Patents

Literature

48results about How to "Effect of mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material and preparation method thereof

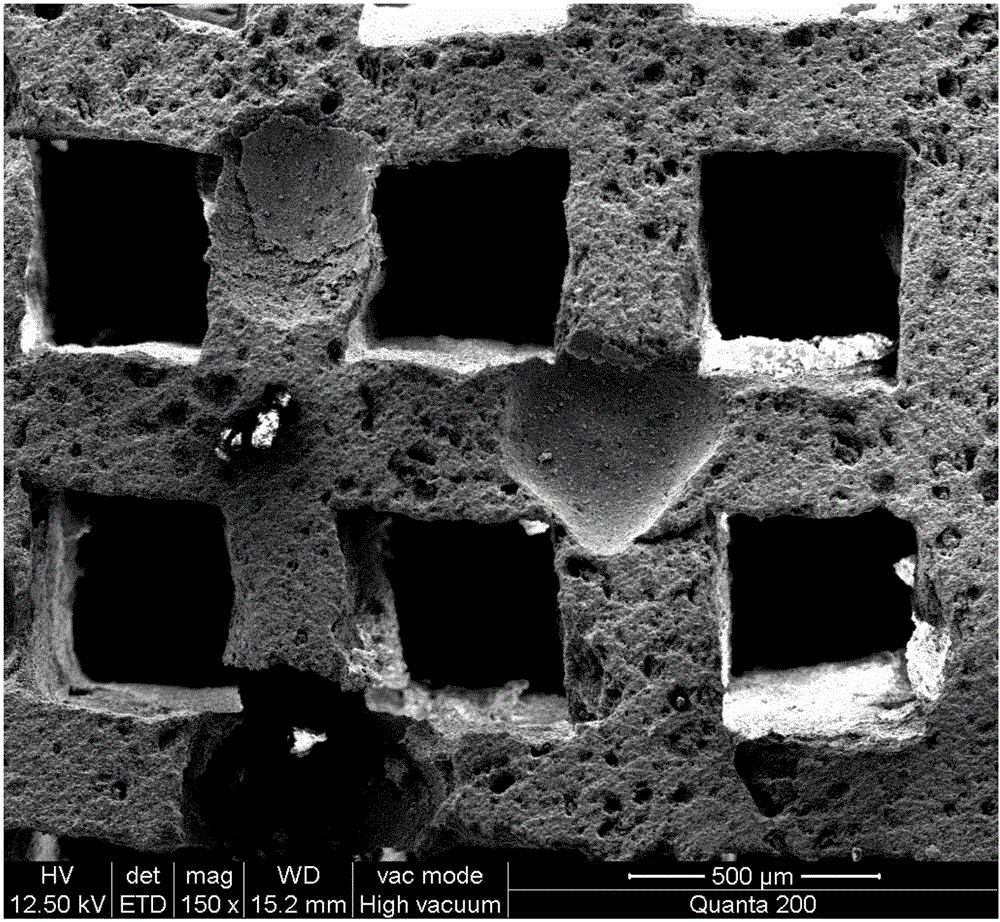

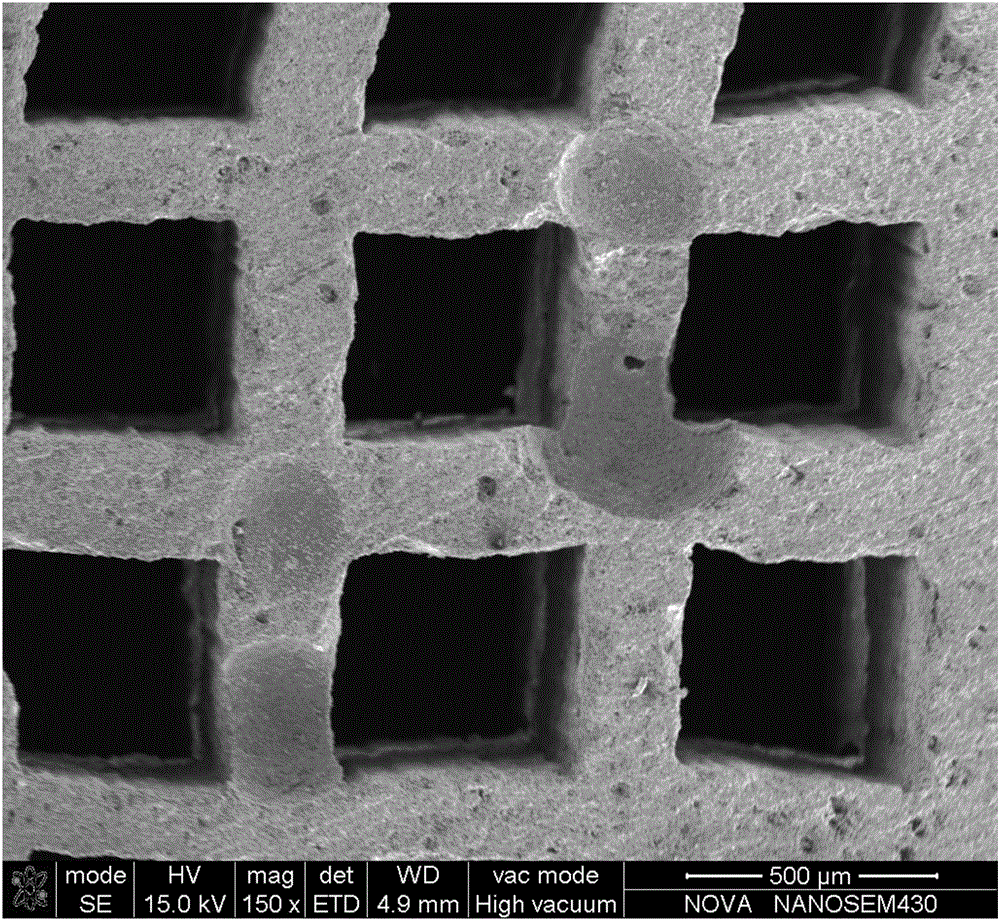

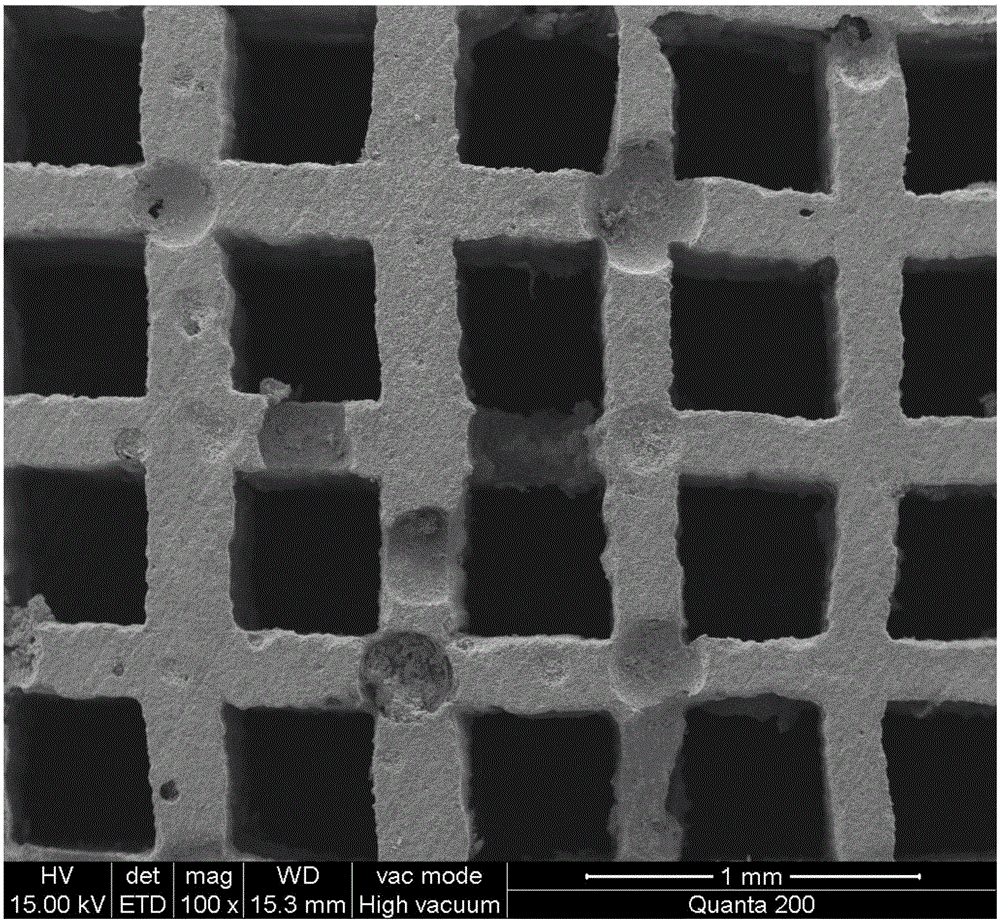

InactiveCN106518143AHigh porosityAperture controllableTissue regenerationProsthesisPorosityMetabolite

The invention discloses a three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material. A plurality of longitudinal straight-through holes are distributed in the calcium phosphate ceramic artificial bone material in a honeycomb manner; and a plurality of transverse through holes are distributed in the hole walls of the straight-through holes to connect the adjacent straight-through holes. The invention also discloses a preparation method of the three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material. The three-dimensional connected honeycomb porous calcium phosphate ceramic artificial bone material is prepared once through an extrusion molding technology and a pore forming agent adding technology. The straight-through holes are helpful for growing newborn bone tissues and forming blood vessels, and the three-dimensional connected holes are helpful for connecting cells into pieces and facilitate transportation of nutrient substances and discharging of metabolites. The preparation method is simple and can realize continuous production; and the prepared porous calcium phosphate ceramic has the advantages of high porosity, high connectivity and good mechanical performances.

