Three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material and preparation method thereof

A technology of porous calcium phosphate and calcium phosphate ceramics, applied in ceramic products, other household utensils, applications, etc., can solve the problems of lower mechanical properties of supports, random distribution of pores, and low connectivity of pores, and achieve a high degree of automation and industrialization The effect of simple production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

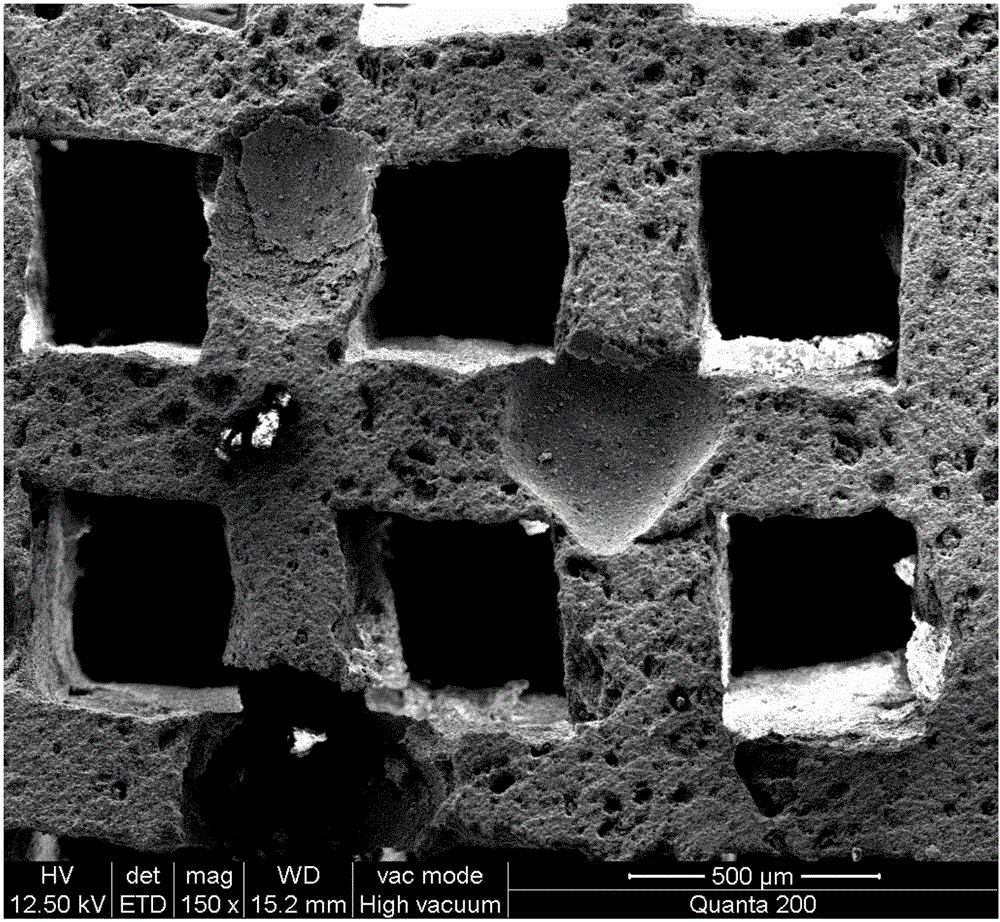

[0035] Preparation of mud mass: Mix 100g of β-phase tricalcium phosphate powder, 10g of paraffin microspheres (with a particle size of 400-500μm) and 5g of methyl cellulose in a high-speed mixer to make a solid phase; mix 10g of ethylene glycol, 1g Liquid paraffin and 20mL deionized water were mixed evenly, and then added dropwise to the solid phase to make a mud mass.

[0036] Practicing mud and stale: use a mud training machine to refine the mud balls for 3 times, and then seal and stale for 12 hours to obtain plastic mud balls.

[0037] Extrusion molding: put the stale mud into the mold (the width of the discharge groove is 0.6mm, and the center distance of the discharge groove is 1.0mm) for extrusion molding. The extrusion die in the mold is a square hole. Extrusion The speed is 2mm / min.

