Patents

Literature

179results about How to "Lower Mooney Viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

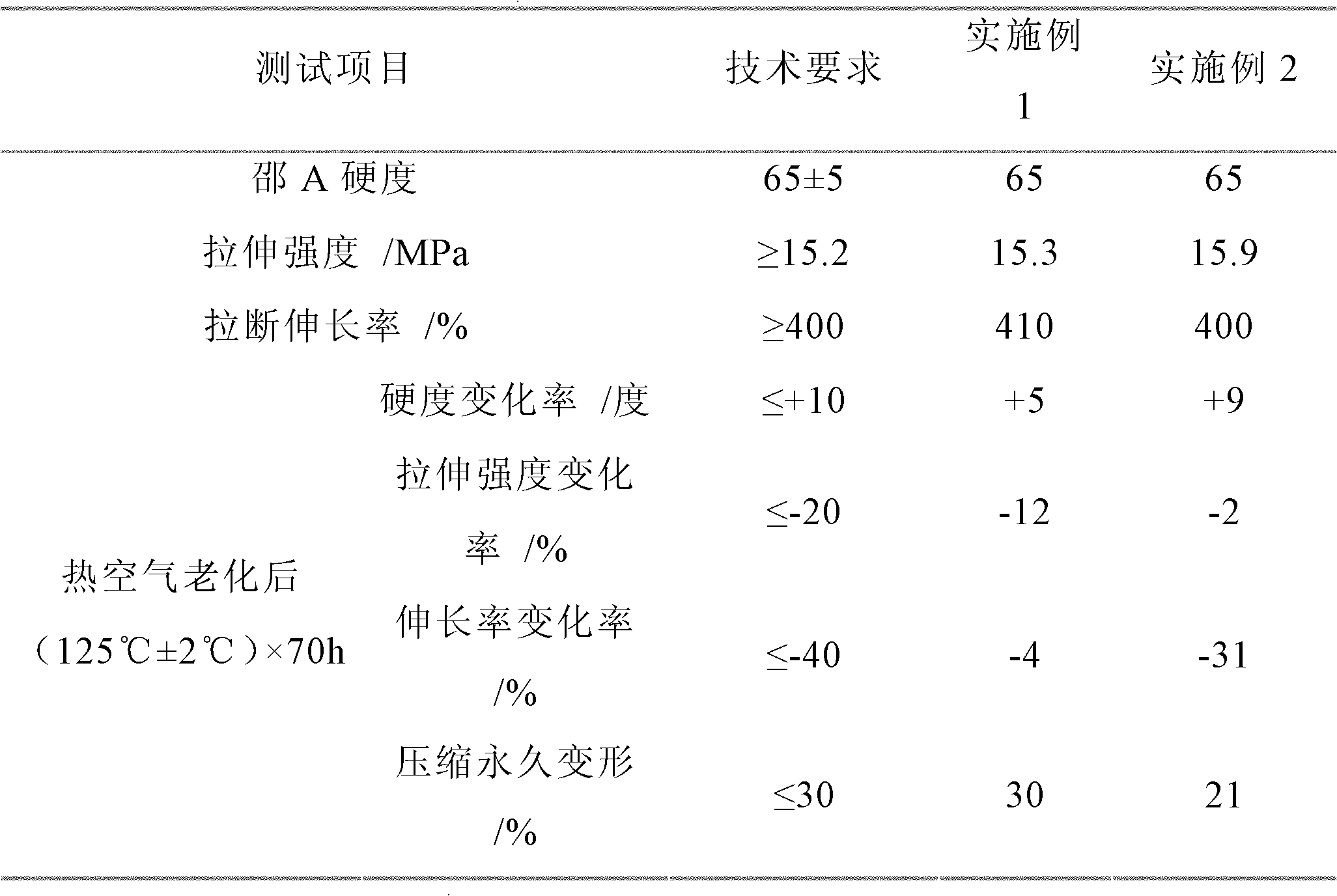

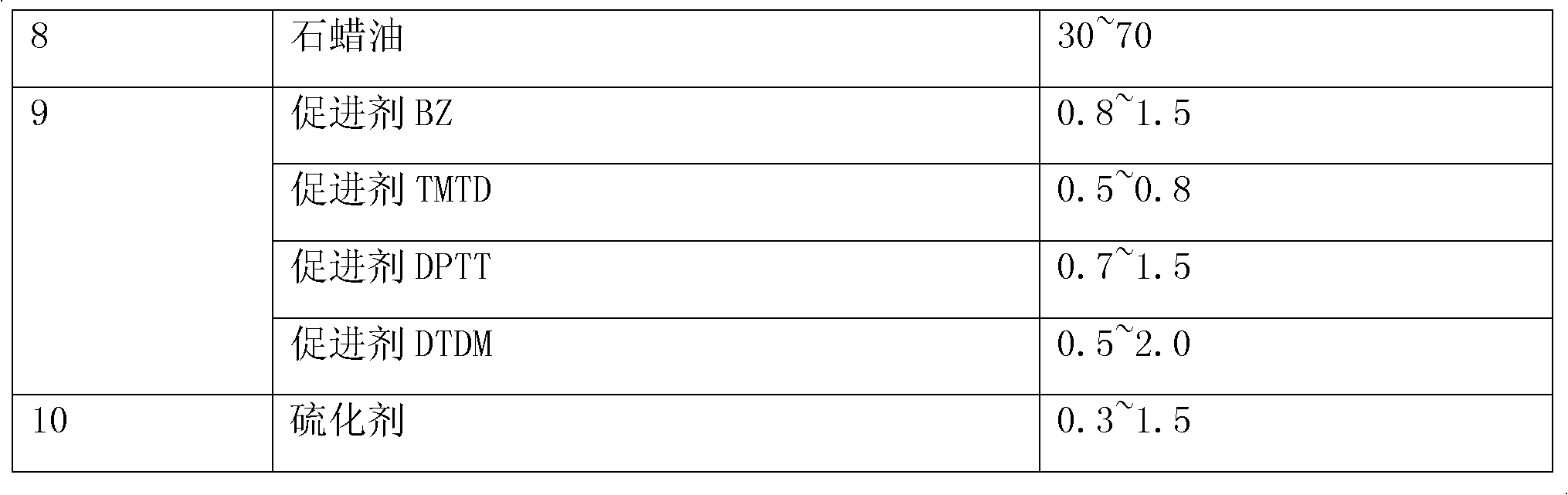

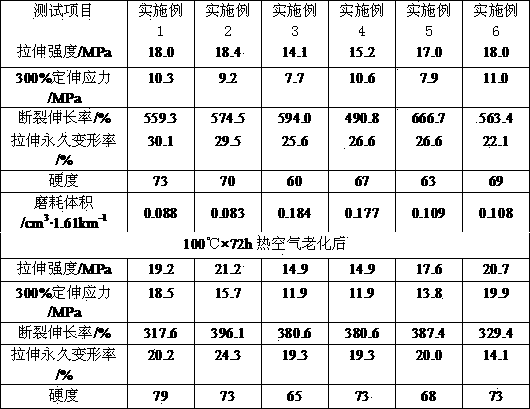

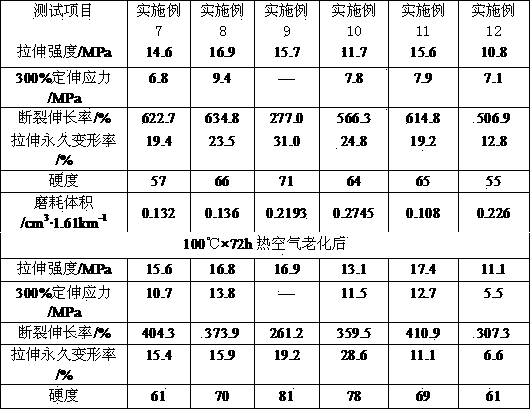

Ethylene propylene diene rubber composition and preparation method

The invention discloses an ethylene propylene diene rubber composition and a preparation method. The preparation method comprises the following steps of: firstly, performing after plastication on ethylene propylene diene rubber; then, adding zinc oxide, stearic acid, anti-aging agent, carbon black, plasticizers, accelerant, vulcanizer and the like in sequence; evenly mixing and then extruding a sheet; and preparing the sheet into the ethylene propylene diene rubber / carbon black nanometer composite material by adopting the after vulcanization process. Through adding various plasticizers and adopting special process treatment, the tensile strength of the ethylene propylene diene rubber composition disclosed by the invention is at least 15.2MPa, the elongation at break is at least 400 percent, and the compression set is lower than 30 percent under the condition of 125 DEG C*70h. The composite material can be used as a sealing article of rubber, especially a rubber sealing washer applied to a groove-type pipeline joint part of an automatic water spray fire extinguishing system, and thereby, a long-term sealing effect is ensured.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