Owner:SOUTH CHINA UNIV OF TECH

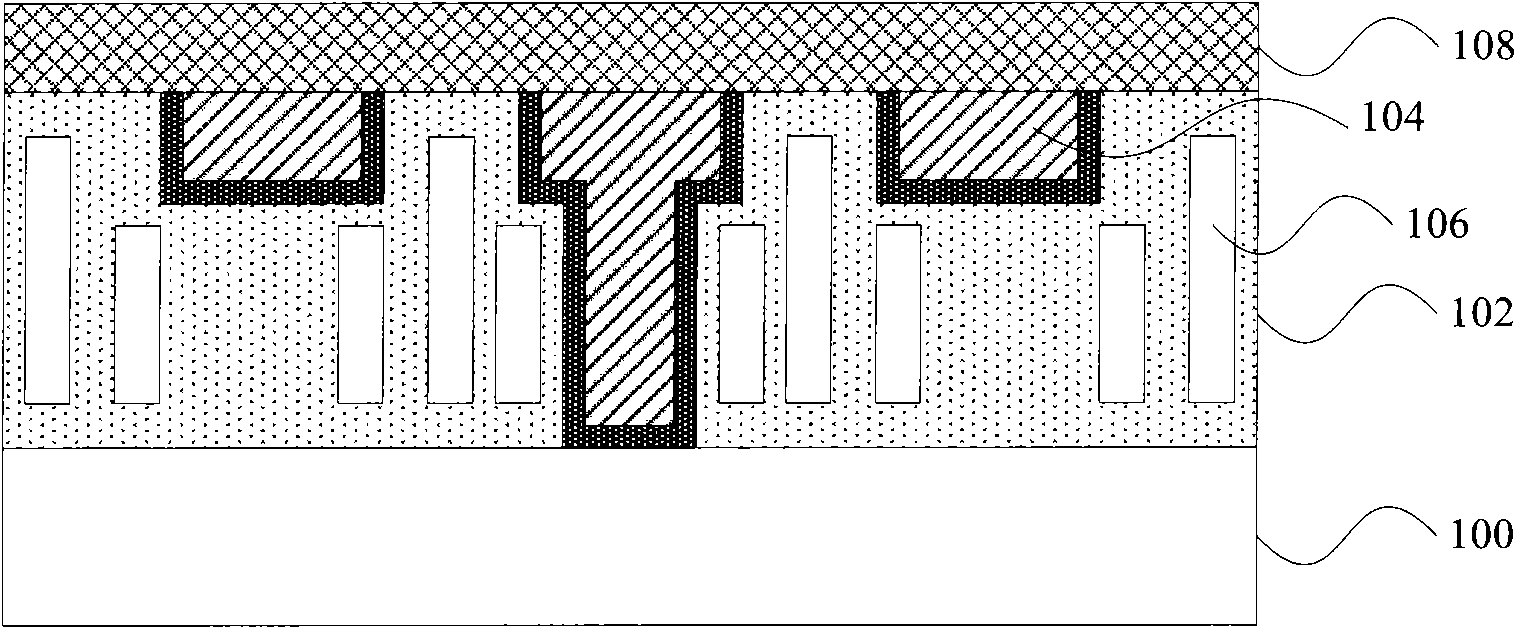

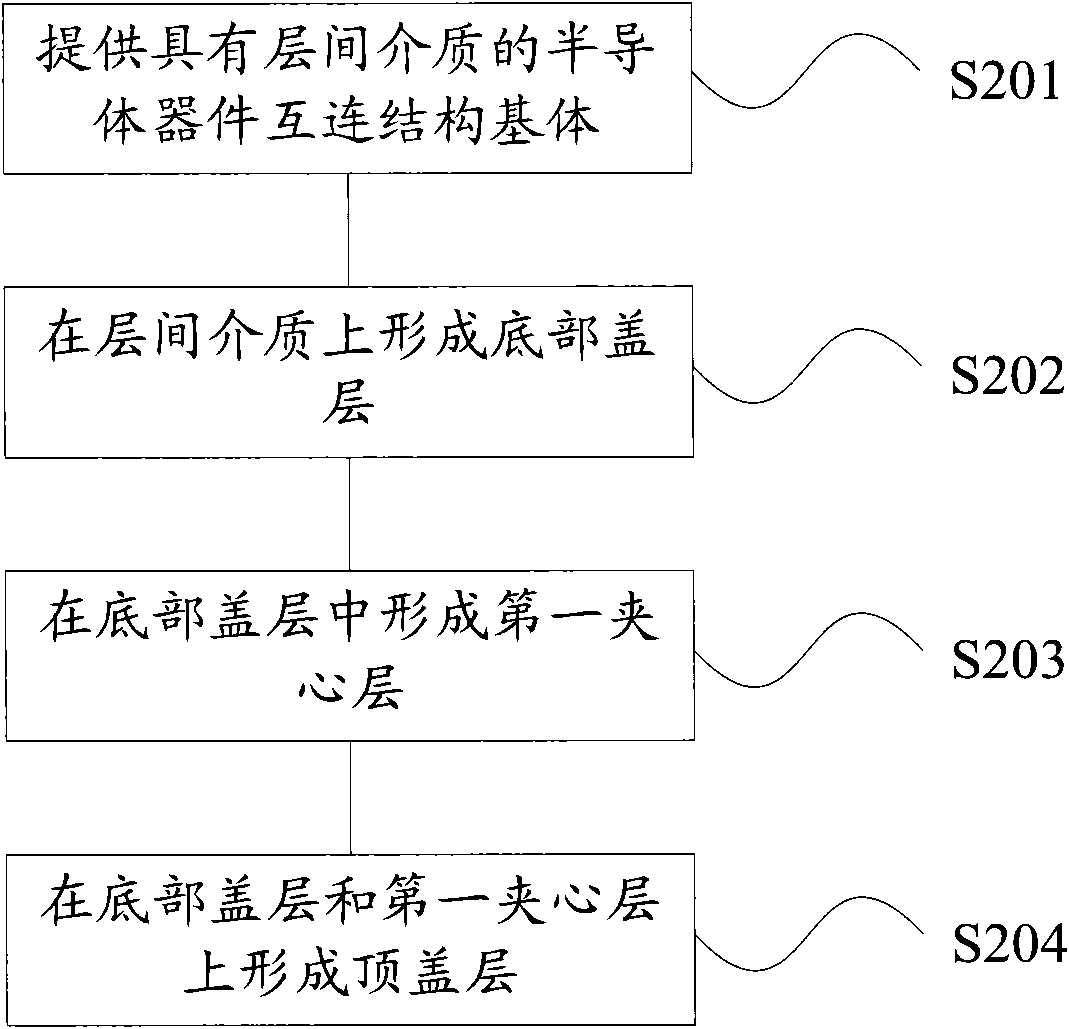

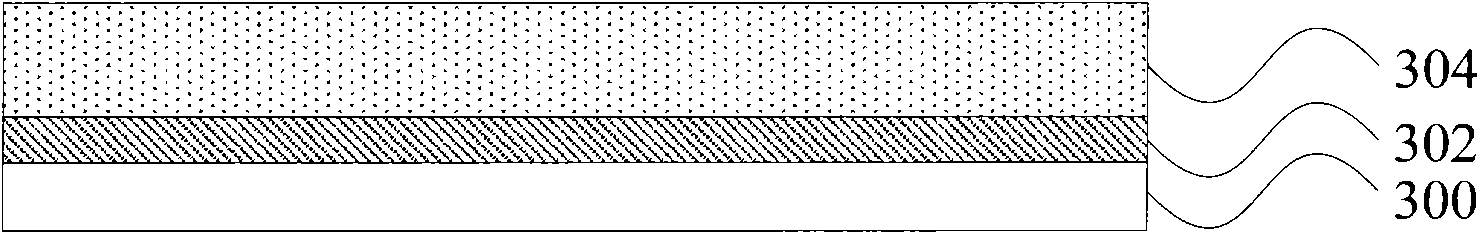

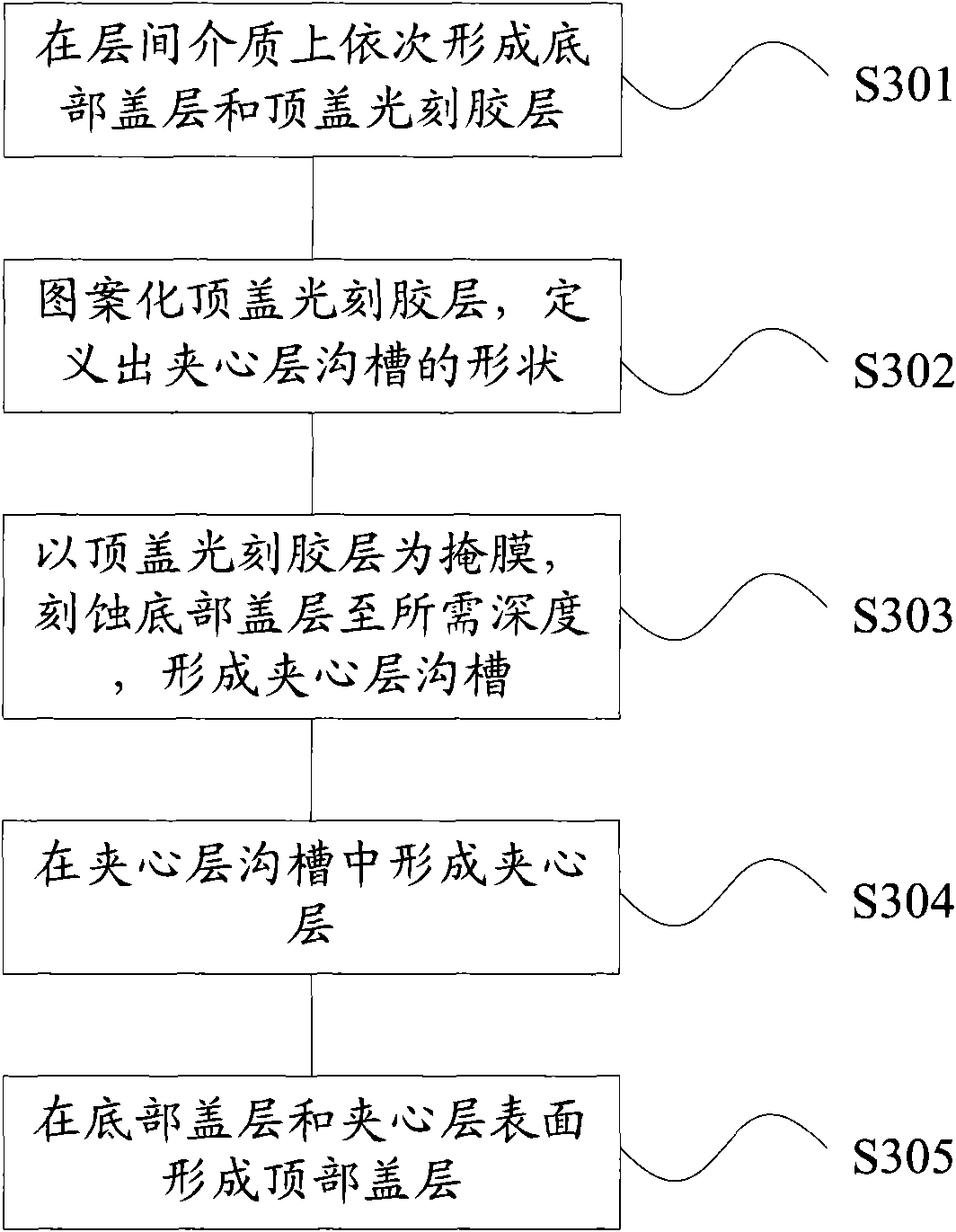

Cover layer of semiconductor device interconnected structure and manufacturing method thereof

InactiveCN101587857AHigh mechanical strengthEffect of mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesDielectricMetallic materials

The invention relates to a manufacturing method for a cover layer of a semiconductor device interconnected structure. The manufacturing method comprises the following steps: providing a semiconductor device interconnected structure matrix provided with interlevel dielectrics; forming a bottom cover layer on the interlevel dielectrics; forming a first sandwich layer in the bottom cover layer; and forming a top cover layer on the bottom cover layer and the first sandwich layer. Correspondingly, the invention also provides the cover layer of the semiconductor device interconnected structure. The invention adopts a compound medium layer as the cover layer of the semiconductor device interconnected structure, improves the mechanical strength of the whole interconnected structure and ensures that a chip is not easy to break in the use process. While further improving the mechanical strength of the whole interconnected structure, the metal material with higher thermal conduction in the cover layer can easily and timely dissipate heat generated in the working process of the chip so as to ensure that the chip cannot be burned down due to overhigh temperature and ensure the working efficiency and the stability of the chip.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

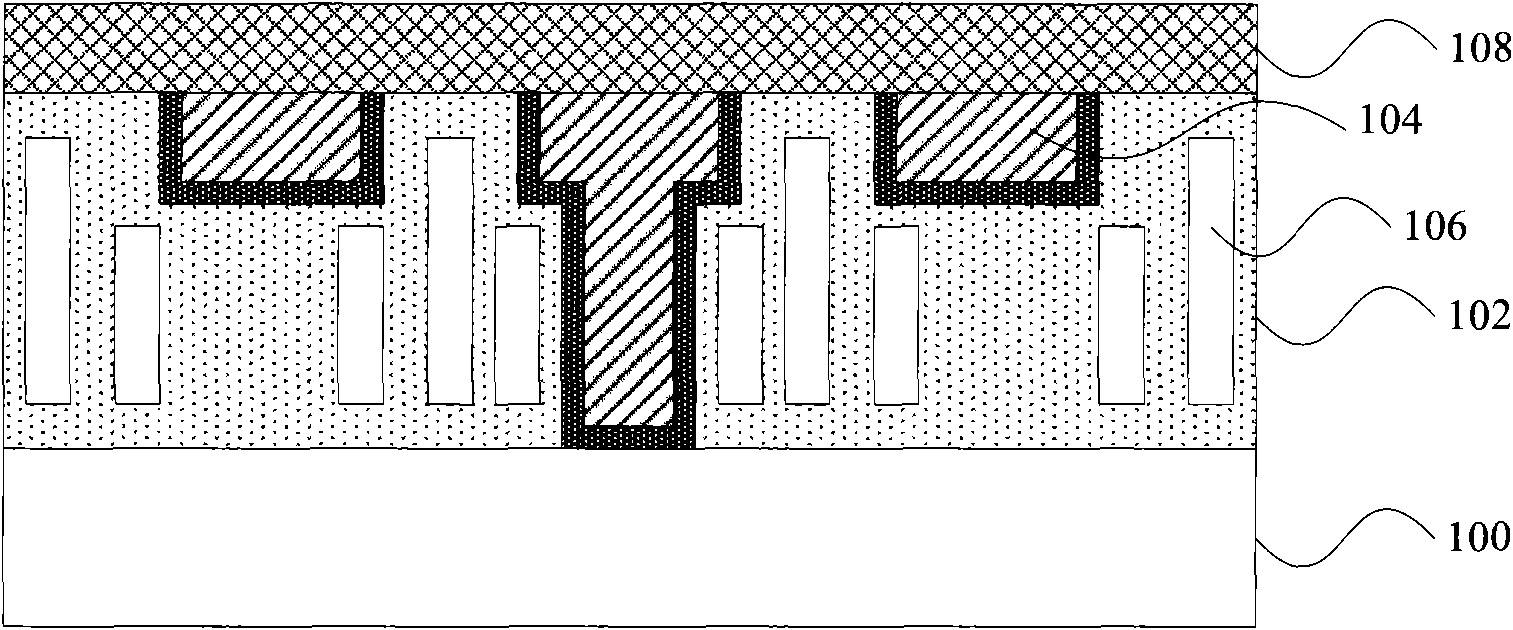

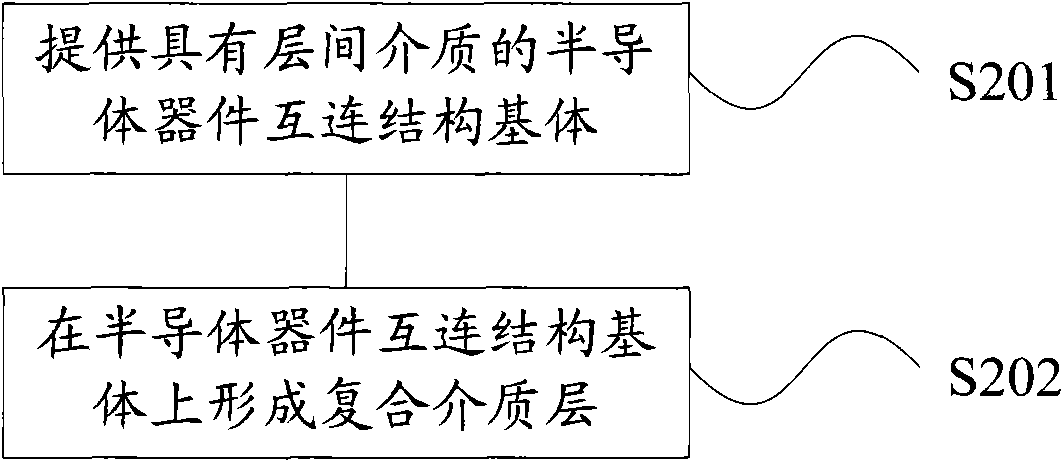

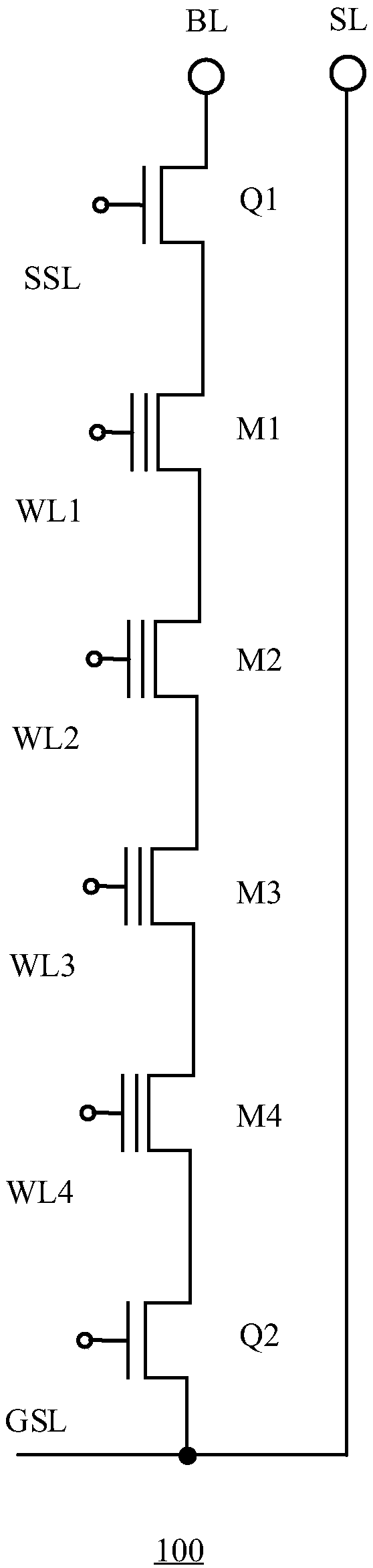

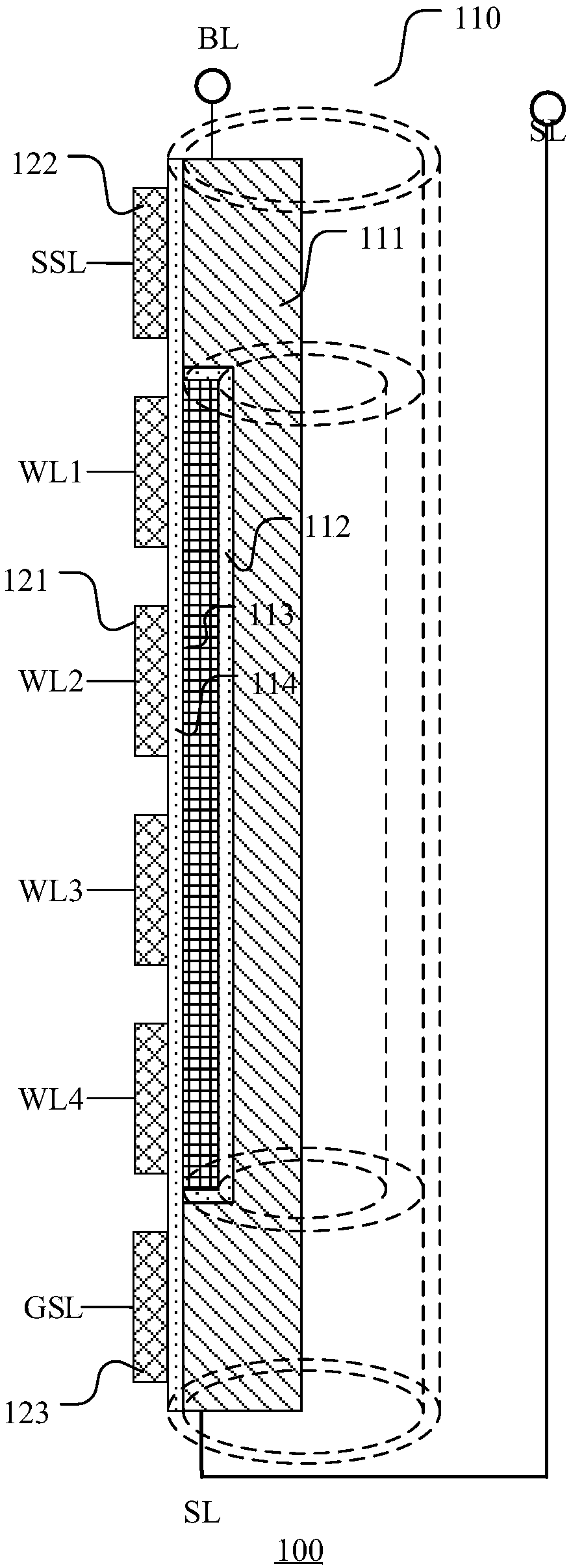

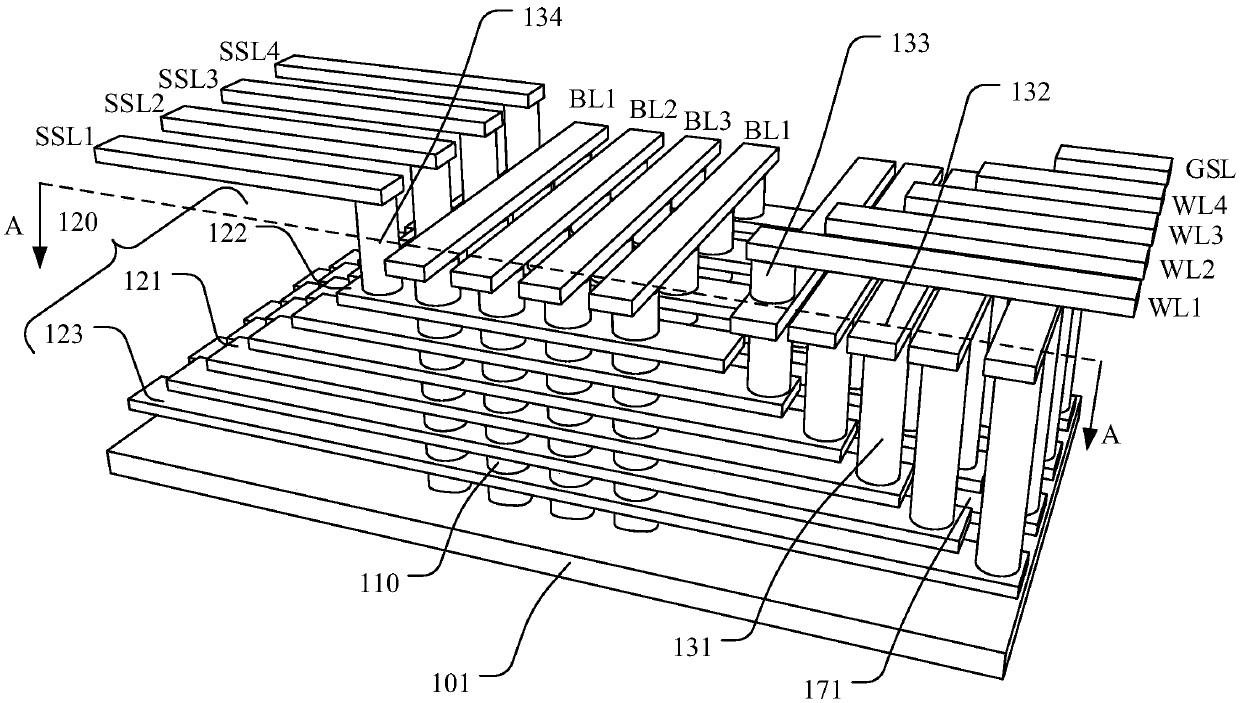

Semiconductor device interconnected structure and manufacturing method thereof

InactiveCN101587858AHigh mechanical strengthAvoid breakingSemiconductor/solid-state device detailsSolid-state devicesDielectricEngineering

