Patents

Literature

536results about How to "Fully oxidized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

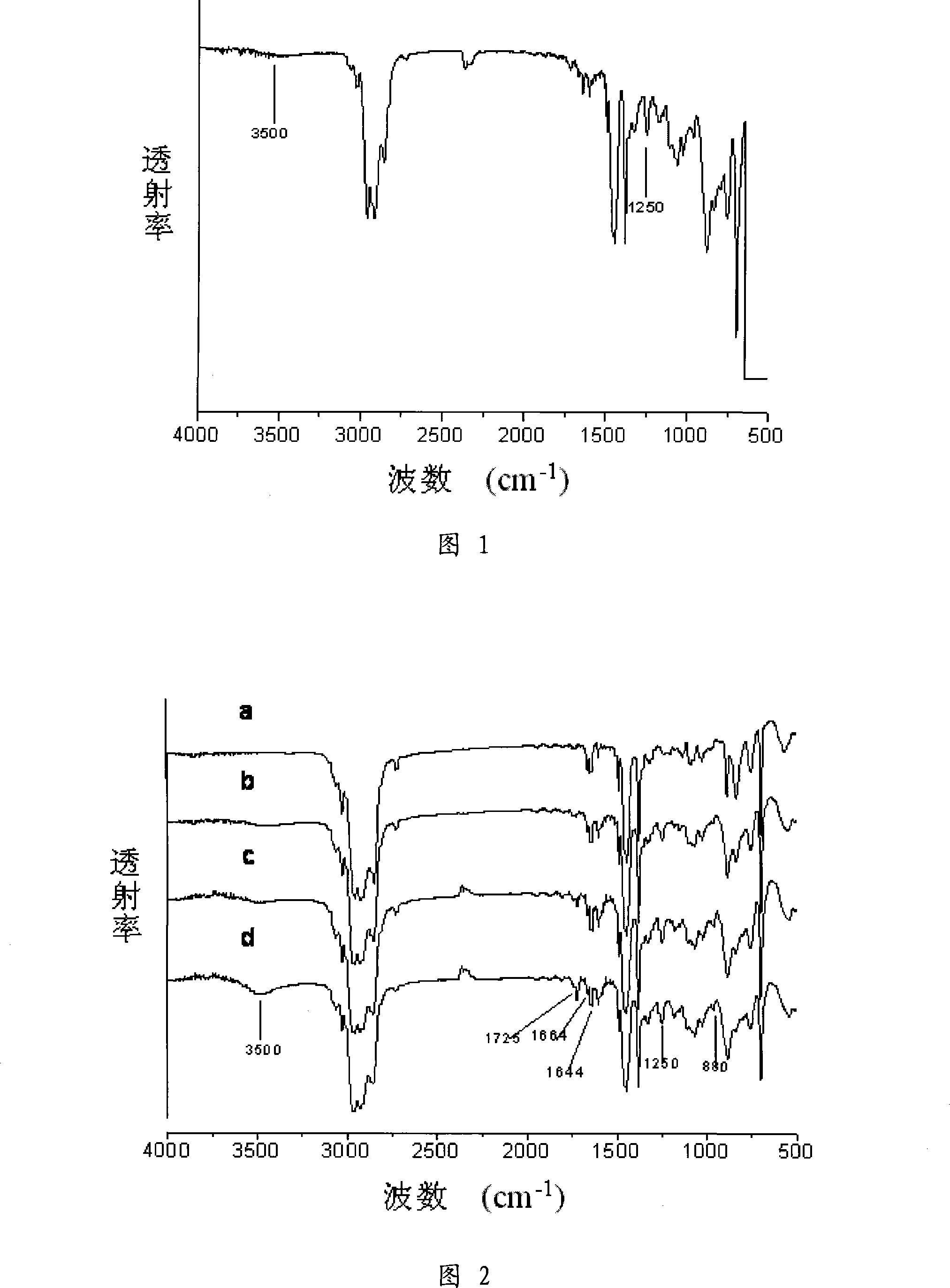

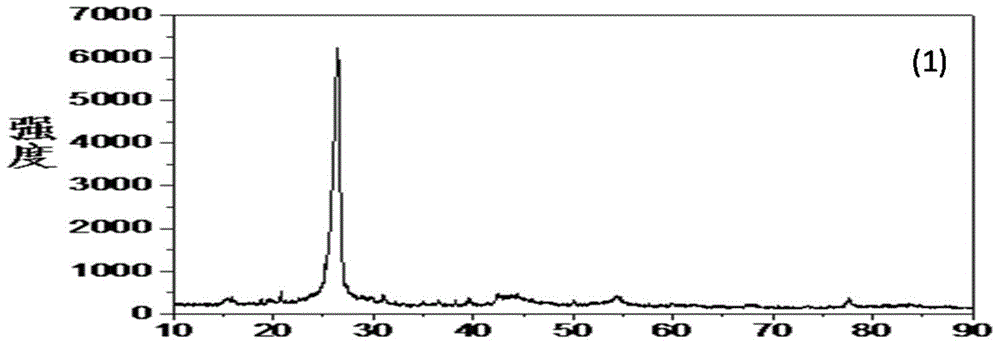

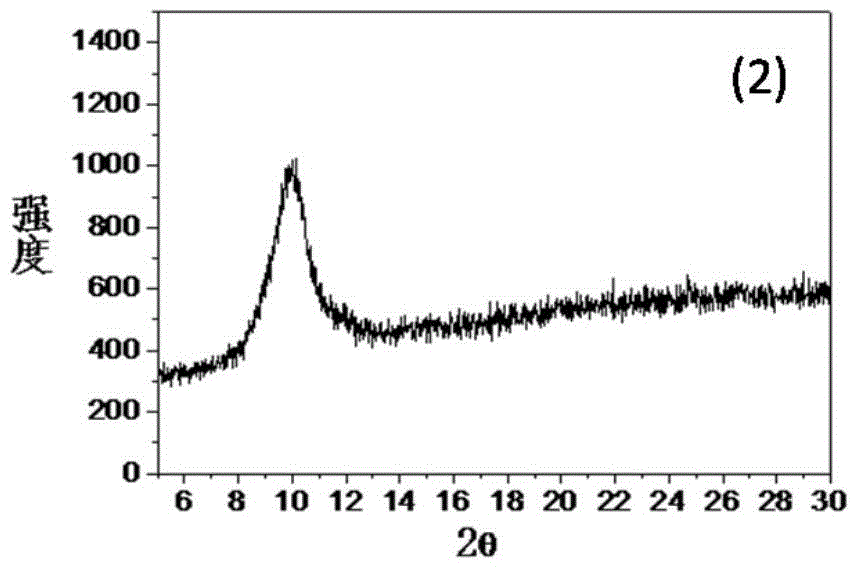

A kind of preparation method of graphene material

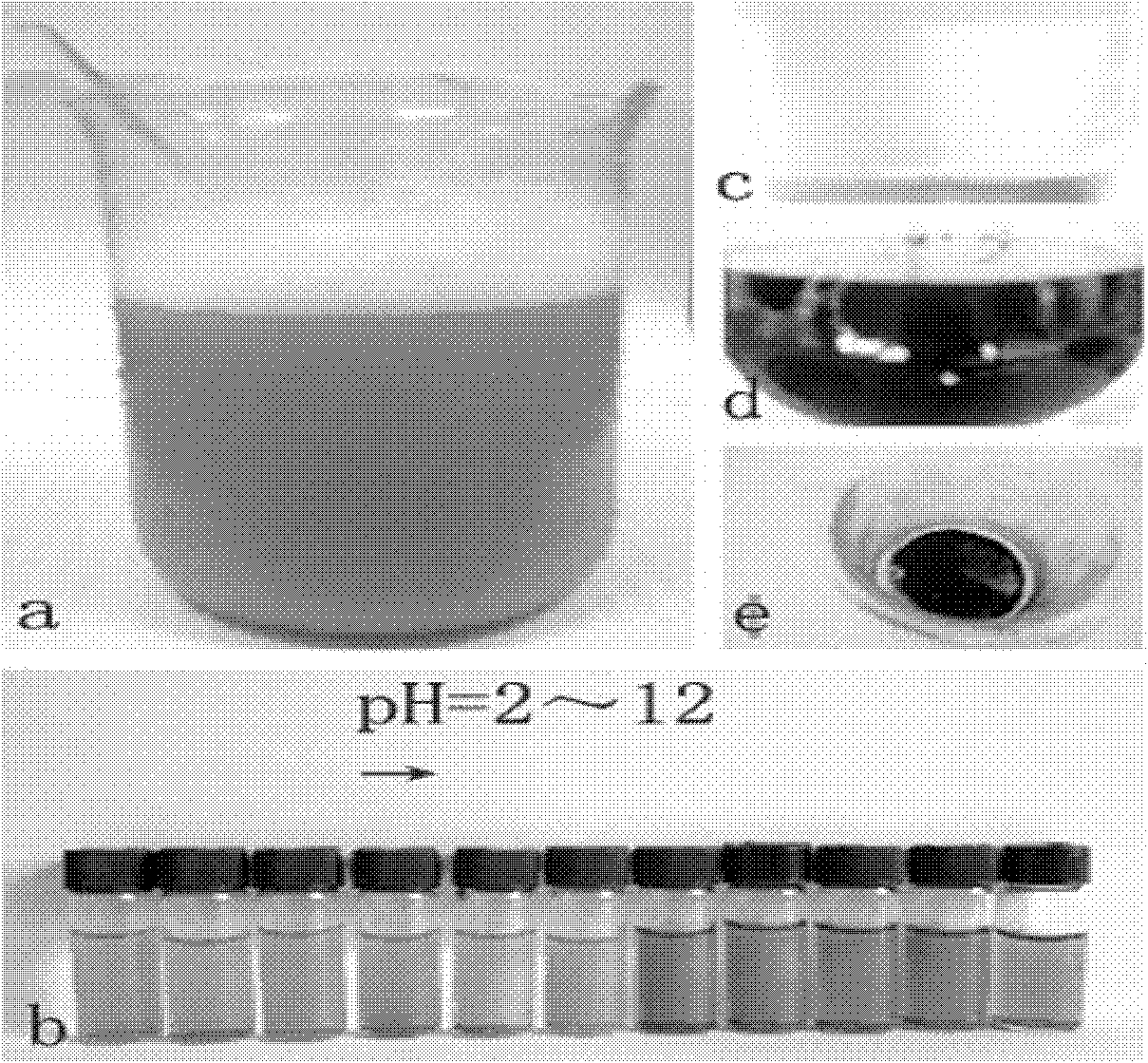

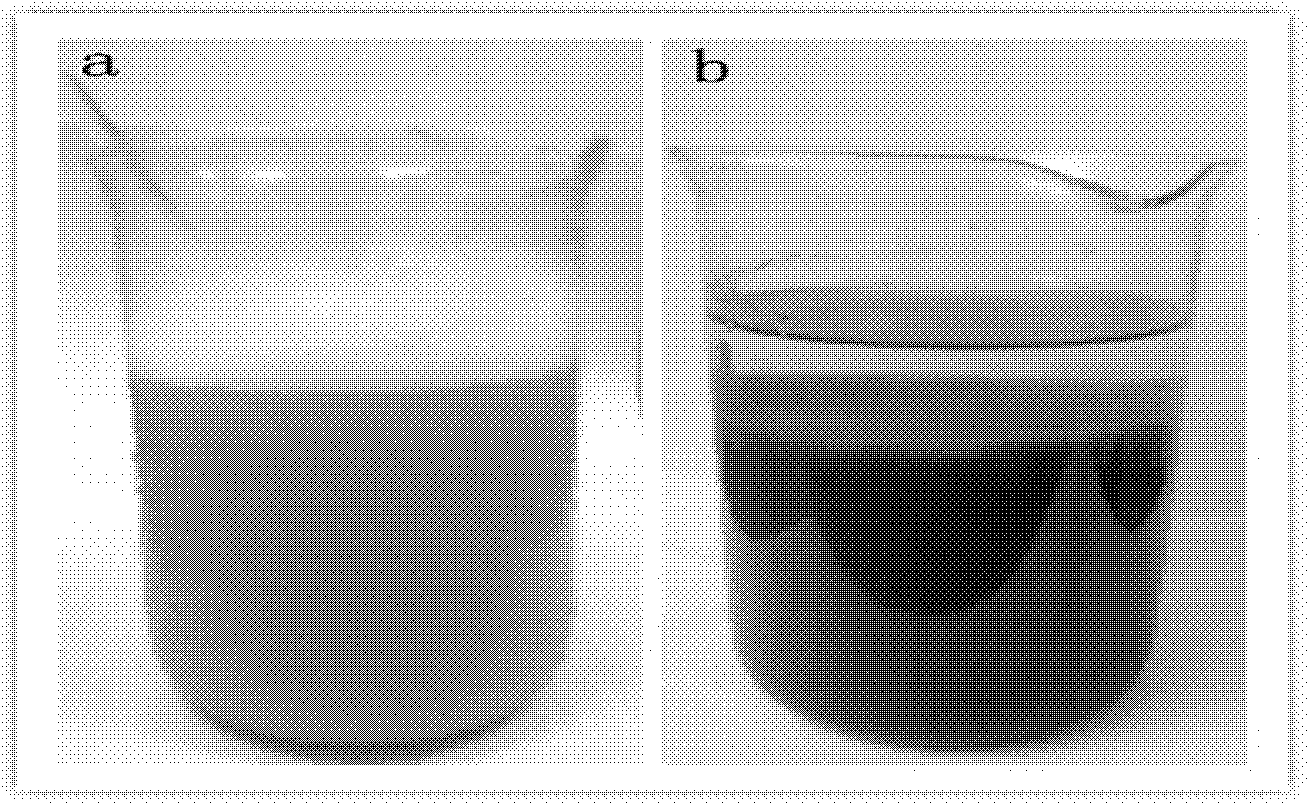

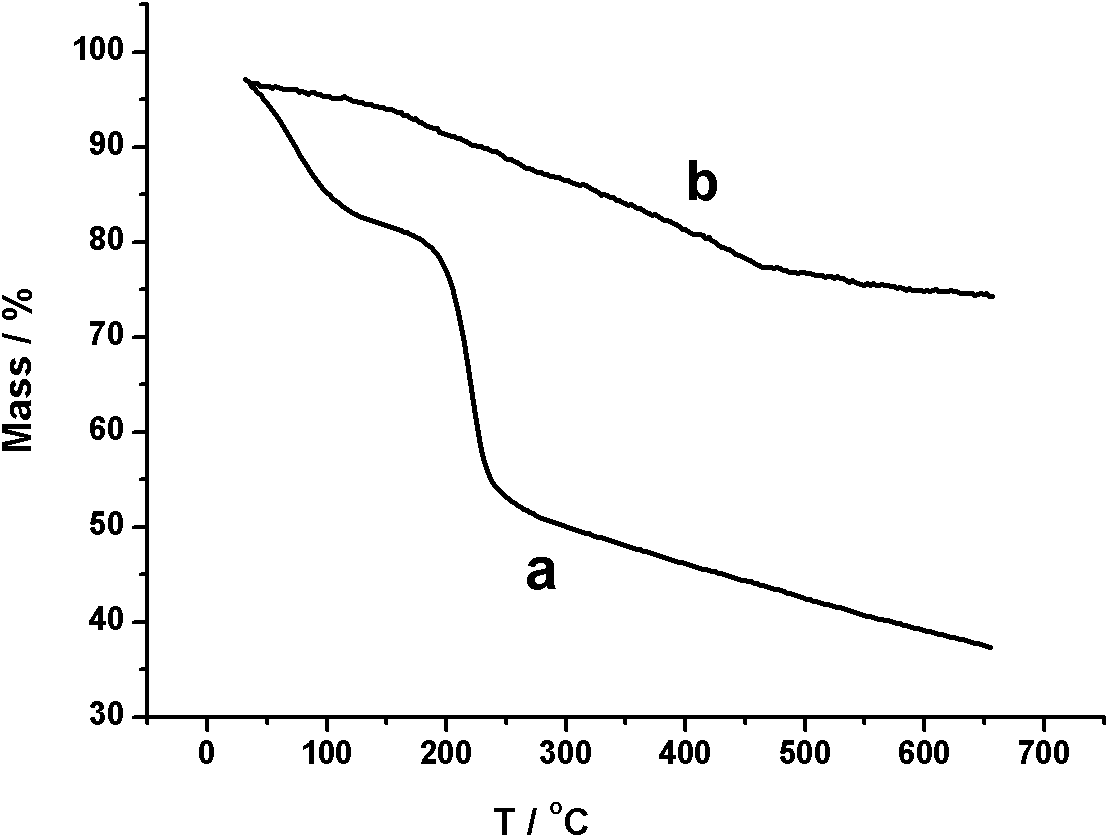

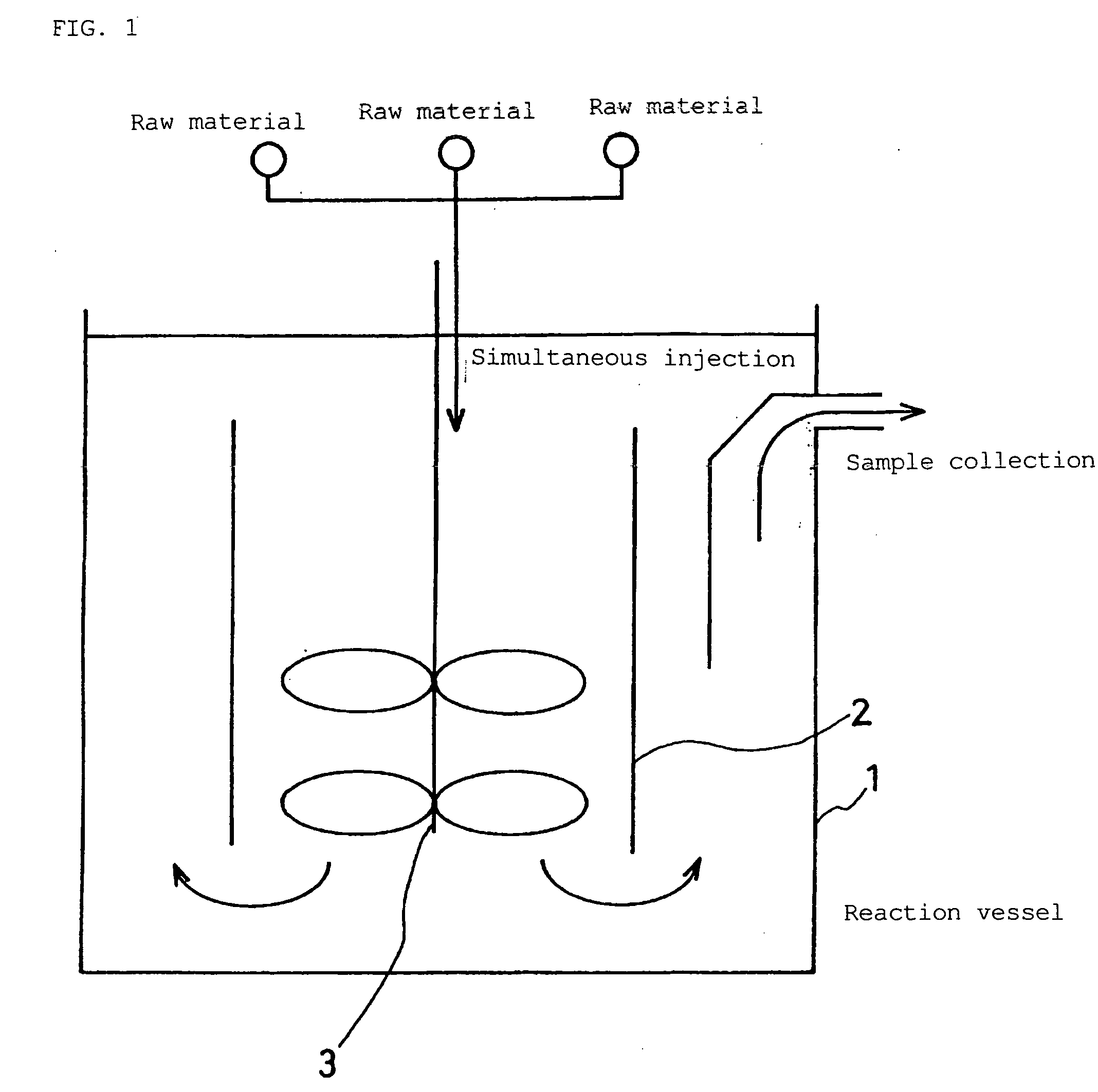

The invention discloses a preparation method of a graphene material. The preparation method comprises the following steps of: with graphite carbon as a raw material, adding potassium hypermanganate and concentrated sulfuric acid in batches in different stages to control an oxidation process of graphite; adjusting the pH value of the oxidized solution to obtain graphene oxide colloidal dispersing solutions (GOS) with different concentrations; dropwise adding the GOS on the surface of a carrier or spreading out the GOS on a non-intersolubility liquid / liquid interface and drawing into a grapheneoxide thin-film (GOF); carrying out high-speed centrifugation and drying treatment on the GOS to obtain graphene oxide solid powder (GOP); reducing the GOS by selecting an appropriate reducing agent,and centrifugally drying to obtain reduced graphene solid powder (GRP); dispersing a proper amount of GRP in an organic solvent to prepare a reduced graphene oxide colloidal dispersing solution (GRS); and dropwise adding the GRS on the surface of the carrier or spreading out on the non-intersolubility liquid / liquid interface and drawing into the reduced graphene thin-film (GRF). Various graphene materials prepared by the invention are easy to mutually transform; and the concentration of the colloidal solution and the thickness of the thin-film can be controlled in a certain range.

