Patents

Literature

86 results about "Calcium phosphate ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous composite containing calcium phosphate and process for producing the same

ActiveUS20060292350A1Small apertureImprove thermal conductivityImpression capsSynthetic resin layered productsLinking collagenCalcium biphosphate

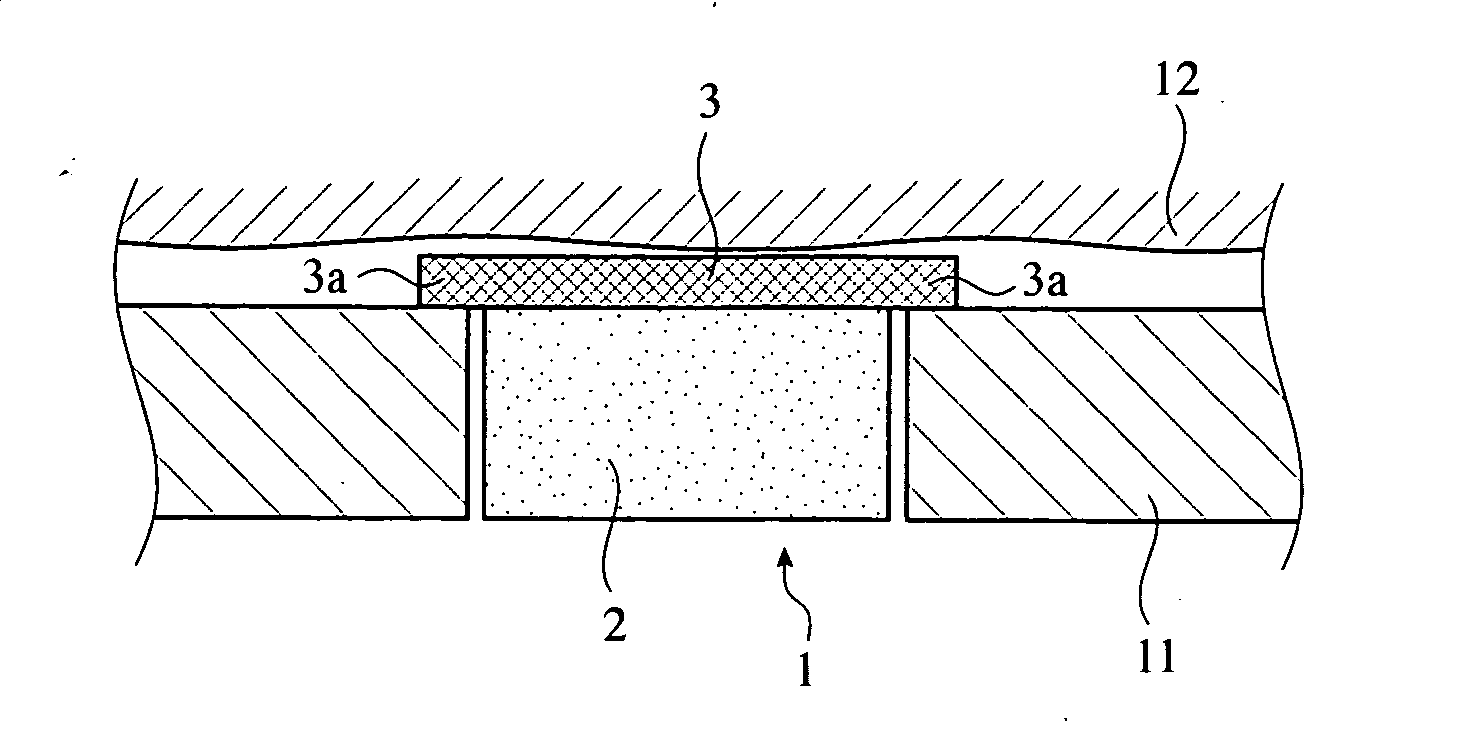

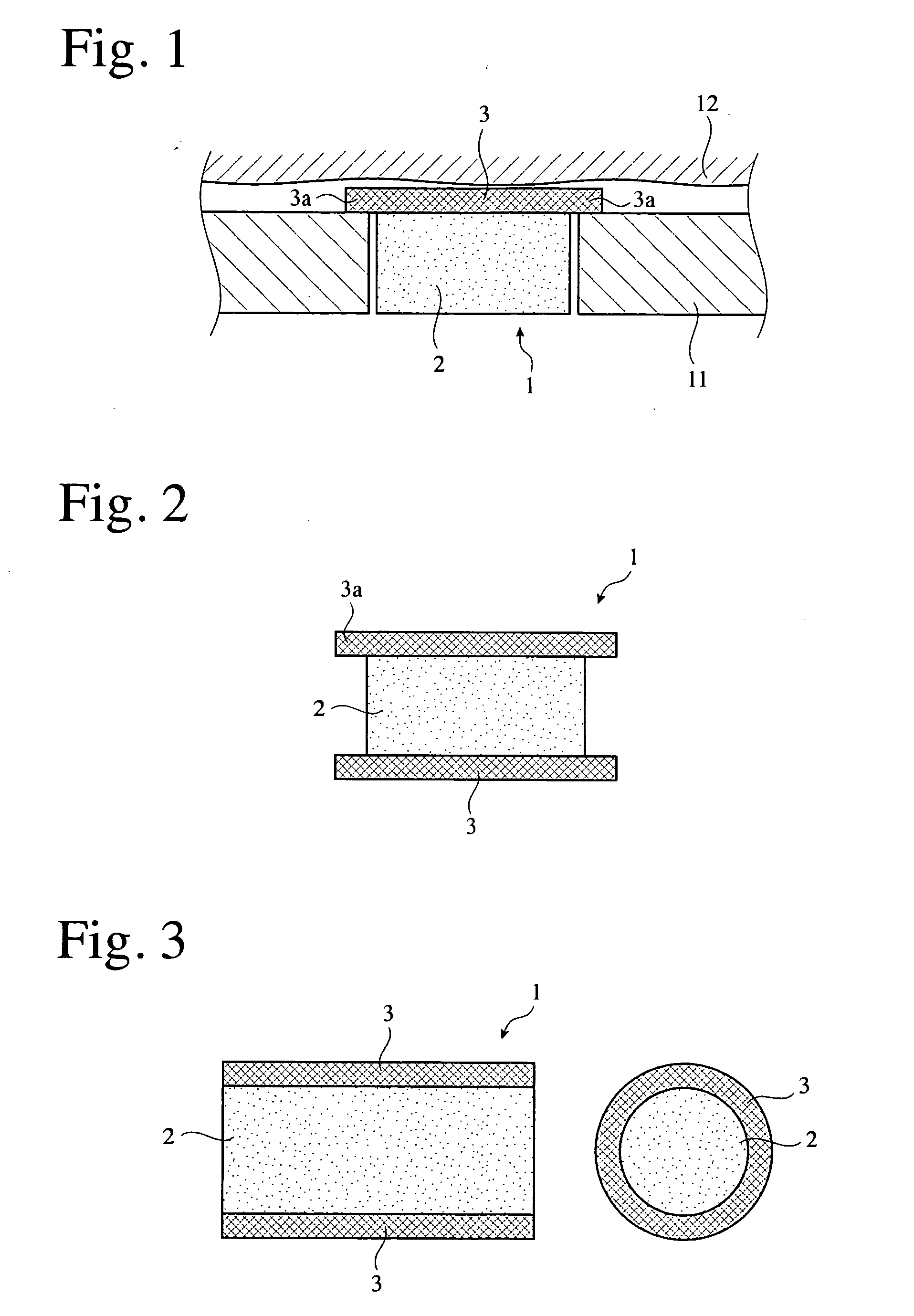

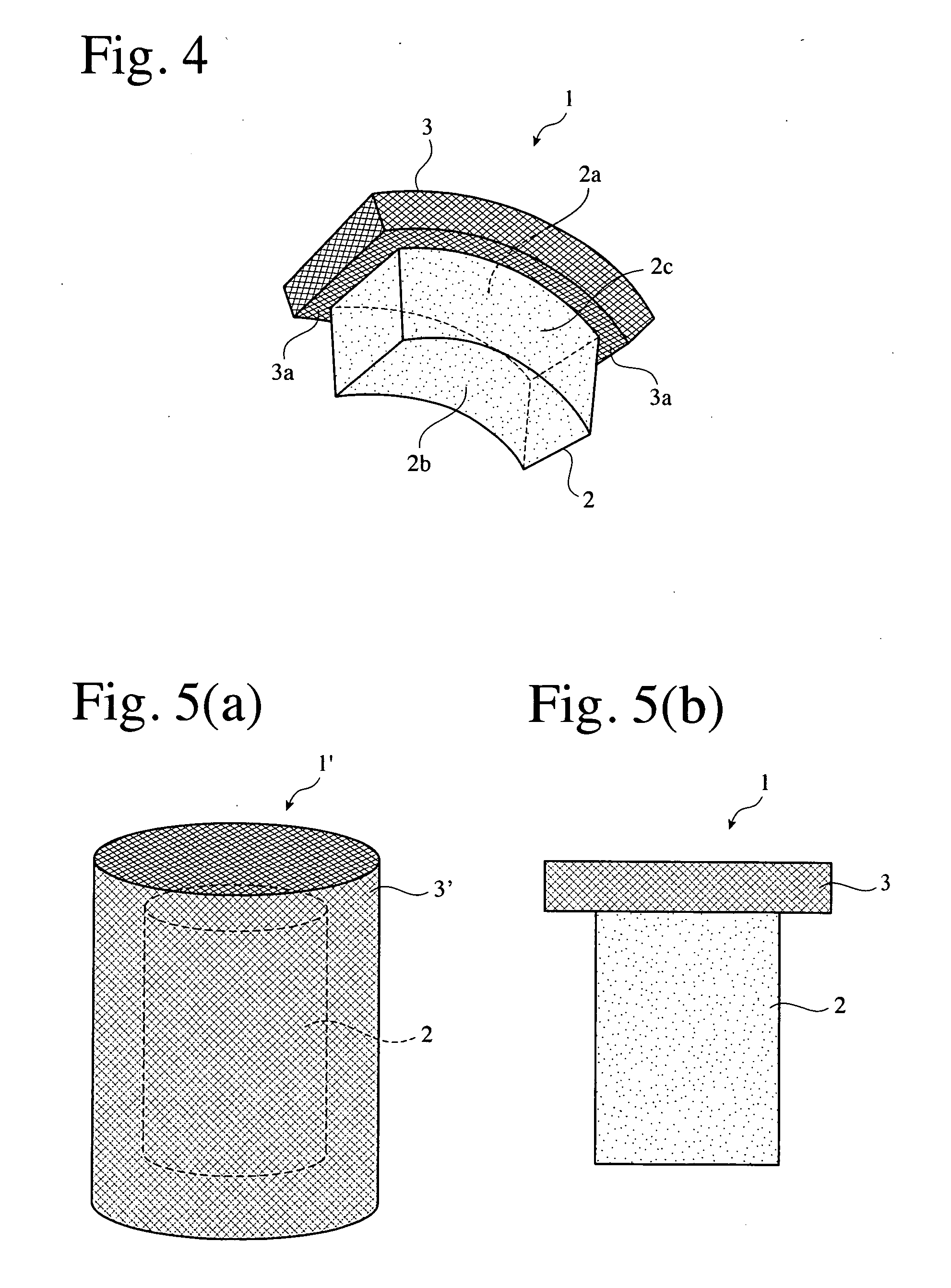

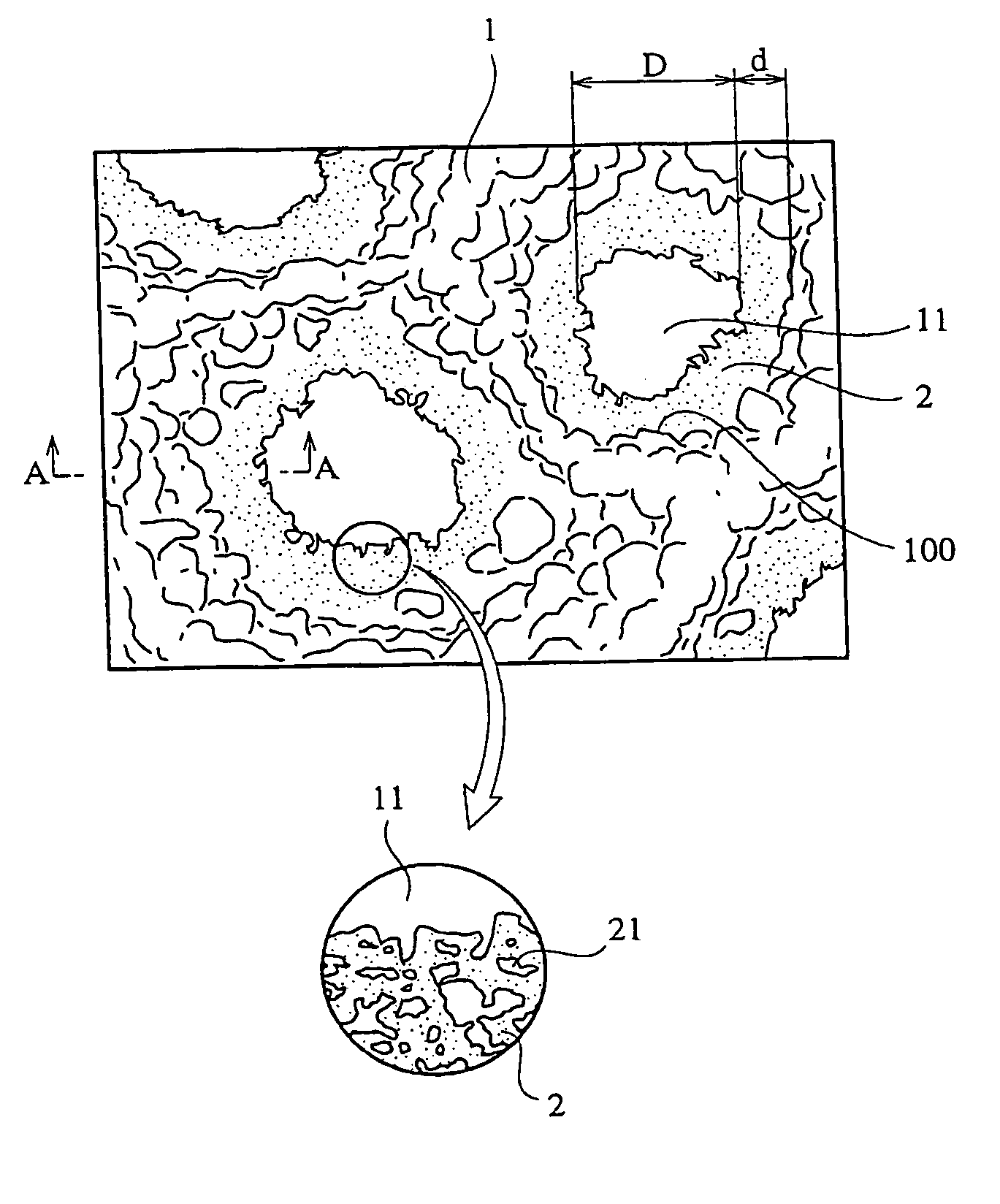

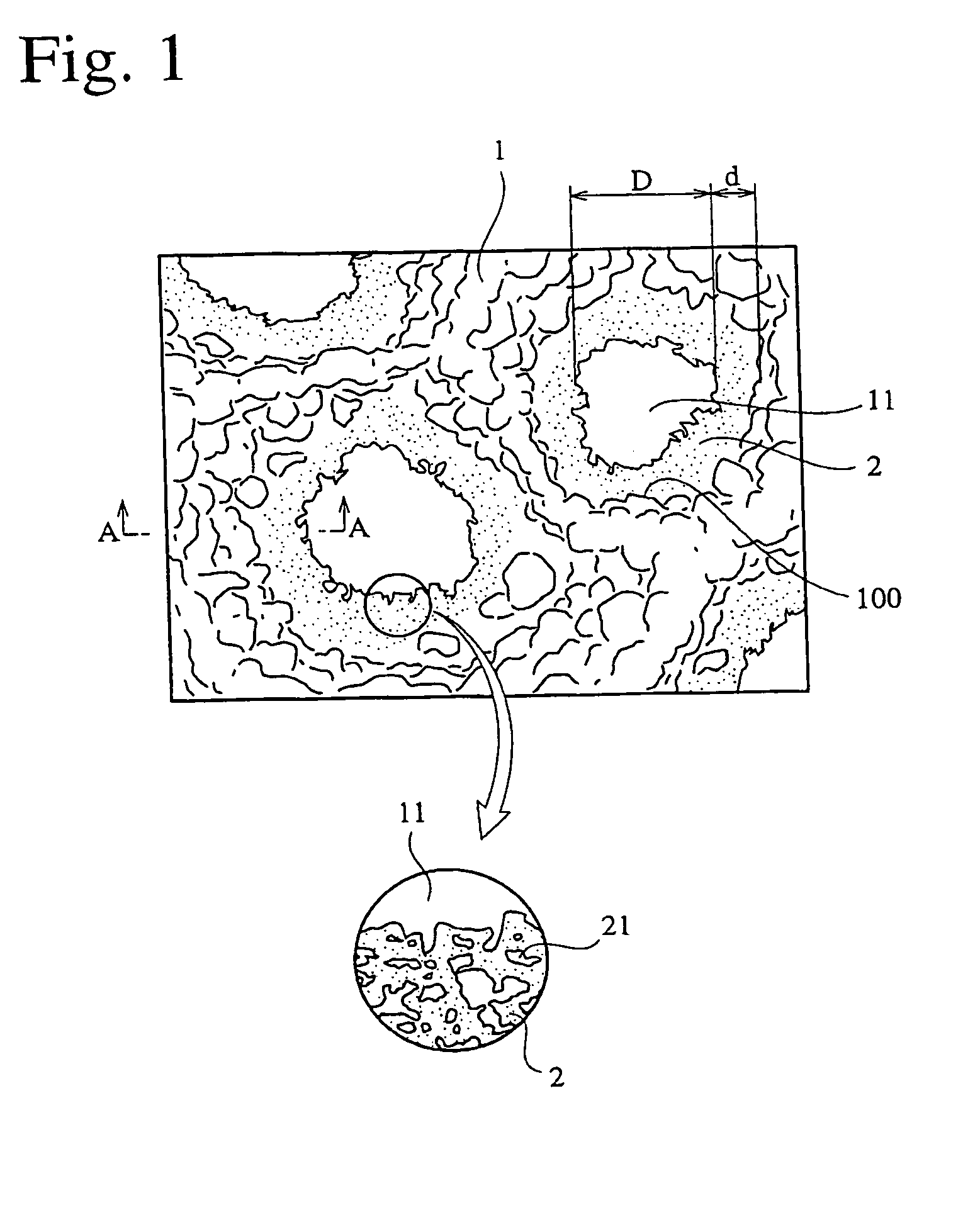

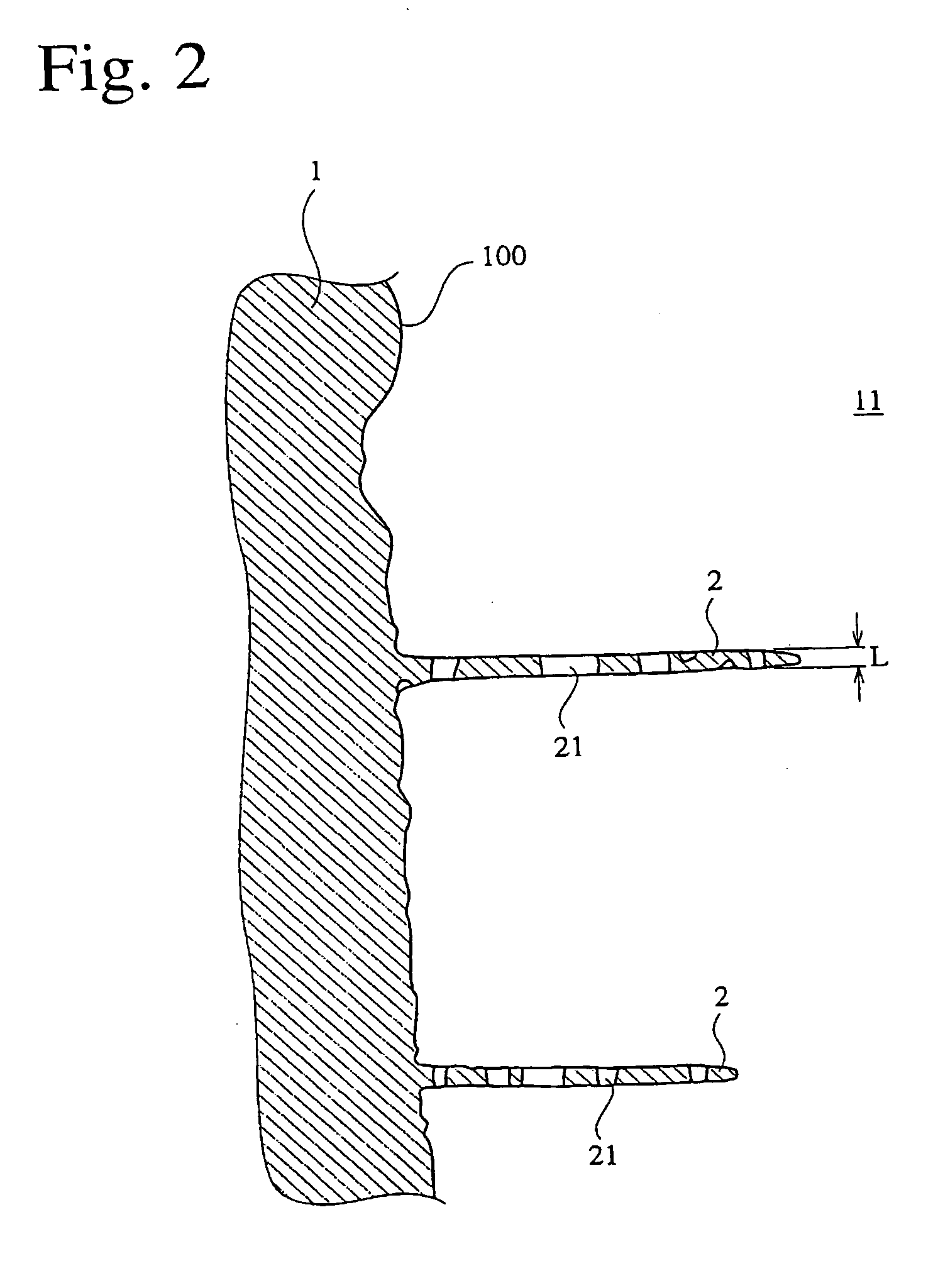

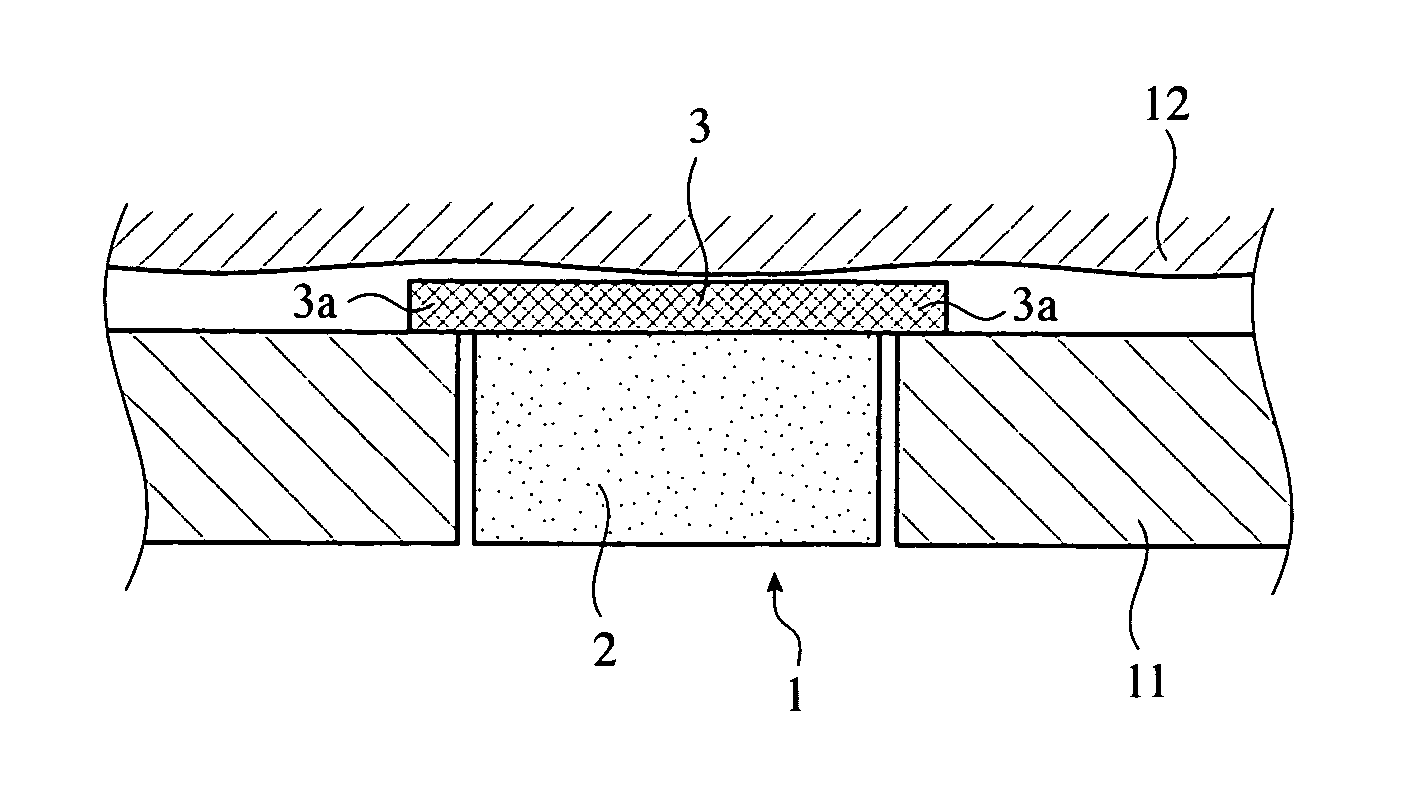

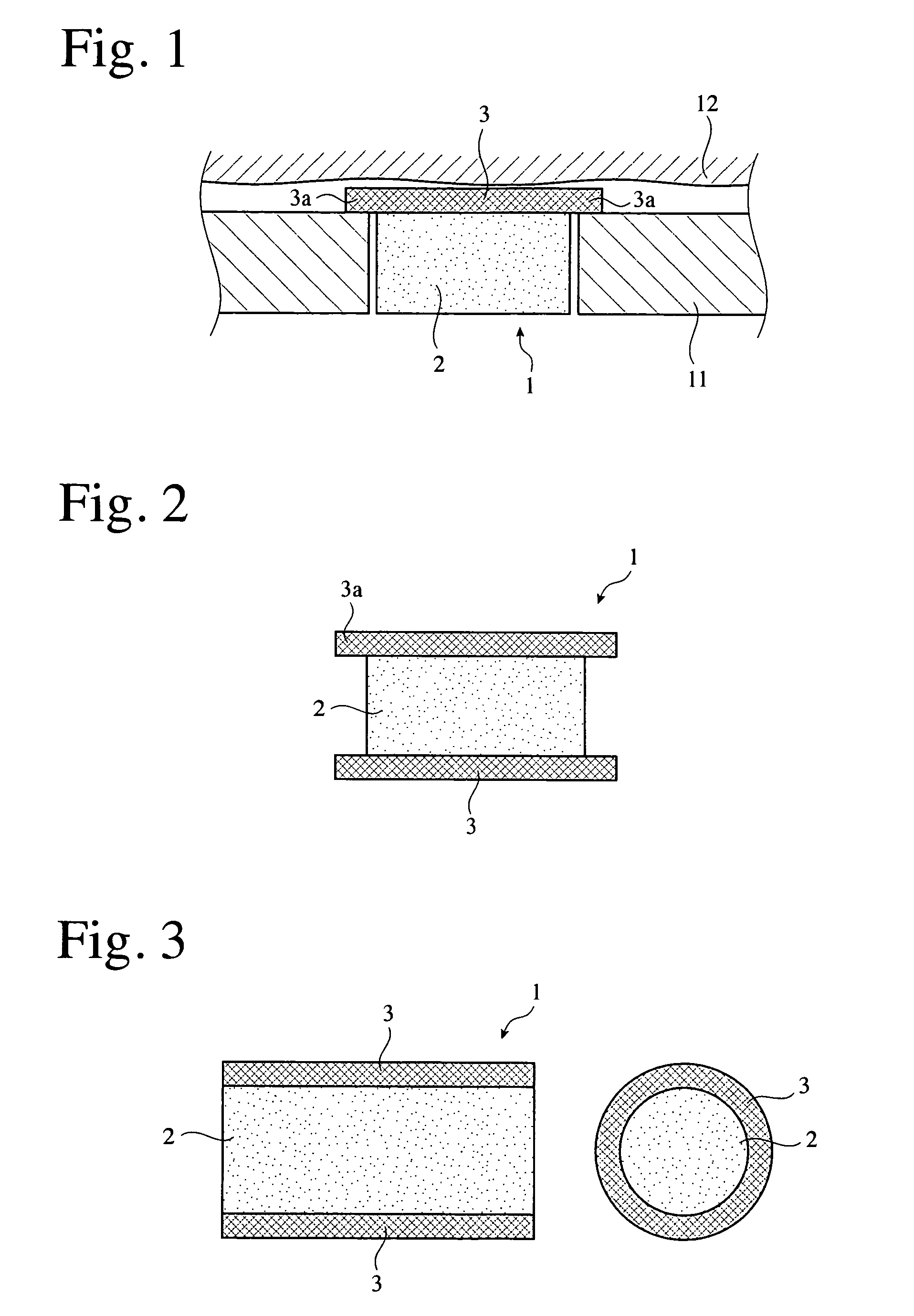

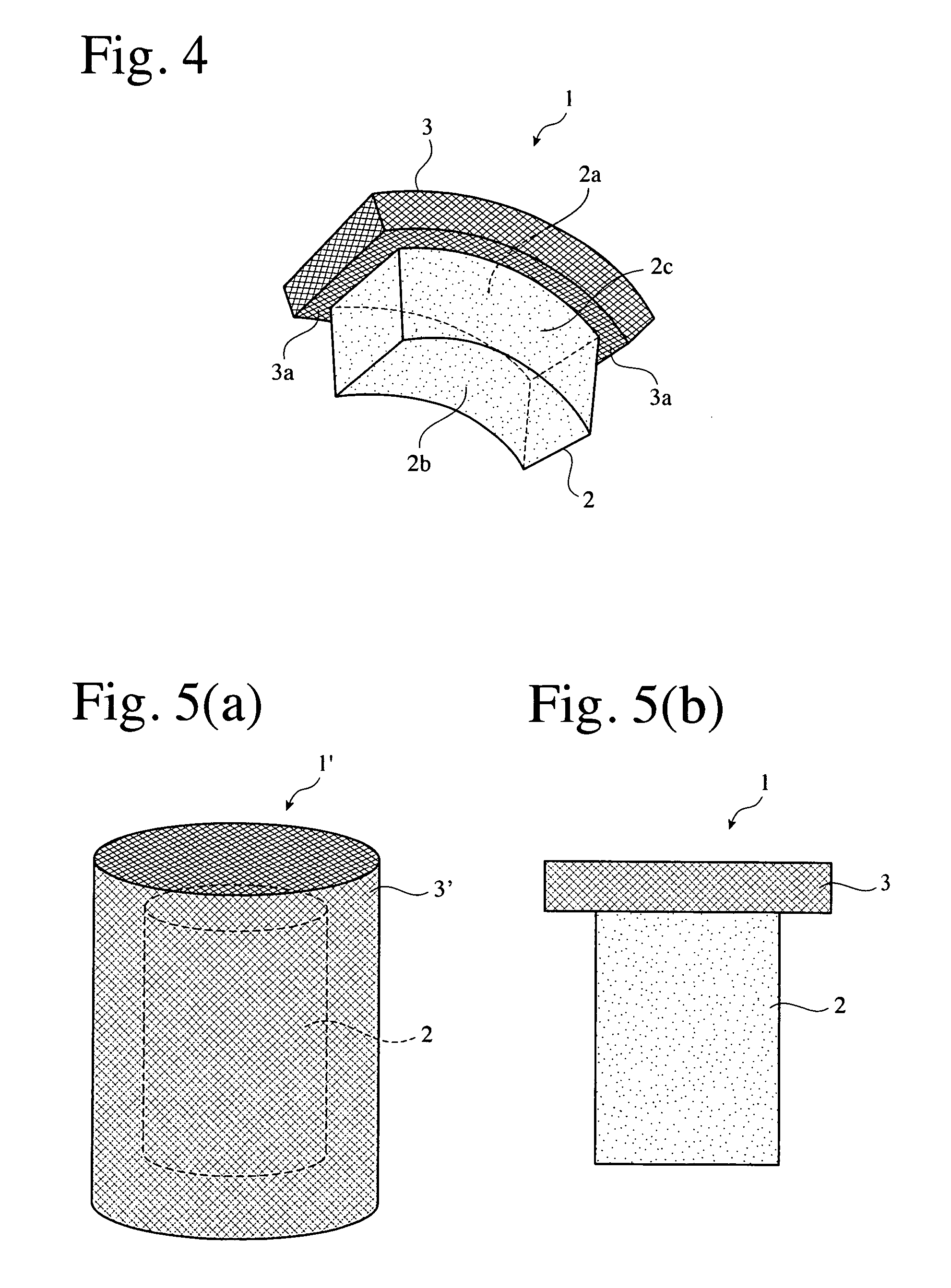

A porous composite comprising a porous layer containing a calcium phosphate ceramic, and a dense layer formed on part of the porous layer and having a smaller average pore size than that of the porous layer. The porous composite can be produced by (1) introducing a slurry containing a calcium phosphate ceramic / collagen composite and collagen into a molding die having a high thermal conductivity, (2) rapidly freezing and drying the slurry in the molding die, to form a porous body comprising a porous layer and a dense layer formed on the porous layer, (3) cross-linking collagen in the porous body, and (4) removing the dense layer except for a portion thereof on a surface coming into contact with a soft tissue when implanted in a human body, so that the porous layer is exposed.

Owner:NAT INST FOR MATERIALS SCI +1

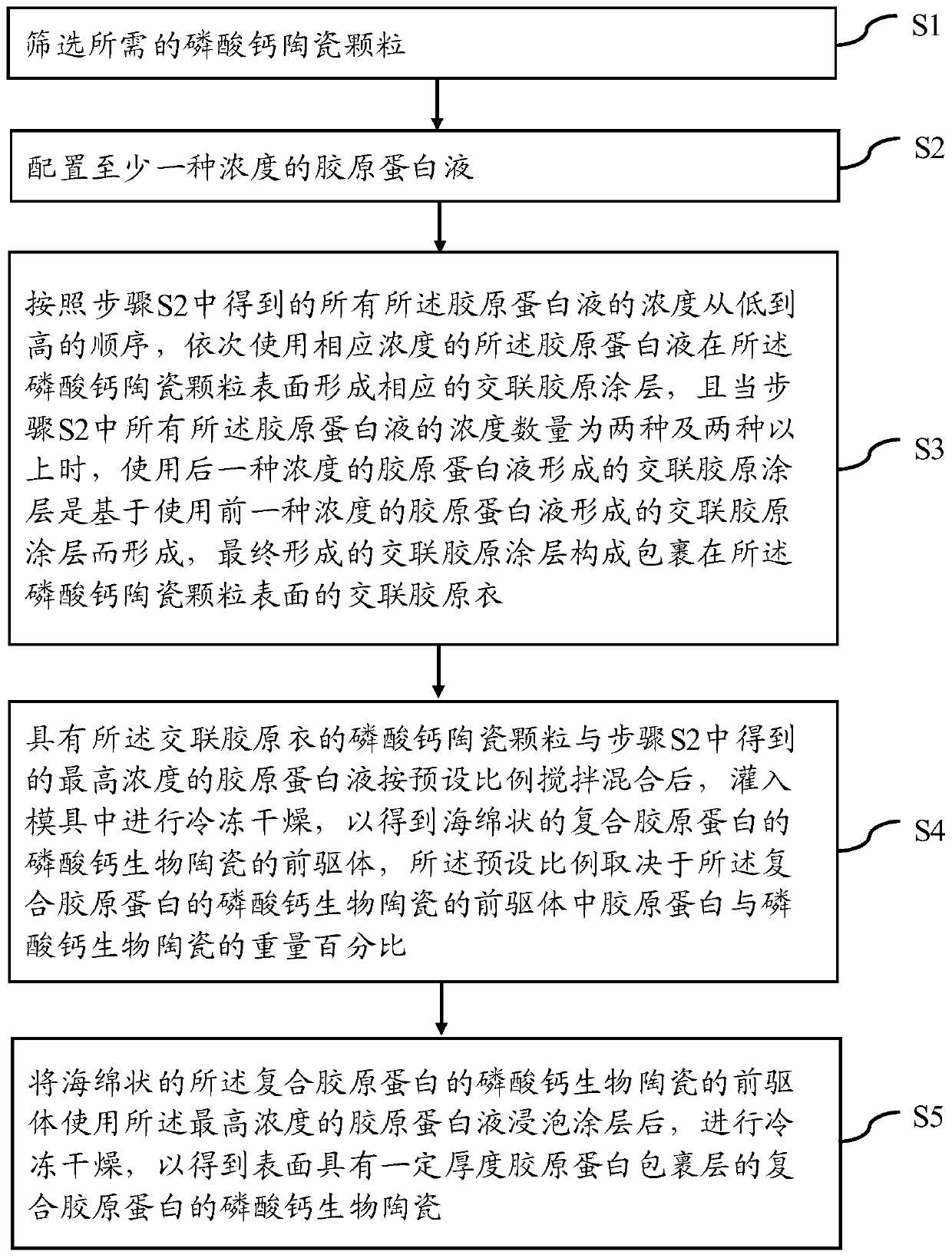