The invention relates to a manufacturing method for a semiconductor device interconnected structure. The manufacturing method comprises the steps of providing a semiconductor device interconnected structure matrix provided with interlevel dielectrics, and forming a compound medium layer on the semiconductor device interconnected structure matrix. The compound medium layer comprises a bottom cover layer arranged on the bottom of the compound medium layer, a sandwich layer arranged in a sandwich layer groove, and a top cover layer arranged on the top of the compound medium layer, wherein the sandwich layer groove is arranged in the bottom cover layer. The invention also provides the semiconductor device interconnected structure. The invention adopts the compound medium layer as the top cover layer, improves the mechanical strength of the whole interconnected structure and ensures that a chip is not easy to break in the use process. The material with higher thermal conduction in the top cover layer can easily and timely dissipate the heat generated in the working process of the chip, ensures that the chip cannot be burned down due to overhigh temperature and ensures the working efficiency and the stability of the chip.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

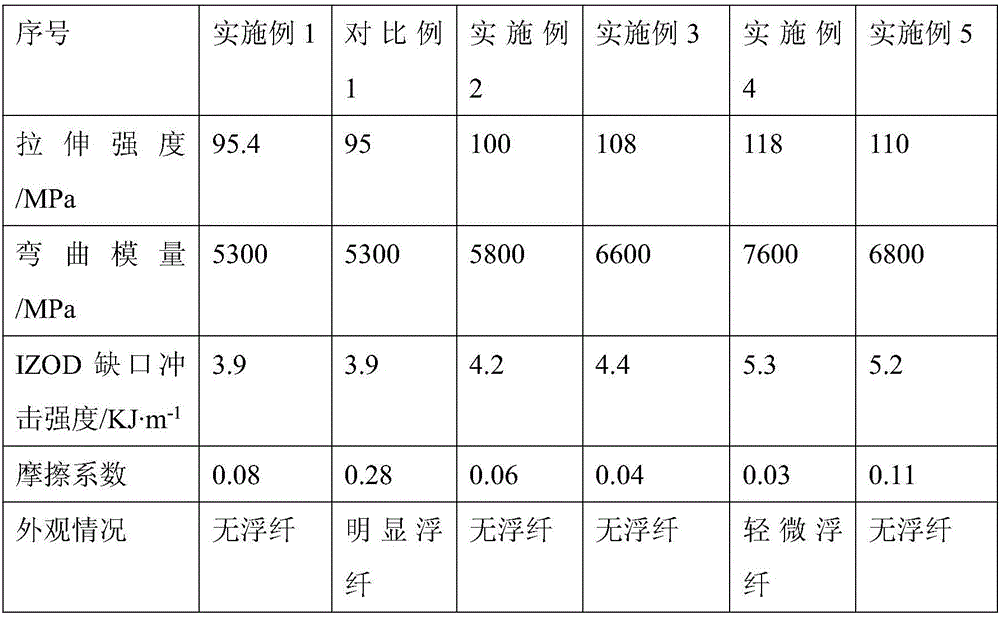

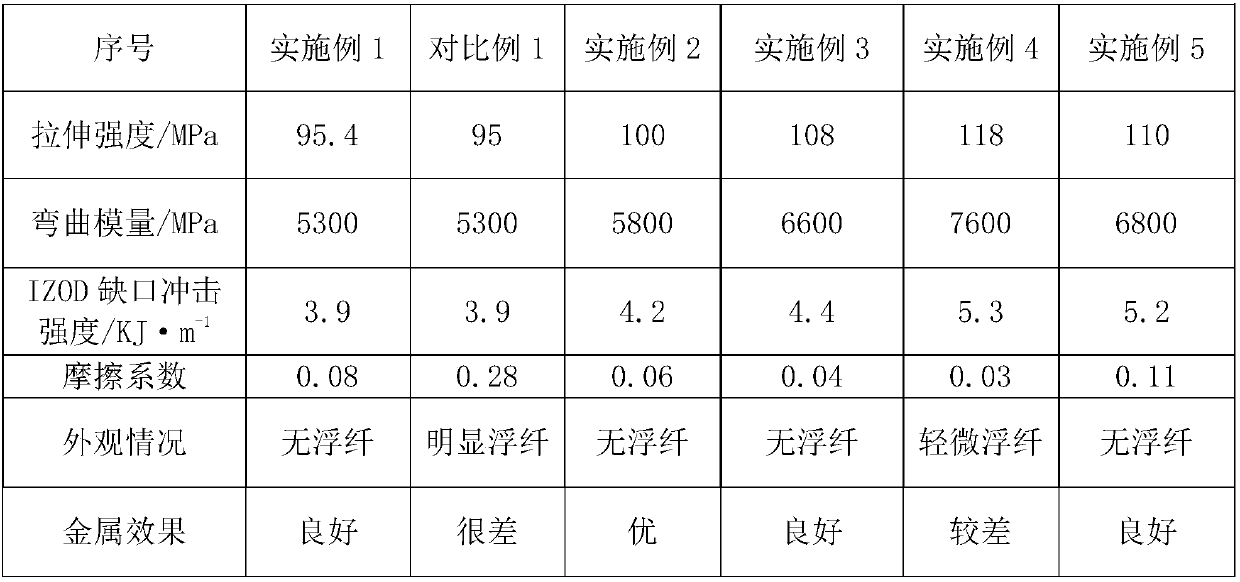

Wear-resistant low-floating fiber glass fiber-reinforced polyphenylene sulfide composite material and preparation method thereof

InactiveCN106380846AReduce the amount of anti-wear agent usedImprove wear resistanceWear resistantMolybdenum disulfide

The invention relates to a wear-resistant low-floating fiber glass fiber-reinforced polyphenylene sulfide composite material and a preparation method thereof. The composite material comprises 45-85wt% of polyphenylene sulfide resin, 5-45wt% of glass fibers, 1-15wt% of wear-resistant anti-floating fiber master batches, 0.1-1.5wt% of an anti-oxidant, 0.1-1wt% of a coupling agent, 0.3-1.5wt% of a compatilizer and 0-2.5wt% of other auxiliary agents. The wear-resistant anti-floating fiber master batch comprises 65-95wt% of polyphenylene sulfide resin, 1-25wt% of molybdenum disulfide, 1-25wt% of graphite, 0.1-1wt% of an anti-oxidant, 0.1-2wt% of a compatilizer and 0-2.5wt% of other auxiliary agents. The composite material can eliminate floating fiber-caused influence on product appearance, reduce a wear-resisting agent use amount and improve wear resistance. The preparation method has simple processes and high production efficiency.

Owner:上海聚威新材料股份有限公司

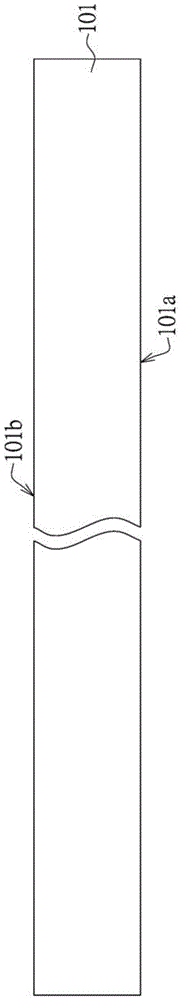

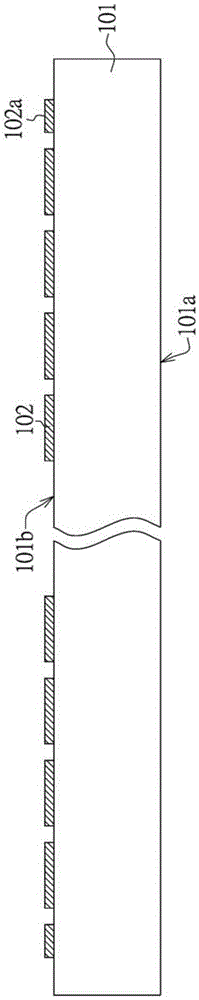

Surface correction structure and correction method of semiconductor structure

ActiveCN109524312AImprove yieldImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureCorrection method

The application discloses a surface correction structure and correction method of a semiconductor structure. The surface correction structure comprises a back film and a stress layer adjacent to the back film. The back film is arranged on the surface of the semiconductor structure and is adjacent to the surface of the semiconductor structure. According to the correction structure, a flat surface is provided for the follow-up cover layer and the correction structure is suitable for surface warping with various directivity, so that the yield and reliability of the semiconductor device are improved.

Owner:YANGTZE MEMORY TECH CO LTD

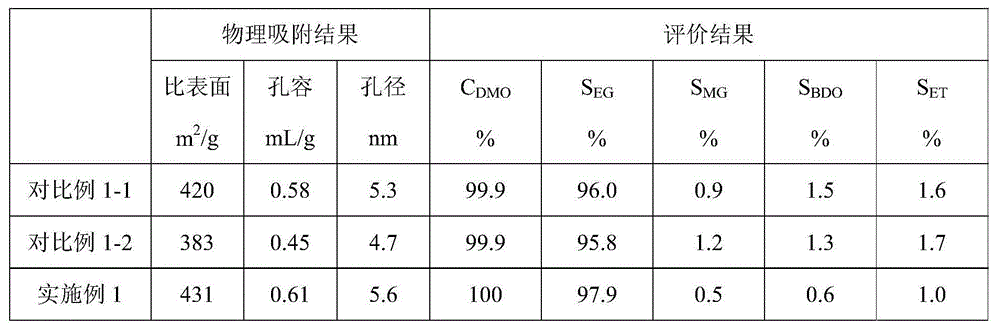

Catalyst for preparing ethylene glycol through dimethyl oxalate gas phase hydrogenation, and preparation method and application thereof

InactiveCN105727956AImprove pore structureHigh activityOrganic compound preparationHydroxy compound preparationGas phaseWear resistance

The invention relates to a catalyst for preparing ethylene glycol through dimethyl oxalate gas phase hydrogenation. The catalyst comprises the following components, by mass: 20-70 wt% of CuO, 25-79 wt% of SiO2, and 1.0-5.0wt% of oxide of a metal auxiliary agent. The catalyst has a specific surface area of 100-500m<2> / g, a pore volume of 0.3-1.5mL / g, and a pore size of 1.0-15.0nm. According to the invention, a pore-expanding agent and an environment-friendly auxiliary agent are added during a preparation process, such that the pore structure of the catalyst is effectively improved. When the prepared catalyst is used in a reaction for preparing ethylene glycol through oxalate gas phase hydrogenation, catalyst activity and ethylene glycol selectivity can be effectively improved; catalyst bed layer temperature can be stabilized; impurity generation can be significantly inhibited; no adverse influence is caused on the mechanical strength of the catalyst; and the wear resistance of the catalyst is improved. The service life of the catalyst can be longer than 1 year, such that the needs of industrial production can be satisfied.

Owner:SHANGHAI HUAYI ENERGY CHEM

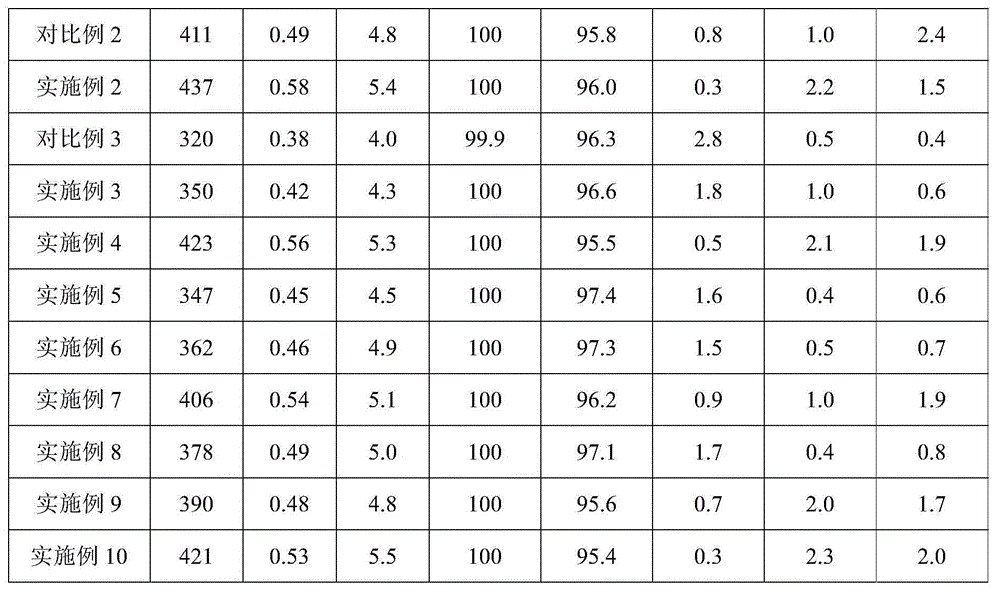

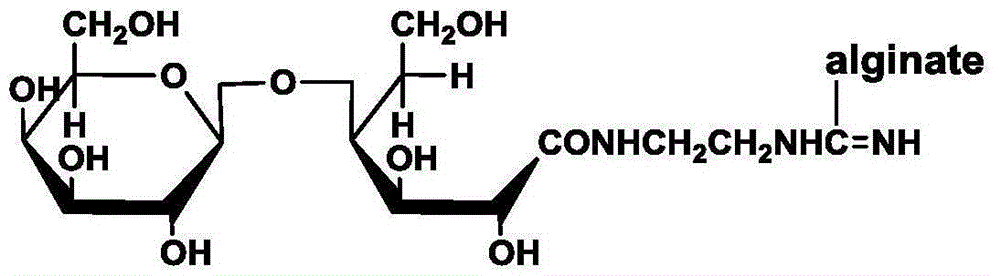

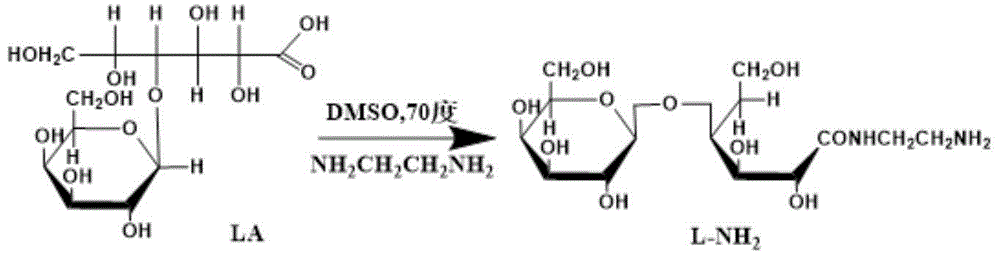

Galactosyl grafted-modified alginate microspheres and applications thereof

InactiveCN106399291AAffect gelationEffect of mechanical strengthOn/in organic carrierGraft reactionHydrogel microspheres

The present invention relates to a galactosyl grafted-modified alginate hydrogel microsphere carrier preparation method. According to the present invention, the occupation on the hydroxyl site of alginic acid does not affect the gelation performance of the alginic acid, such that the embedding type hydrogel microsphere carrier with characteristics of good sphericity and good stability can be prepared from the galactosyl alginic acid being subjected to the grafting reaction, and can further be subjected to the film forming reaction with polycations to form the galactosyl alginate / polycation microcapsule.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Waterproof and dampproof gypsum board and preparation method thereof

The invention discloses a waterproof and dampproof gypsum board and a preparation method thereof, and relates to the technical field of novel building materials. The gypsum board is prepared from the following raw materials in parts by weight: calcined desulphurization gypsum, Faku clay, laumontite powder, polyimide fiber, sodium bentonite, silicone polyether emulsion, dimethyl sulfoxide, methyl chlorostearate, a starch adhesive, a waterproofing agent, an activator, a foaming agent and a water reducer. The preparation method of the waterproof and dampproof gypsum board comprises the steps: adding water into the raw materials stage by stage, uniformly mixing and aging the raw materials, and performing pouring, preforming and drying operation, thus obtaining the waterproof and dampproof gypsum board. By improvement and optimization of the production raw materials and the process, a finished product board is high in waterproof and dampproof property, so that reduction of the mechanical strength of the board and deterioration of an indoor environment can be prevented; the service life of the gypsum board is prolonged; and the gypsum board is higher in reliability and safety and suitable for being popularized and applied.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