[0038] Drying: Dry in an oven at 30°C for 72h.

[0039] Sintering: The dried green body is fired in an air atmosphere furnace at 1100°C for 2 hours to obtain a three-dimensionally conn...

Embodiment 2

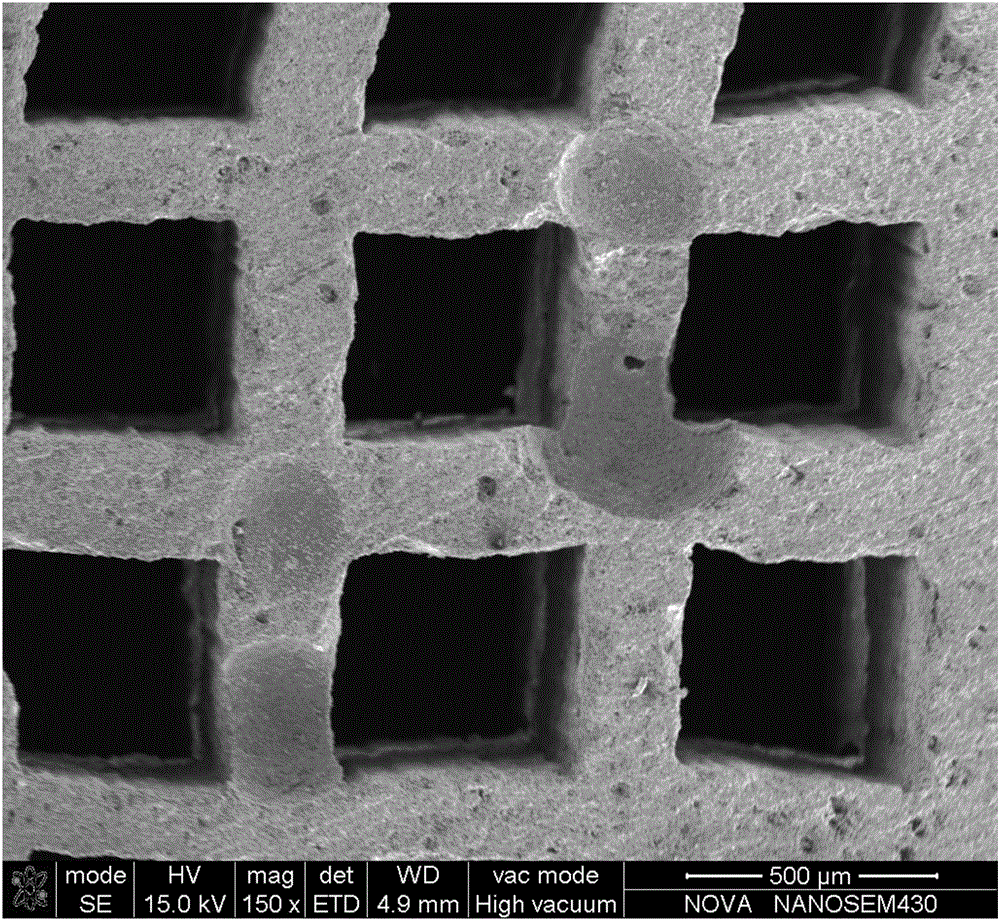

[0042] Preparation of mud mass: Mix 100g of hydroxyapatite powder, 10g of gelatin microspheres (300-400μm in particle size) and 10g of dextrin in a high-speed mixer to make a solid phase; 5g of glycerin, 10g of tung oil and 25mL of Ionized water is mixed evenly, and then added dropwise to the solid phase to make a mud mass.

[0043] Practicing mud and stale: use a mud refining machine to refine the mud balls for 5 times, and then seal and stale for 24 hours to obtain plastic mud balls.

[0044] Extrusion molding: put the stale mud into the mold (the width of the discharge groove is 0.5mm, and the center distance of the discharge groove is 0.8mm) for extrusion molding. The extrusion die in the mold is a square hole. Extrusion The speed is 8mm / min.

[0045] Drying: Dry in an oven at 120°C for 12 hours.

