Patents

Literature

218 results about "Tetramethylthiuram disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

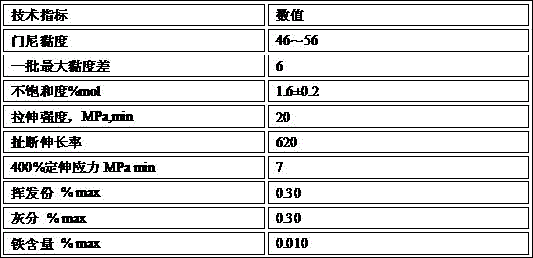

Cable jacket rubber and preparation method

ActiveCN101580606AScorch slowFast vulcanizationRubber insulatorsInsulated cablesTetramethylthiuram disulfideElectricity

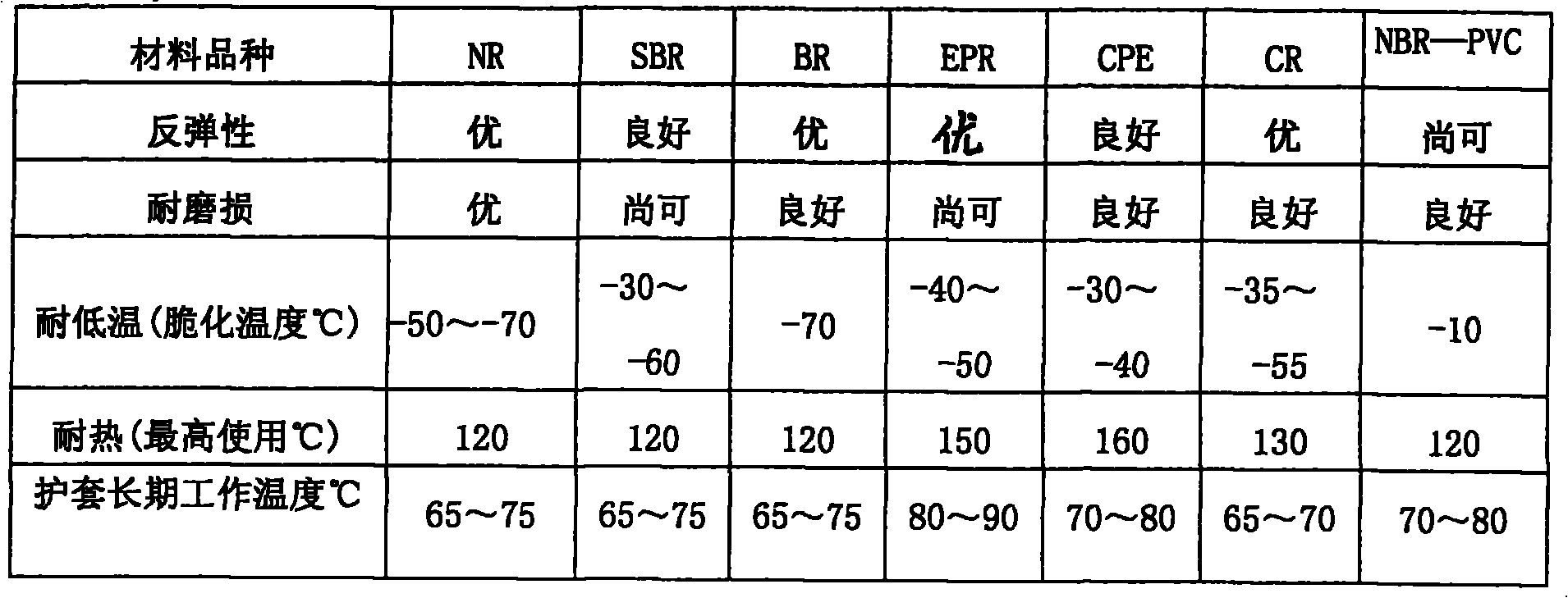

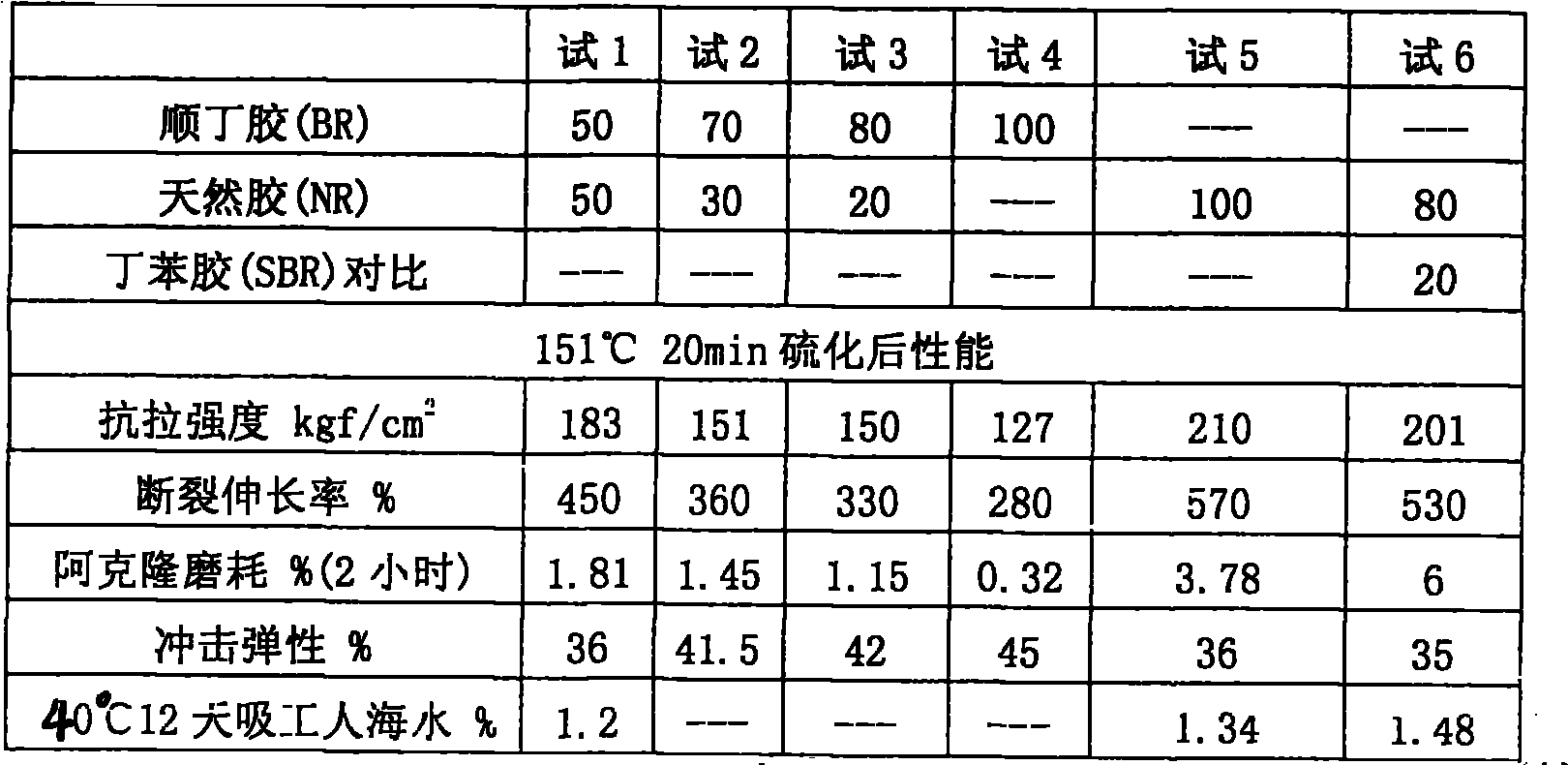

The invention relates to a cable jacket rubber and a preparation method, wherein the cable jacket rubber has high elastic resilience, softness and abrasive resistance at a low temperature. The cable jacket rubber is characterized in that a base material of the rubber is formed by mixing 30 to 50 weight percent of natural gum and 50 to 70 weight percent of cis-butadiene rubber; a vulcanizing system in a rubber compounding agent is a low-sulfur high-accelerant vulcanizing system, the addition of sulfur is 0.3 to 0.6 weight percent of that of the base material of the rubbere, the addition of the accelerant tetramethylthiuram disulfide is between 1.0 and 1.3 weight percent, the addition of the accelerant N-cyclohexyl-2-benzothiazole sulfonamide is between 1.8 and 2.2 weight percent, and the addition of the accelerant diphenyl disulfide benzothiazole is between 0.6 and 0.9 weight percent. The cable jacket rubber has wide range of working temperature, and can be bent and distorted randomly without cracking at a long-term usage temperature of between 50 DEG C below zero and 70 DEG C, the impact elasticity is high and can reach 42 percent, the specific elongation is more than 350 percent, and the Akron abrasion loss is less than 2 percent, thus the cable jacket rubber is particularly suitable for wind-power generated electricity tower tube cables.