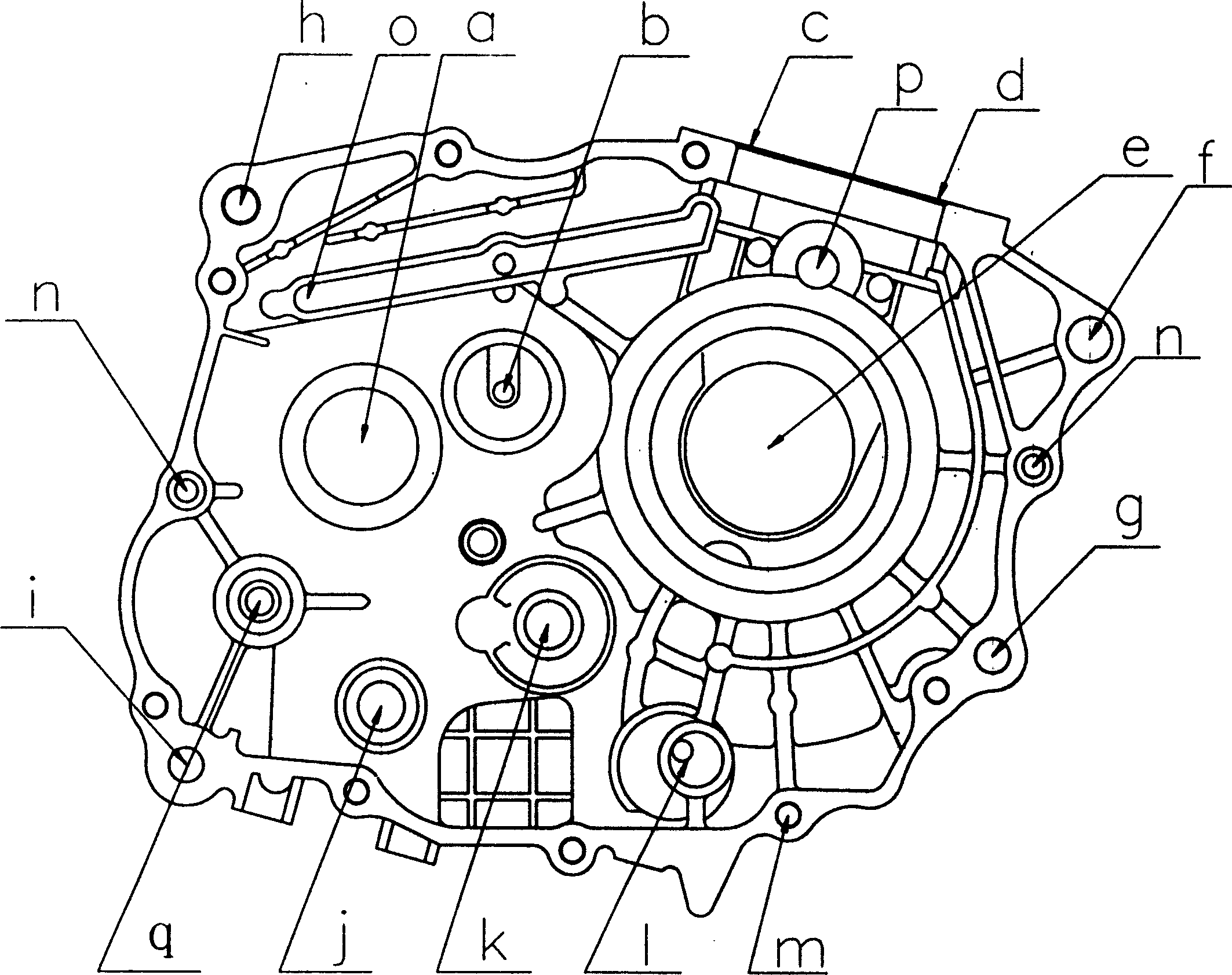

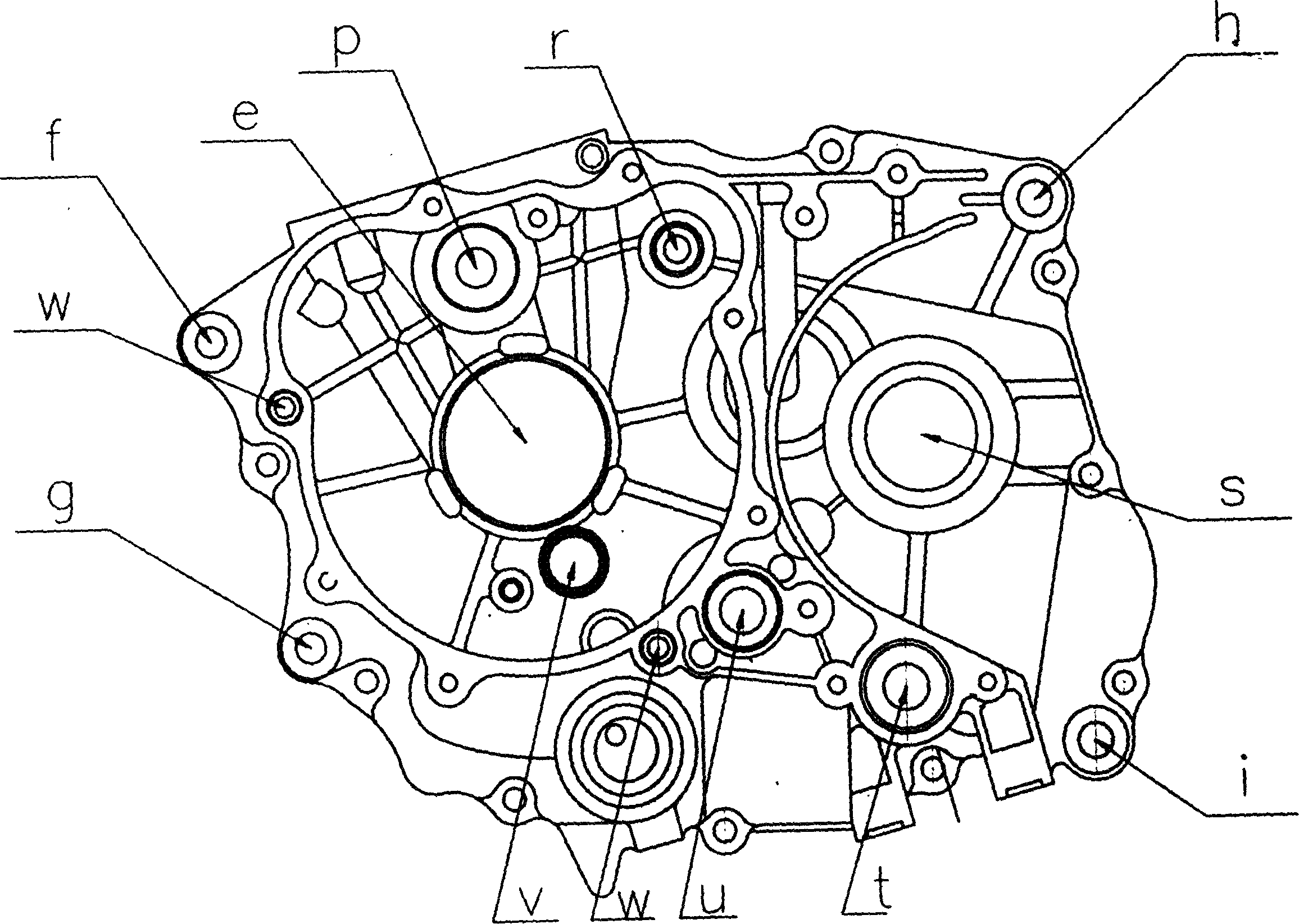

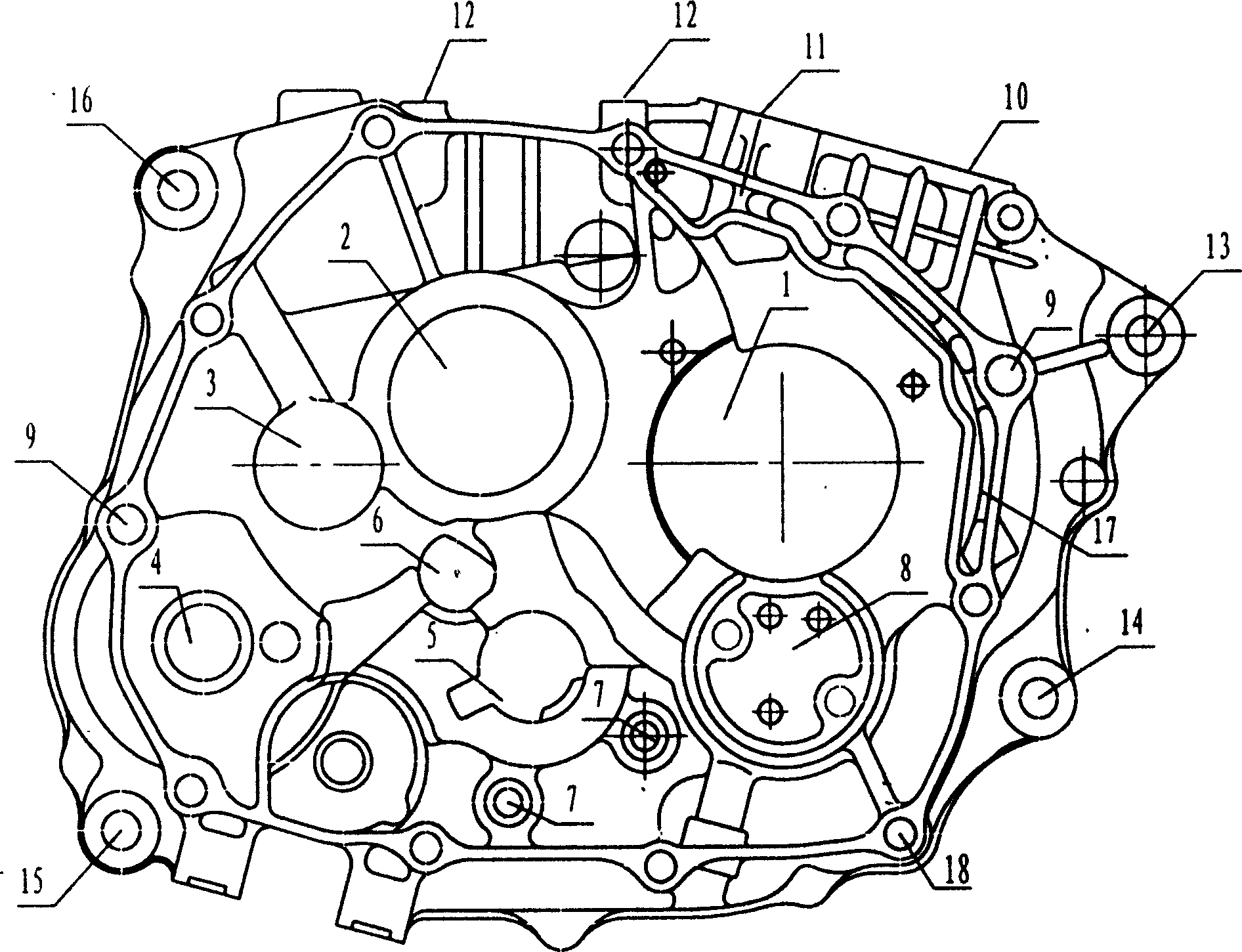

Reducing vibration type engine crankcase of motorcycle

InactiveCN1560460AImprove structural strengthIncrease cooling areaCasingsMachines/enginesCrankcaseEngineering

The invention belongs to combustion engine crank box, which is a crank box for the vibration damping motorcycle engine, made up of left crank box and the right crank box, the character lies in: the left and the right crank boxes use magnesium alloy to be cast and formed, the thickness of the box wall is 3.5-6mm, several reinforcing ribs with width of 3-5mm are arranged on the box surface and the cover. Compared to the gearing aluminum alloy crank box, when the structure intensity of the box is upgraded, the heat irradiating area is also increased, it can reduce the high temperature creep, the mechanical intensity of the magnesium alloy crank box in the high temperature environment is not affected; the experience to the same motorcycle LC125 testifies, the crank box of the invention caters all the demands of engine, and the weight is reduced, thus it can save 0.4l oil per hundred kilometers, the average heat vibration and noise only the 1 / 3 of the traditional crank box.

Owner:重庆镁业科技股份有限公司

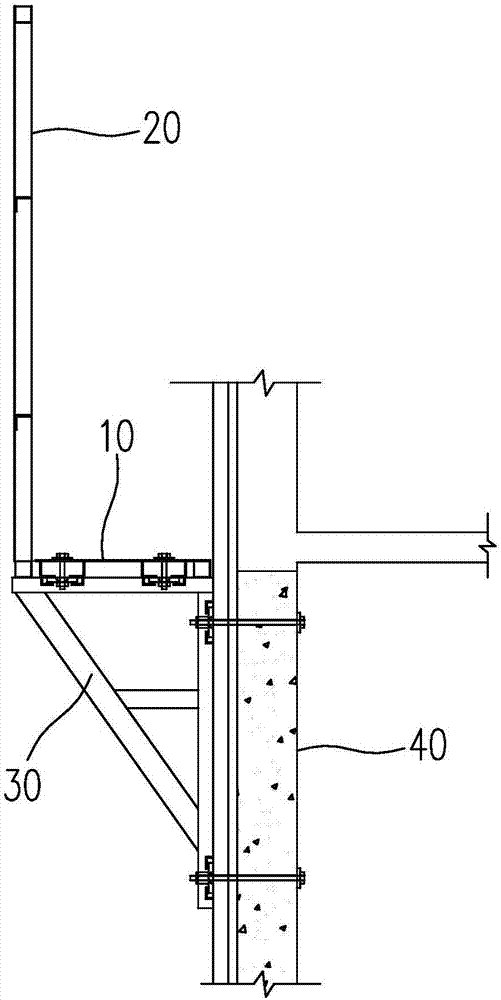

Modular external-hanging type scaffold

ActiveCN106894625AAvoid wastingEasy to produceBuilding support scaffoldsConstruction engineeringStructural engineering

The invention relates to a modular external-hanging type scaffold. The scaffold comprises a protective net rack arranged at one side of each walking platform, the walking platforms and the protective net racks are arranged in pairs to form an integral modular structure which is laid in a sectional mode along a building or a structure wall and can be spliced together. The walking platforms and the protective net racks matched with the walking platforms form the modular structure, in on-site construction, a constructor can make multiple scaffold modules according to the technical scheme, the length of each scaffold module can be set to be fixed size or set to be a combination of different sizes, and therefore construction of building walls of different lengths and building wall corners or corners can be adapted. Accordingly, the scaffold is set to be of a modular structure, assembling and disassembling are convenient, the transportation and storage cost is greatly lowered, splicing combination is easy, reusing can be conducted, the construction cost is greatly lowered, waste of materials and labor is avoided, and the construction efficiency is effectively improved.

Owner:赵东平 +1

Wood preservative

InactiveCN105171867AUniform effectEffect of mechanical strengthWood impregnation detailsToxicityAmmonium

The present invention belongs to the field of preservatives, and particularly relates to a wood preservative, which comprises, by weight, 2-15% of a quaternary ammonium salt compound of boron, 2-6% of triazole, 3-10% of acetic acid, 5-15% of lignin, 2-6% of a silicon resin, and the balance of deionized water, wherein the quaternary ammonium salt compound of the boron is at least one selected from a dimethyldidecyl boron tetrafluoride quaternary ammonium salt (DBF), a boron tetrafluoride quaternary ammonium salt, an alkoxy methyl decyl dimethyl boron tetrafluoride quaternary ammonium salt and a nitrate. According to the present invention, the wood preservative has characteristics of long-term efficiency, uniform action, no trace on the wood surface, no toxicity on human and animals, no environmental pollution or destruction, and no influence on mechanical strength, good texture and good color.

Owner:张萍

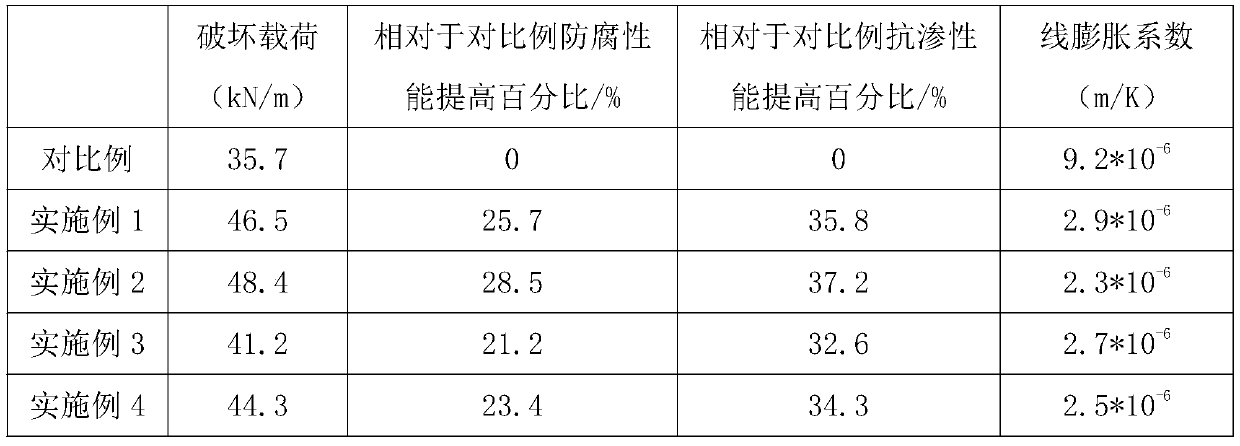

Road inspection well and manufacturing process and construction method thereof

InactiveCN111268963AReduces the chance of microcracksImprove crack resistanceArtificial islandsSewerage structuresSuper absorbentSilicate Cement

The invention relates to the technical field of road inspection well construction, in particular to a road inspection well and a manufacturing process and a construction method thereof. The concrete is prepared from the following raw materials: Portland cement, medium sand, super absorbent resin, pebbles, a fiber mixture, fly ash, an expanding agent, a polycarboxylate superplasticizer, gravel-typegranules, montmorillonite powder, attapulgite, a retarder, an early strength agent and water. The fiber mixture is used as a raw material for preparing the road inspection well, wherein the fiber mixture is formed by mixing polypropylene fibers and steel fibers according to a certain proportion, as a result, the polypropylene fibers and the steel fibers are matched with each other to effectivelyreduce the volume shrinkage phenomenon of the road inspection well in the early stage, and the anti-cracking performance of the road inspection well is improved; and moreover, proper vibration compaction treatment is carried out on the concrete during pouring, so that the compactness and the uniformity of the concrete are improved and guaranteed, the crack resistance and the bearing capacity of the road inspection well are remarkably improved, and the service life of the road inspection well is effectively prolonged.

