Method of preparing superfine micro-particle and nano granule

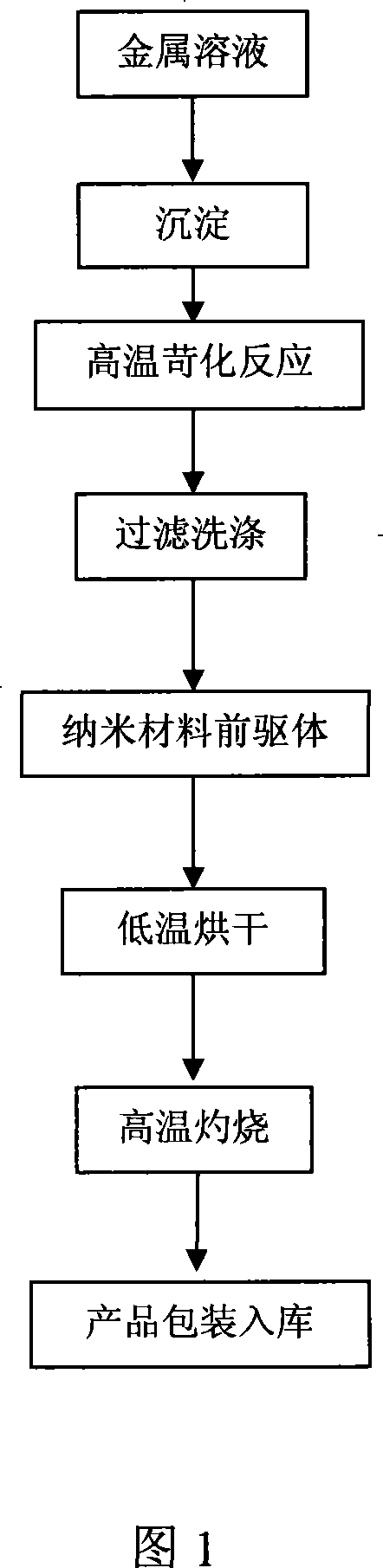

A nanoparticle and ultrafine particle technology, applied in the direction of nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve the problems of unfavorable industrial production, high technical equipment requirements, and low purity of nanoparticles, and achieve easy sedimentation and washing and Filtration, uniform and single shape, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1L of 0.5mol / L yttrium nitrate solution, 1L of a mixed solution of 1mol / L NaOH and 0.5mol / L KOH was added at 25°C as a precipitant, wherein Na + 、K + The total concentration of metal ions is 1.5mol / L, and the amount of precipitant added is 100% of the theoretical amount. Add 240g of NaOH solid and 336g of KOH solid to make the system OH - 6mol / L, heated to 150°C for 2 hours, filtered and washed with water until neutral, dried at 80°C for 1 hour, and burned at 600°C for 1 hour. Yttrium oxide particles were obtained, D50 = 300 nm.

Embodiment 2

[0040] After mixing 1L of 2mol / L lanthanum chloride solution and 1L of 0.5mol / L cerium chloride solution evenly, add 2.8L of mixed solution of 2mol / L ammonia water and 2mol / L ammonium bicarbonate at 80°C for precipitation, in which NH 4 + The total ion concentration is 4mol / L, and the amount of precipitant added is 150% of the theoretical amount. Add 768g of NaOH solid to make the system OH -4mol / L, heated to 130°C for 2 hours, filtered and washed with water until neutral, dried at 150°C for 4 hours, and burned at 900°C for 2 hours. Lanthanum cerium oxide particles were obtained, D50=600nm.

Embodiment 3

[0042] 0.5mol / L samarium europium gadolinium chloride solution 1L, add 0.5mol / L ammonium carbonate and 0.5mol / L sodium carbonate mixed solution 2.25L precipitation at 95 ℃, wherein Na + , NH 4 + The total ion concentration is 2mol / L, and the amount of precipitant added is 300% of the theoretical amount. Add 35wt% liquid caustic soda 190g, make system OH - 0.5mol / L, heated to 95°C for 10 hours, filtered and washed with water until neutral, dried at 220°C for 10 hours, and burned at 1000°C for 10 hours. Samarium europium gadolinium oxide particles were obtained, D50 = 1.2 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com