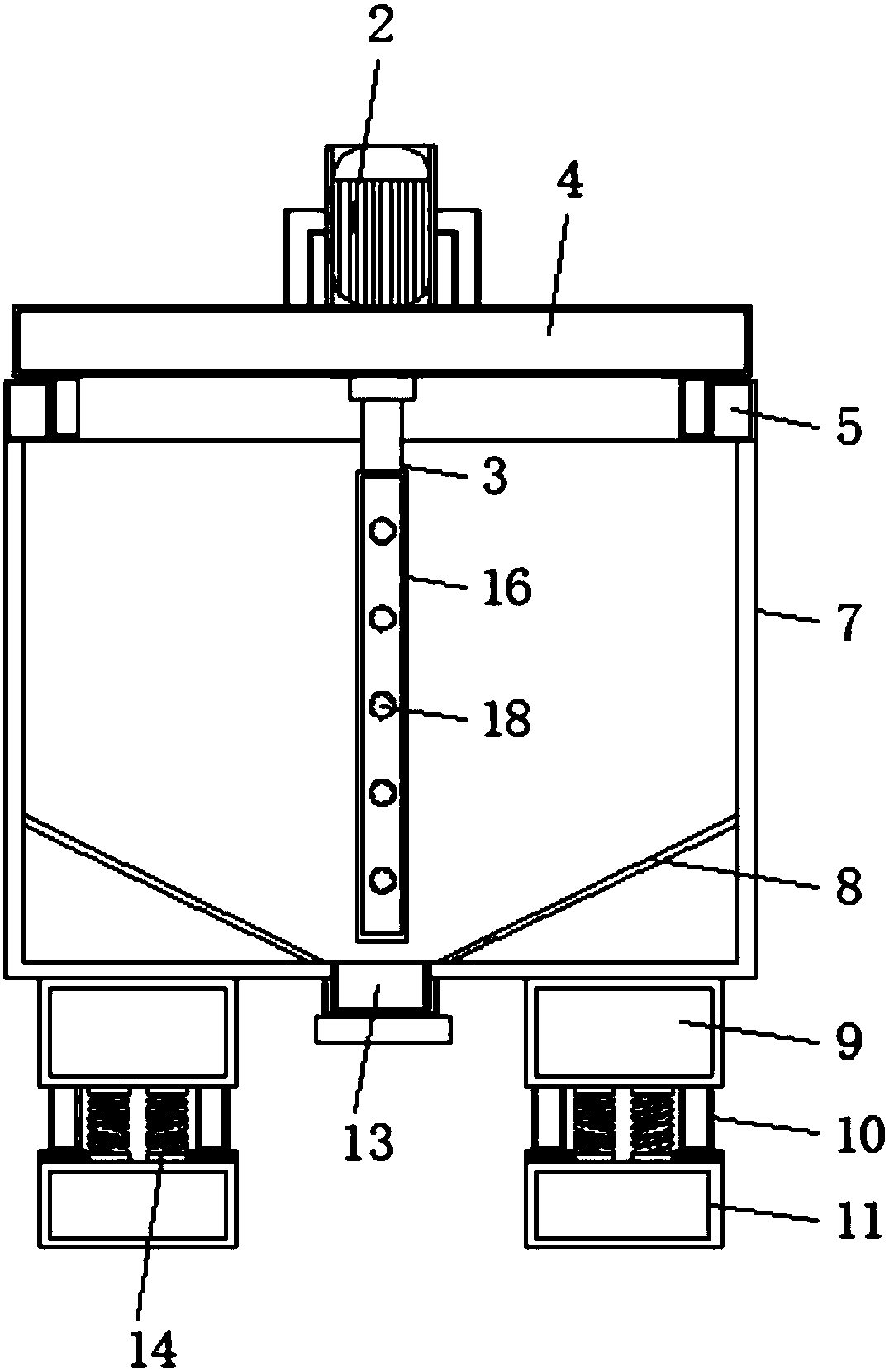

Biological enzyme stirring barrel

InactiveCN108485922AEasy to disassembleQuick Stir to MixBioreactor/fermenter combinationsBiological substance pretreatmentsABSORPTION BASEEngineering