Owner:漳州明威建材发展有限公司

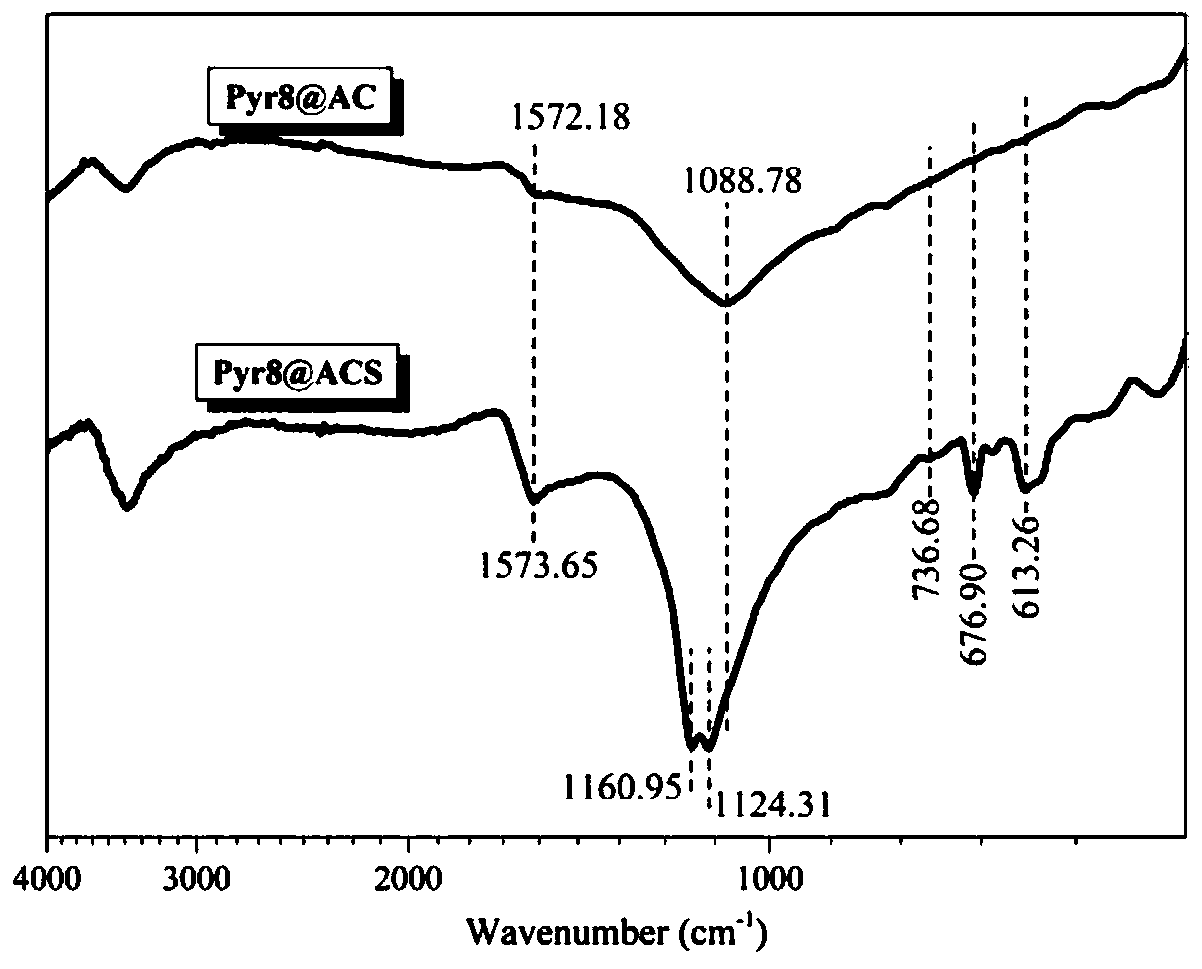

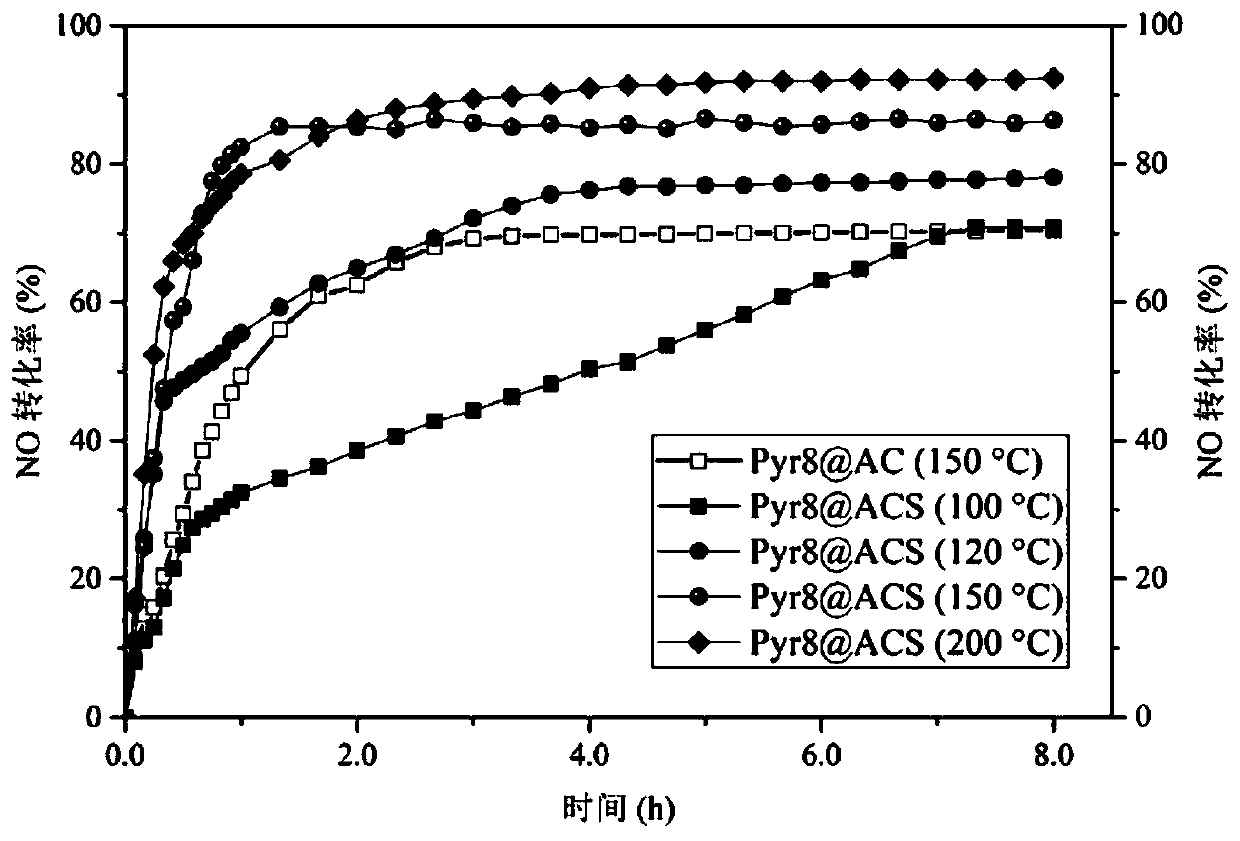

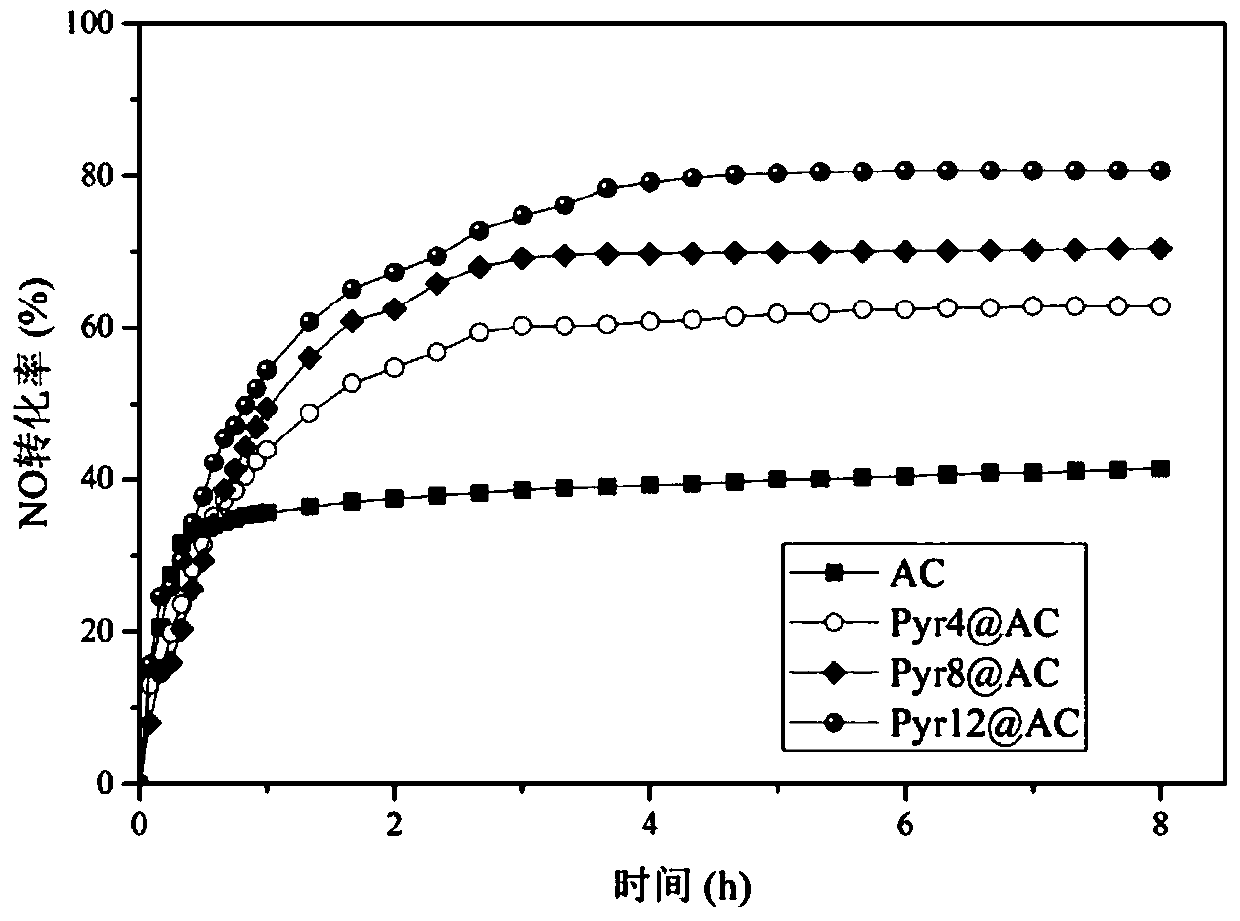

Surface-modified high-activity low-temperature denitration active coke and preparation method thereof

ActiveCN111099591AImprove the efficiency of denitrification reactionPromote denitrification reactionGas treatmentOther chemical processesNitrogen oxidesLow nitrogen

The invention provides surface-modified high-activity low-temperature denitration active coke and a preparation method thereof. The denitration active coke is activated and surface-modified, the maincomponent of the denitration active coke is a forming material of carbonized coal and natural manganese ore, and sulfur-containing functional groups and sulfate which mainly provide acidic adsorptionsites are formed on the surface of the forming material through surface modification. According to the invention, the problem of low nitrogen oxide removal rate of an existing denitration active cokeproduct in an adsorption-dominated denitration mode can be solved, the nitrogen oxide removal rate of the active coke product is improved through the dual effects of chemical catalysis and adsorptiondenitration, and the requirement of low-temperature denitration can be better met.

Owner:SICHUAN UNIV

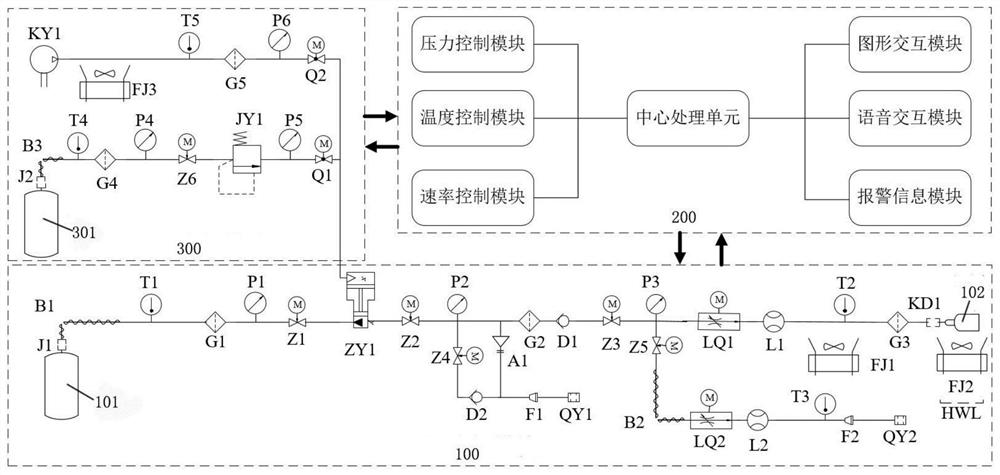

Automatic spaceflight high-pressure inflation and deflation system and method

ActiveCN114001271AEffect of mechanical strengthHigh medical safetyVessel mounting detailsGas handling applicationsThermodynamicsGas cylinder

The invention relates to an automatic spaceflight high-pressure inflation and deflation system and method. The system comprises a gas adding module, a gas driving module and a control module. The gas adding module comprises a first standard gas cylinder, a target gas cylinder and a gas adding pipeline, and a booster pump is arranged on the gas adding pipeline; the two ends of the gas adding pipeline are connected with the first standard gas cylinder and the target gas cylinder correspondingly, and the gas adding pipeline is used for adding gas in the first standard gas cylinder into the target gas cylinder. The gasdriving module is connected with the booster pump through a driving gas pipeline; a pressure detection assembly, a pressure adjusting assembly, a temperature detection assembly and a temperature adjusting mechanism are arranged on the gas adding pipeline, the pressure detection assembly is used for collecting a first gas pressure signal in the gas adding pipeline and sending the first gas pressure signal to the control module, and the temperature detection assembly is used for collecting a temperature signal of the gas adding pipeline and sending the temperature signal to the control module; the control module controls the pressure adjusting assembly to enable the inflation pressure change rate of the gas adding pipeline to be within a preset safety range. The control module regulates and controls the temperature of the gas adding pipeline to be within a preset temperature range.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

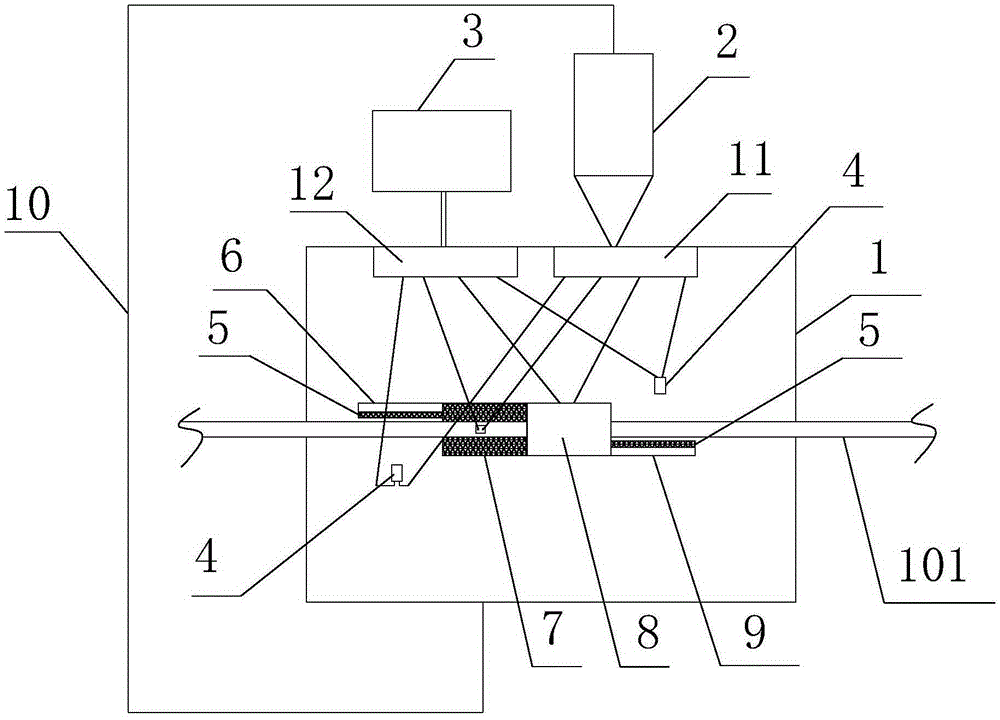

Machining device for matt cable

ActiveCN105382705AEffect of mechanical strengthAffect conductivityAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses a machining device for a matt cable. The machining device comprises a sand blasting box, a centrifugal chamber and a high-pressure gas source. A sand guide pipe and a high-pressure gas pipe are arranged in the sand blasting box. The centrifugal chamber is arranged above the sand blasting box and communicated with the sand guide pipe. The high-pressure gas source is communicated with the high-pressure gas pipe. A cable inlet and a cable outlet are formed in the two sides of the sand blasting box respectively. Multiple baffles are arranged at the portion, between the cable inlet and the cable outlet, in the sand blasting box and distributed criss-cross in the cable conveying direction. One side of each baffle is provided with at least one spray gun, spray openings of the spray guns face the baffle faces, close to the conveyed cable, of the baffles, gaps allowing the cable to pass are reserved between the spray guns and the baffle faces of the baffles, each spray gun is provided with two inlets, one inlet of each spray gun is connected with the sand guide pipe, and the other inlet of each spray gun is connected with the high-pressure gas pipe. By the adoption of the machining device, the baffles are arranged criss-cross in the cable conveying direction, so that the situation that the cable swings and shakes due to blasting force in the sand blasting process, the sand blasting face is uneven, and conveyance is unstable is avoided.