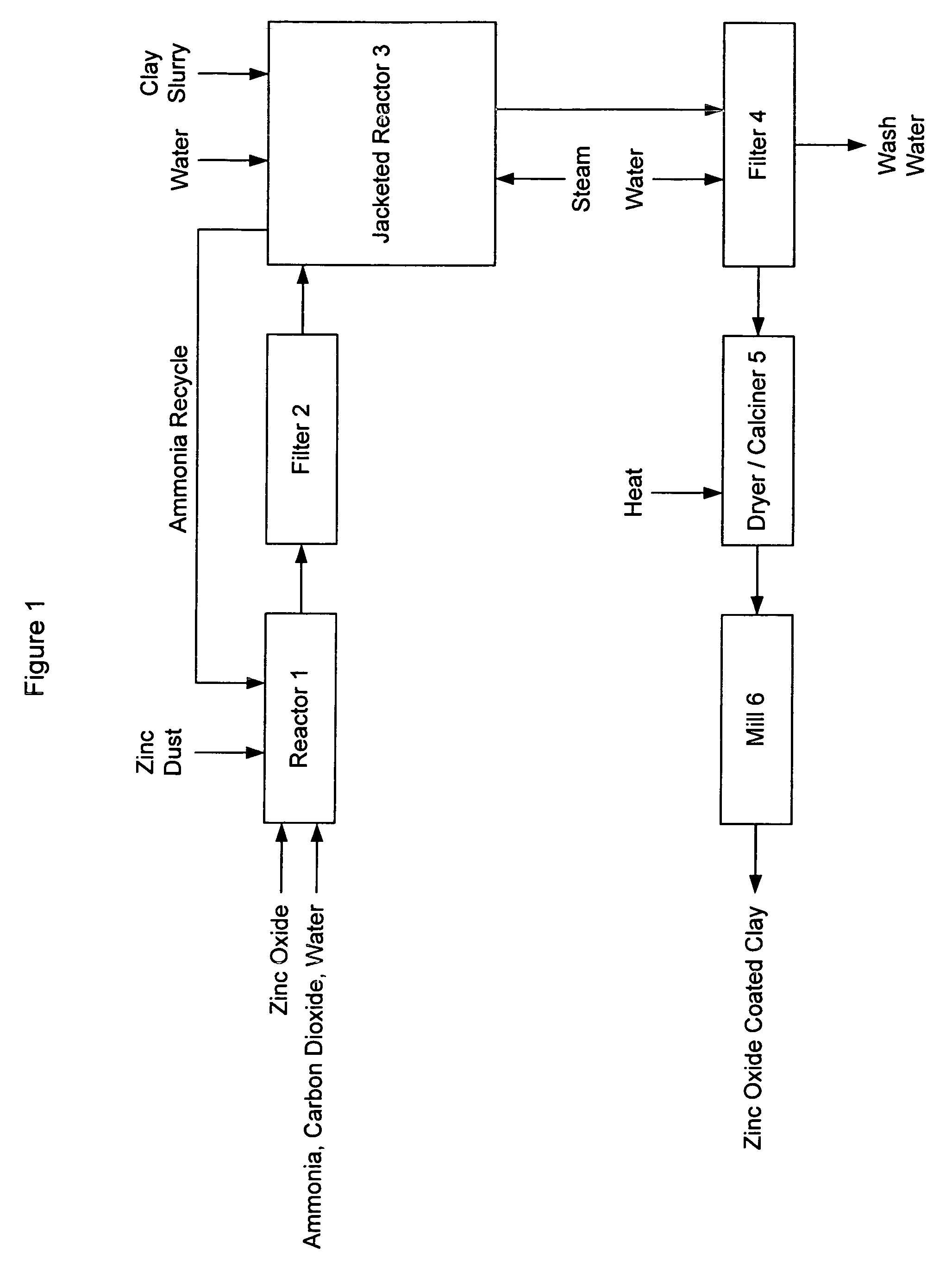

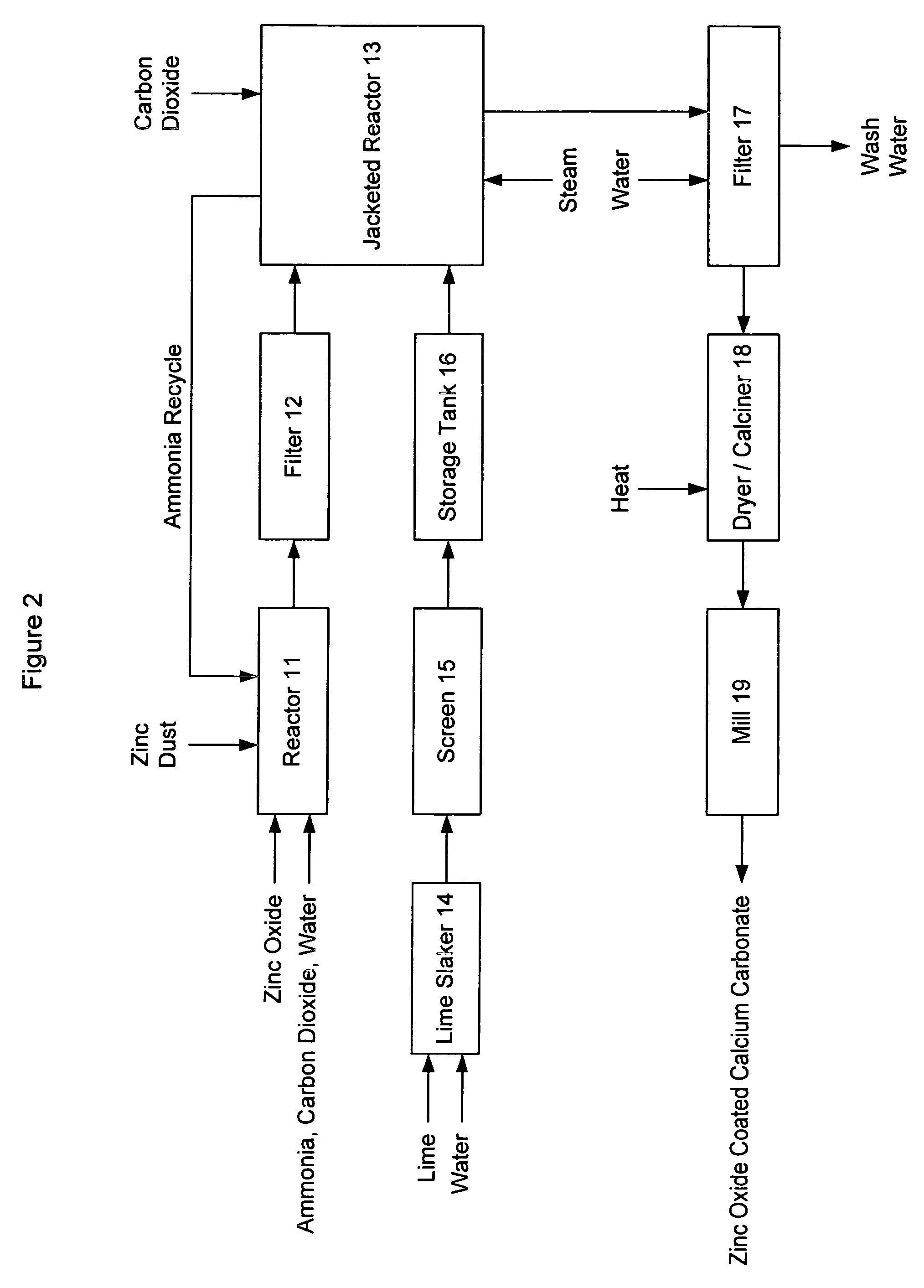

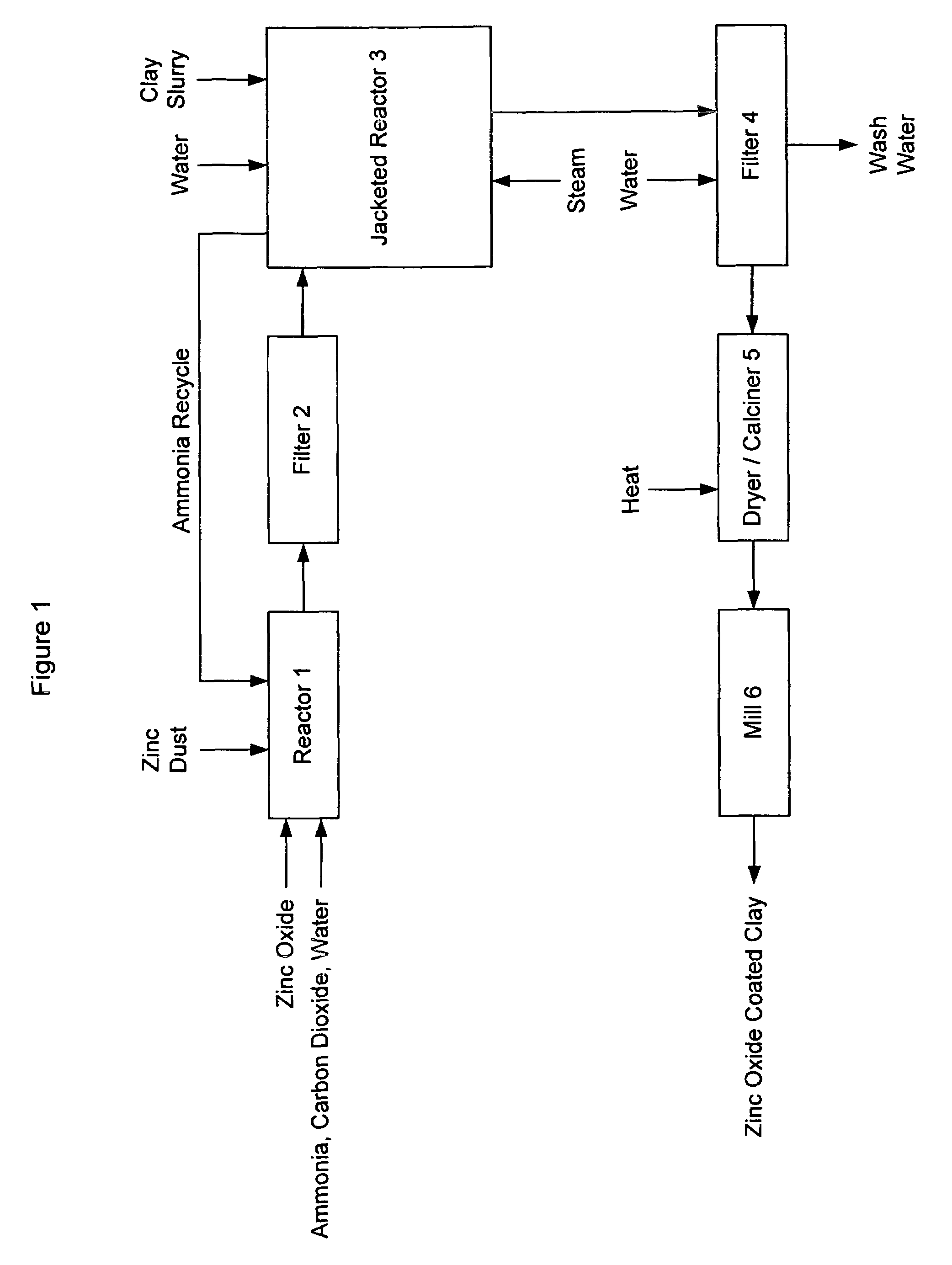

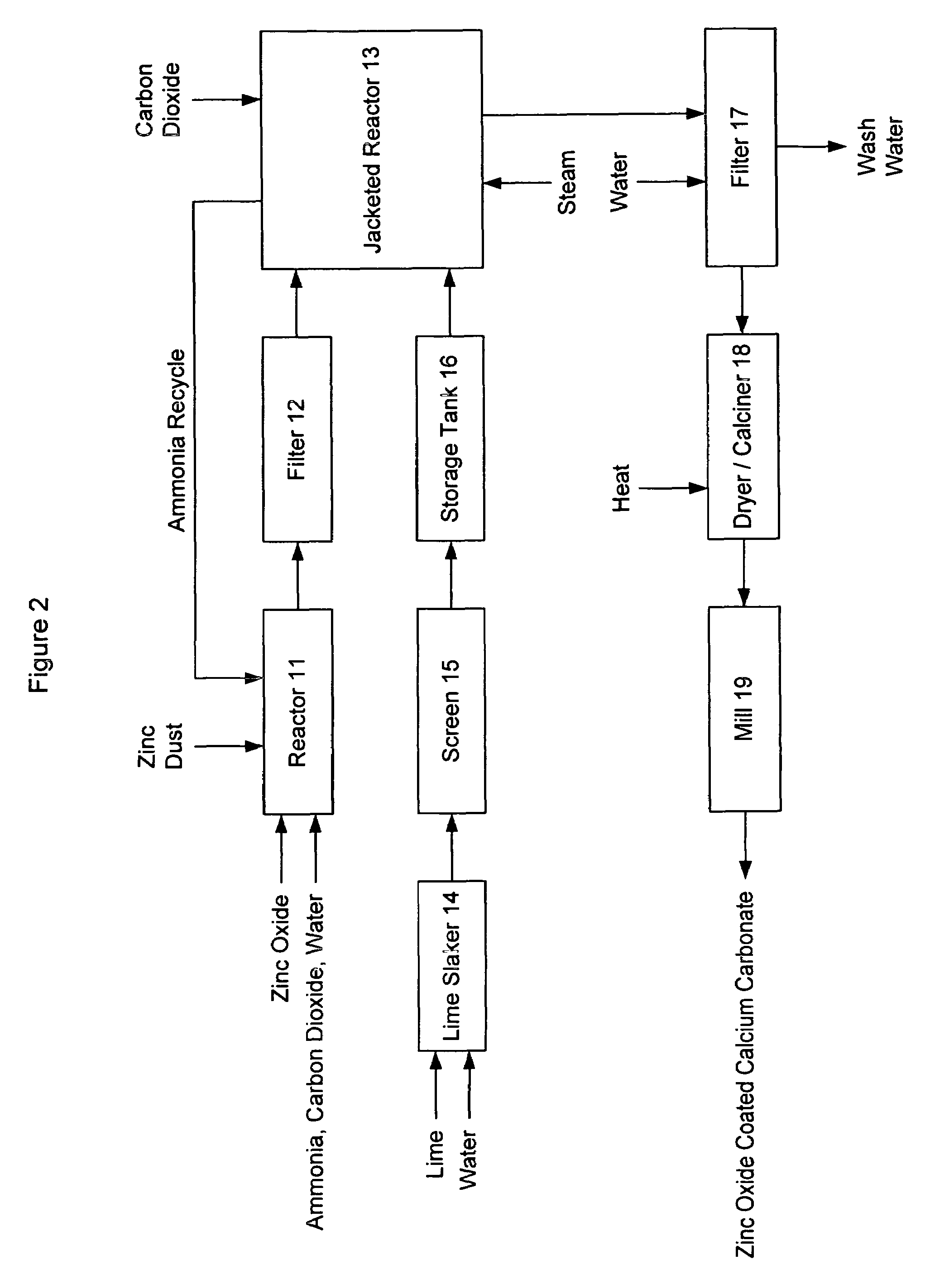

Zinc oxide coated particles, compositions containing the same, and methods for making the same

ActiveUS20070072959A1High modulusHigh tensile strengthInorganic pigment treatmentSynthetic resin layered productsCost savingsZinc

Zinc oxide and / or zinc carbonate coated particles, methods of coating particles with zinc oxide and / or zinc carbonate, and various applications of such coated particles, including applications in cosmetics, rubber, and other polymer materials, are disclosed. As compared to rubber formulations with zinc oxide and core materials added separately, formulations including the present coated particles may have a higher transparency, lower Mooney viscosity and lower minimum torque, improved dispersability, a higher modulus at 100% and / or at 300% elongation, a higher tensile strength, better aging resistance, better abrasion resistance, lower density, and / or lower heat build up. Thus, products containing the present coated particles may enjoy similar or better properties than comparative products that include a conventional filler and / or zinc oxide per se, and the present coated particles may result in cost savings for the corresponding product formulations.

Owner:NIP RAYMOND LEE

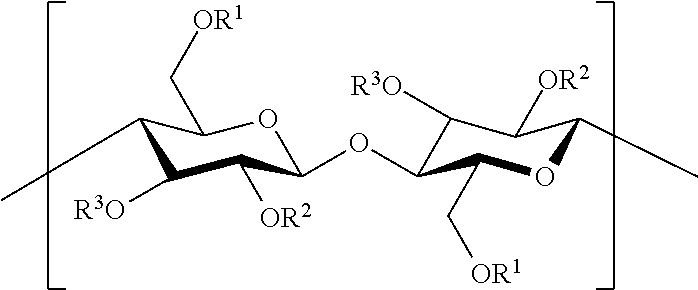

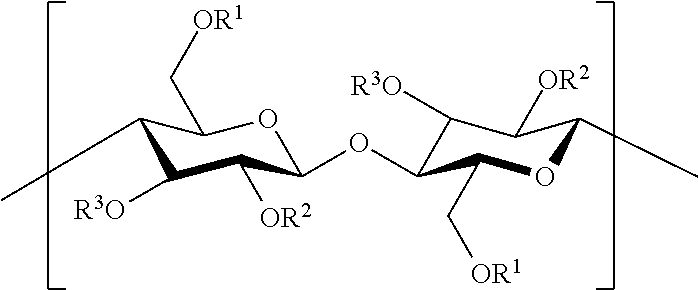

Cellulose ester/elastomer compositions

InactiveUS20110319529A1Lower Mooney ViscosityImprove stress conditionImpression capsDentistry preparationsCellulosePolymer science

A cellulose ester composition is provided comprising at least one cellulose ester and at least one additive selected from the group consisting of a compatibilizer, and a plasticizer. Processes for producing the cellulose ester composition are also provided. In another embodiment, a cellulose ester / elastomer composition is provided comprising at least one elastomer, at least one cellulose ester; and at least one additive; wherein the additive is at least one selected from the group consisting of a compatibilizer and a plasticizer. Processes for producing the cellulose ester / elastomer composition is also provided as well as articles comprising the cellulose ester / elastomer composition.

Owner:EASTMAN CHEM CO

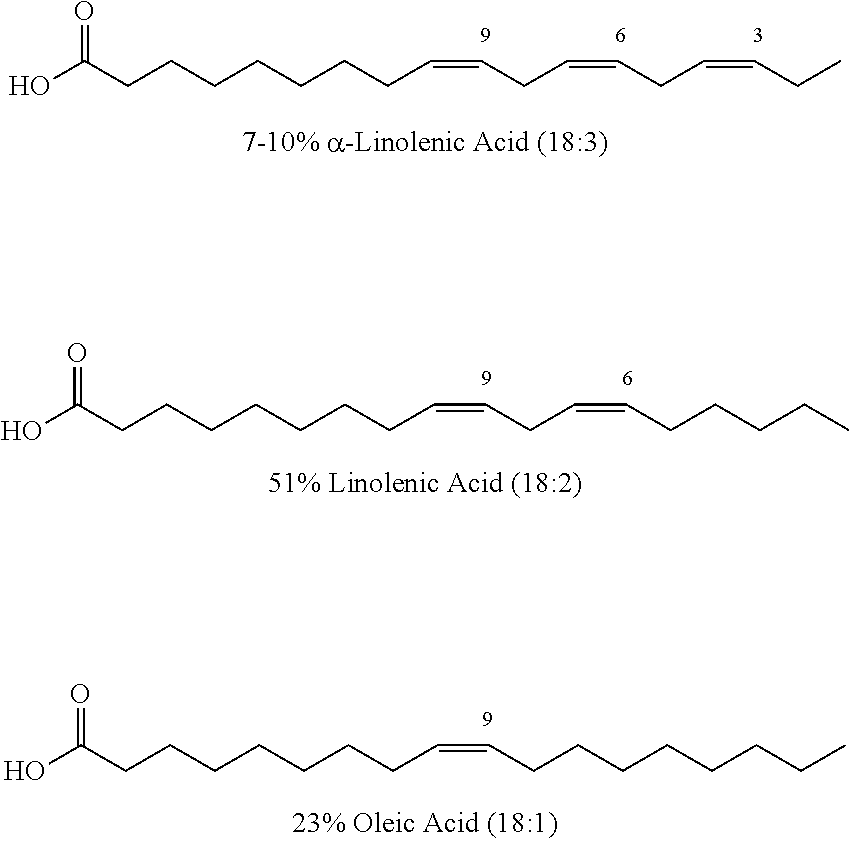

Triglyceride containing solution polymerization prepared styrene/butadiene elastomer and tire with component

InactiveUS20130289183A1High Mooney viscosityHigh molecular weightSpecial tyresInksElastomerTriglyceride

This invention relates to vegetable oil extended rubber containing soy oil and tire with a component of such oil extended rubber.

Owner:KERNS MICHAEL LESTER +3

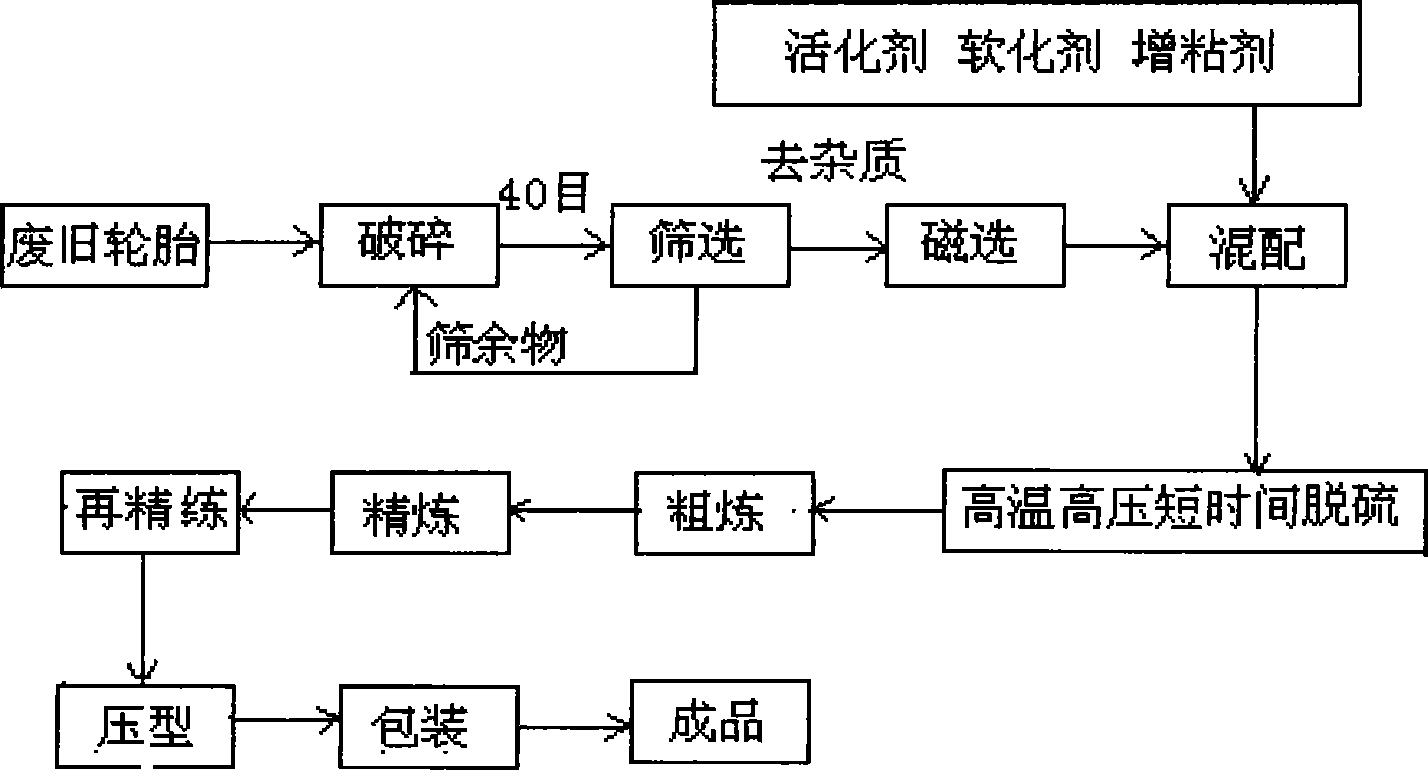

High-quality regenerated rubber and its production

InactiveCN101074302AStrong wear resistanceExtended service lifePlastic recyclingHigh pressureTemperature and pressure

A high-quality regenerated rubber and its production are disclosed. It improves composition and proportion, it adopts high-temperature and pressure desulfurizing method in short time and refining process is added. The tensile strength and breaking extensibility can be increased by 30-60%; it can substitute natural rubber or synthetic rubber and be used as various tyre and raw material of rubber products. It's simple, efficient and smokeless, has excellent abrasive performance, long life, less noise and no refused water discharge.

Owner:QINGWEI RUBBER SUQIAN

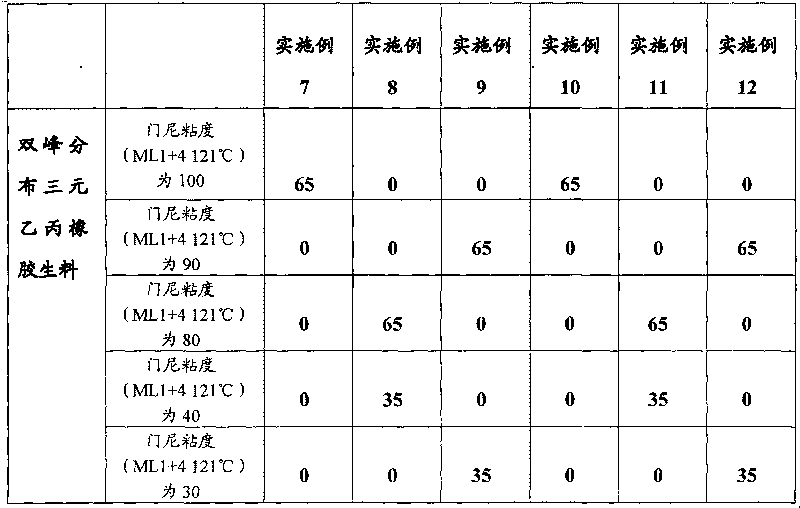

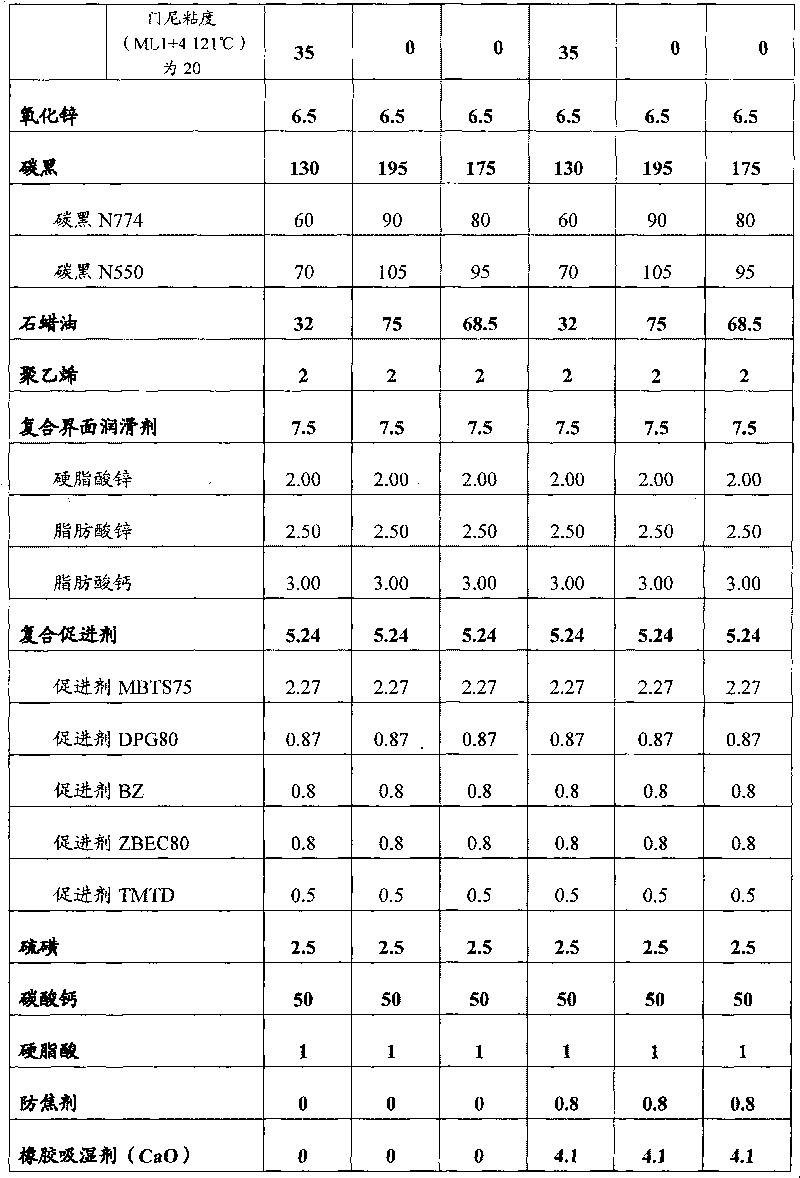

Rubber additive and ethylene propylene diene monomer containing same

The invention relates to a rubber additive and ethylene propylene diene monomer containing the same. The rubber additive is characterized by comprising the following components in part by weight: 6.5 parts of zinc oxide, 2.5 parts of sulfur, 1 part of stearic acid, 2 parts of polyethylene with the melting point of between 85 and 100 DEG C, 7.5 parts of composite interface lubricating agent, 130 to 195 parts of carbon black, 50 parts of carbonate, 32 to 75 parts of paraffin oil, and 5.24 pats of complex accelerant. The invention aims to solve the technical problems that the ethylene propylene diene monomer in the prior art has a high cost under the condition of the same hardness and the same Mooney viscosity, provides an additive which saves more cost and the ethylene propylene diene monomer using the additive, and further provides the ethylene propylene diene monomer with large tensile strength and elongation at break.

