Patents

Literature

348 results about "Selective non-catalytic reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

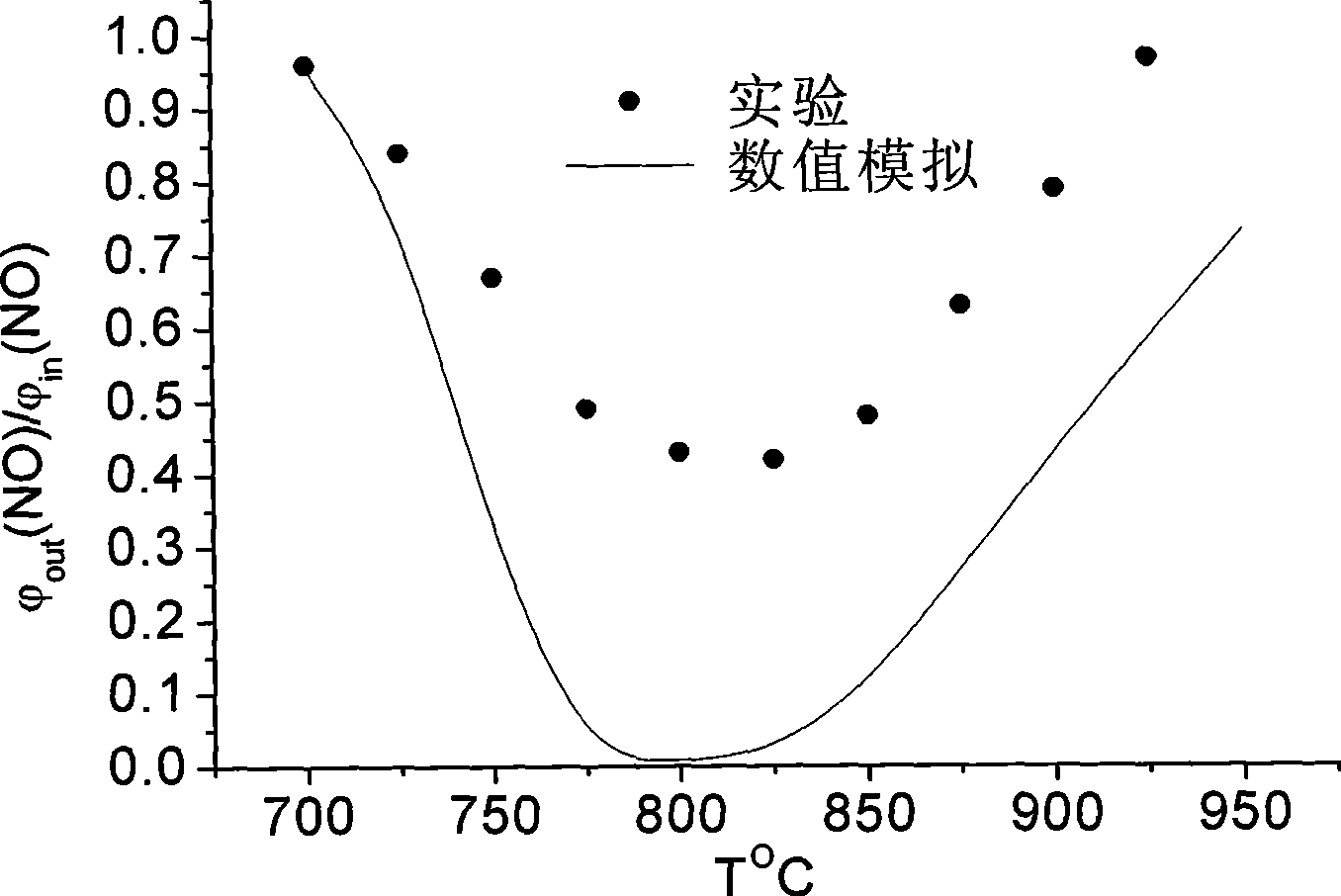

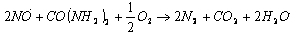

Selective non-catalytic reduction (SNCR) is a method to lessen nitrogen oxide emissions in conventional power plants that burn biomass, waste and coal. The process involves injecting either ammonia or urea into the firebox of the boiler at a location where the flue gas is between 1,400 and 2,000 °F (760 and 1,090 °C) to react with the nitrogen oxides formed in the combustion process. The resulting product of the chemical redox reaction is molecular nitrogen (N₂), carbon dioxide (CO₂), and water (H₂O).

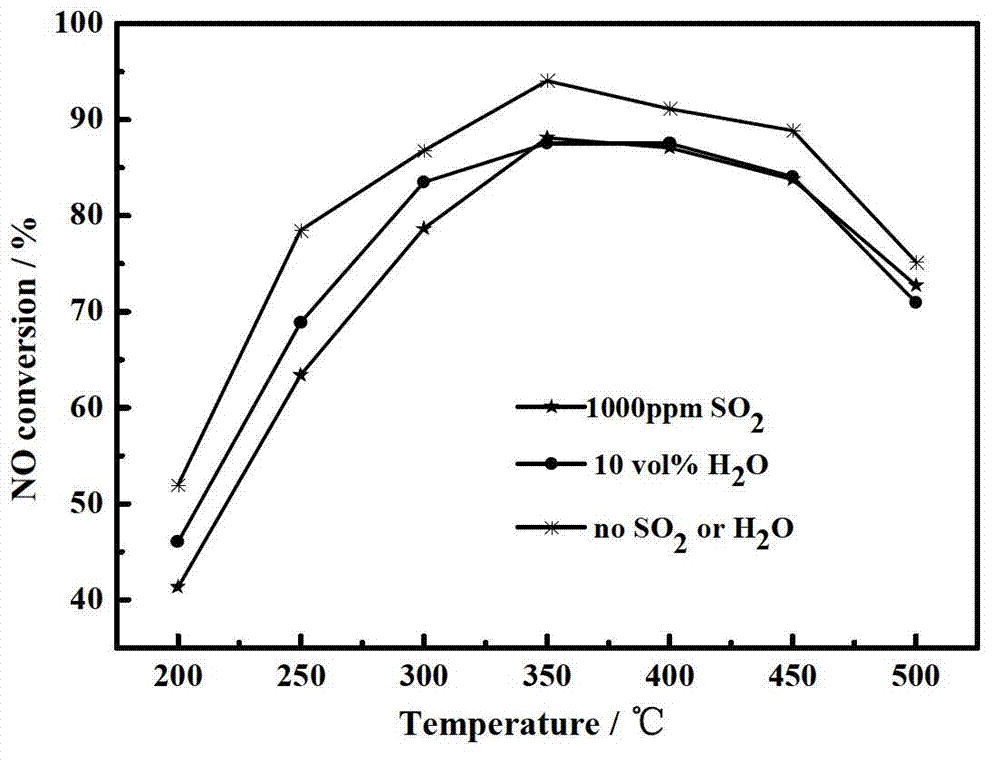

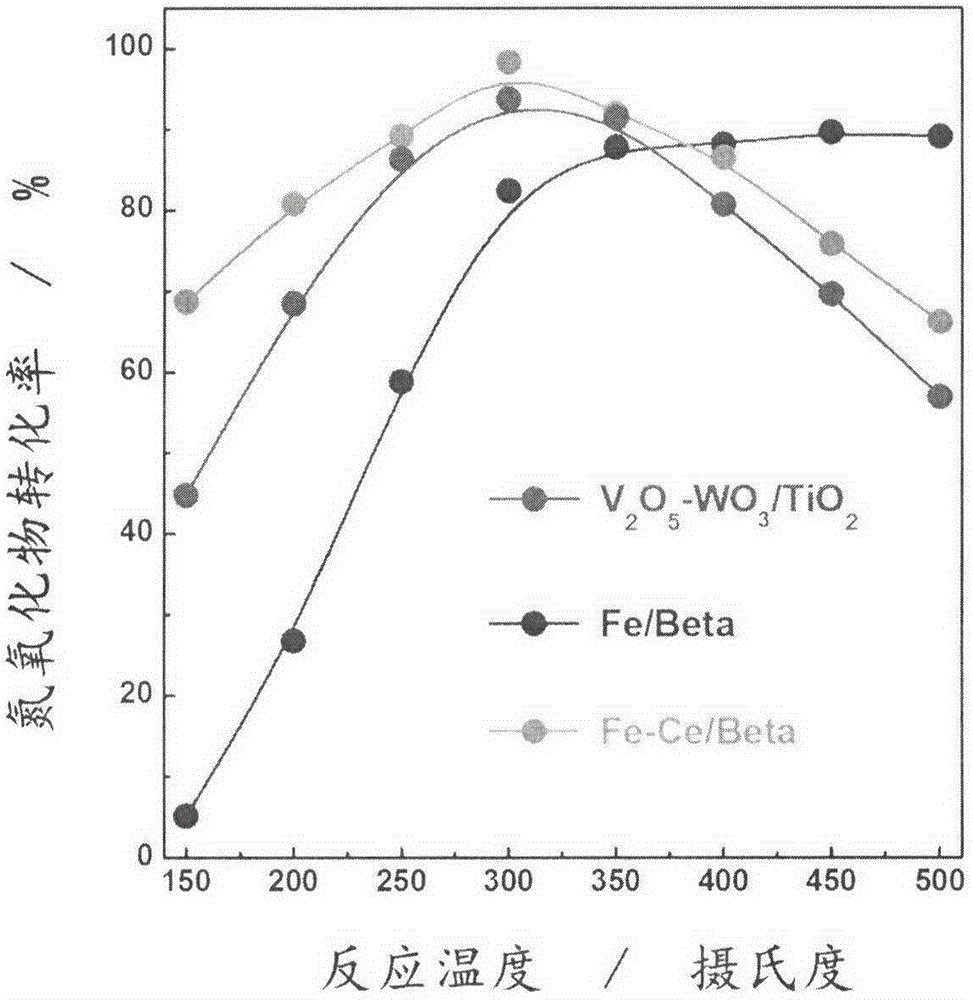

Method for preparing low-temperature SCR (selective catalytic reduction) denitration catalyst

InactiveCN102716752AGood activity at low temperatureHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideAmmonium metavanadate

The invention relates to a method for preparing a low-temperature SCR (selective catalytic reduction) denitration catalyst, and belongs to the technical field of catalysis. The denitration catalyst has a good nitric oxide removal rate, water resistance and sulfur resistance when the temperature of flue gas ranges from 150 DEG C to 250 DEG C. The method includes dissolving ammonium metavanadate, transition metal salts and titanium and tungsten powder in water; and drying and calcining the mixed liquor to prepare the low-temperature SCR denitration catalyst. The prepared catalyst is good in low-temperature activity, and can keep the good nitric oxide removal rate, the water resistance and the sulfur resistance at the temperature ranging from 150 DEG C to 250 DEG C. In addition, owing to the high activity and poison resistance at the temperature ranging from 150 DEG C to 250 DEG C, the catalyst can be applied to the field of flue gas after the flue gas flows via dust catchers of thermal power plants and flue gas, with the temperature ranging from 150 DEG C to 250 DEG C, of industrial furnaces and the like, and denitration catalyst technology and application breakthrough is realized.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

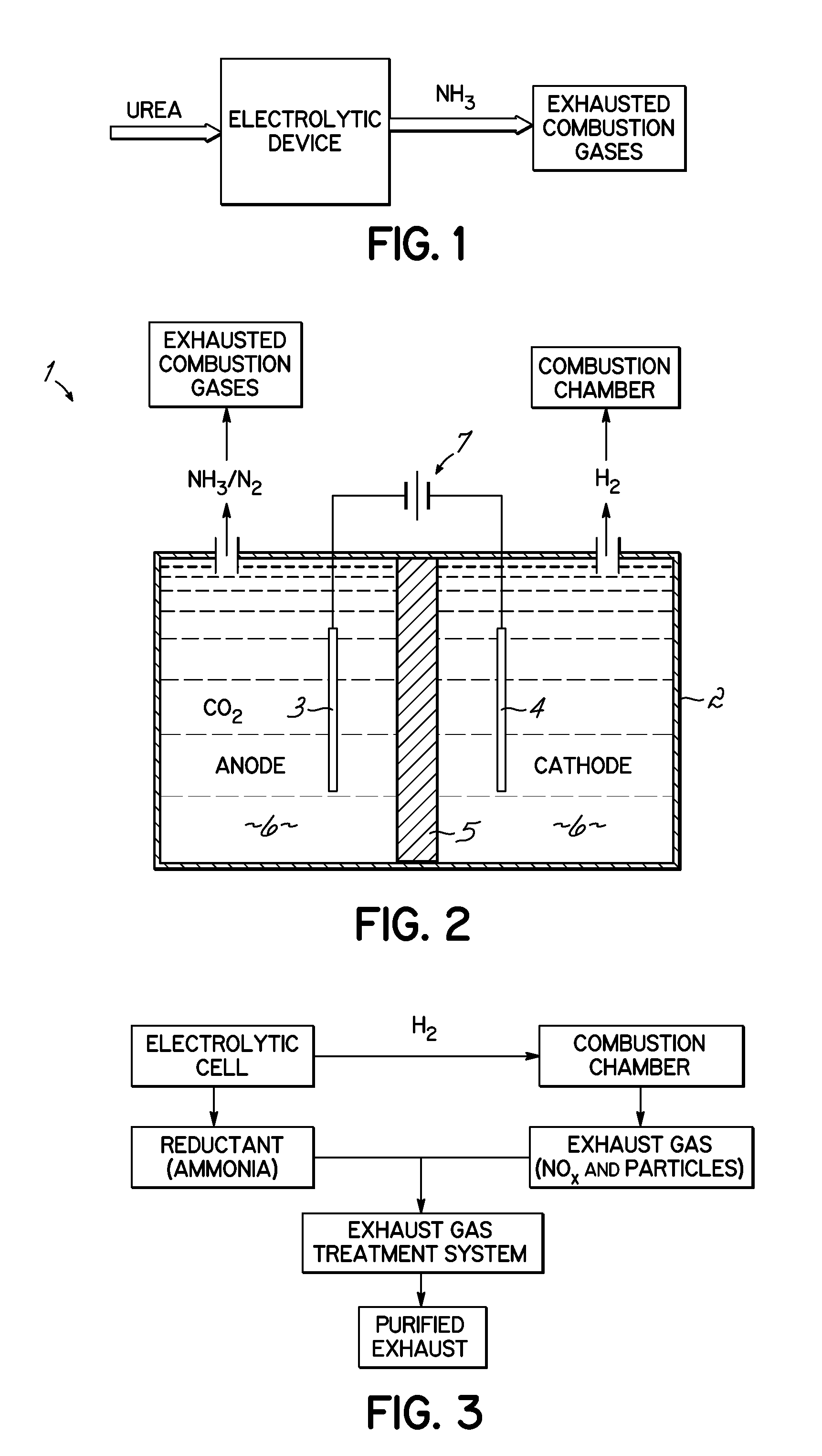

Selective Catalytic Reduction Via Electrolysis of Urea

A method for producing ammonia suitable for use as a reductant in a combustion exhaust gas treatment system is provided that includes the electrolytic hydrolysis of urea under mild conditions. The ammonia generator, which includes an electrolysis apparatus including an electrolytic flow cell, an alkaline electrolyte composition, and a recirculation system, may be operatively coupled to an exhaust gas treatment system to provide an apparatus for reducing nitrogen oxides (NOx) and / or particulate in exhaust gases.

Owner:OHIO UNIV

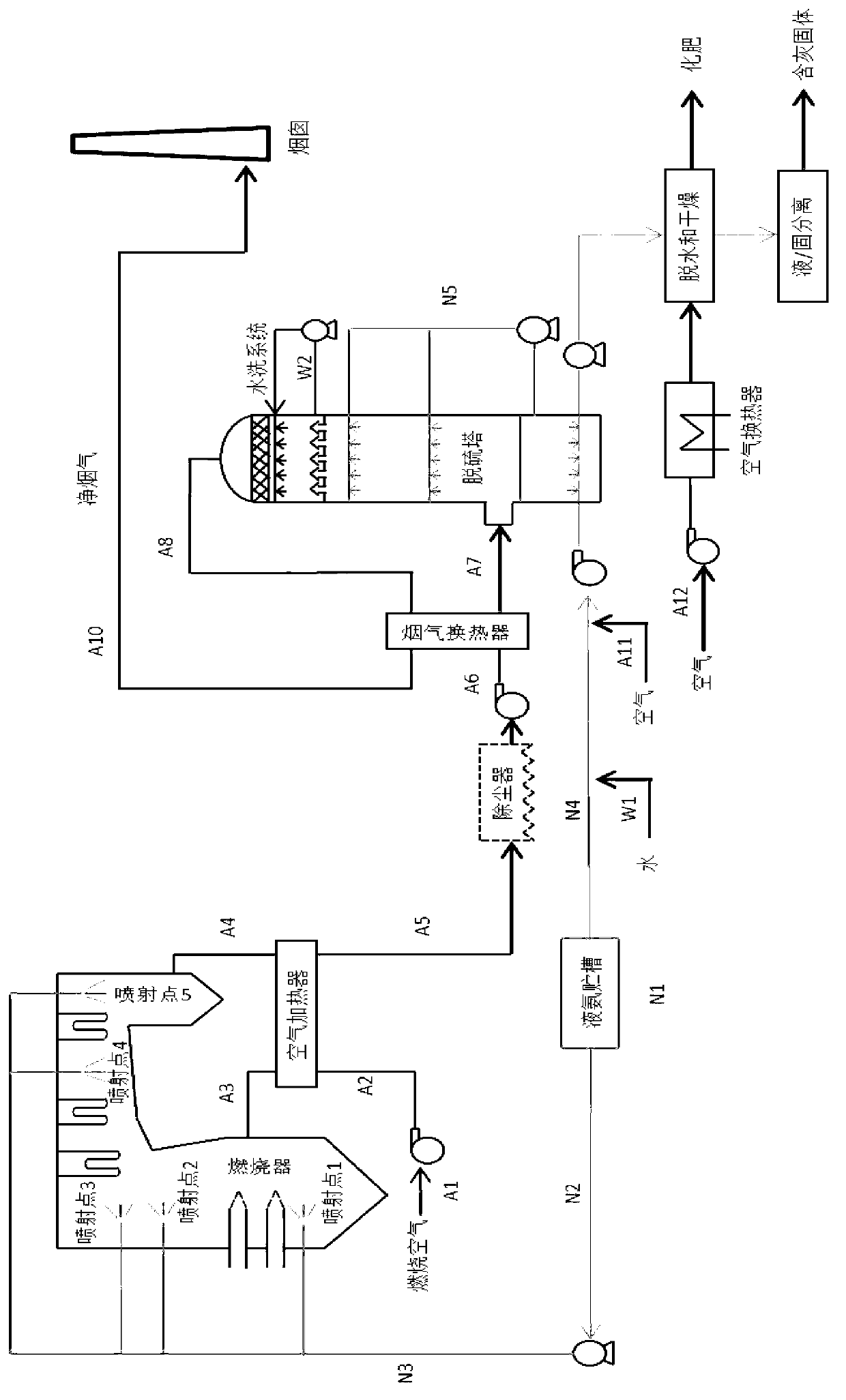

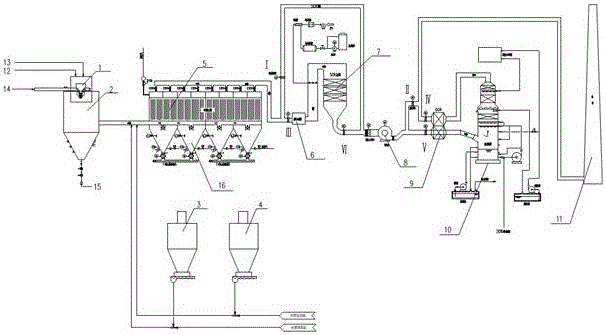

Method and device for combined removal of nitric oxide and sulfide in flue gas

InactiveCN103212284AGet rid of industrial designFully contactedDispersed particle separationAmmonium salt fertilisersBoiler furnaceFlue gas

The invention relates to a method for combined removal of nitric oxide and sulfide in flue gas. The method is characterized by comprising the following steps: spraying gasified ammonia into a furnace of a reaction boiler; reducing NOX in the flue gas to N2 by using a selective non-catalytic reduction method; sending the flue gas into a desulfurization tower; absorbing the SO2 in the flue gas by ammonia water added into the desulfurization tower; and discharging purified gas through a chimney. The invention also relates to a device for combined removal of nitrogen oxide and sulfide in flue gas. The device includes: (A) a combustion boiler used for the combustion of coal and provided with more than one ammonia injection points in the boiler furnace; (B) the desulfurization tower; and (C) an emptying device.

Owner:孙琦 +1

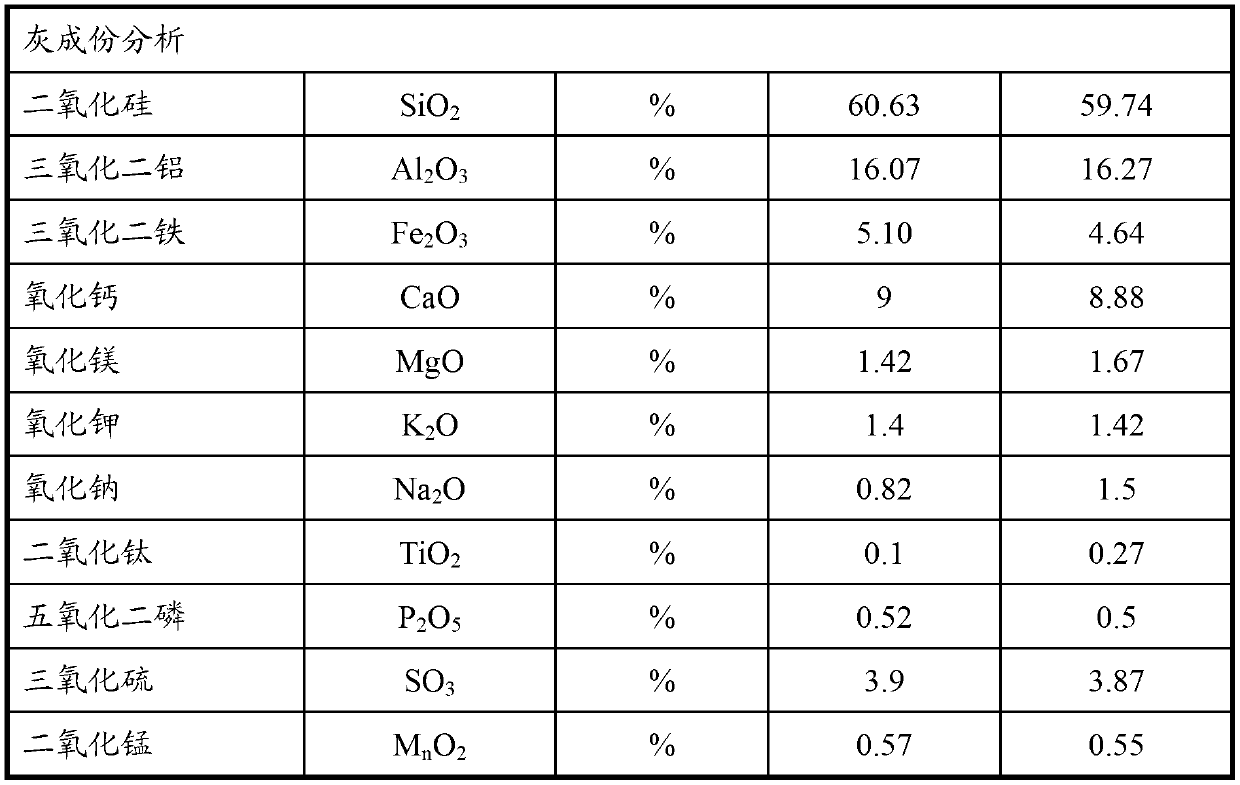

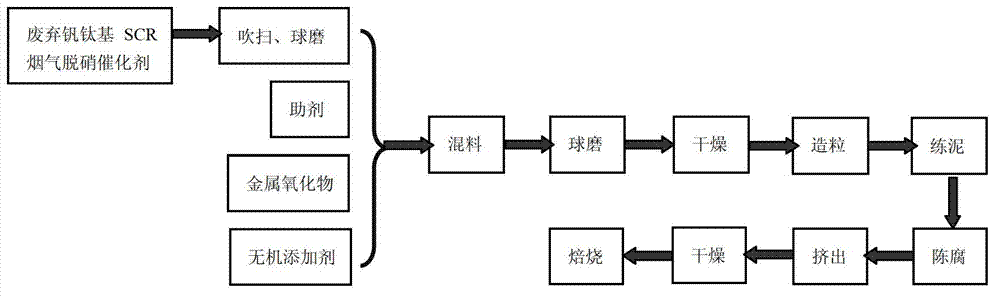

Regeneration method for waste vanadium-titanium-based SCR (Selective Catalytic Reduction) flue gas denitrification catalyst

ActiveCN102962079AIncrease profitReduce governance costsMetal/metal-oxides/metal-hydroxide catalystsBall millWater intoxication

The invention relates to a regeneration method for a waste vanadium-titanium-based SCR (Selective Catalytic Reduction) flue gas denitrification catalyst, comprising the following concrete steps of: (1) purging the waste vanadium-titanium-based SCR flue gas denitrification catalyst and ball-milling the purged waste vanadium-titanium-based SCR flue gas denitrification catalyst to obtain a reclaimed material of the waste vanadium-titanium-based SCR flue gas denitrification catalyst; (2) mixing a metal oxide, an assistant, an inorganic additive and the reclaimed material of the waste vanadium-titanium-based SCR flue gas denitrification catalyst, ball-milling and drying to obtain regenerated SCR flue gas denitrification catalyst powder; (3) adding a proper amount of binder, lubricating agent and water into the regenerated SCR flue gas denitrification catalyst powder to be uniform, then, pelleting, pugging, ageing and carrying out extrusion molding to obtain a regenerated SCR flue gas denitrification catalyst green body; and (4) drying and calcining the green body to obtain a regenerated SCR flue gas denitrification catalyst. The regeneration method provided by the invention is simple in process, low in cost and low in environment pressure. The regenerated SCR flue gas denitrification catalyst is higher in denitrification activity, wider in activity temperature window, better in sulfur and water intoxication resistance and higher in mechanical strength.

