Patents

Literature

32results about How to "Improve the efficiency of denitrification reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

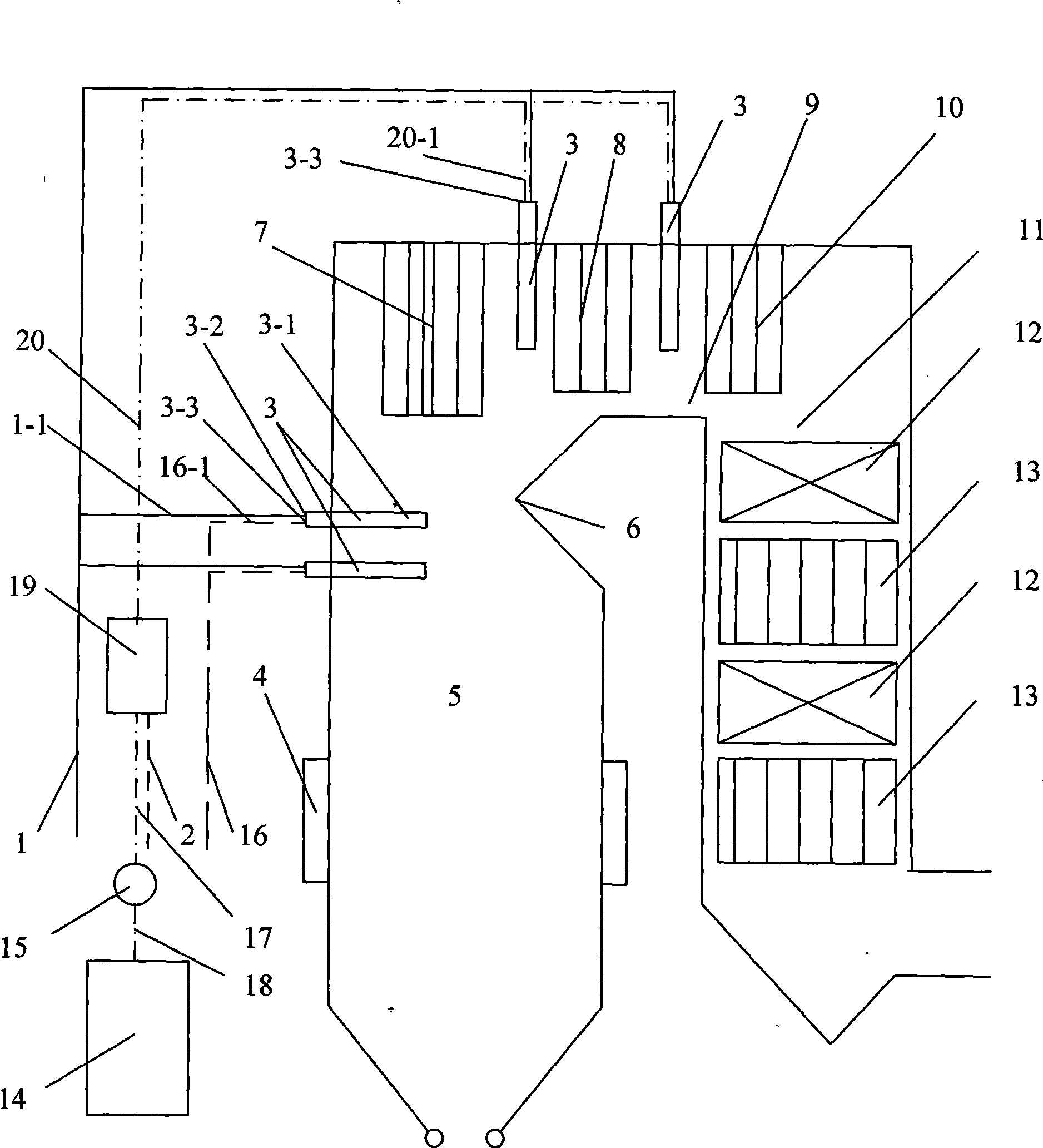

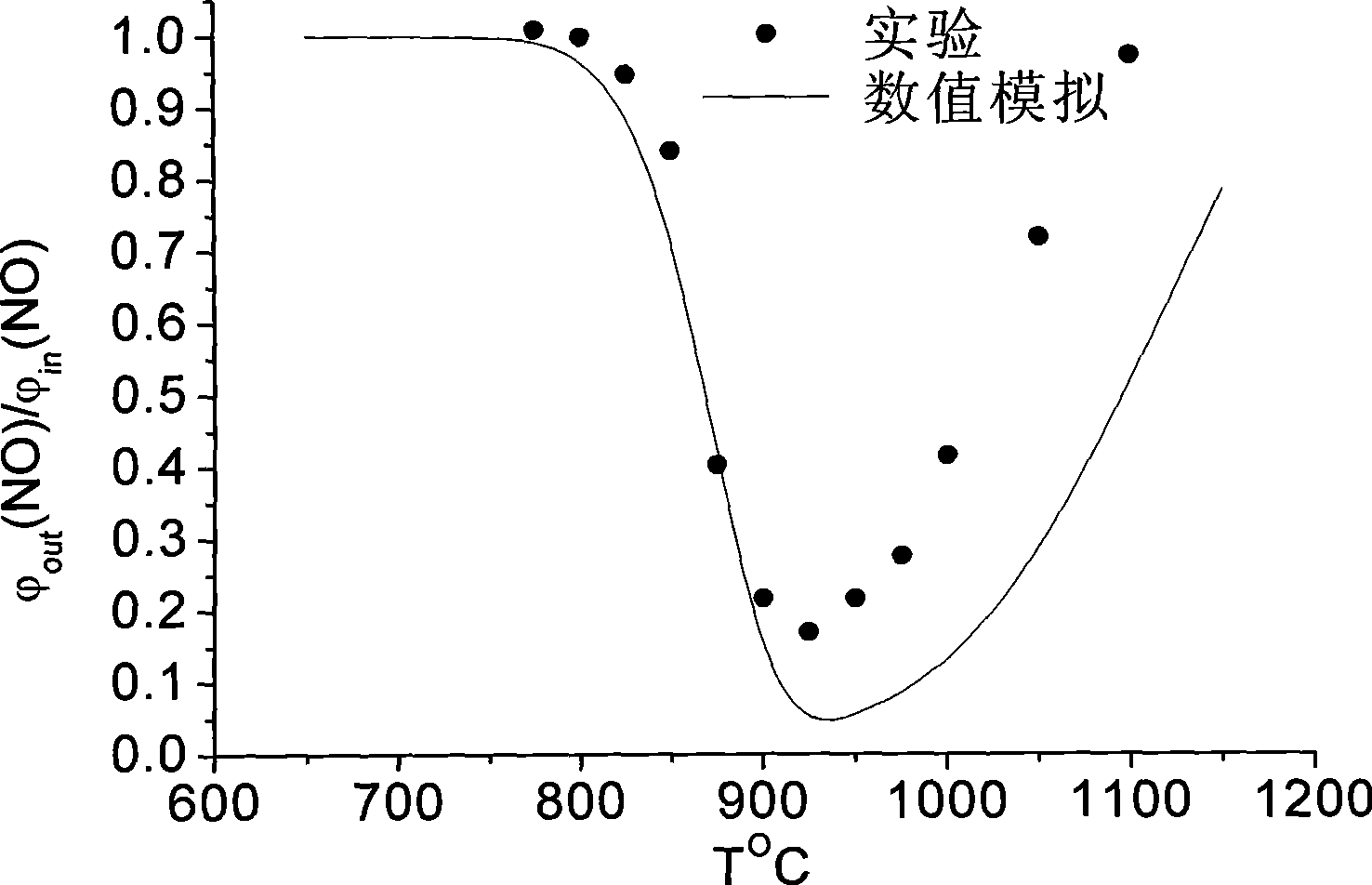

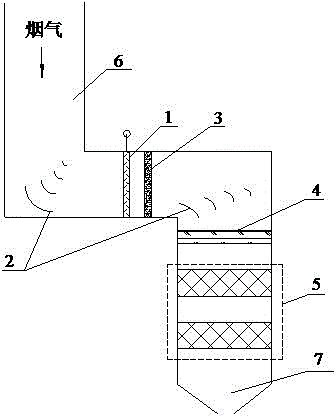

Selective non-catalytic reduction method for gasifying and atomizing biomass and used boiler

InactiveCN101433799AWidely distributedWell mixedLighting and heating apparatusDispersed particle separationProcess engineeringMixed gas

The invention relates to a selective non-catalytic reduction method for gasifying and atomizing biomass and a boiler used by the same, which relate to the selective non-catalytic reduction method and the boiler used by the same. The invention solves the problems that the prior selective non-catalytic reduction method has narrow temperature window, low denitration efficiency at a low temperature region and single effective component in synthesis gas of a reaction additive. The inlet of a gas mixer of the boiler is communicated with a gas additive pipeline and a compressed air pipeline respectively, while the outlet of the gas mixer is communicated with an atomizing medium pipeline. The selective non-catalytic reduction method mixes the biomass gasified gas in the gas additive pipeline with the compressed air through the gas mixer, uses the mixed gas as an atomizing medium for an amino reducing agent solution, and sprays the atomizing medium and the amino reducing agent solution together into a furnace chamber and a horizontal flue in a region with a temperature of between 800 and 950 DGE C through nozzles arranged in the furnace chamber and the horizontal flue. The selective non-catalytic reduction method improves the denitration efficiency and enlarges the temperature window. The boiler system of the invention is simple and has high reliability.

Owner:HARBIN INST OF TECH

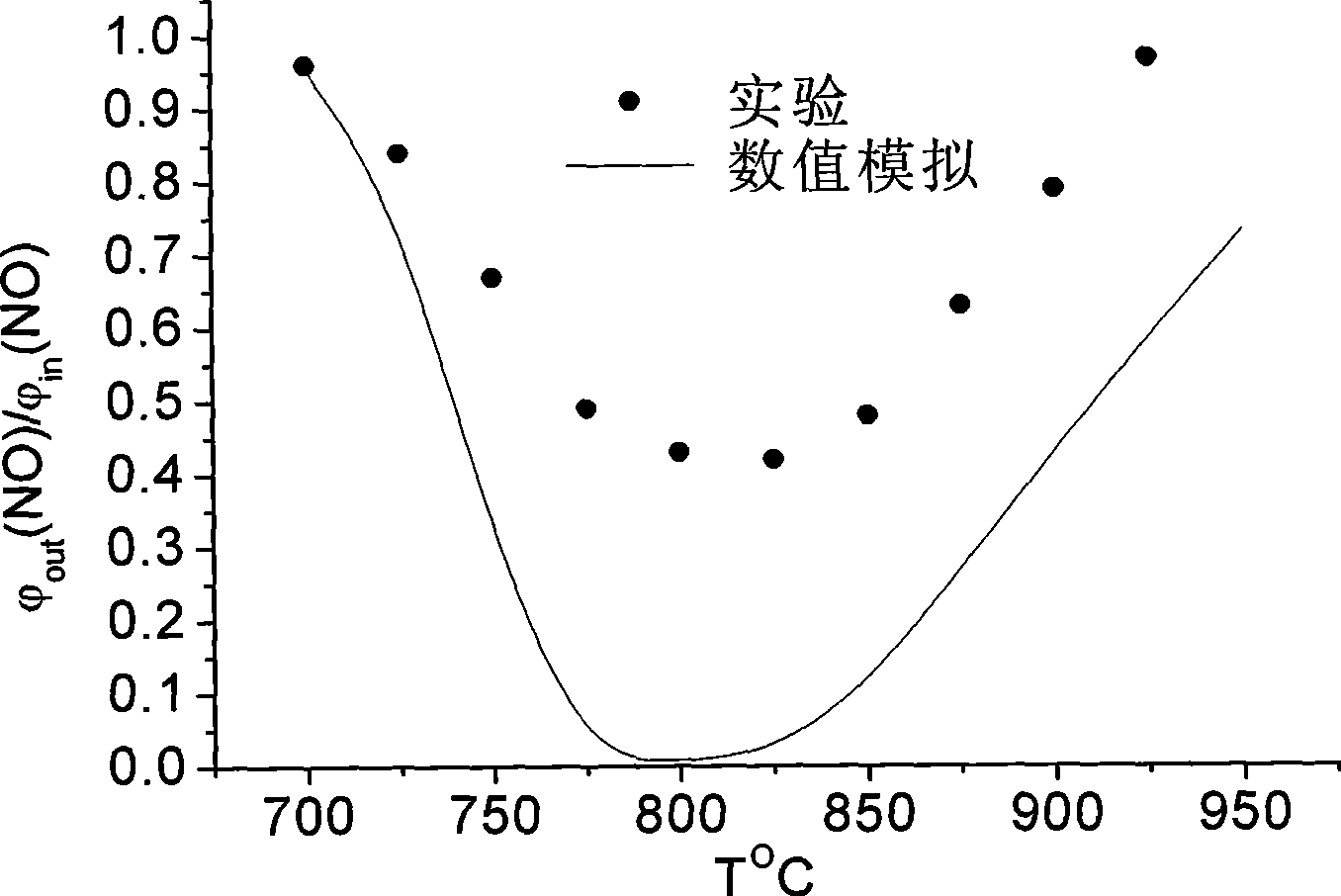

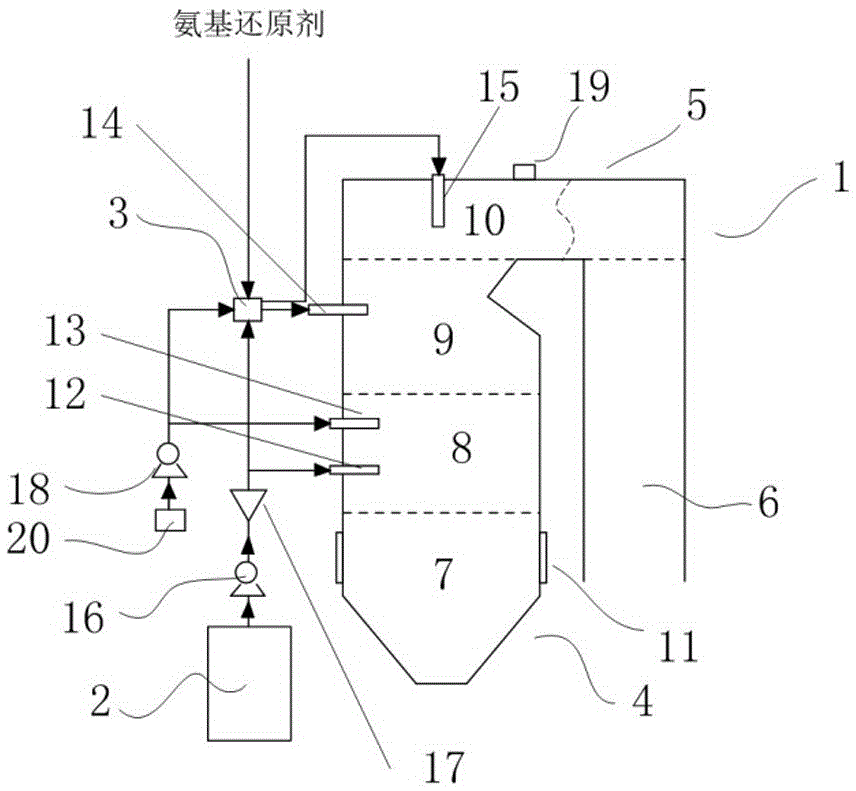

Composite denitration method and device

ActiveCN105485664ALess quantityImprove denitrification efficiencyGas treatmentDispersed particle separationReaction temperatureEngineering

The invention relates to the technical field of boiler improvement, in particular to a composite denitration method and device suitable for power station boilers, industrial boilers and other burning devices. A method is provided, reducibility industrial waste gas serves as a composite additive, on one hand, the reducibility industrial waste gas serves as reburning gas to reduce nitric oxide in the reducing atmosphere, the amount of nitric oxide generated through burning is reduced; and on the other hand, the SNCR reaction temperature is reduced, the SNCR proper temperature area is widened, the reduction of nitric oxide through SNCR is promoted, accordingly, the denitration rate is increased, and ammonia leakage is reduced. The industrially-common reducibility waste gas is effectively and resourcefully utilized, meanwhile, the burning denitration efficiency of a boiler is improved from two aspects, and the emission load of nitric oxide is reduced by more than 80%. The boiler equipment is simple, implementation is easy, the adopted additive is low in price and easy to obtain, the burning process in the boiler is not affected, obvious secondary pollution cannot be generated, and reliability is high. The method is mainly applied to the industrial waste gas reutilization and nitric oxide control aspects.

