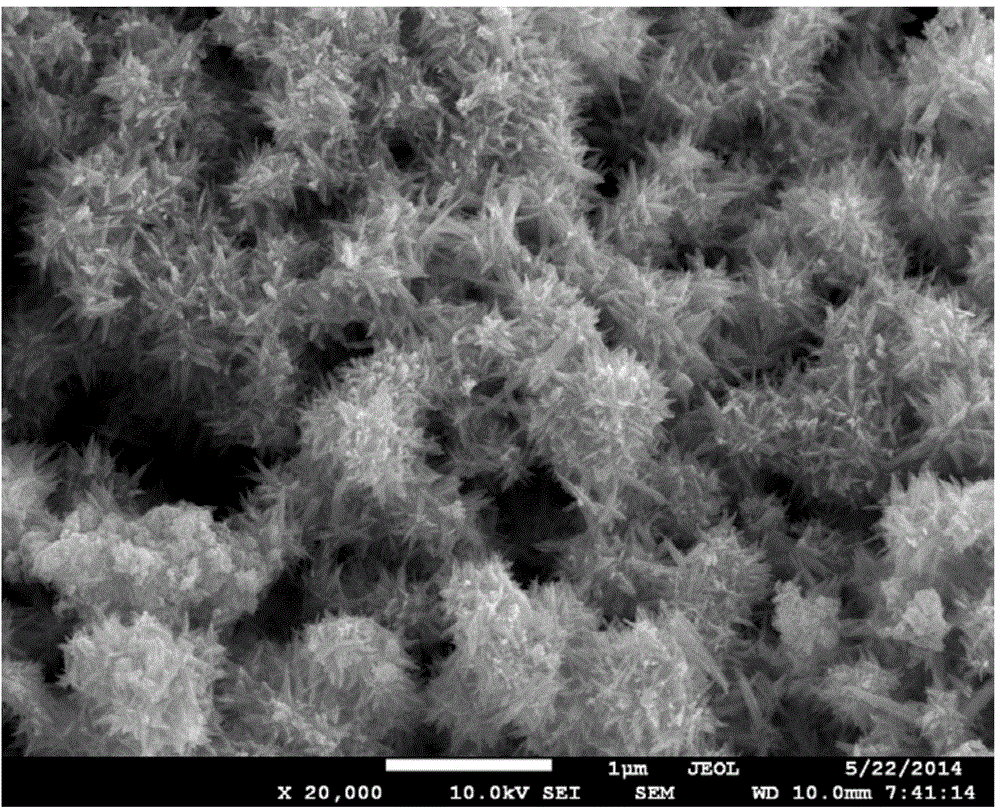

Flower-like nano-WO3/graphene composite gas-sensitive material and preparation method and application thereof

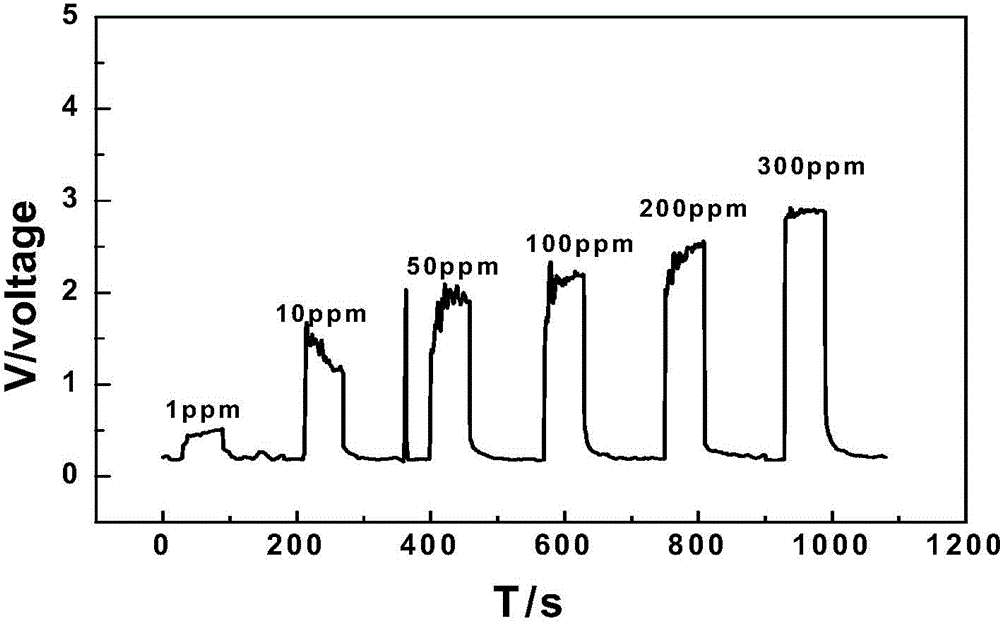

A technology of graphene composite and gas-sensing materials, which is applied in the field of flower-shaped nano-WO3/graphene composite gas-sensing materials and its preparation, can solve the problems of rare aniline gas sensors, and achieve unique morphology, high yield and selectivity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