Owner:瀚德(中国)汽车密封系统有限公司

Zinc oxide coated particles, compositions containing the same, and methods for making the same

ActiveUS7635729B2High modulusHigh tensile strengthInorganic pigment treatmentSynthetic resin layered productsAging resistanceMooney viscosity

Zinc oxide and / or zinc carbonate coated particles, methods of coating particles with zinc oxide and / or zinc carbonate, and various applications of such coated particles, including applications in cosmetics, rubber, and other polymer materials, are disclosed. As compared to rubber formulations with zinc oxide and core materials added separately, formulations including the present coated particles may have a higher transparency, lower Mooney viscosity and lower minimum torque, improved dispersability, a higher modulus at 100% and / or at 300% elongation, a higher tensile strength, better aging resistance, better abrasion resistance, lower density, and / or lower heat build up. Thus, products containing the present coated particles may enjoy similar or better properties than comparative products that include a conventional filler and / or zinc oxide per se, and the present coated particles may result in cost savings for the corresponding product formulations.

Owner:NIP RAYMOND LEE

Rubber composition for manufacturing high temperature-resistant compression type packer tubling

The invention relates rubber composition used for high-temperature compression packer, comprising the following characteristics: using the hydrogenated nitrile rubber as main material, the organic peroxide as cross linking agent, the hard black and soft black as enhancing filler, the polyfunctional monomer as cross-linking active agent. The money viscosity of the composition is below 180, the hardness of the composition is above shore A90, and the production can be used in oil well at 150Deg.C.

Owner:SHANGHAI PLASTICS RES INST CO LTD

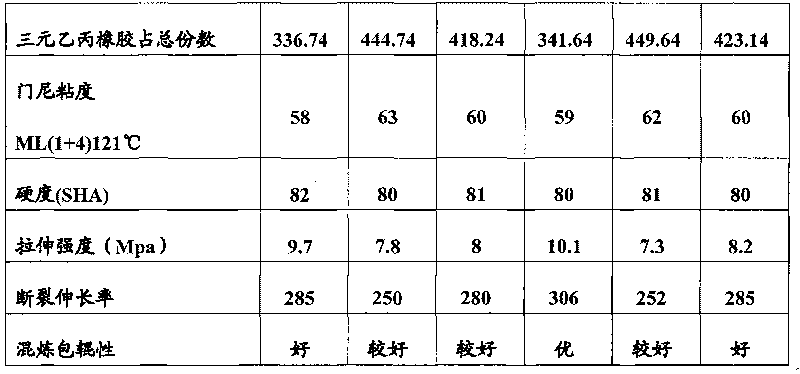

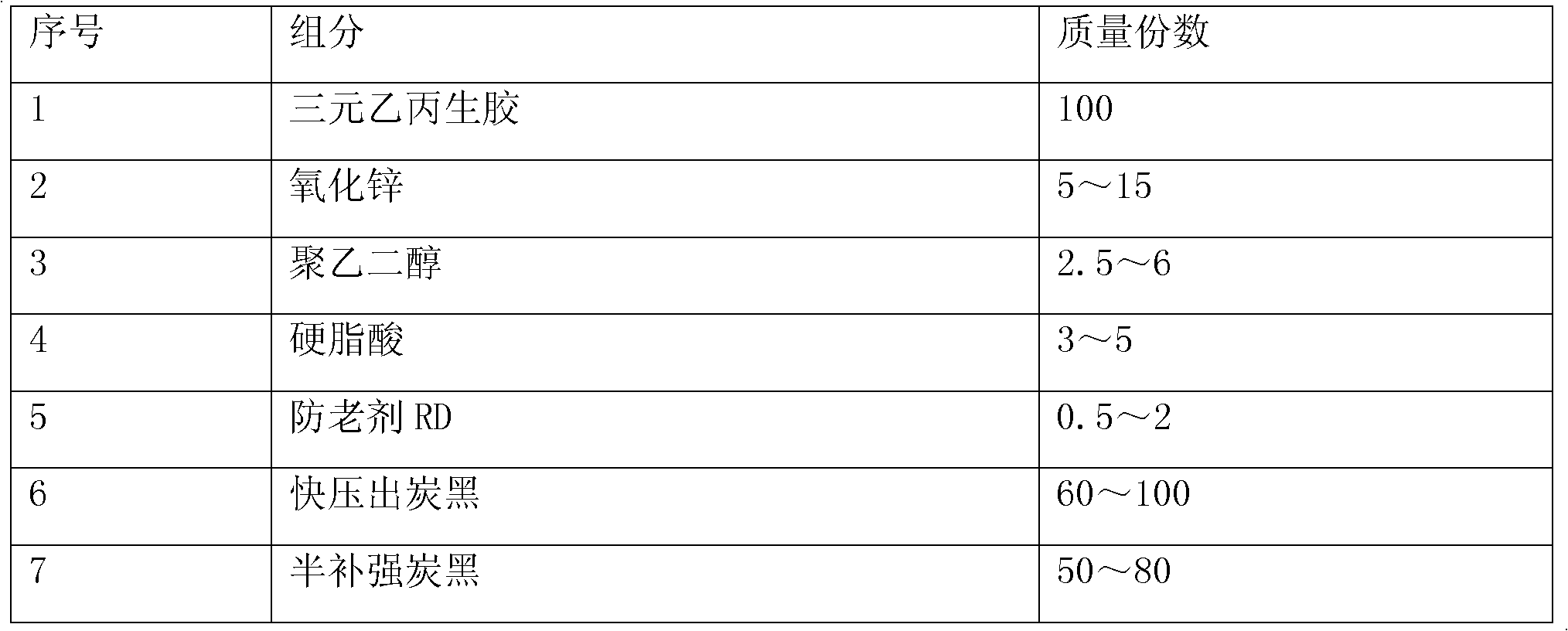

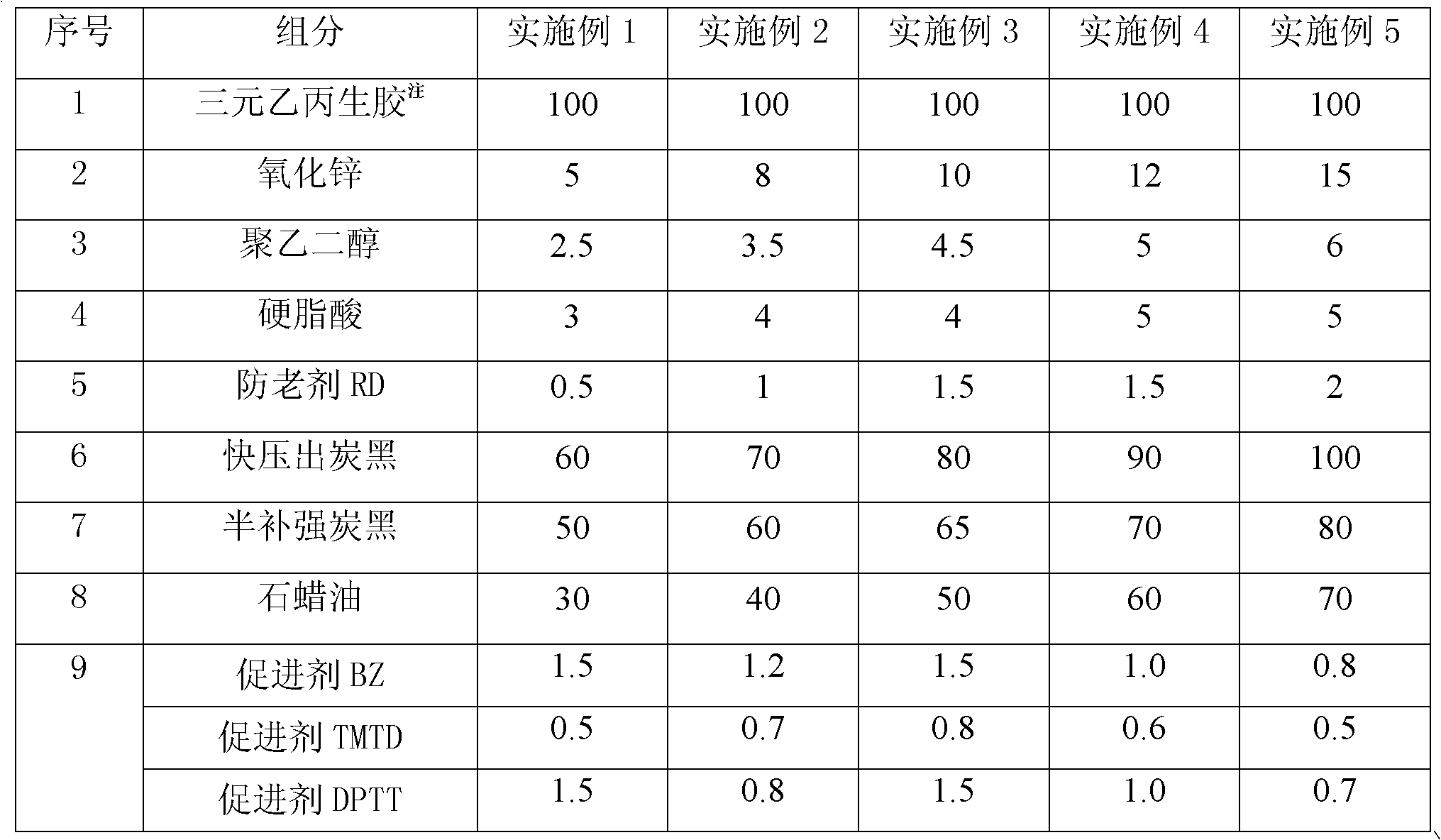

High-hardness ethylene-propylene-diene monomer (EPDM) rubber for extrusion

The invention relates to a high-hardness ethylene-propylene-diene monomer (EPDM) rubber for extrusion, which comprises the following components of EPDM crude rubbers, zinc oxide, polyethylene glycol, stearic acid, an antiager 1,2-dihydro-2,2,4-trimethylquinoline (RD), fast-extruding carbon black, semi-reinforcing carbon black, paraffinoil, accelerating agent BZ, accelerating agent tetramethylthiuram disulfide (TMTD), accelerating agent dipentamethylenethiuram tetrasulfide (DPTT), accelerating agent 4,4`-dithiodimorpholine (DTDM) and vulcanizing agent. The high-hardness ethylene-propylene-diene monomer rubber for extrusion has the advantages that the extrusion technology is good; the physical properties of the product are greatly higher than the standard of the traditional product; the hardness is above 80 Shore A; and the EPDM rubber can meet the current use requirements through the practical application in the seal of doors and windows.

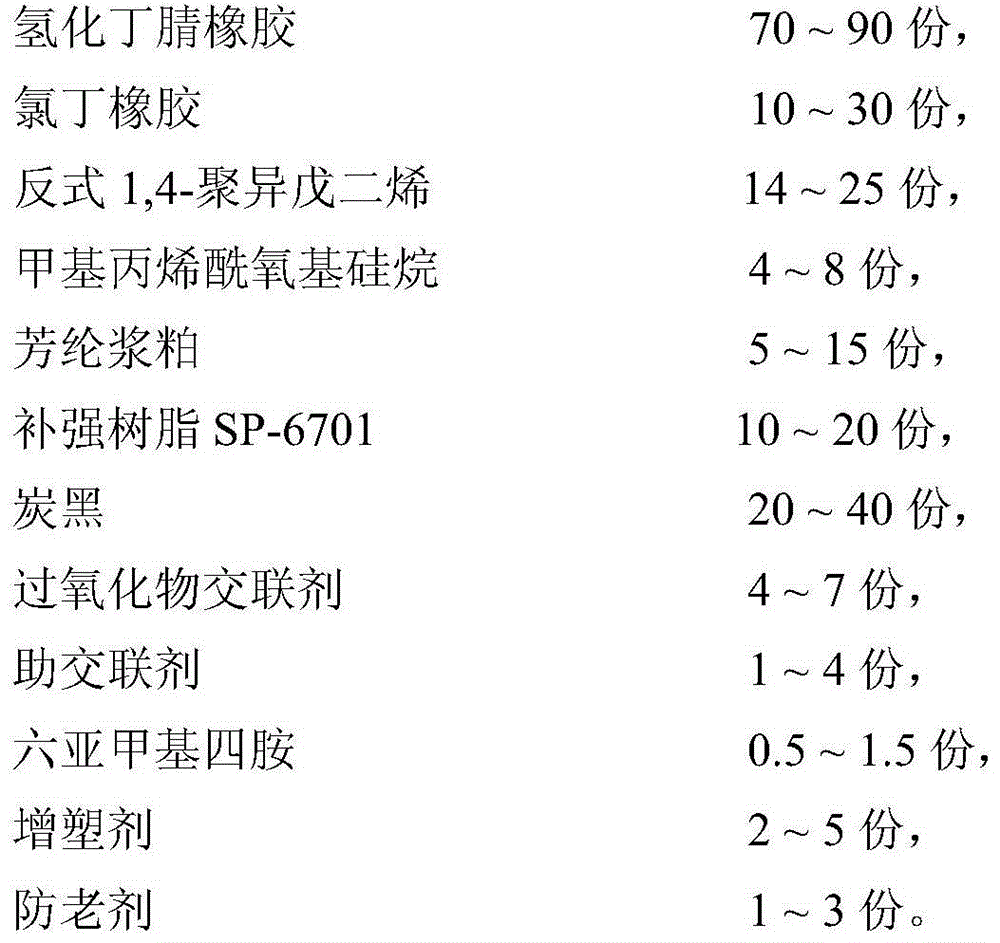

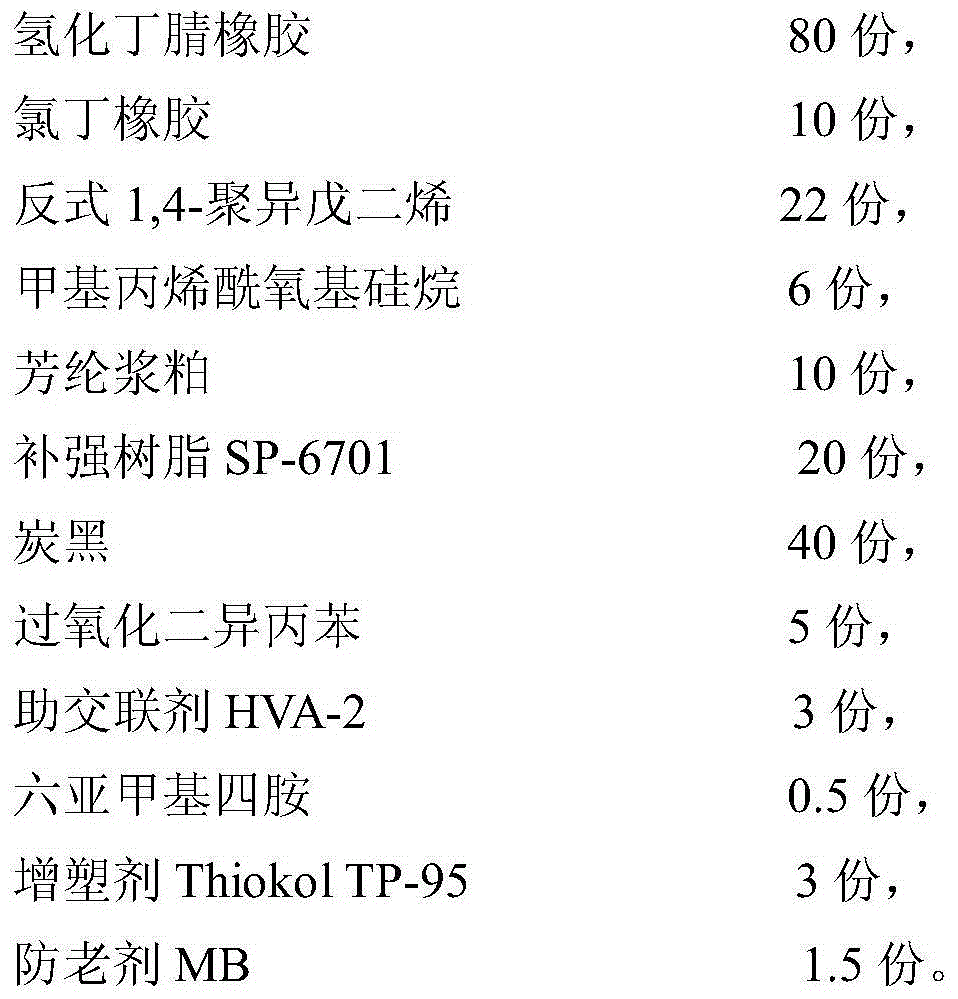

High-strength synchronous belt and manufacturing method thereof

ActiveCN104675922AGood wear resistanceImprove heat resistanceDriving beltsMonocomponent synthetic polymer artificial filamentCarbon blackPlasticizer

The invention relates to a high-strength synchronous belt. The synchronous belt comprises a synchronous belt framework and an adhesive piece attached to the outer side of the synchronous belt frame. The adhesive piece comprises the following components in parts by weight: 70-90 parts of hydrogenated butadiene-acrylonitrile rubber, 10-30 parts of chloroprene rubber, 14-25 parts of trans 1, 4-polyisoprene, 4-8 parts of methylacryloyl silane, 5-15 parts of aramid pulp, 10-20 parts of reinforced fiber SP-6701, 20-40 parts of carbon black, 4-7 parts of peroxide crosslinking agent, 1-4 parts of assistant crosslinking agent, 0.5-1.5 parts of hexamine, 2-5 parts of plasticizer and 1-3 parts of antiaging agent. The invention also relates to a manufacturing method of the synchronous belt. According to the high-strength synchronous belt and the manufacturing method thereof, the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are used together, so that the performances of the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are complementary, and thus the wear resistance and the heat resistance of the adhesive piece of the synchronous belt can be effectively improved; the shear strength and the quality stability of the synchronous belt are improved by use of the trans 1, 4-polyisoprene, the methylacryloyl silane and the aramid pulp.

