Patents

Literature

78results about How to "Short vulcanization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone-polymer-modified vulcanized-rubber compositions, processes for their production, and also windshield wipers encompassing said material

InactiveUS8148467B2Change resistanceImprove long-term stabilityLiquid processingCarpet cleanersPolymer scienceVulcanization

A silicone-polymer-modified vulcanized-rubber composition based on unvulcanized rubber, characterized in that the composition can be produced by co-vulcanization from the following components:A1) at least one vinyl-reactive polysiloxane component, and / orA2) at least one mercapto-reactive polysiloxane component, andB) at least one unsaturated vulcanizable unvulcanized-rubber component, and to a process for the production of said silicone-polymer-modified vulcanized-rubber composition based on unvulcanized rubber, and also to a windshield-wiper blade encompassing a silicone-polymer-modified vulcanized-rubber composition based on unvulcanized rubber.

Owner:ROBERT BOSCH GMBH

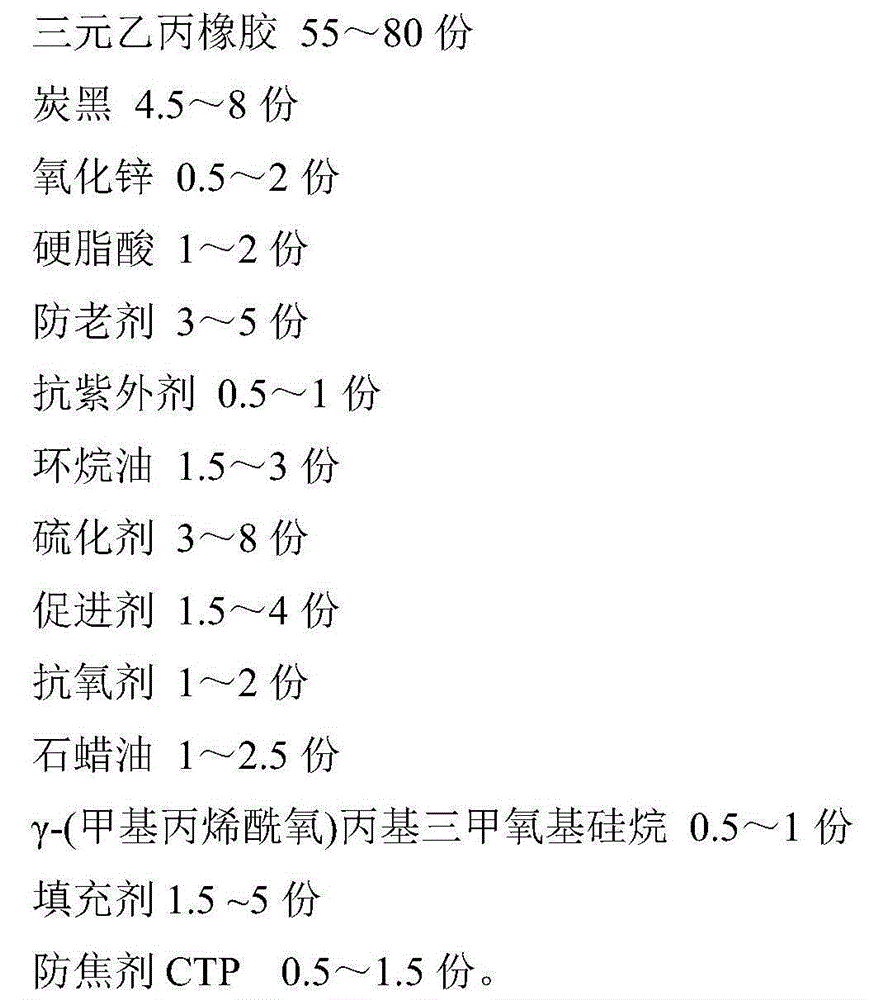

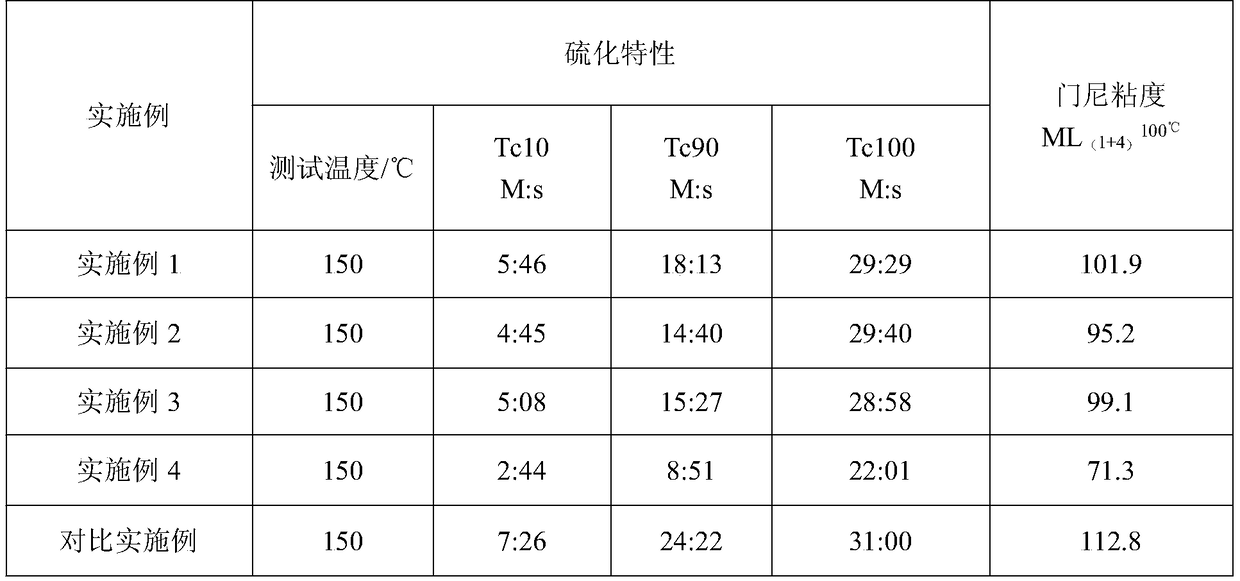

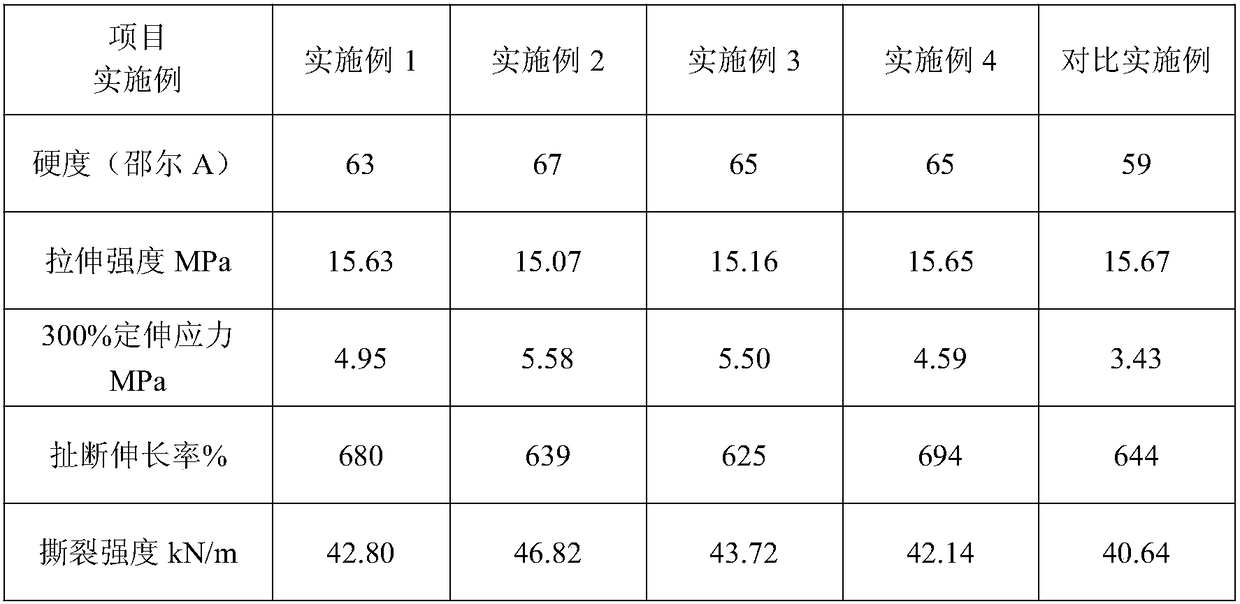

Automobile rubber sealing strip and preparation method thereof

The invention discloses an automobile rubber sealing strip and a preparation method thereof. The automobile rubber sealing strip comprises the following components in parts by weight: 55-80 parts of ethylene propylene diene monomer rubber, 4.5-8 parts of carbon black, 0.5-2 parts of zinc oxide, 1-2 parts of stearic acid, 3-5 parts of anti-aging agent, 0.5-1 part of ultraviolet-resistant agent, 1.5-3 parts of naphthenic oil, 3-8 parts of vulcanizing agent, 1.5-4 parts of accelerator, 1-2 parts of antioxidant, 1-2.5 parts of paraffin oil, 0.5-1 part of gamma-(methylacryloyloxy)propyltrimethoxy silane, 1.5-5 parts of filler and 0.5-1.5 parts of anti-scorching agent CTP. The automobile rubber sealing strip enhances the high temperature resistance, low temperature resistance, stability to light, ozone. oxygen and the like and other comprehensive properties of the product and improves the interface compatibility on the premise of keeping the original mechanical properties. The preparation method has the advantages of simple technique, short vulcanization time, lower energy consumption and lower production cost.

