Selective non-catalytic reduction method for gasifying and atomizing biomass and used boiler

A biomass and gasification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low denitrification rate, single active ingredient, narrow temperature window, etc., and achieve simple boiler system and wide distribution , the effect of wide temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

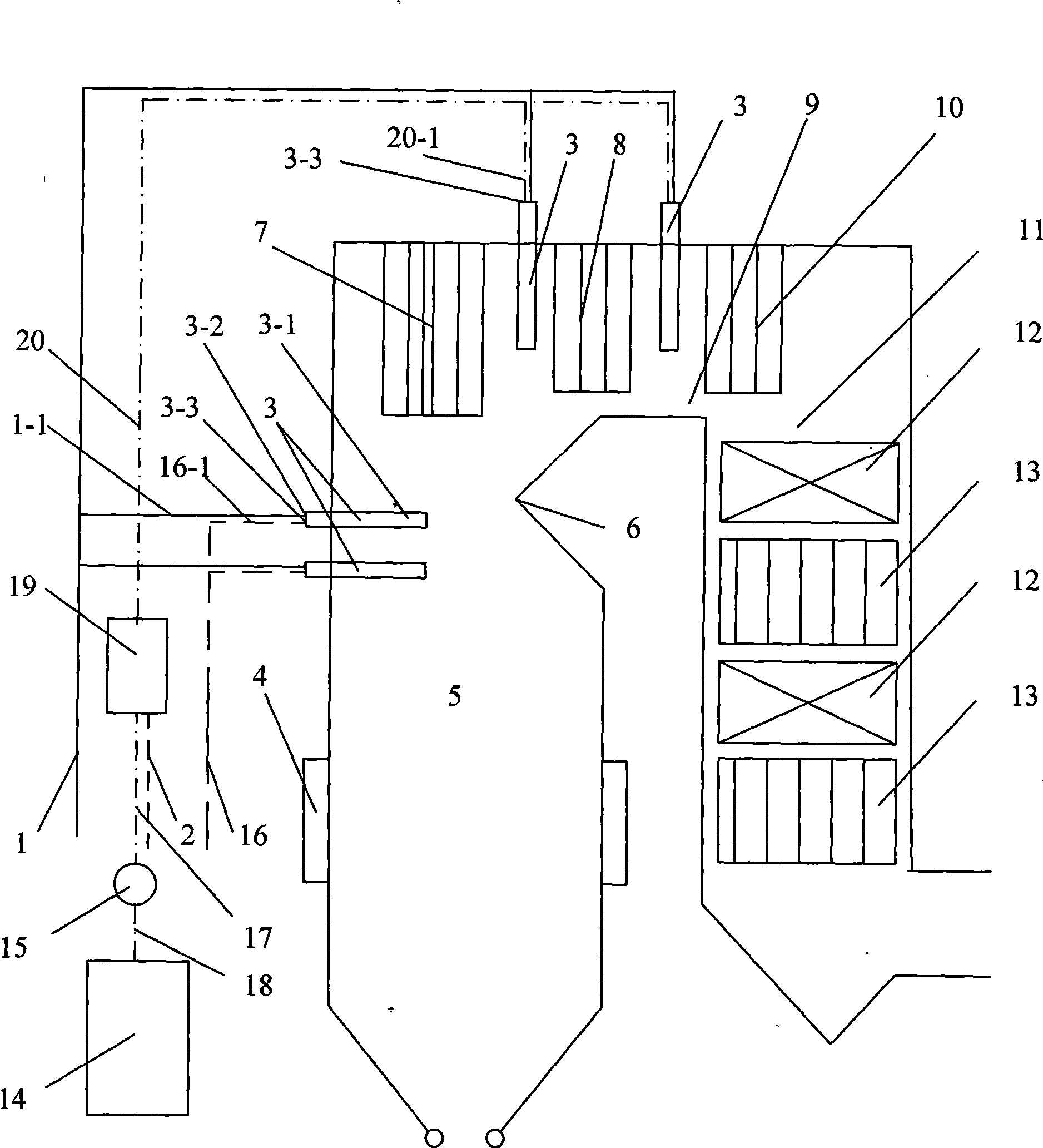

[0010] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a body, a burner 4, a panel superheater 7, a high and low temperature superheater 8, a reheater 10, two economizers 12 and two air preheaters 13, the body It is made of a furnace 5, a horizontal flue 9 and a tail flue 11. The outer wall of the furnace 5 is equipped with a burner 4, the panel superheater 7, a high and low temperature superheater 8 and a reheater 10 along the flue The flow direction of the gas in the horizontal flue 9 is installed in the horizontal flue 9 in sequence, and the two economizers 12 and the two air preheaters 13 are arranged at the tail at intervals along the flow direction of the flue gas in the tail flue 11 In the flue 11, the boiler also includes an amino reducing agent solution pipeline 1, a compressed air pipeline 2, an atomizing air pipeline 16, a plurality of spray guns 3, a biomass gasification device 14, a pressurizing device 15, an ...