The invention discloses a biological enzyme stirring barrel. The biological enzyme stirring barrel comprises a rotating shaft, a closed cover and a stirring barrel body, wherein the lower end of the stirring barrel body is fixedly provided with a shock-absorption base, the lower end surface of the shock-absorption base is connected with a supporting base by virtue of a shock-absorption spring, oneside of the upper end surface of the supporting base is fixedly provided with a sliding connecting rod, the tail end of the sliding connecting rod is installed in the shock-absorption base in a sliding manner, an oblique unloading plate is installed in the stirring barrel body, the closed cover is installed on the upper end of the stirring barrel body in a threading manner, one side of the upperend surface of the closed cover is provided with a material inlet, one side of the material inlet is provided with a motor, the rotating shaft is installed on the lower end surface of the closed coverin a rotating manner, the lower end of the rotating shaft is provided with an installation column, a threaded hole is formed in the installation column, the interior of the threaded hole is providedwith a threaded shaft in a threading manner, and the tail end of the threaded shaft is separately provided with a first stirring blade, a second stirring blade and a third stirring blade. The biological enzyme stirring barrel has the advantages of rapidness and uniformity in stirring, convenience in cleaning, and convenience for disassembling the stirring blade.

Owner:佛山市尚柏科技有限公司

Turbulence fluctuation type stirring device for mixing water-based zinc-rich coating

InactiveCN112354464AQuick Stir to MixImprove mixing efficiencyTransportation and packagingMixer accessoriesEngineeringMechanical engineering

The invention discloses a turbulence fluctuation type stirring device for mixing water-based zinc-rich paint, which relates to the technical field of paint production and comprises a mixing box, a middle stirring mechanism and a side stirring mechanism are arranged in the mixing box, a conveying pipe is arranged between the middle stirring mechanism and the side stirring mechanism, and a conveyingmechanism is arranged in the conveying pipe. The top end of the interior of the mixing box is rotatably connected with an upper rotating cover, the bottom end of the upper rotating cover is fixedly connected with a lower rotating cover, a middle cylinder is arranged below the center of the lower rotating cover, and an extrusion device is arranged in the middle cylinder. The forced flowing of materials in the mixing box can be achieved by arranging the conveying mechanism, the uniformity of coating of all liquid level layers is improved, intermittent pressing can be achieved by arranging the extrusion device, fluctuation type extrusion is formed, coating in the middle barrel and the conveying pipe forms turbulent flow, the mixing efficiency of the coating is improved, and the coating quality is improved. Therefore, the mixing efficiency and speed of the coating are high.

Owner:SHANDONG YILI OIL PAINT

Reaction kettle for producing benzoyl peroxide

PendingCN113856590AFacilitate material movementImprove processing efficiencyOrganic compound preparationChemical/physical/physico-chemical stationary reactorsProcess engineeringDibenzoyl Peroxide

The invention relates to a reaction kettle for producing benzoyl peroxide, and belongs to the technical field of benzoyl peroxide production devices. The reaction kettle comprises a reaction tank body, a stirrer is arranged in the middle of the reaction tank body, the stirrer comprises a central main shaft and a sleeve shaft, the sleeve shaft is slidably arranged outside the central main shaft in a sleeving manner, and stirring blades and a temperature control distribution ring are arranged on the outer wall of the sleeve shaft; the lower end of the sleeve shaft penetrates through the lower end of the reaction tank body and is connected with an up-down swinging mechanism; the outer wall of the reaction tank body is connected with a precise feeding device through a plurality of injection heads; and a reaction end prompter is arranged on one side of the top of the reaction tank body. According to the device, the stirring blades and the temperature control distribution ring can horizontally rotate at a high speed and vibrate up and down at the same time, material movement is promoted, materials are driven to be mixed and reacted more efficiently, ingredients can be automatically and accurately added through the accurate adding device, the processing efficiency is improved, and the product quality is guaranteed; and automatic reminding of reaction completion can be realized through the reaction completion prompter.

