Patents

Literature

454 results about "2-mercaptobenzothiazole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Mercaptobenzothiazole is an active ingredient in Sulfodene Medication for Dogs (liquid solution). Sulfodene is an ingredient in the following dog care products: Sulfodene Skin Medication for Dogs, Sulfodene 3-Way Ointment for Dogs, Sulfodene Medicated Shampoo & Conditioner for Dogs, and Sulfodene Ear Cleaner.

Method for manufacturing ultrathin electrolytic copper foil

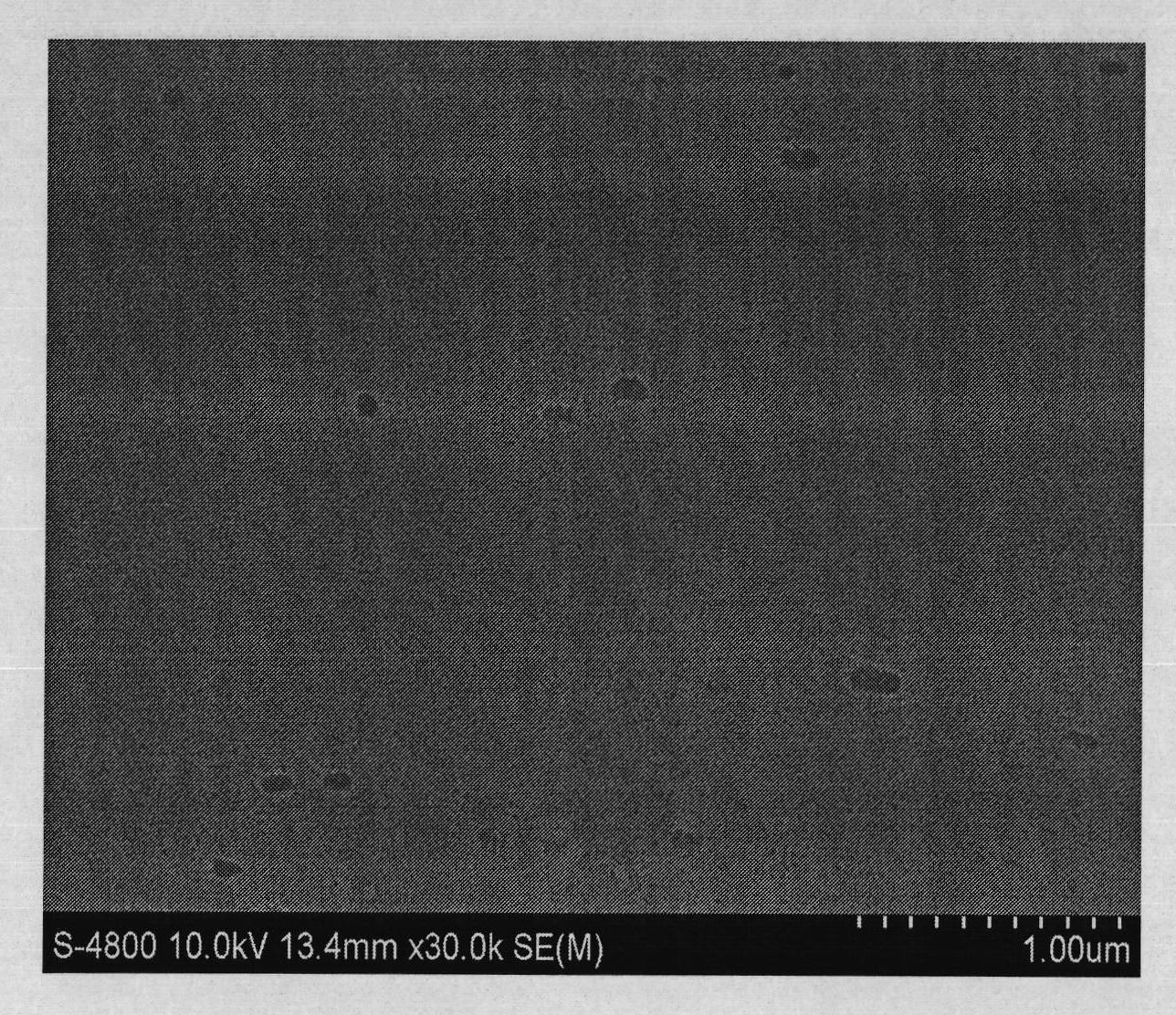

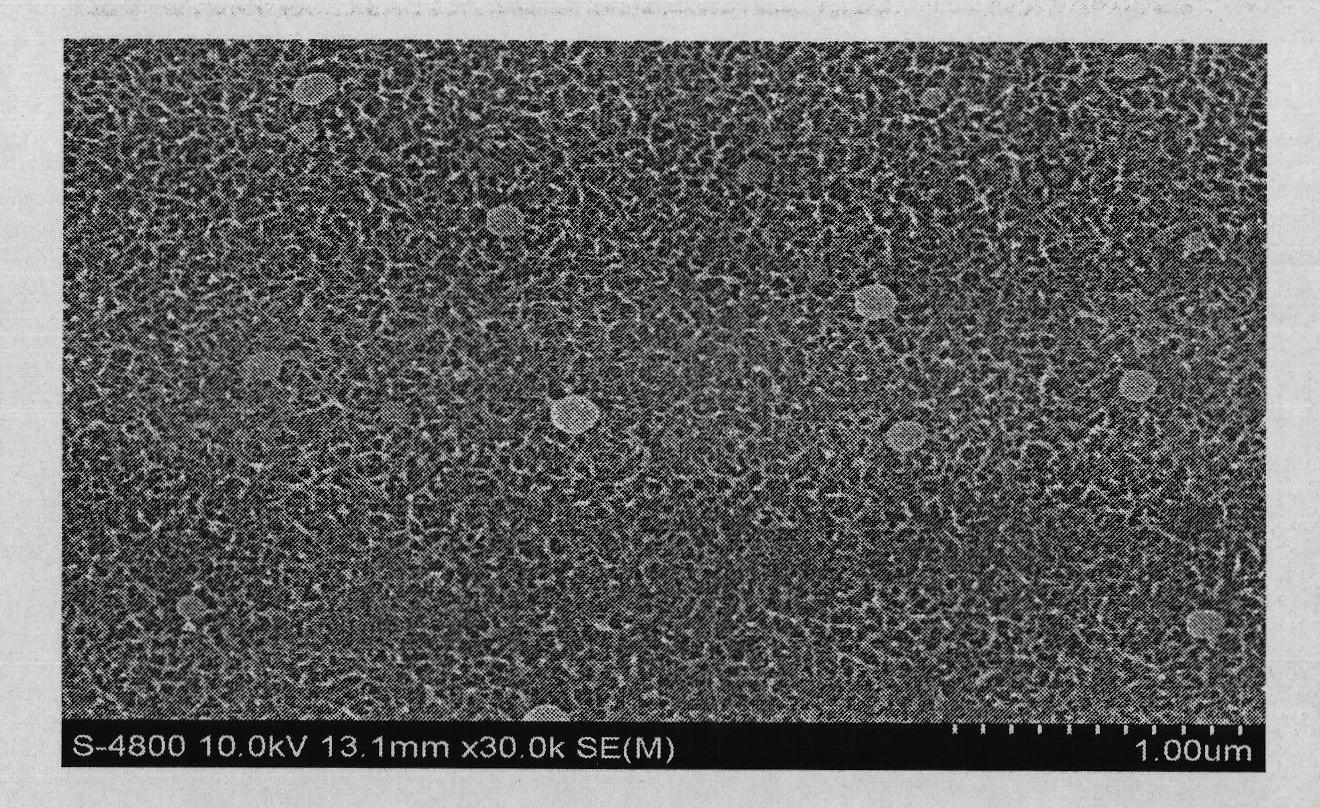

ActiveCN101476138ANeatly distributedAvoid breakingElectroforming processesElectrolysisPolyethylene glycol

The invention relates to a method for manufacturing a super-thin electrolytic copper foil. (1) An electrolyte contains 90-130g / L copper, 130-150g / L sulphuric acid. (2) The electrolyte is heated 55-66 DEG. C, 5-12 parts dithio-bis-propylene sulfonic acid sodium salt, 0.1-0.9 parts urinary sulfur, 0.9-2.2 parts 2-mercaptobenzothiazole and 20-50 parts polyethyleneglycol molecular weight 400 by weight ratio are added into the electrolyte in 1000 volume part per hour for entering an anode groove after being mixing well. (3) In an electric field, the current density is 65-75A / dm(2) for reacting and obtaining the super-thin electrolytic copper foil. The super-thin electrolytic copper foil crystal is tiny and uniform, difference of thickness uniform is less than 0.3 mum, Ra is less than 0.2 mum, Rz is not larger than 2.0 mum, tensile strength is in between 380-420 N / mm(2). A lithium battery with big capacity manufactured by the super-thin electrolytic copper foil has long cycle life of charge / discharge, and is not easy rupture during over charge.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Engine antifreezing solution

ActiveCN101691484AAvoid the disadvantages of instabilityWith boiling suppressionHeat-exchange elementsCooperative interactionSebacic acid

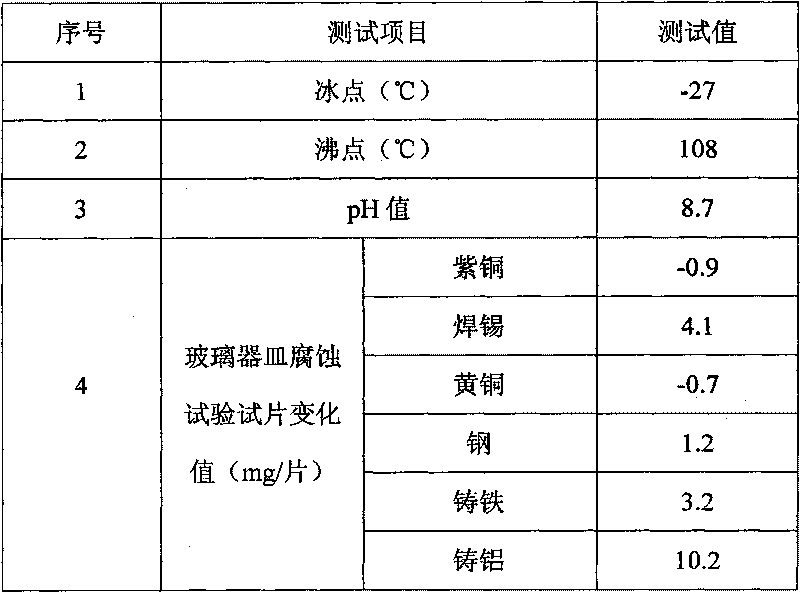

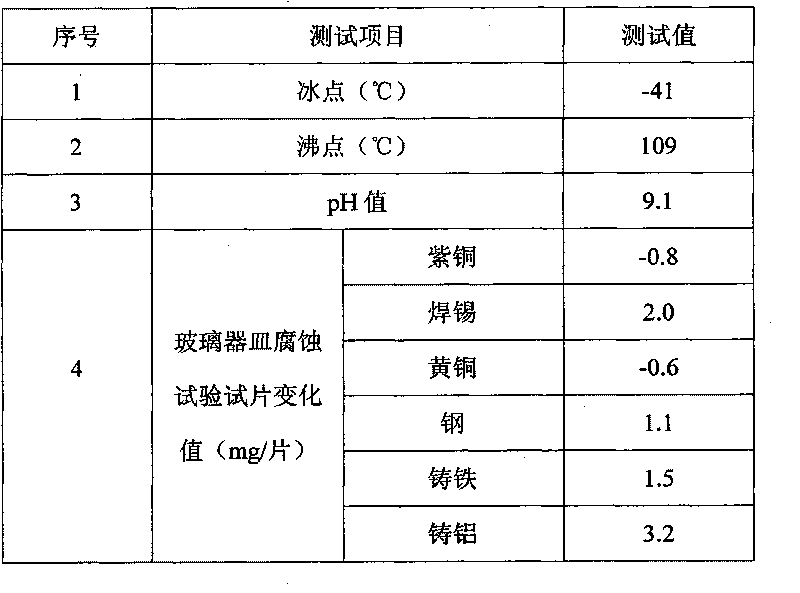

The invention relates to an engine antifreezing solution which is prepared by mixing the following components to react: glycol, sodium molybdate, sodium hydroxide, isooctanoic acid, sebacic acid, sodium benzoate, benzotriazole, sodium 2-mercaptobenzothiazole, dye and deionized water. The invention adopts a new formula which uses organic matter as main component and inorganic matter as auxiliary component to reach the aim of controlled release on the basis of conventional inorganic and all-organic engine antifreezing solution technologies, wherein the organic acid uses the combination of monoacid and binary acid. The invention does not contain sodium borate and silicate so as to avoid the defect that precipitate is easy to generate due to the existence of sodium borate and silicate in glycol series antifreezing solution and the antifreezing solution is unstable; and the engine antifreezing solution of the invention does not contain amine, nitrate, phosphate and other substances which are harmful to the environment and human body. The researched antifreezing solution has good performances of stability, freeze-proofing, boil-proofing, corrosion-proofing and scale prevention through the cooperative interaction of components so as to perform multi-level anticorrosion protection for the cooling system of the vehicle.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