Owner:WUXI HUAMEI CABLE

Oil resistant rubber

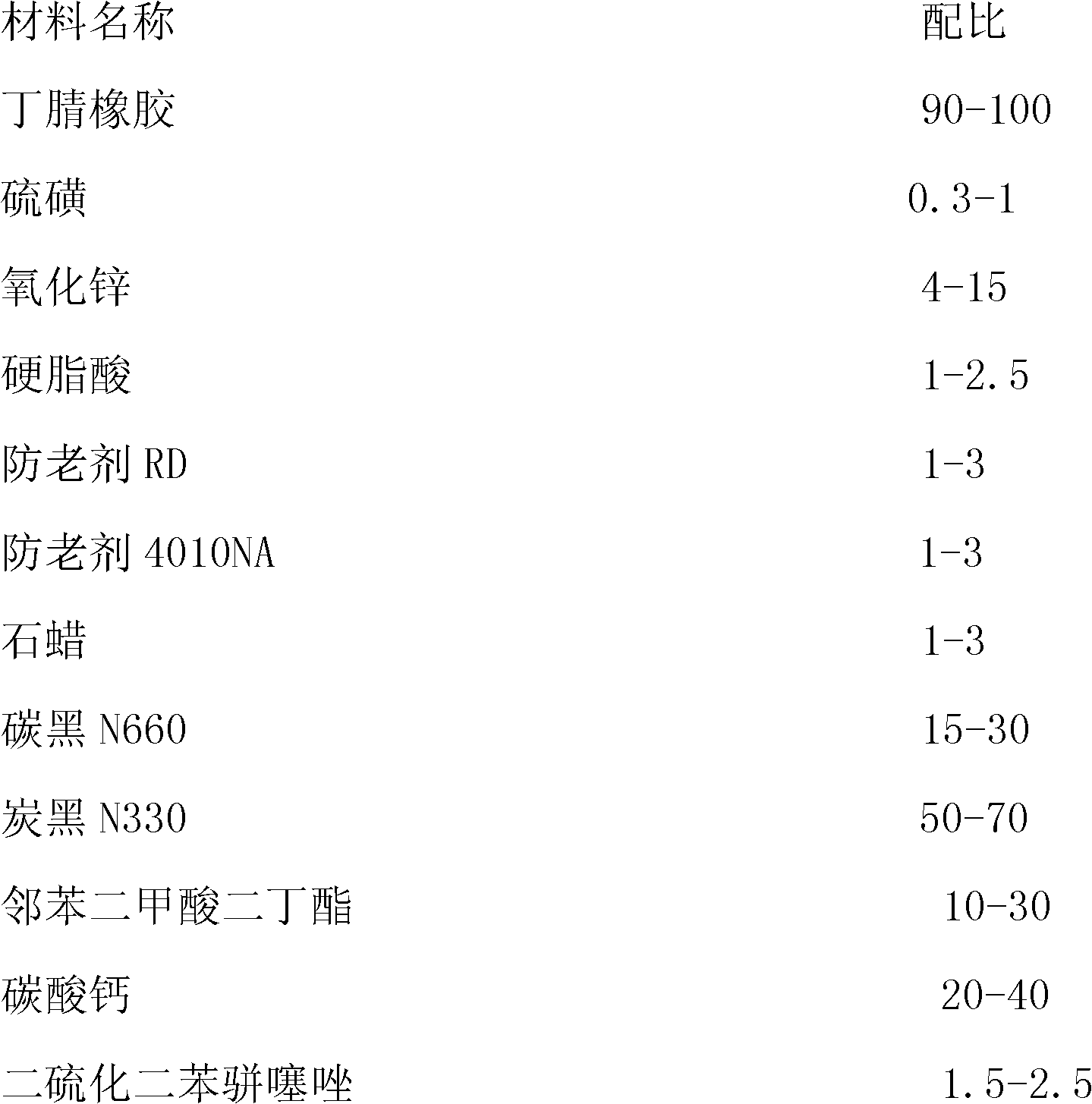

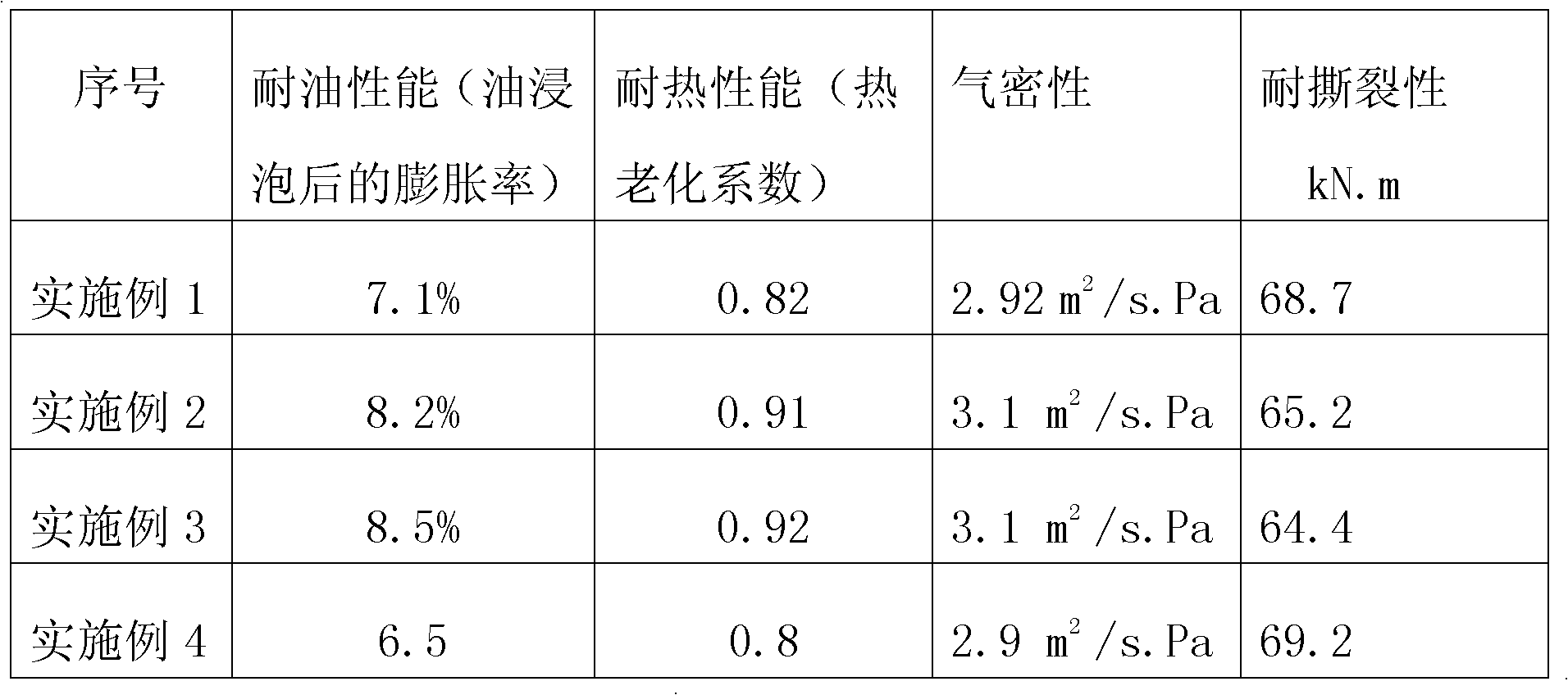

The invention discloses an oil resistant rubber, which contains the following substances in part by weight: nitrile rubber, sulfur, zinc oxide, stearic acid, anti-aging agent RD, anti-aging agent 4010NA, paraffin, carbon black N660, carbon black N330, dibutyl phthalate, calcium carbonate, dibenzothiazyl disulfide, tetramethylthiuram disulfide and tetraethylthiuram disulfide. Compared with the prior art, the oil resistant rubber has the advantages that: the oil resistance of the oil resistant rubber produced by using the rubber formula is less than 8.5 percent, and the oil resistant rubber has good heat resistance and air tightness.

Owner:芜湖禾田汽车工业有限公司

Elastomeric Copolymers, Copolymer Compositions, and Their Use in Articles

A copolymer is formed from an isoolefin having from 4 to 7 carbon atoms and an alkylstyrene. The copolymer has a substantially homogeneous compositional distribution. The copolymer has from about 8 to about 12 wt % of alkylstyrene and at least 85 wt % of isoolefin. The copolymer is preferably halogenated with about 1.1 to about 1.5 wt % of a halogen. The copolymer may in elastomeric nanocomposites. To obtain a good dispersion of the nanoclay in a formulated compound, at least one cure accelerator is selected from the group consisting of mercaptobenzothiazole disulfide, mercaptobenzothiazole, cyclohexyl benzothiazole disulfide, dibutyl thiourea, tetramethylthiuram disulfide, 4-4-dithiodimropholine, zinc dimethyldithiocarbamate, and zinc dibutylphosphorodithiate.

Owner:RODGERS MICHAEL BRENDAN +4

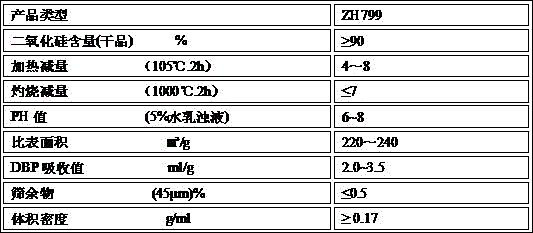

Fluorosilicone rubber cable material for coal mine cable and preparation method of cable material

The invention relates to a fluorosilicone rubber cable material for a coal mine cable and a preparation method of the cable material. The cable material comprises the following raw materials: fluorosilicone rubber, methyl vinyl silicone rubber, precipitation-method white carbon black, light calcium carbonate, zinc oxide, magnesium oxide, stearic acid, an accelerator N, N-tetramethylthiuram disulfide, an antiager-2-mercapto benzimidazole, a vulcanizer-2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, a flame retardant-ammonium polyphosphate, diphenyl silanediol, talcum powder and vaseline. According to the cable material, the advantages of the fluorosilicone rubber and the methyl vinyl silicone rubber as raw materials are combined, the performance of a conventional fluorosilicone rubber cable material is improved, the cable material has excellent performances such as friction and collision resistance, high and low temperature resistance, medium resistance, ageing resistance, flame retardance, waterproof and moistureproof properties, long service life and the like, the requirement of safety use in a coal mine in a special environment is met, and the preparation method of the cable material is simple in process and free of environmental pollution and three-waste emission.

Owner:WUXI HUAMEI CABLE

Novel rubber packing plate and production technique thereof

InactiveCN101220184AExtended service lifeGood weather resistanceRail fastenersTetramethylthiuram disulfideElastomer

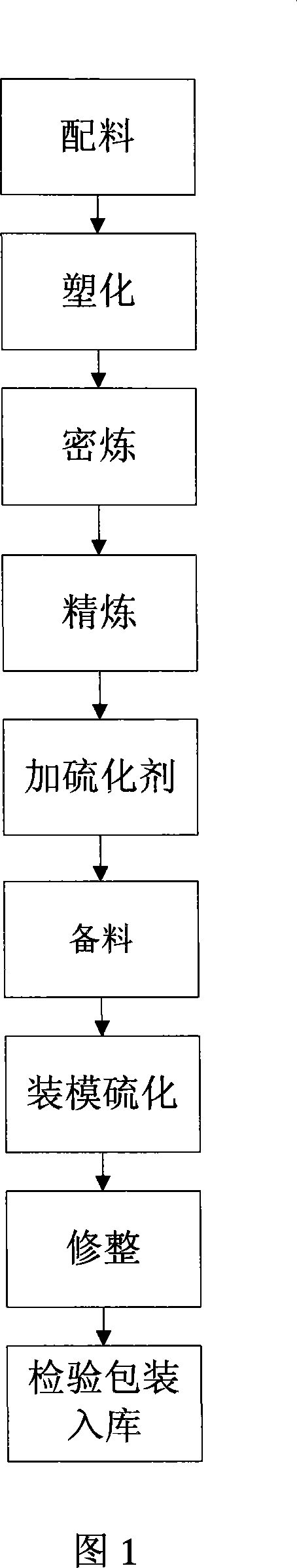

The invention relates to a novel rubber pad, the parts by weight of components of which are: 80-95 portions of ethylene propylene diene monomer rubber, 5-20 portions of elastomer, 0.6-2.5 portions of sulfur, 0.5-2.0 portions of dicumyl peroxide, 0.5-1.5 portions of 2-Mercaptobenzothiazole, 0.8-1.6 portions of tetramethylthiuram disulfide, 2 portions of p-Phenylenediamine or naphthylamine antioxidant, 60-90 portions of carbon black, 15-45 portions of argil, 15-50 portions of calcium carbonate and 35-45 portions of operation oil. Production technique of the pad is according to the processes of mixing - plasticizing - banburying - refining - adding sulfidizer - preparing material - diefilling and sufidizing - finishing - inspecting packages and putting in storage. The invention has the advantages that: the rigidity, the vibration and the noise of railway are reduced; the service life and compression deforming quality of the pad are enhanced; elasticity loss of the pad and line maintenance expense are reduced; the invention also has the advantages of sufficient raw materials, low cost, innocuity and no pollution.

Owner:四川宏亿复合材料工程技术有限公司

Slag pot carrier cable sheath material and manufacturing method thereof

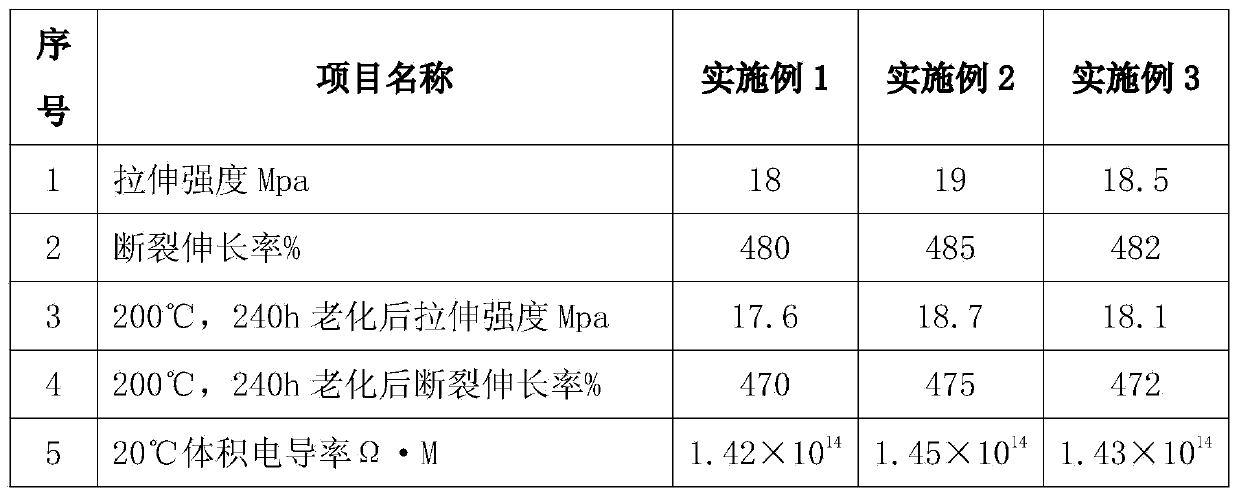

InactiveCN102344590AImprove mechanical propertiesHigh tensile strengthInsulated cablesInsulated conductorsHigh fractureSlag

The invention discloses a slag pot carrier cable sheath material and a manufacturing method thereof. The slag pot carrier cable sheath material comprises 23 parts of chloroprene rubber CR3221, 1.2 to 1.5 parts of zinc oxide, 1 to 1.5 parts of magnesium oxide, 0.1 to 0.3 parts of tetramethylthiuram disulfide (TMTD), 0.2 to 0.3 parts of ethylene thiourea (ETU), 1.0 to 1.3 parts of dioctyl sebacate (DOS), 0.45 to 0.6 parts of dioctyl phthalate (DOP), 0.1 to 0.15 parts of stearic acid (SA), 1.2 to 1.4 parts of microcrystalline paraffin, 0.9 to 1.2 parts of iso-octyl decyl adipate (ODA), 0.1 to 0.15 parts of N-(p-toluene-sulphonylamido-N'-phenylene diamine) (TPPD), 0.2 to 0.4 parts of 4,4-bis(alpha,alpha-dimethylbenzyl)diphenylamine (HS)-911, 5 to 8 parts of carbon black, 4.5 to 6 parts of semi-reinforced carbon black, 0.5 to 0.7 parts of vaseline, 8 to 10 parts of calcining potter's clay and 3 to 4 parts of calcium carbonate. The manufacturing method comprises the following steps of 1, mixing the chloroprene rubber CR3221 for 5 to 7 minutes, 2, adding the magnesium oxide as an active agent, the zinc oxide as an active agent, the microcrystalline paraffin, the SA, the calcium carbonate, the DOP, the carbon black, the DOS, the semi-reinforced carbon black and the vaseline into the mixture obtained by the step 1 to carry out mix for 9 to 11 minutes, 3, adding the calcining potter's clay, the ODA, the TPPD, the HS-911, the TMTD and the ETU into the mixture obtained by the step 2 to carry out mixing, wherein the TMTD and the ETU are added at the last 90 seconds, and 4, moving the mixture obtained by the step 3 to an open mill to carry out tabletting, turning eight triangular cornerites, and cutting into tablets. A cable sheath prepared from the slag pot carrier cable sheath material has the advantages of excellent mechanical properties, high tensile strength, high fracture elongation, aging resistance and oil resistance.