Owner:SUZHOU GOODTIME TECH DEV

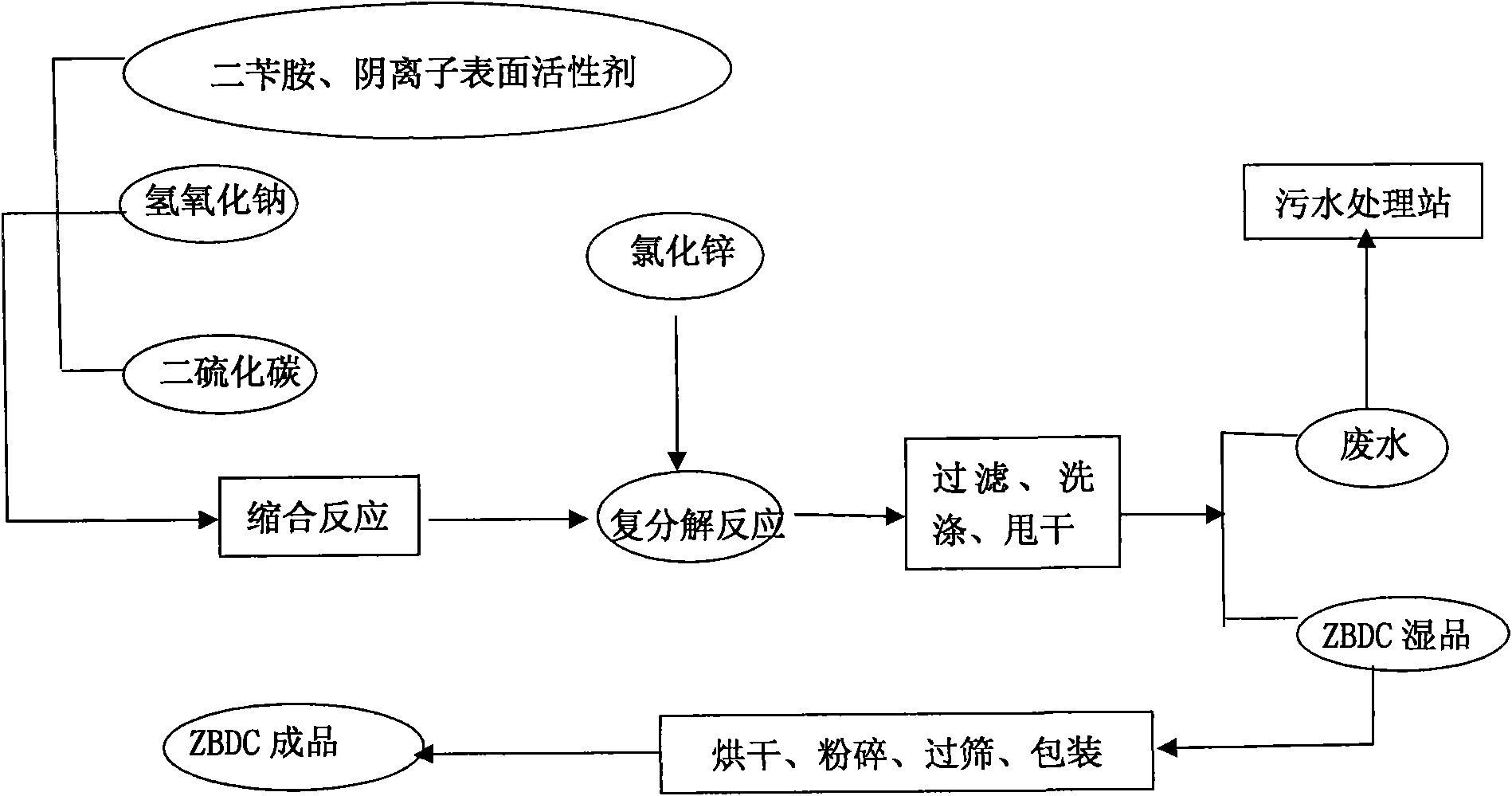

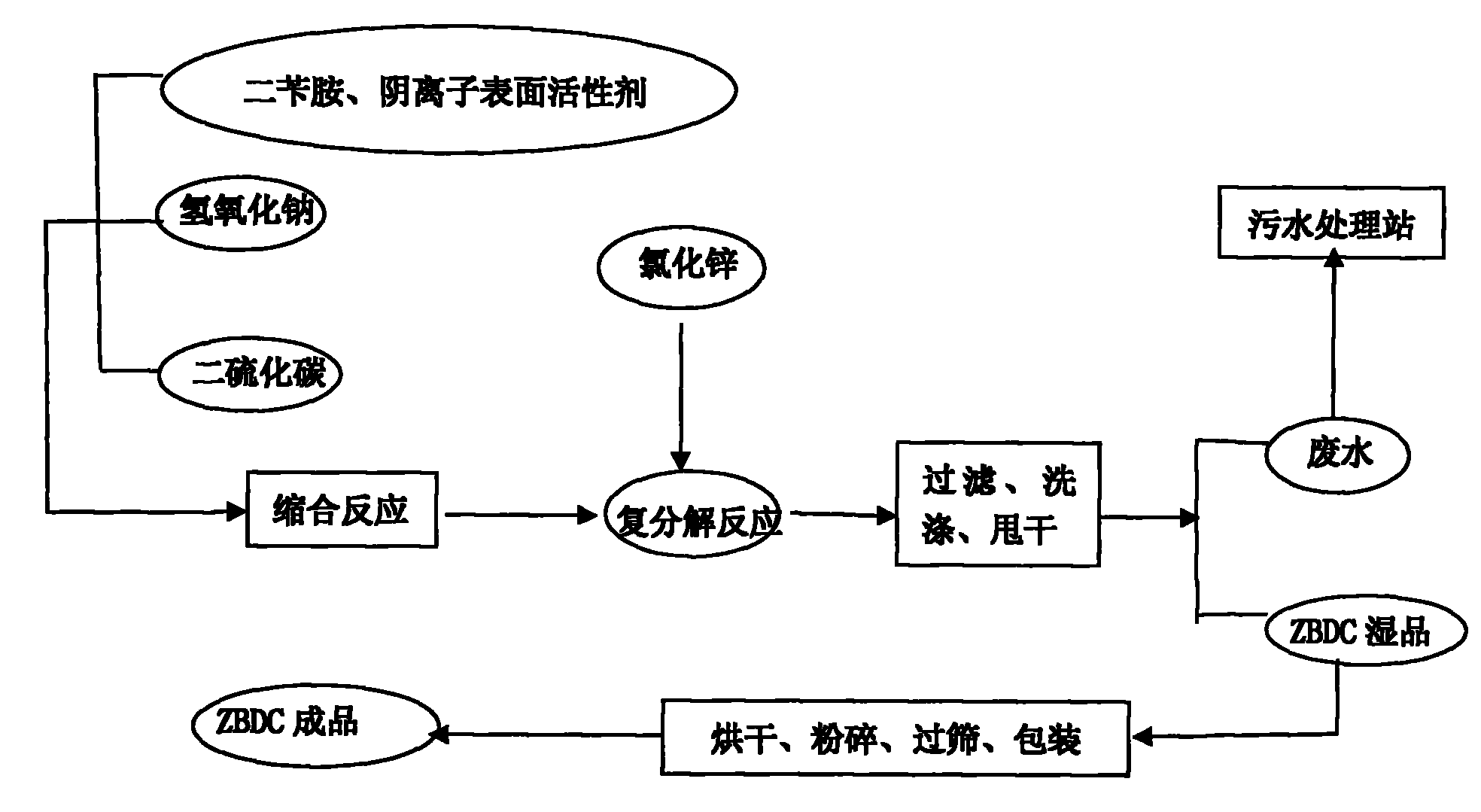

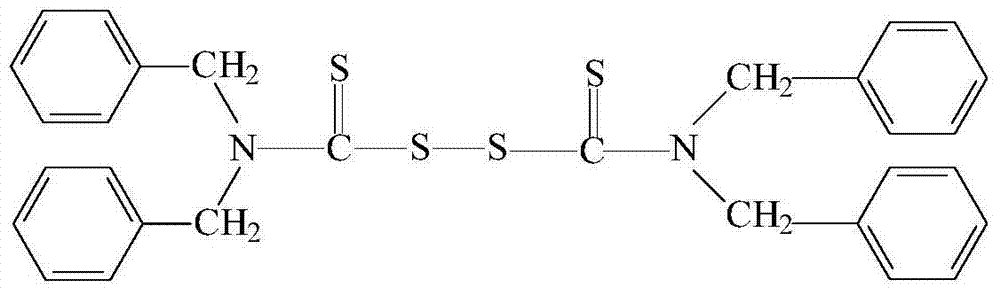

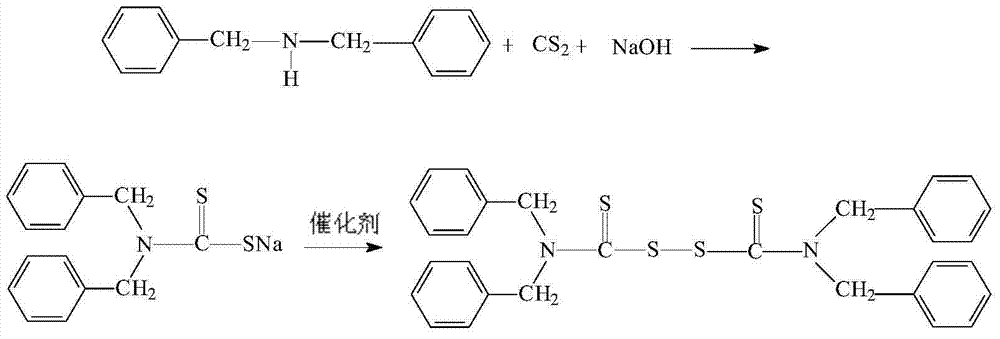

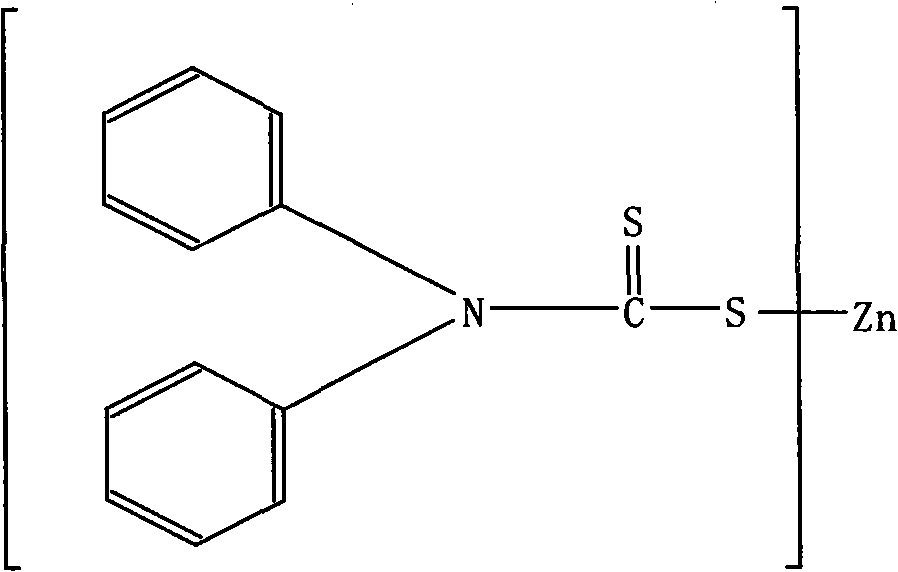

Method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide

ActiveCN101955452AReduce pollutionLess waste waterOrganic chemistryZinc dibenzyldithiocarbamateDodecylsulfonic acid

The invention provides a method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide, which comprises that: the raw materials used are dibenzylamine, carbon disulfide, sodium hydroxide and anionic surfactant, wherein the stoichiometric molar ratio of dibenzylamine to carbon disulfide to sodium hydroxide and anionic surfactant to zinc chloride to sulfuric acid is 1:1.05-1.2:1.05-1.2:0.020-0.025:0.53-0.58:0.005-0.015; and the process comprises: adding dibenzylamine, carbon disulfide, sodium hydroxide and anionic surfactant in a given amount into a reaction kettle holding purified water with stirring in turn, lower the temperature by 10 to 20 DEG C totally, dripping carbon disulfide liquid in a given amount within 6 to 7 hours, stirring for 0.5 to 1 hours after the dripping is finished, keeping the temperature at 30 to 38 DEG C constantly, dripping solution of zinc chloride, performing replacement reaction, regulating the pH value of the reaction liquid to 7 to 9 with sulfuric acid after the replacement reaction is finished, finishing the reaction, stirring for 1 to 2 hours, performing solid-liquid separation, discarding liquid and drying, crushing, sieving and packaging the solid. The anionic surfactant is sodium dodecyl sulfate.

Owner:WILLING NEW MATERIALS TECH CO LTD

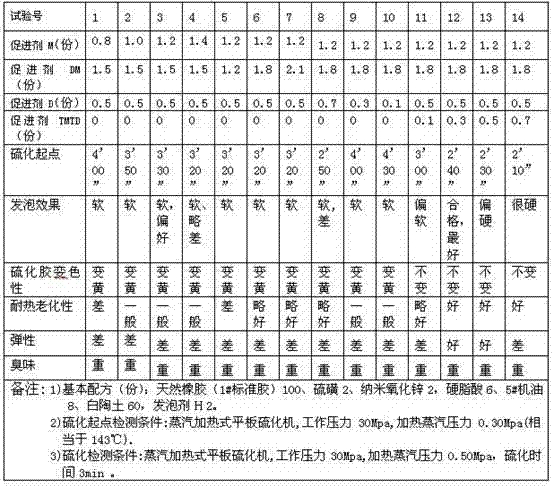

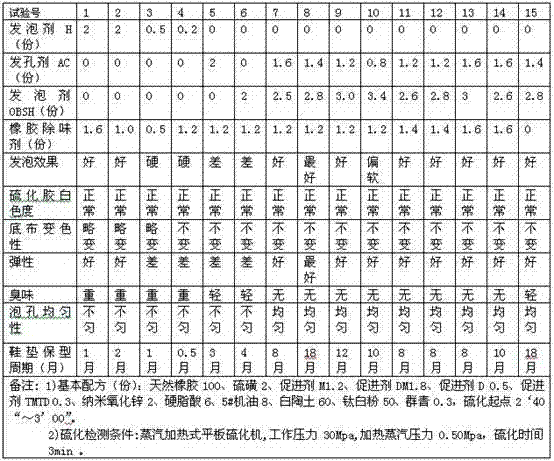

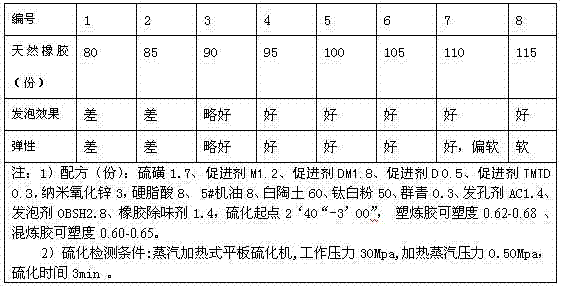

Natural rubber white odorless spongy cushion for in situ color-protecting shoes and preparation method thereof

ActiveCN102391550APrevent high temperature agingShort vulcanization timeInsolesLaminationActivated carbonPolymer science

The invention discloses a natural rubber white odorless spongy cushion for in situ color-protecting shoes and a preparation method thereof. The raw materials of the spongy cushion comprises natural rubber, sulfur, an accelerating agent, a vulcanizing active agent, a hole-forming agent AC (activated carbon), titanium white, 5# engine oil, kaolin, a rubber odor-removing agent and a foaming agent OBSH (oxybis(benzenesulfonyl hydrazide)). In the invention, the odorless spongy for shoes is prepared by utilizing the natural rubber as a main body; vulcanization is promoted by using a thiuram accelerating agent TMTD (tetramethyl thiuram disulfide) to inhibit the high-temperature ageing of the natural rubber, thereby ensuring that titanium white and kaolin filled white spongy rubber do not generate high yellowing to discolor the bottom surfaces in the shoes; the foaming agent AC and OBSH are jointly used, so as to achieve the shape keeping property and even bubbles and low odor of the inner bottoms of the spongy shoes; because no water gas is generated in the foaming process of spongy, heterochromatic substances are not dissolved and transported to cause the yellowing and discoloring of white soft goods of the inner bottoms of the shoes, thus the spongy cushion has abundant white keeping capacity; and the odor generated in the process of vulcanizing the spongy rubber can be effectively removed through the rubber odor-removing agent.

Owner:际华制鞋工业有限公司

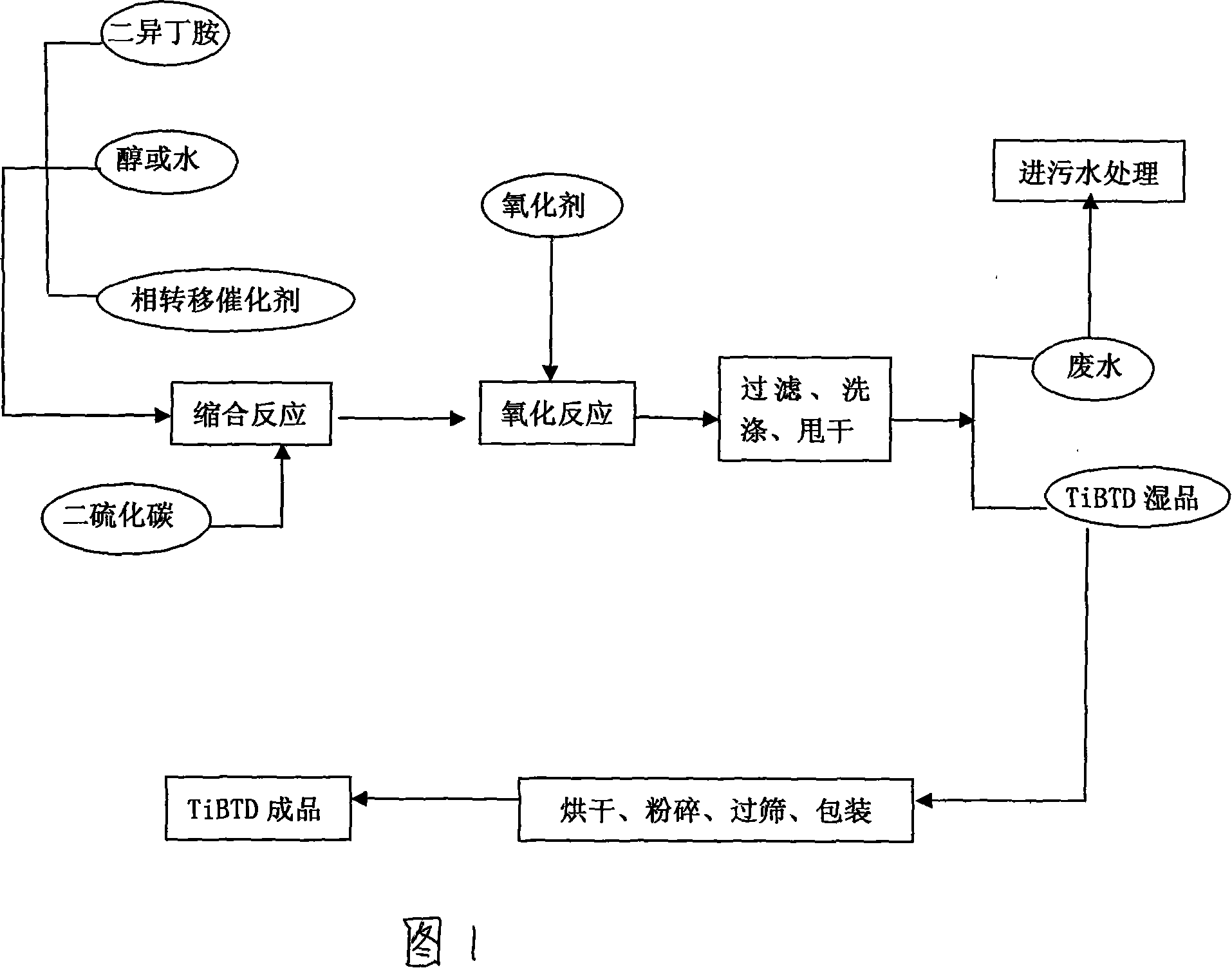

Process for producing vulcanization of rubber accelerant disulfide diisobutyl thiuram

A production method of the diisobutylthiuram disulfide-accelerant of the vulcanization of rubber is provided, which is the production method of the accelerant of the vulcanization of rubber. The method overcomes the defects existing when others produce the product. The raw materials and the mixture ratio of the invention are diisobutylamine : carbon disulfide : oxidant equals to 1 : 1-1.3 : 0.35-0.55; the production method is that enamel reaction axe with volume of 2000L is added with the diisobutylamine, alcohols or water and phase transfer catalyst with specified amount in turns; the cooling water is turned on with temperature reduced to the preferential temperature and is added with carbon disulfide liquid measured accurately by drops, and the time is controlled; after added by drops, the pH value of the reaction liquid is measured to the specialized range; after the pH value is stable, the preferential temperature is controlled and the oxidant is added by drops to carry out oxidation reaction. After the oxidation reaction, the insulation temperature is kept for 1h and solid-liquid separation is conducted to abandon the liquid and dry, crush, sieve and pack the solid.

Owner:WILLING NEW MATERIALS TECH CO LTD

Novel vulcanization system-containing chlorinated polyethylene mixed rubber and processing technology

The invention provides novel vulcanization system-containing chlorinated polyethylene mixed rubber and a processing technology, and relates to a novel vulcanization system of chlorinated polyethylene rubber mixed rubber and a processing technology for the mixed rubber. The system is composed of, by weight, 100 parts of chlorinated polyethylene, 8-20 parts of light magnesium oxide, 3-9 parts of calcium hydroxide, 0-2 parts of methyl tin, 0-5 parts of mold releasing agents, 20-200 parts of reinforcing filling agents, 10-100 parts of plasticizers and 2-6 parts of vulcanization crosslinking systems. The technology process relates to the mixing temperature and the charging sequence, and the mixed rubber which is mixed uniformly and suitable for processing products is ensured. When the mixed rubber is compared with traditional products, the vulcanization speed is fast, and the vulcanized rubber has good mechanical properties. The mixed rubber has low cost compared with foreign products with the same effects.

Owner:烟台恒鑫化工科技有限公司

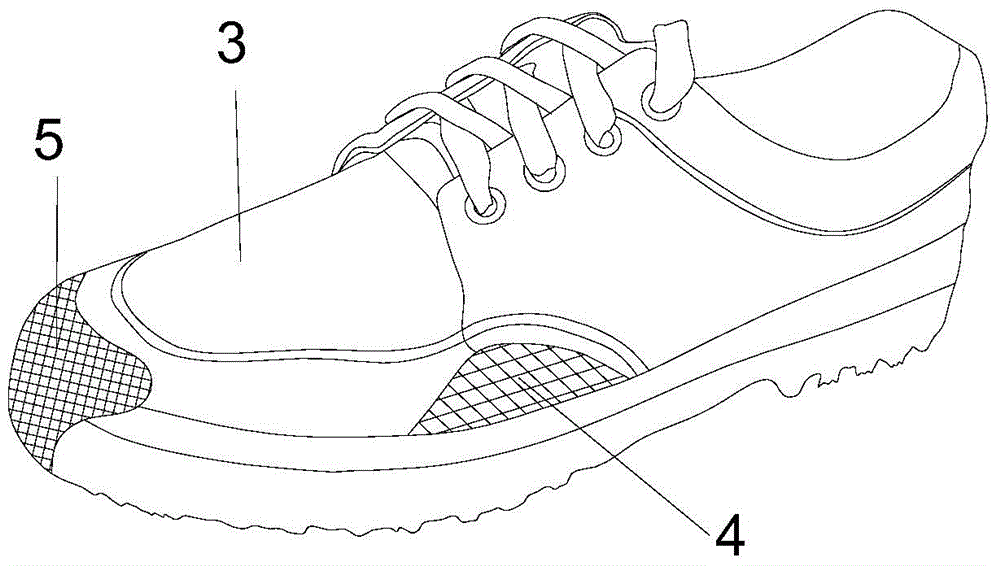

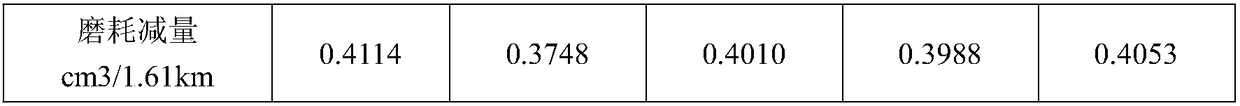

Wear-resistant insulating shoe

The invention discloses a wear-resistant insulating shoe. The wear-resistant insulating shoe comprises a shoe upper and a shoe outsole. The shoe upper and the shoe outsole are glued together through heat vulcanization rubber latex paste. The shoe outsole is made of a rubber compound raw material. The rubber compound raw material comprises, by weight, 20-35 parts of domestic number two standard rubber, 65-75 parts of butadiene rubber, 2-5 parts of accelerant, 2-7 parts of insoluble sulfur, 1-3 parts of activated zinc oxide, 1-3 parts of stearic acid, 1-3 parts of anti-aging agent, 1-4 parts of active agent, 45-65 parts of white carbon black, 25-35 parts of softener, 8-12 parts of tackifier, 1-5 parts of intermediate super abrasion furnace black, and 0.01-1 part of peptizer. Due to the fact that the shoe outsole is made of the novel rubber compound raw material, the wear-resistant insulating shoe has the advantages of being high in strength, high in wear resistance, resistant to flexing and long in service life.