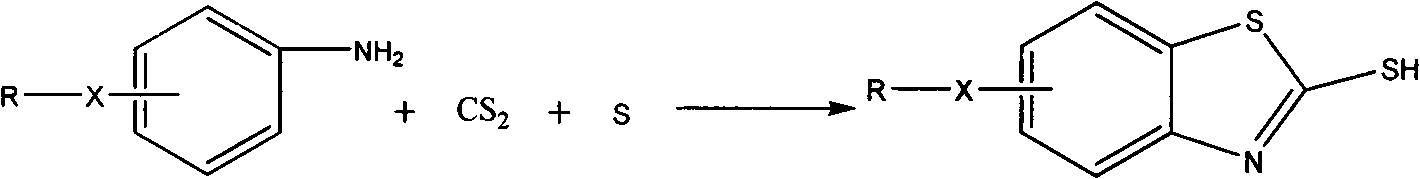

Method for preparing 2-mercaptobenzothiazole

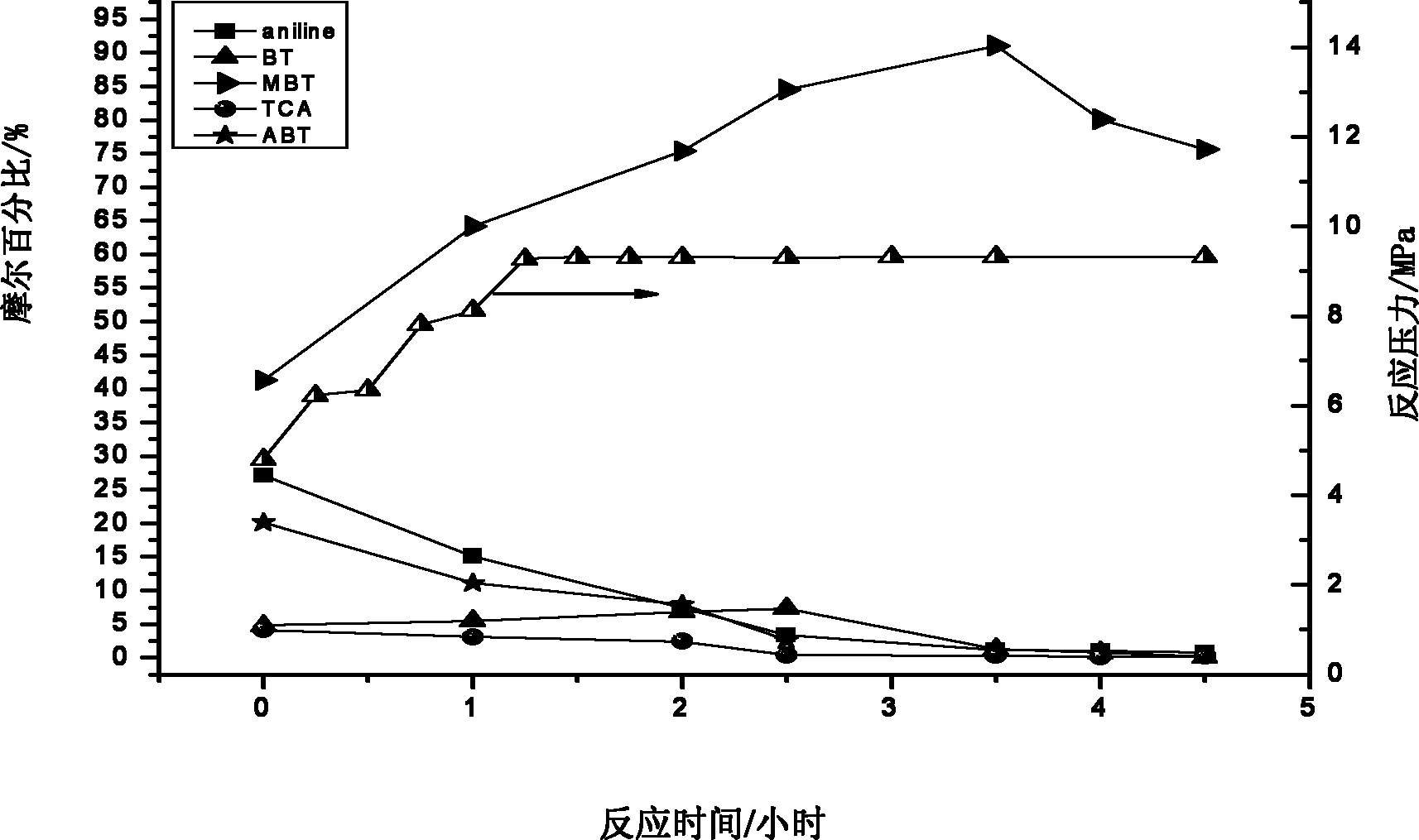

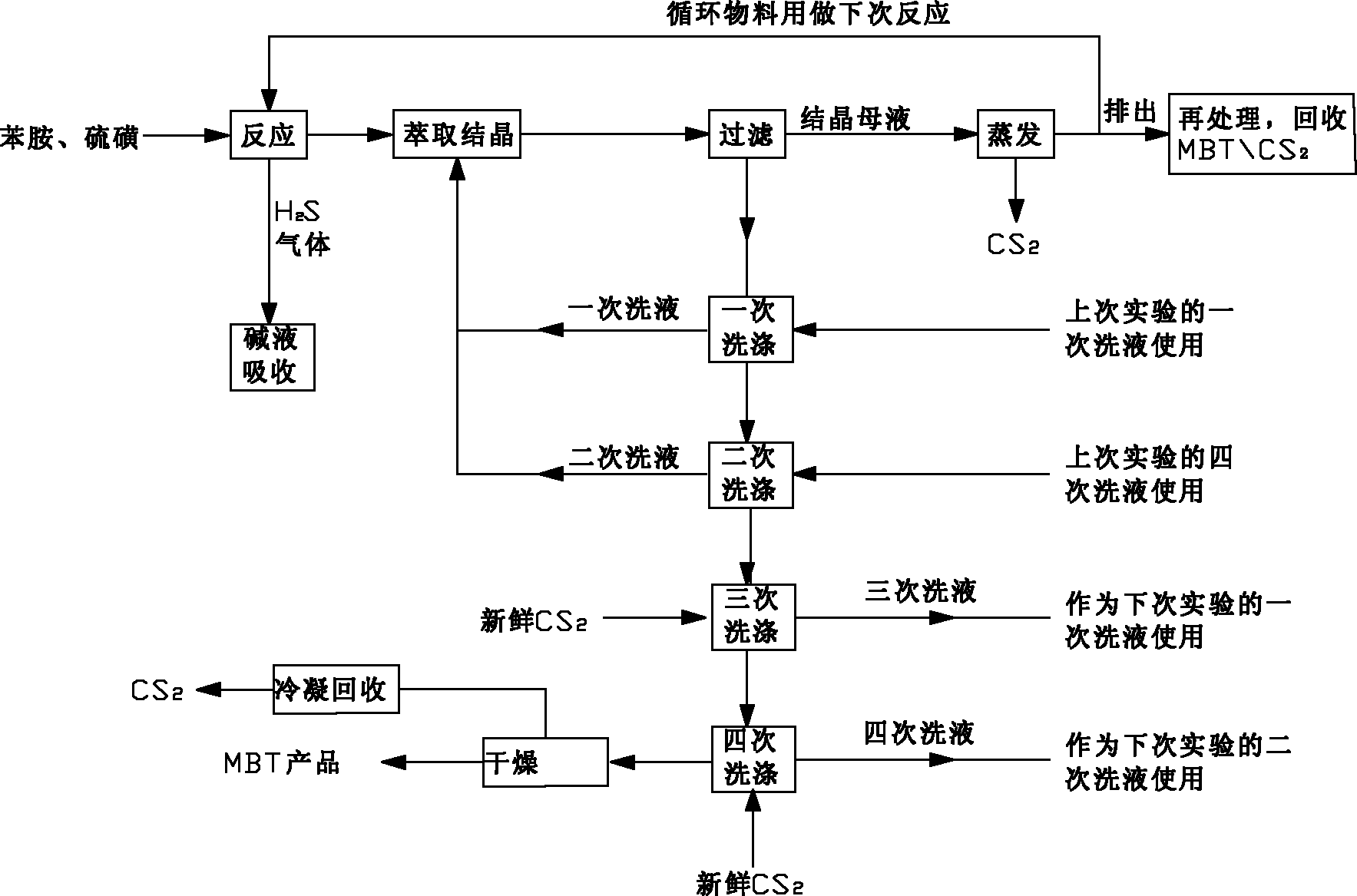

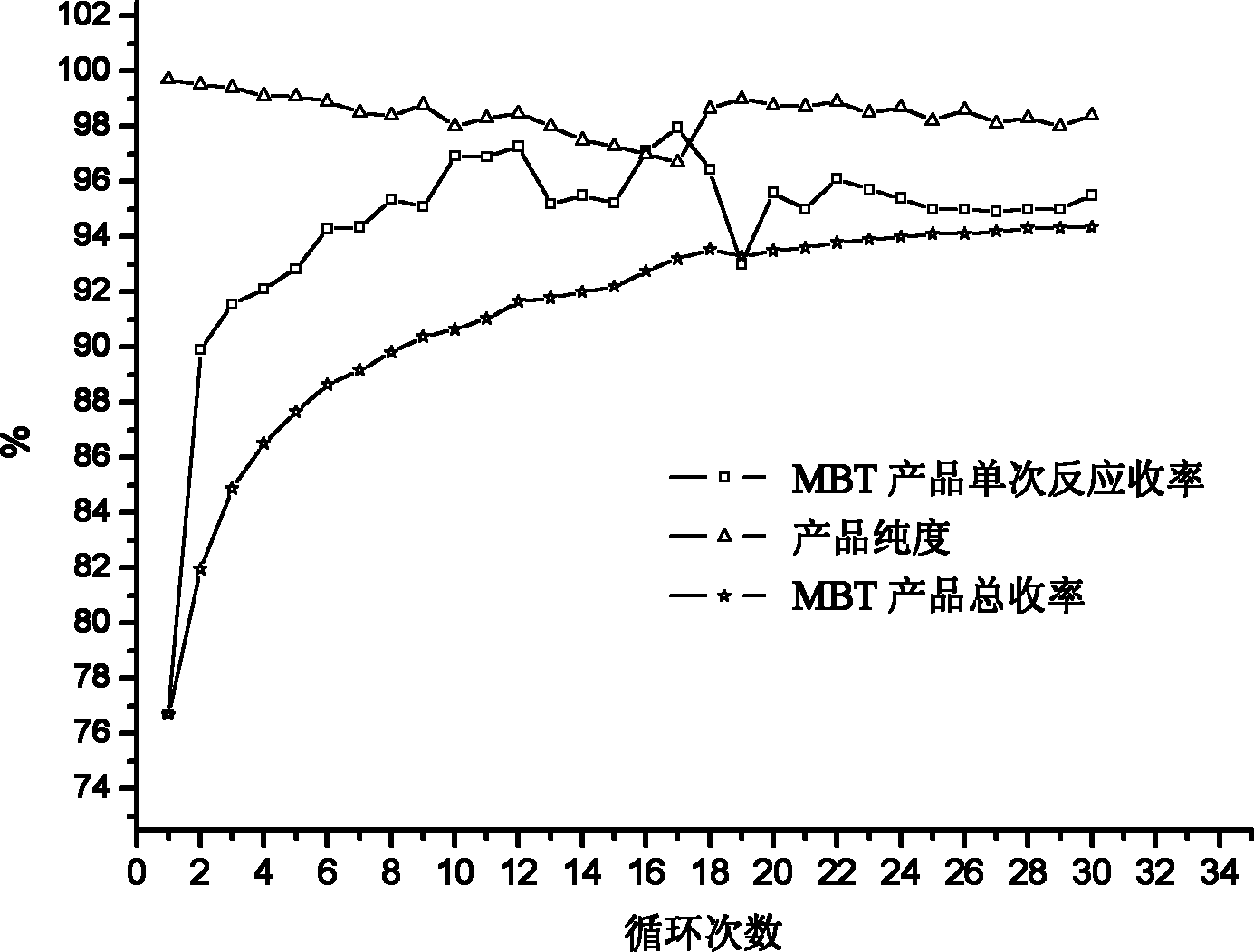

The invention discloses a method for preparing 2-mercaptobenzothiazole, which comprises the steps of: adding carbon disulfide, aniline and sulfur into a reaction kettle; and heating the mixture, finishing a reaction under the reaction pressure of 6.8 to 9.5MPa to obtain a crude product, namely a melt, pressing the melt into a crystallizer loaded with carbon disulfide, controlling the initial temperature of the crystallization, reducing the temperature, beginning to discharge hydrogen sulfide when the material temperature in the crystallizer is reduced to be between 70 and 100 DEG C, controlling the discharge time of hydrogen sulfide to be between 20 and 60min, cooling the obtained product to be between 15 and 20 DEG C, filtering the obtained product to obtain a filter cake and carbon disulfide mother liquor, washing the filter cake for 2 to 5 times by using carbon disulfide in an amount which is 1 to 3 times mass of the filter cake, and drying the scrubbed filter cake to obtain the 2-mercaptobenzothiazole at the mass percentage concentration of over 98 percent. By the method, no 'waste water' and 'waste gas' are discharged, and asphalt-like wastes are greatly reduced. The circulation of crystallization mother liquor realizes the recycling of intermediate products, and the total yield of the process is improved to be over 94 percent.

