Patents

Literature

31results about How to "Meet material performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

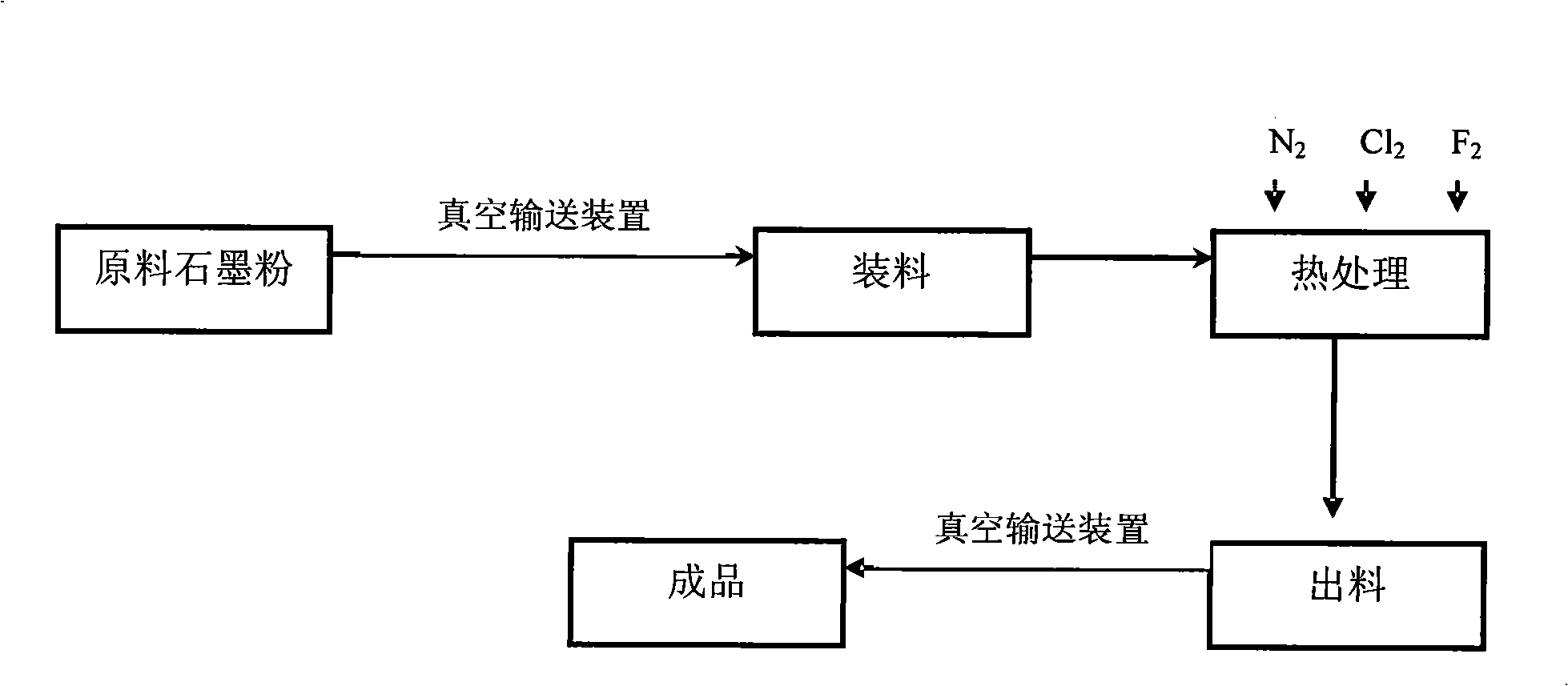

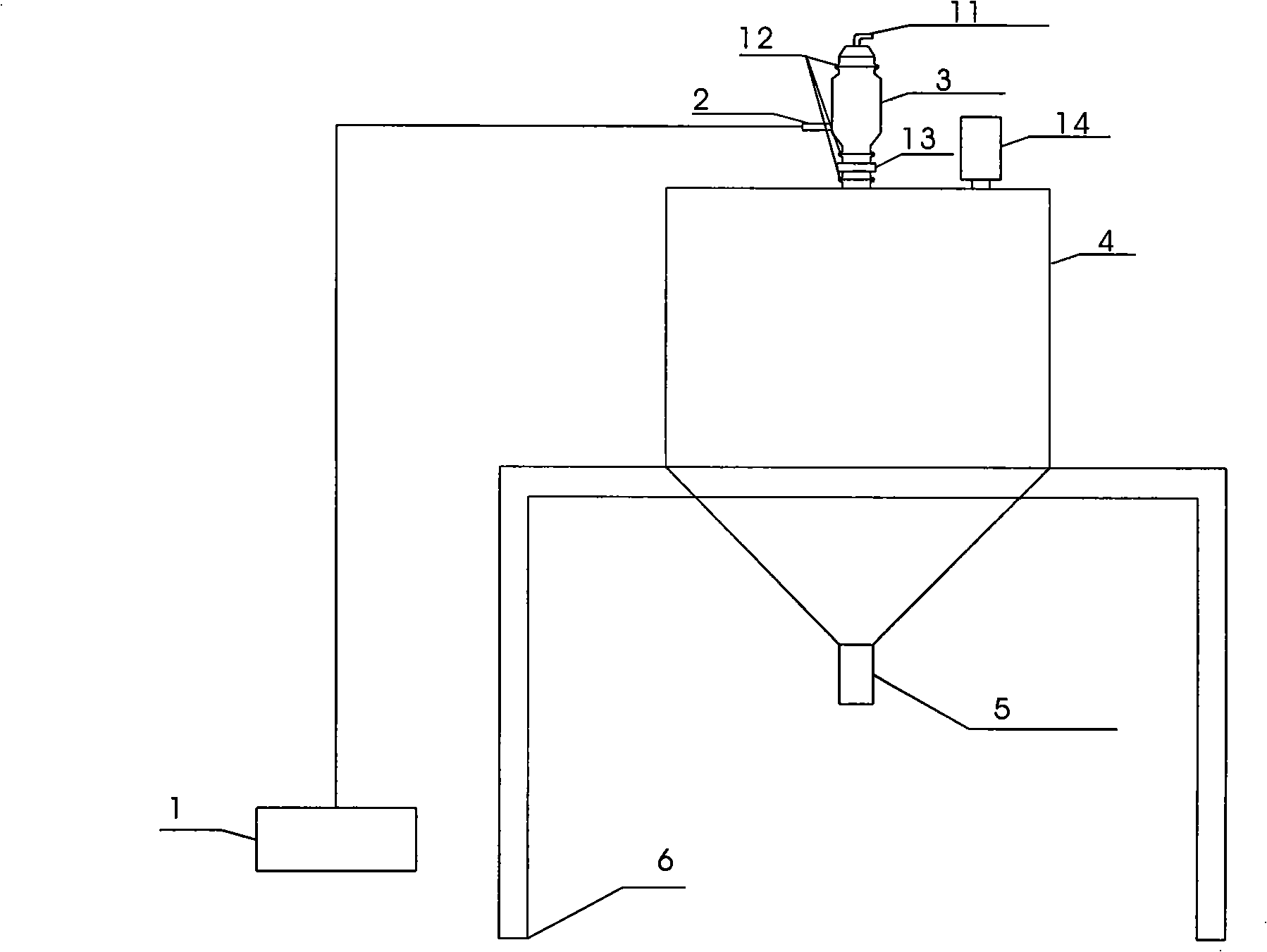

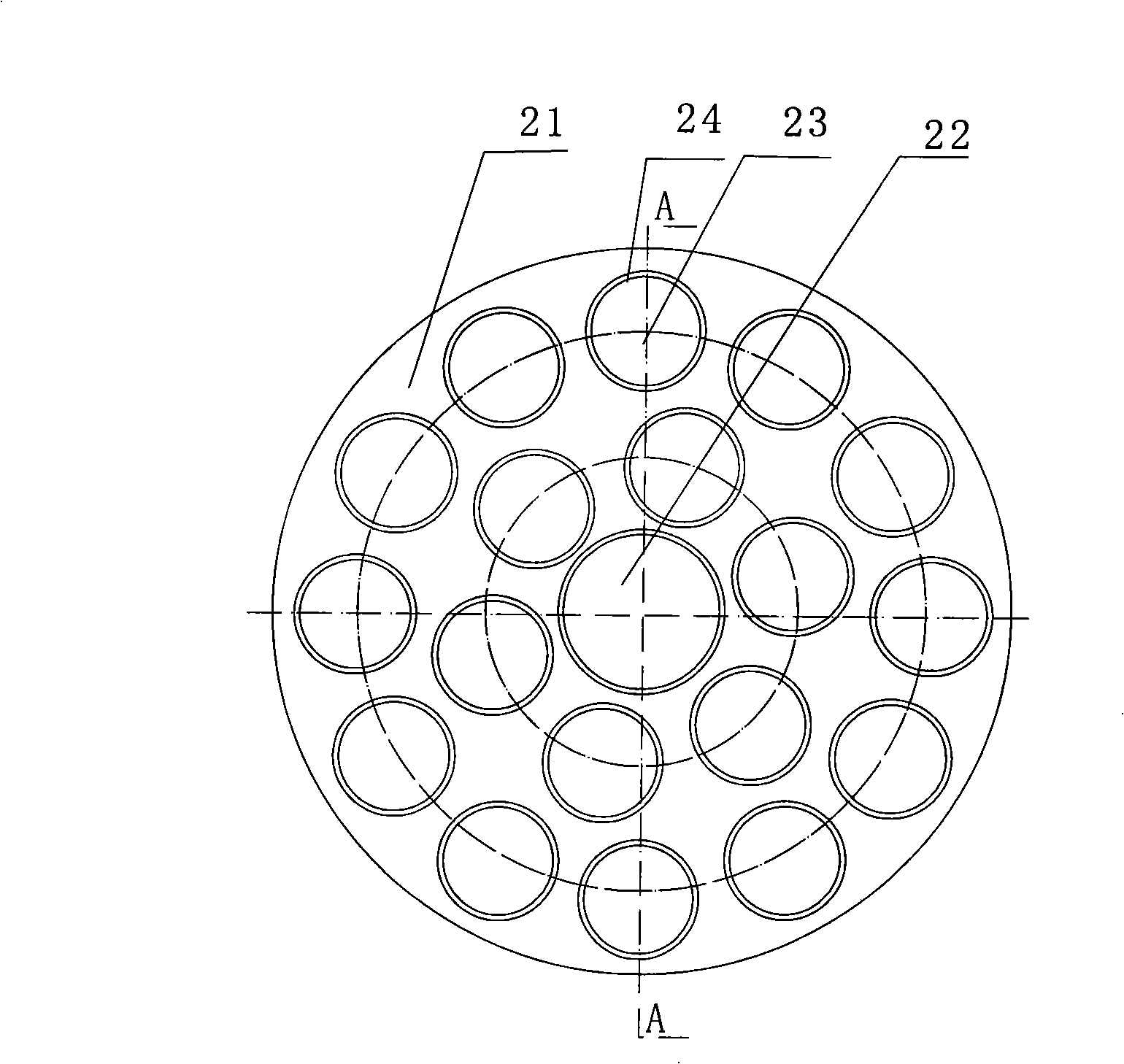

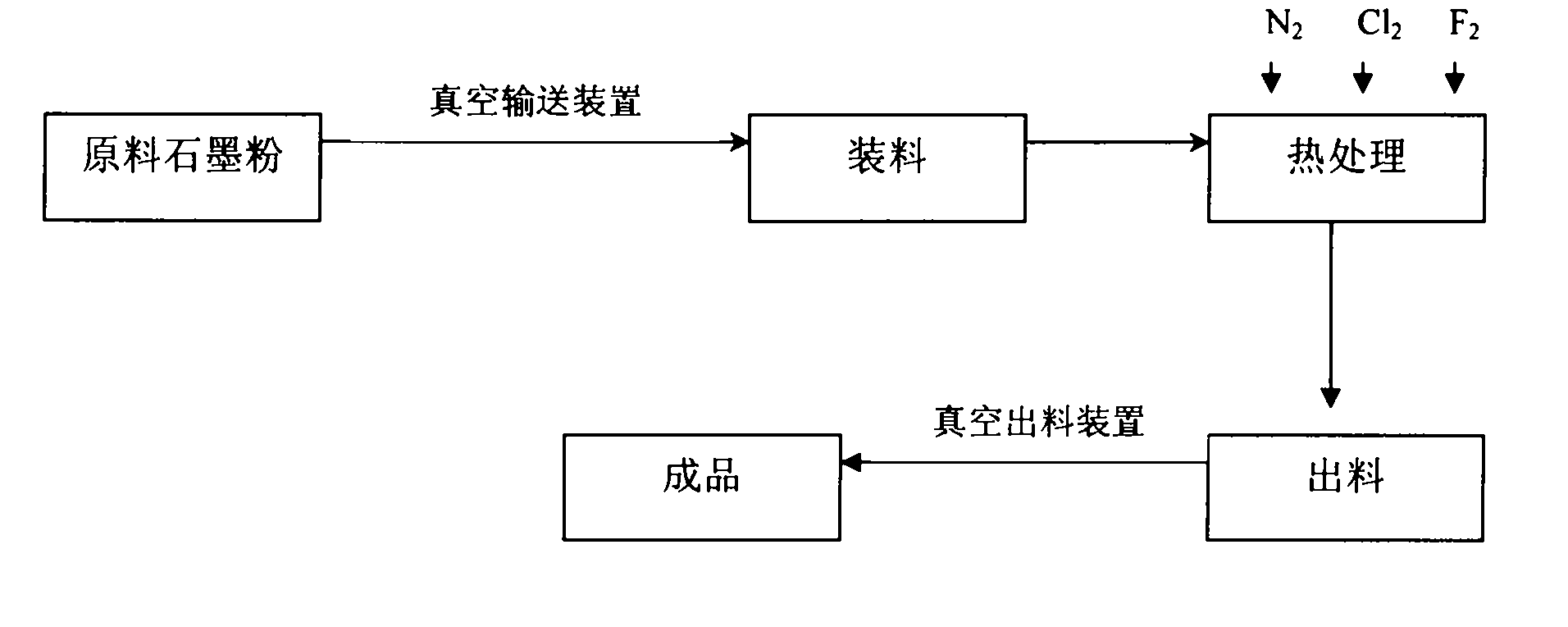

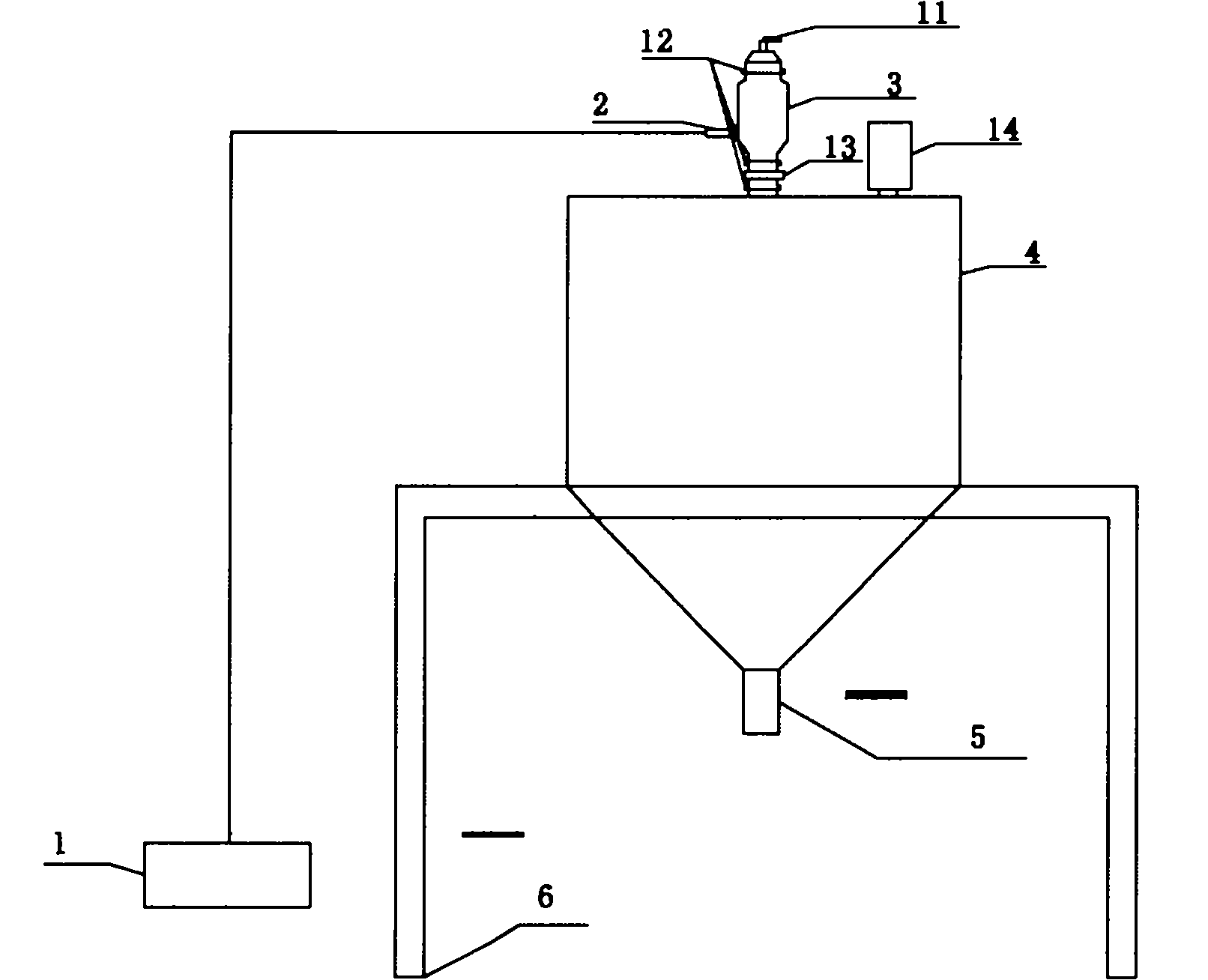

Process and equipment for producing graphite dust

ActiveCN101318648AReduce entryImprove graphitization heat treatment efficiencyCell electrodesChemical industryState of artVacuum delivery

The invention discloses a method for preparing graphite powder and the equipment thereof and aims at solving the technical problems of improving the purity of graphite powder and reducing cost. The method of the invention comprises the following steps: the raw micro powder is delivered to a graphite crucible under vacuum state and put into a graphitizing furnace; and a graphite powder product is obtained after heat treatment and cooling. The preparation equipment of graphite powder is composed of a vacuum delivery device, a graphitizing furnace and a vacuum discharging device sequentially connected; the graphitizing furnace is equipped with a graphite crucible and connected with a gas filling system. Compared with the prior art, the method and the equipment of the invention are characterized in that the raw micro power is put into the graphite crucible after vacuum delivery, thus the entry of impurities is reduced in the treatment process, the product purity is greatly improved after heat treatment, graphitization is even, the consistency of the product is good, the graphitization and heat treatment efficiency of the powder material is improved, the technique is simple and the cost is low.