Owner:JIANGSU YUANYANG DONGZE CABLE

Nitrile-butadiene rubber bonded with fluororesin or fluororubber and application thereof in fuel pipe

ActiveCN102146173APerformance is not affectedAccelerated corrosionFlexible pipesPolymer scienceStearic acid

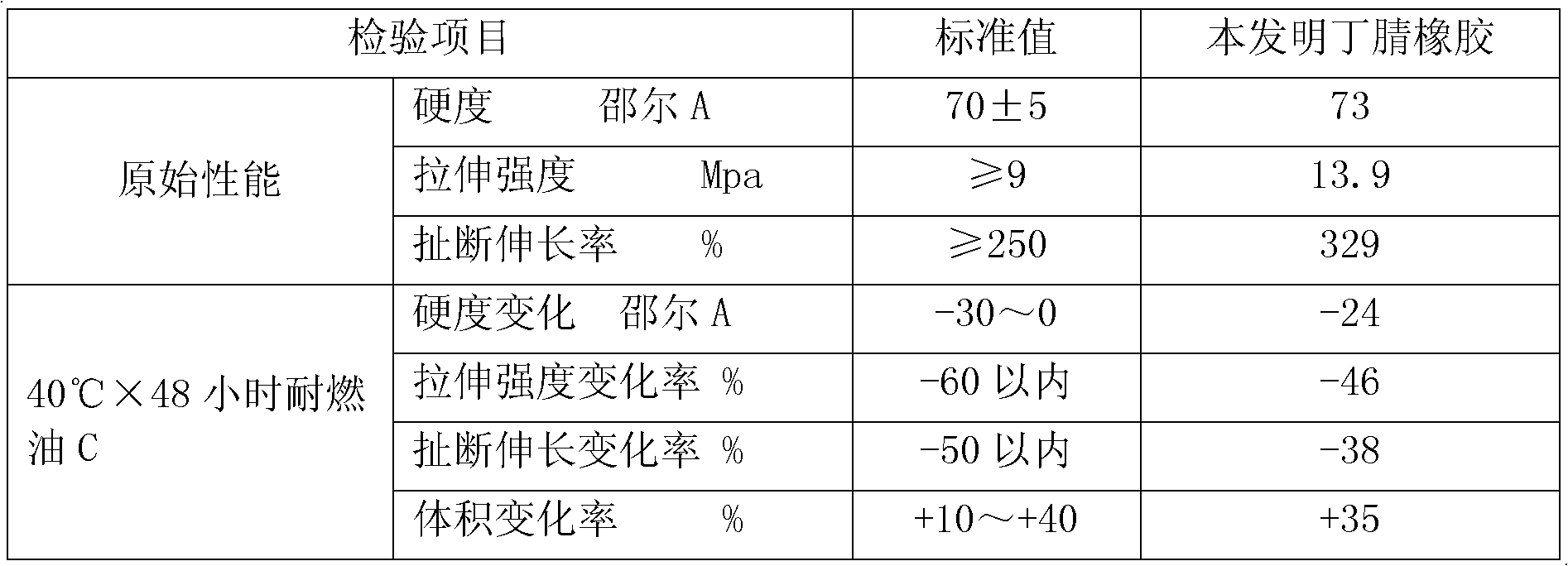

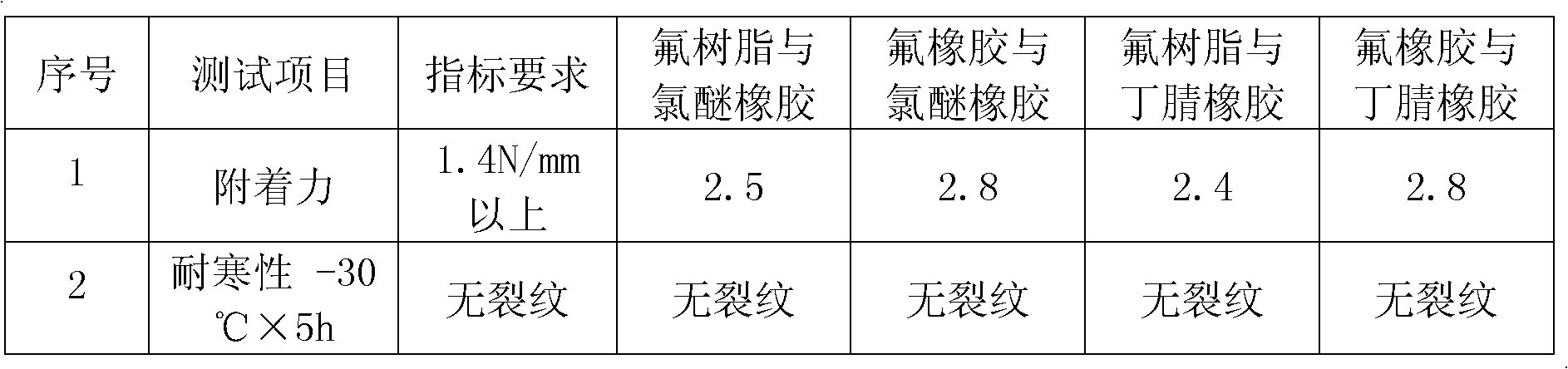

The invention relates to nitrile-butadiene rubber bonded with fluororesin or fluororubber and an application thereof in a fuel pipe. The rubber comprises the following components: raw nitrile-butadiene rubber, magnesium oxide, calcium hydroxide, stearic acid, an antiager RD, an antiager NBC, coumarone, an adhesive Ricobond 2031, fast extruding furnace black N550, high abrasion furnace black N330, white carbon black, trioctyl trimellitate, liquid nitrile-butadiene rubber 26, sulfur, an accelerator CZ and an accelerator TMTD (tetramethylthiuram disulfide). The experimental contrastive analysis on nitrile-butadiene rubber, epichlorohydrin rubber and ethyene-propylene rubber shows that the performances of the nitrile-butadiene rubber can fully meet the standard and the nitrile-butadiene rubber can replace epichlorohydrin rubber and ethyene-propylene rubber. A vehicle rubber pipe prepared from the nitrile-butadiene rubber can meet the normal production conditions and performance requirement, and simultaneously, the material cost can be reduced.

