High-hardness ethylene-propylene-diene monomer (EPDM) rubber for extrusion

A technology of EPDM rubber with high hardness, which is applied in the field of rubber, which can solve the problems affecting the appearance of the product, such as door and window sealing, surface micro-wrinkling, etc., and achieve the effects of good reinforcement performance, long service life and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

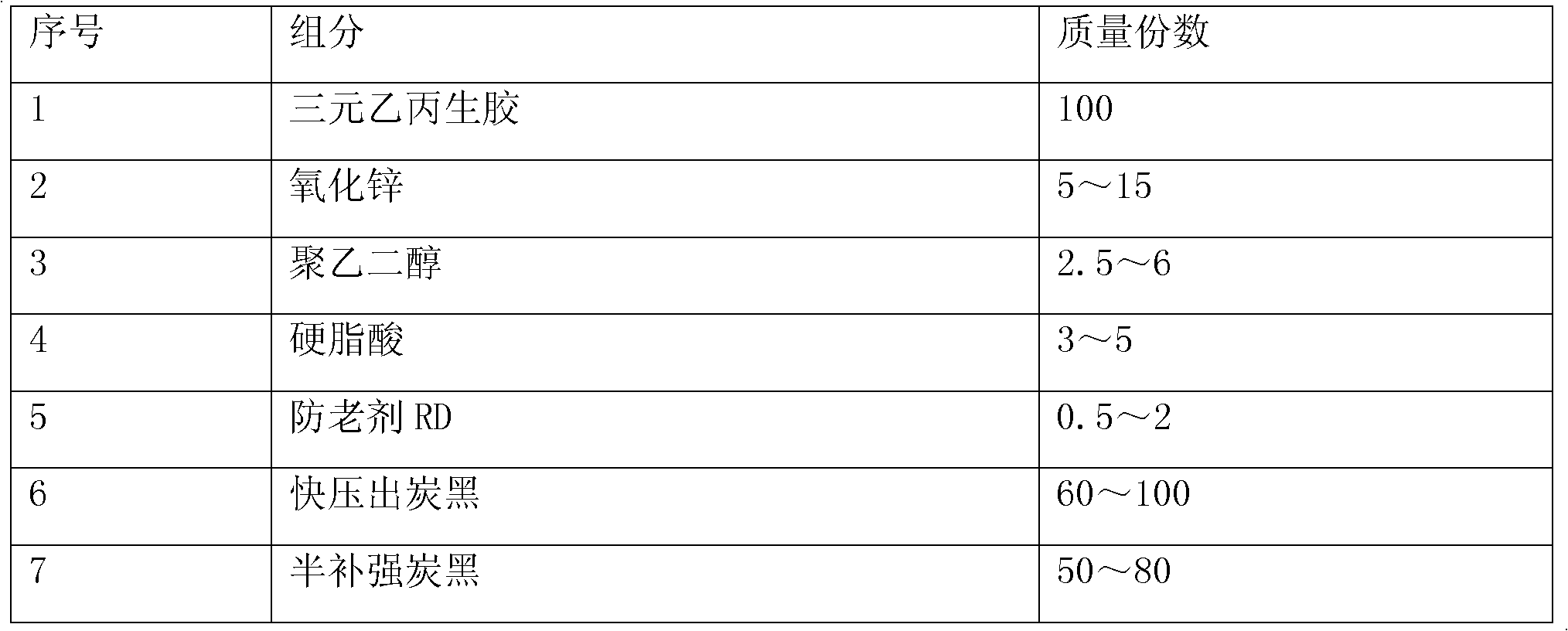

[0013] In parts by mass

[0014]

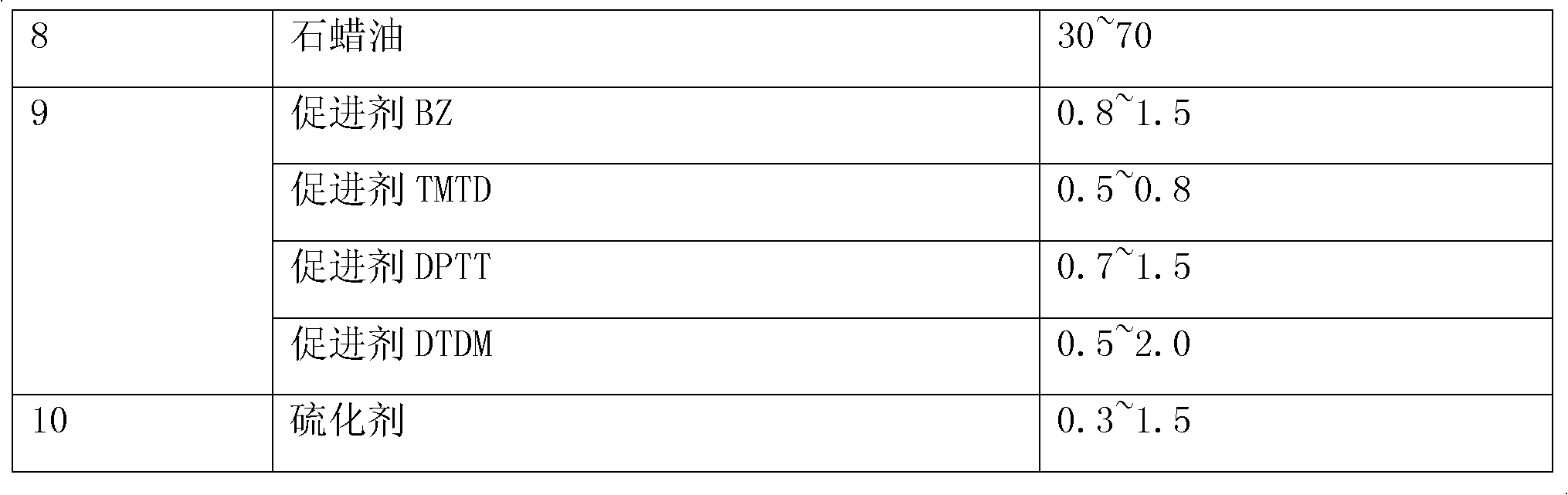

[0015]

