Heavy metal stabilization method in garbage incineration ash

A technology of waste incineration and heavy metals, which is applied in the removal of solid wastes, etc., can solve the problems of poor hexavalent chromium effect, no effect of stabilizing heavy metals in grinding, and achieve the effect of improving sintering effect and preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

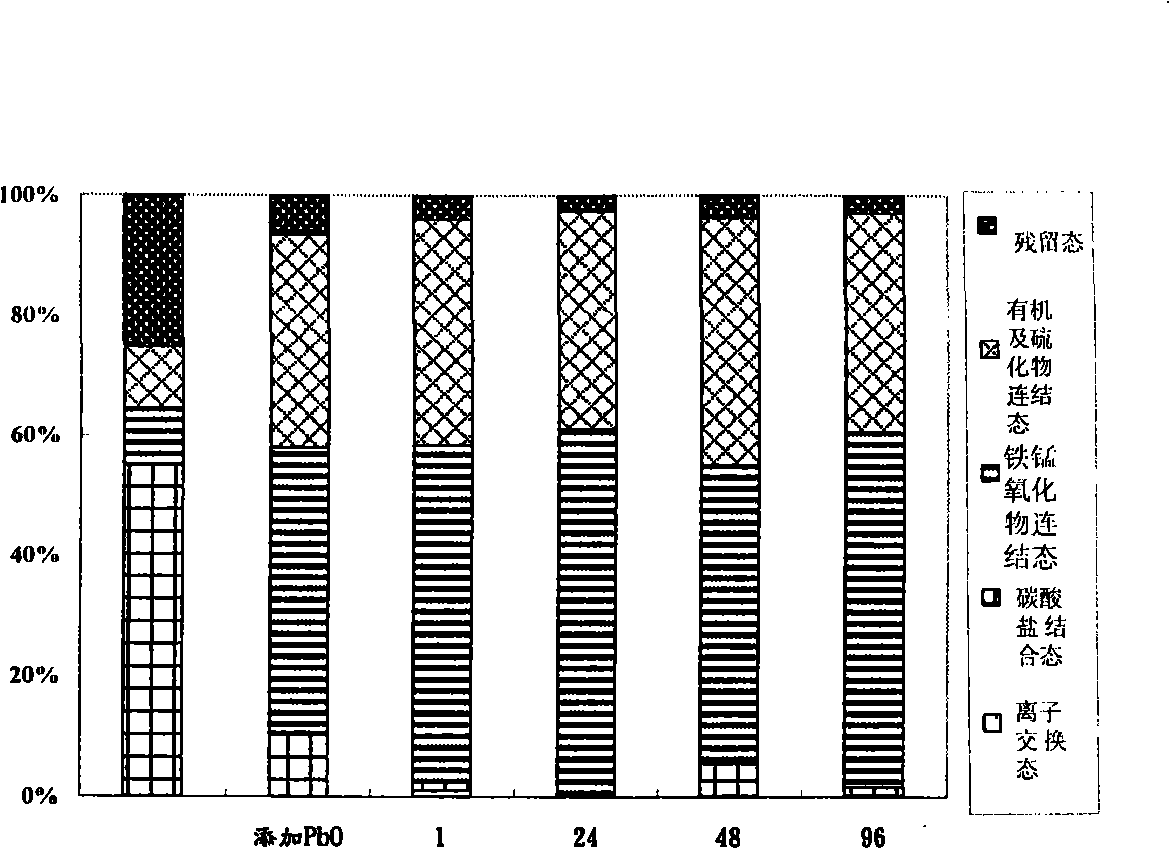

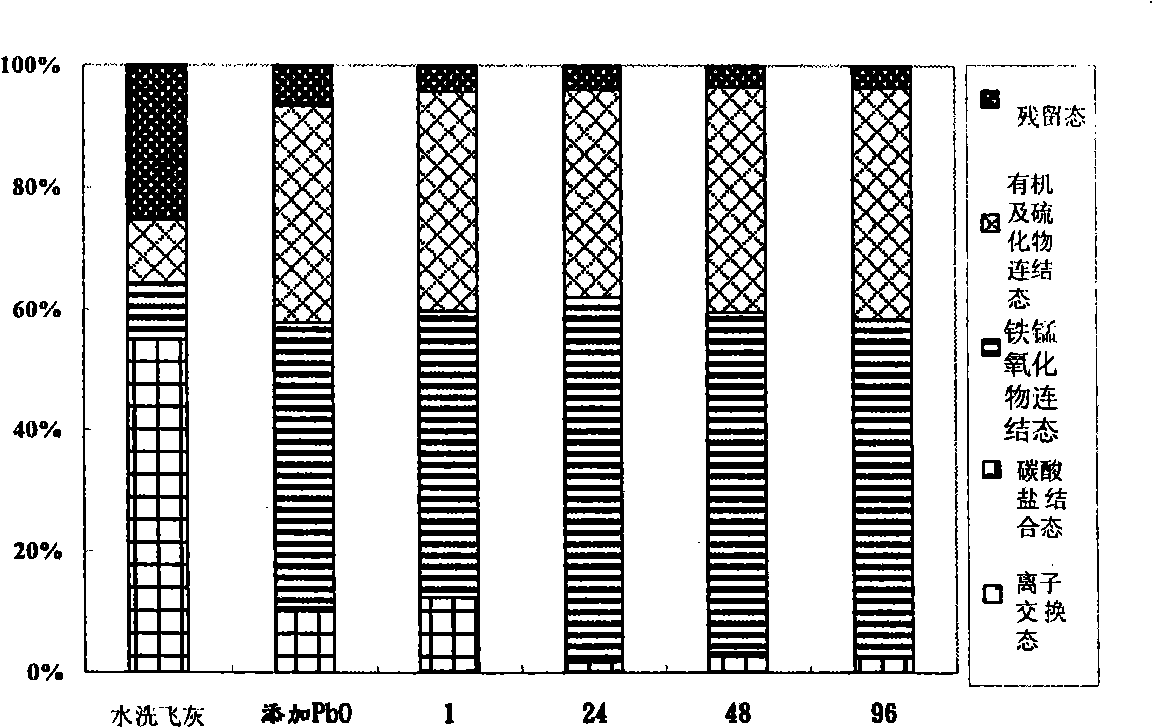

[0080] Ordinary ball milling equipment (model: BM-104 (manufactured by OPTIMUMINSTRUMEN APPLICATI CO LTD) in Taiwan), the size of the grinding tank is 20.6 cm long, 20.5 cm inner diameter, and the volume is 6.8 liters, the grinding tank speed is 93rpm, grinding The material of the ball is alumina, the particle size is 5mm and 15mm, the combination of grinding balls is a mixture of two particle sizes and half the weight of each, and the filling volume of the grinding ball is 50% of the volume of the grinding tank (actually about 27% of the volume of the grinding tank) , The concentration of the grinding slurry (including the fly ash and water extracted by water, and the liquid-solid weight ratio of water to fly ash is 9) is 10% by weight (the liquid weight is 9 parts, and the solid weight is 1 part, so after conversion The weight concentration is 10% by weight), the slurry is about 33% of the grinding tank volume, the grinding dispersant is water, and the grinding time is 96 hou...

Embodiment 2

[0082] Take high-energy ball milling equipment, with planetary grinding equipment (Germany Retsch company manufacture, model: PM 100), rotating speed: 400rpm, time: 30 minutes, grinding slurry (comprising the fly ash after water extraction and water, water and fly ash Liquid-solid weight ratio is 5.67) weight concentration is 15% (water is 5.67 weight parts, and fly ash is 1 weight part, so weight concentration after conversion is 15 weight %), uses water as the wet grinding of grinding dispersant, fly after grinding Gray heavy metal TCLP concentration: lead below 0.2mg / L, copper below 0.1mg / L, zinc below 0.3mg / L, chromium below 0.6mg / L, cadmium below 0.01mg / L.