Owner:芜湖优机环保科技有限公司

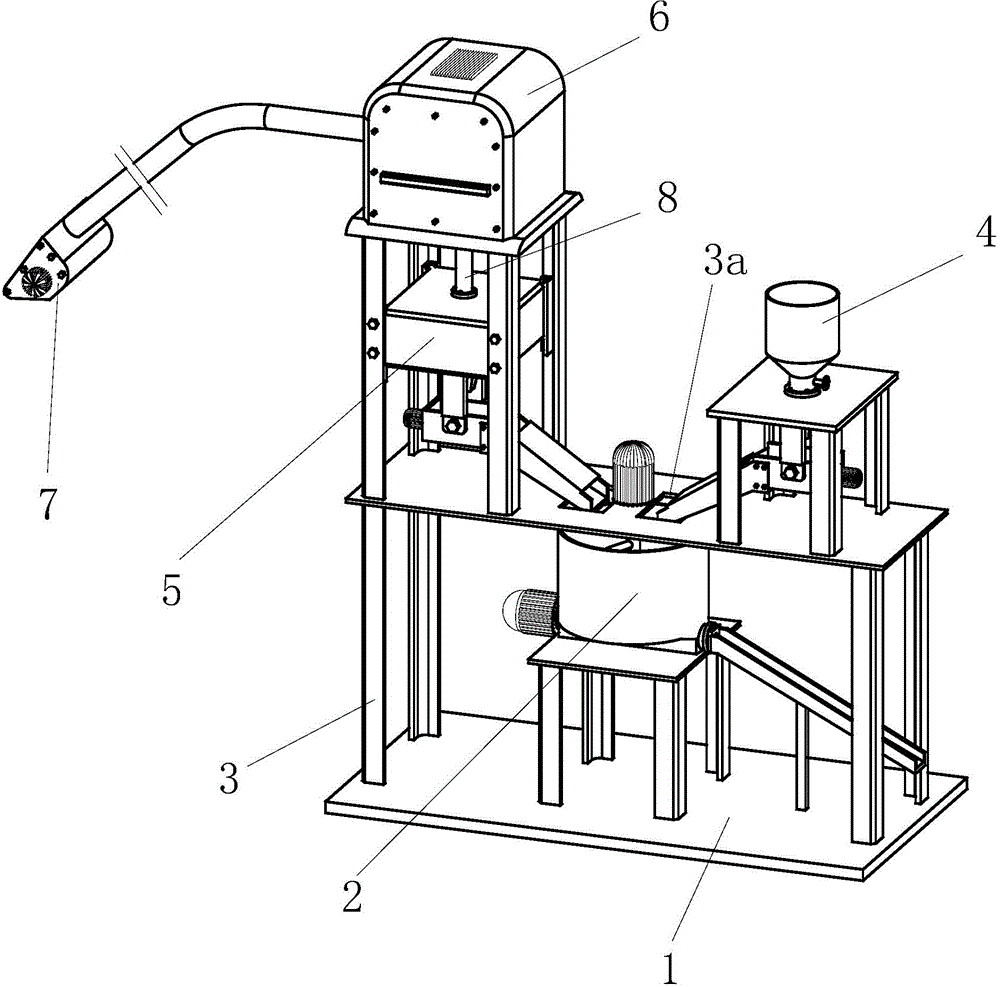

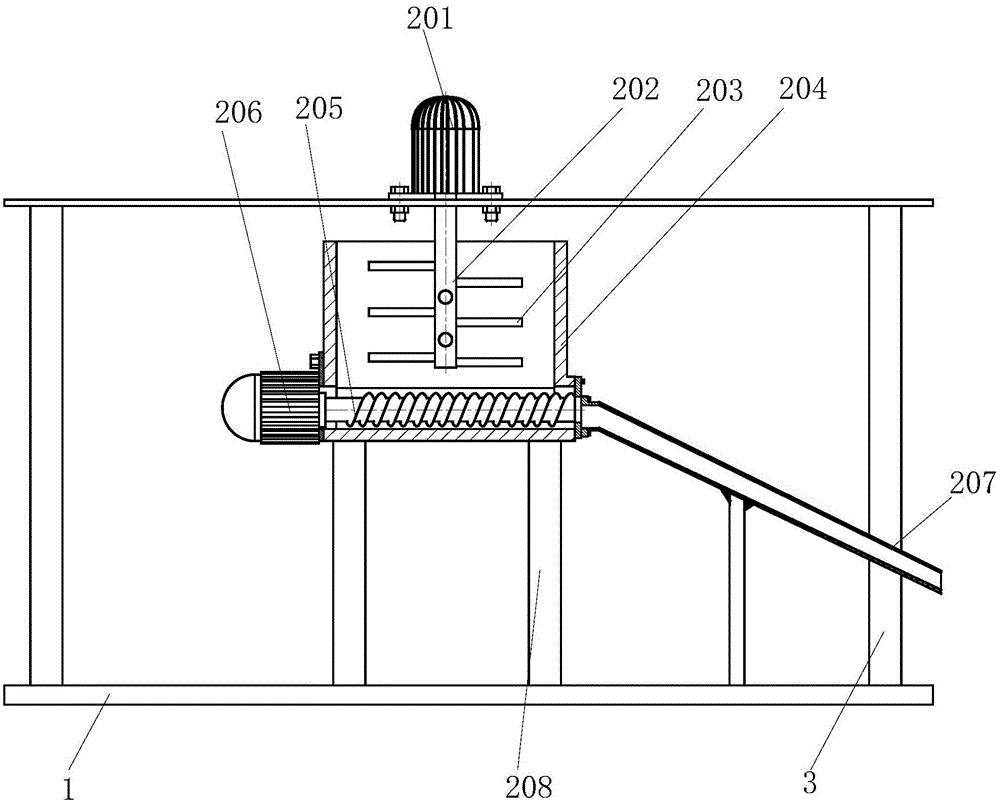

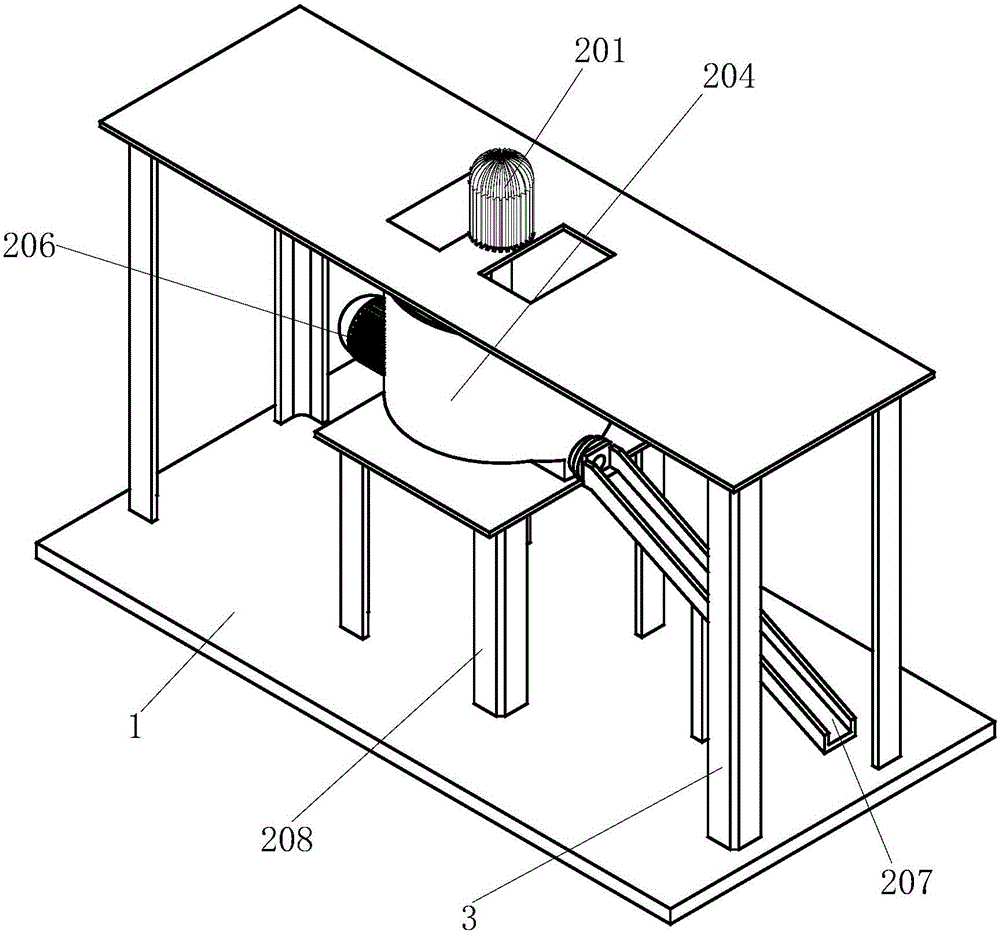

Mixing stirring all-in-one machine

InactiveCN104307403AQuick Stir to MixReduce labor intensityFeeding-stuffRotary stirring mixersEngineeringUltimate tensile strength

The invention relates to a mixing stirring all-in-one machine. The mixing stirring all-in-one machine comprises a base, a mixing stirring device, a support table, an accessory material feeding device, a material adsorption device 2, a material adsorption device 1, a material adsorption box and a communication pipe. The base is provided with the mixing stirring device. The support table is provided with two quadrate through holes. The support table is fixed to the base. The material adsorption device 1 is installed on the left side of the support table and the material adsorption device 2 is located below the material adsorption device 1. The communication pipe is installed between