Owner:TIANJIN PENGYI GRP CO LTD

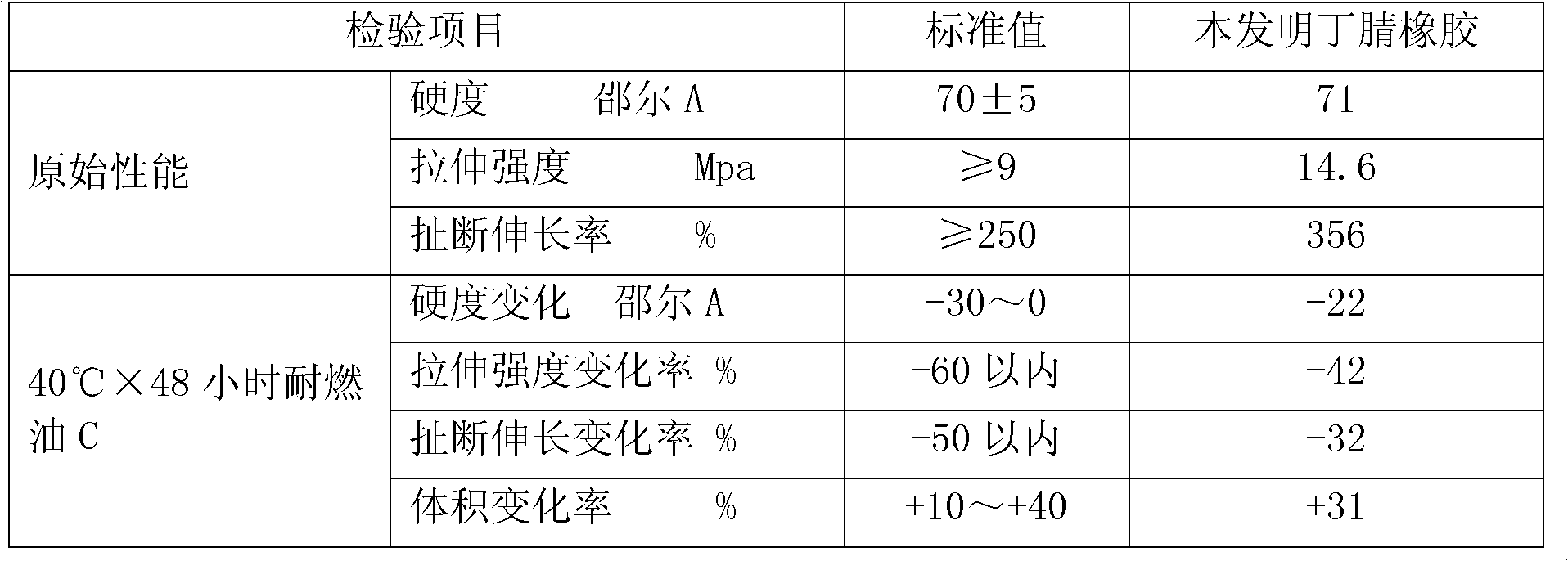

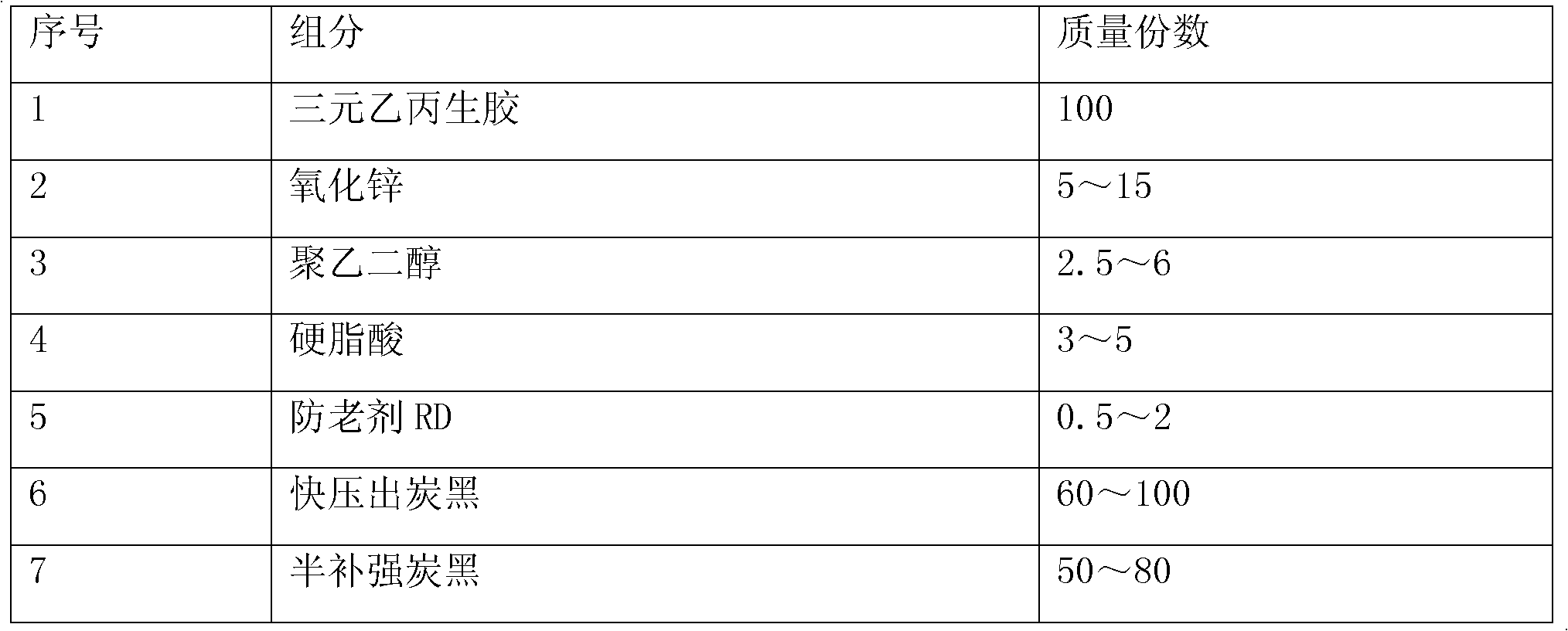

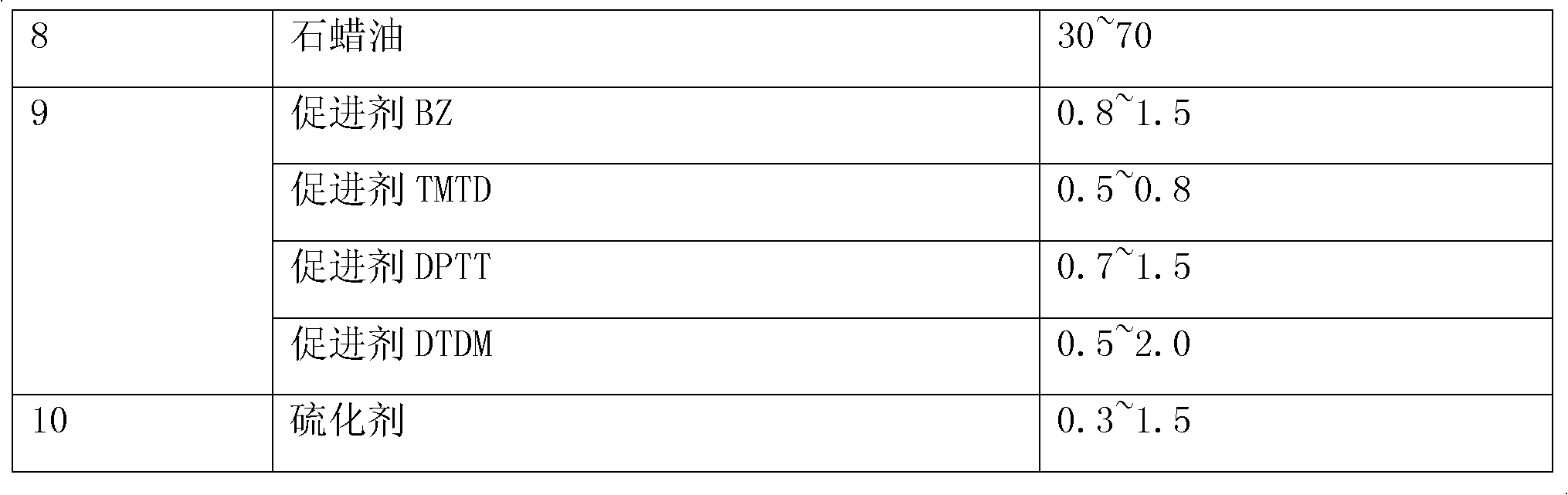

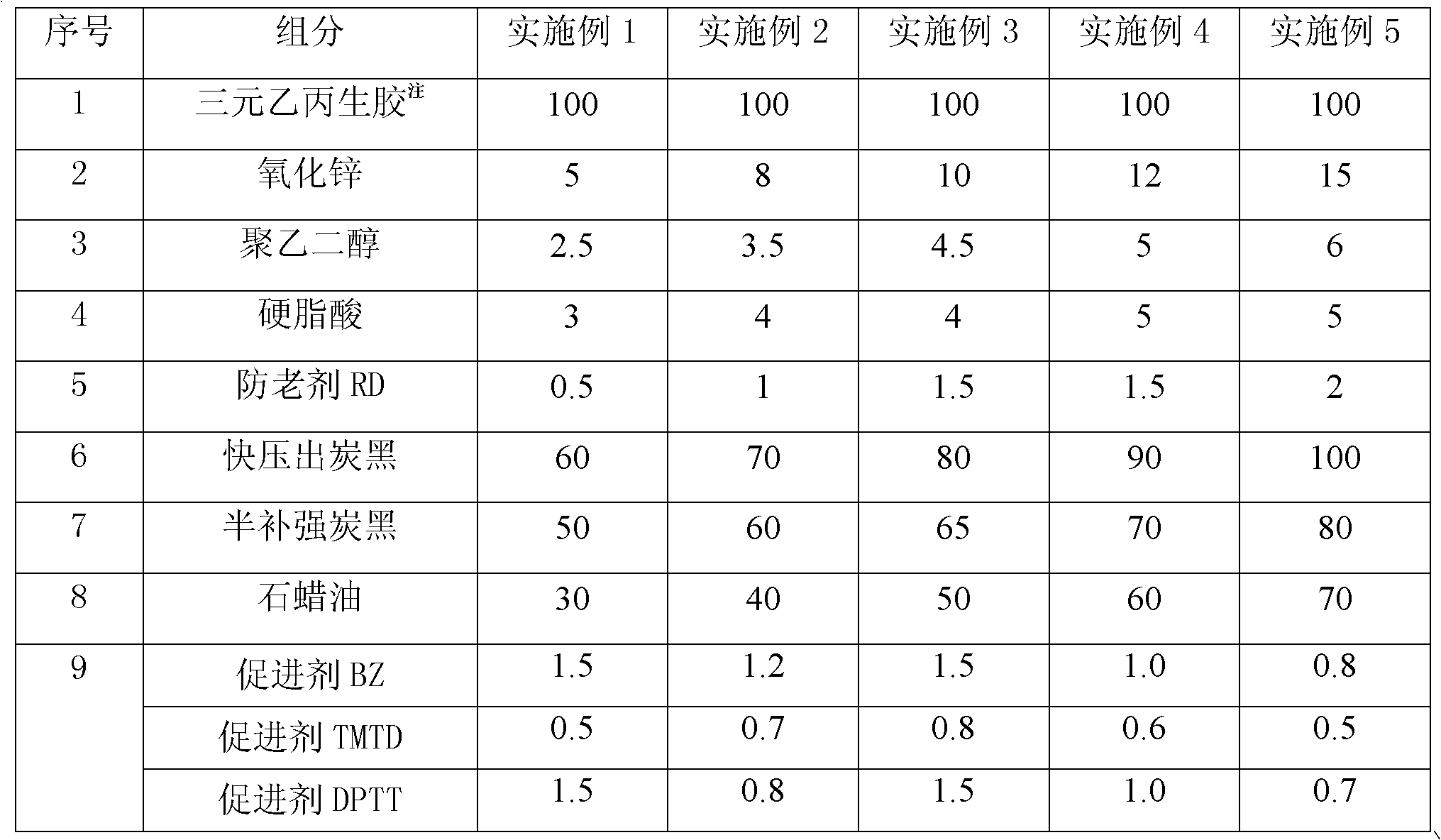

High-hardness ethylene-propylene-diene monomer (EPDM) rubber for extrusion

The invention relates to a high-hardness ethylene-propylene-diene monomer (EPDM) rubber for extrusion, which comprises the following components of EPDM crude rubbers, zinc oxide, polyethylene glycol, stearic acid, an antiager 1,2-dihydro-2,2,4-trimethylquinoline (RD), fast-extruding carbon black, semi-reinforcing carbon black, paraffinoil, accelerating agent BZ, accelerating agent tetramethylthiuram disulfide (TMTD), accelerating agent dipentamethylenethiuram tetrasulfide (DPTT), accelerating agent 4,4`-dithiodimorpholine (DTDM) and vulcanizing agent. The high-hardness ethylene-propylene-diene monomer rubber for extrusion has the advantages that the extrusion technology is good; the physical properties of the product are greatly higher than the standard of the traditional product; the hardness is above 80 Shore A; and the EPDM rubber can meet the current use requirements through the practical application in the seal of doors and windows.

Ion liquid high-temperature-resistant conveying belt rubber material and preparation method and application thereof

InactiveCN102336932AHeat-resistant temperature adjustableImprove thermal stabilityConveyorsRubber materialPhosphate

The invention discloses an ion liquid high-temperature-resistant conveying belt rubber material, which comprises the following raw material components in parts by weight: 80-100 parts of sizing material, 6-10 parts of DCP (Dicumyl Peroxide) vulcanizing agent, 0.5-2 parts of DM (Dibenzothiazyl Disulfide) accelerator, 1-5 parts of TT (Tetramethylthiuram Disulfide) accelerator, 5-10 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of RD (2-dihydroquinoline polymer) anti-aging agent, 0.5-1.5 parts of BLE (Acetone-Diphenylamine High-Temperature Condensate) anti-aging agent, 6-12 parts of TCP (Triorthocresol Phosphate) flame retardant, 2-5 parts of chlorinated paraffin, 3-8 parts of terpine resin, 5-8 parts of coumarone, 50-90 parts of carbon black, 3-8 parts of NO.300 paraffin oil, 0.5-1 part of sulfur and 1-10 parts of ion liquid phyllosilicate. The invention has the advantages: the ion liquid phyllosilicate is added into a formula of an adhesive tape, so that the heat-resistant temperature of the adhesive tape is adjustable, and resistance to the temperature 300-500 DEG C can be realized.

Owner:NINGBO UNIV

High-performance nitrile butadiene rubber cable jacket material and preparation method thereof

InactiveCN105254953AGood mechanical propertiesImprove water resistanceInsulated cablesInsulated conductorsCarbon nanotubeCorrosion

The invention discloses a high-performance nitrile butadiene rubber cable jacket material. The high-performance nitrile butadiene rubber cable jacket material comprises following raw materials: nitrile butadiene rubber, polyvinyl chloride, chlorinated polyethylene, fluororubber, zinc oxide, trithiocyanuric acid, dicumyl peroxide, triallyl isocyanurate, the accelerator TMTD (tetramethylthiuram disulfide), the accelerator CZ, carbon nano tubes, nano silicon nitride, nano boron nitride, nano titanium dioxide, dibutyl phthalate, dioctyl sebacate, trioctyl trimellitate, coumarone resin, stearic acid, zinc stearate, calcium stearate, the anti-aging agent MB, the anti-aging agent RD, lanthanum stearate and a silane coupling agent. The invention further provides a preparation method of the high-performance nitrile butadiene rubber cable jacket material. The method has simple process and mild condition; the obtained jacket material has high strength, good weather resistance, good corrosion resistance and excellent processability, can meet requirements of cables in multiple fields and has long service life.