Owner:SHANXI UNIV +1

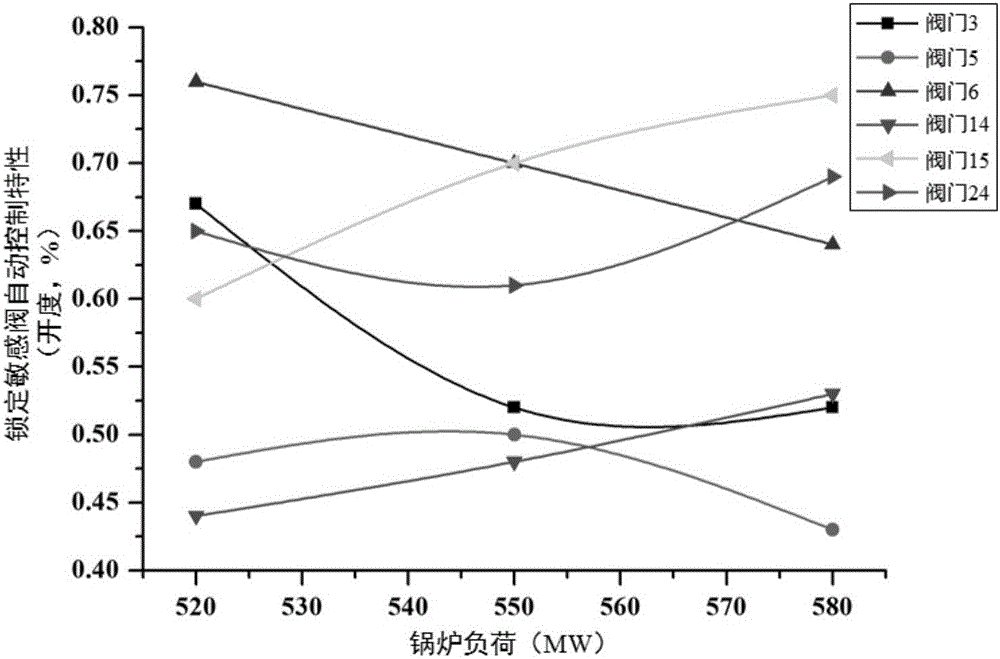

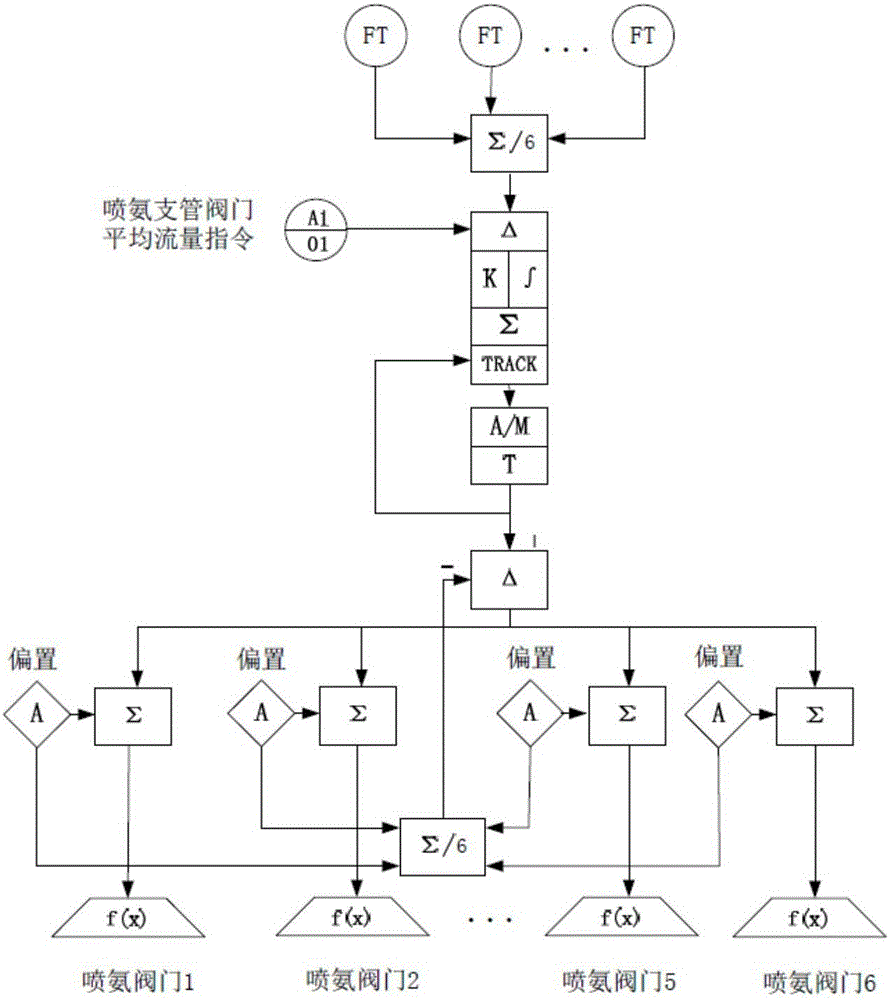

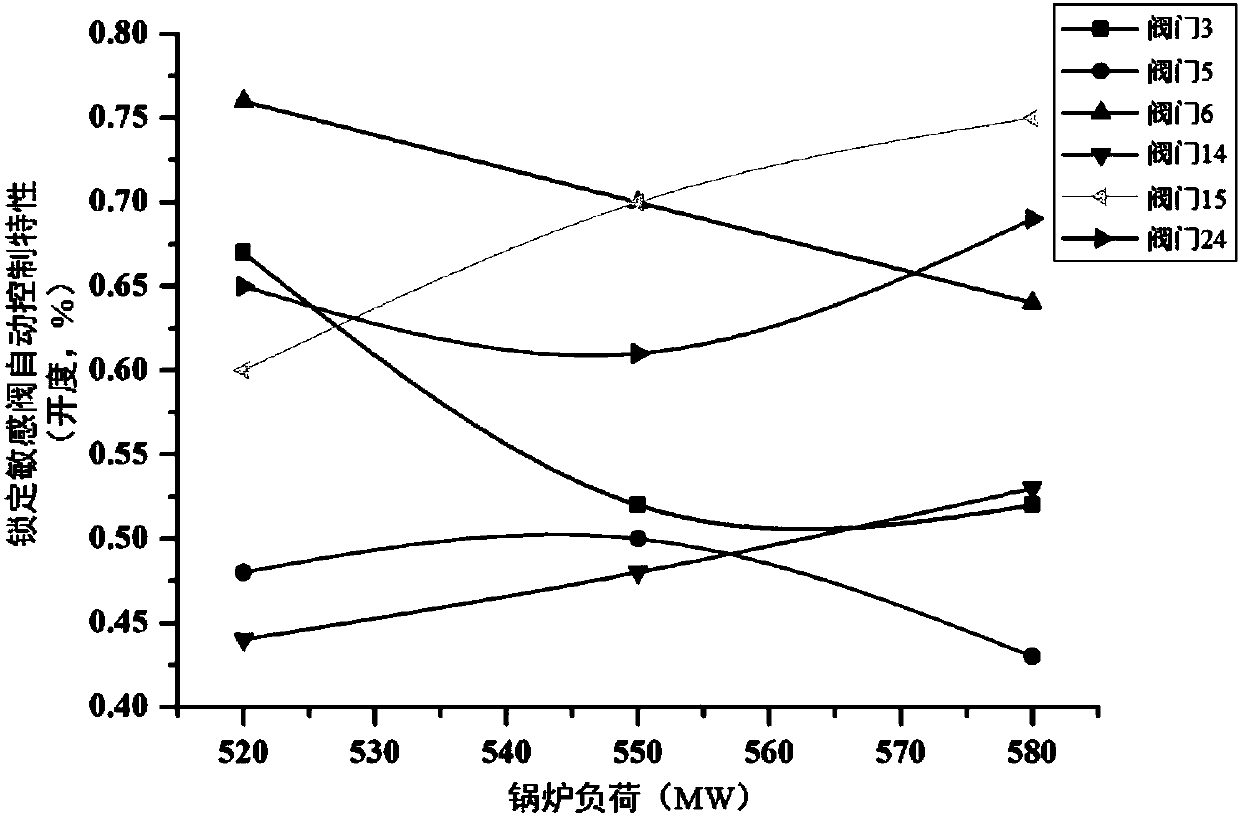

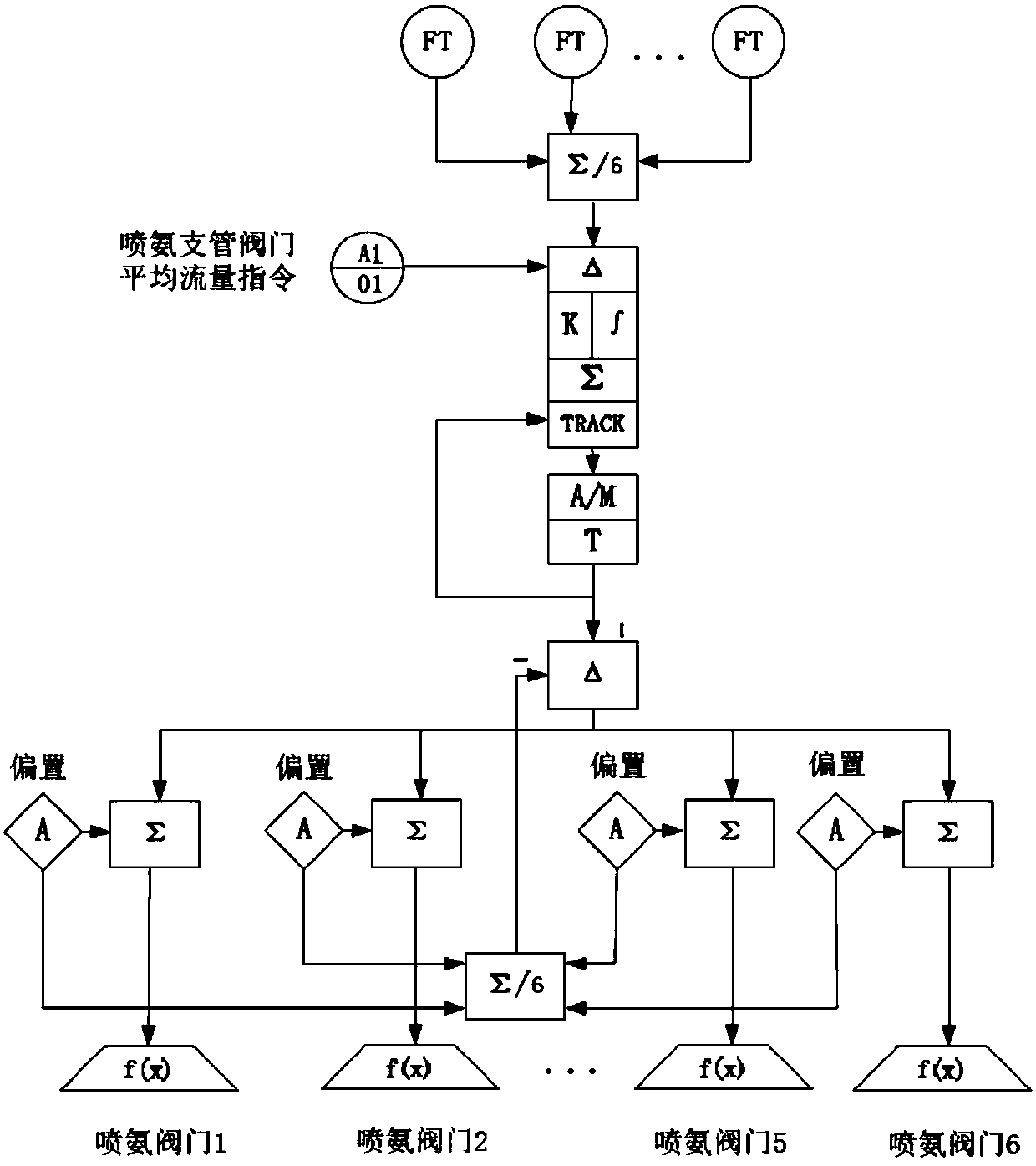

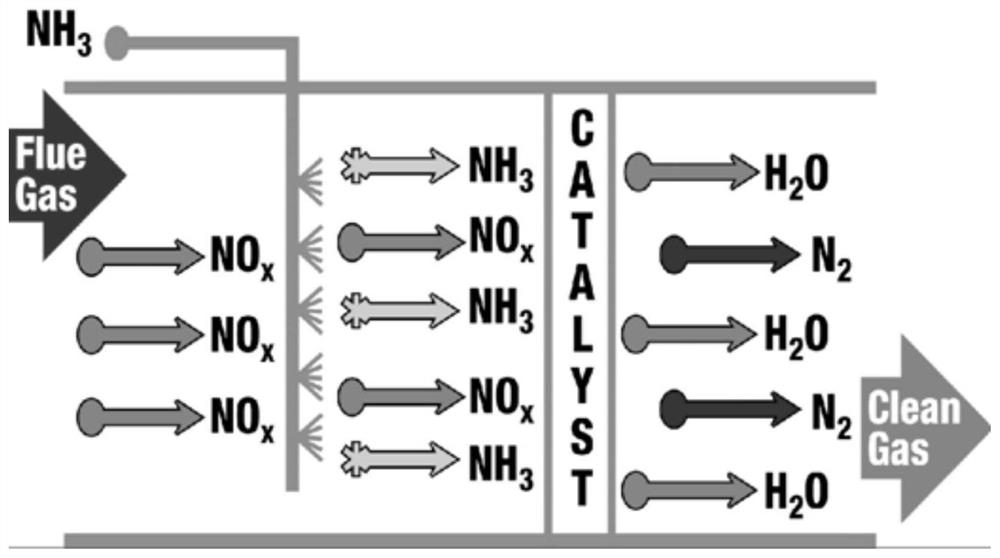

SCR system automatic control method based on ammonia spraying sensitive valve locking

ActiveCN105700504AImprove reaction efficiencySave ammonia consumptionGas treatmentDispersed particle separationAutomatic controlField tests

The present invention discloses a SCR system automatic control method based on ammonia spraying sensitive valve locking. The method comprises three steps: firstly, performing comprehensive analysis of varying load condition operation characteristics of the SCR system based on a field test and a CFD numerical simulation technology to obtain flue gas 'NOx flow' regional continuous distribution characteristics matching an AIG type; then determining the weight of each ammonia spraying branch pipe valve, locking a certain number of sensitive valves according to a preset sensitive valve locking principle, and installing an automatic regulating valve at a corresponding ammonia spraying region; finally, developing an ammonia spraying logic controller and corresponding main control and sub-control logics, realizing multistage optimization setting of parameters of the control system, and realizing the accurate automatic control of the main ammonia spraying regulating valve of the SCR system and the locking sensitive valves. The SCR system automatic control method based on ammonia spraying sensitive valve locking is able to overcome the problems of characteristics of the SCR system such as nonlinearity, large delay and the like so as to realize the accurate automatic control of the ammonia spraying of the SCR system, substantially enhance the SCR denitration reaction efficiency, save the dosage of ammonia, reduce the ammonia escape and effectively inhibit the generation of ABS.

Owner:SOUTHEAST UNIV +1

Flue gas denitration reaction system

PendingCN106540544AImprove denitrification efficiencyImprove economyGas treatmentDispersed particle separationFlueChemistry

The invention provides a flue gas denitration reaction system, belonging to the technical field of flue gas denitration. The flue gas denitration reaction system comprises a first ammonia spraying grid, a catalyst pre-reaction area, a second ammonia spraying grid and a catalyst main reaction area, wherein the first ammonia spraying grid, the catalyst pre-reaction area, the second ammonia spraying grid and the catalyst main reaction area are arranged in a flue in sequence along a flue gas flowing direction, the first ammonia spraying grid is connected with an inlet flue, and the catalyst main reaction area is connected with an outlet flue. Under the condition of keeping certain catalyst content and ammonia content, by separately arranging the catalyst pre-reaction area and the catalyst main reaction area and correspondingly matching the first ammonia spraying grid and the second ammonia spraying grid, the denitration efficiency is improved; the amount of ammonia escape caused by insufficient denitration reaction and uneven flow field distribution is reduced, and meanwhile the economical efficiency of the system is improved.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

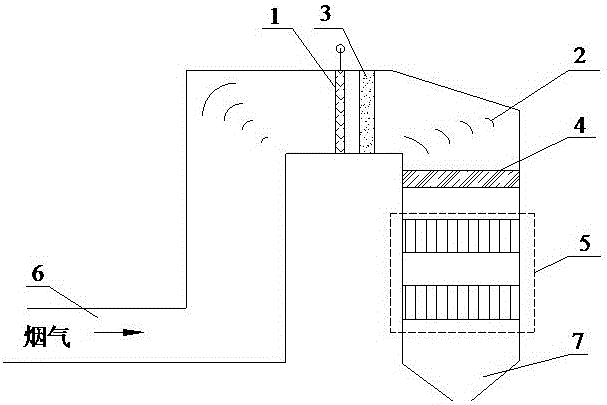

Flue gas dust removal, denitration and waste heat utilization integrated device and treatment method thereof

PendingCN109331647ASimple internal structureSimple structureGas treatmentDispersed particle filtrationAir preheaterFlue gas

The invention relates to the technical field of fuel gas purification, and discloses a flue gas dust removal, denitration and waste heat utilization integrated device and a treatment method thereof. The device is connected with a position between a boiler economizer and a desulfurizing tower, and comprises a casing, wherein the interior of the casing is divided into a dust removal zone and a comprehensive reaction zone which are horizontally arranged side by side and communicated with each other through a baffle; a denitration zone and an air preheating zone are sequentially arranged in the comprehensive reaction zone along the flue gas flowing direction; a fuel gas inlet is formed in the side wall of the casing of the dust removal zone; a fuel gas outlet is formed in the side wall of thecasing at the bottom of the comprehensive reaction zone; a high-temperature dust removal module which can directly perform dust removal and filtering on 350 to 400 DEG C fuel gas is arranged in the dust removal zone; the denitration zone is arranged at the upper part of the comprehensive reaction zone; the air preheating zone is positioned under the denitration zone; an air preheater is arranged inside the air preheating zone. The device is simple in structure, low in economic cost and operation cost, simple in structure, good in dust removal effect, high in denitration efficiency and small inequipment volume.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

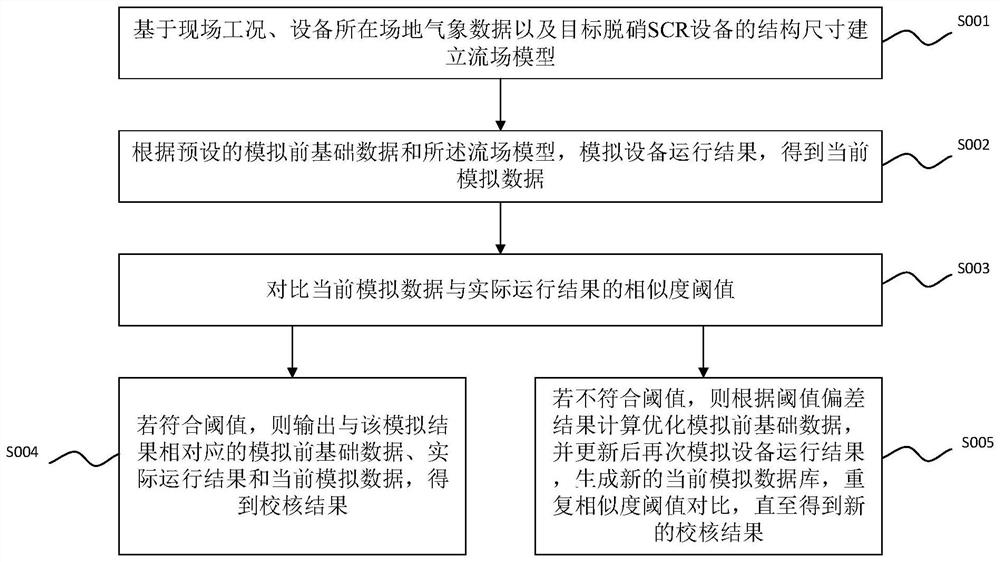

Flue gas denitration flow field simulation checking method and system

PendingCN113941251AImprove the efficiency of denitrification reactionDispersed particle separationDesign optimisation/simulationProcess engineeringFlue gas

The invention provides a flue gas denitration flow field simulation checking method and system. The method comprises the following steps of: establishing a flow field model based on field working conditions, meteorological data of a site where equipment is located and the structure size of target denitration SCR equipment; according to preset pre-simulation basic data, the flow field model and a simulation equipment operation result, obtaining current simulation data; comparing the similarity between the current simulation data and an actual operation result with a similarity threshold value; if the similarity accords with the similarity threshold value, outputting the pre-simulation basic data corresponding to the simulation result, the actual operation result and the current simulation data to obtain a check result; if the similarity does not accord with the similarity threshold value, calculating optimal pre-simulation basic data according to a threshold value deviation result, simulating an equipment operation result again after performing updating, so as to generate a new current simulation database, and repeating the comparison of the similarity with the similarity threshold value until obtaining a new check result. The method is reasonable in scheme, rapid in simulation, and accurate in checking and can facilitate subsequent data optimization and structural design.

Owner:XIAN THERMAL POWER RES INST CO LTD

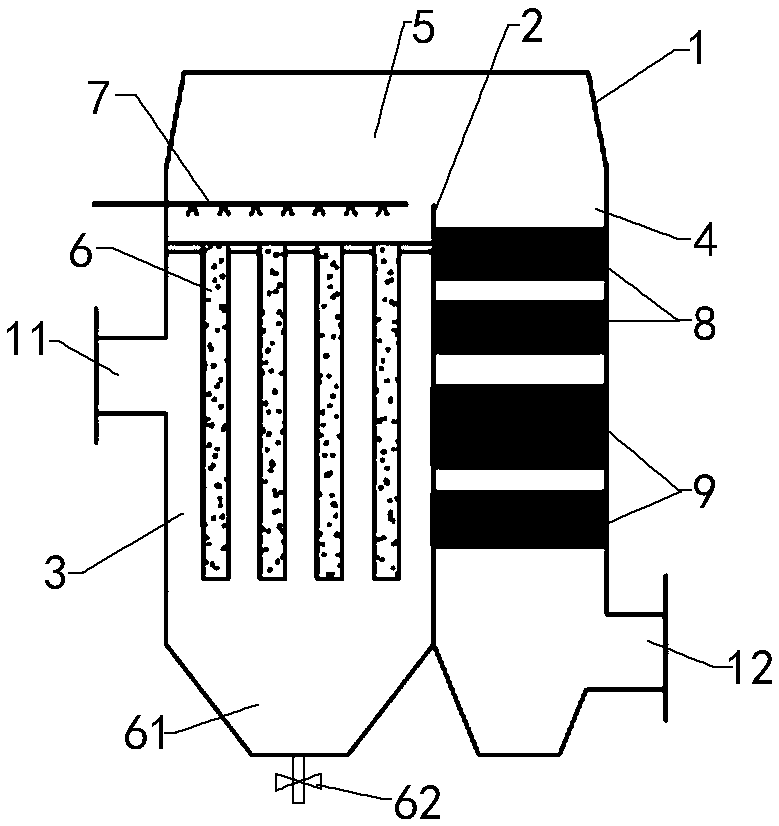

Integrated energy-saving SCR denitration device

ActiveCN105944565AIncrease profitLow running costLighting and heating apparatusDispersed particle separationPipeline transportHeat losses

The invention provides an integrated energy-saving SCR denitration device. The integrated energy-saving SCR denitration device comprises an SCR denitration reaction chamber and a heat exchange chamber. Smoke before reaction is fed through a cold fluid inlet of the heat exchange chamber, and a cold fluid outlet is connected with a smoke inlet of the SCR denitration reaction chamber; a hot fluid inlet of the heat exchange chamber is connected with a smoke outlet of the SCR denitration reaction chamber, and a hot fluid outlet is a smoke outlet. Reacted high-temperature smoke serves as hot fluid to heat the smoke before reaction, waste heat of the reacted high-temperature smoke is sufficiently used, the energy use rate is increased, and running cost is reduced. According to the integrated energy-saving SCR denitration device, a dust removing chamber, the heat exchange chamber, a gas mixing chamber, the SCR denitration reaction chamber and a reduction agent evaporation chamber are integrally arranged in a cylinder shell in an optimized mode, design is compact, the pipe conveying flow of smoke is effectively shortened, no pipe is required between every two adjacent chambers, heat losses of smoke in the pipe conveying process are reduced, and meanwhile the occupied area of the denitration device is saved.

Owner:北京方信立华科技有限公司

Ultralow-emission denitration equipment for cement production

InactiveCN113069920AAvoid cloggingImprove denitrification effectCombination devicesGas treatmentPtru catalystFlue gas

The invention relates to the technical field of cement production, and discloses ultra-low emission denitration equipment for cement production, and solves the problems of incomplete denitration of flue gas discharged during cement processing at present, easy blockage of an SCR denitration catalyst and reduction of denitration efficiency. The equipment comprises a reaction cylinder, the upper end of the reaction cylinder is connected with a cylinder cover; one side of the upper part of the reaction cylinder is connected with a gas inlet pipeline, and the lower part of one end of the reaction cylinder is connected with a gas outlet pipeline. According to the invention, through the arrangement of the dust blowing mechanism, the blockage of the catalyst layer is effectively avoided so that the denitration reaction effect is good; through the arrangement of the spoiler, the rotating shaft rotates to drive the blowing pipeline to rotate, and the spoiler rotates along with the blowing pipeline to flap airflow in the reaction cylinder so that the turbulence of the airflow is increased, the airflow in the reaction cylinder is disordered, the contact time of flue gas between catalyst layers is prolonged, the flue gas can be in full contact with the catalyst layer, and thus the denitration reaction efficiency is improved, the denitration effect is better, and ultralow emission is realized.

Owner:中材萍乡水泥有限公司

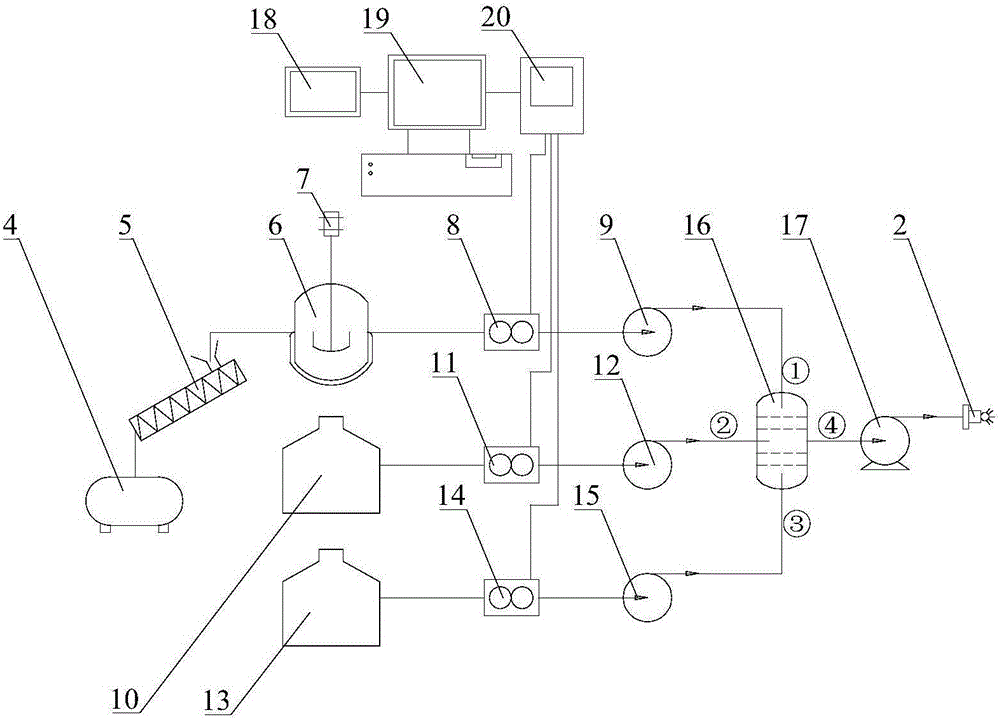

SCR denitration reducing agent preparation device with flue gas heating system and method

PendingCN112774436ASave spacePrevent leakageTransportation and packagingDispersed particle separationFlueChemistry

The invention discloses an SCR denitration reducing agent preparation device with a flue gas heating system and a method. The preparation of an SCR denitration reducing agent is completed by utilizing the flue gas heating system. A reducing agent solution is directly sprayed into a high-temperature flue of a flue gas heating system, ammonia gas evaporated from high-temperature flue gas is mixed with the high-temperature flue gas and then fed into an original flue gas flue through the high-temperature flue to be mixed with original flue gas, a reducing agent required by denitration is provided, and the reducing agent solution can be ammonia water or a urea solution. Compared with a traditional SCR denitration reducing agent preparation system, an evaporator, an ammonia-air mixer, a dilution fan, a dilution air heating device, an ammonia spraying grid and the like do not need to be arranged, and the system has the advantages of being simple, easy to control, small in investment and the like.