Owner:NINGBO FULONG SYNCHRONOUS BELT

Processes for making cellulose estate/elastomer compositions

InactiveUS20110319530A1Lower Mooney ViscosityImprove stress conditionImpression capsDentistry preparationsPlasticizerCellulose

A cellulose ester composition is provided comprising at least one cellulose ester and at least one additive selected from the group consisting of a compatibilizer, and a plasticizer. Processes for producing the cellulose ester composition are also provided. In another embodiment, a cellulose ester / elastomer composition is provided comprising at least one elastomer, at least one cellulose ester; and at least one additive; wherein the additive is at least one selected from the group consisting of a compatibilizer and a plasticizer. Processes for producing the cellulose ester / elastomer composition is also provided as well as articles comprising the cellulose ester / elastomer composition.

Owner:EASTMAN CHEM CO

NBR/PVC elastomer by taking LNBR as plasticizer and preparation method of elastomer

The invention discloses an NBR / PVC elastomer by taking LNBR as a plasticizer and a preparation method of the elastomer and relates to a rubber blended elastic material and a preparation method thereof. The elastomer consists of the following components in parts by mass: 70 parts of butadiene-acrylonitrile rubber, 30 parts of polyvinyl chloride (PVC), 10-50 parts of reinforcing agent, 10-30 parts of plasticizer, 2.5-3.5 parts of anti-aging agent, 1.0-2.0 parts of vulcanizing agent, 5.0-7.0 parts of vulcanizing activator, 1.0-2.0 parts of vulcanization accelerator and 1.5-2.0 parts of stabilizer. According to the preparation method of the elastomer, the used vulcanizing temperature is 165 DEG C, so that the elastomer has excellent performances such as hot air aging resistance, wear resistance, fatigue resistance and solvent extraction resistance. The elastomer can be widely applied to the industries such as printing rubber rolls, fuel oil rubber tubes and accumulator capsules.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

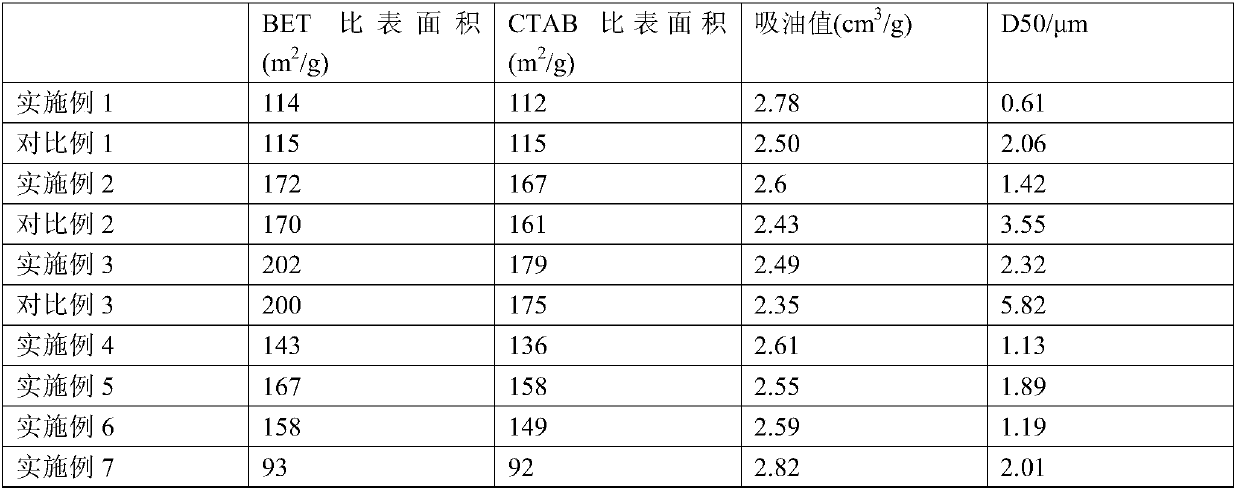

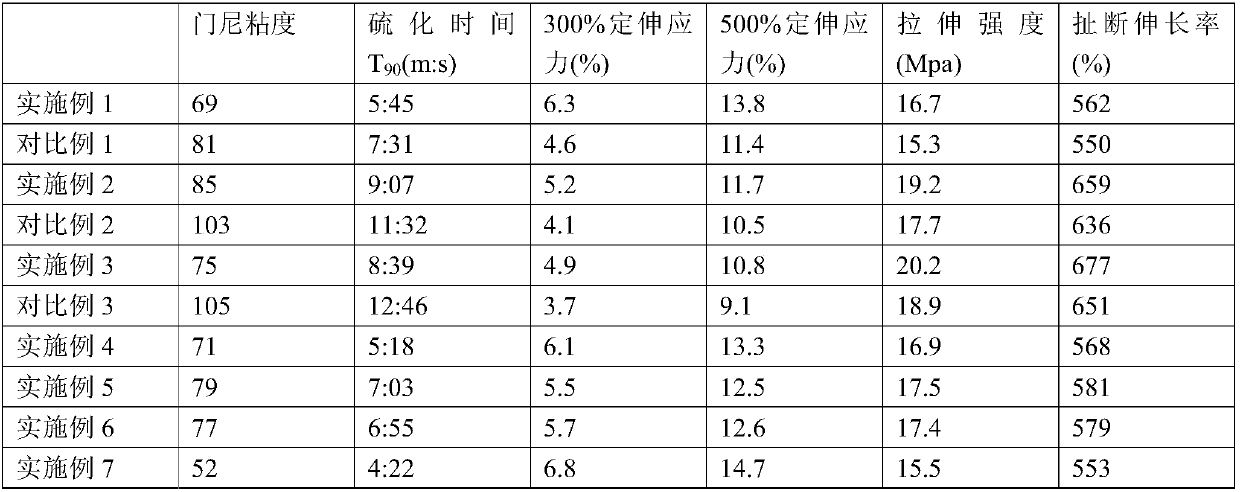

High-dispersity white carbon black and preparation method thereof

ActiveCN107697921ADoes not affect the BET specific surface areaGood dispersionSilicon compoundsDispersityAlcohol

The invention provides high-dispersity white carbon black and a preparation method thereof. The preparation method comprises the following steps: (1) heating water, adding water glass, then adding ethyl alcohol, and mixing the water, the water glass and the ethyl alcohol to obtain a reaction base solution, wherein the temperature in the whole process does not change, the concentration of the waterglass is 0.01 to 1.00 mol / L, and the mass percentage of the ethyl alcohol is 0.1 to 5 weight percent; (2) simultaneously adding acid and water glass into the reaction base solution for mixing for reaction, thereby obtaining white carbon black suspension, wherein the reaction temperature is kept constant and is equal to that of the reaction base solution, and the concentration of the water glass is kept constant and is equal to that of the reaction base solution; (3) stopping adding the water glass into the white carbon black suspension, and independently adding acid to adjust the pH of a reaction system to 3.0 to 5.0, thereby obtaining acidified white carbon black suspension; (4) carrying out solid-liquid separation on the acidified white carbon black suspension to obtain a filter cake, thereby obtaining the white carbon black. The white carbon black provided by the invention is extremely high in dispersivity, and shows a good rubber reinforcing effect.

Owner:WUXI HENGCHENG SILICON IND CO LTD

Rubber anti-recovery agent and preparation thereof

The invention discloses a rubber anti-sulfuration recovery agent, which comprises the following components according to the percentage by weight: 50-55% of zinc fatty acid, 23-28% of aromatic acid zinc, 17-22% of poly zinc carbonate with branched chains. The invention also discloses a preparation method for poly zinc carbonate. The invention discloses a preparation method for the rubber anti-sulfuration recovery agent. The rubber anti-sulfuration recovery agent not only has anti-sulfuration recovery function on vulcanized rubber, but also can reduce the Mooney viscosity of gross rubber, improves the sizing processing performance and can reduce dynamic heat build-up of tread rubber of tyre. The preparation method of the rubber anti-sulfuration recovery agent is different from other simple mixed methods adopted for preparing general multicomponent mixtures. The rubber anti-sulfuration recovery agent is prepared by using the method that organic acid and zinc oxide directly reacts; and the reaction process has no pollution.

Owner:JIANGSU KAOU CHEM

Processes for making cellulose ester compositions

A cellulose ester composition is provided comprising at least one cellulose ester and at least one additive selected from the group consisting of a compatibilizer, and a plasticizer. Processes for producing the cellulose ester composition are also provided. In another embodiment, a cellulose ester / elastomer composition is provided comprising at least one elastomer, at least one cellulose ester; and at least one additive; wherein the additive is at least one selected from the group consisting of a compatibilizer and a plasticizer. Processes for producing the cellulose ester / elastomer composition is also provided as well as articles comprising the cellulose ester / elastomer composition.

Owner:EASTMAN CHEM CO

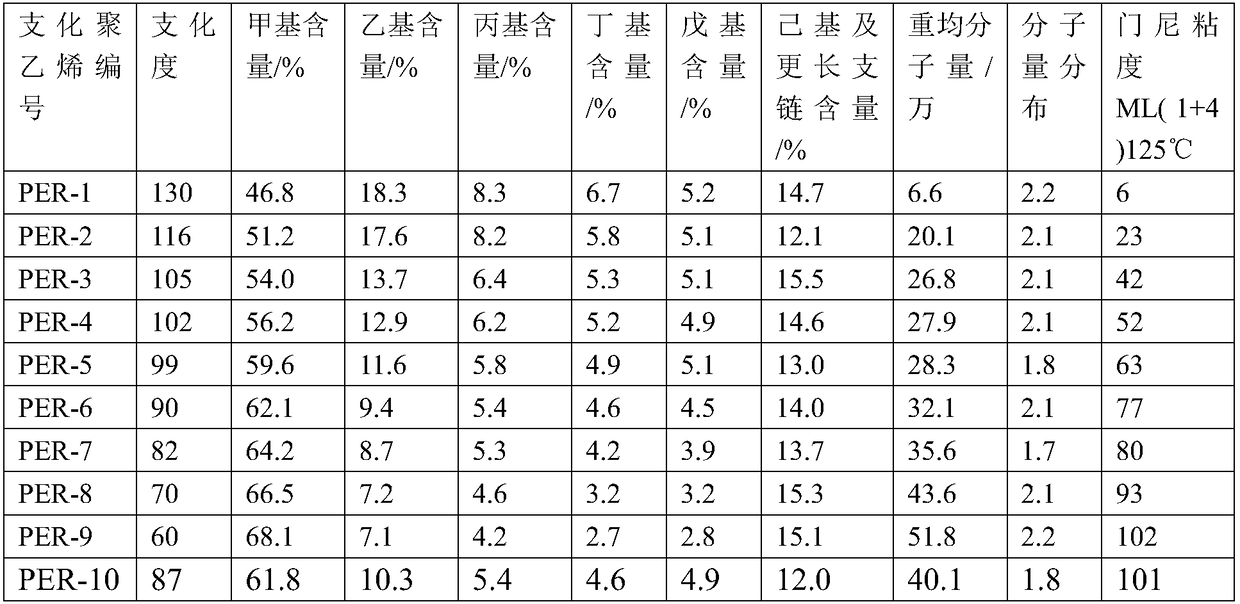

Rubber composition, processing method, application and method for producing flame-retardant products

ActiveCN108299743AReduced mechanical propertiesReduced processing performanceCold airPolymer science

The invention discloses rubber composition, a processing method thereof and an application of the composition to processing of flame-retardant products. The rubber composition is prepared from a rubber matrix and essential components, wherein the rubber matrix contains a parts of branched polyethylene and b parts of EPM rubber and EPDM rubber, a is larger than 0 and smaller than or equal to 100 parts, and b is larger than or equal to 0 and smaller than 100 parts; the essential components comprise 1.5-10 parts of a crosslinking agent and 40-300 parts of a flame retardant. The rubber compositionapplies to production of flame-retardant products such as flame-retardant cables, flame-retardant cold air hoses of automobiles, flame-retardant sealing strips, high-temperature-resistant flame-retardant conveyor belts, flame-retardant waterproof rolls and the like, and the flame-retardant products have good flame retardance and mechanical properties.