Owner:NANJING UNIV OF TECH

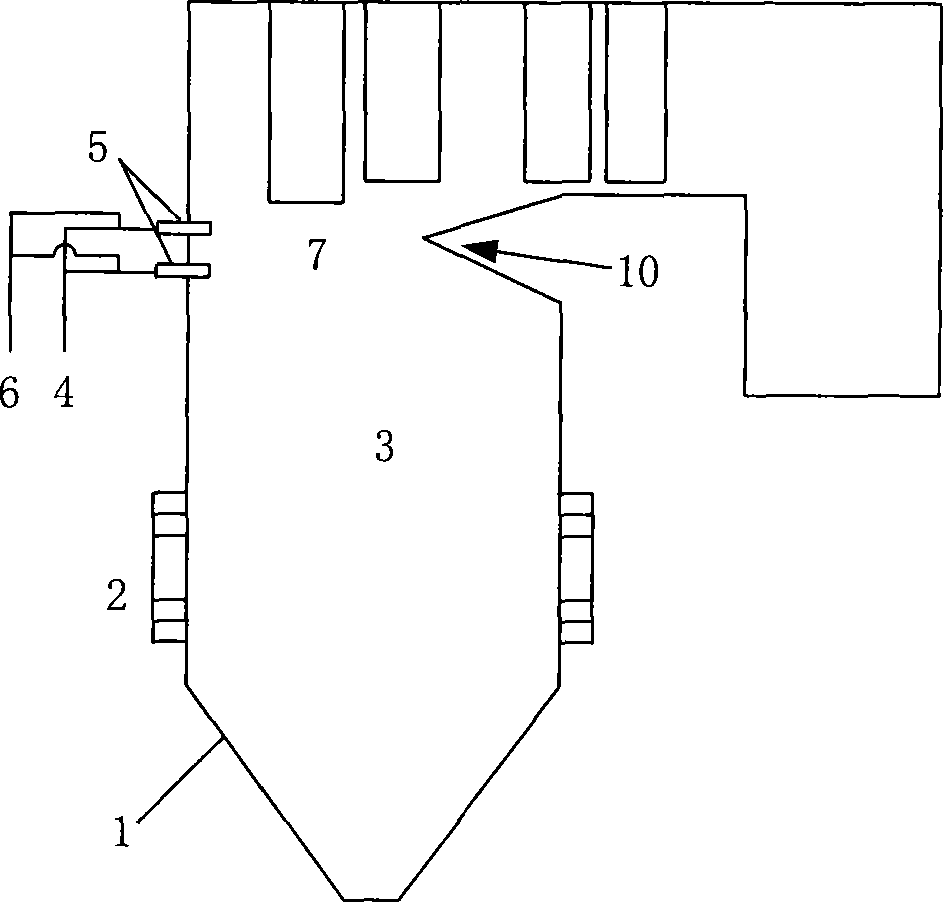

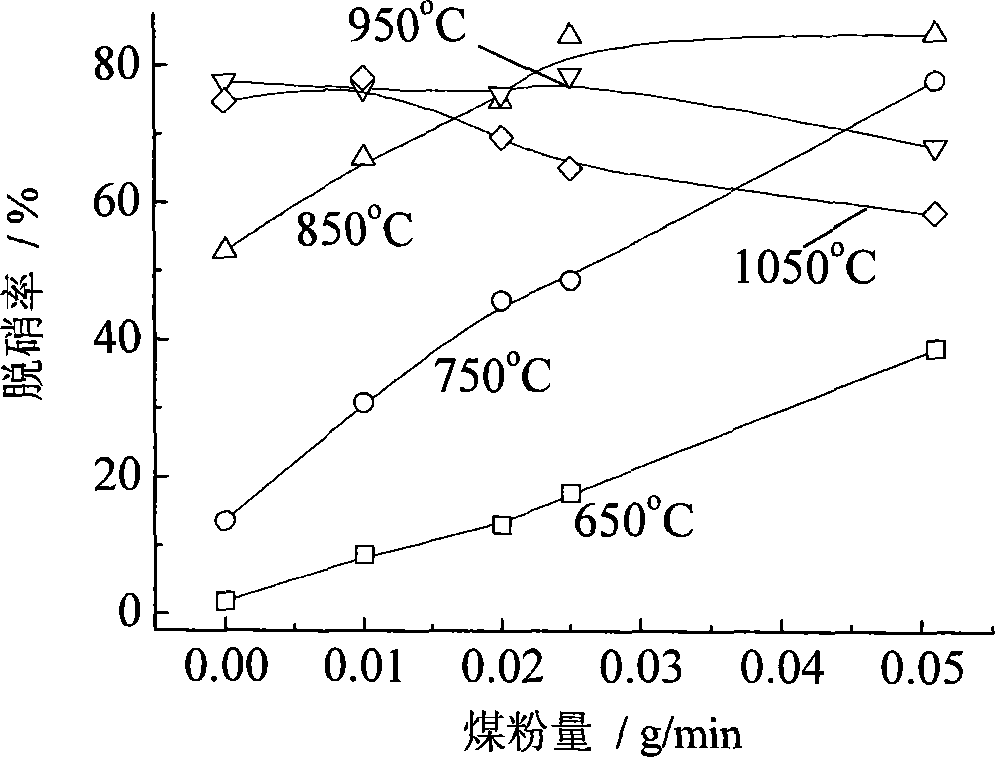

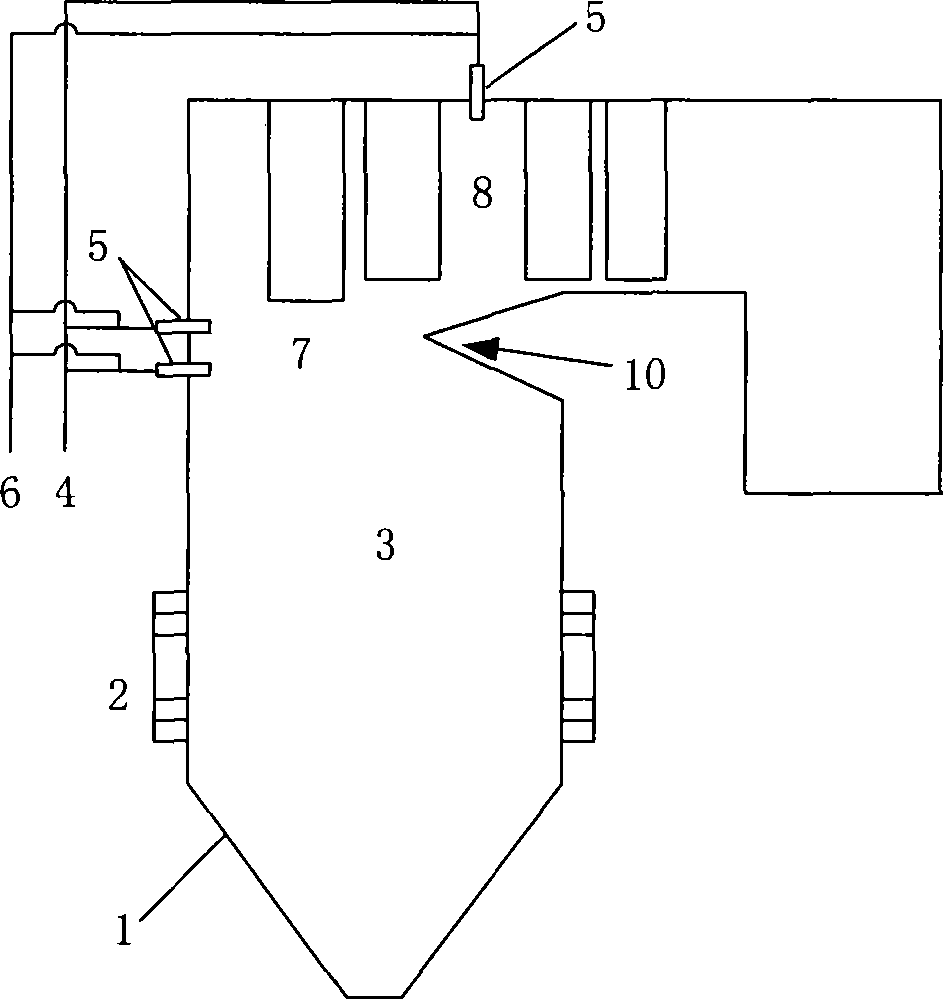

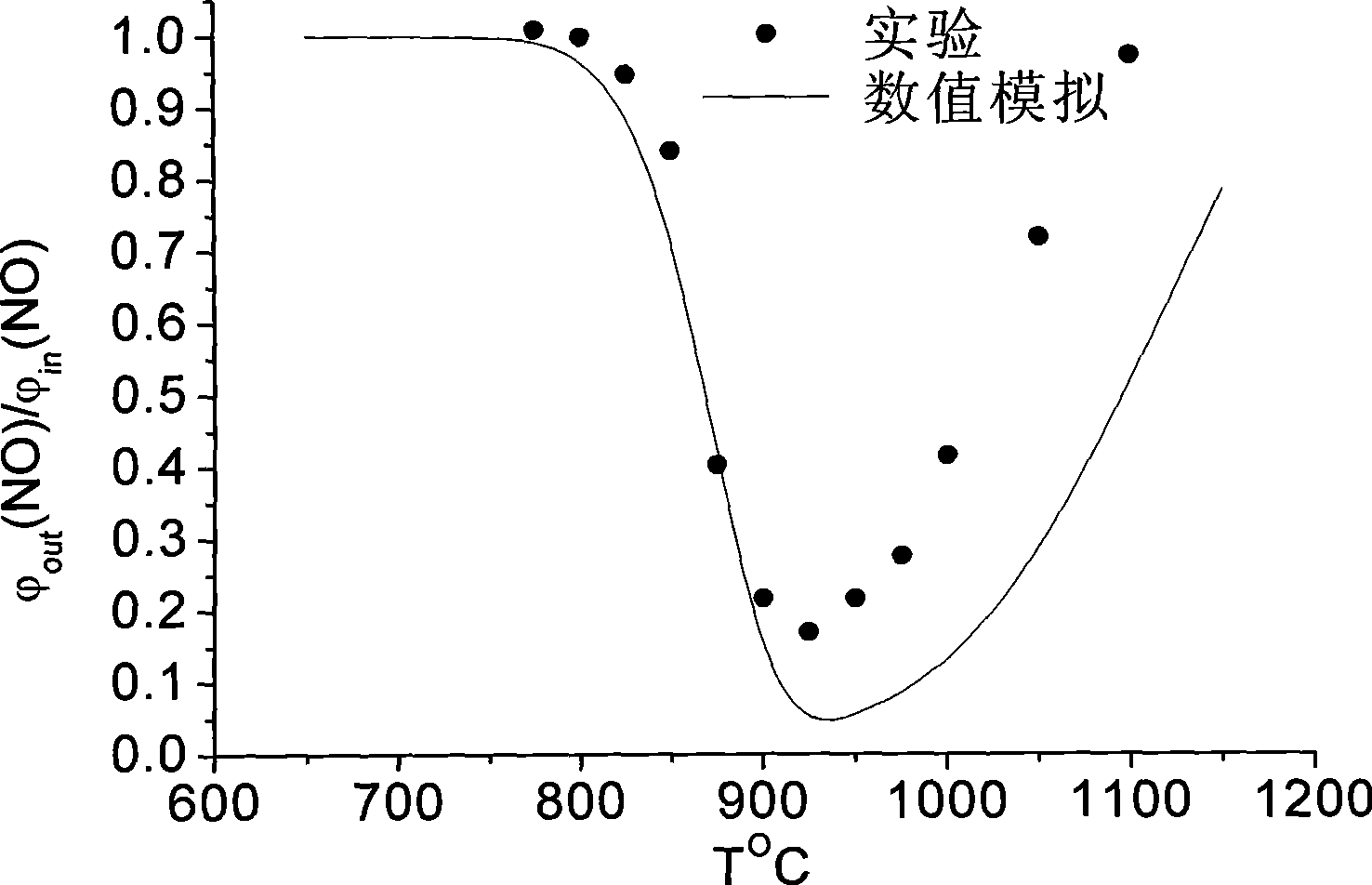

Method for accelerating selective non-catalytic reduction of nitrogen oxides

InactiveCN101244361AWiden the temperature rangeIncrease reaction rateDispersed particle separationRetention timeReaction rate

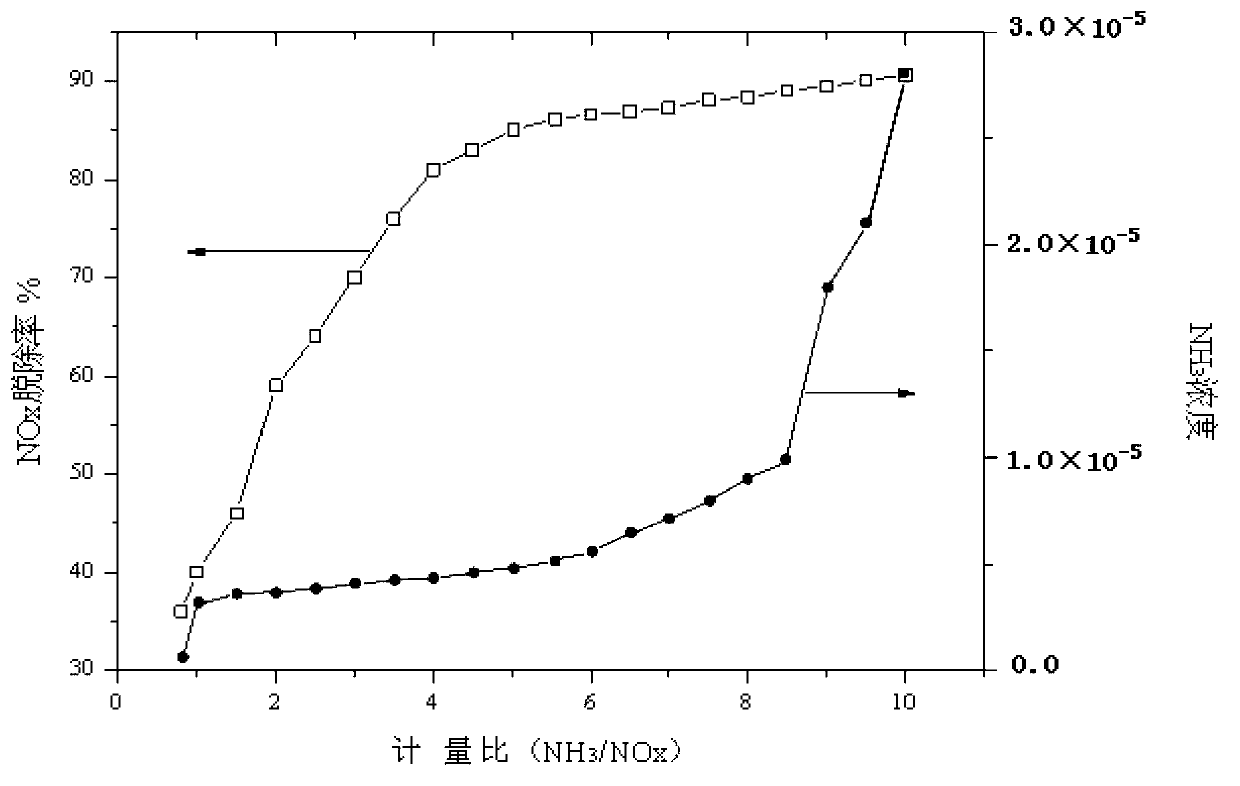

The invention relates to a promoting method for selective non-catalytic reduction (SNCR) of nitrogen-oxide, which is a technological method of adding addition agent to promote the denitrification process in the SNCR denitrification process for the power plant boiler and industrial furnace and other members, belonging to the nitrogen-oxide control technical field. The invention discloses a SNCR nitrogen-oxide method with the coal dust, natural gas or syngas as addition agent, in allusion to the problem of narrow suitable temperature range and lacking retention time existing in general SNCR denitrification technical application, which is characterized in that: the denitrification reaction rate is increased; the temperature range suitable for SNCR reaction is widen; the denitrification rate is increased and the leakage of ammonia is decreased. The promoting SNCR nitrogen-oxide method has advantages that: the reform is simple; the implementing is easy; the adoptive addition agent is cheap and available; the dosage is a little, so the combust process in the furnace is not influenced and no obvious secondary pollution is brought.

Owner:TSINGHUA UNIV

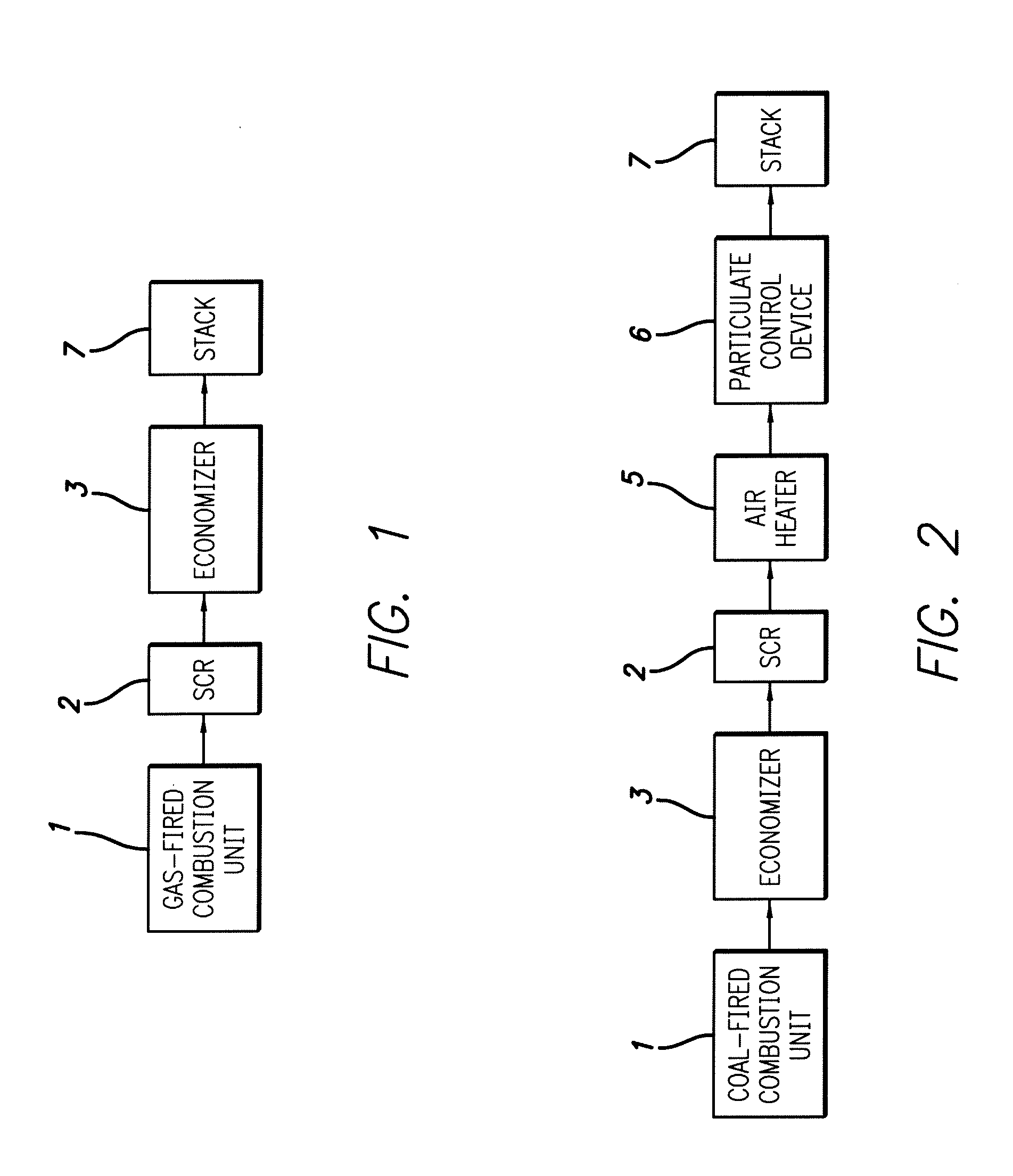

BIOMASS BOILER SCR NOx AND CO REDUCTION SYSTEM

InactiveUS20110311424A1High NOx control efficiencyWide temperature rangeCombination devicesNitrogen compoundsParticulatesFlue gas

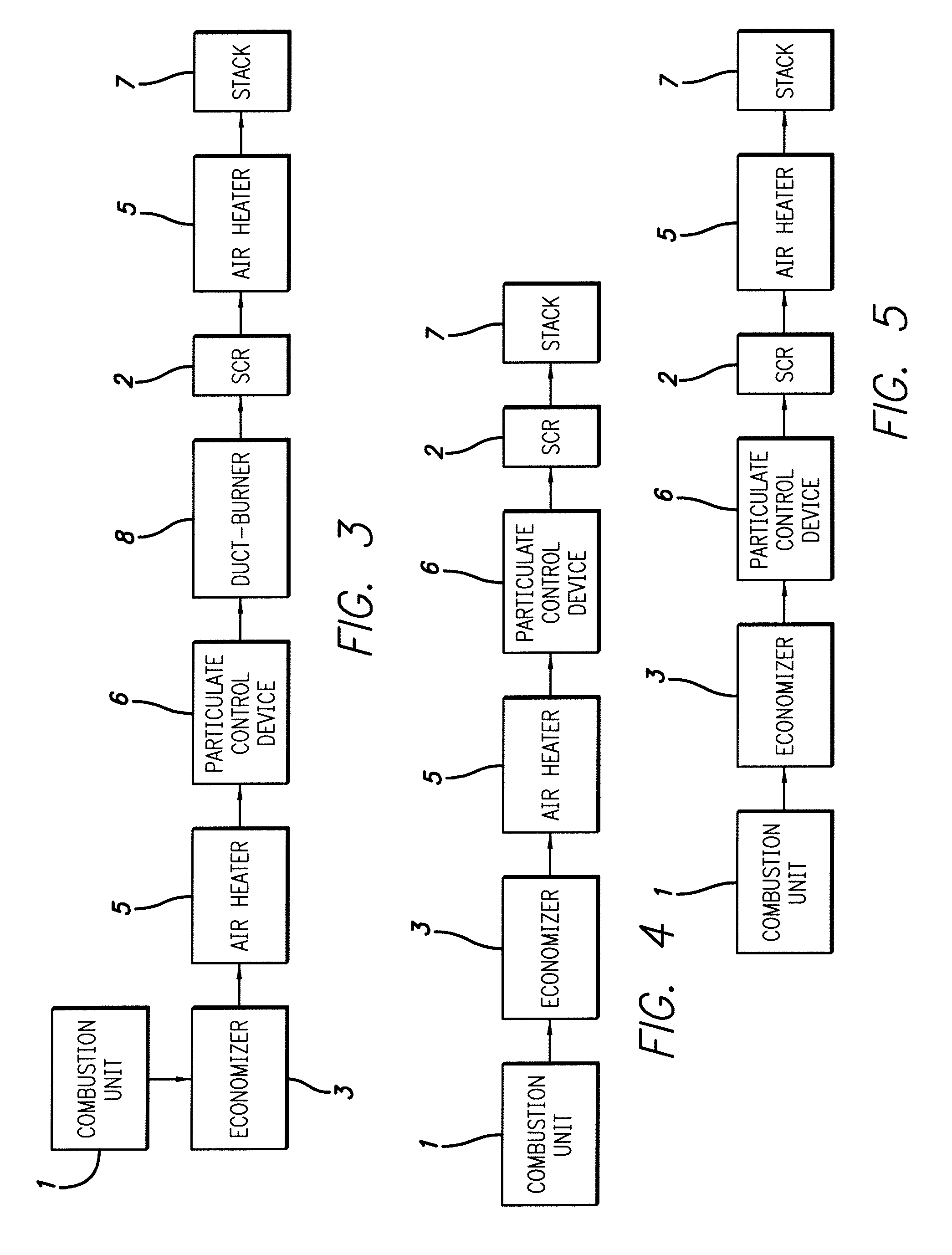

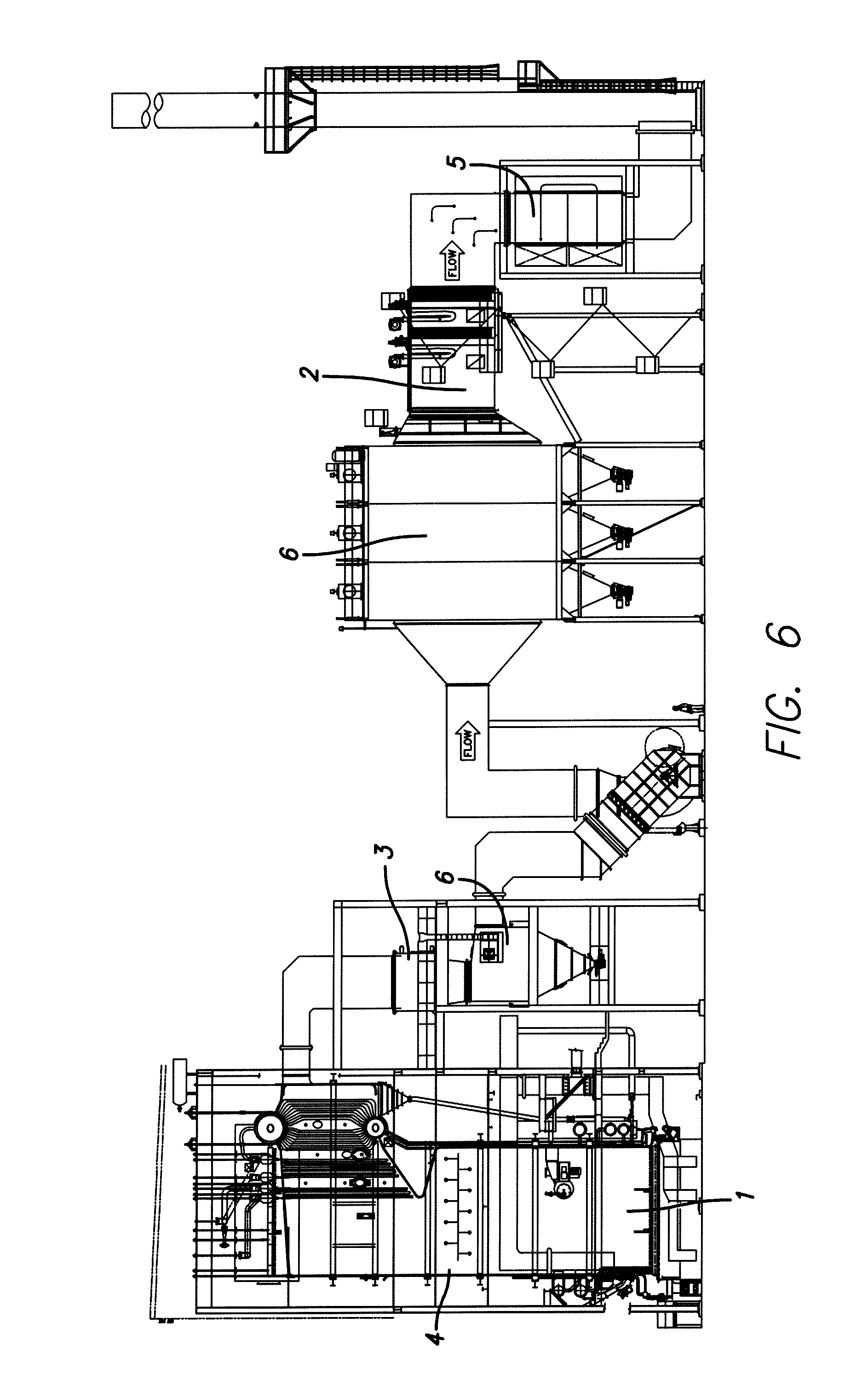

A selective catalytic reduction system and method for reducing nitrogen oxide (NOx) emissions comprising a boiler producing flue gas emissions, a particulate control device receiving flue gas emissions from the boiler, a selective catalytic reduction unit (SCR) receiving flue gas emissions from the particulate control device and reducing nitrogen oxide (NOx) emissions, and a heat exchanger located downstream of the selective catalytic reduction unit (SCR) for removing heat from the flue gas for preheating at least one of boiler feed water and combustion air for the boiler.