Owner:BEIJING SHOUGANG INT ENG TECH

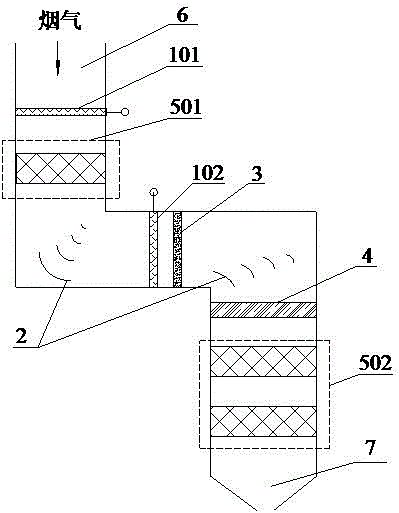

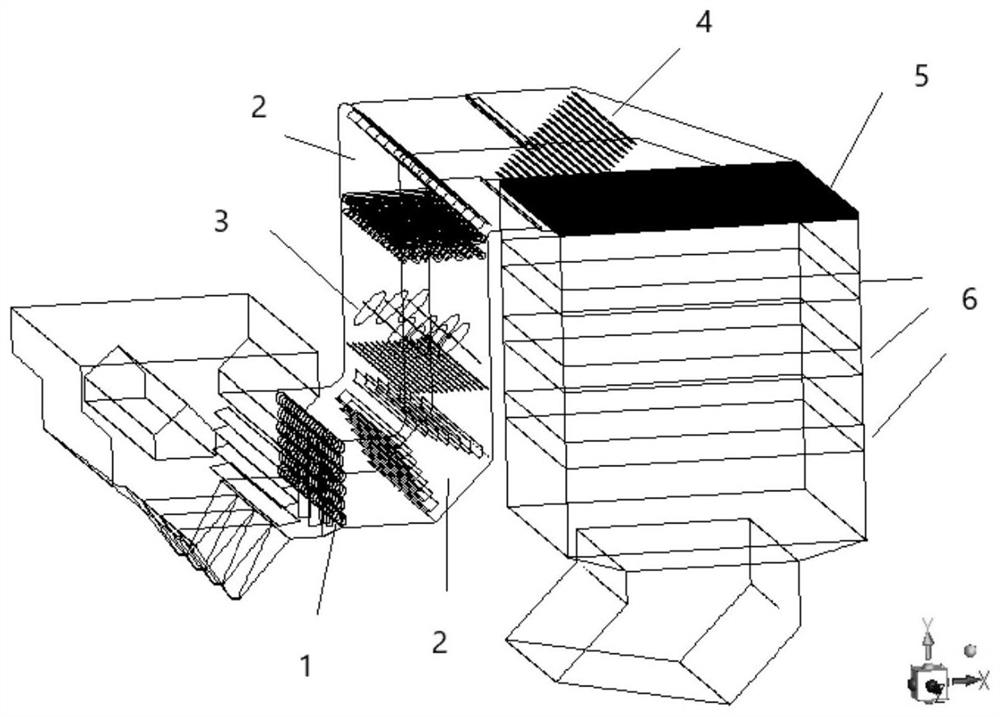

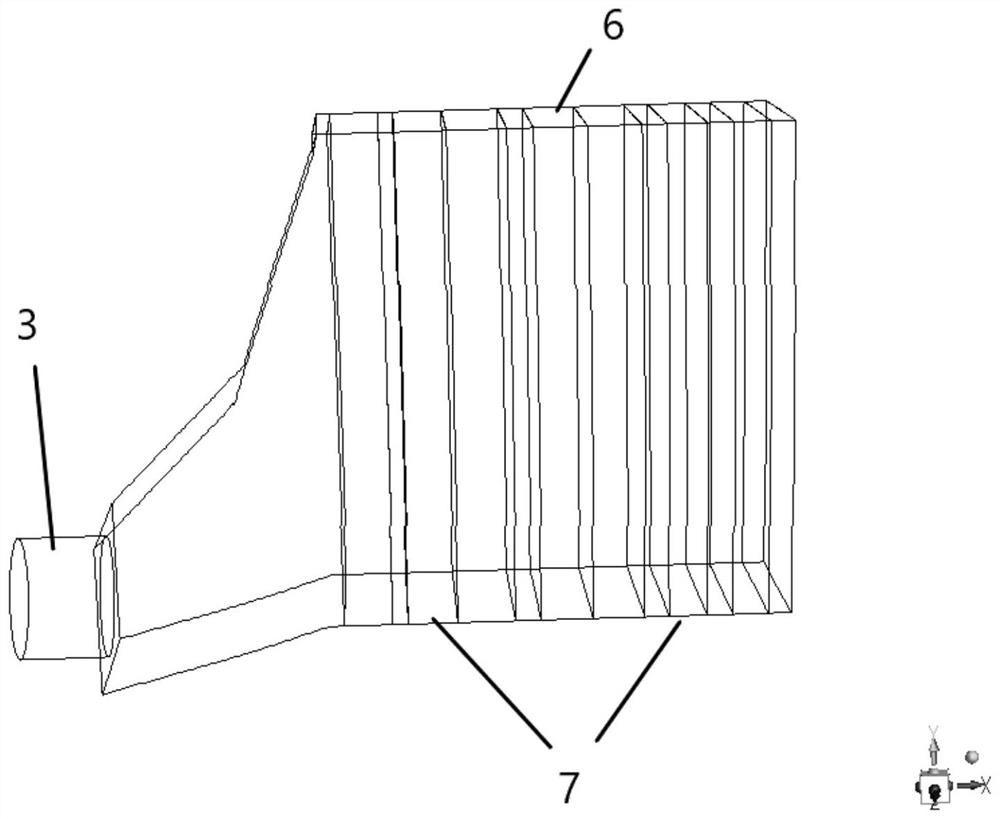

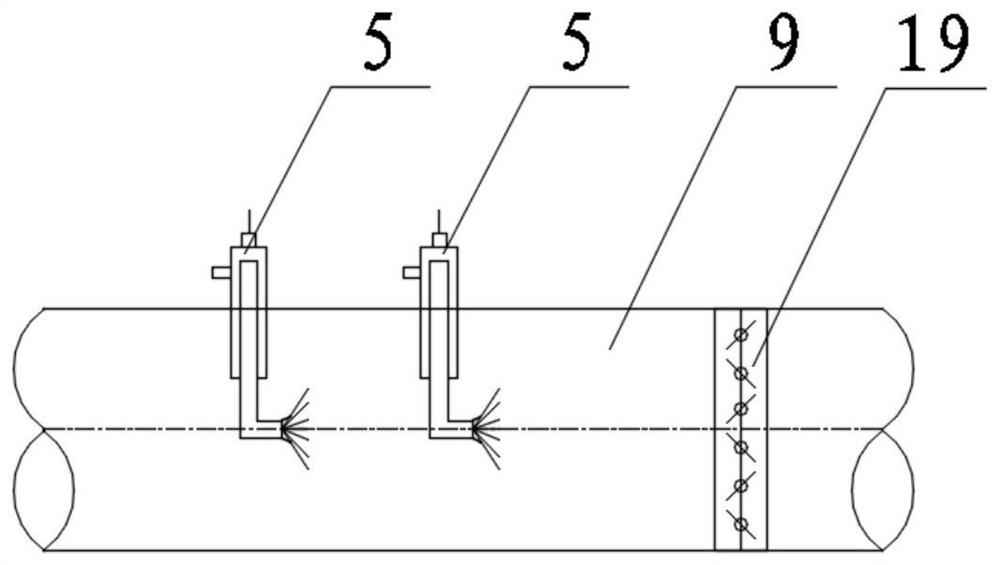

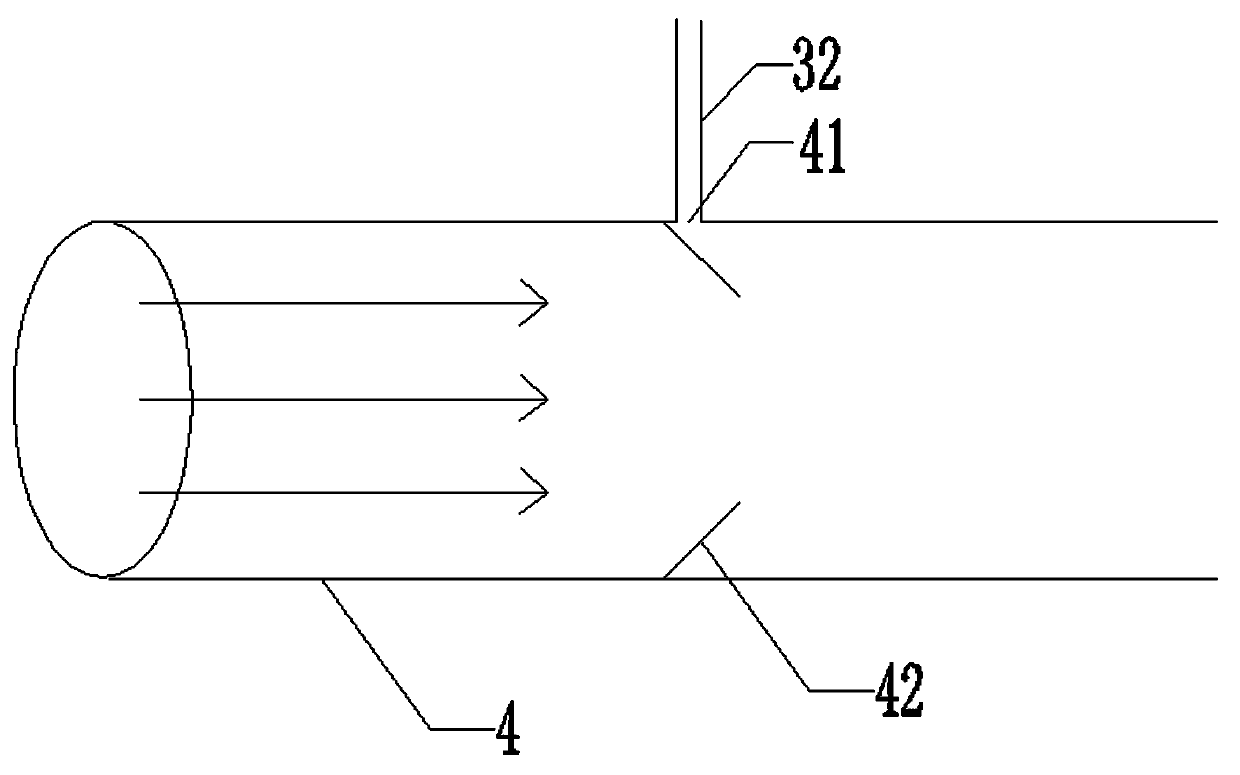

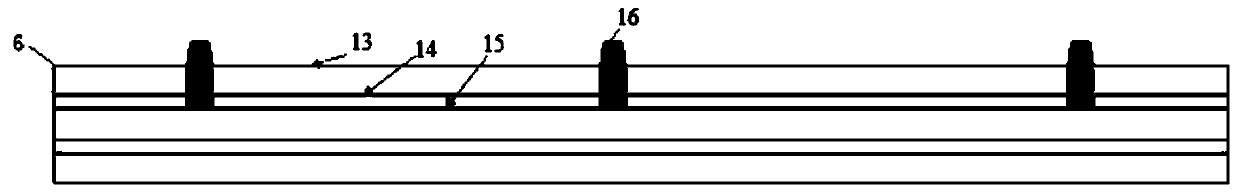

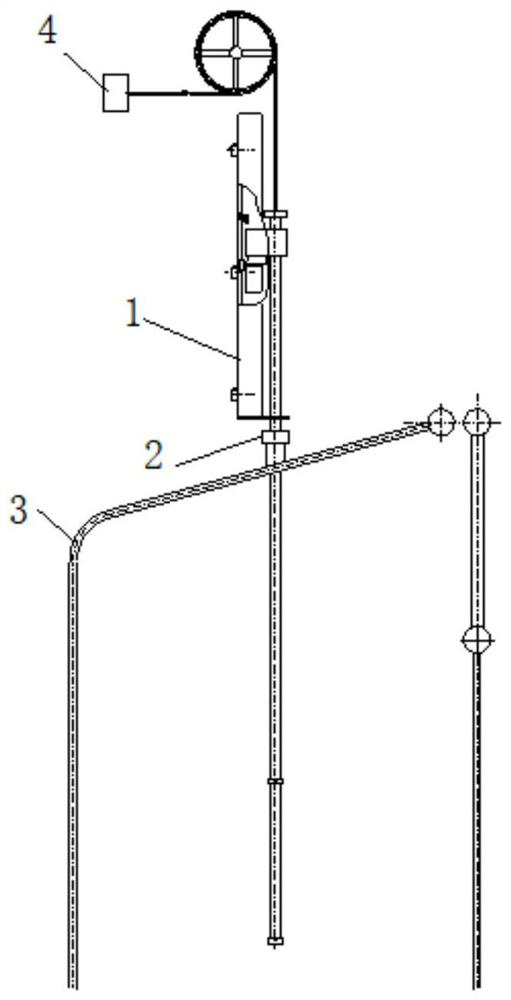

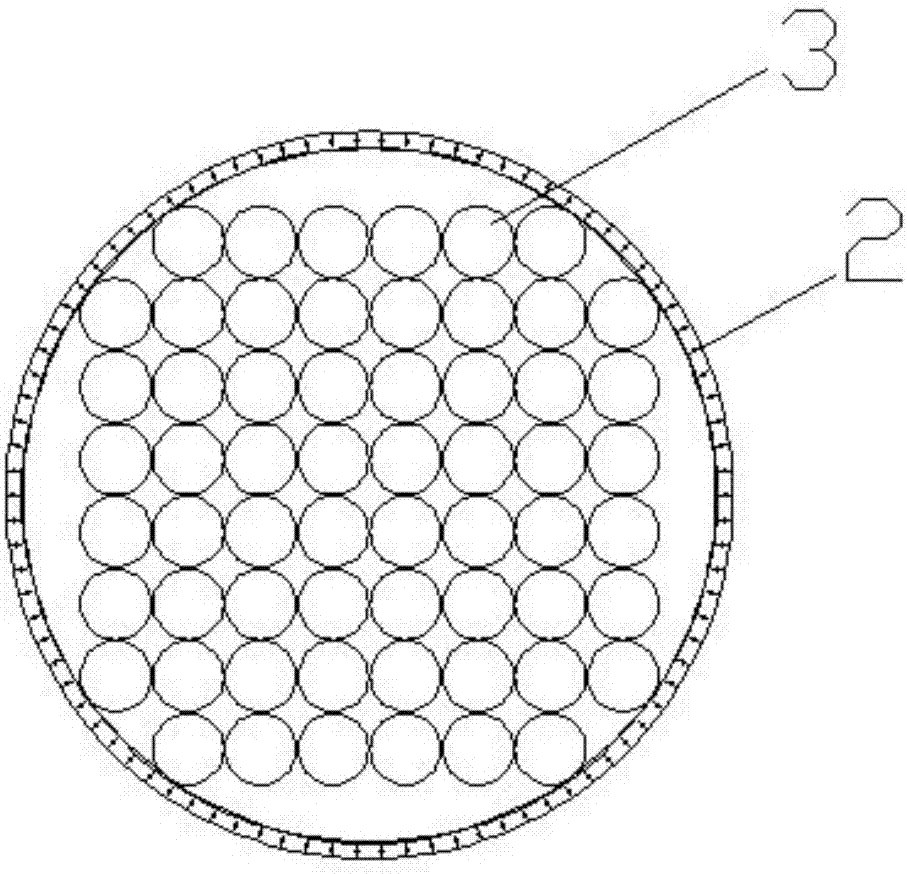

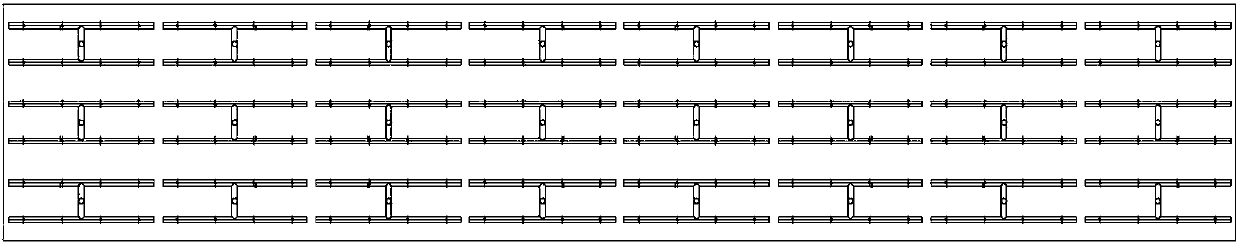

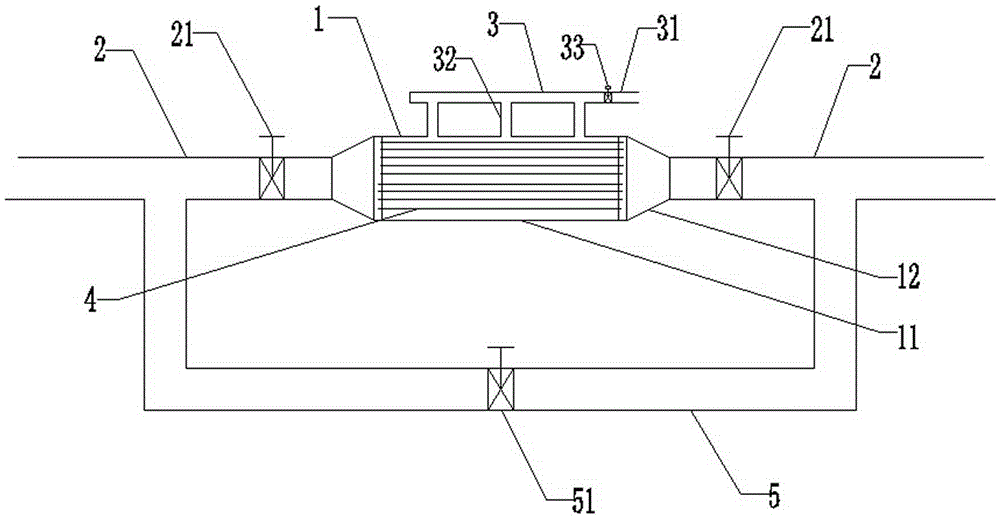

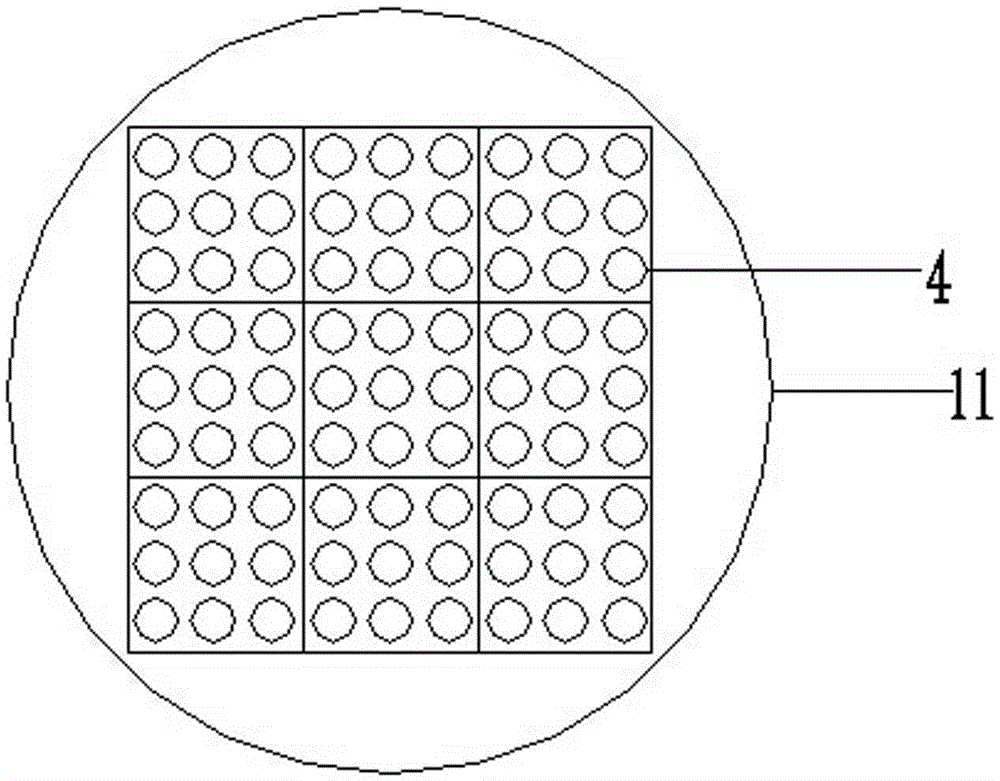

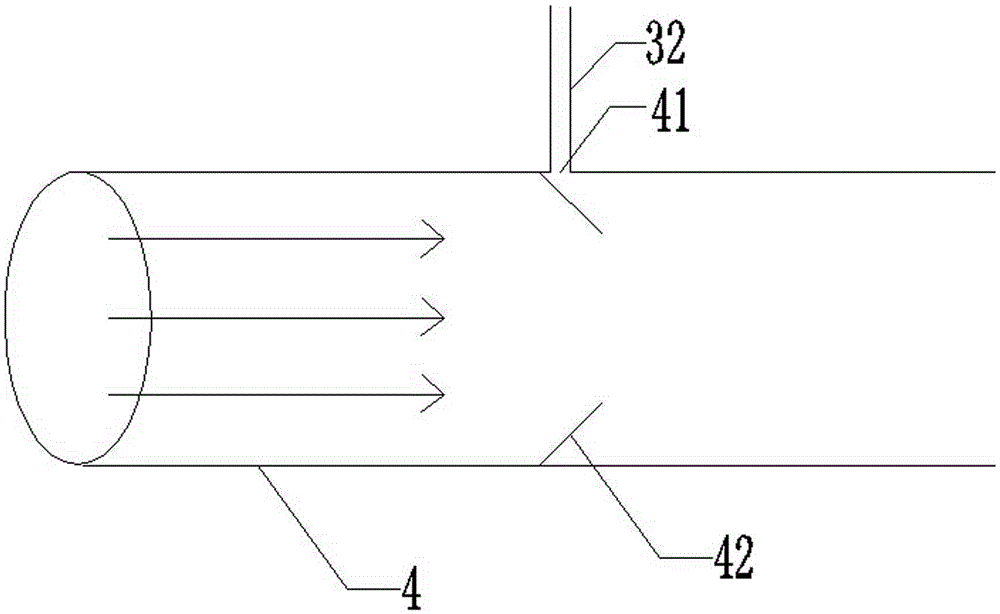

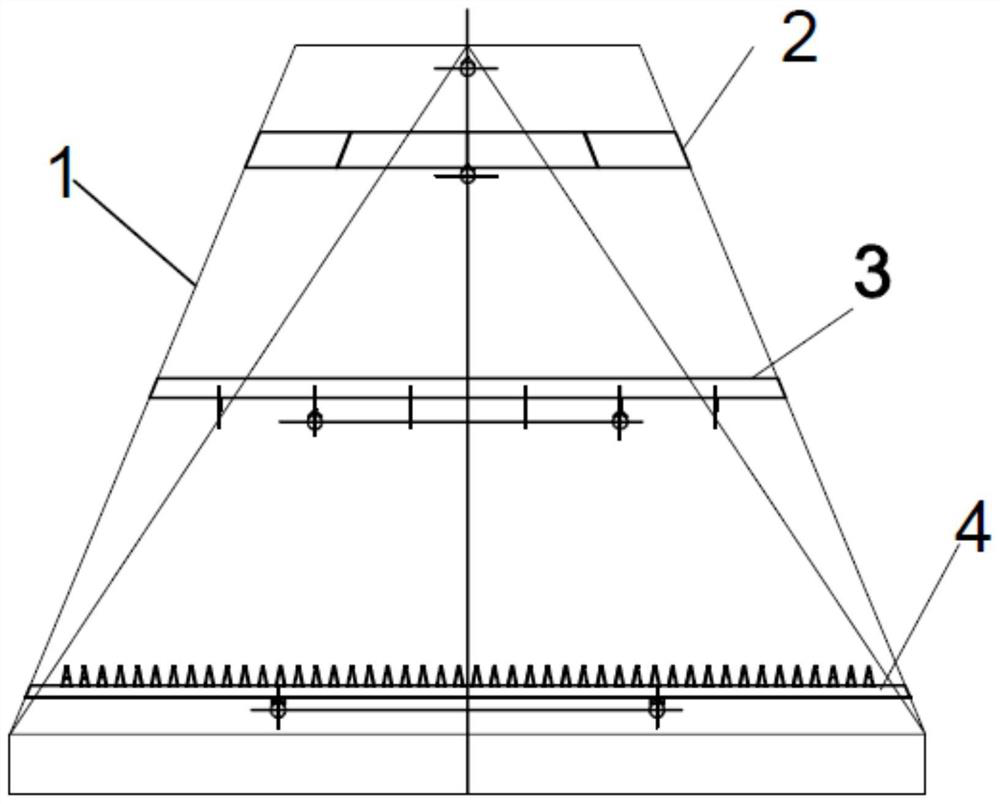

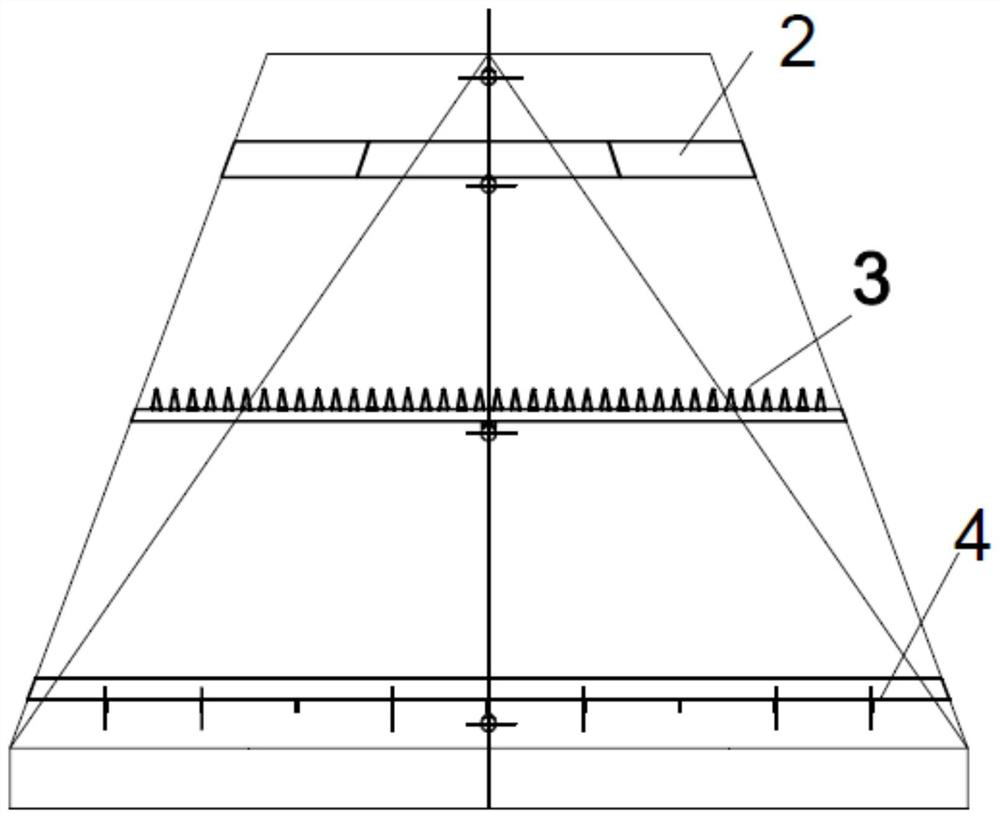

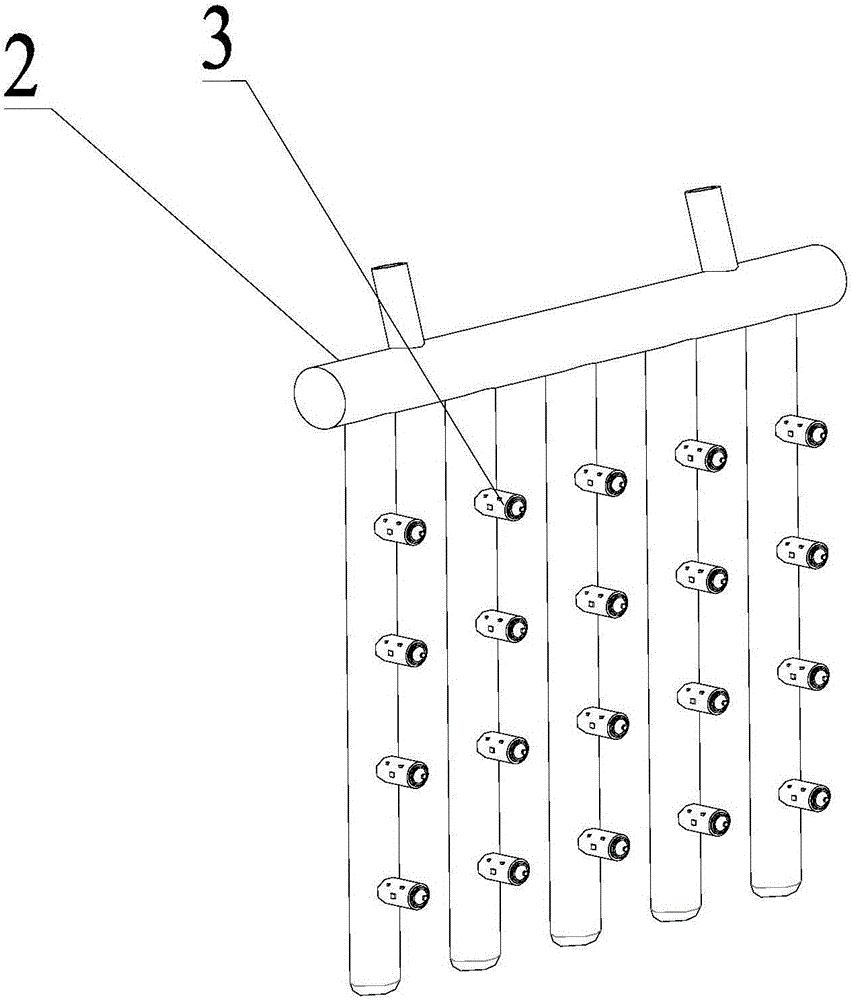

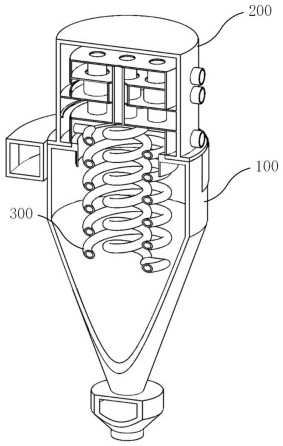

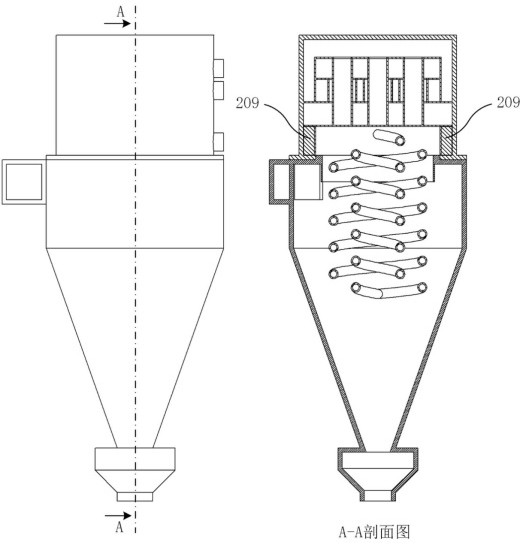

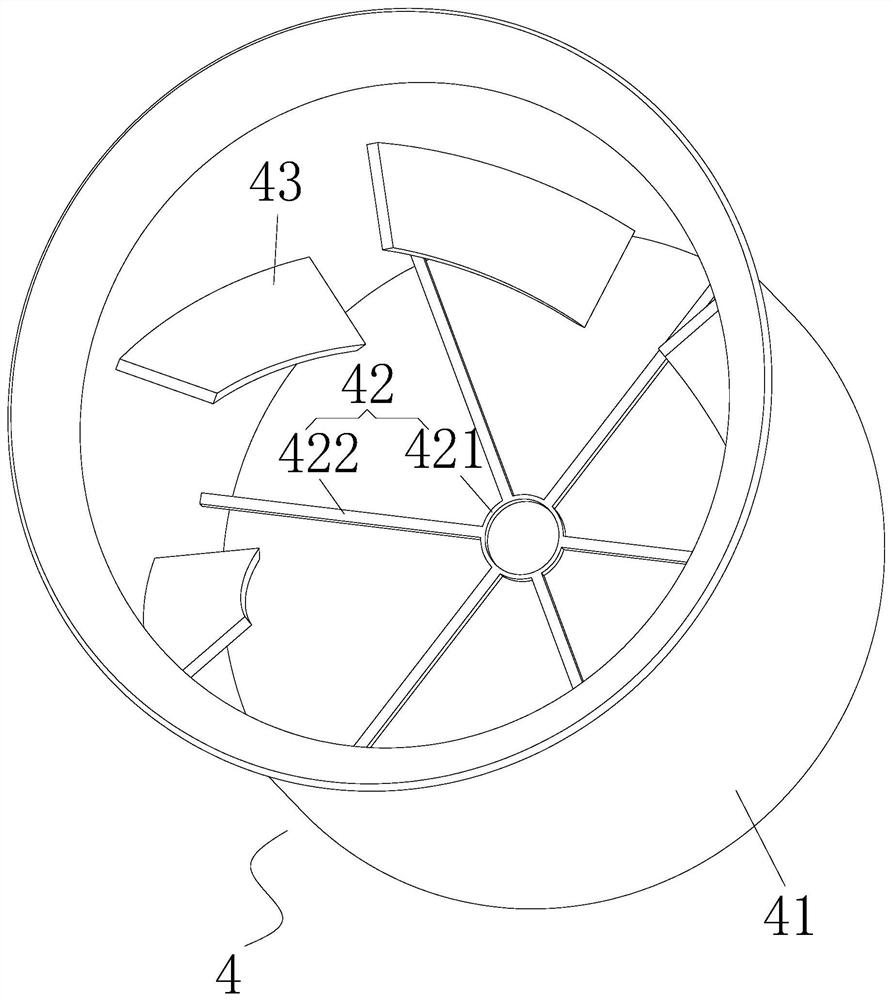

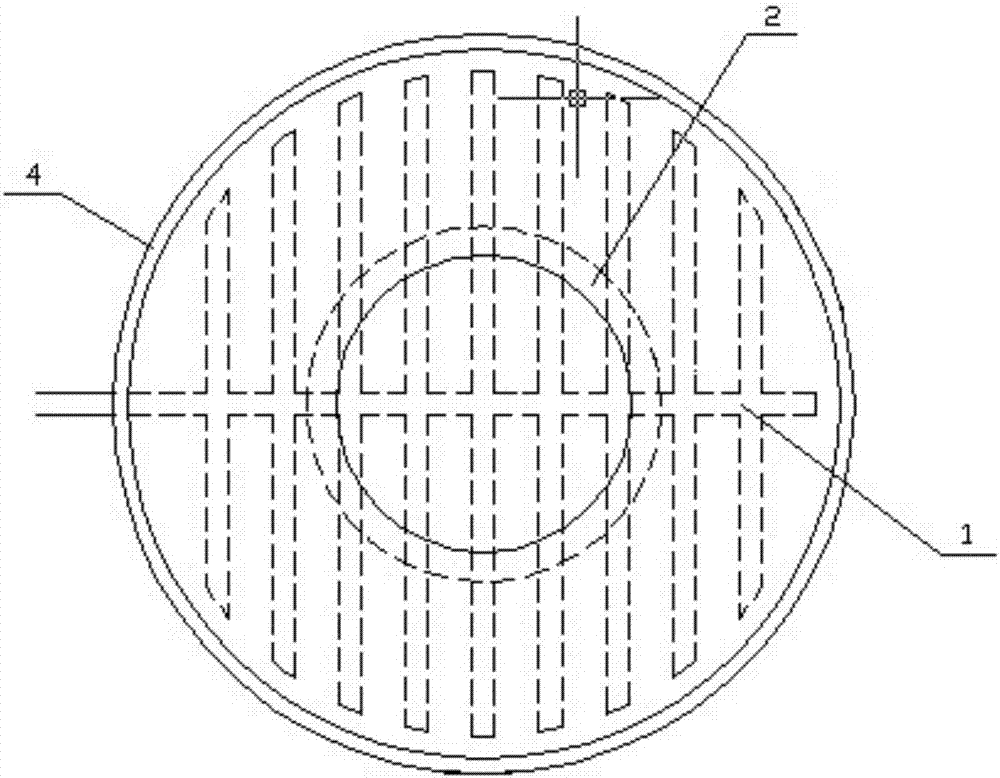

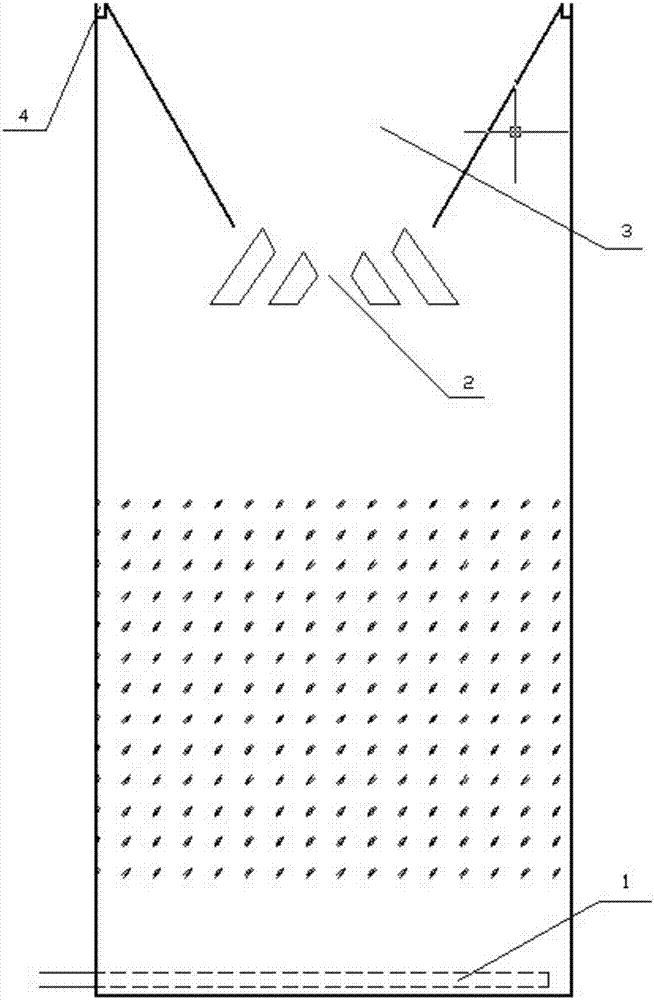

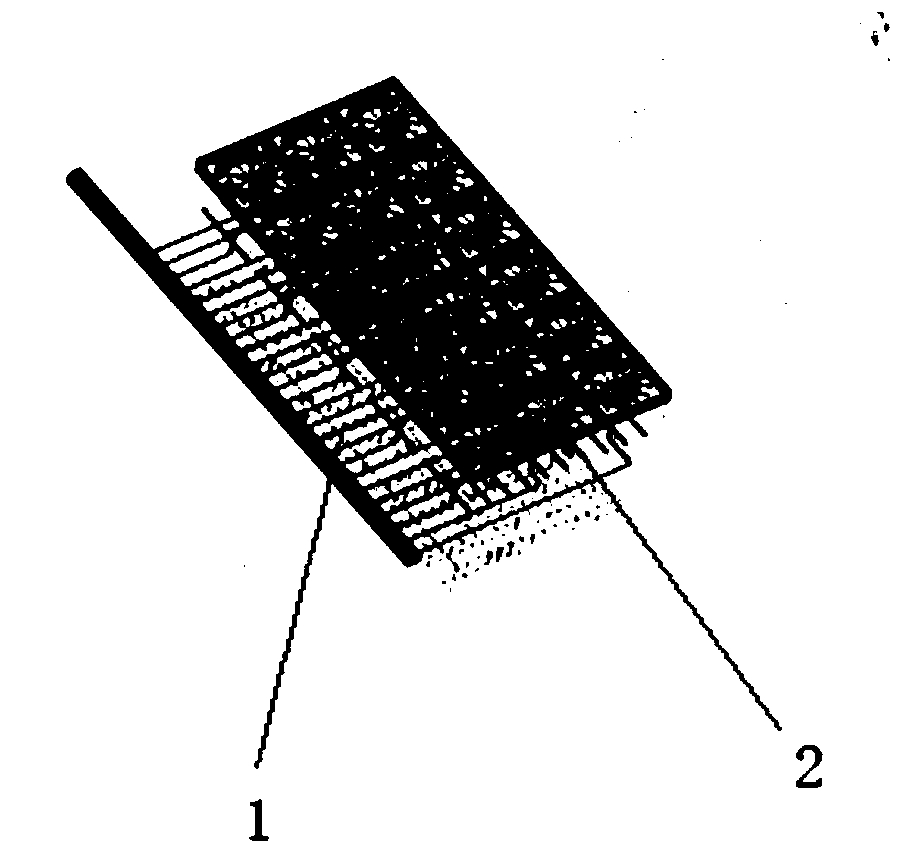

Reverse multi-point swirl-injection denitrating device

ActiveCN104190238AWell mixedImprove the efficiency of denitrification reactionDispersed particle separationFlue gasEngineering

The invention discloses a reverse multi-point swirl-injection denitrating device. The reverse multi-point swirl-injection denitrating device comprises a reverse multi-point swirl injector for denitrating flue gas, a flue gas passage communicated with the gas inlet end and the gas outlet end of the reverse multi-point swirl injector, and a denitrating agent passage communicated with the interior of the reverse multi-point swirl injector, wherein a plurality of swirl tubes parallel to the axis of the reverse multi-point swirl injector are arranged inside the reverse multi-point swirl injector; a denitrating agent inlet communicated with the denitrating agent passage is arranged on each swirl tube; two inclined swirl plates which are vertically symmetrical are arranged on the side, near the gas inlet end of the reverse multi-point swirl injector, of each denitrating agent inlet. The reverse multi-point swirl-injection denitrating device can mix the flue gas and the denitrating agent thoroughly, so that the problem that the flue gas removing efficiency is low is solved.

