Patents

Literature

106 results about "Dithiodimorpholine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

4,4'-DITHIODIMORPHOLINE INDUCED DERMATITIS OF VARIOUS DEGREES OF SPREADING ACCORDING TO THE MODE OF EXPOSURE. HEYDENREICH G, OELHOLM-LARSEN P; CONTACT DERMATITIS 2(5) 292 (1976) from HSDB. Non-Human Toxicity Excerpts. Non-Human Toxicity Excerpts.

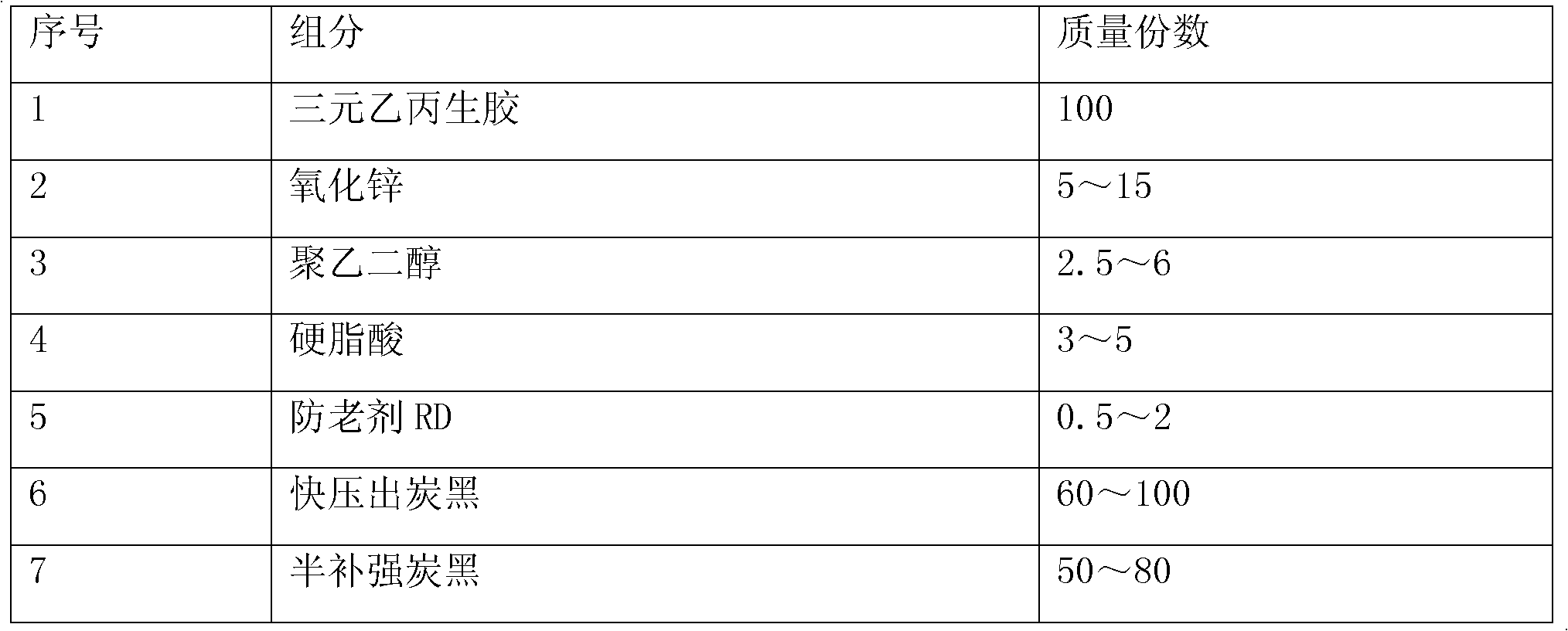

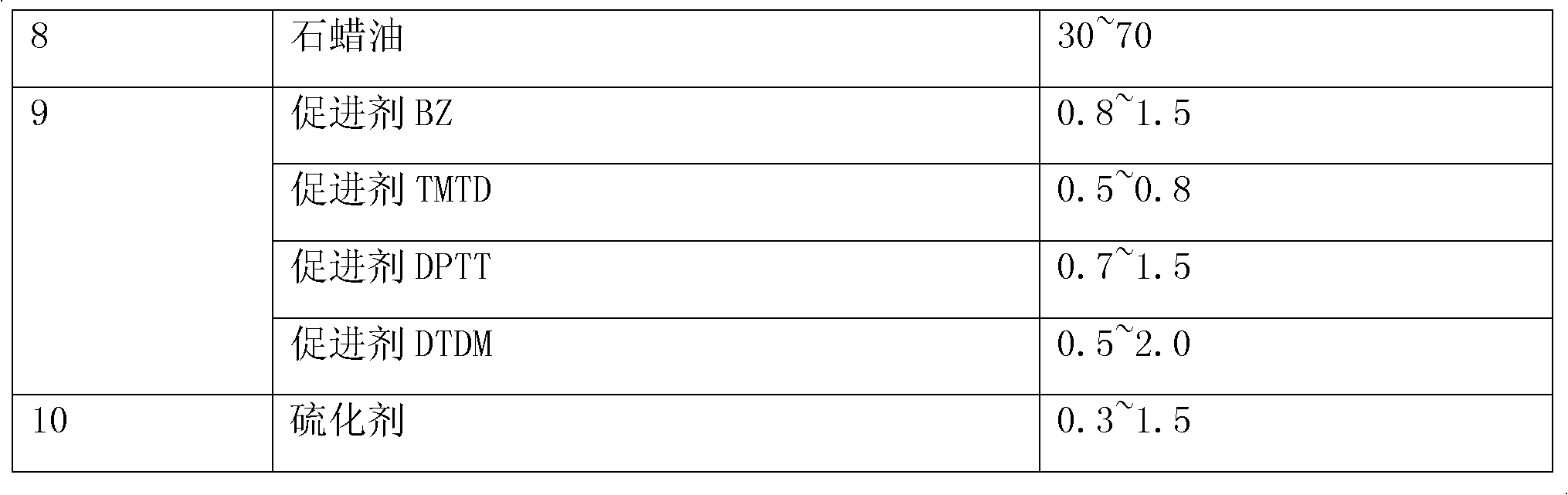

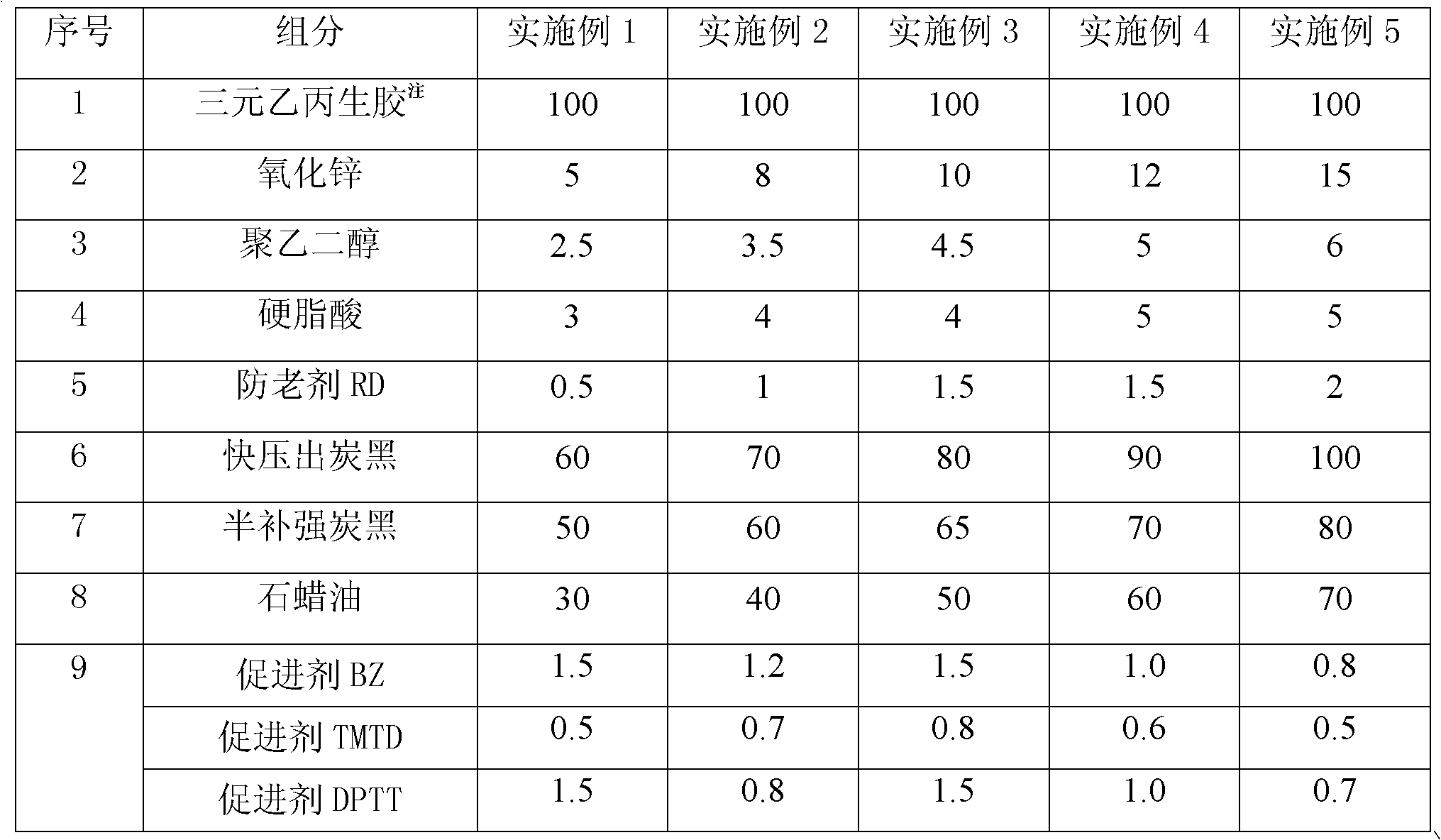

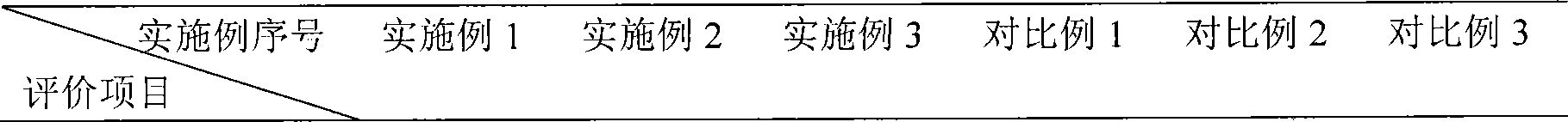

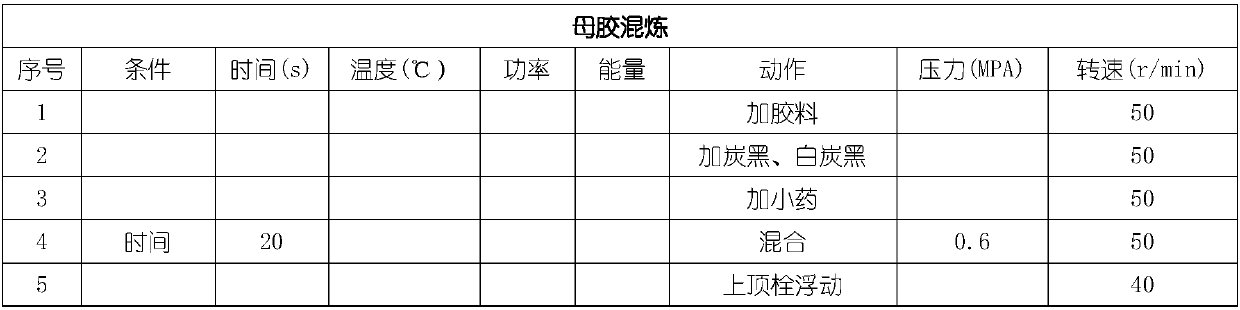

High-hardness ethylene-propylene-diene monomer (EPDM) rubber for extrusion

The invention relates to a high-hardness ethylene-propylene-diene monomer (EPDM) rubber for extrusion, which comprises the following components of EPDM crude rubbers, zinc oxide, polyethylene glycol, stearic acid, an antiager 1,2-dihydro-2,2,4-trimethylquinoline (RD), fast-extruding carbon black, semi-reinforcing carbon black, paraffinoil, accelerating agent BZ, accelerating agent tetramethylthiuram disulfide (TMTD), accelerating agent dipentamethylenethiuram tetrasulfide (DPTT), accelerating agent 4,4`-dithiodimorpholine (DTDM) and vulcanizing agent. The high-hardness ethylene-propylene-diene monomer rubber for extrusion has the advantages that the extrusion technology is good; the physical properties of the product are greatly higher than the standard of the traditional product; the hardness is above 80 Shore A; and the EPDM rubber can meet the current use requirements through the practical application in the seal of doors and windows.

Formula of multi-functional rubber soles

InactiveCN102660057ATo achieve the purpose of multi-functionLow costSolesPolymer scienceStearic acid

The invention relates to a formula of a pair of multi-functional rubber soles, which comprises 50 to 70 parts of butadiene rubber, 8 to 12 parts of natural rubber SCR No.10, 18 to 22 parts of regenerated rubber, 5 to 5.5 parts of zinc oxide, 24 to 28 parts of N774 carbon black, 24 to 28 parts of N550 carbon black, 5 to 8.5 parts of polyisoprene, 1 to 1.5 parts of jianlumizuoxin, 1.5 to 2.5 parts of stearic acid, 1.5 to 2.5 parts of dibenzothiazyl disulfide, 2.5 to 3.5 parts of N-tertiary butyl-(2-benzothiazole) sulfenamide, 0.8 to 1.2 parts of dithiodimorpholine, 3.5 to 4.5 parts of barium sulfate, 5.5 to 8 parts of organic silicon rubber, 10 to 15 parts of nitrile rubber and 5 to 8 parts of polyurethane anti-static agent. According to the soles, the aim of a plurality of functions is achieved; and moreover, the cost is also very low, and the economic benefit is very considerable.

Owner:新疆泰安鞋业有限公司

Composition of nitrile rubber and polyformaldehyde and preparation method thereof

The invention relates to composition of nitrile rubber and metaformaldehyde. The invention consists of the raw material with the following parts by weight: 25 to 55 parts of nitrile rubber, 60 to 100 parts of metaformaldehyde master batch, 3 to 5 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 0.5 to 1 part of antiaging agent, 50 to 75 parts of black carbon, 8 to 15 parts of plasticizer, 2 to 3 parts of dicumyl peroxide, 2 to 4 parts of 4, 4(1)-dithiodimorpholine, 1.5 to 2.5 parts of dibenzothiazole disulfide, 0.5 to 2 parts of N-cyclohexyl-2-benzothiazolesulfonamide, and 0.2 to 0.3 parts of sulphur. The invention includes the preparation method that the metaformaldehyde master batch is firstly prepared, the raw material with the parts by weight is added into a rubber refining machine to be mixed to be even, and then the composition of the nitrile rubber and the metaformaldehyde is obtained. The composition of the nitrile rubber and the metaformaldehyde eliminates the imperfect status in the process of mixing, extrudion, mould pressing and sulfuration, enhances the wear-resistant, pressure-proof and endurance qualities of the material, and is applicable for preparing the rubber seal material of a Y-shaped seal ring, a dust ring and other rubber seal products.