Owner:TIANJIN UNIV +1

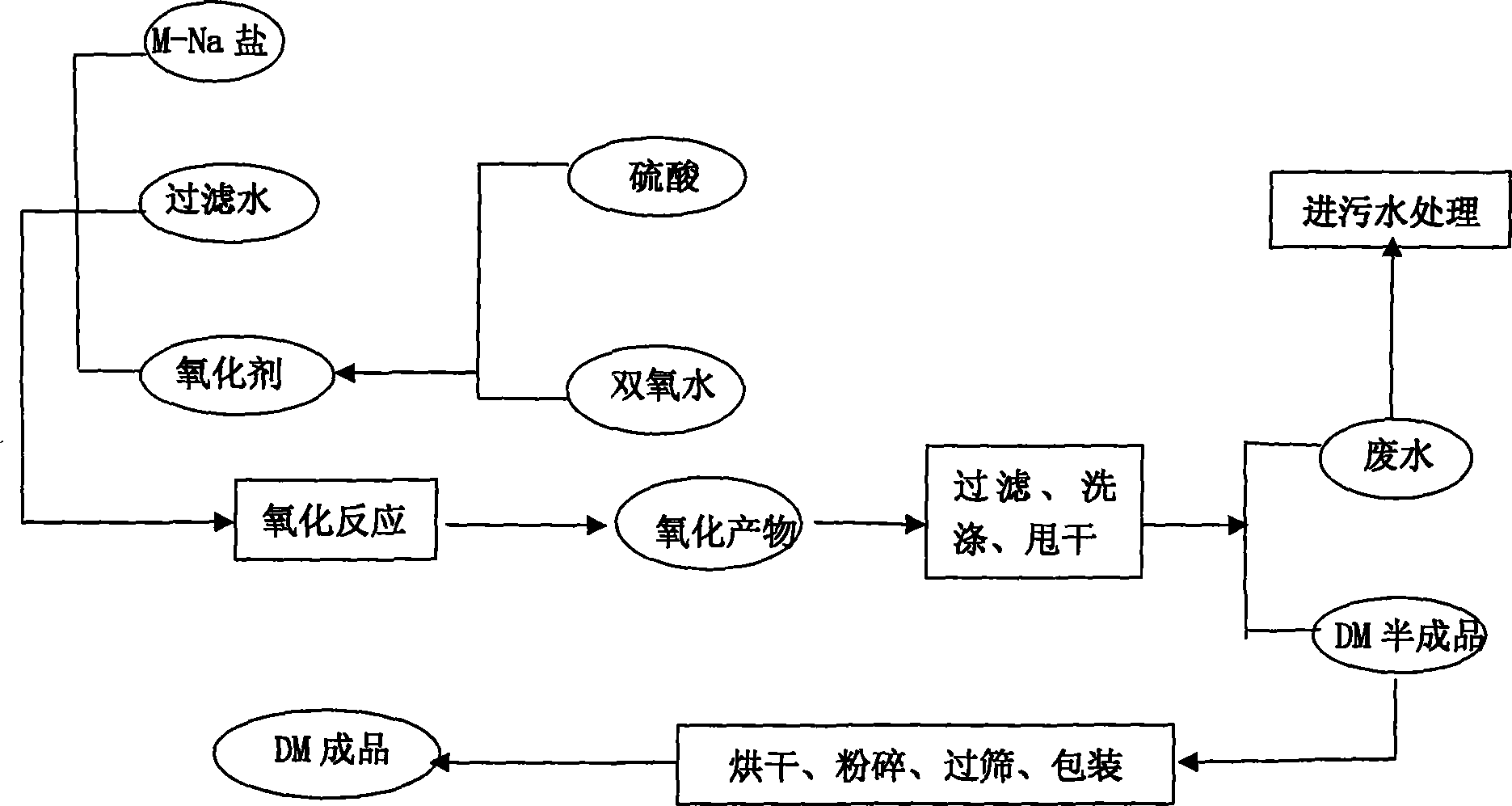

Preparation of rubber vulcanization accelerator dibenzothiazyl disulfide

ActiveCN101463018AReduce displacementReduce the burden onOrganic chemistryDIBENZOTHIAZYL DISULFIDEMercaptobenzothiazole

The invention relates to a preparation method of a thiofide (dibenzothiazyl disulfide), wherein, 2-mercaptobenzothiazole sodium salt is taken as a raw material, mixture of hydrogen peroxide and sulfuric acid is taken as an oxidizing agent, and the mol ratio of the hydrogen peroxide to the sulfuric acid is 0.5-2.5:1, and the method comprises the following steps (1) preparation process of the oxidizing agent: evenly mixing the hydrogen peroxide and the sulfuric acid in a container according to the mol ratio; and (2) oxidization process of the product: dropwise adding the mixture of the hydrogen peroxide and the sulfuric acid to a reaction kettle with the 2-mercaptobenzothiazole sodium salt at the temperature of 55 DEG C-65 DEG C while stirring for oxidization reaction for 60-80 minutes, keeping warm for about 0.5 hour after the oxidizing agent is added dropwise; then measuring pH value of the reaction solution, performing solid-liquid separation at the temperature of 30 DEG C when the pH value is stabilized within a range of 6.5-7.5, drying, crushing, screening and packaging the obtained solid to obtain the product. The method can help effectively enhance quality of the product, save energy and lower consumption and reduce 'three wastes' pollution.

Owner:WILLING NEW MATERIALS TECH CO LTD

Flatting agent for epoxy-polyester powder paint and preparation method thereof

InactiveCN102268203AAddress mechanical propertiesSolve technical problems that are prone to yellowingPowdery paintsEpoxy resin coatingsEpoxyPolyester

The invention relates to a compound, and in particular relates to a flatting agent for epoxy-polyester powder paint and a preparation method thereof. The flatting agent for the paint is prepared by blending a catalyst with a synthetic carboxyl acrylic resin or synthetic epoxy acrylic resin. The flatting agent is characterized in that based on a 2-mercaptobenzothiazole zinc salt as the catalyst and the synthetic carboxyl acrylic resin or synthetic epoxy acrylic resin as a reactant, the catalyst and the reactant are mixed so as to prepare the flatting agent, wherein the reactant of the synthetic carboxyl acrylic resin comprises a monomer containing a carboxyl group, and the acidic value of the synthetic carboxyl acrylic resin is 100-600KOHg / mg; and the reactant monomer of the synthetic epoxy acrylic resin comprises a monomer containing an epoxy group, and the epoxy equivalent of the synthetic epoxy acrylic resin is 100-600g / eq. The preparation method provided by the invention is practicable; and by using the preparation method in the invention, the obtained flatting agent has good flatting stability and mechanical property, thereby solving the technical problems that the traditional flatting agent is poor in mechanical property and is easy to turn yellow.

Owner:NINGBO SOUTH SEA CHEM

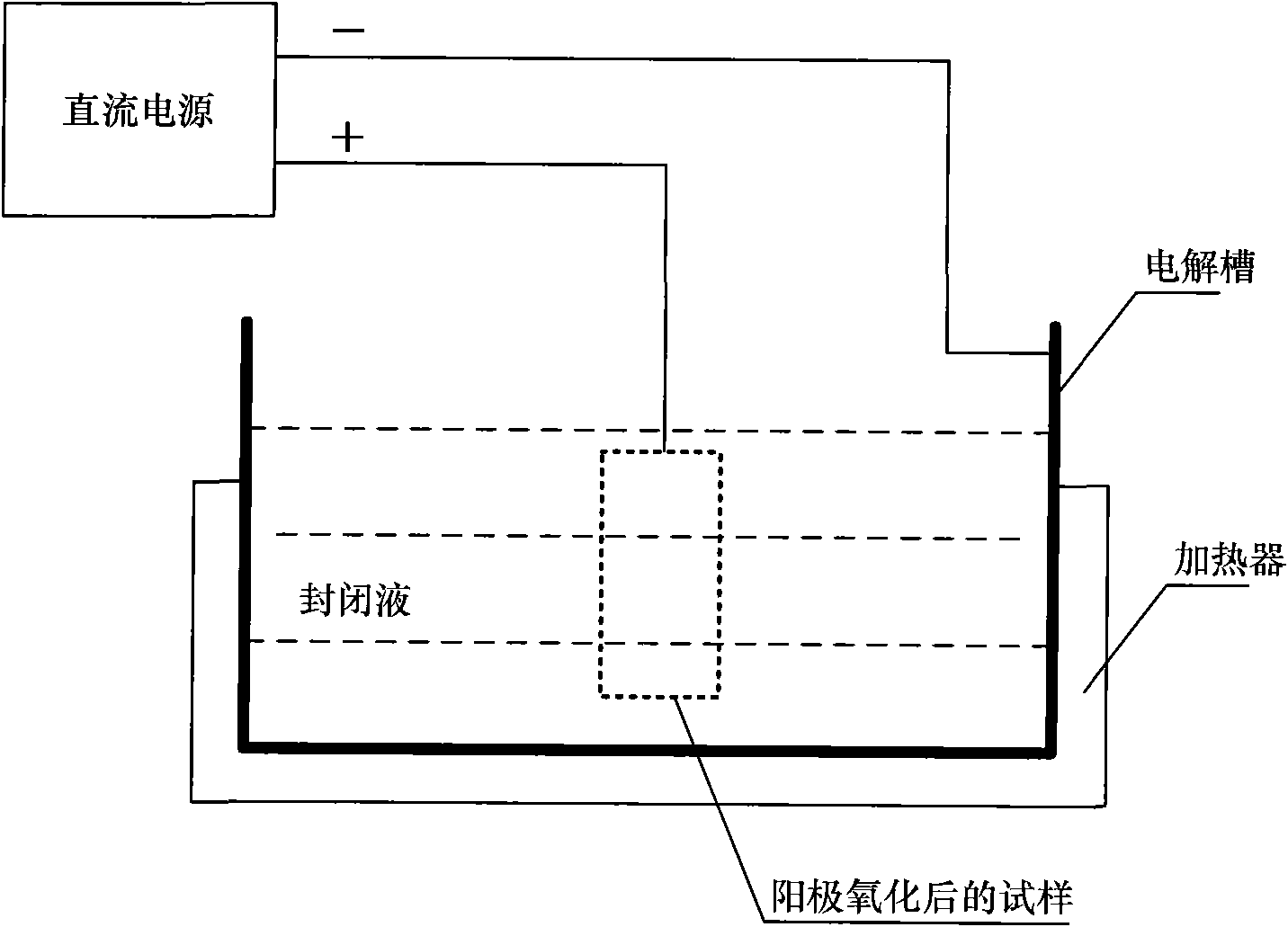

Anticorrosive sealing liquid and method for sealing anodic oxide film containing copper-aluminium alloy by utilizing same

InactiveCN101792922AImprove corrosion resistanceSmall currentSurface reaction electrolytic coating8-HydroxyquinolineAdipate

The invention discloses anticorrosive sealing liquid and a method for sealing an anodic oxide film containing a copper-aluminium alloy by utilizing the same. The anticorrosive sealing liquid is prepared by dissolving 5-15g of adipate and 10-100mu g of anticorrosive in 100ml of deionized water. The anticorrosive is 2-mercaptobenzothiazole, benzotriazole, salicylaldoxime, 8-hydroxyquinoline or quinaldic acid. The sealing method is characterized by sealing the anodized copper-aluminium alloy in the electric field. By the sealing method, not only the micropores of the anodic oxide film are sealed, but also the anticorrosive is adsorbed in the anodic oxide film in the applied electric field, when the anodic oxide film is corroded, the anticorrosive is released from the micropores of the anodic oxide film through capillarity to play a role of corrosion inhibition to the copper-bearing phases in the base materials containing the copper-aluminium alloys to prevent further corrosion.

Owner:BEIHANG UNIV

Purification process for vulcanization accelerator 2-mercaptobenzothiazole

The invention relates to a purification process for vulcanization accelerator 2-mercaptobenzothiazole, which includes that crude 2-mercaptobenzothiazole molten pulp prepared through high-temperature high-pressure condensation is directly led into an extraction kettle filled with organic solvents after complete replacement with nitrogen in advance; impurities are removed by conducting liquid-liquid extraction reaction; the temperature of the extraction kettle is kept no more than 50 DEG C in the process of extraction; mass ratio of the organic solvents to the crude 2-mercaptobenzothiazole molten pulp is (2-10) : 1; after extraction is finished, mixture inside the extraction kettle is filtered; obtained filter cakes are dried so as to obtain the vulcanization accelerator 2-mercaptobenzothiazole; the organic solvents recycled by distilling obtained filter liquor can be reused; and organic solvents evaporated in the extraction process condensate and flow back, and non-condensable gas is recycled by using active carbon to absorb the non-condensable gas. The purification process has safe extraction, shortens process flow, saves labor, material resources and energy sources, and can obtain high-purity vulcanization accelerator 2-mercaptobenzothiazole.

Owner:山东戴瑞克新材料有限公司

Preparation method and application of 2-mercaptobenzothiazole modified activated carbon

ActiveCN107215872ASimple processLow modification costOther chemical processesCarbon compoundsActivated carbonOrganic solvent

The invention discloses a preparation method and application of 2-mercaptobenzothiazole modified activated carbon, belonging to the fields of wet metallurgy and precious metal recovery. The preparation method comprises the steps of dissolving 2-mercaptobenzothiazole as an activated carbon modifying agent with an organic solvent or a strong base solution, and preparing 2-mercaptobenzothiazole modified activated carbon by virtue of an impregnation method, wherein the 2-mercaptobenzothiazole modified activated carbon is used for adsorbing Au(S2O3)2<3->. According to the preparation method, the disadvantages that cyanogen is polluted during adsorption recovery of activated carbon supported copper cyanide complex ions (Cu(CN)4<2->), a modifying process of loaded prussian blue is complicated, and continuous adsorption is difficultly realized, and the like are solved; the modified activated carbon is capable of adsorbing gold in thiosulfate gold leaching and has the advantages of multistage adsorption capacity and the like.