Owner:CENT SOUTH UNIV

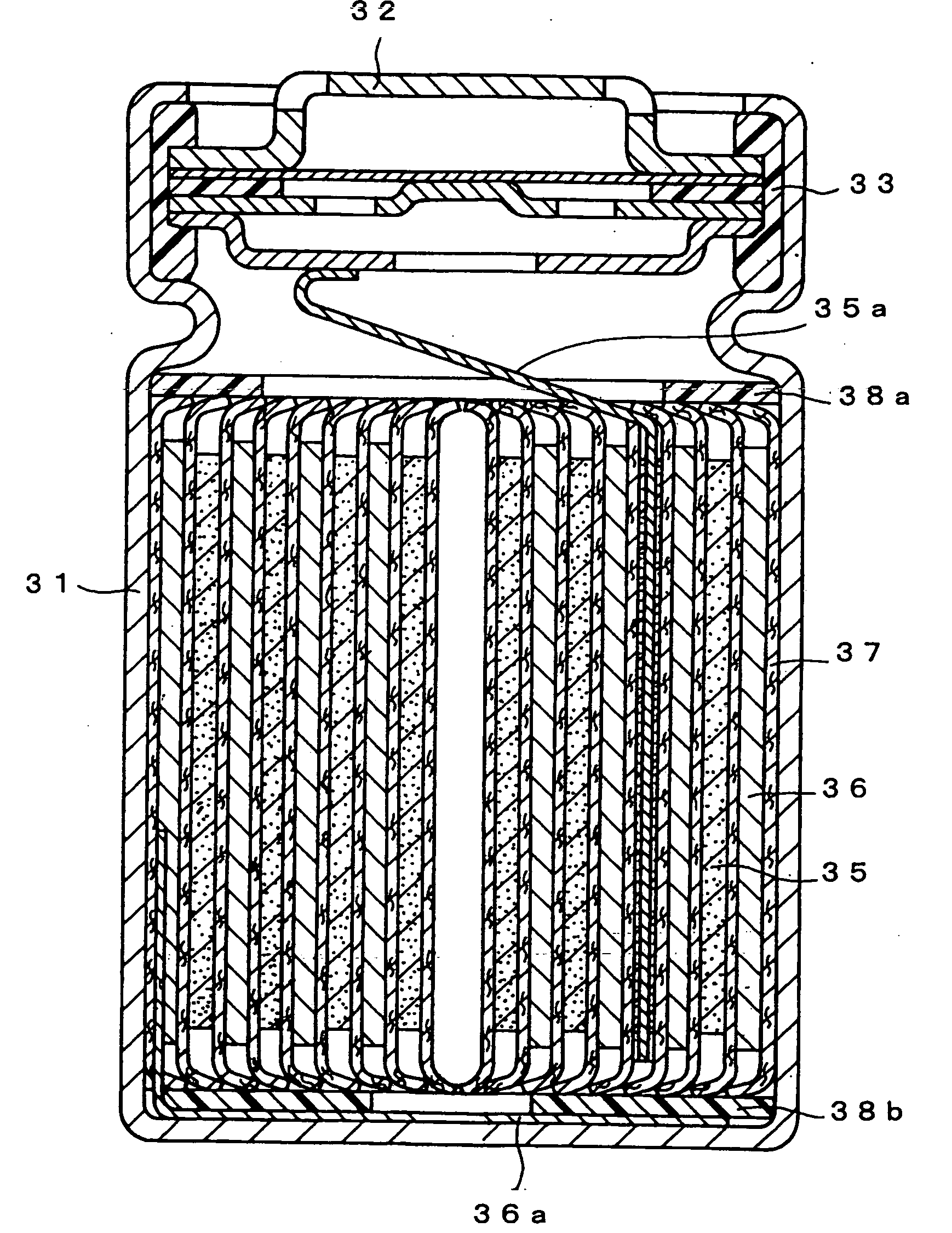

Positive electrode active material for non-aqueous electrolyte secondary battery and method for producing the same

ActiveUS20100112447A1High volume resistivityLow volume resistivityNon-aqueous electrolyte accumulatorsActive material electrodesComposite oxideMaterials science

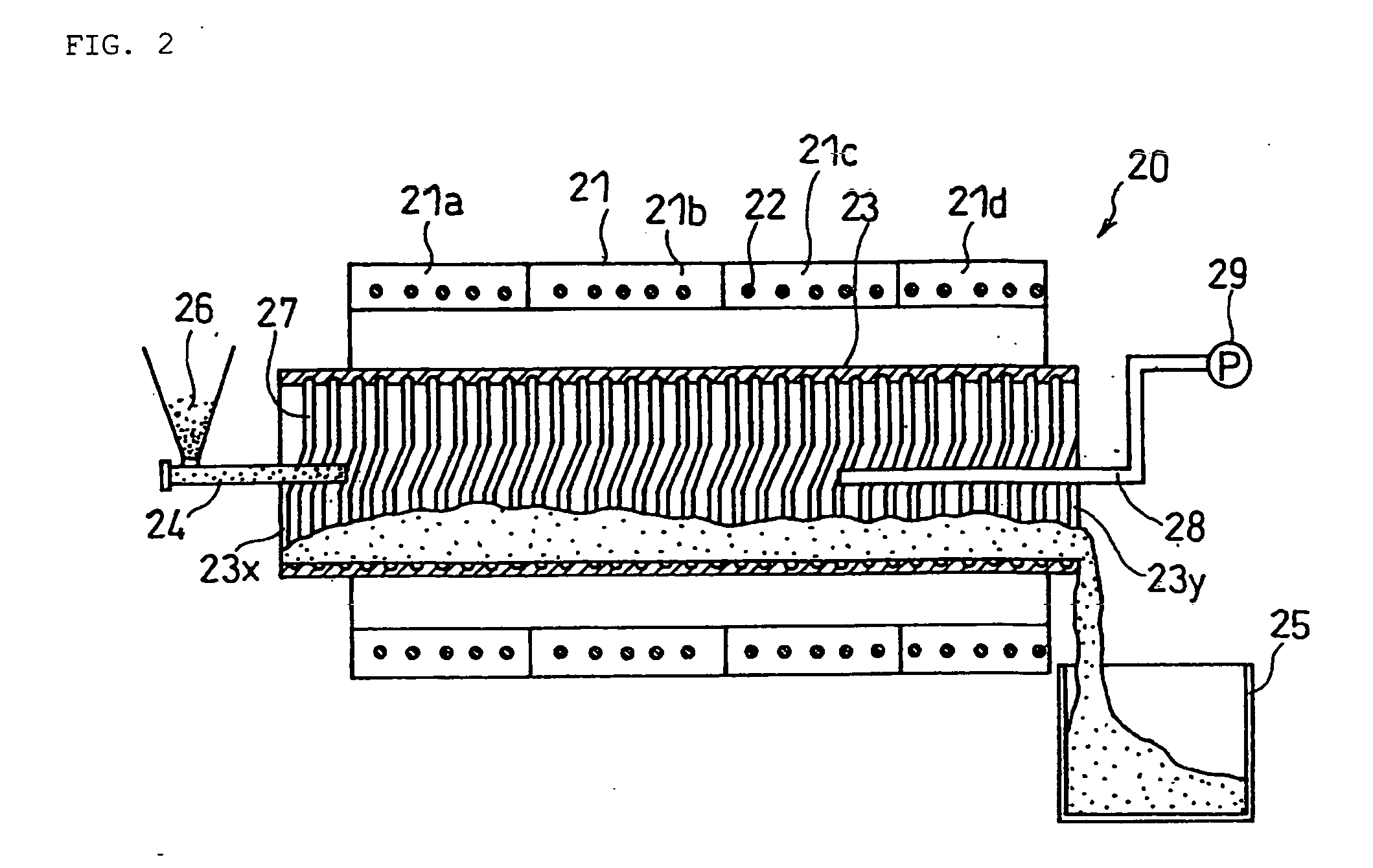

A positive electrode active material for a non-aqueous electrolyte secondary battery is provided. The positive electrode active material includes a composite oxide containing lithium and metal M other than lithium, and M contains Ni, Mn, and Co. The molar ratio of Ni to the total of Ni, Mn, and Co is from 0.45 to 0.65, and the molar ratio of Mn to the total of Ni, Mn, and Co is from 0.15 to 0.35. The positive electrode active material has a pressed density under a compression of 60 MPa of 3.3 g / cm3 or more and 4.3 g / cm3 or less. The positive electrode active material has a volume resistivity under a compression of 60 MPa of 100 Ω·cm or more and less than 1000 Ω·cm.

Owner:PANASONIC CORP

Process for preparing 4,4'-dichlorodiphenylsulfone employing sulfoxide oxidation method

InactiveCN104557626AMeet the synthesis requirementsFully contactedOrganic chemistryOrganic compound preparationSolventHydrogen peroxide

The invention relates to a process for preparing 4,4'-dichlorodiphenylsulfone, in particular to a process for preparing 4,4'-dichlorodiphenylsulfone employing a sulfoxide oxidation method. The process comprises the following steps: carrying out friedel-crafts reaction with chlorobenzene and thionyl chloride under the action of a catalyst to obtain the 4,4'-dichlorodiphenylsulfone; dissolving the obtained 4,4'-dichlorodiphenylsulfone with a solvent; adding hydrogen peroxide and carrying out oxidation reaction to obtain a 4,4'-dichlorodiphenylsulfone crude product; carrying out secondary oxidation refining on the obtained 4,4'-dichlorodiphenylsulfone crude product; and finally preparing high-purity 4,4'-dichlorodiphenylsulfone. The purity of the 4,4'-dichlorodiphenylsulfone purified by the refining process is greater than 99.5%; the refining yield is greater than 98.5%; and the process completely meets the synthesis requirements of high-performance polymers.

Owner:SHANDONG KAISHENG NEW MATERIALS

High-performance silver cadmium oxide material and manufacturing method thereof

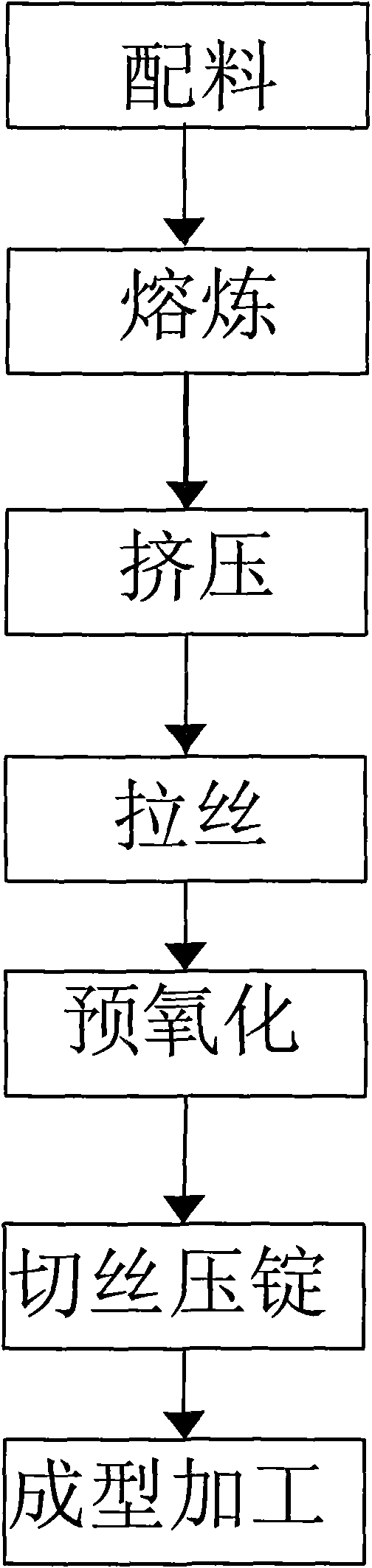

The invention relates to a high-performance silver cadmium oxide material and a manufacturing method thereof, which are characterized in that the silver cadmium oxide material comprises the following components: 85 to 97 percent of silver, 2 to 15 percent of cadmium, 0.01 to 0.5 percent of nickel, 0.01 to 1 percent of tin and 0.01 to 0.5 percent of rear earth mixture. The manufacturing method of the high-performance silver cadmium oxide material is characterized in that: a given quantity of silver, cadmium, nickel, tin and rare earth mixture are measured to be arranged inside a middle-frequency induction furnace to be smelted and cast, the cast ingot is extruded by an extruding machine to be thick wires, the thick wires are stretched by a wire-drawing die to be thin wires, the thin wires are pre-oxidized by an internal oxidization furnace, then the thin wires are cut and preformed and finally is processed and formed. The anti-oxidization performance, electric-arc burning loss resistance and the abrasion resistance of the silver cadmium oxide material are improved, and the service life is prolonged, so the high-performance silver cadmium oxide material can be applied to different working environments, has low production cost, simple manufacturing method and low requirements on the device and the production.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

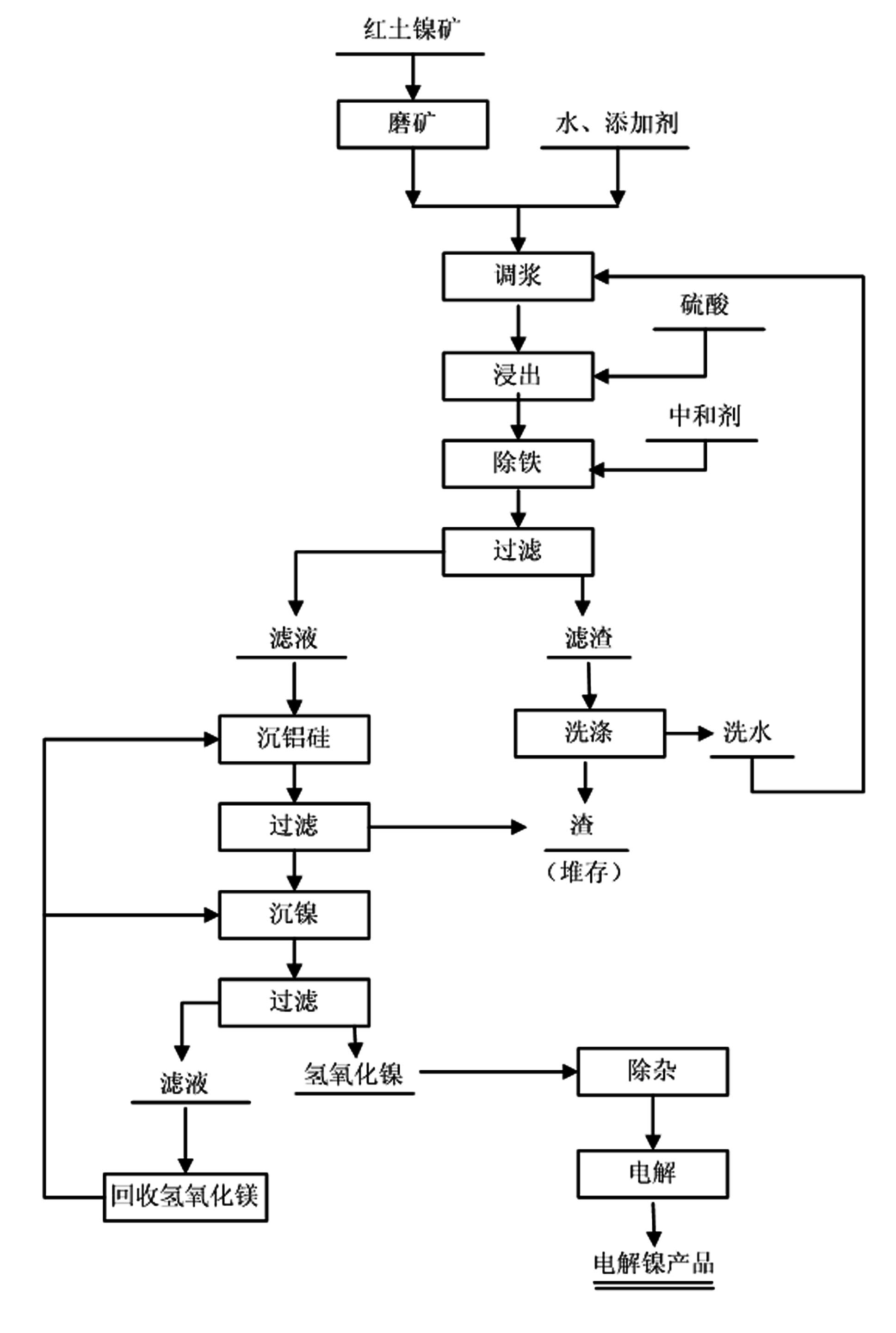

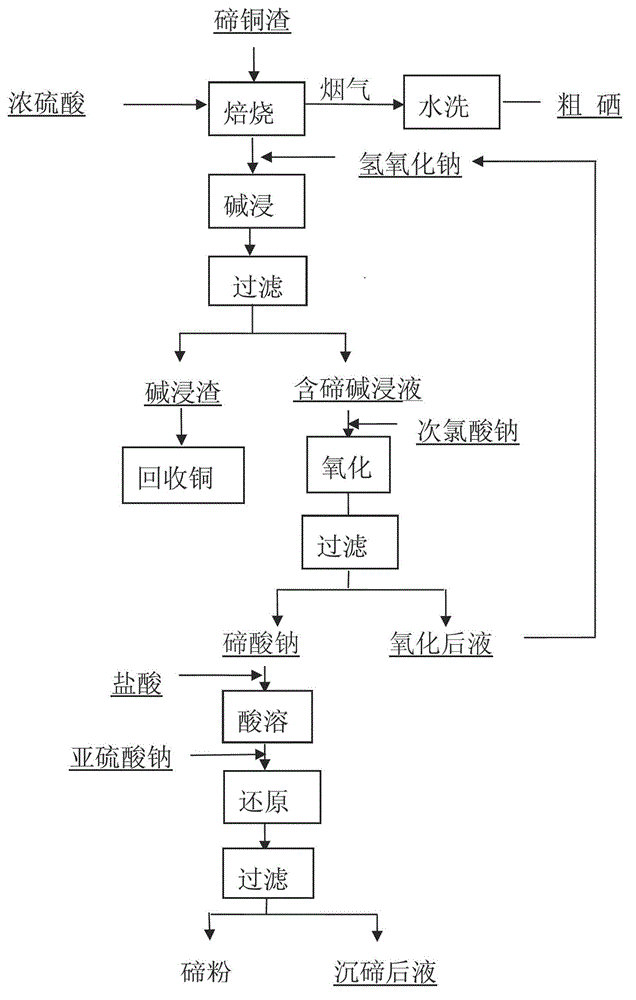

Comprehensive method for processing laterite nickel ore to produce electrolytic nickel through full wet method

InactiveCN102329955AReduce manufacturing costFully oxidizedPhotography auxillary processesProcess efficiency improvementCalcium hydroxideAluminium

The invention provides a comprehensive method for processing laterite nickel ore to produce electrolytic nickel through the full wet process. The invention relates to a method for leaching low-grade laterite nickel ore at atmospheric pressure through sulfuric acid, belonging to the technical field of wet-process metallurgy. The comprehensive method comprises the following steps of: grinding the laterite nickel ore, leaching the laterite nickel ore by using sulfuric acid with acidity of 150-350 g / L under the acid-ore mass ratio of 0.3-1.2:1 at atmospheric pressure, adding a neutralizing agent to adjust the pH value to 3.0 and neutralize the precipitate to remove iron, adding the neutralizing agent into the mother liquid to adjust the pH value to 6.0 and neutralize and remove aluminum and silicon, continuing adding the neutralizing agent into the filtered nickel sulfate solution to adjust the pH value to 9.0 and precipitate nickel hydroxide, redissolving, purifying and electrolyzing the intermediate product of nickel hydroxide to produce the electrolytic nickel product, adding calcium hydroxide into the nickel-precipitated magnesium sulfate solution to neutralize the precipitate, and carbonizing and separating magnesium and calcium to obtain magnesium carbonate. The invention overcomes the defects of long flow, great magniferous sewage amount and difficult treatment in the prior art, magnesium is developed into a product, the production sewage can be directly discharged or recycled, and meanwhile, part of recovered magnesium can be circularly returned to the flow as the neutralizing agent.