specific Embodiment approach 2

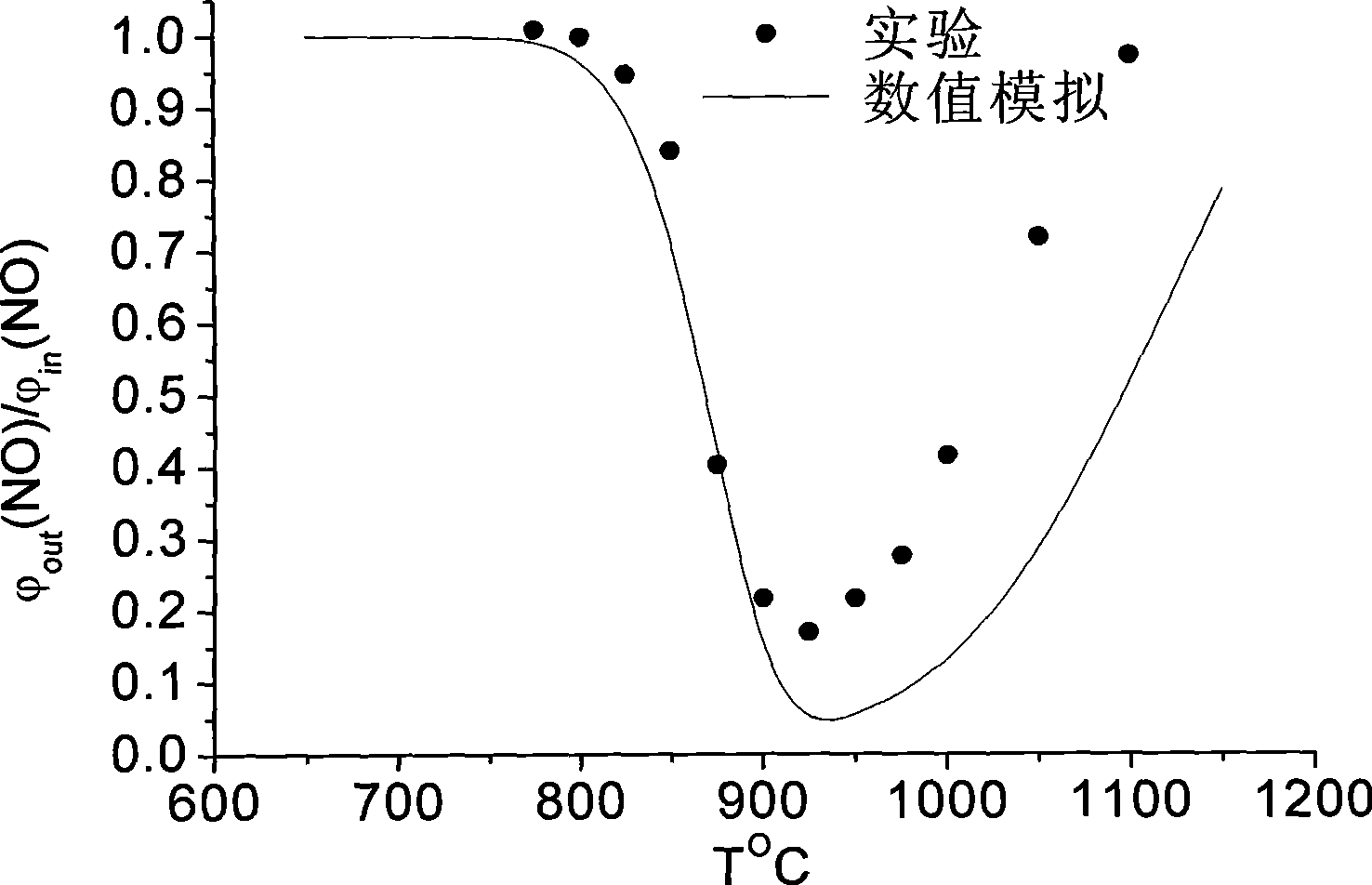

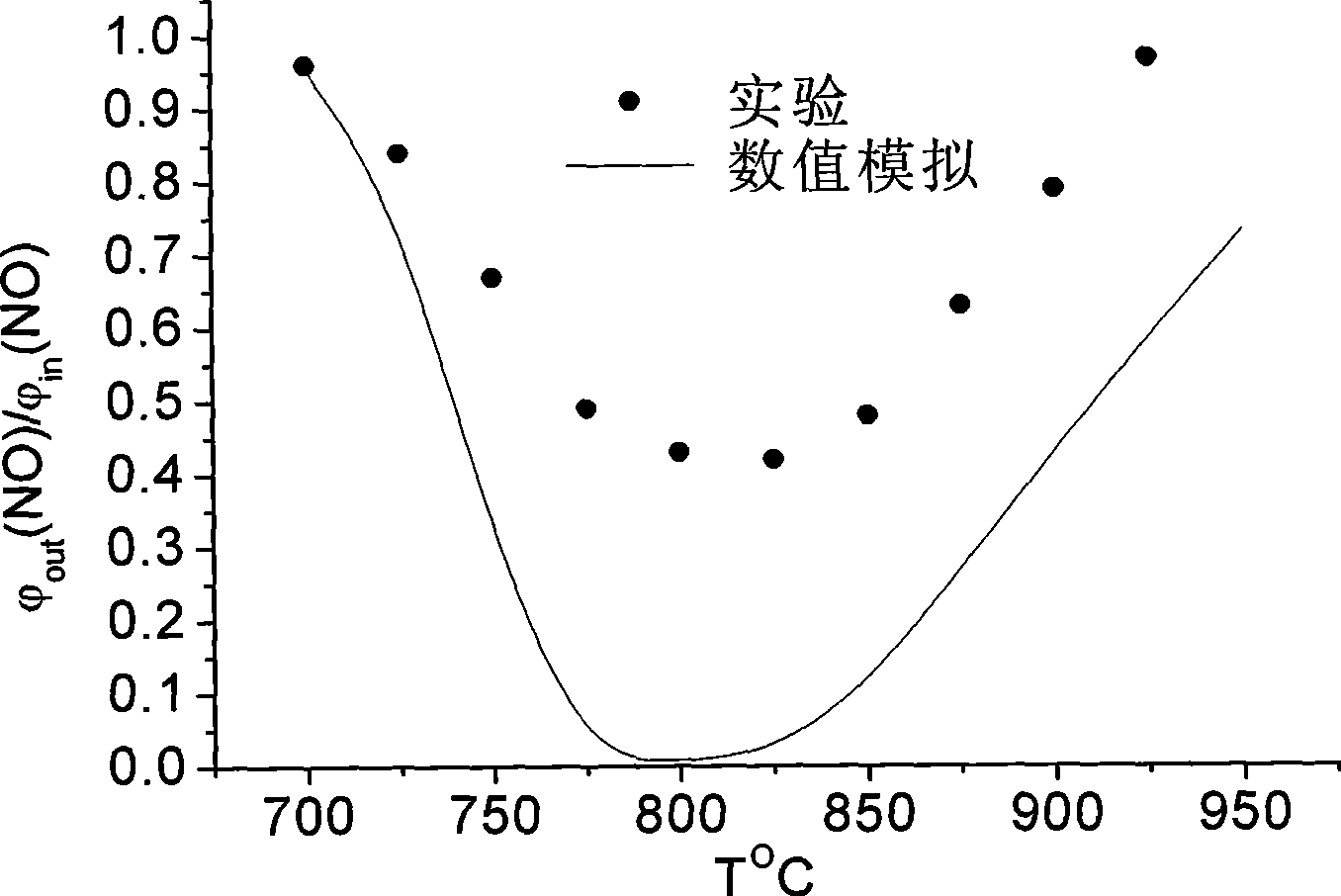

[0011] Specific implementation mode two: combination figure 1 Describe this embodiment, the selective non-catalytic reduction method of biomass gasification gas atomization of this embodiment is as follows: the amino reducing agent solution is filled in the amino reducing agent solution pipeline 1, and the amino reducing agent solution is injected into the amino reducing agent solution through a plurality of spray guns 3 Spray into the furnace 5 and the horizontal flue 9 near the refraction angle 6, the temperature range in the furnace 5 and the horizontal flue 9 near the refraction angle 6 is 900 ° C ~ 1100 ° C, using compressed air as the atomizing medium The atomized air pipeline 16 is sprayed into the furnace 5 and the horizontal flue 9 together with the ammonia reductant solution through the nozzle 3 arranged on the furnace 5 and the horizontal flue 9; the biomass produced by the biomass gasification device 14 is gasified The gas is charged into the biomass gasification ...

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the total amount of the injection of the amino reducing agent solution is based on the NH produced by the reducing agent 3 The molar ratio of NOx in the flue gas before spraying with the amino reducing agent solution is 1.1-1.5. In this embodiment, the consumption of the amino reducing agent solution is equivalent to that of conventional SNCR, and the denitrification efficiency reaches 37-62% by adjusting the injection proportion of the amino reducing agent solution and biomass gasification gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com