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Composite stabilizer for SBS modified asphalt

ActiveCN104513489ASolve the problem of high temperature storage stabilityImprove high and low temperature stabilityBuilding insulationsHigh temperature storageBenzoyl peroxide

The invention relates to a composite stabilizer for SBS modified asphalt. The composite stabilizer comprises the following components in parts by mass: 30 to 60 parts of a cross-linking agent, 10 to 40 parts of an accelerator, 10 to 20 parts of an activating agent and 5 to 20 parts of a compatilizer, wherein the cross-linking agent is one or more of sulfur, dithiomorpholine, polyphosphoric acid and maleic anhydride; the accelerator is one or more of tetraethylthiuram disulfide, 2-mercaptobenzothiazole, benzoyl peroxide, dicumyl peroxide and sodium isopropyl xanthate. Compared with the prior art, the composite stabilizer has the advantages that after the composite stabilizer is added into the SBS modified asphalt, the problem that the high-temperature storage stability of the SBS modified asphalt is poor is well solved, the performances such as high-temperature and low-temperature stability and water stability of an asphalt mixture are comprehensively improved, and high-temperature anti-rutting performance, low-temperature anti-cracking performance, moisture damage resistance and ageing resistance are remarkably improved.

Owner:山西省交通科技研发有限公司

Run flat tyre sidewall supporting rubber and a preparing method thereof

The invention relates to the technical field of tyres, particularly run flat tyre sidewall supporting rubber and a preparing method thereof. Raw materials of the supporting rubber include natural rubber STR20#, polybutadiene, carbon black N550, white carbon black, a silane coupling agent, indirect-process zinc oxide, stearic acid, an antioxidant, 4-tert-butylphenol-acetylene resin, insoluble sulfur 7020, a CZ accelerant, 4,4'-dithiodimorpholine, an anti-reversion agent and a scorch retarder CTP. The supporting rubber has excellent properties superior to those of present products.

Owner:GUANGRAO GEE STAR TIRE CO LTD

Elastomeric copolymers, copolymer compositions, and their use in articles

A copolymer is formed from an isoolefine having from 4 to 7 carbon atoms and an alkylstyrene. The copolymer has a substantially homogeneous compositional distribution. The copolymer has from about 8 to about 12 wt% of alkylstyrene and at least 85 wt% of isoolefine. The copolymer is preferably halogenated with about 1.1 to about 1.5 wt% of a halogen. The copolymer may in elastomeric nanocomposites. To obtain a good dispersion of the nanoclay in a formulated compound, at least one cure accelerator is selected from the group consisting of mercaptobenzothiazole disulfide, mercaptobenzothiazole, cyclohexyl benzothiazole disulfide, dibutyl thiourea, tetramethylthiuram disulfide, 4-4- dithiodimropholine, zinc dimethyldithiocarbamate, and zinc dibutylphosphorodithiate.

