Environment-friendly adhesive for flexible anti-puncture shoes and preparation method thereof

A puncture-resistant and environmentally friendly technology, applied in the direction of adhesive types, cellulose adhesives, natural rubber adhesives, etc., can solve the problems of heavy, high fatigue and high production costs of hard puncture-resistant insoles, and achieve Improve safety and environmental performance, improve adhesive strength, improve the effect of intrinsic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

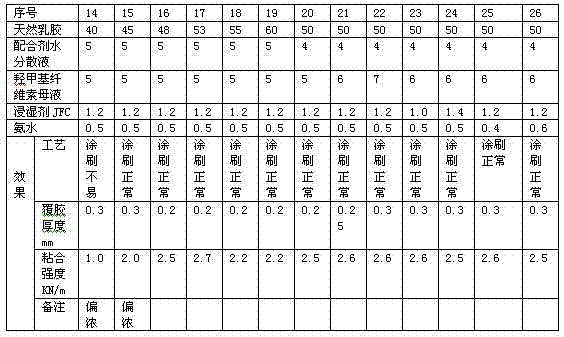

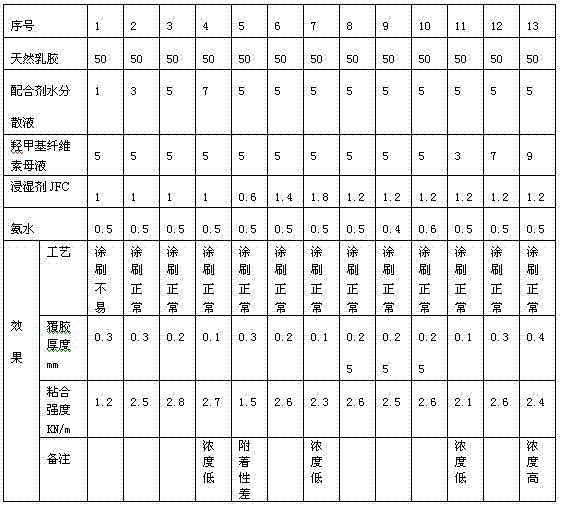

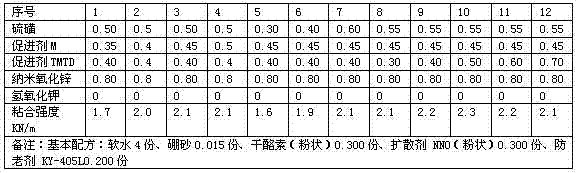

[0027] Embodiment 1 of the present invention: the preparation of environment-friendly adhesive for flexible puncture-resistant shoes, first prepare the hydroxymethyl cellulose mother liquor, calculate by weight parts, mix 5 parts of hydroxymethyl cellulose and 0.1 part of antifungal agent BCM Add 100 parts of soft water, stir slowly and add 0.5 parts of potassium hydroxide, and continue to stir until the cellulose sodium is evenly dispersed and becomes a thick liquid without agglomeration, that is, the hydroxymethyl cellulose mother liquor is obtained. Take the hydroxymethyl cellulose mother liquor 6 parts for later use; prepare the aqueous dispersion of the compounding agent, put 0.15 parts of potassium hydroxide into the ball mill tank, add 3 parts of soft water to dissolve the potassium hydroxide, then add 0.3 parts of casein, 0.3 parts of diffusing agent NNO and 0.015 parts of part of borax, stir evenly, add 0.55 part of sulfur, 0.45 part of accelerator M, 0.5 part of accel...

Embodiment 2

[0028] Embodiment 2 of the present invention: the preparation of the environment-friendly adhesive for flexible anti-puncture shoes, first prepare the hydroxymethyl cellulose mother liquor, calculate by weight parts, mix 5 parts of hydroxymethyl cellulose and 0.1 part of antifungal agent BCM Add 100 parts of soft water, stir slowly and add 0.5 parts of potassium hydroxide, and continue to stir until the cellulose sodium is evenly dispersed and becomes a thick liquid without agglomeration, that is, the hydroxymethyl cellulose mother liquor is obtained. Take the hydroxymethyl cellulose mother liquor 5 parts for later use; prepare the aqueous dispersion of the compounding agent, put 0.15 parts of potassium hydroxide into the ball mill tank, add 3 parts of soft water to dissolve the potassium hydroxide, then add 0.3 parts of casein, 0.3 parts of diffusing agent NNO and 0.015 parts of part of borax, stir evenly, add 0.55 part of sulfur, 0.45 part of accelerator M, 0.5 part of accele...

Embodiment 3

[0029] Embodiment 3 of the present invention: the preparation of the environment-friendly adhesive for flexible puncture-proof shoes, first prepare the hydroxymethyl cellulose mother liquor, calculate by weight parts, mix 5 parts of hydroxymethyl cellulose and 0.1 part of antifungal agent BCM Add 100 parts of soft water, stir slowly and add 0.5 parts of potassium hydroxide, and continue to stir until the cellulose sodium is evenly dispersed and becomes a thick liquid without agglomeration, that is, the hydroxymethyl cellulose mother liquor is obtained. Take the hydroxymethyl cellulose mother liquor 7 parts for later use; then prepare the aqueous dispersion of the compounding agent, put 0.15 parts of potassium hydroxide into the ball mill tank, add 3 parts of soft water to dissolve the potassium hydroxide, then add 0.3 parts of casein, 0.3 parts of diffusing agent NNO and 0.015 parts of part of borax, stir evenly, add 0.55 part of sulfur, 0.45 part of accelerator M, 0.5 part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com