Owner:HANGZHOU XINGLU TECH CO LTD +1

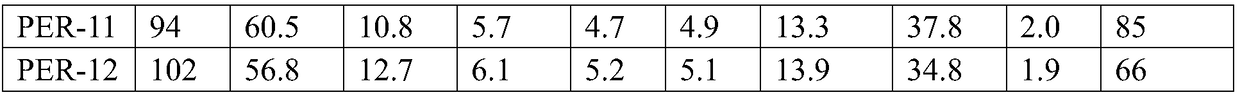

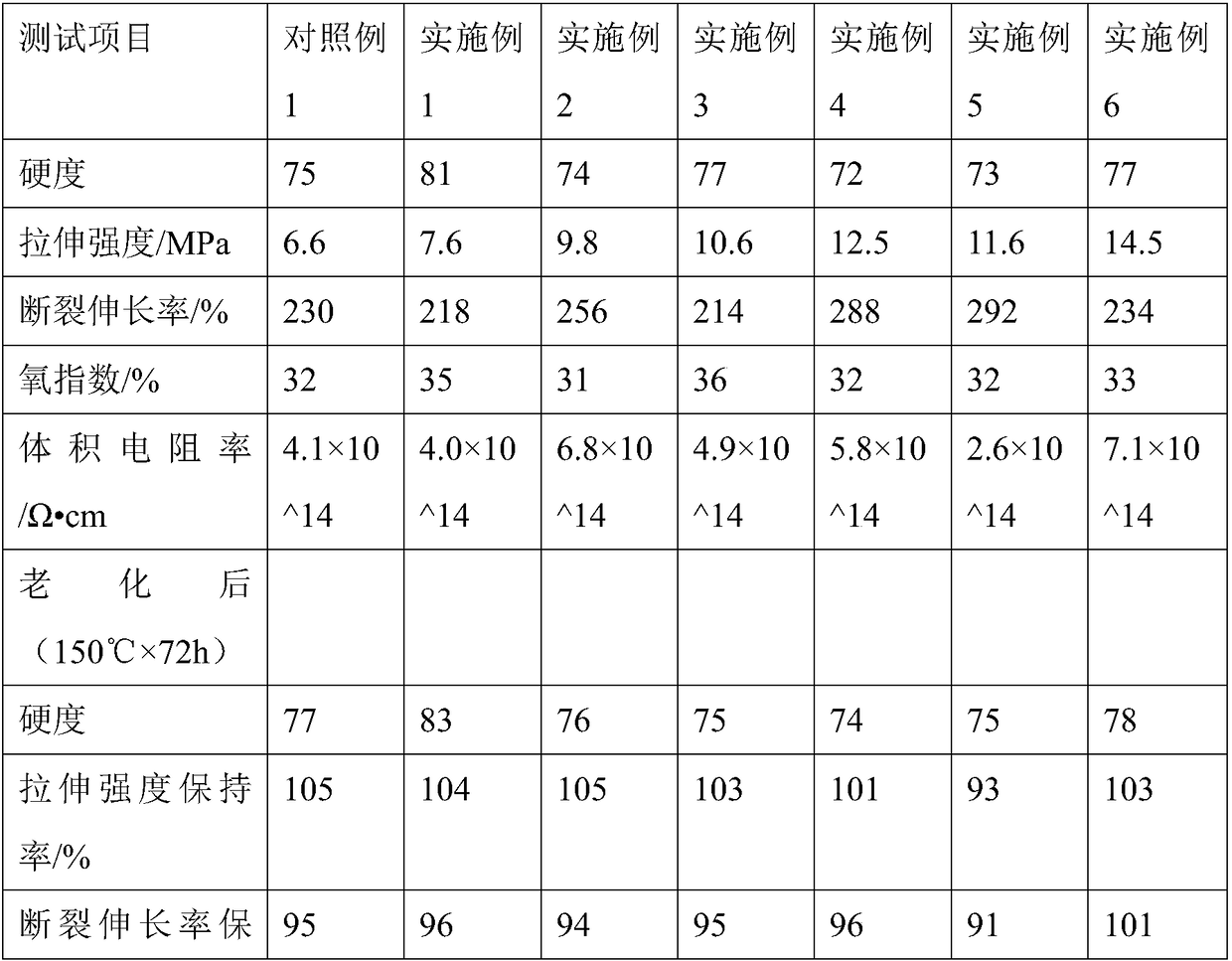

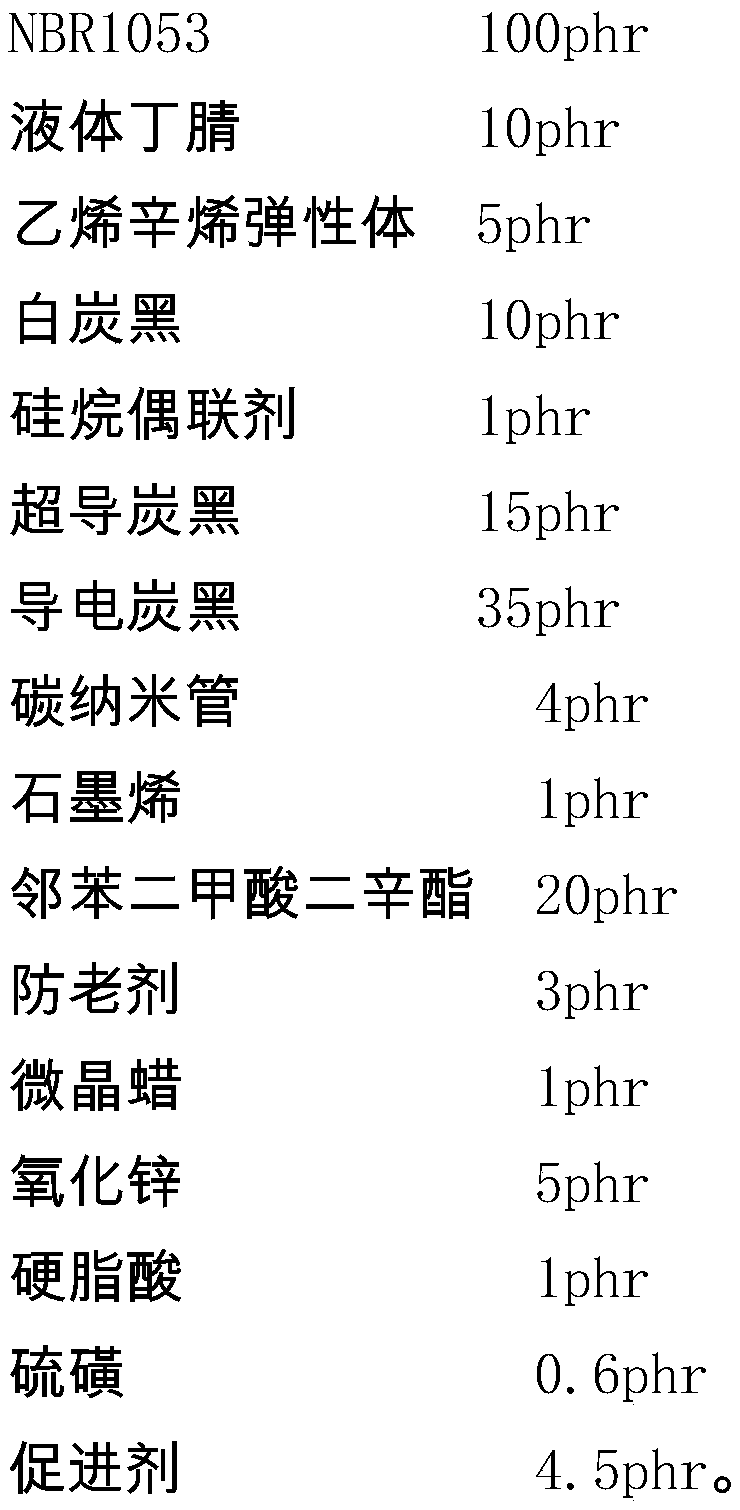

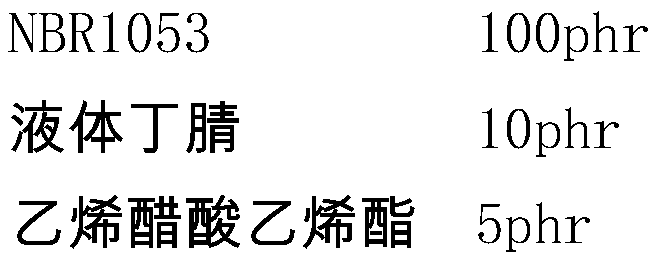

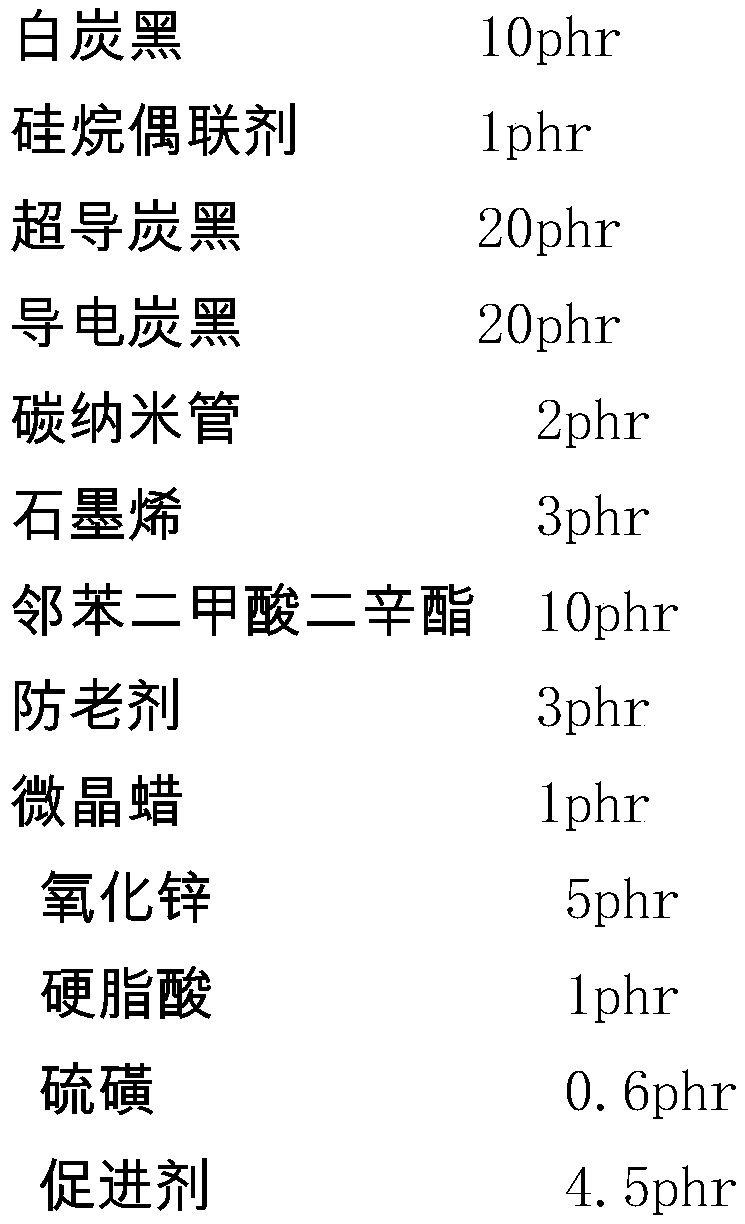

High-conductivity and low-hardness NBR (nitrile-butadiene rubber) blended rubber and preparation method thereof

Owner:环球石墨烯(青岛)有限公司

Cellulose ester compositions

A cellulose ester composition is provided comprising at least one cellulose ester and at least one additive selected from the group consisting of a compatibilizer, and a plasticizer. Processes for producing the cellulose ester composition are also provided. In another embodiment, a cellulose ester / elastomer composition is provided comprising at least one elastomer, at least one cellulose ester; and at least one additive; wherein the additive is at least one selected from the group consisting of a compatibilizer and a plasticizer. Processes for producing the cellulose ester / elastomer composition is also provided as well as articles comprising the cellulose ester / elastomer composition.

Owner:EASTMAN CHEM CO

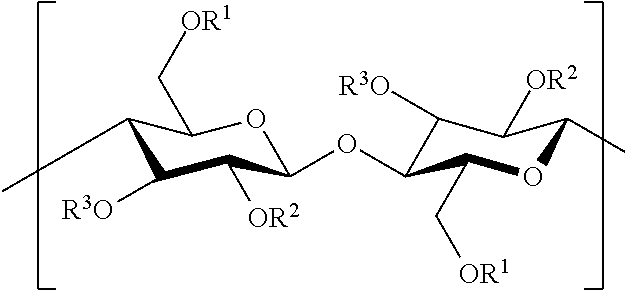

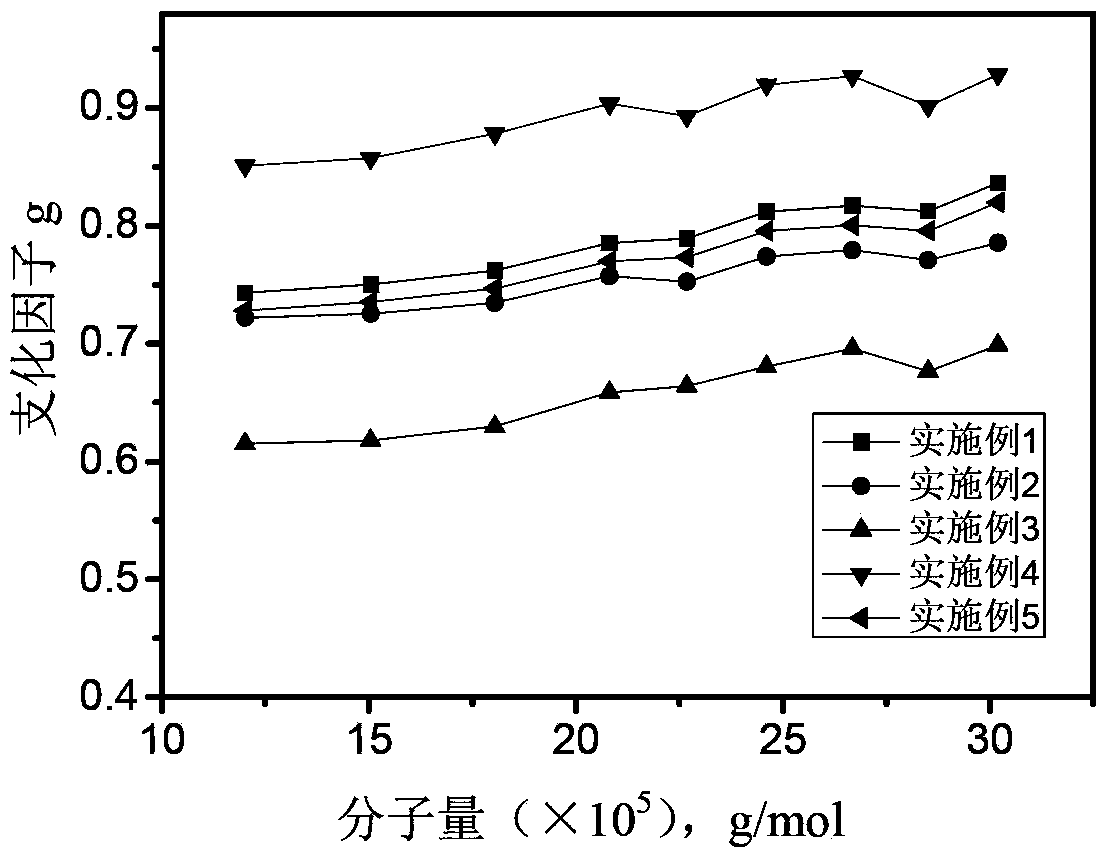

Polybutadiene grafted isoprene rubber and preparation method thereof, vulcanizate and rubber compound

The invention provides a polybutadiene grafted isoprene rubber and a preparation method thereof / the polybutadiene grafted isoprene rubber prepared by using the method, and a rubber compound and a vulcanizate prepared by using the polybutadiene grafted isoprene rubber. The polybutadiene grafted isoprene rubber comprises, on the basis of the total weight of the polybutadiene grafted isoprene rubber, 0.5 to 8 wt% of a butadiene constitutional unit and 92 to 99.5 wt% of an isoprene constitutional unit; the polybutadiene grafted isoprene rubber has number-average molecular weight of 2 * 10<5> to 5 * 10<5>, molecular weight distribution of 3 to 4, a branching factor of 0.5 to 0.98 and cis-1,4 structure content of 95 to 99 wt%. The polybutadiene grafted isoprene rubber provided by the invention has excellent mechanical properties and good processability. Moreover, the preparation method is simple and easily controllable, can highly efficiently and accurately control the composition and molecular weight of a prepared polymer and has good industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cellulose ester/elastomer compositions

InactiveUS9068063B2Lower Mooney ViscosityImprove stress conditionImpression capsDentistry preparationsCelluloseElastomer

A cellulose ester composition is provided comprising at least one cellulose ester and at least one additive selected from the group consisting of a compatibilizer, and a plasticizer. Processes for producing the cellulose ester composition are also provided. In another embodiment, a cellulose ester / elastomer composition is provided comprising at least one elastomer, at least one cellulose ester; and at least one additive; wherein the additive is at least one selected from the group consisting of a compatibilizer and a plasticizer. Processes for producing the cellulose ester / elastomer composition is also provided as well as articles comprising the cellulose ester / elastomer composition.