Owner:EXXONMOBIL CHEM PAT INC

Conductive rubber

Owner:广东丰能环保科技股份有限公司

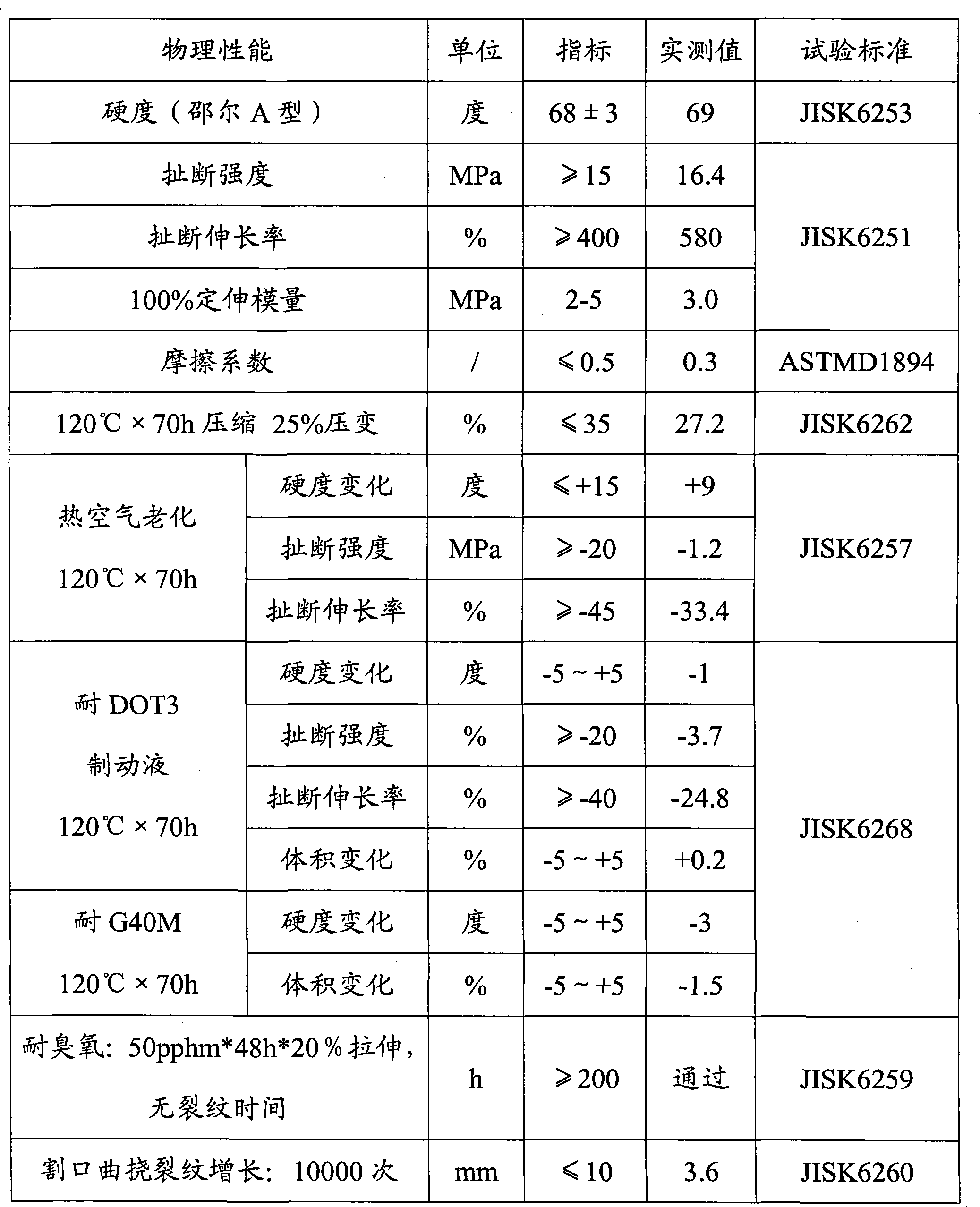

Self-lubricating material for filter sealing piece and preparation method thereof

InactiveCN102504370AReduce coefficient of frictionAvoid stickingOther chemical processesRubber materialPolymer science

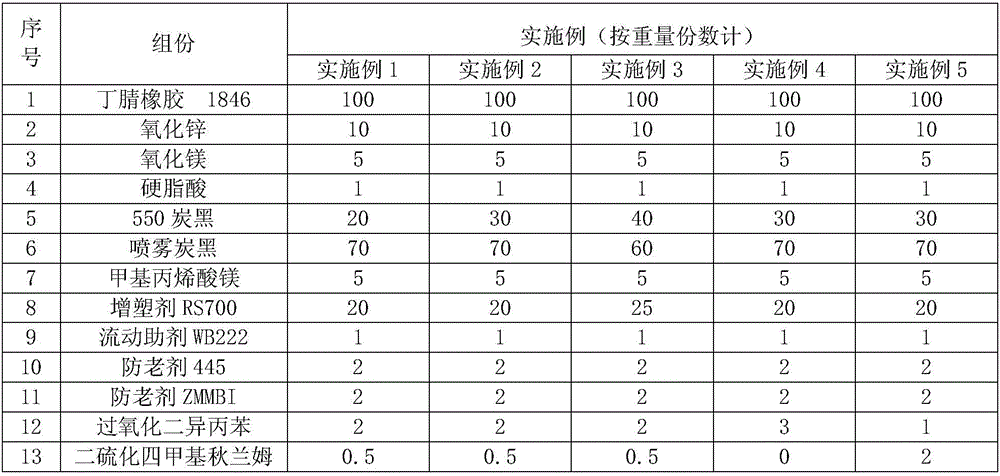

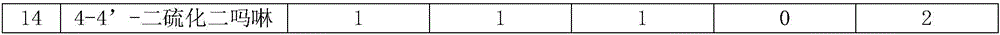

The invention discloses a self-lubricating material for a filter sealing piece and a preparation method thereof, belonging to the fields of sealing rubber materials and preparation methods thereof. The self-lubricating material consists of the following components in percentage by weight: 40-45 percent of nitrile rubber, 20-25 percent of high-wear-resistance carbon black, 10-15 percent of semi-reinforced carbon black, 3.0-5.0 percent of zinc oxide, 0.5-1.0 percent of stearic acid, 1.0-1.5 percent of 4,4'-di(phenyl isopropyl)diphenylamine, 0.5-1.0 percent of 1,3-dihydro-4(or 5)-methyl-2H-benzimidazole-2-thione zinc salt, 0.1-0.3 percent of sulfur, 1.0-2.0 percent of accelerant DTDM (Dithiodimorpholine), 0.5-1.0 percent of accelerant CZ, 3.0-6.0 percent of hexanedioic acid di[2-(2-butoxy oxethyl)ethyl ester] and 1.0-1.5 percent of fluorine wax FU-305. The method comprises the following preparation steps of: compounding a master batch; performing two-stage vulcanization on the master batch; and vulcanizing. A layer of uniform, transparent and bright film with high adhesion is formed when the fluorine wax FU-305 is transferred onto the surface of a rubber product, so that the frictioncoefficient of the surface of the rubber sealing piece is reduced, bonding between the rubber piece and a metal body is prevented effectively, and the ozone aging resistance is enhanced effectively.

Owner:南京金三力高分子科技有限公司

High-performance urban rail cable sheathing material

InactiveCN103772764AIncrease in sizeReduce releaseInsulated cablesInsulated conductorsMicrocrystalline waxAcrylonitrile

The invention discloses a high-performance urban rail cable sheathing material. The high-performance urban rail cable sheathing material comprises main materials and auxiliary materials, wherein the main materials comprise butadiene-acrylonitrile rubber and chlorinated cis-butadiene rubber; the auxiliary materials comprise zinc oxide, an activating agent mercuric oxide, barium oxide, stearic acid, methylthiuram disulfide, an accelerator DTDM (4,4'-Dithiodimorpholine), ethylene thiourea, tribasic lead sulfate, dioctyl phthalate, microcrystalline wax, an anti-aging agent 4040, an anti-aging agent 4040NA, an anti-aging agent 445, high-wear-resisting carbon black, semi-enhanced carbon black, talcum powder, calcined pottery clay and calcium carbonate; the main materials are put into an open mill to be mixed uniformly and the mixing temperature is 40-52 DEG C; then the auxiliary materials are added to be mixed uniformly; the obtained mixed materials are put into a flat plate vulcanization machine to carry out vulcanization to obtain the high-performance urban rail cable sheathing material; the vulcanization temperature is 141-147 DEG C and the vulcanization time is 1-5 minutes. According to the high-performance urban rail cable sheathing material disclosed by the invention, the physical and mechanical properties are good, the combustion smoke is less and the flame retardant efficiency is good.

