High-performance silver cadmium oxide material and manufacturing method thereof

A technology of silver cadmium oxide and a manufacturing method, applied in the directions of contacts, electrical components, electrical switches, etc., can solve the problems of inability to adapt to the working environment, unreachable electrical life, high production costs, and improve oxidation resistance and arc resistance. The effect of burn-out capability, low manufacturing cost, and low equipment and production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

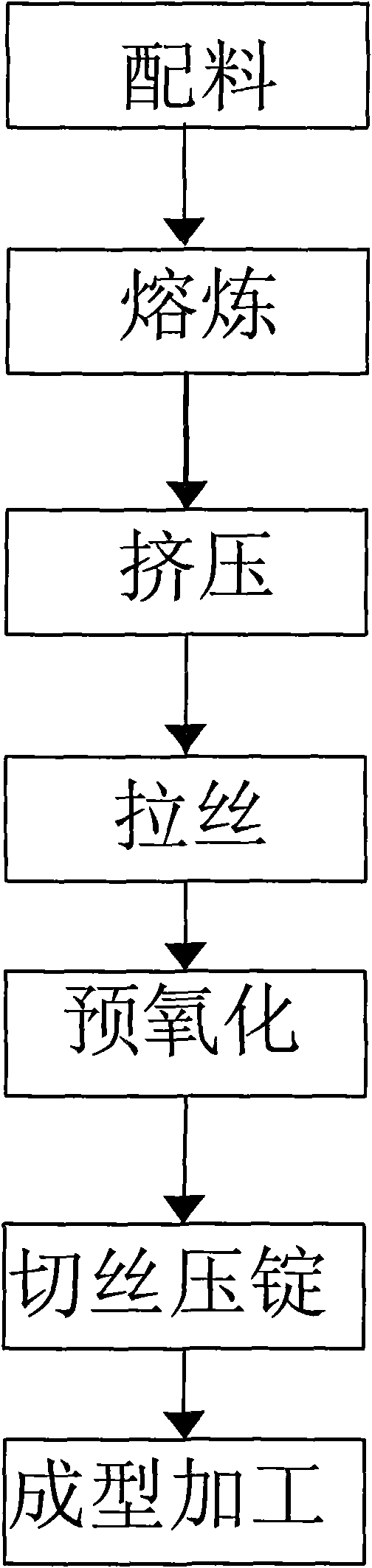

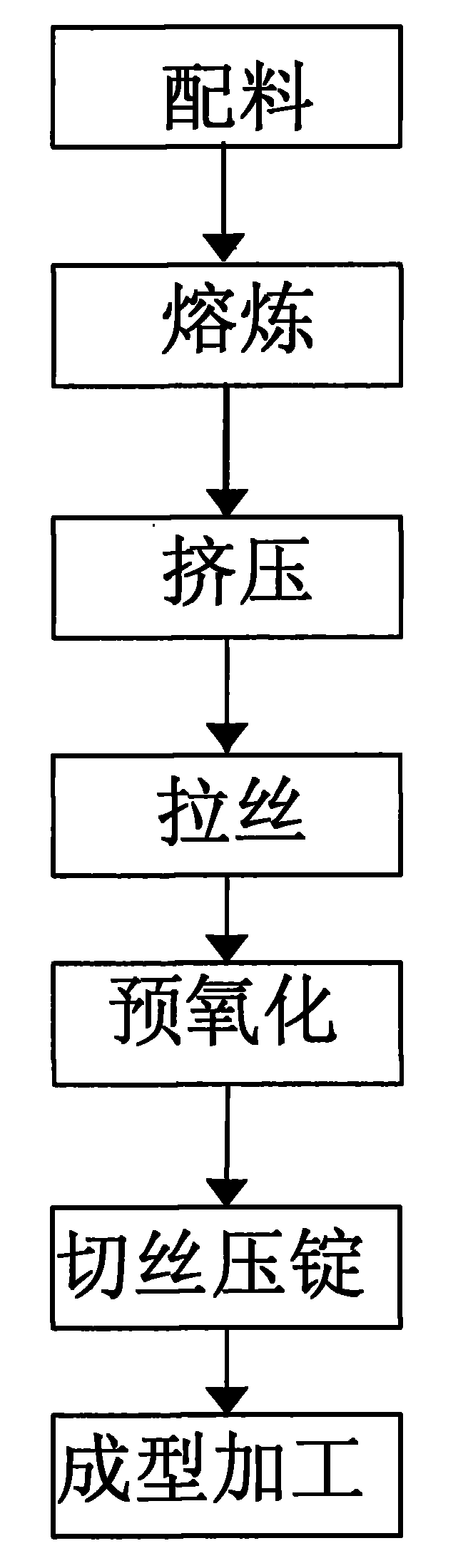

[0033] 91.1% of silver, 8.75% of cadmium, 0.1% of nickel, 0.01% of tin, and 0.05% of rare earth mixture are used for batching; the rare earth mixture contains 65% of yttrium, and 35% of lanthanum and cerium mixture. Place the prepared material in a medium frequency induction furnace for smelting for 0.5-2 hours; then cast it into an ingot. Put the ingot into the medium frequency induction furnace to preheat for 2-6 hours, the preheating temperature is 600-900°C; then use a 930T extruder to extrude the ingot into a thick wire with a diameter of Φ4mm-Φ8mm, and the pressure is 10-30MPa . Then use the wire drawing die to draw the thick wire into a wire with a diameter of Φ1.0mm-Φ4.0mm. Then use an internal oxidation furnace to pre-oxidize the wire rod formed by drawing. The pre-oxidation temperature is 600-800°C and the oxygen pressure is 1-6ka / cm 2 , the pre-oxidation time is 8-20 hours. The pre-oxidized wire is cut into small pieces and pressed into ingots with an extruder. ...

Embodiment 2