Owner:BTR NEW MATERIAL GRP CO LTD

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261AHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

The invention relates to a preparation method of high-conductivity aluminum alloy and belongs to the field of nonferrous metal materials. The preparation method comprises the following steps of: preparing an aluminum ingot comprising the following alloy elements in percentage by weight: 4.5 to 13.5 percent of Si (silicon), 0.1 to 1.5 percent of Mg (magnesium) and not more than 0.1 percent of impurity elements, smelting the aluminum ingot in a furnace, adding 0.1 to 0.3 percent of zirconium which serves as additive for the alloying treatment, uniformly mixing, then adding 0.1 to 1.35 percent of rare-earth element for degeneration, purifying, degassing and deslagging, and covering the surface of aluminum liquid with a solid covering agent; casting to prepare the aluminum alloy conductor material; and carrying out the first-stage aging treatment and the second-stage aging treatment on the aluminum alloy conductor material, discharging and cooling with air. The manufactured aluminum-silicon alloy can meet the requirements on the aluminum alloy material conductivity and the mechanical property; and moreover, the preparation process is simple, the cost is low, and the mass production is easy to realize.

Owner:JIANGSU UNIV

Low alloy steel for railway vehicle brake disc and heat treatment method of low alloy steel

The invention relates to low alloy steel for a railway vehicle brake disc and a heat treatment method of the low alloy steel. The low alloy steel for the railway vehicle brake disc comprises chemicalcomponents including, by weight percent, 0.15%-0.30% of carbon, 0.4%-1.0% of silicon, 0.4%-1.0% of manganese, 0.6%-1.4% of chrome, 0.4%-1.2% of nickel, 0.2%-0.6% of molybdenum, 0.15%-0.4% of vanadium,0.15%-0.35% of copper, 0.1%-0.3% of tungsten, 0.025%-0.045% of niobium, 0.025%-0.045% of zirconium, and the balance ferrum and Re, Al and unavoidable impurities, wherein the Re, the Al and the unavoidable impurities are left in purification. According to the low alloy steel, based on the characteristics of the railway vehicle steel brake disc in the service working condition, the environment andthe forming process, material component design is carried out on the aspects of improving the high-temperature strength of the material, enhancing weather ability, refining grains, improving plasticity and the like, a proper forging ratio and a proper quenched-tempered heat treatment process are selected, and the mechanical performance of the material at the room temperature can meet the materialperformance requirement of a forged steel brake disc or a cast steel brake disc. For the condition of different scales of smelting, different control methods for the material purity degree are put forward to improve the purity degree of alloy steel.

Owner:BEIJING JIAOTONG UNIV +1

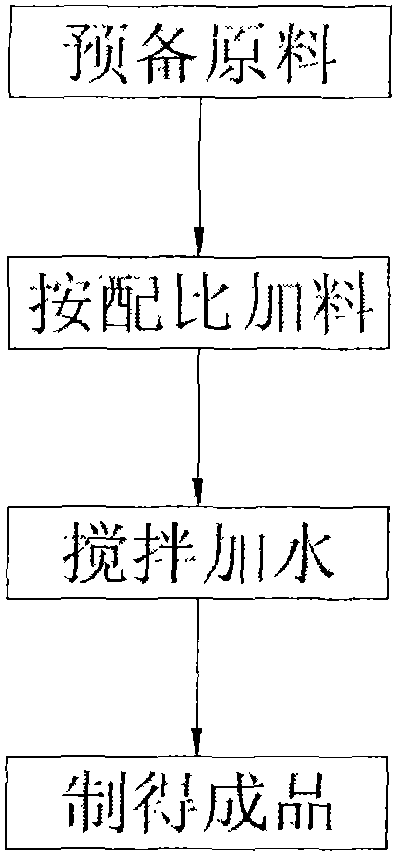

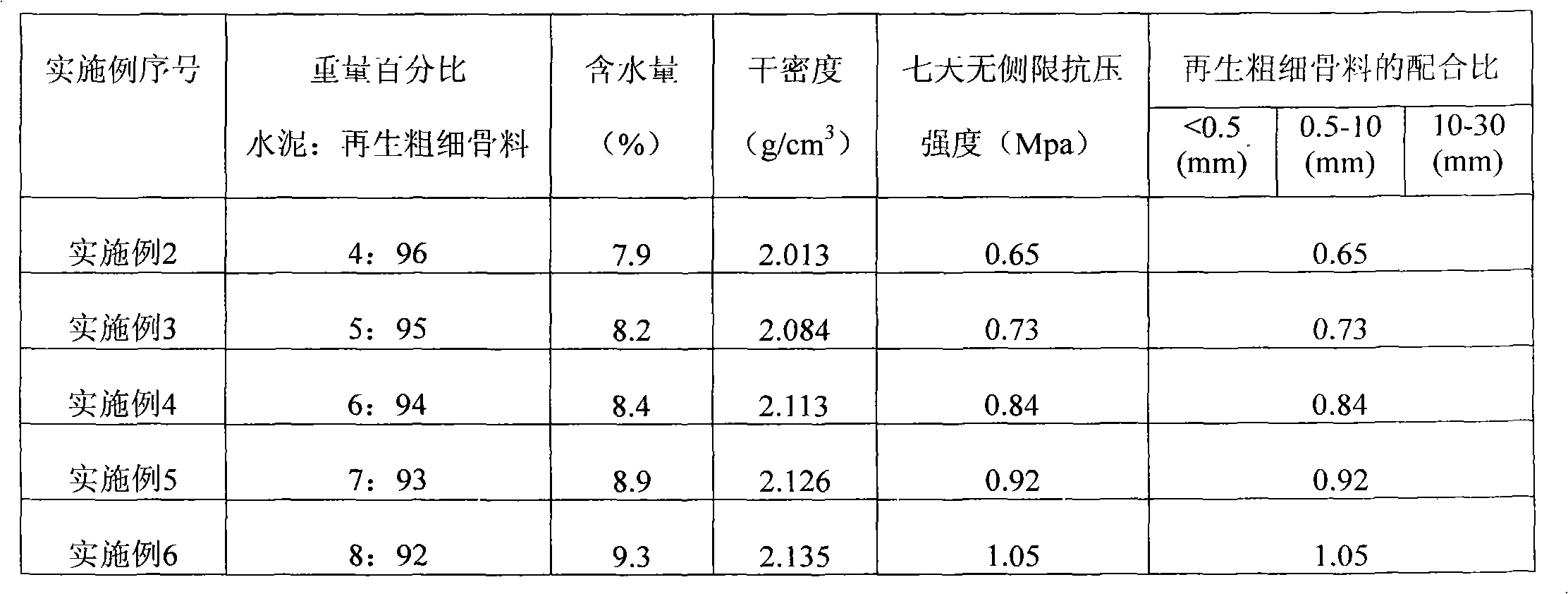

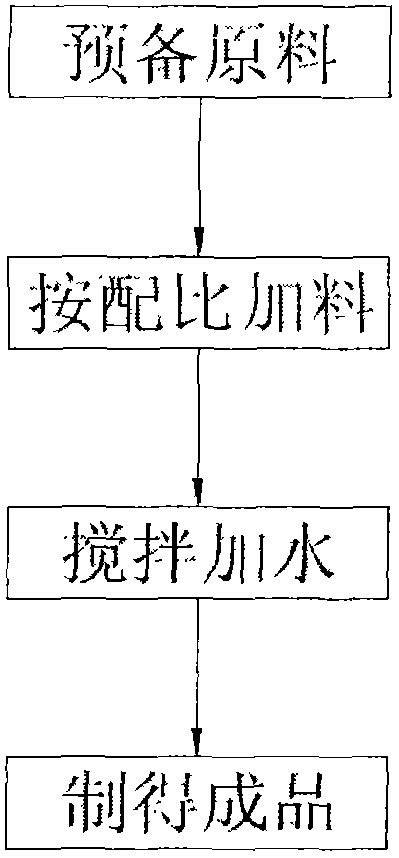

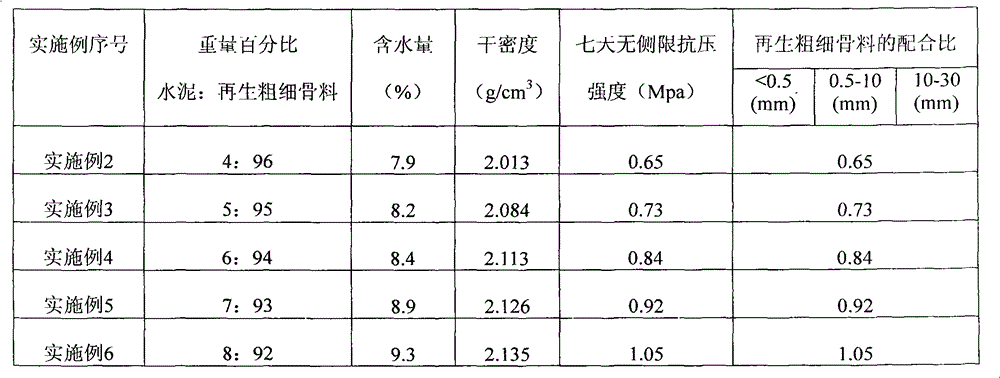

Method of stably regenerating gravel from cement, and product of the method

ActiveCN103848605AEasy to getHigh compressive strengthSolid waste managementSocial benefitsTime limit

The invention discloses a method of stably regenerating gravel from cement. The method includes steps of: 1) preparing raw materials comprising the cement and regenerated crude and fine aggregate; 2) adding the raw materials according to a ratio; and 3) stirring, and adding water to obtain a finished product. The invention also discloses a product obtained by the method. The method is simple in preparation technology, easy to achieve, and high in production efficiency, and can rapidly and stably produce the gravel product with high compressive strength by utilization of the cement. The method has high production efficiency, largely reduced cost, and good economic and social benefit, and protects the environment. The design of the formula is reasonable. The raw materials are easily available. Processes of traditional gravel exploiting are effectively simplified. The compressive strength of the product is high and can meet requirements of buildings with respect to material performances, thus solving the gravel resource shortage problem and achieving objectives of environment protection and sustainable development. The product is easy to construct, shortens the time limit for a project, improves the construction efficiency and facilitates wide popularization and application.

Owner:北京鼎创环保有限公司

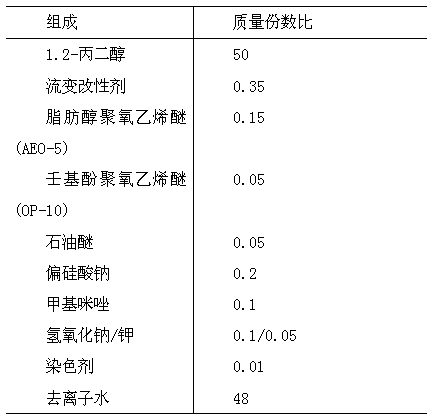

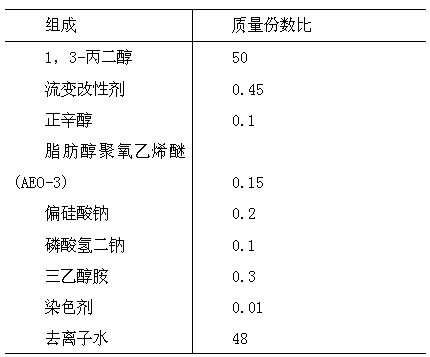

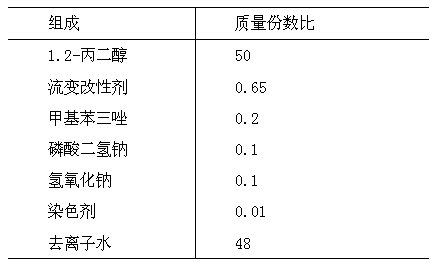

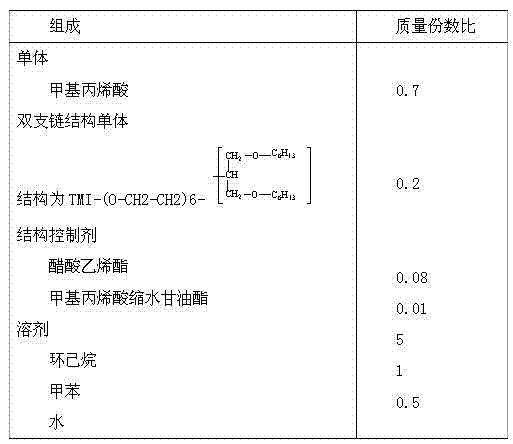

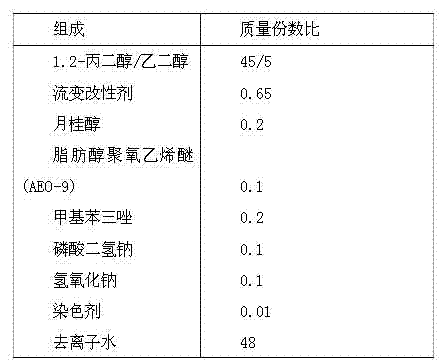

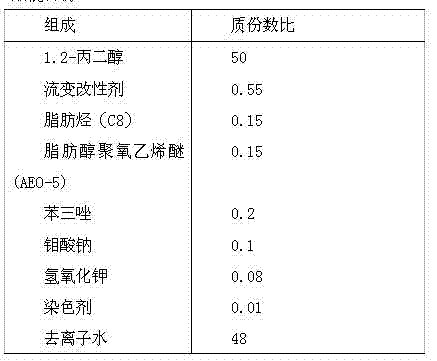

Non-Newtonian fuselage deicing and anti-icing fluid and preparation method thereof

ActiveCN103059813AExcellent shear recovery abilityLong anti-icing timeOther chemical processesPhysical chemistryRheopecty

The invention relates to a deicing and anti-icing fluid, particularly a non-Newtonian fuselage deicing and anti-icing fluid and a preparation method thereof. The non-Newtonian fuselage deicing and anti-icing fluid can reduce adhesion of ice on the object surface to eliminate and prevent icing on the aircraft fuselage surface, and has superlong anti-icing retention time. The non-Newtonian fuselage deicing and anti-icing fluid comprises the following components in parts by mass: 40-60 parts of freezing-point depressant, 0.05-1.2 parts of rheologic modifier, 0.01-0.3 part of anti-icing compounding agent, 0.01-3 parts of pH regulator, 0.01-3 parts of corrosion inhibitor, 0.01-0.5 part of staining agent and 40-60 parts of deionized water. The invention is based on the low-temperature rheologic research, especially aims at the low-temperature operating environment and characteristics of the deicing and anti-icing fluid, and determines the distribution and arrangement of the main chain and branch chain of the rheologic modifier as well as the preparation and acquisition method of the low-temperature conformation. By combining the anti-icing compounding agent, corrosion inhibitor and other assistants in the formula, the prepared deicing and anti-icing fluid has the characteristics of excellent shearing restorability, excellent ice adhesion inhibition capacity at 0 to -20 DEG C, and long anti-icing time.