Owner:JIHUA 3539 SHOE MAKING

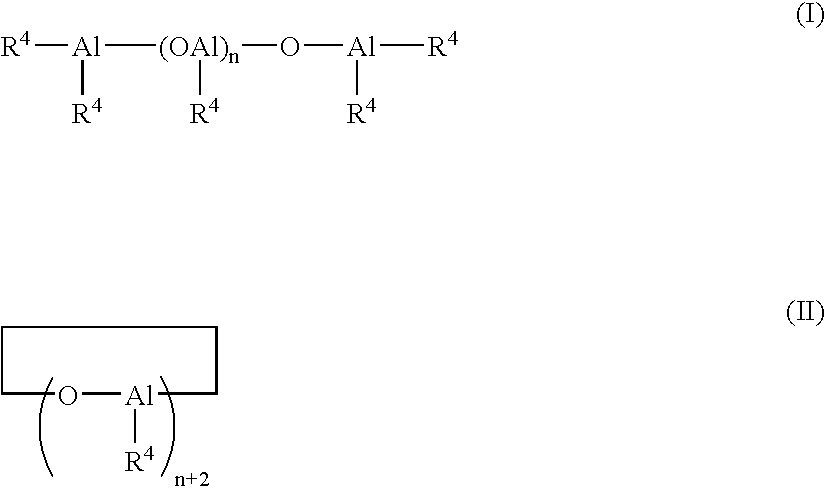

Silane-Coupling-Agent-Treated Silica, Preparation Method Thereof, And Vibration-Damping And Vibration-Isolating Rubber Composition Containing The Same

InactiveUS20090143538A1Lower Mooney ViscosityImprove machinabilitySilicon organic compoundsPigmenting treatmentTO-18Polymer science

A silane-coupling-agent-treated silica having a sulfur-deviation range of 50 to 200%, comprising 100 parts by mass of silica surface-treated with 1 to 50 parts by mass of a silane coupling agent represented by the following general formula (1): Y3-Si-Z-S—CO—R (wherein Y is an acetoxy group or an alkoxy group with 1 to 6 carbon atoms, Z is an alkylene group with 1 to 8 carbon atoms, and R is a hydrocarbon group with 1 to 18 carbon atoms) is disclosed. Furthermore, a vibration-damping and vibration-isolating rubber composition comprising 100 parts by mass of a raw rubber material having C—C bonds in the main chain and 1 to 200 parts of the aforementioned silane-coupling-agent-treated silica is claimed.

Owner:DOW CORNING TORAY CO LTD

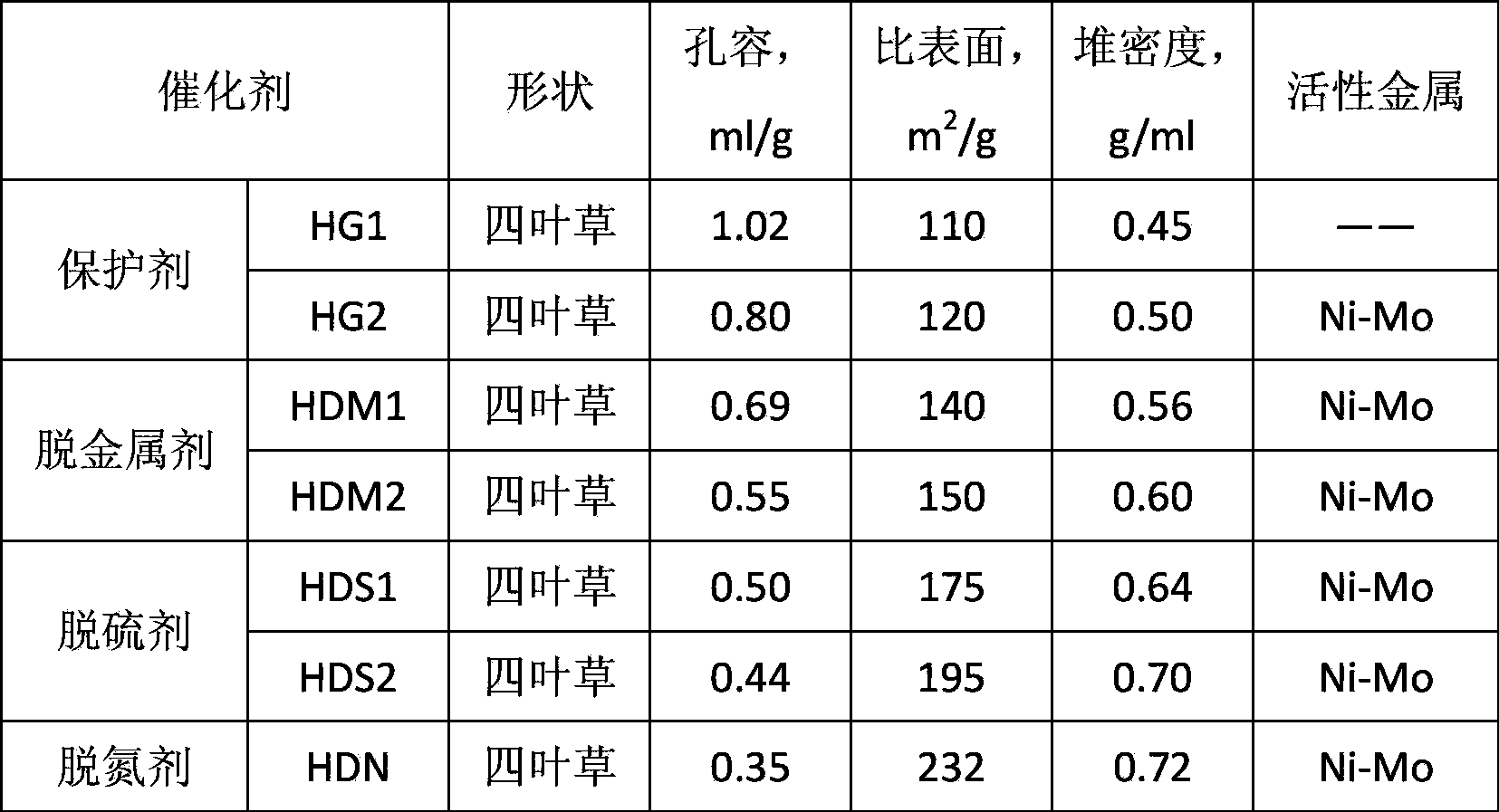

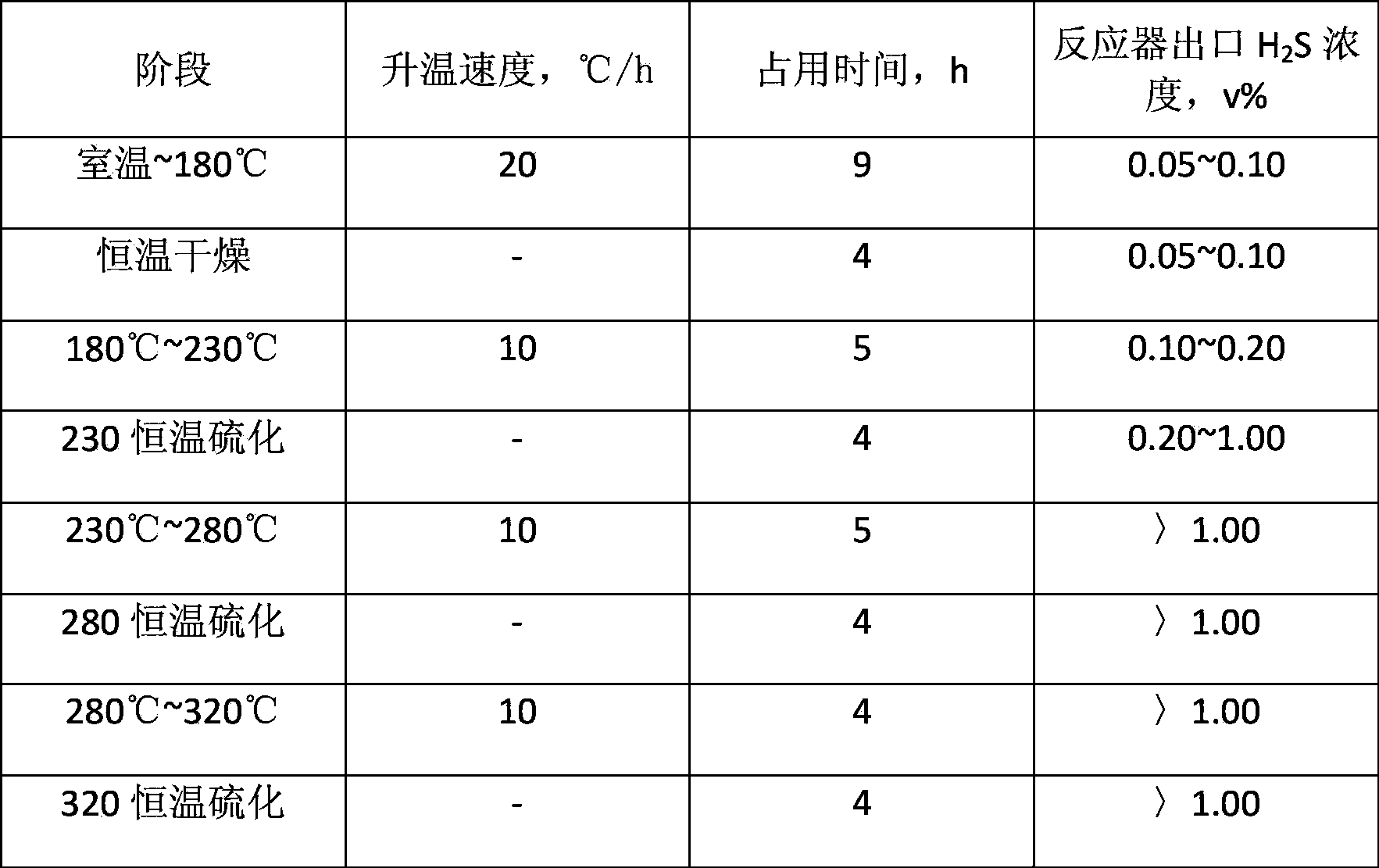

Pre-sulfurizing process of hydrogenation catalyst

InactiveCN101041143AReduce lossesReduce the impact of diffusionCatalyst activation/preparationRefining to eliminate hetero atomsOxidation stateNickel sulfide

The invention relates to a prevulcanization method of hydrogeneration catalyst. The method makes ammonium thiosulfate be loaded on oxidation state catalyst of ni-mo or ni-w and the load quantity is based on the sulfur in ammonium thiosulfate. According to the stoichiometric method, needed sulfur when molybdenum trioxide or tungten trioxide is reduced and sulfurized into molybdenum dioxide or tungten dioxide is 0.5-2 times of needed sulfur when nickel oxide is transferred to nickel sulfide and 1-2 times is selected optically. The load method is that the oxidation state catalyst of ni-mo or ni-w is dipped into the ammonium thiosulfate solution and it is dipped for 0.5-8 hours. The catalyst after dipped is dried for 1-24 hours under the room temperature to 100deg.C in air with normal pressure. The invention is provided with low price, no pollution, simple operation and short sulfurized time.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