Owner:ANHUI LAND GRP

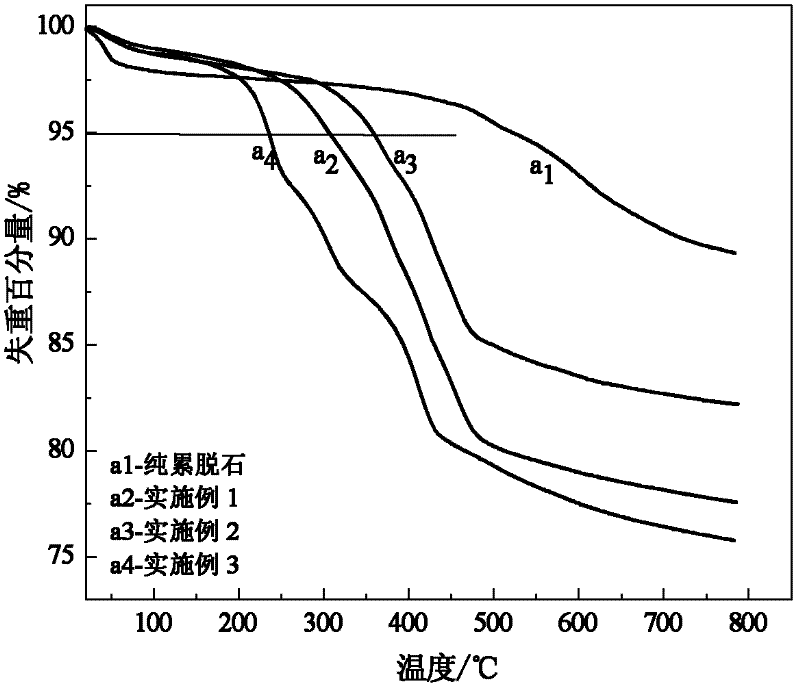

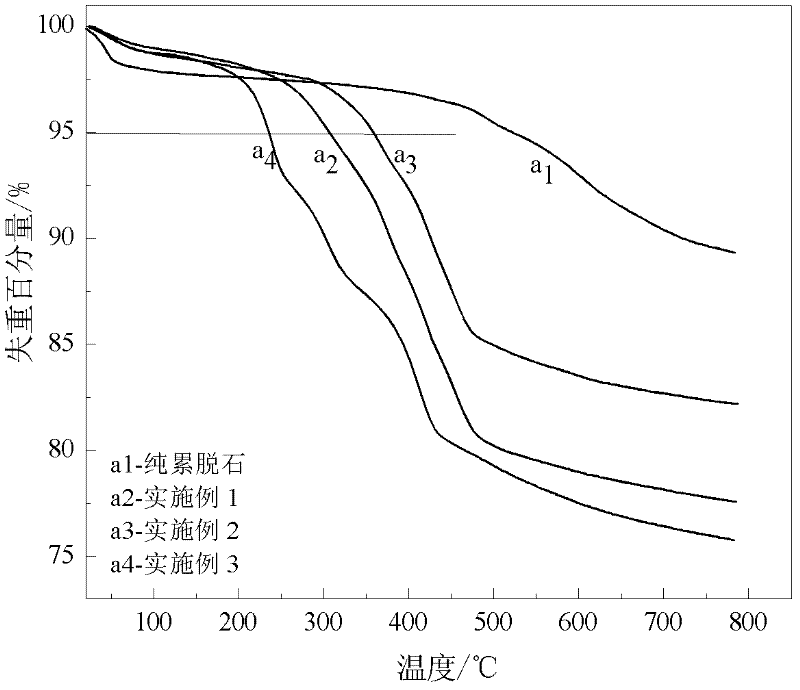

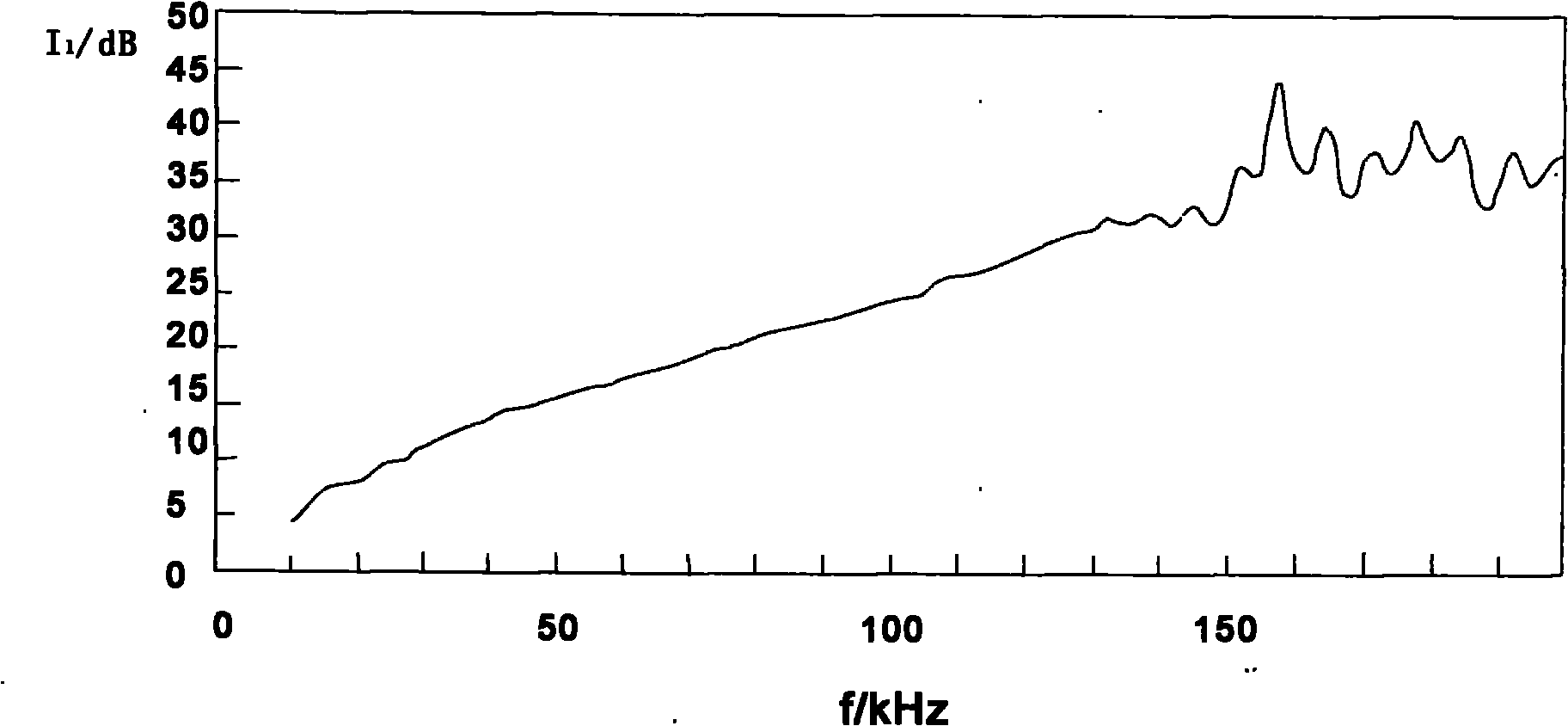

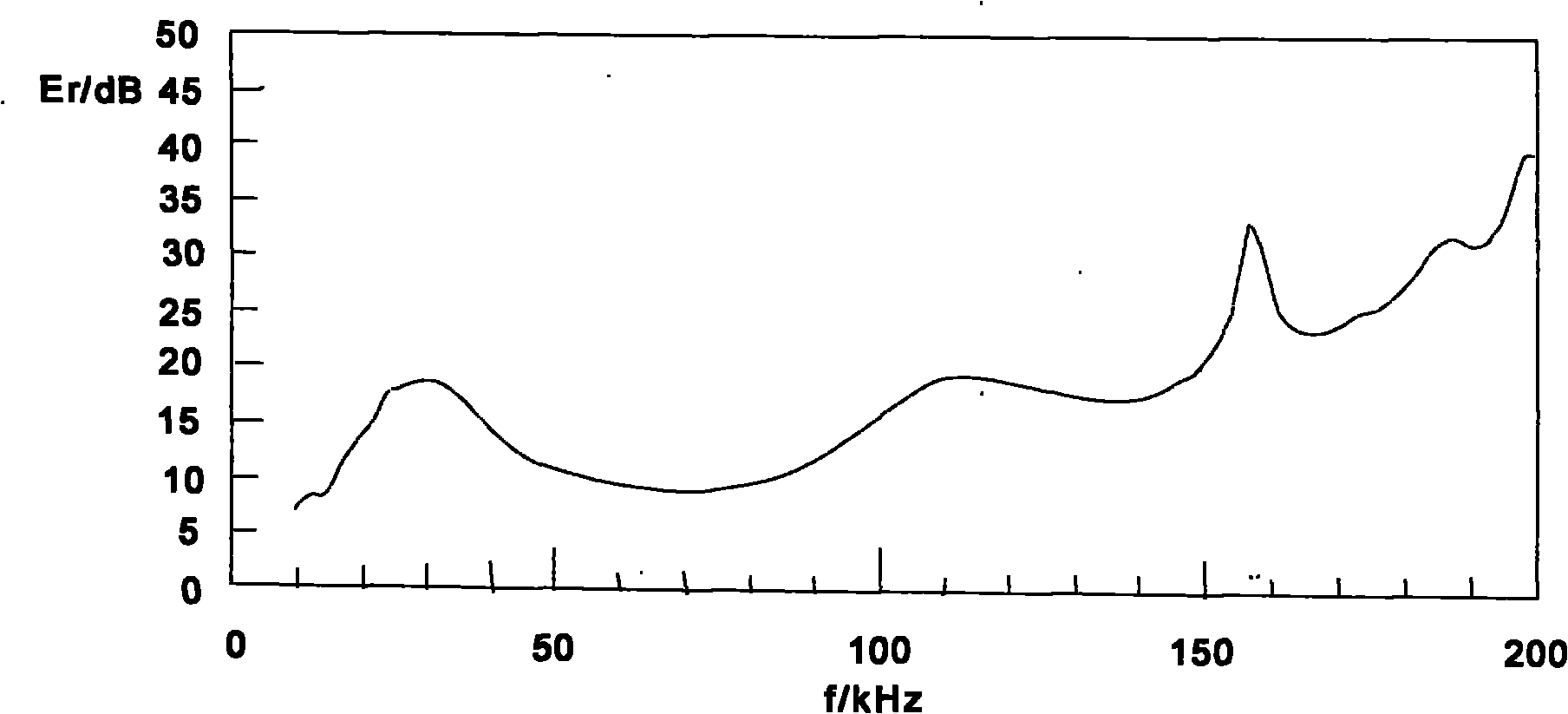

Wideband underwater acoustic absorption and transmission material and preparation method thereof

ActiveCN101934617AWith low frequency sound transmissionMeet the use requirementsTransducers for subaqueous useRubber layered productsRubber materialAcoustic absorption

The invention discloses a wideband underwater acoustic absorption and transmission material and a preparation method thereof. The wideband underwater acoustic absorption and transmission material is prepared by adhering and compounding an acoustic absorption layer with the thickness of 2-5 mm and an acoustic transmission layer with the thickness of 10-15 mm, the acoustic transmission layer is prepared from the following components in parts by weight: 100 parts of chlorinated butyl rubber, 20-40 parts of carbon black, 5-10 parts of calcium carbonate, 5 parts of dioctyl sebacate, 5-35 parts of zinc oxide, 5-35 parts of stearic acid, 0.5-1.5 part of age resister D, 0.5-1.5 parts of accelerant TMTD (Tetramethylthiuram Disulfide) and 0.5-2.0 parts of sulfur; and the acoustic absorption layer is prepared from the following components in percentage by weight: 100 parts of chlorinated butyl rubber, 20-40 parts of carbon black, 5-10 parts of calcium carbonate, 5 parts of dioctyl sebacate, 5-35parts of zinc oxide, 5-35 parts of stearic acid, 0.5-1.5 part of age resister D, 0.5-1.5 parts of accelerant TMTD, 0.5-2.0 parts of sulfur and 0.5-2.0 parts of zinc powder or iron powder. The underwater acoustic absorption and transmission rubber material has excellent physical mechanical performance as well as and acoustic transmission and absorption characteristics and can be used for researching a special underwater acoustic frequency band.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

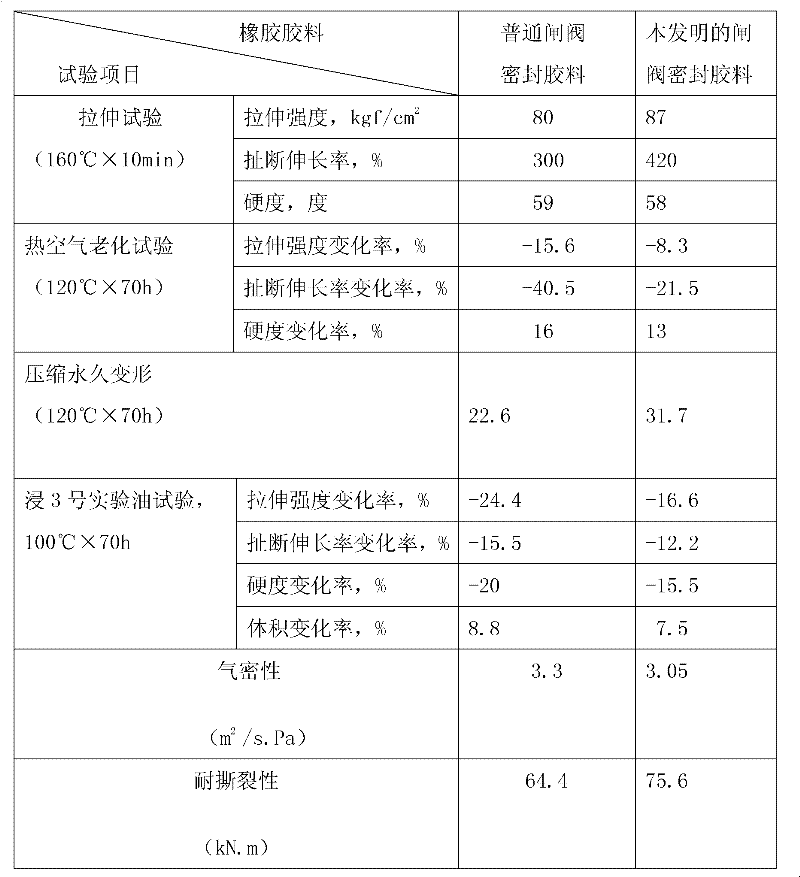

O-shaped seal ring rubber sizing material of gate valve end surface and preparation method thereof

The invention discloses an O-shaped seal ring rubber sizing material of a gate valve end surface, which is formed by mixing a rubber sizing material A and a rubber sizing material B, wherein the rubber sizing material A comprises the following raw materials in part by weight: 85-95 parts of nitrile rubber 3304, 0.3-0.5 parts of sulphur, 4-6 parts of zinc oxide, 1-1.5 parts of stearic acid, 1-2 parts of 2,6-Di-tert-butyl-p-methyl phenol (BHT), 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent 4010Na, 3-4 parts of microcrystalline wax, 22-25 parts of fast extruding carbon black N660, 62-65 parts of high wear-resistant carbon block N330, 18-22 parts of sebacic acid dioctyl phthalate, 10-15 parts of kieselguhr, 3-4 parts of accelerator M, 1-2 parts of 2,2'-dibenzothiazoledisulfde (DM) and 1-2 parts of tetramethylthiuram disulfide (TMTD); and the rubber sizing material B comprises the following raw materials in part by weight: 82-87 parts of polyacrylate rubber, 13-18 parts of ethylene propylene rubber, 1-2 parts of sodium stearate, 1-3 parts of anti-aging agent RD, 0.4-0.6 parts of gum easyT-78, 1-2 parts of Rhine wax, 45-55 parts of fast extruding carbon black, 10-14 parts of graphite powder, 5-8 parts of sebacic acid dioctyl phthalate, 0.5-1.5 parts of dicumyl peroxide (DCP), 0.2-0.8 part of Triallyl Iso cyanurate (TAIC) and 1-2 parts of accelerator Na-2. The seal ring rubber lining sizing material disclosed by the invention has good comprehensive performance. The produced O-shaped seal ring of the gate valve end surface has the characteristics of good gas tightness, weather resistance, low temperature resistance, oil resistance and the like, and also has low material cost.

Owner:TONGLING XINTE VALVE

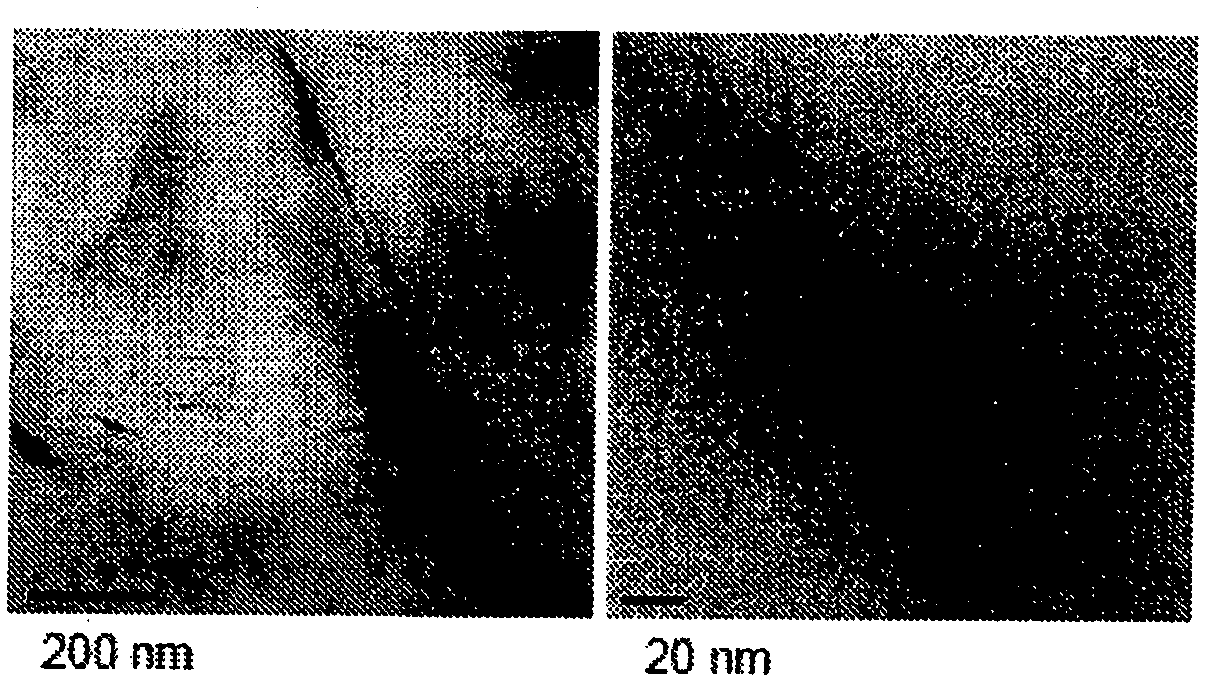

Elastomeric copolymers, copolymer compositions, and their use in articles

A copolymer is formed from an isoolefine having from 4 to 7 carbon atoms and an alkylstyrene. The copolymer has a substantially homogeneous compositional distribution. The copolymer has from about 8 to about 12 wt% of alkylstyrene and at least 85 wt% of isoolefine. The copolymer is preferably halogenated with about 1.1 to about 1.5 wt% of a halogen. The copolymer may in elastomeric nanocomposites. To obtain a good dispersion of the nanoclay in a formulated compound, at least one cure accelerator is selected from the group consisting of mercaptobenzothiazole disulfide, mercaptobenzothiazole, cyclohexyl benzothiazole disulfide, dibutyl thiourea, tetramethylthiuram disulfide, 4-4- dithiodimropholine, zinc dimethyldithiocarbamate, and zinc dibutylphosphorodithiate.

