Nitrile-butadiene rubber bonded with fluororesin or fluororubber and application thereof in fuel pipe

A technology of nitrile rubber and fluororesin, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problem of high cost of ethylene acrylate rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In parts by mass

[0026] Nitrile rubber raw rubber 100

[0029] stearic acid 1

[0030] Antiager RD 1

[0031] Antiaging agent NBC 0.5

[0032] Coumarone 2

[0033] Adhesive Ricobond 2031 3

[0034] Quick Extrusion Carbon Black N550 20

[0035] High wear-resistant carbon black N330 50

[0036] White carbon black 10

[0037] Trioctyl trimellitate 5

[0038] Liquid Nitrile Rubber 26 20

[0039] Sulfur 0.3

[0040] Accelerator CZ 1

[0041] Accelerator TMTD 2

[0042] Total: 221.8

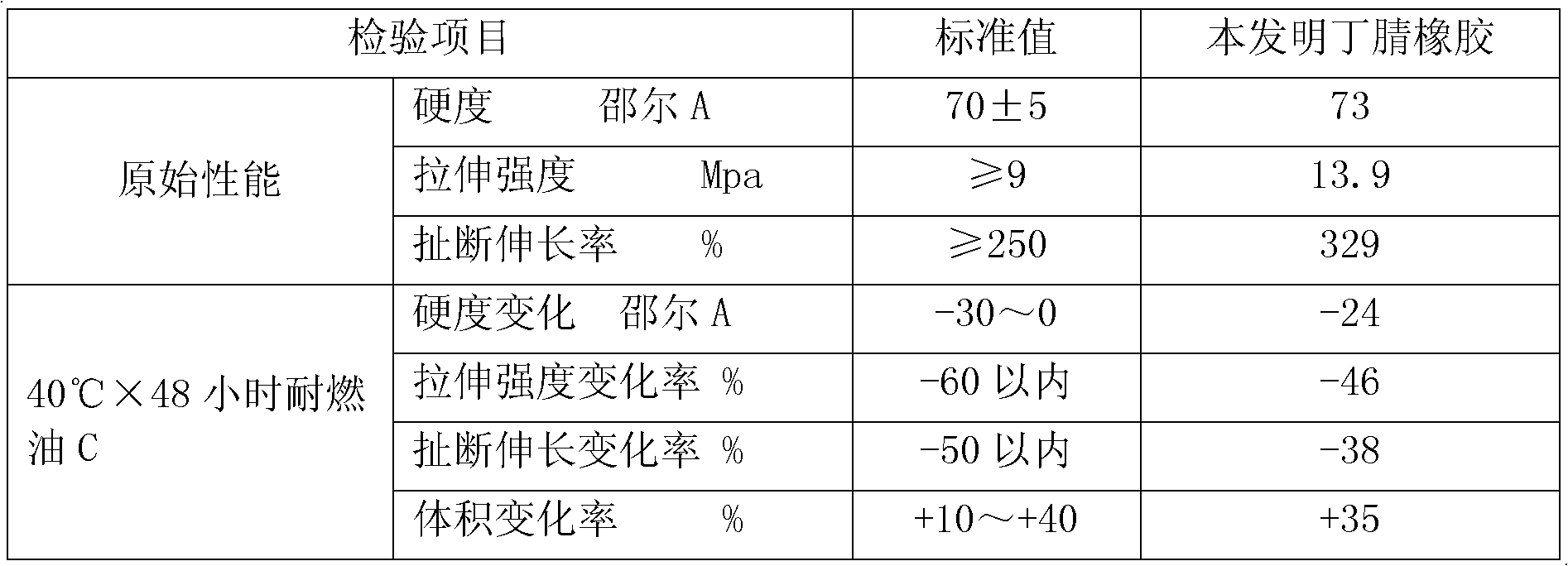

[0043] Material properties:

[0044]

[0045] Hose performance:

[0046]

[0047]

Embodiment 2

[0049] In parts by mass

[0050] Nitrile rubber raw rubber 100

[0053] Stearic acid 1.5

[0054] Antiaging agent RD 1.5

[0055] Antiaging agent NBC 0.8

[0056] Coumarone 3

[0057] Adhesive Ricobond 2031 5

[0058] Quick press carbon black N550 30

[0059] High wear-resistant carbon black N330 40

[0060] White carbon black 15

[0061] Trioctyl trimellitate 10

[0062] Liquid Nitrile Rubber 26 10

[0063] Sulfur 0.5

[0064] Accelerator CZ 1.2

[0065] Accelerator TMTD 1.5

[0066] Total: 230

[0067] Material properties:

[0068]