Calcium phosphate/collagen composite biologic ceramic material and preparation method thereof

InactiveCN103055352AImprove mechanical propertiesPromote repair and regenerationProsthesisCalcium biphosphateBone tissue engineering

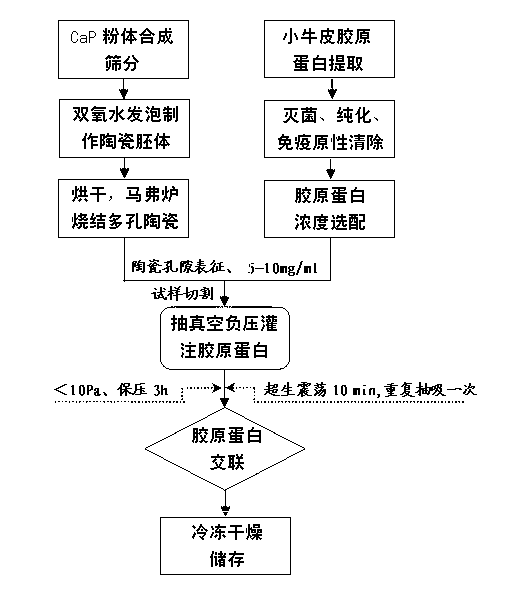

The invention relates to a CaP (Calcium Phosphate) / collagen composite biologic ceramic material and a preparation method thereof. The composite biologic ceramic is prepared by adopting a porous calcium phosphate ceramic as the substrate and I-type collage as the toughening reinforcing phase in a vacuum negative pressure pouring and crosslinking mode. The process is as follows: firstly, preparing the first type through porous calcium phosphate ceramic, wherein the porosity is 60-95%; dipping the porous calcium phosphate ceramic into a collagen solution of which the concentration is 5-20mg / ml; and vacuuming to 0-10Pa at normal temperature and pouring, keeping the pressure for 1-3 hours and carrying out ultrasonic oscillation. The vacuum negative pressure pouring process can be repeated according to demands. The calcium phosphate ceramic poured with the collagen is frozen and dried to prepare the composite biologic ceramic after being subjected to crosslinking. The prepared biologic ceramic has good biocompatibility and biological activity, and at the same time has a mechanical strength better than that of a pure calcium phosphate ceramic material, so that the biologic ceramic can be used as artificial bones and bone tissue engineering bracket materials, and has wide clinical application prospects in orthopedics.

