Cable with fluorine-modified polyacrylate sheath layer

A polyacrylate and sheath technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of destroying the molecular structure of the outer surface of the cable, affecting the safe service life of the cable, and corrosion of the cable, and achieves good waterproof and oil-proof performance. Good anti-oxidation and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

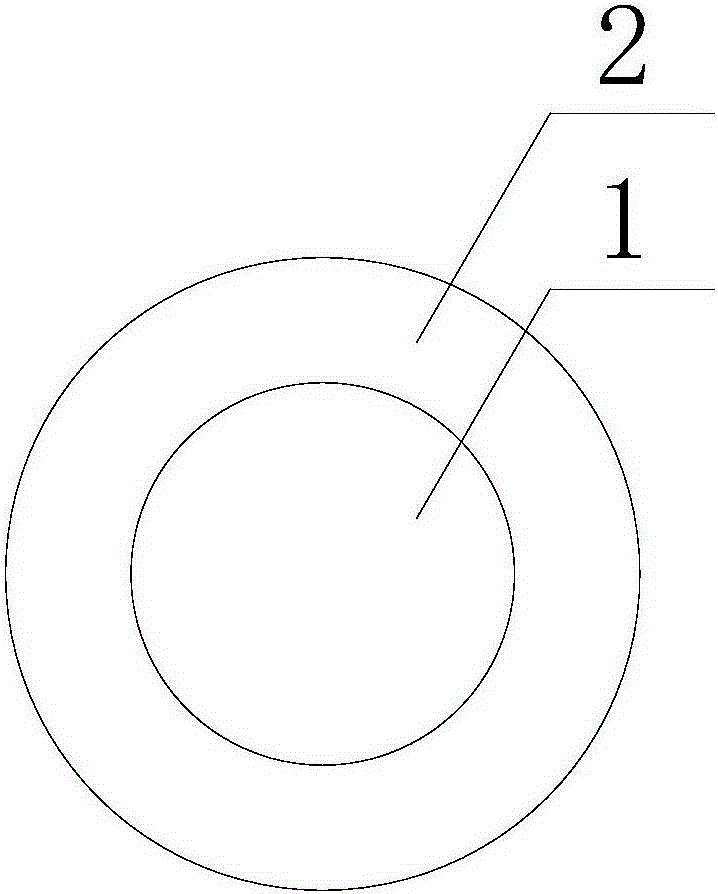

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a cable with a fluorine-modified polyacrylate sheath layer proposed by the present invention.

[0019] refer to figure 1 , a cable with a fluorine-modified polyacrylate sheath layer proposed by the present invention, comprising a cable core 1 and a sheath layer 2 coated on the outside of the cable core;

[0020] The raw materials of the sheath layer 2 include by weight: 270735 parts of nitrile rubber, 24 parts of fluorine-modified polyacrylate, 26 parts of EPDM rubber, 13 parts of para-aramid fiber, 14 parts of furnace carbon black, mica 17 parts of powder, 11 parts of sepiolite, 3 parts of monoalkoxy titanate coupling agent, 3.5 parts of sulfur, 1.5 parts of accelerator TT, 2.5 parts of accelerator DM, 1.1 parts of anti-aging agent SP, anti-aging 2.6 parts of RD, 0.7 parts of stearic acid, 11 parts of phenyl petroleum sulfonate, and 1 part of castor oil;

[0021] In the preparation process ...

Embodiment 2

[0023]The present invention proposes a cable with a fluorine-modified polyacrylate sheath layer, comprising a cable core 1 and a sheath layer 2 coated on the outside of the cable core; the raw materials of the sheath layer 2 include by weight: nitrile rubber 270732 parts, 27 parts of fluorine-modified polyacrylate, 23 parts of EPDM rubber, 16 parts of para-aramid fiber, 11 parts of furnace carbon black, 20 parts of mica powder, 8 parts of sepiolite, monoalkoxy 5 parts of type titanate coupling agent, 2.3 parts of sulfur, 1.8 parts of accelerator TT, 2.2 parts of accelerator DM, 1.4 parts of anti-aging agent SP, 2.3 parts of anti-aging agent RD, 1.1 parts of stearic acid, petroleum sulfur 7 parts of phenyl ester, 3 parts of castor oil;

[0024] During the preparation of fluorine-modified polyacrylate, 20 parts of deionized water, 4 parts of perfluoroalkyl acrylate, 2.5 parts of silane coupling agent KH570, 7 parts of butyl acrylate, and 2 parts of methyl methacrylate were mixed...

Embodiment 3

[0026] The present invention proposes a cable with a fluorine-modified polyacrylate sheath layer, comprising a cable core 1 and a sheath layer 2 coated on the outside of the cable core; the raw materials of the sheath layer 2 include by weight: nitrile rubber 270734 parts, 25 parts of fluorine-modified polyacrylate, 25 parts of EPDM rubber, 14 parts of para-aramid fiber, 13 parts of furnace carbon black, 18 parts of mica powder, 10 parts of sepiolite, monoalkoxy Type titanate coupling agent 3.5 parts, sulfur 3.2 parts, accelerator TT1.6 parts, accelerator DM2.4 parts, antioxidant SP1.2 parts, antioxidant RD2.5 parts, stearic acid 0.8 parts, petroleum sulfur 10 parts of phenyl ester, 1.5 parts of castor oil;

[0027] In the preparation process of fluorine-modified polyacrylate, 22 parts of deionized water, 2.5 parts of perfluoroalkyl acrylate, 3.2 parts of silane coupling agent KH570, 5.5 parts of butyl acrylate, 3.5 parts of methyl methacrylate were mixed by weight. Esters, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com