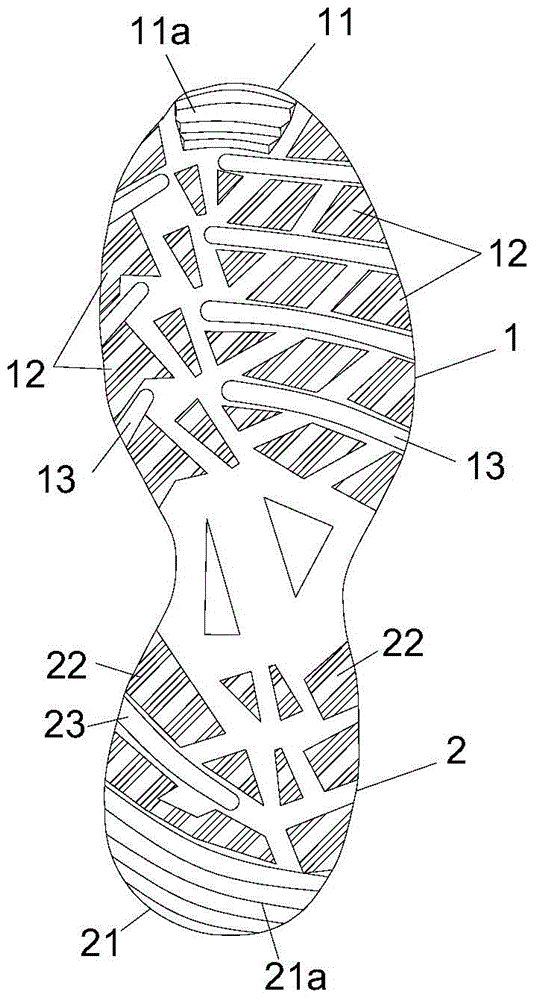

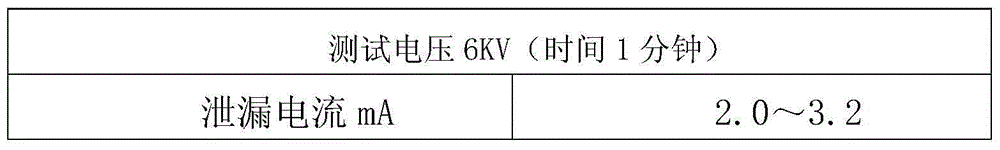

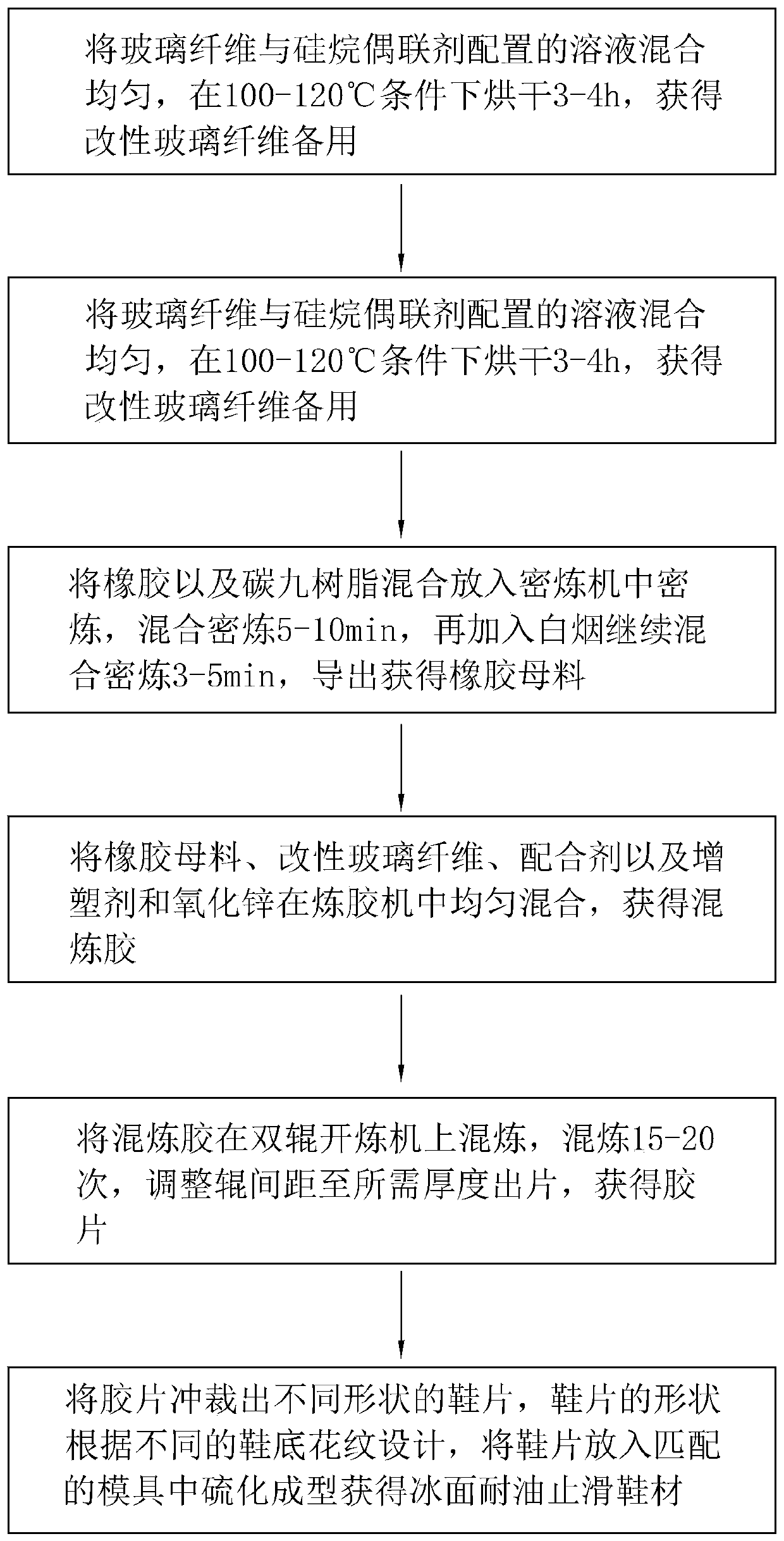

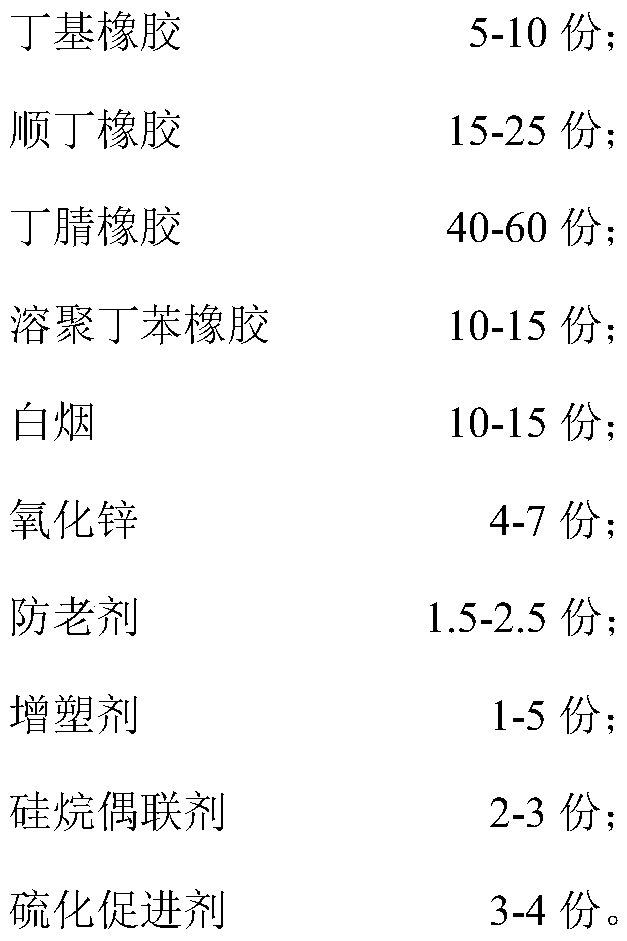

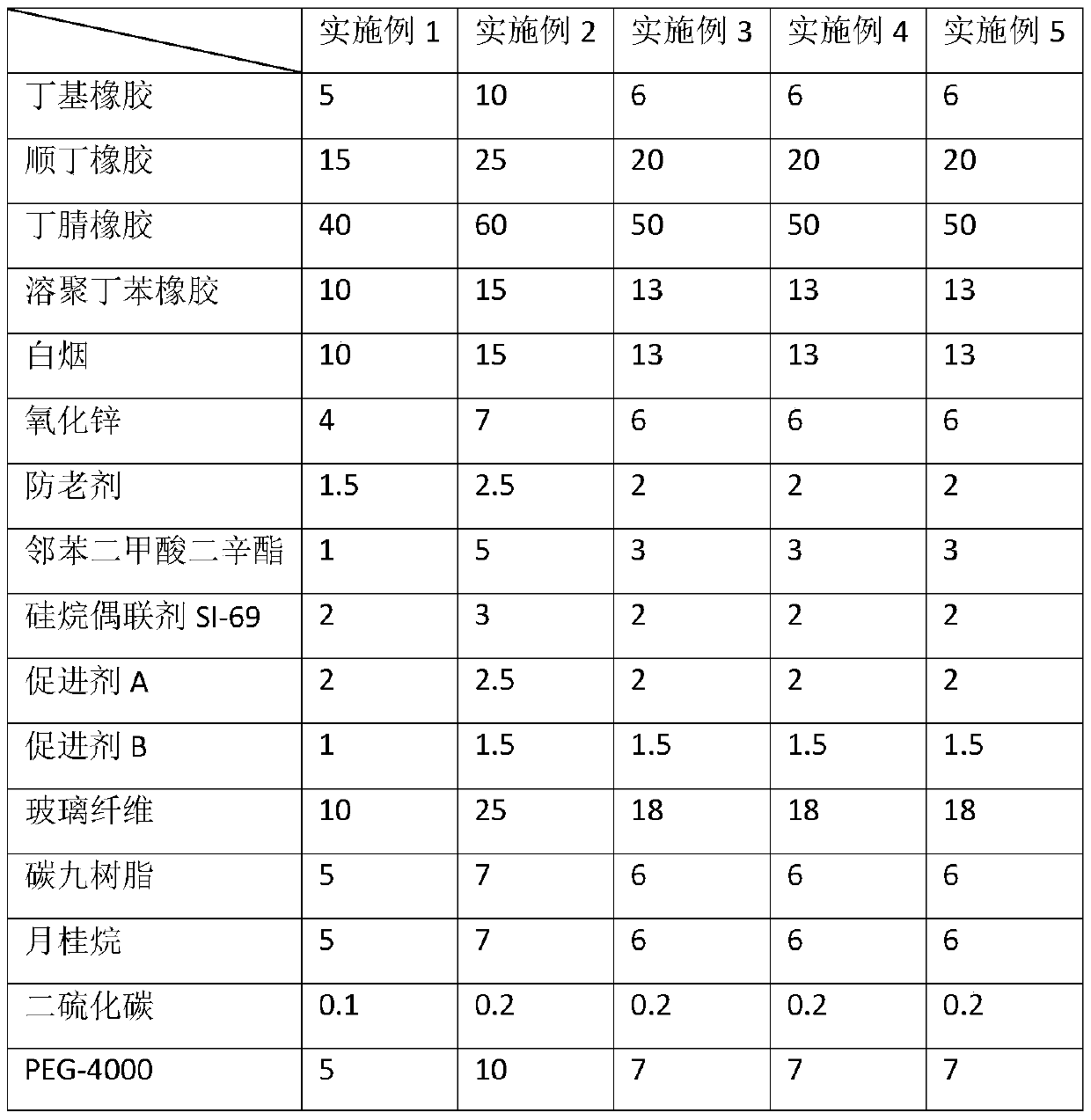

Ice-surface oil-resistant non-slip shoe material and preparation method thereof

The invention discloses an ice-surface oil-resistant non-slip shoe material and a preparation method thereof, and relates to the technical field of shoe materials. The shoe material is prepared from butyl rubber, butadiene rubber, nitrile rubber, solution polymerized styrene-butadiene rubber, white smoke, zinc oxide, an anti-ageing agent, a plasticizer, a silane coupling agent and a vulcanizationaccelerator. The shoe material prepared through the formula is combined with the specific pattern of an outsole and integrally formed or adhered to the outsole, and the obtained sole has the advantages of being resistant to oil and slip, good in mechanical performance, free of fog return and the like. The anti-slip performance is excellent, and the shoe material is suitable for being used on the ice and snow ground.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

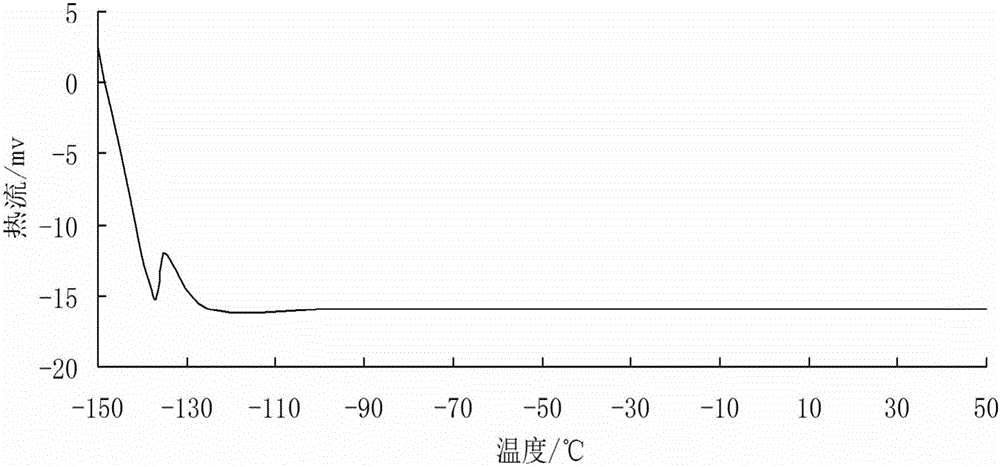

Low-temperature-resistant mixed silicone rubber and preparation method thereof

The invention relates to low-temperature-resistant mixed silicone rubber and a preparation method thereof. The silicone rubber is prepared from raw materials in parts by weight as follows: 100 parts of low-temperature-resistant raw silicone rubber, 7-10 parts of high-vinyl low-temperature-resistant raw silicone rubber, 50-60 parts of white carbon black, 3-5 parts of hydroxyl silicone oil, 0.3-1 part of dimethoxydimethylsilane, 5-10 parts of hydrogen-containing silicone oil and 0.01-0.05 parts of a platinum catalyst. The invention further relates to the preparation method of the silicone rubber. The silicone rubber has good low-temperature resistance, the tensile strength, the tear strength and other mechanical properties are greatly improved, and the preparation method is simple.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

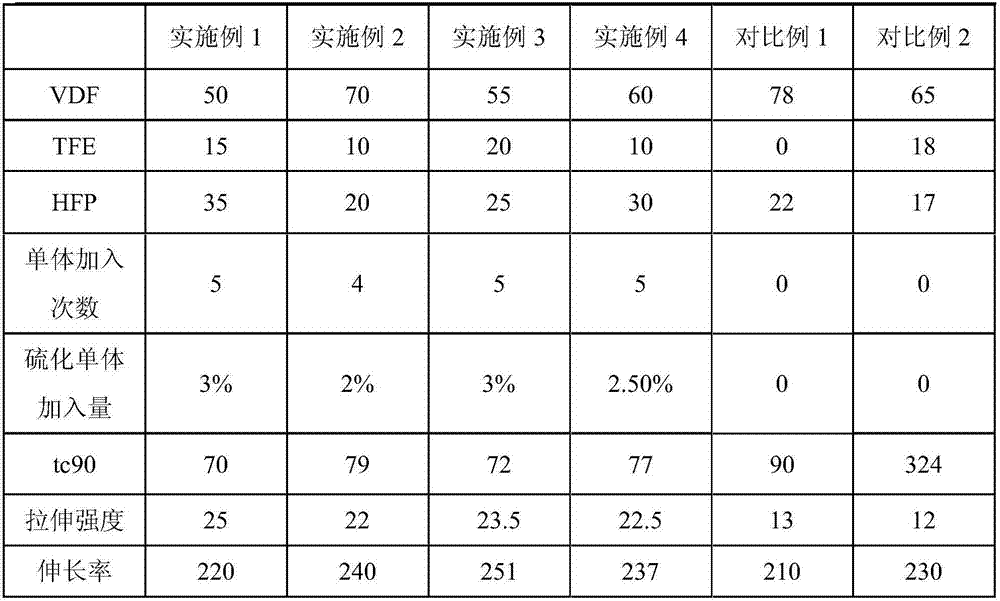

Rapidly vulcanized fluoroelastomer and preparation method thereof

The invention relates to a rapidly vulcanized fluoroelastomer and a preparation method thereof. The rapidly vulcanized fluoroelastomer comprises comonomers. The comonomers comprise two or more of vinylidene fluoride, chlorotrifluoroethylene, tetrafluoroethylene, 3, 3, 3-trifluoropropene, hexafluoropropylene and a perfluoroalkyl ether monomer, and a vulcanization point monomer, wherein a use amount of the vulcanization point monomer is 2-3% that of the comonomers. The rapidly vulcanized fluoroelastomer has high fuel permeability resistance, short vulcanization time, a fast vulcanization rate, low Mooney viscosity and high mechanical properties. The preparation method controls vulcanization time tc90 of the fluoroelastomer within 80s. The rapidly vulcanized fluoroelastomer has Mooney viscosity [ML(1+10 121 DEG C)] of 50-80 DEG C, tensile strength of greater than or equal to 22MPa and elongation of greater than or equal to 230%.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