Owner:EXXONMOBIL CHEM PAT INC

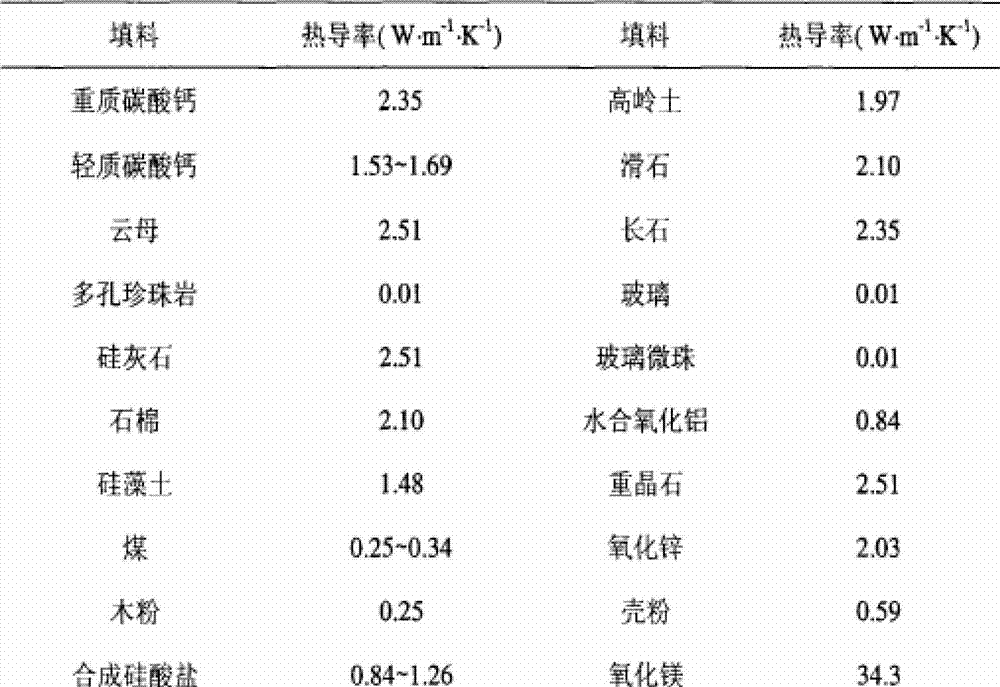

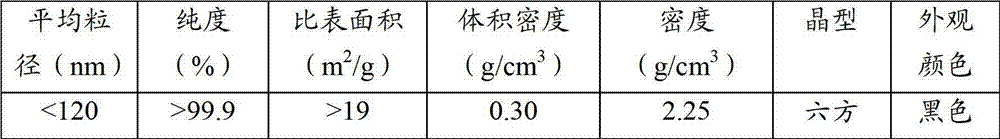

High-heat-conductivity ternary rubber

InactiveCN103044784AImprove thermal conductivityEnhanced interactionHeat conductingVolumetric Mass Density

The invention discloses high-heat-conductivity ternary rubber. An anti-aging agent is one type or more types of the following reagents: N-phenyl-alpha-aniline, N-phenyl-beta-naphthylamine, N-phenyl-N'-cyclohexyl p-phenylenediamine, N-phenyl-N'-isopropyl-p-phenylenediamine and N-N'-diphenyl-p-phenylenediamine. An accelerant is one type or more types of the following reagents: an accelerant T, N,N-tetramethyl dithio-dithiocarbonyl amine, tetramethylthiuram disulfide, thiram, a vulcanization accelerant TMTD and tetramethylthiuram disulfide. By adoption of mixed fillers, the heat conductivity of the composite material is greatly improved. Granules and crystal whiskers with a certain length-diameter ratio form continuous heat-conducting network chain; combination of fillers with different grain size is selected, so high filling density is achieved; and the interface of the fillers and a matrix is improved by a coupling agent, so the heat resistance at the interface is reduced.

Owner:深圳桐源科技有限公司

Tire air-tight layer rubber composite containing nano filler StronWiNTC

InactiveCN102675760AGood dispersionImprove mechanical propertiesSpecial tyresHeat stabilityStearic acid

The invention relates to the field of rubber and particularly relates to a tire air-tight layer rubber composite containing a nano filler StronWiNTC. The tire air-tight layer rubber composite is characterized by comprising the following raw materials in parts by weight: 25-45 parts of natural rubber, 20-40 parts of butylbenzene rubber, 15-55 parts of chlorinated butyl rubber, 52-60 parts of carbon black N660, 20-28 parts of StronWiNTC, 4-6 parts of aromatic hydrocarbon oil, 3-5 parts of zinc oxide, 1-2 parts of stearic acid, 1-2 parts of anti-ageing agent 4020, 1-2 parts of anti-ageing agent RD, 3-4 parts of protective wax OK5194, 3-4 parts of tackifying resin A-90, 1-2 parts of accelerator TMTD (Tetramethylthiuram Disulfide), 1-2 parts of accelerator CZ and 0.5-1.0 part of vulcanizing agent WP5. The tire air-tight layer rubber composite disclosed by the invention can endow good mechanical property and heat stability to the air-tight layer and can improve the air tightness of air-tight layer rubber; and particularly, the tire air-tight layer rubber composite has appropriate advantages on the aspects of performances of elasticity, flexing resistance, stable size, separation performance, elongation at rupture, compression and deformation and the like.

Owner:TIUMSUN RUBBER TIRE WEIHAI

Fluorocarbon-modified super-hydrophobic material and preparation method thereof

InactiveCN102382366ASuper hydrophobic effect is remarkableSimple processing methodOther chemical processesBenzoic acidCarbon monofluoride

The invention discloses a fluorocarbon-modified super-hydrophobic material, which is prepared from silicon rubber, a vulcanizing agent, a fluorocarbon material, polypropylene and an aid serving as raw materials, wherein the static contact angles of the raw materials are respectively greater than 150 degrees, and the drift angles are respectively smaller than 10 degrees; the vulcanizing agent is one or more of TMTD (Tetramethylthiuram Disulfide), PDM (N,N'-m-Phenylenedimaleimide), t-butyl perbenzoate and tertiary capryl peroxyester; the fluorocarbon material is prepared by fluorating a carbon material; the carbon material is one or more of carbon black, active carbon, coke, a carbon nanotube and graphene; and the aid is one or more of stearic acid, magnesium stearate and zinc stearate. A preparation method of the fluorocarbon-modified super-hydrophobic material comprises the following steps of: (1) smelting a premix compound; (2) fluorating a carbon material; (3) extruding and pelletizing; (4), performing hot pressing and cold pressing; and (5) grinding and removing scraps. The super-hydrophobic material has a remarkable super-hydrophobic effect, a simple processing method and a good application prospect. Moreover, the inside and the surface of a product substrate are provided with the same component, so that a needed super-hydrophobic surface can be formed by grinding once again when the surface is damaged.

Owner:WENGFU (GRP) CO LTD +1

Rubber gasket material for bogie shaft box of rail wagon

ActiveCN101921414AHigh strengthImprove fatigue resistanceNon-rotating vibration suppressionBogieEngineering

The invention relates to a component damping material for a rail wagon, in particular to a rubber gasket material for a bogie shaft box of the rail wagon, which is applied to a K6 type bogie shaft box. The material comprises the following components in part by weight: 80 to 110 parts of natural rubber, 10 to 30 parts of butadiene rubber, 3 to 8 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 0.2 to 2.0 parts of anti-aging agent 4010NA, 0.2 to 2.0 parts of anti-aging agent RD, 0.5 to 2.0 parts of accelerator CZ, 0.3 to 1.0 part of sulfur, 0.5 to 2.0 parts of tetramethylthiuram disulfide (TMTD) serving as an accelerator, 30 to 100 parts of carbon black and 0 to 10 parts of plasticizer. The rubber gasket material for the bogie shaft box of the rail wagon has the advantages of meeting the basic requirements of elastic supporting and elastic damping, greatly improving intensity, fatigue resistance and permanent deformation resistance, prolonging service life and adapting to a larger application temperature range.

Owner:JIANGSU TIEKE NEW MATERIAL CO LTD

High-temperature-resistant halogen-free flame-retarding thermoplastic elastomer and preparation method of high-temperature-resistant halogen-free flame-retarding thermoplastic elastomer

InactiveCN106750860AImprove mechanical propertiesImprove flame retardant performanceTemperature resistanceAccelerant

The invention discloses a high-temperature-resistant halogen-free flame-retarding thermoplastic elastomer. The high-temperature-resistant halogen-free flame-retarding thermoplastic elastomer is prepared from the following raw materials in parts by weight: 60 to 80 parts of EVA (Ethylene-vinyl Acetate copolymer), 25 to 45 parts of EPDM (Ethylene-Propylene-Diene Monomer), 15 to 35 parts of an ethylene-octene copolymer, 1 to 15 parts of high density polyethylene, 5 to 20 parts of organic modified siloxane, 10 to 30 parts of ammonium polyphosphate, 2 to 5 parts of aluminum hydroxide, 1 to 3 parts of zinc borate, 1 to 5 parts of sulfur, 0.5 to 1.5 parts of an accelerant TMTD (Tetramethylthiuram Disulfide), 0.5 to 2 parts of an accelerant CZ, 0.5 to 2 parts of zinc oxide, 1 to 3 parts of an anti-ageing agent RD, 4 to 18 parts of calcium carbonate, 3 to 5 parts of ground quartz, 5 to 10 parts of an interface compatibilizer, 5 to 20 parts of a plasticizer, 0.5 to 2 parts of an antioxygen, 0.2 to 2 parts of a lubricant and 1 to 3 parts of a processing auxiliary agent. The thermoplastic elastomer disclosed by the invention has excellent high-temperature resistance and flame-retarding performance and has no halogen, low toxin and good comprehensive properties.

Owner:TIANCHANG KANGNING PLASTIC TECH

Ethylene propylene diene monomer hose for microwave vulcanization

InactiveCN101985504ASlow initial sulfur pointEasy extrusionFlexible pipesPolyethylene glycolStearic acid

Owner:TIANJIN PENGYI GRP CO LTD

Formula of EPDM (ethylene propylene diene monomer) material applied to dynamic-fatigue-resistant products and preparation method of EPDM material

InactiveCN103834113AImprove mechanical propertiesSuperior dynamic fatigue resistanceTetramethylthiuram disulfidePolymer science

The invention discloses a formula of an EPDM (ethylene propylene diene monomer) material applied to dynamic-fatigue-resistant products and a preparation method of the EPDM material. The formula of the EPDM material comprises the following raw materials in parts by weight: 90-110 parts of EPDM rubber, 3.5-8 parts of zinc oxide, 0.5-2 parts of stearic acid, 10-90 parts of carbon black N774, 20-50 parts of paraffin oil 2280, 0.2-4 parts of vulcanizing agent S-80, 0.2-3 parts of accelerator TMTD (tetramethylthiuram disulfide) and 0.1-2 parts of antioxidant MBD. According to the formula disclosed by the invention, the EPDM rubber is used as a base material, the TMTD is used as the accelerator, the MBD is used as the antioxidant, and other auxiliary materials are compatible, so that the EPDM material prepared by adopting an optimized formula not only has superior physical and mechanical properties and dynamic fatigue resistance, but also has greatly-improved heat resistance and air aging resistance compared with conventional materials.

