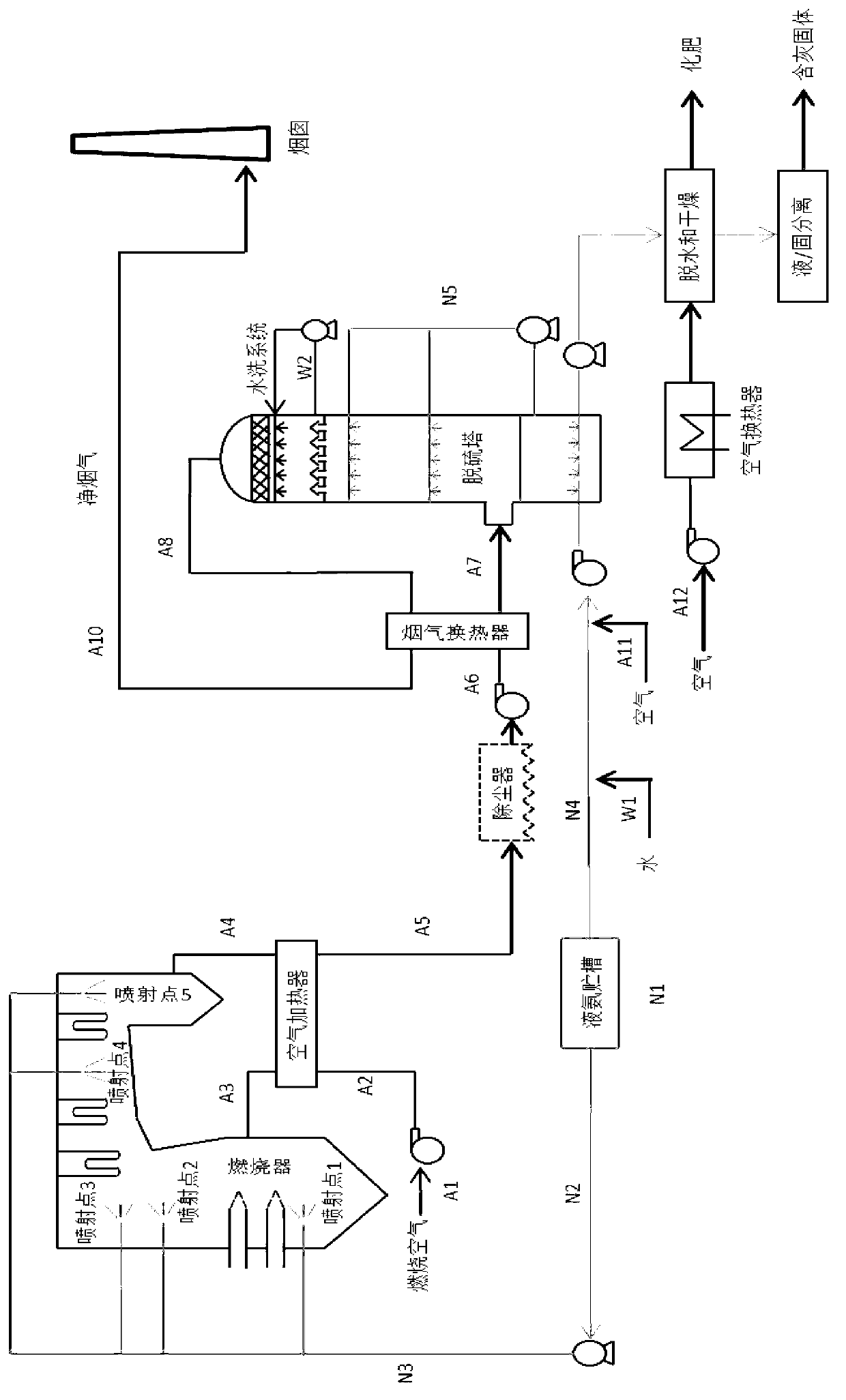

Method and device for combined removal of nitric oxide and sulfide in flue gas

A technology for combined removal of nitrogen oxides, applied in the field of flue gas purification, can solve the problems of increased power consumption of blowers, suitable for coastal areas, large demand for limestone, etc. The effect of improving the denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