the material adsorption device 2 and the material adsorption device 1. The accessory material feeding device is installed at the right side of the support table. The mixing stirring all-in-one machine has the advantages of reasonable structure design and high work efficiency, realizes fast mixing stirring of various substances, reduces peasant labor intensity, and adopts a centrifugal fan for feed transport thereby saving labor and greatly improving work efficiency.

Owner:WUHU HENGHAO MACHINERY MFG

Building outer wall coating spraying device

The invention discloses a building outer wall coating spraying device which comprises a base. Locking universal wheels are arranged on the lower surface of the base, and a supporting frame is arrangedin the middle of the upper surface of the base. A supporting plate is arranged on the upper surface of the supporting frame, and a stirring barrel is arranged on the upper surface of the supporting plate. An upper end cover is arranged on the upper end face of the stirring barrel, and a stirring motor is arranged in the middle of the upper surface of the upper end cover. An output shaft of the stirring motor is provided with a stirring shaft, and stirring blades are arranged on the outer side face of the stirring shaft. A tapered feeding nozzle is arranged at the right end of the upper surface of the upper end cover, and a second supporting plate is arranged at the rear end of the outer side face of the stirring barrel. The building outer wall coating spraying device is compact in structure, convenient to operate, small in occupied space during using and capable of conducting coating quick spraying on the building outer wall, through arrangement of the universal wheels combining witha push rod, the building outer wall coating spraying device can be moved very conveniently, through the stirring blades, coating can be quickly stirred and mixed, and through arrangement of a storingbox, storing of a spraying tool is facilitated.