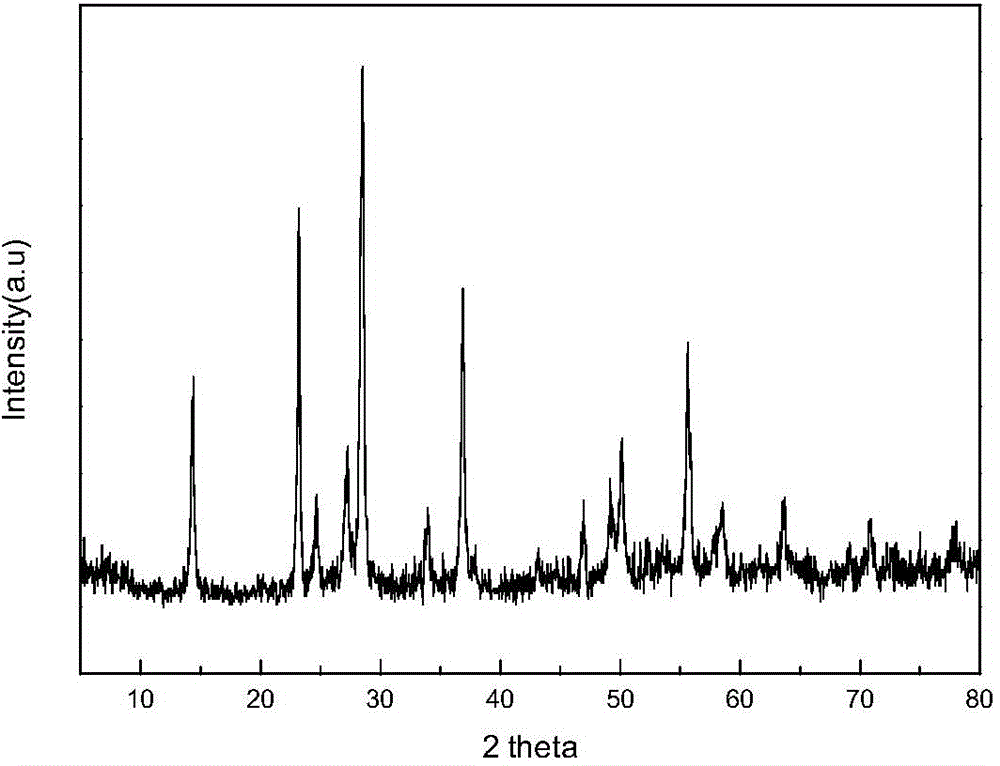

[0029] Flower-shaped Nano WO 3 / Preparation of graphene composite gas sensitive material and gas sensor (i.e. gas sensor)

[0030] 1. Preparation of gas-sensitive materials:

[0031] 1) Take 10ml of 1.146mg / ml graphene oxide solution, add deionized water to dilute to 80ml, ultrasonically disperse for 30min, weigh 2.0g Na 2 WO 4 2H 2 O, 3.40 g Na 2 SO 4 , 1.50g oxalic acid. Add the above-mentioned solid drug into the graphene oxide solution that has been ultrasonically dispersed, place it on a magnetic stirrer and stir evenly for 2 hours until the solid dissolves evenly.

[0032] 2) Add 2M dilute hydrochloric acid dropwise to the above homogeneous solution to make the pH of the solution reach 1.5, and then uniformly stir for 10 minutes. Then the above-mentioned stirred solution was transferred into a reaction kettle and heated by microwave. Set the reaction program, heat up to 180°C in 25 minutes, and hold for 40 minutes. The rotation speed is set to 400r / min, the magn...

Embodiment 2

[0042] Take 15ml of 0.726mg / ml graphene oxide solution, add deionized water to dilute to 80ml, ultrasonically disperse for 30min, weigh 1.5g Na 2 WO 4 ·2H 2 O, 3.00g Na 2 SO 4 , 1.00g oxalic acid. The above-mentioned solid drug was added to the ultrasonically dispersed graphene oxide solution, placed on a magnetic stirrer and stirred uniformly for 2 hours until the solid was uniformly dissolved. 1.5M dilute hydrochloric acid was added dropwise to the above uniform solution to make the pH of the solution reach 1.5, and then uniformly stirred for 20min.

[0043] Then the above-mentioned stirred solution was transferred into the reaction kettle and heated by microwave. The reaction program was set, the temperature was raised to 180° C. in 30 min, and the holding time was 60 min; the rotational speed was set to 450 r / min, the magnetic stirring device was adjusted, and the reaction was started. After the reaction was completed, it was cooled to room temperature naturally, the...

Embodiment 3

[0046] Take 30ml of 0.582mg / ml graphene oxide solution, add deionized water to dilute to 80ml, ultrasonically disperse for 20min, weigh 2.5g Na 2 WO 4 ·2H 2 O, 3.00g Na 2 SO 4 , 1.50g oxalic acid. The above-mentioned solid was added to the graphene oxide solution that had been dispersed by ultrasonic, and magnetic stirring was carried out for 1.5h. 1.0M dilute sulfuric acid was added dropwise to the above homogeneous solution to make the pH of the solution reach 1.0, and then uniformly stirred for 20 min.

[0047] The above-mentioned stirred solution was transferred into the reaction kettle, heated by microwave, and the reaction program was set, and the temperature was raised to 200° C. for 30 minutes, and the holding time was 40 minutes. The rotating speed was set to 400r / min, the magnetic stirring device was adjusted, and the reaction was started. After the reaction was completed, it was cooled to room temperature naturally, the obtained sample was centrifuged, washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com