Embodiment 3

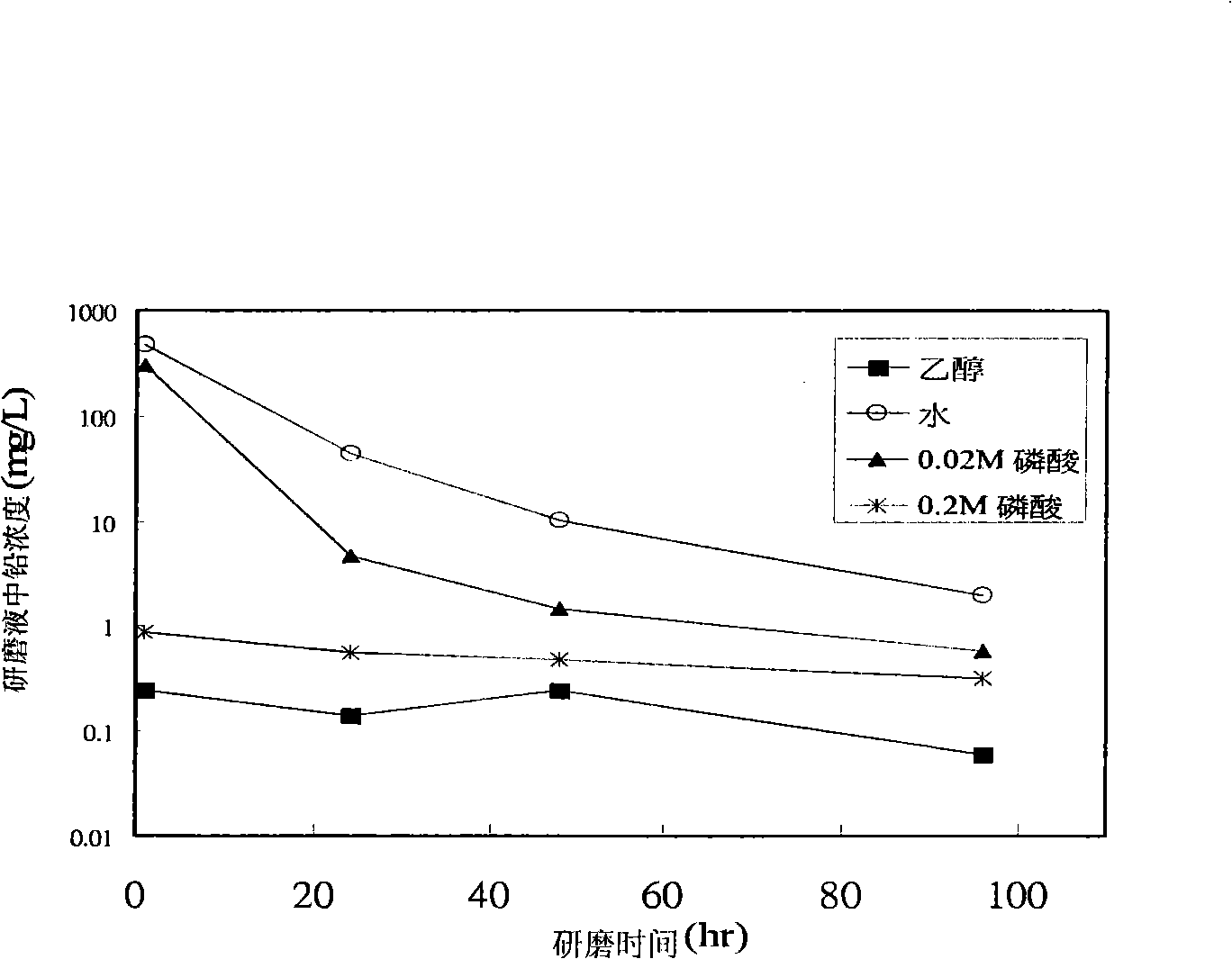

[0084] The volatilization rates of heavy metals in the fly ash after water extraction are: more than 25% of lead, more than 15% of copper, and more than 40% of cadmium at high temperature of 1000°C. Then adopt high-energy ball milling equipment, planetary grinding equipment (manufactured by German Retsch company, model: PM 100), speed: 400rpm, time: 30 minutes, use different grinding dispersants for wet grinding, respectively, can reduce the volatilization rate of heavy metals: lead It can be reduced to less than 4% (grinding with 0.8mole / L phosphoric acid solution), copper can be reduced to less than 3% (30% alumina is added, and water is used as a grinding dispersant to grind together), cadmium can be reduced to less than 6% ( Grinding with 0.2mole / L phosphoric acid solution).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com