Method for improving ceramic sintering performance by adding a small amount of polylactic acid in artificial bone prepared by laser

A technology of laser sintering and sintering performance, which is applied in the field of bone tissue engineering, can solve problems such as aseptic inflammatory reactions, achieve the effects of improving sintering performance, improving mechanical properties, and avoiding residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be further described below in conjunction with an embodiment.

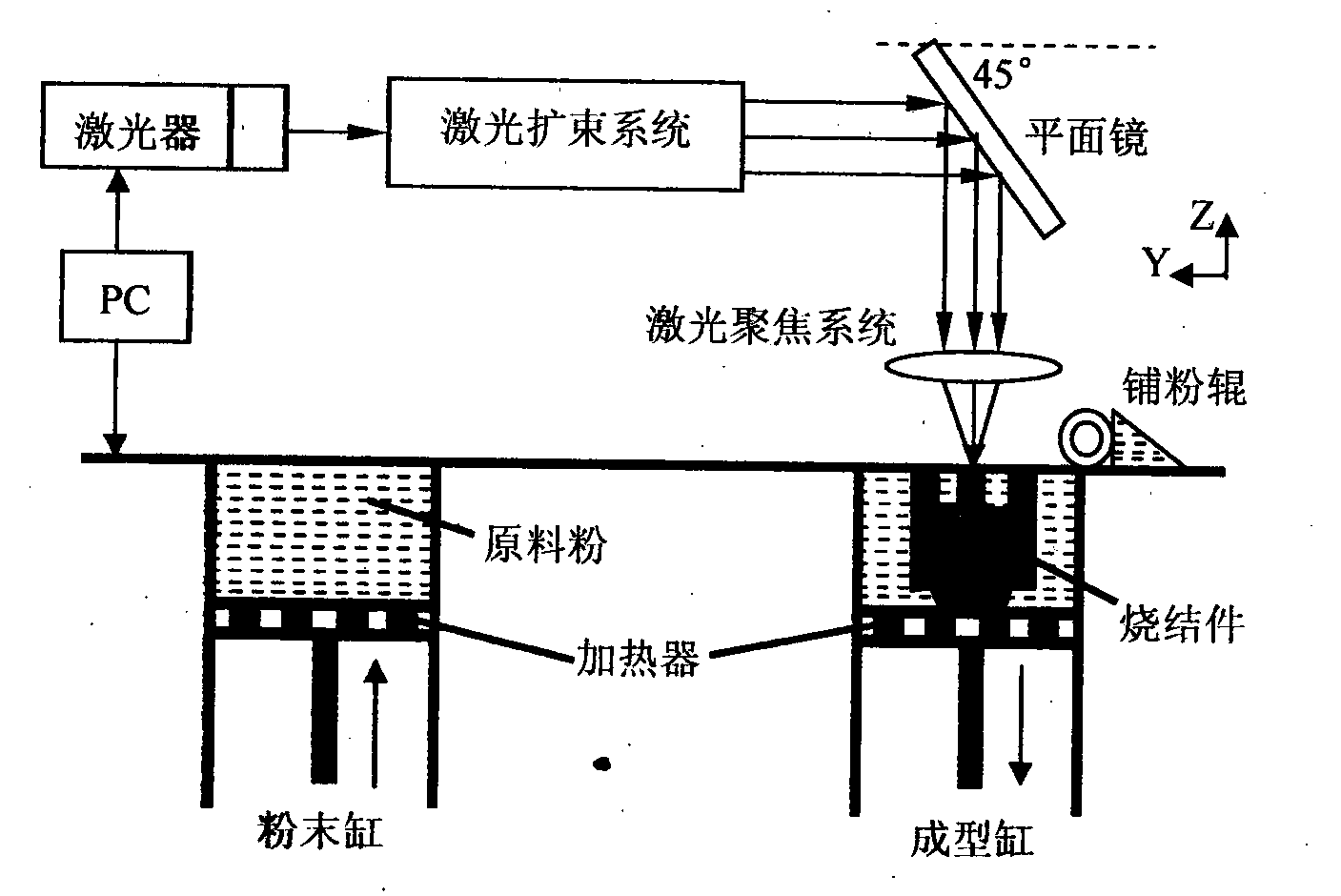

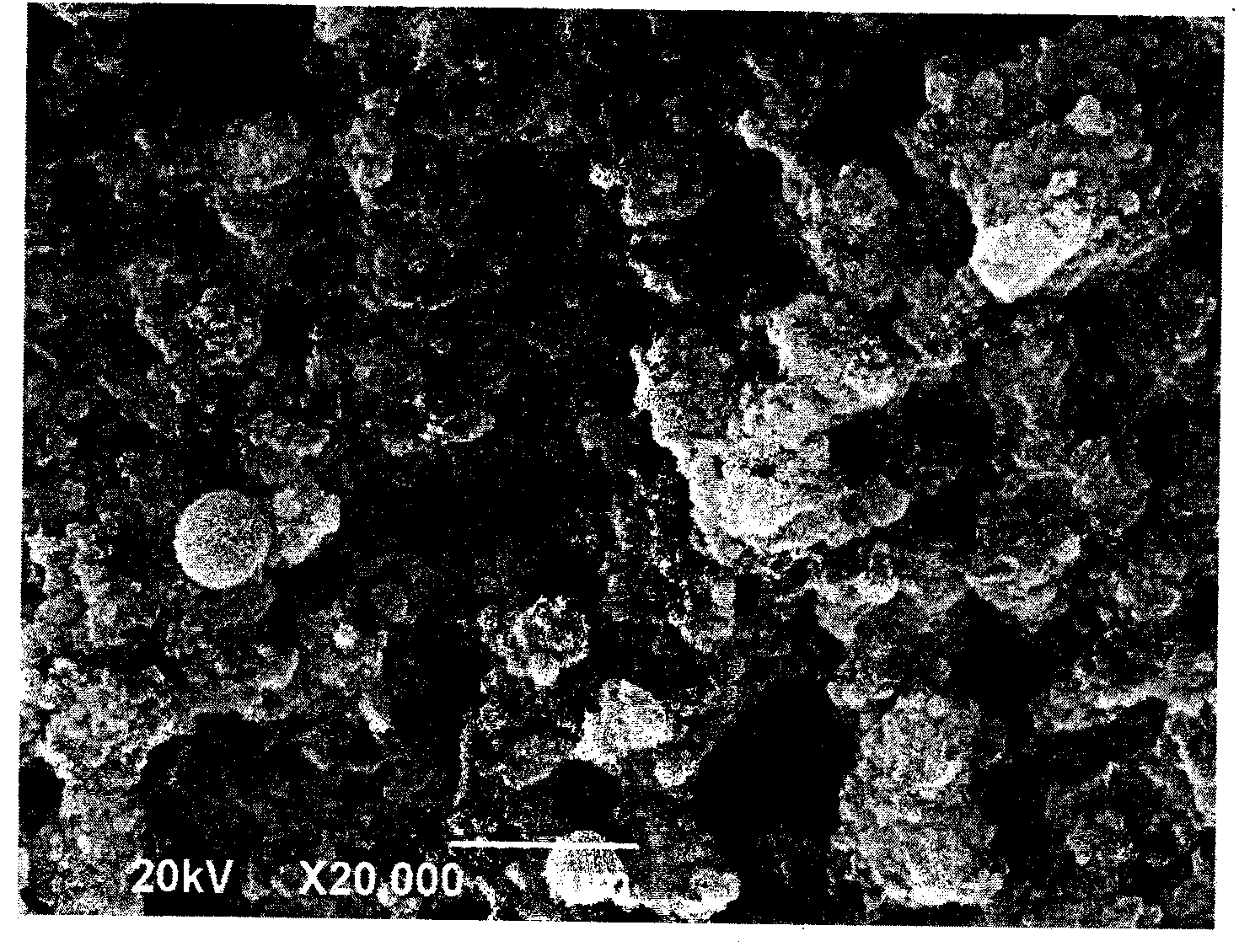

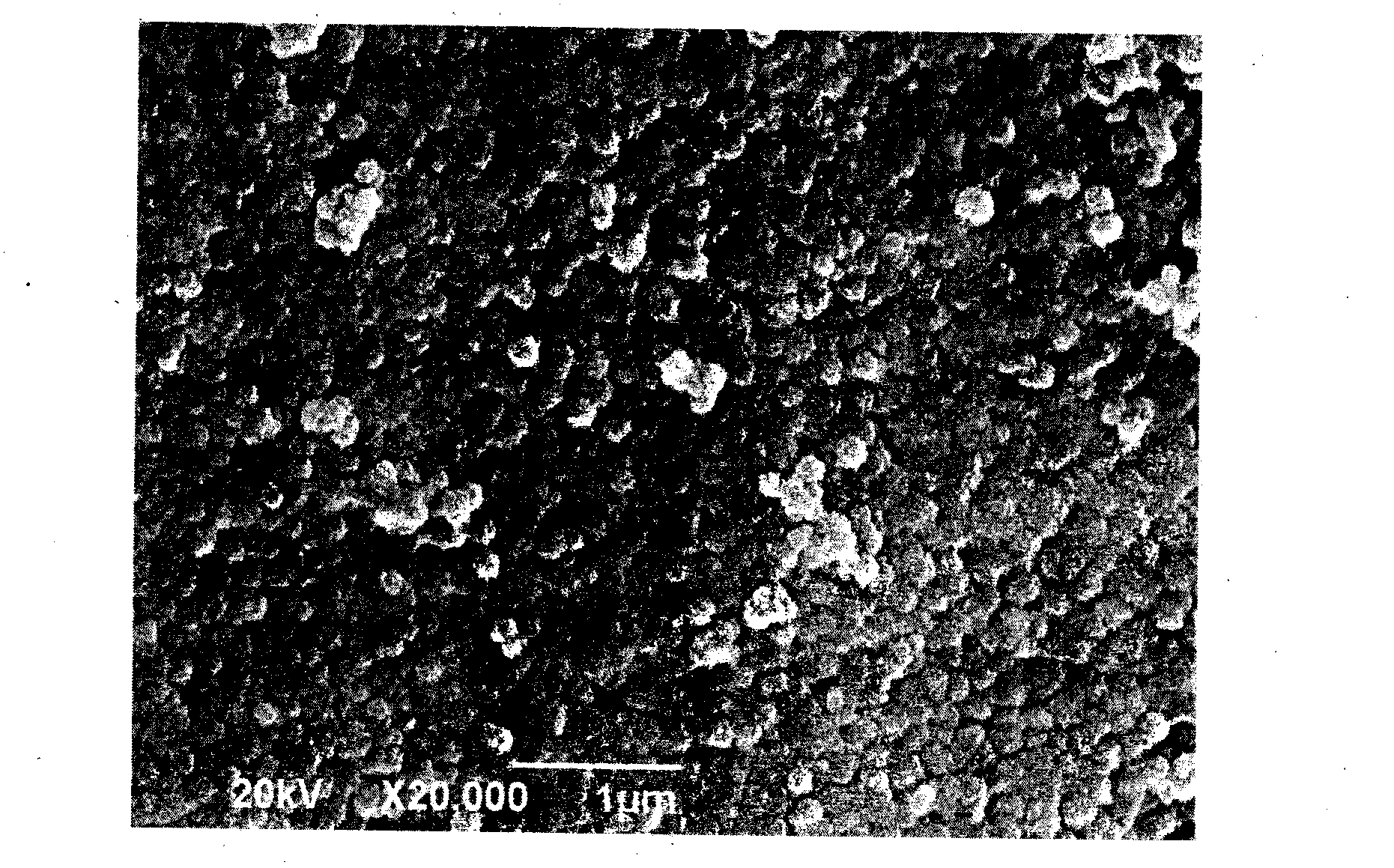

[0021] A method for improving the sintering performance of BCP by adding a small amount of PLLA to the porous ceramic artificial bone prepared by laser, using HAP and β-TCP powder at a mass ratio of 1:1, and using a mechanical mixing method to prepare evenly mixed BCP powder. Then, a small amount of PLLA was added to the BCP powder, and a BCP / PLLA mixed powder with a PLLA mass fraction of 1% was prepared by mechanical mixing. The obtained BCP / PLLA mixed powder was placed in a self-developed SLS system, and sintered to prepare porous BCP artificial bone. Among them, the spot diameter is 2mm, the powder coating thickness is 0.2mm, the laser power is 10W, and the scanning speed is 100mm / min. Compared with the BCP artificial bone obtained without adding PLLA, it was found that when 1% PLLA was added to the BCP powder, the microstructure of the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com