Preparation of rubber vulcanization accelerator dibenzothiazyl disulfide

A technology of dibenzothiazole disulfide and rubber vulcanization, applied in organic chemistry and other directions, can solve the problems of non-compliance with the production requirements of national environmental protection policies, high content of 2-mercaptobenzothiazole, and difficult to clean "green" production, etc. Achieve the effects of superior vulcanization performance, white product appearance, and long product shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

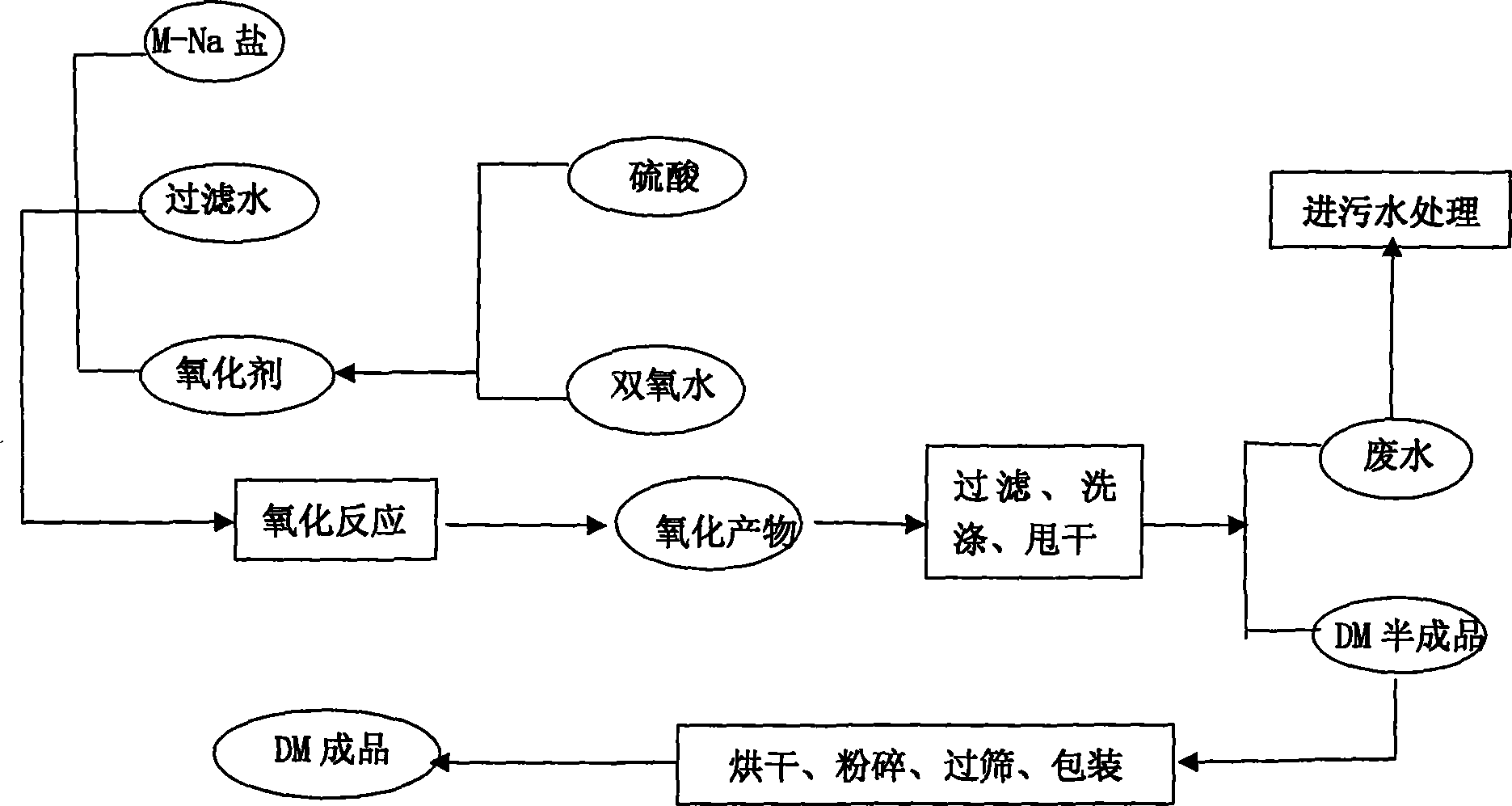

Image

Examples

Embodiment 1

[0040] 2-Mercaptobenzothiazole sodium salt (M-Na), hydrogen peroxide, and sulfuric acid are used as raw materials, and the ratio of the oxidizing agent is hydrogen peroxide: sulfuric acid = 1: 1mol;

[0041] The preparation process is: add the mixed mixture of hydrogen peroxide and sulfuric acid dropwise into a reaction kettle containing 2-mercaptobenzothiazole sodium salt (M-Na) at a temperature of 55°C under stirring to carry out oxidation reaction , the oxidation reaction time is 75 minutes; after the oxidant is added dropwise, keep warm for 0.5 hours; after that, measure the pH value of the reaction solution, after the pH value of the reaction solution is stabilized to 6.8, control the temperature at 30°C for solid-liquid separation, The obtained solid is dried, pulverized, sieved and packaged to obtain the finished product dibenzothiazole disulfide (DM), which has an initial melting point of 175°C, a purity of 99.5%, and a product yield of 98%.

Embodiment 2

[0043] Use 2-mercaptobenzothiazole sodium salt (M-Na), hydrogen peroxide, and sulfuric acid as raw materials, wherein the ratio of oxidant is hydrogen peroxide: sulfuric acid = 1.5: 1mol;

[0044]The preparation process is: add the mixed mixture of hydrogen peroxide and sulfuric acid dropwise into a reaction kettle containing 2-mercaptobenzothiazole sodium salt (M-Na) at a temperature of 65°C under stirring to carry out oxidation reaction , the oxidation reaction time is 65 minutes; after the oxidant is added dropwise, keep warm for 0.5 hours; after that, measure the pH value of the reaction solution, after the pH value of the reaction solution is stabilized to 7.3, control the temperature at 30°C for solid-liquid separation, The obtained solid is dried, pulverized, sieved, and packaged to obtain the finished product dibenzothiazole disulfide (DM), which has an initial melting point of 174°C, a purity of 99.8%, and a product yield of 99%.

Embodiment 3

[0046] Use 2-mercaptobenzothiazole sodium salt (M-Na), hydrogen peroxide and sulfuric acid as raw materials, wherein the ratio of oxidant is hydrogen peroxide: sulfuric acid = 2.0: 1mol;

[0047] The preparation process is: add the mixed mixture of hydrogen peroxide and sulfuric acid dropwise into the reaction kettle containing 2-mercaptobenzothiazole sodium salt (M-Na) at a temperature of 61°C under stirring to carry out the oxidation reaction , the oxidation reaction time is 68 minutes; after the oxidant is added dropwise, keep warm for 0.5 hours; after that, measure the pH value of the reaction solution, after the pH value of the reaction solution is stabilized to 7.0, control the temperature at 30°C for solid-liquid separation, The obtained solid is dried, pulverized, sieved and packaged to obtain the finished product dibenzothiazole disulfide (DM), which has an initial melting point of 174.5°C, a purity of 99.7%, and a product yield of 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com