Owner:SICHUAN UNIV

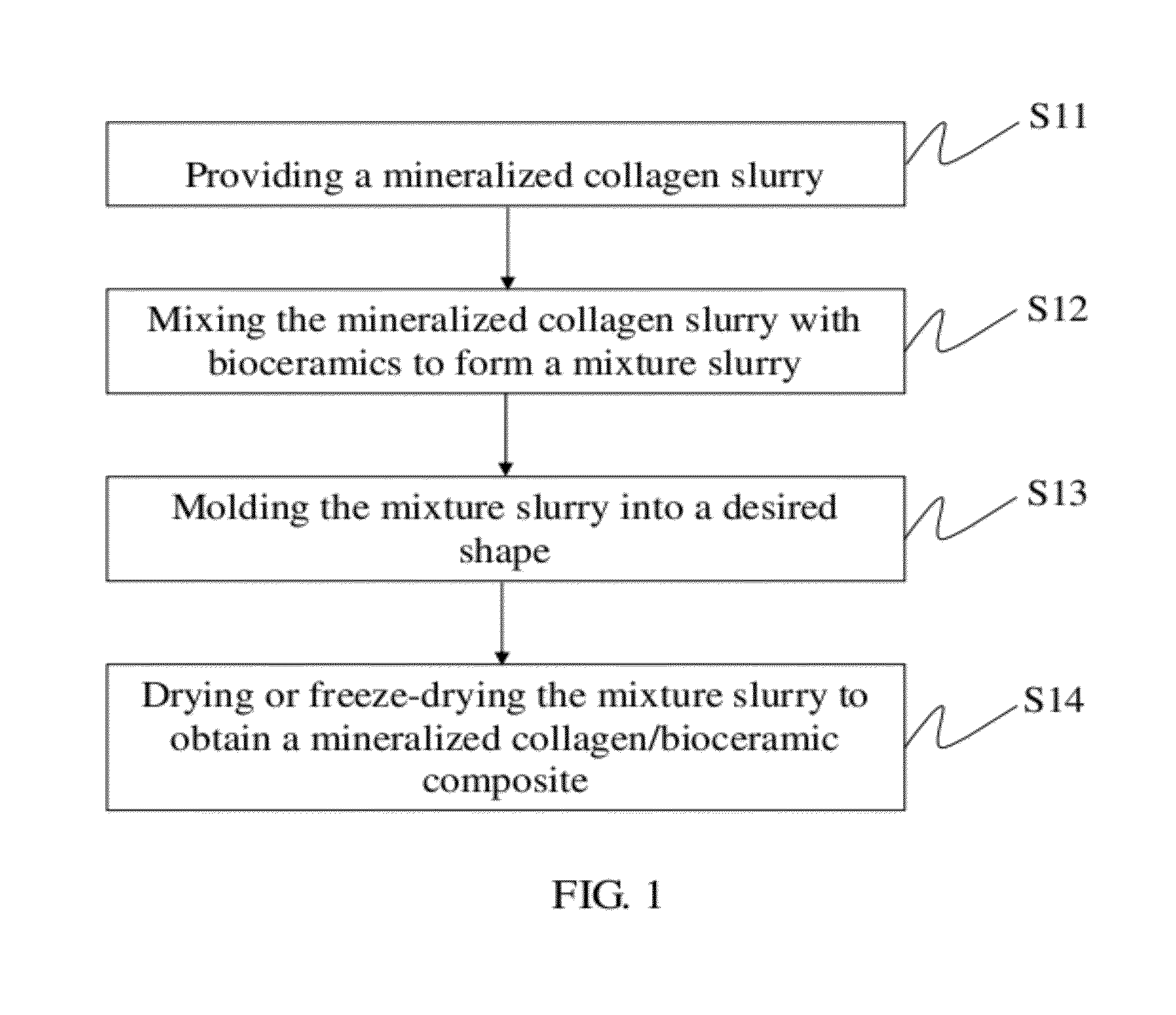

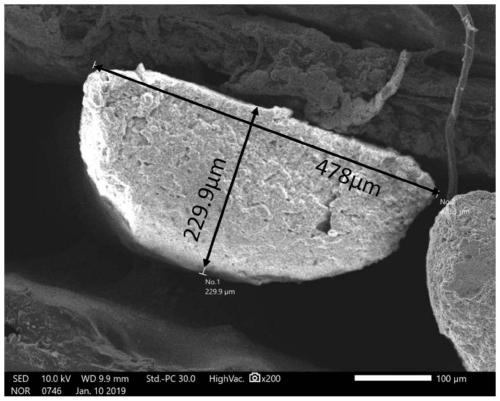

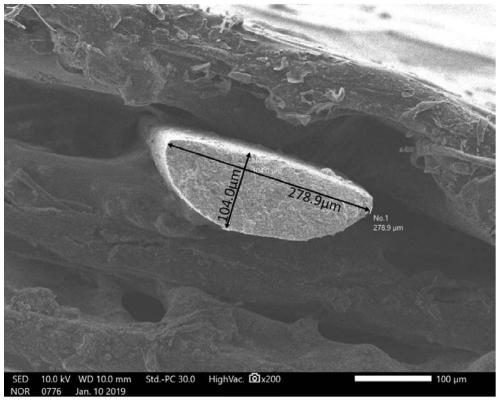

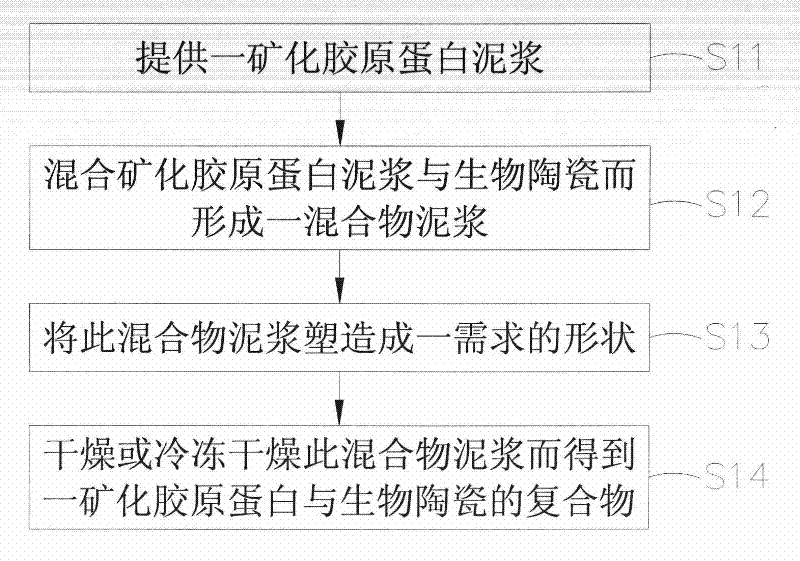

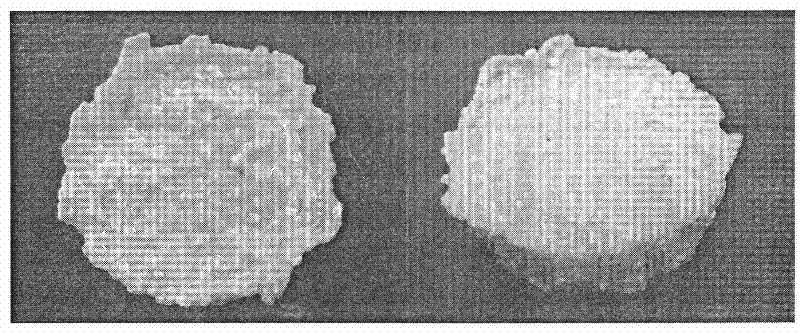

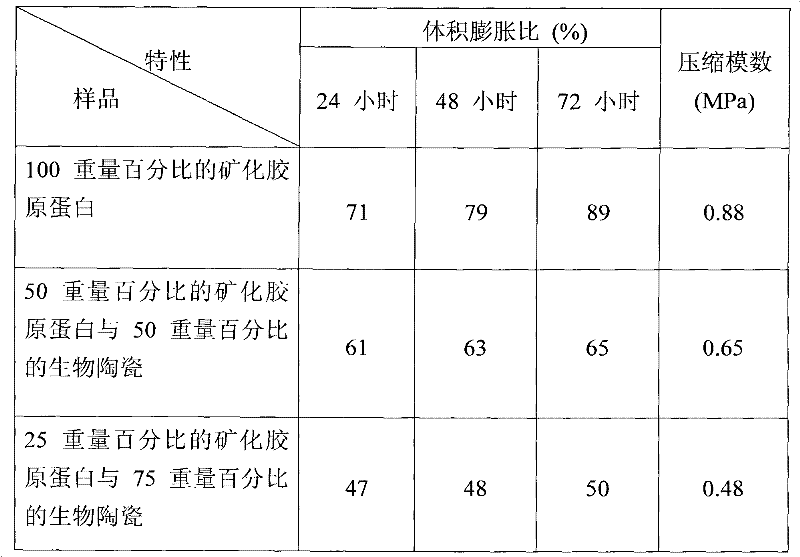

Mineralized Collagen/Bioceramic Composite and Manufacturing Method Thereof

InactiveUS20120207839A1Good biocompatibilityIncrease ratingsBiocidePowder deliveryCalcium biphosphateSulfate

The present invention discloses a mineralized collagen / bioceramic composite useful as a hard tissue replacement material or substitute material, comprising about 10% to 95% by weight of mineralized collagen and about 5% to 90% by weight of bioceramics, and a method of manufacturing the same. Wherein, the mineralized collagen is used as a binder for the bioceramics, such as calcium phosphate ceramics, calcium sulfate ceramics, calcium carbonate ceramics, and other biocompatible ceramics. The bioceramic used in the mineralized collagen / bioceramic composite can be either in powder form or in granular form.