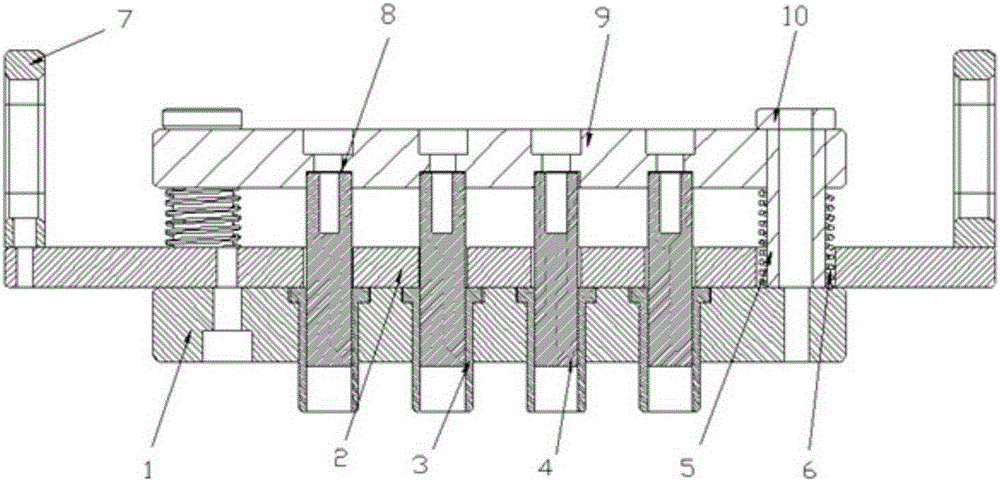

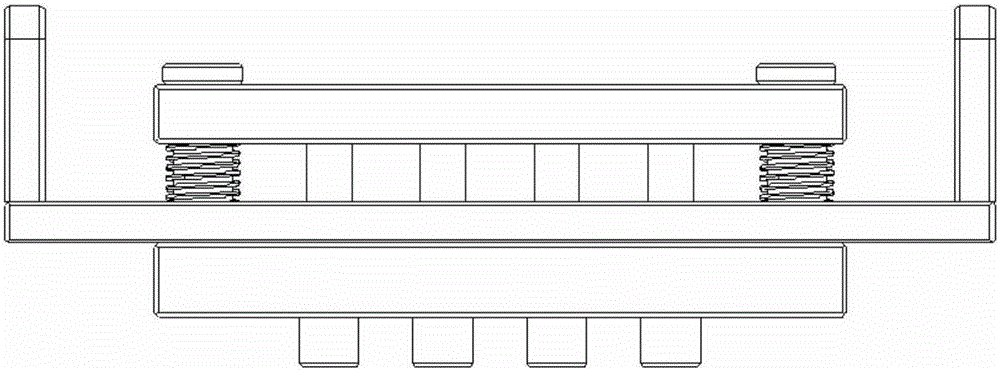

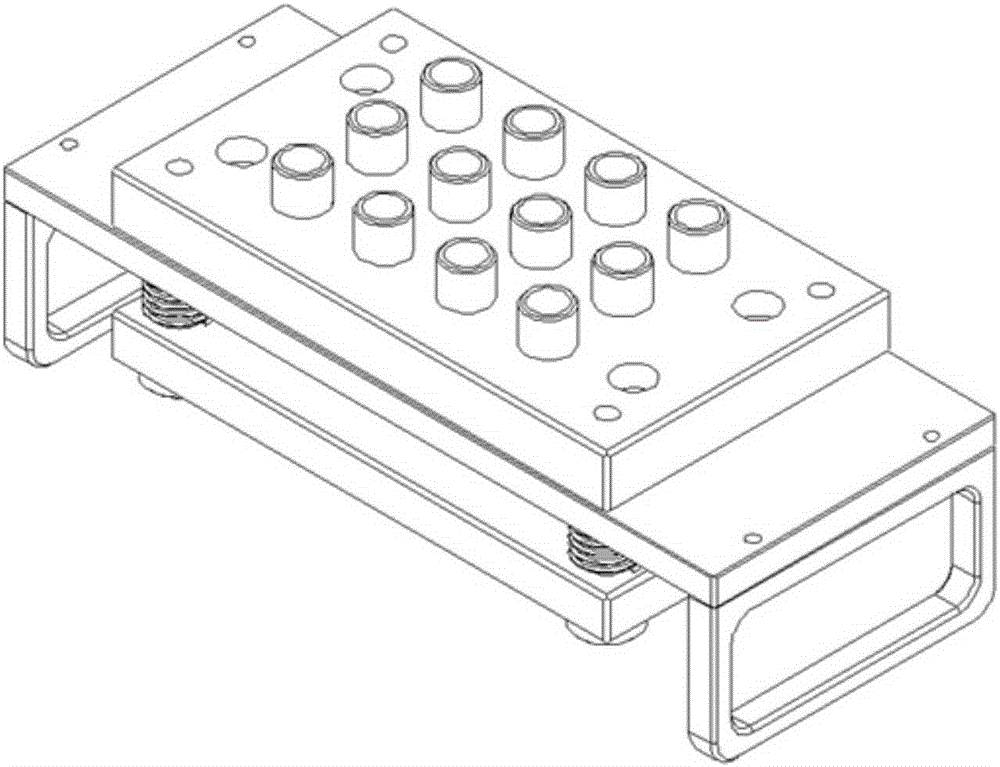

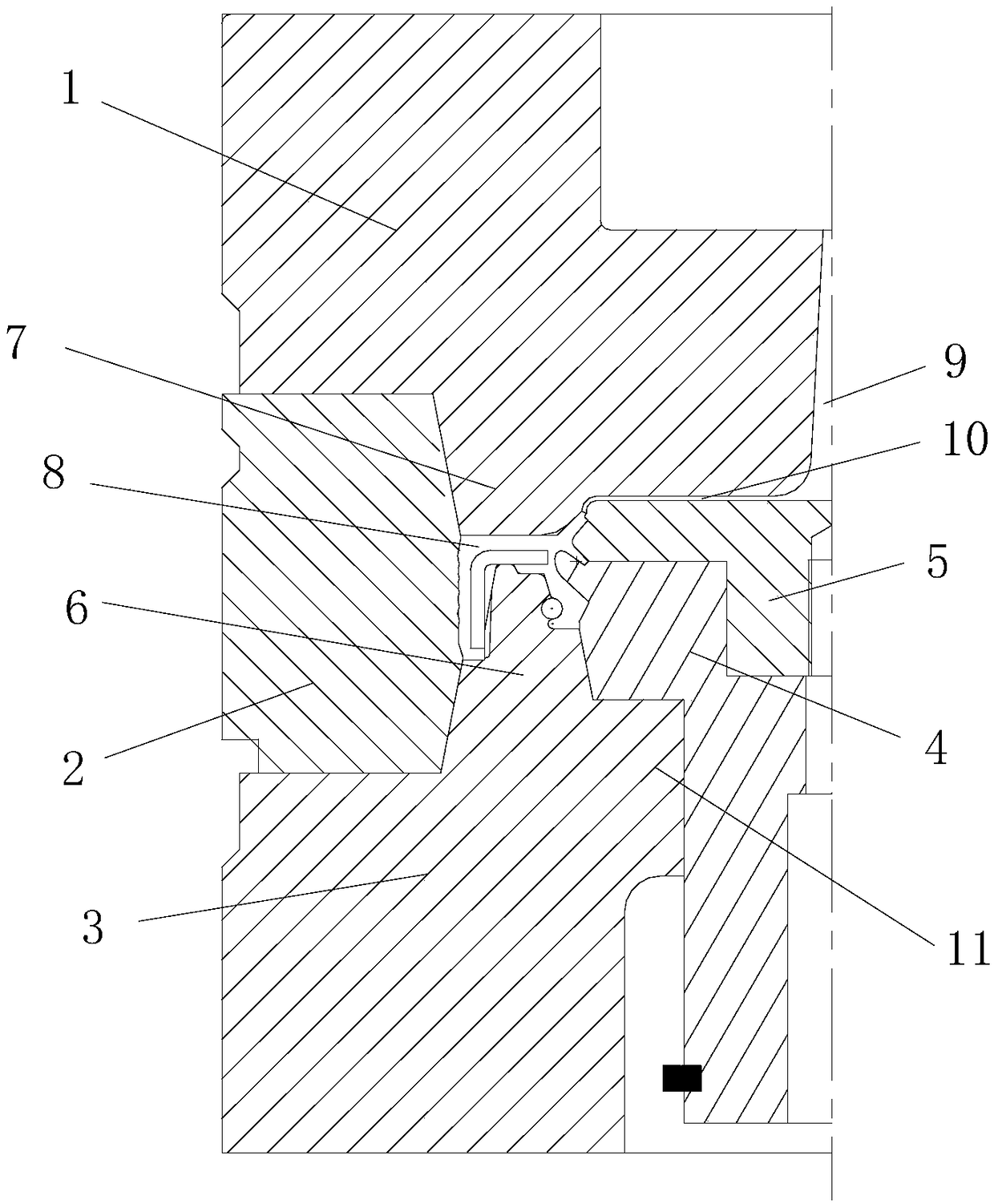

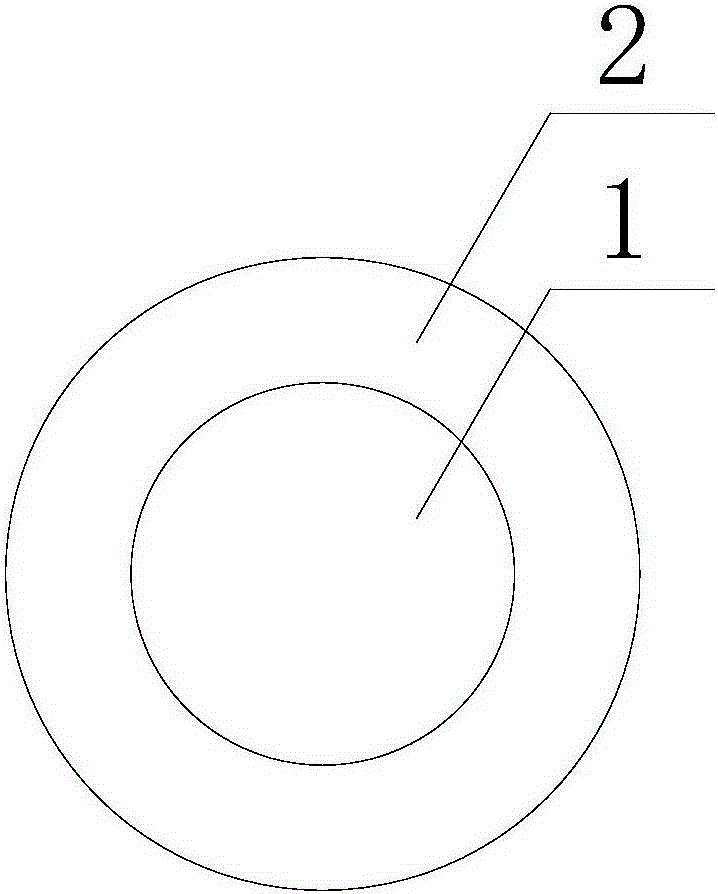

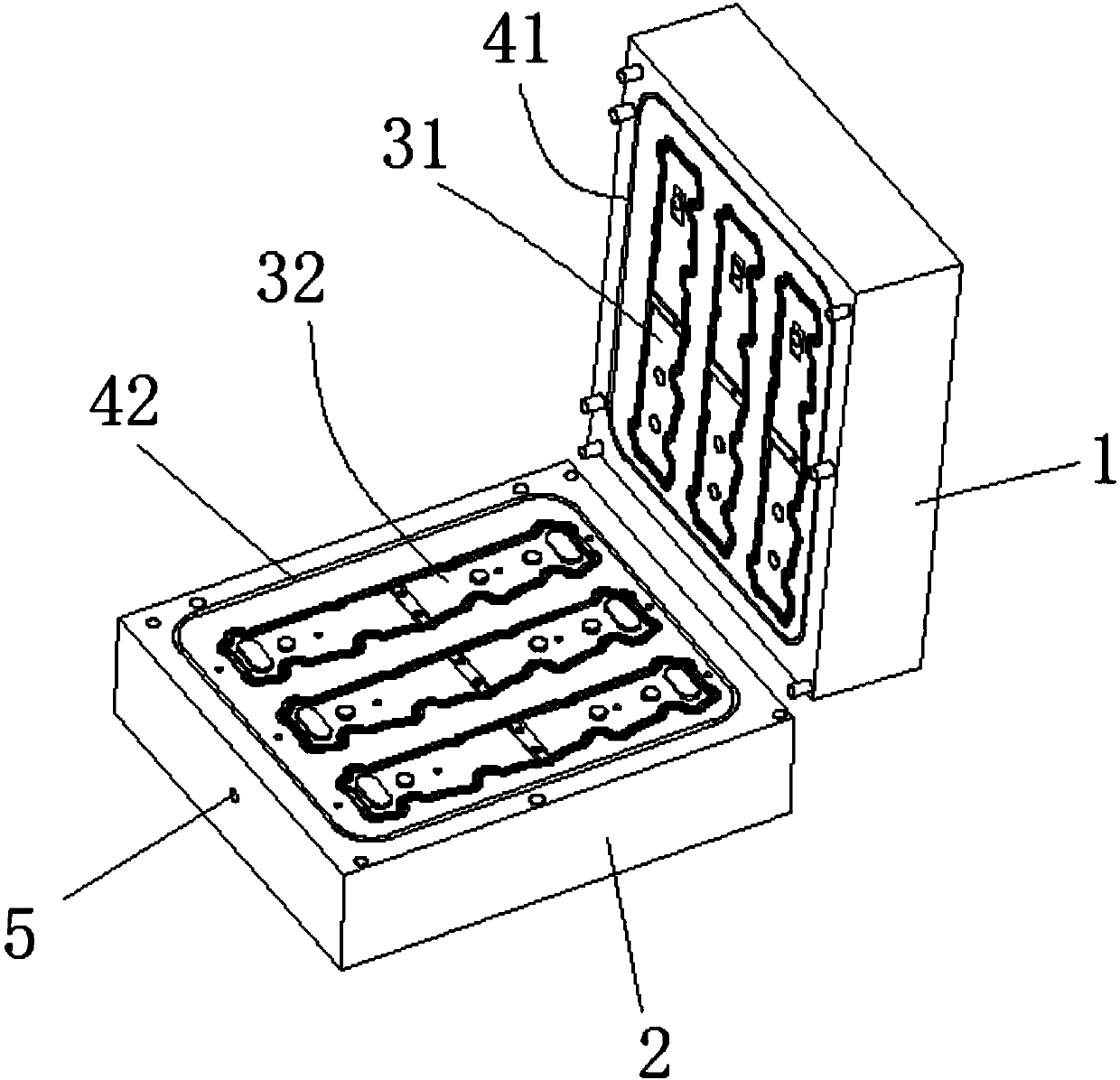

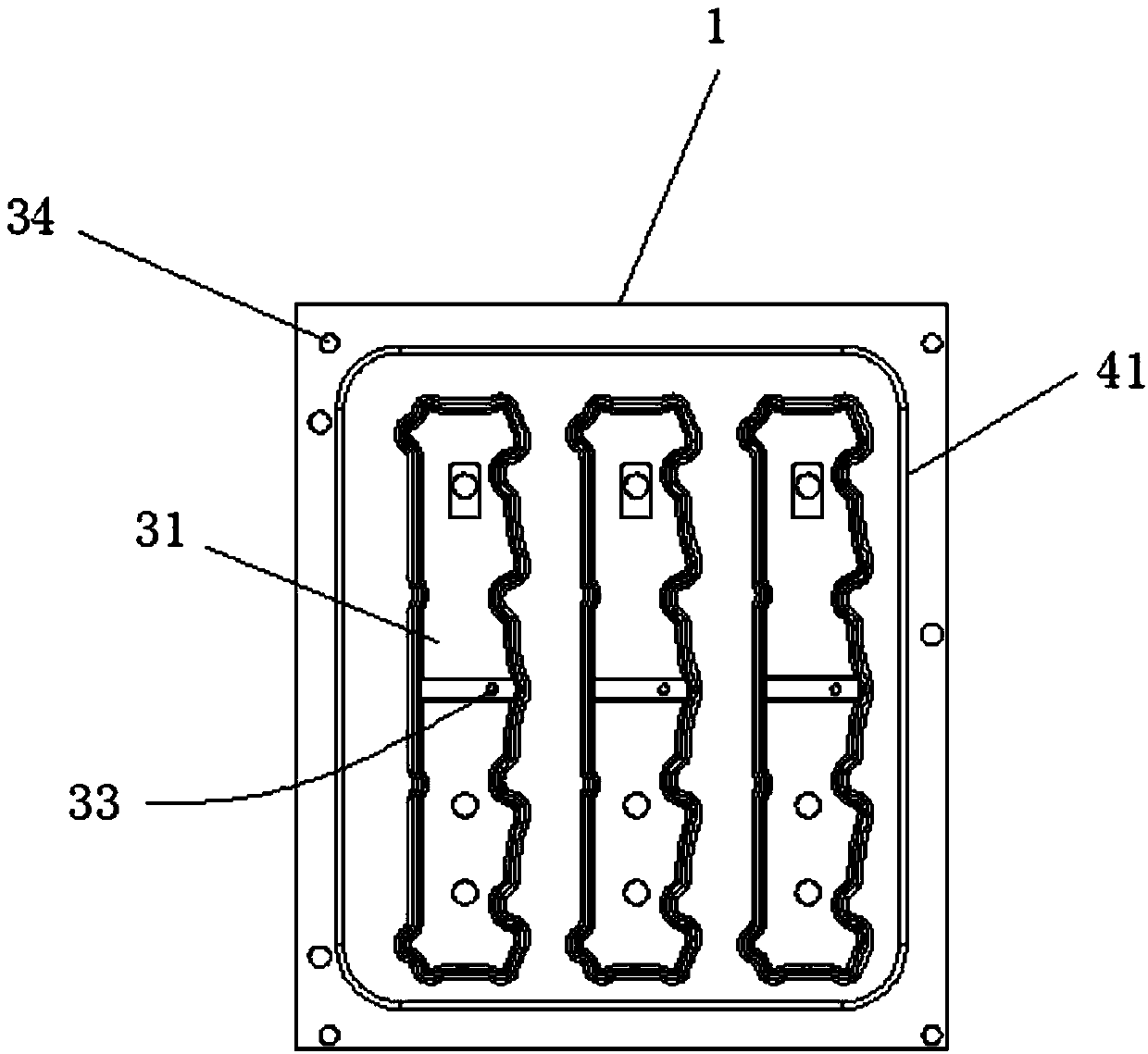

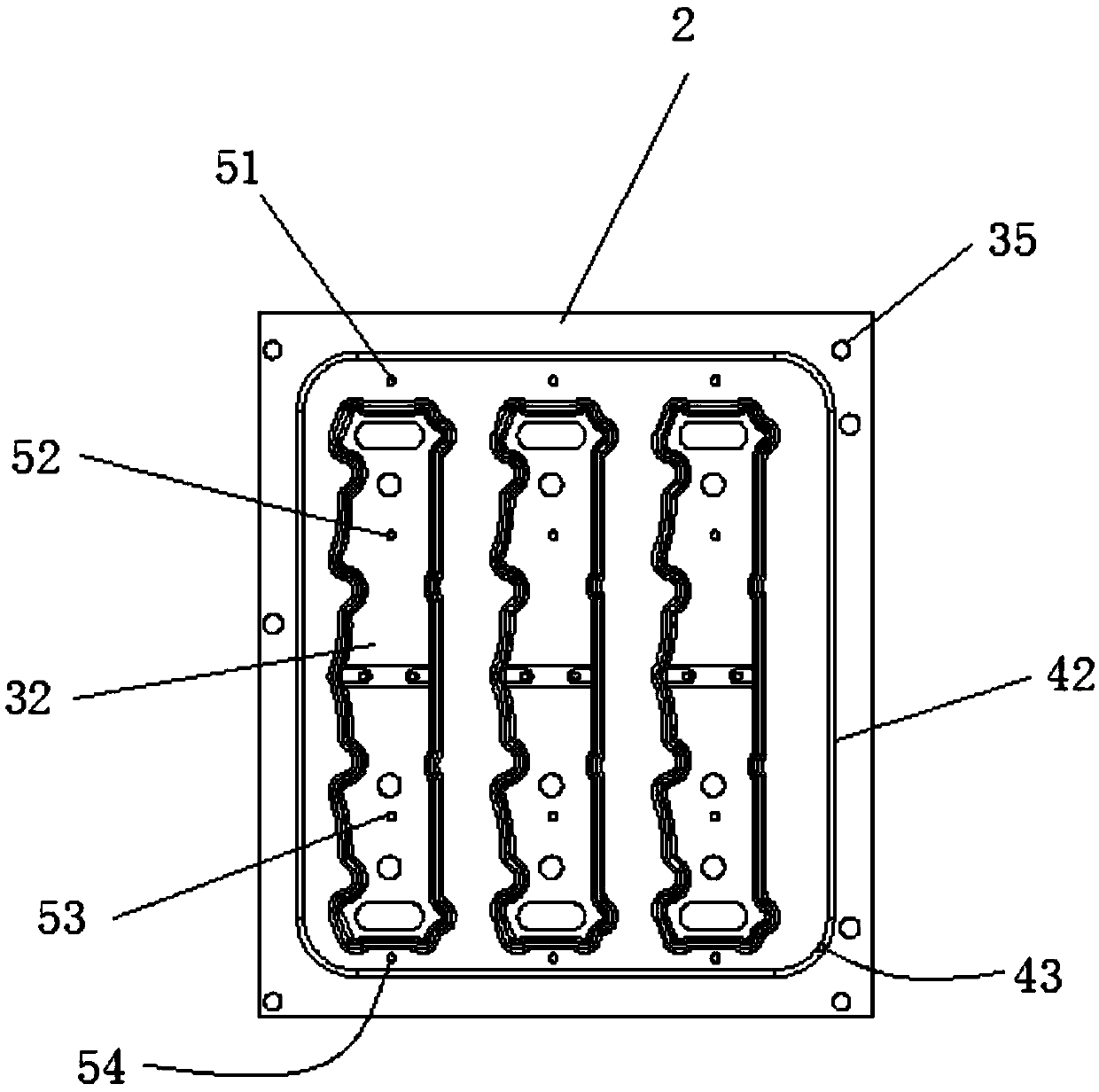

Rapid vulcanization die for building lamination shock insulation rubber bearing

InactiveCN103786282AAvoid heat transfer barriersAchieving direct heat conductionVulcanizationEngineering