Owner:YUNNAN TIN GROUP HLDG

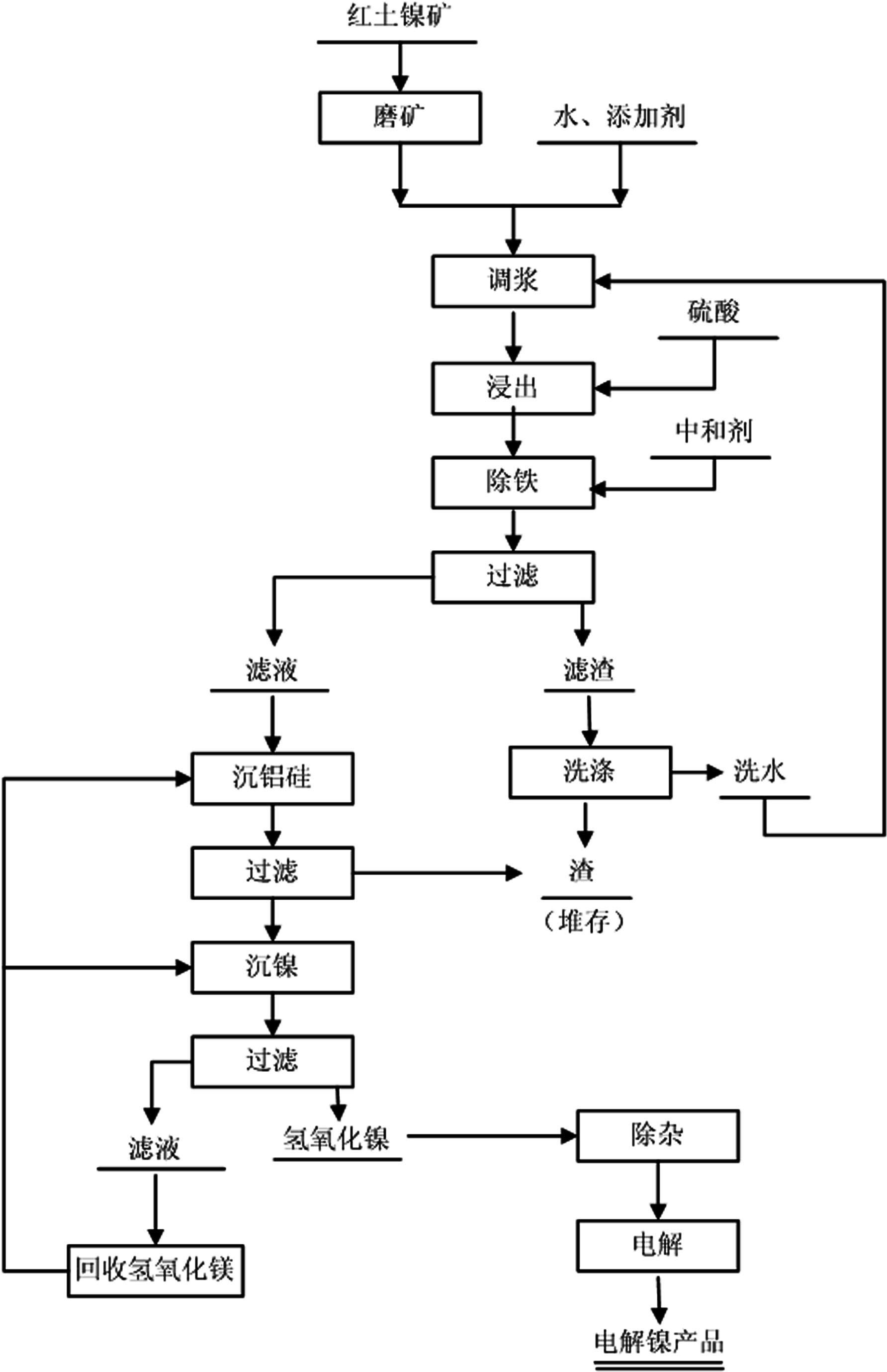

Method for extracting tellurium from tellurium copper slags

ActiveCN102745657AEasy to separateAchieve separationProcess efficiency improvementElemental selenium/telluriumAcid dissolutionCalcination

The invention provides a method for extracting tellurium from tellurium copper slags. The method includes the following steps of (1) sulfating calcination at a high temperature, grinding the tellurium copper slags, mixing ground tellurium copper slags with a concentrated sulfuric acid to calcine, enabling the mass ratio between the concentrated sulfuric acid and the tellurium copper slags to be (1.2-1.5):1, maintaining the calcination temperature in a range from 450 DEG C to 600 DEG C and maintaining the calcination time in a range from 3 hours to 5 hours; (2) alkaline leaching to separate the tellurium, leaching obtained calcination slags by a sodium hydroxide alkaline liquor, and then filtering to obtain a tellurium containing alkali leaching liquid and alkali leaching slags; (3) oxidizing the alkali leaching liquid, oxidizing the tellurium containing alkali leaching liquid by sodium hypochlorite of an oxidant and then filtering to obtain sodium tellurate filtered slags; and (4) acid dissolution reduction, dissolving the sodium tellurate filtered slags by a chloridion containing acidic system, adding a reducing agent to achieve reduction and then filtering to obtain tellurium powders. According to the method for extracting the tellurium from the tellurium copper slags, a complete separation of copper, selenium and tellurium can be fully achieved, a comprehensive recovery of the copper, selenium and tellurium can be achieved, the technological process is simple, tellurium dioxide of an intermediate product is not required, the tellurium powders with a high purity can be directly produced, and the tellurium powders can serve as raw materials of 6N high purity tellurium.

Owner:YANGGU XIANGGUANG COPPER

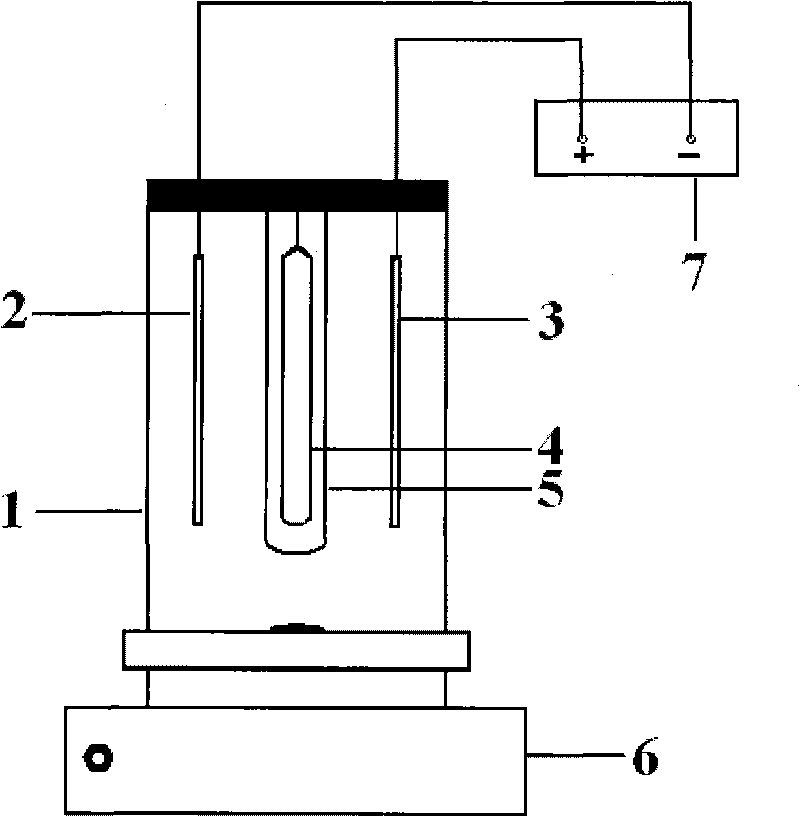

Method for performing electrochemical advanced treatment on landfill leachate based on ultraviolet reinforcement

InactiveCN101734750ALow costStable electrochemical reactionWater/sewage treatment by irradiationHigh concentrationReaction rate

The invention relates to a method for performing electromechanical advanced treatment on landfill leachate containing high-concentration chloride ions based on ultraviolet reinforcement, which belongs to the field of water treatment application. In the method, the biochemical effluent of the landfill leachate is taken as an advanced treatment object; an electrochemical indirect oxidation function (active chlorine produced from the high-concentration chloride ions in the leachate under an electrochemical function serves as a main oxidized group) is mainly utilized; and simultaneously, the active chlorine produced by performing in-situ electrochemistry is subjected to in-situ photodecomposition by introducing ultraviolet light, thereby producing a hydroxyl group, a chlorine free radical and the like with stronger oxidation capacity. The method has the advantages of accelerating reaction rate, simultaneously improving effect on the reduction of the chromaticity of the leachate and the removal of difficultly-degraded organic substances and ammonia nitrogen, so that the treated effluent can reach a set discharge standard.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

High-elastic denim fabric and production process thereof

InactiveCN105401307AMeet the needs of moderate exerciseReduce consumptionMercerising of indefinite length fabricsSingeingYarnFiber

The invention provides a high-elastic denim fabric, wherein PTT fiber filaments and spandex filaments are adopted as core yarns. Fasciated yarns are spun into double stretch yarn core-spun yarns, and then the double stretch yarn core-spun yarns are weaved in a three-upward one-downward right twill-weave mode to form cotton roves. After that, the high-elastic denim fabric is prepared successively through the steps of spinning double stretch yarn core-spun yarns, warping, starch dyeing, singeing, desizing, mercerising and washing finished products. The tensile elastic elongation rate of the high-elastic denim fabric prepared by the above method is up to 53.5% and the tensile elastic recovery rate thereof is up to 92.7%. Meanwhile, through setting the ratio of two types of stretch yarns, stretch yarns of different elastic performances can be obtained to meet different elastic requirements. The current situation that the conventional male denim fabric is not elastic can be changed. Meanwhile, the physical and chemical properties and the wearing comfortness of male denim clothes are improved to a certain degree. The fabric is soft and comfortable in hand feeling, good in shape-retaining ability, high in degree of dyeing and good in color fastness, thereby meeting the moderate sport requirement of men when wearing denim clothes. At the same time, the fabric does not unduly fit, thus having a good development prospect and a large value space.

Owner:FUJIAN SEPTWOLVES IND

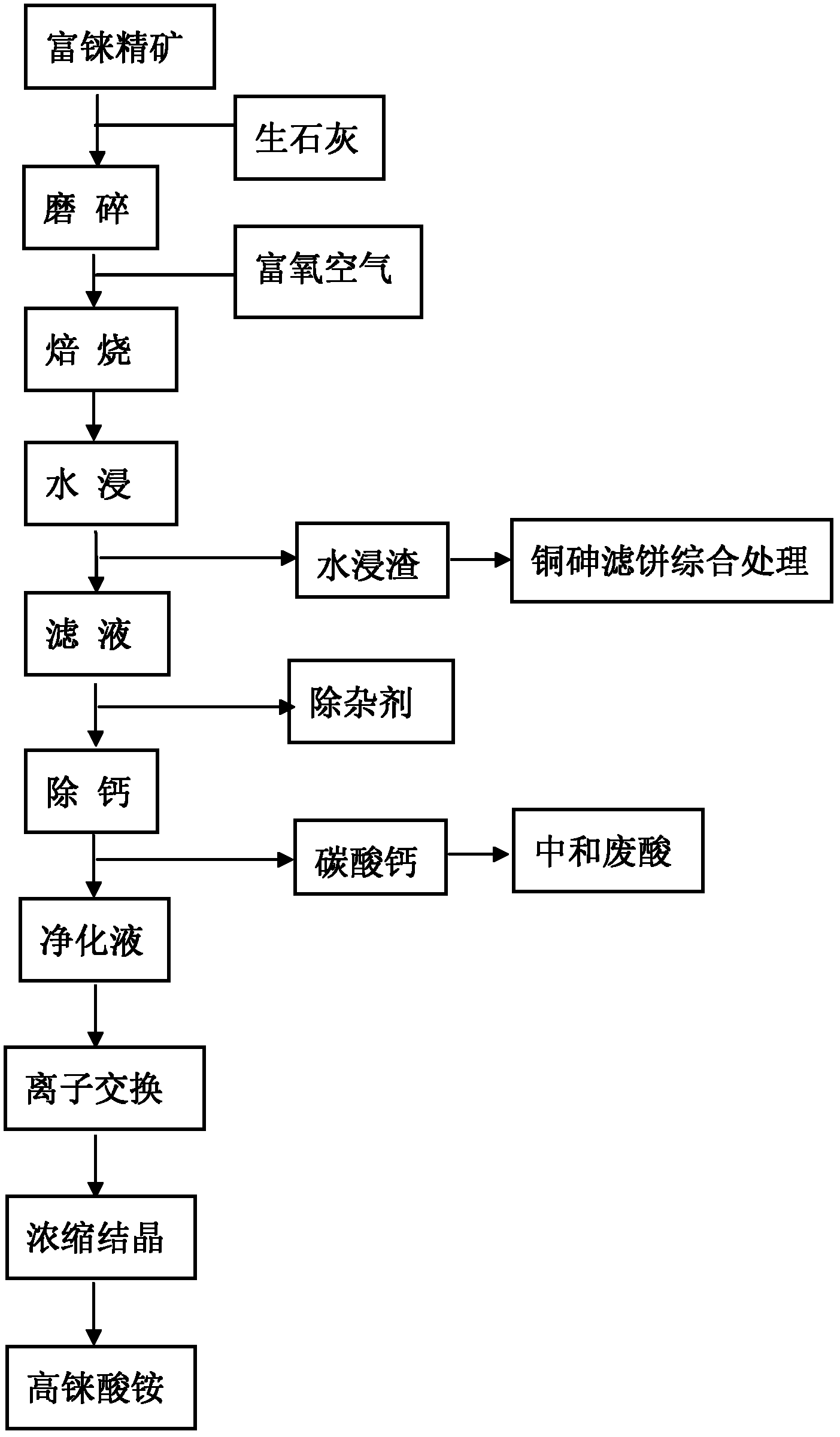

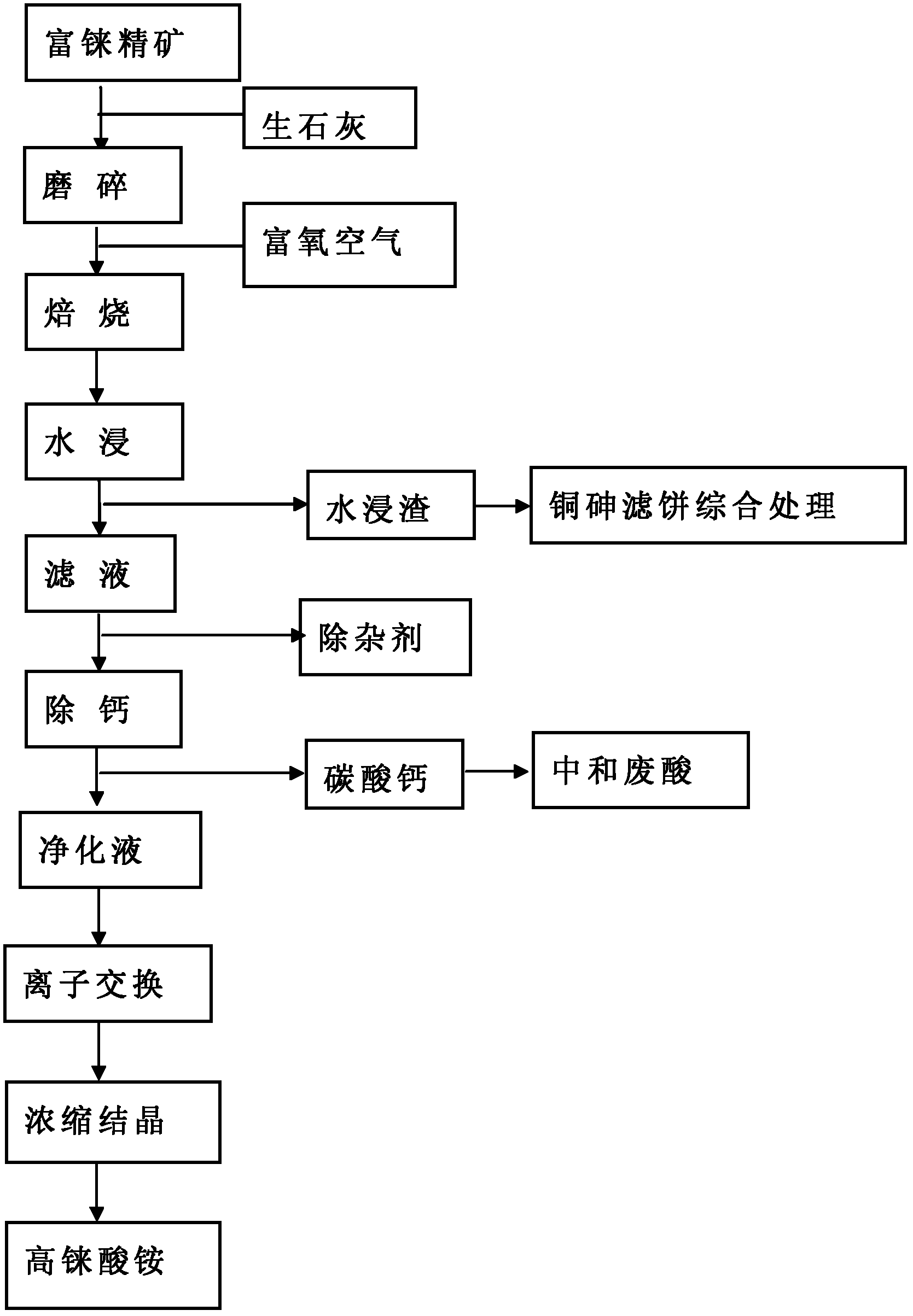

Method for extracting rhenium from rhenium-rich concentrates

ActiveCN102628111AThe effect is thoroughHigh recovery rate of rheniumProcess efficiency improvementIonIon exchange

The invention provides a method for extracting rhenium from rhenium-rich concentrates. The method comprises the following steps of: mixing the rhenium-rich concentrates with quick lime, grinding a mixture, feeding oxygen-enriched air into the mixture, and roasting the mixture at a temperature of 400-900 DEG C; sizing and immersing the roasted mixture by using water, and filtering after the immersion is finished; adding an impurity removing agent into the filtered liquid so as to remove calcium and trace heavy metal ions; filtering after removing impurities; and carrying out ion exchange process on the filtered liquid, which is subjected to impurity removal and filtering, through anion exchange resin, obtaining ammonium rhenate solution after desorption, and obtaining ammonium perrhenate through reconcentration and crystallization. According to the method provided by the invention, quick lime oxygen-enriched roasting and water immersion are used, so that the operations of decoppering, arsenic removal and desulfuration are carried out, therefore rhenium, arsenic and sulfur are oxidized sufficiently under the oxygen enrichment condition; the rhenium, arsenic and sulfur are combined with calcium oxide, so that insoluble substances are generated; the effects of removing copper, arsenic and sulfur are more thorough in the water immersion condition, and the disadvantage that the calcium content is high in the quick lime roasting and water immersion technology is solved through using the impurity removing agent to remove impurities; and the recovery rate of rhenium is high, so that the method provided by the invention is favorable to industrialized application.

Owner:YANGGU XIANGGUANG COPPER

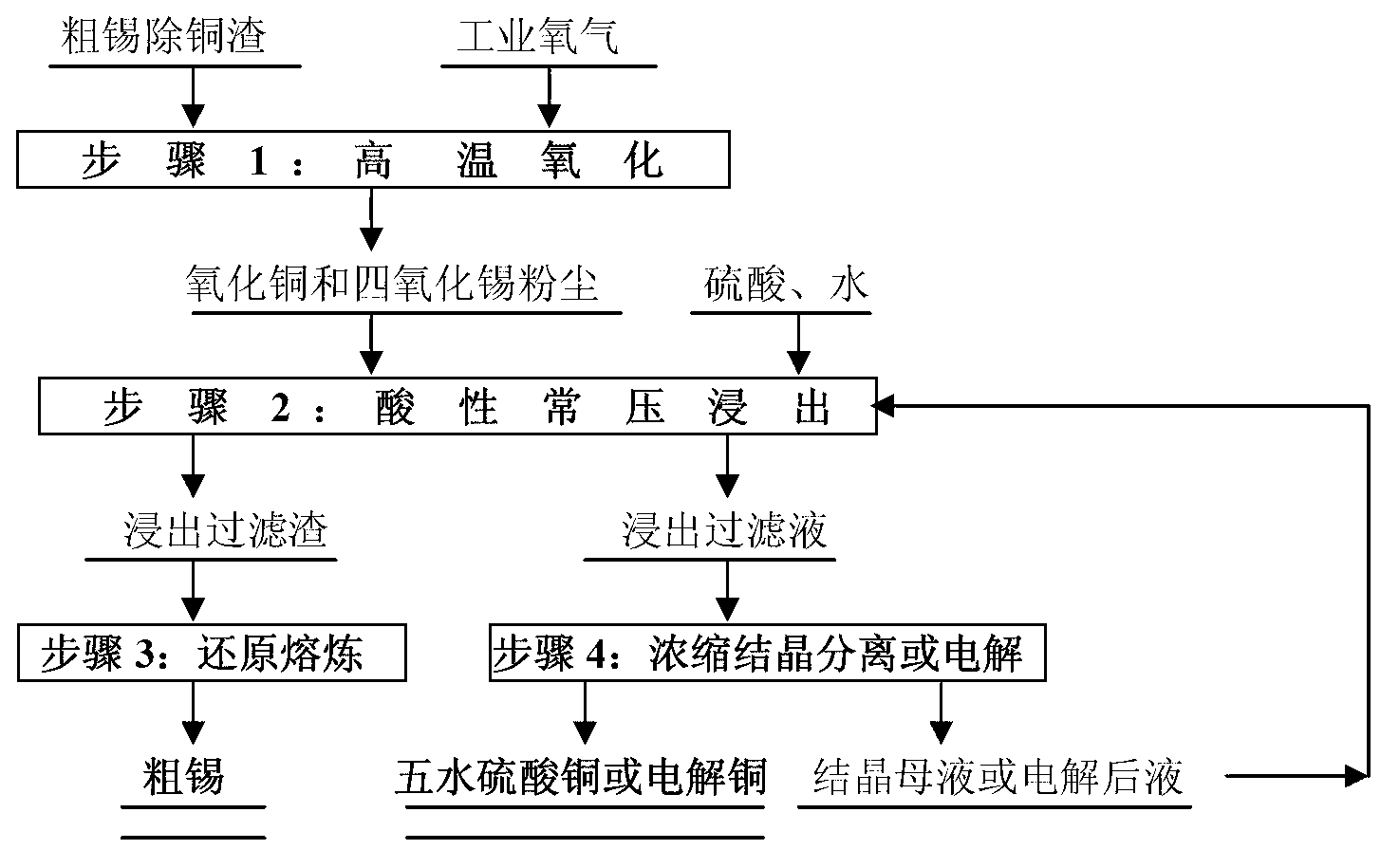

Treatment method of coarse tin decoppered slag

InactiveCN102851514AImprove direct yieldSafe separationProcess efficiency improvementElectrolysisSlag

The invention relates to a treatment method of coarse tin decoppered slag, which comprises the following steps: jetting industrial oxygen with the purity of 93-98.5% to the surface or inside of the coarse tin decoppered slag at the temperature of 850-1250 DEG C until the coarse tin decoppered slag is completely oxidized into copper oxide and tin tetroxide dust; leaching the copper oxide and tin tetroxide dust for 2-3 hours under atmospheric pressure and temperature under the condition of the initial acid of 70-120 g / L to obtain leached filtered slag, and carrying out reduction smelting to produce coarse tin; concentrating the leached filtrate to crystallize, and separating to produce chalcanthite product, or carrying out electrolysis to produce electrolytic copper; and returning the crystallization mother solution or electrolysis solution to the leaching process for solution preparation. The invention can separate tin and copper in the crude tin decoppered slag in a safe and efficient way, and does not generate waste water, waste gas or waste residue.