Owner:蚌埠格识知识产权运营有限公司

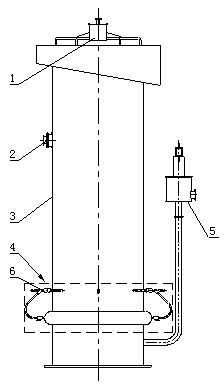

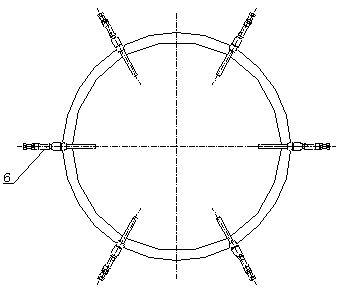

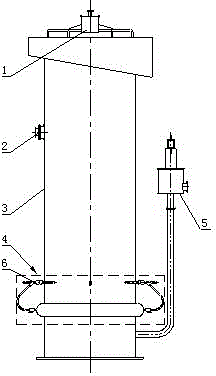

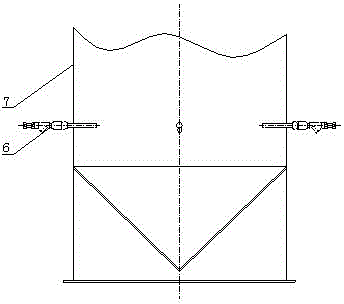

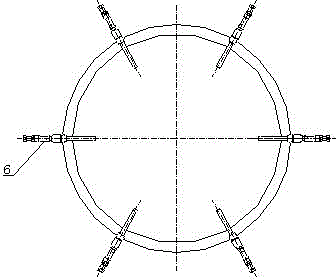

Flotation column

ActiveCN102847613AHigh gas dispersionEasy inspection and maintenanceFlotationSteel tubeWork performance

The invention discloses a flotation column which comprises a spraying water component, a feeding system, a column component and a gangue system, and further comprises a taper column bottom of the flotation column and a plurality of flotation column aerators, wherein the taper column bottom of the flotation column is located on the lower part inside the flotation column; the plurality of flotation column aerators are installed on the taper column bottom; the flotation column aerators are vertically installed at different height positions of the taper column bottom of the flotation column and are distributed along a plurality of circumferences of the taper column bottom of the flotation column. The flotation column aerators are distributed on the plurality of circumferences at different height positions of the taper column bottom of the flotation column, so that the distribution quantity of the aerators in a cross section of a column body is controlled according to the needed air flow and the size of the cross section of the flotation column of a selected process, dispersion degree of gas injected in the column is high; and the flotation column aerators are longer in service lives and stable in work performance under protection of wear-resisting steel tubes.

Owner:BGRIMM MACHINERY & AUTOMATION TECH CO LTD +1

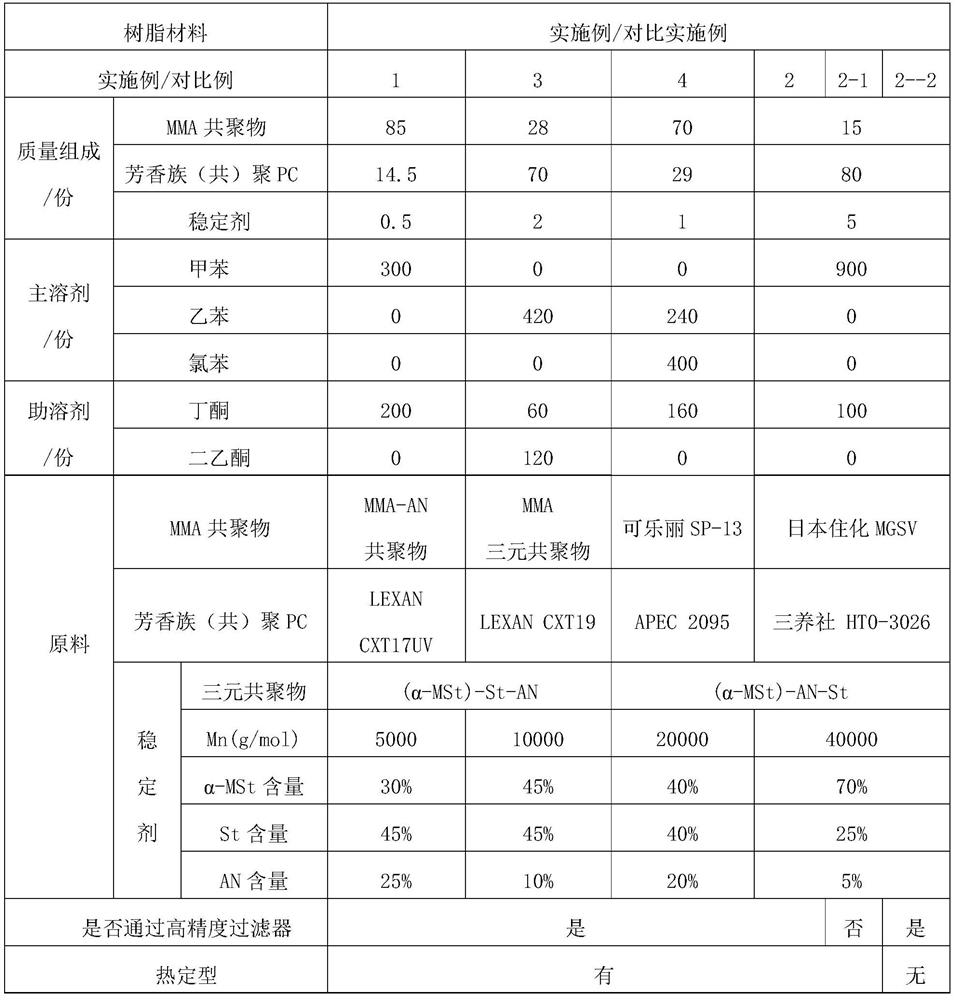

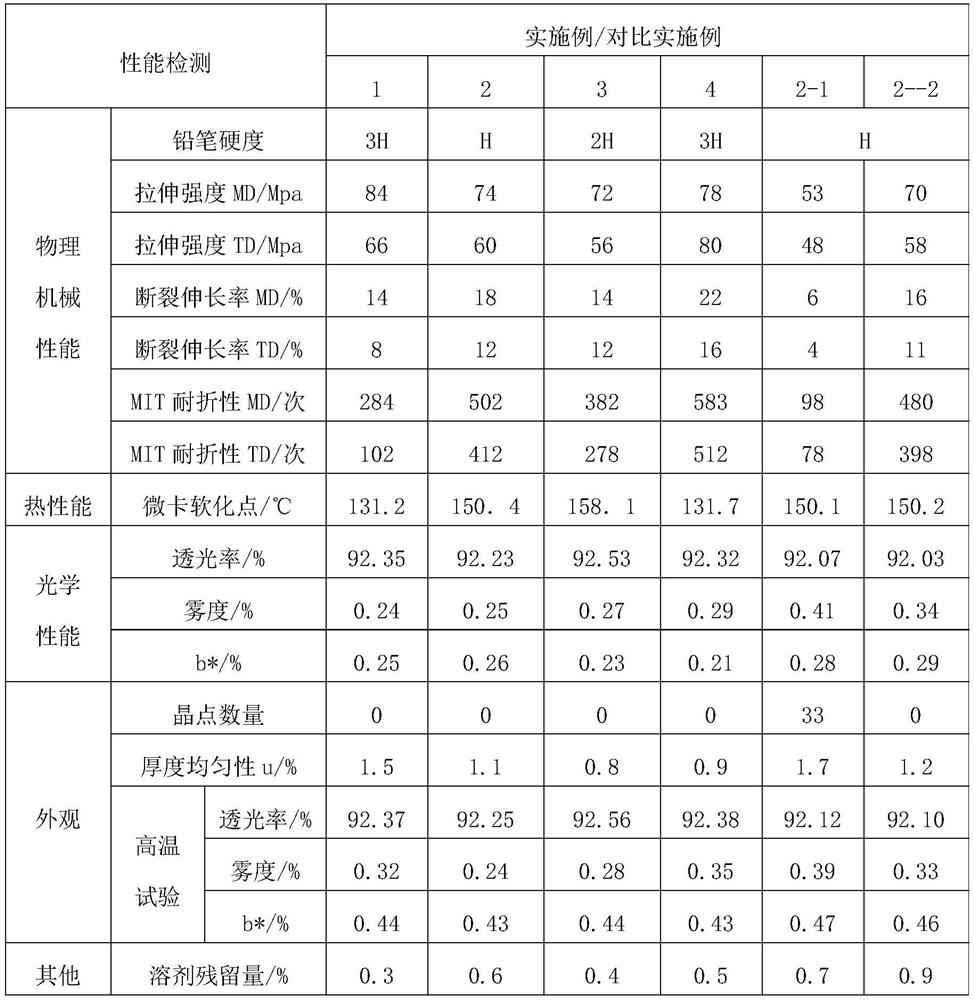

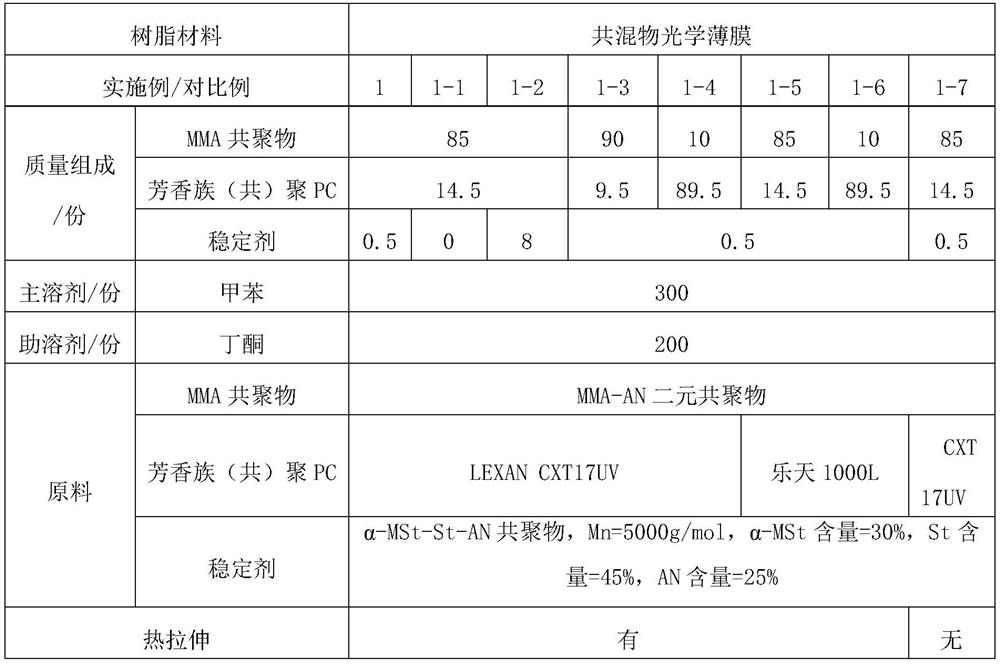

Blend optical film with thermodynamic stability and preparation method thereof

The invention relates to a blend optical film with thermodynamic stability and a preparation method thereof. The blend optical film comprises the following components in parts by weight: 15-85 parts of methacrylate polymer, 14.5-80 parts of aromatic polycarbonate and 0.5-5 parts of stabilizer. The preparation method of the blend film comprises the following steps: pretreating the raw materials, preparing and refining the coating liquid, coating to form a film, thermally stretching the film, thermally shaping the film and the like. When the methacrylic acid polymer is greater than 50%, a film hot stretching step needs to be added in the steps of coating film formation and film heat setting so as to improve the toughness of the film. The method is simple in formula and process, industrial production is easy to realize, and the colorless and transparent blend optical film with thermodynamic stability can be prepared. The blend optical film provided by the invention not only has excellentoptical characteristics of the methacrylate copolymer, but also has excellent heat resistance and toughness of aromatic (co) polycarbonate, and still shows a stable thermodynamic compatibility state at a high temperature.

Owner:聚纶材料科技(深圳)有限公司 +1

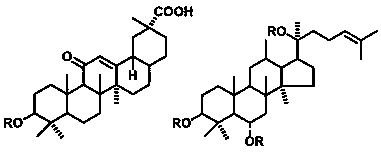

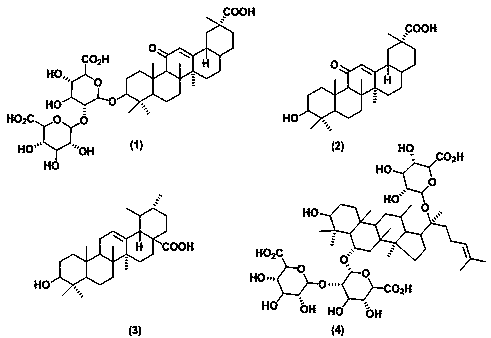

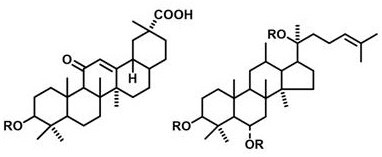

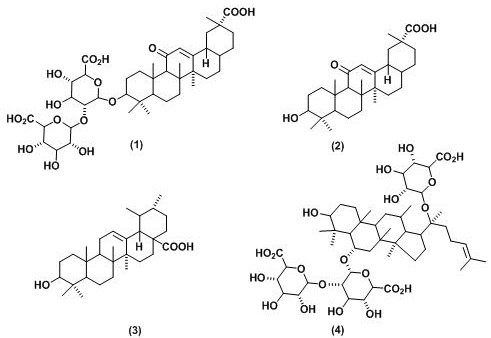

Injectable natural triterpene compound antibacterial hydrogel and preparation method thereof

ActiveCN110585122ALow toxicityAvoid biotoxicityAntibacterial agentsOrganic active ingredientsPhosphoric acidSolvent

The invention relates to the field of biological antibacterial hydrogel materials, in particular to injectable natural triterpene compound antibacterial hydrogel and a preparation method thereof. Thehydrogel disclosed by the invention is obtained by employing a mixture of glycyrrhizic acid and a pentacyclic triterpene compound or a tetracyclic triterpene compound as a gel molecule and phosphoricacid buffer salt solution (PBS) as a gel solvent, and utilizing non-covalent bond acting force formed between mixture through a micromolecule self-assembly mechanism. The prepared hydrogel can show antibacterial property without adding antibacterial drugs, and the mechanical property of the hydrogel is remarkably improved. The preparation method of the injectable antibacterial hydrogel is simple,a preparation process of the injectable antibacterial hydrogel can be simplified, and the application field of the triterpenoids is expanded. Therefore, a novel injectable antibacterial material withbiomedical application characteristics and mechanical strength can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