Owner:山东志伟环保科技有限公司

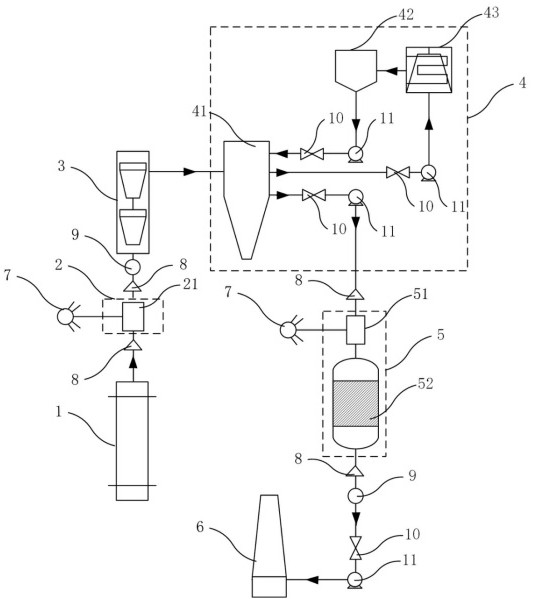

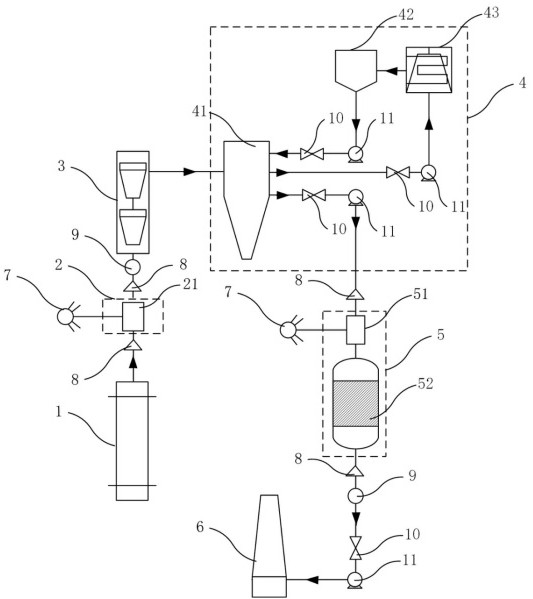

Ultra-clean emission system for cooperatively treating VOCs-containing waste gas and coke oven flue gas

PendingCN112691540AAvoid poisoning and inactivationImprove purification efficiencyDispersed particle separationIncinerator apparatusNitrogen oxidesExhaust fumes

The invention relates to an ultra-clean emission system for cooperatively treating VOCs-containing waste gas and coke oven flue gas. The ultra-clean emission system comprises a combustion device, a cooling device, a desulfurization device, a dust removal device, a heating device, a denitration device and an emission device which are connected in sequence, wherein the combustion device is used for carrying out combustion treatment on the VOCs-containing waste gas; the cooling device is used for cooling the combusted waste gas; the desulfurization device is used for carrying out desulfurization treatment on mixed gas of the coke oven flue gas and the cooled waste gas; the dust removal device is used for carrying out dust removal treatment on the desulfurized gas; the heating device is used for heating the dedusted gas; the denitration device is used for carrying out denitration treatment on the heated gas; and the emission device is used for discharging the denitrated gas into the atmosphere. The system can be used for cooperatively treating VOCs-containing waste gas and coke oven flue gas, has the characteristic of simultaneously treating VOCs, sulfur dioxide and nitric oxide, can enable the treated flue gas to reach the ultra-clean emission standard, and is simple in process flow, stable in operation and relatively low in cost.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