Owner:2E ENVIRONMENTAL

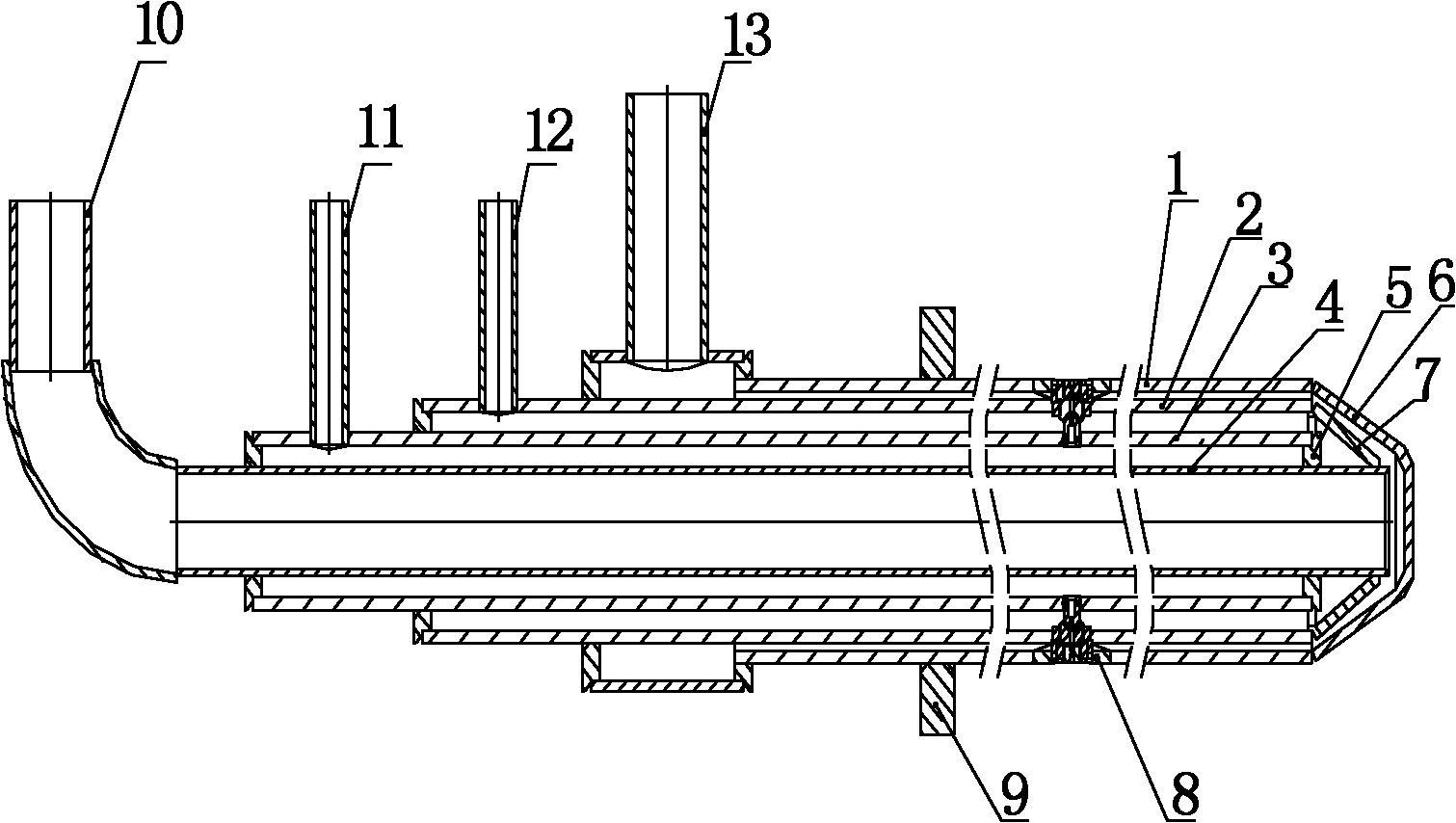

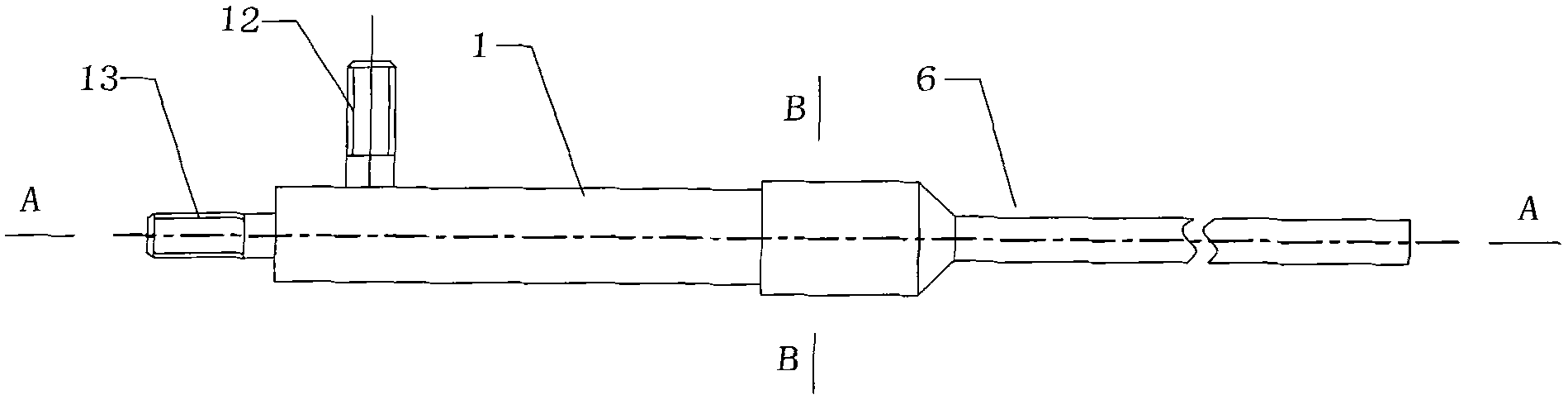

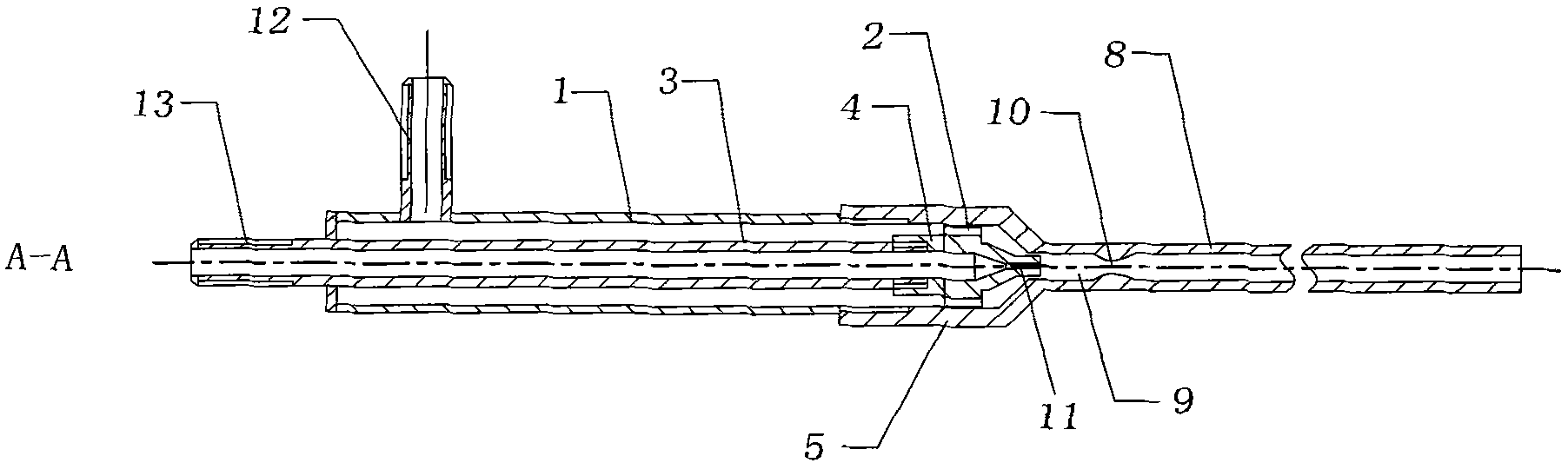

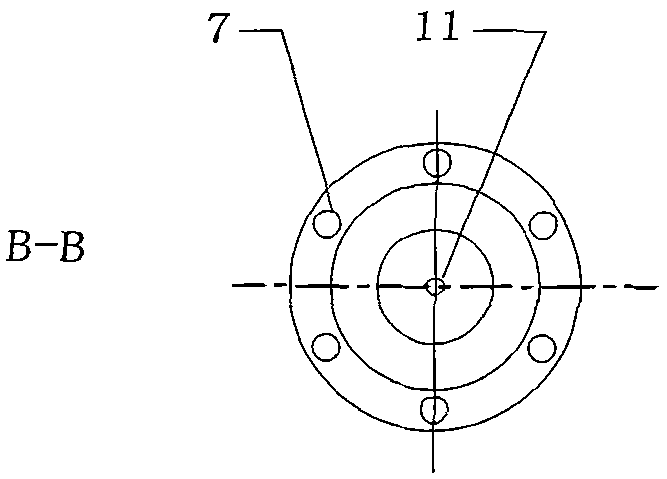

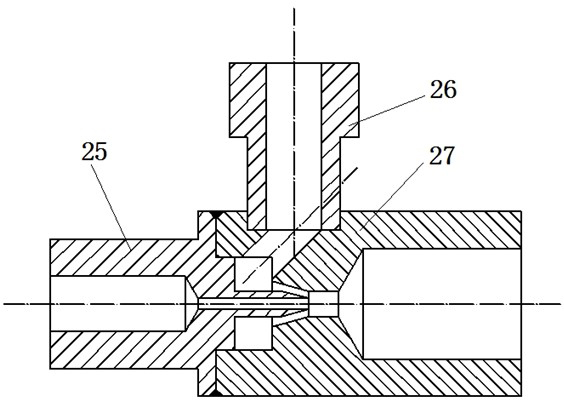

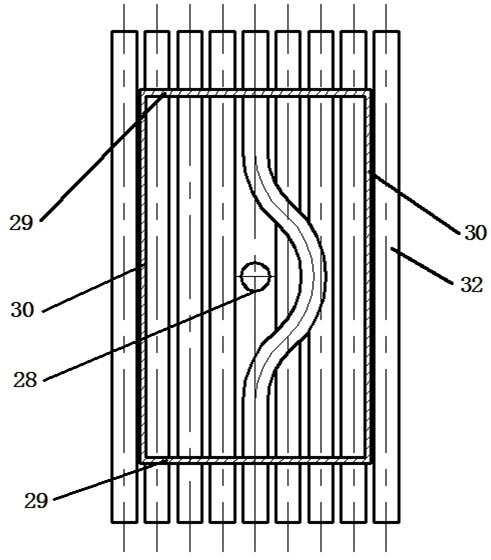

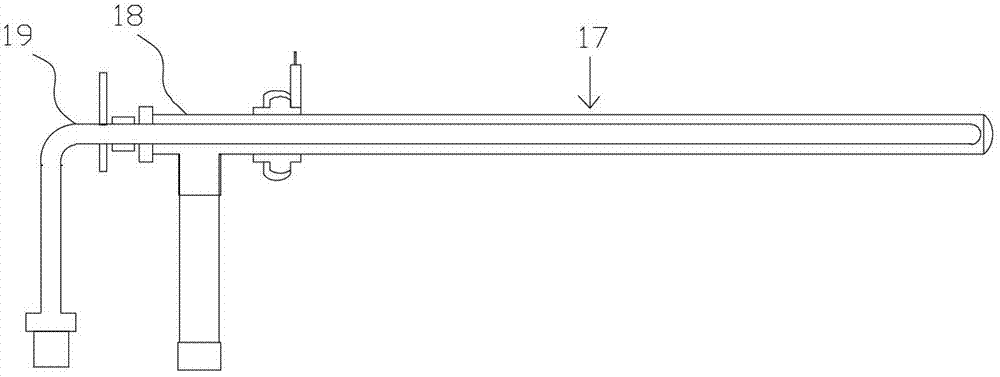

Selective non-catalytic reduction (SNCR) denitration multi-nozzle long-gun injector

ActiveCN102160964ASolve the defect that the spray cannot cover the smoke in the central areaIncrease coverageDispersed particle separationFlue gasSpray nozzle

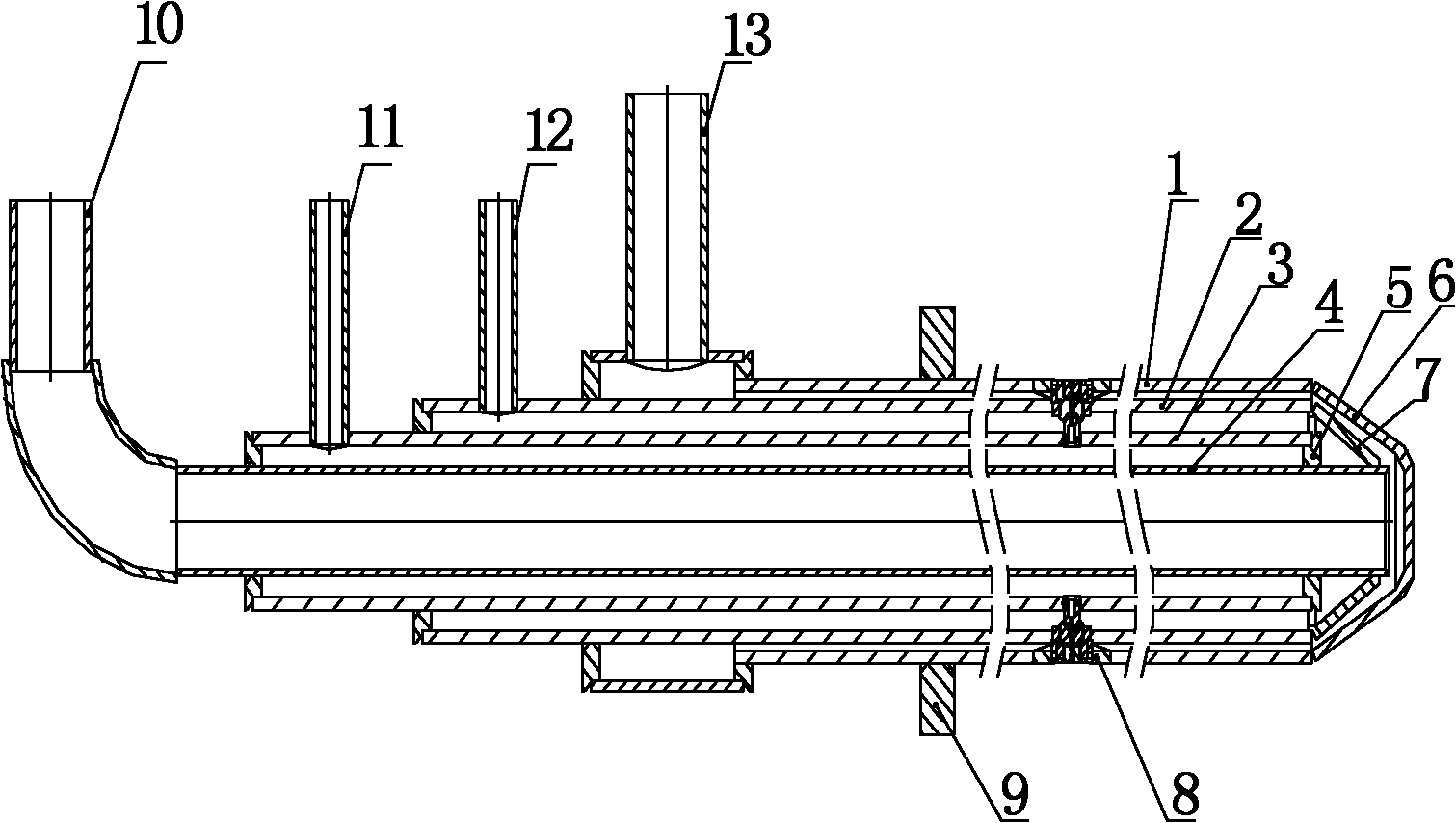

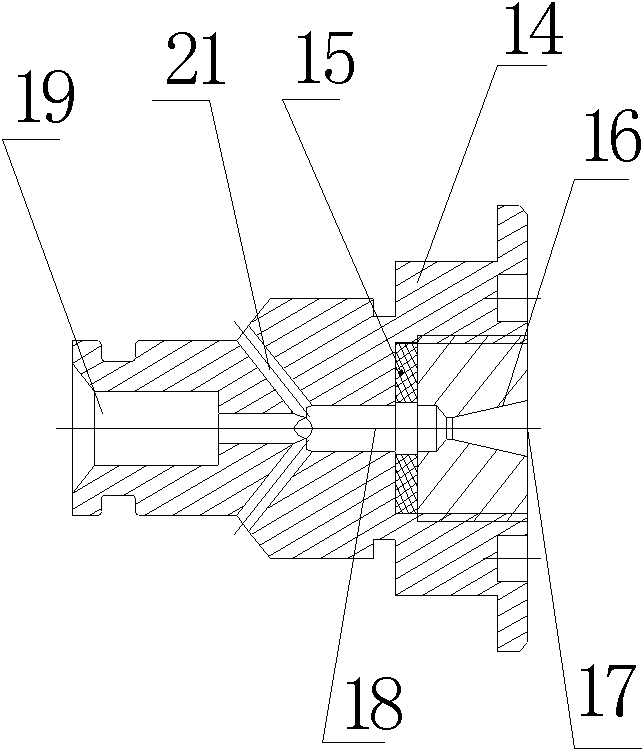

The invention relates to a selective non-catalytic reduction (SNCR) denitration multi-nozzle long-gun injector, which comprises a gun body assembly and at least two nozzles, wherein the gun body assembly comprises a pipeline assembly, an input assembly and a gun head; the pipeline assembly comprises a cooling water input pipe, a urea pipe, an air pipe and a cooling water output pipe from the interior to the exterior in turn; the input assembly comprises a water inlet joint, a urea joint, an air joint and a water outlet joint; the gun head comprises a urea seal head, an air seal head which is arranged at an outlet end of the air pipe, and a cooling water seal head which is arranged between an inlet end and a cooling water outlet end of the cooling water output pipe; each nozzle is an internal-mixing nozzle arranged on the gun assembly; a mixing chamber of each nozzle is communicated with a urea cavity and an air cavity respectively; and an opening of each nozzle is formed on a side wall of the cooling water output pipe. The technical problem that the conventional SNCR denitration multi-nozzle long-gun injector is low in denitration efficiency and unstable in performance in a high-temperature high-corrosion and high-abrasion flue gas environment is solved, and the injector is reasonable in design, stable in operation and high in denitration efficiency.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH +1

Reducing agent atomization spray gun for selective non-catalytic reduction denitration process

InactiveCN102085452ASimple structureLow costDispersed particle separationLiquid spraying apparatusInjection portSpray nozzle

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method and device for reducing emission limits of nitrogen oxides in waste incineration flue gas

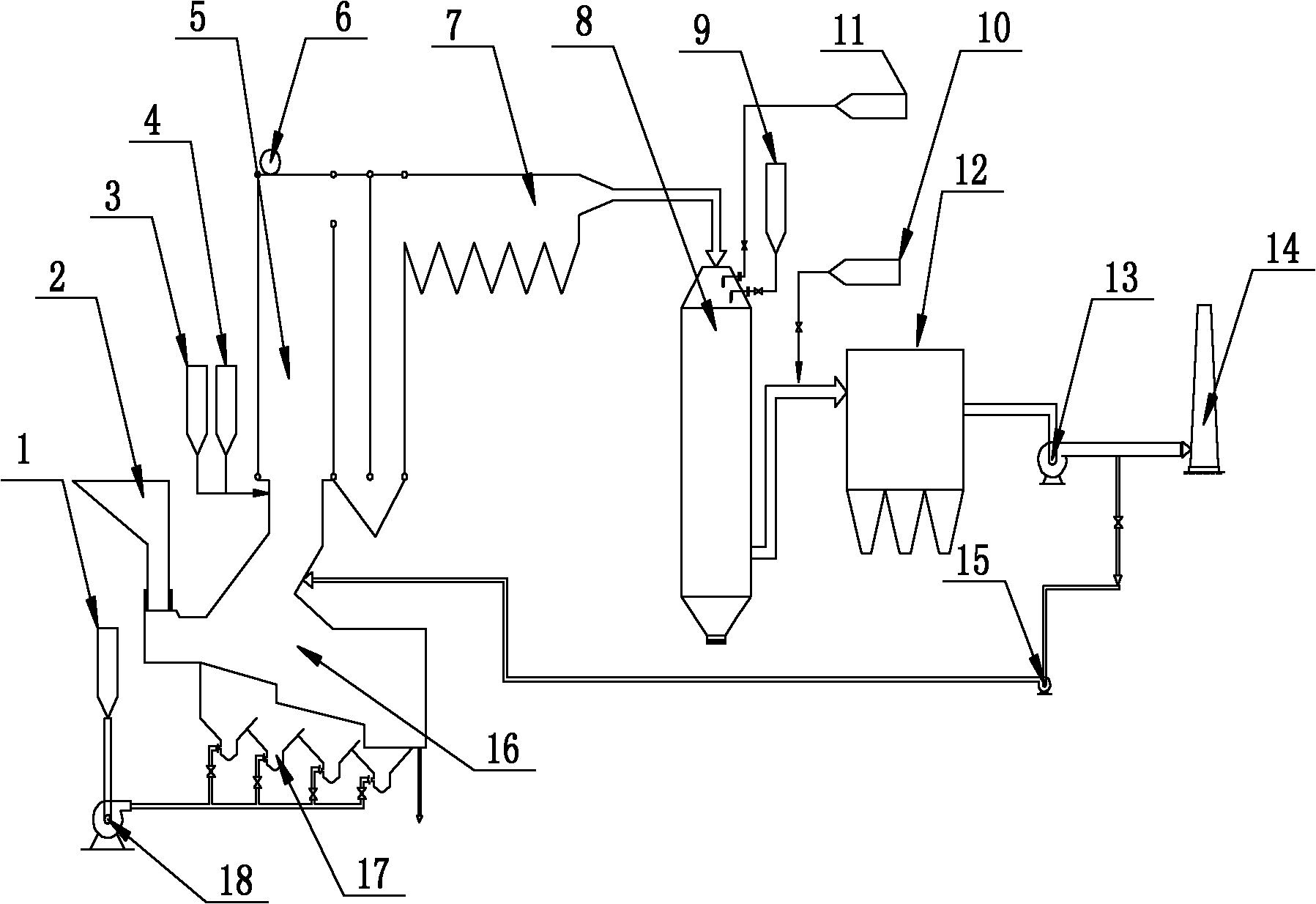

InactiveCN102168852APromote harmlessnessImprove utilizationDispersed particle separationIncinerator apparatusFlue gasNitrogen oxide

The invention relates to a method and a device for reducing emission limits of nitrogen oxides in waste incineration flue gas. In the method, processes of a waste incineration processing device, an optimizing air supply device, an exhaust-heat boiler device, a selective non-catalytic reduction (SNCR) device, a tail gas processing device and the like are integrated into a whole; by combining clean flue gas serving as secondary air supply and the SNCR device, the situation that the nitrogen oxides in the discharge of tail gas generated after wastes are processed by national waste incineration equipment is not removed effectively in low cost can be changed, and the removal ratio of the nitrogen oxides can be improved; and the removal rate of the nitrogen oxides after the device is optimized is more than 70 percent, so that the concentration of the tail gas discharged finally is lower than 150 mg / Nm<3> specified in the European Union standard 2000. Simultaneously, the optimizing device requires less increment investment and low running cost and is suitable to be applied and popularized in waste incineration equipment at home and abroad, and a denitration device is small in newly increased floor space.

Owner:BMEI

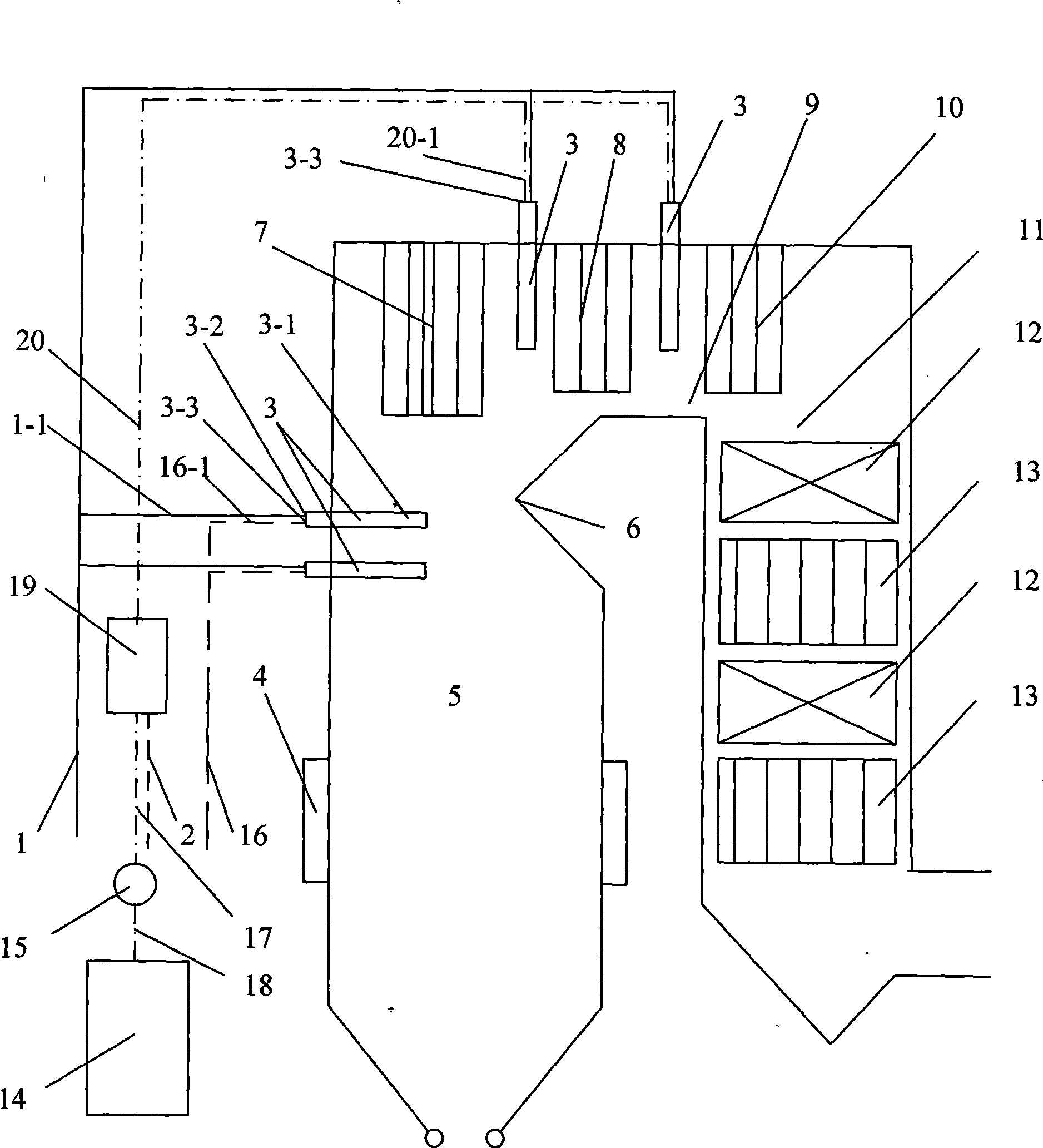

Selective non-catalytic reduction method for gasifying and atomizing biomass and used boiler

InactiveCN101433799AWidely distributedWell mixedLighting and heating apparatusDispersed particle separationProcess engineeringMixed gas

The invention relates to a selective non-catalytic reduction method for gasifying and atomizing biomass and a boiler used by the same, which relate to the selective non-catalytic reduction method and the boiler used by the same. The invention solves the problems that the prior selective non-catalytic reduction method has narrow temperature window, low denitration efficiency at a low temperature region and single effective component in synthesis gas of a reaction additive. The inlet of a gas mixer of the boiler is communicated with a gas additive pipeline and a compressed air pipeline respectively, while the outlet of the gas mixer is communicated with an atomizing medium pipeline. The selective non-catalytic reduction method mixes the biomass gasified gas in the gas additive pipeline with the compressed air through the gas mixer, uses the mixed gas as an atomizing medium for an amino reducing agent solution, and sprays the atomizing medium and the amino reducing agent solution together into a furnace chamber and a horizontal flue in a region with a temperature of between 800 and 950 DGE C through nozzles arranged in the furnace chamber and the horizontal flue. The selective non-catalytic reduction method improves the denitration efficiency and enlarges the temperature window. The boiler system of the invention is simple and has high reliability.