Owner:ANHUI HUALIAN CABLE GROUP

Rubber composition with low temperature resistance, grease resistance and high temperature resistance, preparation method, use and application product thereof

The invention discloses a rubber composition with low temperature resistance, grease resistance and high temperature resistance, a preparation method, a use and an application product thereof. The composition is prepared by the following raw materials: 100 parts of nitrile rubber, 1-35 parts of an active agent, 1-150 parts of carbon black, 1-5 parts of a reinforcing agent, 20-50 parts of plasticizer, 1-5 parts of a flow promotor, 1-10 parts of anti-aging agent, 1-5 parts of dicumyl peroxide, 1-3 parts of tetramethyl thiuram disulfide, and 1-5 parts of 4-4'-dithiodimorpholine. The rubber composition has three characters of the low temperature resistance, grease resistance and high temperature resistance on the basis of the good characters of the pure nitrile rubber, the production process is simple, and the cost is low.

Owner:NANJING ORIENTLEADER TECH CO LTD

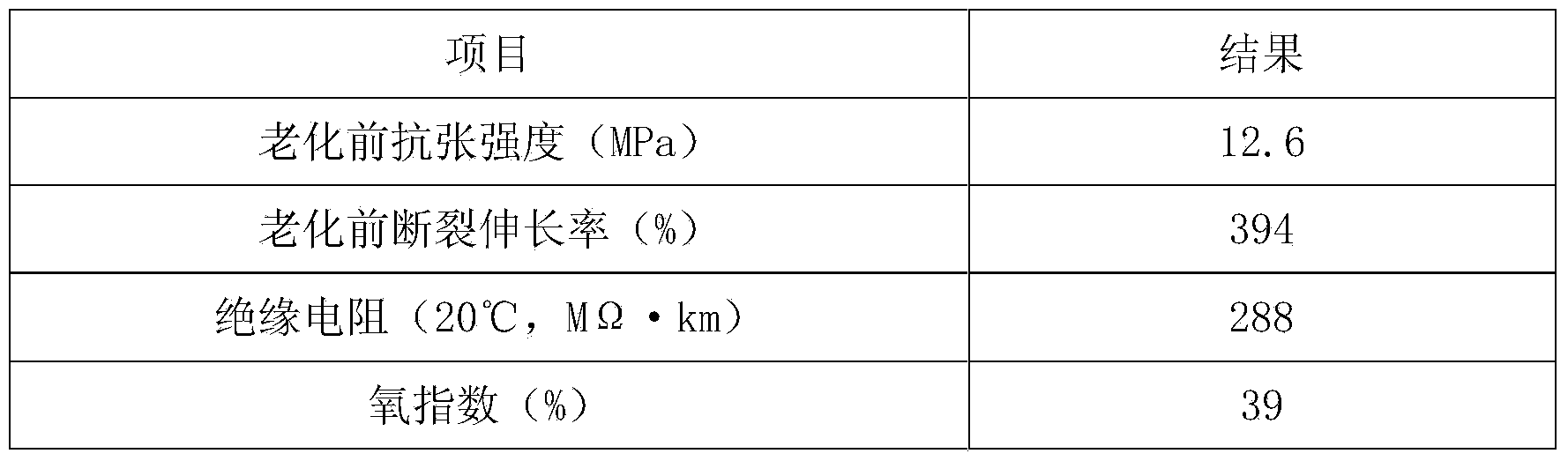

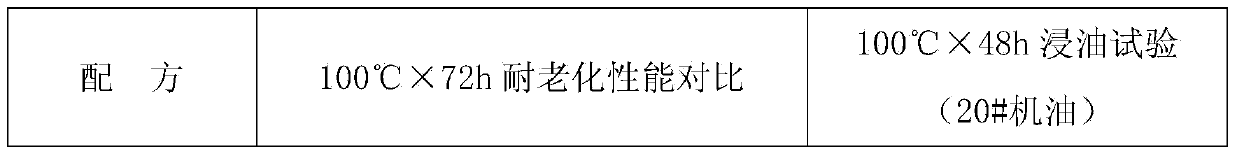

Nitrile rubber for extra-high voltage large-scale oil-immersed type transformer

The invention belongs to the technical field of rubber, and mainly relates to a nitrile rubber for an extra-high voltage large-scale oil-immersed type transformer. The nitrile rubber comprises the following components in parts by mass: 100 parts of nitrile rubber NBR (nitrile -butadiene rubber), 0.1 to 20 parts of stearic acid, 10 to 80 parts of carbon black, 10 to 80 parts of spraying carbon black, 1 to 30 parts of zinc oxide, 0.1 to 20 parts of a vulcanizing agent DTDM (4,4'-Dithiodimorpholine), 0.1 to 20 parts of a vulcanizing agent TETD (Tetraethylthiuram Disufide), 0.1 to 20 parts of a vulcanizing agent TMTD (Tetramethyl Thiuram Disulfide), 0.1 to 20 parts of an accelerant CZ, 0 to 20 parts of an antioxidant RD, 0.1 to 20 parts of an antioxidant RB, 0.1 to 20 parts of an antioxidant 4010, 1 to 20 parts of paraffin, 1 to 30 parts of coumarone and 5 to 50 parts of decadioctyl. The compatibility of the nitrile rubber with respect to the oil of the transformer is further improved, so that the problem that the gas is generated by the rubber in the transformer can be solved, and the stability and the safety of the extra-high voltage large-scale oil-immersed type transformer in running can be ensured.

Owner:SHENYANG POLYTECHNIC UNIV

Self-lubricating rubber leather diaphragm material and preparation method thereof

ActiveCN101935415AGood high and low temperature resistanceReduce surface friction coefficientMorpholineN-phenyl-p-phenylenediamine

The invention discloses an engine suspending heat-resistant material and a preparation method thereof. The heat-resistant material comprises the following components in part by weight: 70 to 80 parts of styrene-butadiene rubber, 10 to 20 parts of 3-polybutadiene rubber, 3 to 4 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of 2,2,4-trimethyl-1,2-dihyaroquinoline polymer, 2 to 4 parts of N-isopropyl-N-phenyl-p-phenylenediamine, 5 to 9 parts of oleamide, 5 to 8 parts of polyethylene wax, 30 to 50 parts of high abrasion furnace black, 20 to 40 parts of fast extruding furnace black, 1 to 3 parts of 4',4-dithio morpholine, 1 to 3 parts of tetramethylthiuram disulfide, and 3 to 5 parts of N-cyclohexyl-2-benzothiazole sulfonamide. A fatigue-resistant self-lubricating rubber leather diaphragm material with high high-temperature and low-temperature resistance is prepared by a special refining process, and the material has the advantages of long service life, high production efficiency and low cost.

Owner:ASIMCO NVH TECH CO LTD ANHUI

Anti-tear cable material used for high-speed railway motor train unit and preparation method of anti-tear cable material

The invention discloses an anti-tear cable material used for a high-speed railway motor train unit and a preparation method of the anti-tear cable material. The anti-tear cable material used for the high-speed railway motor train unit comprises the following raw materials in parts by weight: 67 to 89 parts of polyurethane rubber, 22 to 36 parts of styrene-butadiene rubber, 15 to 25 parts of thermoplastic polyester elastic bodies, 4 to 8 parts of vinyl silicone oil, 17 to 26 parts of fumed silica, 3 to 6 parts of cadmium carbonate, 2 to 3 parts of lauroyl peroxide, 1.5 to 2.5 parts of triallyl isocyanurate, 1 to 2 parts of ammonium benzoate, 3 to 5 parts of poly-alpha-olefin, 5 to 10 parts of tert-butyl phenolic tackifying resin, 2 to 4 parts of triethylhexanoin, 10 to 15 parts of methylpentachlorostearate, 14 to 18 parts of carbon nano tubes, 10 to 15 parts of a diopside powder, 1 to 2 parts of 4,4'-dithiodimorpholine, 0.5 to 1 part of P-tert-butylphenol, and 20 to 25 parts of a composite flame retardant. The cable material provided by the invention combines the advantages of the raw materials such as the polyurethane rubber, the styrene-butadiene rubber, and the thermoplastic polyester elastic bodies, the tearing strength of a conventional cable material is improved, and the cable material is enabled to have excellent tear resistance, has the effect of bearing relatively great mechanical external force, and has the advantages of excellent chemical stability, heat resistance and age resistance, and long service life.

Owner:ANHUI KANGLIYA CO LTD

Flame retarding aging resistant plastic for mobile phone shell

The invention discloses flame retarding aging resistant plastic for a mobile phone shell. The flame retarding aging resistant plastic is prepared from, by weight, 10-30 parts of styrene-butadiene-styrene copolymer, 15-30 parts of organic silicon resin, 5-18 parts of polypropylene, 5-15 parts of polyurethane, 5-15 parts of acrylnitrile-butadiene-styrene copolymer, 2-8 parts of boron nitride, 4-8 parts of Fe-OMT, 1-5 parts of aluminum oxide, 1-2 parts of titanate TTS, 2-8 parts of silicon carbide, 5-15 parts of calcined clay, 5-15 parts of clay, 8-16 parts of modified opal powder, 1-3 parts of polypropylene grafted maleic anhydride, 0.5-1.5 parts of polycaprolactone, 0.5-2 parts of natural rubber grafted poly methyl methacrylate, 0.5-1.5 parts of dithiodimorpholine, 1-2 parts of tert-butyl hydroperoxide, 1-2 parts of methylenebis(2-chloroaniline), 1-2 parts of poly-nitrosobenzene, 0.5-1.5 parts of 1,2-dihydro-2,2,4-trimethylquinoline homopolymer, 0.5-1.5 parts of 1-hexadecanol and 0.5-1.5 parts of distearyl thiodipropionate. The flame retarding aging resistant plastic is resistant to abrasion and aging and superior in flame retarding performance.