Owner:MAXIGEN BIOTECH

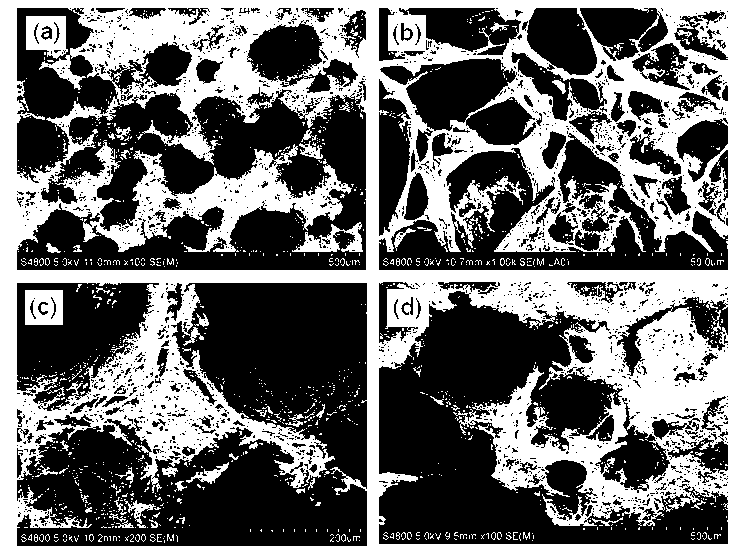

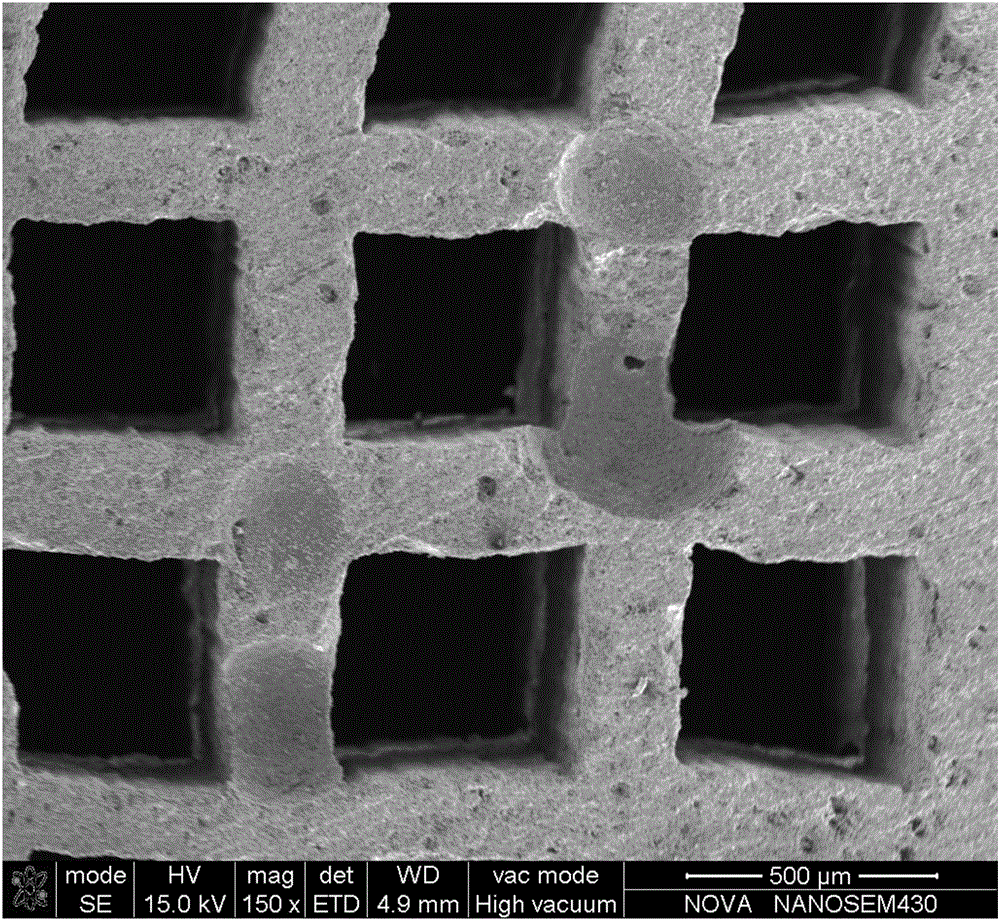

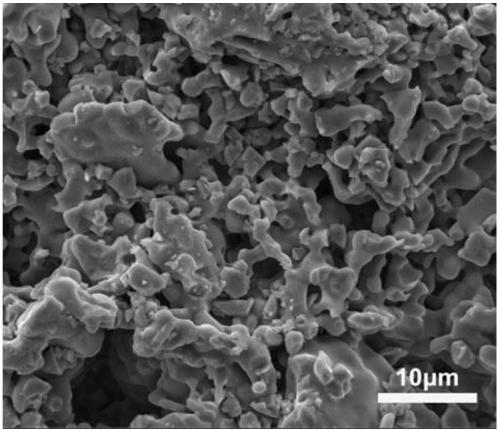

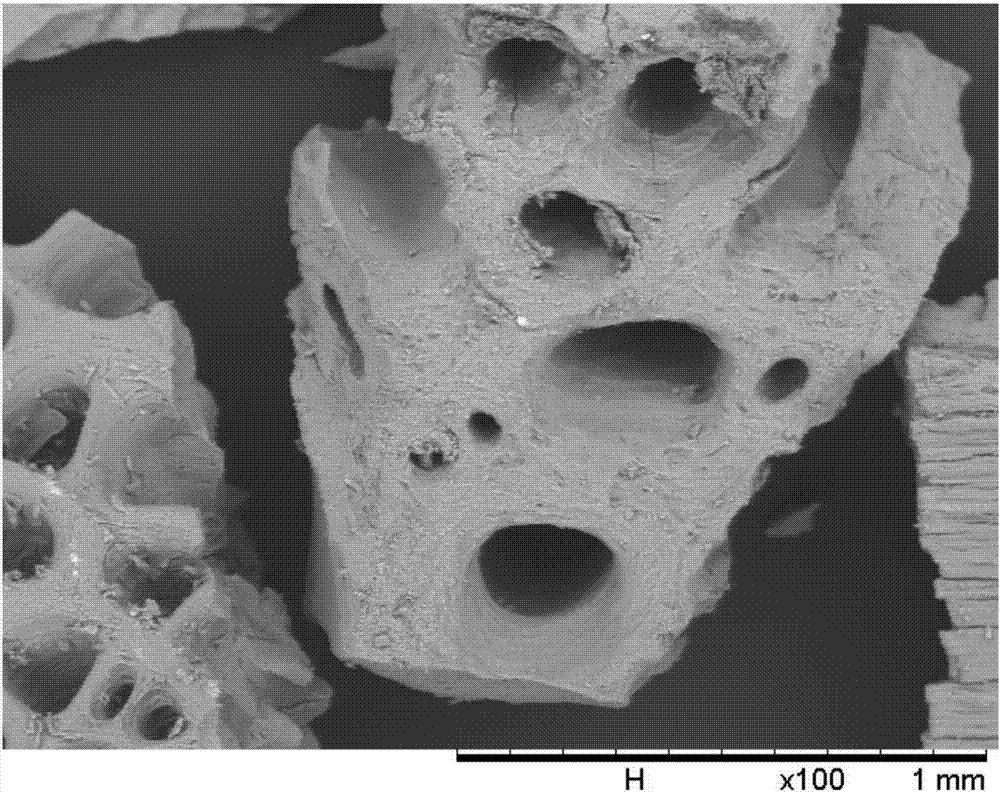

Porous calcium phosphate ceramic and method for producing same

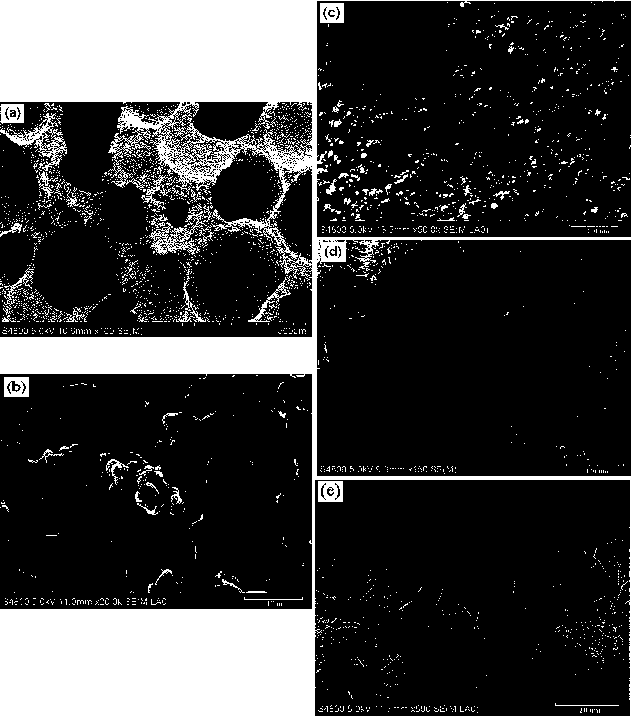

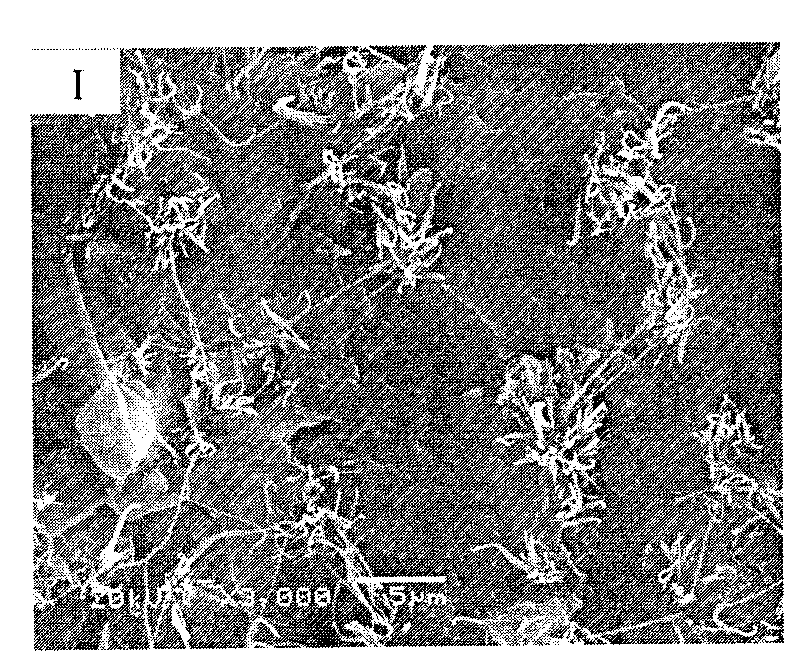

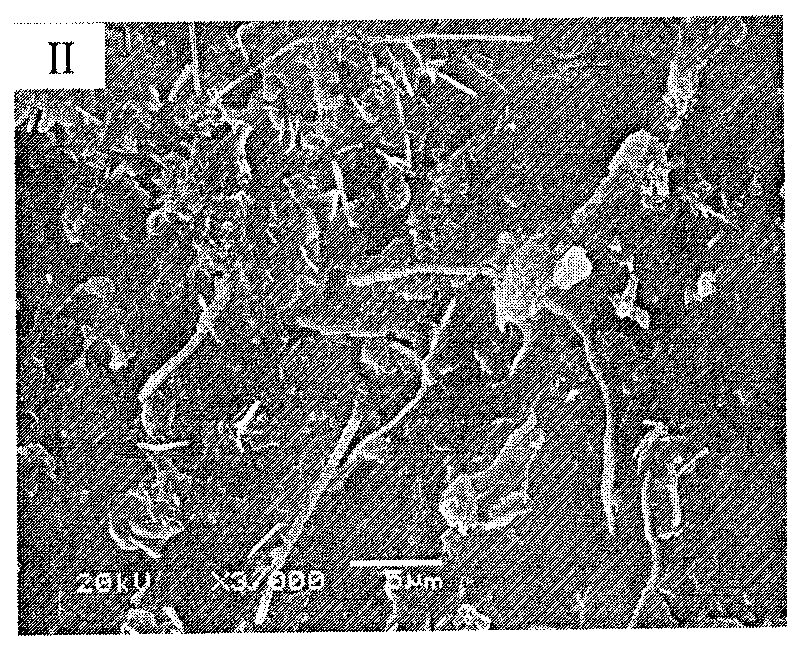

InactiveUS20050119761A1Excellent new-bone-forming capabilityHigh mechanical strengthImpression capsBone implantCalcium biphosphateNetwork structure

A porous calcium phosphate ceramic comprising a support portion having pores, and ring-shaped portions formed in the pores, the ring-shaped portions having pluralities of fine pores so that they have a network structure. A method for producing a porous calcium phosphate ceramic comprising stirring a slurry containing coarse calcium phosphate particles, fine calcium phosphate particles, a nonionic surfactant and a water-soluble high-molecular compound to foam the slurry; gelling the foamed slurry; and then drying the resultant get to obtain a sintered porous calcium phosphate ceramic; the nonionic surfactant being malamide and / or polyoxyethylene lauryl ether.

Owner:HOYA CORP

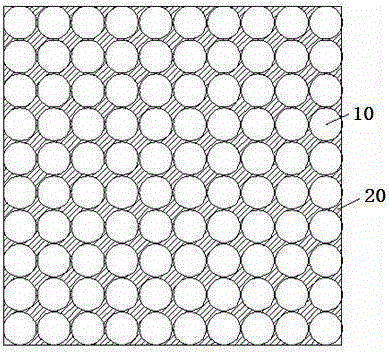

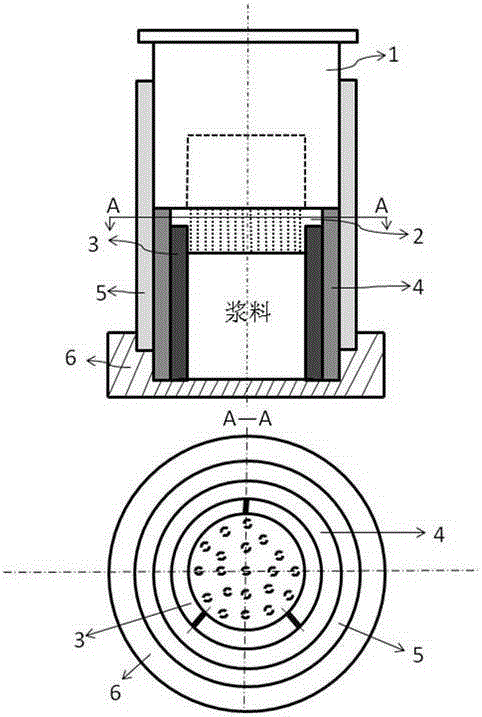

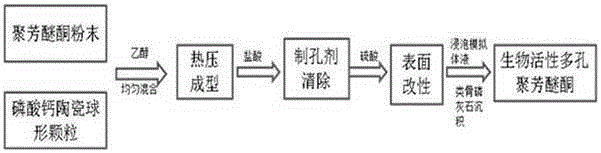

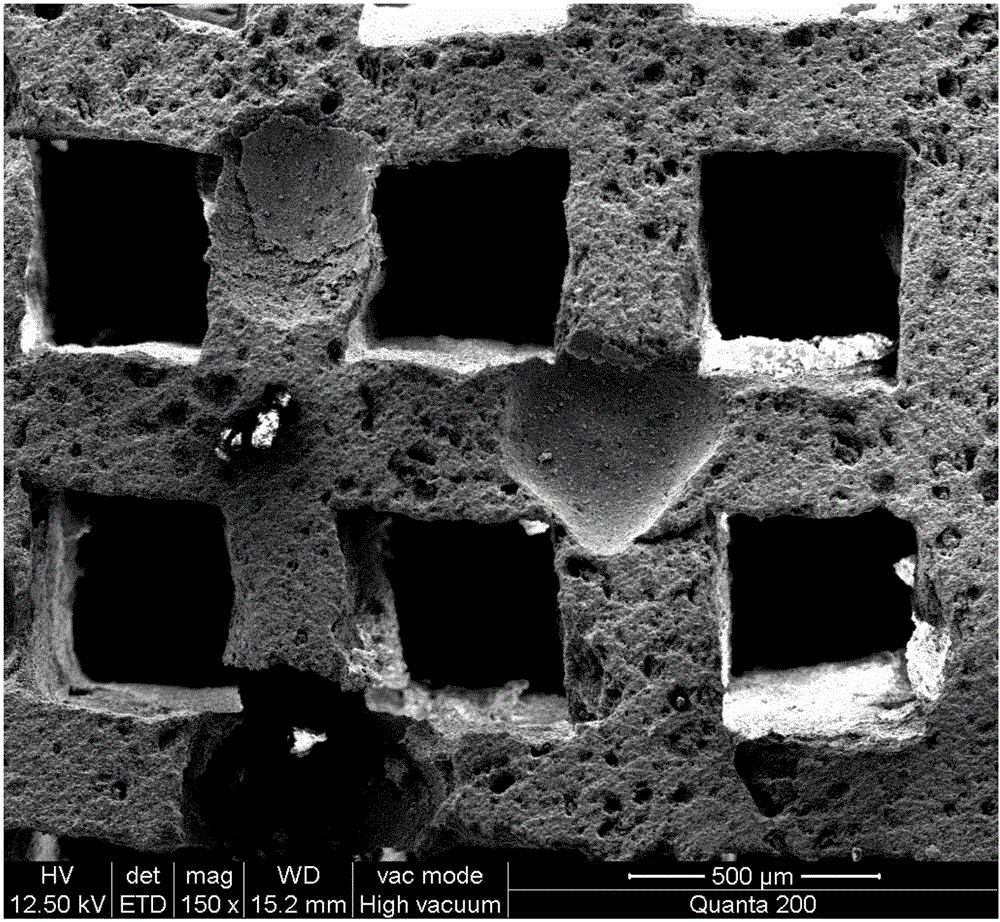

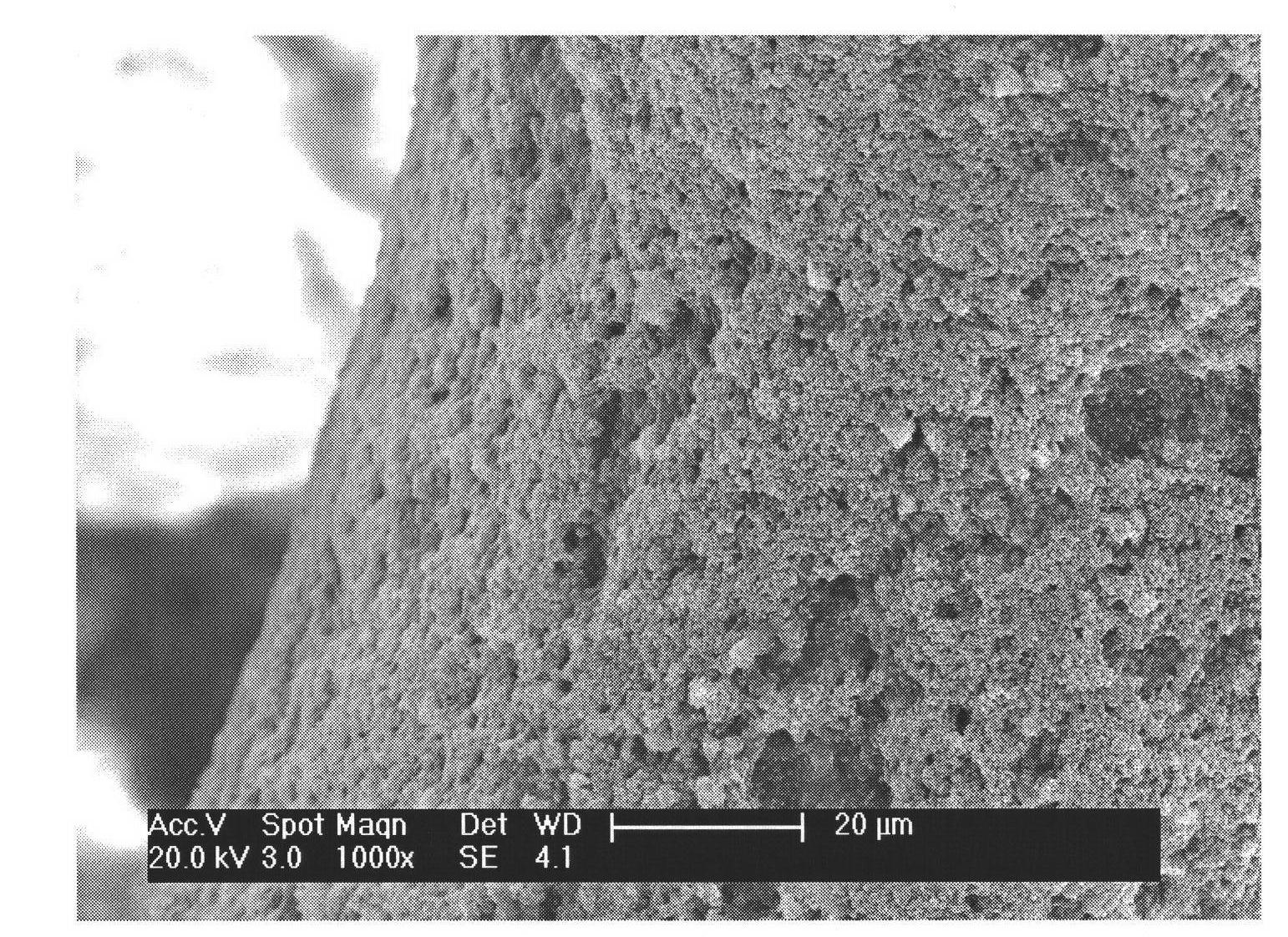

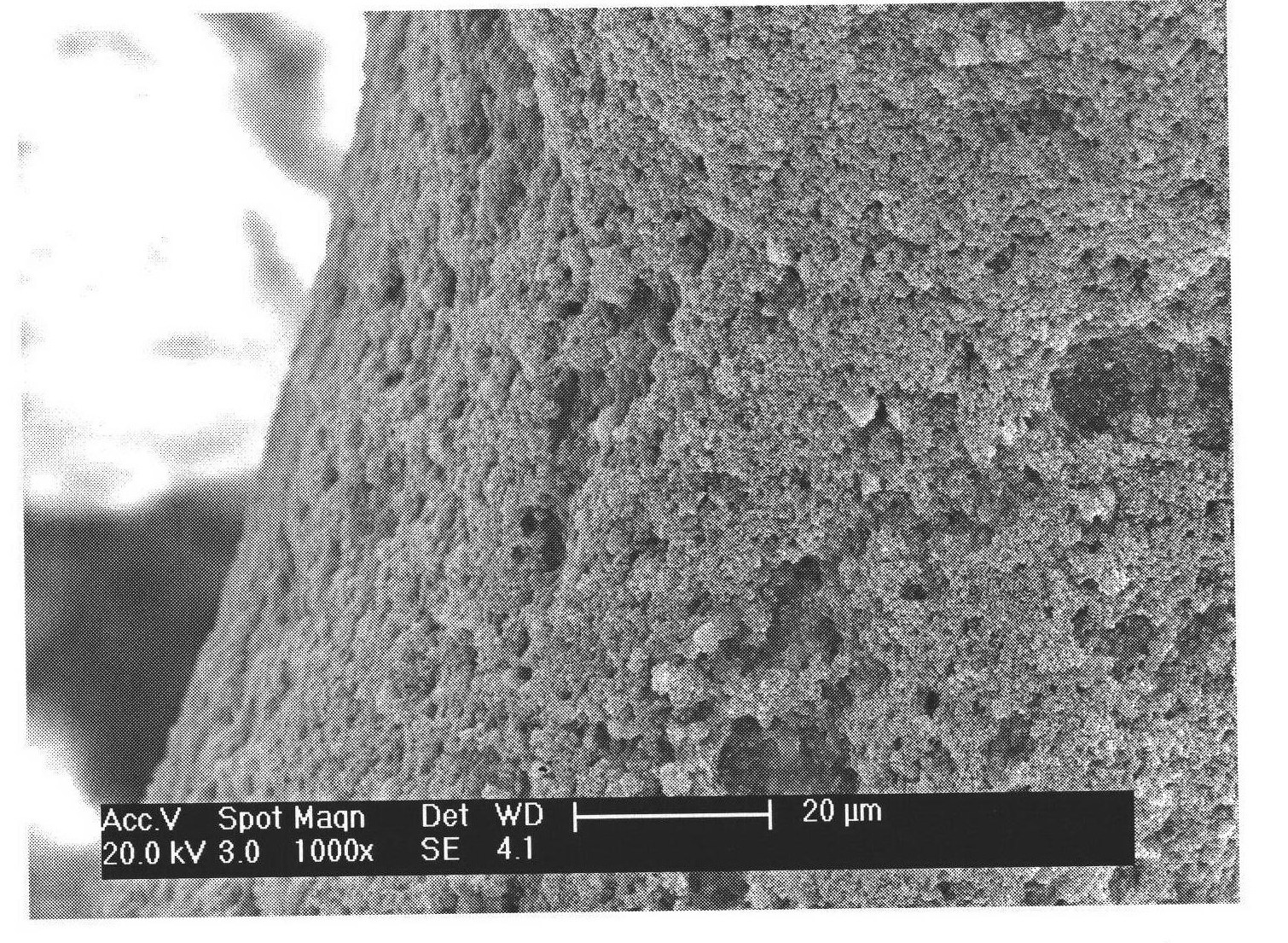

Porous polyaryletherketone material with bioactivity, and preparation method and application thereof

ActiveCN105233335AImprove the deposition effectOvercoming defects such as restricted bindingCoatingsProsthesisSpinal columnBiomedicine

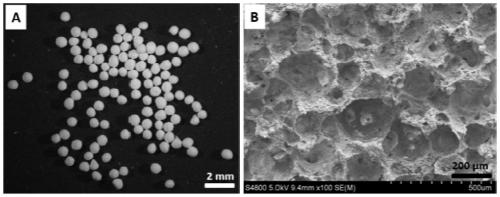

The invention discloses a porous polyaryletherketone (PAEK) material with bioactivity, and a preparation method and an application thereof, and belongs to the field of biomedical materials. The method comprises the following steps: carrying out wet uniform mixing on PAEK powder and a calcium phosphate ceramic (CPC) spherical particle pore forming agent to obtain a mixture, filling a die with the mixture, applying a pressure to make the hard pore forming agent be arranged in a close packing approximating manner and remove superfluous PAEK powder, heating the die to realize fusion molding of the PAEK powder under hot pressing in order to obtain a PAEK / CPC body, and immersing the PAEK / CPC body in diluted hydrochloric acid to remove the pore forming agent CPC in order to obtain the porous PAEK material; and processing through concentrated sulfuric acid, and immersing in a simulated body fluid to obtain the bioactive porous PAEK material with a surface bone like apatite layer. The method has the advantages of simple process and good repeatability, and the obtained bioactive material has completely three dimensional through macro-pores and abundant surface micro-pores, and easily adjustable macro-porous dimension and amount of porosity, and can be used to prepare bioactive materials with a gradient pore structure. The bioactive porous PAEK material can be used to restore bone defects, and is especially suitable for being used in interbody fusion cages for spinal column restoration.