Owner:LAIBIN CHINA TIN SMELTING

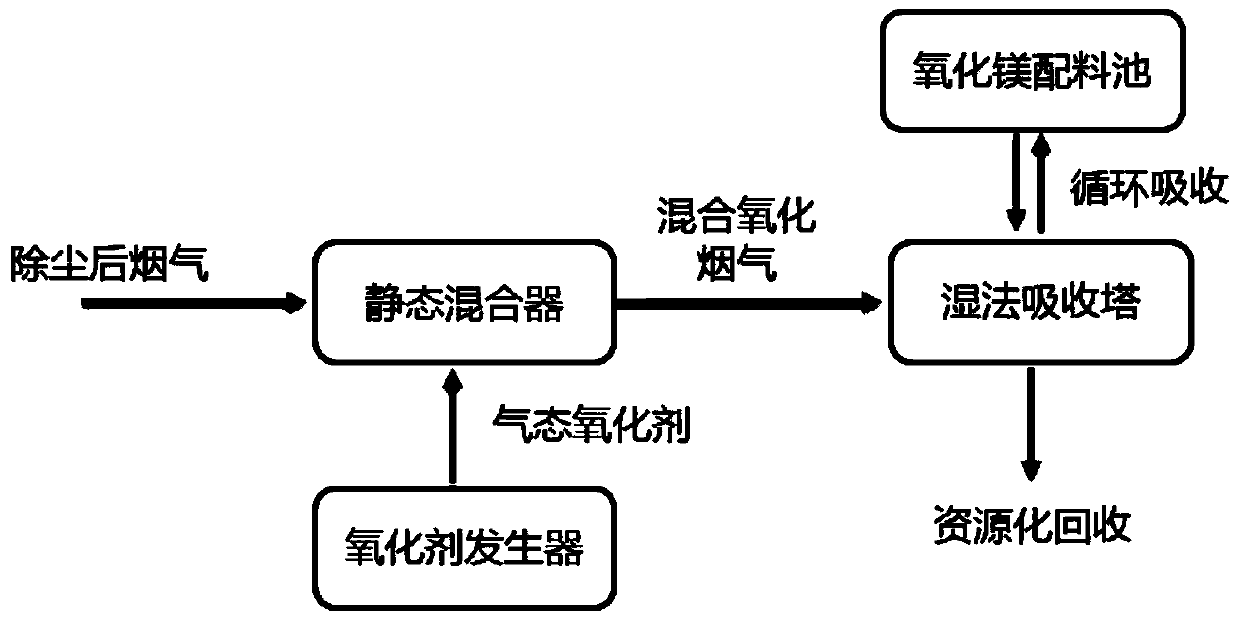

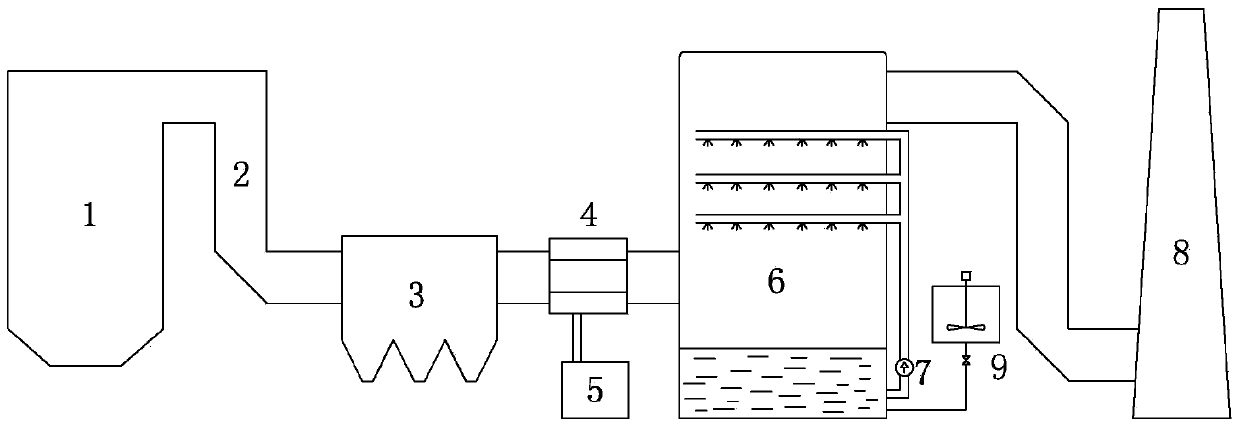

Flue gas treatment method and flue gas treatment device capable of simultaneous desulfurization, de-nitration and mercury removal through magnesium oxide

InactiveCN103736373AFully oxidizedPrevent oxidationDispersed particle separationFlue gasDust control

The invention discloses a flue gas treatment method and a flue gas treatment device for simultaneous desulfurization, de-nitration and mercury removal through magnesium oxide. The flue gas treatment method comprises the following steps: (1) removing dust from boiler flue gas and then transmitting the boiler flue gas into a static mixer, spaying ozone into the static mixer at the same time, mixing and oxidizing the boiler flue gas with the ozone; (2) transmitting the mixed and oxidized mixture gas into an absorbing tower from the bottom part of the absorbing tower, circularly spraying magnesium oxide solution in the absorbing tower; and (3) exhausting the sprayed-absorbed flue gas from the top of the absorbing tower through a chimney. Due to the adoption of combination of oxidization with a gaseous oxidizing agent and absorbing with magnesium oxide solution, the effect of simultaneous desulfurization, de-nitration and mercury removal in one tower is realized, and furthermore, the effects of simultaneous desulfurization, de-nitration and mercury removal are all good.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

White tea and tea cake processing method thereof

InactiveCN105379864AFully oxidizedReduce polyphenol contentPre-extraction tea treatmentFood shapingFlavorBitter taste

The invention relates to the technical field of tea cakes and particularly relates to white tea and a tea cake processing method thereof. According to the white tea, technological parameters and steps in a withering step of a white tea processing process are limited so that the white tea is sufficiently oxidized in a withering process, the content of polyphenols is reduced and the bitter taste is reduced; meanwhile, the defects that more biochemical components are consumed and the taste is light, caused by long-time withering, are also avoided; and on the other hand, phenomena that a biochemical reaction is not sufficient, the tea flavor is light and has a green flavor and the color of tea leaves becomes black are also prevented, the quality of the tea leaves is improved and the nutritional value of the white tea is improved.

Owner:贵州怡壶春生态茶业有限公司

Eggshell Ru porcelain and production process thereof

InactiveCN103193465AIncreased Strength and Thermal StabilityHigh strengthClaywaresVolatile organic compoundOrganic matter

The present invention relates to eggshell Ru porcelain and a production process thereof. According to the eggshell Ru porcelain, 5%-10% of kaolin, 35%-45% of Banpo clay, 11%-23% of Tanggou clay, 20%-25% of black soil, 6%-7% of feldspar and 6%-8% of quartz are used as green body materials. The contents of Al2O3 and SiO2 in the raw material are relatively high, and strength and thermal stability of porcelain can be effectively improved, so that the porcelain is firm and durable and lays a good foundation for eggshell. In the production process, a molded body is subjected to refining and polishing, so the refined porcelain is delicate and smooth, and light and exquisite. An ethanol solution with a content of 5%-15% is used for wiping green bodies, and the purpose is to make the green body surfaces to contain a small amount of combustible and volatile organic compounds, so that the porcelain can be sufficiently oxidized during firing, water and organic matter in the body are promoted to be discharged, the green bodies shrink normally, and the strength of the eggshell Ru porcelain is improved.

Owner:胡忠成

Boiler coke eliminating agent

InactiveCN1487262AReduce dosageEasy to useTreatment using complexing/solubilising chemicalsFlush cleaningMagnesium nitrateCopper nitrate

The present invention relates to the technology of cleaning the inner wall of boiler with chemical solution. The chemical solution consists of potassium nitrate, copper nitrate, magnesium nitrate, aluminum nitrate and boric acid; and it may be jetted via the observation hole to the flame area of operating boiler or sprayed to the surface of formed coke of idle boiler.

Owner:戴琦

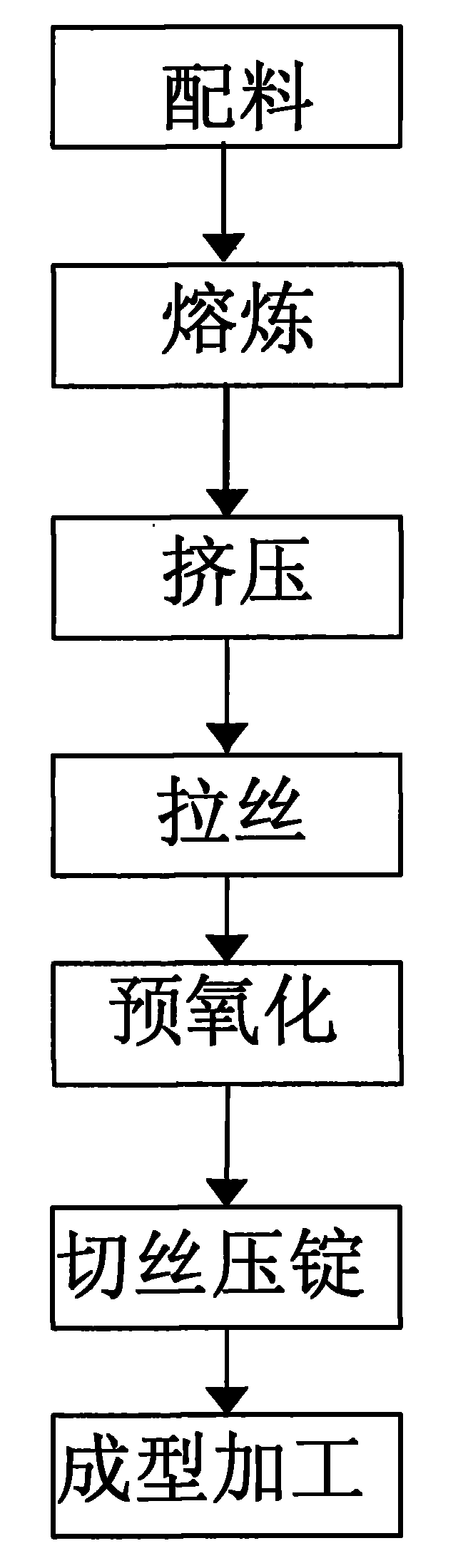

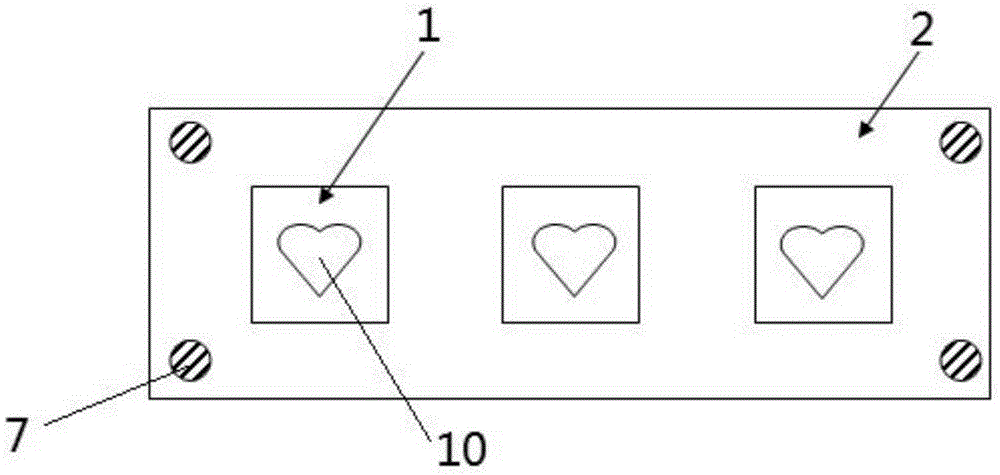

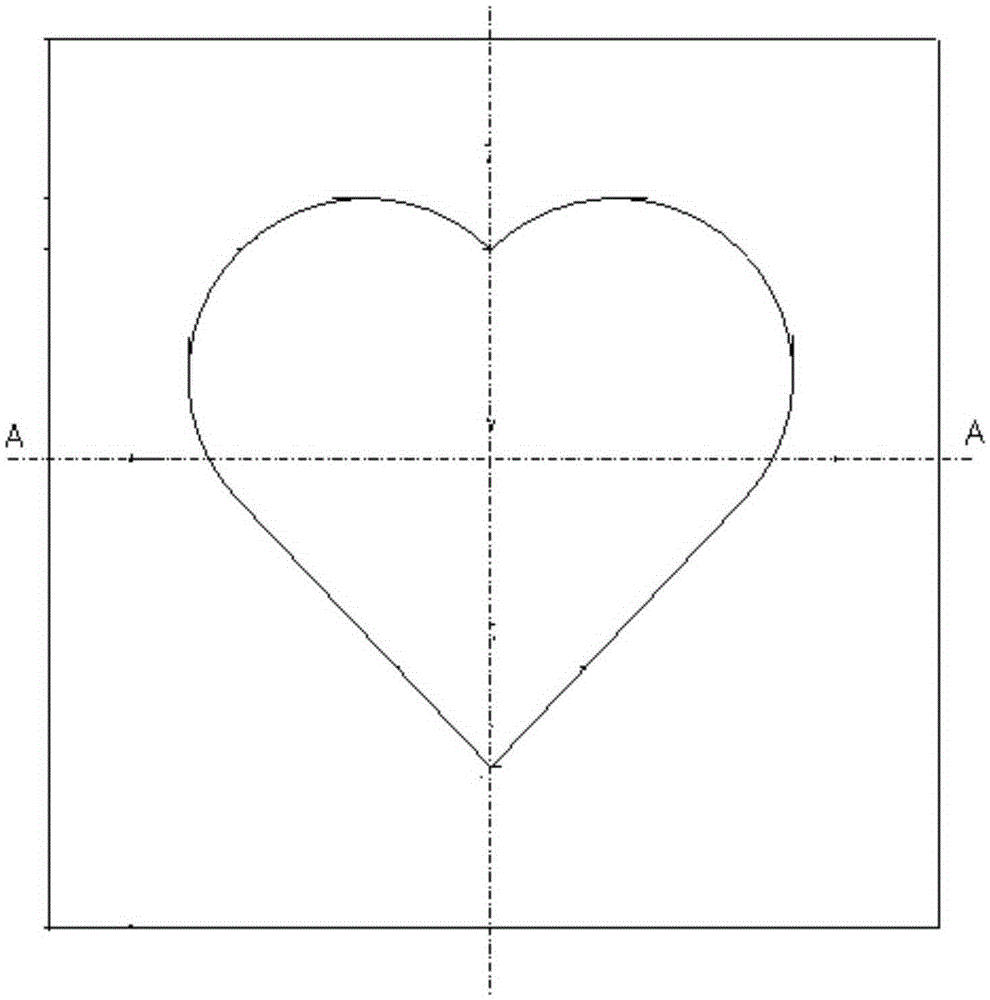

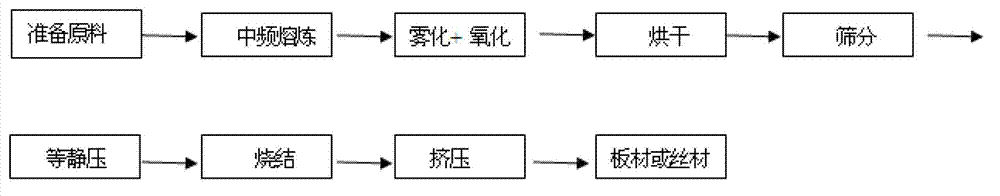

Method for preparing silver tin oxide material

The invention provides a method for preparing a silver tin oxide material. The method comprises the following steps: (1) preparing raw materials, wherein the raw materials are base stocks or mixture of the base stocks and additives; (2) performing intermediate frequency smelting on the raw materials, and performing oxidation treatment while water atomization is performed to obtain alloy powder; (3) drying and sieving the alloy powder, and enabling the alloy powder to form an isostatic pressing ingot blank after isostatic pressing; and (4) burning the isostatic pressing ingot blank in a hydrogen heating furnace, performing thermal extrusion on the burnt ingot blank, and extruding panels or wire stocks made of silver tin oxide materials. By means of the method for preparing the silver tin oxide material, oxidization is finished in an atomization process, the oxidization of the powder is full, the tissue is even, and processing performance of the material is improved; the content of oxide in a material system can be improved to 20%, and using requirements of large-current electrical equipment are met; and the preparation method of the material is free of environment pollution, the technological process is easy to control, the production period is short, and stable large-volume production can be achieved.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