Owner:HARBIN INST OF TECH

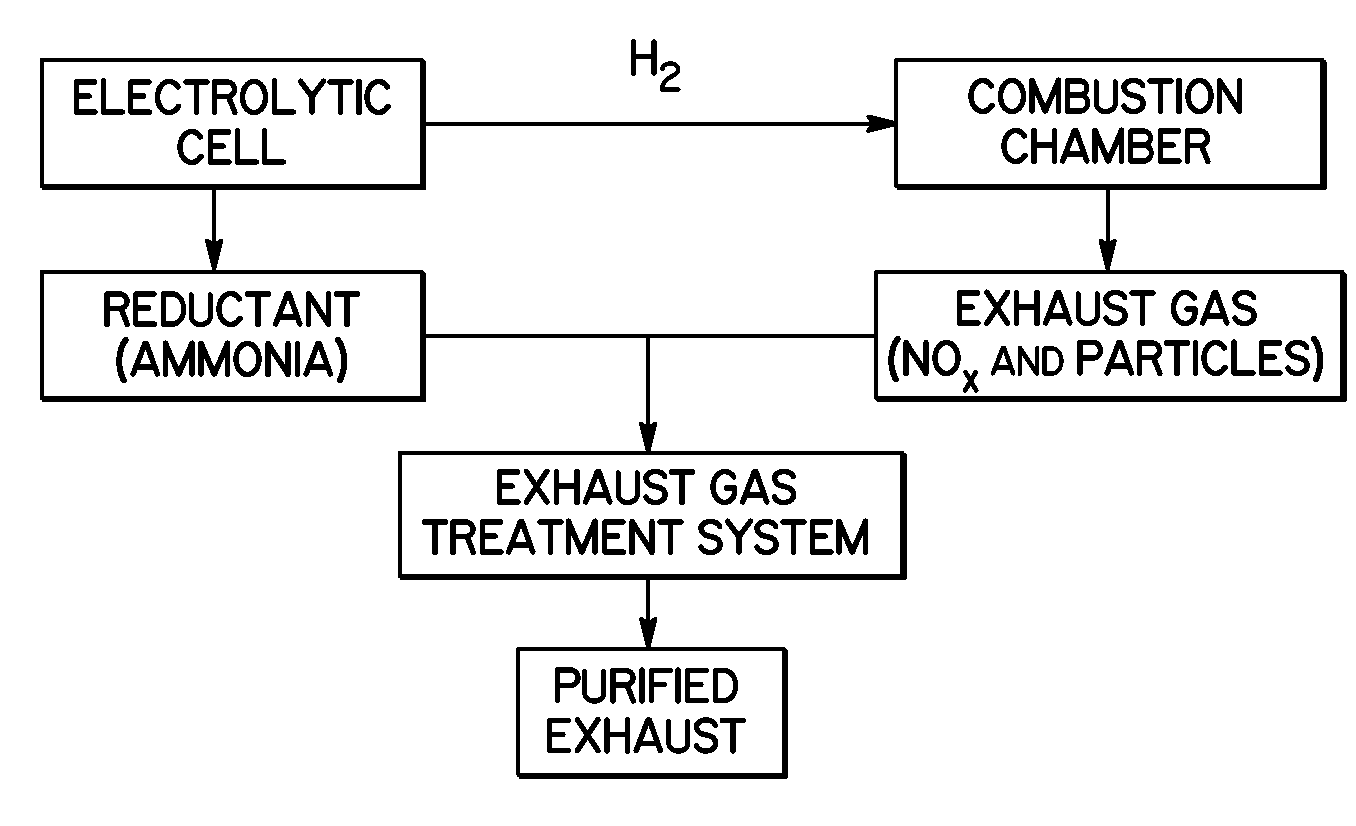

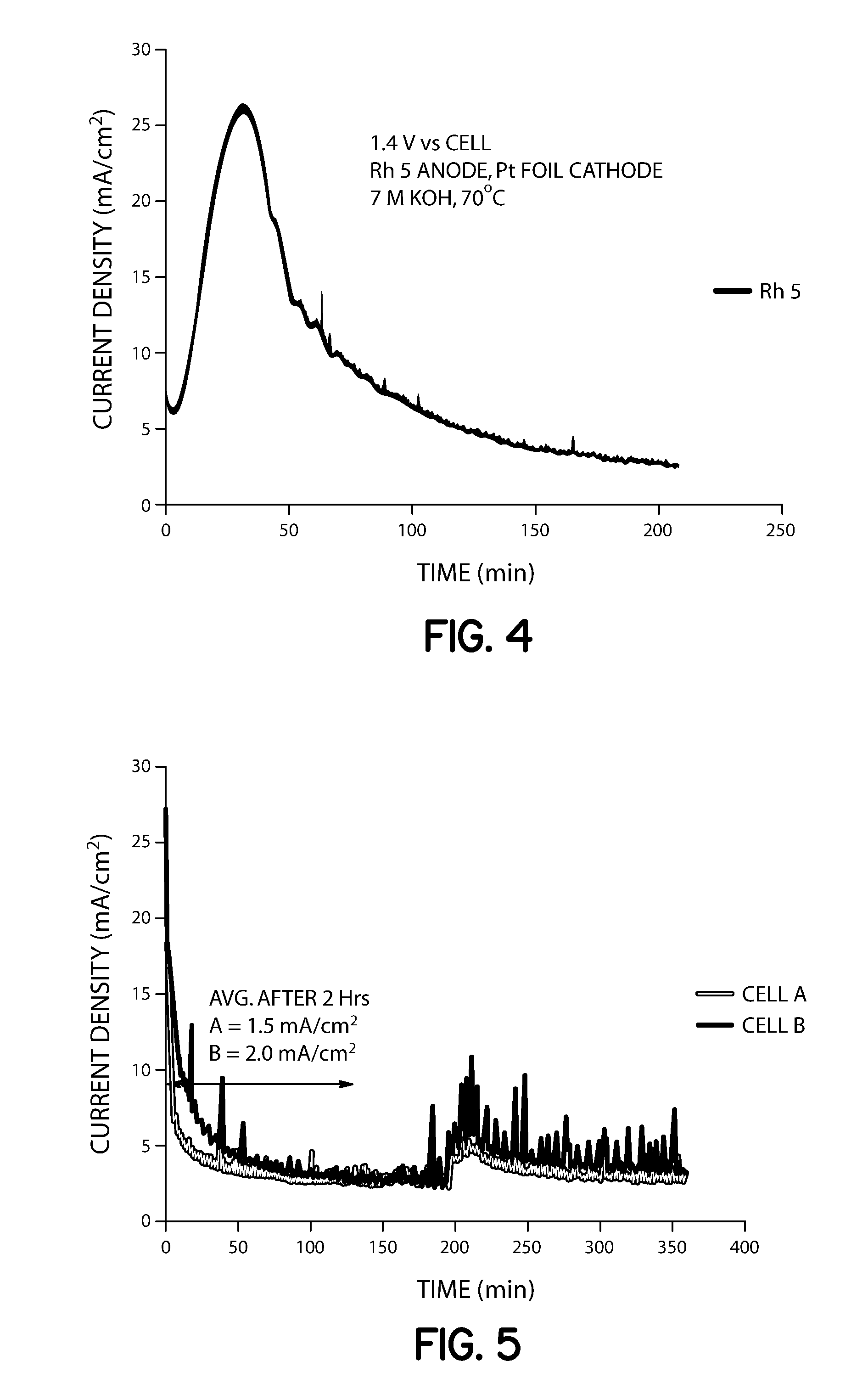

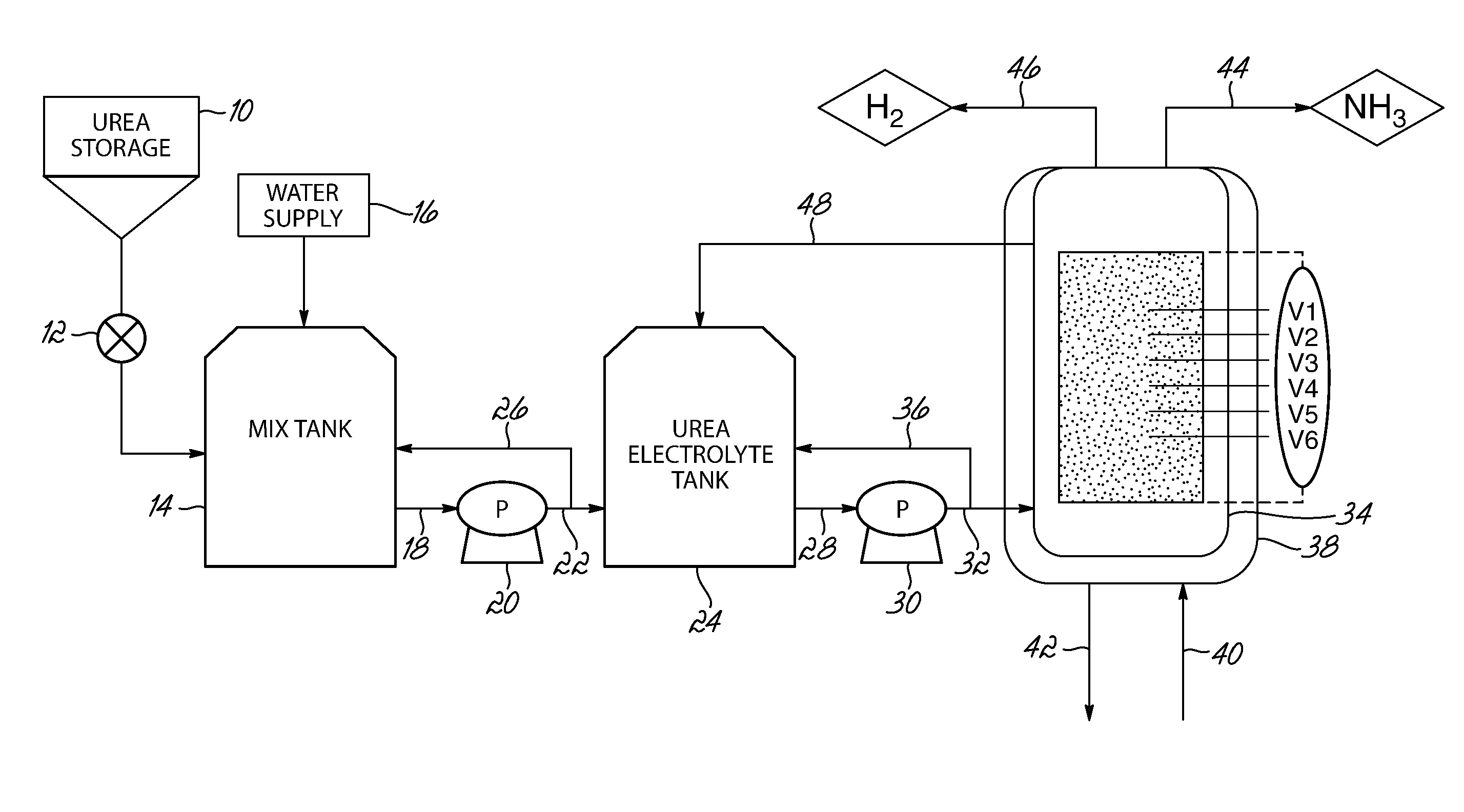

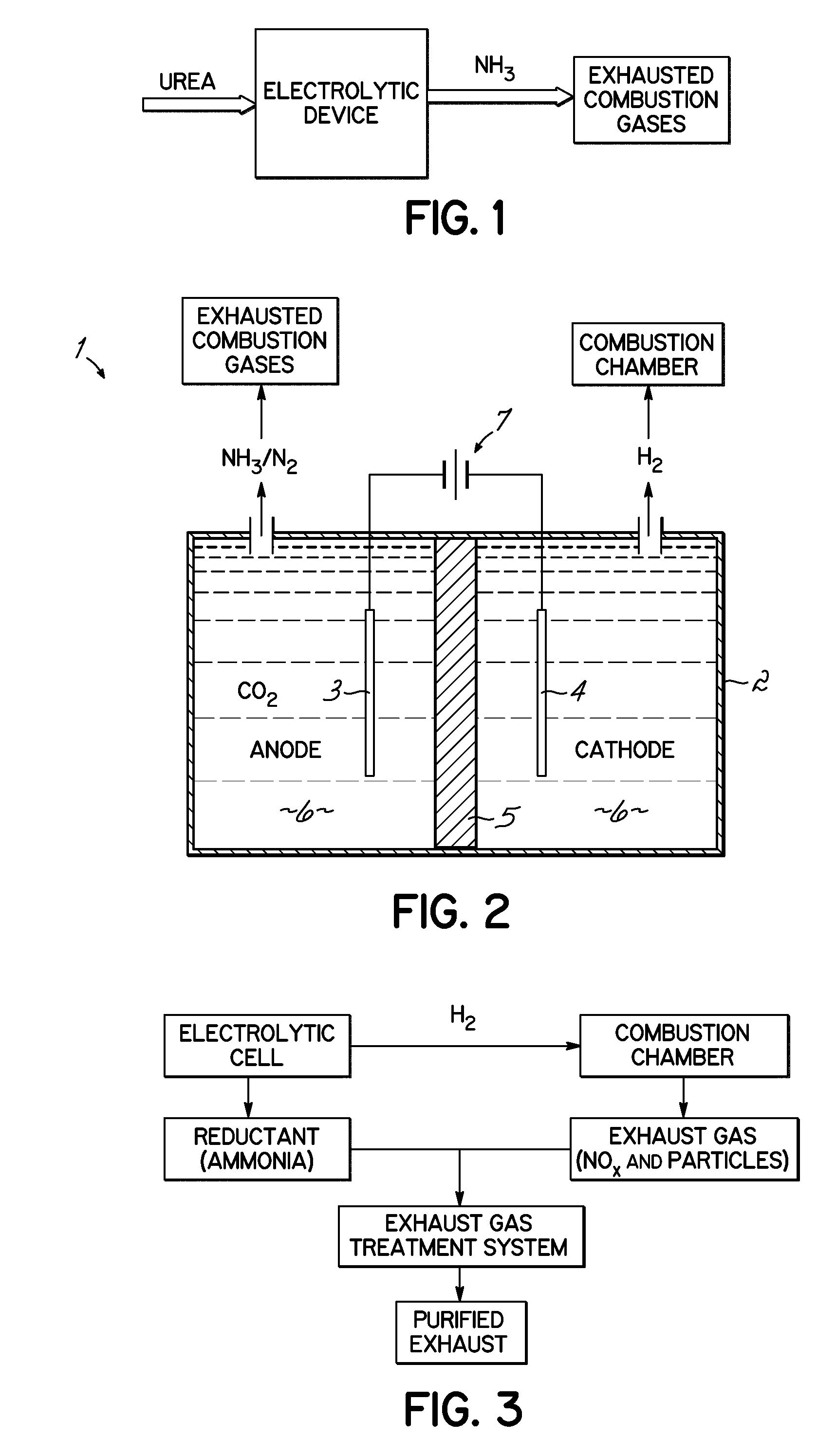

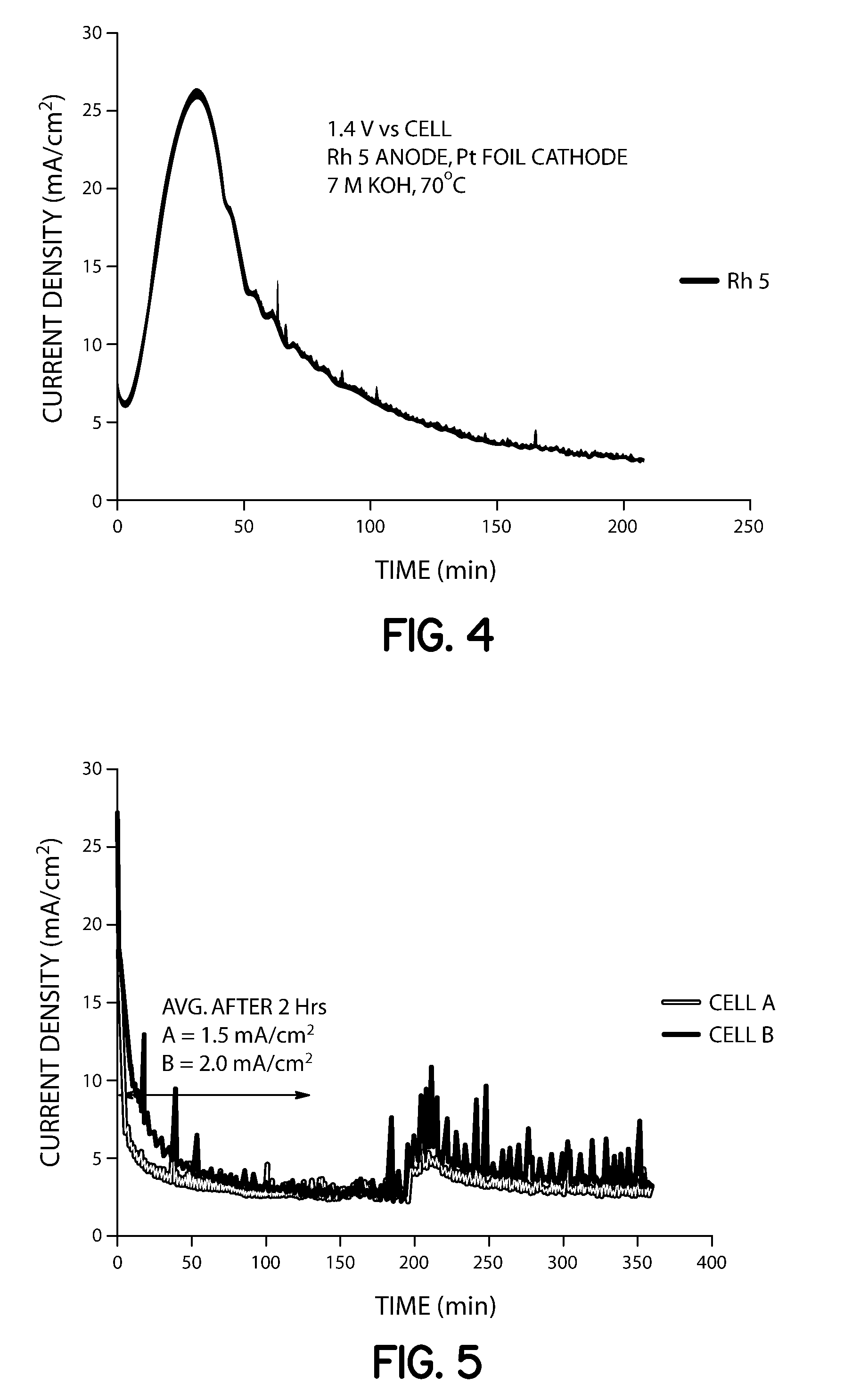

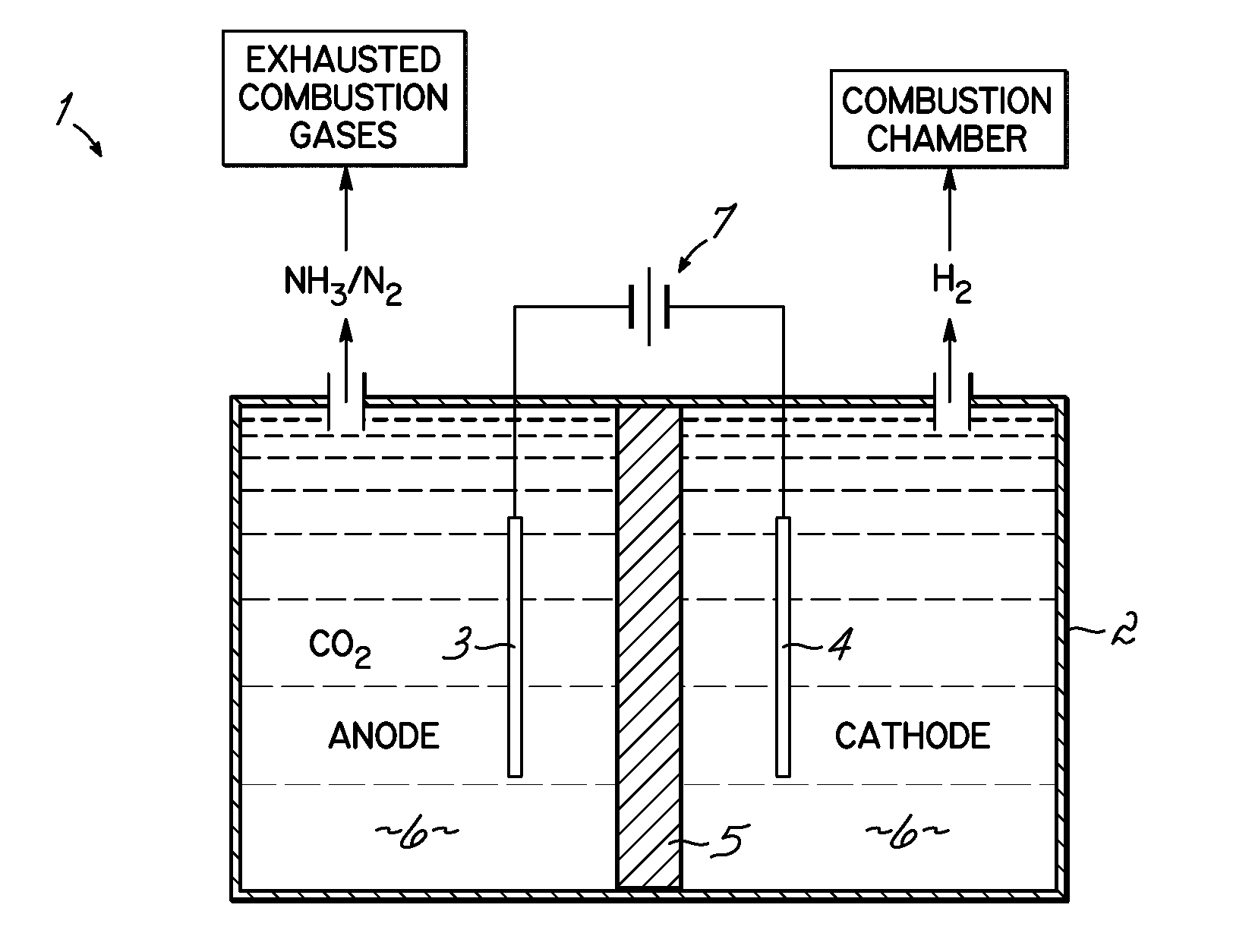

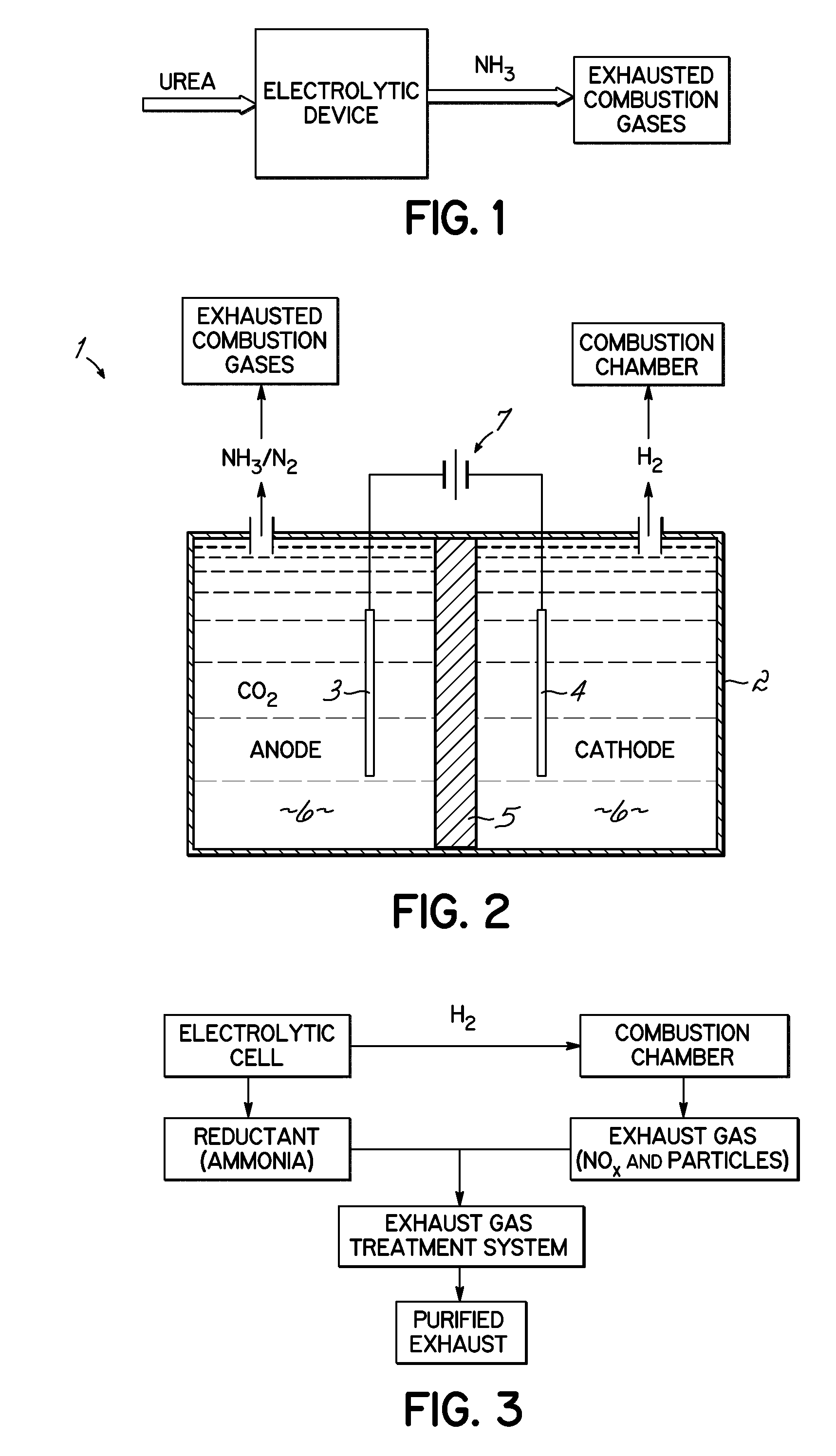

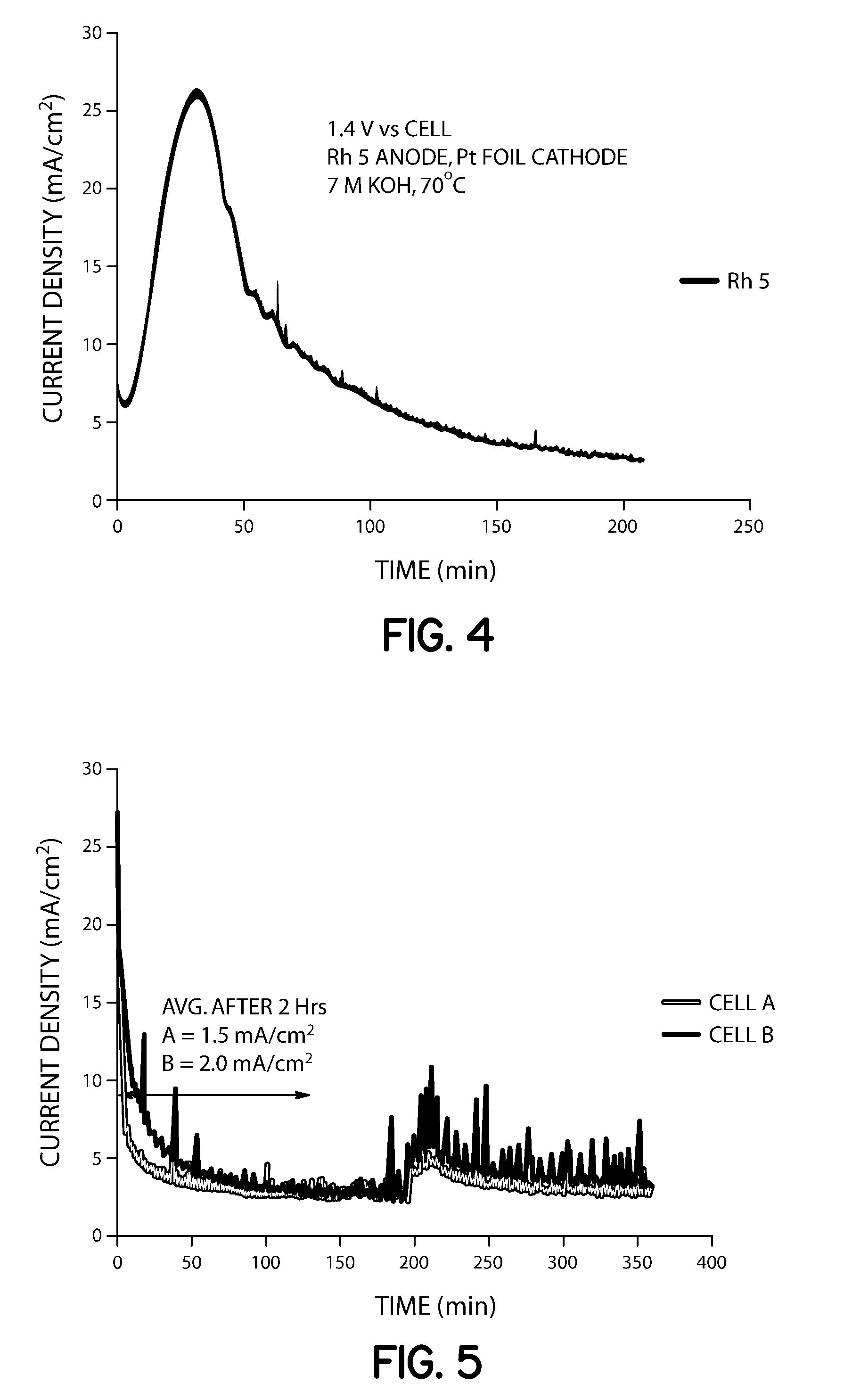

Selective Catalytic Reduction Via Electrolysis of Urea

ActiveUS20110243823A1Emission reductionReducing nitrogen oxideCombination devicesPhotography auxillary processesHydrolysisTreatment system

A method and apparatus for producing ammonia suitable for use as a reductant in a selective catalytic reduction (SCR), a selective non-catalytic reduction (SNCR), or a flue gas conditioning system is provided. A method for treating combustion exhaust gas with ammonia is provided that includes the electrolytic hydrolysis of urea under mild conditions. The electrolysis apparatus includes an electrolytic cell, which may be operatively coupled to an exhaust gas treatment system to provide an apparatus for reducing nitrogen oxides (NOx) and / or particulate in exhaust gases.

Owner:OHIO UNIV

Quadruple-effect denitration agent composition and denitration method thereof

ActiveCN106861431AOvercome temperatureOvercome efficiencyDispersed particle separationSorbentReaction temperature

The invention discloses a quadruple-effect denitration agent composition and a denitration method thereof. A denitration agent is prepared from the following raw materials in parts by weight: 50-78% of reducing agent, 15-30% of catalyst, 1-10% of adsorbent, 1-10% of accelerant, 1-10% of dispersant, 1-10% of activating agent, 1-10% of penetrant, 1-10% of controlled release formulation and 1-10% of initiator. The denitration method comprises the following steps: (1) selecting raw materials, and through mixed working procedures of smashing, grinding, sieving and mixing, preparing the quadruple-effect denitration agent composition of claim 1 from the selected raw materials; (2) injecting the quadruple-effect denitration agent composition prepared in (1) into a denitration reaction area, causing the quadruple-effect denitration agent composition to react with NOx in smoke at the temperature of 500-800 DEG C, and generating CO, CO2, N2 and H2O. Compared with a traditional SCR (Selective Catalytic Reduction) method and an SNCR (Selective Non-Catalytic Reduction) method, the denitration method has the advantages of low reaction temperature, good reaction selectivity, high denitration efficiency and the like.

Owner:广东龙鼎环境科技工程有限公司

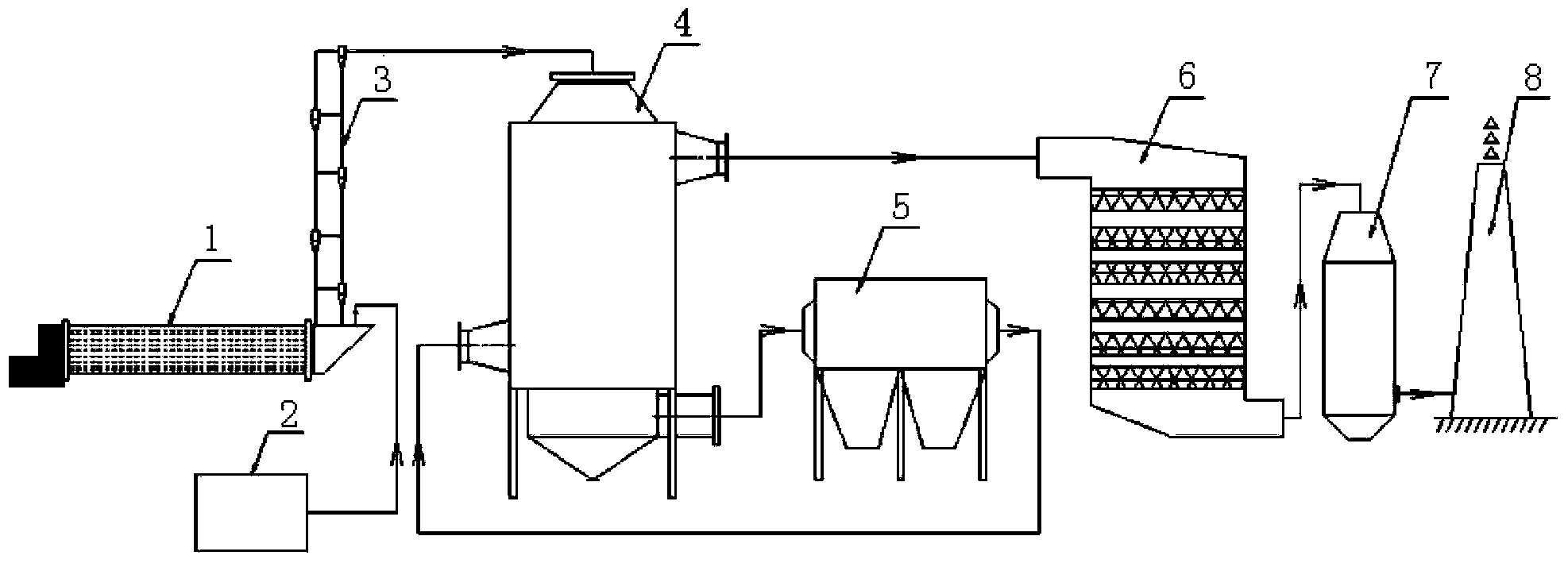

Garbage incineration fume ultralow emission purifying system

PendingCN106621754AImprove removal efficiencyAchieve cleanupCombination devicesGas treatmentActivated carbonPlate heat exchanger

The invention discloses a garbage incineration fume ultralow emission system. A garbage incineration fume purifying treatment device comprises an SNCR (selective non-catalytic reduction) device, a semi-dry type reaction tower, a slaked lime spraying device, an activated carbon spraying device, a bag type deduster, a steam heater, an SCR (selective catalytic reduction) reaction tower, a fume / fume heat exchanger, a wet type scrubbing tower, an induced draft fan and a chimney. The low-temperature fume after washing is performed with heat exchange in the fume / fume heat exchanger, heated, and exhausted out of the chimney. The garbage incineration fume purifying treatment device has the advantage that the emission of the fume is superior to the European Union 2000 standard.

