Ytterbium-doped strontium cerate-alkali metal salt co-melt compound and preparation method thereof

A technology of alkali metal salt and strontium cerate, applied in the field of development of solid fuel cell materials, can solve the problems of limited improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

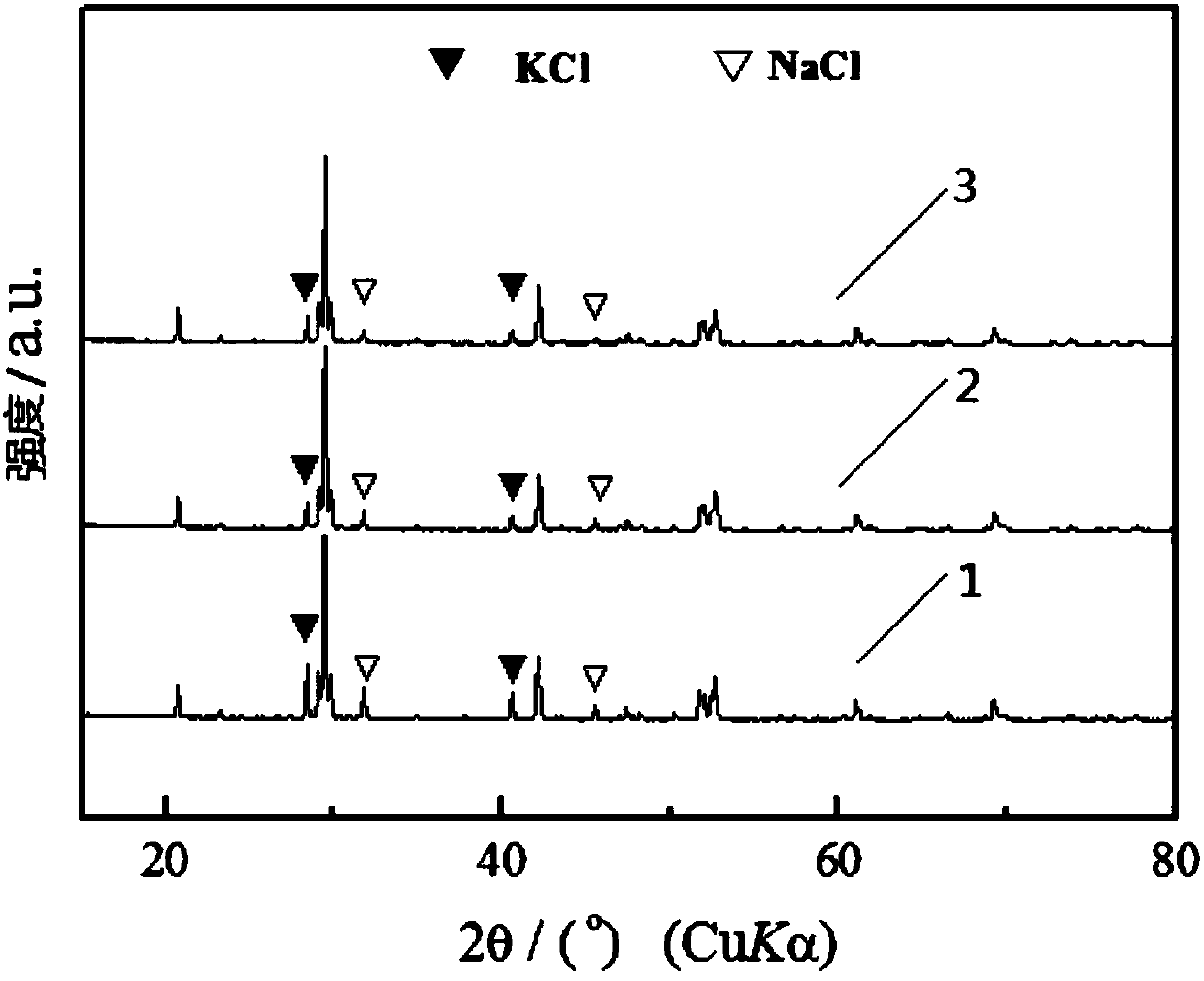

Embodiment 1

[0156] (1) Preparation of ytterbium-doped strontium ceria

[0157] Step 1-1: Weigh 1 mol of strontium carbonate, 0.025 mol of ytterbium oxide and 0.95 mol of cerium oxide, grind and mix, add anhydrous ethanol to a paste after mixing evenly, continue grinding, and wait for the ethanol to evaporate to powder, then continue to add Absolute ethanol, continue to grind, repeat 4 times;

[0158] Step 1-2, firing at 1300°C for 5h and then sintering at 1500°C for 5h to obtain SrCe 0.95 Yb 0.05 O 3-α The open-circuit voltage of the solid fuel cell assembled with the powder as an electrolyte is 1.07V, and the maximum output power density is 12mW·cm at 700°C -2 .

[0159] (2) the preparation of sodium chloride-potassium chloride co-melt

[0160] Step 2-1, weigh 1 mol of sodium chloride and 1 mol of potassium chloride, grind, mix evenly, heat in a box-type resistance furnace, set the temperature to 720°C, heat for about 30 minutes, cool to room temperature, take out, and grind to Fin...

Embodiment 2

[0166] The method used in this example is similar to that in Example 1, except that (1) the amount of ytterbium oxide added in step 1-1 is 0.05 mol, the amount of cerium oxide added is 0.90 mol, and the chemical composition of the product obtained in step 1-2 SrCe 0.9 Yb 0.1 O 3-α , the open circuit voltage of the solid fuel cell assembled with the single ytterbium doped strontium ceria as electrolyte is 1.07V, and the maximum output power density is 18mW cm at 700℃ -2 .

[0167] The solid fuel cell assembled by using the composite obtained in Example 2 as the electrolyte is denoted as SCYb10-NK, its open circuit voltage is 1.07V, and the maximum output power density is 424mW·cm at 700℃ -2 .

Embodiment 3

[0169] The method used in this example is similar to that in Example 1, except that (1) the amount of ytterbium oxide added in step 1-1 is 0.075 mol, the amount of cerium oxide added is 0.85 mol, and the chemical composition of the product obtained in step 1-2 SrCe 0.85 Yb 0.15 O 3-α , the open circuit voltage of the solid fuel cell assembled with the single ytterbium doped strontium ceria as electrolyte is 1.07V, and the maximum output power density is 20mW cm at 700℃ -2 .

[0170] The solid fuel cell assembled by using the composite obtained in Example 3 as the electrolyte is denoted as SCYb15-NK, its open circuit voltage is 1.07V, and the maximum output power density is 615mW·cm at 700℃ -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com