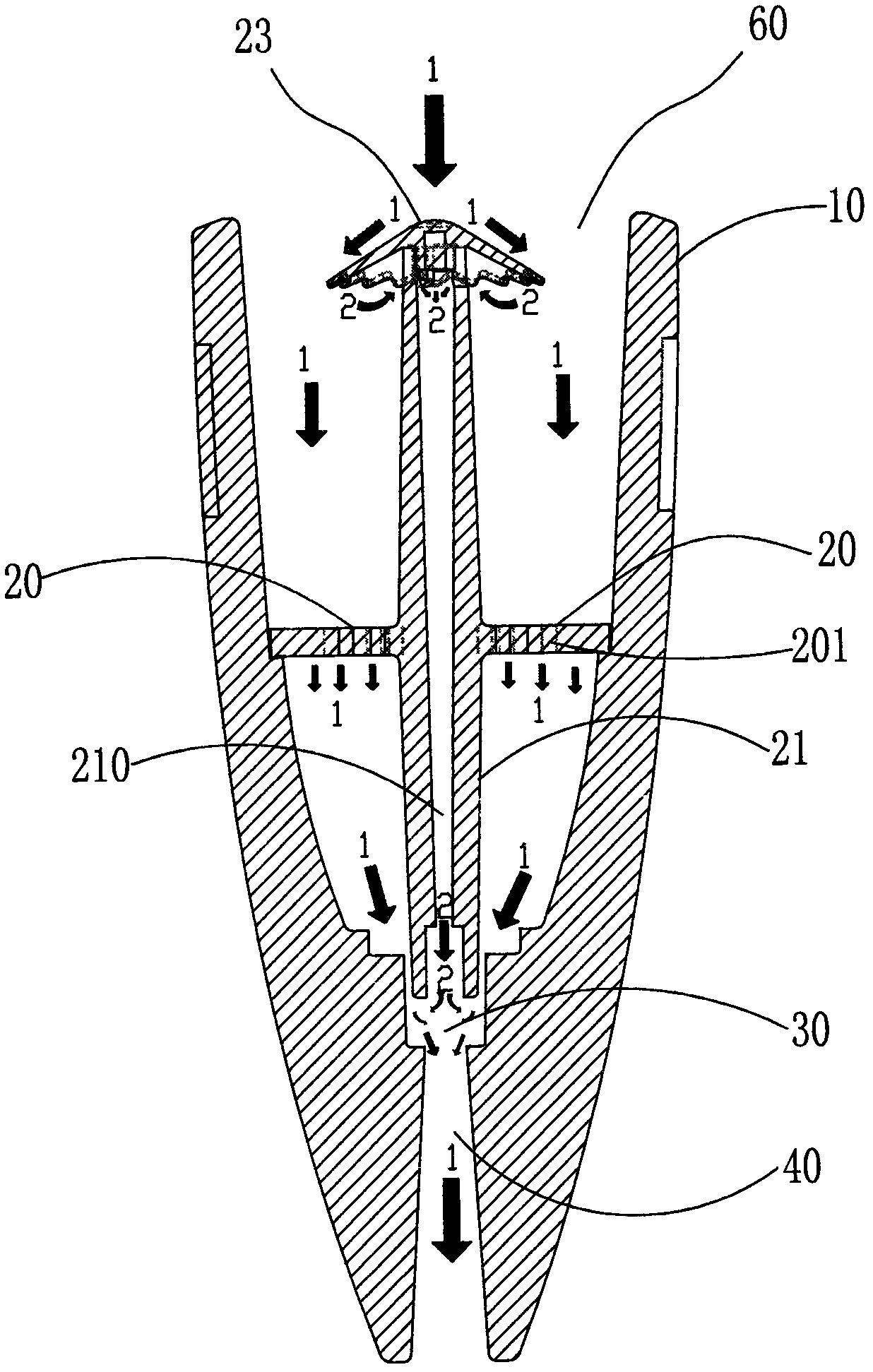

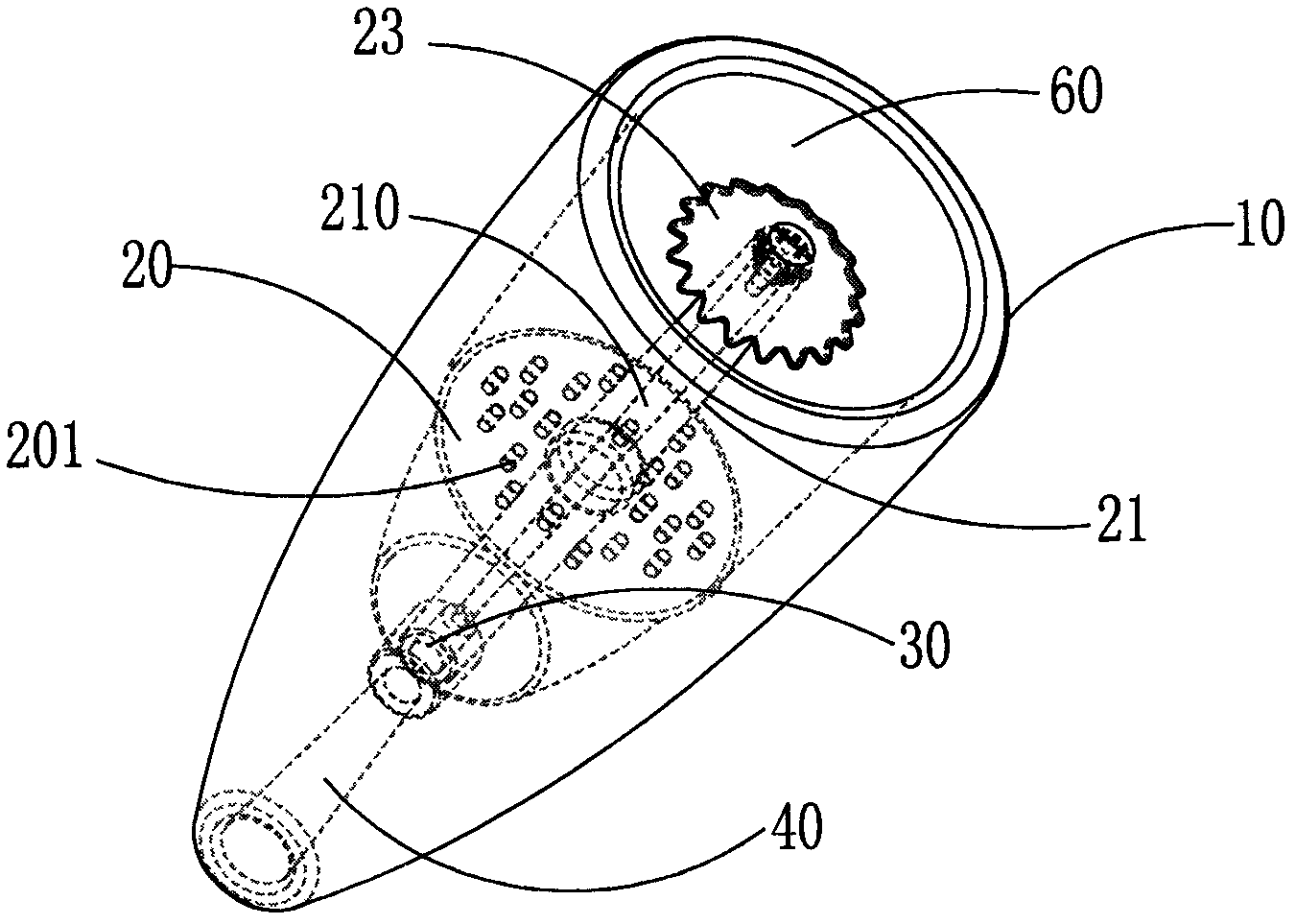

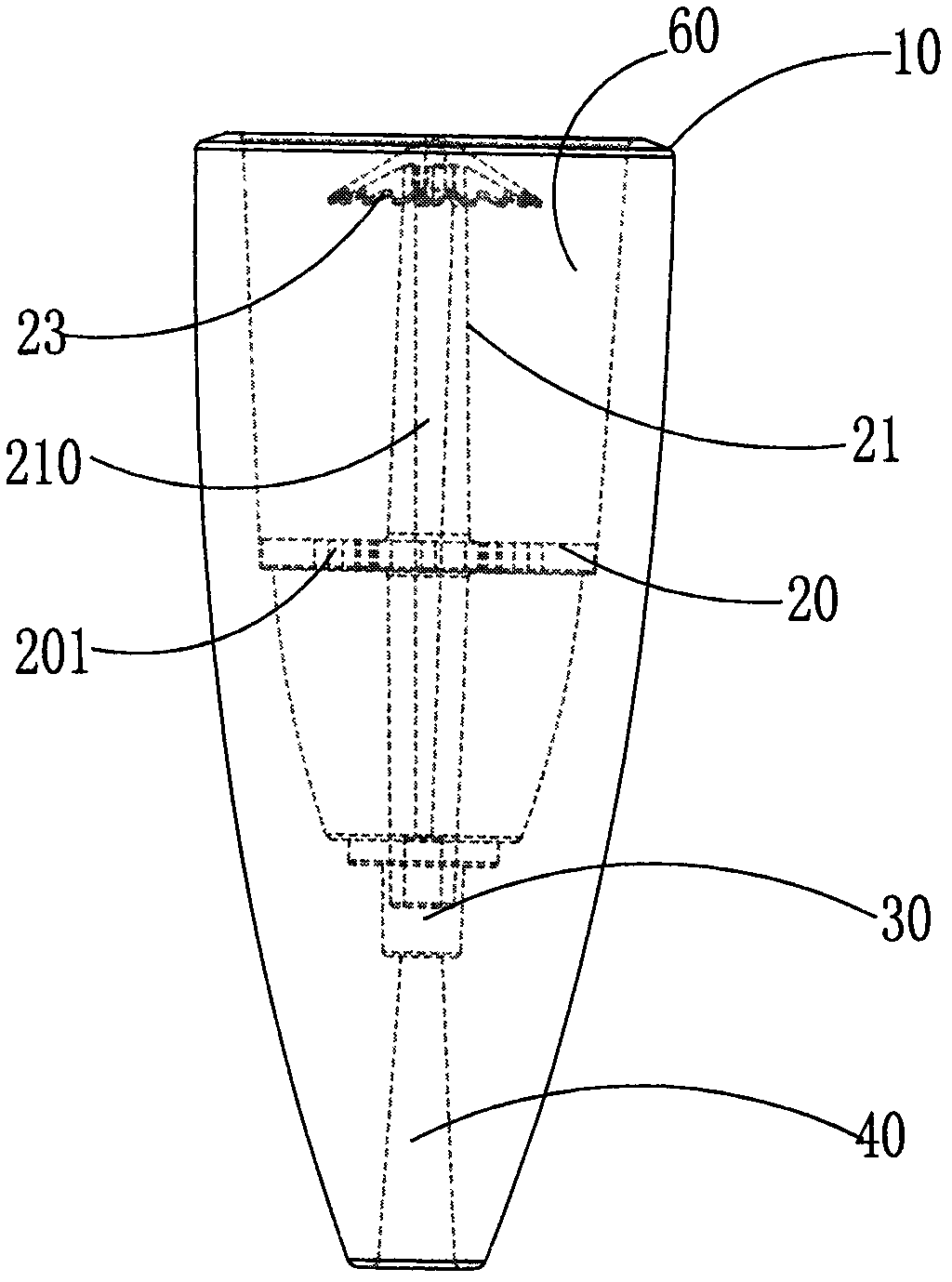

Decanter

ActiveCN102349810AFully oxidizedPromotes rapid oxidationFlow mixersTransportation and packagingGrape wineEngineering

The invention discloses a decanter, which comprises a wine feeding funnel, a mixed cavity and a wine discharging funnel, wherein the wine feeding funnel, the mixed cavity and the wine discharging funnel are arranged on a decanter body and successively axially penetrates through the whole decanter body; at least one air duct is arranged in the wine feeding funnel; one end of the air duct is positioned in the mixed cavity, and the other end of the air duct is provided with an umbrella end which can completely cover an air duct path without blocking the air duct path; the air duct is also provided with a connecting sheet vertical to the axial direction of the air duct; the connecting sheet is provided with a plurality of through holes; the periphery of the connecting sheet is matched and internally connected to the inner wall of the wine feeding funnel; and the wine feeding funnel is divided into an upper chamber and a lower chamber. Because of adopting the decanter, grape wine can fullycontact with air several times, and therefore the taste of the grape wine is condensed, fragrant, smooth and soft. Meanwhile, the phenomena that the air duct path is blocked by operation and dust outof a cup body easily enters the mixed cavity along with negative pressure can be avoided.

Owner:中山市拉菲酷电器有限公司

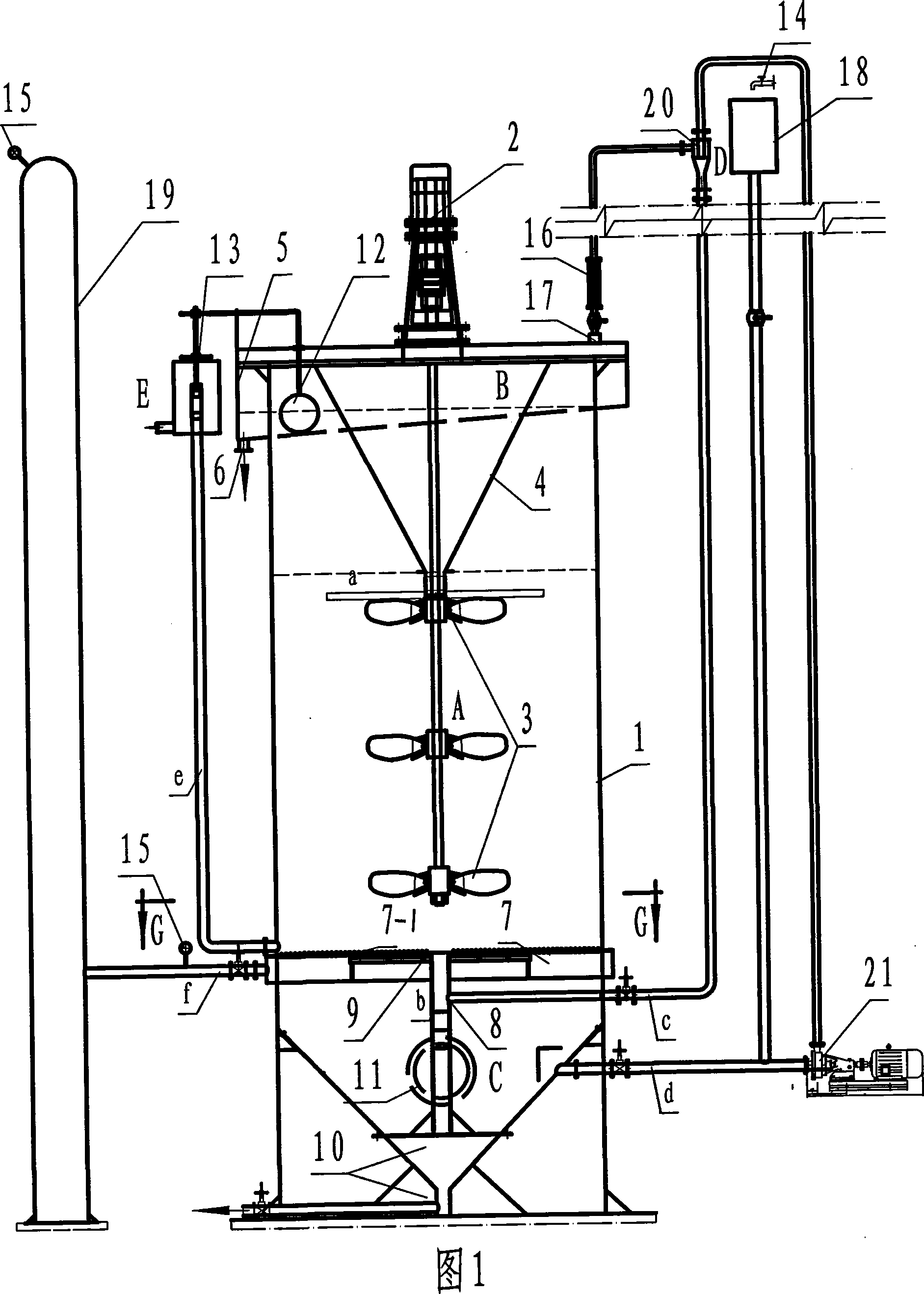

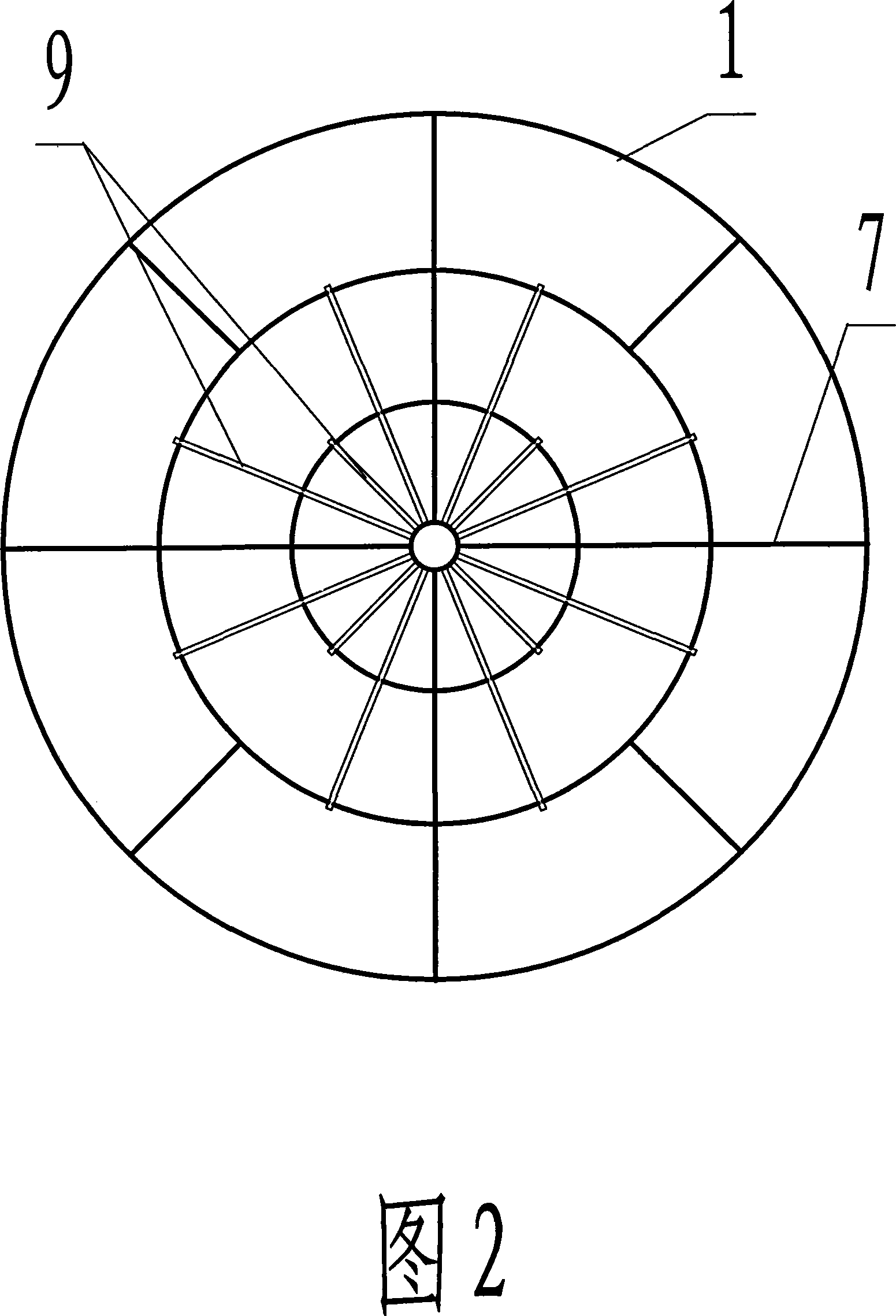

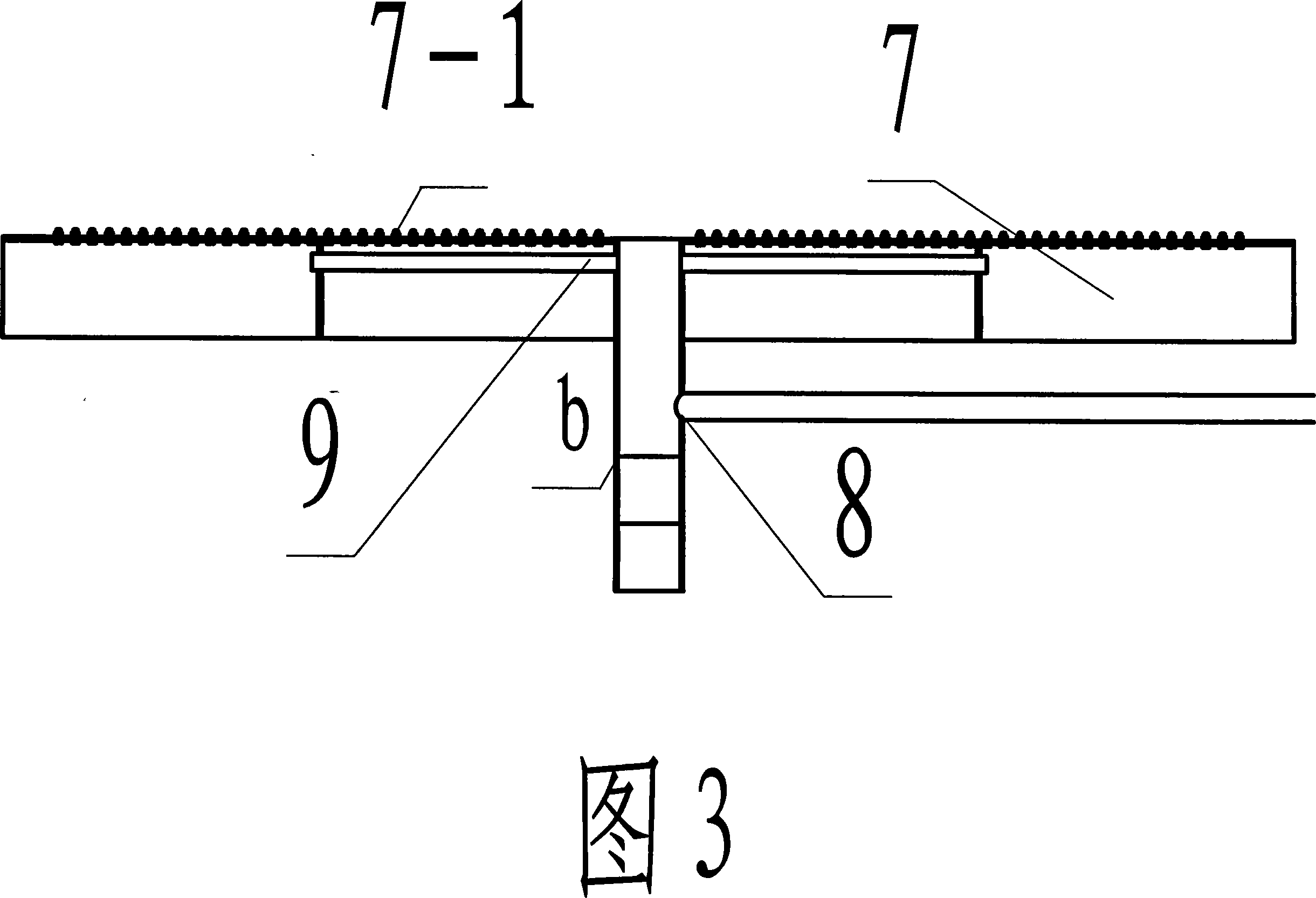

Novel technics of metallurgy mineral dressing flotation air inflation and special equipment

InactiveCN101081379AEnhanced mixing effectImprove flotation recoveryFlotationAutomatic controlMicrobubbles

The present invention discloses inflated metallurgical floatation process and apparatus, and features the completely covered microbubble inflating in the self balanced water separated microbubble generating and inflating mode. The apparatus includes a main machine, a bubble overflowing system, a microbubble generating separator, a microbubble generating system, an automatic mineral slurry regulating mechanism to control the liquid level, etc. Inside the floatation column, leaching tank and oxidation tank, great amount of microbubbles are generated in the bottom and flown in the opposite direction to the falling mineral slurry so as to raise the stirring effect, form stable floating bubble layer, speed oxygen dissolution, increase oxygen utilizing rate, enhance oxidizing leaching and raise floatation recovering rate.

Owner:王树芳

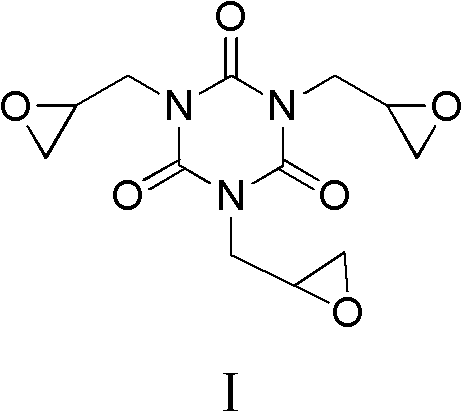

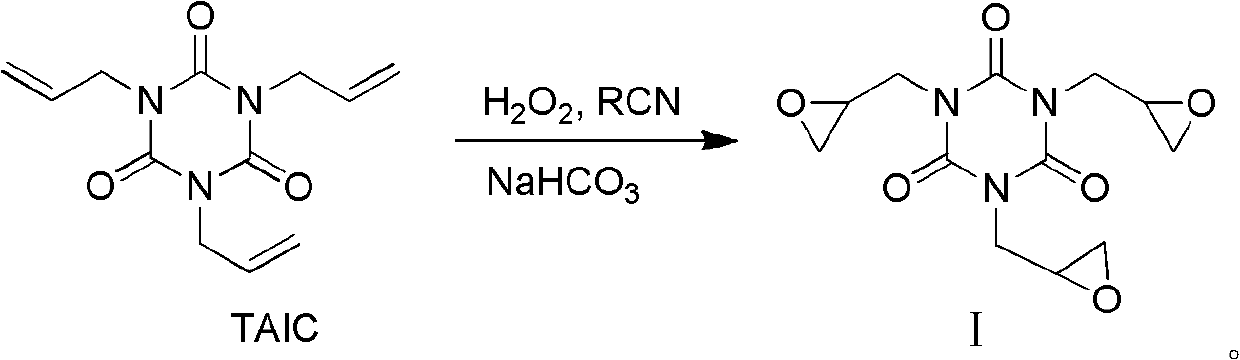

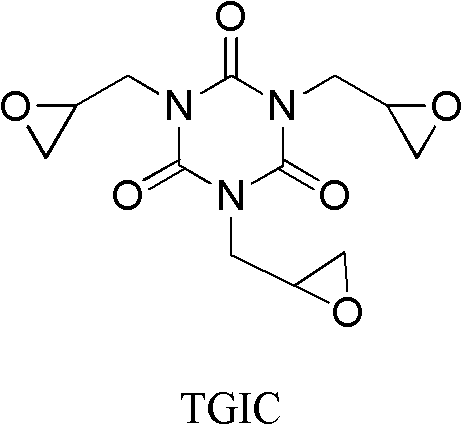

Preparation method of triglycidyl isocyanurate

The invention relates to a preparation method of triglycidyl isocyanurate (I). The preparation method of triglycidyl isocyanurate is characterized by comprising the following steps: stirring triallyl isocyanurate in the presence of alcohol, acid carbonate and nitrile; adding 30% of hydrogen peroxide and stirring the mixture at 25-60 DEG C to keep the reaction for 6-10 hours, and then completing the reaction; performing aftertreatment on the reaction liquid to obtain the triglycidyl isocyanurate. The yield is more than 80.0%.