Owner:中山市加丰机械科技有限公司

Extremely simple high efficiency gas floatation machine, and gas floatation method

PendingCN108622972ANo overflowRealize automatic slag dischargeWater/sewage treatment apparatusWater/sewage treatment by flotationRefluxProcess engineering

The invention discloses an extremely simple high efficiency gas floatation machine. The extremely simple high efficiency gas floatation machine comprises a gas floatation pool main body, a spiral water inlet pipeline, a reflux pump, a gas inflation pipeline, and a gas dissolving pipeline; the upper end and the lower end of the gas floatation pool main body are designed to shape like a cone; the top end and the bottom end of the gas flotation pool main body are provided with a residue discharging pipeline and a water outlet pipe with adjustable height respectively; an agent adding port a and anagent adding port b are arranged on the spiral water inlet pipeline. In applications, agents and sewage are subjected to high speed eddy flow in an eddy flow water inlet pipeline, so that rapid stirring mixing full reaction is realized; the residue discharging pipeline is arranged on the top part of the upper cone-shaped end of the gas floatation pool main body, and is combined with the water outlet pipe with adjustable height, so that automatic residue discharging is realized; an outlet of the reflux pump is provided with the gas inflation pipeline and the gas dissolving pipeline, on the gasinflation pipeline, a venturi tube is used for gas suction, and gas is introduced into an inlet of the reflux pump, so that automatic gas inflation is realized. The extremely simple high efficiency gas floatation machine is capable of solving technical problems in the prior art that the amount of gas floatation machine mechanical equipment is too large, water consumption of per ton is high, and mud is easily accumulated at pool bottoms.

Owner:NINGBO SHANGFUYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Polyurethane elastomer solid tire production feeding device

InactiveCN108748838ACompact structureEasy to operateTyresCoatingsPolyurethane elastomerMicrocomputer

The invention discloses a polyurethane elastomer solid tire production feeding device which comprises a base. A single chip microcomputer is arranged at the rear end of the upper surface of the base,and a rotary shaft is rotationally connected with the base by bearings arranged in the middle of the upper surface of the base. The polyurethane elastomer solid tire production feeding device has theadvantages that the polyurethane elastomer solid tire production feeding device is compact in structure and convenient to operate; tire molds can be conveniently uniformly and quickly fed by the polyurethane elastomer solid tire production feeding device, and lifting adjustment can be conveniently carried out on a cylindrical feeding head by the aid of an electric telescopic rod; production raw materials can be uniformly stirred and mixed with one another by a spiral stirring blade, a first grinding tool fixture block and a second grinding tool fixture block can be driven by a first gear and asecond gear to rotate at the constant speeds, the first grinding tool fixture block is combined with the second grinding tool fixture block, and accordingly the tire molds can be clamped and positioned; a turntable can rotate at the different rotational speeds by the aid of a variable-frequency motor, and initial raw materials can be conveniently added by the aid of first liquid pumps.

Owner:马鞍山久特新材料科技有限公司

Traditional Chinese medicine distillation extractor with lifting function

InactiveCN112316462AWith lifting functionQuick disassemblyDistillation in boilers/stillsSolid solvent extractionBall bearingGear wheel

The invention relates to the technical field of traditional Chinese medicine distillation, and discloses a traditional Chinese medicine distillation extractor with a lifting function. The traditionalChinese medicine distillation extractor comprises a base, the left side of the upper end of the base is fixedly connected with the same bracket through a plurality of supporting columns, and a distillation still is clamped in the bracket; two through holes are symmetrically formed in the upper end of the distillation still, stirring rods are rotatably sleeved with the through holes through ball bearings, a plurality of stirring blades are symmetrically and fixedly connected to the rod walls of the stirring rods, driven gears are fixedly connected to the upper ends of the stirring rods, and a rotating motor is fixedly arranged at the upper end of the distillation still; and a driving gear engaged with the two driven gears is fixedly connected to an output shaft at the upper end of the rotating motor, and a receiver and a vertical plate are further fixedly arranged on the right side of the upper end of the base. The traditional Chinese medicine distillation extractor with a lifting function has the advantages that the relative height position of a condenser can be rapidly adjusted, and use is convenient.

Owner:MAANSHAN SHENLUKERUI PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com