A kind of medium temperature repairing rubber material and its preparation method and application in propellant

A rubber material, medium temperature technology, applied in the field of ablation-resistant materials, can solve problems affecting the quality and reliability of engine products, achieve good mechanical properties, not easy to absorb, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

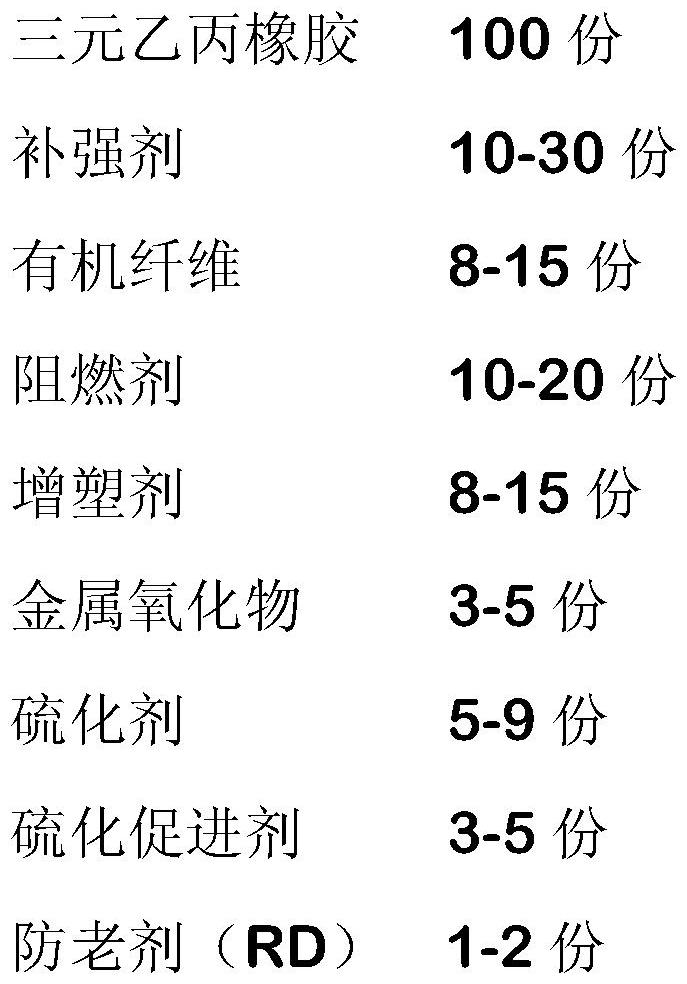

[0046] See Table 3 for the composition and formula of the medium-temperature repair rubber material;

[0047] Table 3 Composition and formula of moderate temperature repair rubber material in embodiment 1

[0048] serial number basic component Proportion effect 1 EPDM 100 base rubber 2 PA 10 organic fiber 3 ZnO 3 Metal oxide 4 SiO 2

20 Reinforcing filler 5 LPO 10 plasticizer 6 app 10 flame retardant 7 RD 1 Antiaging agent 8 CHP 5 Vulcanizing agent 9 DW 5 vulcanization accelerator

[0049] (1) stocking: stocking according to the proportioning of embodiment 1 in table 3;

[0050] (2) Mixing: according to EPDM thin pass 3 times → aramid fiber

[0051] PA→ZnO→SiO 2 →LPO→APP→RD→Vulcanizing agent→Thin pass 6 times→Vulcanization accelerator→Thin pass sheet to refine medium-temperature repair rubber material in sequence;

[0052] When preparing the rubber compound, it is necessar...

Embodiment 2

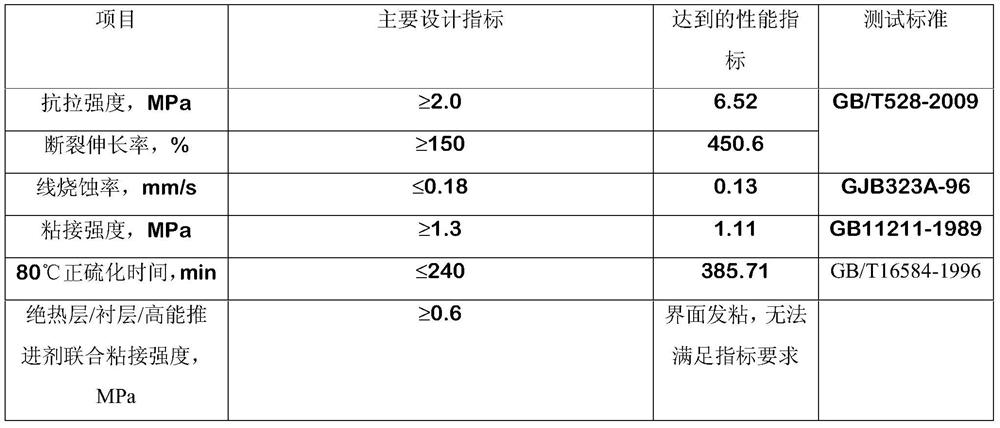

[0058] See Table 5 for the composition and formulation of the medium temperature repair rubber material;

[0059] Composition and formula of middle temperature repair rubber material in table 5 embodiment 2

[0060]

[0061]

[0062] (1) material preparation: prepare materials according to the proportioning of embodiment 2 in table 5;

[0063] (2) Mixing: according to EPDM thin pass 3 times → aramid fiber

[0064] PA→ZnO→SiO 2 →LPO→APP→RD→Vulcanizing agent→Thin pass 6 times→Vulcanization accelerator→Thin pass sheet to refine EPDM thermal insulation material in sequence.

[0065] When preparing the rubber compound, it is necessary to avoid mixing the accelerator and the vulcanizing agent together, and there is direct contact, in order to prevent the rapid decomposition of the hydrogen peroxide compound. The correct method of mixing operation is to first fully and evenly disperse the vulcanizing agent into the raw rubber, and then slowly add the vulcanization accelerato...

Embodiment 3

[0071] See Table 7 for the composition and formula of the medium-temperature repair rubber material;

[0072] Composition and formula of middle temperature repair rubber material in table 7 embodiment 3

[0073] serial number basic component Proportion effect 1 EPDM 100 base rubber 2 PA 10 organic fiber 3 ZnO 3 Metal oxide 4 SiO 2

20 Reinforcing filler 5 LPO 10 plasticizer 6 app 15 flame retardant 7 RD 1 Antiaging agent 8 CHP 7 Vulcanizing agent 9 DW 4 vulcanization accelerator

[0074] (1) stocking: stocking according to the proportioning of embodiment 3 in table 1;

[0075] (2) Mixing: according to EPDM thin pass 3 times → aramid fiber

[0076] PA→ZnO→SiO 2 →LPO→APP→RD→Vulcanizing agent→Thin pass 6 times→Vulcanization accelerator→Thin pass sheet to refine EPDM thermal insulation material in sequence.

[0077] When preparing the rubber compound, it is necessary to avoid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com