Owner:HUNAN UNIV +1

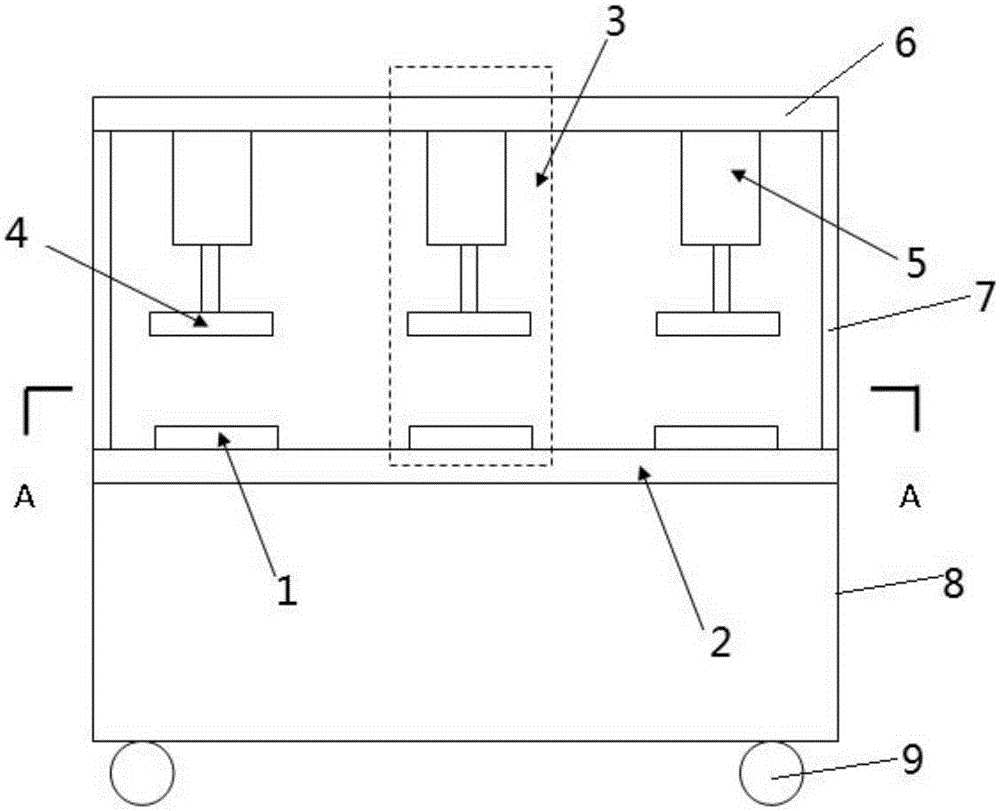

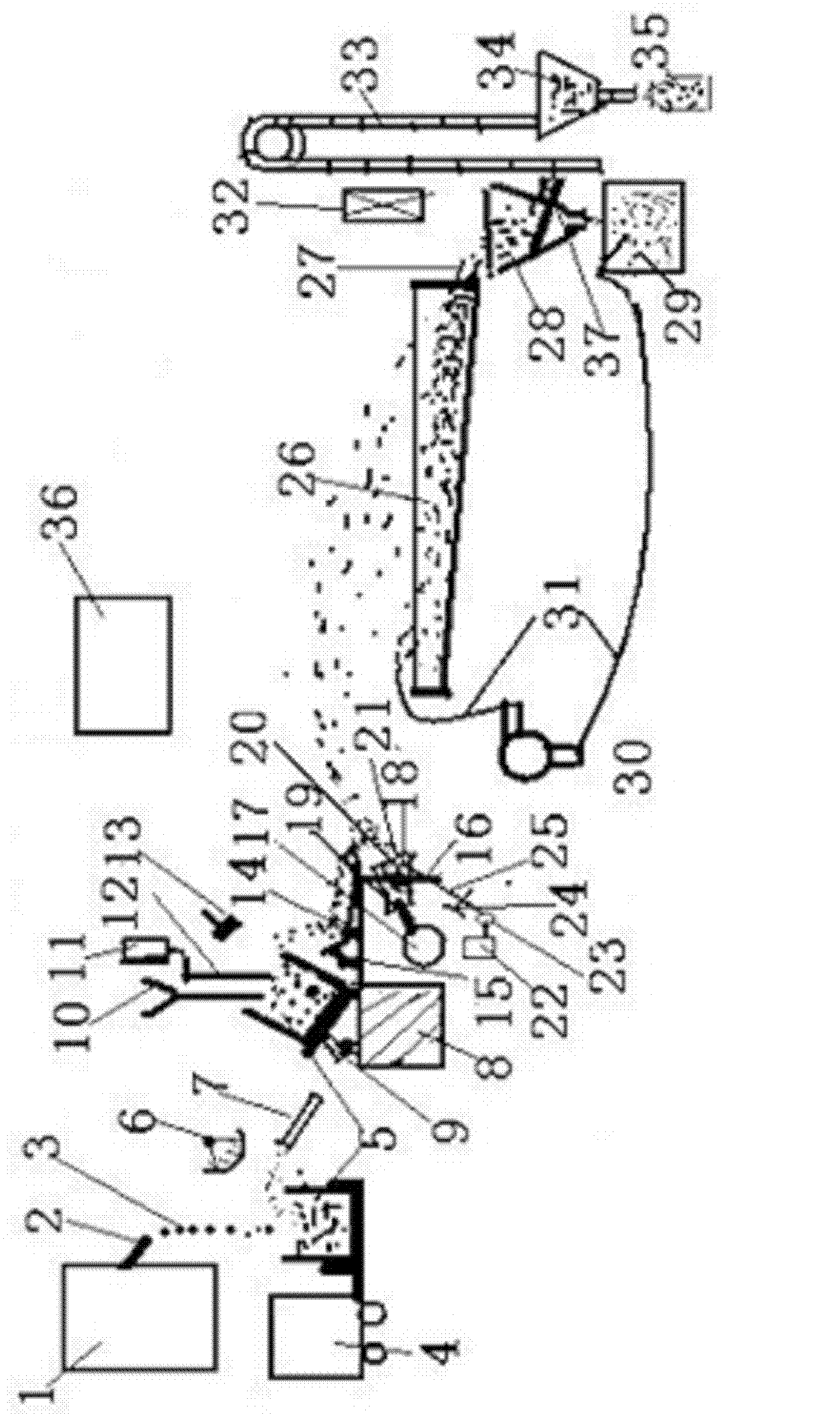

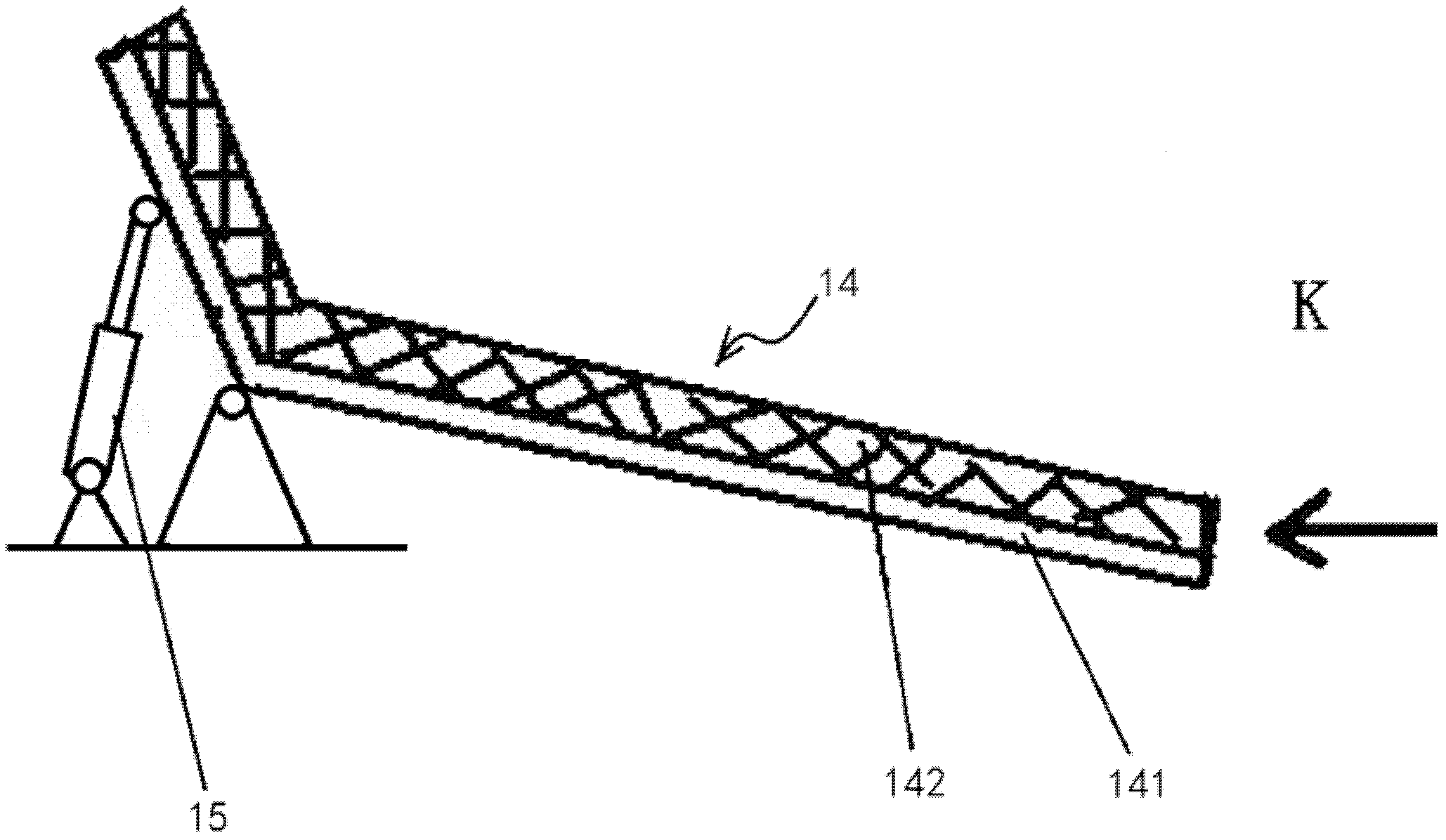

Steel slag ball production equipment and granulating system thereof

InactiveCN102690907AProlong the action timeFully oxidizedRecycling and recovery technologiesSlagAir compressor

The invention discloses steel slag ball production equipment and a granulating system thereof. The steel slag ball production equipment comprises the granulating system for spraying and cooling steel slag flowing out from a flowing groove by using high-pressure air water flow, wherein the granulating system comprises an air spraying mechanism and a cooling liquid spraying mechanism which are distributed up and down; the air spraying mechanism comprises an air compressor or a fan for supplying a high-pressure air source, and an air box for guiding air flow to be sprayed along a certain direction; the air box is provided with an air inlet and an air outlet; an air outlet of the air compressor or the fan is communicated with the air inlet of the air box through a pipeline; spraying panels are arranged at the front end of the air box; the spraying panels are provided with nozzles which are communicated with the air outlet of the air box; and more than two layers of spraying panels are arranged from top to bottom and each layer of spraying panel is horizontally provided with a plurality of nozzles in parallel. The granulating system of the steel slag ball production equipment adopts air and cooling liquid to commonly act on steel slag and the acting time in the air is long; the oxidization reaction is sufficient; the configuration of an organization is stable; and the granulating system can be used for grinding materials, building materials, water treatment, desulfurization agents and the like.

Owner:HENAN UNIV OF SCI & TECH

Skimmia japonica scented tea and making technology

ActiveCN103027142AMaximize nutritional valueGood health effectTea substituesBiotechnologyBitter taste

The invention belongs to the health care scented tea technical field, and especially relates to a skimmia japonica scented tea and making technology and a making technology, According to the making technology, 100% of pure natural Skimmia japonica is taken as a raw material, processes of acquiring fresh flower, removing the impurities, deactivating enzymes, frying to shape, drying, distilling flavor, and airing and packaging the finished product to prepare the skimmia japonica scented tea. The prepared skimmia japonica scented tea can fully perform the original natural performance of the skimmia japonica, no other compatibility component is added, the bitter taste of the skimmia japonica scented tea can be alleviated from the essence, the infused skimmia japonica scented tea has yellow tea color, aromatic flavor, good mouth feel and sweet taste and has strong health care efficacy, and the skimmia japonica scented tea is the green health care scented tea suitable for long-term drinking. The making technology of the skimmia japonica scented tea has the advantages of reasonable design, short processing time and low equipment cost.

Owner:东莞市莞香园艺科技有限公司

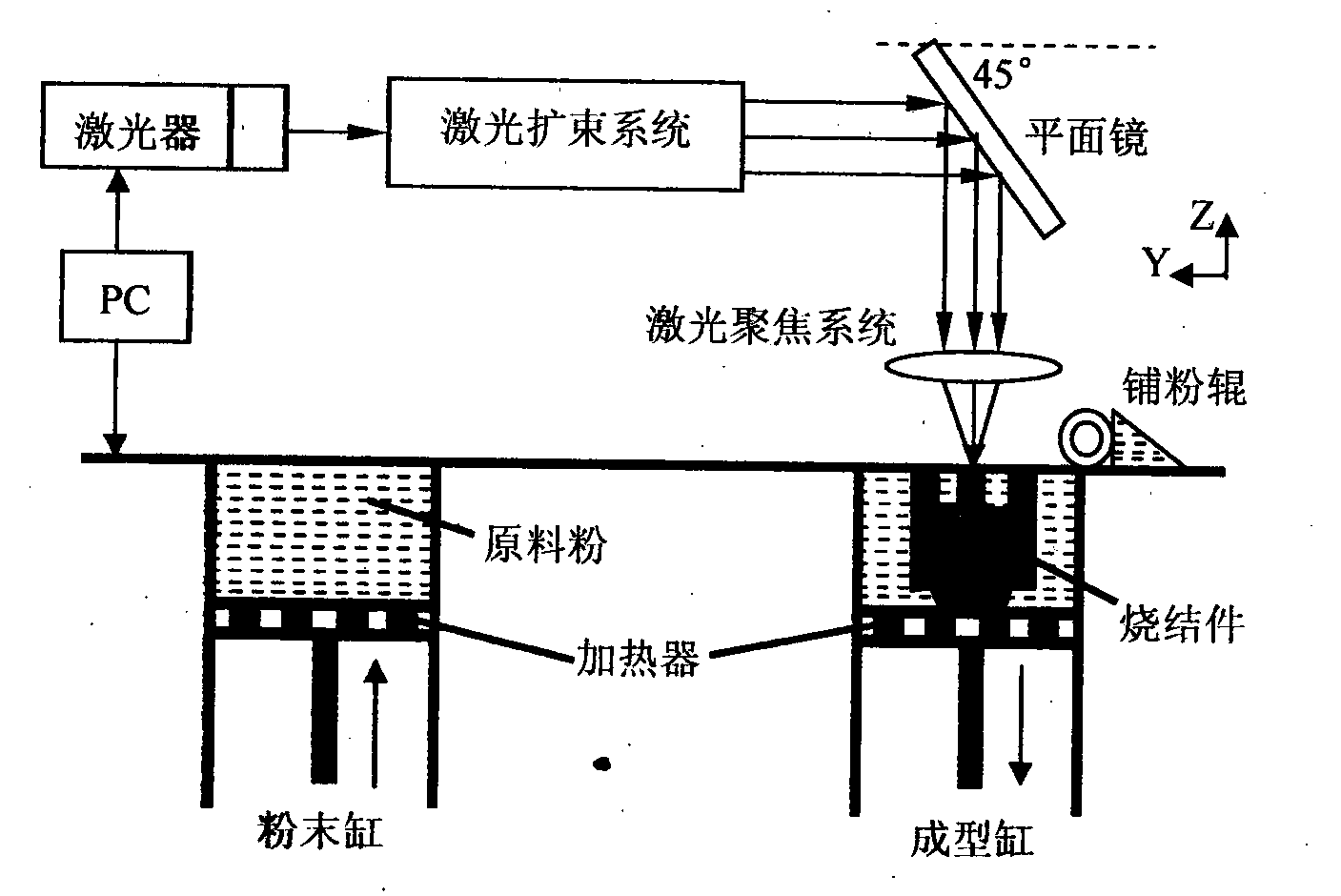

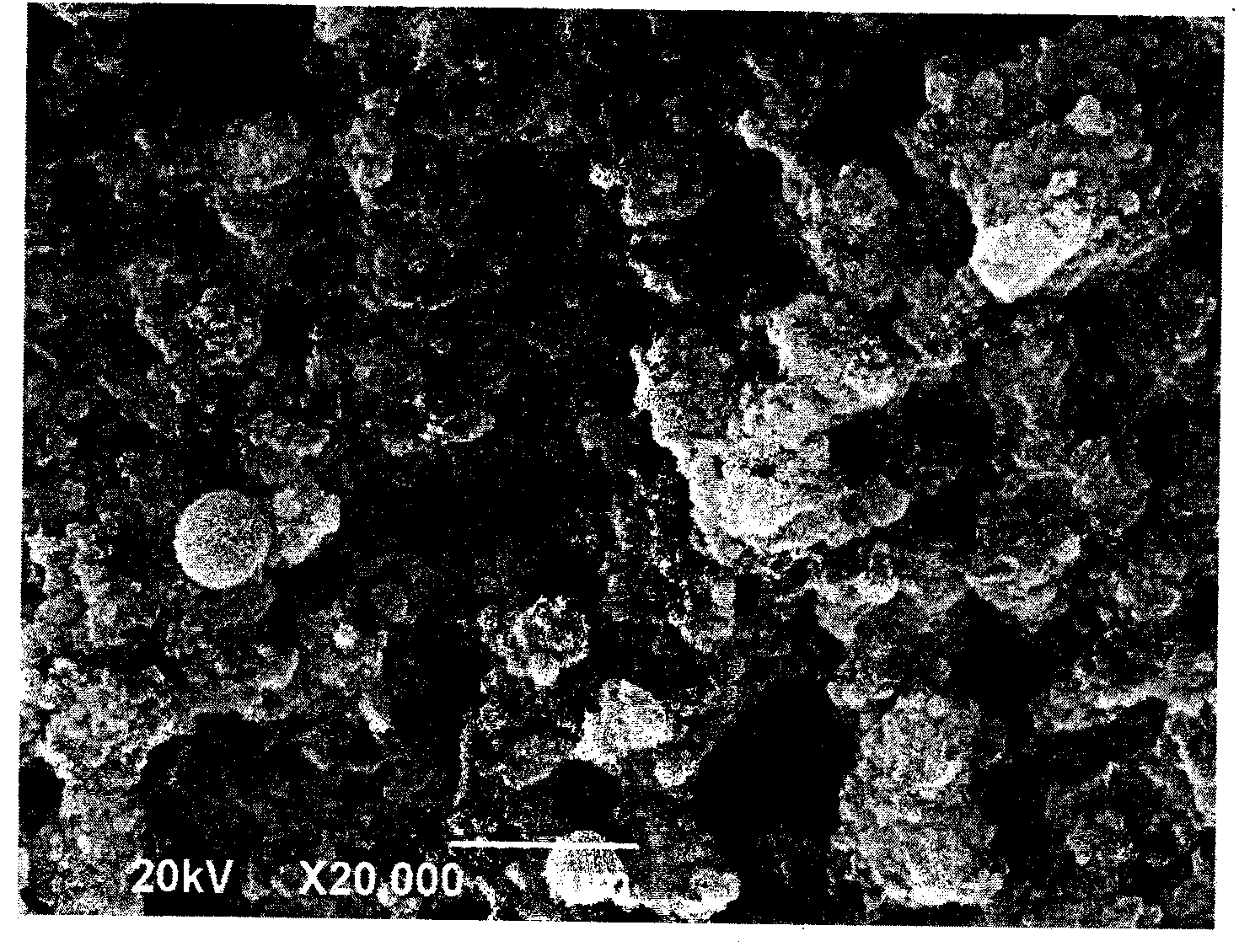

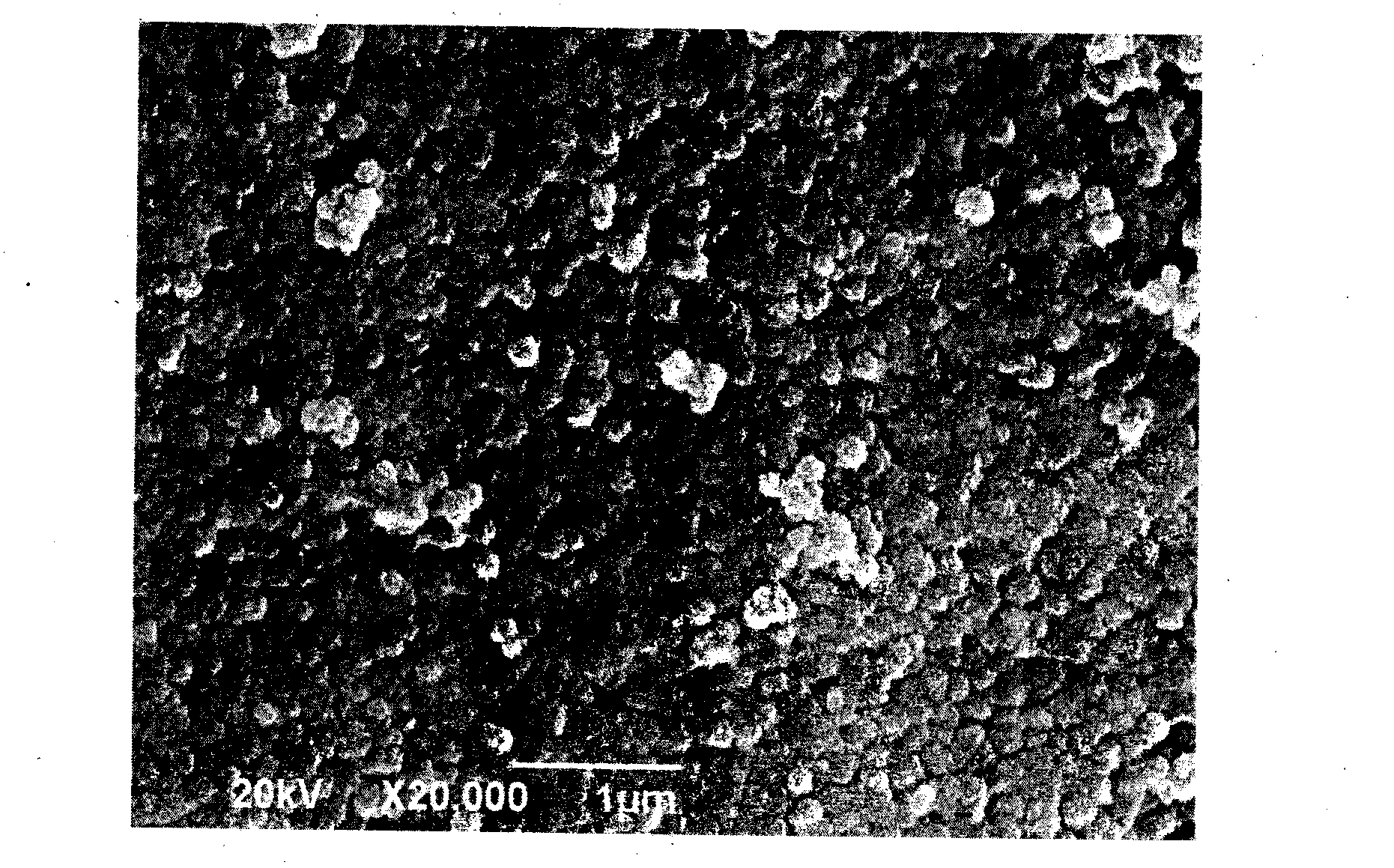

Method for improving ceramic sintering performance by adding a small amount of polylactic acid in artificial bone prepared by laser

InactiveCN103467104APromote rearrangement and densificationImprove sintering performanceProsthesisBone tissue engineeringDisadvantage

A method for improving ceramic sintering performance by adding a small amount of polylactic acid in an artificial bone prepared by laser belongs to the field of bone tissue engineering. When a selective laser sintering (SLS) technology is used for preparing a porous biphasic calcium phosphate ceramic (BCP) artificial bone, a sintering part has the disadvantages of low density and insufficient mechanical properties, and the invention aiming at the disadvantages provides the method for improving BCP sintering performance by adding 0.1-1% by mass percentage of poly-L-lactic acid (PLLA). The advantages of the method are that: a transient liquid phase introduced by use of low temperature fusion of the PLLA can promote the rearrangement and densification of BCP particles so as to improve BCP sintering performance; the PLLA can be fully oxidized until complete disappearance under reasonable process parameters, PLLA residual in the artificial bone can be avoided, and finally the high-performance porous artificial bone completely made from BCP is prepared. The invention relates to the method for improving calcium phosphate bioceramic laser sintering performance by adding a small amount of a polymer material, and the method has the characteristics of simple operation process, good product performance and wide application range.