Owner:成都民航六维航化有限责任公司

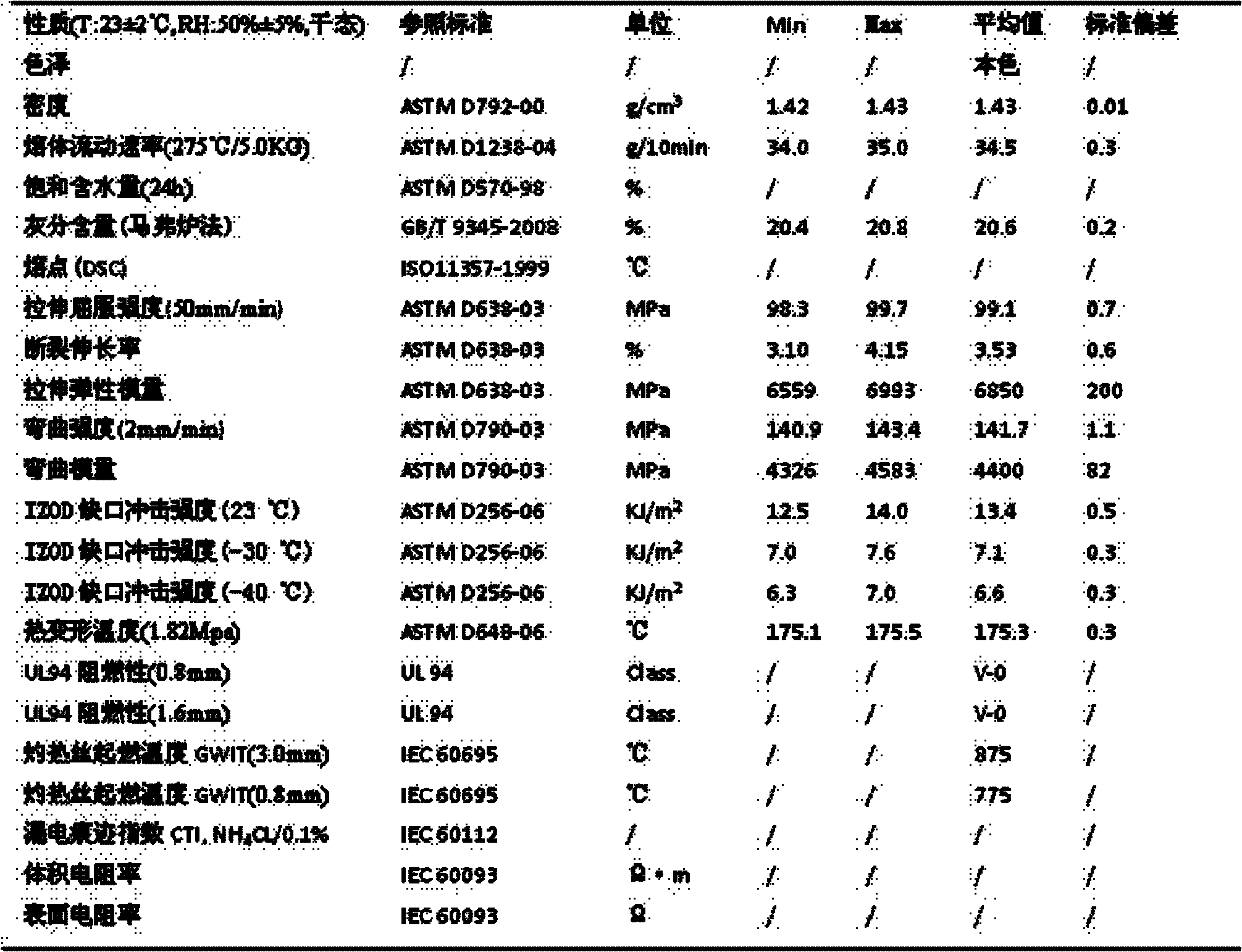

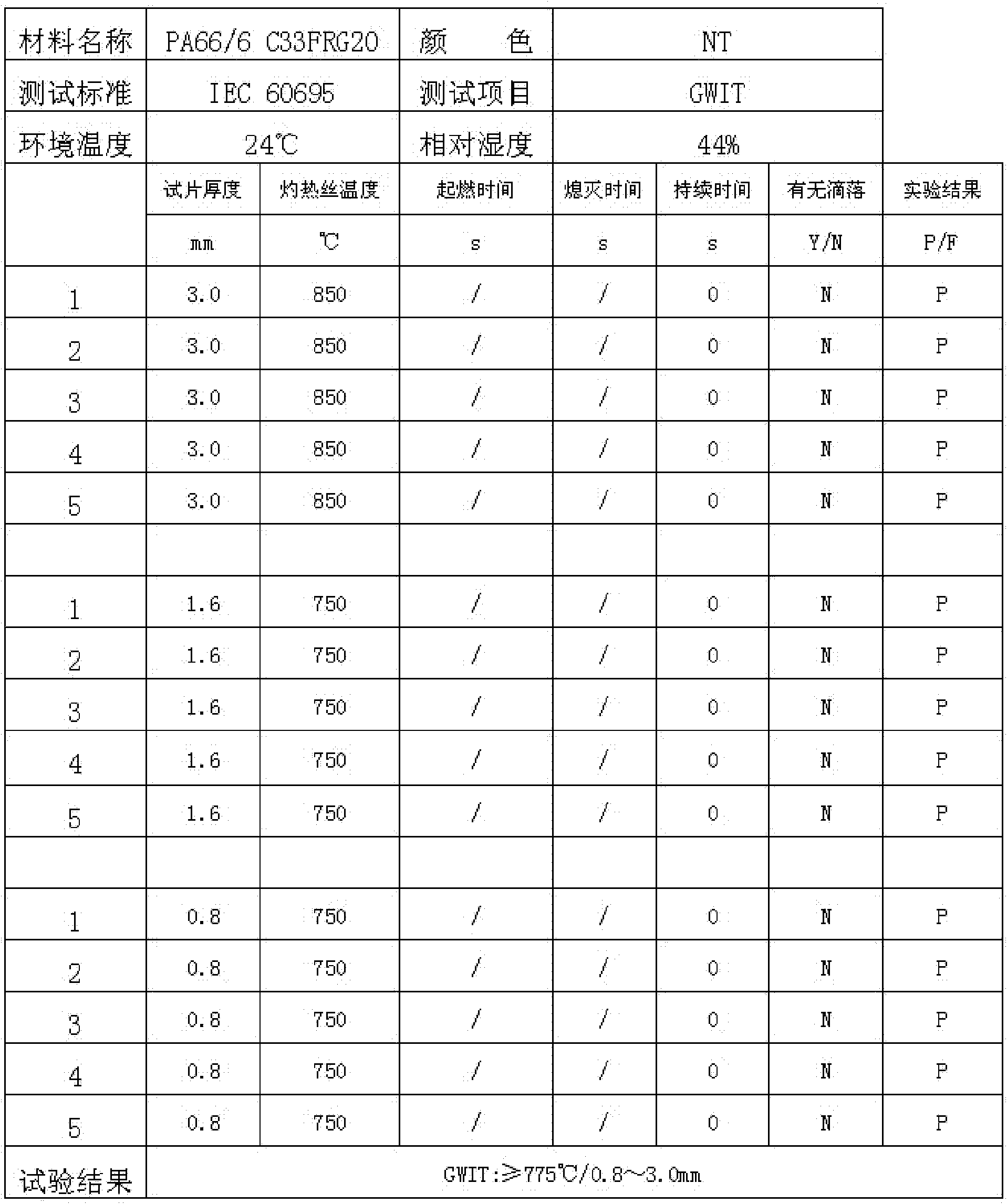

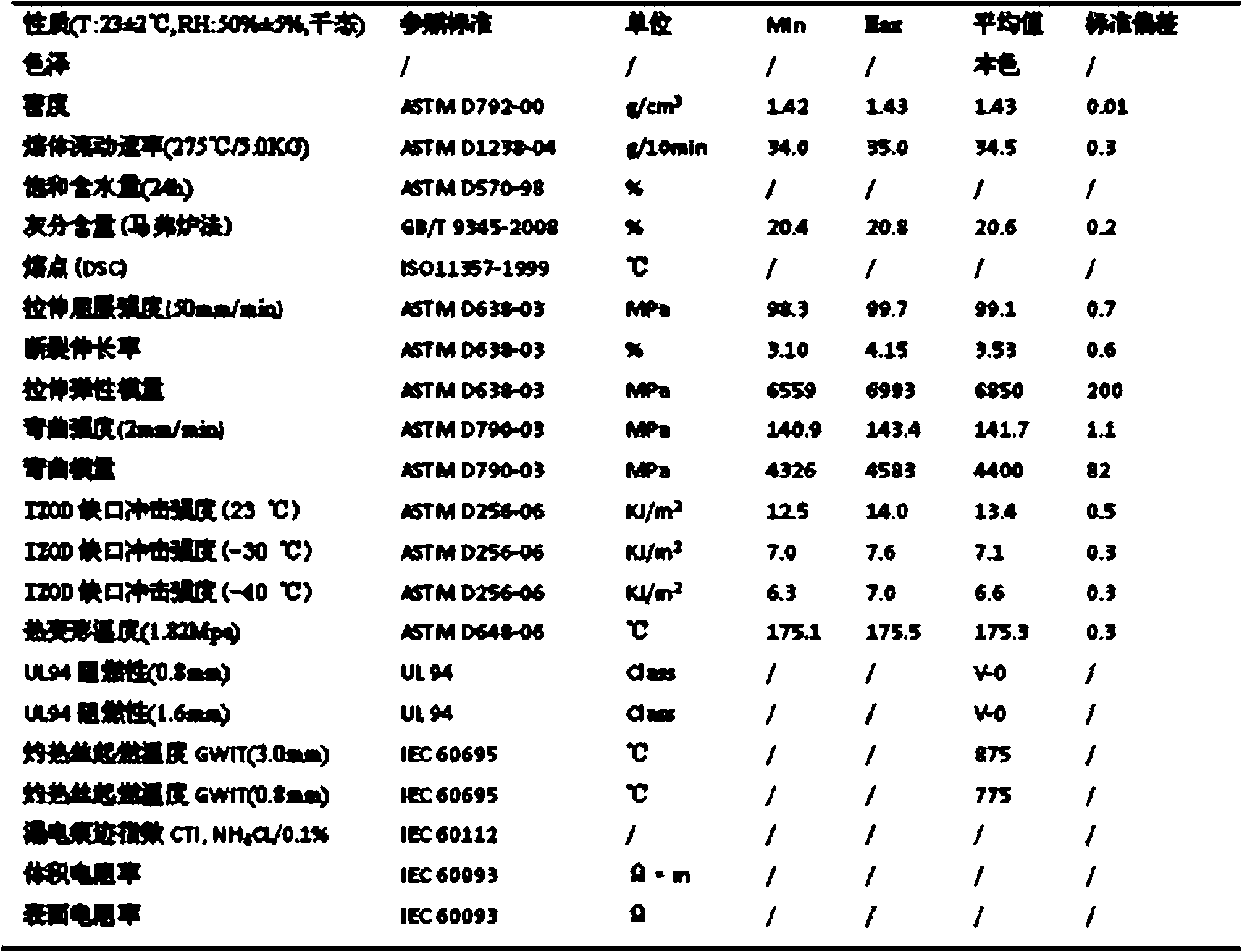

Flame retardant reinforced co-polymerized nylon composite with high temperature of glowing filaments and preparation technology thereof

The invention relates to the field of modified engineering plastics, in particular to a flame retardant reinforced co-polymerized nylon composite with high temperature of glowing filaments and a preparation technology thereof. The composite comprises the following ingredients: 48.7-69.6 wt% of PA66 / 6, 14.5-18.6wt% of polybrominated styrene, 4.3-5.5wt% of diantimony trioxide, 1.7-2.2wt% of layereddihydroxy composite metallic oxide, 0.08-0.11wt% of teflon and 10-30wt% of alkali free glass fiber. Compared with the prior art, the composite has the advantages that: the glowing filament ignition temperature GWIT is not less than 775 DEG C, the flame resistance that in accordance with 94UL-V0 standard is rated V-0 at 0.8 mm to 1.6 mm, and the composite meets VDE standard, has good low-temperature (less or equal to -30 DEG C)toughness, and satisfies the requirements of electronic components used in unattended white goods working in low-temperature (less or equal to -30 DEG C) environment to material qualities.

Owner:上海珐工材料科技有限公司

Aluminum alloy material and manufacturing method thereof

The invention relates to an aluminum alloy material and a manufacturing method thereof. The main component of the aluminum alloy material is aluminum. The aluminum alloy material further comprises tin, cadmium, zinc, copper, silicon, manganese, chromium, nickel and titanium. The manufacturing method comprises the following steps of (1) preheating the tin, the cadmium, the zinc, the copper, the silicon, the manganese, the chromium, the nickel and the titanium respectively, and stirring the components respectively until all the components are completely fused; (2) quickly heating all the fused components until the temperature rises up to 1,857 DEG C, and simultaneously mixing and uniformly stirring the components; (3) pouring a mixed solution of all the fused components obtained in the step (2), and performing natural cooling after pouring is completed. The aluminum alloy material can meet requirements on the material performances, particularly the performances of machining forming, surface quality, heat treatment and the like, of high-strength aluminum alloys in the field of industry; the manufacturing method is simple and is convenient to implement and popularize.

Owner:WUXI LEHUA AUTOMATION TECH

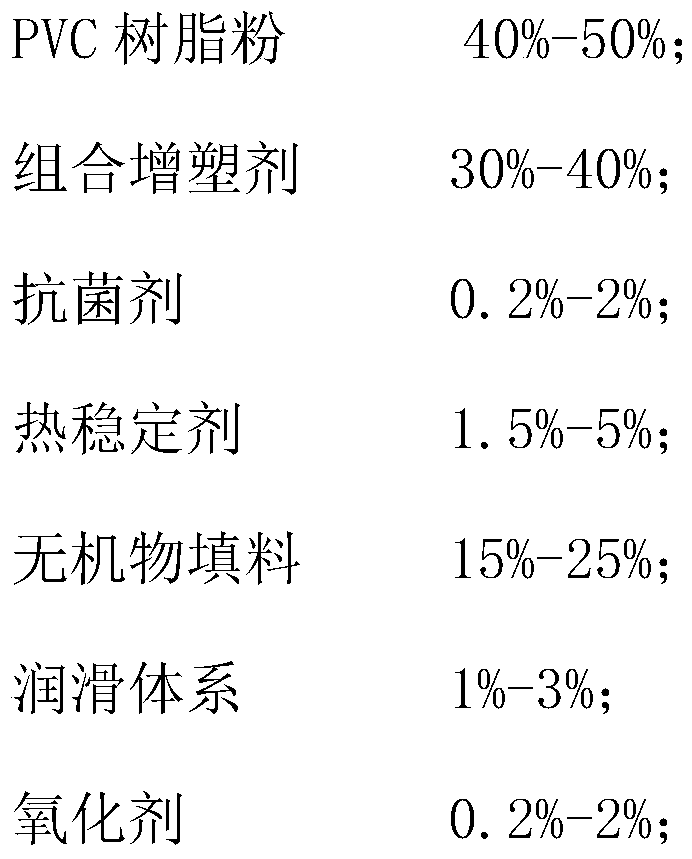

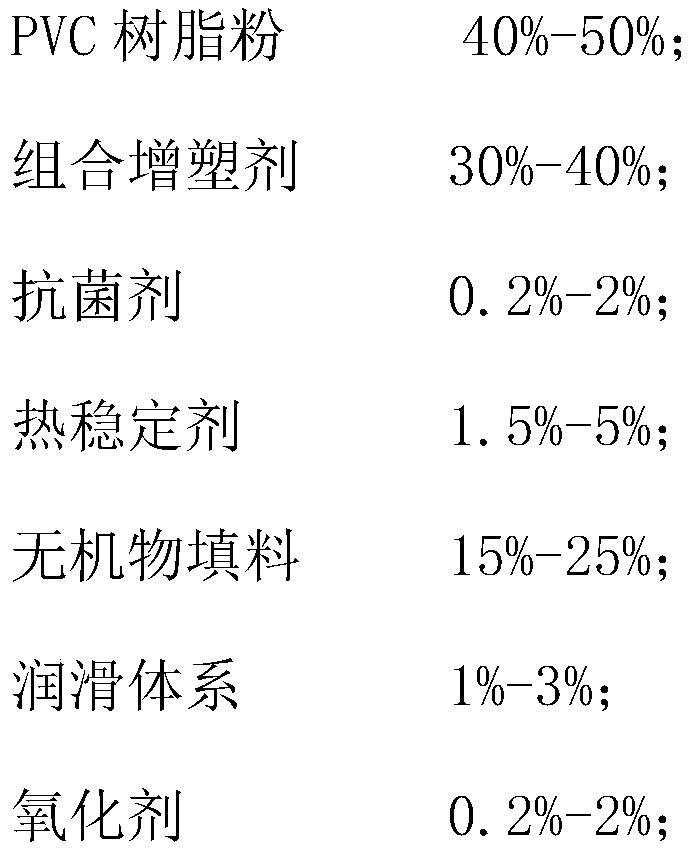

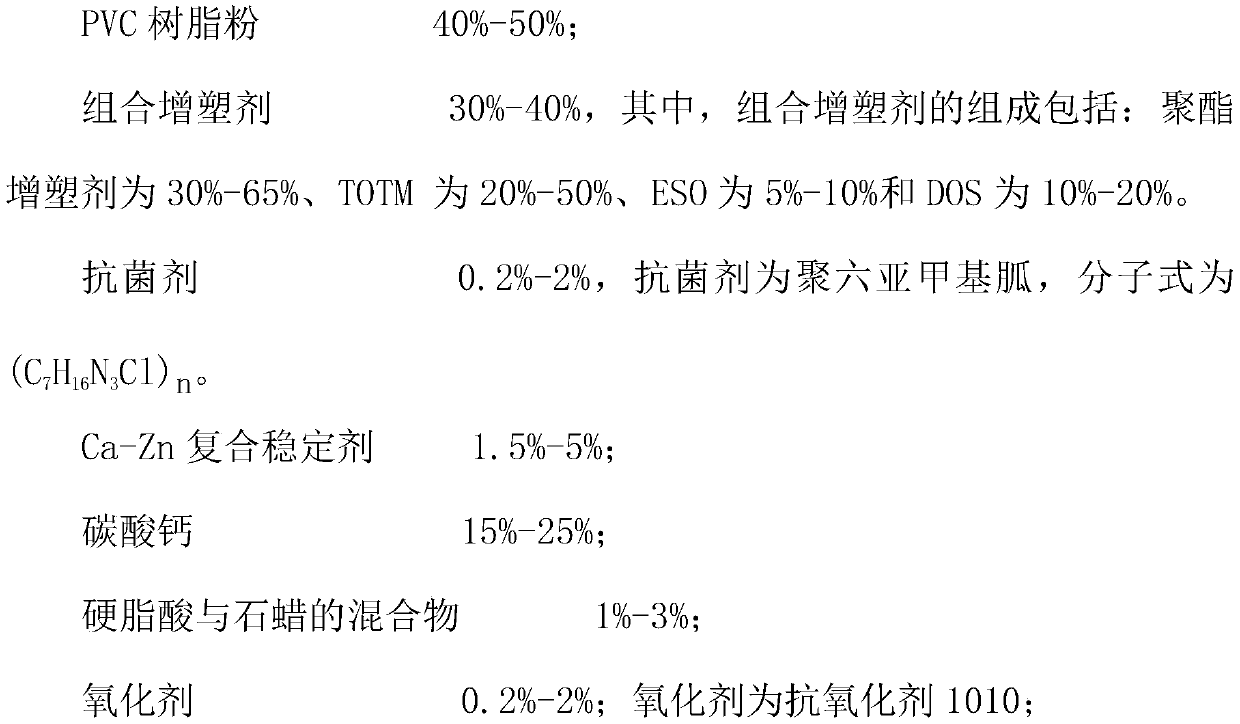

Antibacterial PVC door seal for refrigerator and preparation method thereof

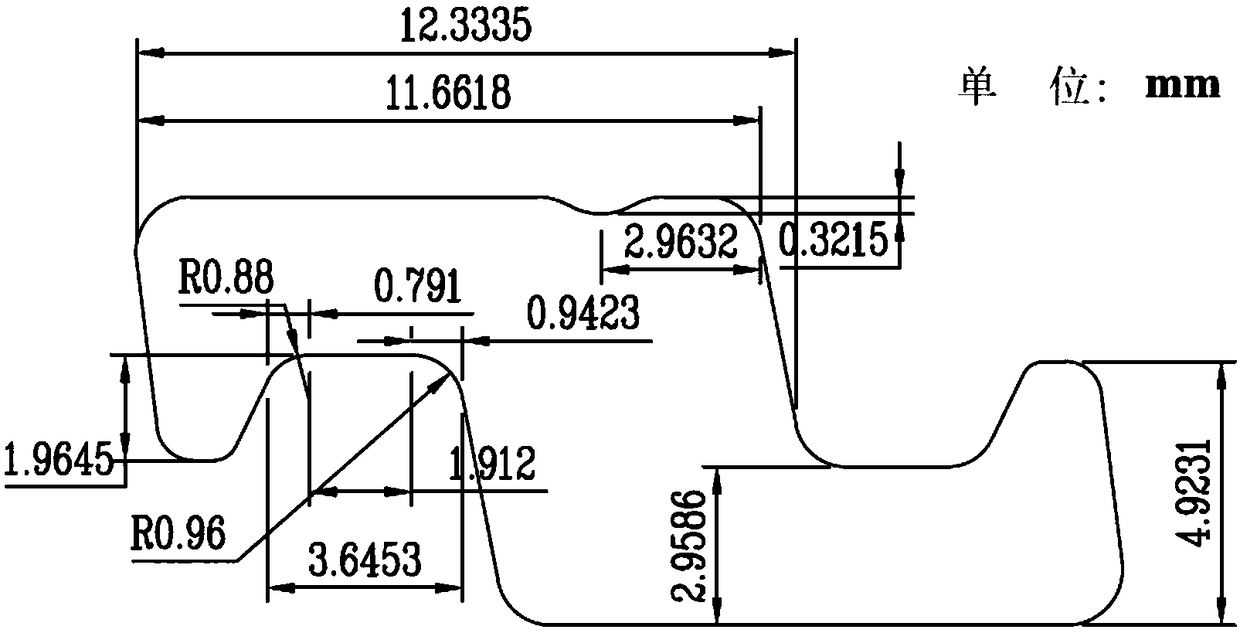

InactiveCN111393765AMeet material performance requirementsAvoid stabilityOther chemical processesIceboxPlasticizer

The invention discloses an antibacterial PVC door seal for a refrigerator, and relates to the technical field of refrigerator door seals. The antibacterial PVC door seal comprises the following raw materials in parts by weight: 40-50% of PVC resin powder; 30%-40% of a combined plasticizer; 0.2%-2% of an antibacterial agent; 1.5%-5% of a heat stabilizer; 15%-25% of an inorganic filler; 1%-3% of a lubricating system; and 0.2%-2% of an oxidizing agent, wherein the antibacterial agent is polyhexamethylene guanidine, and the molecular formula of the antibacterial agent is (C7H16N3Cl) n. The antibacterial agent polyhexamethylene guanidine is added into the formula, and the antibacterial PVC door seal is obtained through proportion adjustment and processing so that the door seal can achieve a long-term antibacterial effect, and the problems that theexisting refrigerator door seal is poor in long-term antibacterial stability and low in sterilization efficiency are solved.

