Sodium persulfate sustained-release agent suitable for catalytic oxidation degradation of antibiotics and its preparation and application

A technology of sodium persulfate and catalytic oxidation, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of manganese dioxide research, etc., and achieve good coating effect and oxidative degradation performance The effect of lifting and releasing for a long period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of ordered mesoporous manganese oxide in the specific embodiment:

[0047] (1) Add 4mL of 50wt% manganese nitrate aqueous solution into 50mL of absolute ethanol suspension containing 3g of SBA-15, stir at 0°C for 4h and then add ammonia to adjust the pH of the reaction system to 11 after stirring for 4h, centrifuge after continuing to stir for 15min Separating, washing the solid product until neutral, drying at room temperature and calcining at 400°C for 4 hours to obtain the calcined product;

[0048] (II) replace SBA-15 with described calcined product, repeat step (I), obtain composite product;

[0049] (III) Disperse the composite product evenly in 200mL of 2mol / L sodium hydroxide solution, heat to boil, react to remove SBA-15 under reflux conditions, centrifuge after the reaction, wash the solid precipitate until neutral, vacuum at 60°C Dry for 24 hours to obtain the ordered mesoporous manganese oxide.

Embodiment 1

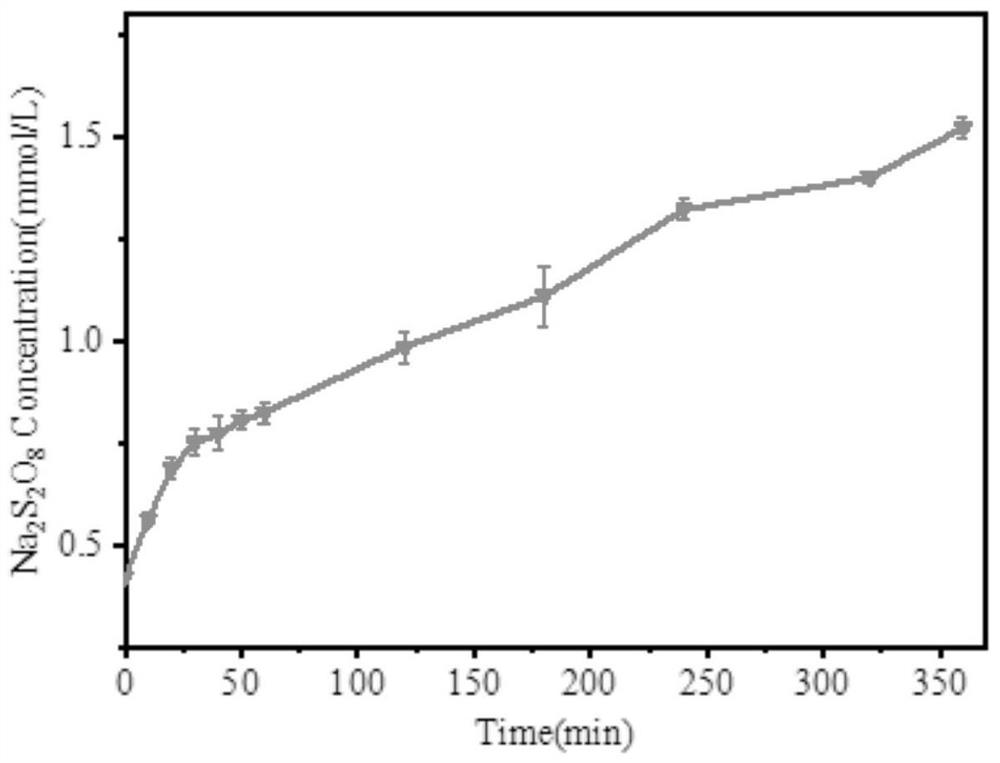

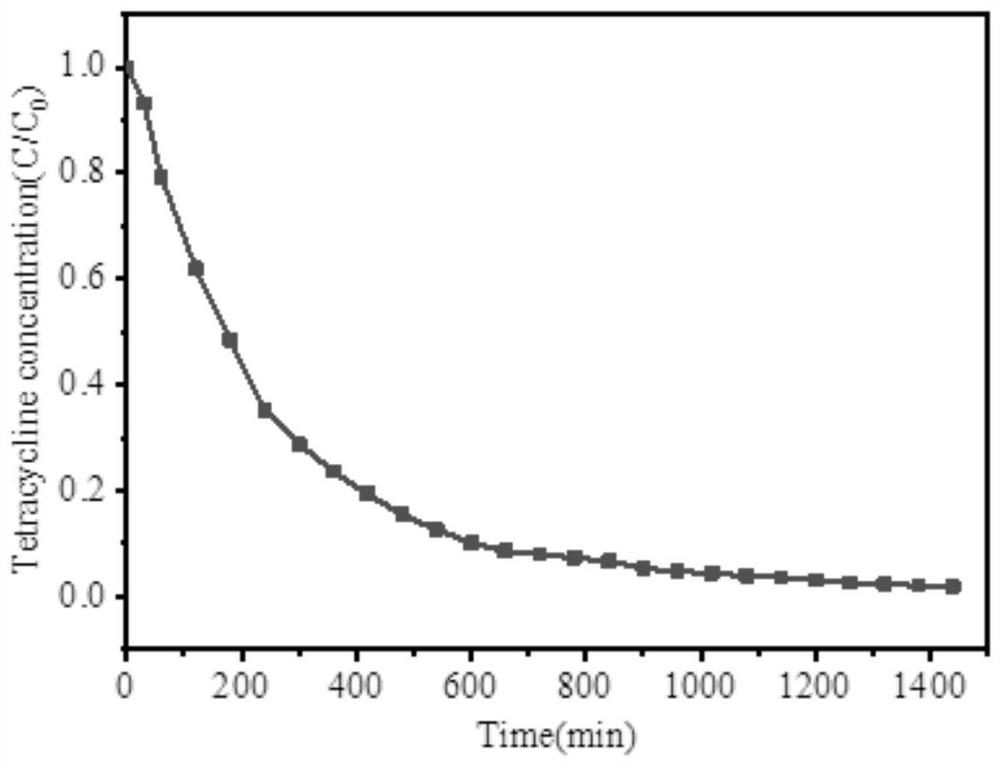

[0051] Use commercial manganese dioxide (Sinopharm Chemical Reagent Co., Ltd., analytically pure) to be a catalyzer, catalyze sodium persulfate to degrade tetracycline, control the initial concentration of tetracycline to be 20mg / L, catalyzer=0.1g / L, Na 2 S 2 o 8 = 2 mmol / L.

Embodiment 2

[0053] Use ordered mesoporous manganese oxide as a catalyst to catalyze sodium persulfate to degrade tetracycline, adopt the same test conditions as in Example 1, control the initial concentration of tetracycline to be 20mg / L, catalyst=0.1g / L, Na 2 S 2 o 8 = 2 mmol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com