High electromagnetic shielding rubber composition and preparation method thereof

A rubber composition and electromagnetic shielding technology, applied in the field of rubber, can solve the problems of high hardness of electromagnetic shielding rubber and low electromagnetic shielding performance, and achieve the effects of good processing performance, improved mechanical properties, and superior molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

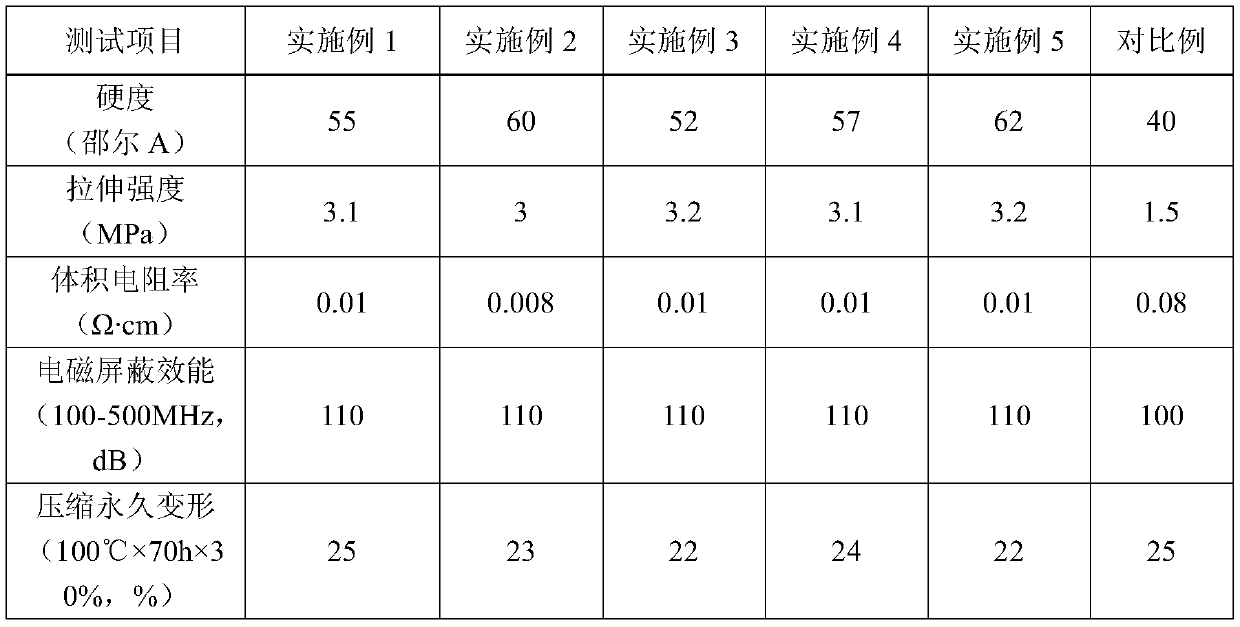

Examples

Embodiment 1

[0036] The high electromagnetic shielding rubber composition of this embodiment is a high electromagnetic shielding rubber composition with low hardness and low compression set, and is made of the following raw materials: methyl vinyl silicone rubber 100kg, plasticizer paraffin oil 20kg, gas phase white Carbon black 3kg, vulcanization aid TAIC (triallyl isocyanurate, also known as triallyl isocyanurate) 1kg, vulcanizing agent dicumyl peroxide 1.2kg, calcium sulfate whisker 2kg , Conductive filler graphene 0.5kg, conductive filler carbon nanotube 0.1kg, conductive filler silver-plated aluminum powder 100kg.

[0037] The preparation method of the high electromagnetic shielding rubber composition of the present embodiment comprises the steps:

[0038] 1) adding methyl vinyl silicone rubber into a mixer, then sequentially adding white carbon black and a plasticizer for mixing to obtain a rubber compound;

[0039] 2) Put the rubber material obtained in step 1) into an open mill, t...

Embodiment 2

[0042] The high electromagnetic shielding rubber composition of this embodiment is a high electromagnetic shielding rubber composition with low hardness and low compression set, and is made of the following raw materials: 100 kg of methyl phenyl silicone rubber, 30 kg of plasticizer soybean oil, precipitated white Carbon black 10kg, vulcanization aid DTDM (4,4'-dimorpholine disulfide) 1kg, vulcanization agent 2,4-dichlorobenzoyl peroxide 0.9kg, potassium titanate whiskers 5kg, conductive filler graphene 0.6 kg, conductive filler carbon nanotube 0.2kg, conductive filler silver powder 130kg.

[0043] The preparation method of the high electromagnetic shielding rubber composition of the present embodiment comprises the steps:

[0044] 1) adding methyl phenyl silicone rubber into a mixer, then adding white carbon black and a plasticizer in turn for mixing to obtain a rubber compound;

[0045] 2) Put the rubber material obtained in step 1) into an open mill, then add vulcanization a...

Embodiment 3

[0048] The high electromagnetic shielding rubber composition of this embodiment is a high electromagnetic shielding rubber composition with low hardness and low compression set, and is made of the following raw materials: 100 kg of methyl vinyl phenyl silicone rubber, plasticizer 1,2 propylene glycol 20kg, plasticizer silicone oil 20kg, precipitated silica 30kg, vulcanization aid TMTD (tetramethylthiuram disulfide) 4kg, vulcanization agent 2,5-dimethyl-2,5-di(tert-butyl peroxide) Oxygen) hexane 1kg, zinc oxide whisker 10kg, conductive filler graphene 1kg, conductive filler carbon nanotube 0.01kg, conductive filler nickel-plated graphite powder 195kg.

[0049] The preparation method of the high electromagnetic shielding rubber composition of the present embodiment comprises the steps:

[0050] 1) adding methyl vinyl phenyl silicone rubber into a mixer, then adding white carbon black and a plasticizer in turn for mixing to obtain a rubber compound;

[0051] 2) Put the rubber ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com