Owner:KUNMING UNIV OF SCI & TECH

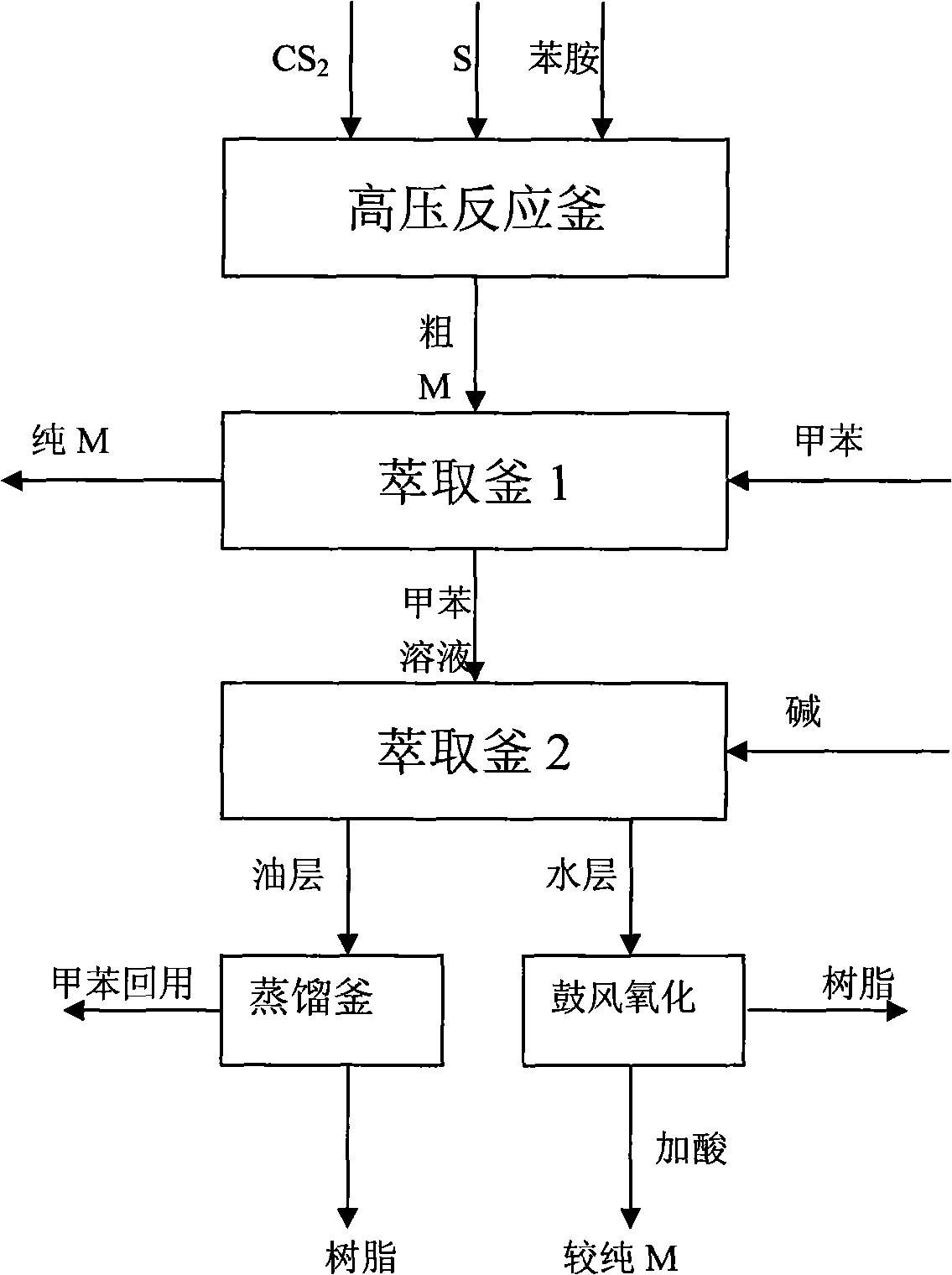

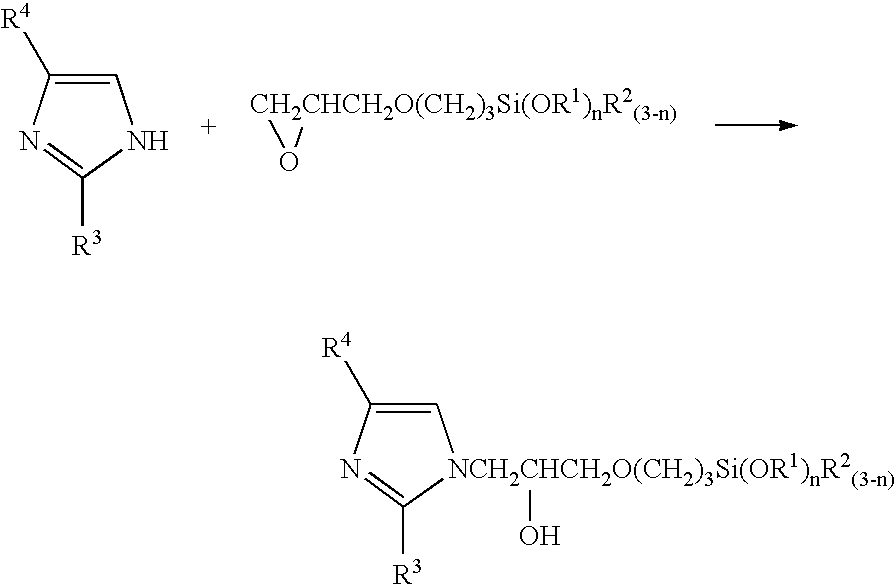

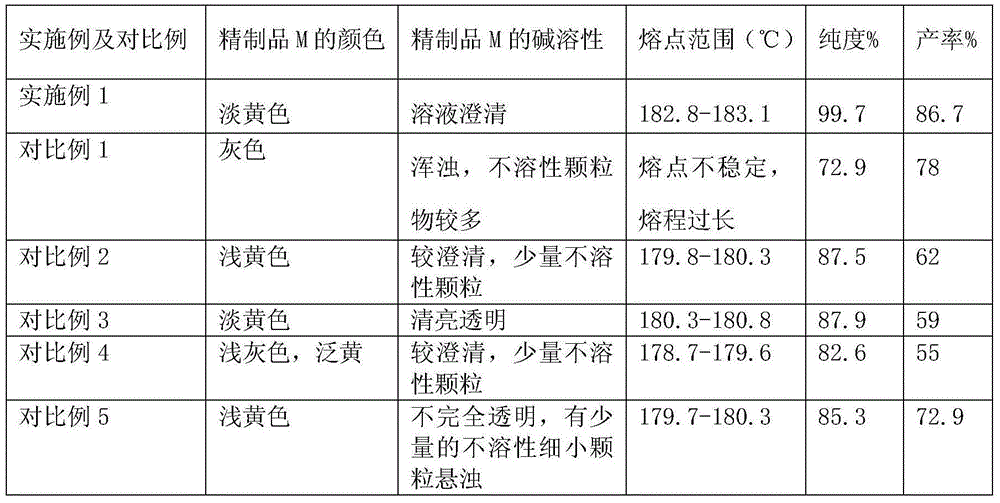

Fine purification method for rubber vulcanization accelerant 2-mercaptobenzothiazole (M)

The invention relates to a method for refining a thiofide 2-mercaptobenzothiazole (M). The method is characterized in that an extraction method and an alkali dissolving and acid isolation method are creatively combined. The method comprises the following steps: crude thiofide M is extracted by using toluene for three times to remove resin impurities so as to obtain high-purity thiofide M; the thiofide M in the resin is purified by the alkali dissolving and acid isolation method; and the thiofideoluene is reclaimed by a distillation method. By adopting the processing, the thiofide M with high purity, high melting point and short melting period can be obtained.