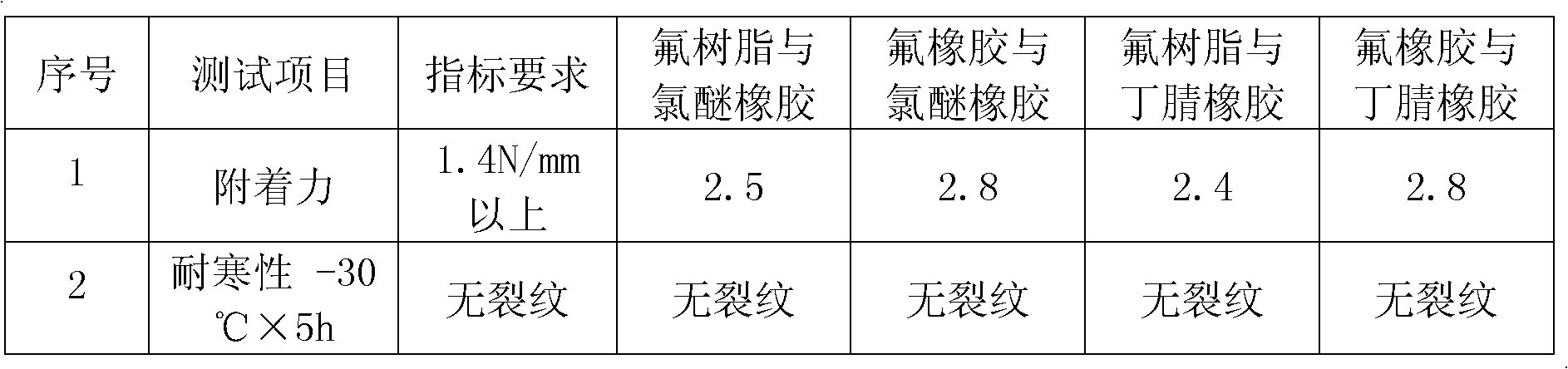

[0069] Hose performance:

[0070]

[0071]

Embodiment 3

[0073] In parts by mass

[0074] Nitrile rubber raw rubber 100

[0075] Magnesium oxide 8

[0076] calcium hydroxide 8

[0077] stearic acid 2

[0078] Antiaging agent RD 1.5

[0079] Antiaging agent NBC 0.8

[0080] Coumarone 4

[0081] Adhesive Ricobond 2031 8

[0082] Fast press carbon black N550 40

[0083] High wear-resistant carbon black N330 30

[0084]White carbon black 15

[0085] Trioctyl trimellitate 15

[0086] Liquid Nitrile Rubber 26 15

[0087] sulfur 1

[0088] Accelerator CZ 1.5

[0089] Accelerator TMTD 1.5

[0090] Total: 251.3

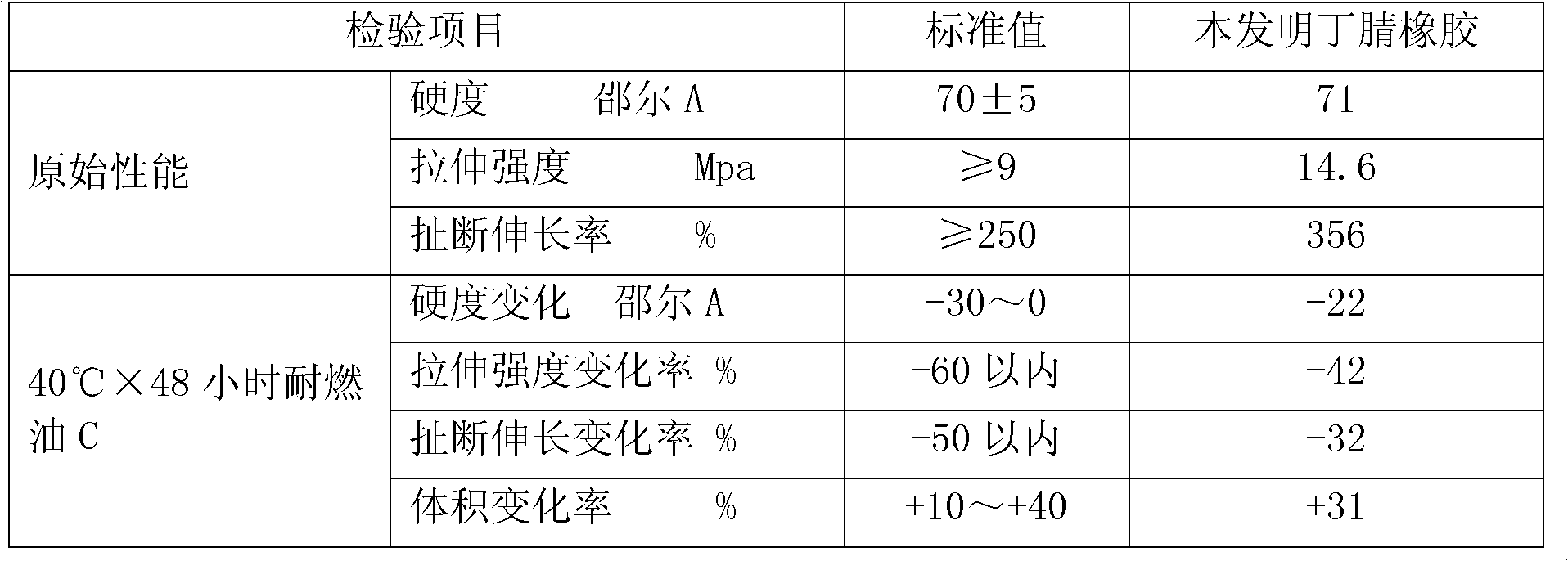

[0091] Material properties:

[0092]

[0093] Hose performance:

[0094]

[0095]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com