Owner:SHANGHAI SUS ENVIRONMENT

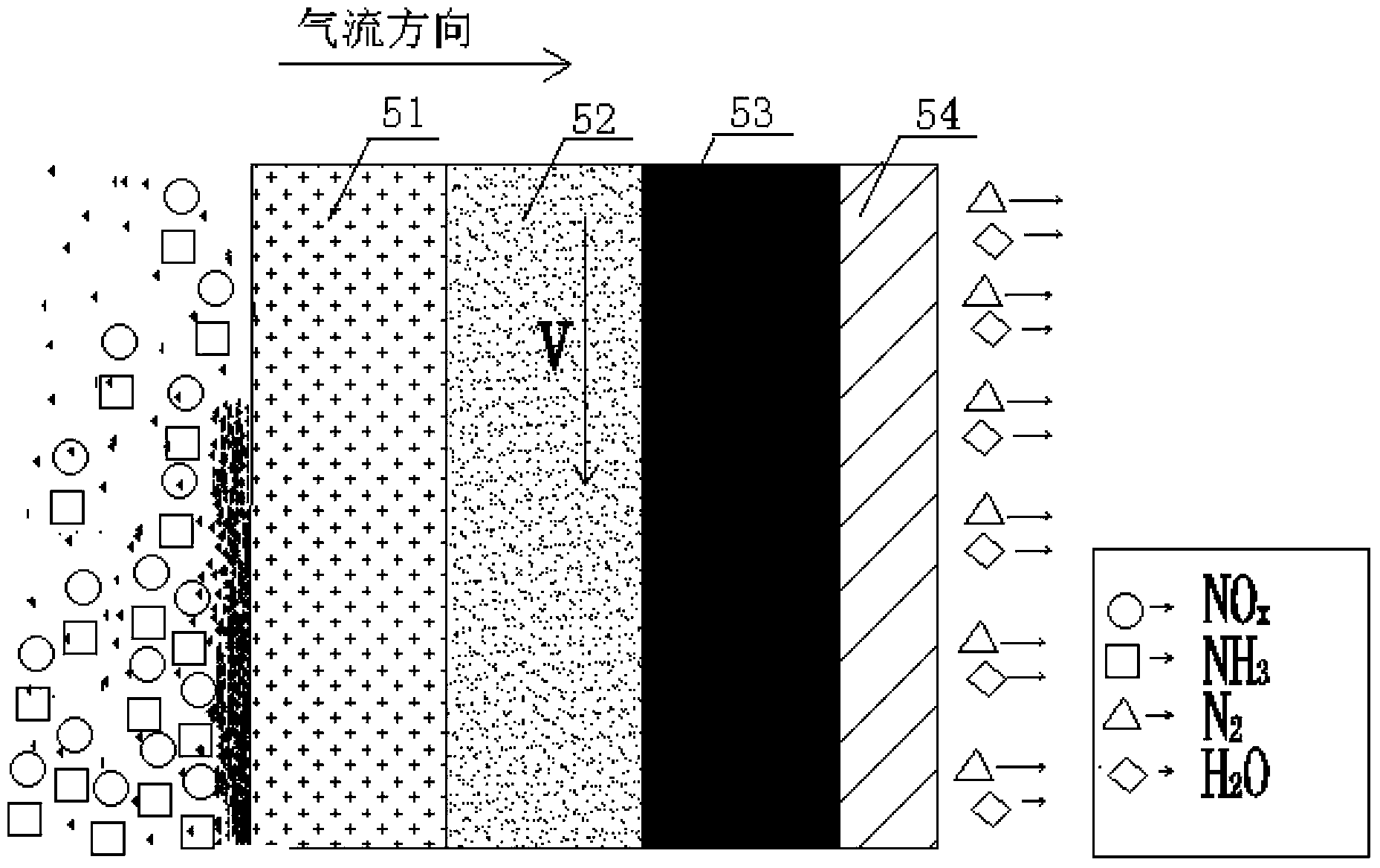

Novel SNCR (selective non-catalytic reduction) and SCR (selective catalytic reduction) hybrid denitrification system

InactiveCN103691293AReduce escapeReduce generationNitrous oxide captureDispersed particle separationAutomatic controlNitric oxide

The invention relates to the technical field of industrial smoke nitric oxide emission reduction and denitrification and relates to a novel SNCR (selective non-catalytic reduction) and SCR (selective catalytic reduction) hybrid denitrification system. The novel SNCR and SCR hybrid denitrification system comprises a preparation and storage module, a conveying circulating module, a metering and diluting module, an on-line NOX monitoring module, an automatic control module, a distribution module, a spraying module, a boiler and an SCR reactor. According to the novel SNCR and SCR hybrid denitrification system, an existing SNCR and SCR denitrification system is improved and united, so that full-automatic intelligent operation is realized; the automatic control module can accurately calculate a demand of a denitrification reducing agent by monitoring a nitride generation amount and other data in smoke gas on line and in real time according to the real-time change of a load of the boiler and feed back information to the metering and diluting module; the metering and diluting module can quickly adjust corresponding equipment to accurately provide the corresponding amount of the reducing agent to the distribution module and the spraying module; the reducing agent and smoke gas are sprayed in the boiler and a flue and are then mixed to enter the SCR reactor to implement denitrification reaction; therefore, the beneficial effects of high denitrification efficiency, high automation degree, low investment cost and good denitrification effect are achieved.

Owner:广东清华中邦热能科技有限公司

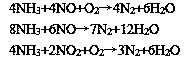

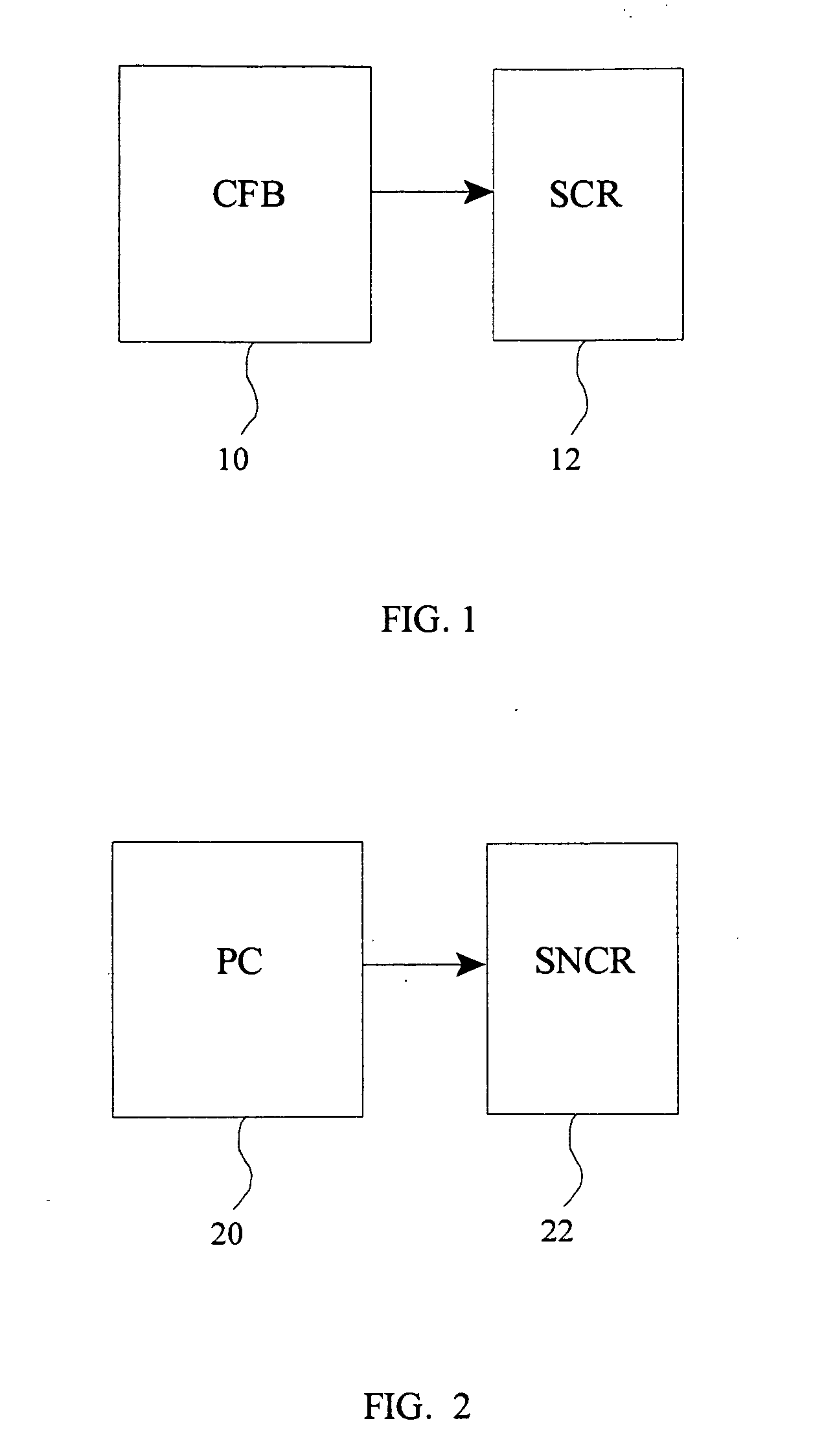

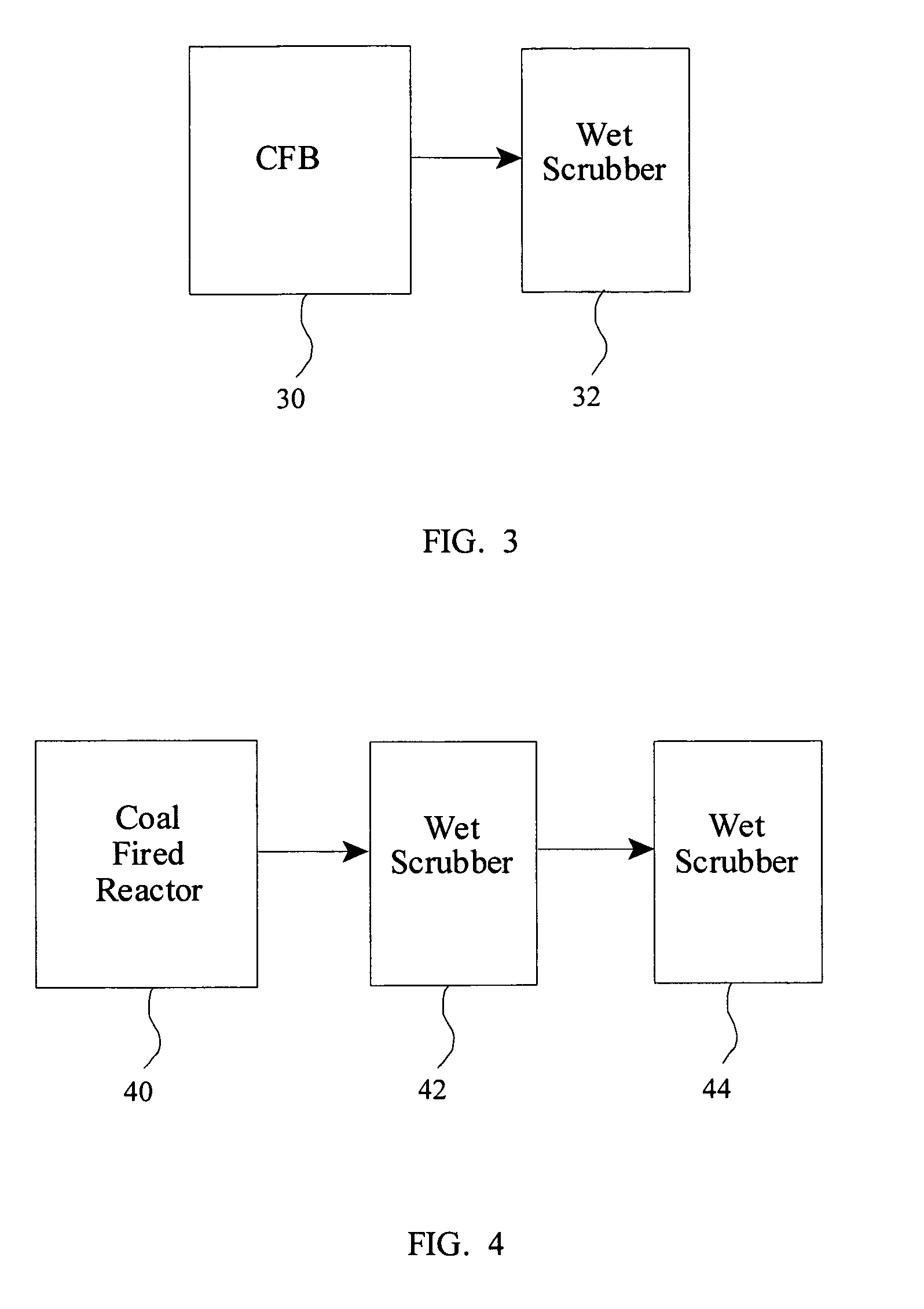

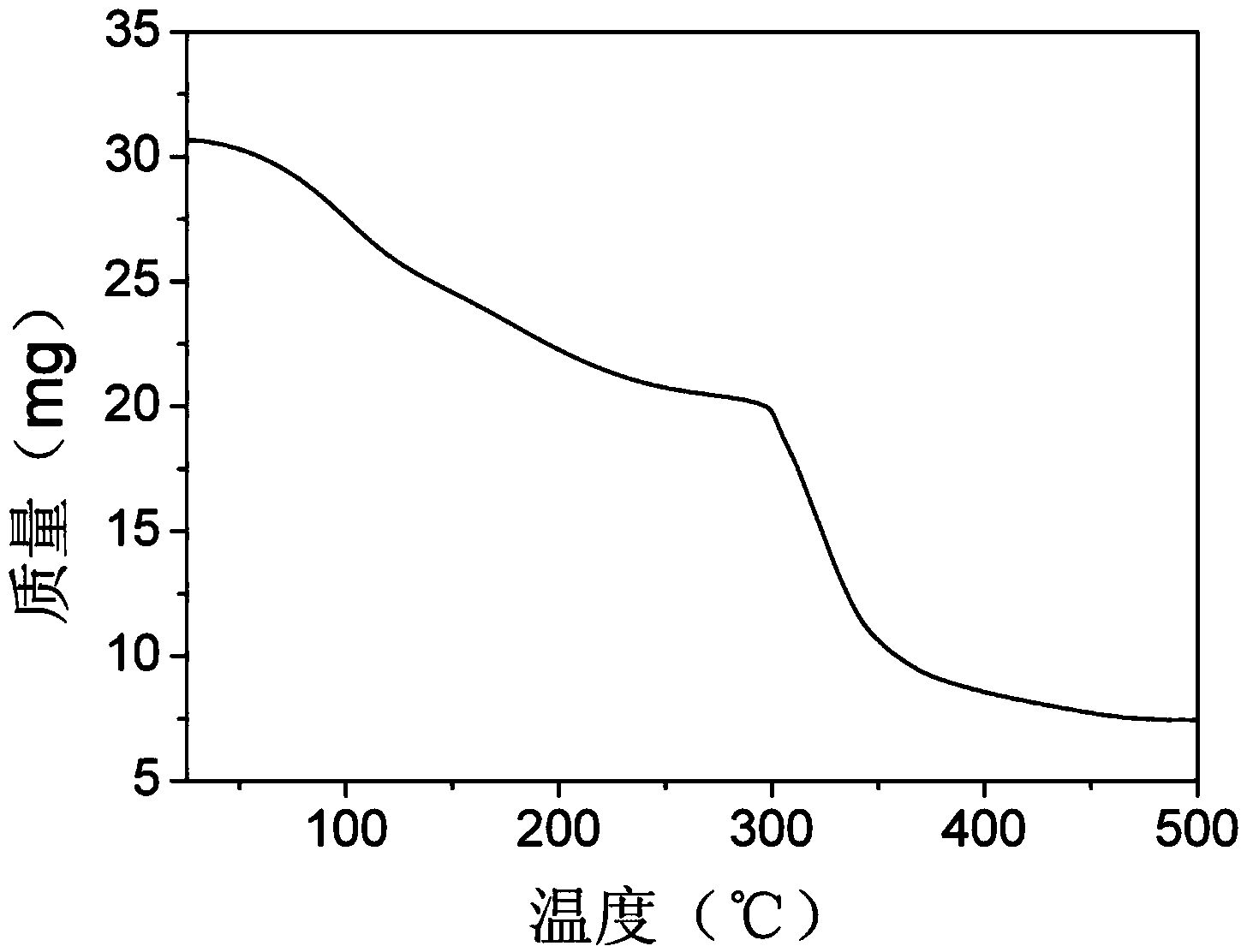

Scrubbing systems and methods for coal fired combustion units

InactiveUS20050084434A1Reduce nitrogen oxide emissionsHigh ppmCombination devicesFluidized bed combustionUnit systemWet scrubber

Systems and methods for removing toxic emissions from flue gas of coal fired combustions units can be achieved. Decreasing nitrogen oxide and sulfur emissions from a coal fired circulating fluidized bed reactor can include treating flue gas using a selective catalytic reduction system and a wet scrubber. Furthermore, reducing the nitrogen oxide emissions from a pulverized coal reactor can be accomplished with a selective non-catalytic reduction system. Additionally, the reduction of sulfur oxide emissions from a pulverized coal reactor can be enhanced using dry and / or wet scrubbers. Such systems and methods provide improved levels of toxic emissions over currently available technologies.

