Method for performing electrochemical advanced treatment on landfill leachate based on ultraviolet reinforcement

A technology of advanced treatment and ultraviolet light, which is applied in the direction of chemical instruments and methods, light water/sewage treatment, water/sewage treatment, etc., to achieve the effect of cost saving, compact equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

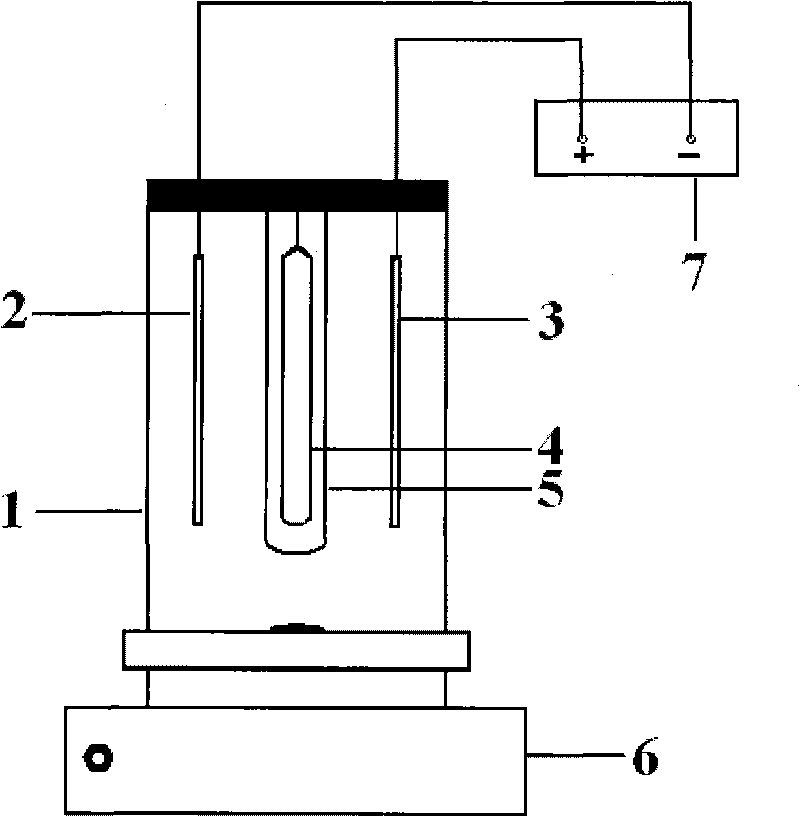

Image

Examples

Embodiment 1

[0023] Take the effluent from a landfill leachate in Beijing after anaerobic, aerobic and coagulation treatment. The effluent quality: COD 560mg L -1 , TOC 190mg L -1 , NH 3 -N 700mg L -1 , pH 7.8, conductivity 14.74mS cm -1 , chloride ion concentration 4500mgL -1 .

[0024] with RuO 2 / Ti is the anode, the current density is 50mA cm -2 , treated by electrochemical method for 90 minutes, the TOC removal rate was 26.5%, NH 3 -N removal rate was 72.7%, COD removal rate was 41.1%; after treatment for 120 minutes, TOC removal rate was 48.4%, NH 3 -N removal rate is close to 100%, and COD removal rate is 58.1%.

[0025] with RuO 2 / Ti is the anode, the current density is 50mA cm -2 , introduced a 10W low-pressure mercury lamp, and treated with ultraviolet light-enhanced electrochemical method for 90 minutes, the removal rate of TOC was 45.2%, and the removal rate of NH 3 -N removal rate reached 99.2%, COD removal rate was 54.8%; after treatment for 120 minutes, TOC remov...

Embodiment 2

[0027] Take the leachate from a landfill site, and after anaerobic and aerobic treatment, the effluent water quality: COD 1400mg L -1 , NH 3 -N 1250mgL -1 , conductivity 21.5mS cm -1 , chloride ion concentration 5800mg L -1 .

[0028] with RuO 2 / Ti is the anode, the current density is 50mA cm -2 , 10W low-pressure mercury lamp as light source, electrochemical method for 120 minutes, NH 3 -N removal rate reached 80%, COD removal rate was 31.2%; after 180 minutes of treatment, NH 3 -N removal rate is close to 100%, COD removal rate is 71.9%; after 210 minutes of treatment, NH 3 -N removal rate is close to 100%, and COD removal rate is 75.9%.

[0029] with RuO 2 / Ti is the anode, the current density is 50mA cm -2 , 10W low-pressure mercury lamp as the light source, treated with ultraviolet light-enhanced electrochemical method for 120 minutes, NH 3 -N removal rate reached 88.6%, COD removal rate was 36.3%; after 180 minutes of treatment, NH 3 -N removal rate is close...

Embodiment 3

[0031] Ammonia nitrogen simulated wastewater, initial concentration 700mg L -1 (calculated as nitrogen), pH 5.7, chlorine concentration is 5325mg L -1 , with a current density of 40mA cm -2 , processed for 90 minutes.

[0032] with RuO 2 / Ti is the anode, and the concentration of ammonia nitrogen in the effluent treated by electrochemical method is 264mg L -1 , the removal rate was 62.3%; the concentration of ammonia nitrogen in the effluent treated by the ultraviolet light-enhanced electrochemical method was below the detection limit, and the removal rate was close to 100%.

[0033] to IrO 2 / Ti is the anode, and the concentration of ammonia nitrogen in the effluent treated by electrochemical method is 284mg L -1, the removal rate was 59.4%; the concentration of ammonia nitrogen in the effluent treated by ultraviolet light enhanced electrochemical method was below the detection limit, and the removal rate was close to 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com