[0016] Note: Examples 1 and 2 are EPDM raw rubber with a Mooney viscosity of 40 at ML (1+4) at 125°C; Example 3 is EPDM with a Mooney viscosity of 30 at ML (1+4) at 125°C Acrylic raw rubber; Embodiment 4 and 5 are the EPDM raw rubber that ML (1+4) 125 ℃ Mooney viscosity is 20;

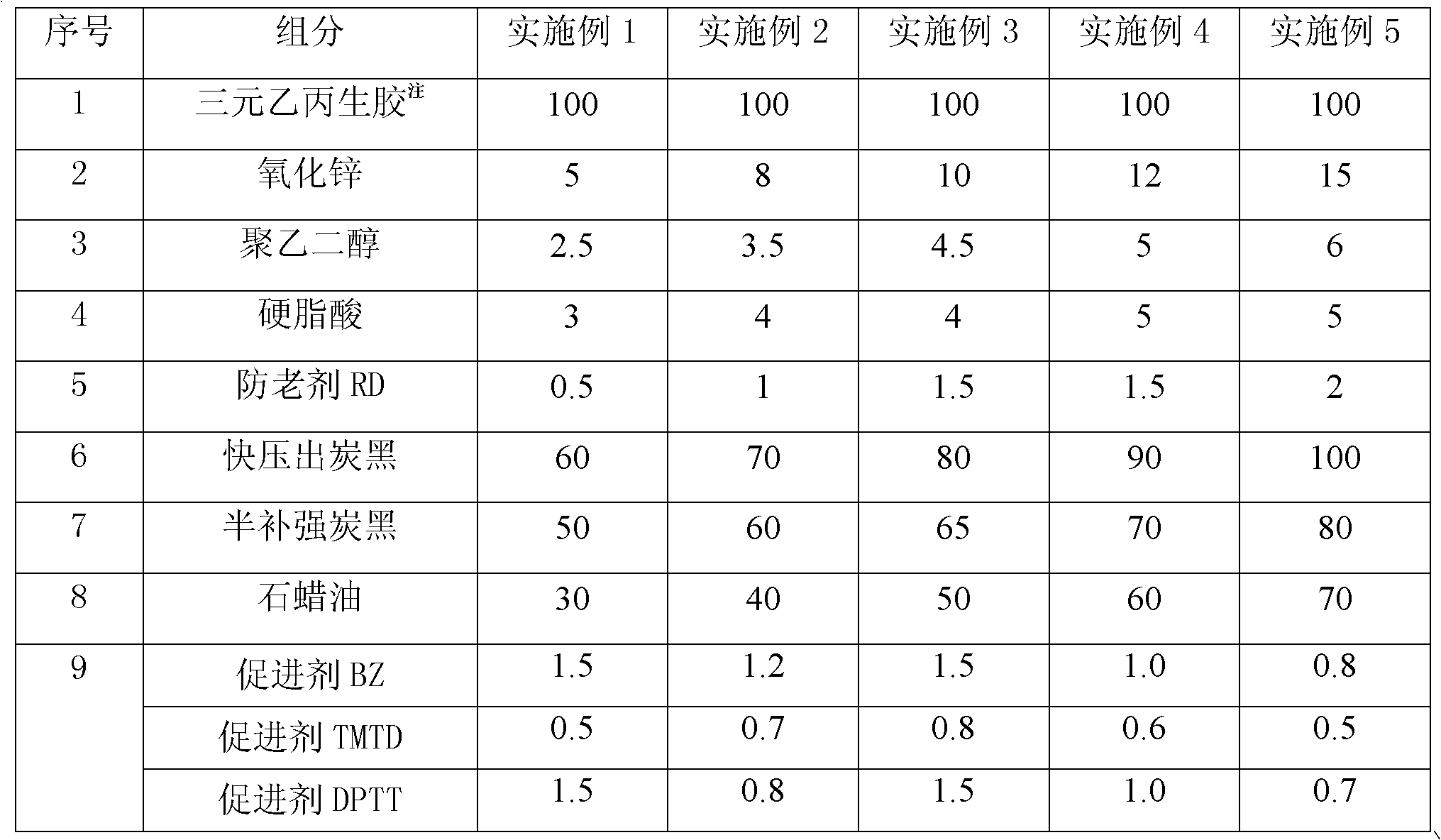

[0017] According to the raw materials in the embodiment formula, the film is made into a film for testing and detection. The properties of the high hardness EPDM rubber used for extrusion are as follows:

[0018]

[0019] From the data in the above table, it can be concluded that the high-hardness EPDM rubber used for extrusion not only has a good extrusion process, but also the physical properties of the product are much higher than the standards of the old products. The practical application in it can meet the current use requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com