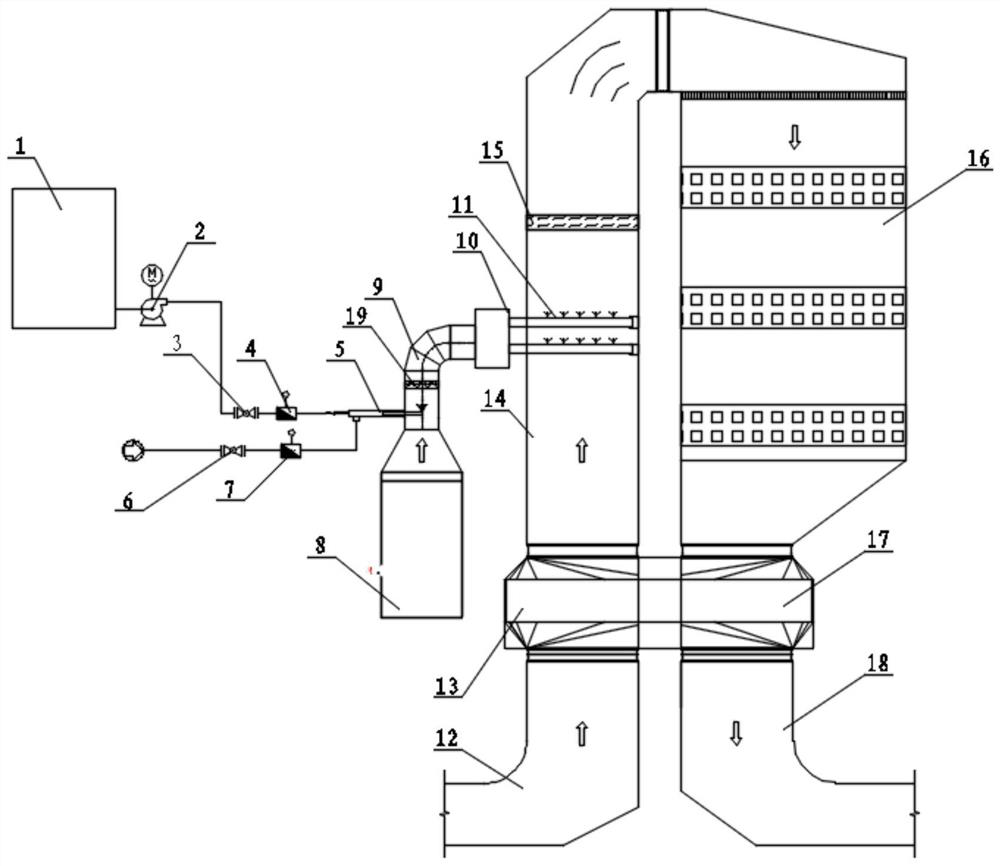

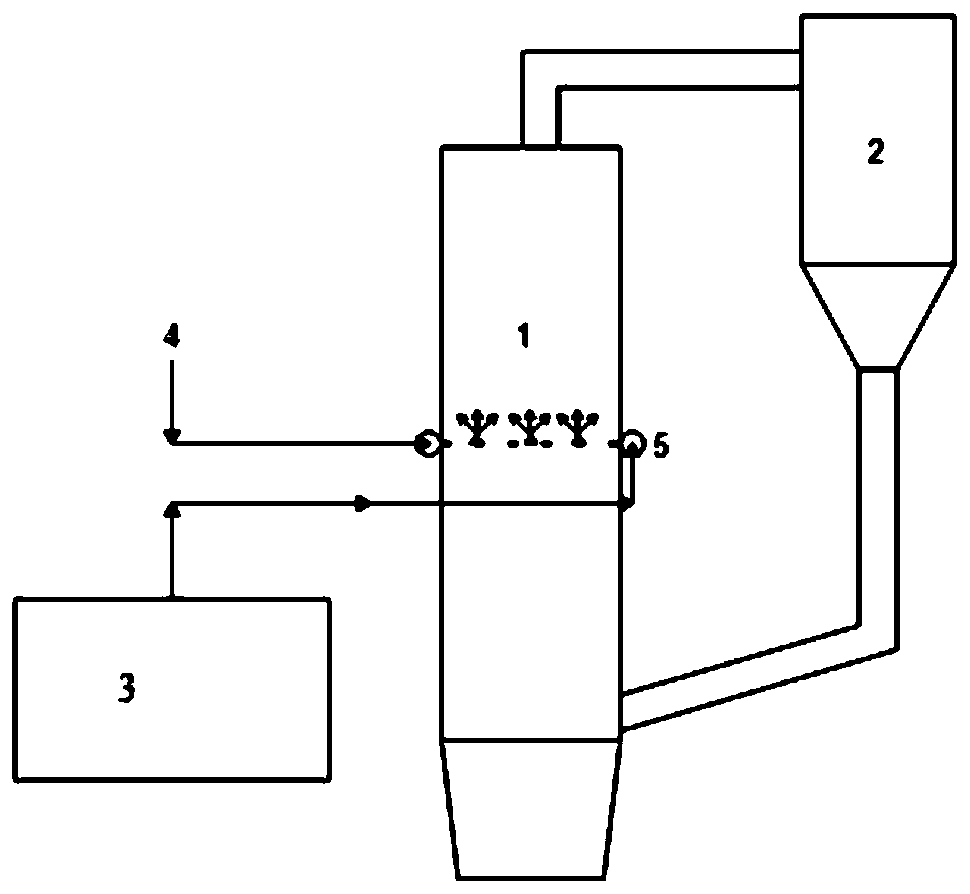

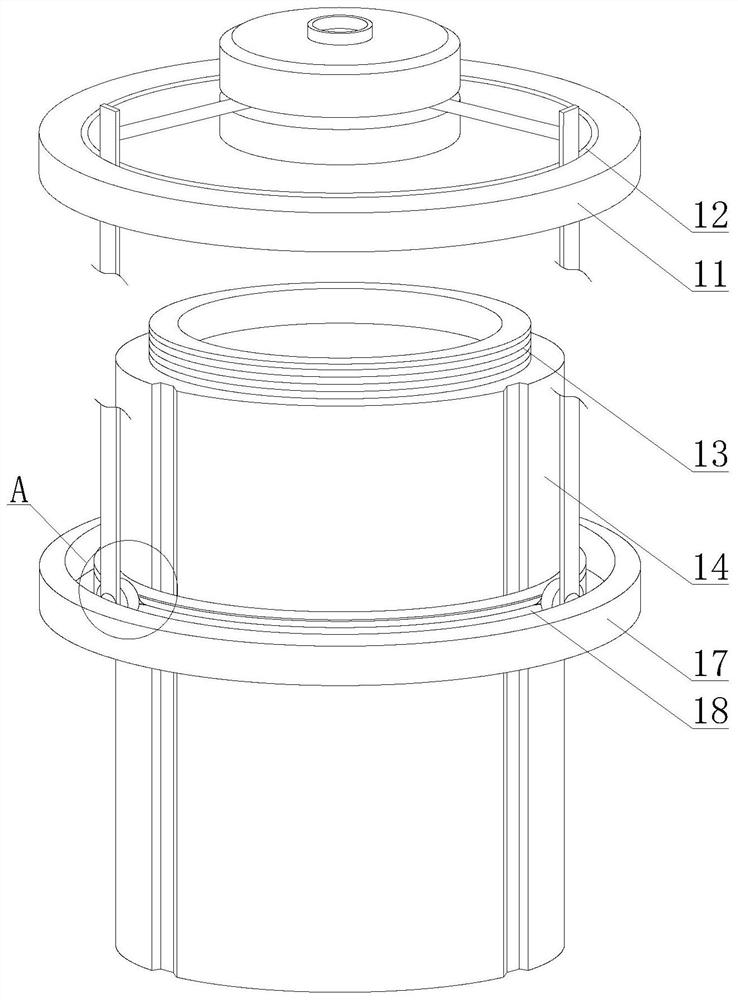

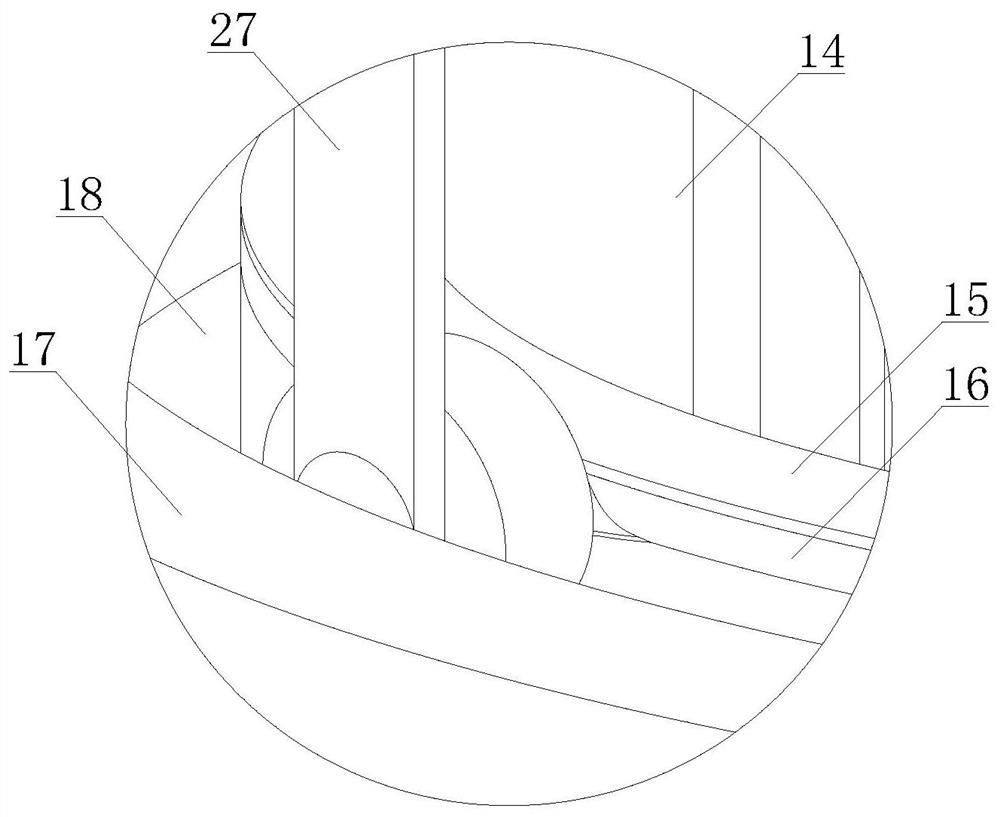

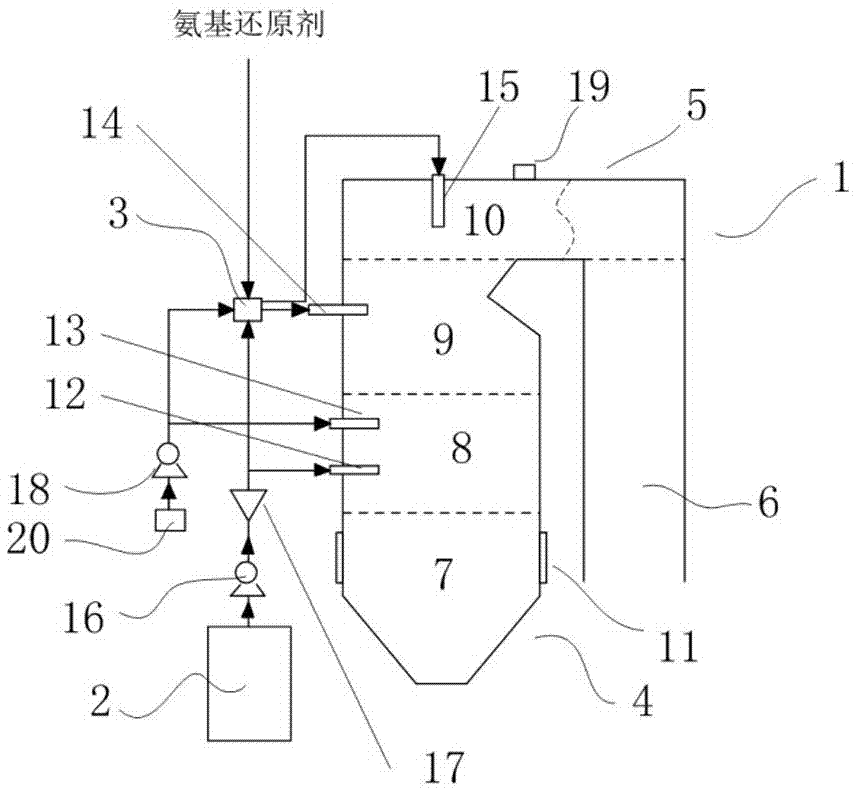

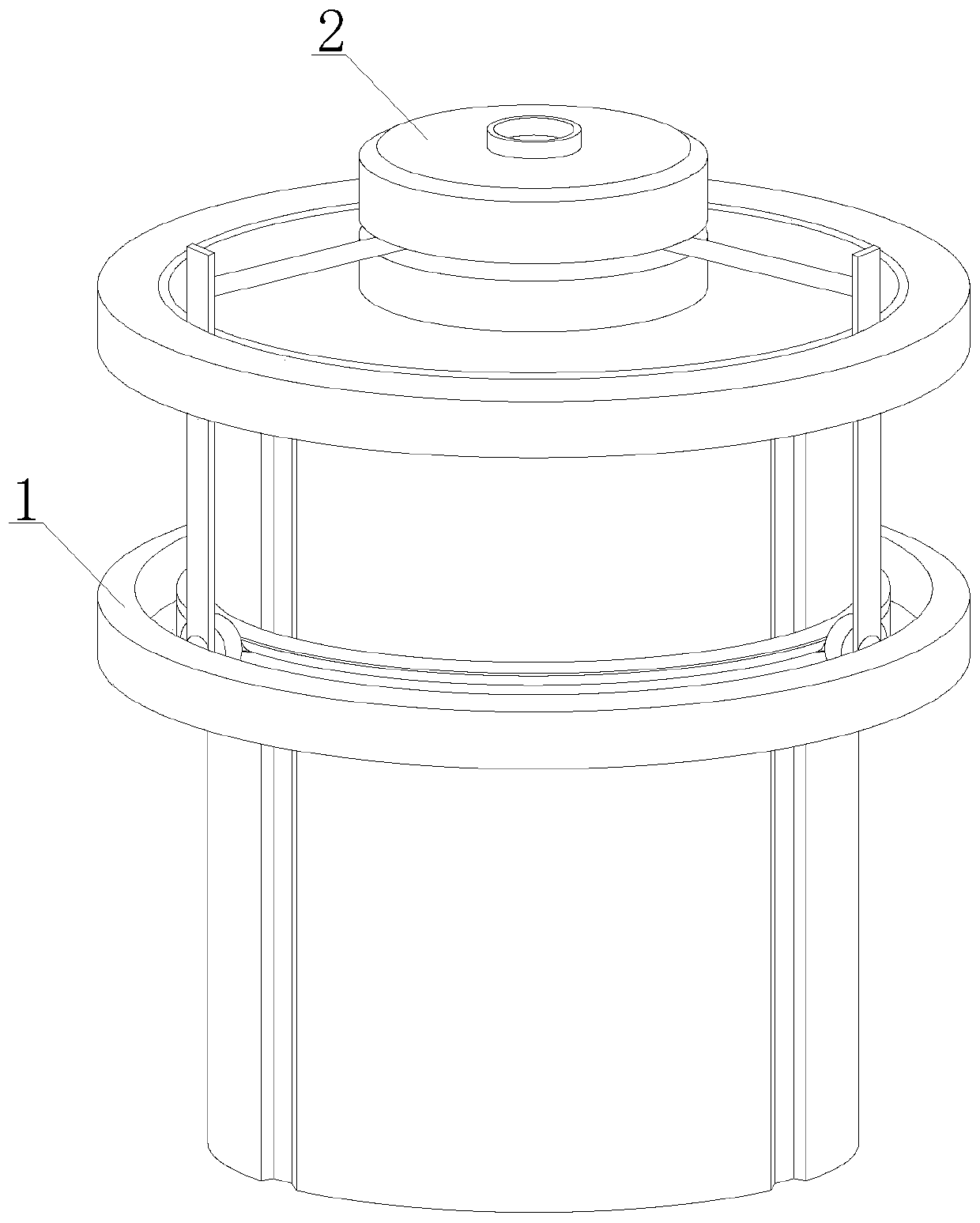

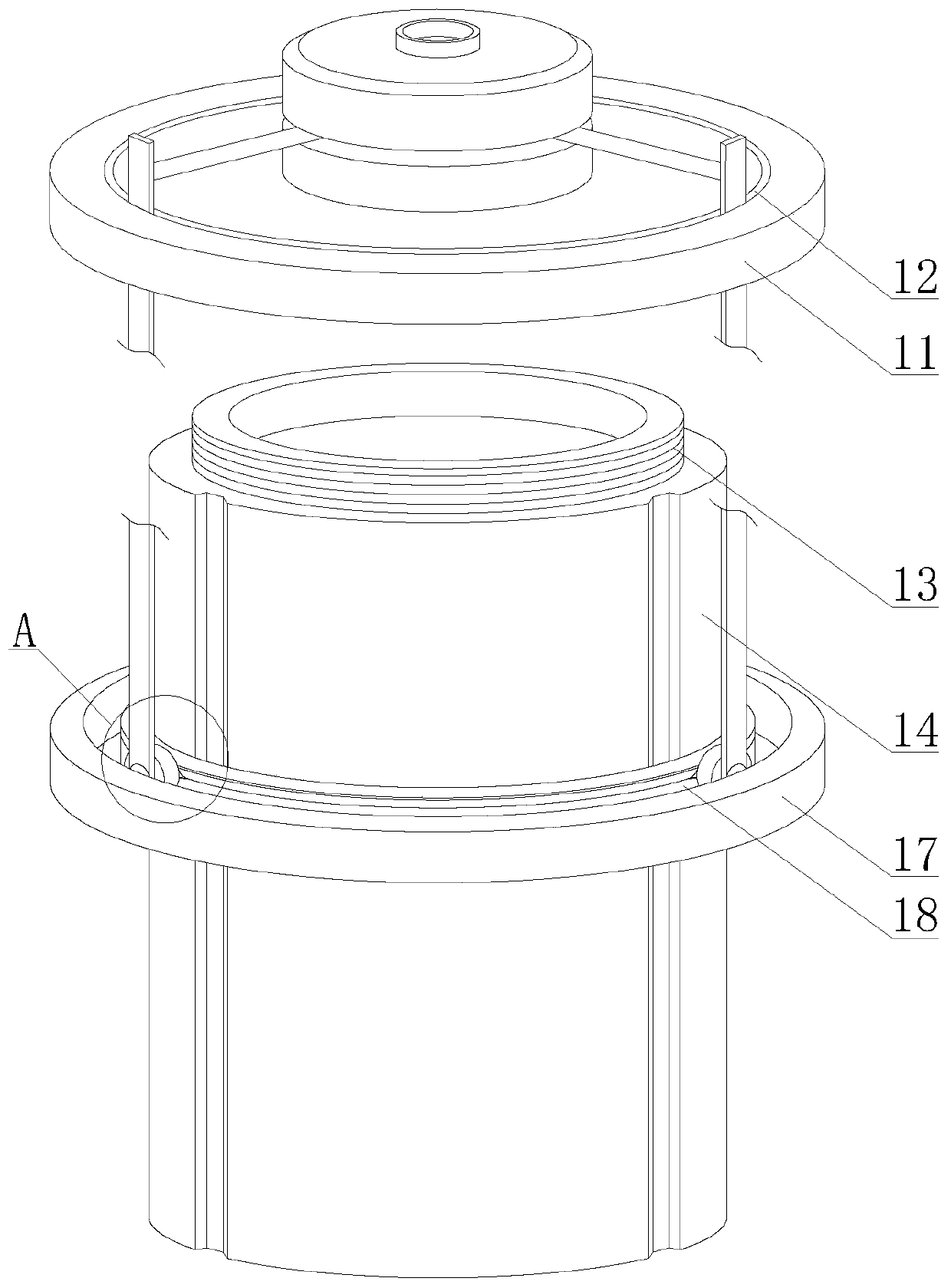

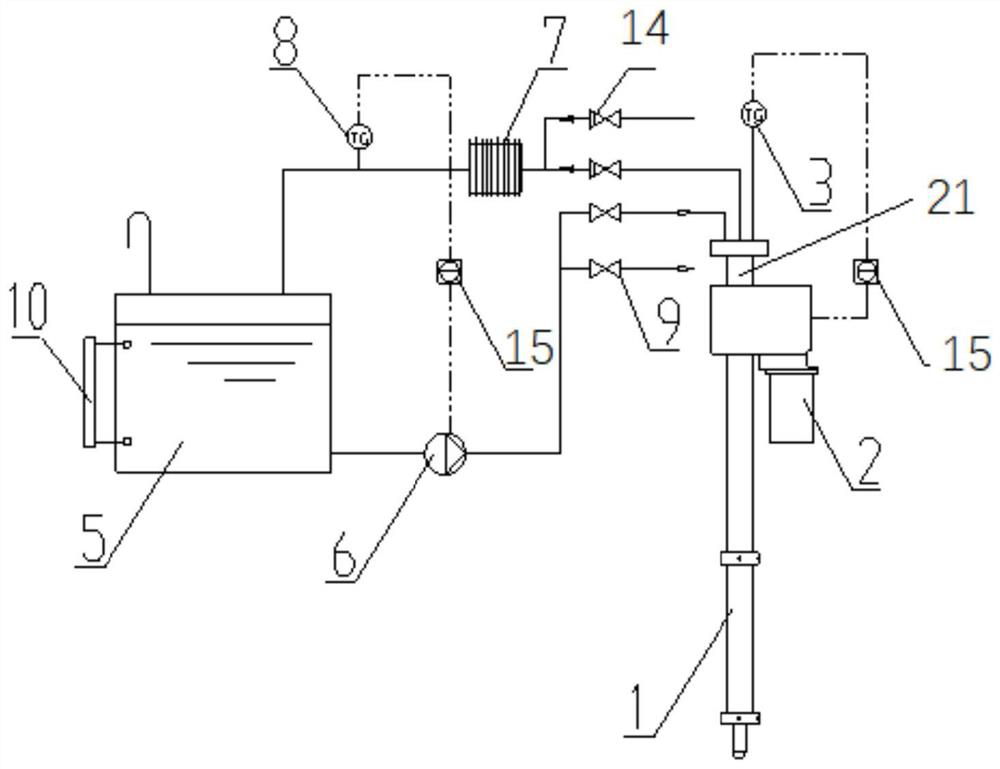

Circulating fluidized bed boiler and in-furnace SNCR denitration device and process

PendingCN111346493AReduce consumptionLow running costGas treatmentDispersed particle separationNitrogen oxidesFlue gas

The invention discloses a circulating fluidized bed boiler and an in-boiler SNCR denitration device and process. The SNCR denitration device comprises an injection system, a medium inlet of the injection system is communicated with a cooling air system, a urea conveying pipeline and a compressed air conveying pipeline; the injection system comprises a plurality of multi-point continuous injectiondevices; the multi-point continuous injection device is coaxially provided with a injection device casing pipe, a compressed air pipeline and a urea solution pipeline from outside to inside; a plurality of injection device atomizing nozzles are arranged in the axis direction of the multi-point continuous injection devices; the injection device atomizing nozzles are communicated with the injectiondevice casing pipe, the compressed air pipeline and the urea solution pipeline; a reducing agent solution and compressed air are distributed and then enter the multi-point continuous injection devices, then atomized and then jetted into the flue gas in a downstream manner to realize section coverage; and meanwhile, the device is cooled, so that the denitration efficiency can be improved, the consumption of a reducing agent and the operation cost are reduced, and the problem that the ultralow emission of nitric oxide of a circulating fluidized bed boiler meets the standard under the medium-lowload condition is solved.

Owner:HUANENG POWER INTERNATIONAL +1

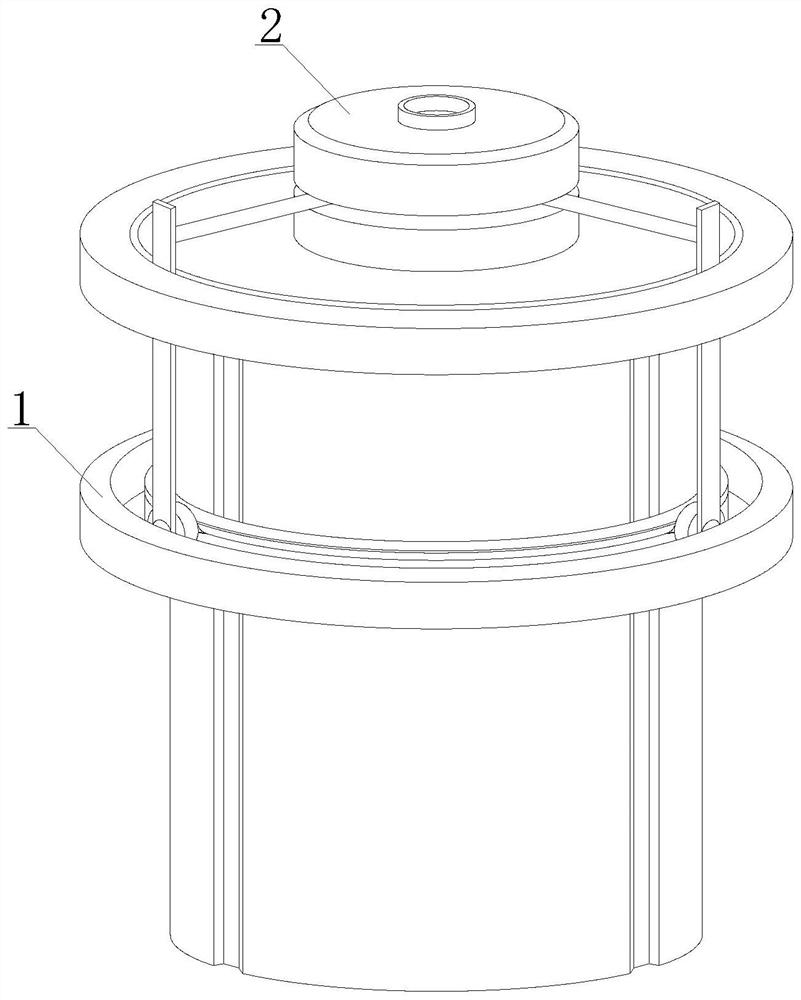

A high temperature and high dust scr denitrification device for cement kiln

ActiveCN110787629BAvoid uneven responseAdequate responseDispersed particle separationRubber ringAmmonia storage

The invention discloses a high-temperature and high-dust SCR denitrification device for a cement kiln, which includes a reaction component and an ammonia injection component. The hole overflows into the connecting pipe, and the connecting pipe, connecting plate and ammonia storage tank form an ammonia circulation pipeline. The ammonia gas enters the nozzle from the circulation pipeline and overflows into the reaction vessel body to react with flue gas. The power output end of the motor Drive the rotating cover to rotate to realize the rotation process of the connecting pipe. The connecting pipe drives the connecting plate, ammonia storage tank and ammonia delivery pipe to move together, so that the overflow point of ammonia gas changes continuously inside the reaction vessel body, and the setting of the rubber ring does not affect The moving process of the ammonia pipe can also ensure the airtightness of the reaction vessel to the greatest extent, so that the flue gas inside the reaction vessel can fully react with the ammonia gas, avoid the uneven reaction between the flue gas and the ammonia gas, and improve the denitrification reaction efficiency.

