Electroless Copper Plating Solutions for Microvia Filling

A technology of electroless copper plating and solution, applied in liquid chemical plating, coating, electrical components and other directions, can solve the problems of inability to realize micro-holes, poor stability of plating solution, filling, etc., to achieve stable electroless copper plating solution and deposit copper. good film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

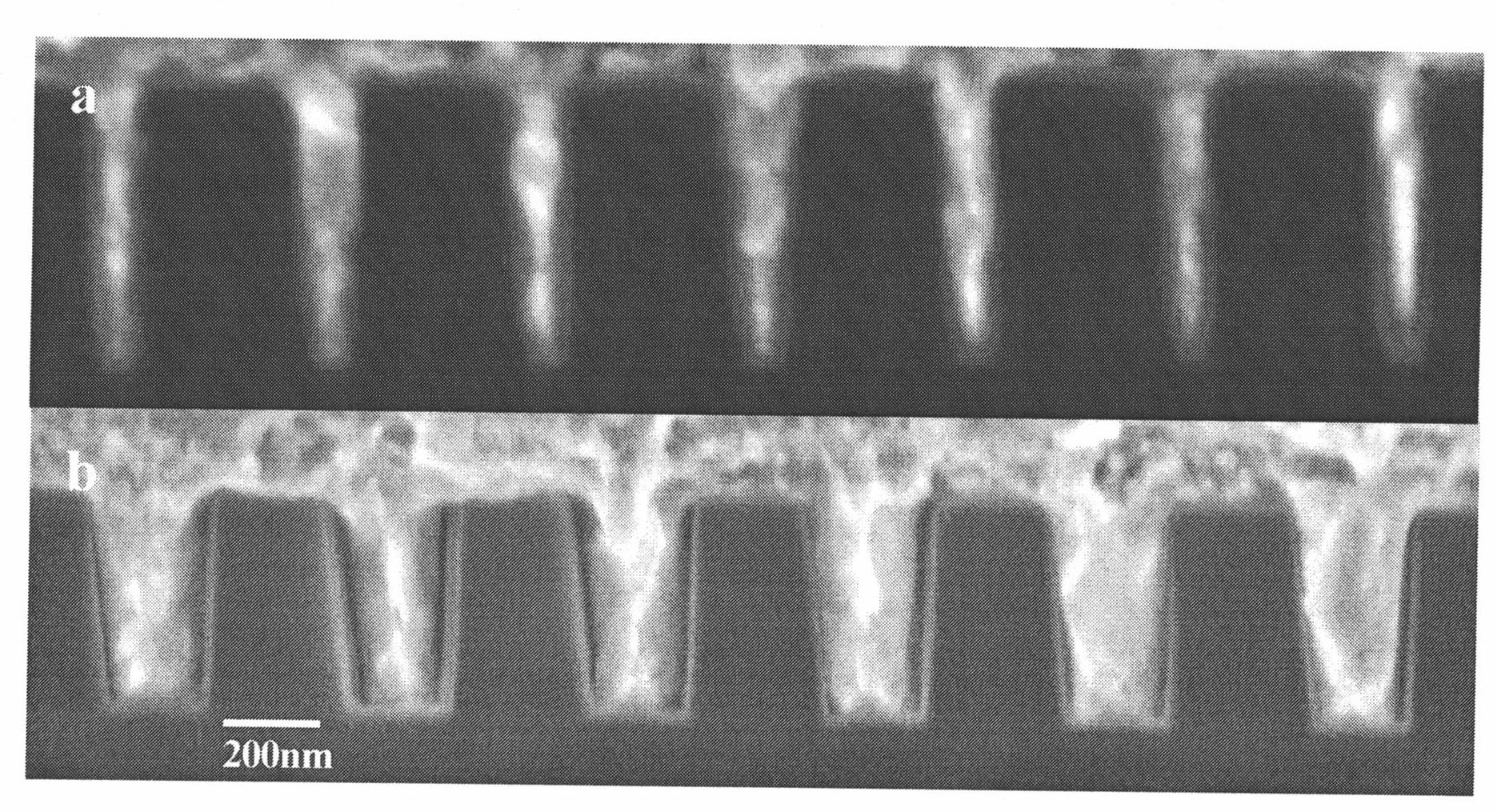

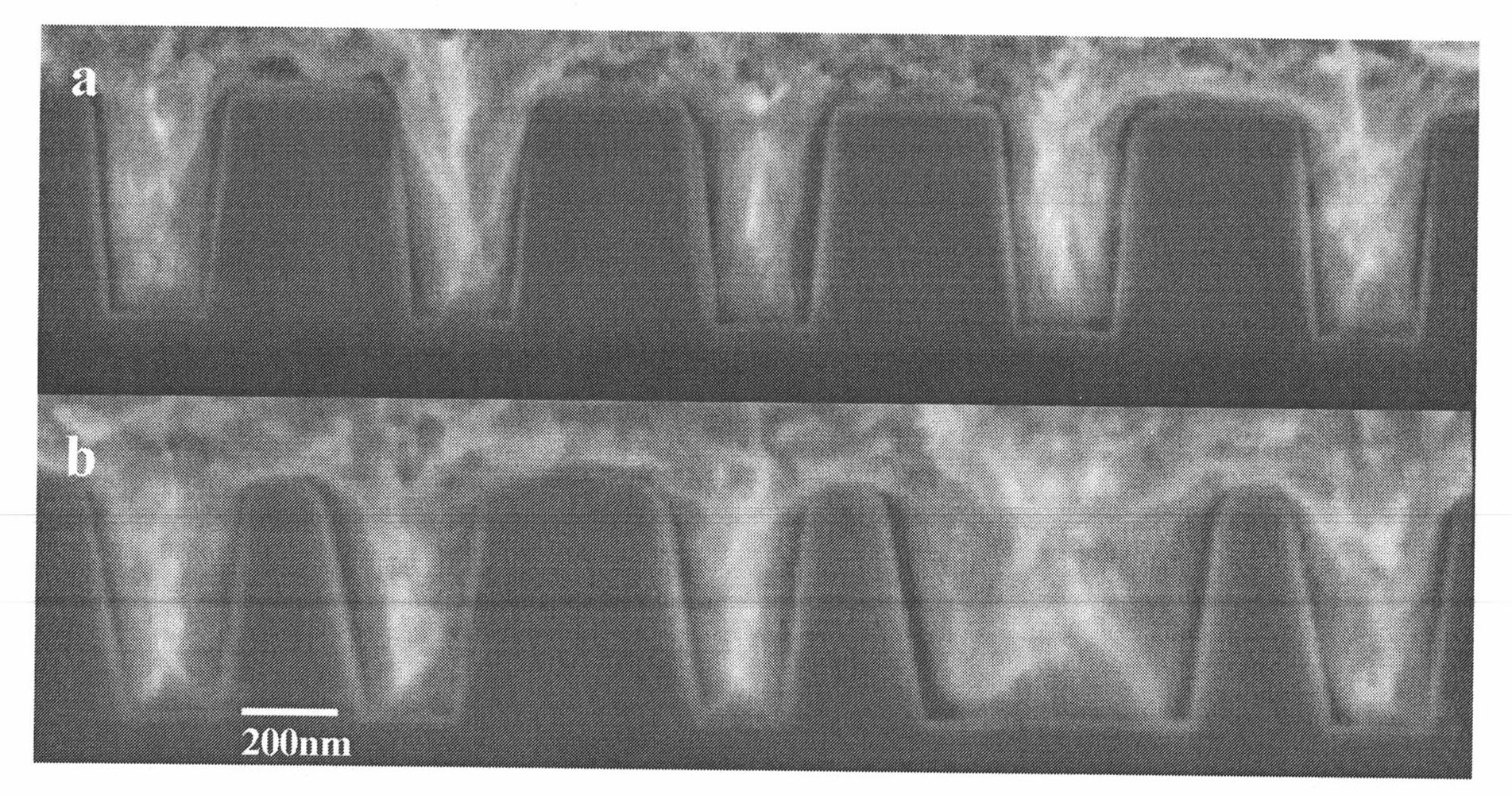

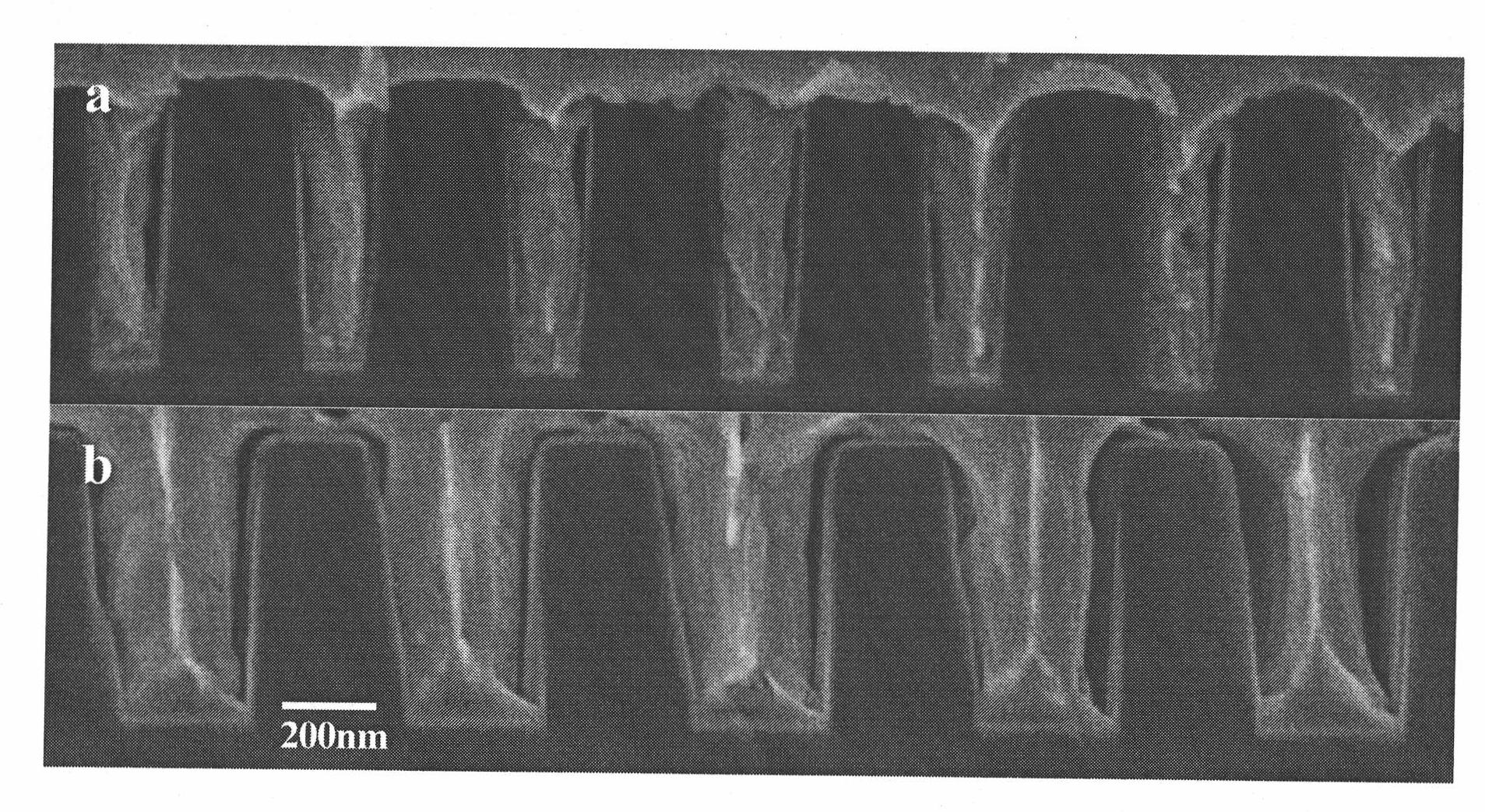

Image

Examples

Embodiment 1

[0028] Taking the preparation of electroless copper plating solution 1L of the present invention as an example, the raw materials used and their mass proportions are:

[0029]

[0030]

[0031] Its preparation method is as follows:

[0032] According to the mass ratio of the above raw materials, add copper sulfate pentahydrate and disodium edetate into the beaker, add 900mL of distilled water until the solids are completely dissolved, then add formaldehyde or glyoxylic acid, and 2- Mercaptobenzothiazole, polyether with an average molecular weight of 3650 at a mass concentration of 4g / L, and an aqueous NaOH solution of 6mol / L were stirred evenly, and the volume was adjusted to 1L with distilled water to prepare an electroless copper plating solution.

Embodiment 2

[0034] Taking the preparation of electroless copper plating solution 1L of the present invention as an example, the raw materials used and their mass proportions are:

[0035]

[0036] Its preparation method is identical with embodiment 1.

Embodiment 3

[0038] Taking the preparation of electroless copper plating solution 1L of the present invention as an example, the raw materials used and their mass proportions are:

[0039]

[0040]

[0041] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com