Owner:CHANGHONG MEILING CO LTD

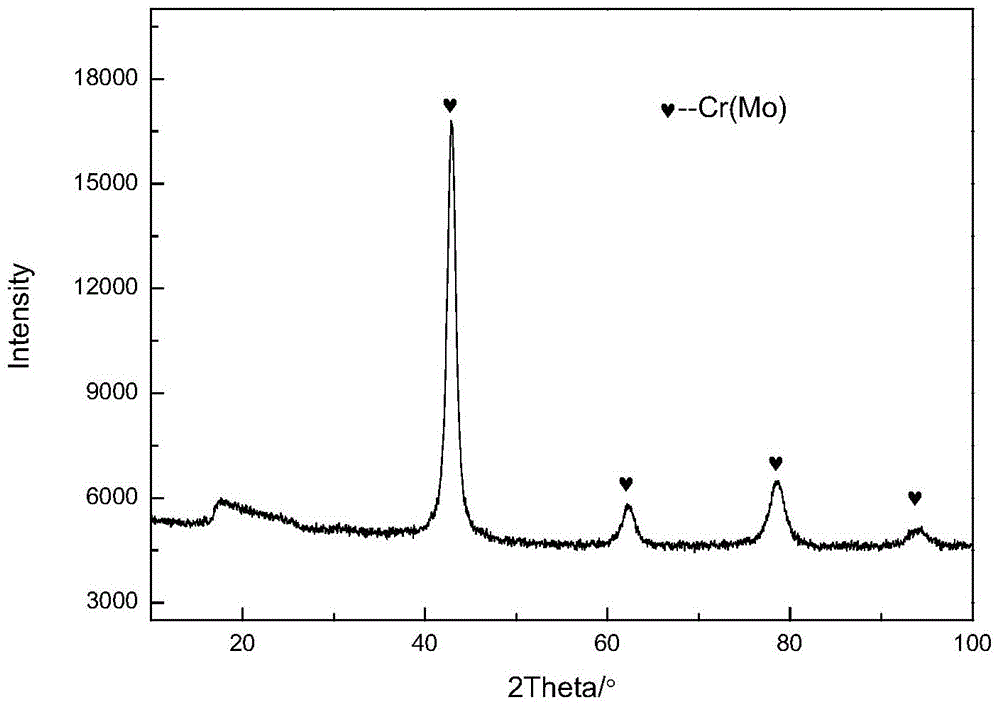

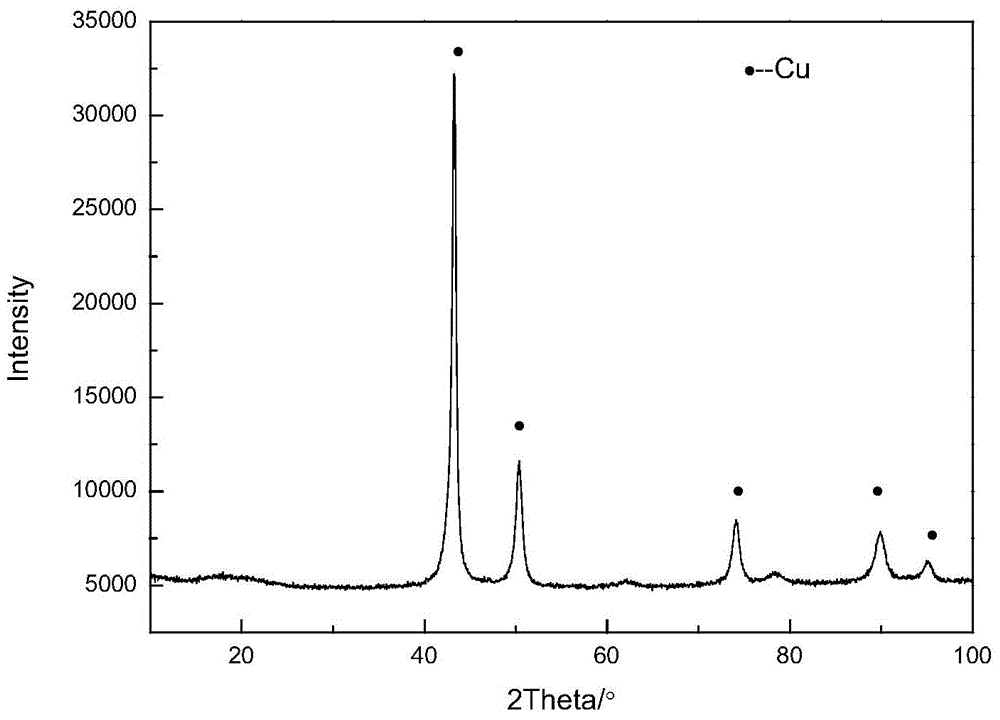

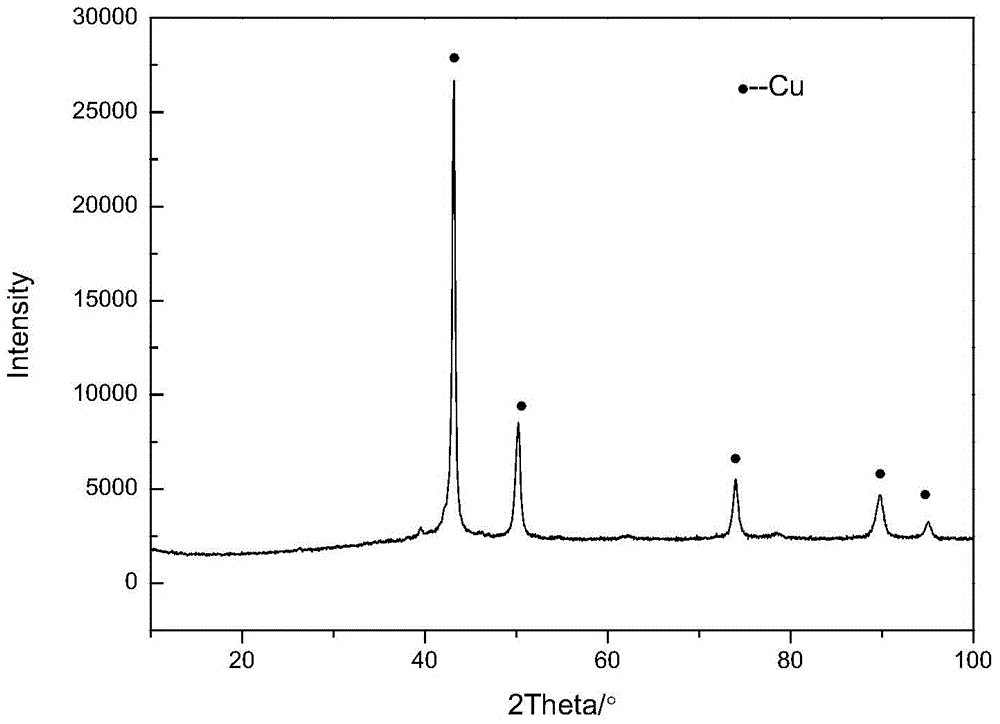

High-hardness wear-resistant copper alloy for plastic mould and preparation method thereof

InactiveCN104561644AHigh hardnessMeet material performance requirementsWear resistantSolid solution strengthening

The invention provides a high-hardness wear-resistant copper alloy for a plastic mould and a preparation method thereof. The copper alloy provided by the invention is composed of the following components in percentage by weight: 8-10% of Mo, 8-10% of Cr, more than or equal to 78% and less than 80% of Cu, and the balance of impurities. According to the invention, mechanical alloying, namely a non-equilibrium alloy preparation process, is mainly utilized, so that the two alloy elements including Mo and Cr difficult to solidly solute in Cu are solidly solute greatly; the solid solubility of Cr and Mo in Cu is beyond 8% in terms of weight percentage; a certain degree of dispersed precipitation of Mo and Cr exists in the subsequent hot-pressing and sintering processes; the hardness of Cu alloy is greatly increased under the combined action of dispersed precipitation and solution strengthening; therefore, the Cu-Cr-Mo alloy, the hardness of which is above 38 HRC and the heat conductivity of which is above 80 W / K.m, is obtained; and the alloy disclosed by the invention is a high-hardness alloy, which can satisfy the material property requirements of the plastic mould and is free from beryllium.

Owner:XI AN JIAOTONG UNIV

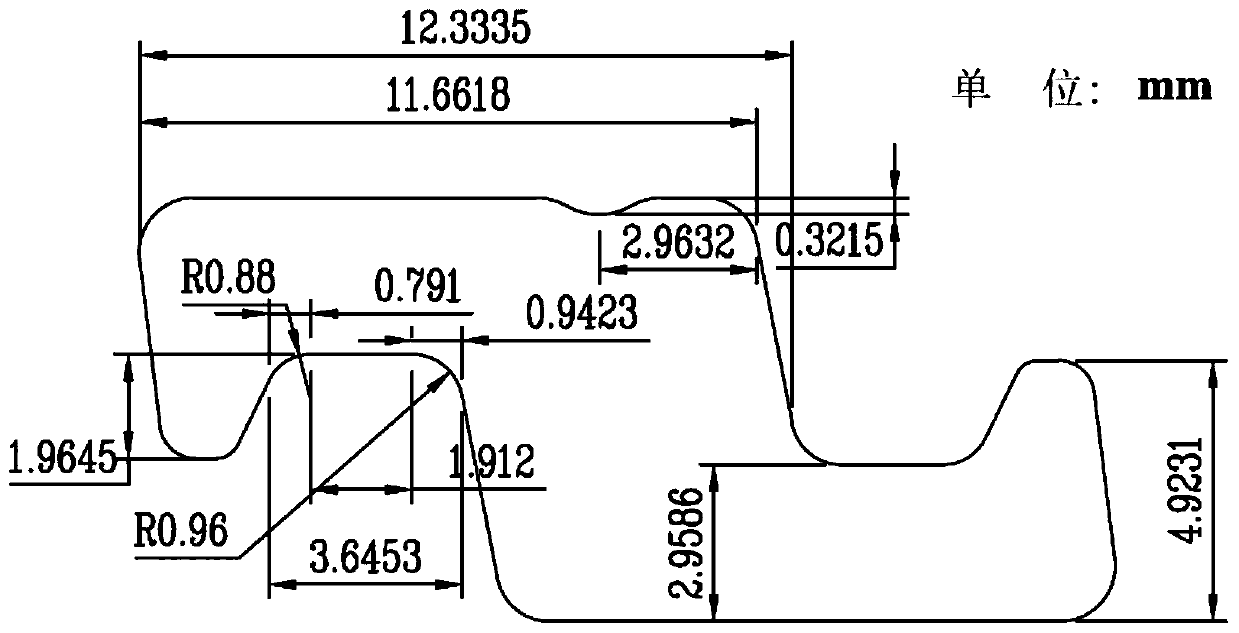

Acid-resistant ultrahigh-strength steel for deep-sea dynamic flexible vertical pipe and preparation method of acid-resistant ultrahigh-strength steel

The invention relates to acid-resistant ultrahigh-strength steel for a deep-sea dynamic flexible vertical pipe and a preparation method of the acid-resistant ultrahigh-strength steel and belongs to the technical field of metallurgy. The steel comprises, by weight percentage, 0.04-0.1% of C, not more than 0.4% of Si, 0.3-1.4% of Mn, not more than 0.02% of P, not more than 0.008% of S, 0.8-2.0% of Cr, 0.8-1.5% of Mo, 0.3-0.8% of Ni, 0.012-0.045% of Nb, 0.01-0.02% of Ti and the balance Fe and inevitable impurities. The preparation method includes: performing smelting, refining and pouring according to the set components to obtain continuous casting billets; secondly, performing heating and heat preservation on the continuous casting billets, and performing multi-pass hot rolling to obtain hot-rolled wire rods; performing multi-pass cold rolling to obtain the Z-shaped steel for a dynamic flexible vertical pipe; thirdly, performing heating and heat preservation on the Z-shaped steel, and performing water quenching to allow the Z-shaped steel reach room temperature; annealing to obtain the ultrahigh-strength steel for the deep-sea dynamic flexible vertical pipe. The microscopic structureof the ultrahigh-strength steel is of a tempered martensite structure, the yield strength of the ultrahigh-strength steel is not smaller than 800MPa, the tensile strength of the ultrahigh-strength steel is not smaller than 880MPa, and the ductility of the ultrahigh-strength steel is not smaller than 10%.

Owner:NORTHEASTERN UNIV +1

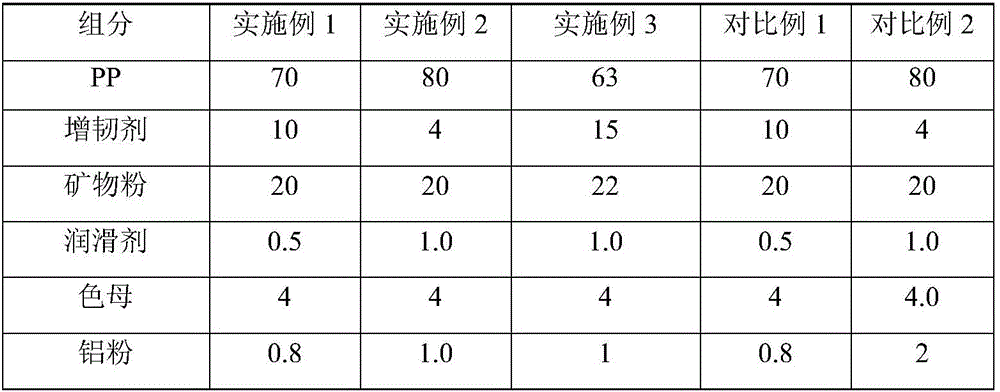

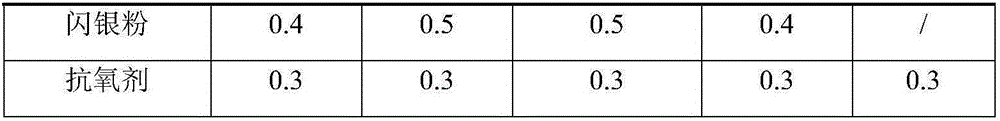

Polypropylene composite material with spraying-free and high-rigidity metal texture effect and preparation method thereof

The invention discloses a polypropylene composite material with a spraying-free and high-rigidity metal texture effect and a preparation method thereof and belongs to the technical field of macromolecular engineering plastics. The composite material is prepared from the following raw materials in parts by weight: 60-85 parts of polypropylene resin, 5-15 parts of toughener, 15-30 parts of mineral powder, 2-4 parts of color master batch, 0.3-1 part of lubricant, 0.5-1.5 parts of aluminum powder, 0.25-1 part of bright silver powder and 0.2-0.4 part of antioxidant. According to the polypropylene composite material and the preparation method thereof, physical properties of the polypropylene composite material are reasonably regulated, and the added aluminum powder and bright silver powder can enable the metal-imitating effect of the alloy material to meet the operating requirements of electrical appliance products on appearance, so that the polypropylene composite material has the advantages of good environment-friendliness, high smoothness, and the like.

Owner:MIANYANG SHENGYU NEW MATERIALS

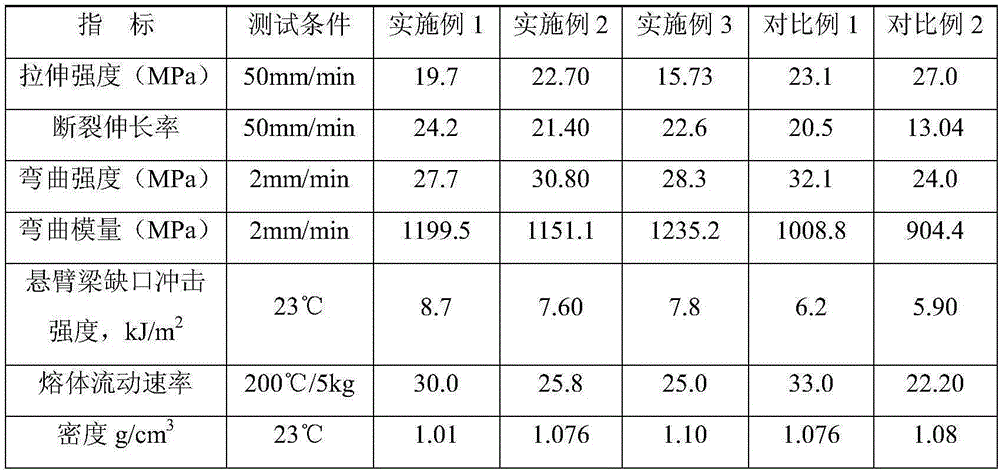

Aluminum alloy material and production process thereof

The invention discloses an aluminum alloy material. The material comprises the following raw materials of aluminum ingots, magnesium ingots, aluminum-silicon alloy, copper blocks, zinc blocks, iron blocks, manganese blocks, magnesium-lanthanum alloy, dysprosium powder, aluminum-neodymium alloy, magnesium-holmium alloy, molybdenum powder, chromium powder, vanadium powder, erbium powder, silicon carbide and refining agents. The aluminum alloy material are prepared through the following steps that alloy liquid is produced and then is subjected to modification treatment, then casting molding and precooling treatment are conducted, and then quenching treatment and tempering treatment and the like are conducted. According to the aluminum alloy material, components and smelting and heat treatmentprocess parameters of the aluminum alloy are optimized, so that the tensile strength and elongation index of products are improved, the tensile strength of the aluminum alloy material reaches 128.9MPa or above, the elongation rate reaches 40.9% or above, the performance requirements of the market and existing product materials can be greatly met, and the material has the significance of wide popularization and application.