Owner:山东戴瑞克新材料有限公司

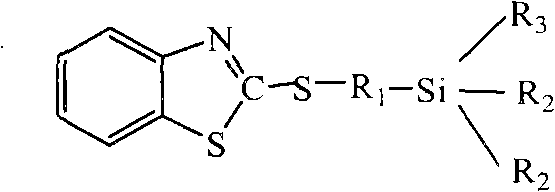

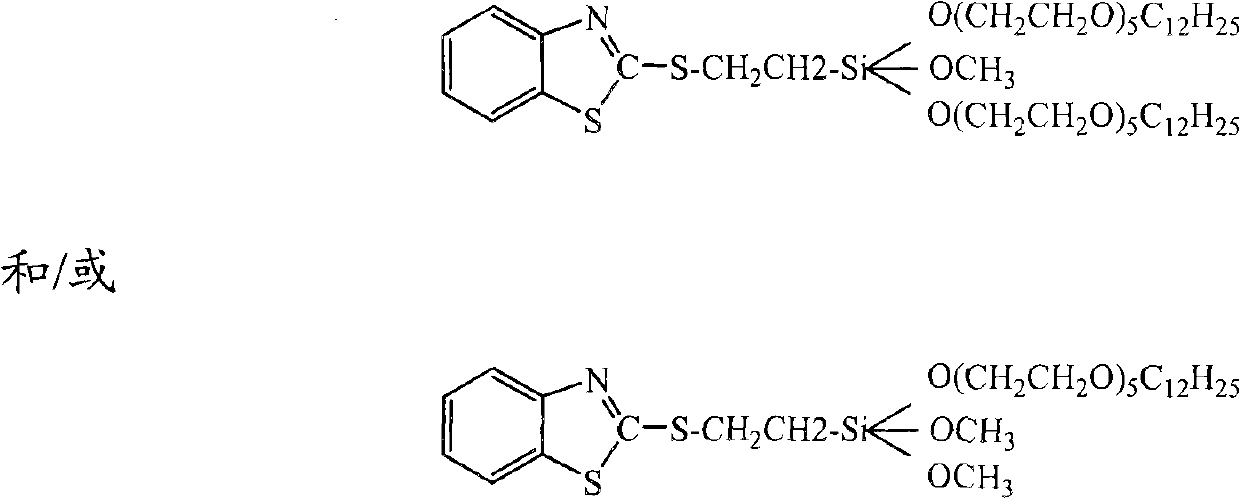

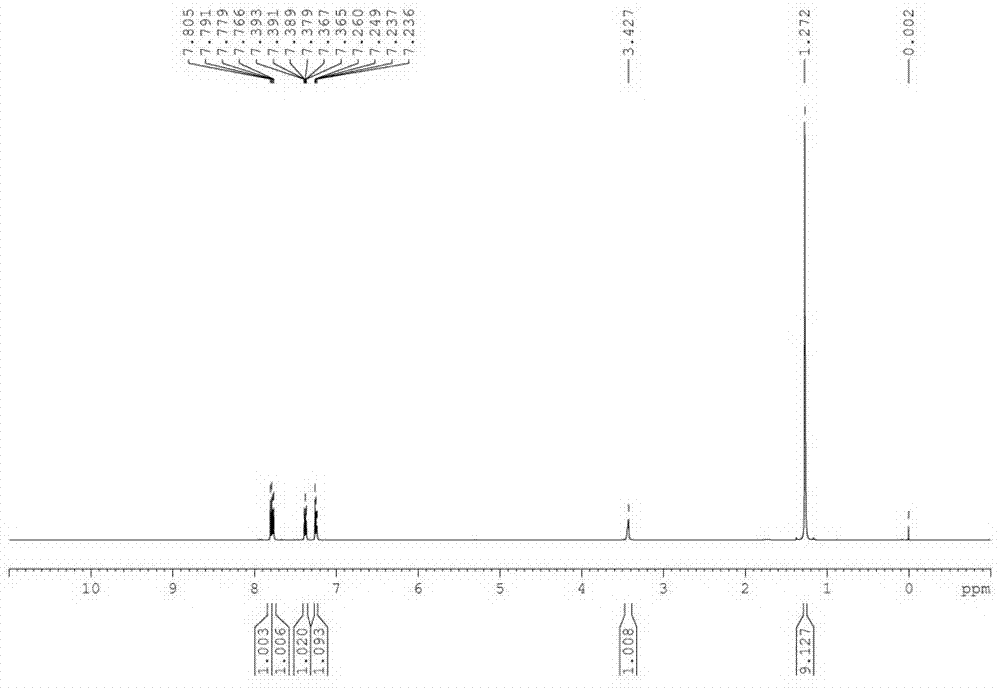

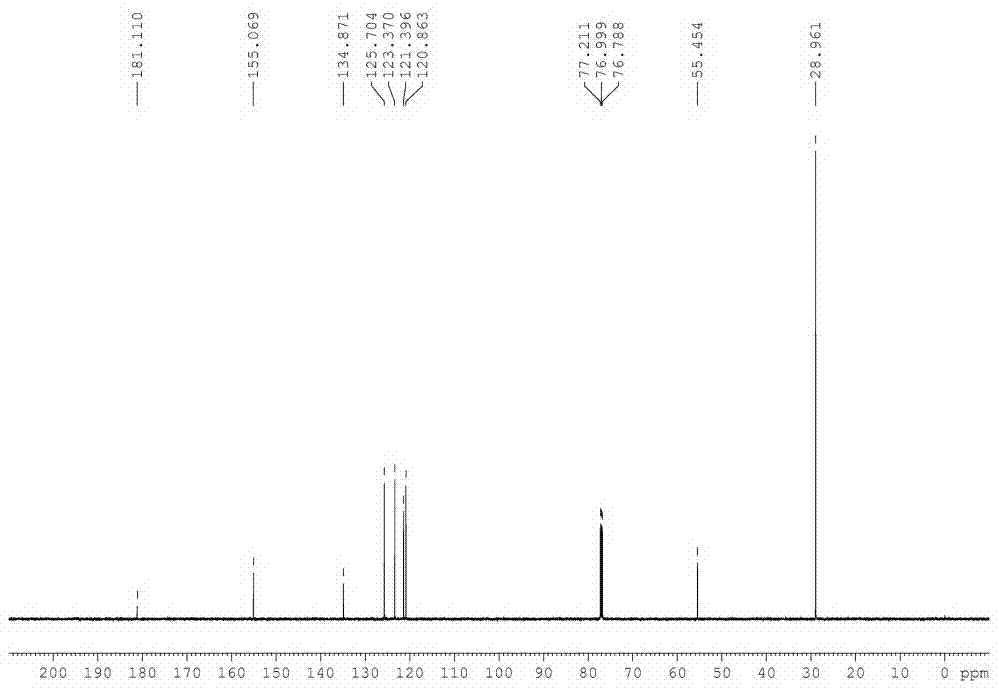

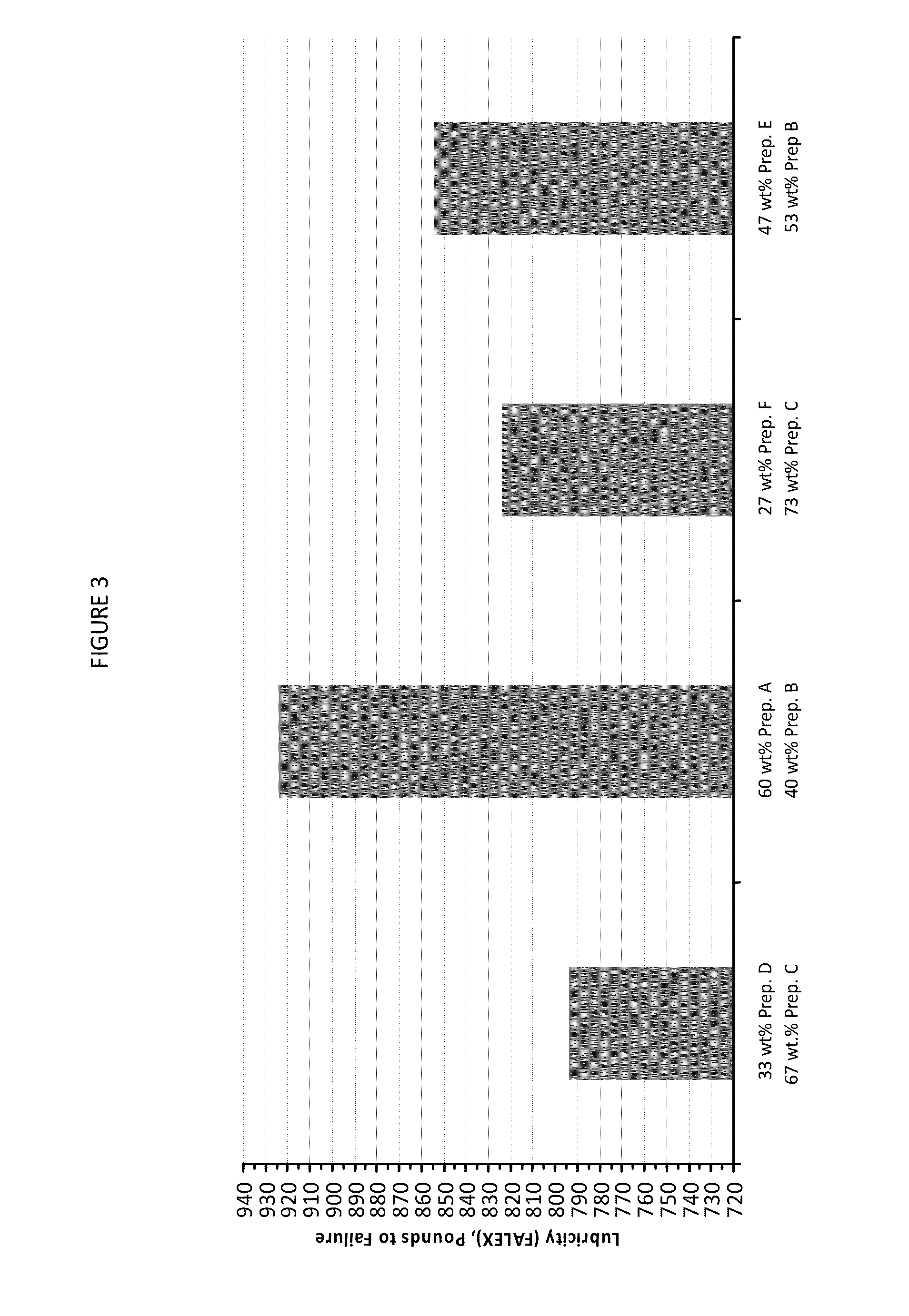

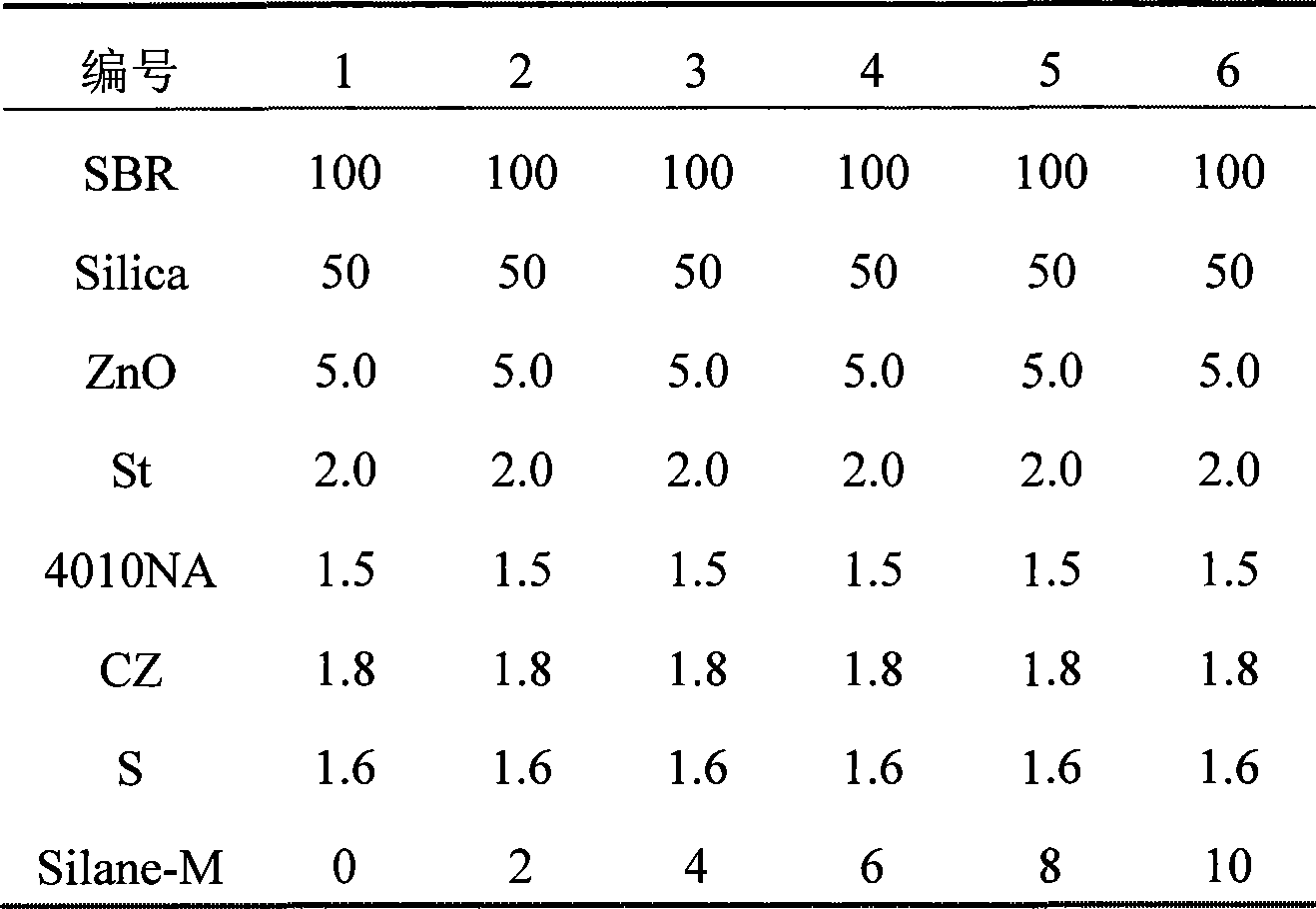

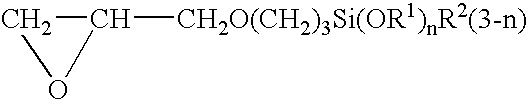

Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

ActiveCN102344462AImprove bindingImprove mechanical propertiesGroup 4/14 element organic compoundsRubber materialPolymer science

The invention discloses a low-volatility benzothiazolyl mercaptosilane and a preparation method thereof. A molecular structural formula of the low-volatility benzothiazolyl mercaptosilane is shown in the patent specification. The preparation method of the low-volatility benzothiazolyl mercaptosilane comprises the following steps that 1, a polyether and a chloroalkyl silane undergo a reaction at a temperature of 30 to 180 DEG C in the presence of one or more catalysts; and R3-H is separated from the reaction products so that a silane semi-finished product is obtained; and 2, 2-mercaptobenzothiazole is added into an organic solvent; and one or more alkalis and semi-finished silane are added into the 2-mercaptobenzothiazole solution to undergo a reaction with stirring at a temperature of 20 to 120 DEG C in a nitrogen atmosphere for 0.5 to 24 hours; the reaction products are subjected to filtration, washing and reduced pressure distillation to produce a brown-red liquid desired product. The low-volatility benzothiazolyl mercaptosilane can release a small quantity of alcohols, can improve reinforcing effects, mechanical properties and dynamic mechanical properties of vulcanized rubbers, and rolling resistance and wet skid resistance of tread rubber, has long scorch time and fast sulfuration speed, and can improve greatly sulfuration performances of rubber materials.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

Method for preparing sulfenamide thiofide by catalyzing oxidization of molecular oxygen in water phase

ActiveCN106866577AHigh catalytic activityImprove reaction efficiencyOrganic chemistryChemical recyclingPhthalocyanineBy-product

The invention relates to a method for preparing sulfenamide thiofide by catalyzing oxidation of molecular oxygen in a water phase. According to the method, a water-soluble transition metal phthalocyanine compound is utilized as a catalyst, and 2-mercaptobenzothiazole generates oxidation cross coupling reaction with amine (tert-butylamine or cyclohexane) for 1 to 30 hours to generate sulfenamide thiofide in the water phase under the conditions that oxygen (or air) pressure is 0,01 to 1MPa, and temperature is 40 to 100 DEG C. Reaction of the preparation method disclosed by the invention is performed in the water phase, other organic solvents are prevented from being added, catalyst activity is high, reaction efficiency is high, the catalyst can be used repeatedly, a synthesizing technology is concise, product selectivity is high, by products are few, waste is little, environmental friendliness is achieved, and the preparation method has stronger industrial application prospect.

Owner:WILLING NEW MATERIALS TECH CO LTD

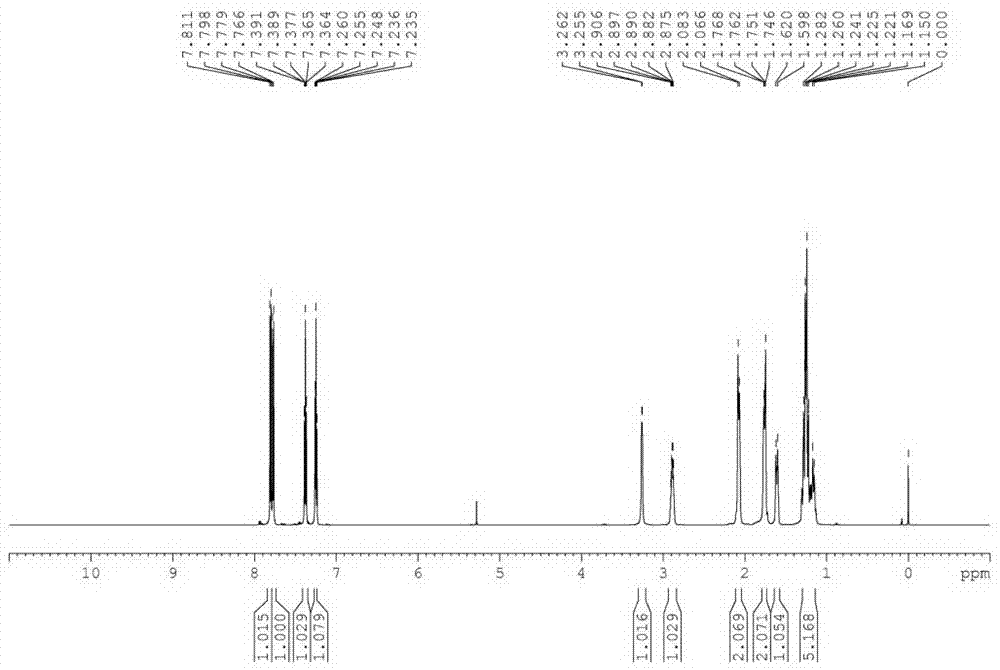

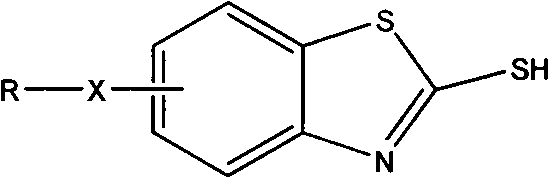

Improved method for synthesizing 2-mercaptobenzothiazole derivative

The invention discloses an improved method for synthesizing a 2-mercaptobenzothiazole derivative. The method comprises the following steps of: putting relatively simple raw materials consisting of a phenylamine derivative, carbon disulfide and sulphur in a reaction kettle; introducing N2 till the reaction pressure is kept in a range of 6-15 MPa; raising the temperature to 200-260 DEG C; reacting for 2-5 h; dissolving the product by using alkali; filtering and removing side-effect impurities; and acidizing and separating the product, the content of which is above 99%. The reaction yield can be increased to 90-100% by optimizing a reaction condition. The method disclosed by the invention has the advantages that: the cost of reaction raw materials is saved; the reaction time is shortened; furthermore, the reaction purity and the yield are increased; and the method can be popularized for large-scale industrial production.