Owner:EASTMAN CHEM CO

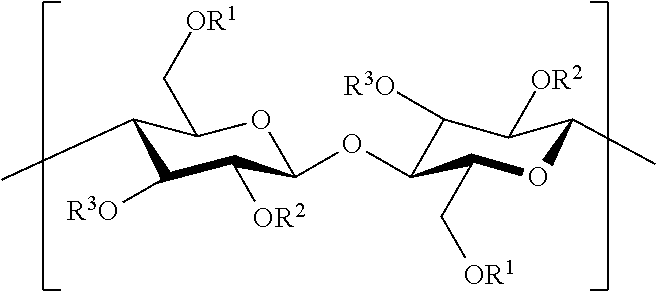

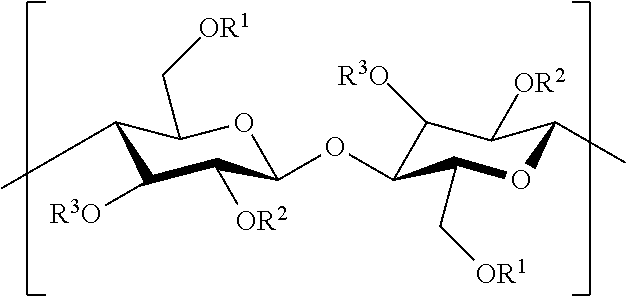

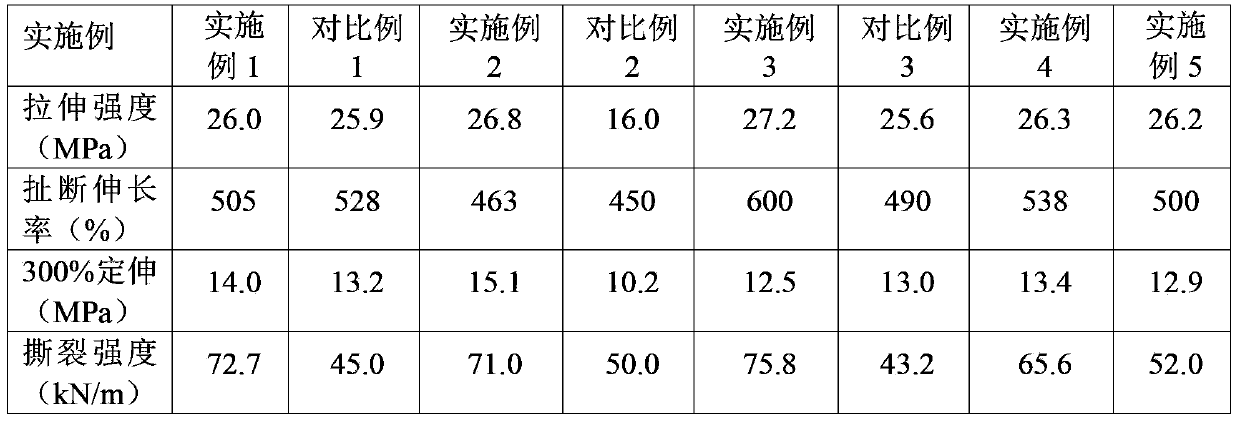

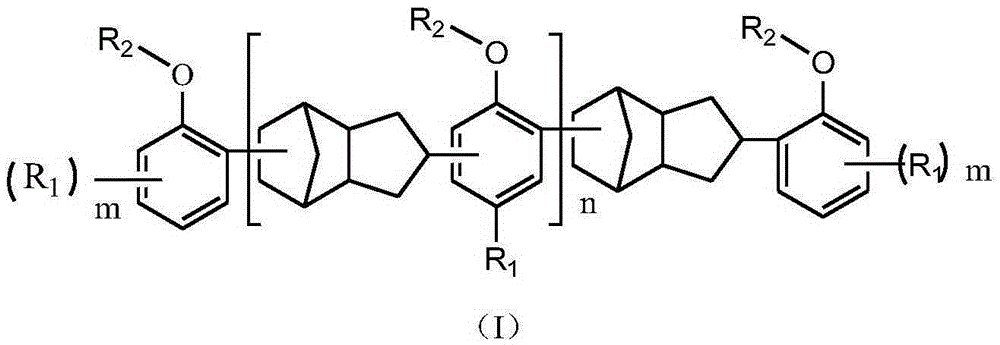

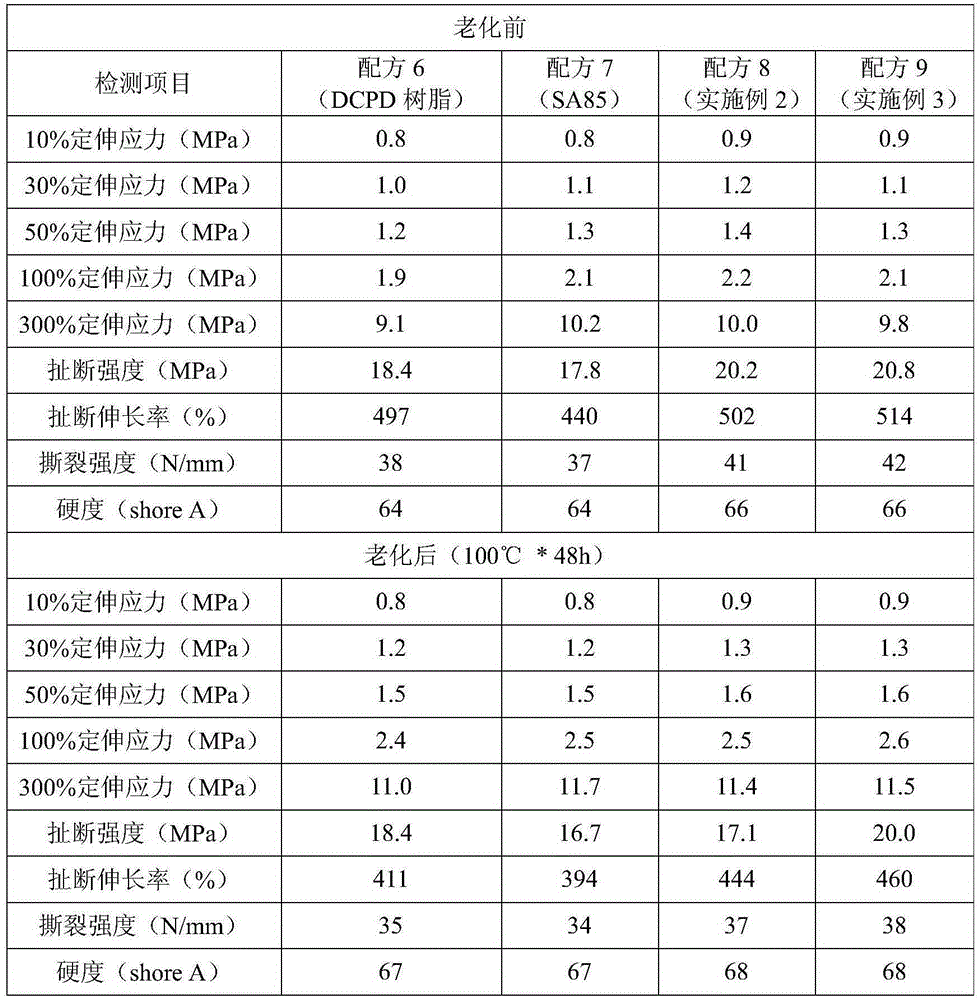

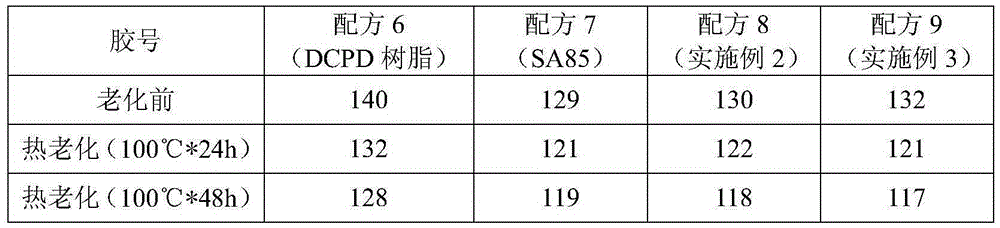

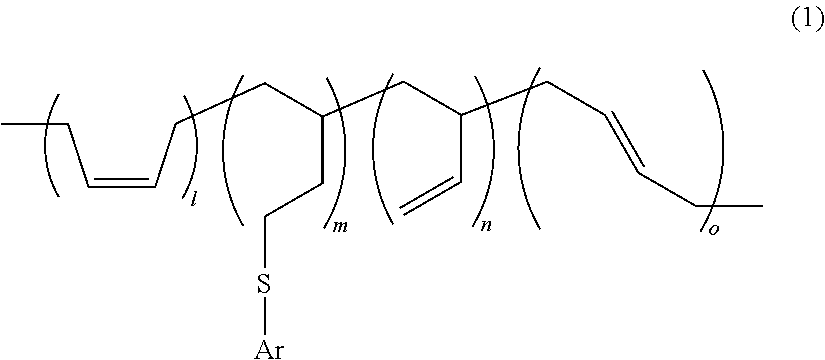

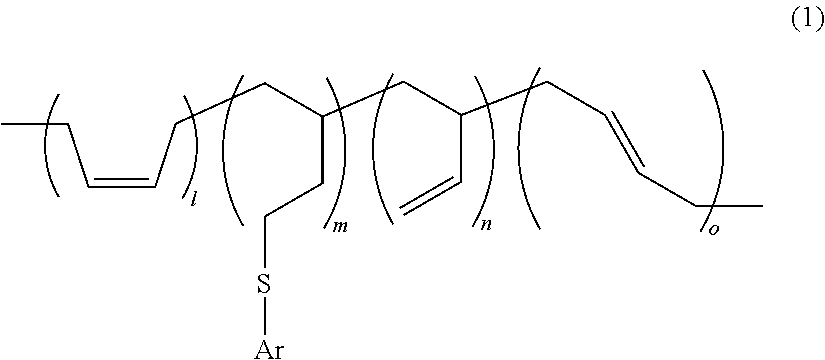

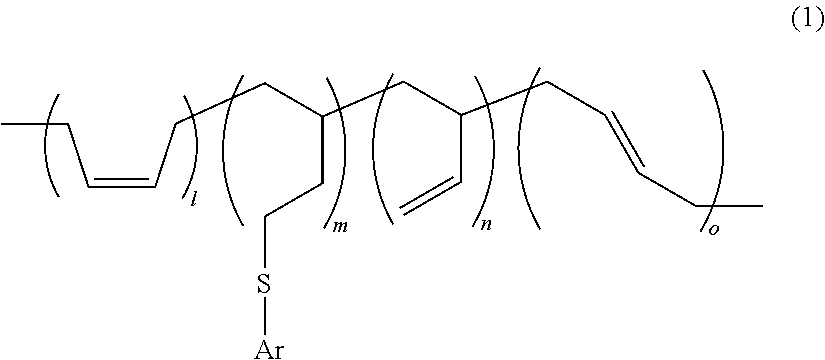

Rubber composition for improving tearing property of rubber and application

Provided is a tire tread rubber composition. The composition contains rosin-modified phenol-DCPD resin, and the structure of the rosin-modified phenol-DCPD resin is shown as a formula (I). According to the rubber composition, the tearing property and the machining property are both improved, the abrasive resistance is improved, and the dynamic property is improved.

Owner:BEIJING RED AVENUE INNOVA

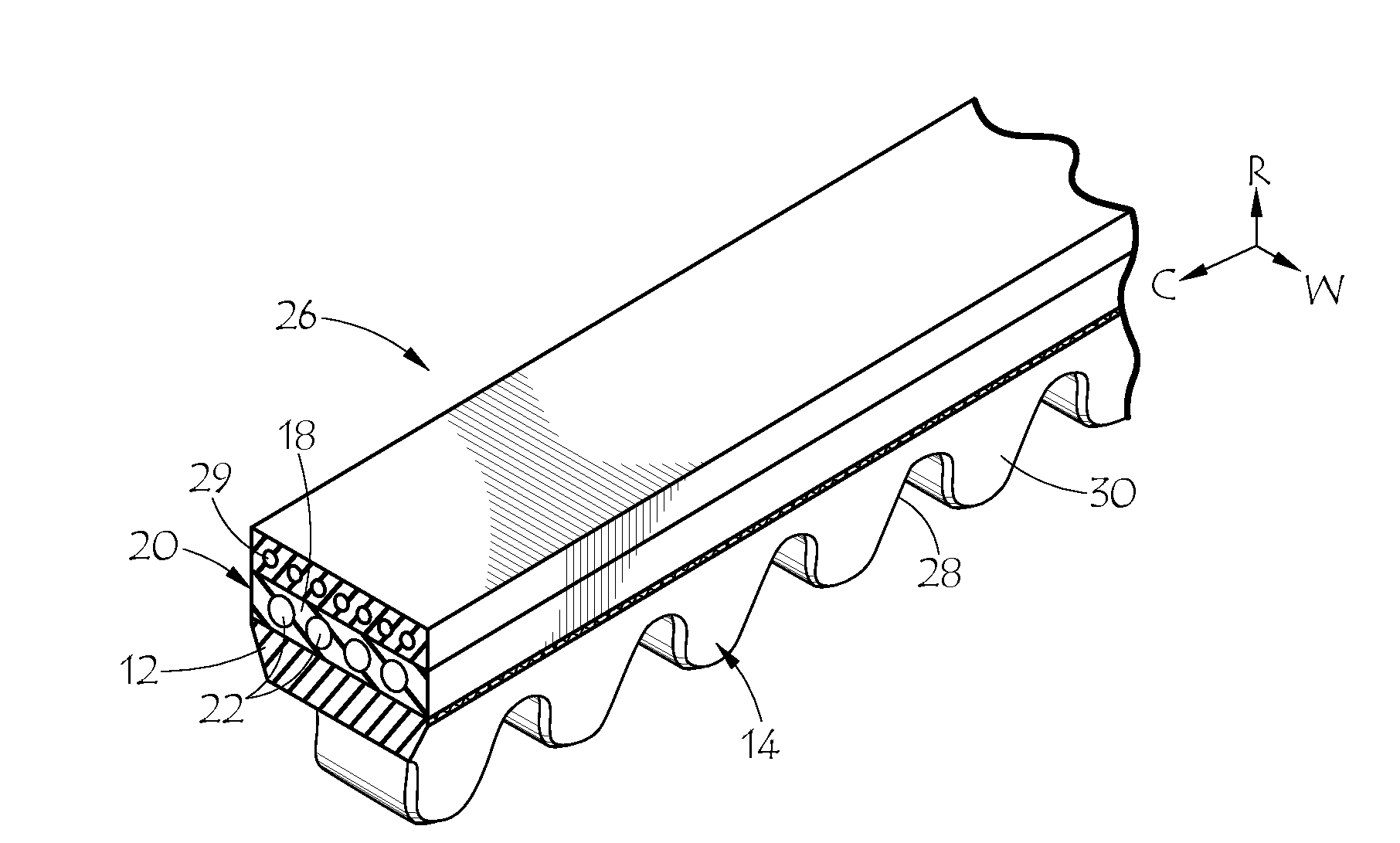

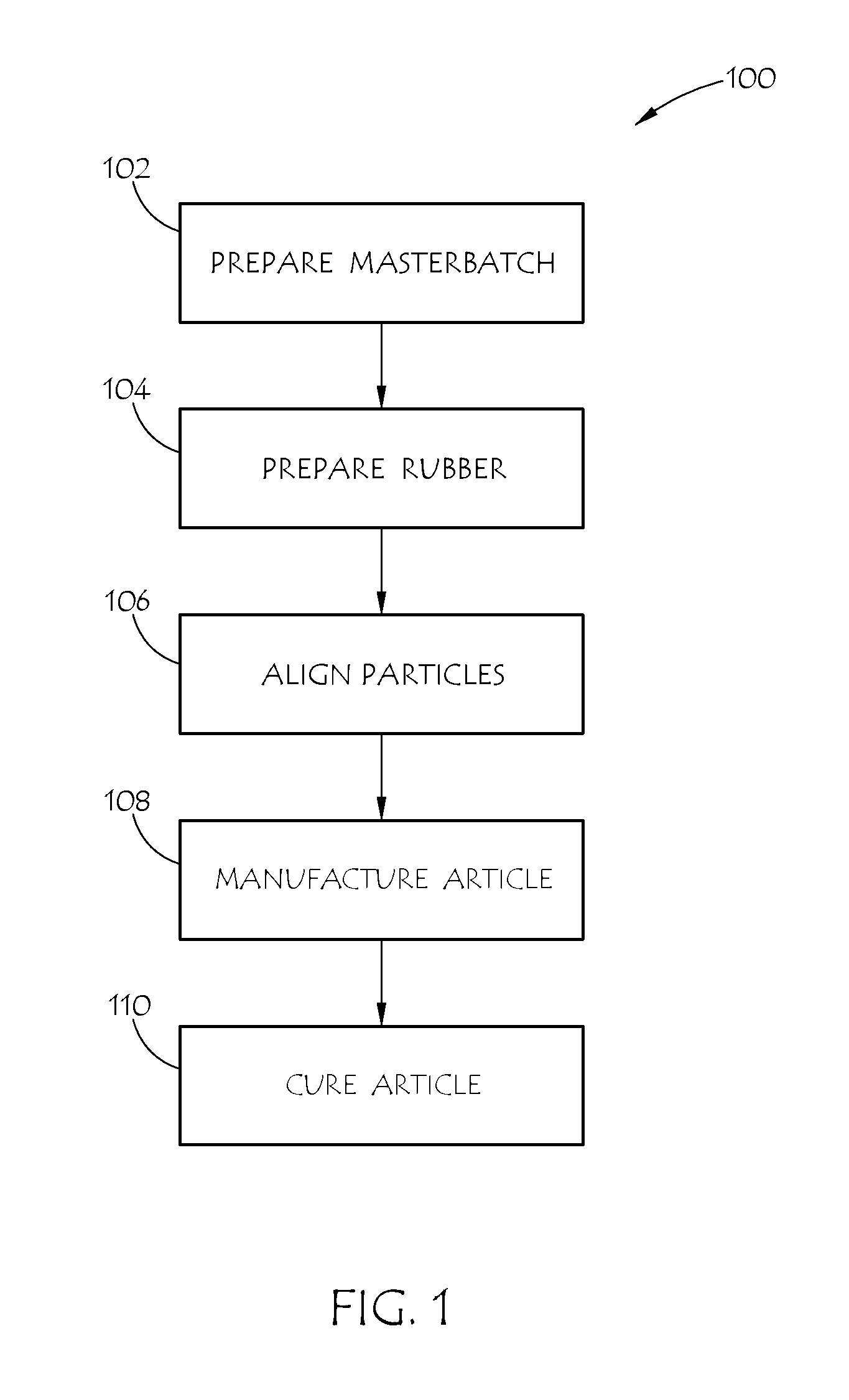

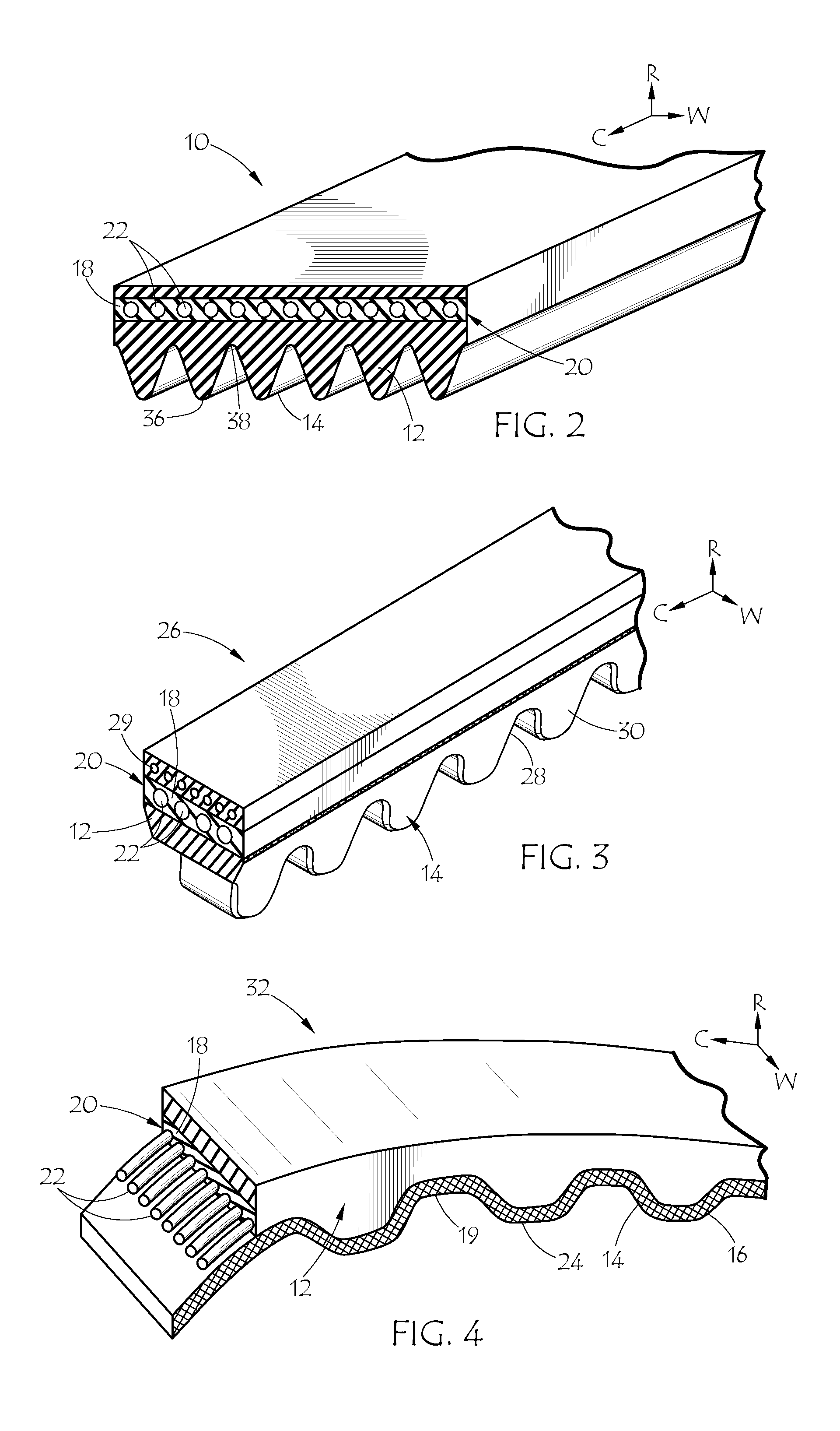

Power transmission belt

InactiveUS20170023098A1Improve performanceLower Mooney ViscosityV-beltsDriving beltsOrganic acidLongitudinal plane

This disclosure describes systems and methods which utilize organoclays compounded with zinc acrylates to improve the performance of drive belts. In performing research on organoclays, the inventors created formulations and methods of compatibilizing organoclays with metal salts of α-β-unsaturated organic acids and incorporating the compatibilized organoclays into the belt compound so that the planar organoclay particles are substantially aligned with the longitudinal plane of the belt. This is shown to provide a) lower Mooney viscosity (resulting in greater ease of processing), b) higher stiffness (both tensile and dynamic) c) improved tear resistance, d) lower crack growth rate and e) nearly equivalent fatigue resistance in spite of the increased stiffness. This combination of traits in the belts created utilizing the organoclay / zinc acrylate technology described herein results in an unexpectedly improved belt.