Owner:RIZHAO DONGDU RUBBER & PLASTIC PROD

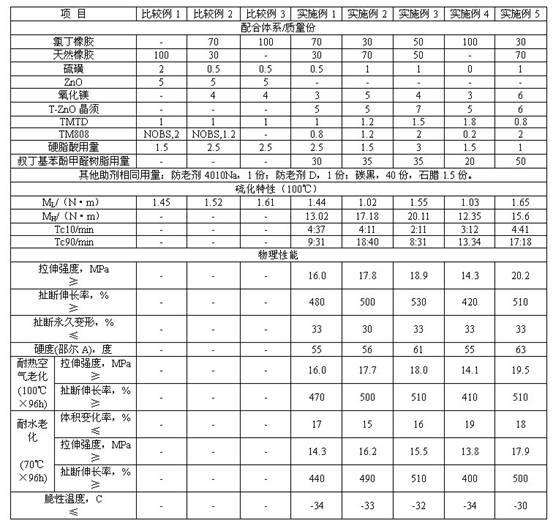

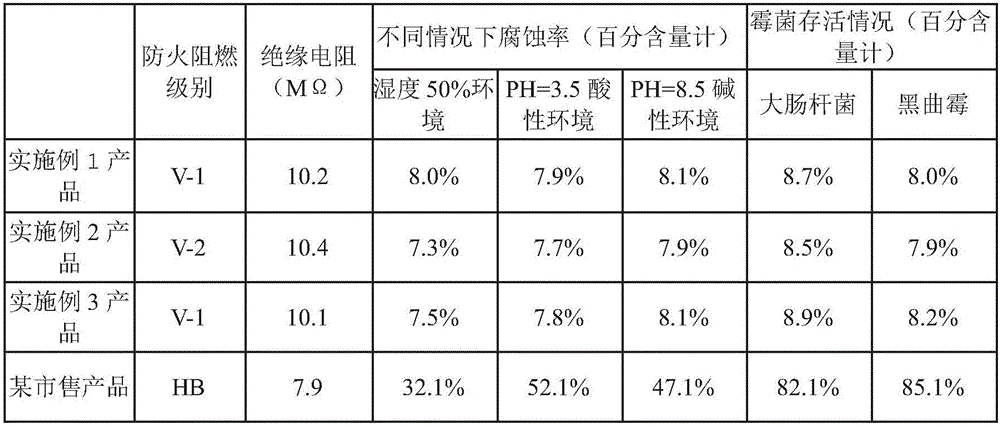

Room temperature/low temperature vulcanized chloroprene rubber sizing material

ActiveCN102115553AStable room temperature/low temperature vulcanization performanceImproved scorch performancePolymer scienceTert butyl phenol

The invention discloses a room temperature / low temperature vulcanized chloroprene rubber sizing material, which relates to rubber. The rubber sizing material is obtained by mixing and processing the following components in parts by mass: 100-30 parts of chloroprene rubber, 0-70 parts of natural rubber, 0-1 part of sulfur S, 4-7 parts of T-ZnO crystal whiskers, 1-6 parts of magnesium oxide, 0-3 parts of TM808, 0.5-1.5 parts of accelerating agent TMTD (Tetramethylthiuram Disulfide), 20-50 parts of tert-butyl phenol formaldehyde resin, 1-6 parts of stearic acid and the balance of compound anti-ageing system consisting of 4010Na and D, carbon black and a paraffin aid, wherein the sulfur S, the T-ZnO crystal whiskers and the magnesium oxide jointly serve as a dual vulcanizing agent, and the TM808 and the accelerating agent TMTD jointly serve as a compound accelerating agent. The chloroprene rubber sizing material obtained by the invention can be vulcanized at room temperature / low temperature, has high scorching property, high adhesion on a framework material and the advantages of ageing resistance, high physical and mechanical performance, high ozone resistance, high oxidation resistance, combustion resistance and the like, and is particularly suitable for the production of large-sized rubber products or the construction of field vulcanization.

Owner:陈尔凡

Formula for negative pressure bellows

The invention relates to a formula for a negative pressure bellows, comprising the following ingredients by weight percentage: 30-50wt percent of butyronitrile rubber, 5-20wt percent of polyvinyl chloride, 4-8wt percent of dioctyl-phthalate (DOP), 10-16wt percent of fast extruding furnace black (FEF), 5-15wt percent of figuline, 1-2wt percent of anti-aging agent A, 1.5-2.5wt percent of zinc oxide, 0.5-1.5wt percent of stearic acid, 0.5-1.5wt percent of paraffin, 0.2-0.4wt percent of tetramethylthiuram disulfide, 0.5-1.5wt percent of brimstone, 0.2-0.6wt percent of mercaptobenzothiazole, and 1-5wt percent of aramid short fiber; after study and experiment, semi-reinforcing strong carbon black is removed in the new formula, one weighting program can be reduced and the cost is reduced; the argilla, paraffin and TMTD in the new formula can lead the aramid short fiber to be uniformly dispersed in the rubber, and the elasticity and flowability of the rubber can be increased.

Owner:TIANJIN PENGYI GRP CO LTD

Aluminum alloy door and window protection coating layer material used for smart homes

InactiveCN105925123AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsCobaltDibromomethane

The invention relates to an aluminum alloy door and window protection coating layer material used for smart homes. The material comprises melamine copolycondensation resin, fluoroether rubber, modified phenolic resin, nanometer zinc oxide, potassium titanate whisker reinforcement, nanometer magnesium hydroxide, polyethylene wax, zinc pyrithione, 10,10'-oxybisphenoxarsine, carbendazim, tetramethylthiuram disulfide, dibromomethane, titanium nitride powder, zeolite powder, sodium dihydrogen phosphate, disodium hydrogen phosphate, barium sulfate powder, lead oxide powder, barite powder, molybdenum disulfide powder, sodium carbonate, lead iodate powder, diethylene glycol butyl ether, soybean oil, amyl acetate, petroleum sulfonate, vinyl benzene, cobalt isooctoate, sulfamic acid and isopropyl titanate. The material has superior flame, acid-alkali, mildew and bacterium resistance, and improved performances.

Owner:梁方英

Mouse-proof optical cable rubber sleeve

InactiveCN105802233AExtended retention timeGuaranteed anti-rodent effectFibre mechanical structuresPolymer sciencePolyethylene glycol

The invention discloses a mouse-proof optical cable rubber sleeve. The mouse-proof optical cable rubber sleeve is composed of an insulating layer on the innermost layer, a sandwiched layer in the middle and a protection layer on the outermost layer, wherein the insulating layer is prepared from ethylene propylene diene monomer, silicon rubber, stearic acid, polyethylene glycol PEG4000, white carbon black, carbon black N568, carbon black N765, light calcium carbonate and paraffin oil 2280; the sandwiched layer is prepared from natural rubber, polyurethane rubber, mustard, chili, ground pepper, carbon black N550, carbon black N774, a plasticizer DEDB (Diethylene Glycol Dibenzoate), an anti-ageing agent A, a vulcanizing agent, diatomite, an accelerant TMTD (Tetramethylthiuram Disulfide) and gas-phase white carbon black; the protection layer is prepared from the ethylene propylene diene monomer, butyl rubber, fluorous rubber, chloroprene rubber, carbon black N660, carbon black N539, the accelerant TMTD, magnesium oxide and modified talcum powder. The mustard, the chili and the pepper, which have spicy and stimulating smells, are added into the sandwiched layer, so that oral mucosa and gustatory nerves of mice are strongly stimulated, and the mice reject eating, and furthermore, the mouse-proof optical cable rubber sleeve can prevent the mice from biting.

Owner:韩静静

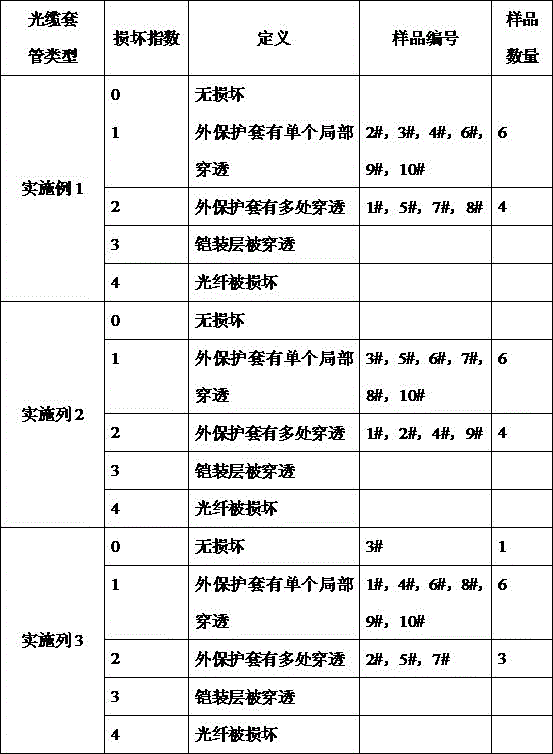

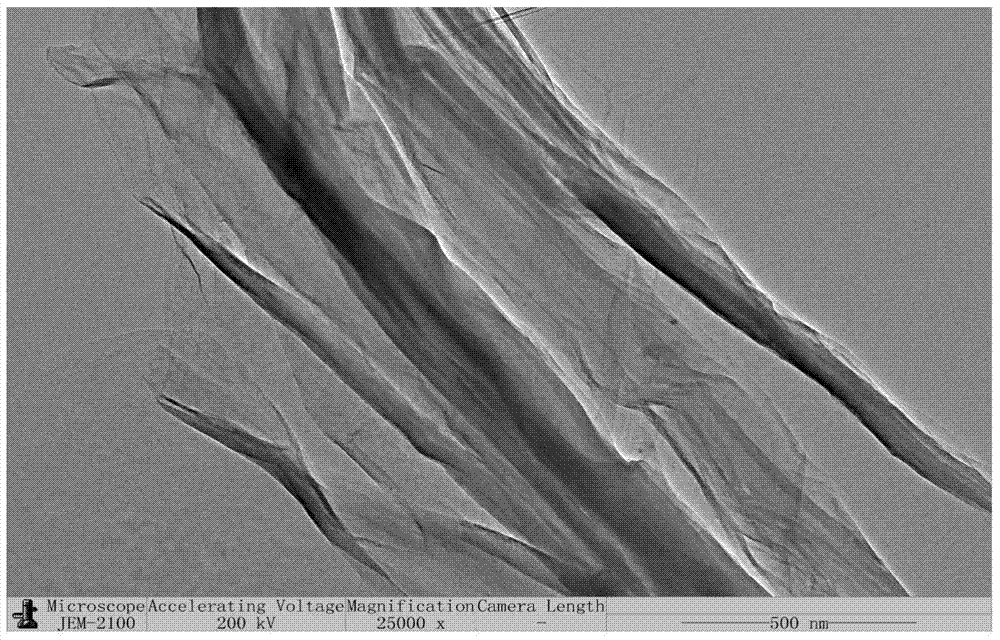

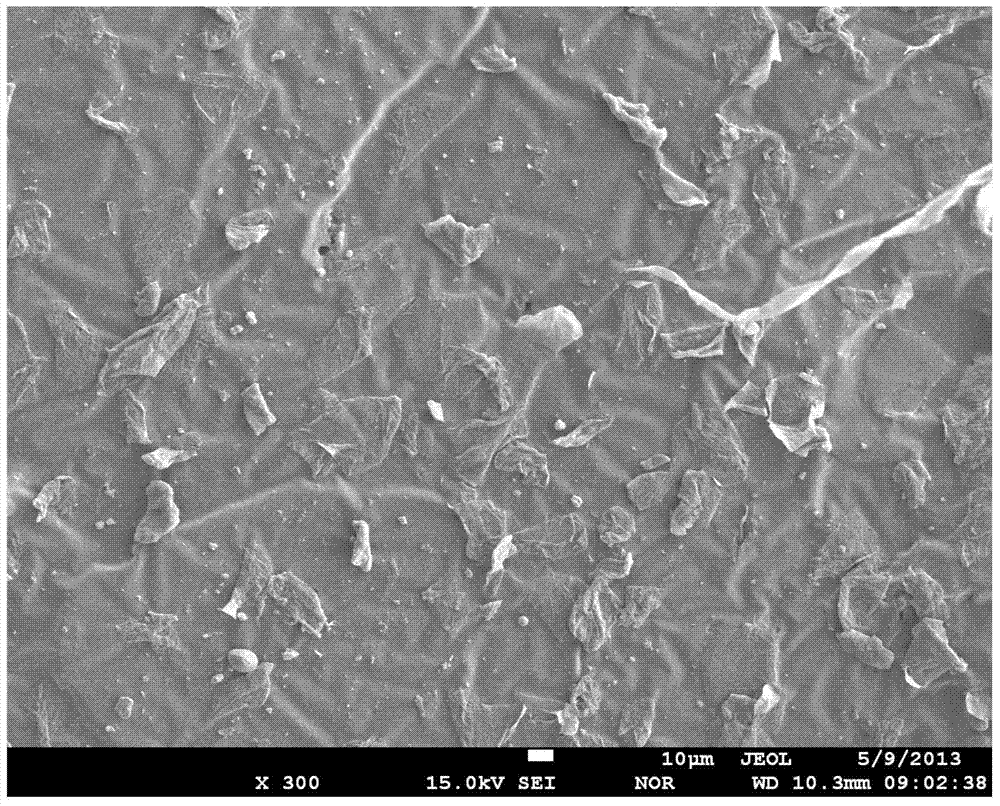

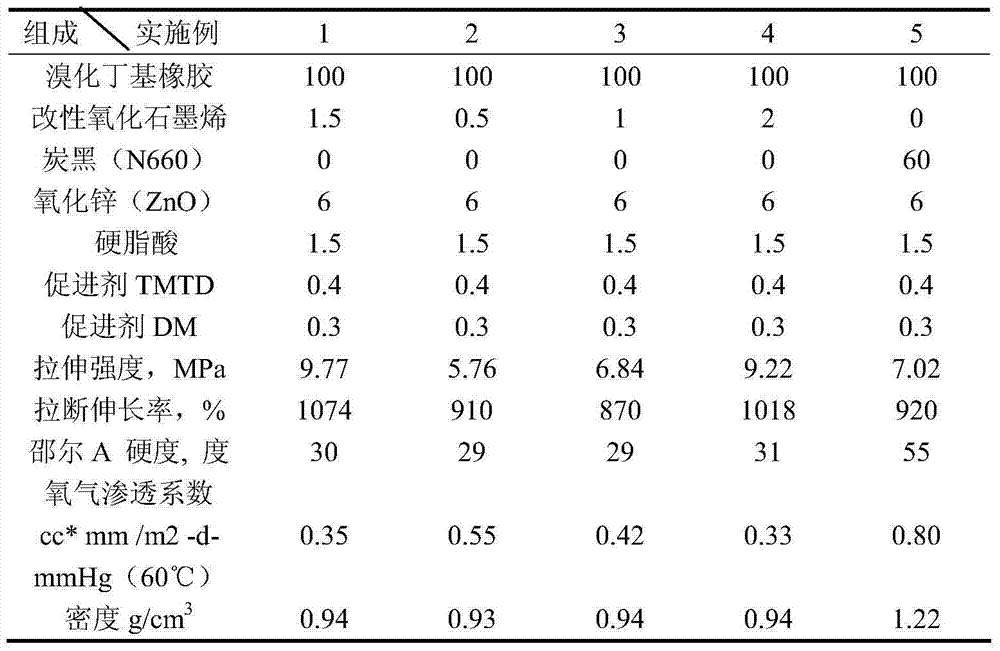

Light high-strength brominated butyl rubber gas tightness material and preparation method and application thereof