Owner:CENT SOUTH UNIV

Preparation method of aqueous single-layer graphene solution

The invention discloses a preparation method of an aqueous single-layer graphene solution. According to the method, natural graphite, calcium nitrate, potassium nitrate, concentrated sulfuric acid and potassium permanganate are mixed and processed to obtain a graphite oxide solution, and after the graphite oxide solution is prepared into an aqueous single-layer graphene oxide solution, a reducing agent is added for a reaction, and the aqueous single-layer graphene solution is obtained. According to the method, the aqueous single-layer graphene solution with high single layer rate, strong compositing feature and uniform dispersion is prepared finally after multiple times of ultrasonic stripping.

Owner:北京纳新天地科技发展有限公司

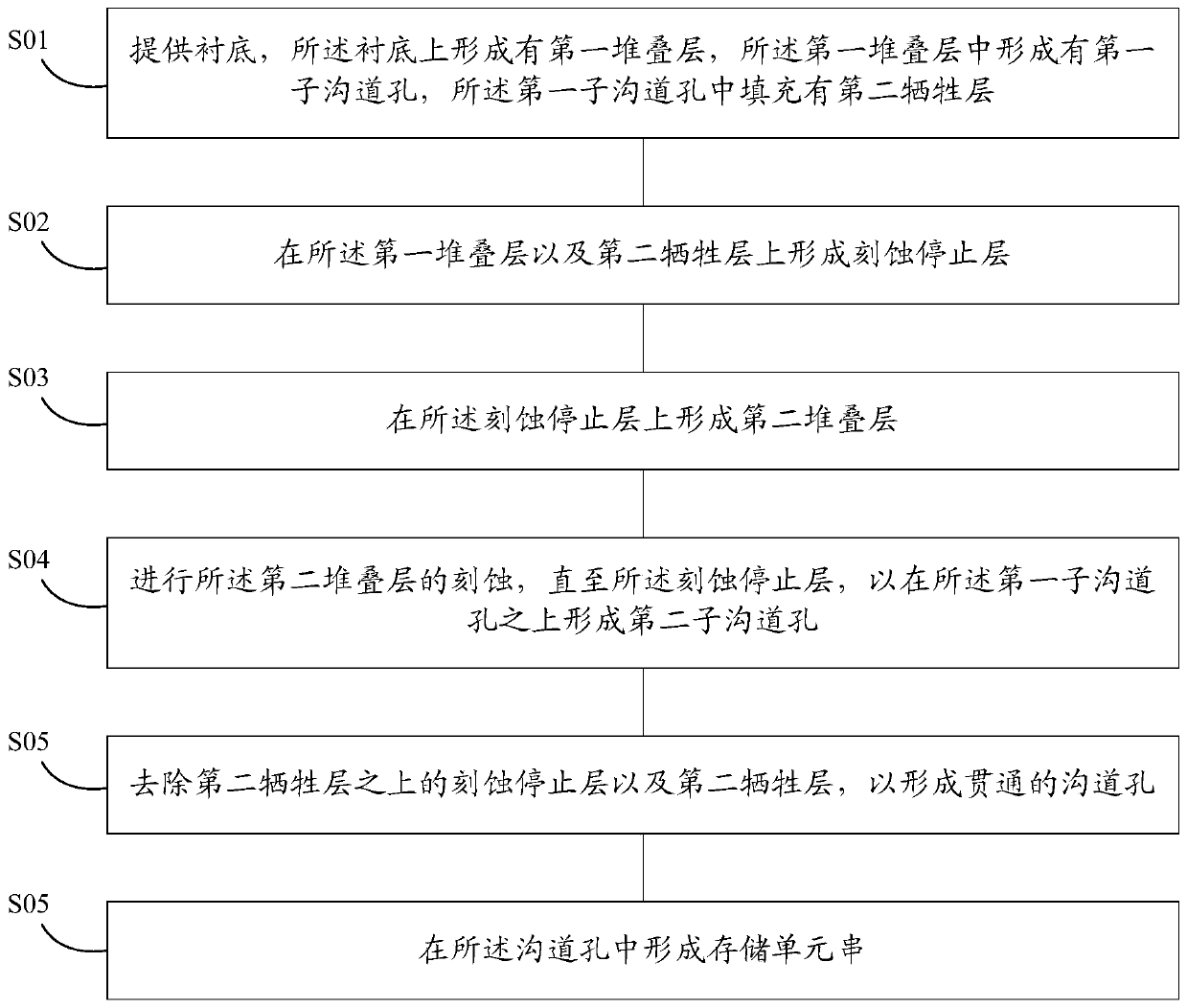

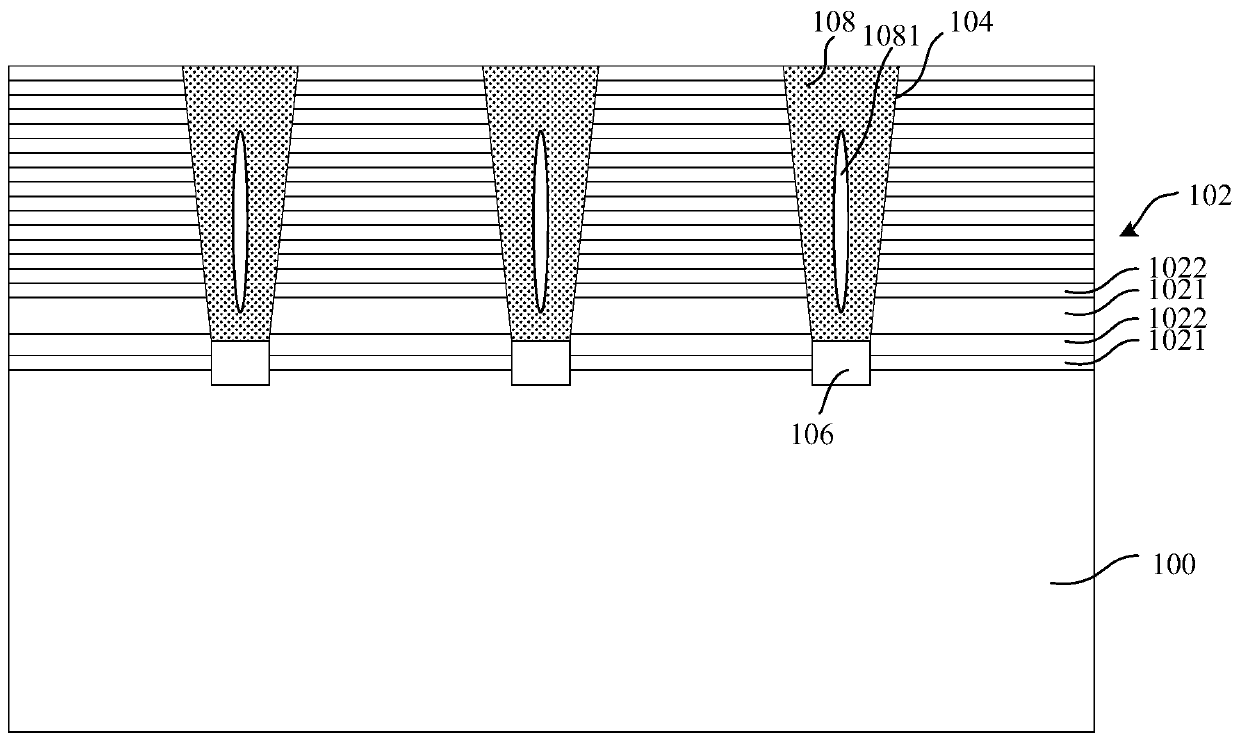

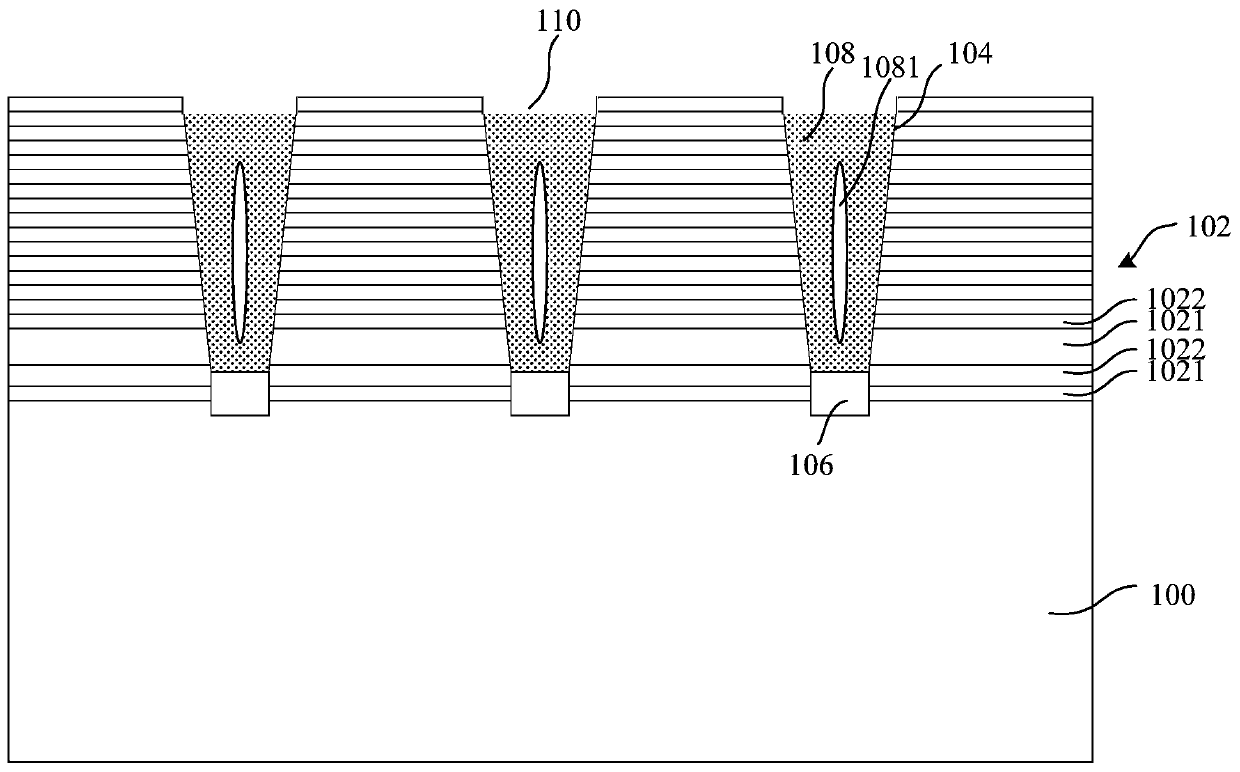

Memory device and manufacturing method thereof

ActiveCN109755252AImprove yieldAvoid over etchingSolid-state devicesSemiconductor devicesEngineeringElectrical and Electronics engineering

The invention provides a memory device and a manufacturing method thereof. Forming a sacrificial layer in a first sub-channel hole in a first stacked layer; then forming an etch stopping layer; and then continuing to form a second stacked layer over the etch stopping layer; forming a second sub-channel hole above the first sub-channel hole using the etch stopping layer as an etching focus when thesecond sub-channel hole is formed in the second stacked layer; so that a through channel hole is formed after the etch stopping layer above a second sacrificial layer and the second sacrificial layerare removed. Therefore, the integration of the memory device is effectively improved; meanwhile, the over etching to the second sacrificial layer is avoided during etching of the second sub-channel hole by setting the etch stopping layer; therefore, the process stability is improved, and the device yield is increased.

Owner:YANGTZE MEMORY TECH CO LTD

Preparation method of expandable graphite

The invention discloses a preparation method of expandable graphite, comprising the following steps of: A. adding 35-40wt% of hydrogen peroxide with 10-14% of graphite by taking crystalline flake graphite as the raw material, cooling and stirring for 3-5min or enabling the hydrogen peroxide to be uniformly attached on the surface of a material; B. adding 98wt% of sulfuric acid which is 2-2.5timesof the weight of the graphite into the mixture, cooling, stirring, and reacting for 10-16min; C. adding mixed acids which is 13-20% of the weight of the graphite into the mixture, and reacting for 160-180min; D. washing the material to the pH value not less than 5, dehydrating and drying to obtain the expandable graphite. By using the method provided by the invention, the expansion ratio of a final product can be stabilized, and the cost can be reduced.

Owner:湖北联投恒达石墨有限公司

Catalyst used for purifying volatile organic compound and preparation method of catalyst

ActiveCN107335447AIncrease loadOvercoming the lengthy preparation processGas treatmentDispersed particle separationCordieriteTemperature resistance

The invention discloses a catalyst used for purifying a volatile organic compound and a preparation method of the catalyst. According to the catalyst, aluminum oxide modified by iron, cobalt and nickel serves as a carrier, cordierite honeycomb ceramic serves as a substrate, and a mixture of platinum in a very low content and palladium serves as an active component, wherein the molar ratio of the platinum to the palladium is (0-1):(0-9), the mixture of the platinum and the palladium accounts for 0.01-0.05% of the substrate by mass, and the mass of the carrier is 3-5% of the mass of the substrate. The preparation method comprises the steps that firstly, the carrier is coated; secondly, discharge enhancing pretreatment is conducted; thirdly, an active component impregnation liquid is prepared; fourthly, the active component is subjected to support and reduction. By means of the method, the defects that an existing catalyst used for purifying the volatile organic compound is too complex in modification, tedious in preparation technology process and high in noble metal supported content, and accordingly the cost is high are overcome, and the catalyst prepared by using the method is good in low-temperature activity and excellent in high-temperature resistance.

Owner:东莞中维环保工程有限公司

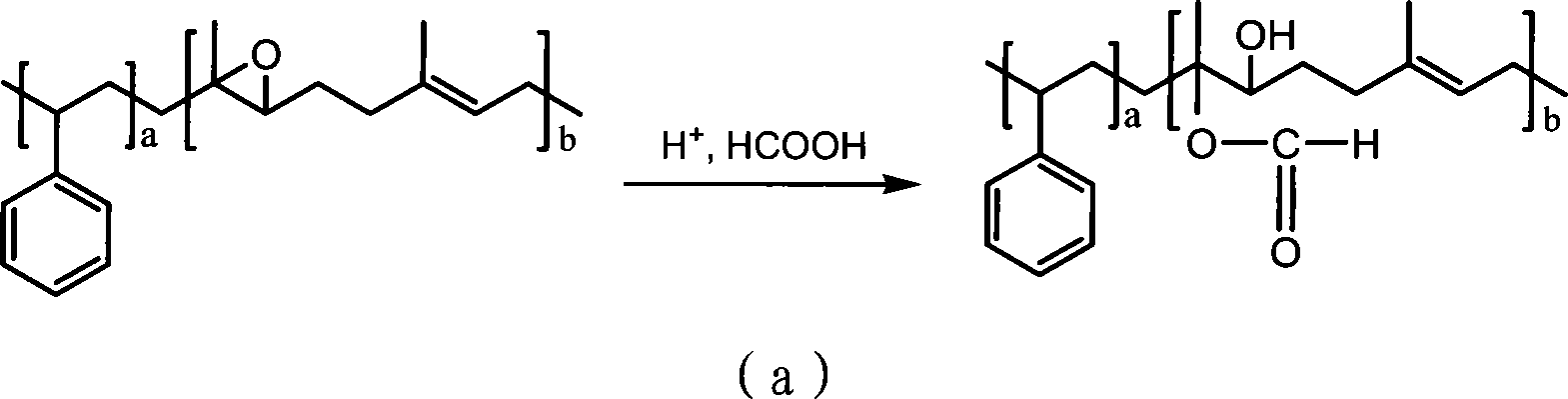

Method for preparing epoxidized styrene-isoprene-phenylethene block copolymer and use thereof

The invention relates to a preparation method of epoxidized styrene-isoprene-cinnamene block copolymer. In organic solvent, polyethylene glycol is taken as phase transfer catalyst, the styrene-isoprene-cinnamene block copolymer is epoxidized through organic peroxy acid generated by organic acid and hydrogen peroxide in situ, to ensure that double bonds on a polyisoprene chain segment are transformed into epoxy radical, and then sodium hydroxide solution is added to neutralize the system, simultaneously, antioxidant is added to prevent the epoxidized styrene-isoprene-cinnamene block copolymer from being oxidized, and after azeotropy, the organic solvent is removed through vaporization to obtain the epoxidized styrene-isoprene-cinnamene block copolymer. The used solvent can be circularly utilized. The epoxidized styrene-isoprene-cinnamene block copolymer prepared with the method is provided with certain polarity and cohesive strength, the adhesion property to the polar material is strong, the oil resistance is good, and the epoxidized styrene-isoprene-cinnamene block copolymer can be used as thermoplastic elastomer to prepare hot melt pressure-sensitive and adhesive sealant, etc.