Owner:安徽酷米智能科技股份有限公司

Colorized ethylene propylene terpolymer rubber sealing strip and preparation method thereof

The invention relates to a colorized ethylene propylene terpolymer rubber sealing strip which is prepared from the following raw materials in parts by weight: 90-100 parts of ethylene propylene terpolymer rubber, 160-180 parts of complex mineral filler, 60-80 parts of colorless paroline, 0.8-1.2 part of toner, 0.3-0.6 part of sulfur, 1-2 parts of zinc dibutyldithiocarbamate, 0.8-1.5 part of 2-mercaptobenzothiazole, 0.3-0.8 part of tetramethyl thiuram disulfide, 0.2-0.6 part of Zinc dimethyldithiocarbamate, 0.8-2 parts of 4,4'-dithiodimorpholine, 4-6 parts of zinc oxide and 0.8-1.2 part of stearic acid. The colorized ethylene propylene terpolymer rubber sealing strip provided by the invention is easy for extruding production, and has the advantages that the color assortment effect is good, no aromatic hydrocarbon is separated out so that the attractive appearance is ensured, and the ageing resistance and the weather fastness are better.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

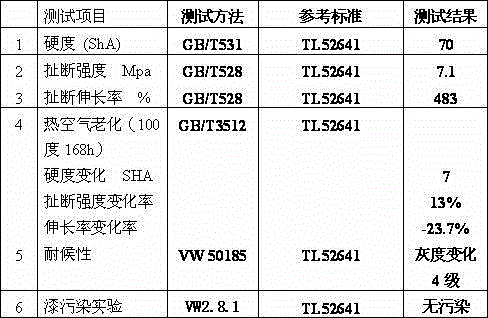

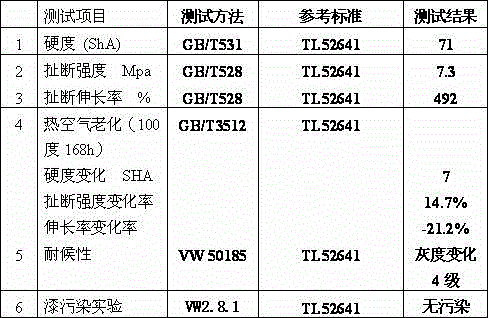

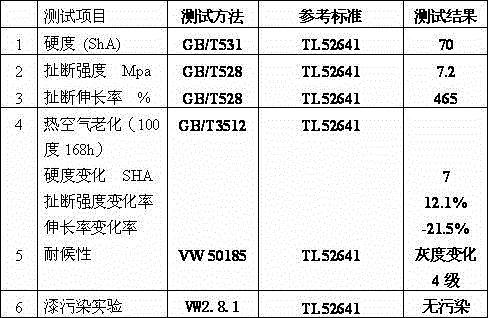

Rubber composition for automobile engine compartment heat insulation pad skeleton layer

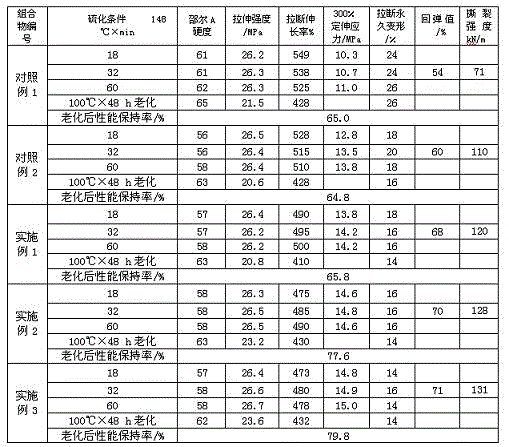

InactiveCN106751008AHigh tensile strengthGood resistance to hot air agingPolyethylene glycolEngineering

The invention discloses a rubber composition for an automobile engine compartment heat insulation pad skeleton layer. The rubber composition is prepared from oil-extended EPDM (Ethylene-Propylene-Diene Monomer) rubber, zinc oxide, stearic acid, polyethylene glycol, an anti-aging agent, carbon black N550, carbon black N774, silica powder, paroline, an accelerating agent DTDM (Dithiodimorpholine), an accelerating agent BZ (Benzodiazepine), an accelerating agent DPTT (Dipentamethylenethiuram Tetrasulfide) and an accelerating agent TMTD (Tetramethylthiuram Disulfide). The rubber composition disclosed by the invention is higher in tensile strength, better in hot air aging resistance, low in compression deformation, good in ozone resistance, excellent in low-temperature brittleness and good in low temperature resistance, and the use under a low temperature environment in winter can be met; meanwhile, the wear resistance and warping and fracturing resistance are also very good, the service life of a heat insulation pad is prolonged, the requirements of passengers on comfort and functions of an automobile can be well met, the automobile engine compartment heat insulation pad skeleton layer is arranged at the periphery of an automobile engine, and the automobile engine compartment heat insulation pad skeleton layer has the maximum function of protecting the paint brightness of an automobile engine hood; the rubber composition disclosed by the invention is used for the automobile engine compartment heat insulation pad skeleton layer and has certain sound insulation and heat insulation properties, and noise caused by automobile vibration can be reduced.

Owner:BRILLIANCE AUTO

Rubber material, and preparation method and use thereof

The invention discloses a rubber material, and a preparation method and a use thereof. The rubber material comprises natural rubber, butadiene rubber, a diaryl secondary amine antioxidant, a dihydroquinoline antioxidant, a physical antioxidant, an activator zinc oxide, stearic acid, a silane coupling agent, carbon black, sulfur, 4,4'-dithiodimorpholine, tetramethylthiuram disulfide, N-cyclohexyl-2-benzothiazole sulfenamide and an anti-scorching agent. The rubber material has the advantages of low damping coefficient, good mechanical strength, good elastic ductility and satisfactory temperature resistance. The preparation method of the rubber material has the advantages of simple steps, convenience in operation, and suitableness for industrial production. An exhaust system cold end hanger made of the rubber material has the advantages of large pulling strength, long service life, wide vibration isolation frequency, and excellent NVH control efficiency in the acceleration stage in the high speed (90 km / h or more) driving process of an automobile.

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

Novel oil-resistant sealing pad material and preparation method thereof

The invention discloses a novel oil-resistant sealing pad material. The novel oil-resistant sealing pad material is prepared from the following material in parts by weight: 45-50 parts of fluororubber, 20-25 parts of nitrile rubber, 20-25 parts of SG-5 type PVC (Polyvinyl Chloride) resin, 5-8 parts of acetyl triethyl citrate, 2-3 parts of zinc oxide, 1-2 parts of phthalic anhydride, 2-3 parts of zinc chromate, 1-2 parts of sulfur, 2-3 parts of magnesium oxide, 1-2 parts of an accelerant DTDM (Dithiodimorpholine), 1-2 parts of di-n-octyl tin dimercaptoiso-octyl acetate, 1-2 parts of a cross-linking agent TAIC (Triallyl Isocyanurate), 1-2 parts of zinc stearate, 30-35 parts of semi-reinforcing carbon black and 10-12 parts of modified attapulgite clay. According to the invention, the modified attapulgite clay is added, so that process performances of the rubber material are improved; and an environment-friendly compounding agent is used, so that toxic or side effect and pollution to environment are reduced. According to the novel oil-resistant sealing pad material and the preparation method disclosed by the invention, formula is reasonable, cost is lowered, process is simple, and oil resistance and insulativity are good.

Owner:TONGLING SIDE TECH

Cable sheath material capable of resisting temperature of 150 DEG C and being used for bullet train with nominal voltage of 3,600 V, and preparation method thereof

InactiveCN104017367AImprove insulation performanceImprove high temperature resistanceGlycerolBoron carbide

The invention discloses a cable sheath material capable of resisting a temperature of 150 DEG C and being used for a bullet train with a nominal voltage of 3,600 V, and a preparation method thereof. The cable sheath material is prepared from the following raw materials by weight: 70-90 parts of phenylatylene silicone rubber, 25-45 parts of chloroprene rubber, 3-5 parts of titanium(diisopropoxide)bis(2,4-pentanedionate), 2-4 parts of dicumyl peroxide, 1.5-2.5 parts of tert-butyl peroxybenzoate, 2-4 parts of trimethylolpropane trimethacrylate, 15-25 parts of carbon black N660, 10-15 parts of tris(2,3-dibromopropyl)isocyanurate, 5-10 parts of spindle oil, 6-12 parts of hydrogenated rosin glycerol ester, 5-10 parts of boron carbide, 12-16 parts of glass powder, 4-6 parts of nano bismuth oxide, 2-4 parts of nano beta zeolite, 16-22 parts of organic bentonite, 5-10 parts of stone needle powder, 10-15 parts of aluminium hypophosphite, 3-6 parts of nickel molybdate, 8-14 parts of modified stone powder, 2-3 parts of 4,4'-dithiodimorpholine, 1-2 parts of polycarbodiimide and 2-3 parts of styrenated phenol. The cable sheath material provided by the invention has excellent electrical insulation property and high temperature resistance; a voltage class reaches 3,600 KV; a high temperature resistance level reaches 150 DEG C; and the cable sheath material can keep good physical and mechanical properties at high voltage and high temperature.