Owner:NANKAI UNIV

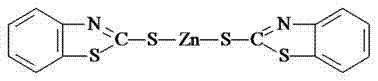

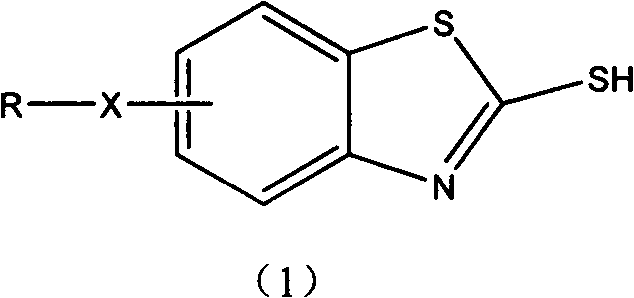

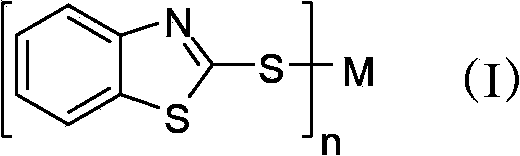

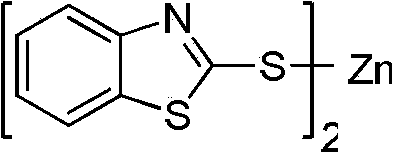

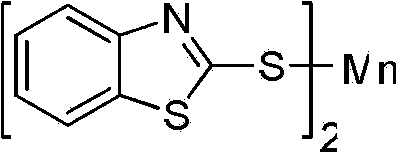

Use of 2-mercaptobenzothiazole metal salt

ActiveCN103461348AImprove biological activityIncreased drug resistanceBiocidePlant growth regulatorsDiseaseMercaptobenzothiazole

The invention relates to use of a 2-mercaptobenzothiazole metal salt, and especially provides a crop disease prevention and treatment bactericide. The bactericide is characterized in that the bactericide includes the 2-mercaptobenzothiazole metal salt represented by formula (I) and a pesticide carrier; and in the formula (I), M is Zn, Mn, Fe, Sn or Al, and n is 2, 3 or 4. The bactericide has a very high biological activity against most bacteria and an excellent inhibition effect on fungi, and is an ideal drug for comprehensively preventing and treating diseases of crops.

Owner:ZHEJIANG XINNONG CHEM CO LTD +1

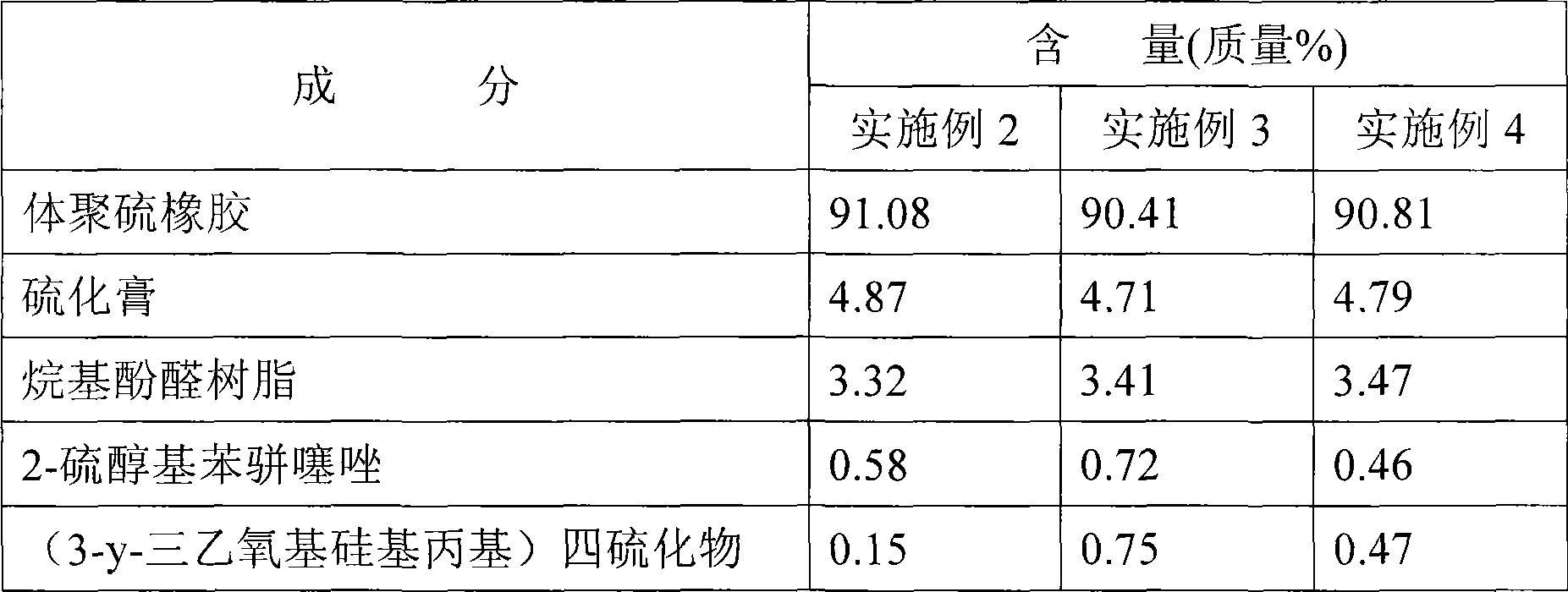

On-line repair method for bellows

InactiveCN101469801AImprove mechanical propertiesGood oil resistancePipe elementsVulcanizationAdhesive

An online repairing method for corrugated pipes comprises quickly plugging, pretreating a repairing surface, activatedly processing the repairing surface, laying strengthening layer, sticking a protective film, and curing for 24h at room temperature. The flexible composite adhesive for repairing has the components by weight percentage: 4.7-4.9 of vulcanization paste, 3.3-3.5 of alkyl phenol-formaldehyde resin, 0.45-0.75 of 2-mercaptobenzothiazole, 0.10-0.80 of (3-gamma-triethoxysilylpropyl)-tetrasulfide, the balance being Thiokol. The method can repair and strengthen on-line the corrugated pipes in the pipelines at normal temperature and pressure without open fire, and has the advantage of safety, reliability, energy and environment conservation, thereby having low influence to equipment, lower repairing cost than the cost of jacketing a new corrugated pipe, expanding space for repeatedly repairing, and greatly increasing the service life of the equipment.

Owner:上海宝钢综合开发公司

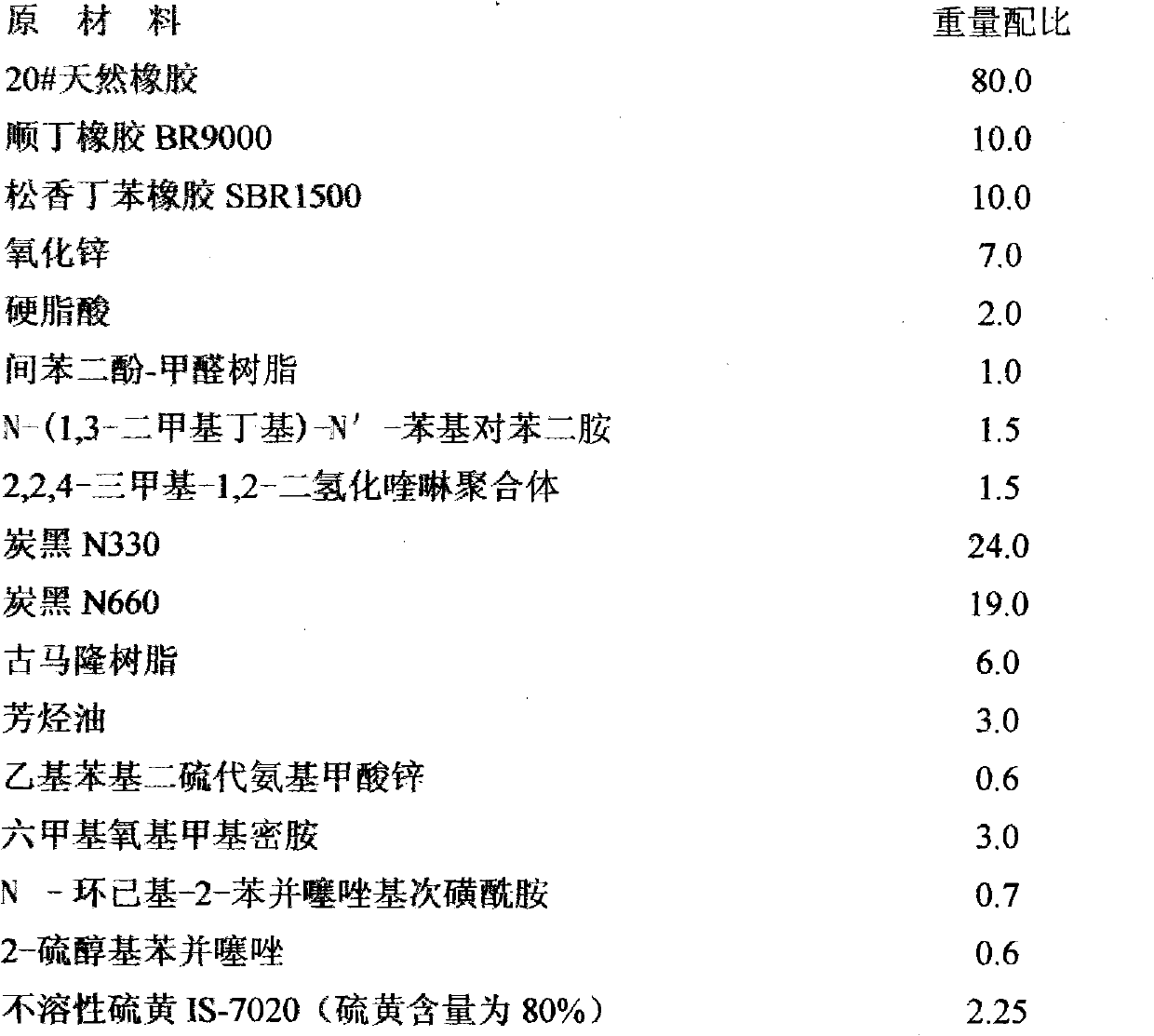

Intermediate adhesive material for retreaded tires

InactiveCN102086353AImprove adhesionImprove driving safetyNatural rubber adhesivesQuinolineHigh doses

The invention discloses an intermediate adhesive material for retreaded tires. The adhesive material disclosed by the invention contains resorcinol-formaldehyde resin, hexamethoxy methyl melamine, zinc oxide (in high dose ratio), and N-ethyl-N-phenyldithiocarbamic acid zinc salt serving as a low-temperature promoter. The key points of the intermediate adhesive material include: the intermediate adhesive material is prepared from various raw materials including No.20 natural rubber, cis-1,3-butadiene rubber (BR)9000, abietic styrene butadiene rubber (SBR)1500, resorcinol-formaldehyde resin, zinc oxide (in high dose ratio), stearic acid, N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine,poly(1,2-dihydro-2,2,4-trimethyl-quinoline), poly(2-dihydroquinoline), carbon black N330, carbon black N660, coumarone-indene resin, aromatic oil, zinc ethylphenyl dithiocarbamate, hexamethoxy methyl melamine, N-cyclohexylbenzolthiazole-2-sulfenamide, 2-mercaptobenzothiazole, and insoluble sulphur (IS)-7020( the sulfur content is 80 percent). The adhesive material disclosed by the invention is mainly used in the intermediate adhesive layers of retreated diagonal tires and retreaded steel-belted radial tires and when the adhesive material disclosed by the invention is used, the tire tread and tire body adhering strength of the intermediate adhesive material is improved obviously; the H drawing force of the adhesive material with all-steel cords and nylon cords is improved to reduce the tire tread and tire body separation phenomenon of the finished retreaded diagonal tires and retreaded steel-belted radial tires; and thus, the driving safety and service life of the diagonal tires and the retreaded steel-belted radial tires are improved.

Owner:SICHUAN TYRE & RUBBER CO LTD

Recycling of Natural and Synthetic Rubber

InactiveUS20100317752A1Efficient recyclingWide applicabilityOther chemical processesPlastic recyclingElastomerThiocarbamate

A delinking composition in the form of a combined solid dose comprising: (i) one or more elastomer delinking accelerators selected from the group consisting of zinc salts of thiocarbamates and zinc salts of dialkyl dithiophosphates; and (ii) one or more elastomer delinking accelerators selected from the group consisting of 2-mercaptobenzothiazole or derivatives thereof, thiurams, guanidines, 4,4′-dithiomorpholine and sulpenamides; and (iii) at least one elastomer delinking activator.