Owner:ENVIROSERVE ASSOCS

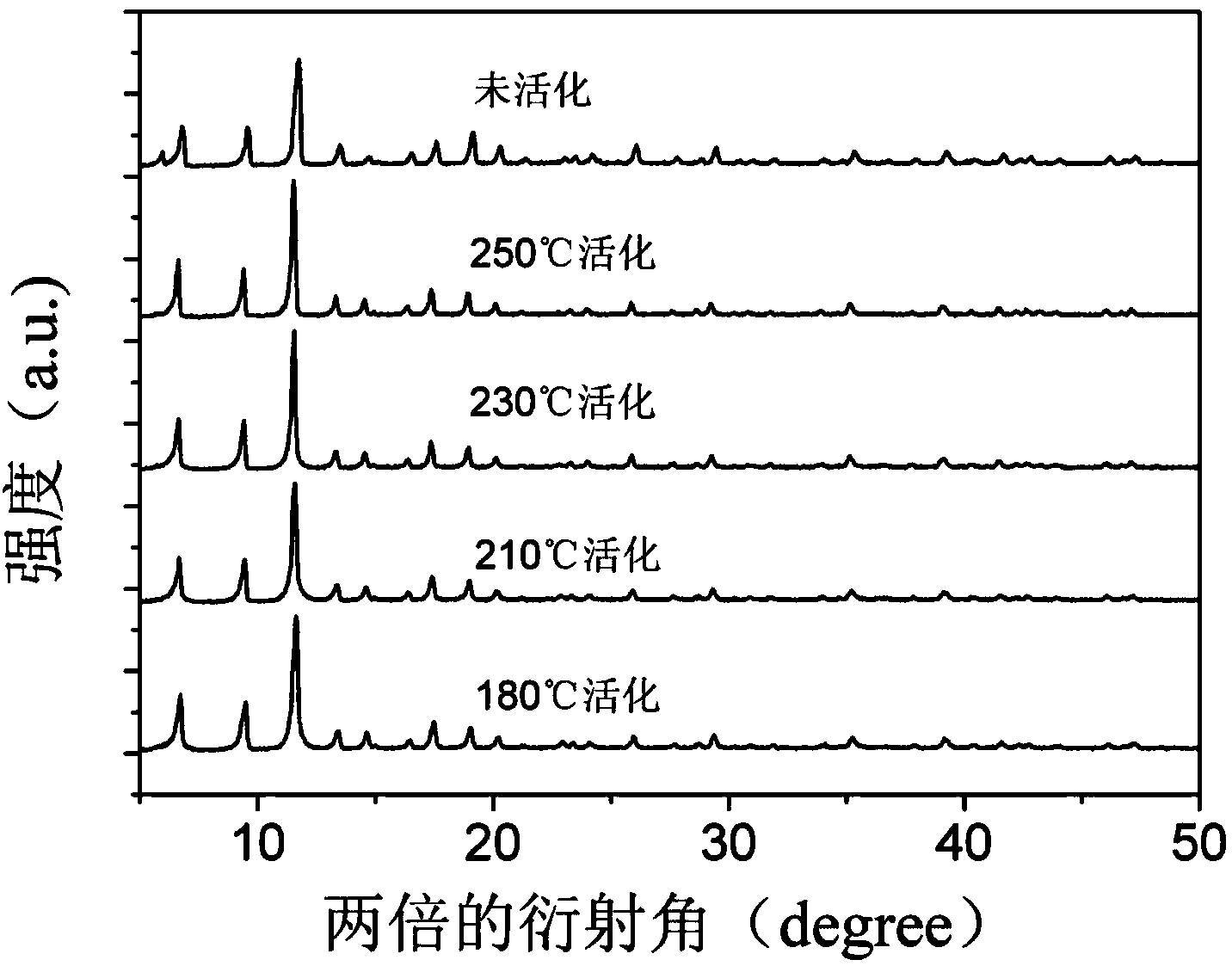

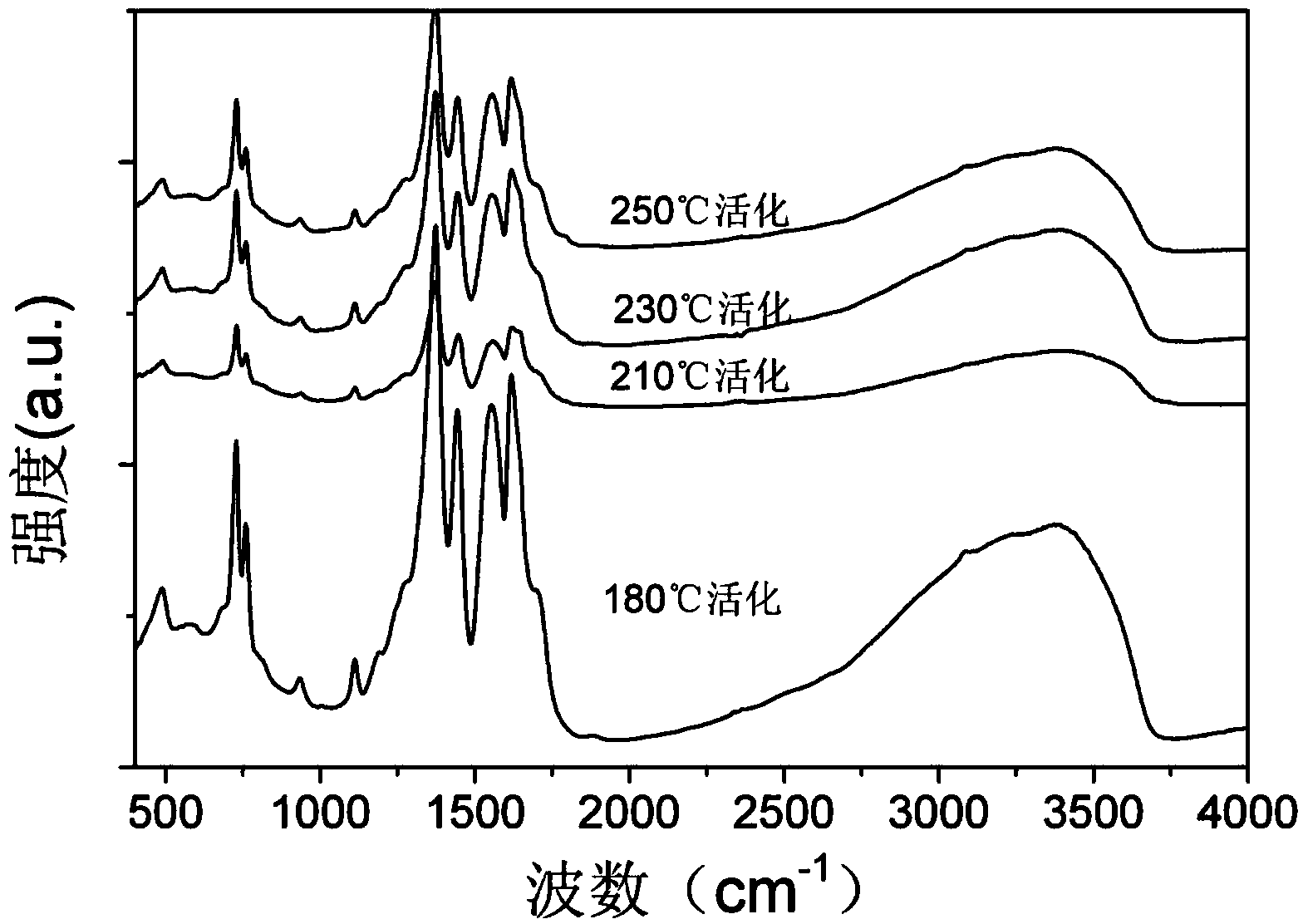

Metal-organic frame material Cu-BTC for removing nitric oxide with selective catalytic reduction method

InactiveCN103752169AOptimal activation temperatureAchieve removalOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNitric oxideMixed gas

The invention provides a metal-organic frame material Cu-BTC for removing nitric oxide with the selective catalytic reduction method, and belongs to the field of flue gas denitrification. The metal-organic frame material Cu-BTC for removing nitric oxide with the selective catalytic reduction method is characterized by adding Cu-BTC to a reaction tube, charging N2, heating to reach 180 to 250 DEG C, maintaining for more than 1.5 hours, preparing particles of 20-60 meshes through activated Cu-BTC, transferring into another reaction tube with silica wool plugged, and then charging NO, NH3, O2 and N2, wherein the mixed gas is at flow rate of 100-200ml / min; and each of gases is at the concentration shown as NO=NH3=500-1,000ppm, O2 accounts for 2 to 5%, and N2 serves as balanced gas; and the reaction condition is that the temperature is 140 to 320 DEG C. The metal-organic frame material Cu-BTC is used for the first time in the selective catalytic reduction method for removing nitric oxide by using NH3 as a reducing agent, and shows a good catalyzing effect in the low-temperature selective catalytic reduction method for removing nitric oxide; and the material has the advantages of being nontoxic, harmless, convenient to manufacture, low in price, etc., and is a potential good catalyzing material.

Owner:DALIAN UNIV OF TECH

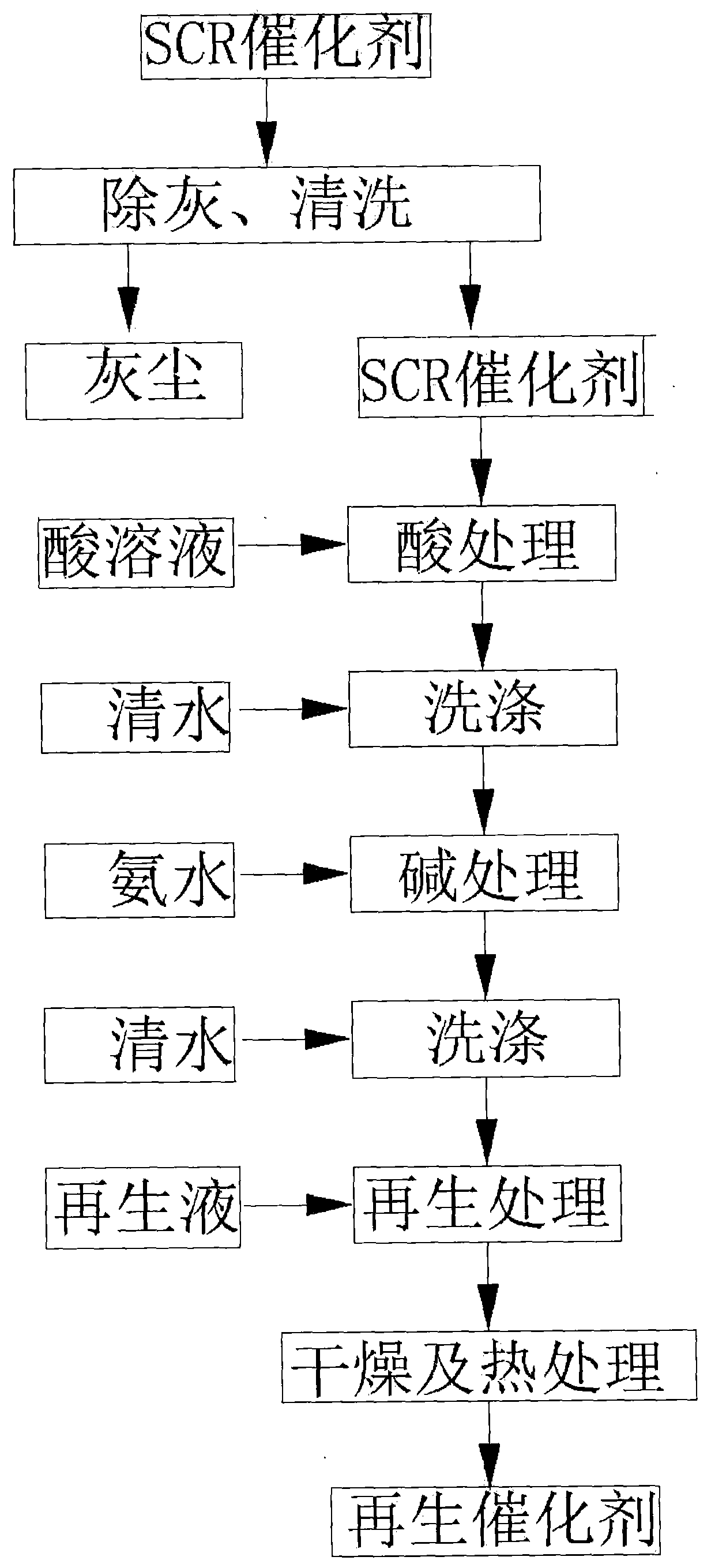

Method for regenerating titanium-based vanadium-series SCR (Selective Catalytic Reduction) denitration catalyst

InactiveCN104190477ALow priceReduce processing costsCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsTitaniumHigh pressure

The invention relates to a method for regenerating a titanium-based vanadium-series SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps: removing dusts from the surface of the waste titanium-based vanadium-series SCR denitration catalyst through high-pressure purging and ultrasonic wave treatment; carrying out acid treatment on the dust removed catalyst and washing the catalyst subjected to acid treatment with clean water; carrying out alkali treatment on the washed catalyst and washing the catalyst subjected to alkali treatment with clean water; adding the catalyst subjected to alkali treatment into a regeneration solution, soaking in a standing manner at 20-80 DEG C for 1-10h; drying the regenerated catalyst at low temperature; carrying out heat treatment on the dried catalyst in drying equipment at 200-500 DEG C for 1-3h, thereby obtaining a regenerated SCR denitration catalyst. The method has the beneficial effects of low treatment cost, simplicity in operation, easiness in automation and continuity, low corrosion to equipment, and good regenerating method and regenerating effect.

Owner:HUADIAN HIGH TECH GAOBEIDIAN ENVIRONMENTAL TECH +1

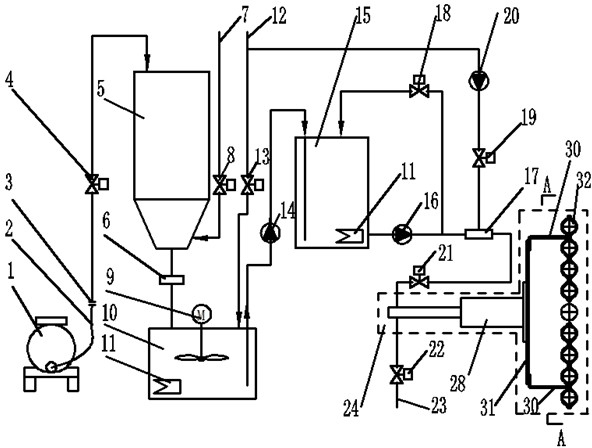

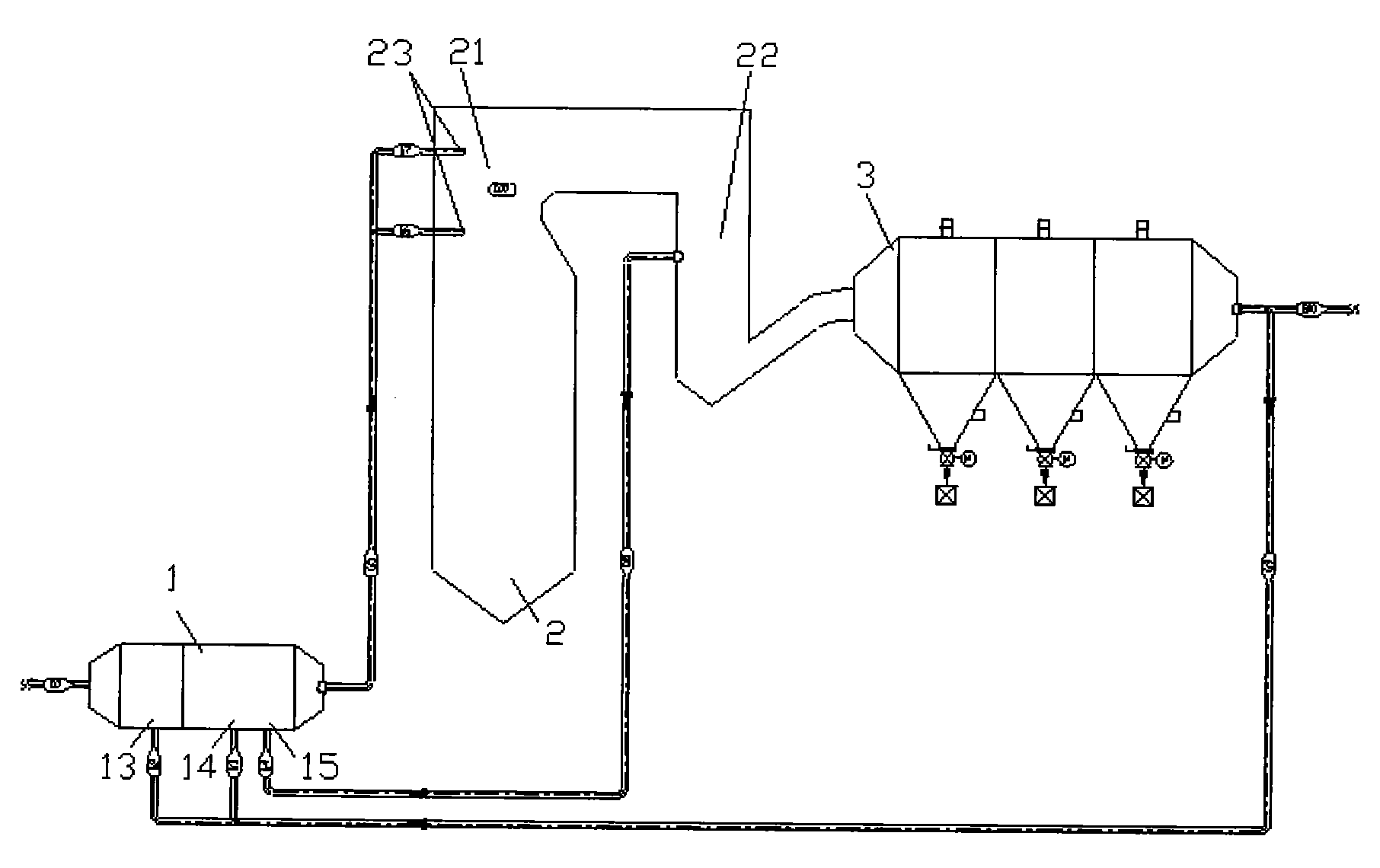

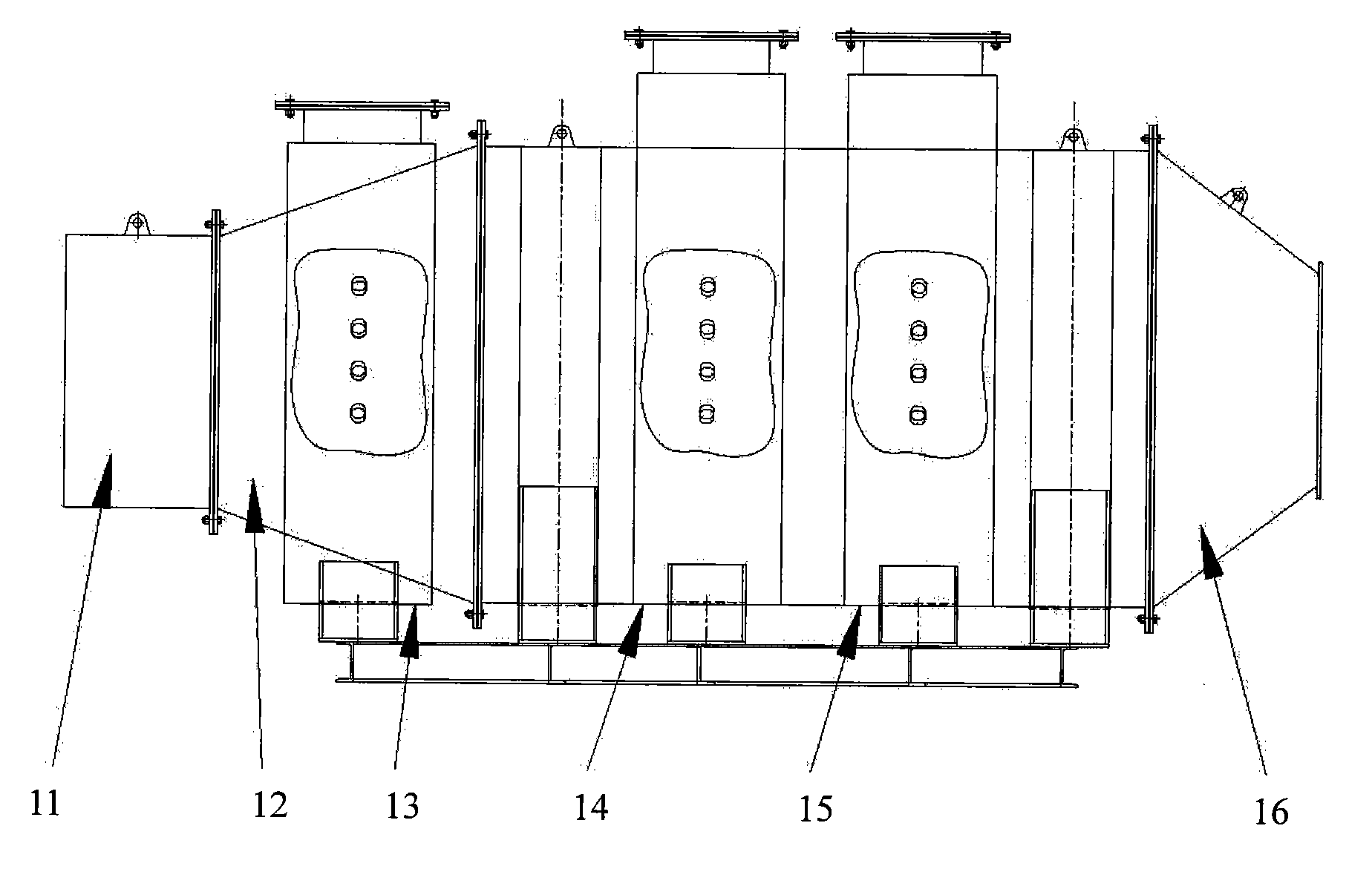

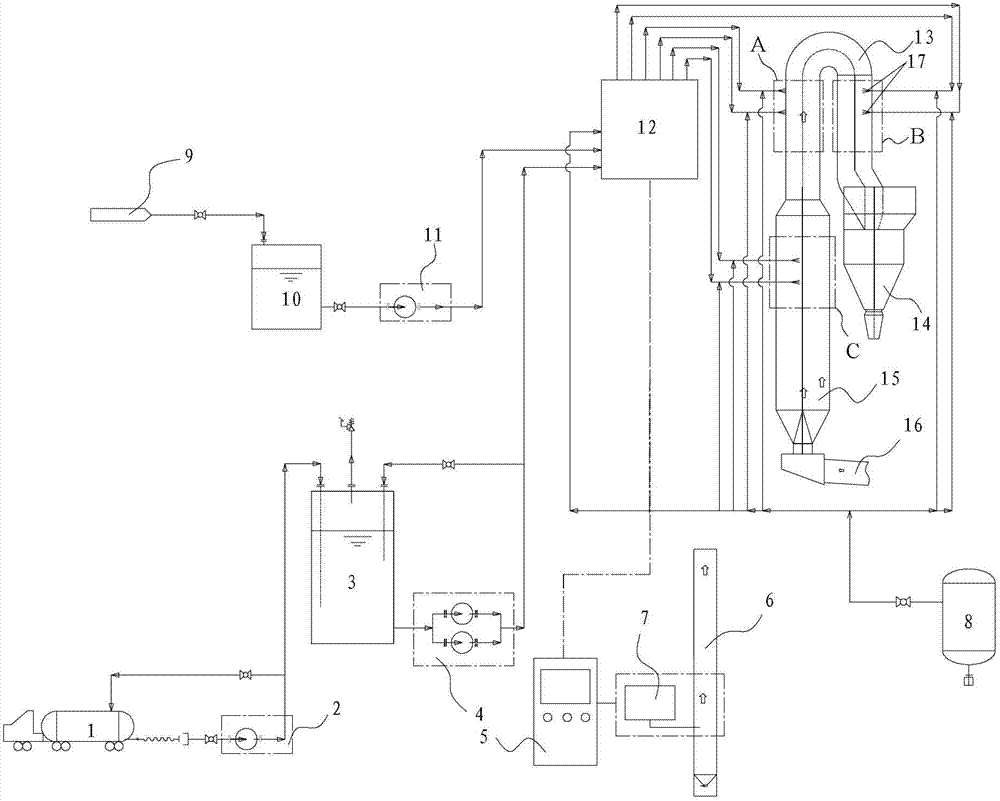

sncr flue gas denitrification device using urea as reducing agent

InactiveCN102274687ARealize automatic continuous feedingGuaranteed concentrationNitrous oxide captureFlow mixersRefluxFlue gas

The invention discloses an SNCR (Selective Non-Catalytic Reduction) flue gas denitration device taking urea as a reducting agent. The denitration device comprises a solid urea tank vehicle, a hose, a movable joint, a solid urea adjusting valve, a solid urea storing tank, a solid urea feeder, a compressed air main pipe, a compressed air adjusting valve, a stirrer, a urea solution preparing tank, aheater, an industrial water main pipe, an industrial water adjusting valve, a urea conveying pump, a urea solution storing tank, a urea spraying pump, a mixer, a urea reflux adjusting valve, a pressurized industrial water adjusting valve, an industrial water pump, a urea dilute solution adjusting valve, an atomization steam adjusting valve, an atomization steam main pipe and a urea spraying unit.During canning of urea, full-automatic and continuous feeding is realized, the concentration and uniformity of a urea solution are ensured, the urea flow is automatically adjusted according to the emission of NOx from combustion equipment, the emission of NOx from the combustion equipment is within a controlled range, and the denitration efficiency is 60 percent; and during supplying of bagged urea, the urea solution preparing tank is fed manually, and an intermittent urea preparing way is adopted.

