High-efficiency ammonia-method denitration process and device thereof

A denitrification and ammonia method technology, which is applied to the process and device field of non-coal ammonia denitration method, can solve the problems of uneven temperature, zero denitration effect, cooling in high temperature reaction zone, etc., and achieve the effect of improving the denitration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

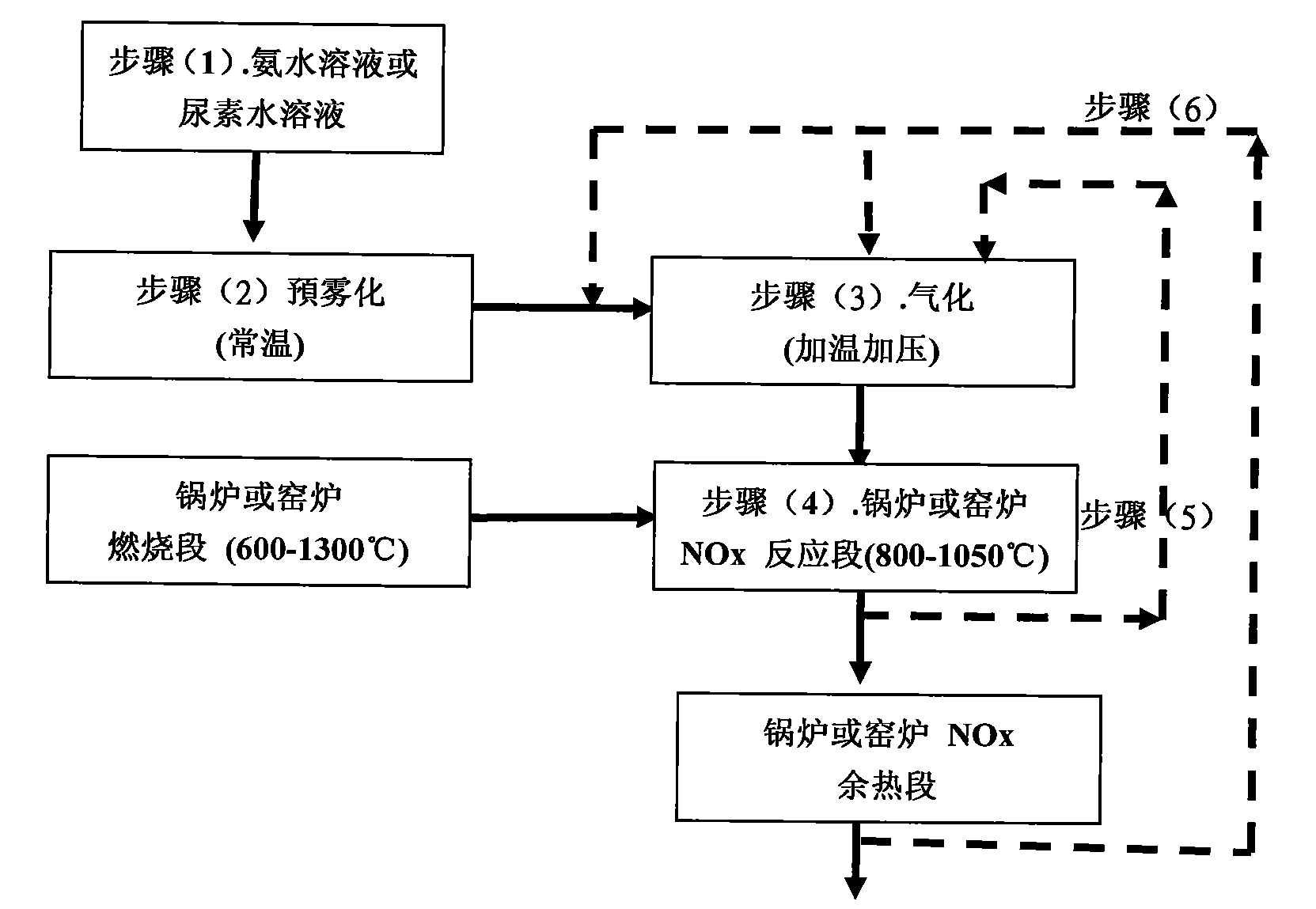

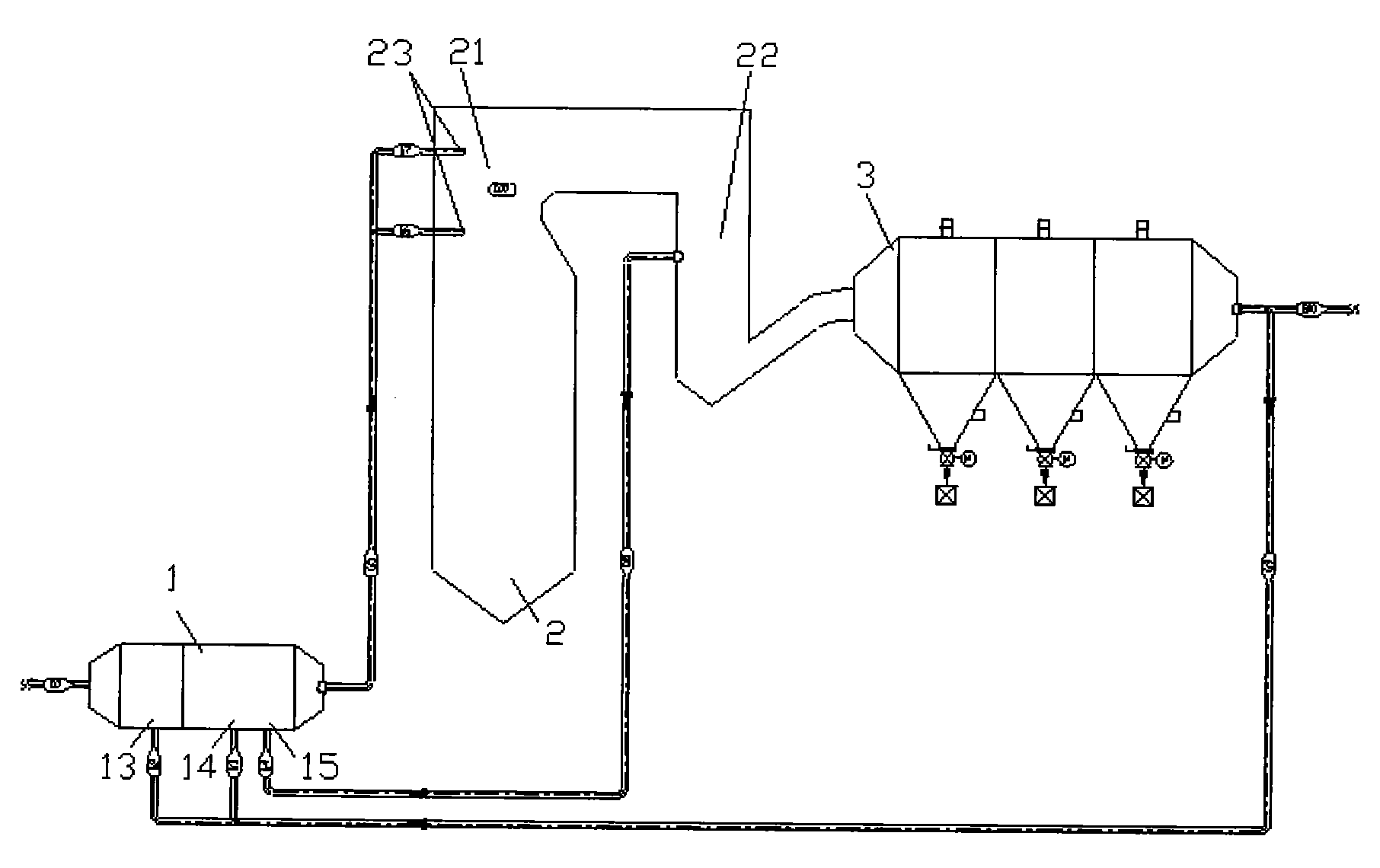

[0018] Such as Figure 1-3 Shown, technological process of the present invention is:

[0019] Step 1. Prepare ammonia solution or urea solution;