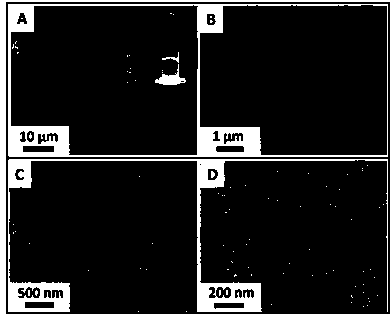

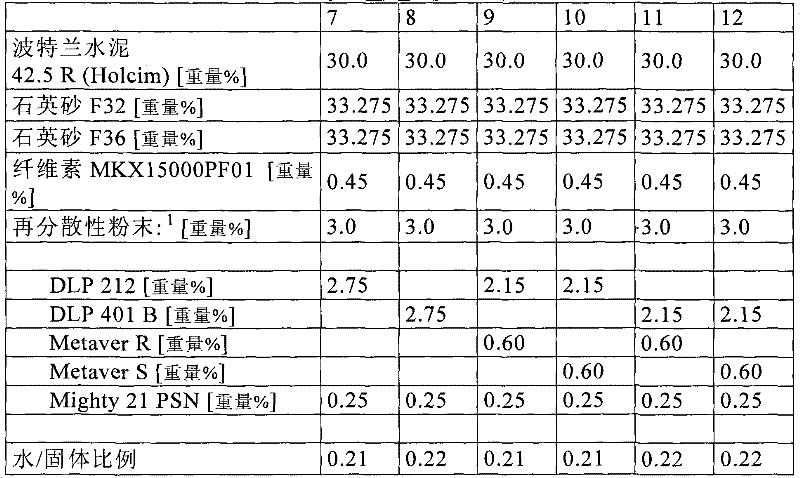

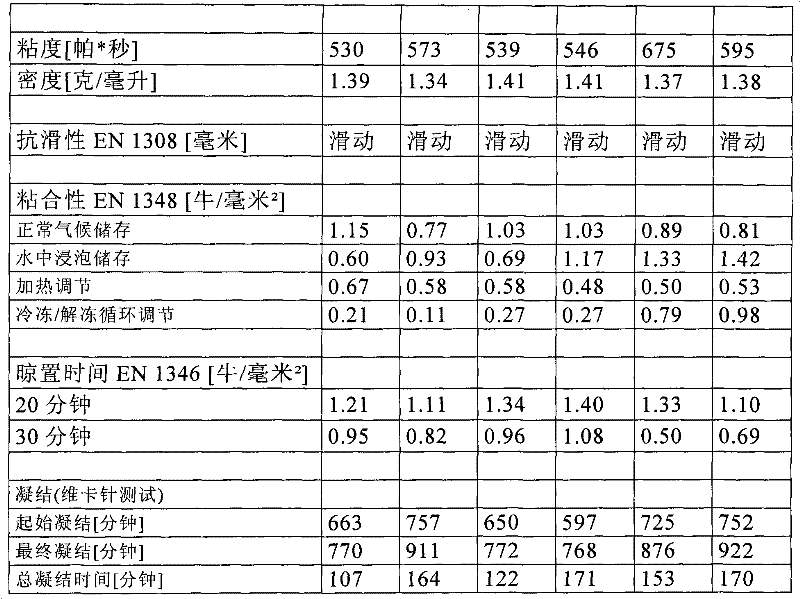

Redispersible powder composition for dry mortar formulations

InactiveCN102358795AImprove liquidityExtended opening timeSolid waste managementAdhesiveMaterials science

The present invention relates to a redispersible powder composition for use in the preparation of dry mortar formulations, especially of cementitious bound tile adhesives (CBTA). The invention further relates to a dry mortar formulation comprising said redispersible powder composition. Furthermore, the invention is directed to a method of increasing the open time of a dry mortar formulation without deteriorating the mechanical strength of the cured dry mortar formulation.

Owner:DOW GLOBAL TECH LLC

Wear-resistant low floating fiber glass fiber enhanced polyphenylene sulfide free-spraying composite material and preparation method thereof

The invention relates to a wear-resistant low floating fiber glass fiber enhanced polyphenylene sulfide free-spraying composite material, which is prepared from the following raw materials in proportion: 45 to 85 parts of polyphenyl thioether with low melt flowing speed, 5 to 45 parts of alkali-free glass fiber, 1 to 15 parts of wear-resistant anti-floating fiber master batch, 0.1 to 1.5 parts ofantioxidants, 0.1 to 1 part of coupling agents, 0.3 to 1.5 parts of compatilizers, 0 to 2.5 parts of other auxiliary agents; the wear-resistant anti-floating fiber master batch is prepared from 45 to95 parts of polyphenyl thioether with high melt flowing speed, 1 to 25 parts of molybdenum disulfide, 1 to 25 parts of graphite, 0.1 to 5 parts of special toner, 0.1 to 1 part of antioxidants, 0.1 to2 parts of compatilizers and 0 to 2.5 parts of other auxiliary agents. The composite material has the advantages that the one-step formation free-spraying beautiful effect is achieved; the influence of floating fiber on the product appearance can be eliminated; meanwhile, the consumption of wear-resistant agents is reduced; the wear-resistant performance is improved; the process is simple; the production efficiency is high.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

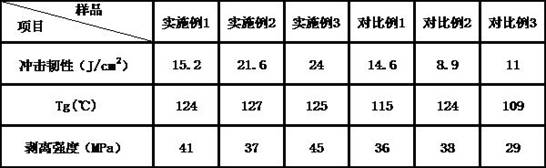

Flexible toughening composition, toughening type epoxy resin adhesive and preparation method of toughening type epoxy resin adhesive

PendingCN112708384APrevent movementImprove toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceFirming agent

The invention provides a flexible toughening composition. The flexible toughening composition comprises the following components in parts by weight: 50-70 parts of epoxy resin A, 20-35 parts of a curing agent A, 5-15 parts of dihydric alcohol, 0.2-0.8 part of a curing accelerator A, 0.1-0.5 part of a coupling agent and 10-20 parts of inorganic nanoparticles, the toughening type epoxy resin adhesive is prepared from the following components in parts by weight: 5-20 parts of the flexible toughening composition, 35-58 parts of epoxy resin B, 25-45 parts of a curing agent B and 0.2-0.6 part of a curing accelerator B. The invention also provides preparation methods of the flexible toughening composition and the toughening type epoxy resin adhesive. The flexible toughening composition provided by the invention has no obvious adverse effect on the high temperature resistance of the material and the bonding performance of the metal substrate while obviously improving the toughness of the epoxy resin adhesive.

Owner:NICHE TECH KAISER SHANTOU

A kind of injectable natural triterpenoid antibacterial hydrogel and preparation method thereof

ActiveCN110585122BLow toxicityAvoid biotoxicityAntibacterial agentsOrganic active ingredientsPolymer scienceAntimicrobial drug

Owner:BEIJING UNIV OF CHEM TECH

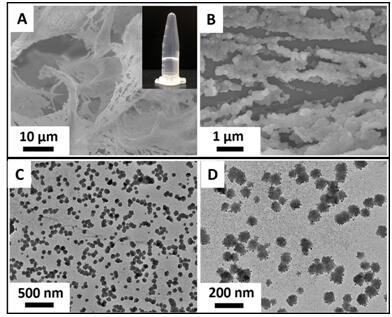

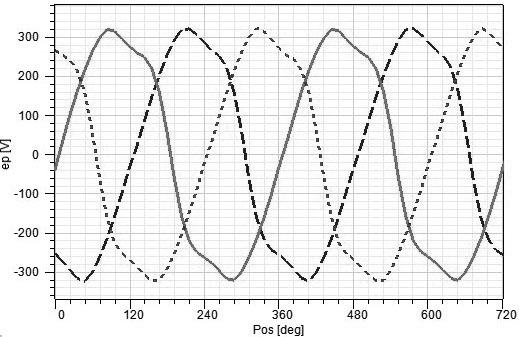

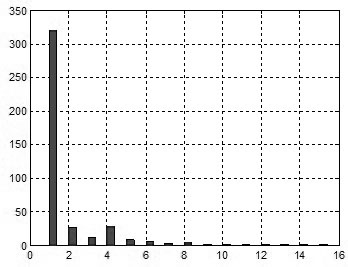

Three-phase doubly salient motor with non-uniformly distributed stator pole widths

ActiveCN112713668AReduce output torque rippleGuaranteed uptimeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineClassical mechanics

The invention discloses a three-phase doubly salient motor with non-uniform stator pole width distribution. The three-phase doubly salient motor comprises a stator iron core, a rotor iron core, an excitation element, an armature winding and a rotating shaft, and is characterized in that the rotor iron core is arranged inside the stator iron core, the rotating shaft is arranged inside the rotor iron core, the excitation element is arranged at the yoke part of the stator iron core, the armature winding is wound on the stator pole of the stator iron core, a rotor pole is arranged on the rotor iron core, the pole width of the stator pole is unevenly distributed, the pole width of the rotor pole is evenly distributed, the maximum pole width dmax of the stator pole is equal to the pole width of the rotor pole, the minimum pole width dmin is two thirds of the pole width of the rotor pole, the rotor iron core and the stator iron core are both of a salient pole structure, the number of the rotor poles is 4N, the pole-arc coefficient of the rotor is 0.5, the number of the stator poles is 6N, and N is a positive integer. According to the invention, approximate sine of the induction electromotive force of the armature winding of the doubly salient motor is realized, so that the doubly salient motor can adopt sine wave power supply, the torque ripple of the doubly salient motor is reduced, and the iron core loss of the motor is reduced.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

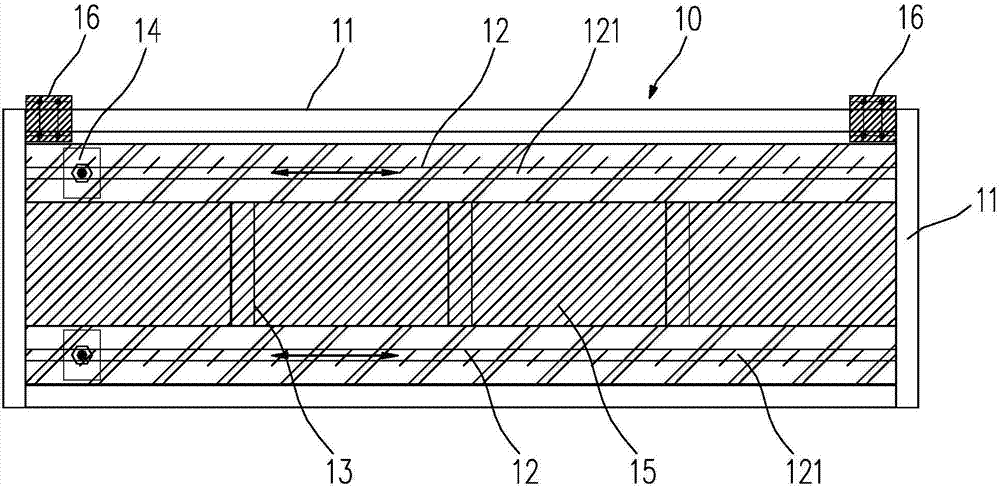

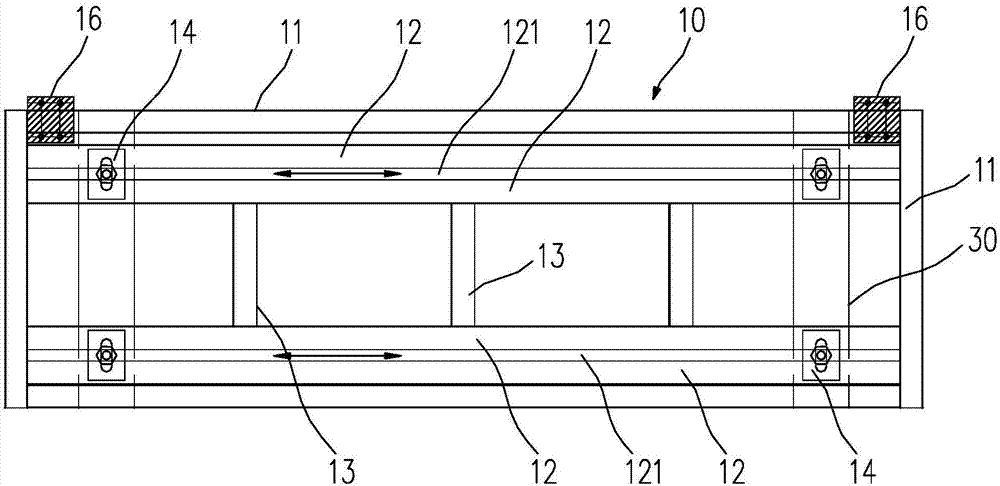

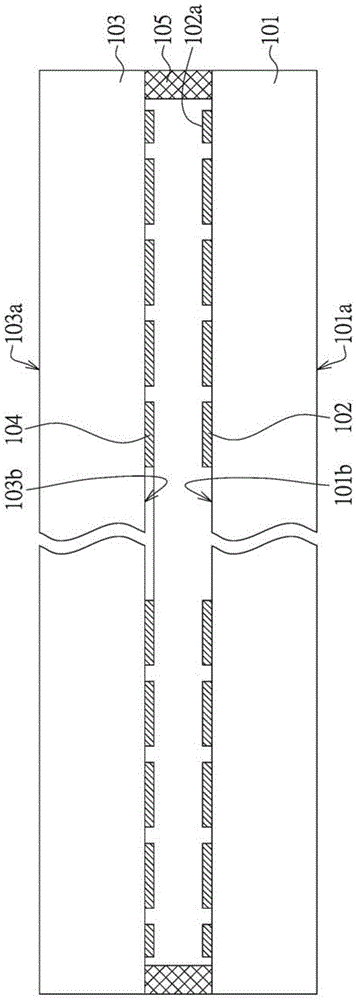

Touch-control structure and manufacture method and application device thereof

InactiveCN106886321AEffect of mechanical strengthReduce the chance of breakageInput/output processes for data processingOptoelectronicsElectrode

The invention discloses a touch-control structure and a manufacture method and an application device thereof. The touch-control structure comprises a conductive glass unit and a conductive film unit located on one side of the conductive glass unit. The conductive glass unit comprises a glass substrate and a first patterned electrode layer. The glass substrate is provided with a first surface and a second surface opposite to the first surface. The first surface has first roughness. The second surface has second roughness. The first roughness is larger than the second roughness. The first patterned electrode layer is located on the second surface. The conductive film unit comprises a light-transmitting film and a second patterned electrode layer located on the light-transmitting film.