Owner:SICHUAN UNIV

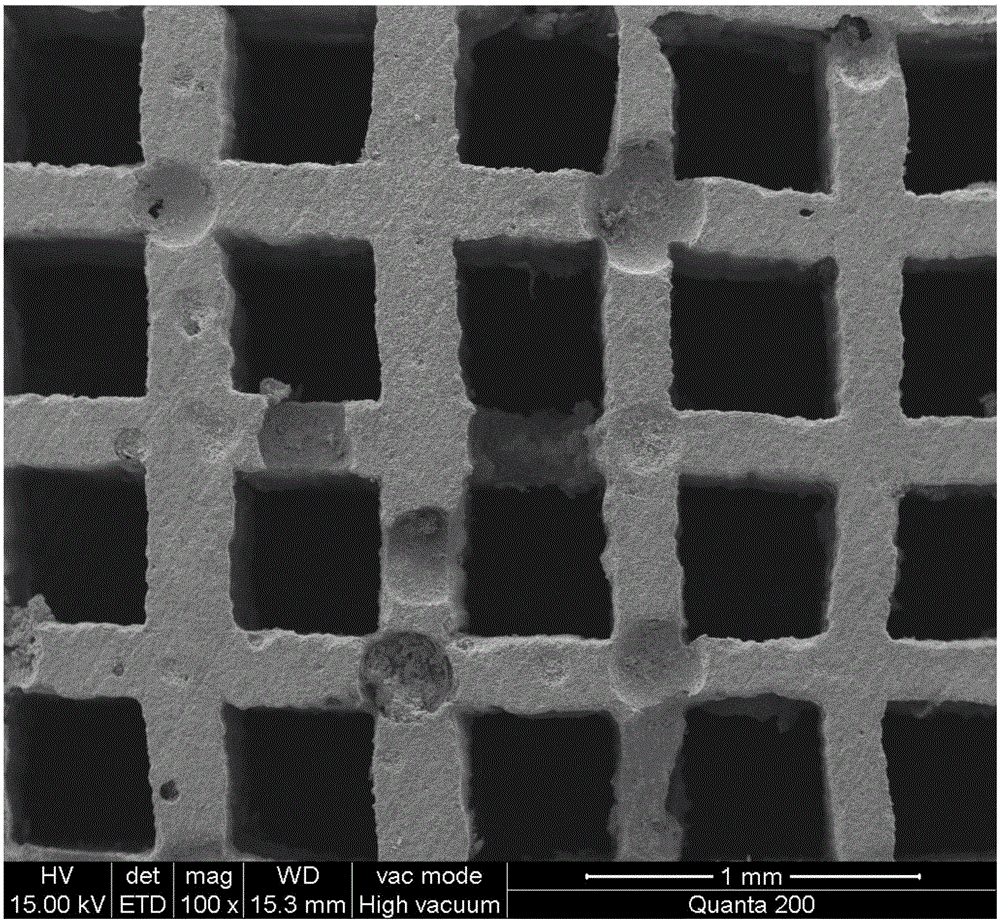

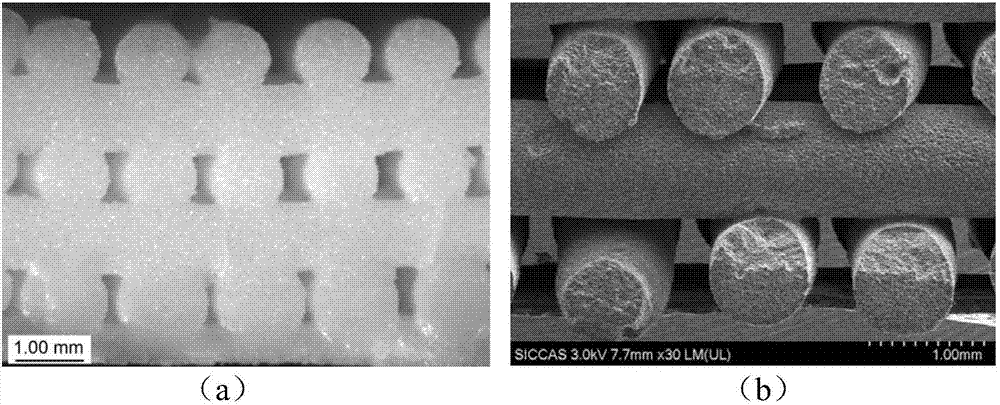

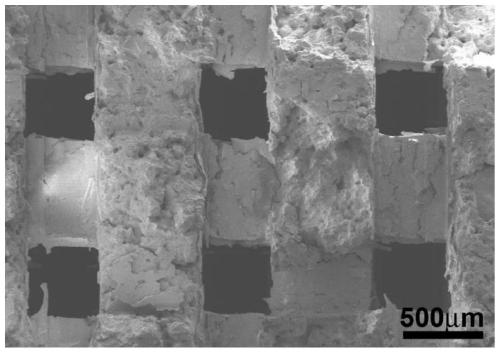

Three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material and preparation method thereof

InactiveCN106518143AHigh porosityAperture controllableTissue regenerationProsthesisPorosityMetabolite

The invention discloses a three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material. A plurality of longitudinal straight-through holes are distributed in the calcium phosphate ceramic artificial bone material in a honeycomb manner; and a plurality of transverse through holes are distributed in the hole walls of the straight-through holes to connect the adjacent straight-through holes. The invention also discloses a preparation method of the three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material. The three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material is prepared once through an extrusion molding technology and a pore forming agent adding technology. The straight-through holes are helpful for growing newborn bone tissues and forming blood vessels, and the three-dimensional connected holes are helpful for connecting cells into pieces and facilitate transportation of nutrient substances and discharging of metabolites. The preparation method is simple and can realize continuous production; and the prepared porous calcium phosphate ceramic has the advantages of high porosity, high connectivity and good mechanical performances.

Owner:SOUTH CHINA UNIV OF TECH

Method for forming osteolith class layer on surface of calcium phosphate ceramics

InactiveCN1562894AImprove surface activityFast depositionBone implantCalcium biphosphateSimulated body fluid

Owner:TSINGHUA UNIV

Preparation method for calcium polyphosphate-tricalcium phosphate bone bracket

A preparation method for calcium polyphosphate-tricalcium phosphate bone bracket comprises the steps of proportionally ball-milling and mixing calcium phosphate ceramic powder, size stabilizer methylcellulose, surfactant polyvinyl alcohol, foaming agent hydrogen peroxide and de-ionized water in order to prepare compound ceramic slurry, pouring the slurry into a mould, drying in an oven with four-step drying method, and then sintering the dried green body under high temperature in order to acquire porous calcium phosphate ceramic bracket. The big aperture of a big pore of the acquired porous calcium phosphate ceramic bracket of the invention is 200 to 600 microns, the micro-pore aperture thereof is 2 to 5 microns, the whole porosity thereof is from 60 to 90 percent and the compressive strength thereof is 0.5 to 7.0 Mpa. Furthermore, the method has low cost and high efficiency and can be applied to large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH +1

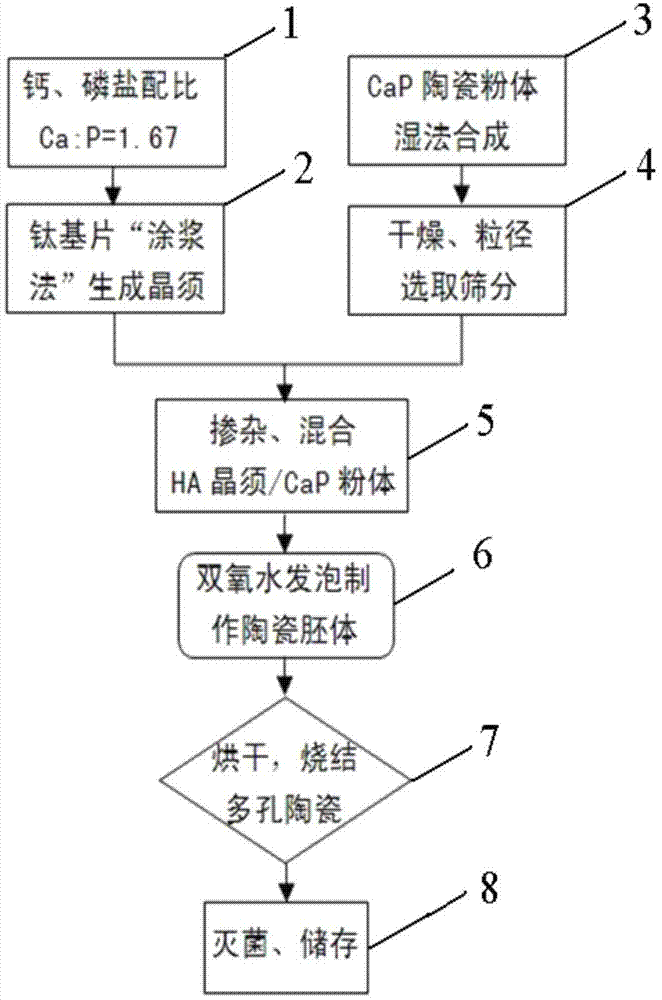

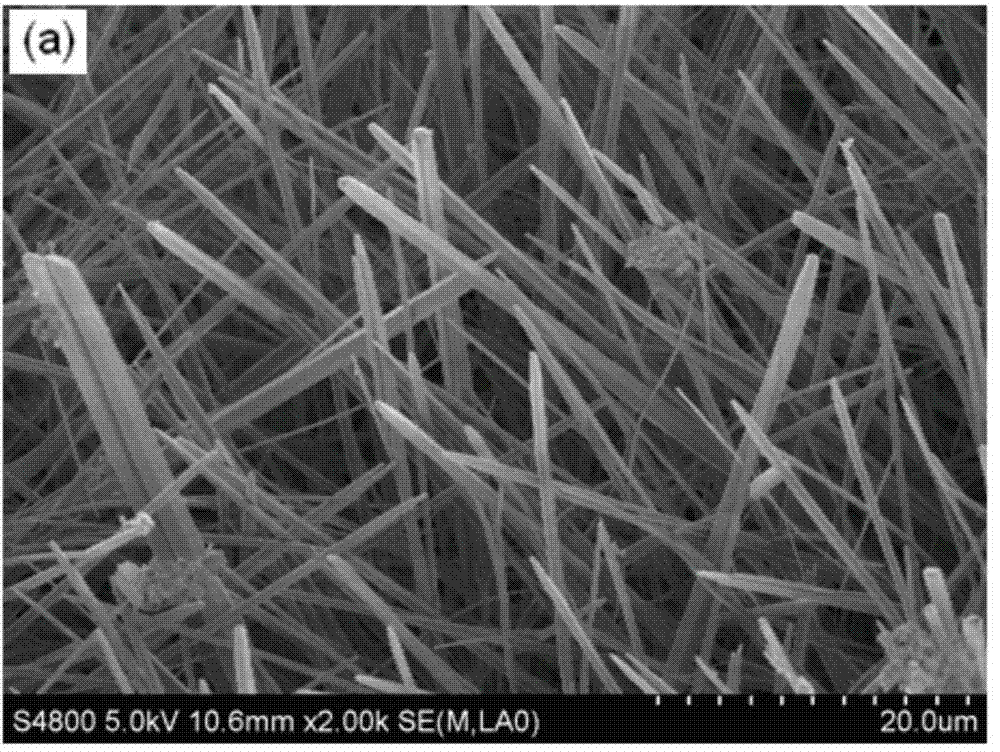

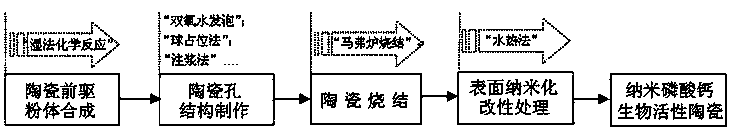

HA (hydroxylapatite) micro-nano whisker reinforced calcium phosphate ceramic material and preparation method and application thereof

InactiveCN103585677AEnhanced maximum compressive strengthImprove biological activityProsthesisMicro nanoApatite

The invention discloses a HA (hydroxylapatite) micro-nano whisker reinforced calcium phosphate ceramic material which is characterized by using calcium phosphate as a material matrix phase and mixing hydroxyapatite (HA) micro-nano whisker as a reinforcing phase for improving material mechanical properties. The preparation process is as follows: respectively synthesizing a calcium phosphate matrix phase precursor powder material and a hydroxyapatite micro-nano whisker reinforced phase material; then doping 3 ~ 10% of the hydroxyapatite micro-nano whisker to composite into ceramic body powder for preparing a porous ceramic body, finally calcining by a muffle furnace to obtain the reinforced porous bioactive calcium phosphate ceramic. Biological materials are a calcium phosphate component and a hydroxyapatite component which have similar chemical compositions with natural bones, the ceramic has excellent bioactivity due to a finely specially made porous structure, the mechanical properties of the ceramic are reinforced by doping of the micro-nano hydroxyapatite whisker, and the porous ceramic used as a bone repair material has the excellent bioactivity and good mechanical properties and has a wide application prospect in clinical departments of orthopedics.

Owner:SICHUAN UNIV

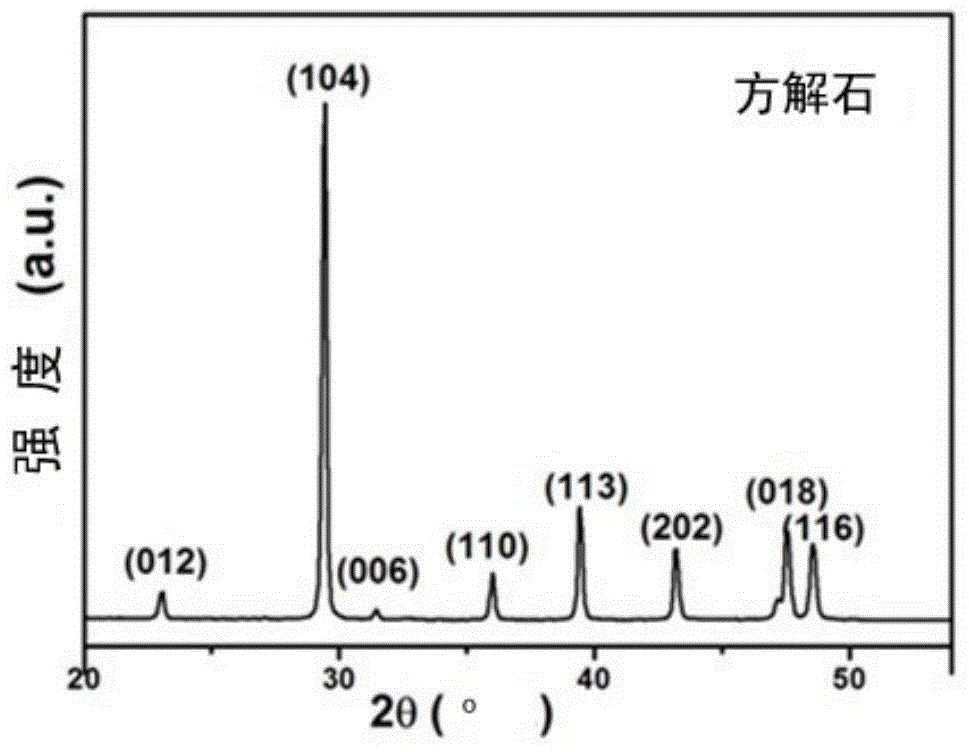

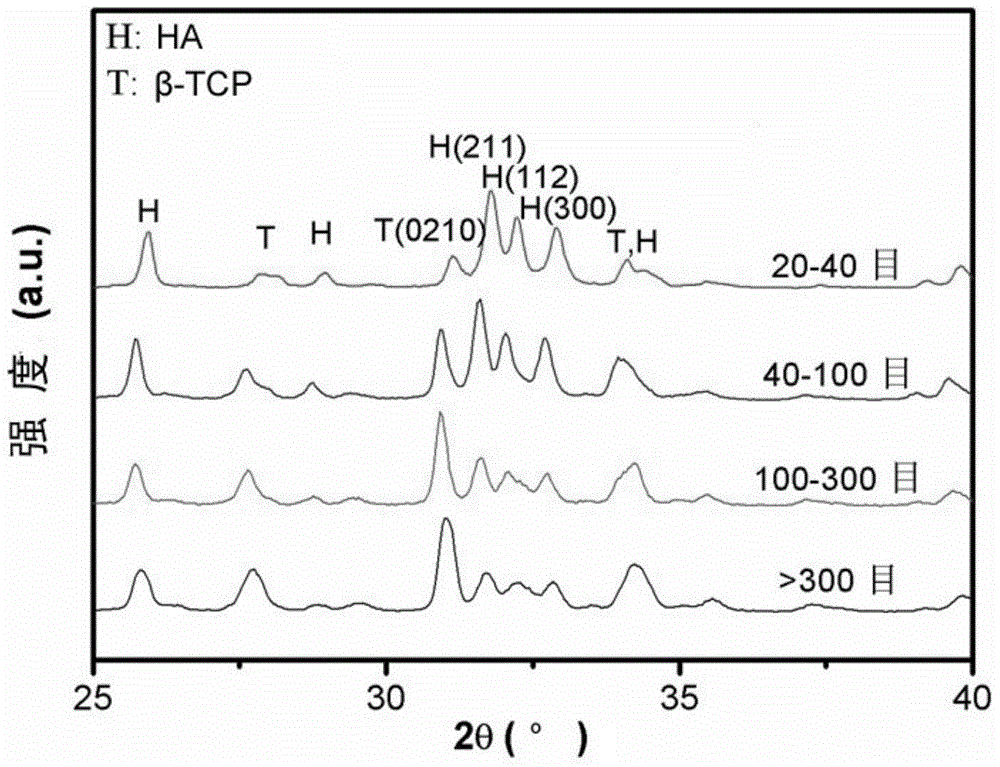

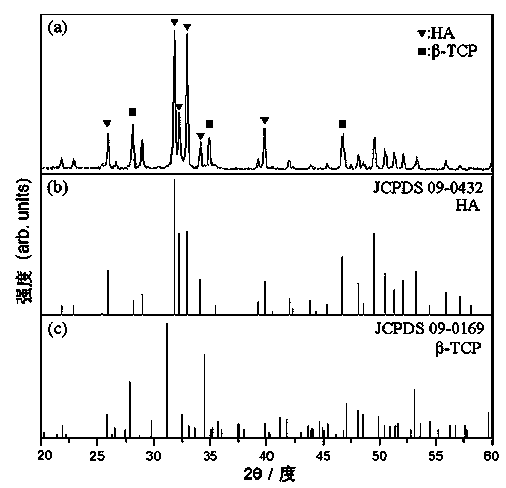

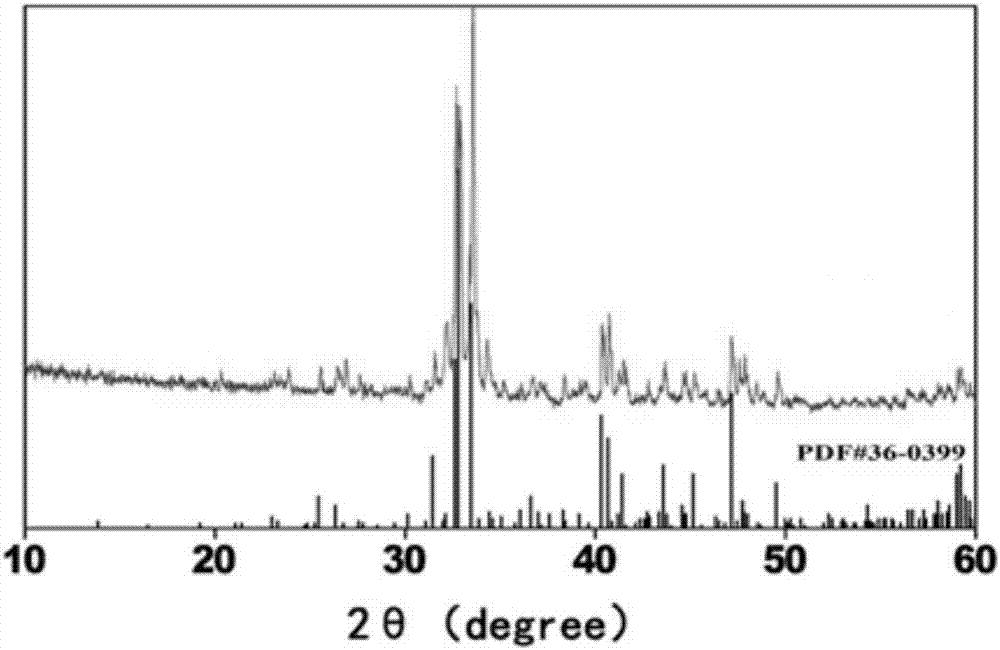

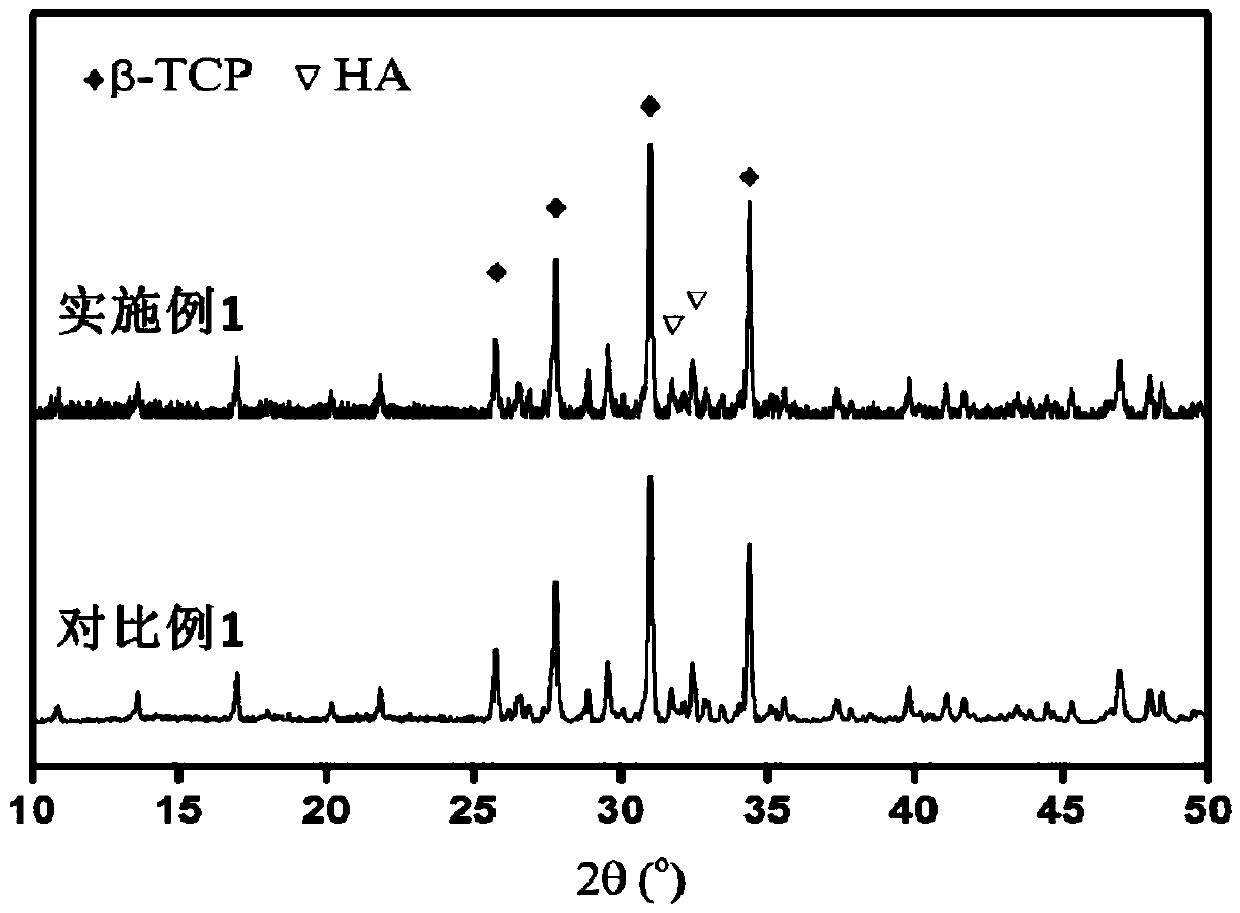

Two-phase calcium phosphate material, preparation method thereof, and two-phase calcium phosphate artificial bone ceramic