Owner:ELASTOMER TECH

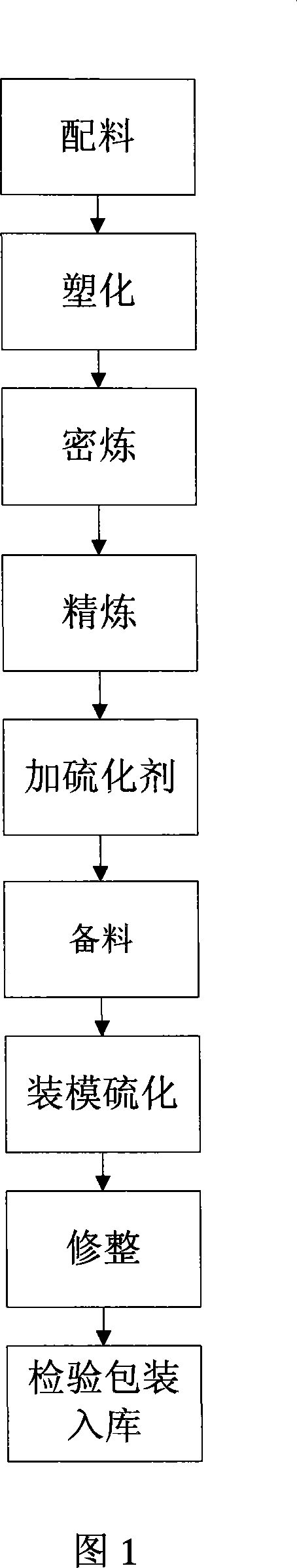

Novel rubber packing plate and production technique thereof

InactiveCN101220184AExtended service lifeGood weather resistanceRail fastenersTetramethylthiuram disulfideElastomer

The invention relates to a novel rubber pad, the parts by weight of components of which are: 80-95 portions of ethylene propylene diene monomer rubber, 5-20 portions of elastomer, 0.6-2.5 portions of sulfur, 0.5-2.0 portions of dicumyl peroxide, 0.5-1.5 portions of 2-Mercaptobenzothiazole, 0.8-1.6 portions of tetramethylthiuram disulfide, 2 portions of p-Phenylenediamine or naphthylamine antioxidant, 60-90 portions of carbon black, 15-45 portions of argil, 15-50 portions of calcium carbonate and 35-45 portions of operation oil. Production technique of the pad is according to the processes of mixing - plasticizing - banburying - refining - adding sulfidizer - preparing material - diefilling and sufidizing - finishing - inspecting packages and putting in storage. The invention has the advantages that: the rigidity, the vibration and the noise of railway are reduced; the service life and compression deforming quality of the pad are enhanced; elasticity loss of the pad and line maintenance expense are reduced; the invention also has the advantages of sufficient raw materials, low cost, innocuity and no pollution.

Owner:四川宏亿复合材料工程技术有限公司

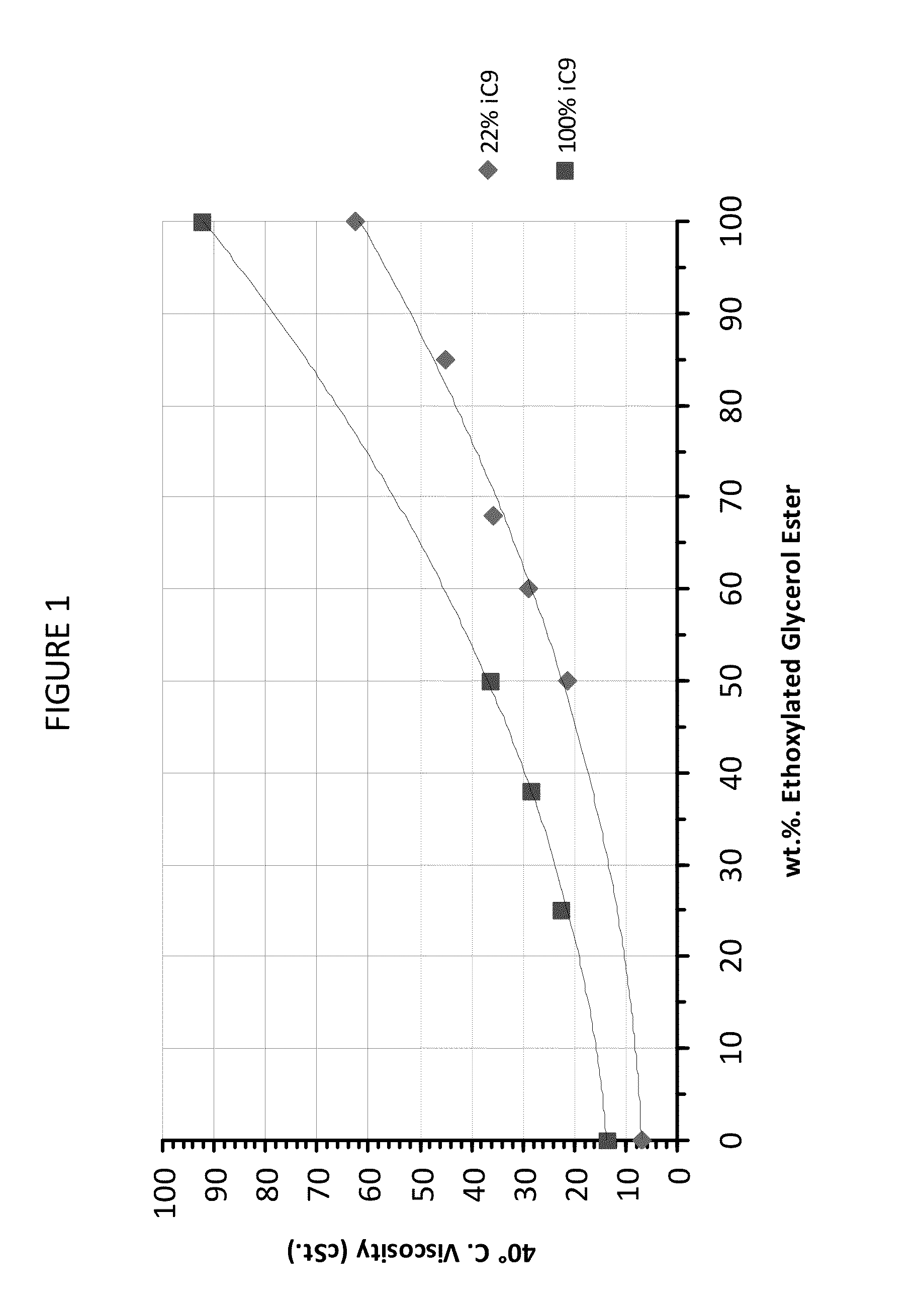

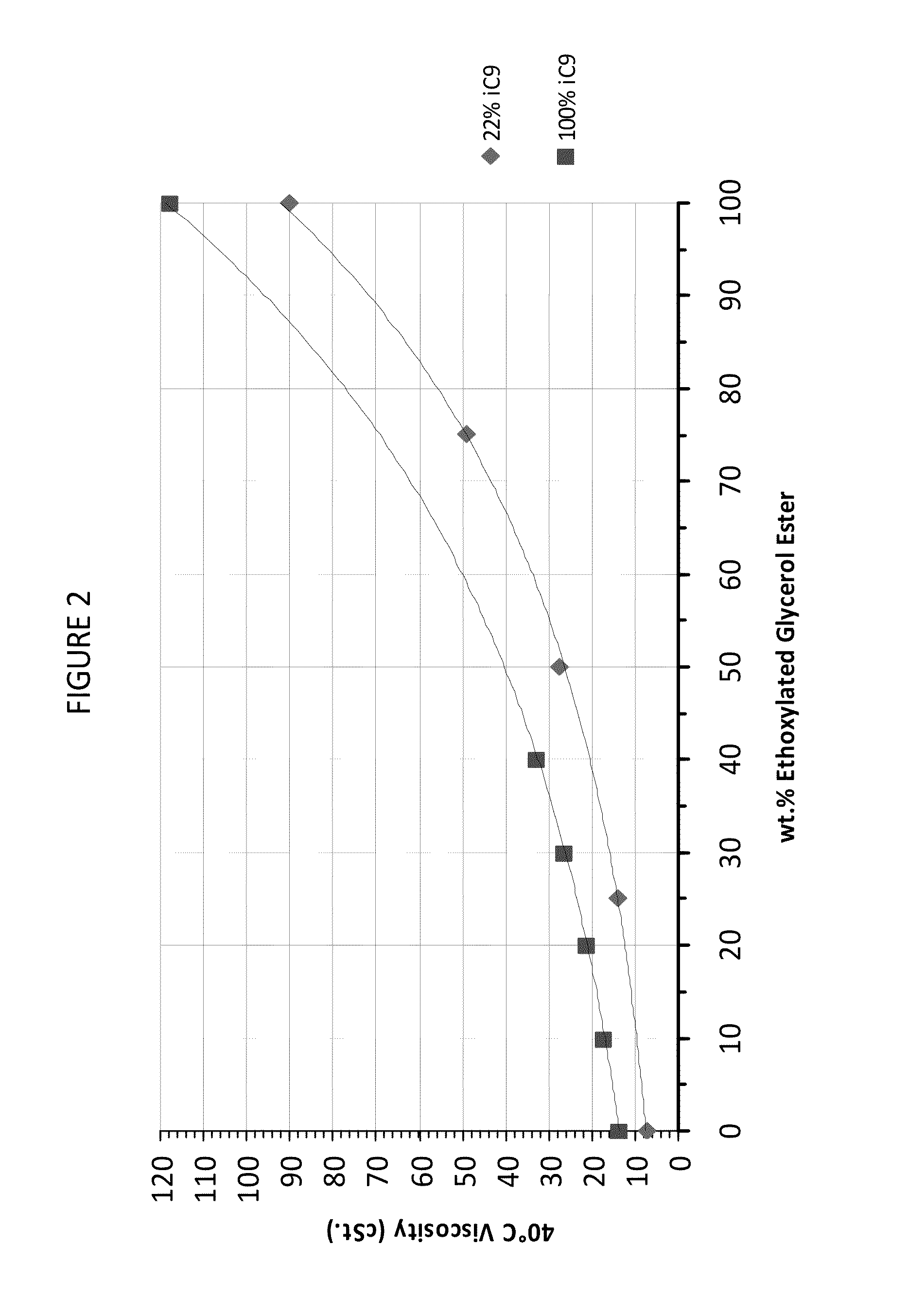

Refrigeration compressor lubricant

ActiveUS20130200295A1Good compatibilityExcellent indexHeat-exchange elementsAdditivesRefrigeration compressorDichlorodifluoromethane

Owner:COPELAND LP

Preparation method of ceftriaxone sodium

InactiveCN102702233ASimple production processReduce manufacturing costOrganic chemistryOrganic basePotassium

The invention discloses a preparation method of ceftriaxone sodium. The method comprises the following steps: with 7-ACA and triazine ring as raw materials, reacting under the catalysis of boron trifluoride acetonitrile, crystallizing to obtain 7-ACT, recovering potassium fluoborate and acetonitrile from the mother solution, dissolving 7-ACT and AE-active ester in a unitary or binary solvent system, reacting under catalysis of an organic base, adding a salifying agent and a water-soluble organic solvent in the water phase to separate out sodium salt and obtain ceftriaxone sodium, and recovering 2-mercaptobenzothiazole from the organic phase. The preparation method of ceftriaxone sodium provided by the invention has simple production process and low production cost, the yields in two steps are both higher than 90 percent, the solvents, organic matters, inorganic salts and the like in the reaction system can be recycled, and no or little waste water is generated.

Owner:苏州盛达药业有限公司

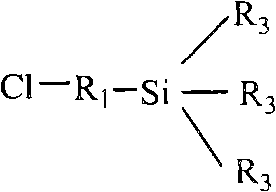

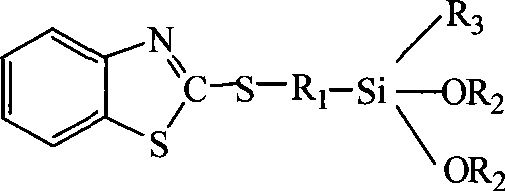

Multi-functional rubber additive and method for preparing same

InactiveCN101445620AImprove mechanical propertiesEasy to processGroup 4/14 element organic compoundsViscous liquidPolymer science

The invention provides a multi-functional rubber additive and a method for preparing same. The multi-functional rubber additive has an abovementioned molecular structural formula; wherein, the left side of the formula is provided with a benzothiazolyl radical; R1 is methylene, ethylidene or propylidene; R2 is cymene or ethyl; R3 is ethylidene, propylidene, methoxy or ethoxy. The preparation method comprises the steps as follows: 2-mercaptobenzothiazole (accelerant M) and alkali are dissolved in organic solvent; subsequently, chlorocarbon silane is added and reacts for 0.5-24 hours at the temperature of 20-120 DEG C under the mixing condition; the reaction products are filtrated, washed, and distilled by pressure-reduction so as to gain viscous liquid-shaped target products finally. The multi-functional rubber additive has multi-functions such as plasticizing, dispersing, promoting, reinforcing, and the like, simple preparation flow, high yield and simple separation process.

Owner:SOUTH CHINA UNIV OF TECH

Electroless copper plating solution and electroless copper plating method

InactiveUS20070071904A1Improve responseEfficient productionLiquid surface applicatorsSemiconductor/solid-state device manufacturingCopper platingThiourea

Owner:JX NIPPON MINING & METALS CO LTD

2-mercaptobenzothiazole refining method

The invention belongs to the field of organic chemistry refining and discloses a 2-mercaptobenzothiazole refining method. The 2-mercaptobenzothiazole refining method comprises that under action of a composite solvent comprising toluene and isopropanol or comprising toluene and acetone, 2-mercaptobenzothiazole is subjected to recrystallization purification so that a 2-mercaptobenzothiazole refined product is obtained. The 2-mercaptobenzothiazole refining method has the advantages of simple and convenient processes, small organic solvent use amount, small environmental pollution and industrialization easiness.

Owner:QINGDAO UNIV OF SCI & TECH

Brightness-retaining agent for silverware

The invention discloses a brightness-retaining agent for silverware and belongs to the technical field of silverware maintenance. The brightness-retaining agent is used for solving the problem that the surface of the silverware is easily oxidized, vulcanized and discolored. The brightness-retaining agent is prepared from the following components in parts by weight: 5-10 parts of sodium hypophosphite or sodium phosphite, 1-5 parts of coconut oil fatty acid diethanolamide, 1-3 parts of deionized water, 1-2 parts of Tween-20, 1-3 parts of potassium dihydrogen phosphate, 1-3 parts of sodium dihydrogen phosphate, 3-5 parts of sodium carbonate, 1-3 parts of methyl benzotriazole, 1-3 parts of 2-mercaptobenzothiazole thiadiazole, 1-2 parts of sodium lauryl sulfate and 0.5-1 part of sodium stearate. During use, the brightness-retaining agent is dissolved in deionized water to obtain a 5-10% aqueous liquid. The brightness-retaining agent is stably stored, is convenient to operate and is free of potential safety hazard and the surface texture of the silverware is not affected.