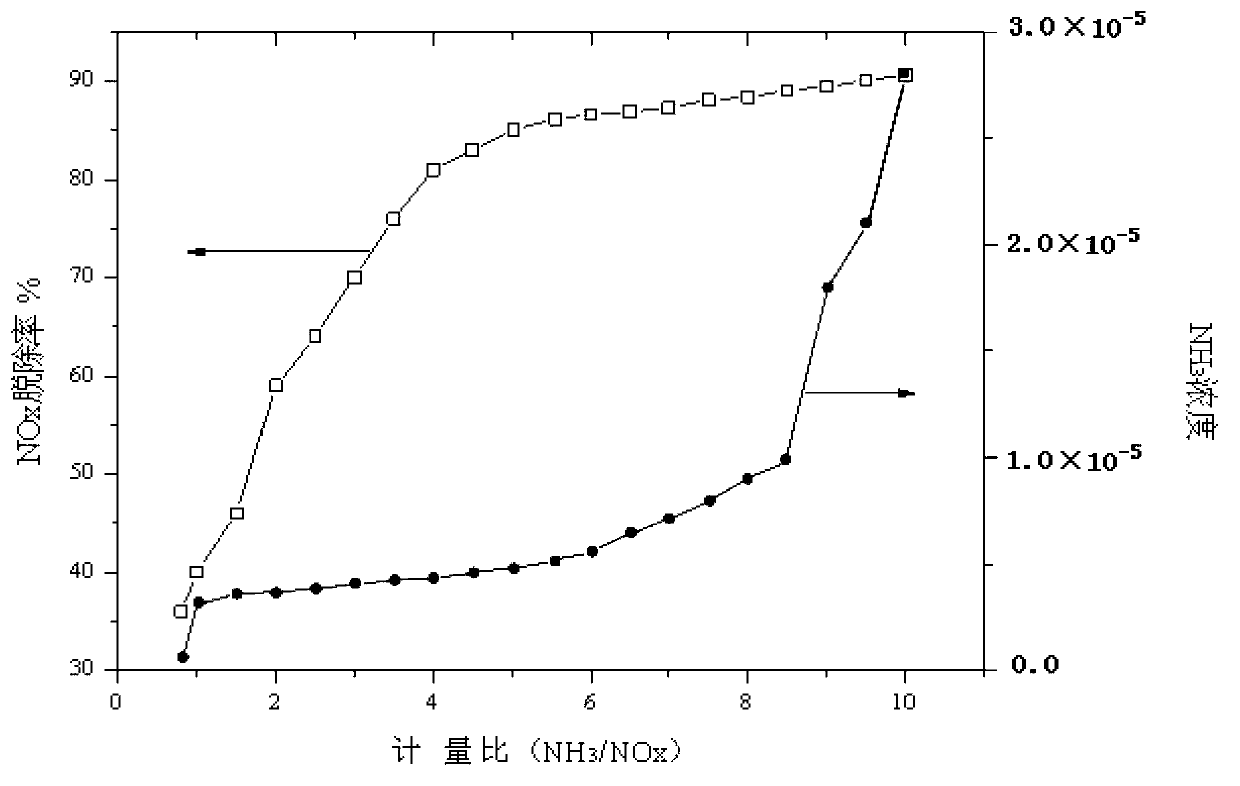

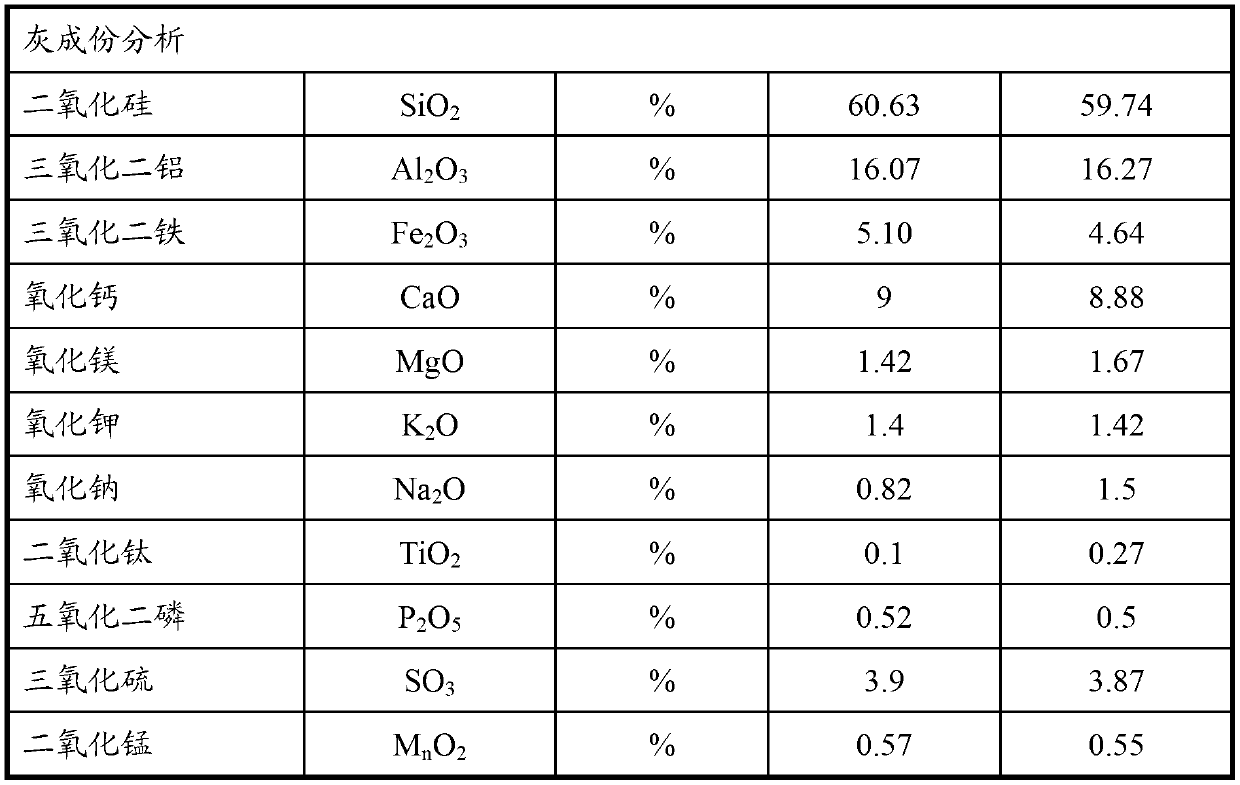

[0069] In this example, the boiler uses a 200MW unit. In this example, first refer to the following table 1 to analyze the raw coal supply, according to 548225Nm 3 / h combustion air intake to calculate the NO produced by combustion X The amount is 432Nm 3 / h, based on NH 3 / NO X Molar ratio = 5 feed ratio through the injection points 1,2,3,4,5 while injecting ammonia into the furnace. The NH 3 The feed amount can also be adjusted according to the measured value of flue gas without denitrification treatment. The flue gas measurement device adopts a conventional measuring device. figure 1 omitted. When spraying ammonia water, the reaction temperature in the furnace is 1000°C, and the reaction time (residence time) is 0.5s.

[0070] Table 1: Analysis of Raw Coal Quality

[0071] project

the symbol

unit

Design coal

Check coal type

received base moisture

Mar.

%

33.44

34.52

received base carbon

car

%

33.41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com