The invention discloses a two-phase calcium phosphate material, a preparation method thereof, and a two-phase calcium phosphate artificial bone ceramic, and belongs to the field of biological ceramic materials. The two-phase calcium phosphate artificial bone ceramic is prepared through preparing a beta phase tricalcium phosphate (beta-TCP) and hydroxy apatite (HA) mixture (the two-phase calcium phosphate material) from egg shells and carrying out a sintering process. The beta-TCP and the HA are prepared from the egg shells with abundant sources through a one-step chemical synthesis process, the mass proportions of the beta-TCP and the HA in the two-phase calcium phosphate are controlled through changing the particle dimensions of the egg shells in the hydrothermal synthesis process, and the preparation cost of the two-phase calcium phosphate material is low. The two-phase calcium phosphate ceramic is prepared through a template process under pressureless sintering conditions, and the two-phase calcium phosphate ceramic with different degradation speeds can be prepared through controlling the mass proportions of the beta-TCP and the HA, so different demands of bone defect patients on the degradation period of artificial bone scaffold materials due to individual difference are met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of calcium phosphate ceramics/chitosan-hydroxyapatite composite coating porous material

InactiveCN101829358AHighlight substantive featuresSignificant progressCoatingsProsthesisMass ratioApatite

The invention provides a method for preparing a calcium phosphate ceramics / chitosan-hydroxyapatite composite coating porous material, which comprises steps of: selecting porous calcium phosphate ceramics with hole size of 300-600 microns and of a net-shaped hole structure, adding nano-hydroxyapatite in chitosan acetum with the mass percent of 0.5-5 percent to prepare a suspension, coating the surface of the porous calcium phosphate ceramics, and carrying out crosslinking process to obtain the calcium phosphate ceramics / chitosan-hydroxyapatite composite coating porous material, wherein the mass ratio of the hydroxyapatite to the chitosan in the chitosan-hydroxyapatite suspension is (6-1):(1-5). The invention has the technical scheme that a chitosan-hydroxyapatite coating is prepared on the porous calcium phosphate ceramics, thereby enhancing the surface bioactivity of the porous material; the coating is an organic-inorganic composite material and integrates the advantages of the chitosan and the hydroxyapatite, and the constitution of the surface of the material can be conveniently adjusted according to the actual need, thereby endowing the porous material with better combination property.

Owner:SUZHOU PULIN BIO TECH

Process for the preparation of protein mediated calcium hydroxyapatite (HAP) coating on metal substrate

InactiveUS20090181161A1Increase coating thicknessReduce time consumptionPretreated surfacesCoatingsInterfacial reactionBiological apatite

This invention provides a process for the preparation of protein mediated calcium hydroxyapatite (HAp) coating on metal substrates particularly on stainless steel (316 L) by biomimetic route, capable of rapid and effective osteointegration with the host tissue following controlled interfacial reactions. For the purpose, calcium deficient, carbonated hydroxyapatite (HAp) coating was developed on metal substrates particularly on stainless steel (316L) alloy through biomimetic route after a surface treatment step using aqueous solution (4-10 wt %) of BSA at room temperature. The coating was characterised with respect to phase composition, crystallinity, morphology and thickness. The protein mediated calcium phosphate ceramic coating is porous (pore dia—100-200 μm) having uniform pore distribution and coverage. There is multifold enhancement in thickness and crystallinity (data provided) of the as-prepared coating. The process in the present invention is designed to mimic the structural and characteristic properties of the biological apatite to expedite osteointegration kinetics and to further improve biocompatibility of the metallic implant.

Owner:COUNCIL OF SCI & IND RES

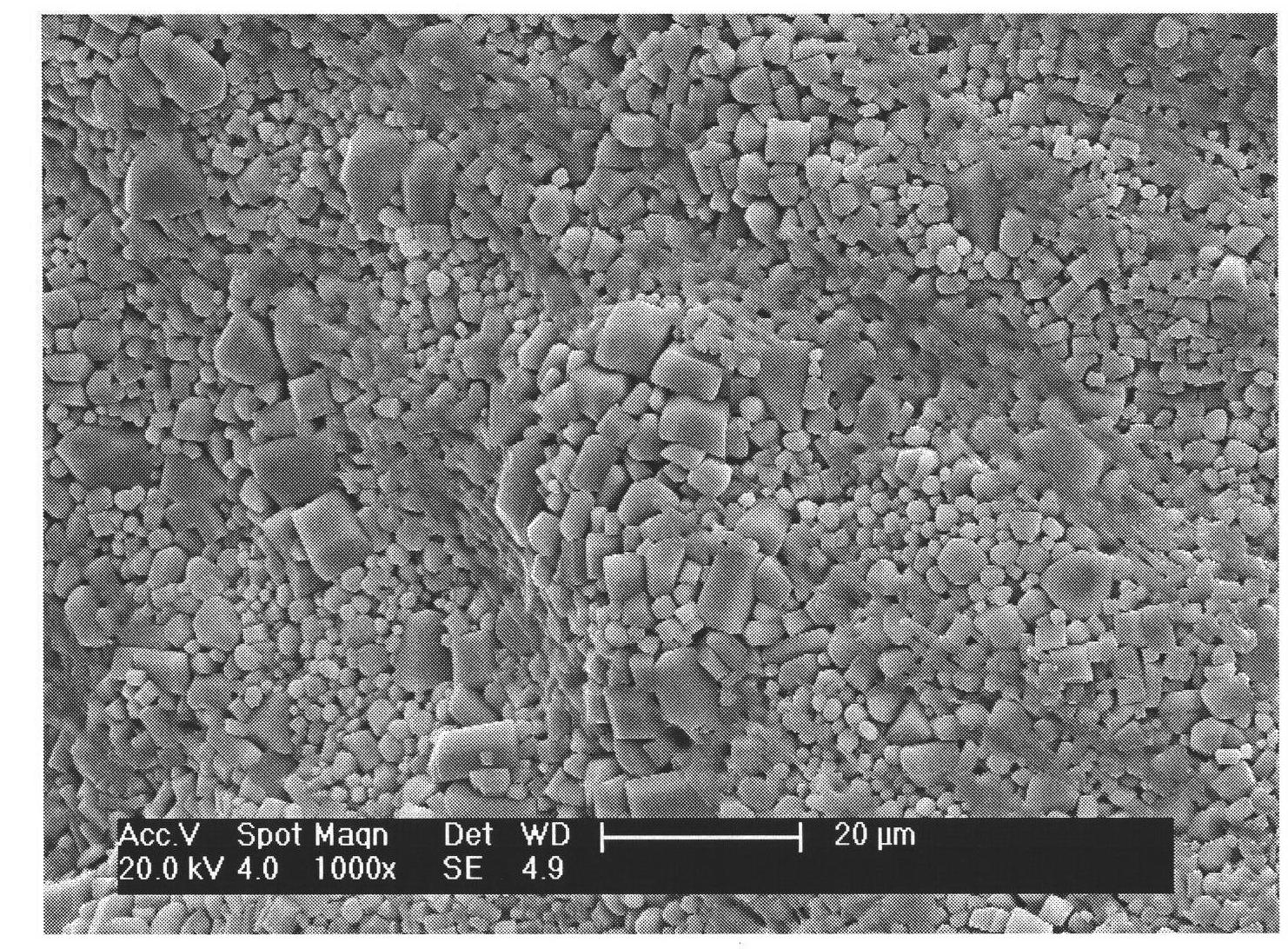

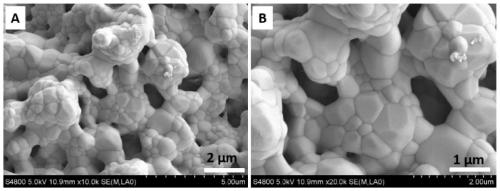

Surface nano-scale modified calcium phosphate bioactive ceramic as well as preparation method and application thereof

ActiveCN103638556AImprove biological activityLarge specific surface areaCoatingsProsthesisCalcium biphosphateCalcium phosphate ceramics

The invention discloses surface nano-scale modified calcium phosphate bioactive ceramic and a preparation method thereof. The surface nano-scale modified calcium phosphate bioactive ceramic comprises a porous calcium phosphate ceramic base body and a nano modifying layer. The preparation method of the surface nano-scale modified calcium phosphate bioactive ceramic comprises the following steps: carrying out surface nano-scale modification onto the porous calcium phosphate ceramic base body by a hydrothermal method in acid liquor; and self-assembling the material surface to form a layer of nano calcium phosphate by modification treatment. Therefore, the material surface / interface has a relatively large specific surface area and is beneficial to adsorbing osteogenesis-associated proteins and cells; after being planted into a body, the material can quickly release calcium and phosphor ions to promote osteogenesis, so that the material has better biological activity and osteoconduction; meanwhile, the ceramic has better mechanical performance.

Owner:SICHUAN UNIV

Method for preparing nano-multiple phase calcium phosphate/fibroin protein composite bracket

InactiveCN101293114AUniform biological propertiesMaintain biological activityProsthesisApatiteCytoskeleton

A preparation method of nanometer multiphase calcium phosphate / fibroin protein composite bracket relates to a preparation method of tissue engineering cytoskeleton. The existing preparation technology has the defects that organic solvent goes against the introduction of active material, sealed stomata goes against the growth of osseous tissue, low mechanical strength is unsuitable for bearing bone reparative regeneration and tissue distribution is uneven. The method provided by the present invention includes: a. calcium-deficient nanometer hydroxyapatite powder is synthesized by the effect offibroin organic template; b. pore-foaming agent sintering technique is adopted to crack the calcium-deficient nanometer hydroxyapatite powder after press molding for further preparation of nano-porous multiphase calcium phosphate ceramic matrix, the sintering temperature is 900 to 1,100 DEG C, the time is 2 to 3 hours and the pore-foaming agent is fibroin powder with the gain diameter of 90 to 300Mum; c. the matrix is dipped in 1 to 5 percent fibroin solution, frozen and dried to obtain the nanometer multiphase calcium phosphate / fibroin protein composite bracket material. The low-temperature sintering of the method provided by the present invention maintains the biological activity of the ceramics and overcomes the defects of the existing technology.

Owner:JIAMUSI UNIVERSITY

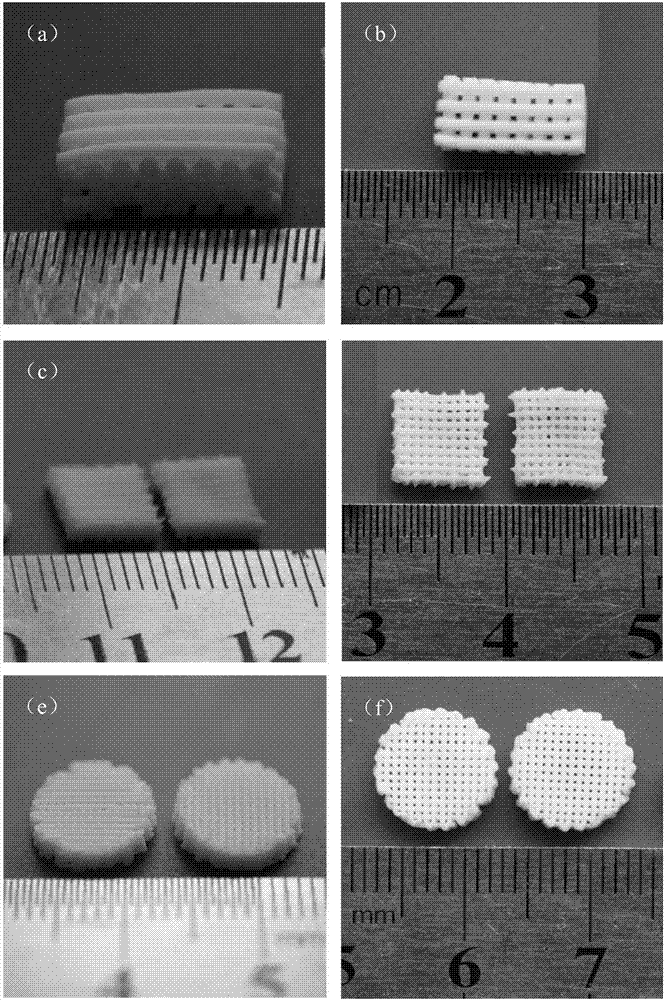

Three-dimensional printing porous bredigite biological ceramic bracket, and preparation method and application thereof

ActiveCN107235721AGood Aperture ConnectivityHigh porosityAdditive manufacturing apparatusCeramic shaping apparatusCalcium biphosphateBone tissue

The invention discloses a three-dimensional printing porous bredigite biological ceramic bracket, and a preparation method and application thereof. The method comprises the following steps: firstly, obtaining a sizing agent by blending bredigite powder, sintering aids and a binder aqueous solution at a certain ratio, then utilizing a three-dimensional printing technique to prepare a ceramic bracket blank with a controllable porous structure, and then sintering at high temperature, thereby obtaining a bredigite biological ceramic bracket material with a porous structure and excellent mechanical properties. The three-dimensional printing porous bredigite biological ceramic bracket prepared according to the preparation method has controllable pore diameter and porosity, high biocompatibility, excellent mechanical properties obviously better than the mechanical properties of a calcium phosphate ceramic bracket with the same structure, and excellent induced osteogenesis activity and angiogenesis activity, and is expected to be used for boosting the regeneration repairing of various defected bone tissues.

Owner:YANTAI ZHENGHAI BIO TECH

Porous composite containing calcium phosphate and process for producing the same

ActiveUS8039090B2Improve bone formationInhibit growthImpression capsSynthetic resin layered productsCross-linkLinking collagen

A porous composite comprising a porous layer containing a calcium phosphate ceramic, and a dense layer formed on part of the porous layer and having a smaller average pore size than that of the porous layer. The porous composite can be produced by (1) introducing a slurry containing a calcium phosphate ceramic / collagen composite and collagen into a molding die having a high thermal conductivity, (2) rapidly freezing and drying the slurry in the molding die, to form a porous body comprising a porous layer and a dense layer formed on the porous layer, (3) cross-linking collagen in the porous body, and (4) removing the dense layer except for a portion thereof on a surface coming into contact with a soft tissue when implanted in a human body, so that the porous layer is exposed.

Owner:NAT INST FOR MATERIALS SCI +1

Composite material containing microelement for hard tissue repair and reconstruction and preparation method thereof

The invention relates to a composite material containing microelement for hard tissue repair and reconstruction and a preparation method thereof. The composite material further contains at least one of three microelements of strontium, zinc and copper acceptable in human body with the calcium mole ratio of 0.01-0.5% in ceramic component of calcium phosphate in the ceramic component containing the calcium phosphate and the substrate material of multi-amino acid polymer, wherein the mass ratio of the ceramic component of calcium phosphate is 30-65%, and the balance of multi-amino acid polymer polymerized by epsilon-aminocaproic acid and other amino acids. The process for preparing the calcium phosphate ceramic comprises the following steps of: adding microelement, then mixing the amino acid components evenly, removing water of various forms in the mixture at a temperature lower than or equal to 200 DEG C under the protection of inert gas, then composing in situ polymerization under the condition of 210-250 DEG C and pH of 6.5-7.5. The composite material is a bionic biomedical and tissue engineering material which has controllable degradation speed, good bioactivity and compatibility and overcomes deficiencies and problems of similar repair materials at present.

Owner:SICHUAN GUONA TECH

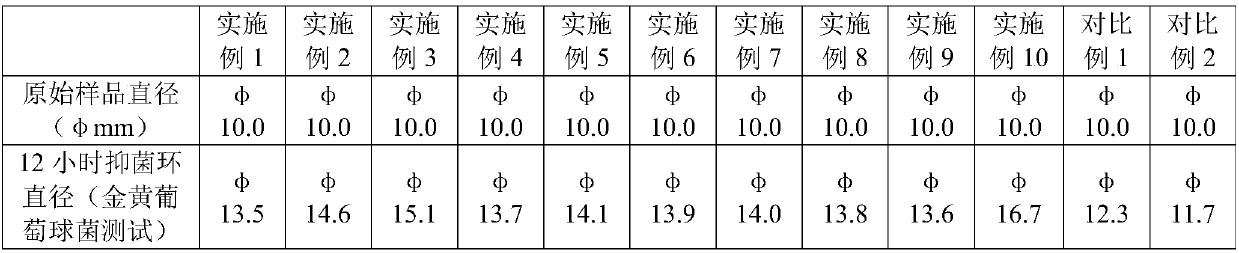

Nanometer silver/berberine slow release coating loaded calcium phosphate ceramic material and preparation method

InactiveCN109550078AGood broad-spectrum antibacterial effectLow cytotoxicityPharmaceutical delivery mechanismTissue regenerationCalcium biphosphateBerberine

The invention discloses a nanometer silver / berberine slow release coating loaded calcium phosphate ceramic material and a preparation method. The nanometer silver / berberine slow release coating loadedcalcium phosphate ceramic material consists of calcium phosphate ceramics and nanometer silver / berberine composite slow release coating loaded on the surface of the calcium phosphate ceramics. The calcium phosphate ceramics are prepared through sintering calcium phosphate ceramic raw material powder, nanometer silver is prepared through in-situ reduction of silver nitrate through silk fibroin, berberine molecules are mixed, nanometer silver / berberine mixed liquor is obtained and is connected to the surface of the calcium phosphate ceramics through polydopamine, and the nanometer silver / berberine slow release coating loaded calcium phosphate ceramic material is prepared. According to the nanometer silver / berberine slow release coating loaded calcium phosphate ceramic material and the preparation method disclosed by the invention, berberine and antibacterial effects of nanometer silver granules are combined, so that the potential effects of the berberine for promoting osteogenic differentiation of cells can be sufficiently exerted. The berberine and the nanometer silver have the effect of cooperating for resisting bacteria, so that the concentration of the nanometer silver is reduced, and reduction of cytotoxicity of implantation materials is facilitated. The composite material can be applied to bone defect repair and oral cavity implants.