Owner:THE GATES CORP

Pre-dispersion masterbatch used as rubber ultra-fast accelerator ZDMC and preparation method of pre-dispersion masterbatch

The invention discloses a pre-dispersion masterbatch used as a rubber ultra-fast accelerator ZDMC. The pre-dispersion masterbatch used as the rubber ultra-fast accelerator ZDMC consists of the following components in parts by weight: 75-82 parts of zinc dimethyldithiocarbamate, 10-14 parts of a rubber carrier, 2-6 parts of naphthenic oil, 1 part of stearic acid, 1 part of triethanolamine, and 2-5 parts of a mixture of saturated and unsaturated fatty acid zinc soap. The zinc dimethyldithiocarbamate is prepared into the pre-dispersion masterbatch, so that the original activity of the zinc dimethyldithiocarbamate can be guaranteed effectively. The pre-dispersion masterbatch cannot be caked at room temperature, and batching is convenient and accurate, when the pre-dispersion masterbatch is used as an ultra-fast accelerator in the follow-up process, dust flying is avoided in a rubber melting process, a working environment of an operator can be improved, the use level of the accelerator is reduced, and the utilization rate of the zinc dimethyldithiocarbamate is increased; the pre-dispersion masterbatch has relatively low Mooney viscosity at the relatively low temperature of 50 DEG C, and has good dispersibility in rubber, and the quality of a rubber product can be improved.

Owner:NINGBO ACTMIX POLYMER

Silane-Coupling-Agent-Treated Silica, Preparation Method Thereof, And Vibration-Damping And Vibration-Isolating Rubber Composition Containing The Same

InactiveUS20090143538A1Lower Mooney ViscosityImprove machinabilitySilicon organic compoundsPigmenting treatmentTO-18Polymer science

A silane-coupling-agent-treated silica having a sulfur-deviation range of 50 to 200%, comprising 100 parts by mass of silica surface-treated with 1 to 50 parts by mass of a silane coupling agent represented by the following general formula (1): Y3-Si-Z-S—CO—R (wherein Y is an acetoxy group or an alkoxy group with 1 to 6 carbon atoms, Z is an alkylene group with 1 to 8 carbon atoms, and R is a hydrocarbon group with 1 to 18 carbon atoms) is disclosed. Furthermore, a vibration-damping and vibration-isolating rubber composition comprising 100 parts by mass of a raw rubber material having C—C bonds in the main chain and 1 to 200 parts of the aforementioned silane-coupling-agent-treated silica is claimed.

Owner:DOW CORNING TORAY CO LTD

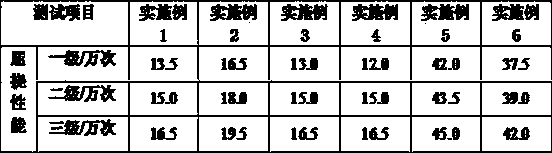

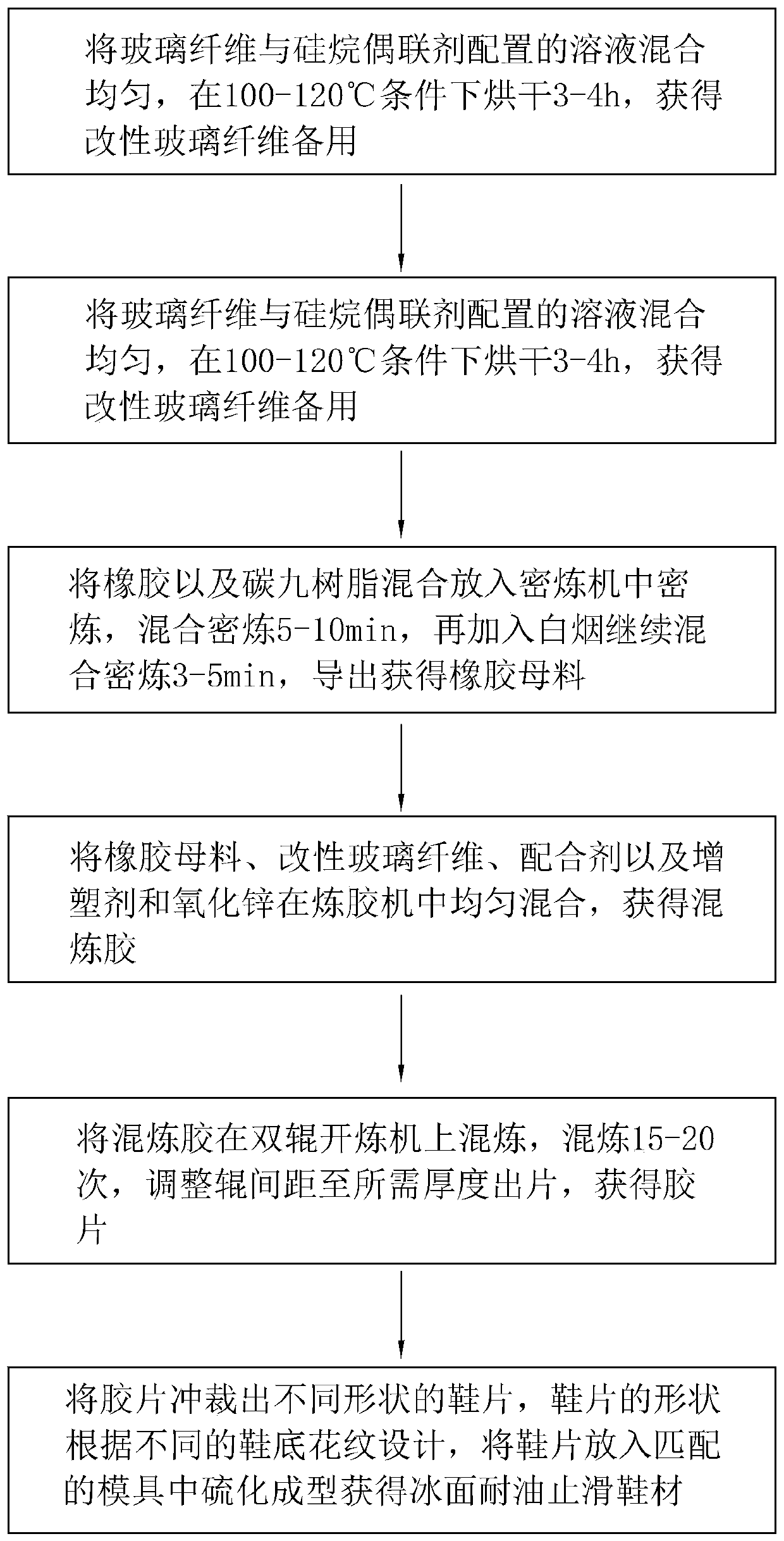

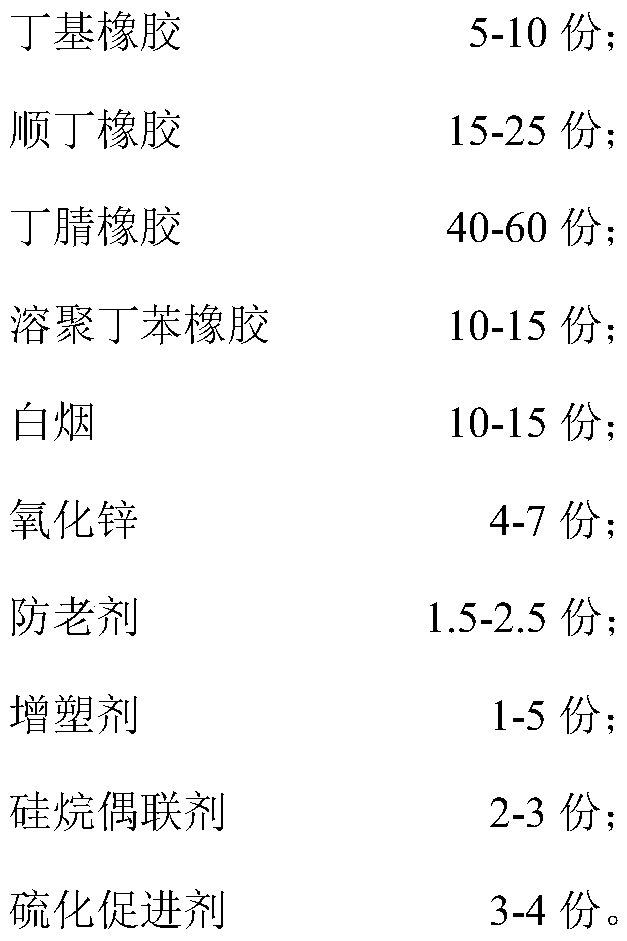

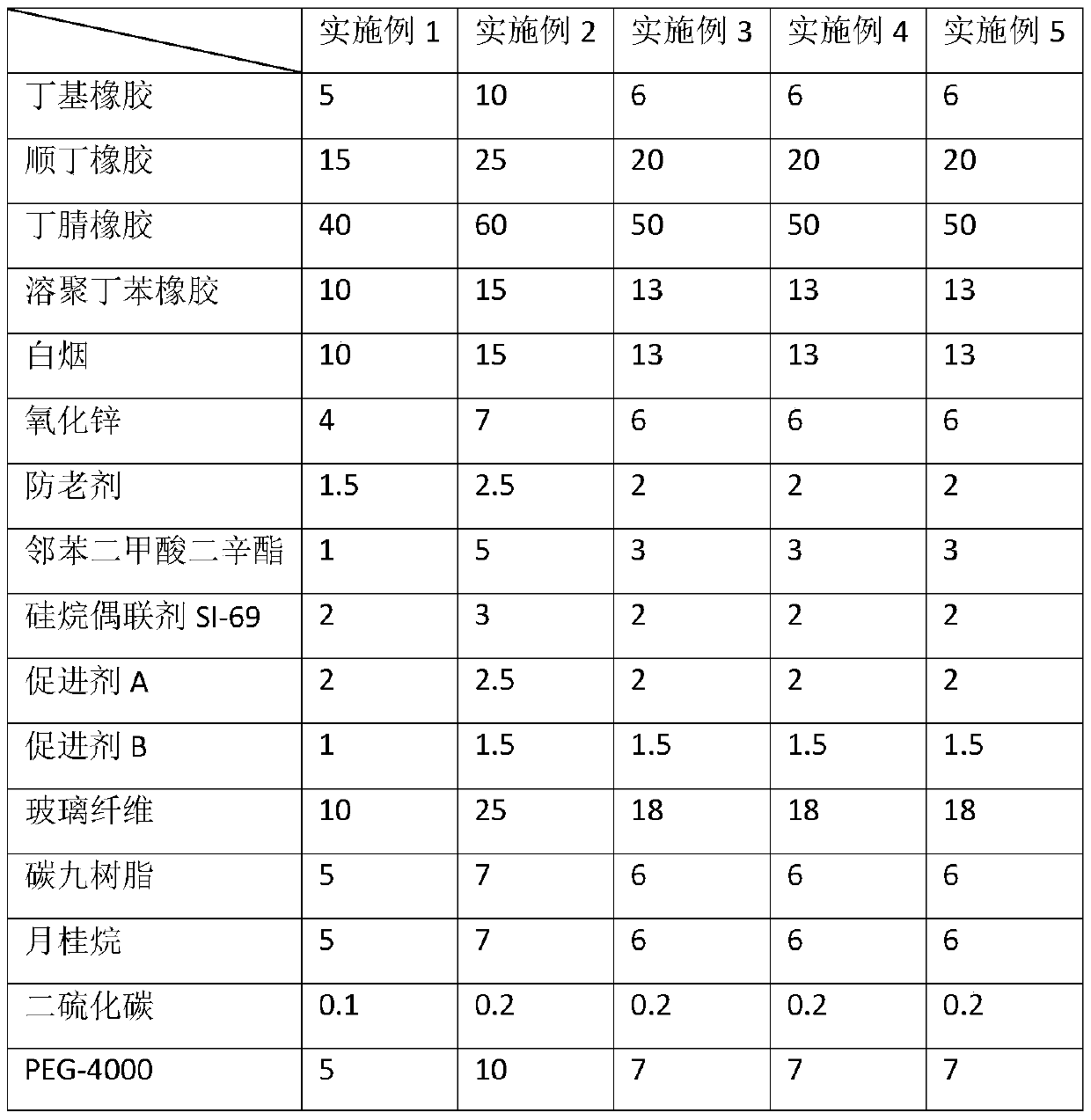

Ice-surface oil-resistant non-slip shoe material and preparation method thereof

The invention discloses an ice-surface oil-resistant non-slip shoe material and a preparation method thereof, and relates to the technical field of shoe materials. The shoe material is prepared from butyl rubber, butadiene rubber, nitrile rubber, solution polymerized styrene-butadiene rubber, white smoke, zinc oxide, an anti-ageing agent, a plasticizer, a silane coupling agent and a vulcanizationaccelerator. The shoe material prepared through the formula is combined with the specific pattern of an outsole and integrally formed or adhered to the outsole, and the obtained sole has the advantages of being resistant to oil and slip, good in mechanical performance, free of fog return and the like. The anti-slip performance is excellent, and the shoe material is suitable for being used on the ice and snow ground.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