Owner:广西平果铝合金精密铸件有限公司

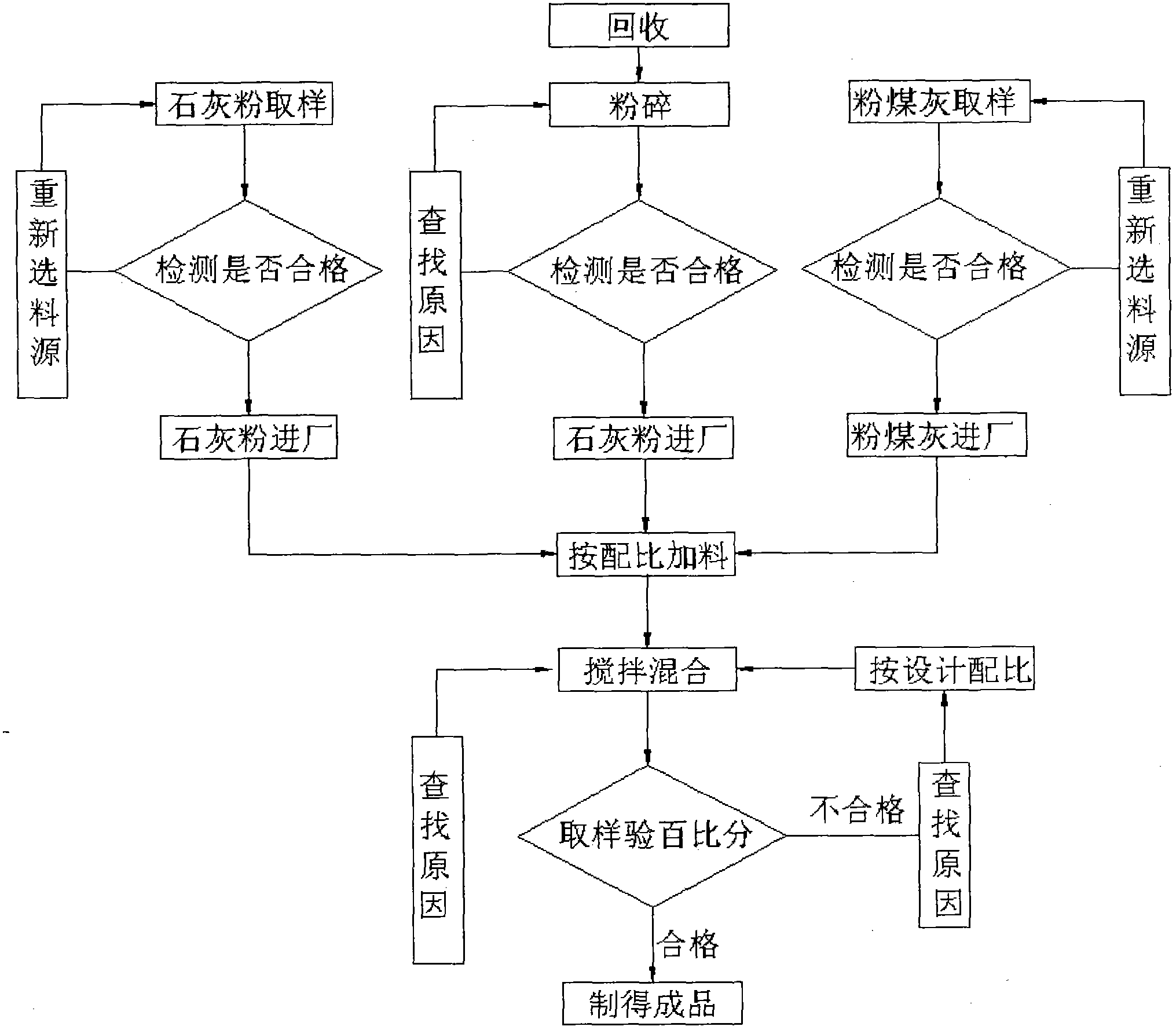

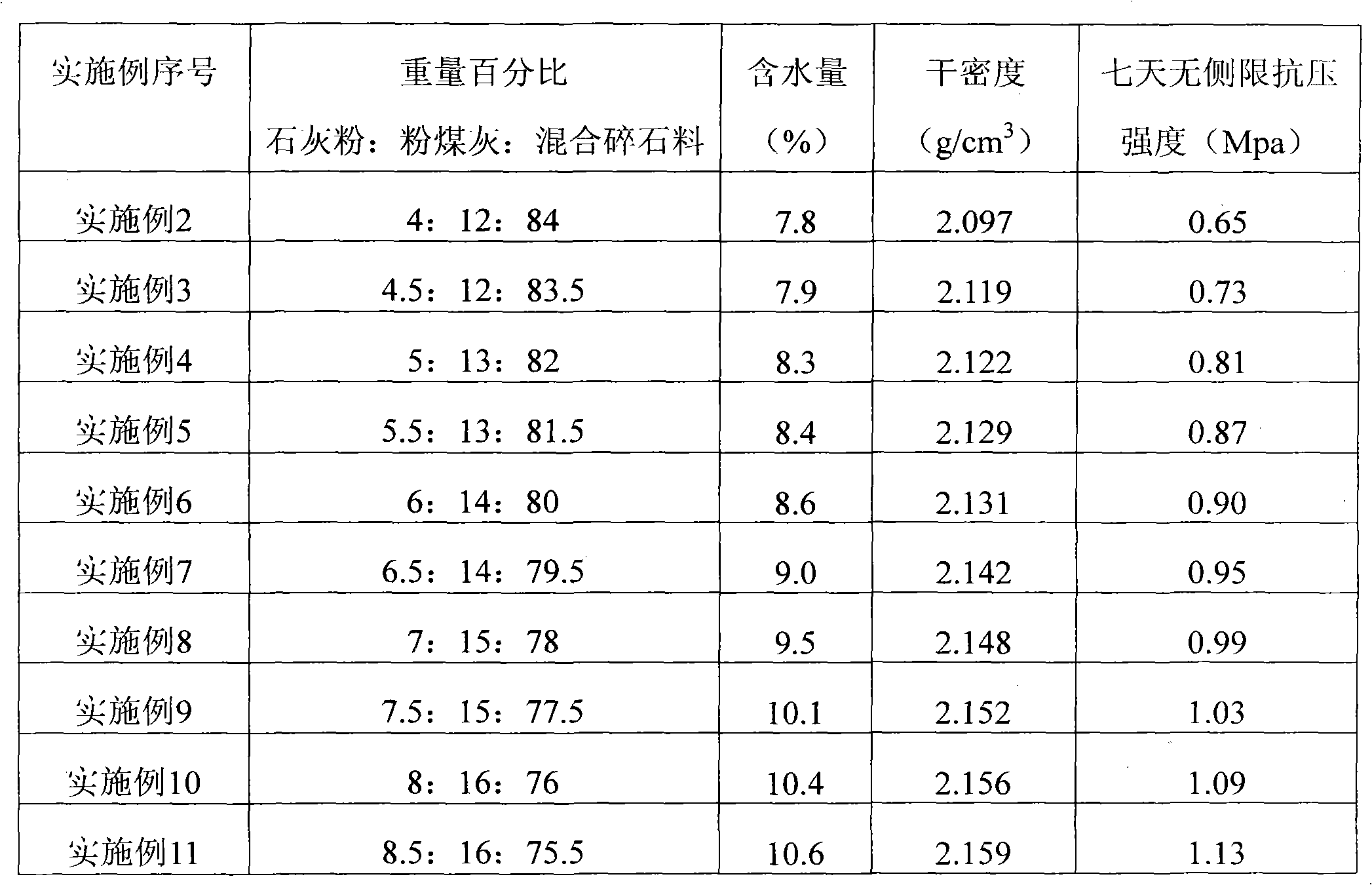

Method used for stable regeneration of broken stone from lime and flyash, and product obtained by using method

InactiveCN103848610ASimple preparation processEasy to implementSolid waste managementSlagCoal gangue

The invention discloses a method used for stable regeneration of broken stone from lime flyash. The method comprises following steps: 1) raw material preparation, wherein lime powder, flyashe, and broken stone are prepared; 2) charging according to a ratio; 3) stirring and mixing; 4) sampling; and 5) preparation of a finished product. The invention also discloses a product obtained by using the method. Preparation processes of the method are simple and are easy to realize; production efficiency is high; waste building rubbish, concrete, components, coal gangue, steel slag, waste stone, muck, shale, and flyash can be recycled effectively; environment is protected, cost is reduced greatly, and excellent economic benefits and social benefits are obtained; in addition, formula design is reasonable, the raw materials are easily available, and traditional regenerated broken stone processes are simplified effectively; compressive strength of the product is high, the product is capable of satisfying demands of buildings on material performance, is convenient for construction, is capable of shortening construction period greatly and increasing construction efficiency, and is beneficial for wide popularization and application.

Owner:北京鼎创环保有限公司

Low-alloyed steel used for brake discs of rail vehicles and heat treatment method of low-alloyed steel used for brake discs of rail vehicles

InactiveCN112281080AMeet material performance requirementsMetal-working apparatusManganeseUltimate tensile strength

The invention relates to low-alloyed steel used for brake discs of rail vehicles and a heat treatment method of the low-alloyed steel used for the brake discs of the rail vehicles. The low-alloyed steel used for the brake discs of the rail vehicles comprises the following chemical components in percentage by weight: 0.15-0.30% of C, 0.4-1.0% of Si, 0.4-1.0% of Mn, 0.6-1.4% of Cr, 0.4-1.2% of Ni, 0.2-0.6% of Mo, 0.15-0.4% of V, 0.15-0.35% of Cu, 0.1-0.3% of W, 0.025-0.045% of Nb, 0.025-0.045% of Zr, and the balance Fe, Re and Al which remains after purification and inevitable impurities. According to the low-alloyed steel used for the brake discs of the rail vehicles and the heat treatment method of the low-alloyed steel used for the brake discs of the rail vehicles, on the basis of the characters of steel brake discs of rail vehicles in service conditions, environments and shaping processes, material component design is conducted from the aspects of improving the high-temperature strength of the material (low-alloyed steel used for the brake discs of the rail vehicles), improving the weather resistance, refining grains, improving the plasticity and the like, and proper forging ratios and a quenched-tempered heat treatment technology are selected, so that the material performance requirements of forged steel brake discs or cast steel brake discs are met separately by the mechanical performance of the material (low-alloyed steel used for the brake discs of the rail vehicles) at a room temperature. For different scales of smelting conditions, different methods for controllingthe material purity are proposed, so that the purity of the alloyed steel is improved.

Owner:BEIJING JIAOTONG UNIV +1

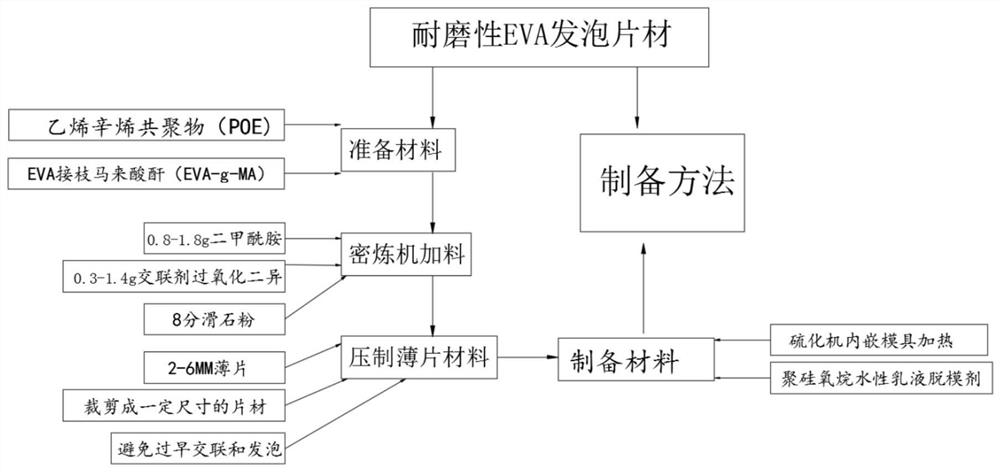

A kind of preparation method of eva/tpu/poe composite foam material

Disclosed is a method for preparing an ethylene vinyl acetate (EVA) / thermoplastic urethane (TPU) / polyolefin elastomer (POE) composite foaming material. The method includes fully and evenly mixing EVA, POE, EVA grafted maleic anhydride and TPU in an internal mixer, adding azodicarbonamide serving as a foaming agent, dicumyl peroxide serving as a cross-linking agent, an auxiliary foaming agent and talcum powders to the internal mixer for mixing to obtain a mixture, pressing the mixture on an open dual-roller mixing mill into sheets, feeding the sheets to a vulcanizing machine, and performing mould pressing, crosslinking and foaming forming to discharge the sheets to obtain the EVA / TPU / POE composite foaming material. By means of EVA-maleic anhydride (MA), the EVA / TPU composite material with good compatibility can be obtained, usage of 4, 4-diaminodiphenylmethane is avoided, the process is simple, costs are saved, and better performances are achieved; and simultaneously, a POE material is introduced to a system, so that important performance indexes of the prepared foaming material are well improved.

