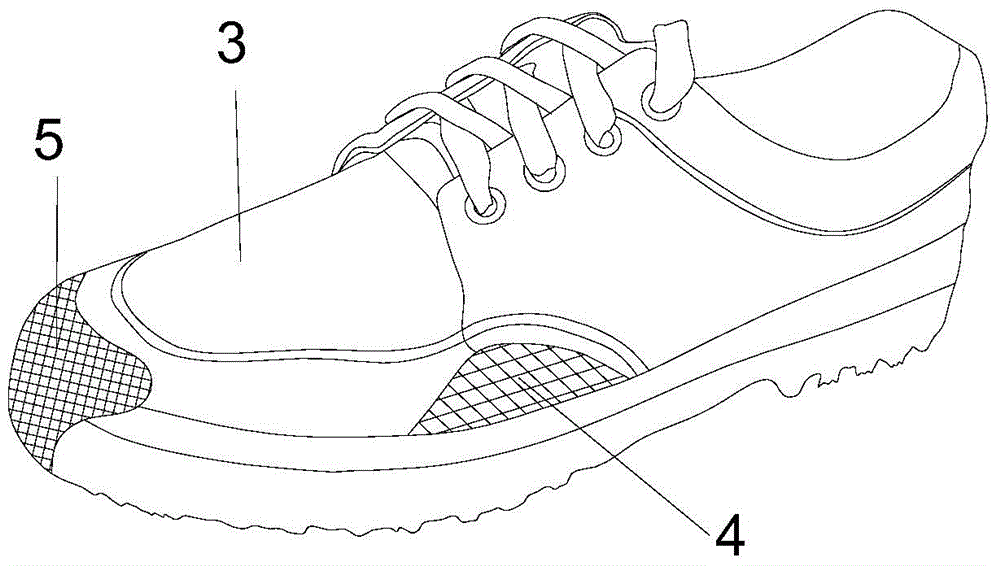

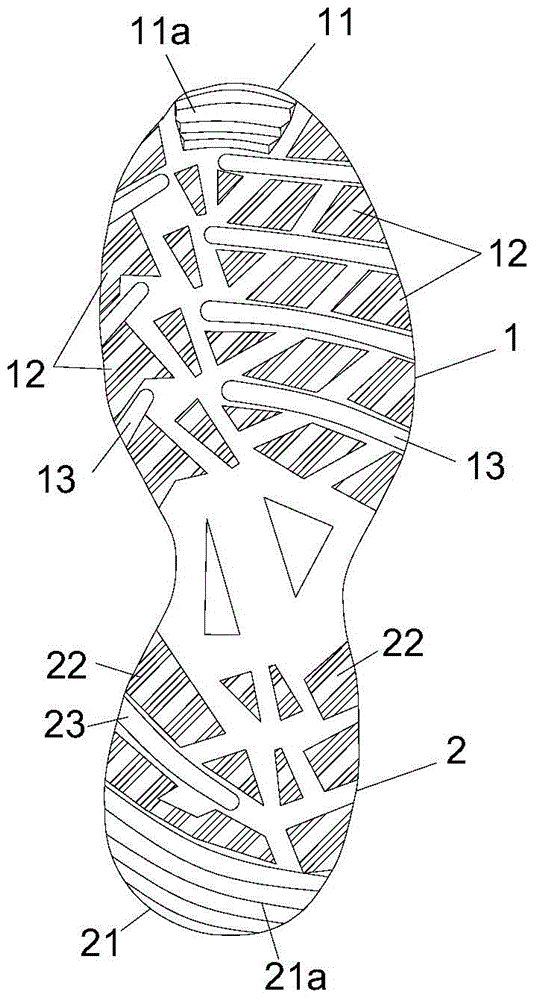

Wear-resistant insulating shoe

A technology for insulated shoes and shoe uppers, applied in the field of shoes, can solve problems such as loss of wear function, non-wearable soles, and broken soles, and achieve the effects of improving the plasticizing effect, improving aging resistance, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

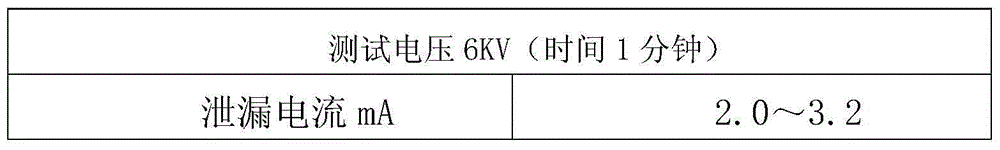

[0045] In the wear-resistant insulating shoes of the present embodiment, its rubber compounding raw material comprises the following components by weight: 28 parts of domestic No. 2 standard rubber, 73 parts of butadiene rubber, 2.8 parts of accelerator, 5 parts of insoluble sulfur, and 2.5 parts of active zinc oxide. 2.3 parts, 2.3 parts of stearic acid, 1.8 parts of antioxidant, 2.4 parts of active agent, 60 parts of white carbon black, 32 parts of softener, 10 parts of tackifier, 3 parts of Zhongchao wear-resistant carbon black, and 0.05 part of peptizer; Described accelerator is the mixture of accelerator DM, accelerator D and accelerator TMTM, and the consumption of wherein said accelerator DM is 2.3 times of the consumption of accelerator D, and the consumption of accelerator TMTM is 0.12 part; Described antioxidant is The mixture of antiaging agent 4010NA and antiaging agent MB, the weight ratio of described antiaging agent 4010NA and antiaging agent MB is 1:1; Described...

Embodiment 2

[0054] The wear-resistant insulating shoes of the present embodiment, its compounded rubber raw material comprises the following components by weight: 20 parts of domestic No. 2 standard rubber, 65 parts of butadiene rubber, 2 parts of accelerator, 2 parts of insoluble sulfur, 1 part of active zinc oxide 1 part, 1 part of stearic acid, 1 part of anti-aging agent, 1 part of activator, 45 parts of white carbon black, 25 parts of softener, 8 parts of tackifier, 1 part of Zhongchao wear-resistant carbon black, and 0.01 part of peptizer; The accelerator is a mixture of accelerator DM, accelerator D and accelerator TMTM, wherein the amount of accelerator DM is 2 times that of accelerator D, and the amount of accelerator TMTM is 0.1 to 0.15 parts; the anti-aging Agent is the mixture of antiaging agent 4010NA and antiaging agent MB, and the weight ratio of described antiaging agent 4010NA and antiaging agent MB is 1:1; Described active agent is the mixture of polyethylene glycol and si...

Embodiment 3

[0063] The wear-resistant insulating shoes of the present embodiment, its compounded rubber raw material comprises following components by weight: 35 parts of domestic No. 2 standard rubbers, 75 parts of butadiene rubber, 5 parts of accelerators, 7 parts of insoluble sulfur, 3 parts of activated zinc oxide 3 parts, 3 parts of stearic acid, 3 parts of anti-aging agent, 4 parts of active agent, 65 parts of white carbon black, 35 parts of softener, 12 parts of tackifier, 5 parts of Zhongchao wear-resistant carbon black, 1 part of peptizer; Described accelerator is the mixture of accelerator DM, accelerator D and accelerator TMTM, and the consumption of wherein said accelerator DM is 2.5 times of the consumption of accelerator D, and the consumption of accelerator TMTM is 0.15 part; Described antioxidant is The mixture of antiaging agent 4010NA and antiaging agent MB, the weight ratio of described antiaging agent 4010NA and antiaging agent MB is 1:1; Described active agent is the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com