Owner:ANHUI KANGLIYA CO LTD

Ozone aging-resistant sidewall rubber used for light truck

InactiveCN103694506AExtended service lifeGood resistance to ozone agingPolymer scienceCrack resistance

The invention belongs to the technical field of production of vehicle rubber, specifically to ozone aging-resistant sidewall rubber used for a light truck. The sidewall rubber comprises the following raw materials: butadiene rubber, polyisoprene rubber, 4,4'-dithiodimorpholine, carbon black N339, aromatic hydrocarbon oil, stearic acid, zinc oxide and di-(N-1,4-dimethylphenyl-p-phenylene-diamino)-3,5-triazine. The sidewall rubber provided by the invention has good ozone aging resistance and crack resistance, does not contain wax and overcomes the problems of decrease of viscosity of a rubber compound and excess surface blooming.

Owner:SHANDONG YONGTAI CHEM GROUP

Sealing gasket material formed by compounding natural rubber and butadiene rubber and preparation method of sealing gasket material

The invention discloses a sealing gasket material formed by compounding natural rubber and butadiene rubber. The sealing gasket material is characterized by being prepared form the following raw materials in parts by weight: 50-55 parts of natural rubber, 30-35 parts of butadiene rubber, 3-4 parts of magnesium oxide, 2-3 parts of stearic acid, 1-2 parts of anti-aging agent 4020, 6-9 parts of dimethyl 5-nitroisophthalate, 1-2 parts of sulphur, 1-2 parts of calcium stearate, 1-2 parts of tin dimethyl diisooctyl thioglycolate, 1-2 parts of accelerant DTDM (dithiodimorpholine), 30-35 parts of N351 carbon black, 3-4 parts of soybean oil, 22-25 parts of nanometer kieselguhr and 10-12 parts of modified attapulgite. According to the sealing gasket material, by adding the modified attapulgite, the process property of a rubber material is improved; by using an environment-friendly compounding agent, the toxic and side effects and the pollution to the environment are reduced. The sealing gasket material has better mechanical property, corrosion resistance and sealing property, and is simple in process, low in cost and suitable for industrialized production.

Owner:马鞍山市中澜橡塑制品有限公司

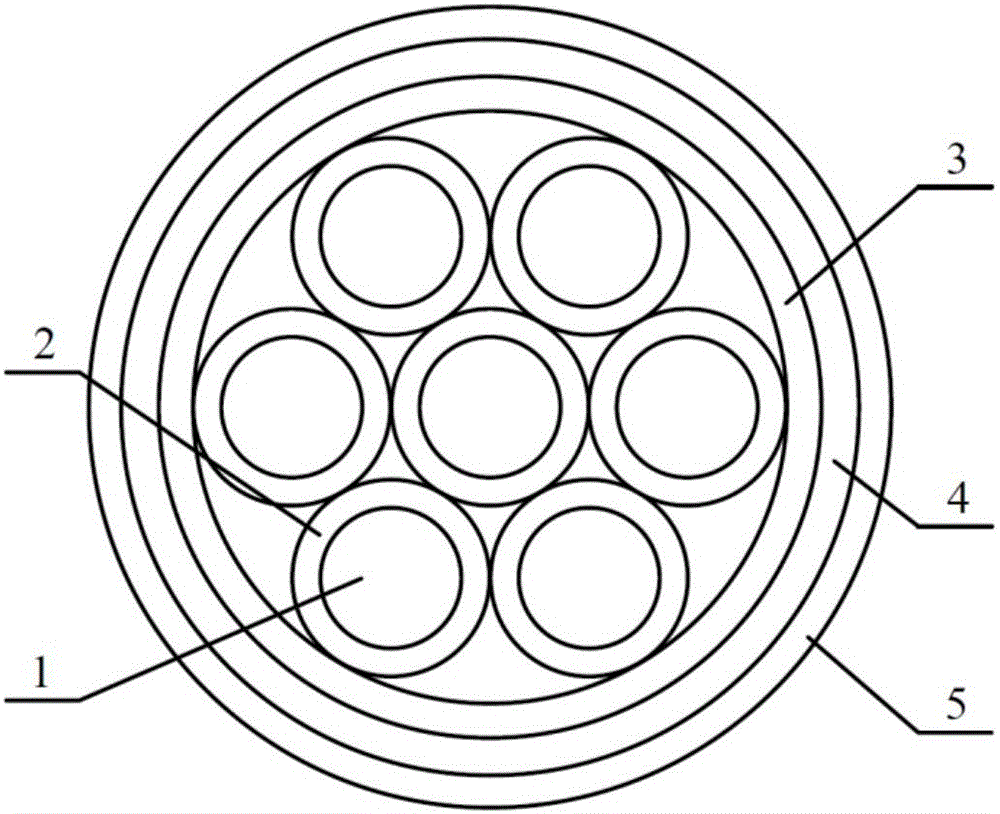

High heat-resistant cable

InactiveCN105131352AHigh strengthImprove heat resistanceInsulated cablesInsulated conductorsElectrical conductorCarbon nanotube

The invention discloses a high heat-resistant cable. The high heat-resistant cable comprises a cable core; the cable core comprises conductors arranged at the middle part, and insulating layers used for coating the conductors; the cable core is coated with an inter sheath layer; the inter sheath layer is coated with a steel belt armour layer; the steel belt armour layer is coated with an outer sheath layer; the outer sheath layer is made of a modified natural rubber material; and the modified natural rubber material comprises following raw materials: natural rubber, fluororubber, carbon nano tube, nanometer aluminium oxide, modified attapulgite, stearic acid, zinc oxide, sulphur, 4,4-dithiodimorpholine, antioxidant 4010NA, lanthanum stearate, accelerant M, accelerant DM, accelerant TMTD, dicyclohexyl phthalate, and dioctyl phthalate. The high heat-resistant cable is excellent in heat resistance, high in strength, excellent in aging resistance, small in compression set, and long in service life.

Owner:合肥市再德高分子材料有限公司

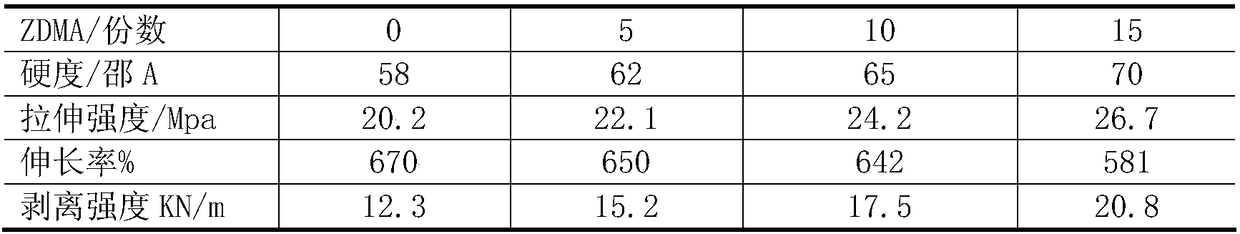

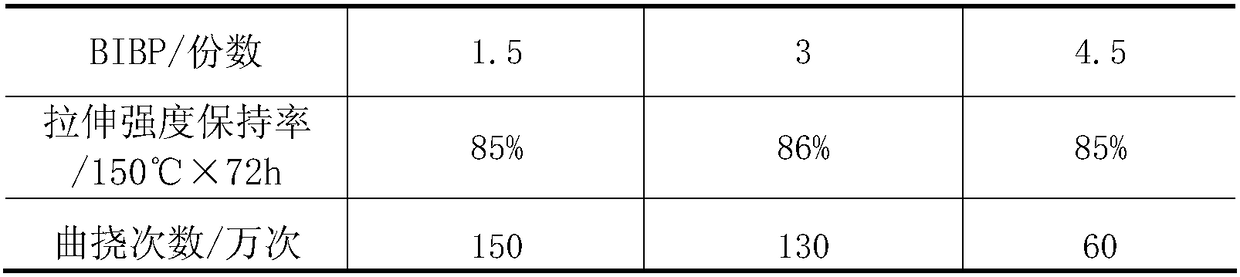

Rubber material for liner bushing of track-laying vehicle

The invention relates to a hydrogenated nitrile butadiene rubber material and in particular relates to a rubber material for a liner bushing of a track-laying vehicle. The material is prepared from the following components in parts by mass: 100 parts of hydrogenated nitrile butadiene rubber, 3 to 5 parts of zinc oxide, 0.5 to 1.0 part of (industrial-grade) stearic acid, 0.5 to 1.0 part of an (industrial-grade) anti-ageing agent TMQ, 0.5 to 1.0 part of an (industrial-grade) anti-ageing agent 4010NA, 2 to 3.5 parts of BIBP (Bis(tert-butyldioxyisopropyl)benzene) (with the purity of 96 percent), 0.5 to 1.5 parts of HVA-2, 0.5 to 1.0 part of sulfur, 0.5 to 0.6 part of DTDM (Dithiodimorpholine), 0.5 to 0.6 part of CZ, 30 to 35 parts of carbon black, 5 to 8 parts of white carbon black, 5 to 15 parts of zinc methacrylate, 3 to 5 parts of a plasticizer DOS (Dioctyl Sebacate) and 1 to 2 parts of a dispersion auxiliary agent. The material provided by the invention has the advantages of excellenthigh temperature resistance, ageing resistance, flexing resistance, ozone resistance, oil resistance, strength and tensile performance, has good adhesion performance with a carbon fiber material and has a long service life.