Owner:广东宏昌新材料科技有限公司

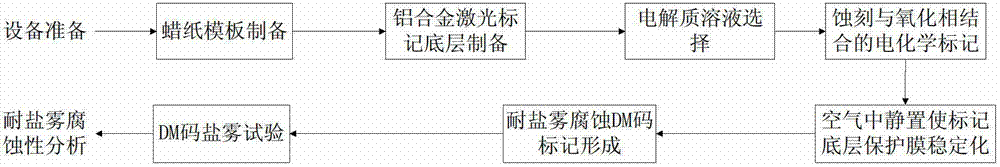

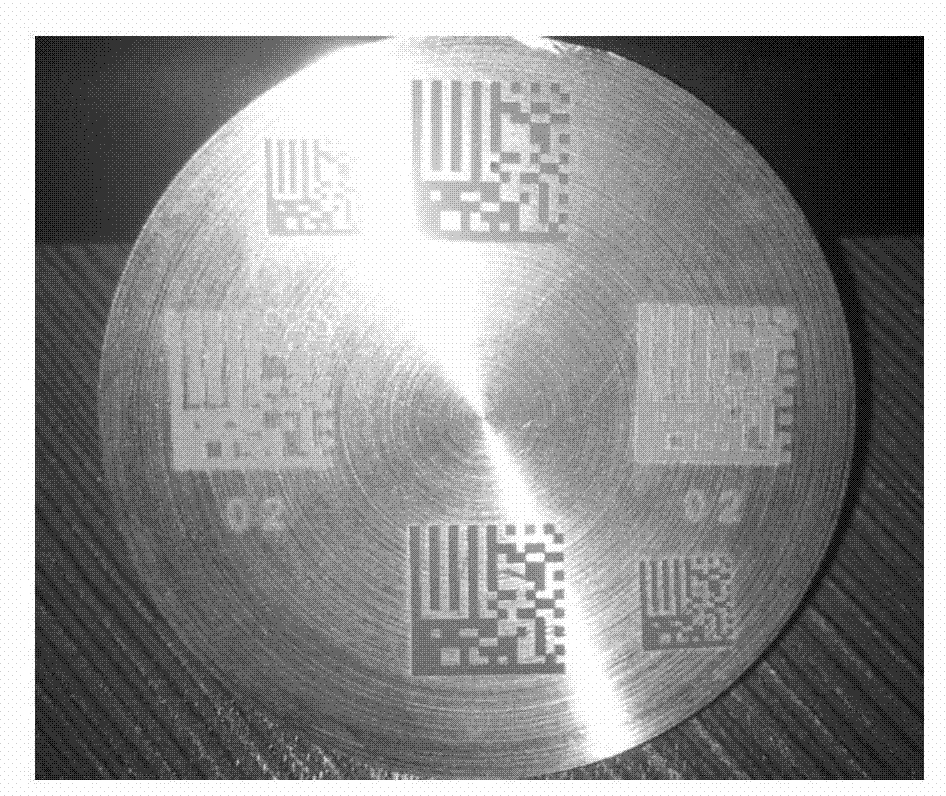

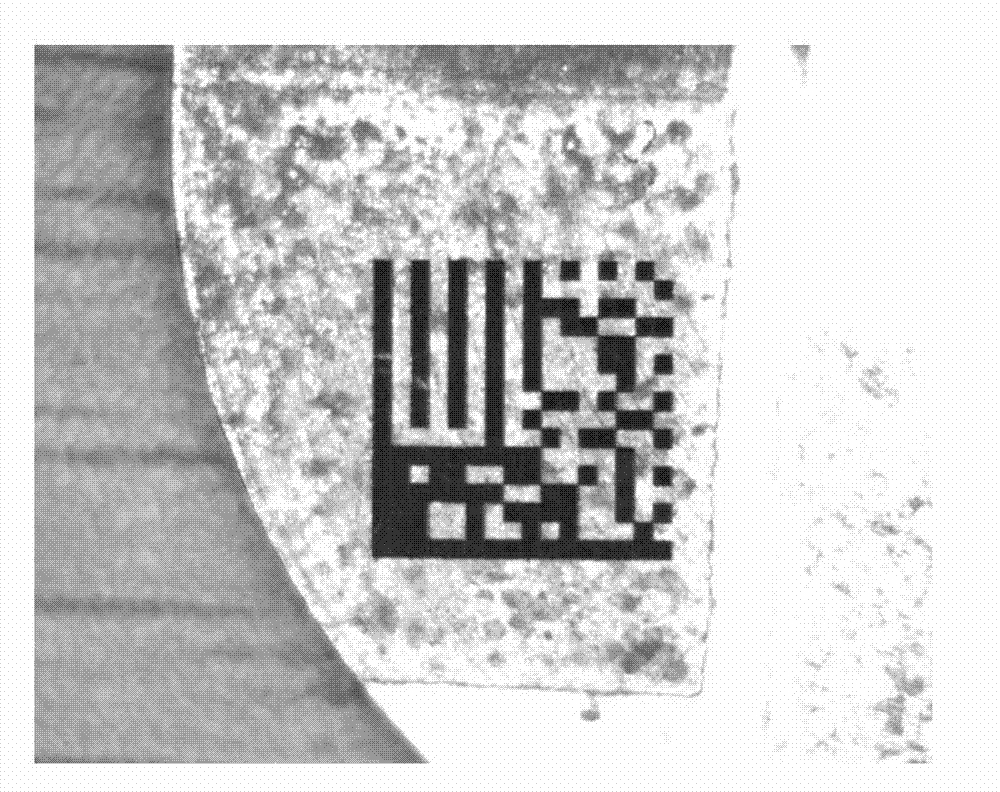

Laser marking method for increasing salt spray corrosion resistance of two-dimension codes on surface of aluminum alloy

InactiveCN102776541AStrong resistance to salt spray corrosionStable structureAnodisationWaxElectrochemistry

The invention provides a laser marking method for increasing salt spray corrosion resistance of two-dimension codes on a surface of an aluminum alloy. A DM code bottom layer is formed by directly marking with laser on an aluminum plate substrate; a square pattern is made on wax paper by using a thermo-sensitive method; the square pattern is larger than specification of existing DM codes on the surface of an aluminum plate; electrochemical etching is carried out in a DM code area of the aluminum plate by using an electrochemical etching method with the wax paper as a template to form a layer of oxidation film having protection function, so that a DM code mark with salt spray corrosion resistance is formed. Compared with the DM code mark directly marked on the surface of the aluminum alloy with laser, salt spray corrosion resistance of the DM code mark generated by the method can be increased greatly, and the oxidation film in a marking area is controllable; the influence of the mark for part matrix out of the marking area is poor; the operation is simple; and the efficiency is higher.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing high-purity small oxidized graphene

The invention belongs to the technical field of oxidized graphene, and particularly relates to a method for preparing small oxidized graphene from cryptocrystalline graphite.The method mainly solves the problems of existing oxidized graphene preparing methods that purity is low, toxicity is high, technology is complicated and cost is high.According to the method, purified cryptocrystalline graphite, concentrated acid and strong oxidant are evenly mixed for reaction in an airtight environment at the temperature of 80-120 DEG C, a reaction mixture is slowly poured into an excessive amount of deionized water, uniform stirring is conducted, then an aqueous hydrogen peroxide solution with the mass concentration of 25% is added till turbid liquid becomes brown or luminous yellow, acid pickling and washing are conducted till pH value becomes 6-7, and then centrifugal separation is conducted to generate the small oxidized graphene.The ratio of the mass of purified cryptocrystalline graphite to the volume of concentrated acid is 1 : (20-80), and the mass ratio of purified cryptocrystalline graphite to purified cryptocrystalline graphite is 1 : (3-10).

Owner:SHANXI UNIV

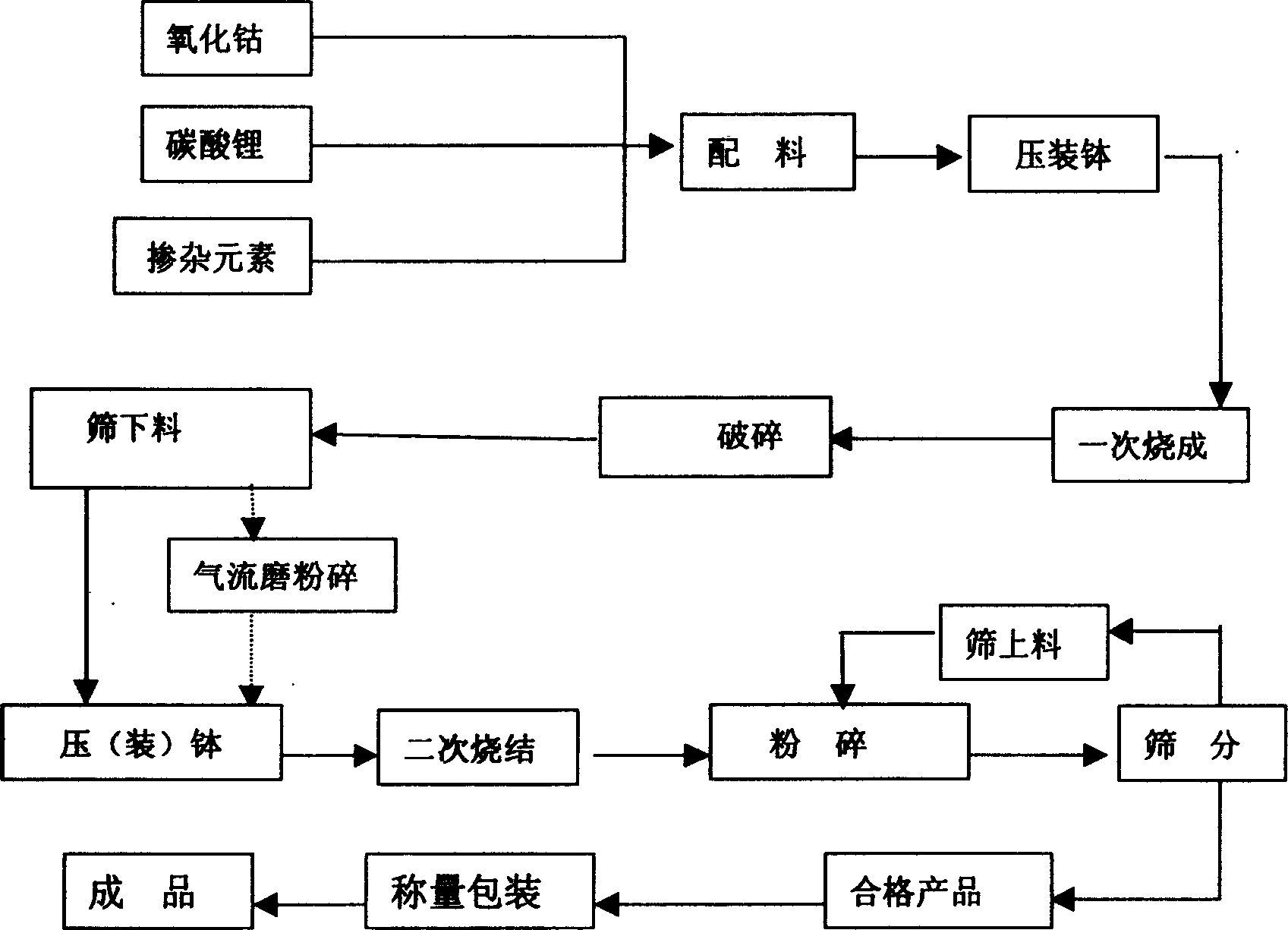

Preparation method of lithium cobaltate material

ActiveCN1556043AIncrease loading capacityFully oxidizedCell electrodesCobalt compoundsOrganic solventLithium carbonate

Owner:JIANGSU DANGSHENG MATERIAL TECH CO LTD +1

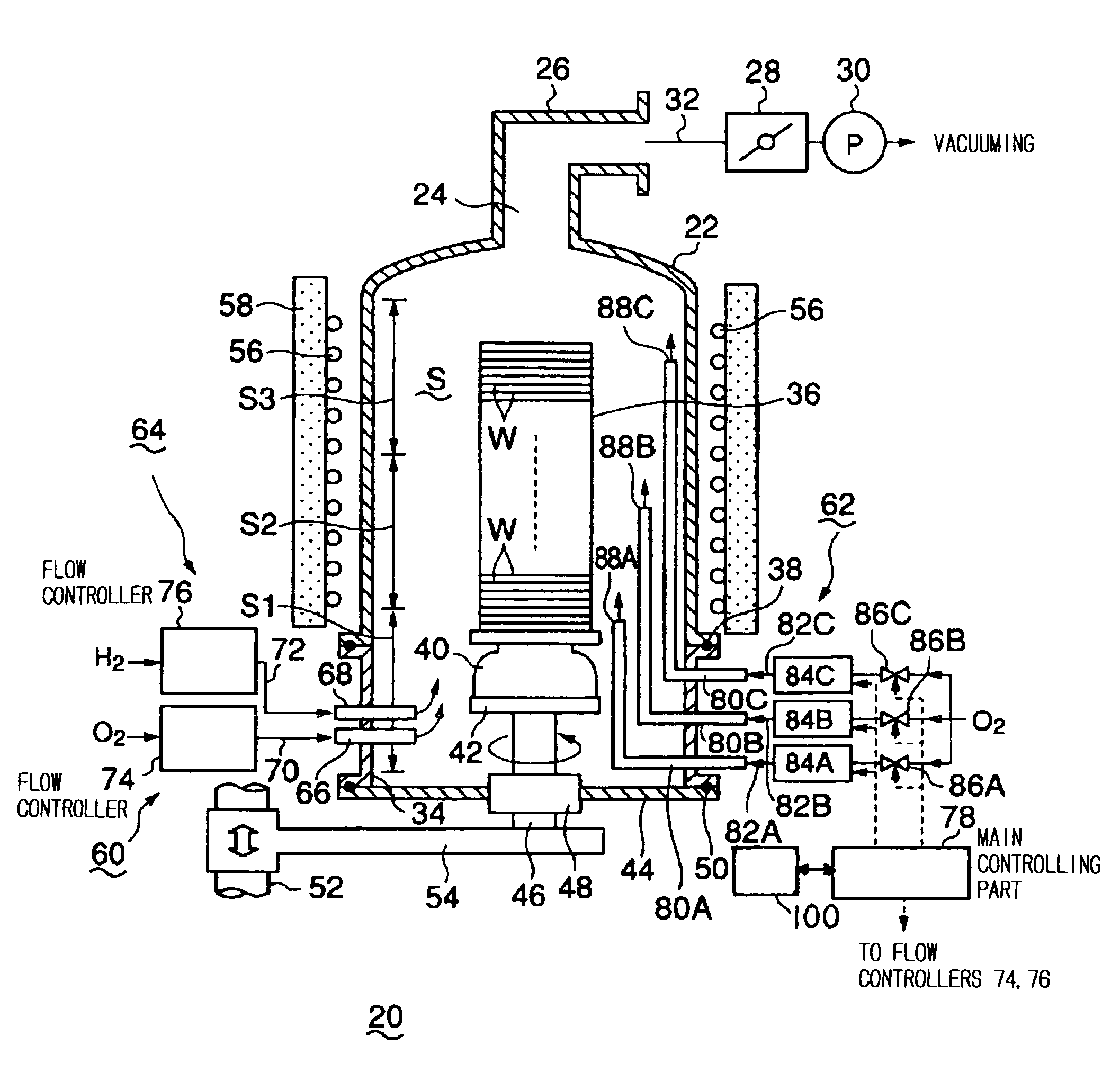

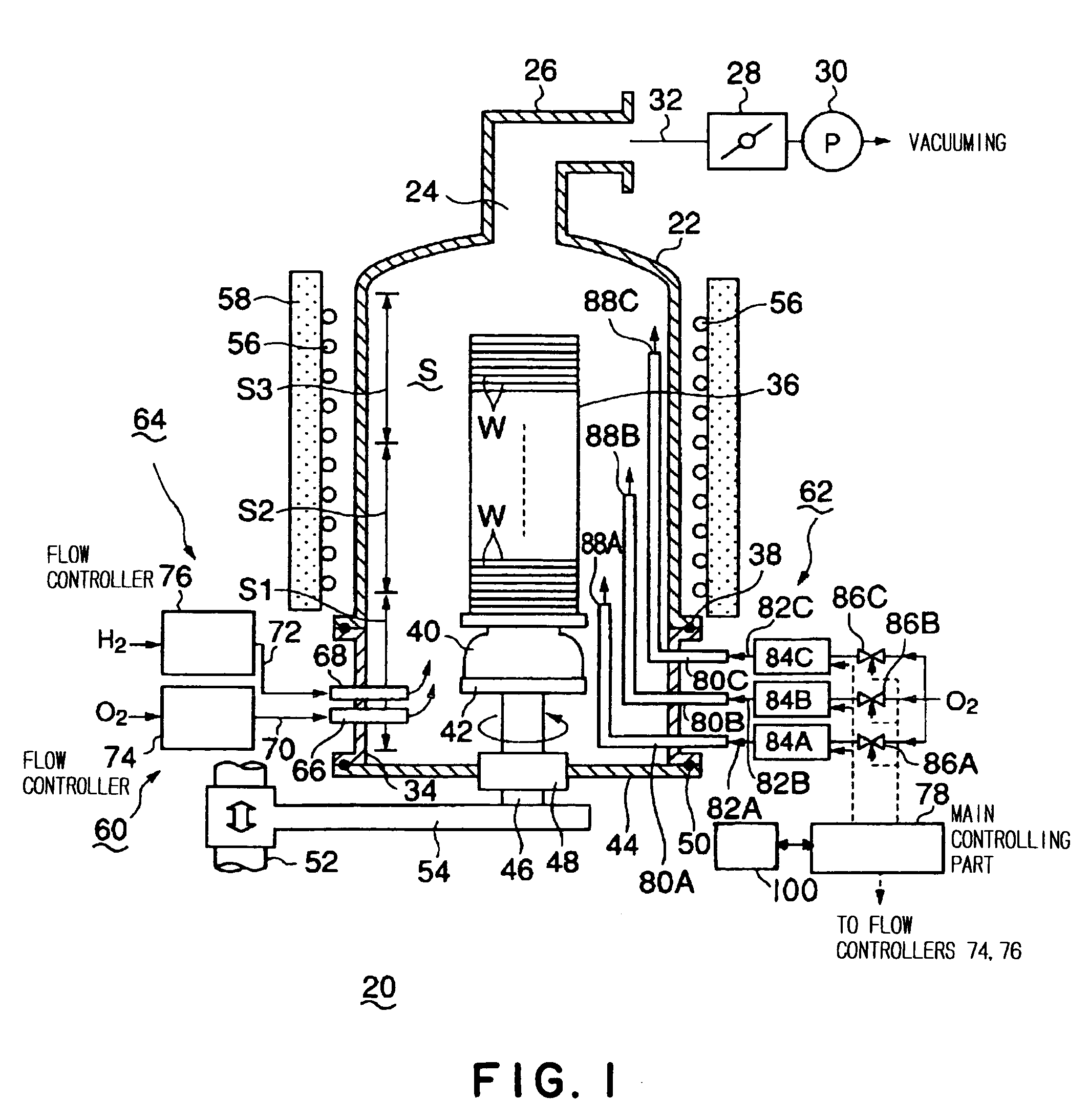

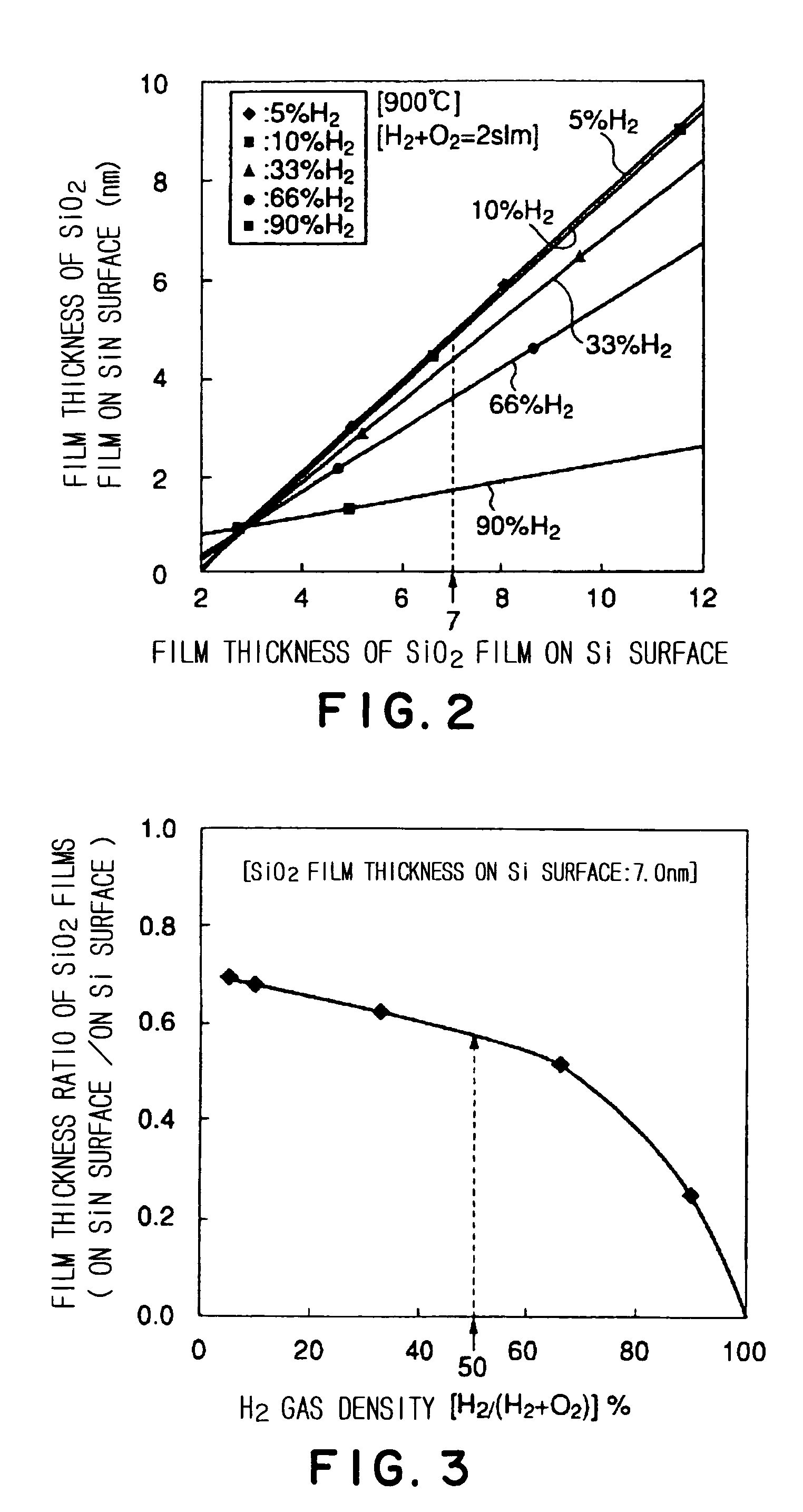

Oxidizing method and oxidizing unit for object to be processed

ActiveUS7304003B2Fully oxidizedUniformitySewerage structuresSemiconductor/solid-state device manufacturingAtmospheric airProduct gas

An oxidizing method for an object to be processed according to the present invention includes: an arranging step of arranging a plurality of objects to be processed in a processing container whose inside can be vacuumed, the processing container having a predetermined length, a main supplying unit of an oxidative gas and a supplying unit of a reducing gas being provided at one end of the processing container, a sub supplying unit of the oxidative gas being provided on a way in a longitudinal direction of the processing container; an atmosphere forming step of supplying the oxidative gas and the reducing gas into the processing container in order to form an atmosphere having active oxygen species and active hydroxyl species in the processing container; and an oxidizing step of oxidizing surfaces of the plurality of objects to be processed in the atmosphere. In the atmosphere forming step, the oxidative gas is adapted to be supplied from the main supplying unit of the oxidative gas and the sub supplying unit of the oxidative gas.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com