The invention discloses a rapid vulcanization die for a building lamination shock insulation rubber bearing. The rapid vulcanization die comprises an inner heating die with a heat conduction strip, an outer heating die with a heat conduction strip, an excessive glue groove, heat conduction strips, an upper heating template, a lower heating template, a positioning shaft, a positioning hole and a positioning shaft mounting groove, wherein the lower heating template is mounted on a support, the outer heating die with the heat conduction strip is arranged on the upper surface of the lower heating template, the inner heating die with the heat conduction strip is arranged in the center of the outer heating die with the heat conduction strip, the height of the outer heating die with the heat conduction strip is equal to that of the inner heating die with the heat conduction strip, and the upper heating template is arranged at the tops of the outer heating die with the heat conduction strip and the inner heating die with the heat conduction strip. The rapid vulcanization die fully utilizes the structural principle of vulcanization equipment and a vulcanization target to realize rapid and uniform vulcanization and efficient mounting, is applicable to vulcanization processing of various rubber bearings, such as a standard rubber bearing, a pencil lead rubber bearing, a high damping rubber bearing and a stacked rubber bearing, and is high in vulcanization efficiency and rapid and convenient to mount and maintain.

Owner:彭勃

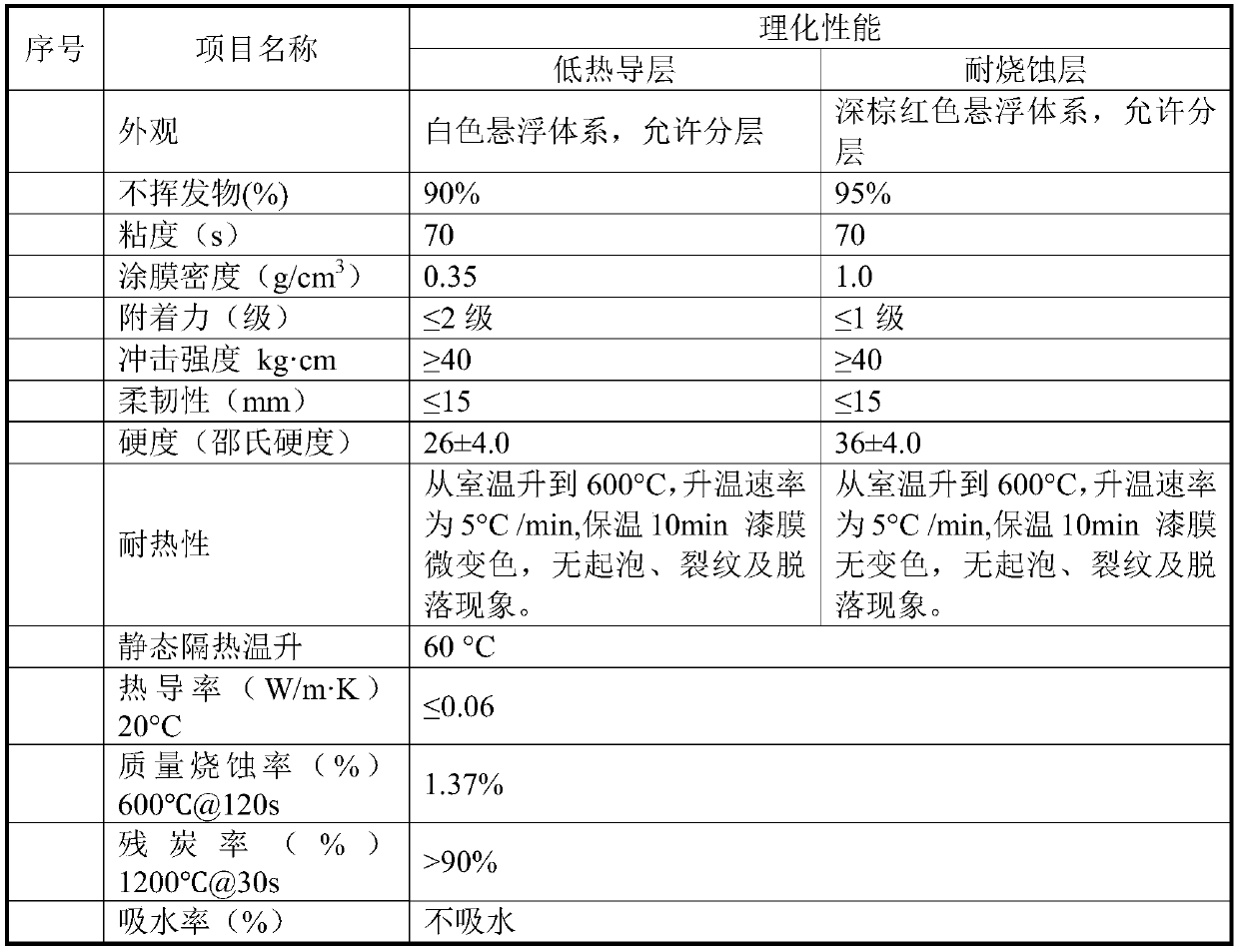

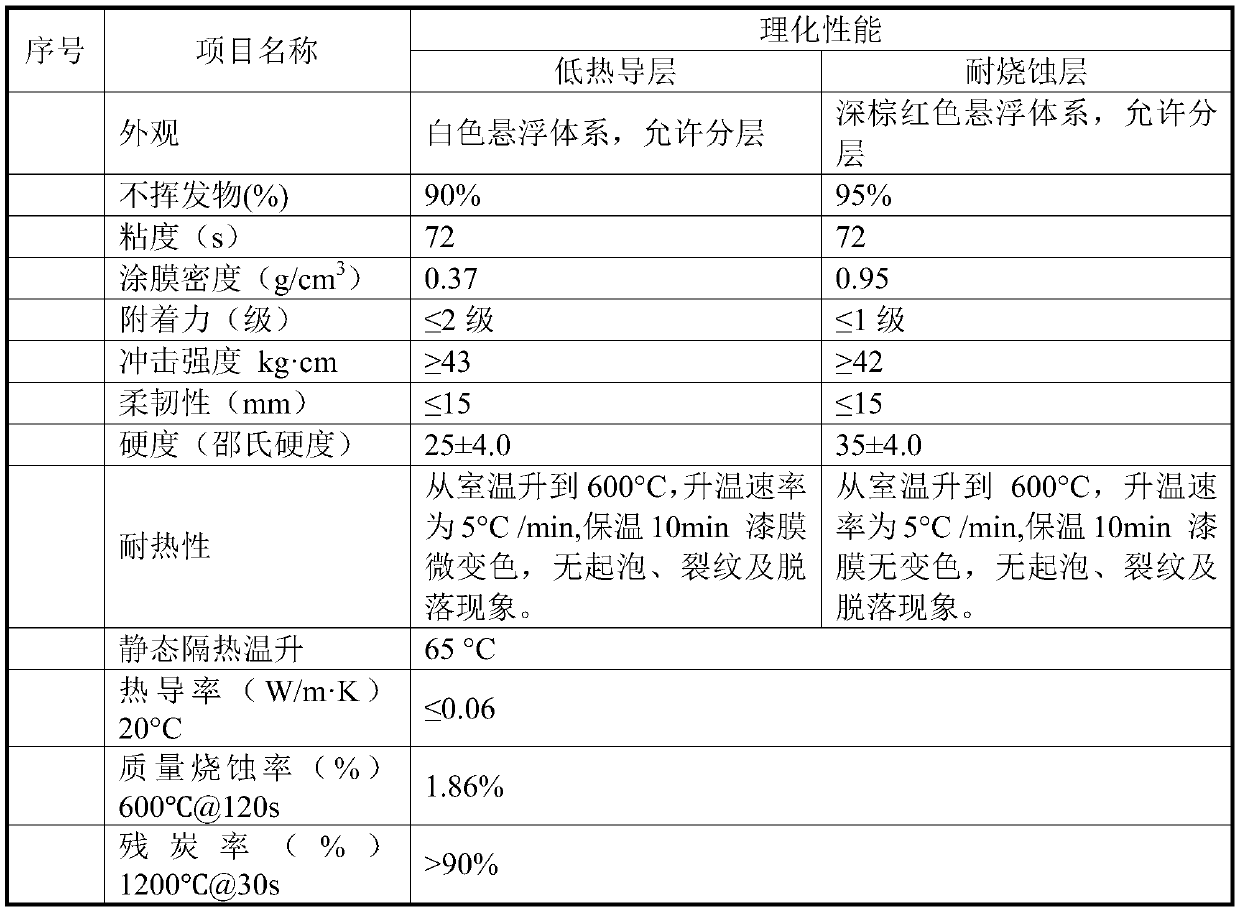

Ablation-resisting light silicone rubber thermal insulation coating

The invention relates to an ablation-resisting light silicone rubber thermal insulation coating. The ablation-resisting light silicone rubber thermal insulation coating comprises an inner low-thermal-conductivity layer and an outer ablation-resisting layer at a thickness ratio of 2-10:1-5, wherein the ablation-resisting layer is prepared from three components and releases heat via mass loss; the low-thermal-conductivity layer is prepared from three components and reduces longitudinal heat conduction through ultra-low thermal conductivity. Compared with the prior art, the ablation-resisting light silicone rubber thermal insulation coating has the advantages of being low in mass ablating rate, high in heat resistance and long in service life at high temperatures and can effectively resist impact of heat flow of 500 kW / m2 and above, reduce temperature increase of base plates and prevent base materials from losing efficacy due to high-temperature erosion.

Owner:SHANGHAI JIAO TONG UNIV +1

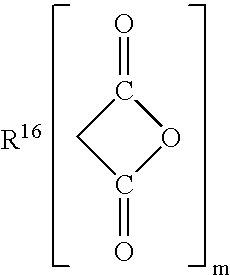

Golf ball

InactiveUS7223819B2Good shot feelGood extrusion processing performanceGolf ballsSolid ballsRare-earth elementOrganosulfur compounds

A golf ball which is formed from a vulcanized rubber compound composed of 100 parts by weight of a rubber base material, 10 to 60 parts by weight of an unsaturated carboxylic acid and / or a metal salt thereof, 0.1 to 5 parts by weight of an organosulfur compound, 5 to 80 parts by weight of an inorganic filler, and 0.1 to 3 parts by weight of an organic peroxide, the rubber base material being composed of a first polybutadiene accounting for 50 to 95 wt % and a second polybutadiene accounting for 5 to 50 wt %, both polybutadiene being synthesized by using a rare earth element-based catalyst, the first polybutadiene containing no less than 60 wt % of cis-1,4 bonds and having a Mooney viscosity (ML1+4 (100° C.)) no lower than 50 and the second polybutadiene containing no less than 60 wt % of cis-1,4 bonds and having a Mooney viscosity (ML1+4 (100° C.)) no higher than 45. The golf ball is characterized by good rebound resilience and good workability with which it is produced.

Owner:BRIDGESTONE SPORTS

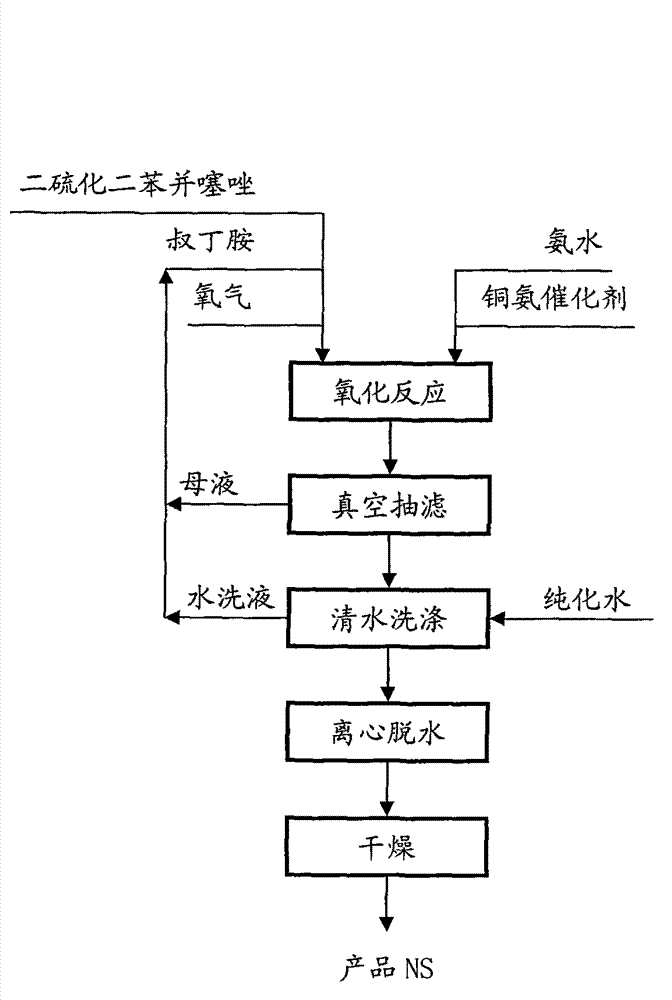

Preparation method of rubber vulcanization accelerator N-tert-butyl-2-benzothiazole sulfonamide (NS)

The invention provides a preparation method of a rubber vulcanization accelerator N-tert-butyl-2-benzothiazole sulfonamide (NS). A specific process as below: adding 30-60ml of ammonia; weighing 33.25g of Dithio-dibenzo thiazole, 0.10-0.25g of a copper ammonia catalyst and a surface active agent under oxygen pressure of 0.2-0.8MPa, and adding into a reaction kettle; slowly injecting 15.36-19.02g of tert-butylamine by a metering pump to generate a target product at a reasonable reaction temperature; and conducting centrifugation, washing and drying to obtain the product NS. The method provided by the invention can effectively reduce the treatment amount of organic wastewater, reduce comprehensive cost, and has advantages of few raw material varieties, high reaction selectivity, high yield and short cycle; and the method is better than a current production method, and can well meet the demand of high-end market.

Owner:WILLING NEW MATERIALS TECH CO LTD

Preparation method of tetrabutylthiuram disulfide used as rubber vulcanization accelerator

ActiveCN104326956AIncrease the rate of oxidation reactionsIncrease concentrationOrganic chemistrySulfonateVulcanization

The invention relates to a preparation method of tetrabutylthiuram disulfide used as a rubber vulcanization accelerator. By virtue of the preparation method, tetrabutylthiuram disulfide is prepared by a two-step process, namely sodium dibenzyl amino sulfonate is prepared from dibenzylamine, carbon disulfide and sodium hydroxide and then oxidized by a hydrogen peroxide oxidant to prepare tetrabutylthiuram disulfide. According to the preparation method, carbon disulfide is excessive, so that dibenzylamine is fully reacted; excessive unreacted carbon disulfide is separated and recycled in time; the production cost is reduced; the pollution to the environment is low; low-concentration hydrogen peroxide with a concentration of 5-20wt% is used as the oxidant and applied to the oxidation reaction; hydrogen peroxide has the characteristics of being low in cost, stable in property, small in pollution, easy to store and transport and high in safety; the cost can be effectively reduced; the pollution to workers in the operation process is alleviated; the safety is improved; meanwhile, the oxidization effect is not reduced.