Owner:HANDAN COLLEGE

Method of obtaining 2-mercaptobenzothiazole

Owner:DUSLO A S

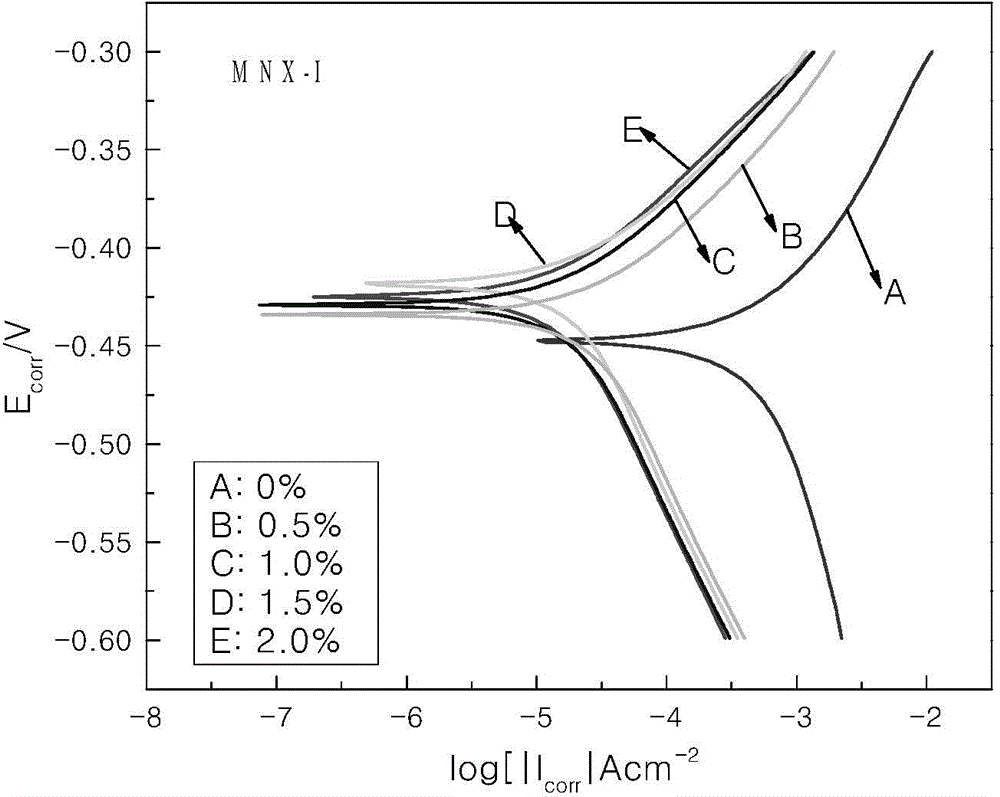

Preparation method of compound copper corrosion inhibitor and surface treatment method by using compound copper corrosion inhibitor

InactiveCN102206826AReduce manufacturing costNo pollution in the processElectrolytic organic material coatingChemical treatmentRare earth

The invention relates to a preparation method of a compound copper corrosion inhibitor and a surface treatment method by using the compound copper corrosion inhibitor, belonging to the technical field of metal surface treatment. The compound copper corrosion inhibitor comprises BTA (benzotriazole), 2-mercaptobenzothiazole, mixed rare earth salt, surfactant, citric acid, copper complexing agent and the balance of water. By combining the surface treatment technique with the electrochemical treatment technique, the invention shortens the formation time of the corrosion inhibition film on the copper surface and enhances the efficiency of the surface treatment technique.

Owner:SHANGHAI JIAO TONG UNIV

Method for extracting 2-mercapto benzothiazole

The present invention relates to a method for extracting 2-mercaptobenzothiazole, said method includes the following steps: (1). placing 1 (weight) portion of 2-mercaptobenzothiazole and 1-5 (weight) portions of toluene solution into extraction kettle, stirring until the external surface of 2-mercaptobenzothiazole has not impurities; (2) placing the above-mentioned mixed liquor into filter tank to make filtration to obtain filtrate and filter cake; and (3) placing the obtained filter cake into double cone rotating drying machine and drying under the condition of that the degree of vacuum is 0.02-0.08 mpa and temp. is 80-120 deg.C, so that it can obtain the invented qualified 2-mercaptobenzothiozole product.

Owner:苏秋利

Method for treating 2-mercaptobenzothiazole production waste

ActiveCN102603668AChemically stableSolve the pollution problemAmino compound purification/separationSulfur compoundsEnvironmental resistanceDistillation

The invention discloses a method for treating 2-mercaptobenzothiazole production waste. The method comprises the steps of: heating the 2-mercaptobenzothiazole production waste to 90-95 DEG C, carrying out solid-liquid separation to obtain solid matter and liquid A, returning the solid matter to an accelerator M workshop, refining and purifying the solid matter to obtain a product accelerator M, distilling and separating the liquid A to obtain a fraction B and a fraction C, cooling residues in a distillation kettle to obtain asphalt-shaped matter D, absorbing hydrogen sulfide gas generated in the distillation separation process by using a sodium hydroxide solution to obtain a sodium hydrosulfide solution, concentrating the sodium hydrosulfide solution to obtain sodium hydrosulfide solids, rectifying and separating the fraction C to obtain aniline and benzothiazole. The method disclosed by the invention is capable of realizing the resourceful treatment of the 2-mercaptobenzothiazole production waste and has the advantages of various by-products, good product quality, simpleness in process flow, easiness in operation, mildness in reaction condition, low production cost and is environment-friendly.

Owner:HEBI HENGLI RUBBER PLASTIC CO LTD

Mannich base type acidizing corrosion inhibitor and preparation method thereof

InactiveCN104560005ABarrier to osmosisRaise the reaction energy barrierDrilling compositionBorehole/well accessoriesEnvironmental resistanceSynthesis methods

The invention relates to a mannich base type acidizing corrosion inhibitor and a preparation method thereof. The mannich base type acidizing corrosion inhibitor is characterized by being prepared from the following components in percentage by mass: 25-30% of a host corrosion inhibitor, 30-45% of an organic solvent and 30-40% of water. The preparation method comprises the following steps: (1) adding 2-mercaptobenzothiazole and benzaldehyde, or 2-mercaptobenzothiazole and furfural or 2-mercaptobenzothiazole and cinnamyl aldehyde in a mole ratio of 1.0:(1.0-1.8) as a host corrosion inhibitor raw material into ethanol, mechanically stirring, slowly dropping adding phenylamine, adjusting the pH value of the solution to be 2-4, implementing reaction for 4-10 hours at 75-90 DEG C, and cooling to be the room temperature, thereby synthesizing a host corrosion inhibitor mannich base compound; and (2) dissolving the host corrosion inhibitor in an organic solvent according to a ratio, and uniformly mixing and stirring with water, thereby obtaining the mannich base type acidizing corrosion inhibitor. As synthesized raw materials which are environment-friendly, low in toxicity and easy to degrade are adopted, the acidizing corrosion inhibitor provided by the invention can effectively prevent corrosion of an acid liquid to metal, and has the characteristics of simple synthesis method, safe production and operation, stable and remarkable corrosion inhibition property, low cost and environment friendliness.

Owner:YANGTZE UNIVERSITY

Composite stabilizer for SBS modified asphalt

ActiveCN104513489ASolve the problem of high temperature storage stabilityImprove high and low temperature stabilityBuilding insulationsHigh temperature storageBenzoyl peroxide

The invention relates to a composite stabilizer for SBS modified asphalt. The composite stabilizer comprises the following components in parts by mass: 30 to 60 parts of a cross-linking agent, 10 to 40 parts of an accelerator, 10 to 20 parts of an activating agent and 5 to 20 parts of a compatilizer, wherein the cross-linking agent is one or more of sulfur, dithiomorpholine, polyphosphoric acid and maleic anhydride; the accelerator is one or more of tetraethylthiuram disulfide, 2-mercaptobenzothiazole, benzoyl peroxide, dicumyl peroxide and sodium isopropyl xanthate. Compared with the prior art, the composite stabilizer has the advantages that after the composite stabilizer is added into the SBS modified asphalt, the problem that the high-temperature storage stability of the SBS modified asphalt is poor is well solved, the performances such as high-temperature and low-temperature stability and water stability of an asphalt mixture are comprehensively improved, and high-temperature anti-rutting performance, low-temperature anti-cracking performance, moisture damage resistance and ageing resistance are remarkably improved.

Owner:山西省交通科技研发有限公司

Electroless Copper Plating Solutions for Microvia Filling

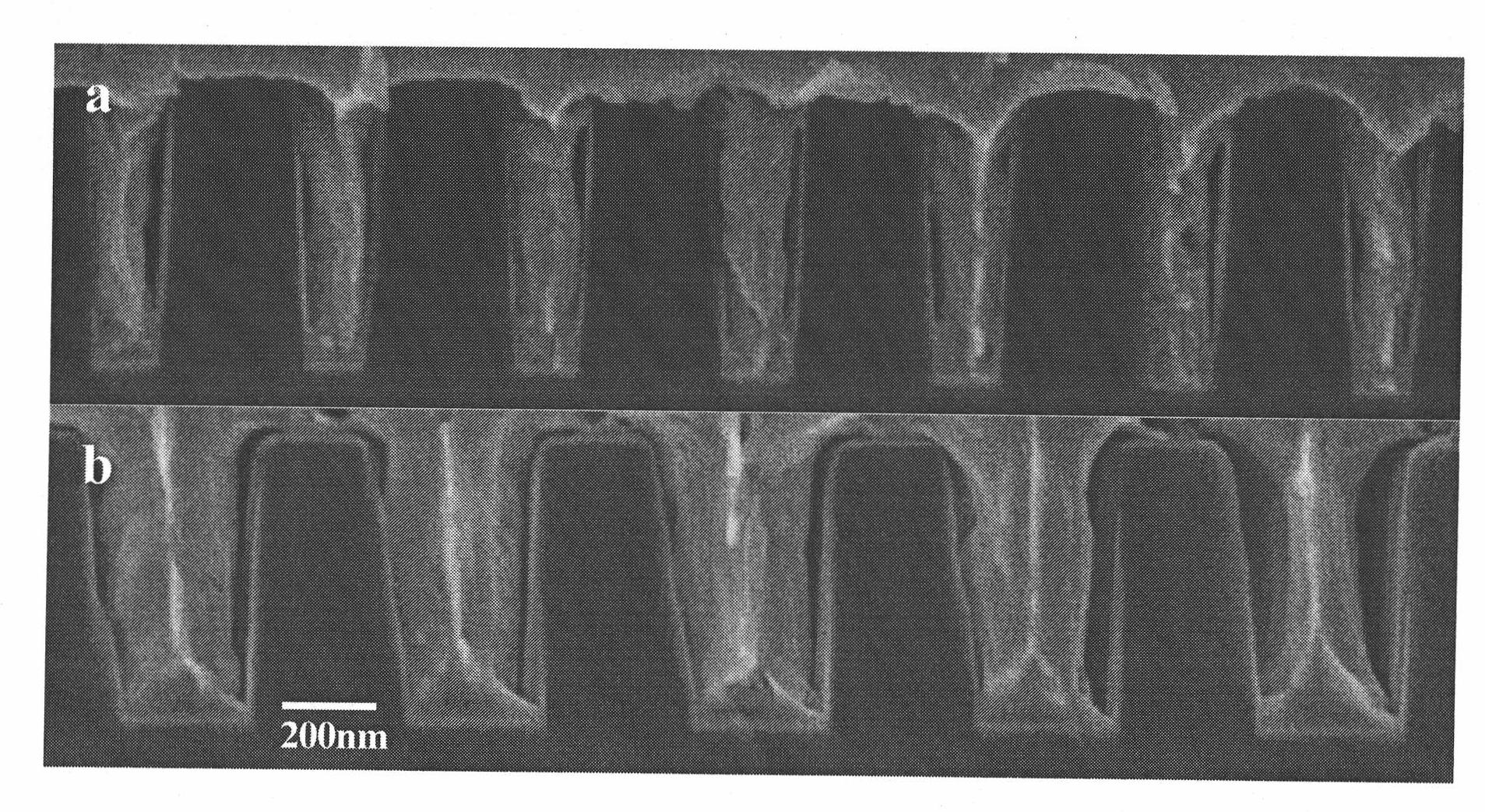

InactiveCN102277567ANo holesSeamlessSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBenzoxazoleCopper plating

A chemical copper plating solution for micropore filling. 1 L of the chemical copper plating solution comprises 5-20 g of copper sulfate pentahydrate, 10-50 g of disodium ethylene diamine tetraacetate, 1.0-1.5 g of formaldehyde or glyoxylic acid, 0.001-0.02 g of mercapto heterocyclic compounds, 0.02-0.04 g of polyether with an average molecular weight of 3650, 1.5-3.5 g of NaOH, and the balance of distilled water; the mercapto heterocyclic compounds are 2-mercapto benzimidazole, 2- mercapto benzoxazole, 1-phenyl-5-mercapto-tetrazole or 2-mercapto benzothiazole. By simultaneously adding mercapto heterocyclic compounds and polyether with an average molecular weight of 3650 into the chemical copper plating solution, the invention realizes no cavity, no gap of micropores, and perfect chemicalcopper filling; the chemical copper plating solution is stable; and the deposited copper film has good quality.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com