Owner:SHAANXI UNIV OF SCI & TECH

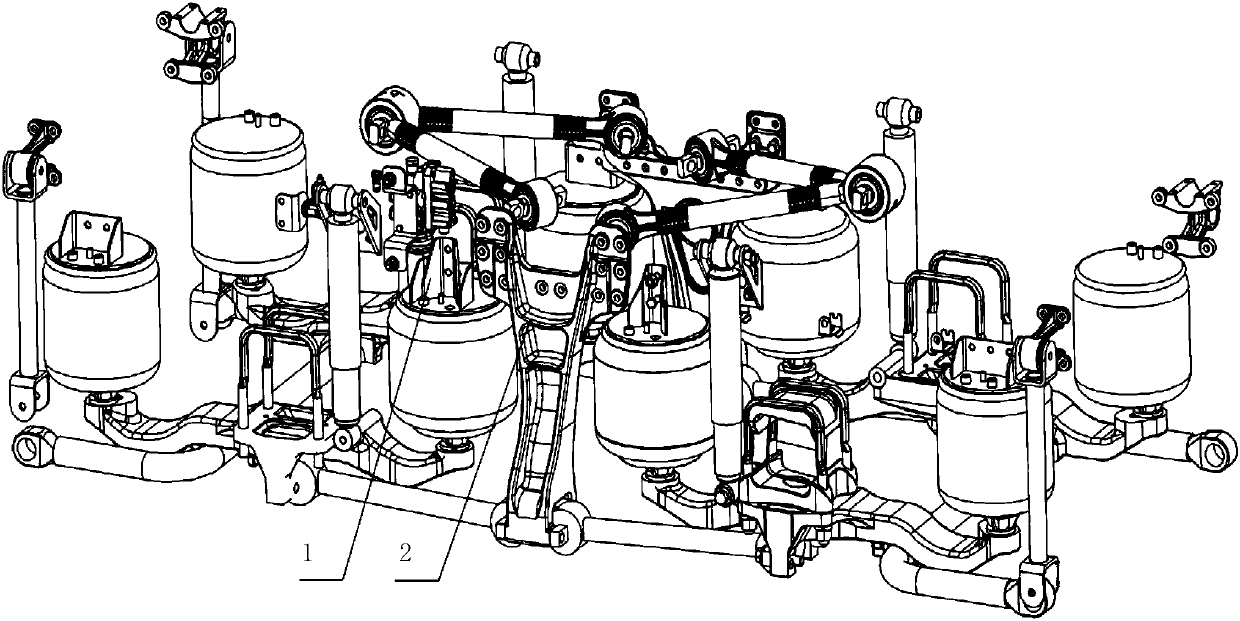

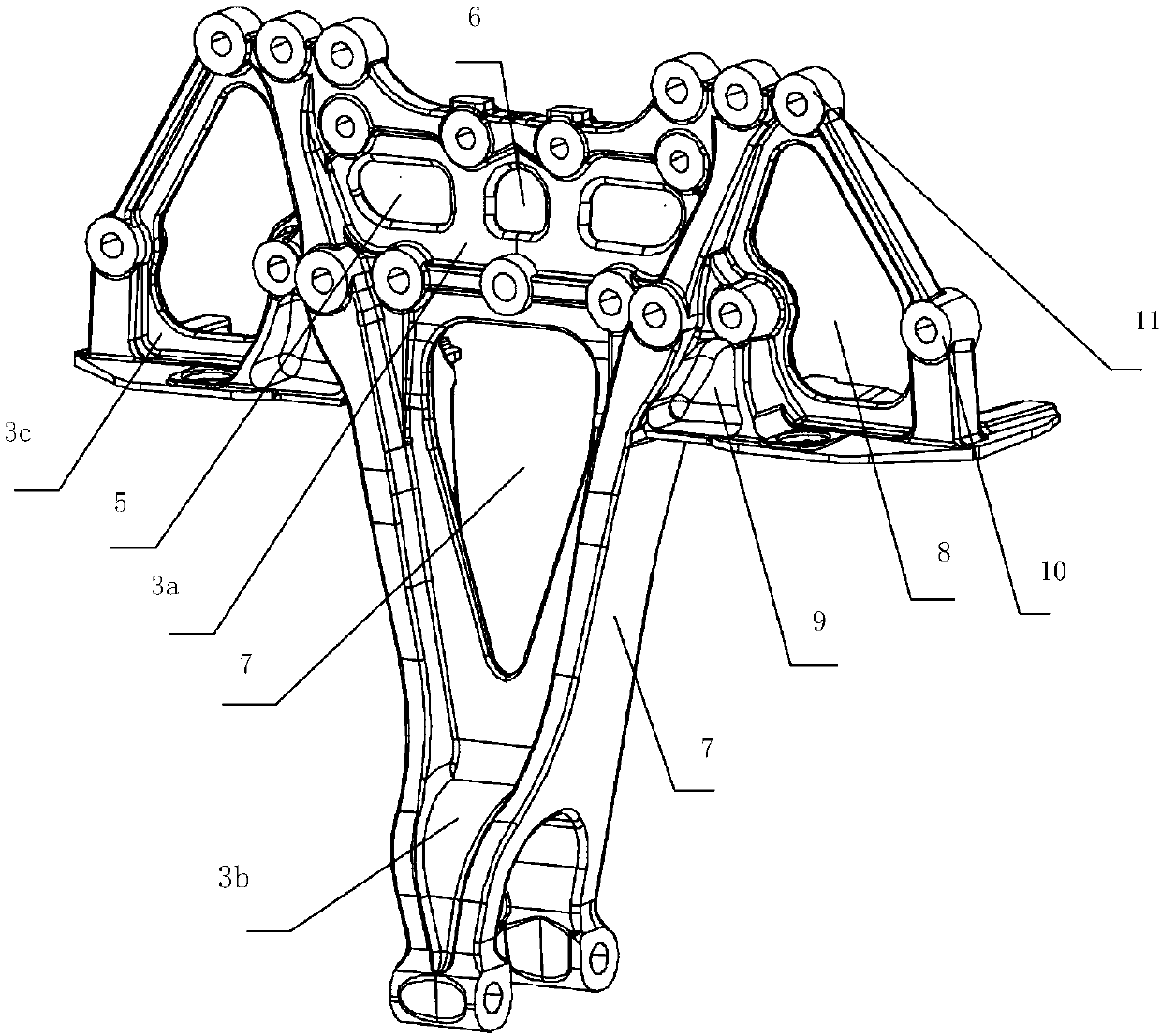

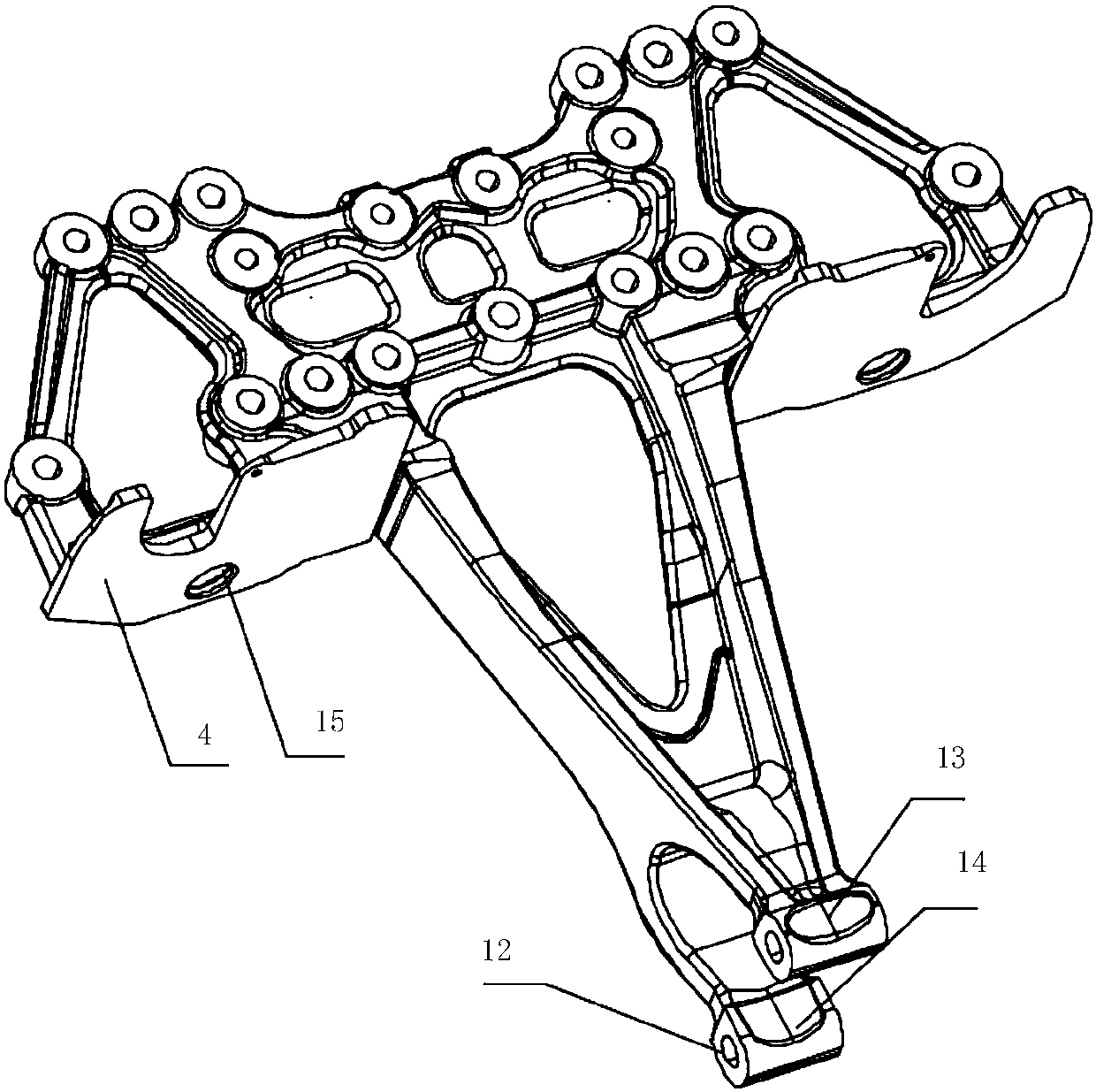

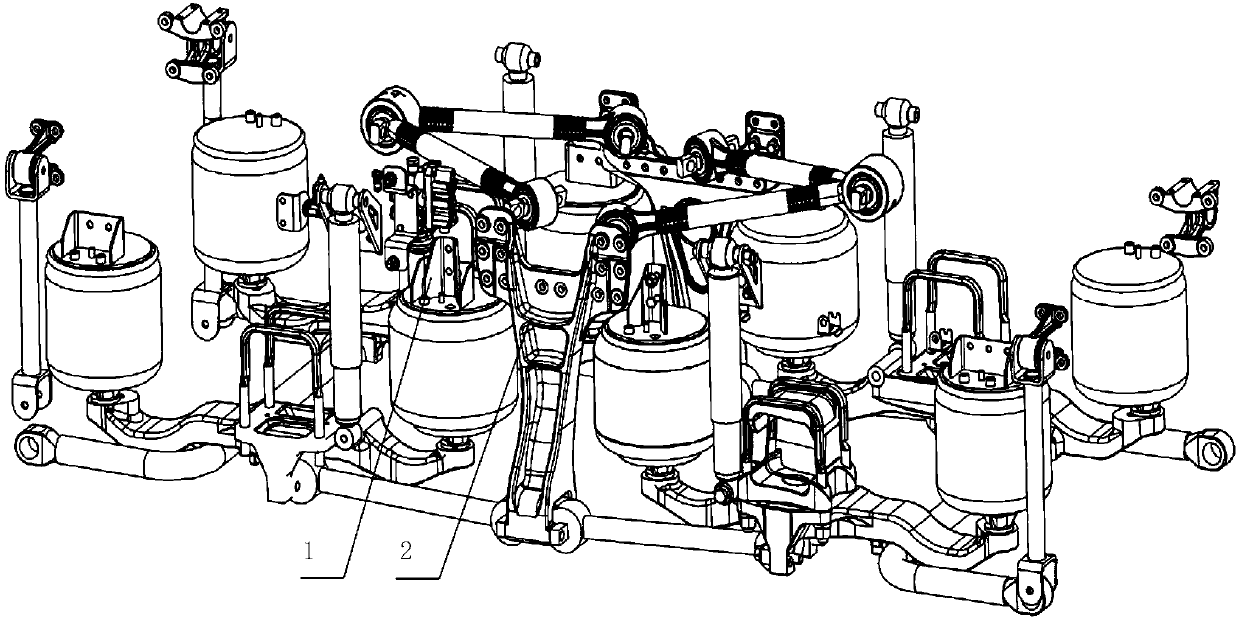

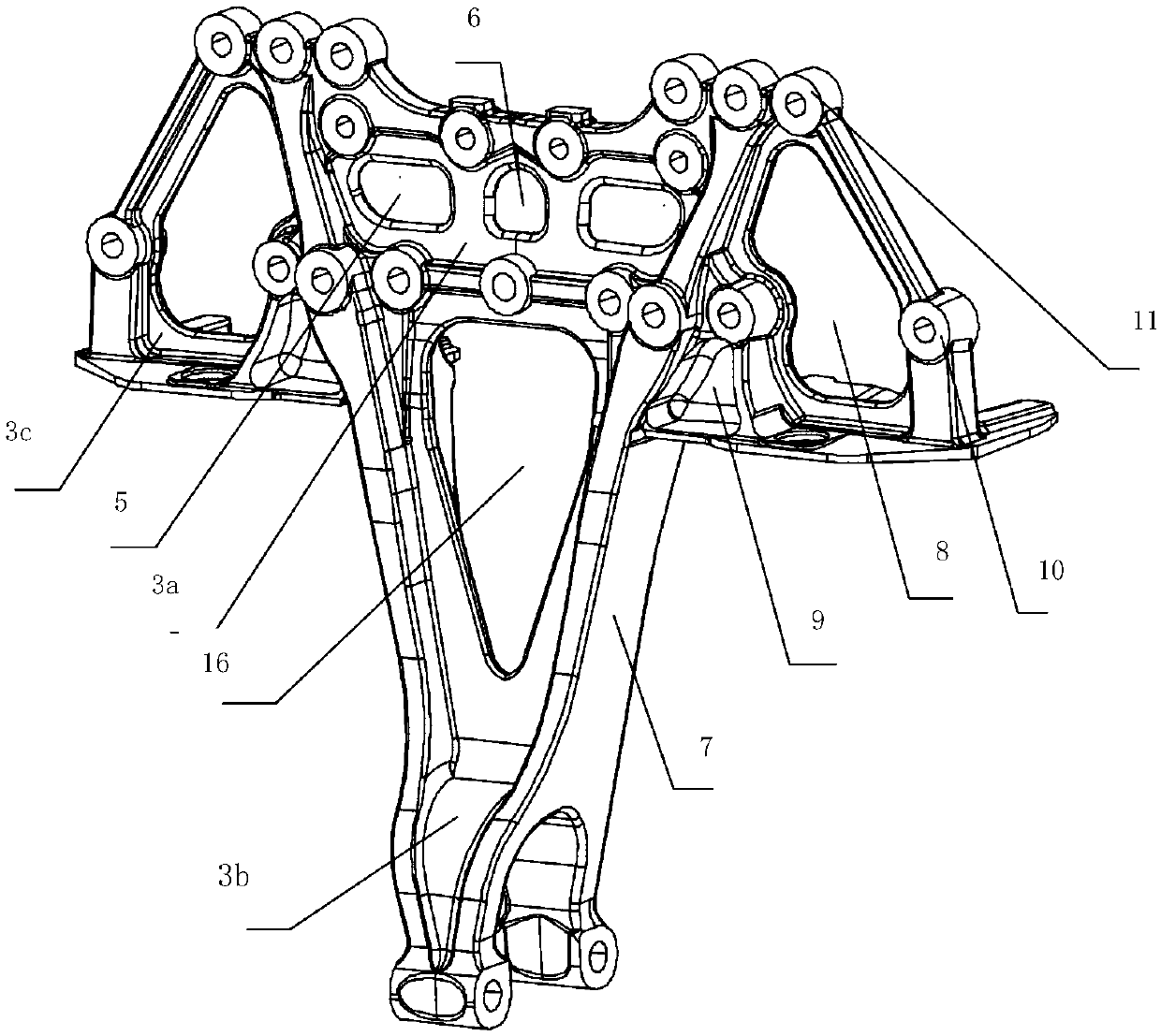

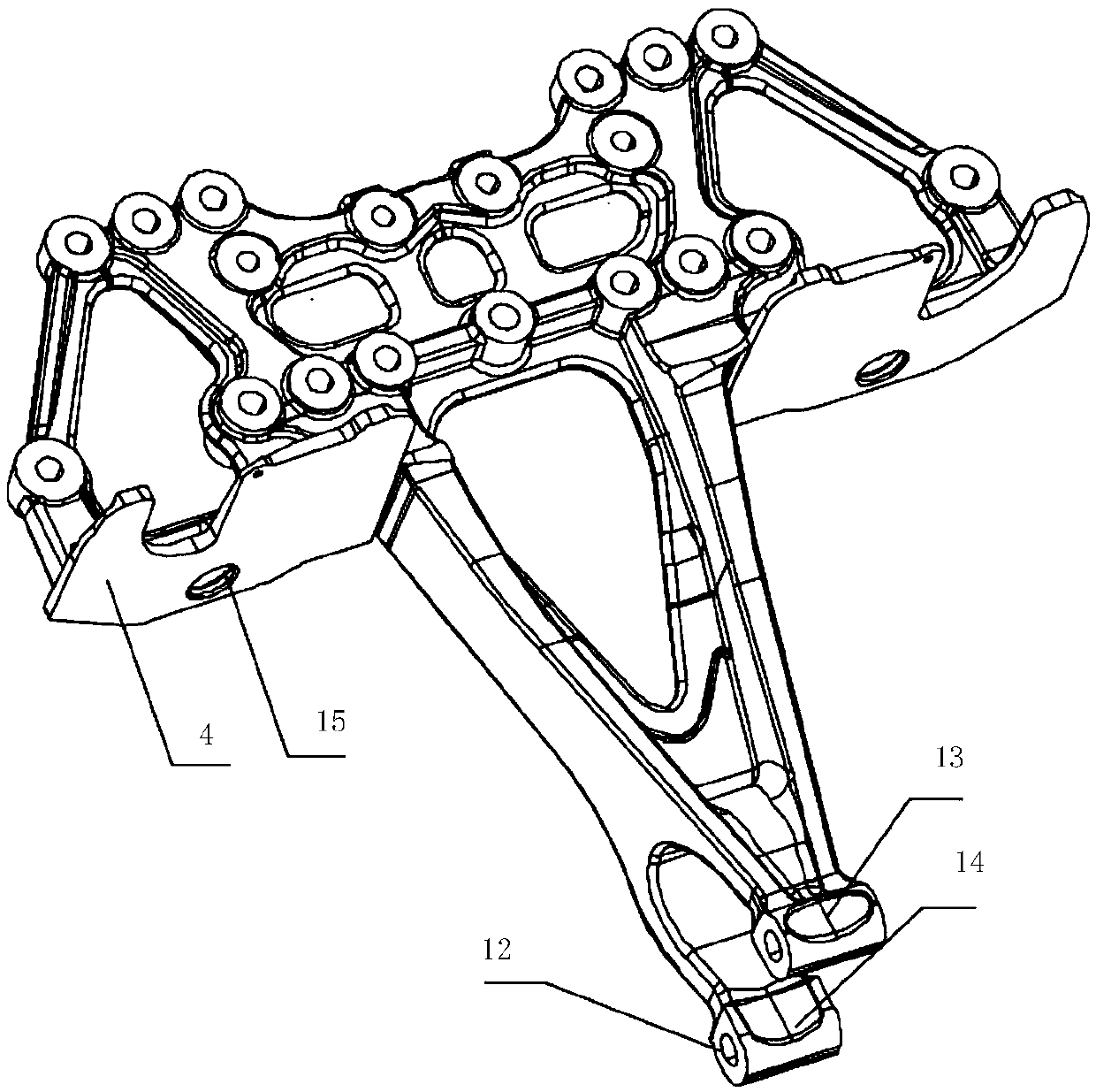

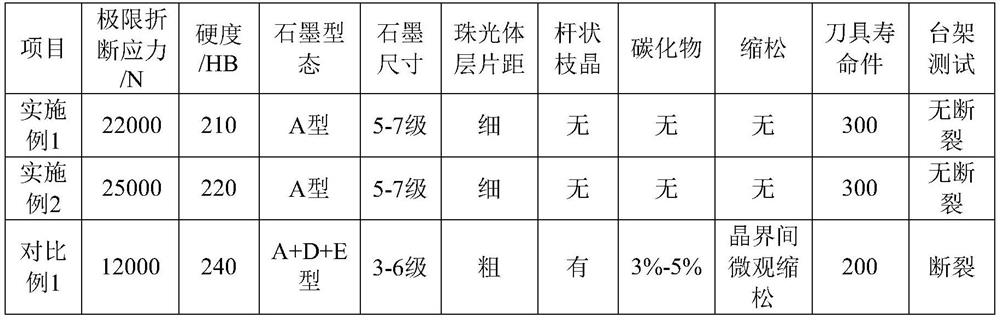

Function integrated support of air suspension and special high-strength cast-state ductile iron material of support

ActiveCN107699784AMeet material performance requirementsHigh yield strengthResilient suspensionsPunchingChemical composition

The invention relates to a support of an air suspension and special high-strength cast-state ductile iron of the support. The high-yield-strength cast-state ductile iron comprises chemical componentsincluding C, S, P, Mn, Si, Cr, Sn, Mg, Re and the balance Fe. The support comprises a support body, an air spring supporting face and a middle and rear axle thrust rod base, and the support is of an integral casting structure. Compared with the prior art, according to the cast-state performance, the tensile strength sigma b is larger than or equal to 600 MPa, sigma 0.2 is larger than or equal to 400 MPa, delta is larger than or equal to 10%, the brinell hardness HB is equal to 245-287, the content of a cast-state base body is 80%, the content of cementite is 1%, the yield strength is improved,and the material performance requirement of a structure bearing piece with the medium heavy truck fatigue resisting strength can be met. In addition, the support is of the integral casting structure,welding, forging, punching and other technologies are not needed, respective assembling is not needed neither, cost is greatly reduced, and time is greatly shortened; the effective strength is guaranteed, and meanwhile material stacking is reduced as well; and the space is more compact, the lightweight degree is higher, and the fuel economy of a whole vehicle can be better improved.