Owner:山东斯递尔化工科技有限公司

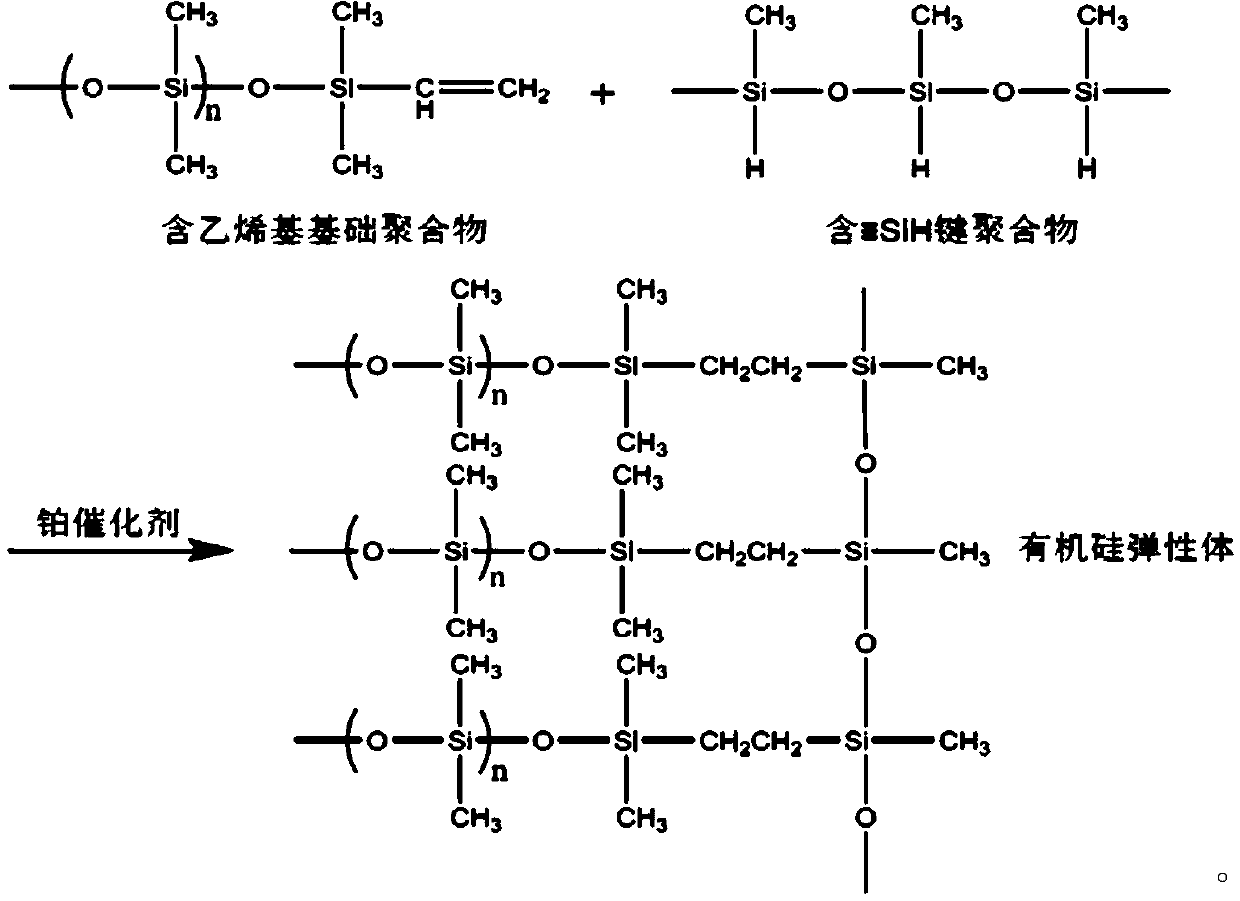

Low-temperature rapidly-vulcanized solid silicon rubber raw material and production method thereof

InactiveCN105255195AShorten vulcanization timeFast vulcanizationMetal working apparatusMasterbatchPlatinum complex

The invention discloses a low-temperature rapidly-vulcanized solid silicon rubber raw material and a production method thereof. The solid silicon rubber raw material contains a silicon rubber raw material, a platinum vulcanizing agent and a color masterbatch which are uniformly mixed together, wherein the platinum vulcanizing agent comprises the main components A and B; the component A is a mixture containing raw vinyl rubber, fumed silica and a platinum complex; the component B is a mixture containing raw vinyl rubber, fumed silica, terminated poly(methylhydrosiloxane) and an inhibitor; the weight ratio of the component A to the component B is 1:1 to 3:1; the mixing ratio of the platinum vulcanizing agent to the silicon rubber raw material is 100:0.1 to 100:5.0; the color masterbatch comprises the following components: raw silicon rubber, an organic toner, silicon oil and a dispersing agent; and the mixing ratio of the mixture of the silicon rubber and the platinum vulcanizing agent to the color masterbatch is 100:0.1 to 100:3.0. The solid silicon rubber raw material disclosed by the invention is particularly suitable for integrally molding a high-temperature-nonresistant material and solid silicon rubber.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Silicone-polymer-modified vulcanized-rubber compositions, processes for their production, and also windshield wipers encompassing said material

InactiveUS20090253866A1Resistance to temperature changeImprove long-term stabilityLiquid processingCarpet cleanersPolymer scienceVulcanization

A silicone-polymer-modified vulcanized-rubber composition based on unvulcanized rubber, characterized in that the composition can be produced by co-vulcanization from the following components:A1) at least one vinyl-reactive polysiloxane component, and / orA2) at least one mercapto-reactive polysiloxane component, andB) at least one unsaturated vulcanizable unvulcanized-rubber component, and to a process for the production of said silicone-polymer-modified vulcanized-rubber composition based on unvulcanized rubber, and also to a windshield-wiper blade encompassing a silicone-polymer-modified vulcanized-rubber composition based on unvulcanized rubber.

Owner:ROBERT BOSCH GMBH

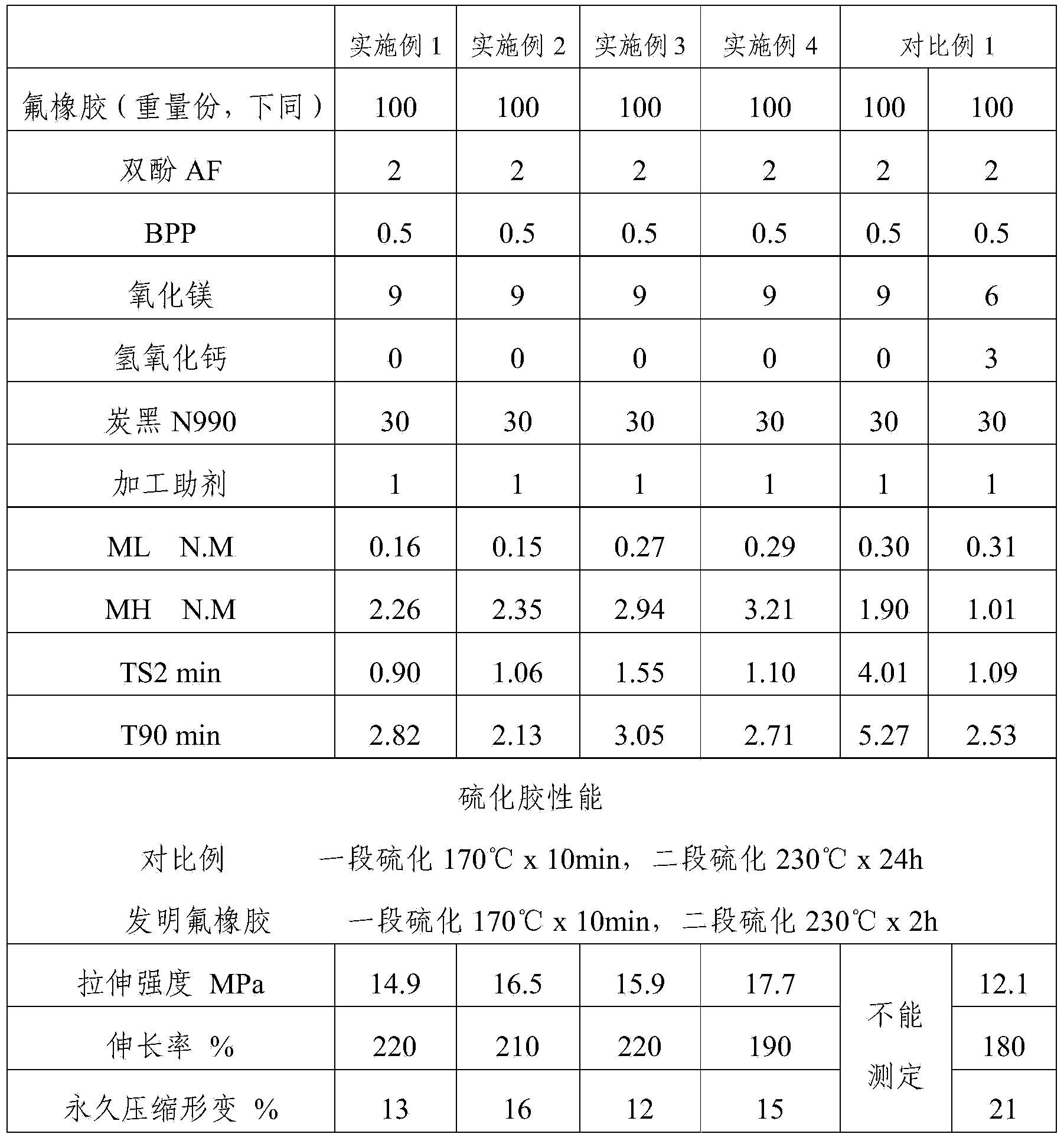

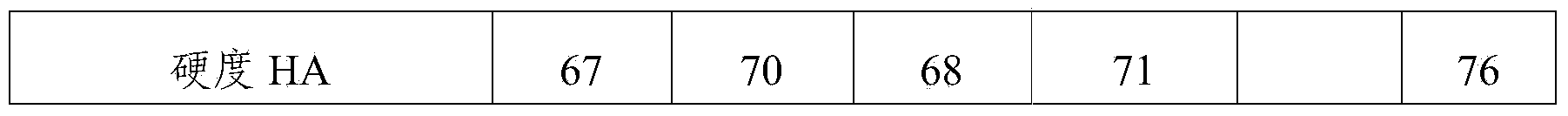

Fluororubber and synthesis method thereof

The invention discloses fluororubber. The monomers of the fluororubber comprise the following components: 30-80mol% of vinylidene fluoride, 10-45mol% of hexafluoropropylene and 0-20mol% of tetrafluoroethylene. The synthesized fluororubber disclosed by the invention is fewer in ionic terminal groups, fast in curing speed, low in hardness, high in tensile strength, and low in pressure change, wherein the number of the ionic terminal groups is smaller than 8 per 106 carbon atoms; the hardness HA is smaller than 74; the tensile strength is greater than 14.5Mpa; and the permanent compression deformation is smaller than 17%.

Owner:CHENGUANG RES INST OF CHEM IND

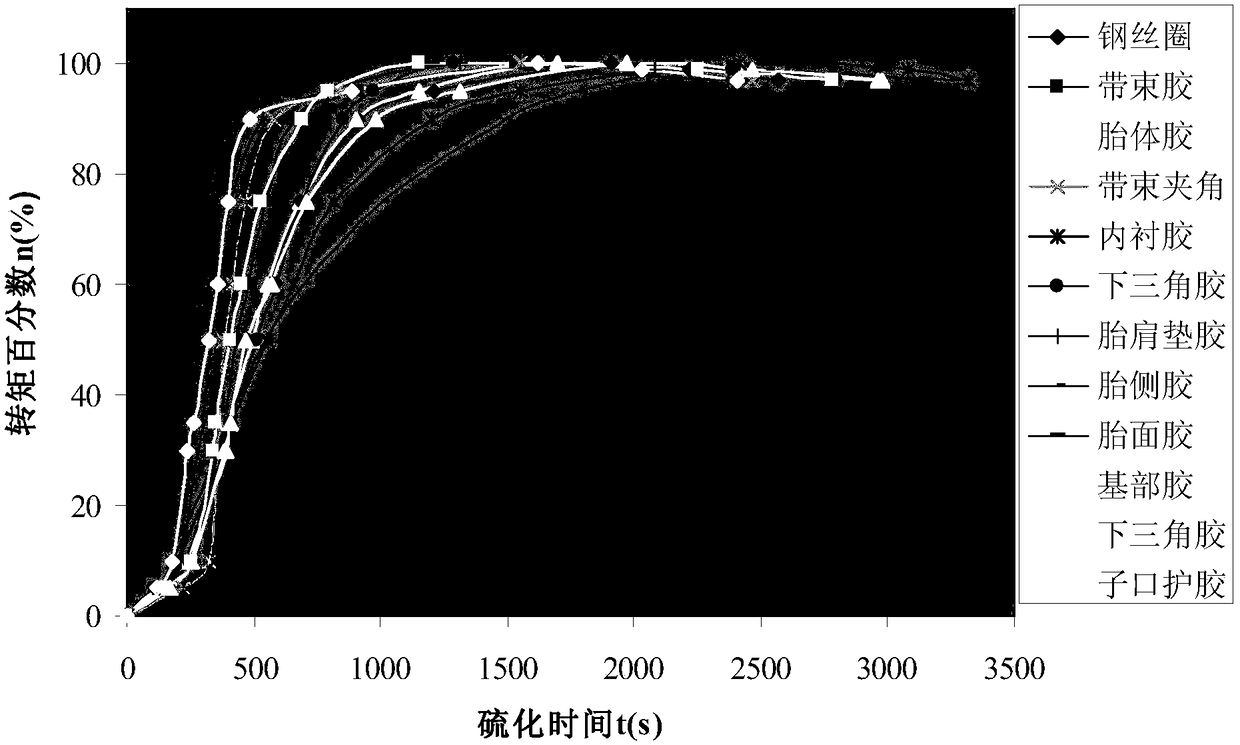

Digital automatic control method for tire vulcanization process

ActiveCN108437309AReduce tire oversulfurShort tire curing timeTyresAutomatic controlProcess engineering

The invention relates to a digital automatic control method for a tire vulcanization process. The pressure and the temperature of high temperature steam in a capsule and the pressures and the temperatures of high temperature steam and superheated water in the flow channel of a vulcanizer are controlled in real time during tire vulcanization according to the structural size of a tire, the vulcanization characteristics of a material, the structural size of a mold and the vulcanization process in order to achieve energy saving and optimal performances in the vulcanization process.