Owner:SICHUAN UNIV

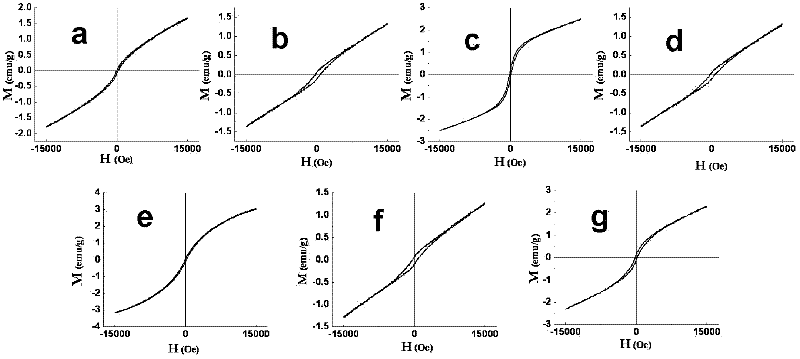

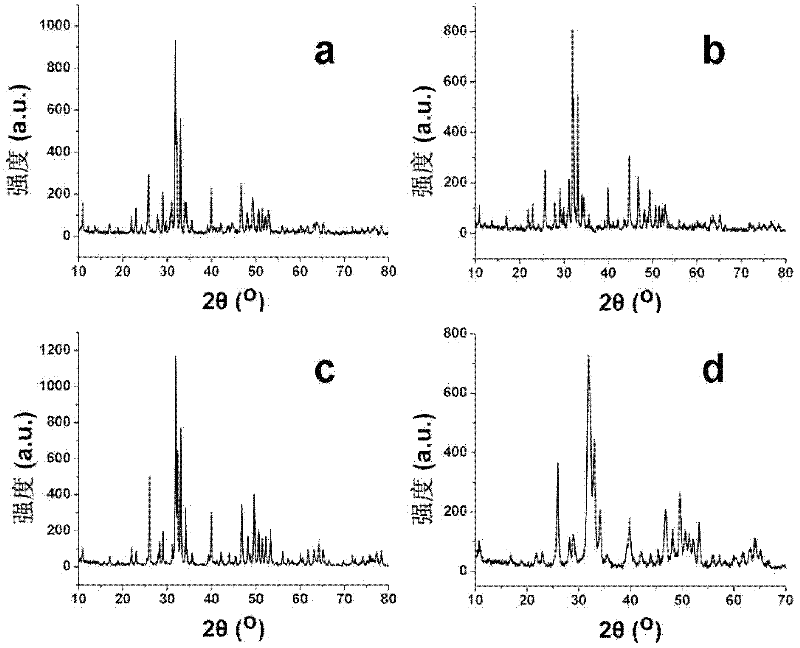

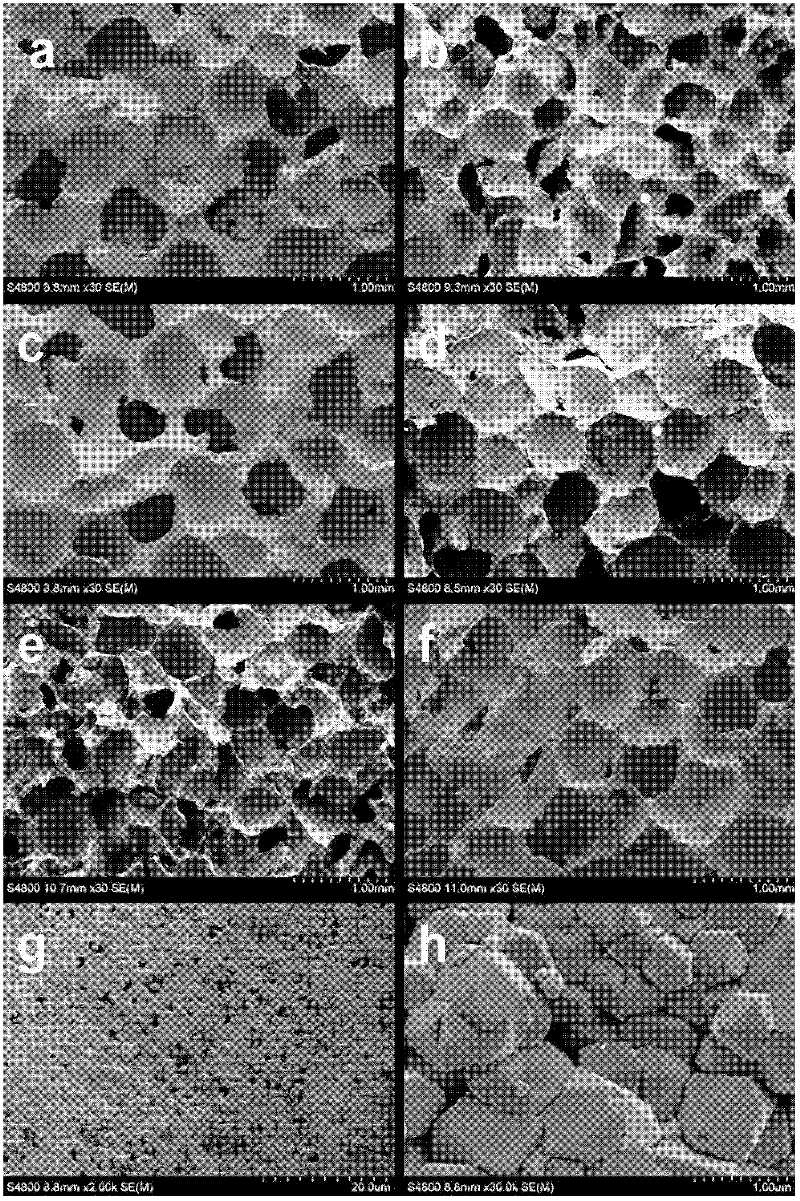

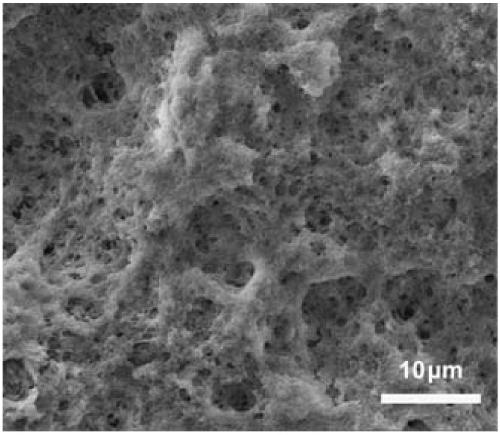

Magnetic nanoparticle/calcium phosphate ceramic composite porous material and preparation method thereof

ActiveCN102329130AEvenly distributedPrecise content controlCeramicwareCalcium biphosphateCeramic composite

The invention relates to a magnetic nanoparticle / calcium phosphate ceramic composite porous material. Calcium phosphate ceramic serves as a matrix; the calcium phosphate ceramic matrix has a porous structure; superparamagnetic Fe3O4 magnetic nanoparticles are distributed on the calcium phosphate ceramic matrix uniformly; the superparamagnetic Fe3O4 magnetic nanoparticles are hydrophobic Fe3O4 or hydrophilic Fe3O4; the average particle size of the superparamagnetic Fe3O4 magnetic nanoparticles is 4 to 20 nm; and the content of the superparamagnetic Fe3O4 magnetic nanoparticles is 1 to 10 percent of the mass of the calcium phosphate ceramic matrix. A preparation method for the magnetic nanoparticle / calcium phosphate ceramic composite porous material comprises the following steps of: (1) preparing Fe3O4 magnetic fluid; (2) preparing composite powder; (3) preparing green bodies; and (4) performing vacuum sintering, namely calcining the green bodies subjected to compression moulding at thetemperature of between 300 and 400 DEG C for 20 to 40 minutes by using a vacuum sintering furnace, heating to 1,000 to 1,200 DEG C, calcining for 1 to 2 hours, and cooling to room temperature along with the furnace to obtain the magnetic nanoparticle / calcium phosphate ceramic composite porous material.

Owner:SICHUAN UNIV

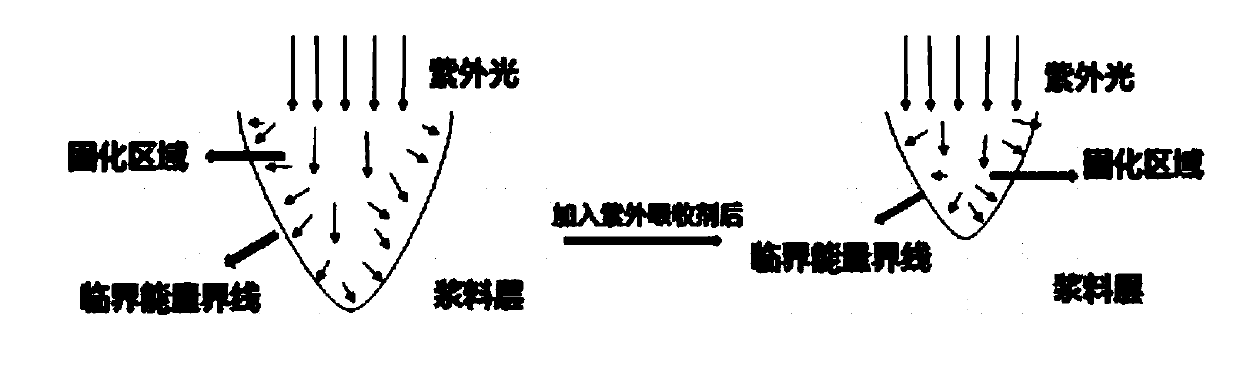

Low over-cured calcium phosphate ceramic slurry for light curing molding and preparation method thereof

ActiveCN110330328ALow viscosityImprove surface qualityAdditive manufacturing apparatusCalcium biphosphateSlurry

The invention relates to a low over-cured calcium phosphate ceramic slurry for light curing molding and a preparation method thereof. The low over-cured calcium phosphate ceramic slurry for light curing molding mainly comprises the following components by mass percentage: 70-80wt% of ceramic powder, 0.5-2wt% of a dispersant, 10-25wt% of a light curable resin monomer and 0.05-0.5wt% of assistants.The preparation method mainly includes: conducting ball-milling and stirring on calcium phosphate ceramic powder, light curable resin, the dispersant, a photoinitiator and an ultraviolet absorber to obtain the slurry. The slurry has the characteristics of low viscosity, high solid content and low over-cured content, and can be used in the field of additive manufacturing of bioceramics.

Owner:WUHAN UNIV OF TECH

Compound biological medical material of biological ceramic silicon rubber

InactiveCN101195045APromote growthImprove adhesionBone implantHydroxyapatite ceramicsCalcium biphosphate

The invention relates to biological medical material which is compounded by biological ceramics, namely, hydroxyapatite ceramics, calcium phosphate ceramics, and silicon rubber. The biological ceramics and silicon rubber compound biological medical material of the invention is used to choose corresponding dies for manufacturing artificial nose bridges, artificial mandibles, artificial temples, artificial malar bones, plastic plates, or other implanted supports. After being implanted in the body, the biological ceramics can gradually degrade peripheral tissues for gradually growing in, which can improve the growth of new bones. The surface has micro-pore type structures, which is favorable for adhesion and growth of cells. The invention provides a preparing process of the biological ceramics and silicon rubber compound biological medical material.

Owner:曾维桥

Mineralized collagen/bioceramic composite and manufacturing method thereof

ActiveCN102631702AReasonable and good mechanical strengthImprove integrityImpression capsSkeletal disorderCalcium biphosphateAdhesive

The present invention discloses a mineralized collagen / bioceramic composite useful as a hard tissue replacement material or substitute material, comprising about 10% to 95% by weight of mineralized collagen and about 5% to 90% by weight of bioceramics, and a method of manufacturing the same. Wherein, the mineralized collagen is used as a binder for the bioceramics, such as calcium phosphate ceramics, calcium sulfate ceramics, calcium carbonate ceramics, and other biocompatible ceramics. The bioceramic used in the mineralized collagen / bioceramic composite can be either in powder form or in granular form.

Owner:MAXIGEN BIOTECH

Ion doping and protein dipping double modified porous calcium phosphate ceramic and preparation method thereof

ActiveCN109678488AImprove mechanical propertiesGood vascularization abilityTissue regenerationCoatingsCalcium biphosphateProtein DIP

The invention belongs to the field of a medical material for bone injury repair and discloses ion doping and protein dipping double modified porous calcium phosphate ceramic and a preparation method thereof. The preparation method comprises the following steps: preparing calcium phosphate powder doped with osteogenesis promoting ions, preparing ion-doped porous calcium phosphate ceramic by a pore-forming mode, dipping the ion-doped porous calcium phosphate ceramic into a silk fibroin solution, and repeatedly dipping and drying to obtain the ion doping and protein dipping double modified porouscalcium phosphate ceramic capable of promoting osteogenesis and promoting vascularization. The porous calcium phosphate ceramic is dipped with multiple layers of protein, so that the mechanical property of the porous calcium phosphate ceramic is improved. By the ion doping and protein dipping double modification mode, mechanical and biological properties of the porous calcium phosphate ceramic are improved and certain significance in expanding the clinical application of the porous calcium phosphate ceramic is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Calcium phosphate bioceramics compounded with collagen, and preparation method and usage method thereof

ActiveCN110180030AClosely connectedAvoid side effectsTissue regenerationCoatingsCross-linkCalcium biphosphate

The invention provides calcium phosphate bioceramics compounded with collagen as well as a preparation method and a usage method thereof. The preparation method of the calcium phosphate bioceramics compounded with collagen comprises the following steps: forming cross-linked collagen coating on surfaces of calcium phosphate bioceramics by using collagen solutions of which the concentrations are from low to high, thereby obtaining cross-linked collagen coating with which the surfaces of the calcium phosphate bioceramics are wrapped; carrying out mixing with a collagen solution, and carrying outfreeze-drying so as to obtain precursors of the calcium phosphate bioceramics compounded with collagen; and then, soaking the coating with a collagen solution, and carrying out freeze-drying so as toobtain the calcium phosphate bioceramics compounded with collagen which comprise collagen wrapping layers. The calcium phosphate bioceramics compounded with collagen prepared according to the technical scheme of the invention have improved repair ability and degradation performance, so that, aseptic inflammation caused by falling off of calcium phosphate ceramic particles in clinical use can be avoided; moreover, the calcium phosphate bioceramics compounded with collagen are plastic in shape and size as well as convenient to use, so that, many problems of bioceramics in clinical application can be solved.

Owner:SHANGHAI BIO LU BIOMATERIALS

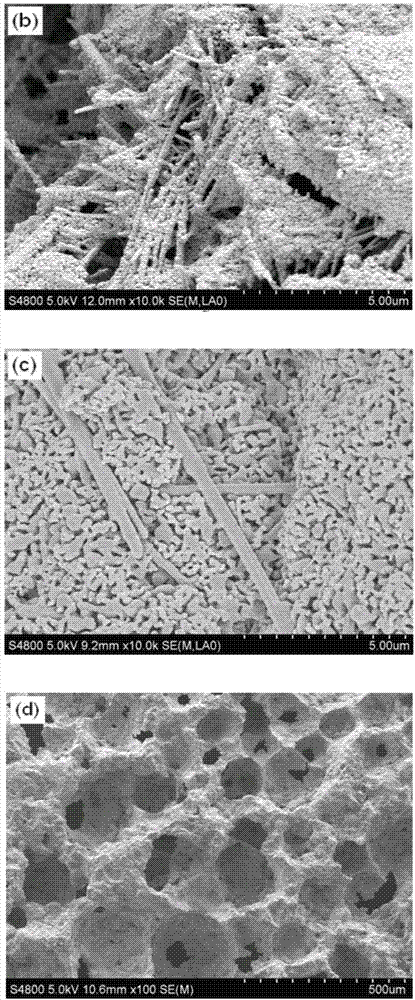

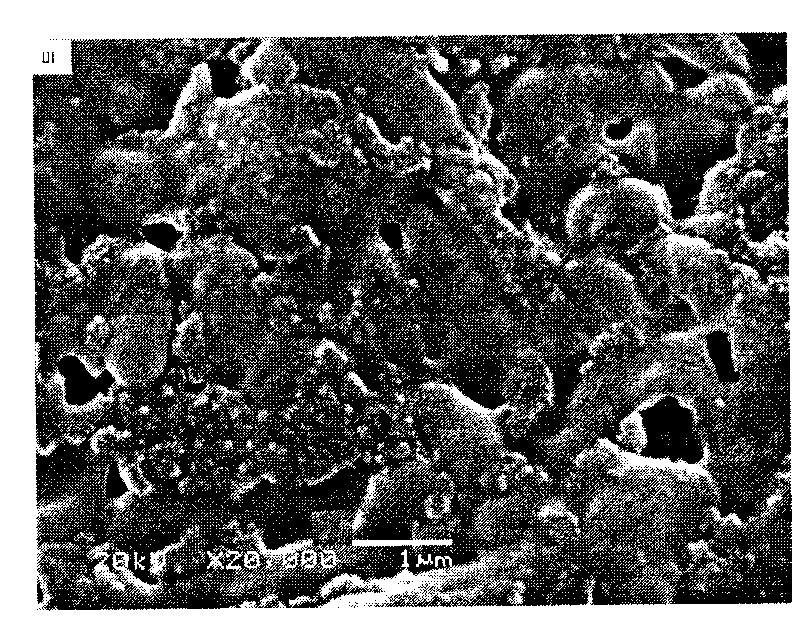

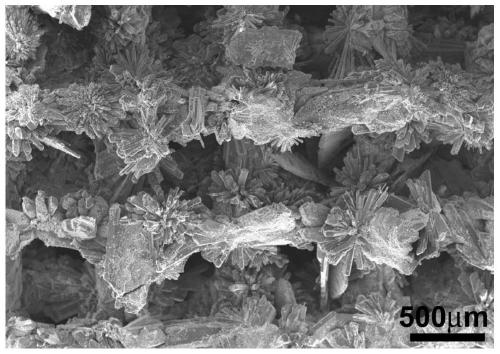

Surface treatment method of silicon-doped calcium phosphate ceramics

The invention discloses a surface treatment method of silicon-doped calcium phosphate ceramics. The surface treatment method is to perform surface hydro-thermal treatment to the silicon-doped calcium phosphate ceramics and comprises the steps of: placing the silicon-doped calcium phosphate ceramics into a sterilization boiler, treating for 0.5-2h at a temperature of 100-180 DEG C, washing by deionized water, drying and thus obtaining the silicon-doped calcium phosphate ceramics with hydroxylapatite crystal whiskers grown on the surface. The surface treatment method provided by the invention is simple in process, and can obtain the hydroxylapatite crystal whiskers which are controllable in size and have the diameters in micron level to nanometer level.