Owner:JIANGSU TIEKE NEW MATERIAL CO LTD

Rubber sealing ring composition

The invention discloses a rubber sealing ring composition. The a rubber sealing ring composition is prepared from nitrile rubber, fluororubber, a promoter, high styrene resin, powdered steatile, zinc monomethacrylate, stearic acid, wear resistant carbon black, calcium sulfate, dibutyl phthalate, sulphur, Gum easy, an antiager RD, Antilux wax and 4, 4'-dithiodimorpholine according to a certain weight part ratio. The rubber sealing ring composition has characteristics of wear resistance, heat resistance, shock resistance, fatigue resistance, high temperature resistance and good gas tightness.

Owner:吴军

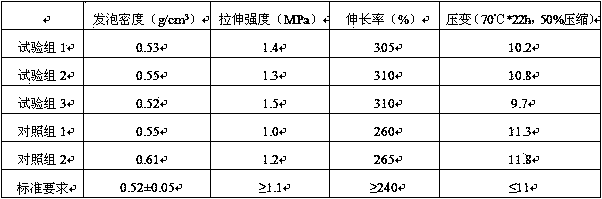

EPDM (Ethylene-Propylene-Diene Monomer) white sponge strip for automobile air conditioner and preparation method of EPDM white sponge strip

The invention relates to an EPDM (Ethylene-Propylene-Diene Monomer) white sponge strip for an automobile air conditioner. The EPDM white sponge strip is prepared from the following materials in part by weight: 100 parts of EPDM K4903 crude rubber, 20 to 30 parts of white carbon black, 80 to 100 parts of silica, 70 to 90 parts of white oil, 15 to 20 parts of titanium dioxide, 5 to 8 parts of zinc oxide, 1 to 2 parts of stearic acid, 2 to 4 parts of PEG4000 (polyethylene glycol 4000), 2 to 3 parts of dispersing agent, 1 to 3 parts of coupling agent, 0.01 part of carbon black N550, 3 to 5 parts of calcium oxide, 1 to 2 parts of MBT-80, 1 to 2 parts of ZDBC-80, 0.5 to 0.8 part of TDEC-75, 3 to 5 parts of AC-75, 3 to 5 parts of OBSH (oxybis benzene sulfonyl hydrazide), 1 to 2 parts of DTDM (4,4'-Dithiodimorpholine) and 1 to 2 parts of S-80. The invention further provides a preparation method of the EPDM white sponge strip. The EPDM white sponge strip and the preparation method have the advantages that the EPDM white sponge strip disclosed by the invention has high tensile strength, low voltage violation and foaming density and excellent performance; a foaming structure is formed inside the EPDM white sponge strip, so that the EPDM white sponge strip has better heat insulation performance and sound adsorption and noise reduction effect.