Owner:哈尔滨泰铭科技有限公司

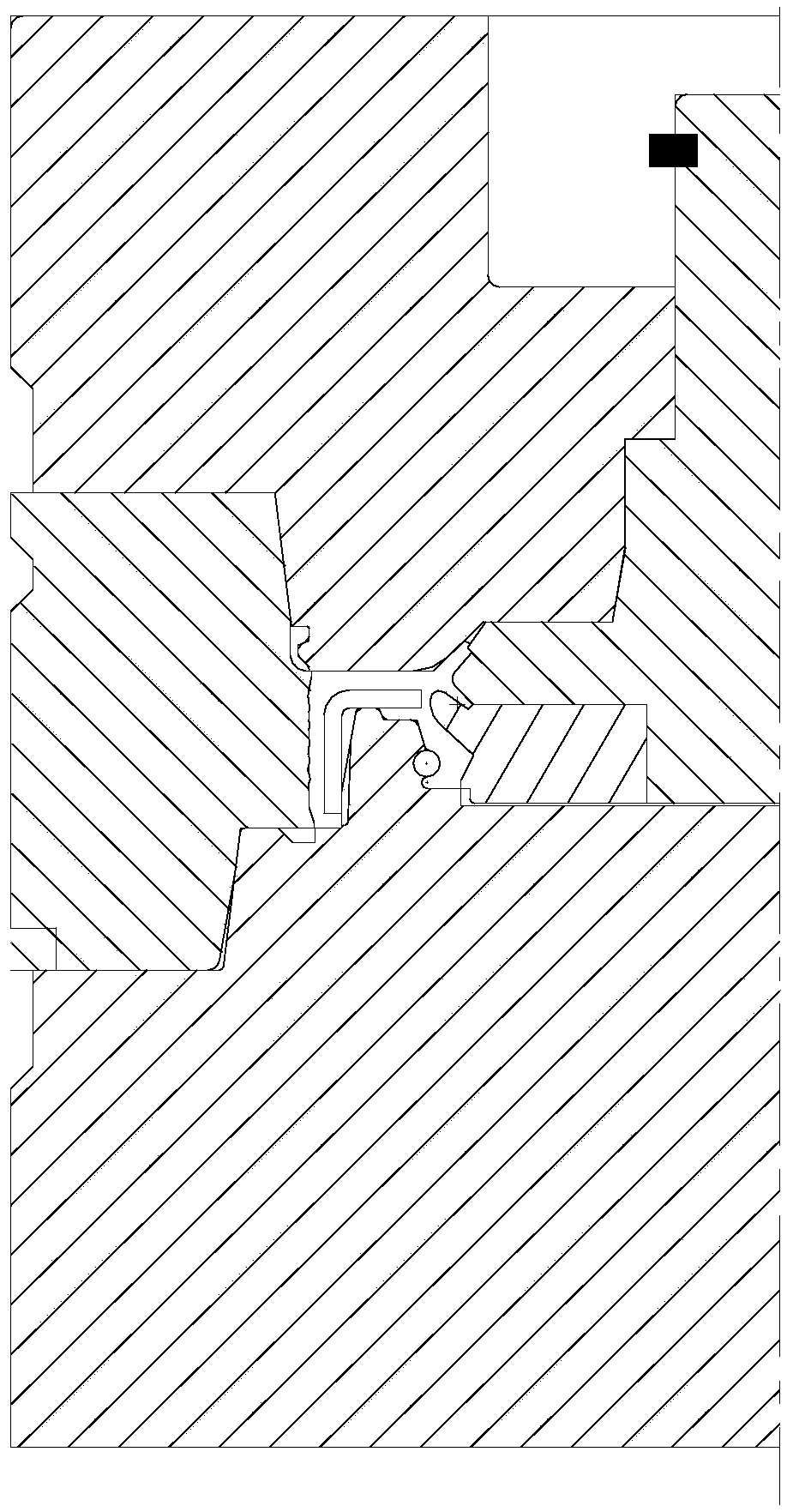

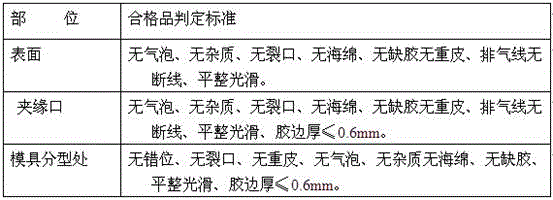

Improved oil seal type mold

ActiveCN108973030AIncrease profitAuxiliary production time is shortDomestic articlesMaterials science

The invention provides an improved oil seal type mold, which comprises an upper mold, a middle mold, a lower mold, a first mold core and a second mold core, wherein the upper mold, the middle mold andthe lower mold are in vertical arrangement; the middle mold is provided with a first die cavity; the top end of the lower mold is provided with an annular support table which extends into the first die cavity and is used for supporting an oil seal framework; the first mold core is arranged in the first die cavity; the bottom end of the first mold core is abutted against the lower mold; the secondmold core is arranged in the first die cavity; the second mold core is abutted against the first mold core; the bottom end of the upper mold is provided with an annular table extending into the firstdie cavity; in the mold matching state, a die cavity is formed among the upper mold, the middle mold, the lower mold, the first mold core and the second mold core; the die cavity is communicated witha glue injection flow passage; a glue injection opening is formed in the upper mold; a glue injection flow passage for connecting the glue injection opening and the die cavity is formed between the upper mold and the second die cavity. The non-flash design and the flash cutting process are used; shaping is used in four parts; the non-flash design is used in three positions; only the flash in theglue inlet position need to be cut.

Owner:安徽宁国中鼎模具制造有限公司

Rubber composition used for valve base, preparation method thereof and the valve base

InactiveCN104974434ACorrosion resistantWith high and low temperature resistanceVulcanizationStearic acid

The invention discloses a rubber composition used for a valve base, wherein the rubber composition includes: ethylene-propylene rubber 4640, carbon black N330, carbon black N220, a carbon black reinforcing agent N774, paraffin oil, light calcium, zinc oxide, stearic acid, a dispersing agent (AFLUX-42), dipentamethylenethiuram tetrasulfide (accelerant TRA), N,N'-m-phenylene dimaleimide (accelerant HVA-2), dicapryl phthalate (plasticizer DCP), and sulfur S. The invention also provides a preparation method of the rubber composition, comprising the steps of internal mixing, open milling and vulcanization. The rubber composition can be used for making a valve base or a wear-resistant valve base of a center line-type butterfly valve. The preparation method is simple in formula and process, is short in vulcanization time, is high in production efficiency, is low in production cost and is easy to achieve industrialization. The valve base made of the rubber composition is good in sealing performance, is uniform in structure, is corrosion-resistant, high-temperature-resistant and low-temperature-resistant, is flame-retarding and environment-friendly, and is wear-resistant.

Owner:天津滨海新区大港汇丰汽车装饰有限公司

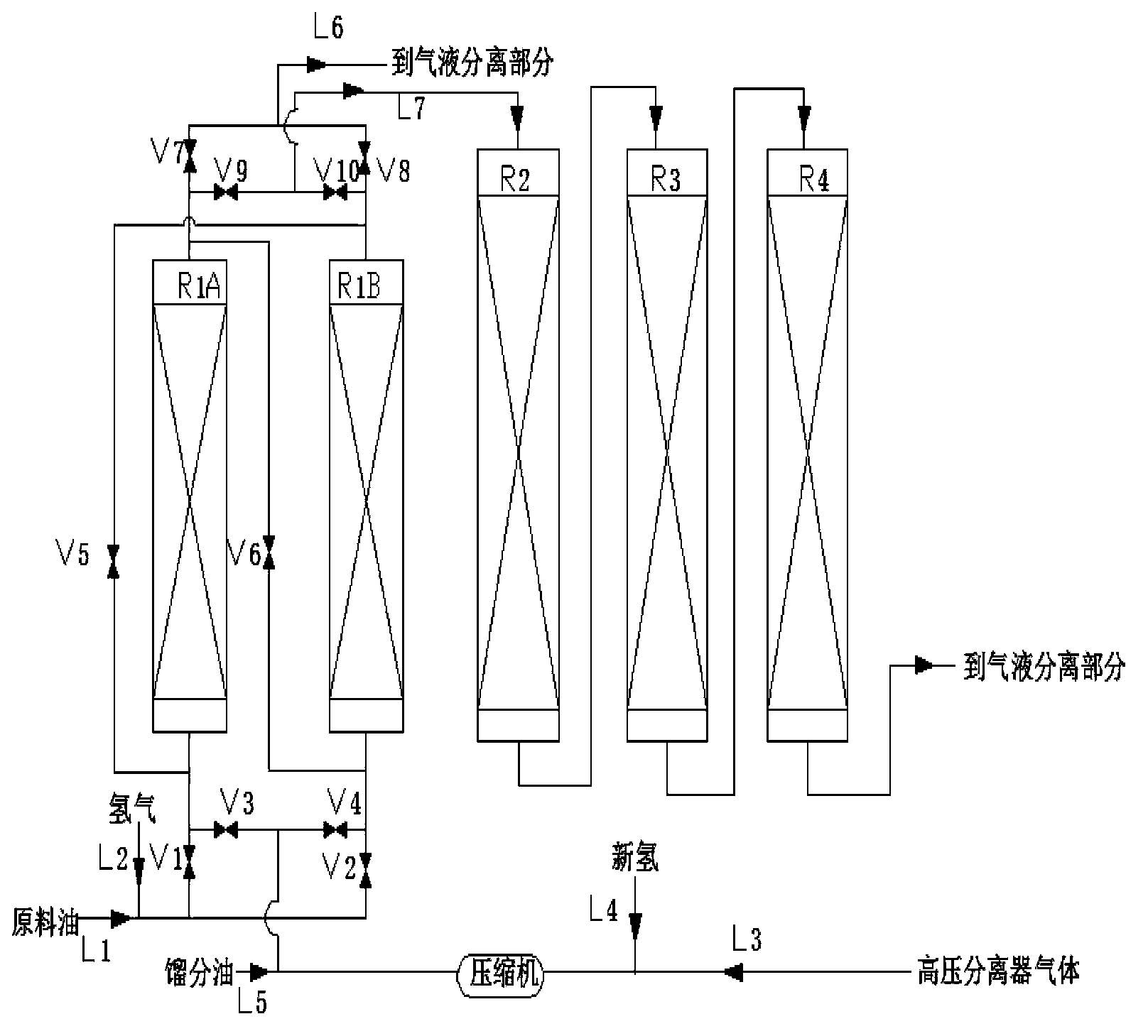

Application of prevulcanization method by hydrogenation catalyst dry method in residue hydrotreating switchable reactor system

InactiveCN103805233AShort vulcanization timeLow vulcanization costRefining to eliminate hetero atomsOxideHydrogen sulfide

The invention relates to an online prevulcanization method by a dry method of a residue hydrotreating switchable reactor system. The application comprises the following steps: carrying out a residue hydrotreating reaction by a switchable up-flow reactor or a fixed bed reactor, prevulcanizing an online cut-in fresh catalyst by a high pressure separator gas of a residue hydrotreating device, and adjusting concentration of hydrogen sulfide in the vulcanized gas by changing the proportion of the high pressure separator gas to the fresh hydrogen, wherein the volume ratio of the fresh hydrogen to the high pressure separator gas is 1:100-100:1; and selectively adding P, Si and F assistants, wherein the catalyst takes aluminum oxide as a carrier and oxides of W, Mo, Co or Ni and the like as a negative carrier. According to the method, the online updated catalyst of the residue hydrotreating switchable reactor system is prevulcanized by means of the high pressure separator gas of the residue hydrotreating device rich in H2S; the method has the advantages of short vulcanizing time, low vulcanizing expense and simplicity in operation.

Owner:PETROCHINA CO LTD

Method for preparing zinc diphenyl dithiocarbamate

The invention relates to a method for preparing zinc diphenyl dithiocarbamate, belonging to the technical field of chemical synthesis. The method comprises the steps of: firstly, reacting carbon disulfide with diphenylamine under the condition that water is used as solvent and sodium hydroxide is used as a catalyst, and then carrying out replacement reaction with zinc chloride. The synthesis can be finished in two steps in the reaction process and is free of complicated processing processes, three wastes are not generated basically, and products have high purity and good color. The invention has the advantages that the sodium hydroxide is cheap and common and is easy to purchase, the method has short production cycle and high safety coefficient, basically no waste gas is discharged, the products have high melting point and white appearance, the total product yield is 80-92% and the comprehensive cost is low.

Owner:JIANGSU FEIYA CHEM IND

Cable with fluorine-modified polyacrylate sheath layer

InactiveCN105175820AGood adhesionGood waterproof and oil-proofRubber insulatorsInsulated cablesEngineeringStearic acid

The invention discloses a cable with a fluorine-modified polyacrylate sheath layer. The cable comprises a cable core and a sheath layer which coats the cable core. Raw materials of the sheath layer comprise, by weight, 32-35 parts of nitrile rubber 2707, 24-27 parts of fluorine-modified polyacrylate, 23-26 parts of ethylene propylene diene monomer, 13-16 parts of para-aramid fibers, 11-14 parts of furnace black, 17-20 parts of mica, 8-11 parts of sepiolite, 3-5 parts of a mono-alkoxy titanate coupling agent, 2.3-3.5 parts of sulphur, 1.5-1.8 parts of an accelerant TT, 2.2-2.5 parts of an accelerant DM, 1.1-1.4 parts of an anti-aging agent SP, 2.3-2.6 parts of an anti-aging agent RD, 0.7-1.1 parts of stearic acid, 7-11 parts of phenyl petroleum sulfonate and 1-3 parts of castor oil. The cable has good waterproofness and oil-proof performance, and has excellent weather fastness and corrosion resistance. The preparation process is simple and easy to operate, and reaction conditions are mild. The cable is convenient for industrial production.

Owner:ANHUI HONGHAI CABLE

Full-terrain tire tread rubber reinforced and filled with diatomite and preparation method of tread rubber

The invention discloses a full-terrain tire tread rubber reinforced and filled with diatomite and a preparation method of the tread rubber, and belongs to the technical field of tire manufacturing. The tread rubber comprises the following raw materials in parts by weight: 20-50 parts of 20# standard rubber, 40-70 parts of styrene-butadiene rubber 1502, 10-15 parts of cis-polybutadiene rubber 9000,20-40 parts of diatomite, 30-50 parts of precipitated white carbon black, 2-2.5 parts of sulfur, 4-5 parts of zinc oxide, 3-4 parts of stearic acid, 1.2-1.5 parts of an accelerator, 2-3 parts of an anti-aging agent, 10-12 parts of engine oil, 1-2 parts of a coupling agent and 1-3 parts of glycerol. The tire tread rubber provided by the invention has the characteristics of low Mooney viscosity, easy processing, short vulcanization time, excellent physical mechanical property, no pollution and the like, the production efficiency is improved, the production energy consumption is reduced, and thedevelopment requirements of energy-saving, low-carbon and environment-friendly green tire.

Owner:常州苏橡橡塑制品有限公司

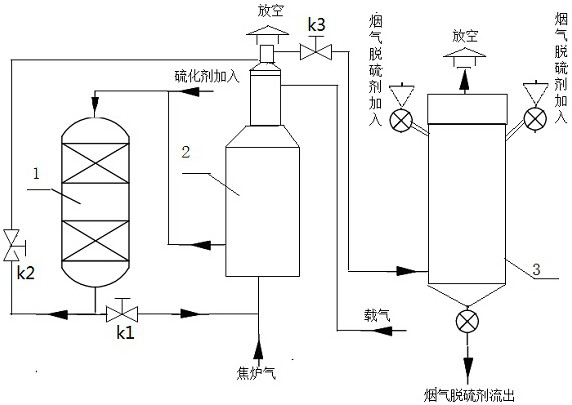

Gas hydrogenation catalyst sulfurization and sulfurization waste gas treatment and emission process

ActiveCN111876205ASolve application problemsAvoid flying temperatureGas treatmentDispersed particle filtrationPtru catalystFlue gas

The invention discloses a gas hydrogenation catalyst sulfurization and sulfurization waste gas treatment and emission process, wherein the problems of concentrated heat release and sulfur release during activation of the out-of-device pre-sulfurized catalyst and reduction of the catalyst before sulfurization are solved by adopting the catalyst and the out-of-device pre-sulfurized catalyst. The total interlayer number is an odd number of 5-15, wherein the uppermost layer and the lowermost layer are both catalysts, in the initial stage of sulfurization, the first layer of catalyst is supplied with sulfur and heat by a system, and the rest odd layers of catalysts are respectively supplied with sulfur and heat by an out-of-reactor pre-sulfurized catalyst on the upper layer; the sulfuration waste gas enters a heating furnace to be combusted, SO2 in the flue gas is removed to 30 mg / m3 or below through a dry flue gas desulfurization device, and the flue gas is discharged after being subjectedto white smoke removal treatment. The sulfurization process is simple in flow, free of pollution and corrosion of power, heat exchange, condensation, gas-liquid separation and other equipment, smallin sulfurization agent dosage, short in sulfurization time and good in sulfurization effect. The whole sulfurization and sulfurization waste gas treatment and discharge process is low in investment cost, solid waste after flue gas desulfurization can be recycled, and the process is green and economical.

Owner:WUHAN KELIN FINE CHEM

Pressure barrel water storage device and manufacturing method thereof

The invention relates to a pressure barrel water storage device and a manufacturing method thereof. The pressure barrel water storage device is made of a rubber material, the rubber material comprises, by weight, 70-90 parts of bromobutyl rubber, 3-8 parts of polyethylene wax, 45-55 parts of N330 carbon black, 0.2-0.6 parts of stearic acid, 3-4 parts of zinc oxide and 2-3 parts of resin SP1045, and the rubber material undergoes charging, preheating, vulcanizing and cavity locking fixing at a limited temperature under a limited pressure for a limited time to obtain the pressure barrel water storage device. The pressure barrel water storage device has a long service life, and a test result shows that the above product is difficult to break after be continuously used 100,000-150,000 times; and the permeation resistance of the material is good, and the obtained product has fine surface being nanometer level, so entrance of purified water to the water storage device is effectively avoided, and secondary pollution of water in the water storage device is prevented.

Owner:浙江华和塑胶科技有限公司

Production mold for rubber product and method for producing rubber product

The invention relates to a production mold for a rubber product and a method for producing the rubber product. The production mold for the rubber product comprises an upper mold plate and a lower moldplate. A rubber product cavity and a sealing ring cavity are formed after the upper mold plate and the lower mold plate are assembled. The lower mold plate is provided with exhaust holes and suctionholes. The suction holes communicate with the exhaust holes. The method for producing the rubber product through the production mold for the rubber product comprises the steps of injection molding, vulcanization, vacuumizing, and vulcanization forming. According to the production mold for the rubber product, the mold is connected with a vacuum pump, so that an inner cavity of the mold is vacuumized rapidly, the investment of production equipment for rubber products is reduced, the production efficiency can be improved, and labor cost and energy consumption are reduced; and meanwhile, the surface of the obtained rubber product is smooth and free of bubbles, the appearance of the rubber product is full, and production requirements are met.

Owner:厦门市金汤橡塑有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com