Owner:MAANSHAN SHUNDA ENVIRONMENTAL PROTECTION EQUIP

A method and device for compound denitrification

ActiveCN105485664BLess quantityImprove denitrification efficiencyGas treatmentDispersed particle separationReaction temperatureNitric oxide

The invention relates to the technical field of boiler improvement, in particular to a composite denitration method and device suitable for power station boilers, industrial boilers and other burning devices. A method is provided, reducibility industrial waste gas serves as a composite additive, on one hand, the reducibility industrial waste gas serves as reburning gas to reduce nitric oxide in the reducing atmosphere, the amount of nitric oxide generated through burning is reduced; and on the other hand, the SNCR reaction temperature is reduced, the SNCR proper temperature area is widened, the reduction of nitric oxide through SNCR is promoted, accordingly, the denitration rate is increased, and ammonia leakage is reduced. The industrially-common reducibility waste gas is effectively and resourcefully utilized, meanwhile, the burning denitration efficiency of a boiler is improved from two aspects, and the emission load of nitric oxide is reduced by more than 80%. The boiler equipment is simple, implementation is easy, the adopted additive is low in price and easy to obtain, the burning process in the boiler is not affected, obvious secondary pollution cannot be generated, and reliability is high. The method is mainly applied to the industrial waste gas reutilization and nitric oxide control aspects.

Owner:SHANXI UNIV +1

High-temperature and high-dust SCR denitrification apparatus for cement kiln

ActiveCN110787629AAvoid uneven responseAdequate responseDispersed particle separationAmmonia storageFlue gas

The invention discloses a high-temperature and high-dust SCR denitrification apparatus for a cement kiln. The apparatus comprises a reaction assembly and an ammonia spraying assembly, wherein the ammonia spraying assembly is fixedly installed on the reaction assembly, an ammonia gas delivery pipe is connected with an ammonia inlet, ammonia gas overflows into connecting pipes through through-holes,the connecting pipes, connecting plates and ammonia storage tanks form an ammonia circulation pipeline, and ammonia gas enters nozzles through the circulation pipeline and overflows into a reaction container body to react with flue gas. A power output end of a motor drives a rotation cover to rotate, a rotating process of the connecting pipes is realized, and the connecting pipes drive the connecting plates, the ammonia storage tanks and ammonia conveying pipes to move together, so that overflow points of ammonia gas are constantly changed inside the reaction container body, and the arrangement of rubber rings has no effects on the moving process of the ammonia conveying pipes, and can ensure the airtightness of the reaction container body to the greatest extent, so that the flue gas inside the reaction container body can fully react with ammonia gas, the uneven reaction between the flue gas and ammonia gas is avoided, and the denitrification reaction efficiency is improved.

Owner:MAANSHAN SHUNDA ENVIRONMENTAL PROTECTION EQUIP

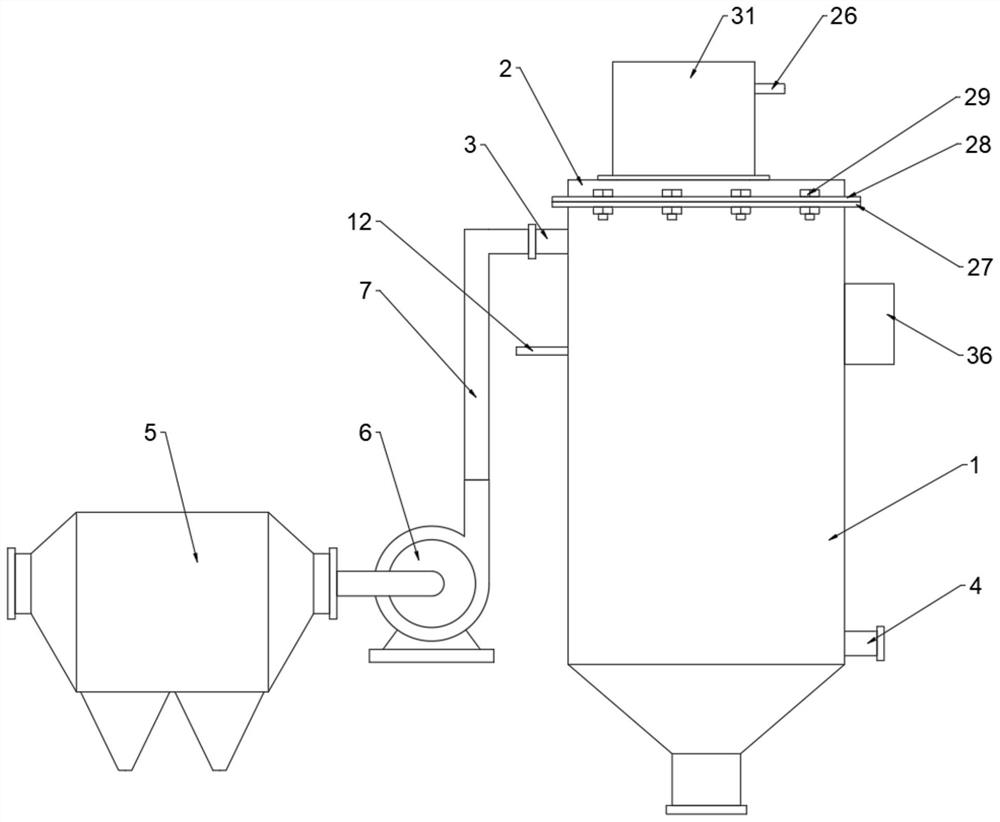

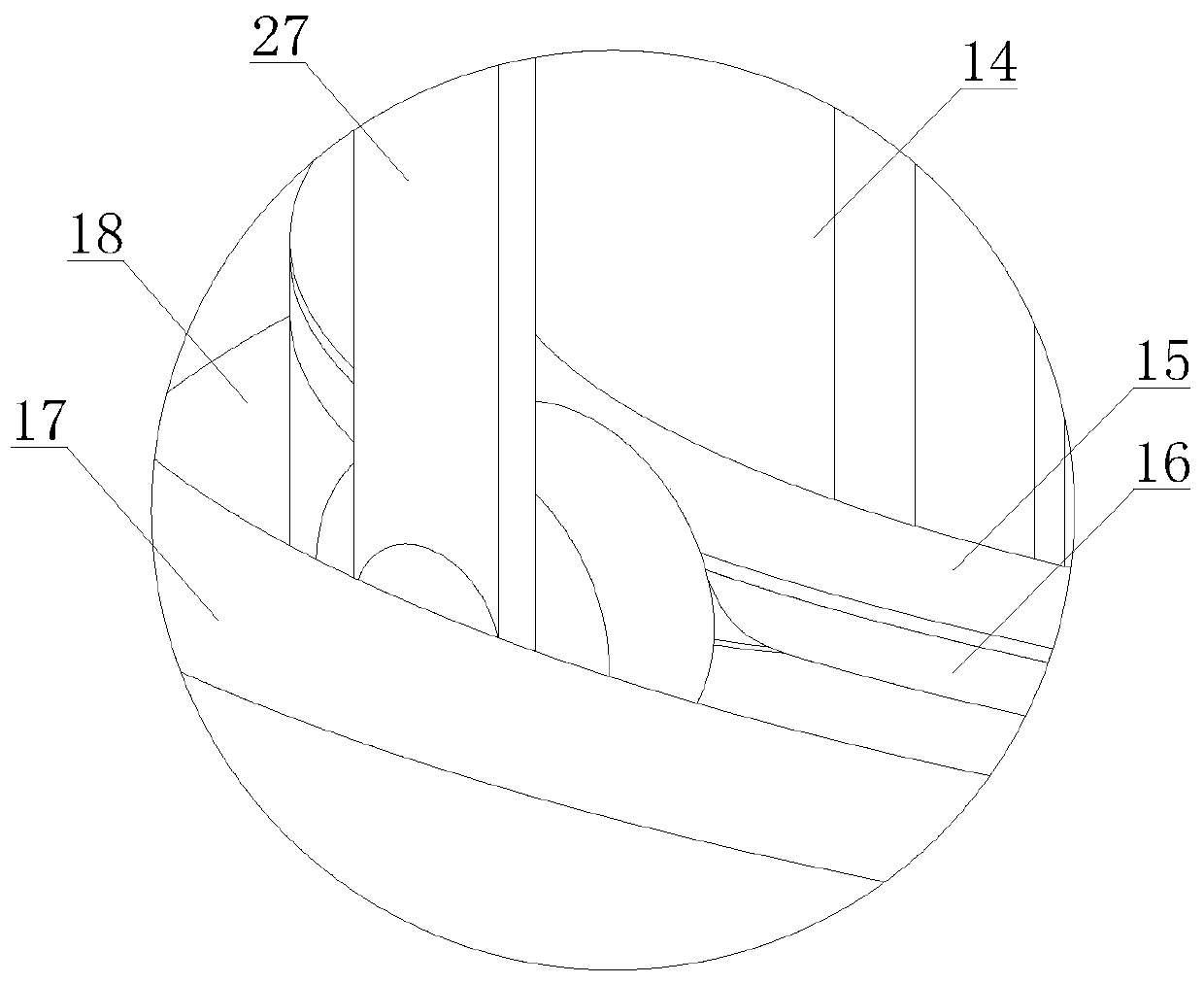

Low-temperature denitration device for hazardous waste incineration flue gas

ActiveCN114225672AReduced risk of plugging corrosionShort processGas treatmentDispersed particle filtrationFlue gasPhysical chemistry

The invention discloses a low-temperature denitration device for hazardous waste incineration flue gas, and the device comprises an alkali spraying and deacidification system which is used for carrying out an acid-base reaction on to-be-treated flue gas and alkali liquor to remove acidic gas in the flue gas to obtain first flue gas; the bag-type dust collector is used for capturing fly ash in the first flue gas to obtain second flue gas; the ammonia spraying system is used for mixing ammonia gas with the heated air to obtain mixed gas, and inputting the mixed gas into the low-temperature denitration reactor, so that the second flue gas reacts with the ammonia gas to convert oxynitride into nitrogen to obtain third flue gas; the low-temperature denitration control system is used for controlling the content of oxynitride and ammonium sulfate in the third flue gas, so that the amount of alkali liquor input by the alkali spraying and deacidification system and the concentration of atomized ammonia sprayed by the ammonia spraying system are controlled and adjusted according to the content of oxynitride and ammonium sulfate. The technical problems of various blockage and low-temperature corrosion in the process line process in the prior art are solved.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

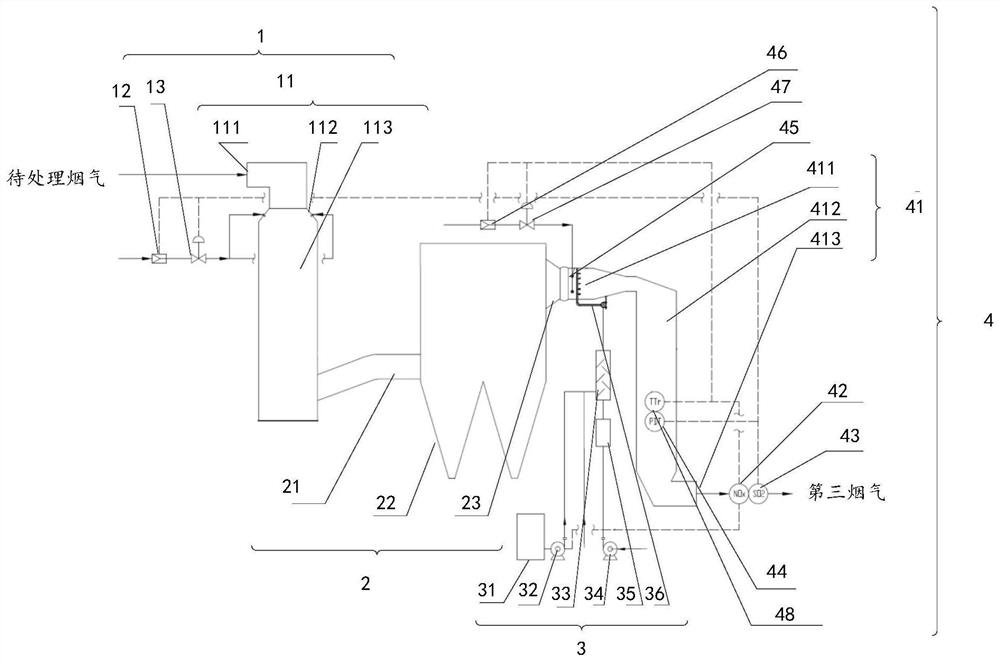

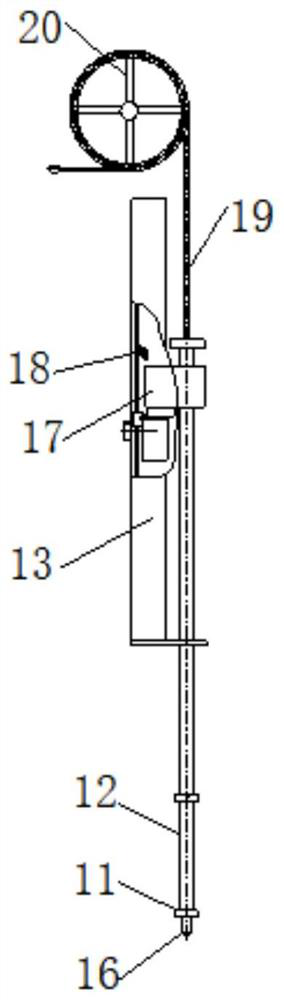

Telescopic in-furnace denitration device arranged at top of boiler

PendingCN113289482AImprove the mixing effectImprove the efficiency of denitrification reactionGas treatmentDispersed particle separationThermodynamicsNitrogen oxides

The invention discloses a telescopic in-furnace denitration device arranged at the top of a boiler. The telescopic in-furnace denitration device comprises a telescopic spray gun, a spray gun height control system, a spray gun cooling system, a positive pressure sealing device and a reducing agent and compressed air conveying and distributing device. The height of the gun barrel can be automatically adjusted according to the flue gas temperature, the spraying point is always kept in the optimal reaction temperature interval of the reducing agent, the denitration efficiency in the furnace is improved to 55%-65%, and the denitration reaction efficiency is improved; reducing agents such as ammonia water and urea are saved, and the operation cost is reduced. And in combination with a flue gas recycling process, the waste incineration power plant with the average value of nitrogen oxide emission index per hour being 90 milligrams per standard cubic meter can achieve up-to-standard emission without using an SCR denitration system, so that the equipment investment and the operation cost are greatly saved.

Owner:上海晟炉环保技术有限公司

Novel SCR (Selective Catalytic Reduction) denitration reactor

PendingCN107335389AHigh mechanical strengthReduce dosageDispersed particle separationChemical/physical processesPtru catalystPhysical chemistry

The invention discloses a novel SCR (Selective Catalytic Reduction) denitration reactor which comprises a reactor body, wherein a plurality layers of pattern plates are arranged in parallel inside the reactor body; a plurality of catalyst cages are uniformly arranged on each layer of the pattern plate; the upper ends of the catalyst cages are arranged on the pattern plates in an upside down manner; the lower ends of the catalyst cages are positioned below the pattern plates; the catalyst cages take the shape of a column; the parts between the inner walls and the outer walls of the catalyst cages are filled with a granular denitration catalyst; the inner walls and the outer walls of the catalyst cages are of steel wire net structures; the bottom ends of the catalyst cages are of airtight plate structures; a manhole gate is arranged on a side wall below each layer of the pattern plate, of the reactor body. The novel SCR denitration reactor is simple and novel in structure, the facility investment is reduced, the problem of reducing operation cost and the like is solved, and the resource utilization rate is increased.

Owner:安徽晨晰洁净科技有限公司

Automatic control method of scr system based on ammonia injection sensitive valve lock

ActiveCN105700504BRealize automatic controlRealize all-round analysisDispersed particle separationTotal factory controlAuto regulationAutomatic control

The present invention discloses a SCR system automatic control method based on ammonia spraying sensitive valve locking. The method comprises three steps: firstly, performing comprehensive analysis of varying load condition operation characteristics of the SCR system based on a field test and a CFD numerical simulation technology to obtain flue gas 'NOx flow' regional continuous distribution characteristics matching an AIG type; then determining the weight of each ammonia spraying branch pipe valve, locking a certain number of sensitive valves according to a preset sensitive valve locking principle, and installing an automatic regulating valve at a corresponding ammonia spraying region; finally, developing an ammonia spraying logic controller and corresponding main control and sub-control logics, realizing multistage optimization setting of parameters of the control system, and realizing the accurate automatic control of the main ammonia spraying regulating valve of the SCR system and the locking sensitive valves. The SCR system automatic control method based on ammonia spraying sensitive valve locking is able to overcome the problems of characteristics of the SCR system such as nonlinearity, large delay and the like so as to realize the accurate automatic control of the ammonia spraying of the SCR system, substantially enhance the SCR denitration reaction efficiency, save the dosage of ammonia, reduce the ammonia escape and effectively inhibit the generation of ABS.

Owner:SOUTHEAST UNIV +1

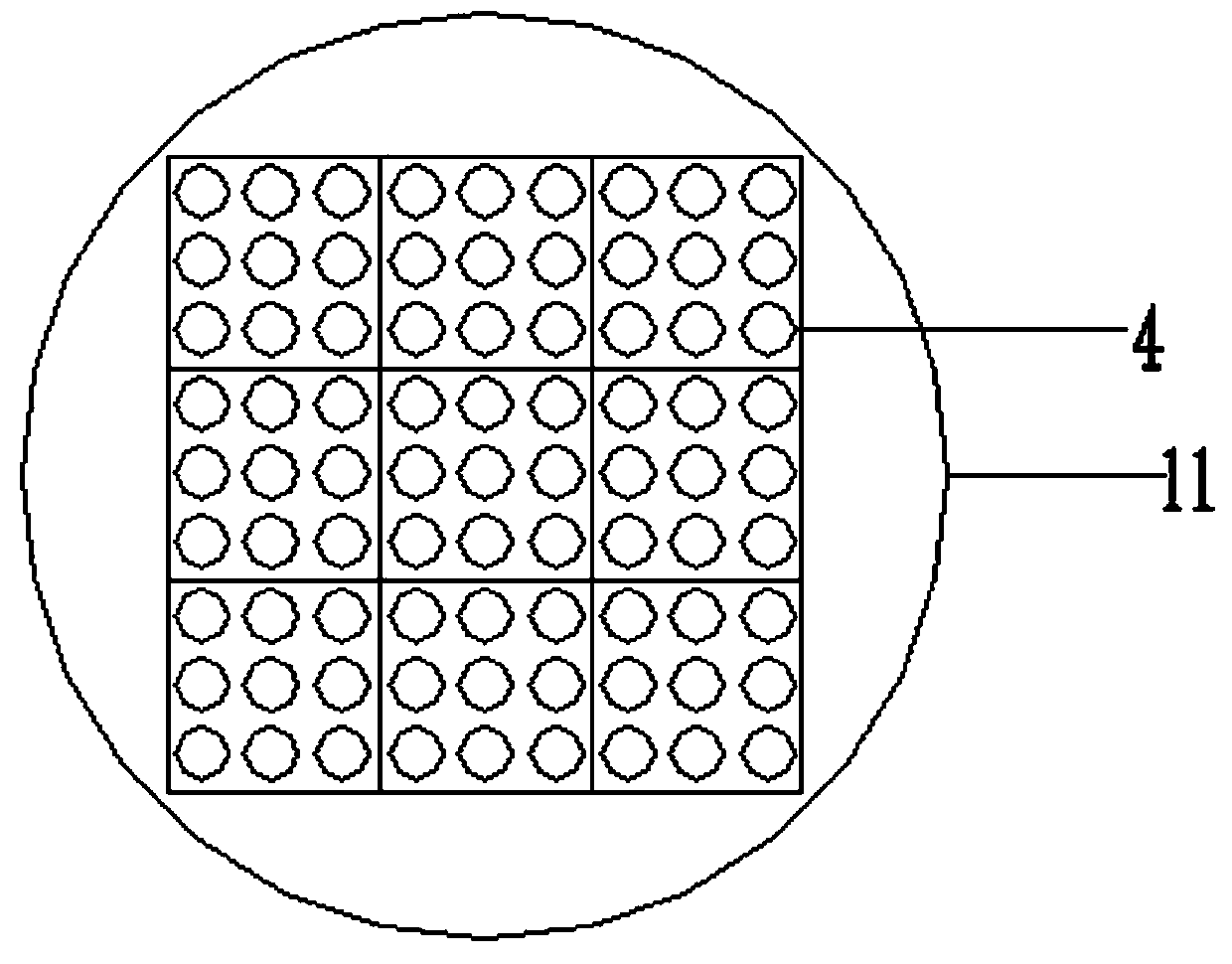

Reverse multi-point swirl jet denitrification device

ActiveCN104190238BWell mixedImprove the efficiency of denitrification reactionDispersed particle separationCycloneFlue gas

The invention discloses a reverse multi-point swirl-injection denitrating device. The reverse multi-point swirl-injection denitrating device comprises a reverse multi-point swirl injector for denitrating flue gas, a flue gas passage communicated with the gas inlet end and the gas outlet end of the reverse multi-point swirl injector, and a denitrating agent passage communicated with the interior of the reverse multi-point swirl injector, wherein a plurality of swirl tubes parallel to the axis of the reverse multi-point swirl injector are arranged inside the reverse multi-point swirl injector; a denitrating agent inlet communicated with the denitrating agent passage is arranged on each swirl tube; two inclined swirl plates which are vertically symmetrical are arranged on the side, near the gas inlet end of the reverse multi-point swirl injector, of each denitrating agent inlet. The reverse multi-point swirl-injection denitrating device can mix the flue gas and the denitrating agent thoroughly, so that the problem that the flue gas removing efficiency is low is solved.