Owner:TAICANG RONGNAN SEAL TECH

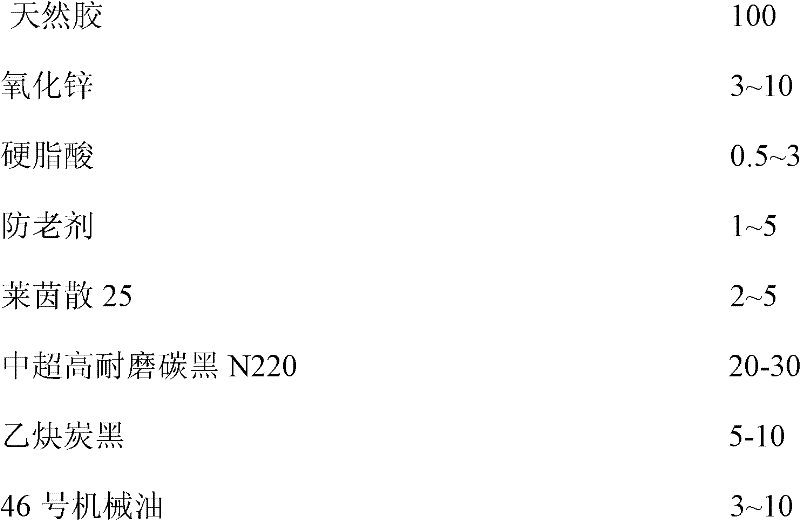

Conductive rubber

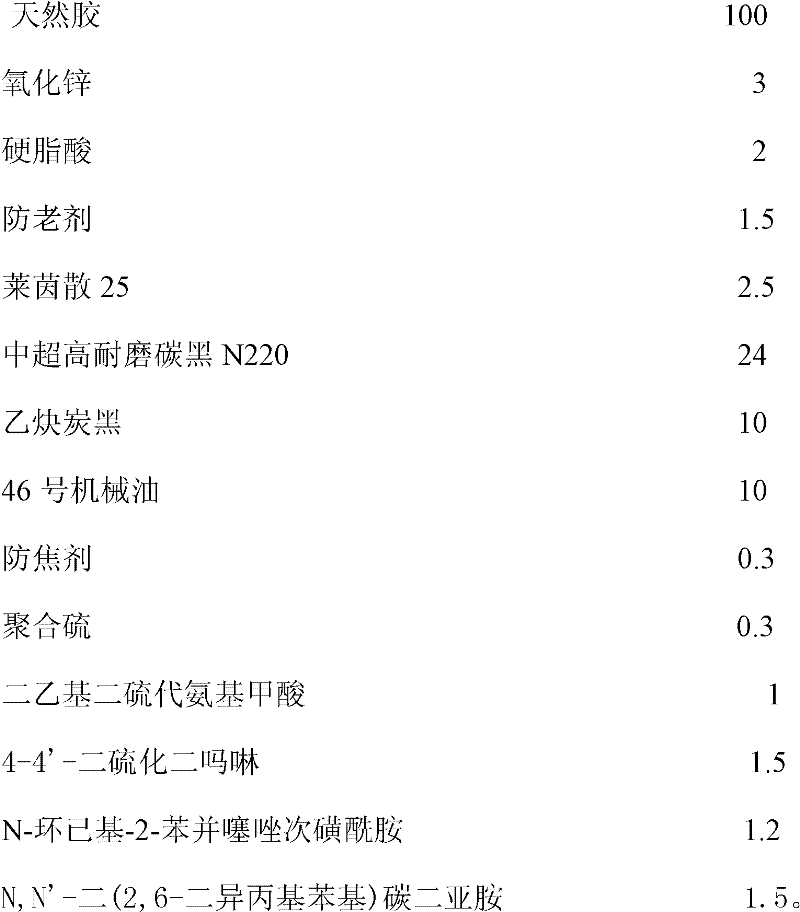

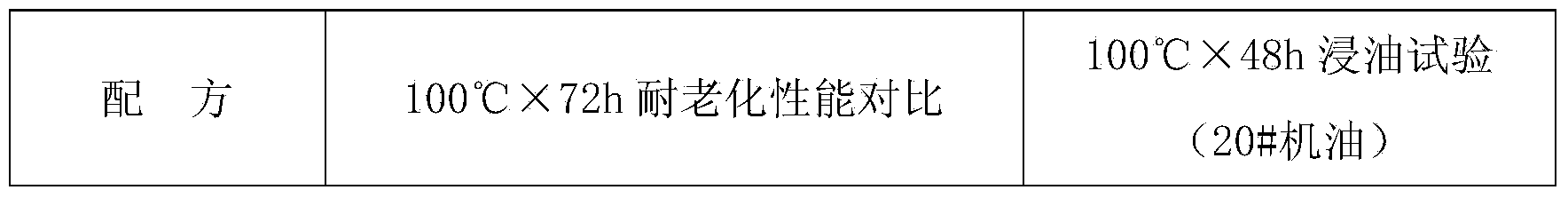

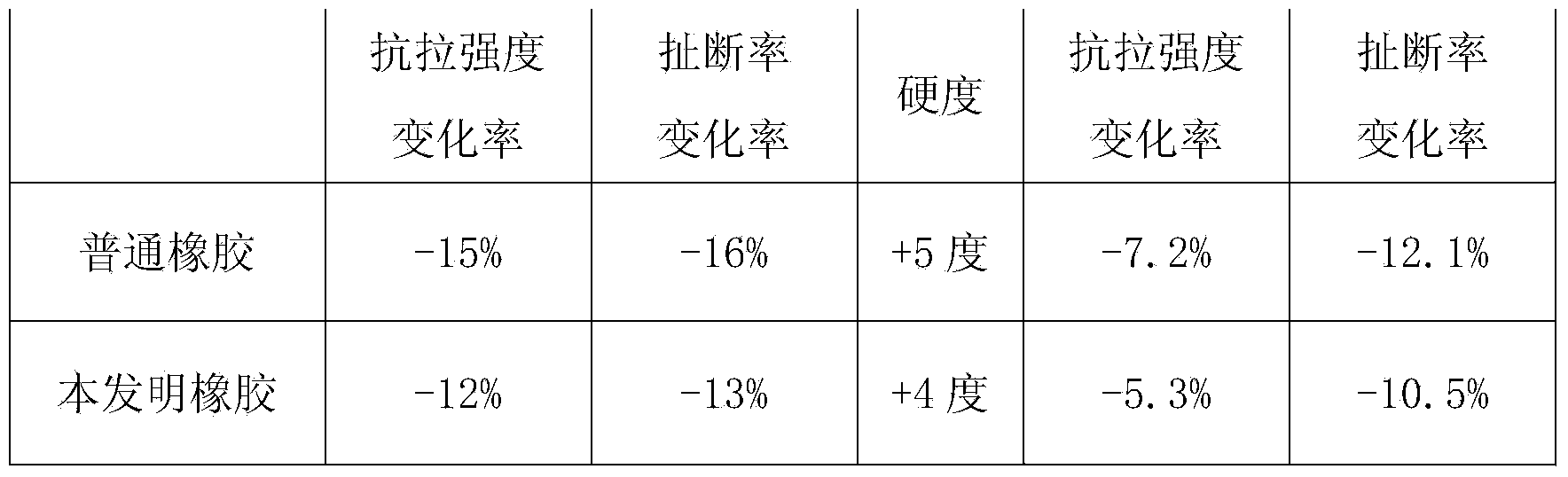

The invention discloses conductive rubber, which contains the following substances: natural rubber, zinc oxide, stearic acid, anti-aging agent, Rhine powder 25, middle and ultrahigh wear-resistance carbon black N220, acetylene carbon black, 46# machine oil, scorch retarder, polymeric sulphur, diethyldithiocarbamicacid, 4-4'-dithiodimorpholine, N-hexamethylene-2-benzothiazole sulfonamide, and N,N'- bis(2,6diisopropyl phenyl )carbodiimide. Compared with the prior art, the produced conductive rubber is an atrous rubber material, is excellent in gross rubber fluidity, is easy to be vulcanized and processed and is high in yield; the conductive rubber can be easily caked with metal; when 500V electricity is conducted by the rubber in a maximum parting position, resistance is not more than 500 kilo-ohms from the rubber to the metal; a tensile strength of the rubber is more than or equal to 25MPa; an elongation at break is more than or equal to 550 percent; and the rubber is excellent in ageing resistance and is suitable for the production of a conductive bush and a conductive rubber damping product.

Owner:芜湖禾田汽车工业有限公司

Heat-insulation heat-preservation noise-reduction coating and preparation method thereof

InactiveCN106010147AImprove insulation effectLow thermal conductivityRosin coatingsEpoxy resin coatingsPolyvinyl alcoholNoise reduction

The invention discloses a heat-insulation heat-preservation noise-reduction coating and a preparation method thereof. The noise-reduction coating is prepared from epoxy modified acrylic emulsion, hydrogenated rosin resin, salicylhydroxamic acid, sulfonated bitumen, tire powder, glass flake, organic modified rectorite, hollow glass beads, sodium fluosilicate, carbitol hexyl acrylate, dioctyl sebacate, maleic anhydride, sodium dodecyl sulfate, simethicone, potassium tripolyphosphate, nonylphenol polyethylene ethoxy ether, dioctyl phthalate, diethyl suberate, 4,4'-dithiomorpholine, zinc methacrylate, polyvinyl alcohol, zinc stannate, toluenesulfonic acid and water. The heat-insulation heat-preservation noise-reduction coating is good in heat insulation and heat preservation, high in bonding strength, high in hardness, strong in adhesive force, good in ultraviolet aging resistance, excellent in comprehensive performance and good in market prospect, and well meets the application requirements for energy conservation and consumption reduction.

Owner:潘明华

Elastic modified acrylonitrile-butadiene rubber sealing gasket material and preparation method thereof

The invention discloses an elastic modified acrylonitrile-butadiene rubber sealing gasket material. The material is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of acrylonitrile-butadiene rubber (N41), 10-12 parts of thermoplastic elastomer (SBS), 10-13 parts of thermoplastic elastomer (SIS), 1-2 parts of ammonium fluoride, 1-2 parts of sodium monofluorophosphate, 15-25 parts of N660 carbon black, 1-2 parts of calcium-zinc stabilizer, 10-15 parts of propanediol sebacate polyester, 1-2 parts of sulfur, 1-2 parts of bisphenol A, 1-2 parts of accelerant DTDM (4,4'-dithiodimorpholine), 3-5 parts of tributyl citrate, 30-35 parts of N330 carbon black, 10-12 parts of fast extruding furnace black and 10-12 parts of modified attapulgite clay. The material has the excellent effects that the processing properties of the rubber material are improved by adding the modified attapulgite clay; the toxic and side effects and environmental pollution of the material are reduced by using an environment-friendly compounding agent; the material has high elasticity, good wear resistance, good ageing resistance, good sealing property, simple process and long service life, and is low in cost.

Owner:安徽宏发节能设备有限公司

Battery cooling liquid resistant rubber tube material

InactiveCN107236197AImprove heat resistanceImprove waterproof performanceN dimethylformamidePolymer science

The invention discloses a battery cooling liquid resistant rubber tube material which comprises ethylene-propylene diene-terpolymer rubber, nitrile rubber, methyl vinyl silicone rubber, ternary nylon, expanded polystyrene, chlorinated polyethylene, zinc oxide, attapulgite, calcium sulfate whiskers, calcium carbonate, white carbon black, aluminum trichloride, ethylene-octene copolymer grafted maleic anhydride, silane coupling agents KH-560, 1, 3-di(tertiary butyl diisopropyl peroxide) benzene, triallyl isocyanurate, 2, 2, 4-trimethyl-1, 2-dihydroquinoline polymer, 2-mercapto benzimidazole, dithiomorpholine, 2-mercaptoimidazoline, accelerants CZ, accelerants BZ, N, N-dimethylformamide, benzoperoxide, stearic acid, polyethylene glycol 4000, paraffin oil, anti-aging agents RD, heat-resistant modified additives and waterproof oil-resistant additives. The battery cooling liquid resistant rubber tube material has excellent heat resistance, oil resistance and waterproof and anti-aging performances.

Owner:ANHUI ZHONGDING KEUMAH AUTO HOSE & PIPE ASSEMBLY

Rubber composition for base rubber of radial giant engineering tire and preparation method thereof

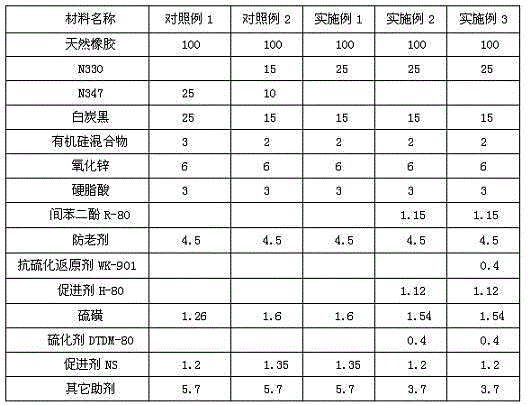

InactiveCN105542241ALow heat resistanceLow reversion resistancePolymer scienceHexamethylenetetramine

The invention relates to the technical field of rubber, specifically to a rubber composition for base rubber of a radial giant engineering tire and a preparation method thereof. The rubber composition comprises: with 100 parts of natural rubber by weight as a reference, 25 to 35 parts of carbon black, 7 to 15 parts of white carbon black, 1 to 3 parts of a silane coupling agent, 1.25 to 1.38 parts of resorcinol-80, 0 to 3 parts of tackifying resin, 4 to 8 parts of zinc oxide, 2 to 3.5 parts of stearic acid, 1 to 2 parts of protective wax, 1 to 4 parts of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine, 1 to 2 parts of a 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0 to 0.5 part of an anti-reversion agent, 1.25 to 1.58 parts of a mixture composed of 80% of hexamethylenetetramine and 20% of a cemented body and a dispersant, 1.4 to 1.8 parts of sulfur, 0 to 0.5 part of a mixture composed of 80% of dithiodimorpholine and 20% of the cemented body and the dispersant, 1.28 to 1.65 parts of a vulcanizing accelerator N-tert-butyl-2-benzothiazolyl sulfonamide and 0.2 to 0.4 part of a scorch retarder N-cyclohexylthiophthalimide.

Owner:TRIANGLE TIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com