[0046] Sintering: The dried green body is fired in an air atmosphere furnace at 1300°C for 3 hours to obtain a three-dimensionally connected honeycomb porous calcium phosphate...

Embodiment 3

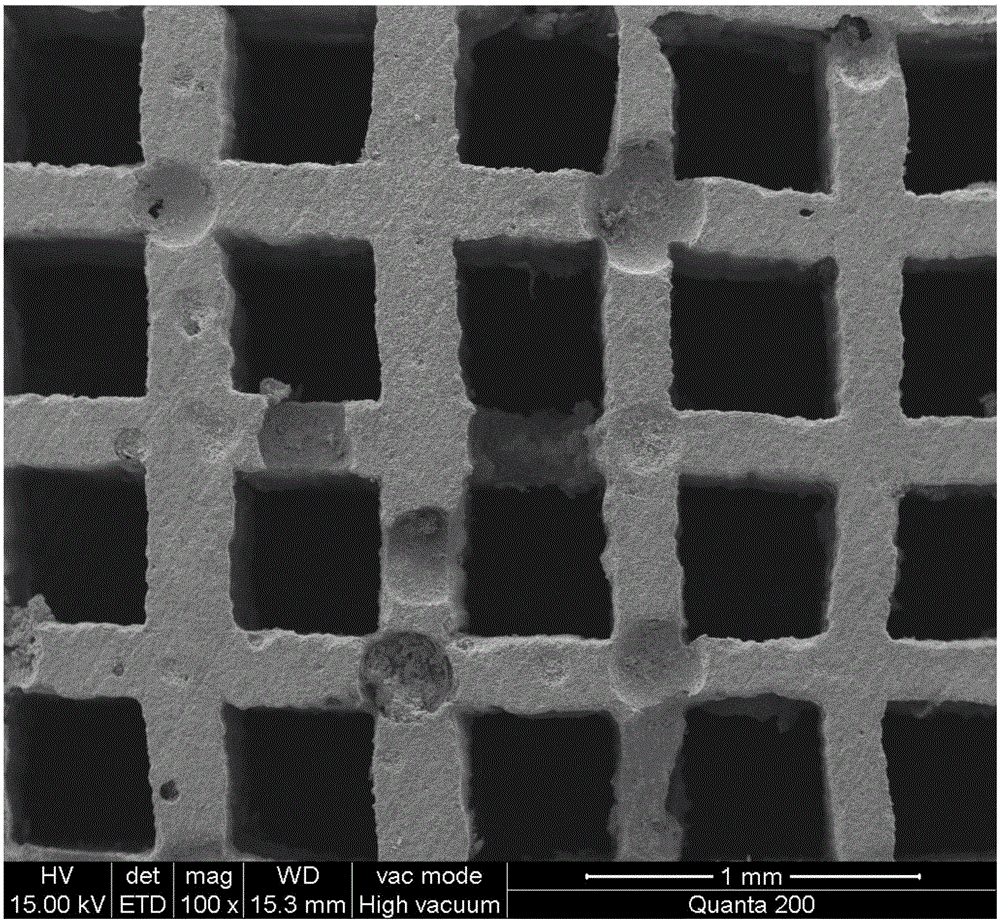

[0049]Preparation of mud mass: Mix 100g of α-phase tricalcium phosphate powder, 20g of polyethylene microspheres (400-500μm) and 10g of carboxymethyl cellulose in a high-speed mixer to make a solid phase; mix 7.5g of oxalic acid, 15g of castor oil Mix well with 28mL of deionized water, then add dropwise to the solid phase to make a mud ball.

[0050] Practicing mud and stale: use a mud training machine to refine the mud ball once, and then seal and stale for 72 hours to obtain plastic mud balls.

[0051] Extrusion molding: Put the dried mud into the mold (the diameter of the outlet chute is 0.5mm, and the center distance of the outlet chute is 0.8mm) for extrusion molding. The extrusion die in the mold is a square hole, and the extrusion speed It is 12mm / min.

[0052] Drying: Dry in an oven at 60°C for 48h.

[0053] Sintering: The dried green body is fired in an air atmosphere furnace at 1300°C for 1 hour to obtain a three-dimensionally connected honeycomb porous calcium pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com