Owner:山东志伟环保科技有限公司

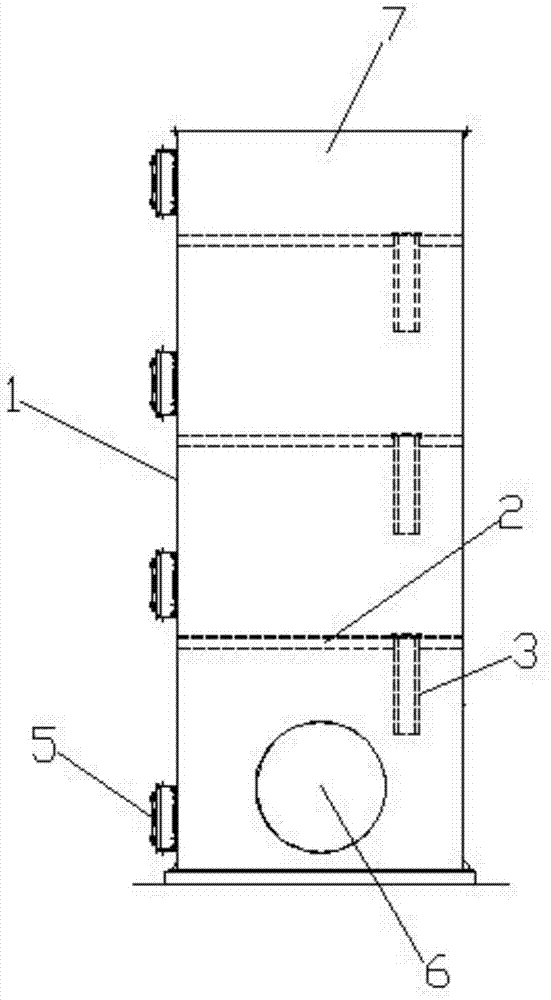

Uniform distribution flow guide system of SCR denitration reaction tower

PendingCN112295402AImprove the efficiency of denitrification reactionEffective distributionGas treatmentDispersed particle separationPtru catalystEngineering

The invention discloses a uniform distribution flow guide system of an SCR denitration reaction tower. Thesystem is characterized in that: a plurality of flow guide layers are arranged at the inlet end of the reaction tower, the flow guide layers are respectively a first flow guide uniform distribution layer, a second flow guide uniform distribution layer and a third flow guide uniform distribution layer from top to bottom, and a second-layer flow guide plate and a third-layer flow guide plate which are vertically arranged are respectively arranged on the second-layer flow guide uniform distribution layer and the third-layer flow guide uniform distribution layer. The uniform distribution flow guide system of the SCR denitration reaction tower is simple in structure and reasonable in arrangement, can effectively distribute gas, enables the gas to uniformly pass through a catalyst, improves the SCR denitration reaction efficiency, and has relatively high practicability and relatively good application prospect.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

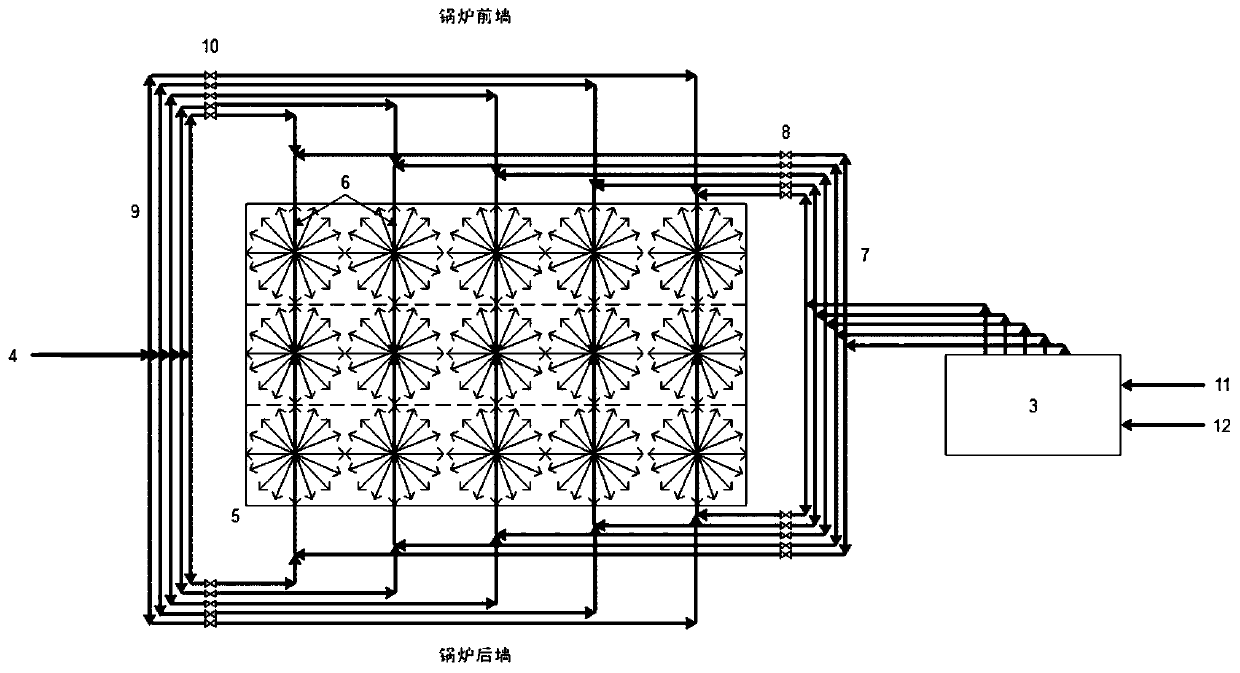

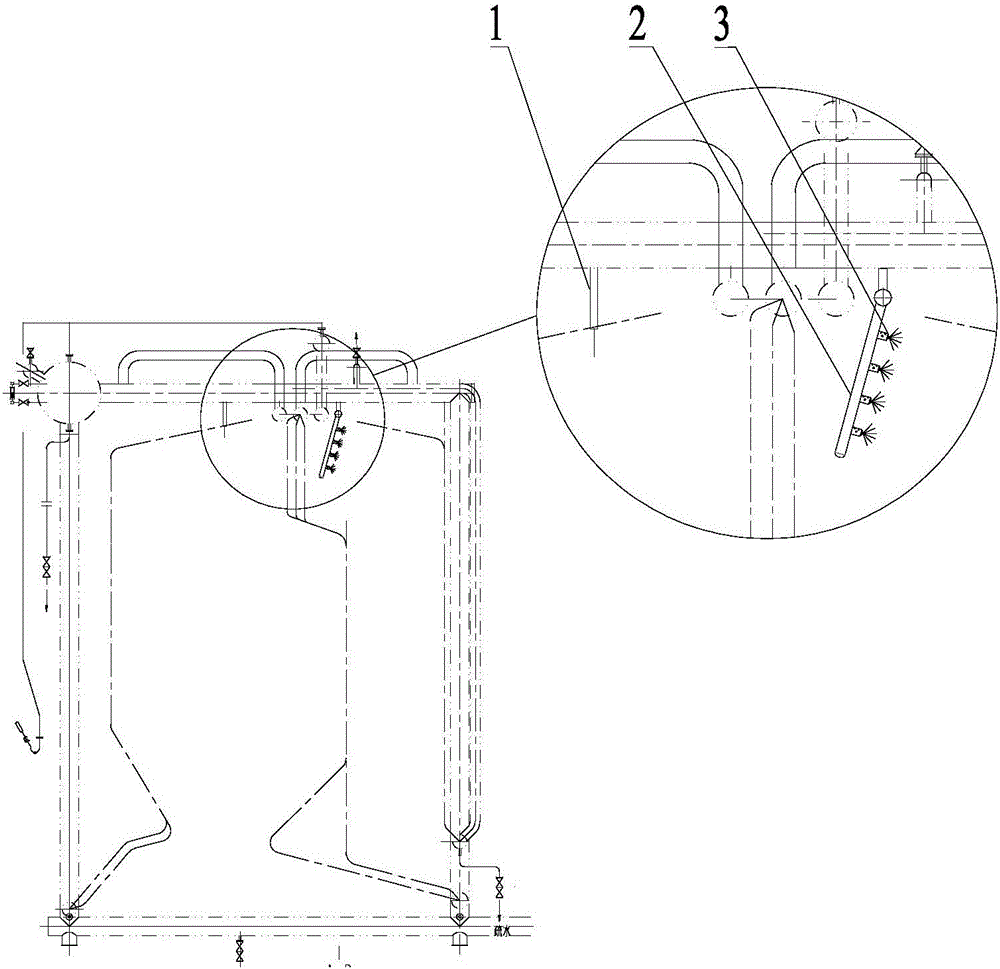

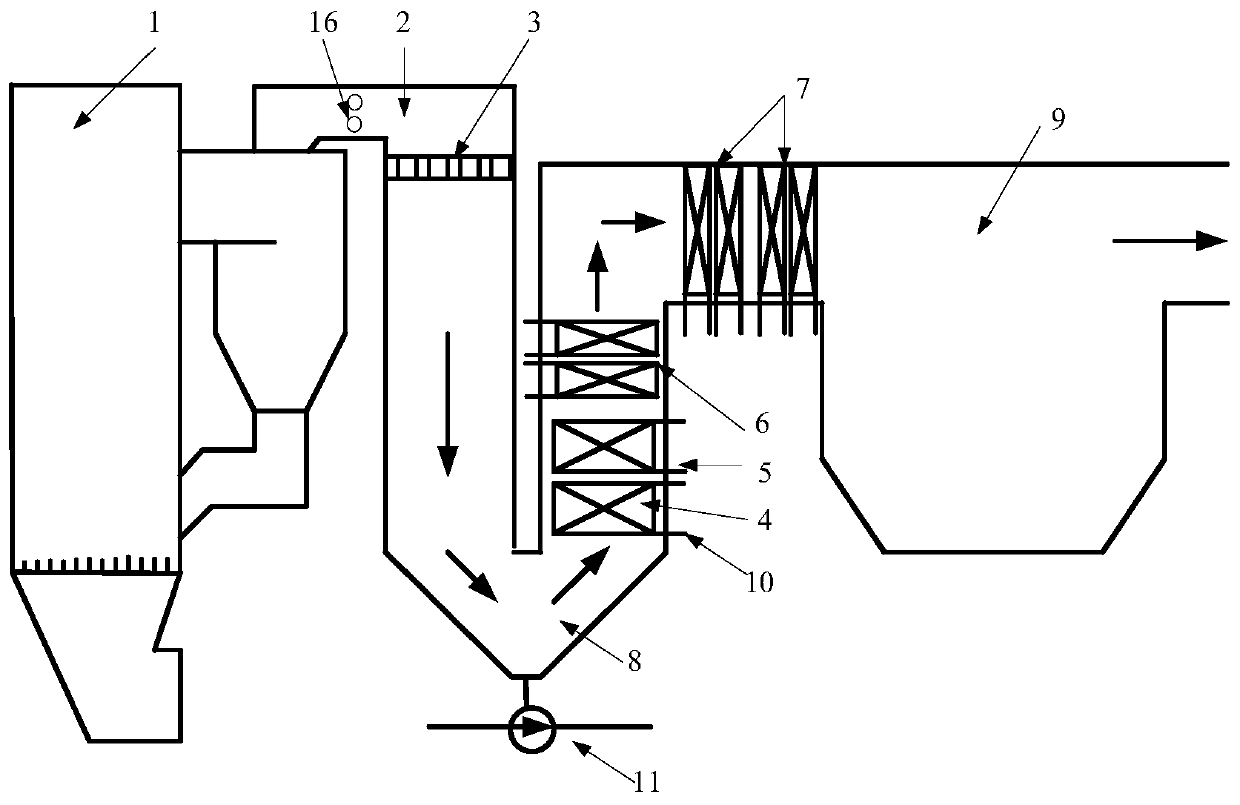

Intermediate temperature efficient modified SNCR denitration device of layer-burning boiler and method

ActiveCN105771608AHigh activityHigh selectivityGas treatmentDispersed particle separationPropanoic acidNitric oxide

The invention discloses an intermediate temperature efficient modified SNCR denitration device of a layer-burning boiler and a method, and belongs to the technical field of coal-fired boiler pollutant control. Amino and imido free radicals are generated by urea under the synergistic effect of H2O2 and organic acid (formic acid or acetic acid or propionic acid), and due to the fact that amino free radicals .NH2 or imido free radicals .NH has higher reaction activity and selectivity on nitric oxide, a temperature window of an SNCR reaction can be greatly reduced; meanwhile, a modified reducing agent atomizing nozzle is located in a furnace outlet turning room of the layer-burning boiler, sufficient mixing of a modified reducing agent and nitric oxide can be assisted by the area, and thus the utilization rate of urea is increased. The device and the method are economical and environmentally friendly, implementation is easy, and the denitration efficiency is high; besides the layer-burning boiler, the device and the method are also applicable to coal-fired power plants and other coal-fried industrial processes, and have wide application prospects and high market popularization value.

Owner:XI AN JIAOTONG UNIV

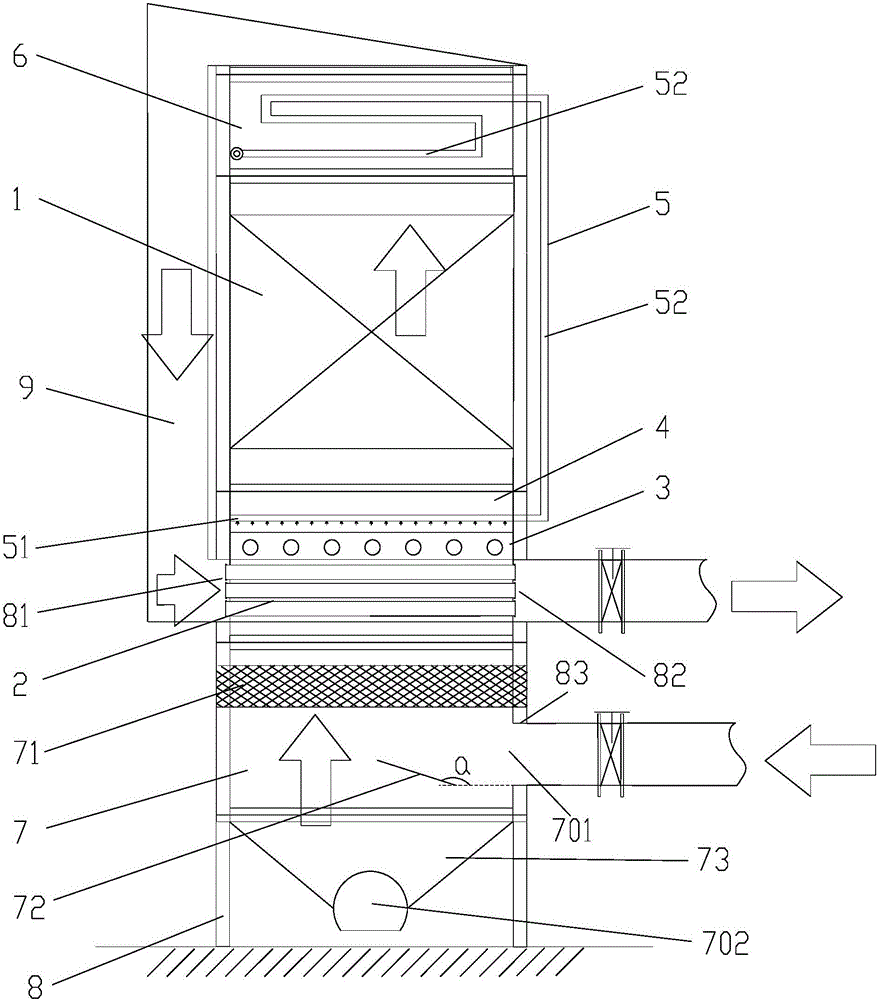

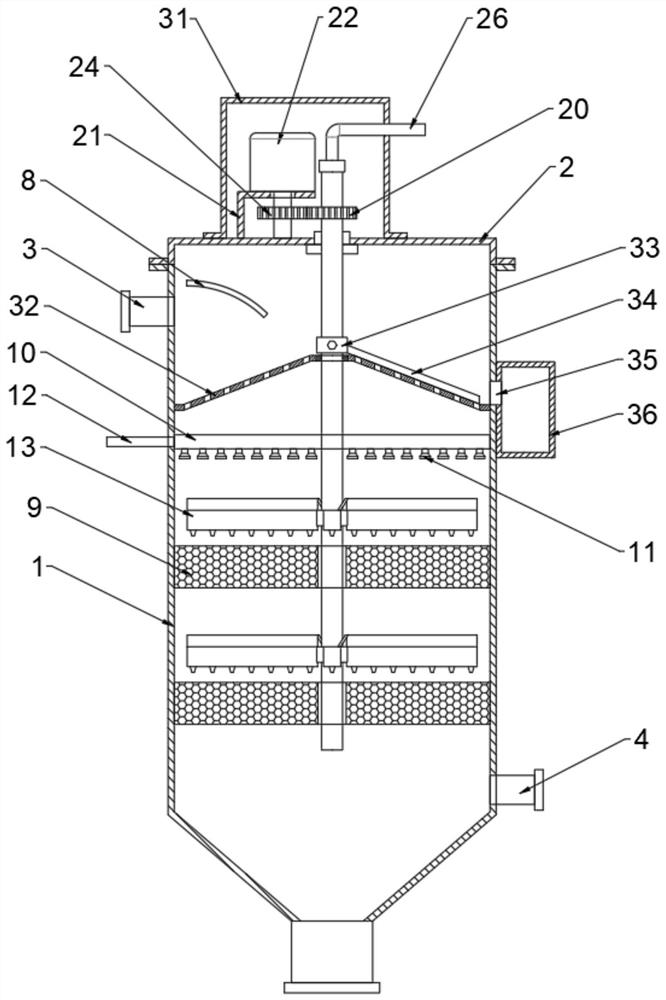

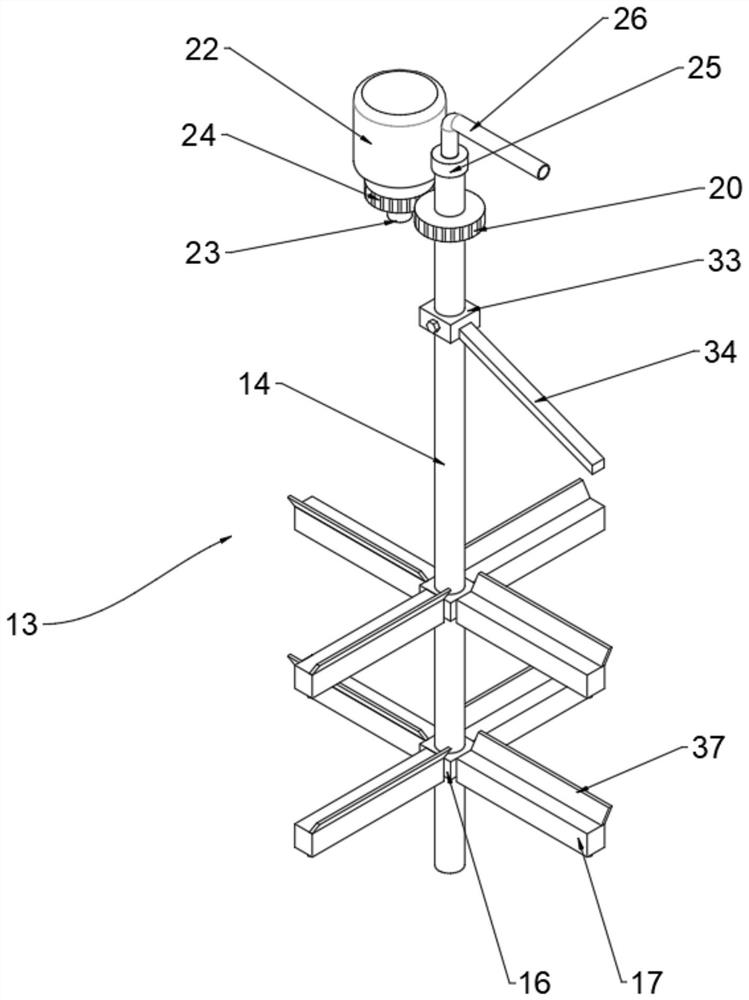

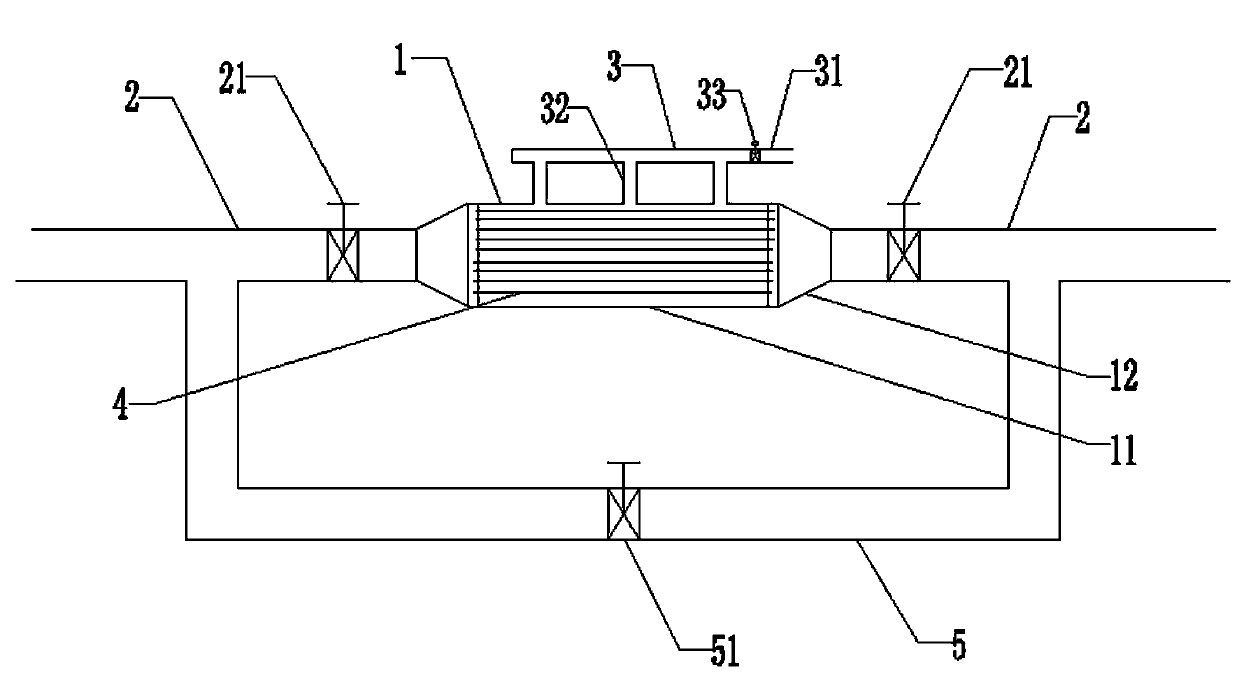

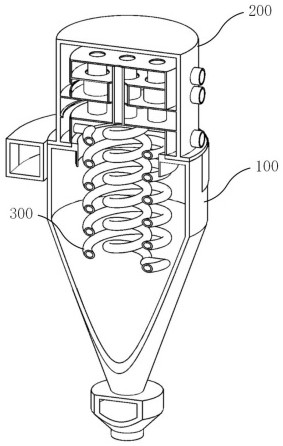

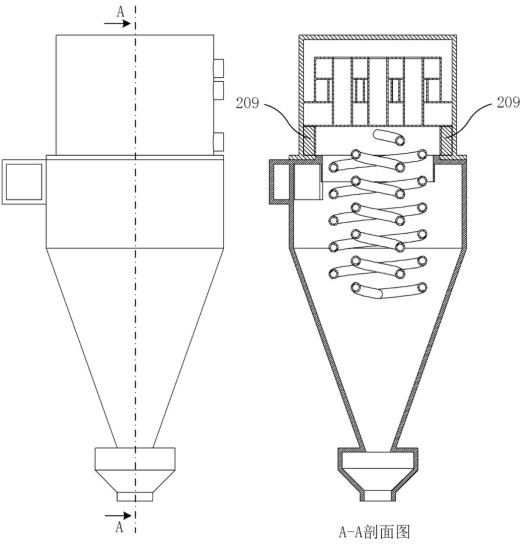

Boiler capable of improving SNCR reaction efficiency

PendingCN111197740AAdequate responseImprove the efficiency of denitrification reactionFluidized bed combustionIndirect carbon-dioxide mitigationThermodynamicsFlue gas

The invention discloses a boiler capable of improving SNCR reaction efficiency. The boiler comprises the boiler and a backpass, a flue gas outlet of the boiler is in communication with an inlet of thebackpass, and an outlet of the backpass is in communication with a dust remover; the backpass comprises a descending section and an ascending section in the medium flowing direction, the descending section and the ascending section communicate at the bottom of the backness, a SNCR reducing agent spray gun and a flow equalizing device are arranged at the inlet of the backpass in the medium flowingdirection, a heat-absorbing surface is arranged in the ascending section, and the flue gas flows through a heat insulation space of the descending section of the backpass after passing through an outlet of a furnace. By optimizing the arrangement of the heat-absorbing surface, so that the space can be within the SNCR reaction window temperature range, and meanwhile, it is guaranteed that SNCR hassufficient reaction time; a high-temperature superheater in the ascending section is arranged at the lowermost layer, so that the use amount of main steam pipeline metal material can be saved to themaximum extent, and the investment cost can be saved; the flue gas in the ascending section flows from bottom to top, dust accumulation can be avoided, and the boiler soot blowing operation cost can be saved.