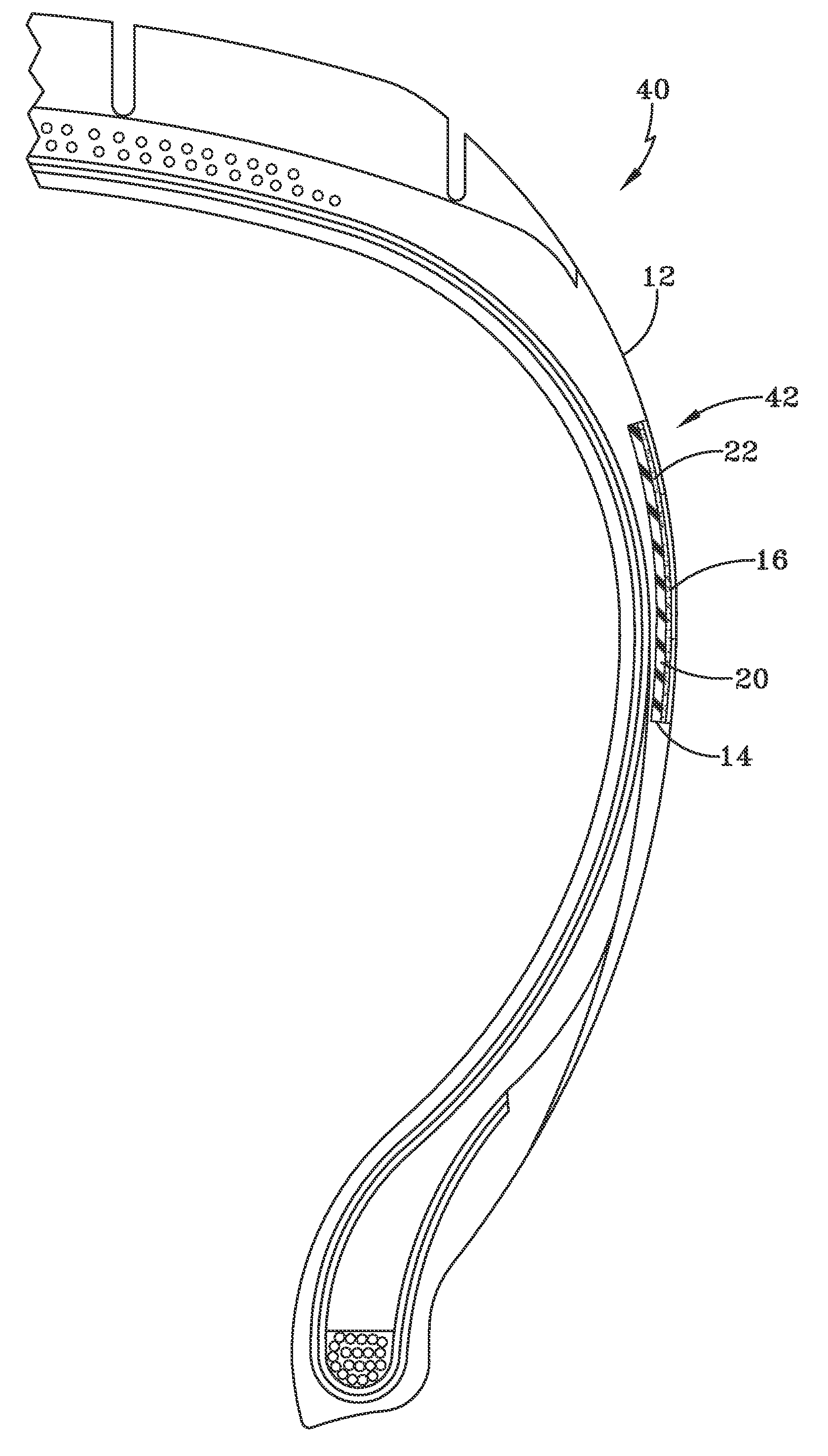

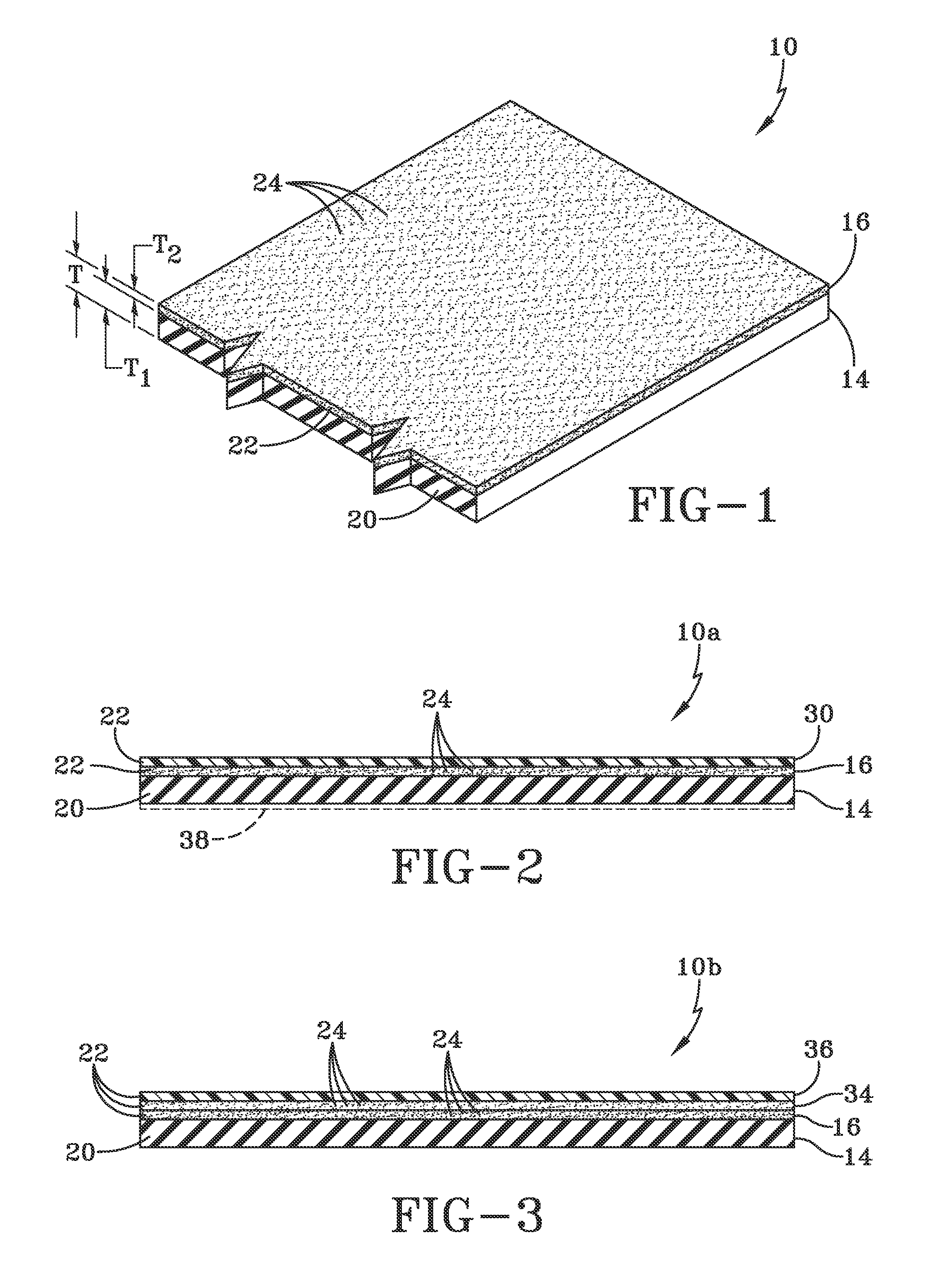

Multi-Layered Veneer For A Tire Sidewall

InactiveUS20070267118A1Desire effectProviding stability and durabilityDecorative surface effectsPneumatic tyre reinforcementsSynthetic polymerEngineering

A multi-layered veneer for a tire sidewall is disclosed wherein one or more layers of the veneer include at least one pigment to provide a desired visual effect for the tire sidewall. In one embodiment, the multi-layered veneer includes a tie layer and a first thermoplastic layer bonded to the tie layer. The tie layer is capable of bonding the veneer to a sidewall compound of a tire sidewall. The first thermoplastic layer includes a thermoplastic material and the tie layer includes no less than about 80% by weight of a synthetic polymer chosen from EPDM, EPR, polyethylene, or combinations thereof. The synthetic polymers have a Mooney Viscosity (ML 1+4 at 125° C.) from about 5 to about 40, and the EPDM and EPR have an ethylene content of about 70% by weight to about 99% by weight of the polymer. One or more pigments are dispersed in the tie layer and / or the first thermoplastic layer so as to provide the visual effect.

Owner:THE GOODYEAR TIRE & RUBBER CO

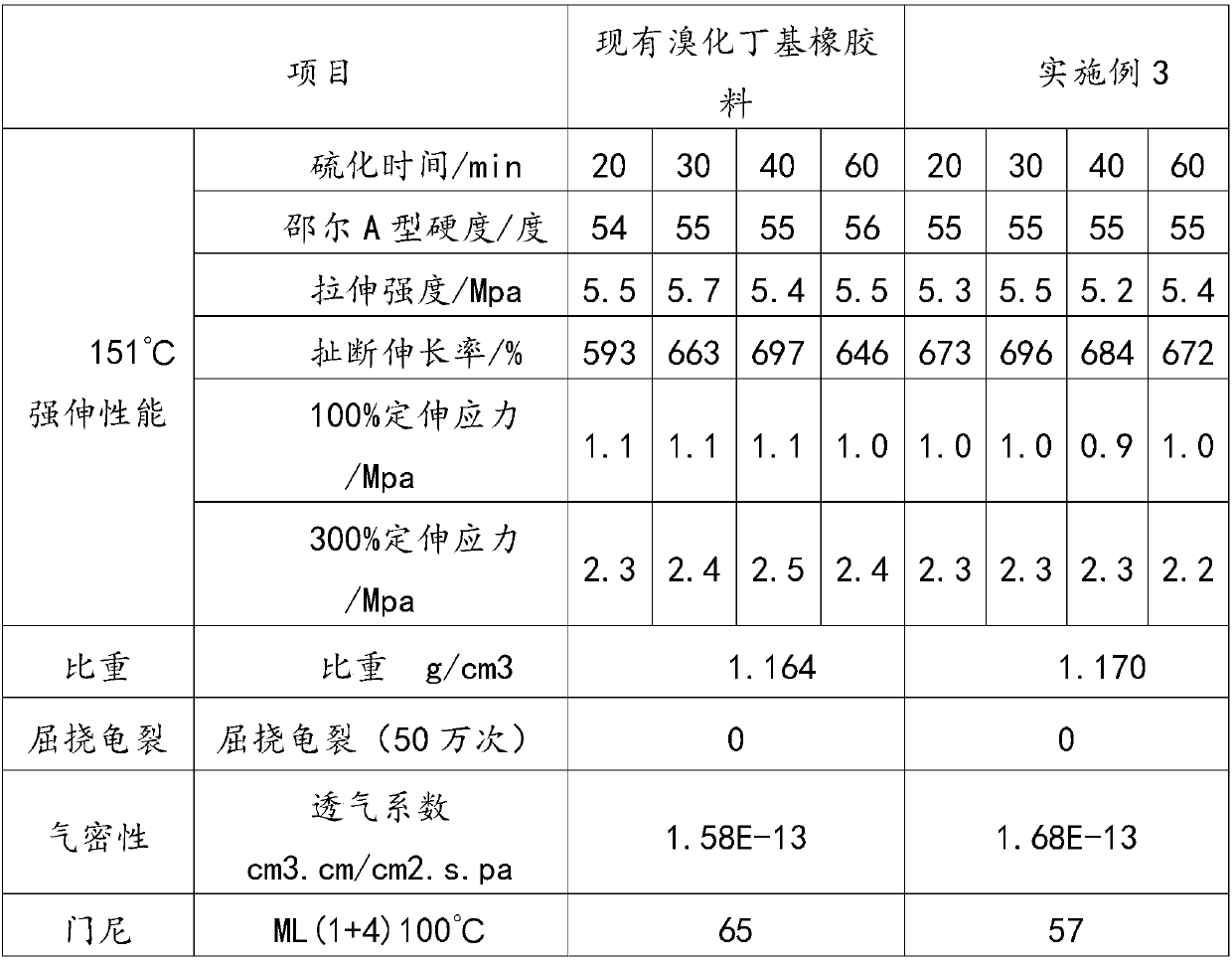

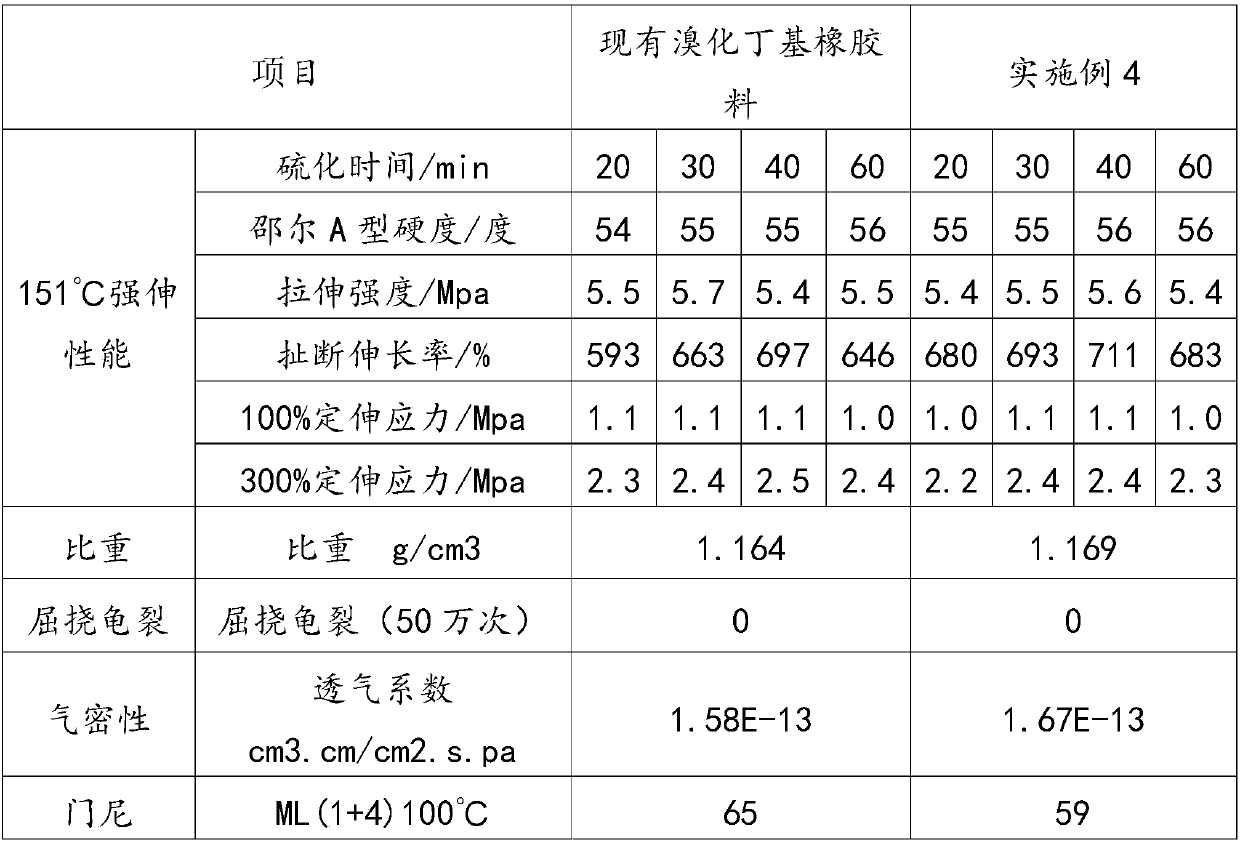

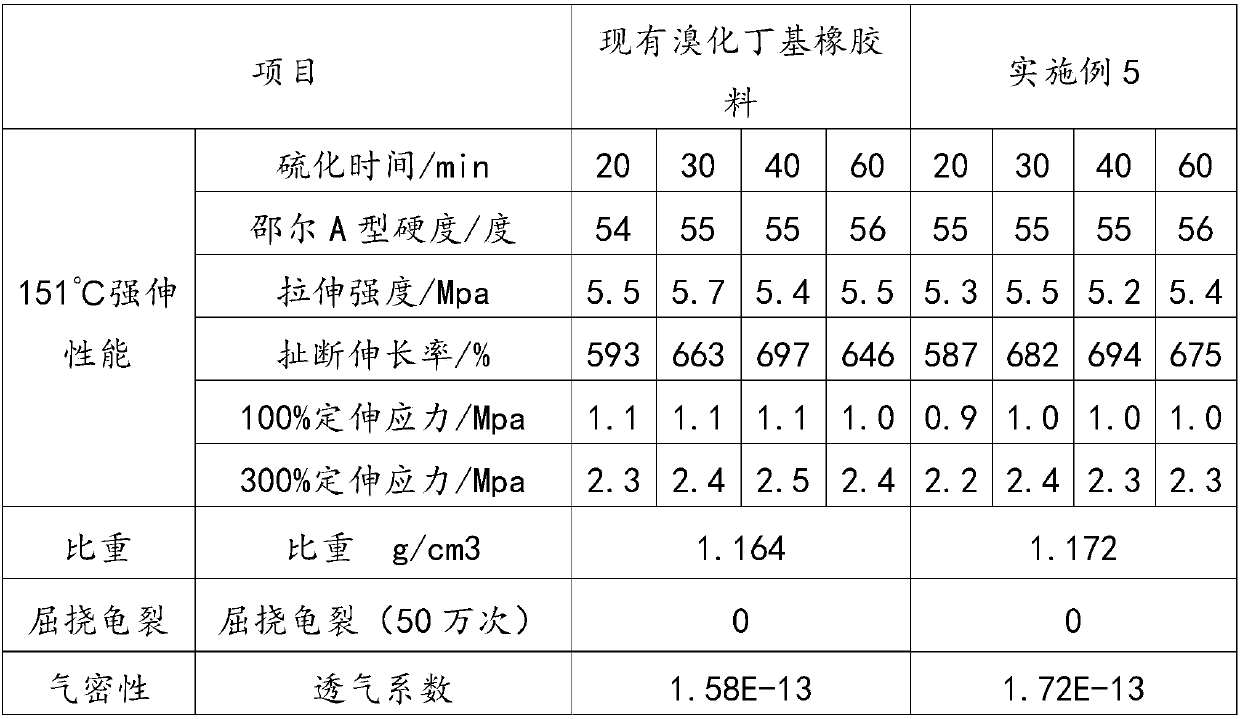

Tire inner liner rubber, application serving as tire inner liner rubber and preparation method of tire inner liner rubber

InactiveCN109517284AReduced ozone resistanceExcellent ozone resistanceSpecial tyresChlorinated polyethyleneButyl rubber

The invention discloses tire inner liner rubber, application serving as tire inner liner rubber and a preparation method of the tire inner liner rubber. The tire inner liner rubber comprises the following raw materials in relative parts by weight: 30-40 parts of natural rubber, 65-75 parts of brominated butyl rubber, 20-30 parts of butyl reclaimed rubber, 5-20 parts of chlorinated polyethylene composite rubber, 2-5 parts of a dispersing agent, 3-5 parts of a tackifier, 0.2-0.5 part of magnesium oxide, 5-10 parts of a homogenizing agent, 10-15 parts of a softening agent, 60-70 parts of a filling agent, 20-30 parts of an air stopper, 0.5-1 part of a vulcanizing agent, 1-1.5 parts of an accelerant and 3-5 parts of an activating agent. The tire inner liner rubber disclosed by the invention canreplace brominated butyl rubber, the performance is improved, and the cost is greatly reduced.

Owner:SHANDONG RIKE CHEM

Branched conjugated diene copolymer, rubber composition and pneumatic tire

ActiveUS20140357824A1Improve performanceIncrease resistanceSpecial tyresPolymer scienceAliphatic hydrocarbon

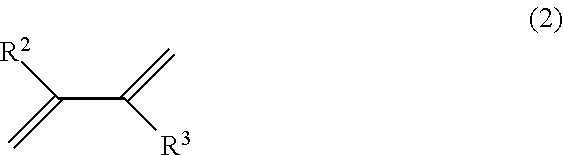

There is provided a branched conjugated diene copolymer prepared by copolymerizing 1 to 99% by weight of a branched conjugated diene compound (1):wherein R1 is an aliphatic hydrocarbon having 6 to 11 carbon atoms,less than 99% by weight of a conjugated diene compound (2):wherein R2 and R3 are the same or different and each is a hydrogen atom, or the like, andless than 99% by weight of a vinyl compound (3):wherein R4 is an aromatic hydrocarbon group having 6 to 10 carbon atoms, or the like. The branched conjugated diene copolymer is useful as a rubber component of a rubber composition for a tire enhancing both of abrasion resistance and grip performance to a high level and exhibiting excellent processability.

Owner:SUMITOMO RUBBER IND LTD

1,4-cis-polybutadiene functionalized with organosulfur compound for preparation of golf ball core

InactiveUS20110136956A1Enhances workability and processabilityImprove performanceOther chemical processesSolid ballsOrganosulfur compoundsMooney viscosity

Disclosed are 1,4-polybutadiene functionalized with an aromatic organosulfur compound, providing improved processability due to decreased Mooney viscosity and providing improved feel on hitting and flying performance due to decreased compression and increased restitution when used to prepare a golf ball core, and a composition for the preparation of a golf ball core including the same.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Branched conjugated diene copolymer, rubber composition and pneumatic tire

ActiveUS20140371415A1Easy to processExcellent abrasion resistanceSpecial tyresPolymer scienceAliphatic hydrocarbon

There is provided a branched conjugated diene copolymer prepared by copolymerizing 1 to 99% by weight of a branched conjugated diene compound (1):wherein R1 is an aliphatic hydrocarbon having 6 to 11 carbon atoms, and 99 to 1% by weight of a conjugated diene compound (2):wherein R2 and R3 are the same or different and each is a hydrogen atom, or the like. The branched conjugated diene copolymer is useful as a rubber component of a rubber composition for a tire enhancing both of abrasion resistance and grip performance to a high level and exhibiting excellent processability.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com