Owner:ZHEJIANG UNIV

High-efficiency ammonia-method denitration process and device thereof

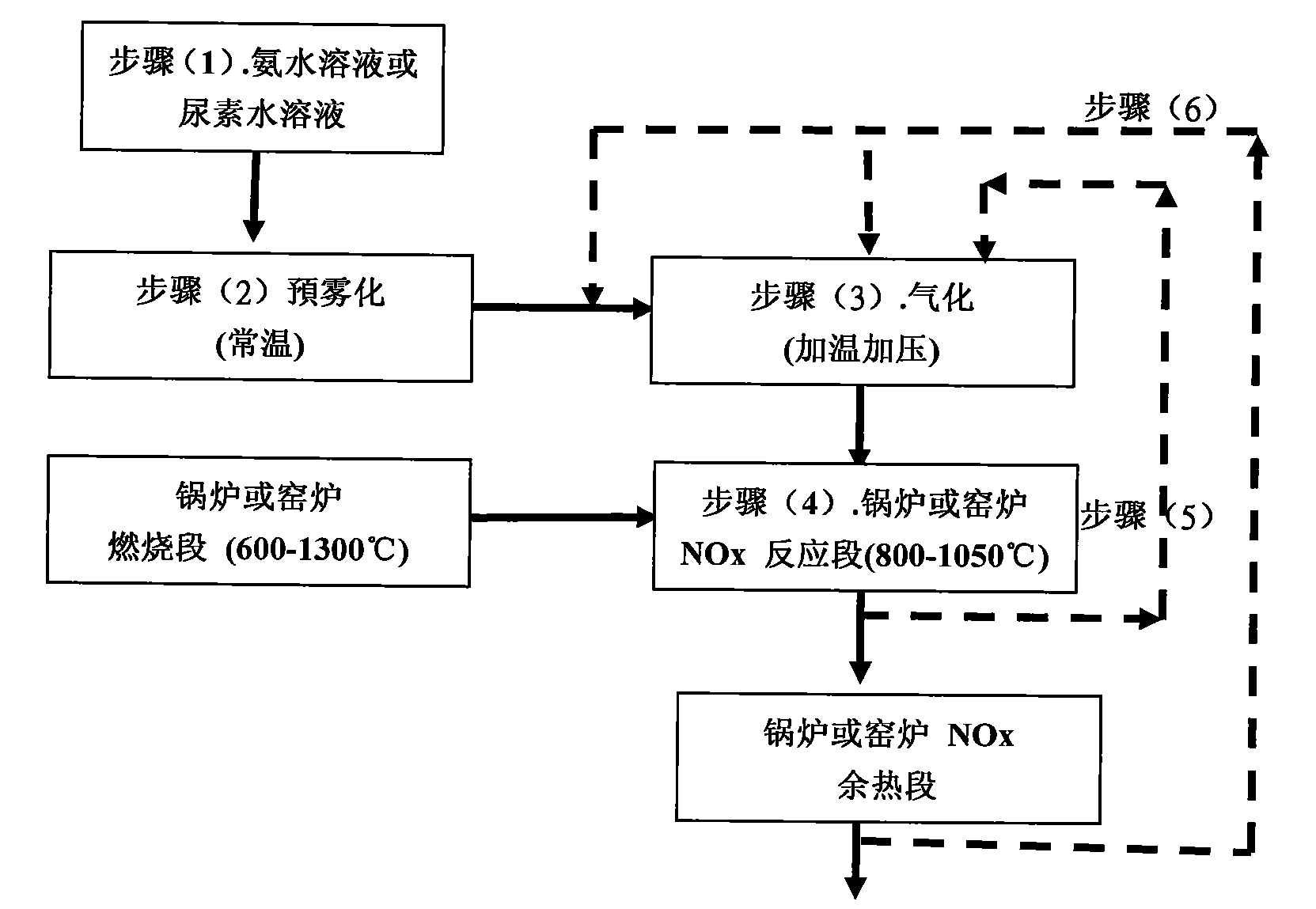

InactiveCN101890279AMix evenly and stablyExpand the effective reaction temperatureDispersed particle separationReaction temperatureWater content

The invention discloses a high-efficiency ammonia-method denitration process and a high-efficiency ammonia-method denitration device. The process comprises the following steps of: first atomizing in advance the aqueous solution of ammonia or urea solution at the normal temperature, then performing high-temperature gasification and pressurization on the atomized aqueous solution of ammonia or ureasolution, spraying the treated aqueous solution of ammonia or urea solution into a denitration reaction area of a smoke generation source, allowing the sprayed aqueous solution of ammonia or urea solution to be fully mixed, contact and react with smoke by using an ammonia temperature-increasing and pressurizing mixer. According to the invention, the atomization and gasification of the aqueous solution of ammonia or urea solution are performed in advance and high-temperature ammonia is introduced into the reaction area of the smoke generation source only after being fully and stably mixed, which improves the denitration effect by about 70 percent, maximally by 85 percent, and raises the effective reaction temperature of conventional selective non-catalytic reduction (SNCR) to 800 to 1,100 DEG C; therefore, the device can be called high-efficiency high-temperature ammonia-method denitration (HE-SNCR) system. Moreover, due to the adoption of ammonia-method selective non-catalytic reduction reaction, the process also can achieve the denitration effect under the condition of high dust thickness, and the denitration effect is better than that of selective catalytic reduction (SCR) or other post-treatment sections (low-dust thickness and low-water content).

Owner:东莞兆能环境科技有限公司 +1

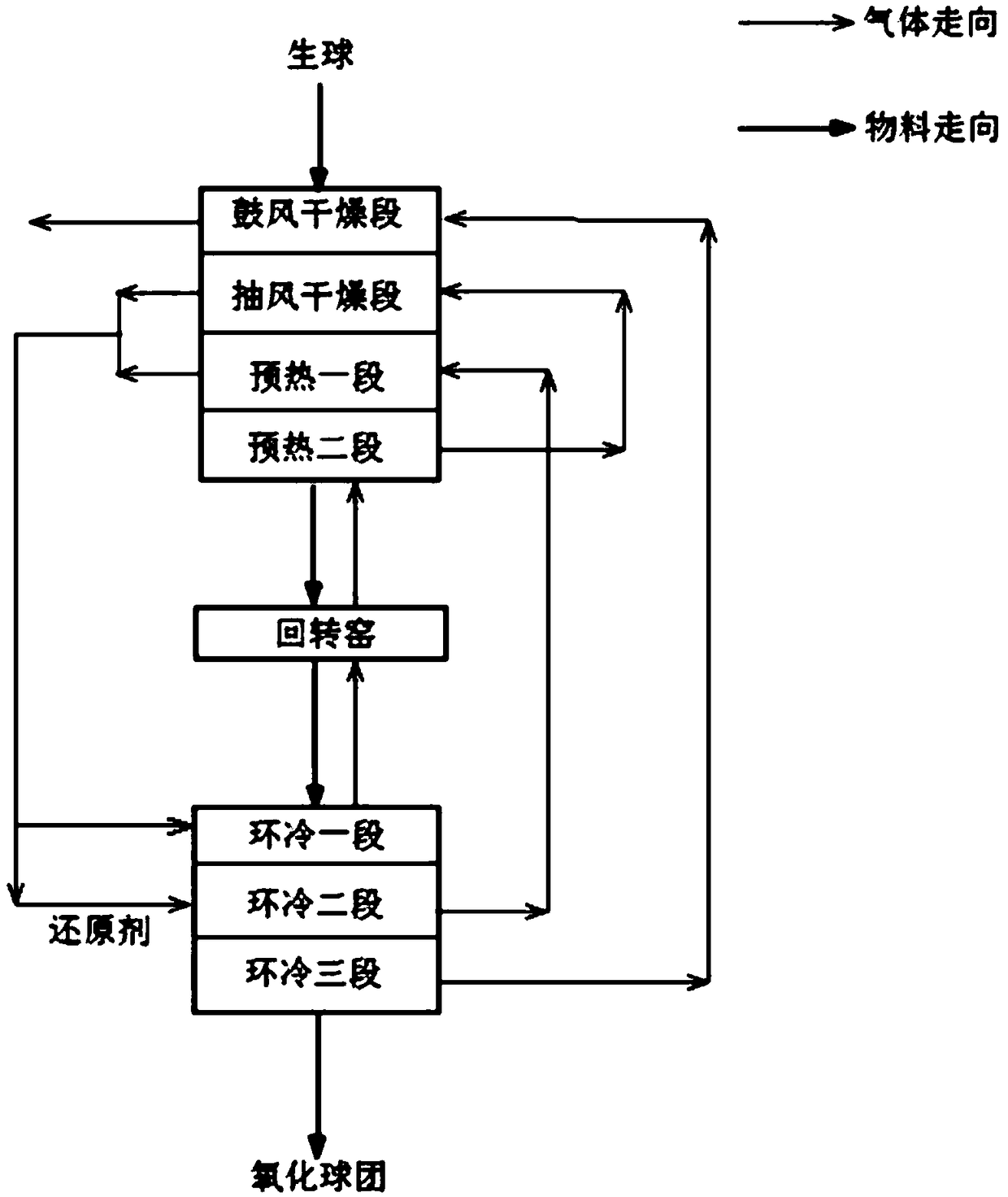

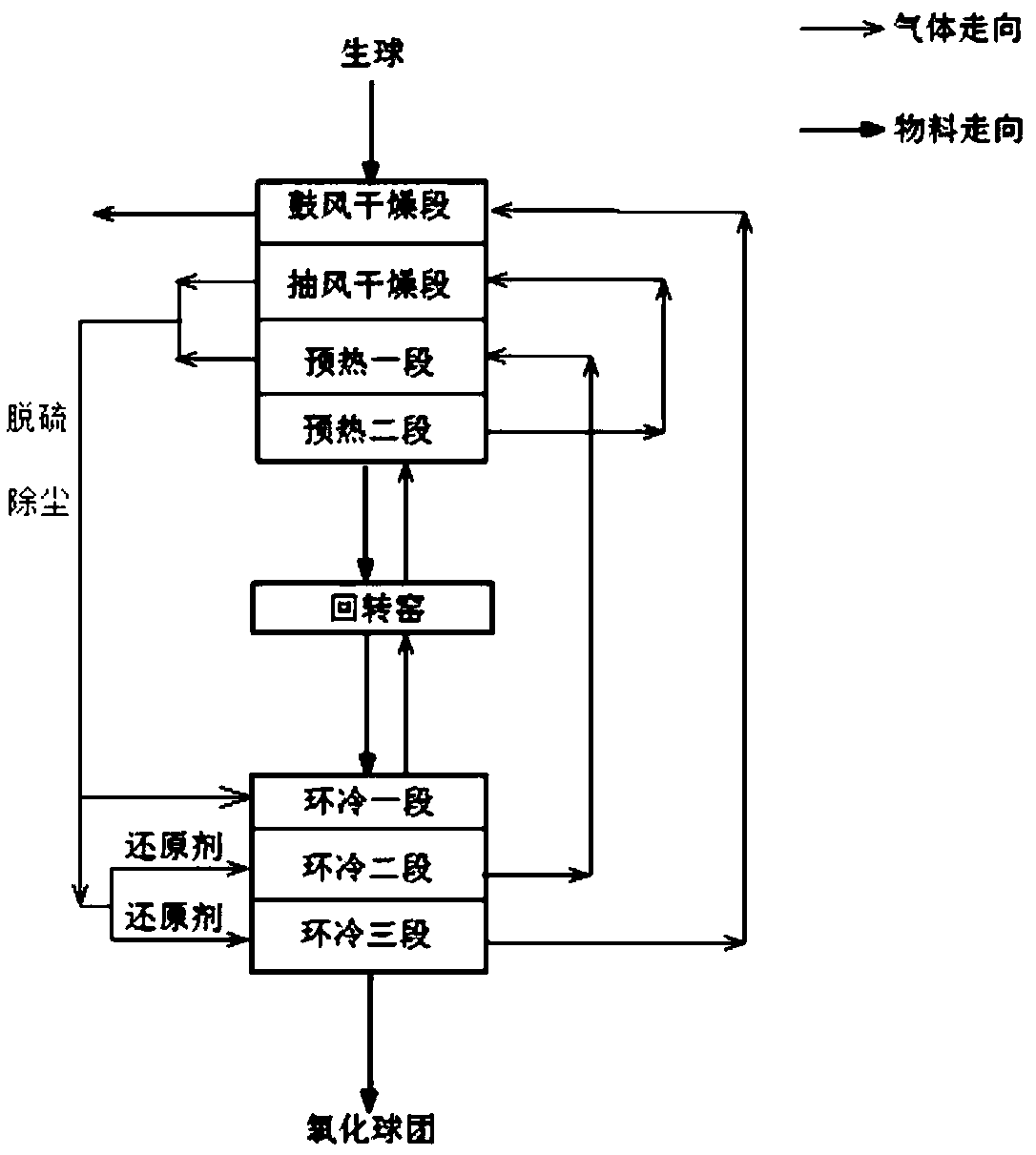

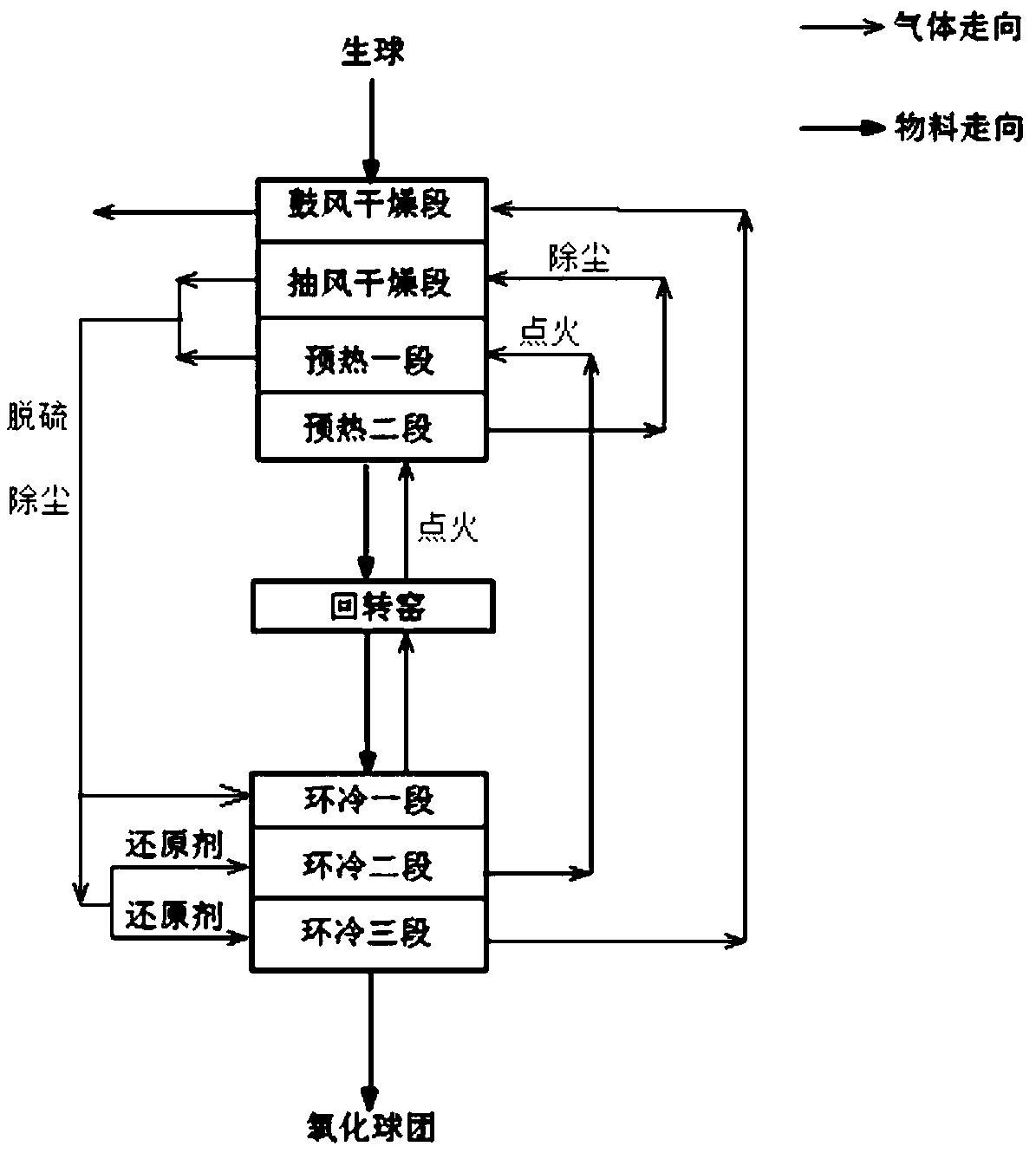

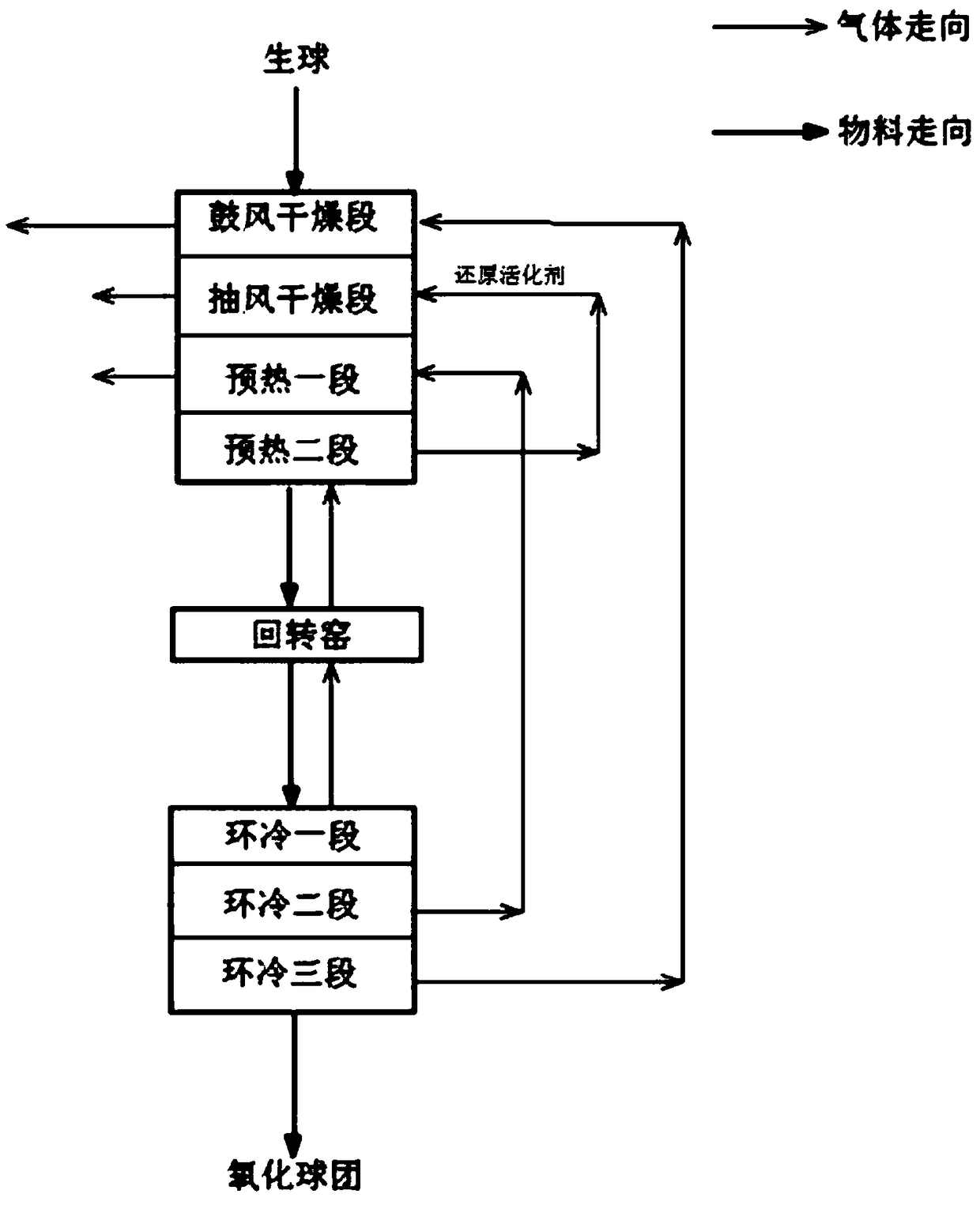

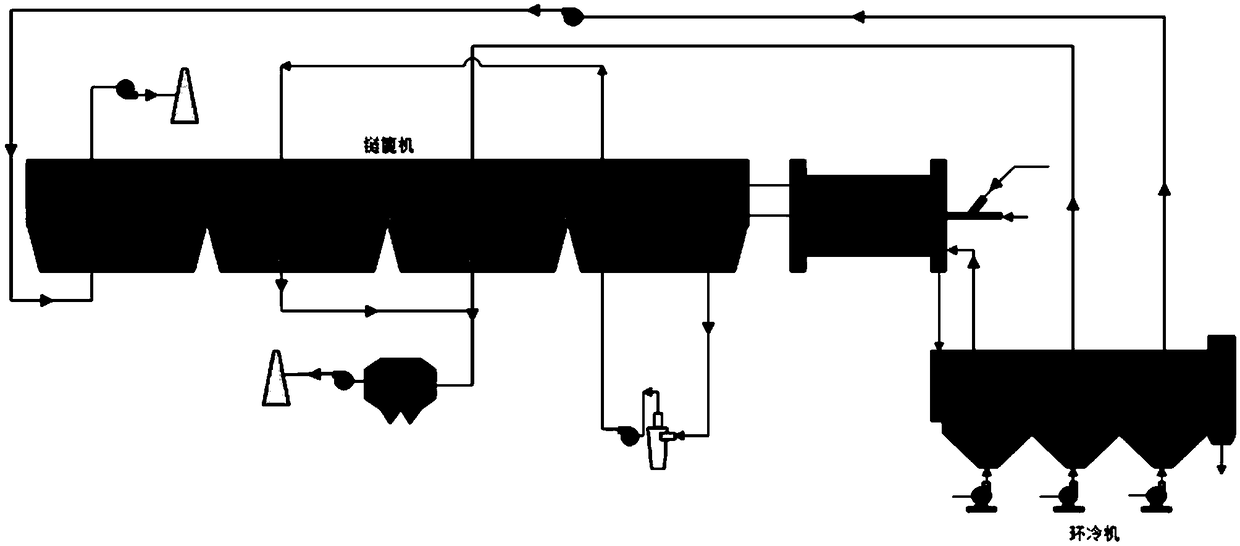

Low-NOx grate-rotary kiln pellet production technology and low-NOx grate-rotary kiln pellet production system

ActiveCN109136545AReduce generationReduce contentRotary drum furnacesDispersed particle separationFlue gasEngineering

The invention provides a low-NOx grate-rotary kiln pellet production technology. The production technology includes utilizing blended flue gas W exhausted from a down-draft drying section (DDD) and aprimary preheating section (TPH) as cooling air to be delivered to an air inlet of (1) a primary circular cooling section (C1) and (2) an air inlet of a secondary circular cooling section (C2), spraying a reducer into a bottom air box of the circular cooling section (C2), making the reducer and the blended flue gas exhausted from the down-draft drying section (DDD) and the primary preheating section (TPH) to react with NOx so as to achieve SNCR (selective non-catalytic reduction) denitration. The low-NOx grate-rotary kiln pellet production technology has the advantages that the production pressure of enterprise atmospheric pollutant emission limits on pellet calcination equipment can be reduced to a certain degree, and the production technology is saving in investment, low in running costand remarkable in NOx emission reduction effect.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Method for removing nitric oxides by absorption and plasma selective catalytic reduction

The invention relates to treatment of nitric oxides in waste gases and aims to provide a method for removing nitric oxides by absorption and plasma selective catalytic reduction. The method comprises: (1) passing the waste gases containing the nitric oxides through a plasma reactor filled with an absorption catalyst to make the nitric oxides absorbed onto the absorption catalyst; and (2) stoppingcharging waste gases, passing a mixed gas of oxygen and a reducing gas through the plasma reactor, and performing a plasma discharge reaction. The absorbed nitric oxides are desorbed and catalytically reduced into nitrogen under the common action of plasma and the absorption catalyst. In the invention, the whole nitric oxide removal process is accomplished on one device; the method can be widely used for removing nitric oxides from industrial tail gases, flue gases and automobile tail gases; the absorbent is low in cost and easy to recycle; the plasma reaction has low requirements on device and reaction conditions; the energy consumption in the whole process is low; and the conversion rate I the reduction of the nitric oxides into N2 reaches over 90 percent.