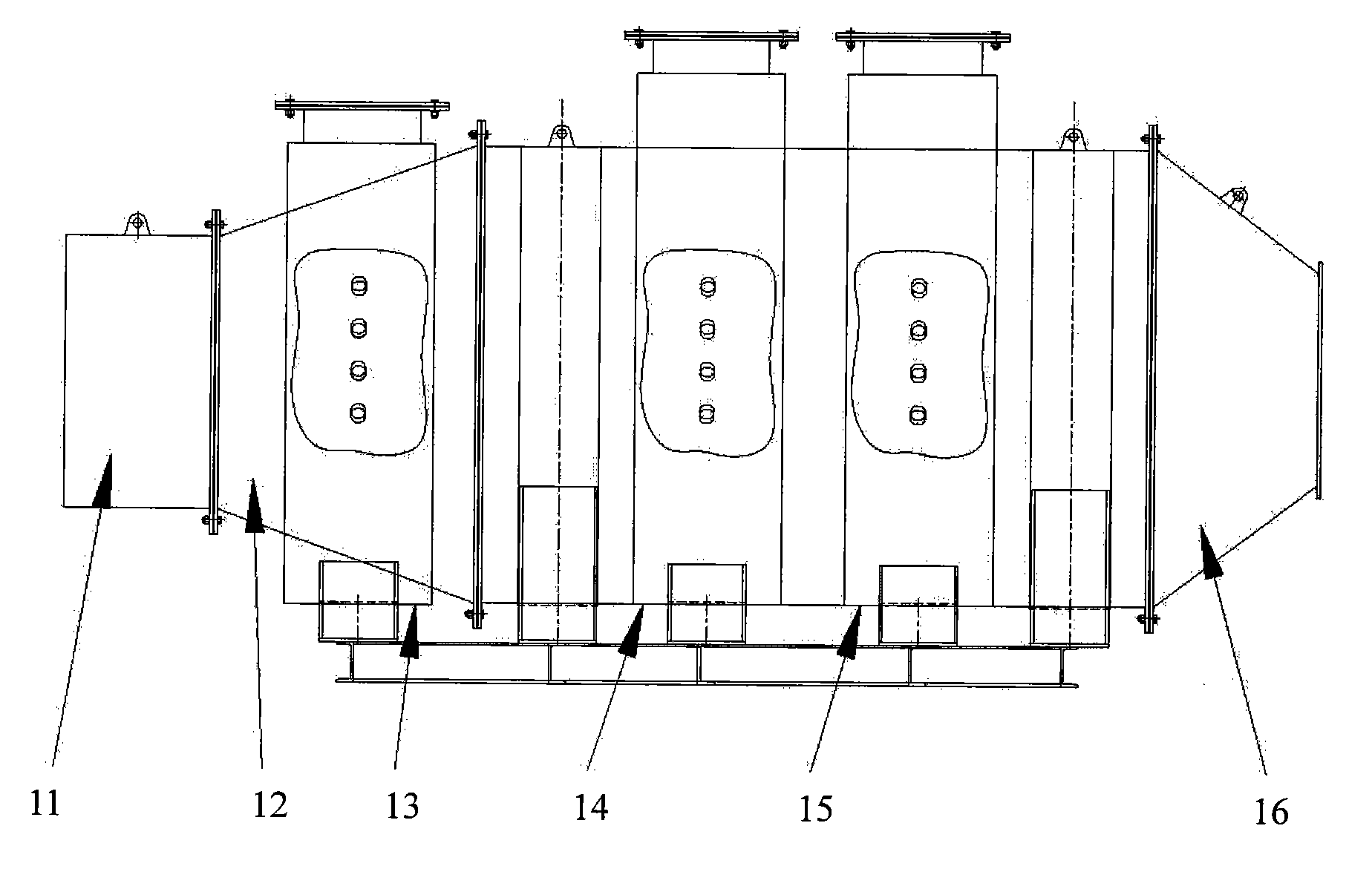

[0020] Step 2. Pass the above-mentioned ammonia solution or urea solution into the external ammonia temperature booster mixer 1, pass through the injection section 11, and enter the atomization section 12 for atomization.

[0021] Step 3. After the atomized ammonia solution or urea solution passes through the first heating section 13, the second heating section 14, and the third heating section 15 in sequence, it undergoes staged heating and gasification, and finally enters the diversion pressurization section 16, Ammonia gas with uniform temperature and pressure is formed. In each heating section, a heat exchanger is provided for heat exchange and temperature increase. In this embodiment, in order to protect the environment and save energy, the gasification heat source adopts the high-temperature flue gas and the medium-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com