Owner:CHINA FIRST AUTOMOBILE

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261BHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

Owner:JIANGSU UNIV

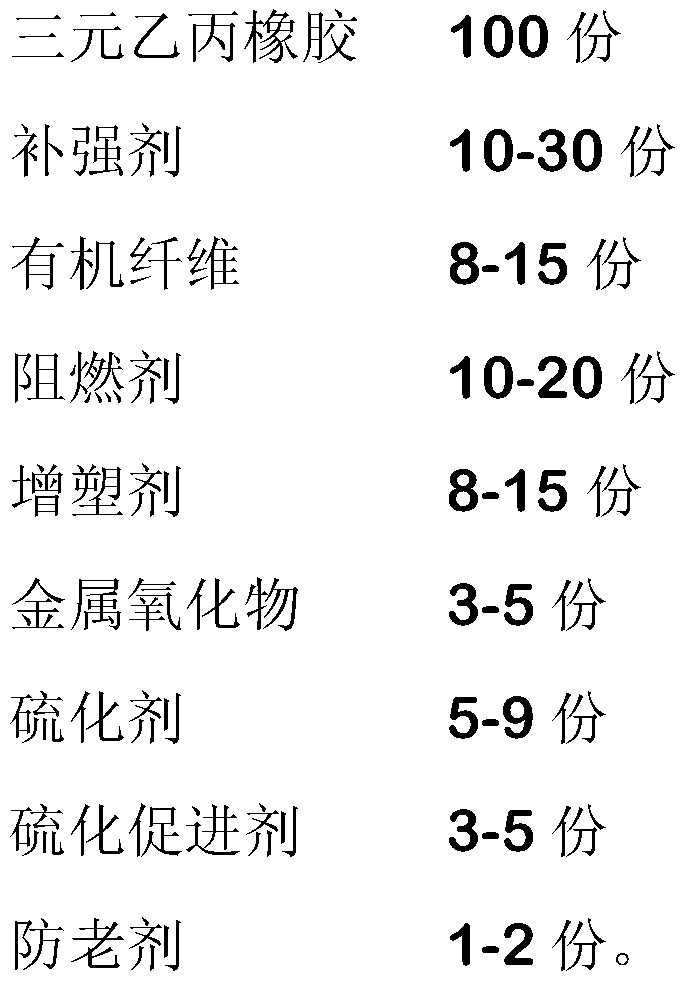

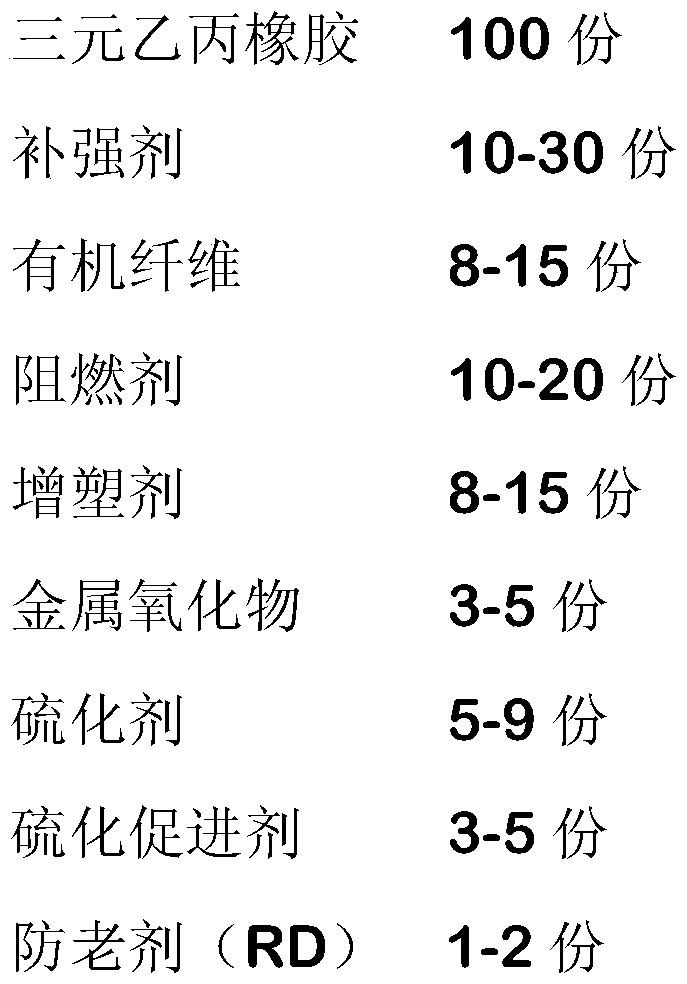

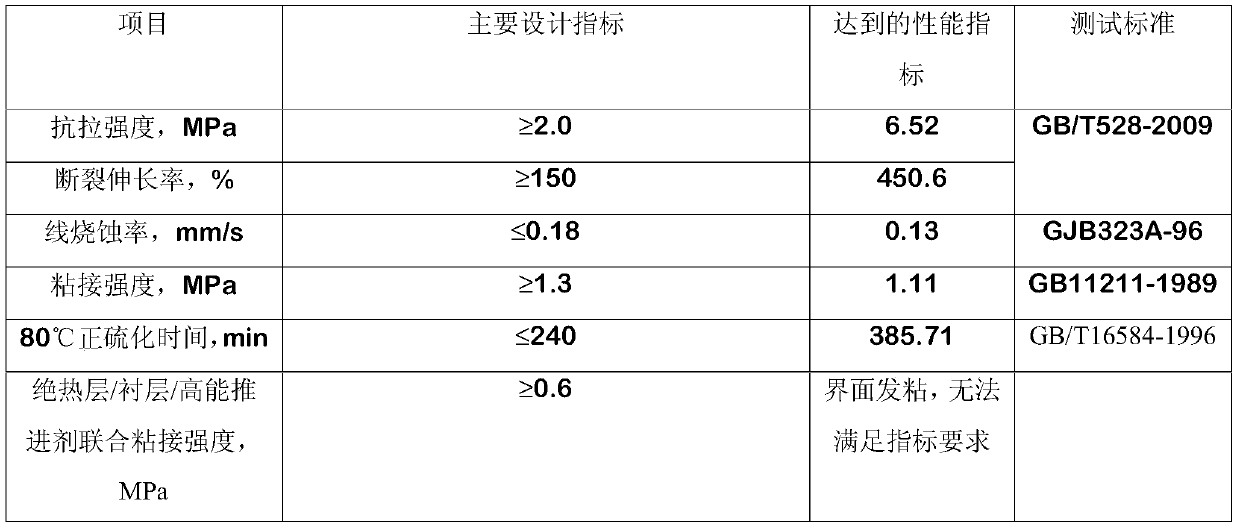

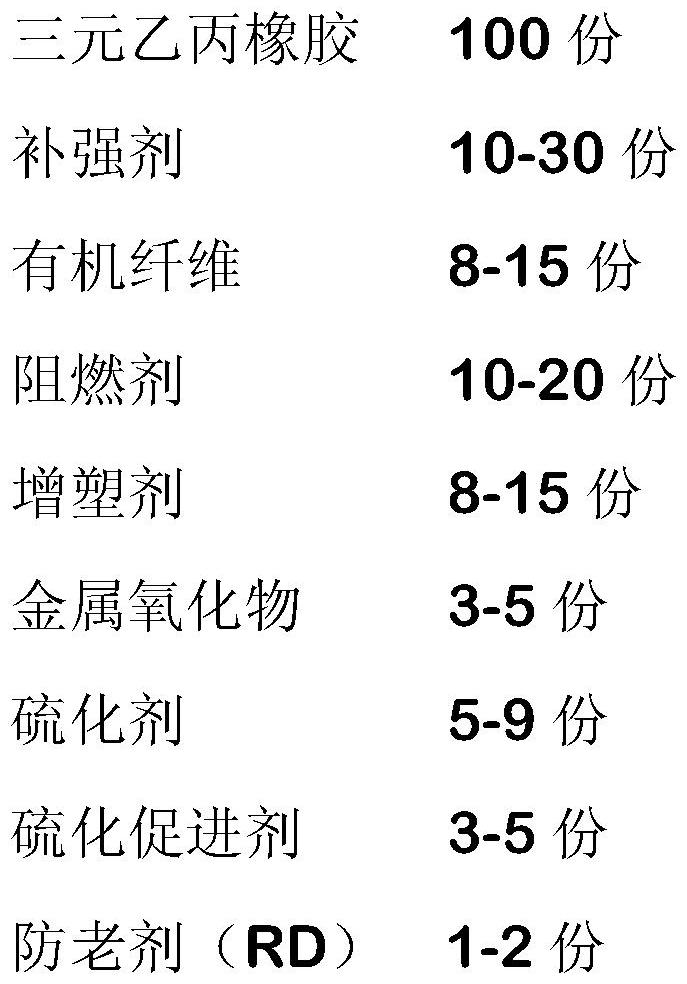

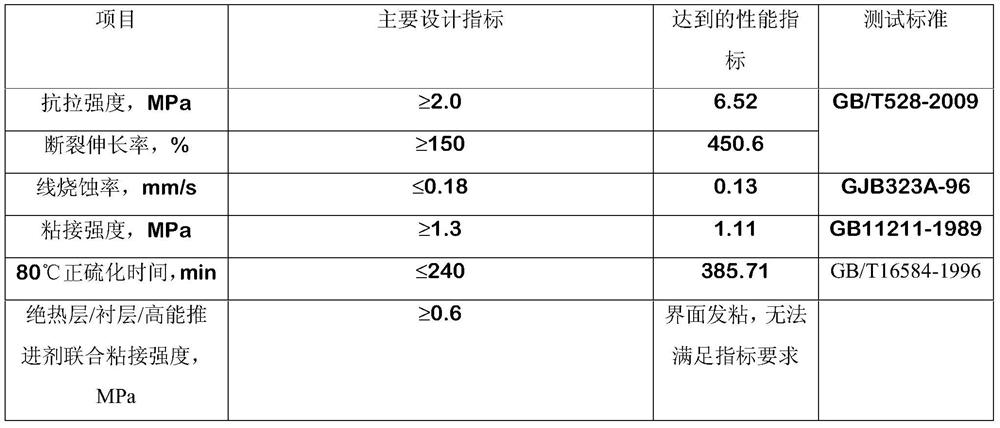

Medium-temperature repairing rubber material, preparation method thereof and application thereof in a propellant

The invention relates to a medium-temperature repairing rubber material, a preparation method thereof and an application thereof in a propellant, belonging to the technical field of ablation-resistantmaterials, in particular to a medium-temperature repairing thermal insulating layer material for a high-energy propellant, a thermal insulating layer capable of rapidly vulcanizing at a medium temperature, and a preparation method thereof. The vulcanization system of the invention adopts a vulcanization system of peroxide and accelerator, the thermal insulating material is difficult to absorb nitrate ester, does not affect the ablation performance of the thermal insulating layer, does not affect the interface adhesion performance of the high-energy propellant, and has good adaptability with the interface of the high-energy propellant.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

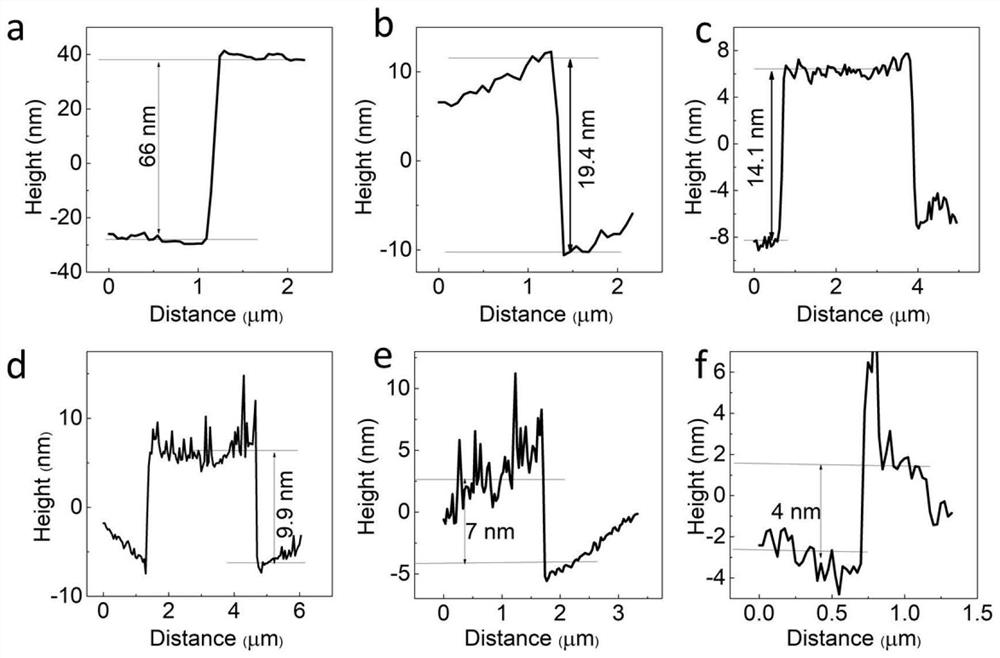

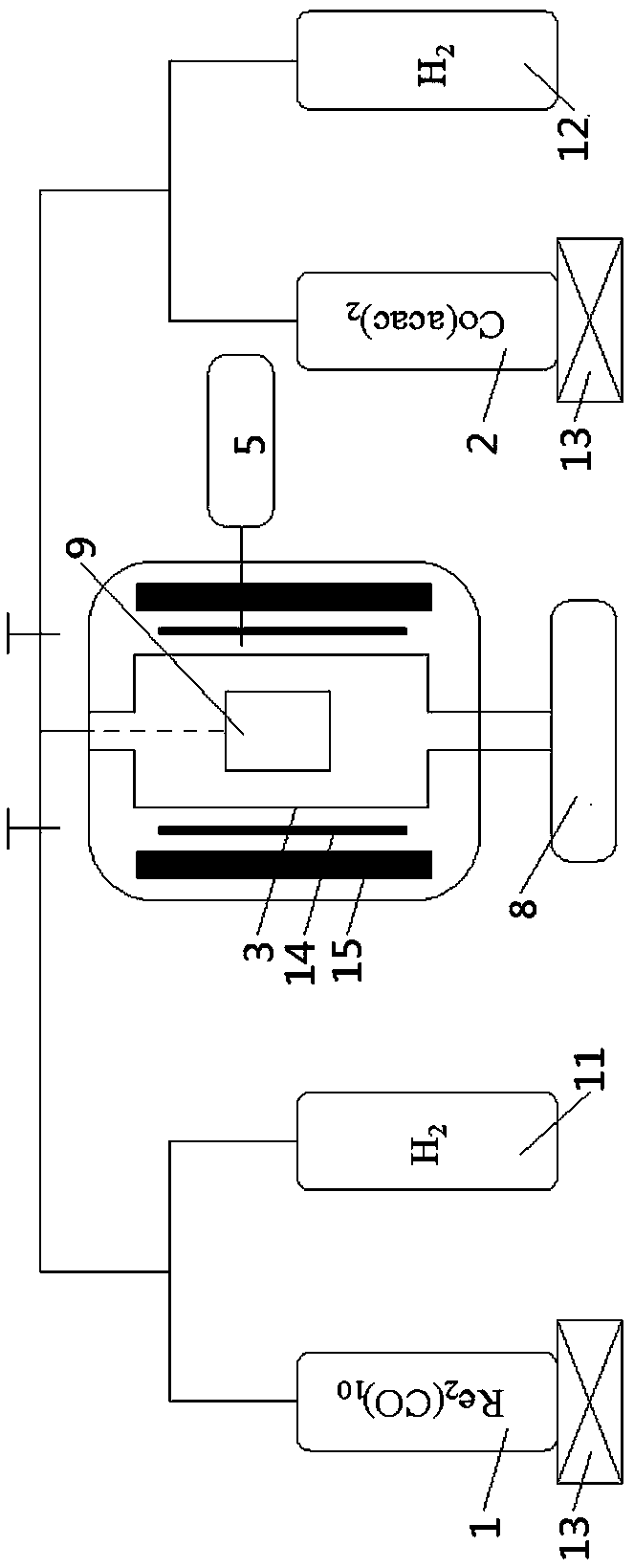

Method for reducing thickness of tellurium nanosheet

ActiveCN113401880APrecise thickness controlMeet material performance requirementsNanotechnologyElemental selenium/telluriumSemiconductor materialsField effect

The invention discloses a method for reducing the thickness of a tellurium nanosheet, and belongs to the technical field of nano materials, the method comprises the following steps: soaking the tellurium nanosheet in a weak oxidizing solution, taking out and drying to obtain the tellurium nanosheet with the reduced thickness, according to the method, the weak oxidizing solution and the surface of the tellurium nanosheet are subjected to mild oxidation reaction, the tellurium nanosheet is thinned, and accurate regulation and control of the thickness of the tellurium nanosheet can be achieved; according to the thin-layer tellurium nanosheet prepared by the method disclosed by the invention, the advantages of the p-type tellurium nanosheet can be fully played, the requirements of different devices on material performance are met, electronic and photoelectric devices based on the tellurium nanosheet can be constructed by utilizing electron beam exposure and vacuum evaporation of an electrode material, and the thin-layer tellurium nanosheet has good compatibility with a traditional semiconductor processing technology; according to the invention, multiple regulation and control of the thickness, the carrier concentration and the field effect switching ratio of the tellurium nanosheet can be realized, and support is provided for developing a two-dimensional p-type semiconductor material which is stable in performance and meets multi-scene requirements.

Owner:UNIV OF SCI & TECH BEIJING

Process and equipment for producing graphite dust

ActiveCN101318648BReduce entryImprove graphitization heat treatment efficiencyCell electrodesChemical industryVacuum deliveryImpurity

The invention discloses a method for preparing graphite powder and the equipment thereof and aims at solving the technical problems of improving the purity of graphite powder and reducing cost. The method of the invention comprises the following steps: the raw micro powder is delivered to a graphite crucible under vacuum state and put into a graphitizing furnace; and a graphite powder product is obtained after heat treatment and cooling. The preparation equipment of graphite powder is composed of a vacuum delivery device, a graphitizing furnace and a vacuum discharging device sequentially connected; the graphitizing furnace is equipped with a graphite crucible and connected with a gas filling system. Compared with the prior art, the method and the equipment of the invention are characterized in that the raw micro power is put into the graphite crucible after vacuum delivery, thus the entry of impurities is reduced in the treatment process, the product purity is greatly improved after heat treatment, graphitization is even, the consistency of the product is good, the graphitization and heat treatment efficiency of the powder material is improved, the technique is simple and the cost is low.