Owner:INNOLUX CORP

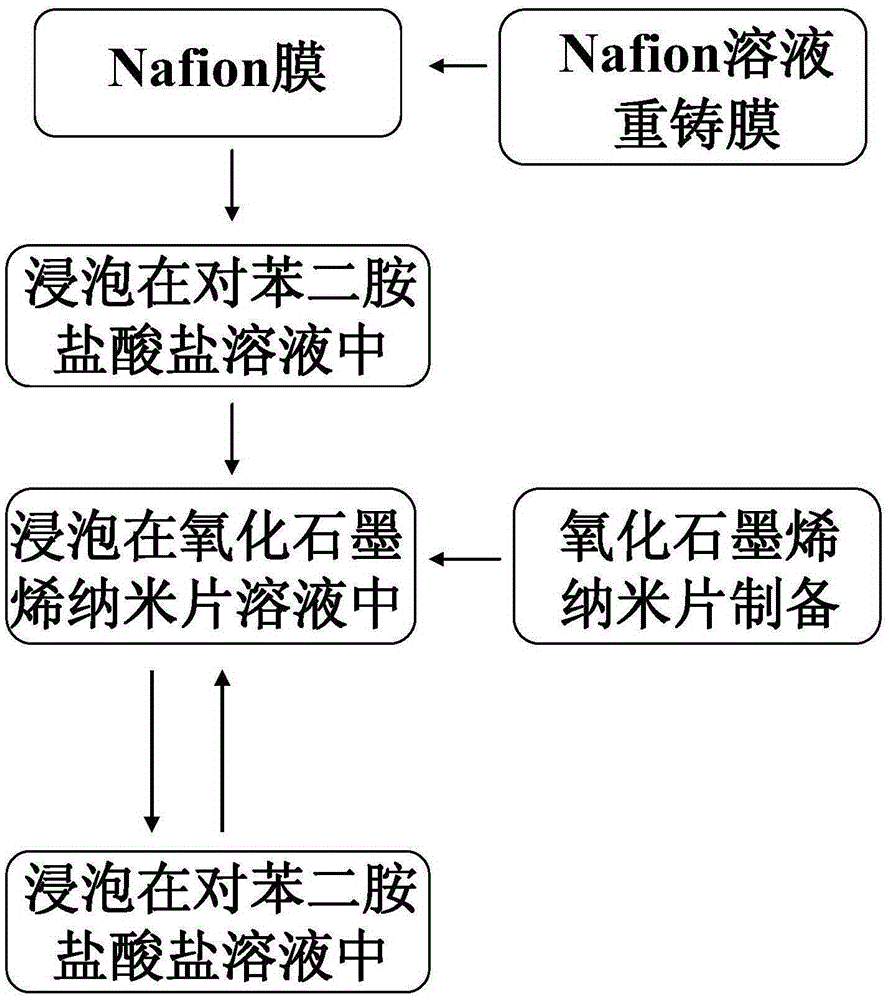

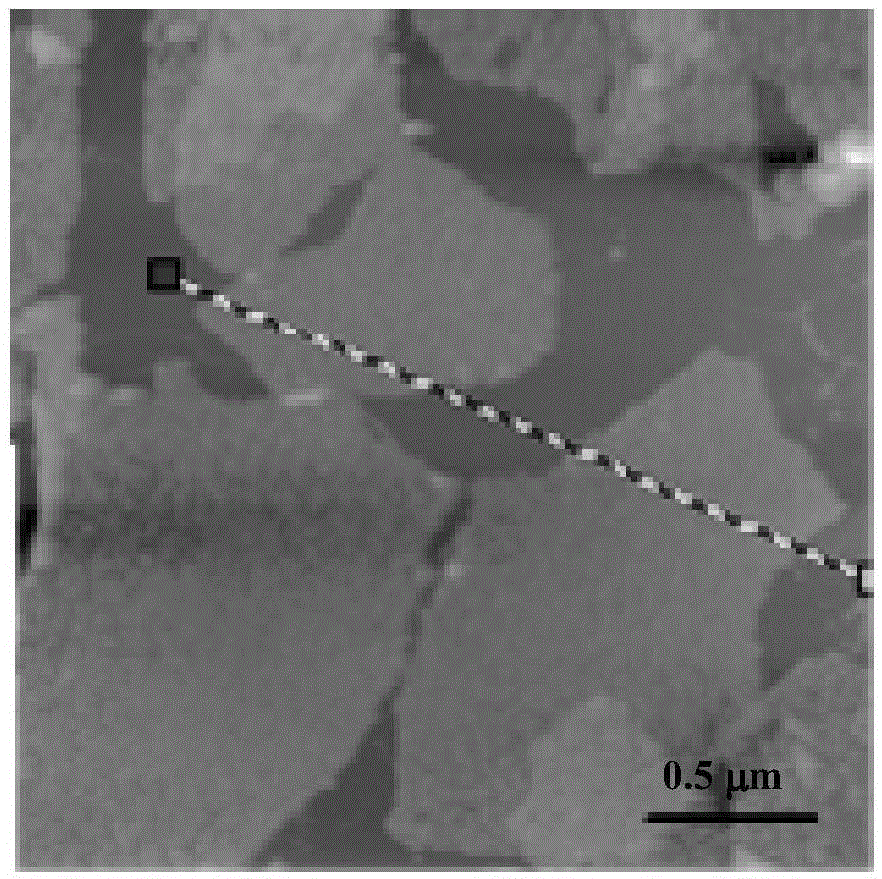

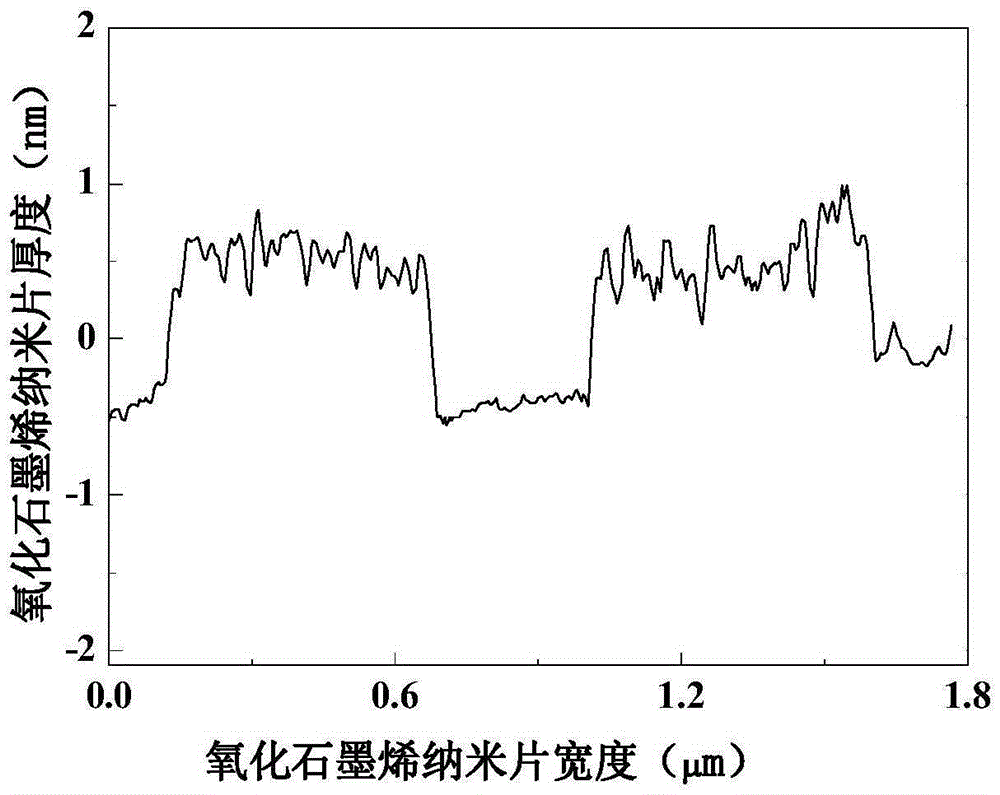

A kind of preparation method of composite proton exchange membrane

InactiveCN104103794BLow methanol permeabilityHigh selectivityCell component detailsFuel cellsFuel cellsMethanol fuel

The invention discloses a preparation method of a composite proton exchange membrane, belonging to direct methanol fuel cells. Ultrasonic stripping of graphite oxide to obtain an aqueous solution of graphene oxide nanosheets; recast the Nafion solution into a film with a film thickness of 25-35 μm, and then pretreat the recast film; use the Nafion film as the base film, and p-phenylenediamine hydrochloride as Adhesive, adopting the method of layer-by-layer assembly, assembling graphene oxide on the surface of Nafion membrane to prepare a composite proton exchange membrane, and post-processing it. By assembling graphene oxide nanosheets on the Nafion membrane, the methanol permeability of the composite proton exchange membrane is greatly reduced, and its selectivity is increased to 5 times that before assembly. The Nafion base film obtained by recasting can be made very thin, reducing the amount of Nafion solution used, and because graphene oxide is easy to obtain, low cost, simple process, strong operability, and will not affect the microstructure and mechanical strength of the film. Obvious impact, no pollution to the environment.

Owner:XIAMEN UNIV

A non-destructive removal method for photographs bonded to glass surfaces

ActiveCN108466473BAchieve lossless extractionMechanical strength has no effectLamination ancillary operationsLaminationNon destructiveAlcohol

The invention discloses a non-destructive peeling method for a picture adhered to the surface of glass. The method comprises the following step: directly soaking a picture adhered to a piece of glassand the glass together into absolute ethyl alcohol at a normal temperature, thereby non-destructively peeling off the picture from the glass. The method disclosed by the invention is simple to operate, image information of the peeled picture can be clear and complete without deformation, in addition, the absolute ethyl alcohol is safe and environmental-friendly to use, and the mechanical strength,the gloss and the color of the picture are not affected.

Owner:SHAANXI NORMAL UNIV

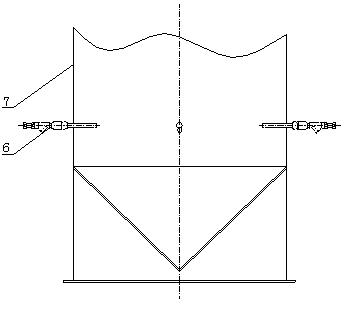

Flotation column

The invention discloses a flotation column which comprises a spraying water component, a feeding system, a column component and a gangue system, and further comprises a taper column bottom of the flotation column and a plurality of flotation column aerators, wherein the taper column bottom of the flotation column is located on the lower part inside the flotation column; the plurality of flotation column aerators are installed on the taper column bottom; the flotation column aerators are vertically installed at different height positions of the taper column bottom of the flotation column and are distributed along a plurality of circumferences of the taper column bottom of the flotation column. The flotation column aerators are distributed on the plurality of circumferences at different height positions of the taper column bottom of the flotation column, so that the distribution quantity of the aerators in a cross section of a column body is controlled according to the needed air flow and the size of the cross section of the flotation column of a selected process, dispersion degree of gas injected in the column is high; and the flotation column aerators are longer in service lives and stable in work performance under protection of wear-resisting steel tubes.

Owner:BGRIMM MACHINERY & AUTOMATION TECH CO LTD +1

A method for restoring the original appearance of paper archives polluted by printing ink

ActiveCN112078268BAchieve removalThe mechanical strength was not significantly affected byPrinting after-treatmentPolyethylene glycolEnvironmental engineering

The invention discloses a method for restoring the original appearance of paper files polluted by printing ink. In the method, the paper files polluted by printing ink are soaked in polyethylene glycol aqueous solution, then soaked in sodium hypochlorite aqueous solution, and finally soaked in ascorbic acid. Soaking in aqueous solution can remove printing ink and restore the original appearance of contaminated files. The method of the invention is easy to operate, and the materials used are safe and environment-friendly, and the written information, seals and red and black neutral signature pens recorded in the recovered paper archives are clear and complete.

Owner:SHAANXI NORMAL UNIV

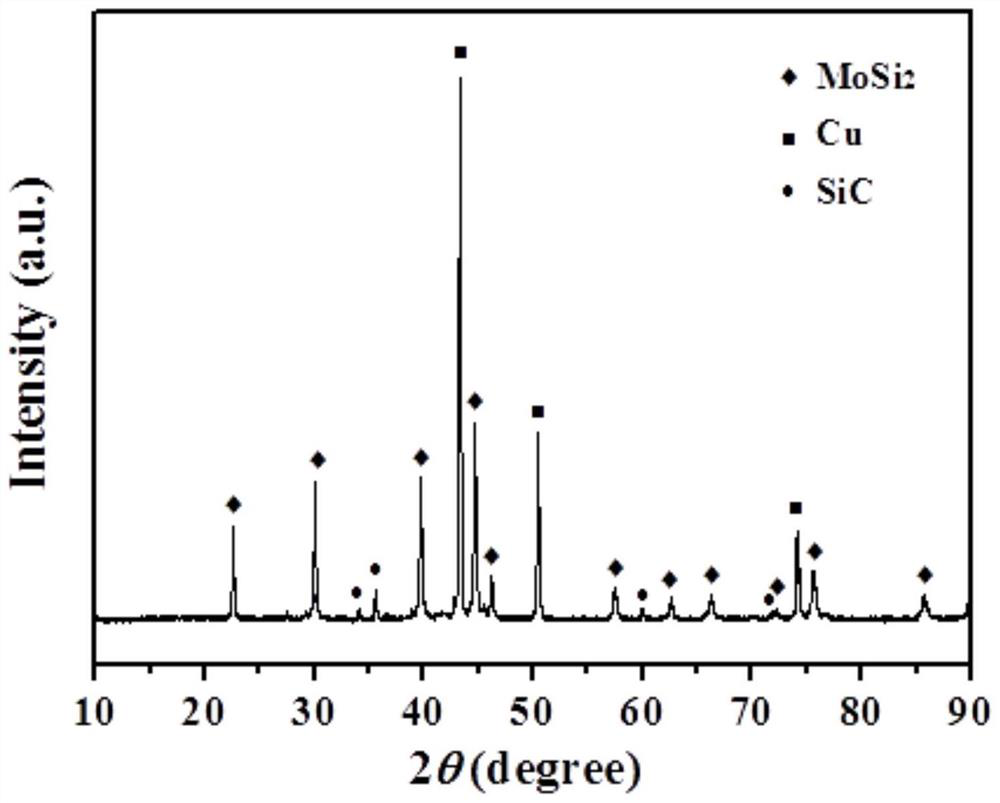

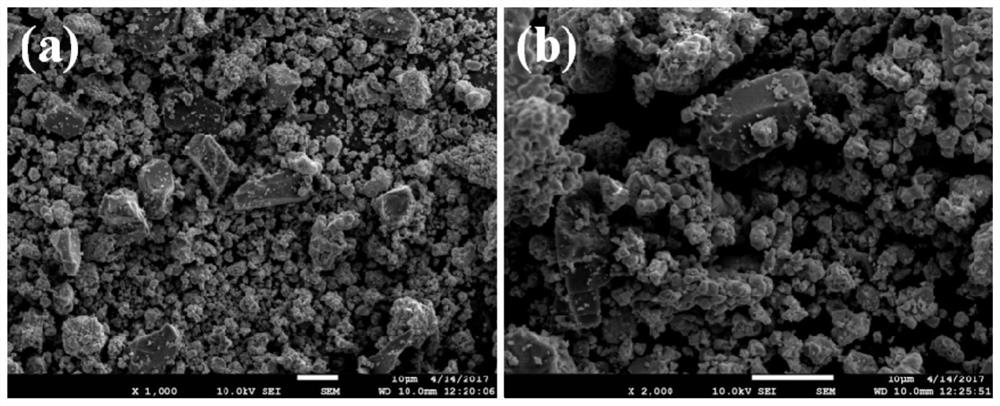

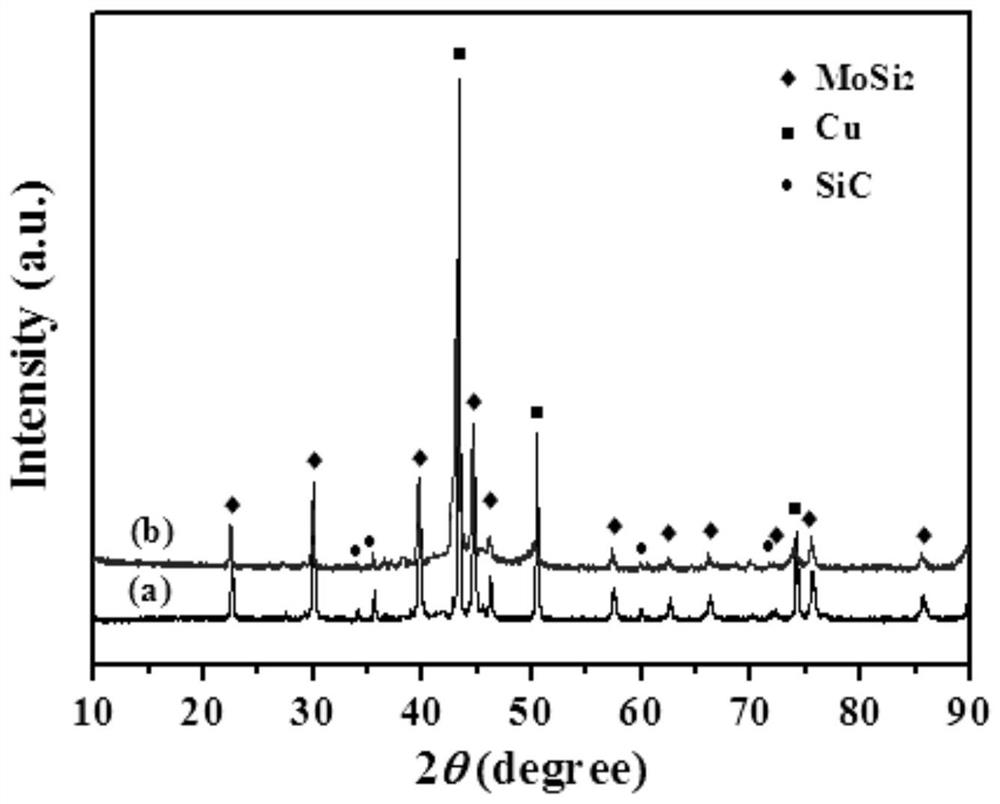

a kind of mosi 2 -sic-cu conductance composite ceramic material and preparation method thereof

ActiveCN109811179BImprove mechanical propertiesImprove conductivityMetal/alloy conductorsComposite ceramicConductive materials

Owner:ZHENGZHOU UNIV

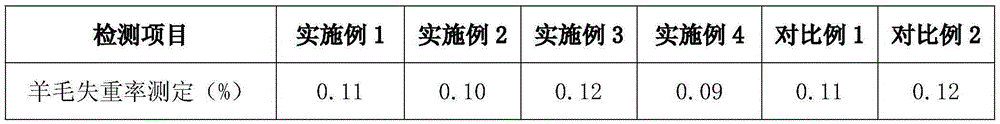

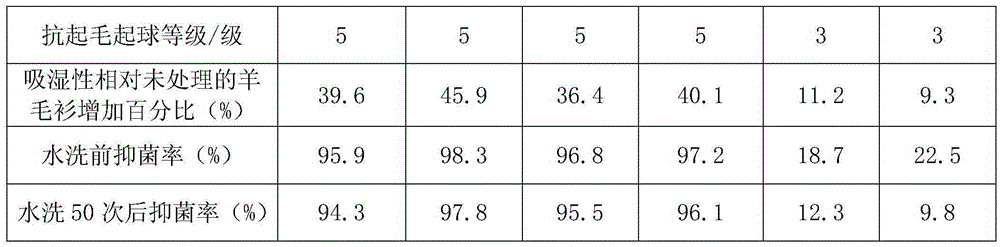

Antibacterial finishing auxiliary of woolen sweater

InactiveCN105256542AGood palatabilityImprove absorption rateAnimal fibresChemistryAntibacterial effect

The invention discloses an antibacterial finishing auxiliary of a woolen sweater. The antibacterial finishing auxiliary comprises a preprocessing protein solution and finishing liquor. The preprocessing protein solution is prepared from, by mass, 0.05-0.09% of hydrolyzed feather meal, 0.02-0.05% of corn gluten meal and 0.8-1.0% of trehalose. The finishing liquor is prepared from, by mass, 60-81 g / L of phosphorus-containing polymaleic acid, 32-38 g / L of sodium hypophosphite and 0.8 g / L of polyoxyethylene fatty acid. The finished woolen sweater has a quite good antibacterial effect, can resist pilling, and has no influences on the whiteness and mechanical strength of the woolen sweater.

Owner:CHANGXING XINTIANLONG PRINTING & DYEING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com