[0035] According to the ratio of silver 89.3%, cadmium 10.5%, nickel 0.05%, tin: 0.05%, rare earth 0.1%, the rare earth mixture contains 70% yttrium, lanthanum and cerium mixture 30%. Place the prepared material in a medium frequency induction furnace for smelting for 0.5-2 hours; then cast it into an ingot. Put the ingot into the medium frequency induction furnace to preheat for 2-6 hours, the preheating temperature is 600-900°C; then use a 930T extruder to extrude the ingot into a thick wire with a diameter of Φ4mm-Φ8mm, and the pressure is 10-30MPa . Then use a wire drawing die to draw the thick wire into a wire with a diameter of Φ1.0mm-Φ4.0mm. Then use an internal oxidation furnace to pre-oxidize the wire rod formed by drawing. The pre-oxidation temperature is 600-800°C and the oxygen pressure is 1-6ka / cm 2 , the pre-oxidation time is 8-20 hours. The pre-oxidized wire is cut into small pieces and pressed into ingots with an extruder. Finally, use the wire drawing die ...

Embodiment 3

[0037] According to the ratio of 85.97% silver, 13.13% cadmium, 0.2% nickel, 0.5% tin, and 0.2% rare earth, the rare earth mixture contains 80% yttrium and 20% lanthanum and cerium mixture. Place the prepared material in a medium frequency induction furnace for smelting for 0.5-2 hours; then cast it into an ingot. Put the ingot into the medium frequency induction furnace to preheat for 2-6 hours, the preheating temperature is 600-900°C; then use a 930T extruder to extrude the ingot into a thick wire with a diameter of Φ4mm-Φ8mm, and the pressure is 10-30MPa . Then use a wire drawing die to draw the thick wire into a wire with a diameter of Φ1.0mm-Φ4.0mm. Then use an internal oxidation furnace to pre-oxidize the wire rod formed by drawing. The pre-oxidation temperature is 600-800°C and the oxygen pressure is 1-6ka / cm 2 , the pre-oxidation time is 8-20 hours. The pre-oxidized wire is cut into small pieces and pressed into ingots with an extruder. Finally, use the wire drawin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com