The invention discloses a light high-strength brominated butyl rubber gas tightness material, and a preparation method and application of the light high-strength brominated butyl rubber gas tightness material. The preparation method includes the steps of fully dissolving and dispersing, by weight, 100 parts of brominated butyl rubber into modified graphene oxide with the part larger than 0 and smaller than or equal to 2, then, adding 6 parts of zinc oxide, 1.5 parts of stearic acid, 0.3 part of accelerator 2, 2'-dithio-dibenzo thiazole and 0.4 part of accelerator tetramethylthiuram disulfide into the mixture, and conducting banburying and vulcanization to obtain the light high-strength brominated butyl rubber gas tightness material. The method is used for producing and processing the light high-strength brominated butyl rubber gas tightness material which is high in strength and good in air tightness, small in use amount of the accelerators and small in density. The material can be widely applied to various fields especially the fields with high requirements for gas tightness.

Owner:青岛美泰塑胶有限公司

High-strength wear-resisting flame-retardant modified ethylene-propylene-diene monomer rubber and preparation method thereof

InactiveCN104312017ALimit active chlorine contentInhibition of disproportionationPolymer sciencePyrophosphate

The invention discloses high-strength wear-resisting flame-retardant modified ethylene-propylene-diene monomer rubber. The high-strength wear-resisting flame-retardant ethylene-propylene-diene monomer rubber is prepared from the following raw materials in parts by weight: 36-44 parts of ethylene-propylene-diene monomer rubber, 20-25 parts of chlorinated butyl rubber, 18-24 parts of natural rubber, 0.8-1.5 parts of a vulcanizing agent LH-C96, 0.5-1.5 parts of N,N'-1,3-Phenylenedimaleimide, 1.5-1.8 parts of an accelerant TMTD (Tetramethylthiuram Disulfide), 2-4 parts of magnesium oxide, 1-3 parts of stearic acid, 5-10 parts of trioctyl trimellitate, 2.5-4 parts of an environment-friendly flame retardant FR-T 801, 0.8-1.6 parts of antimony trioxide, 20-40 parts of modified titanium dioxide, 15-30 parts of coal gangue powder, 20-30 parts of calcined clay, 1.2-1.5 parts of a monoalkoxy pyrophosphate type titanate coupling agent, 1.3-1.8 parts of an antiager 800-B, and 1.5-2.1 parts of an antiager BLE (High temperature condensation compound of diphenylamine and acetone). The invention further discloses a preparation method of the high-strength wear-resisting flame-retardant modified ethylene-propylene-diene monomer rubber.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

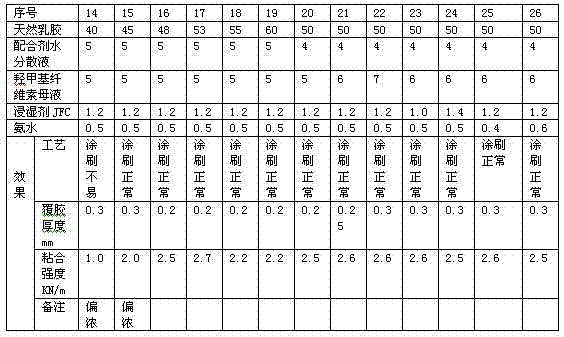

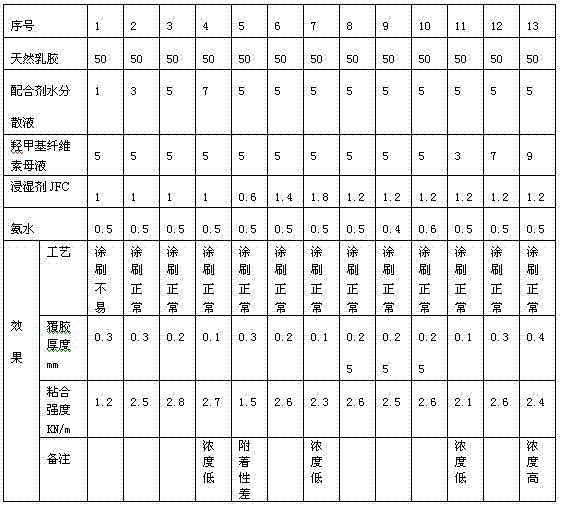

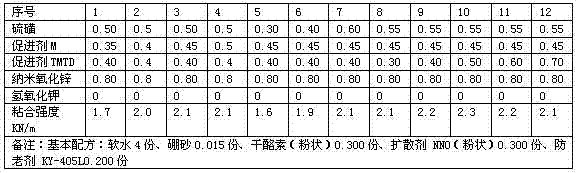

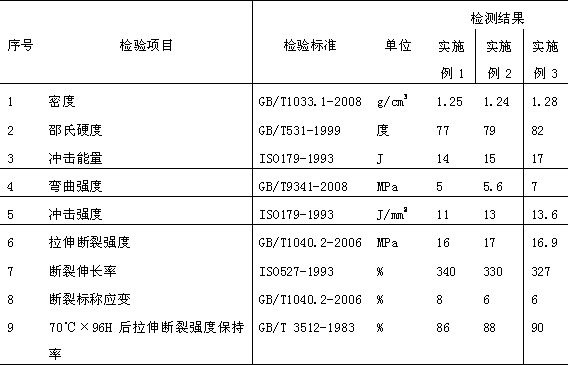

Environment-friendly adhesive for flexible anti-puncture shoes and preparation method thereof

ActiveCN102408850AHigh bonding strengthImprove adhesion strengthNatural rubber adhesivesCellulose adhesivesWater basedAdhesive

The invention discloses an environment-friendly adhesive for flexible anti-puncture shoes, which is prepared from natural emulsion, compounding agent water dispersion, ammonia water, hydroxymethyl cellulose mother liquid and wetting agent JFC. The product disclosed by the invention is a water-based adhesive and is used for replacing a solvent adhesive, thereby improving the safety and environmental friendliness. Because the bonding strength of the adhesive disclosed by the invention is good, a flexible anti-puncture insole and vulcanized rubber can be well bonded, and the bonding strength is not less than 2.5kN / m, thereby solving the problem that the anti-puncture insole is easy to debond; and the anti-puncture insole can be made by adopting a disposable double-sided swabbing process, thus the efficiency is high, the quality is good, and the product percent of pass is high. In the formula, the compounding agent water dispersion adopts an accelerator M (2-mercaptobenzothiazole), accelerator TMTD (tetramethylthiuram disulfide) and sulfur vulcanization combined system, thereby improving the internal performance of a sulfide; and the hydroxymethyl cellulose and the wetting agent JFC are used together, thereby improving the bonding strength of the water-based adhesive and the anti-puncture insole as well as the vulcanized rubber.

Owner:际华制鞋工业有限公司

High-strength shock-absorbing rubber plate for factory equipment

The invention relates to a high-strength shock-absorbing rubber plate for factory equipment. The high-strength shock-absorbing rubber plate comprises the following components in parts by weight: 70-90 parts of 40 type butadiene-acrylonitrile rubber, 30-50 parts of 1# natural rubber, 3-5 parts of magnesium oxide, 0.2-0.4 part of sulphur, 1-1.4 parts of stearic acid, 1-1.3 parts of paraffin, 15-25 parts of vaseline, 30-50 parts of spraying carbon black, 40-60 parts of argil, 2-4 parts of zinc oxide, 1-2 parts of anti-aging agent D with a Chinese name of N-phenyl-2-naphthylamine, 1-1.2 parts of anti-aging agent 4010 with a Chinese name of N-phenyl-N'-cyclohexyl para-phenylene diamine, and 1.4-1.6 parts of accelerant TT with a Chinese name of tetramethylthiuram disulfide. According to the high-strength shock-absorbing rubber plate, a polar material, vulcanization depth and a three-dimensional network structure in sizing materials of the rubber plate are added, thus the tensile failure strength is ensured, the shore hardness is increased, and the high-strength shock-absorbing rubber plate can be normally used in a high-pressure environment.

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

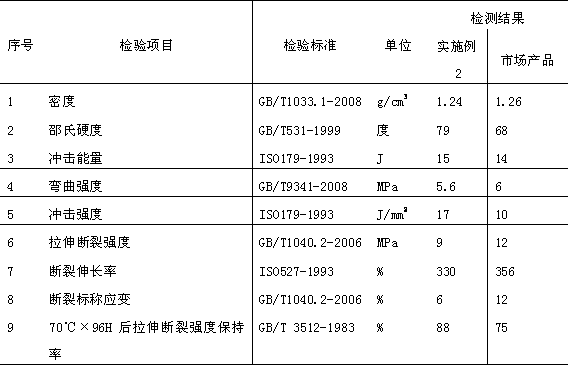

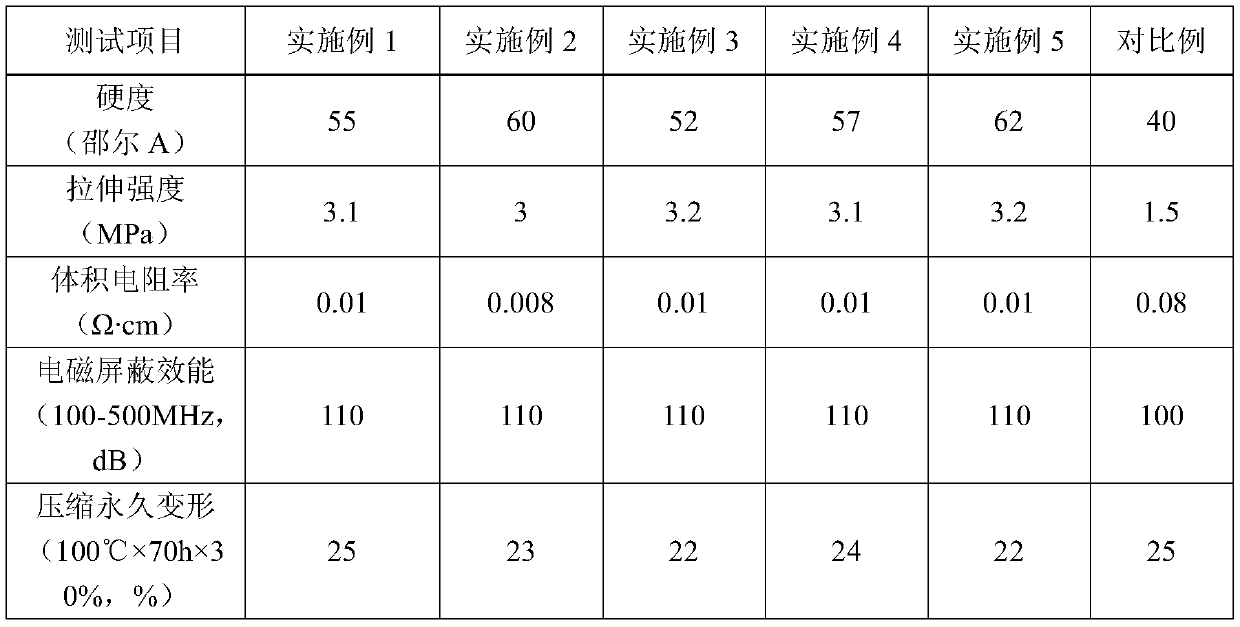

High electromagnetic shielding rubber composition and preparation method thereof

The invention relates to a high electromagnetic shielding rubber composition and a preparation method thereof, and belongs to the technical field of rubbers. The high electromagnetic shielding rubbercomposition is mainly prepared from, by weight, 100 parts of silicone rubber, 1-40 parts of a plasticizer, 1-30 parts of white carbon black, 0.1-5 parts of a vulcanizing aid, 0.6-1.4 parts of a vulcanizing agent, 1-10 parts of inorganic whiskers and 0.01-200 parts of a conductive filler; the vulcanizing aid is one or more of triallyl isocyanurate, a platinum catalyst, 4,4'-dimorpholine disulfide,tetramethylthiuram disulfide and N,N'-m-phenylene bismaleimide; and the vulcanizing agent is one or more of hydrogen-containing silicone oil, 2,4-dichlorobenzoyl peroxide, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane and dicumyl peroxide. The high electromagnetic shielding rubber composition has low hardness and good mechanical properties.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com