Owner:BTR NEW MATERIAL GRP CO LTD

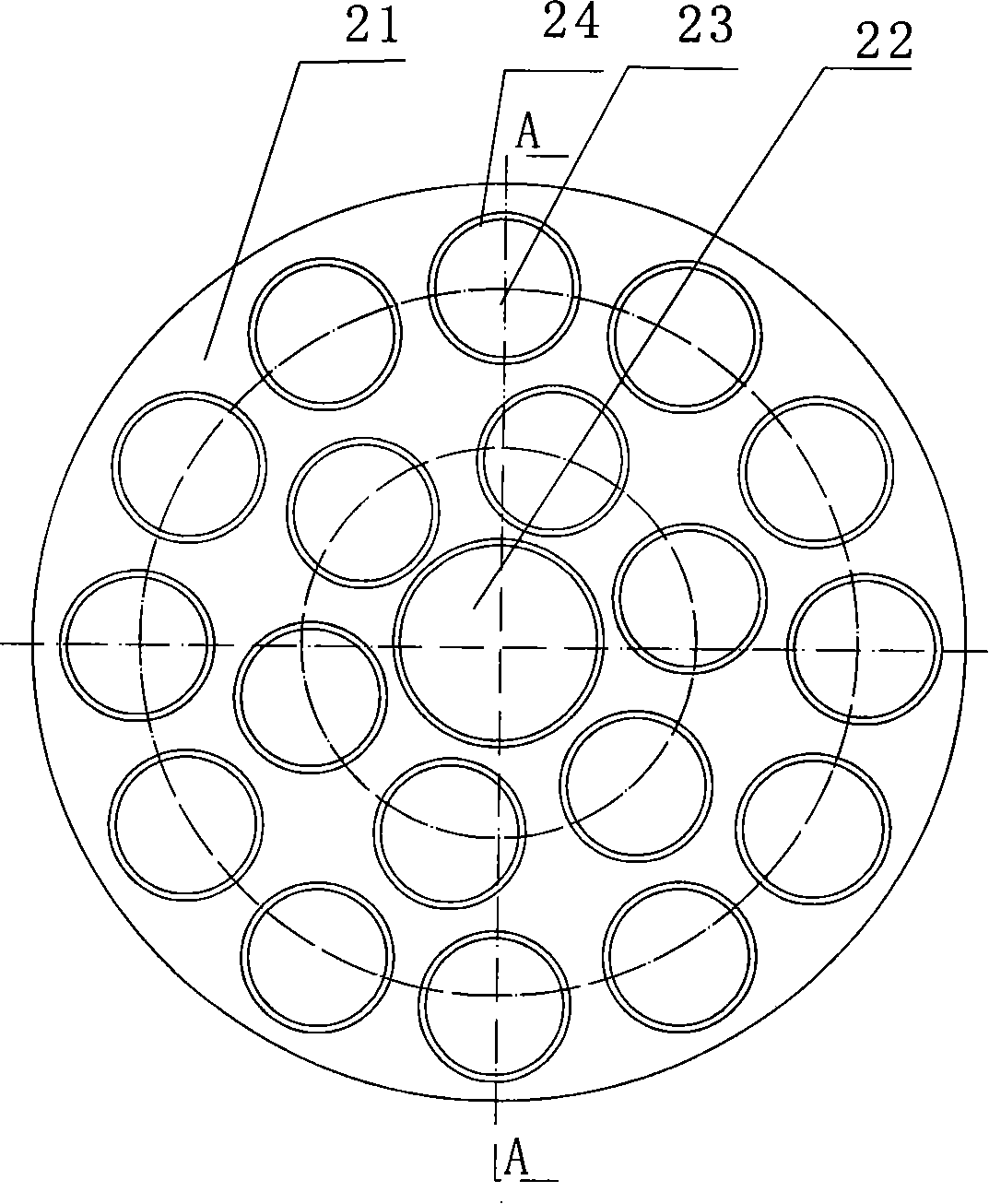

A kind of high temperature resistant and anti-ablation alloy

ActiveCN109722667BQuality improvementQuality assuranceLiquid/solution decomposition chemical coatingChemical vapor deposition coatingCrazingAlloy coating

The invention discloses a high-temperature-resisting burning erosion resistance alloy, and belongs to the field of alloy preparing. The problems that at present, an eletrodeposited chromium layer is commonly adopted to serve as high-temperature burning erosion resistance coatings of a rapid fire weapon, an artillery pipe and the like, in the chromium plating process of the eletrodeposited chromiumlayer, crystal transfer from hexagonal crystals to cubic crystals happens, the chromium layer is full of micro cracks, peeling is prone to happening, toxic substances need to be used, and certain harm is caused to the environment can be solved. The high-temperature-resisting burning erosion resistance alloy comprises a metallic matrix, an Ni-B composite coating, and an Re-Co alloy coating. The Ni-B composite coating serves as the transition layer of the alloy, the chemical vapor deposition is adopted to deposite the Re-Co alloy coating on the surface of the Ni-B composite coating, the prepared alloy has the good high-temperature-resisting and burning erosion resistance properties. Meanwhile, on the basis of the structural improvement, the phenomenon that during alloy coating preparing, Cimpurities are combined with the metallic matrix is effectively avoided, the coating and the alloy have the extremely good combination force, and cracks, peeling and the like are avoided.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of corrosion-resistant EVA foamed sheet

The invention relates to the technical field of EVA foaming material preparation, and discloses a preparation method of a corrosion-resistant EVA foaming sheet. Thepreparation method comprises the following steps: sufficiently preparing the required materials, and proportionally distributing the required ethylene-octene copolymer (POE) composite foaming material, ethylene-vinyl acetate copolymer (EVA) and EVA grafted maleic anhydride (EVA-g-MA) to obtain the corrosion-resistant EVA foaming sheet. The preparation method comprises the following steps: fully and uniformly mixing 52 parts by weight of EVA, 1-8 parts by weight of EVAgMA and 2-6 parts by weight of POE in an internal mixer. According to the preparation method of the corrosion-resistant EVA foamed sheet, the compatibility of EVA and TPU can be remarkably improved through EVA-g-MA; meanwhile, a POE material with high resilience is introduced, so that the prepared EVA / TPU / POE composite foamed material has good mechanical performance, the tensile strength is 2.09 to 2.44 MPa, the elongation at break is 278.2% to 314.2%, the tearing strength is 4.10 to 5.13 N / mm, and the peel strength is 2.70 to 3.72 N / mm. Meanwhile, the material has good resilience of 55-62%, compression set of 25-42% and low density of 0.2-0.25 g / cm3.

Owner:尹志贵

A functionally integrated bracket for an air suspension

ActiveCN107699784BMeet material performance requirementsHigh yield strengthResilient suspensionsEngineeringDuctile iron

The invention relates to a support of an air suspension and special high-strength cast-state ductile iron of the support. The high-yield-strength cast-state ductile iron comprises chemical componentsincluding C, S, P, Mn, Si, Cr, Sn, Mg, Re and the balance Fe. The support comprises a support body, an air spring supporting face and a middle and rear axle thrust rod base, and the support is of an integral casting structure. Compared with the prior art, according to the cast-state performance, the tensile strength sigma b is larger than or equal to 600 MPa, sigma 0.2 is larger than or equal to 400 MPa, delta is larger than or equal to 10%, the brinell hardness HB is equal to 245-287, the content of a cast-state base body is 80%, the content of cementite is 1%, the yield strength is improved,and the material performance requirement of a structure bearing piece with the medium heavy truck fatigue resisting strength can be met. In addition, the support is of the integral casting structure,welding, forging, punching and other technologies are not needed, respective assembling is not needed neither, cost is greatly reduced, and time is greatly shortened; the effective strength is guaranteed, and meanwhile material stacking is reduced as well; and the space is more compact, the lightweight degree is higher, and the fuel economy of a whole vehicle can be better improved.

Owner:CHINA FIRST AUTOMOBILE

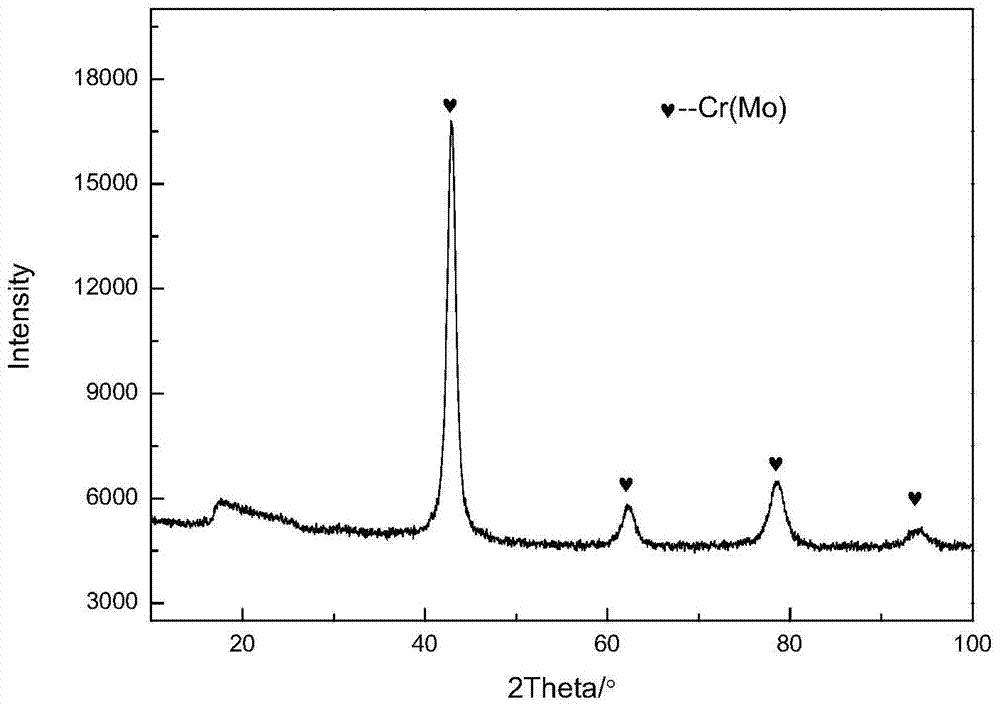

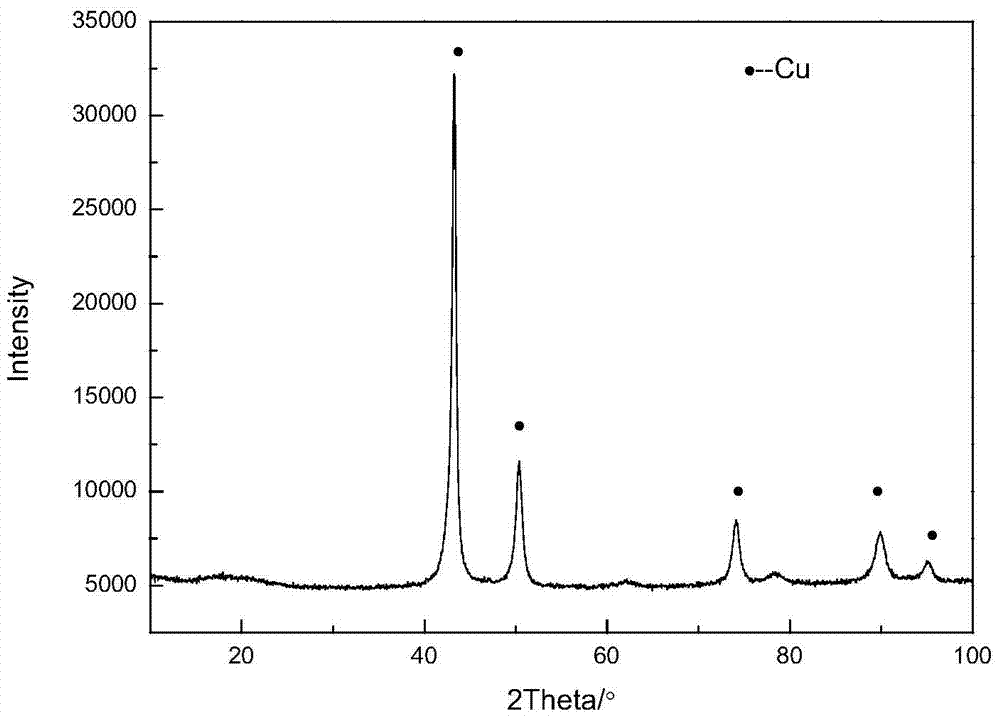

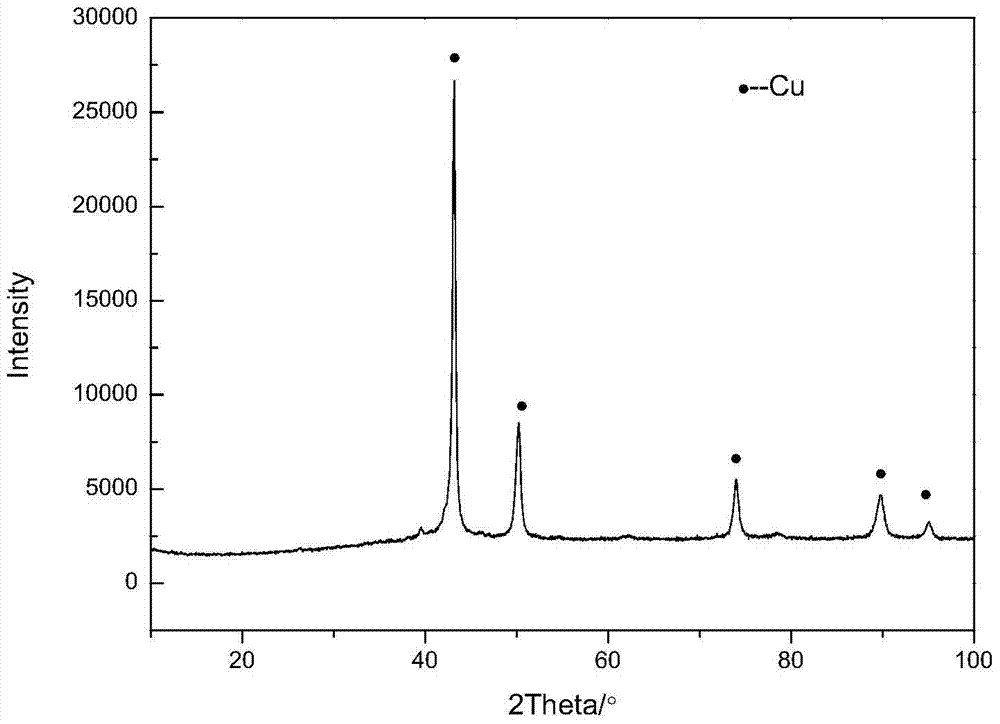

A kind of high-hardness wear-resistant copper alloy for plastic mold and preparation method thereof

The invention provides a high-hardness wear-resistant copper alloy for a plastic mold and a preparation method thereof. The copper alloy is composed of the following components in terms of mass fraction: Mo: 8-10%, Cr: 8-10%, Cu: ≥ 78% And <80%, the remainder is impurities. The invention mainly utilizes the non-equilibrium alloy preparation process of mechanical alloying, so as to realize a large amount of solid solution of Mo and Cr, two alloy elements that are difficult to be dissolved in Cu, and the solid solubility of Cr and Mo in Cu is calculated by mass fraction. More than 8%, in the subsequent hot pressing sintering process, Mo and Cr have a certain degree of dispersion and precipitation. Through the combined action of dispersion and solid solution strengthening, the hardness of the Cu alloy is greatly improved, and the hardness reaches more than 38HRC, and the thermal conductivity reaches The Cu-Cr-Mo alloy above 80W / K·m is a high-hardness copper alloy that can meet the performance requirements of plastic mold materials and does not contain beryllium.

Owner:XI AN JIAOTONG UNIV

Non-Newtonian fuselage deicing and anti-icing fluid and preparation method thereof

ActiveCN103059813BExcellent shear recovery abilityLong anti-icing timeOther chemical processesPhysical chemistryRheopecty

The invention relates to a deicing and anti-icing fluid, particularly a non-Newtonian fuselage deicing and anti-icing fluid and a preparation method thereof. The non-Newtonian fuselage deicing and anti-icing fluid can reduce adhesion of ice on the object surface to eliminate and prevent icing on the aircraft fuselage surface, and has superlong anti-icing retention time. The non-Newtonian fuselage deicing and anti-icing fluid comprises the following components in parts by mass: 40-60 parts of freezing-point depressant, 0.05-1.2 parts of rheologic modifier, 0.01-0.3 part of anti-icing compounding agent, 0.01-3 parts of pH regulator, 0.01-3 parts of corrosion inhibitor, 0.01-0.5 part of staining agent and 40-60 parts of deionized water. The invention is based on the low-temperature rheologic research, especially aims at the low-temperature operating environment and characteristics of the deicing and anti-icing fluid, and determines the distribution and arrangement of the main chain and branch chain of the rheologic modifier as well as the preparation and acquisition method of the low-temperature conformation. By combining the anti-icing compounding agent, corrosion inhibitor and other assistants in the formula, the prepared deicing and anti-icing fluid has the characteristics of excellent shearing restorability, excellent ice adhesion inhibition capacity at 0 to -20 DEG C, and long anti-icing time.

Owner:成都民航六维航化有限责任公司

Pseudo-classic building reinforced concrete beam-slab-column base material and preparation and use method thereof

The invention discloses a pseudo-classic building reinforced concrete beam-slab-column ground layer material which comprises 791 glue and Portland cement. The adhesive comprises the following components in parts by weight: 1000g of 791 glue and 2000g of Portland cement, meanwhile, the invention further provides a preparation and use method of the pseudo-classic building reinforced concrete beam-slab-column base material, and the pseudo-classic building reinforced concrete beam-slab-column base material has the advantages of being convenient in material obtaining, simple in process, short in construction period and obvious in effect, and accords with the technological characteristics of Chinese traditional buildings.

Owner:陕西古锦园林古建工程有限公司

Cement stabilized recycled gravel method and its products

ActiveCN103848605BEasy to getHigh compressive strengthSolid waste managementSocial benefitsTime limit

The invention discloses a method of stably regenerating gravel from cement. The method includes steps of: 1) preparing raw materials comprising the cement and regenerated crude and fine aggregate; 2) adding the raw materials according to a ratio; and 3) stirring, and adding water to obtain a finished product. The invention also discloses a product obtained by the method. The method is simple in preparation technology, easy to achieve, and high in production efficiency, and can rapidly and stably produce the gravel product with high compressive strength by utilization of the cement. The method has high production efficiency, largely reduced cost, and good economic and social benefit, and protects the environment. The design of the formula is reasonable. The raw materials are easily available. Processes of traditional gravel exploiting are effectively simplified. The compressive strength of the product is high and can meet requirements of buildings with respect to material performances, thus solving the gravel resource shortage problem and achieving objectives of environment protection and sustainable development. The product is easy to construct, shortens the time limit for a project, improves the construction efficiency and facilitates wide popularization and application.

Owner:北京鼎创环保有限公司

A zirconium-cerium alloy gray iron casting

ActiveCN113652598BResolve the breakHigh tensile/flexural strengthFoundry mouldsCasting cleaning apparatusCeriumWorking environment

The invention discloses a zirconium-cerium alloy gray iron casting, which is composed of the following components by weight percentage: carbon 3.30%-3.45%, silicon 2.0%-2.2%, manganese 0.7%-0.8%, phosphorus 0.06%-0.1%, sulfur 0.08-0.12%, copper 0.6-0.8%, tin 0.04-0.06%, chromium 0.15-0.25%, zirconium 0.03-0.05%, cerium 0.03%-0.06%, and the balance is iron and casting associated inevitable impurities. The invention can greatly improve the strength and processing performance of thin-walled gray iron castings, and solve the problem that the gray iron castings are easy to break under high-temperature and high-torque working environments.

Owner:苏州勤堡精密机械有限公司

A kind of acid-resistant ultra-high-strength steel for deep-sea dynamic flexible riser and its preparation method

Owner:NORTHEASTERN UNIV LIAONING +1

A kind of medium temperature repairing rubber material and its preparation method and application in propellant

ActiveCN109721858BNot easy to absorbDoes not affect ablation performanceRubber materialPolymer science

The invention relates to a medium-temperature repairing rubber material and its preparation method and application in propellants, belonging to the technical field of ablation-resistant materials, in particular to a medium-temperature repairing insulation layer material for high-energy propellants, which can be used at medium temperatures Heat insulating layer capable of rapid vulcanization and method for making same. The vulcanization system of the present invention adopts the vulcanization system of peroxide plus accelerator, the heat insulating material is not easy to absorb nitrate, does not affect the ablation performance of the heat insulating layer, and does not affect the interface bonding performance of the high-energy propellant, and the interface with the high-energy propellant has Better adaptability.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com