Owner:ZHEJIANG UNIV

Method and device for controlling NOx concentration in smoke gas of cement kiln

ActiveCN102921284AIncrease profitReduce consumptionDispersed particle separationMulti siteMonitoring system

The invention discloses a method and device for controlling NOx concentration in smoke gas of a cement kiln; the device comprises a decomposing kiln, a preheater and a reducing agent supply device, wherein the bottom of the decomposing kiln is communicated with a kiln tail chimney of the cement kiln by an inlet smoke flue; the top of the decomposing kiln is communicated with the preheater by an outlet smoke flue; a plurality of spray guns communicated with the reducing agent supply devices are arranged at or / or in the middle upper part of the decomposing kiln or / and the outlet smoke flue in a layered way; and the device further comprises a central controller and a smoke gas automatic monitoring system, wherein the central controller is connected to the reducing agent supply devices; and the smoke gas automatic monitoring system is used for monitoring NOx concentration and smoke gas flow information in the kiln tail chimney and transmitting the NOx concentration and smoke gas flow information to the central controller. According to the invention, as a reducing agent is sprayed into the decomposing kiln through multi-site combined control, high removal rate of the NOx can be achieved without an SNCR (Selective Non Catalytic Reduction) and SCR (Selective Catalytic Reduction) combined technology.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

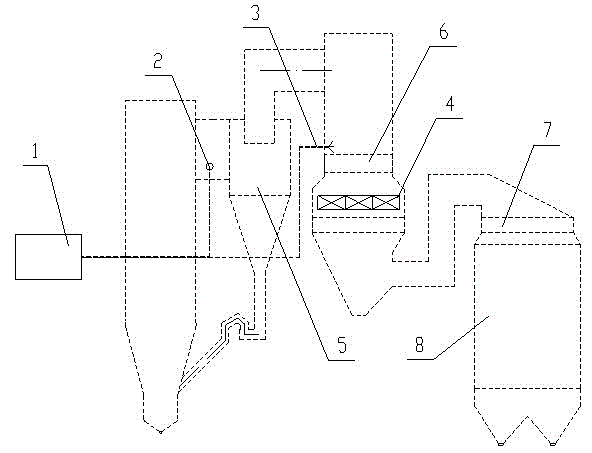

SCR (Selective Catalytic Reduction) denitration device for NOx control of rotary cement kiln

InactiveCN103406006AImprove denitrification efficiencyReduce wearCombination devicesLighting and heating apparatusFlue gasProcess engineering

The invention discloses an SCR (Selective Catalytic Reduction) denitration device for NOx control of a rotary cement kiln, wherein the rotary cement kiln is connected with a heat exchanger; a reducing agent injection system is arranged at the kiln tail part of the rotary cement kiln; the flue gas outlet of the rotary cement kiln is connected with the high-temperature flue gas inlet of the heat exchanger; the low-temperature flue gas outlet of the heat exchanger is connected to the flue gas inlet of a bag type dust collector; the outlet of the bag type dust collector is connected to the low-temperature flue gas inlet of the heat exchanger; the high-temperature flue gas outlet of the heat exchanger is connected to the flue gas inlet of an SCR reactor; the flue gas inlet of a desulfurizing tower is connected with the flue gas outlet of the SCR reactor. The three denitration technologies of SNCR (Selective Non-Catalytic Reduction), integrated dust collection and denitration and SCR are combined so that the flue gas of the rotary cement kiln is denitrated three times; specifically, firstly, NOx in the high-temperature flue gas has a selective non-catalytic reaction with a reducing agent at the tail of the kiln; secondly, the bag type dust collector provided with a denitration-functional catalytic filter bag is used for dust removal and secondary denitration; finally, the third time of denitration is performed in the SCR reactor; as a result, the denitration efficiency is greatly improved.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

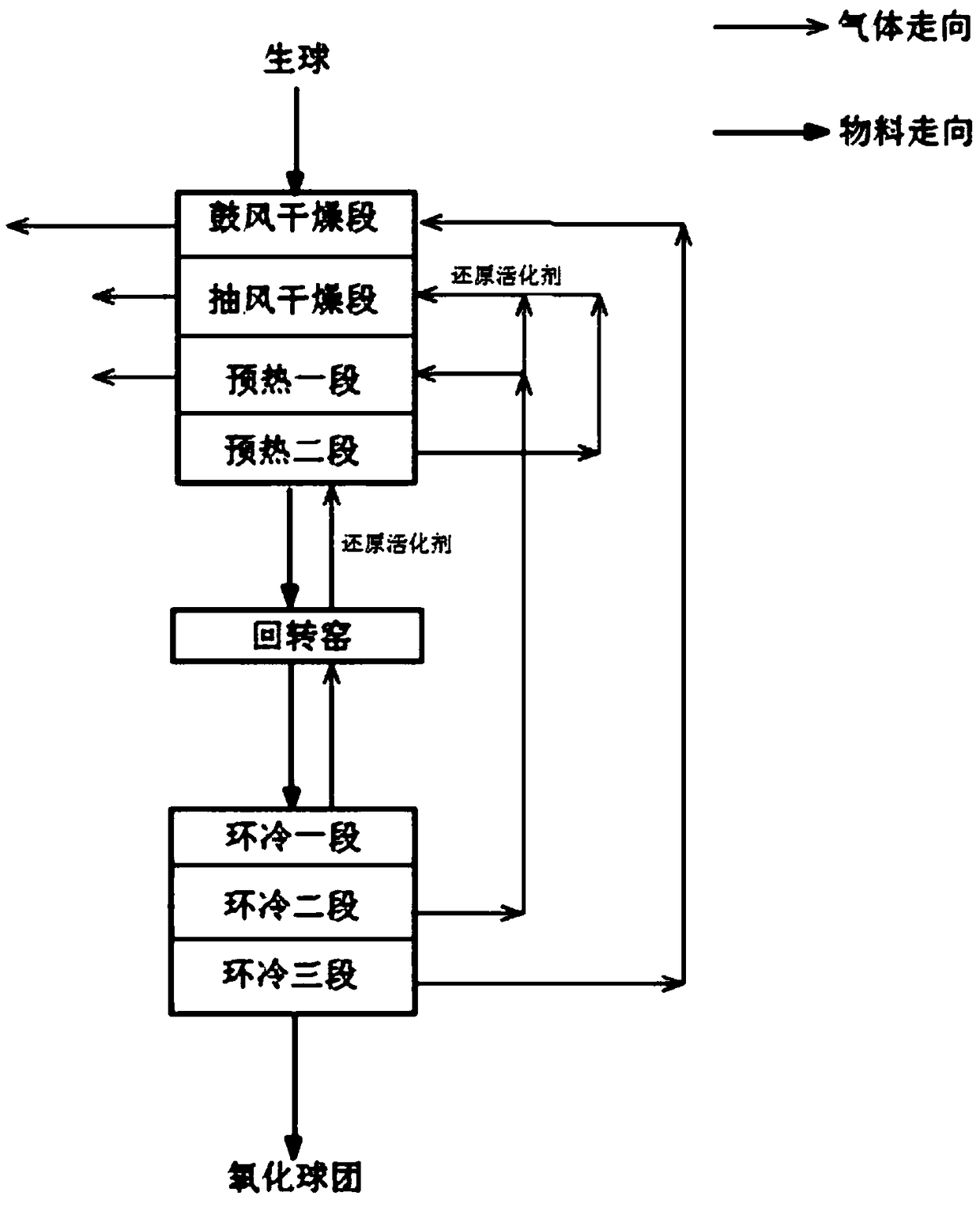

Low-NOx grate-rotary kiln pellet production technology and low-NOx grate-rotary kiln pellet production system

ActiveCN109136544AImprove denitrification efficiencyReduce contentGas treatmentDispersed particle separationCatalytic effectEngineering

The invention provides a low-NOx grate-rotary kiln pellet production technology. The production technology includes spraying a reduction activator into a position, above fresh pellets, in a down-draftdrying section (DDD), and enabling the reduction activator to react with NOx in hot air entering the down-draft drying section (DDD) from a rotary kiln (2) so as to achieve SNCR (selective non-catalytic reduction) denitration. In a preferred scheme, the step of excessively spraying the reduction activator with a catalytic effect into a proper temperature range (950 DEG C) above a material surfaceof a secondary preheating section (PH) is added. The low-NOx grate-rotary kiln pellet production technology solves existing technical problems and has the advantages of lower investment, low runningcost, less ammonia escape and remarkable NOx emission reduction effect.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Selective catalytic reduction via electrolysis of urea

ActiveUS8388920B2Reducing nitrogen oxideCombination devicesElectrolysis componentsHydrolysisTreatment system

A method and apparatus for producing ammonia suitable for use as a reductant in a selective catalytic reduction (SCR), a selective non-catalytic reduction (SNCR), or a flue gas conditioning system is provided. A method for treating combustion exhaust gas with ammonia is provided that includes the electrolytic hydrolysis of urea under mild conditions. The electrolysis apparatus includes an electrolytic cell, which may be operatively coupled to an exhaust gas treatment system to provide an apparatus for reducing nitrogen oxides (NOx) and / or particulate in exhaust gases.

Owner:OHIO UNIV

Preparation process of honeycomb SCR (selective catalytic reduction) denitration catalyst

ActiveCN102872919AHigh mechanical strengthHigh strengthDispersed particle separationCatalyst activation/preparationPolymer scienceHoneycomb

The invention discloses a preparation process of a honeycomb SCR(selective catalytic reduction) denitration catalyst. The preparation process includes steps of (1), subjecting a mixture of raw materials which are mixed proportionally to primary decaying, filtering and pre-extruding the mixture, subjecting the mixture to secondary decaying and finally forming and extruding out a catalyst blank in vacuum; (2), subjecting the catalyst blank formed and extruded in vacuum to primary drying at a temperature ranging from 22-68 DEG C and a humidity ranging from 95-10% gradually; (3), subjecting the catalyst dried primarily to secondary drying at the temperature ranging from 60 DEG C to 105 DEG C within the drying period of 12-24 hours; (4), calcining the catalyst blank dried secondarily at the temperature ranging from 68 DEG C to 600 DEG C for 20-30 hours, and detecting finished products after calcining. The honeycomb SCR denitration catalyst is high in yield and high in strength, manufacturing cost of the catalyst is reduced, and mechanical performance of the catalyst is improved.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Catalyst for performing selective catalytic reduction on nitrogen oxide by ammonia

ActiveCN104437608AImprove purification effectComponents are green and non-toxicMolecular sieve catalystsDispersed particle separationRare-earth elementReaction temperature

The invention relates to a catalyst for performing selective catalytic reduction on nitrogen oxide by ammonia and application thereof. The catalyst comprises the components including an active component Fe, a rare earth element auxiliary (La, Ce or Sm) and a molecular sieve carrier (Beta or a mixture of Beta and ZSM-5); ammonia is used as a reducing agent, and nitrogen oxide can be converted into harmless nitrogen by using the catalyst under an oxygen enrichment condition; the reaction conditions are as follows: the reaction temperature is 200-500 DEG C, the concentration of nitrogen oxide is 100-2000ppm, the proportion of ammonia to nitrogen oxide is 1 to 1.1 and the gaseous hourly space velocity (GHSV) is 1,000-60,000h-1. The catalyst capable of purifying nitrogen oxide with high performance is environmentally friendly, free of toxicity, low in application reaction temperature, high in conversion rate of nitrogen oxide and suitable for large-scale industrial popularization and application.

Owner:NANKAI UNIV

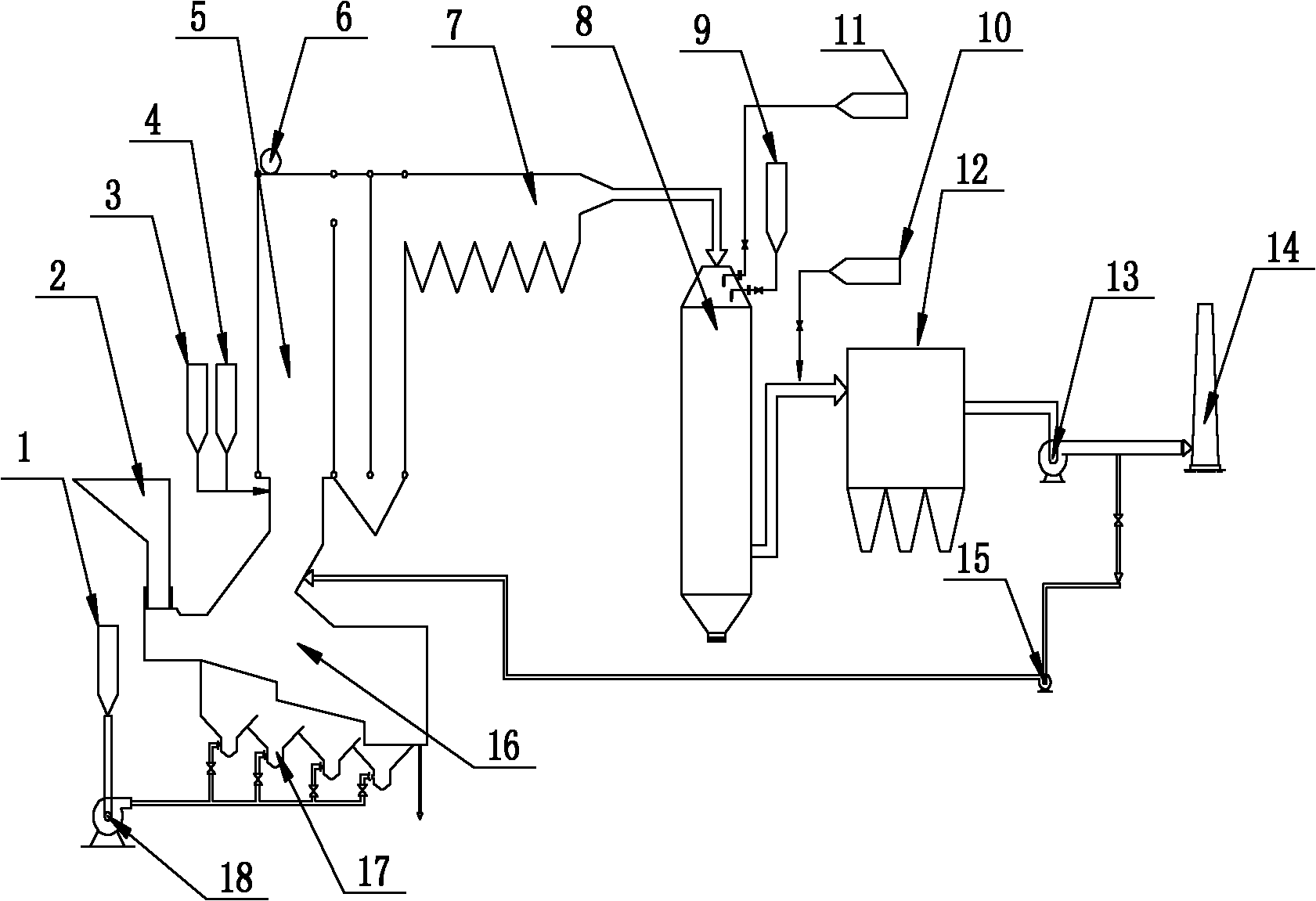

SNCR (selective non-catalytic reduction) and SCR (selective catalytic reduction) combined process flue gas denitrification system of CFB (circulating fluidized bed) boiler

ActiveCN102716665AMeet the purpose of denitrificationImprove economyDispersed particle separationFlue gasFluidized bed

The invention discloses an SNCR (selective non-catalytic reduction) and SCR (selective catalytic reduction) combined process flue gas denitrification system of a CFB (circulating fluidized bed) boiler, wherein the system belongs to a boiler denitrification device. The SNCR and SCR combined process flue gas denitrification system comprises an SNCR denitrification device which is arranged at the upstream of flue gas and an SCR denitrification device which is arranged at the downstream of flue gas. The SNCR and SCR combined process flue gas denitrification system of the CFB boiler has the advantages that the comprehensive removal rate of NOx can reach more than 85 percent, the ammonia escape is less than 3ppm, the system is suitable for the high-dust severe environment of the CFB boiler and can meet the requirement of high denitrification efficiency, and especially under the situation that the NOx content at the outlet of the boiler is high when fuel with high content of nitrogen and volatile matters is used, the economy and the environmental performance are better. At the same time, since a flexible temperature interval and reducing agent injection selection scheme is adopted, the goal of denitrification of any kind of CFB boilers can be achieved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Method for denitrifying flue gas by using amino reducing agent with high reaction activity

InactiveCN102553412AImprove denitrification efficiencyGood reaction selectivityDispersed particle separationFlue gasReaction temperature

The invention relates to a method for denitrifying flue gas by using an amino reducing agent with high reaction activity. The method comprises the following steps of: spraying the amino reducing agent NR3 with high reaction activity into a denitrification reaction zone to ensure that the amino reducing agent and the flue gas are fully mixed, and reacting the amino reducing agent and NOX in the flue gas at the temperature of 350 - 800 DEG C to fulfill the aim of removing the NOX, wherein the denitrification efficiency can reach 70 to 90 percent. By the technology for denitrifying the flue gas by using the active amino reducing agent NR3, the disadvantages of a selective catalytic reduction (SCR) denitrification technology and a selective non-catalytic reduction (SNCR) denitrification technology are overcome, the reaction temperature is moderate, and the reaction selectivity is high. The method is applicable to the flue gas denitrification of multiple kinds of industrial boilers and industrial kilns and the treatment of automobile exhaust.

Owner:SHANDONG UNIV

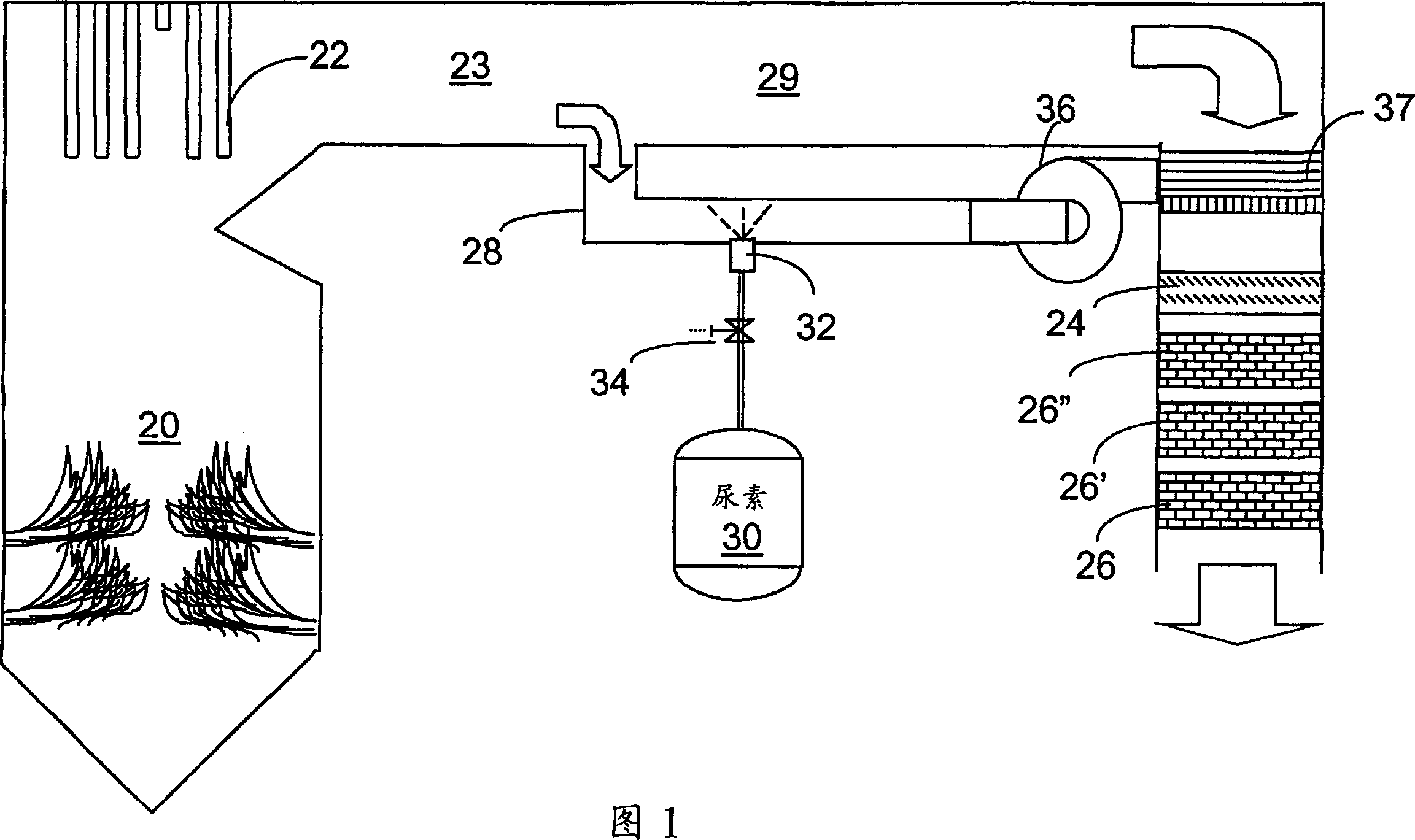

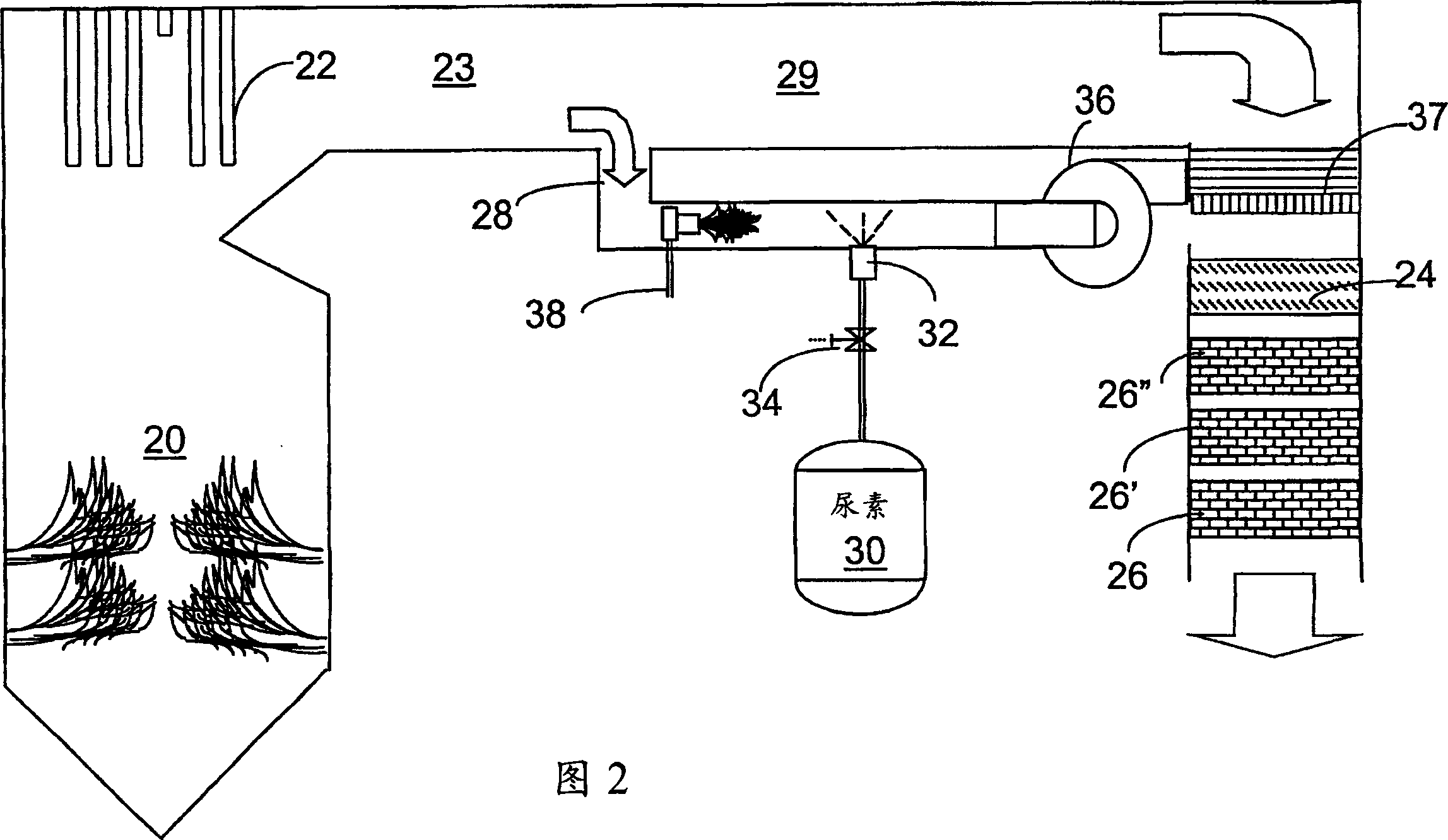

Selective catalytic reduction of NO, enabled by side stream urea decomposition

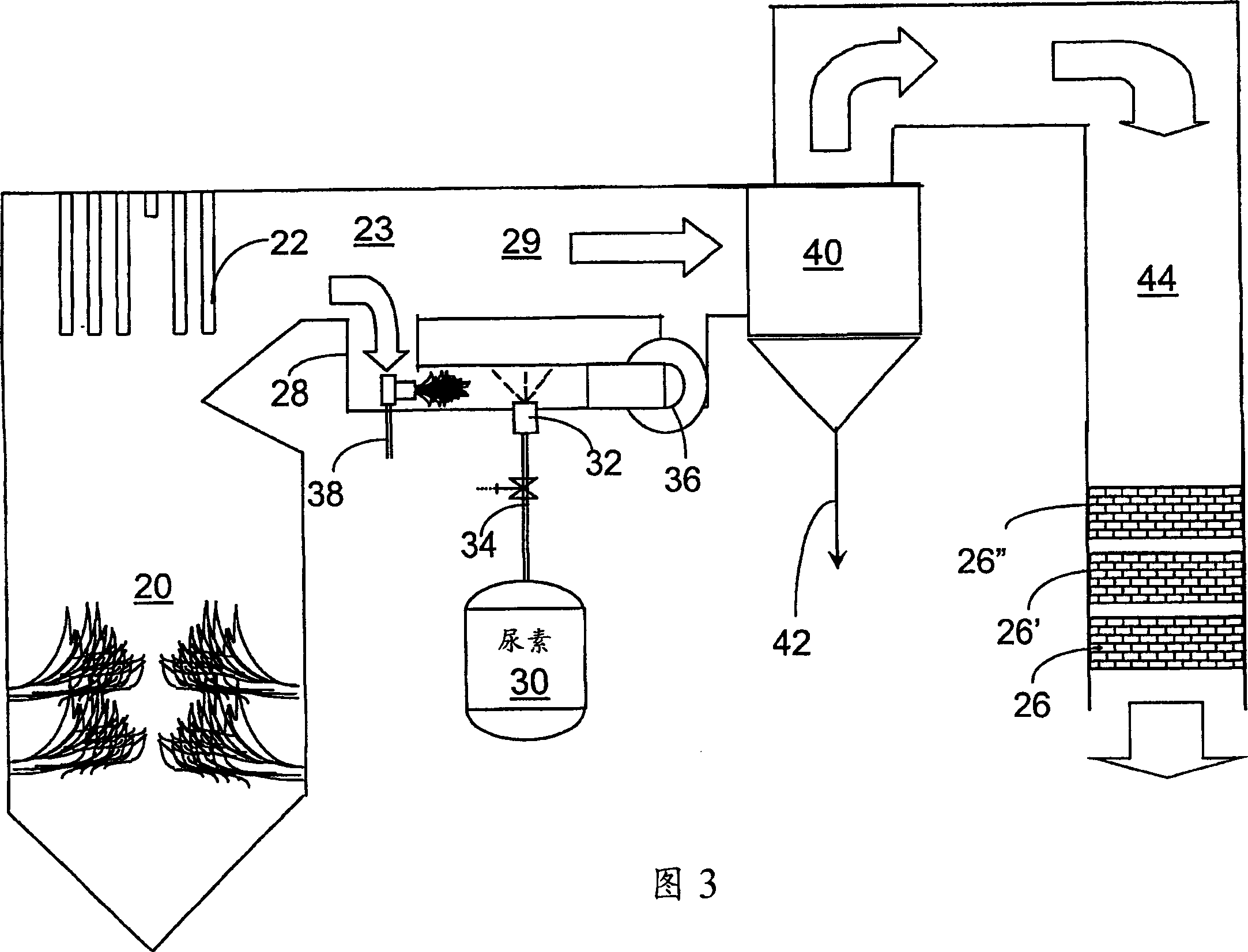

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea ( 30 ) into ammonia for SCR. Urea ( 30 ), which decomposes at temperatures above 140 ° C., is injected ( 32 ) into a flue gas stream split off ( 28 ) after a heat exchanger ( 22 ), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent ( 23 ) or the urea ( 30 ). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea ( 30 ). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid ( 37 ) ahead of SCR using a blower ( 36 ). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com