Owner:SOUTH CHINA UNIV OF TECH

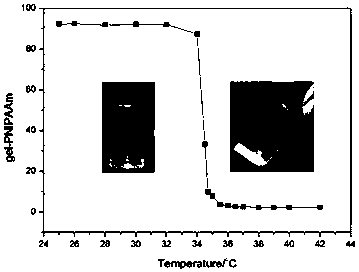

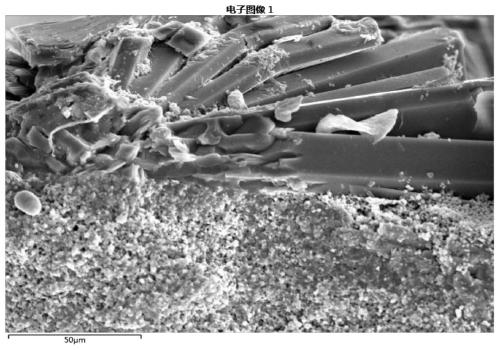

Temperature-sensitive organic-inorganic composite hydrogel material and preparation method thereof

InactiveCN108203513AEffective osteogenic activityEasy to shapeInorganic material artificial filamentsPharmaceutical delivery mechanismBone augmentationCalcium phosphate ceramics

The invention provides a temperature-sensitive organic-inorganic composite hydrogel material and a preparation method thereof. The material has good plasticity, can easily realize filling of a defected part and shows ossification activity. The temperature-sensitive organic-inorganic composite hydrogel material is prepared by compounding synthesized poly(N-isopropylacrylamide)-grafted gelatin withion-doped calcium phosphate ceramic nanofibers. The plasticity of the material is realized in virtue of the characteristic of negative temperature sensitivity of poly(N-isopropylacrylamide) and the capability of an aqueous solution of the poly(N-isopropylacrylamide)-grafted gelatin in forming a hydrogel under the condition of body temperature. The composite hydrogel material may appear to be liquid capable of realizing filling through injection or to be paste easy to operate in the case of different compounding ratios of the hydrogel and the calcium phosphate ceramic nanofibers, can realize effective filling of bone defects of irregular shapes, better meets the needs of clinical treatment of bone defects and accords with the clinical characteristics of bone augmentation repair.

Owner:BEIJING UNIV OF CHEM TECH

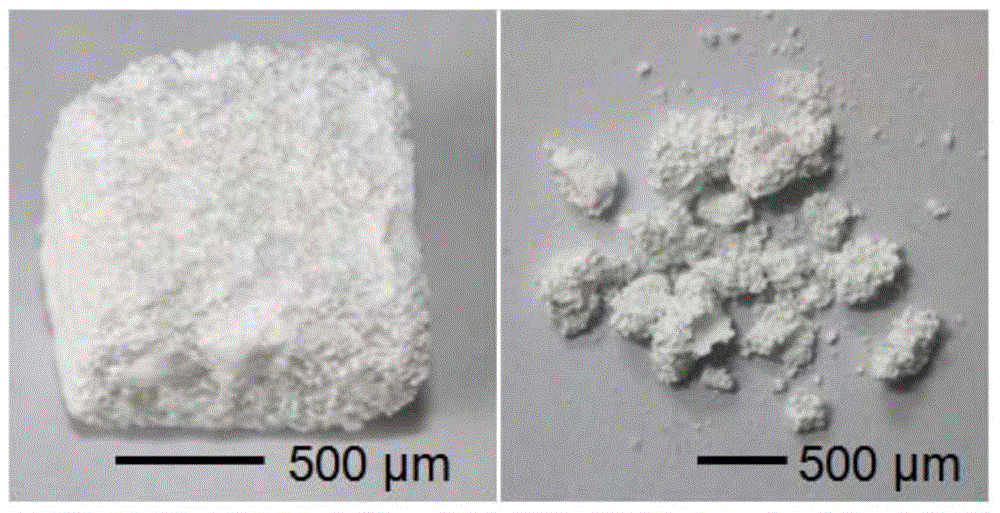

Biphasic calcium phosphate porous bioceramic bone scaffold material and preparation method thereof and application

The invention relates to the field of bioceramic materials, in particular to a biphasic calcium phosphate porous bioceramic bone scaffold material which is prepared from salmon spine as a raw material, is composed of main ingredients hydroxyapatite and beta-tricalcium phosphate , has high porosity, reserves a natural three-dimensional pore structure, has a particle size of 500-1000 [mu]m, and is prepared through steps of washing and drying, high temperature calcination, grinding, sieving and sterilization. The biphasic calcium phosphate porous bioceramic bone scaffold material is rich in sources of raw materials and low in preparation cost, high purity biphasic calcium phosphate ceramic can be prepared without artificial addition of compounds, and the content of hydroxyapatite and beta-tricalcium phosphate can be changed by controlling the calcination temperature in the preparation process, and the biphasic calcium phosphate porous bioceramic bone scaffold material contains a small amount of carbonated hydroxyapatite and various trace elements such as magnesium, potassium and strontium, with the content close to the content in the human body. The calcium phosphate ceramic prepared through the method can serve as a good bone scaffold material to be applied to clinical bone defect repair.

Owner:SHANGHAI CHANGHAI HOSPITAL

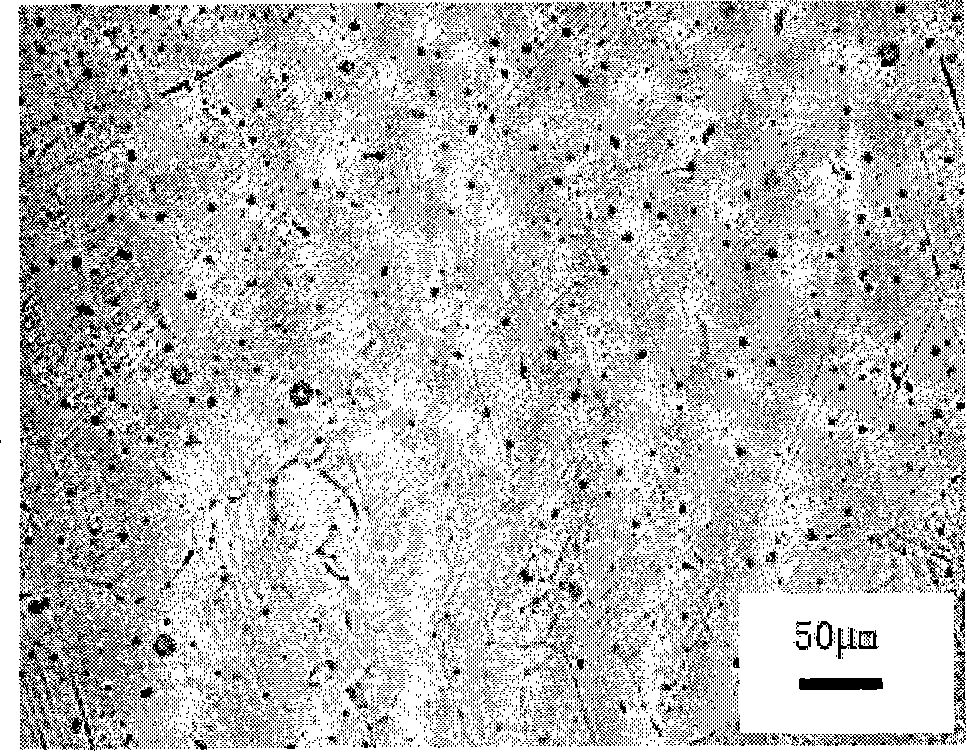

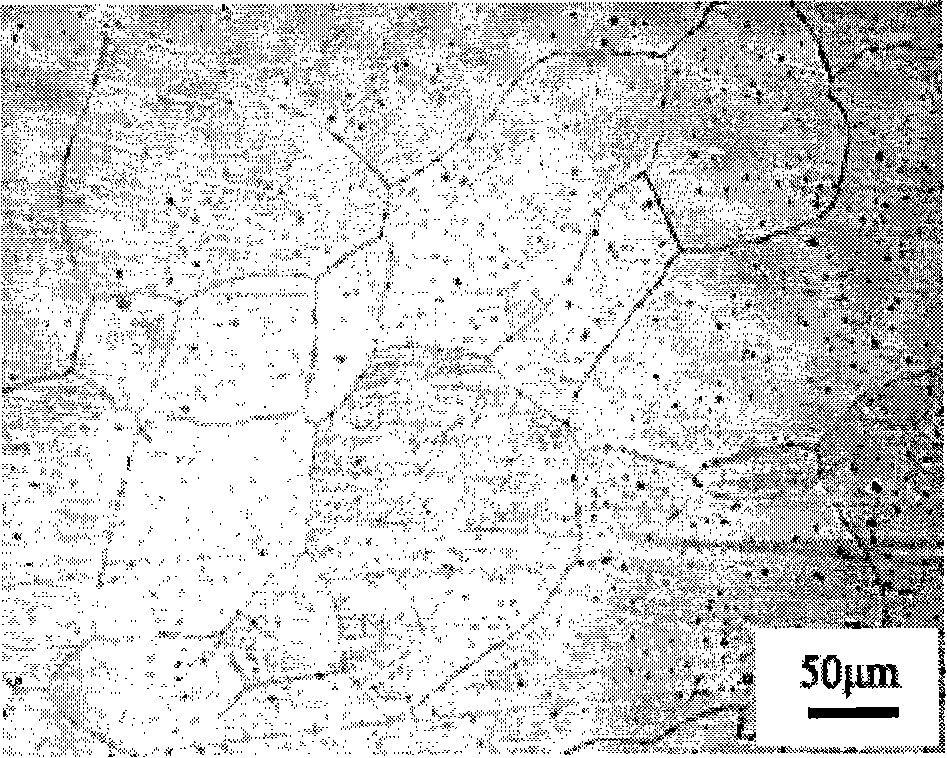

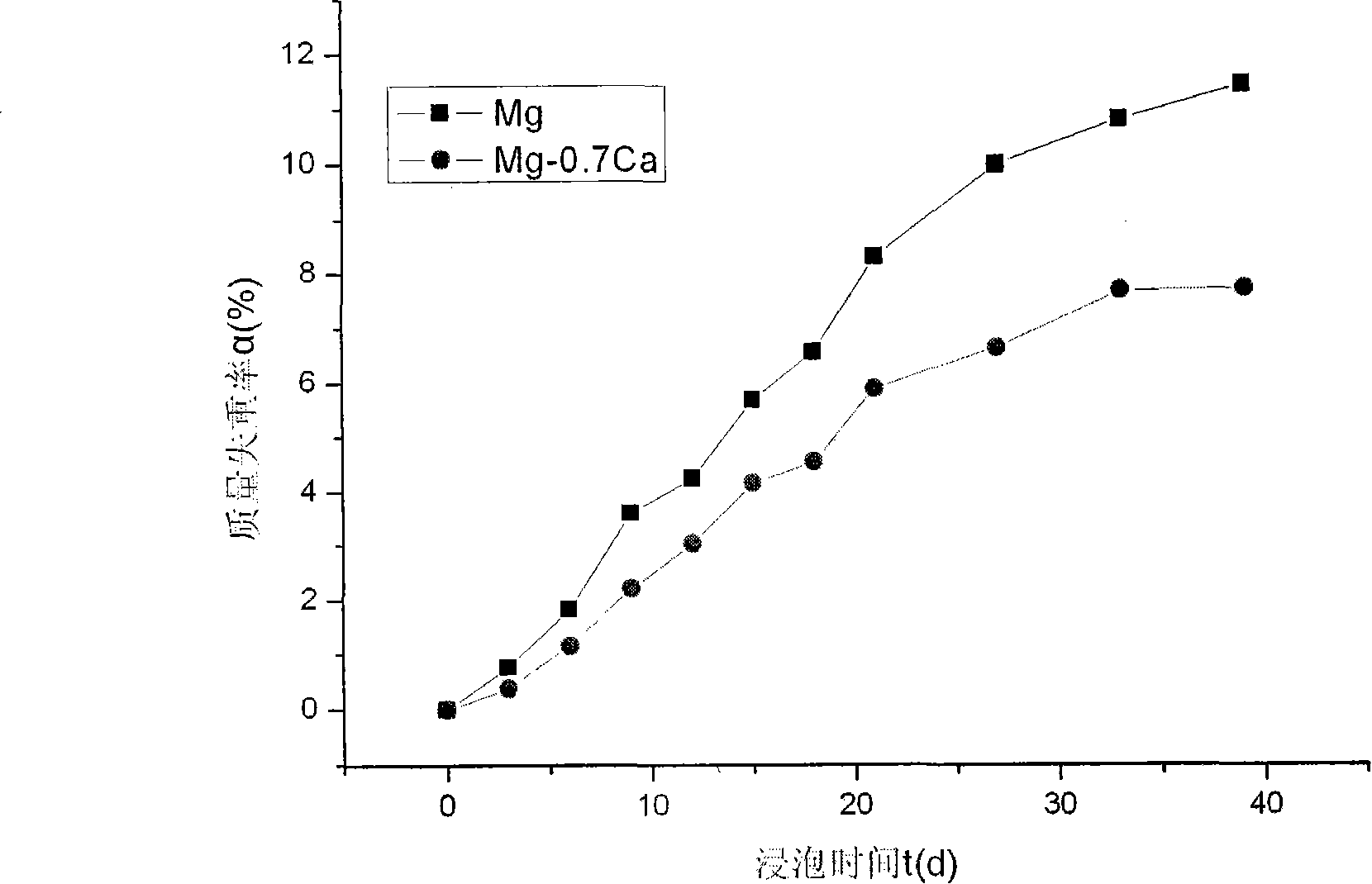

Degradable medical biological MgCa and preparation

The invention relates to a medical biological MgCa alloy which can be degraded and a preparation method thereof. The components of the alloy includes 0.5 to 2.0 percent of calcium, and marginal magnesium; the alloy is made by fire melting, and the process of melting and pouring adopts argon shield; the melting temperature is 700 to 800 DEG C, and the pouring temperature is 650 to 750 DEG C. The thermal treatment process uses nitrogen as the protective atmosphere, with the heating temperature being 450 to 510 DEG C for 1.5 to 3.0 hours. The alloy can degrade by corrosion in physical environment, and induce the deposition of calcium phosphate ceramics; the changing of calcium content can control the degradation speed. The alloy can be used as the material for hard tissue replacement and intervening treatment, can be degraded fully after being implanted in human body for certain time and can transform into natural bone tissue. The medical biological MgCa alloy has the advantages of simple production process, no need of special equipment and low production cost.

Owner:CHONGQING UNIV

Porous calcium phosphate ceramics based on coating of calcium sulfate salt and preparation method of porous calcium phosphate ceramics

PendingCN110282998AGood osteoinductivityEasy accessTissue regenerationCeramicwareCalcium biphosphateSulfate

The invention discloses porous calcium phosphate ceramics based on coating of calcium sulfate salt. Calcium phosphate is taken as a substrate, andthe surface of the calcium phosphate is coated with the calcium sulfate salt to form a porous structure with arbitrary shapes; the hole types of holes in at least one dimension of directions are regular in the three-dimensional space directions in the porous structure, and the distances between the centers and edges of the holes are 50 to 2000 micrometers, and all the holes are interpenetrating. In addition, the invention further provides a preparation method of the porous ceramics. According to the designed porous ceramics, the quickly-degraded calcium sulfate salt is on the surface, and the slowly-degraded calcium phosphate are inside, so after the ceramics are implanted into a body, a gradient degradation processcan be formed, so that the porous ceramics are endowed with very high osteogenic activity, and the ceramics can maintain enough mechanical strength in a given period. Therefore, the designed porous ceramics have very high osteogenic activity, and the risk of rapid disintegration after implantation of the ceramics in the early and middle periods is also reduced.

Owner:陶合体科技(苏州)有限责任公司

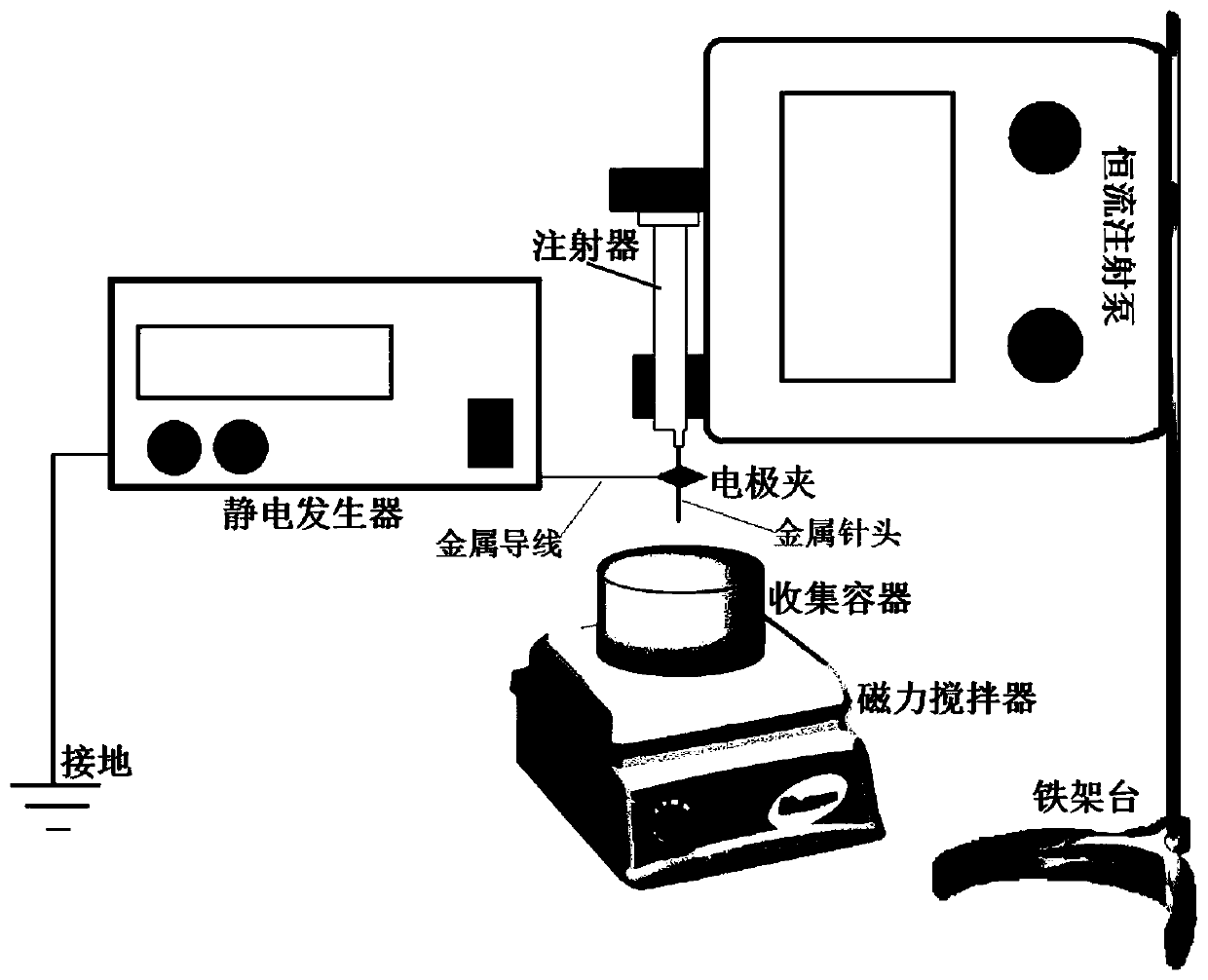

Strontium-doped calcium phosphate ceramic particles for repairing defective alveolar bone, and preparation method of strontium-doped calcium phosphate ceramic particles

ActiveCN110304939AEvenly dopedImprove biological activityTissue regenerationProsthesisPorositySlurry

The invention discloses strontium-doped calcium phosphate ceramic particles for repairing defective alveolar bone, and a preparation method of the strontium-doped calcium phosphate ceramic particles,and solves the problems that calcium phosphate ceramics in the prior art are irregular in morphology, poor in uniformity, low in porosity and poor in bone repair capability. The preparation method comprises the following steps: uniformly mixing calcium phosphate powder, a sodium alginate solution, a binder solution and water to obtain a calcium phosphate mixed slurry; adding a foaming agent solution into the calcium phosphate mixed slurry, and carrying out heating and stirring to obtain foamed slurry; dropwise adding the foamed slurry into a soluble strontium salt solution to form composite hydrogel microspheres, and continuing soaking until the composite hydrogel microspheres are completely cured, and then carrying out washing and drying to obtain composite microspheres; and sintering thecomposite microspheres at a high temperature to obtain the strontium-doped calcium phosphate ceramic particles. According to the invention, strontium ions are uniformly distributed, so that improvement of biological activity and bone induction capability of the calcium phosphate ceramic particles is facilitated, and requirements for regeneration repair of defective alveolar bone are met. The strontium-doped calcium phosphate ceramic particles are regular in morphology and controllable in size.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com