Owner:HUANENG CLEAN ENERGY RES INST

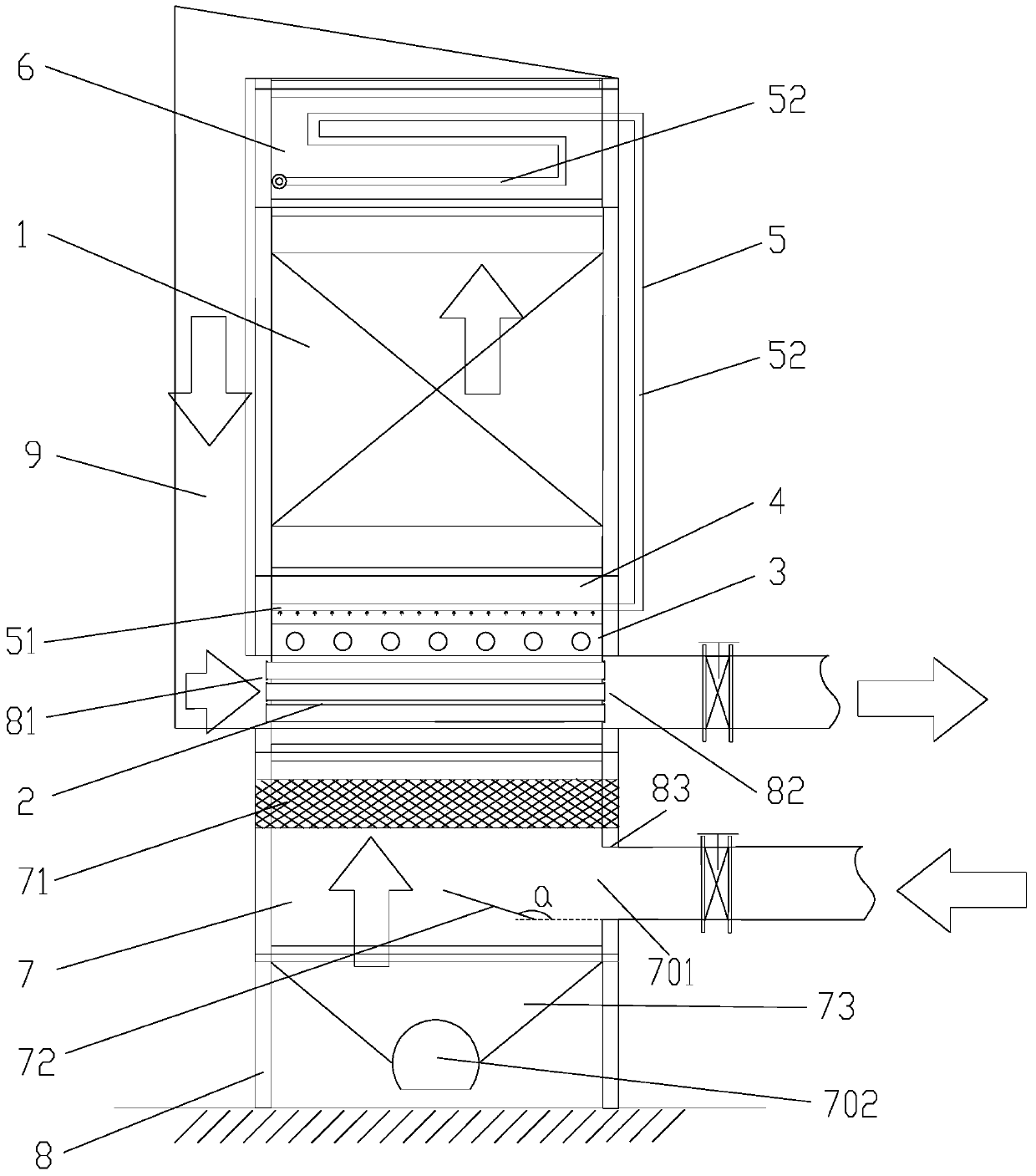

Integrated energy-saving scr denitrification device

ActiveCN105944565BIncrease profitLow running costLighting and heating apparatusDispersed particle separationPipeline transportProcess engineering

The invention provides an integrated energy-saving SCR denitration device. The integrated energy-saving SCR denitration device comprises an SCR denitration reaction chamber and a heat exchange chamber. Smoke before reaction is fed through a cold fluid inlet of the heat exchange chamber, and a cold fluid outlet is connected with a smoke inlet of the SCR denitration reaction chamber; a hot fluid inlet of the heat exchange chamber is connected with a smoke outlet of the SCR denitration reaction chamber, and a hot fluid outlet is a smoke outlet. Reacted high-temperature smoke serves as hot fluid to heat the smoke before reaction, waste heat of the reacted high-temperature smoke is sufficiently used, the energy use rate is increased, and running cost is reduced. According to the integrated energy-saving SCR denitration device, a dust removing chamber, the heat exchange chamber, a gas mixing chamber, the SCR denitration reaction chamber and a reduction agent evaporation chamber are integrally arranged in a cylinder shell in an optimized mode, design is compact, the pipe conveying flow of smoke is effectively shortened, no pipe is required between every two adjacent chambers, heat losses of smoke in the pipe conveying process are reduced, and meanwhile the occupied area of the denitration device is saved.

Owner:北京方信立华科技有限公司

A cement cellar flue gas denitrification device and its application method

ActiveCN113908678BGuaranteed denitrification efficiencyReduce denitrification operating costsDispersed particle separationDust controlCement kiln

Owner:山东东源新材料科技有限公司

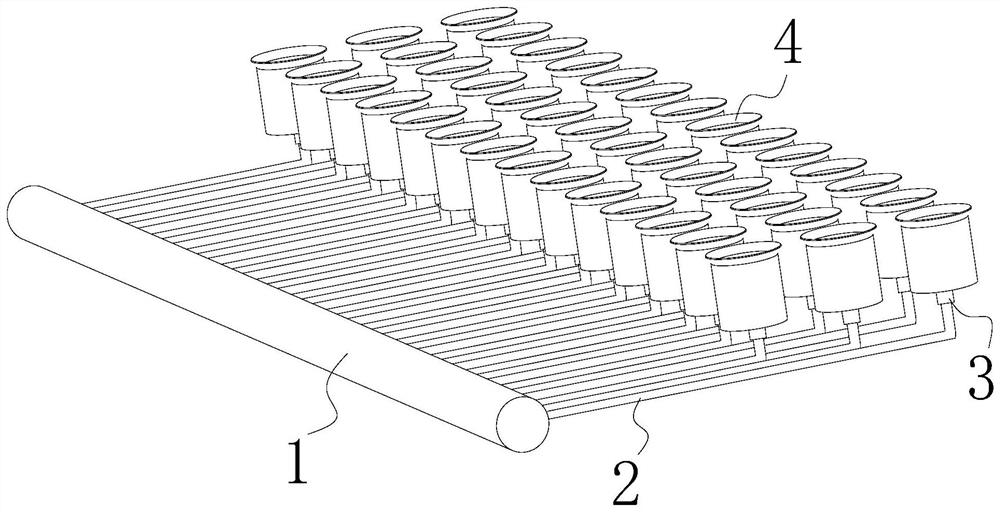

Ammonia spraying grid of SCR denitration system

PendingCN112221346AImprove the mixing effectImprove the efficiency of denitrification reactionGas treatmentDispersed particle separationThermodynamicsFlue gas

The ammonia spraying grid of the SCR denitration system comprises an ammonia spraying main pipe, ammonia spraying branch pipes, spraying heads and a rotational flow mixer, wherein the ammonia sprayingmain pipe is provided with the multiple ammonia spraying branch pipes, the ends, away from the ammonia spraying main pipe, of the ammonia spraying branch pipes are arranged upwards and connected withthe spraying heads, and the rotational flow mixer is fixed to the spraying heads; the rotational flow mixer comprises a barrel, a support and rotational flow blades, the barrel is of an up-down hollow structure, the inner wall of the barrel is connected with the spraying head through the support, and the rotational flow blades are fixed to the portion, above the support, of the inner wall of thebarrel in a circumferential array mode. The system has the advantages that through the arrangement of the rotational flow blades, flue gas in the SCR denitration system can generate strong rotationalmotion after flowing through the the rotational flow blades and can entrainment ammonia gas sprayed out of the spraying heads at the upper parts of the ammonia spraying branch pipes, so that the ammonia gas is strongly mixed with the flue gas, the mixing effect of the flue gas and the ammonia gas is enhanced, and the denitration reaction efficiency is improved.

Owner:CHINA DATANG CORP SCI & TECH RES INST CO LTD EAST CHINA BRANCH +1

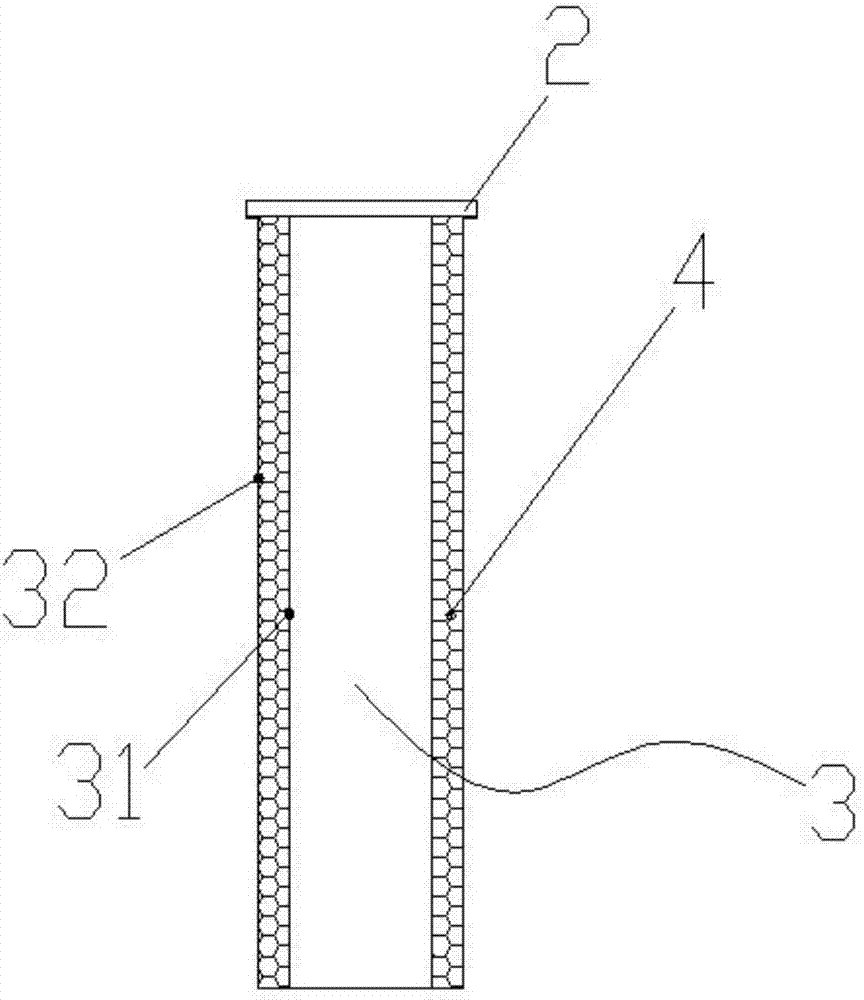

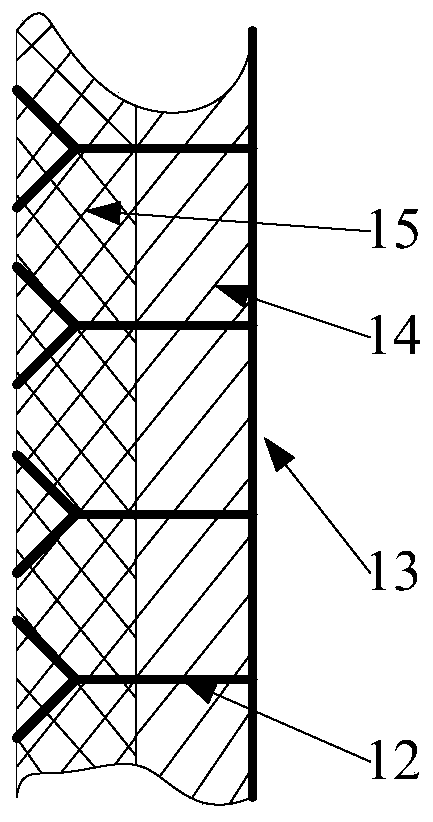

Strengthened biological water treatment denitrification reaction device

PendingCN106865761AEasy to separateImprove the efficiency of denitrification reactionWater contaminantsTreatment with anaerobic digestion processesSludgeSewage

The invention discloses a strengthened biological water treatment denitrification reaction device. The lower end of the reaction device is provided with an inlet water distributor, the upper end of the reaction device is provided with a sludge settling area, and the lower end of the sludge settling area is provided with a sludge backflow seam; a downflow weir is arranged between the reaction device and the sludge settling area. According to the strengthened biological water treatment denitrification reaction device, the denitrification reaction efficiency is high, and the mud-water separation effect is good; the settling area is constructed at the upper part of a reaction region, the structure is compact, a secondary sedimentation tank and a sludge backflow facility are saved, the size of a constructed structure is reduced, and damage of a reflux pump to granule sludge is avoided; reaction sewage continuously flows up at a certain speed in a device, and in the up-flowing process, the sewage makes full contact with the granule sludge to strengthen a mass transfer process; a dead zone does not exist in the reaction device, the fluidifying property of the sludge is good, and the runnability is stable; the reaction device has very good biological denitrification performance.

Owner:HUBEI JUNJI WATER TREATMENT

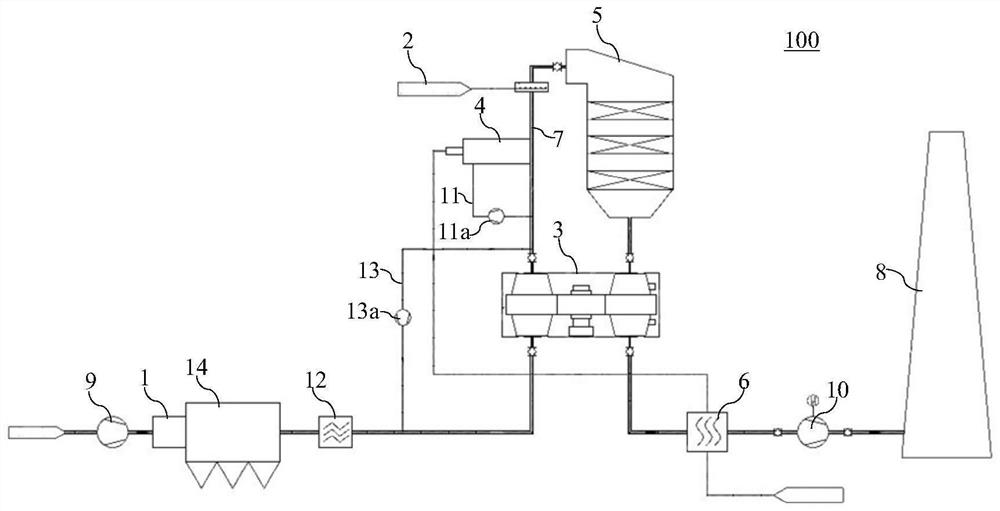

Flue gas treatment system

PendingCN112844044AImprove heat transfer efficiencyImprove the efficiency of denitrification reactionGas treatmentLighting and heating apparatusFlue gasTreatment system

The invention relates to a flue gas treatment system. The flue gas treatment system comprises an ammonia injection device, a first dividing wall type heat exchanger, a flue gas heater and a denitration reactor, wherein a heat absorption side flue gas inlet of the first dividing wall type heat exchanger is used for receiving flue gas, a heat absorption side flue gas outlet of the first dividing wall type heat exchanger is connected with a flue gas inlet of the ammonia injection device, and a flue gas outlet of the ammonia injection device is connected with a flue gas inlet of the denitration reactor; a flue gas outlet of the denitration reactor is connected with a heat release side flue gas inlet of the first dividing wall type heat exchanger, a heat release side flue gas outlet of the first dividing wall type heat exchanger is connected with a chimney, and treated flue gas is discharged through the chimney; and the flue gas heater is arranged between the first dividing wall type heat exchanger and the ammonia injection device and can heat flue gas which passes through the first dividing wall type heat exchanger and is less than 280 DEG C to 280-300 DEG C. The flue gas treatment system disclosed by the invention is used for improving the reaction efficiency of the denitration reaction of the flue gas treatment system when the flue gas temperature is relatively low, and the risk that the discharged flue gas harms the environment can be reduced.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

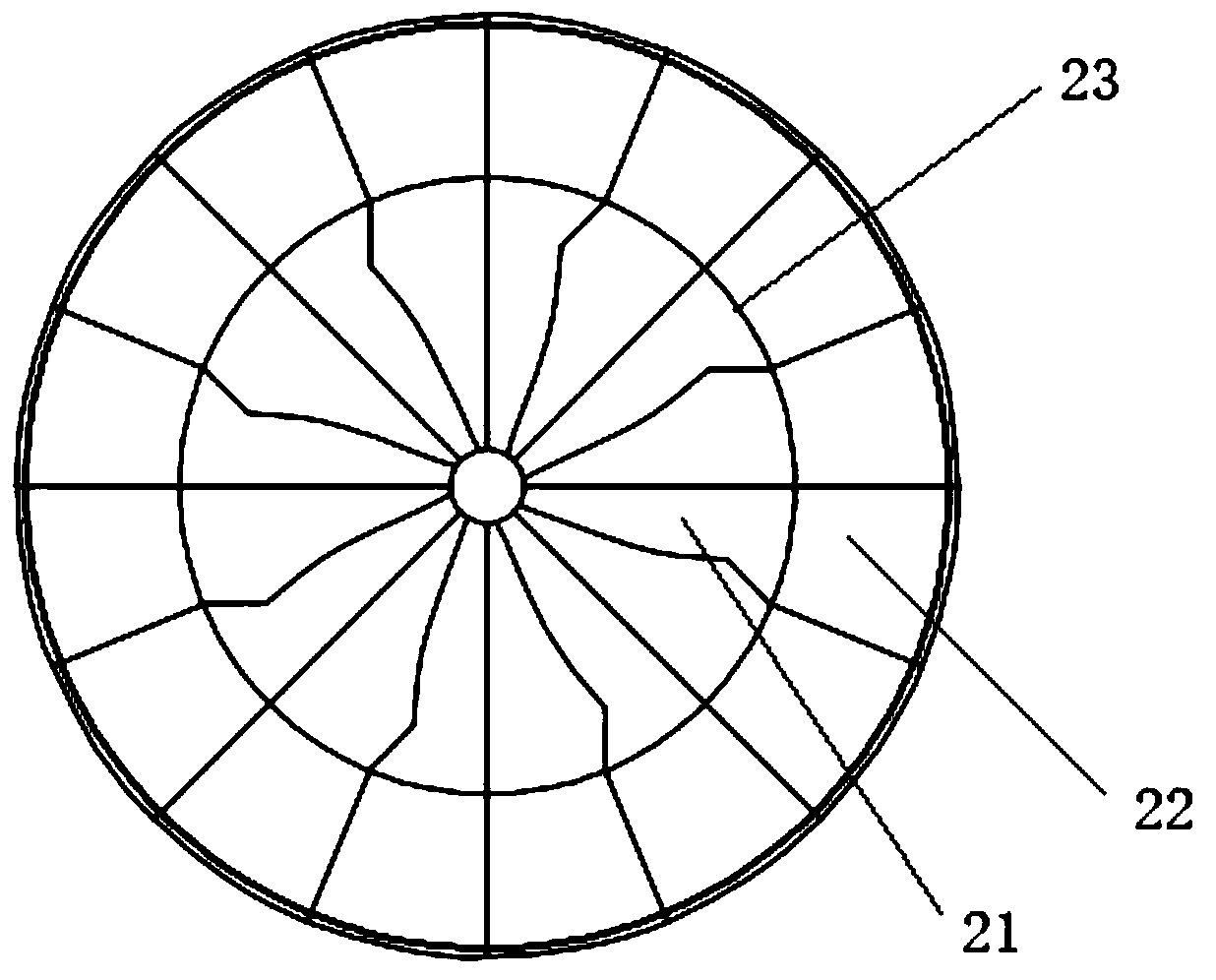

Flue gas cyclone mixing device of SCR denitration system

PendingCN110975656AImprove the mixing effectImprove the efficiency of denitrification reactionGas treatmentFlow mixersThermodynamicsFlue gas

The invention relates to a flue gas cyclone mixing device of an SCR denitration system. The flue gas cyclone mixing device comprises a cyclone mixer homogenizing device arranged behind ammonia spraying branch pipes in a flue gas flowing direction, wherein the cyclone mixer homogenizing device is composed of a plurality of cyclone mixers which are arranged in a tiled mode, and the rotational flow mixers are arranged to face the ammonia spraying branch pipes and used for covering diluted ammonia sprayed out of the ammonia spraying branch pipes; and each cyclone mixer is composed of an inner cyclone blade set and an outer cyclone blade set, the rotating directions of the two cyclone blade sets are opposite, and a circular partition plate used for dividing an airflow channel is arranged between the two cyclone blade sets. With the flue gas cyclone mixing device in the invention, the mixing effect of flue gas and diluted ammonia gas can be enhanced, and denitration reaction efficiency is improved.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST

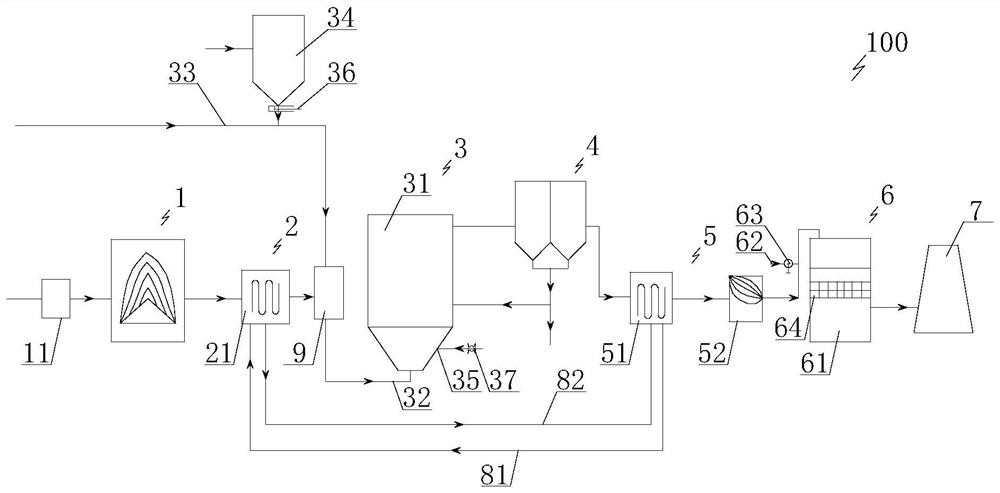

Denitration device for flue gas from cement kiln and use method of denitration device

ActiveCN113908678AGuaranteed denitrification efficiencyReduce denitrification operating costsDispersed particle separationThermodynamicsNitrogen oxides

The invention relates to the technical field of treatment of nitric oxide in flue gas from industrial kilns, in particular to a denitration device for flue gas from a cement kiln and a use method of the denitration device. The denitration device comprises a kiln tail flue, an SNCR denitration reaction unit, a preheater, a low-temperature dust removal unit, an SCR denitration reaction unit and a chimney which are sequentially connected along a flue gas flowing direction, wherein the SNCR denitration reaction unit comprises a first mixer; the SCR denitration reaction unit comprises a second mixer and an SCR reactor which are sequentially connected along the flue gas flowing direction; an ammonia gas source sprays ammonia gas into the first mixer and the second mixer respectively; and the low-temperature dust removal unit comprises a low-temperature dust remover. According to the denitration device for the flue gas from the cement kiln provided by the invention, denitration operation cost is reduced on the basis of ensuring denitration efficiency.

Owner:山东东源新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com